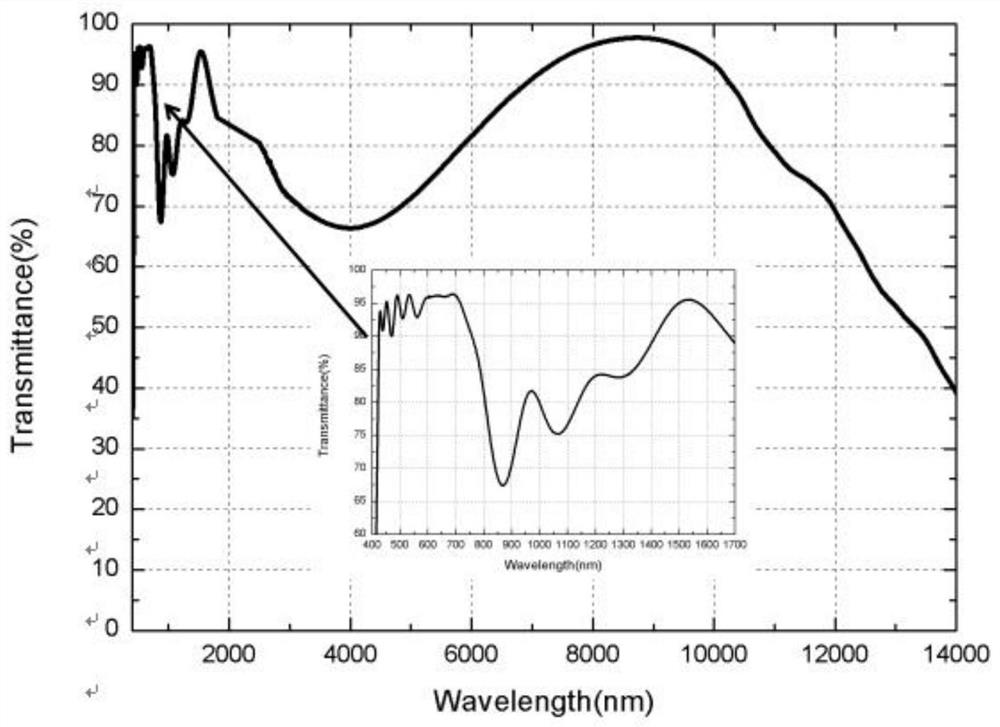

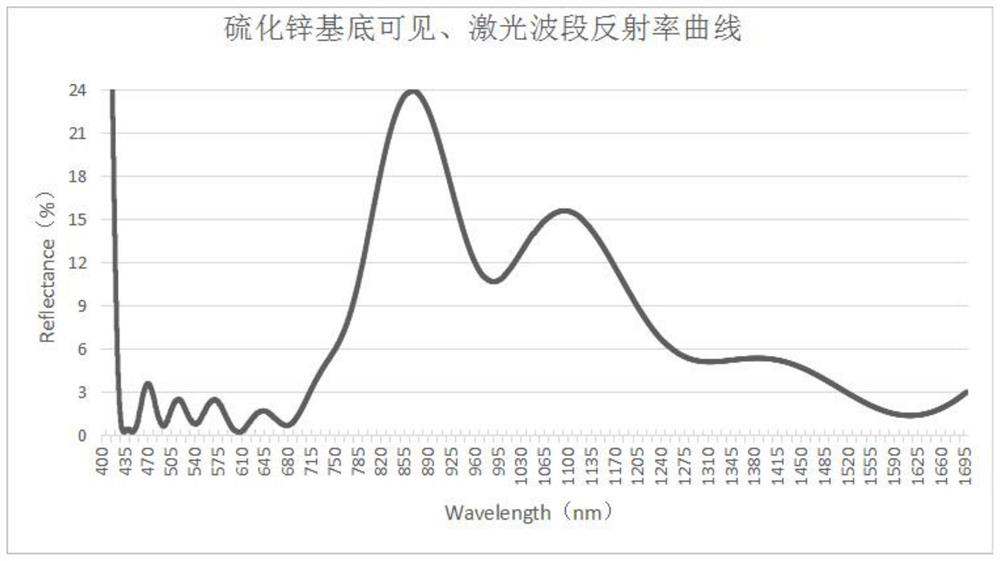

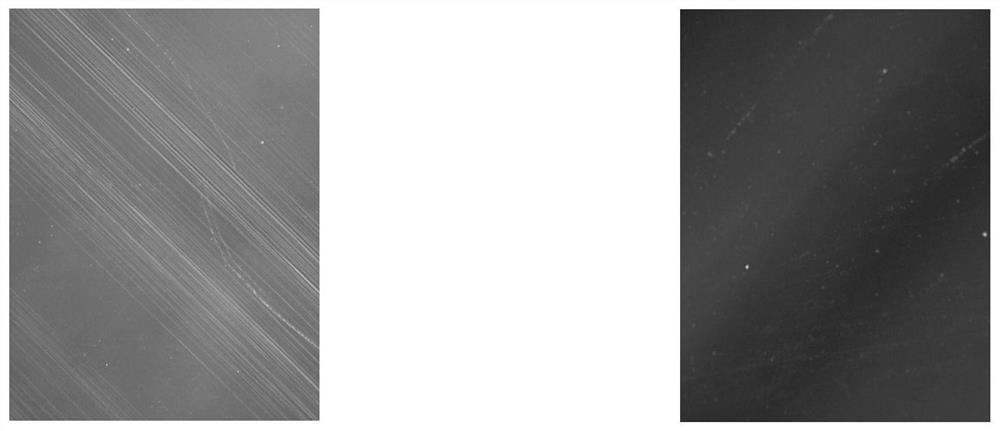

Visible infrared window antireflection film based on magnetron sputtering and preparation method

A technology of infrared window and anti-reflection coating, which is applied in the direction of sputtering coating, ion implantation coating, metal material coating process, etc., can solve the problem of film layer damage, large absorption, single-layer hafnium oxynitride film cannot meet multi-spectrum Anti-reflection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a method for preparing a visible infrared window anti-reflection film based on magnetron sputtering, comprising the following steps:

[0030] Step 1: Clean the cathode target, and install the No. 1 Al target, the No. 2 Ti target, and the No. 3 Y target in sequence;

[0031] Step 2: Put the cleaned parts to be plated into the processed coating fixture, place them in the parts tray of the coating machine, press the vacuum chamber door tightly, and start vacuuming;

[0032] Step 3: background vacuum rP≤3.0×10 -6 When torr, start the coating program;

[0033] Step 4: Pre-sputtering the target material, the pre-sputtering time of each target depends on the surface state, until there are no splashed ideas.

[0034] Step Five: Sputter Y 2 o 3 Film layer, cathode power 3.8kw, argon gas 60-70sccm, ion source power 2kw, oxygen 25sccm, deposition rate 0.23nm / s;

[0035] Step 6: Sputter TiO 2 Film layer, cathode power 4kw, argon gas 50-60sccm, ion sourc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com