Core-shell type LaFeO3@C lithium battery anode material and preparation method thereof

A negative electrode material and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low cycle life, high irreversible capacity, and poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

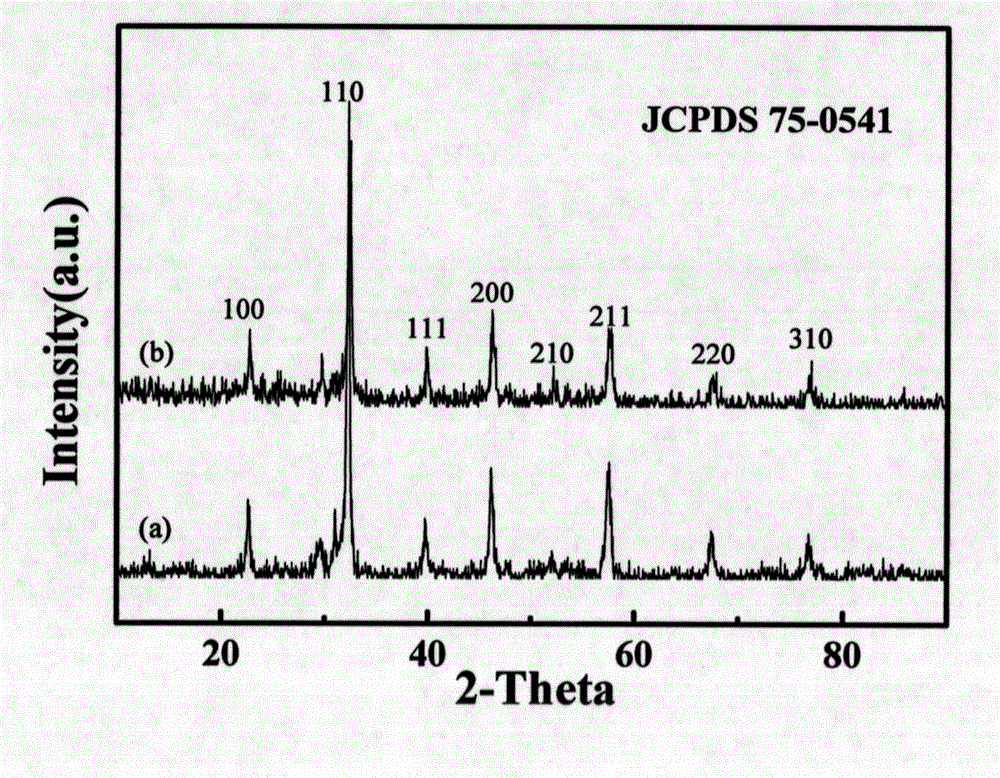

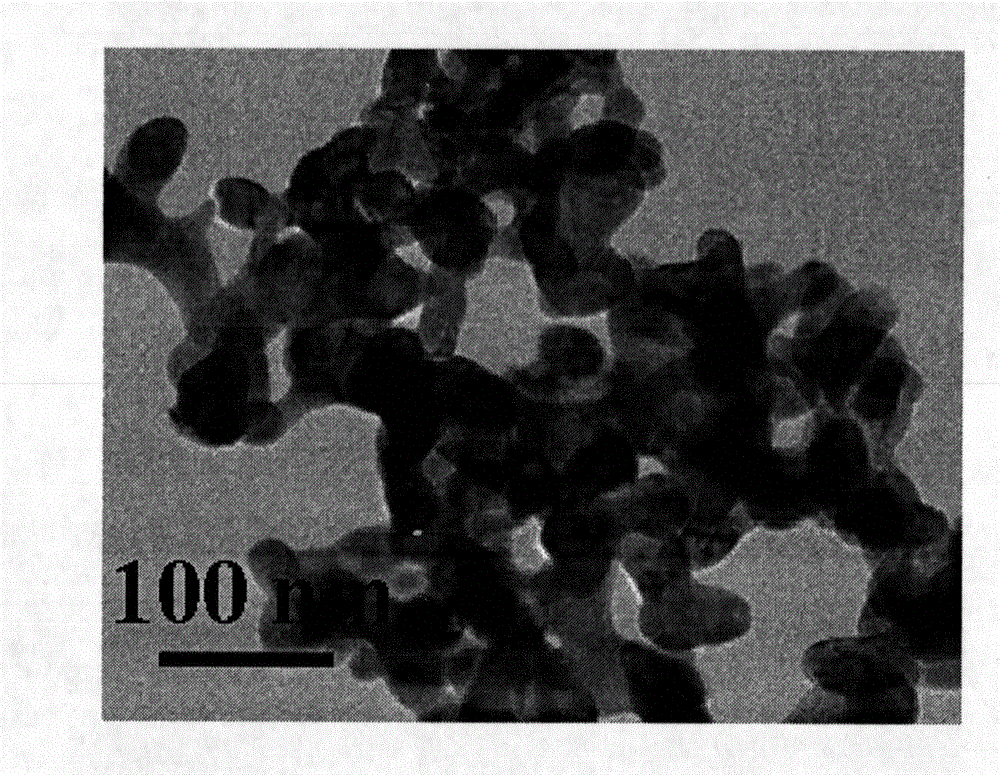

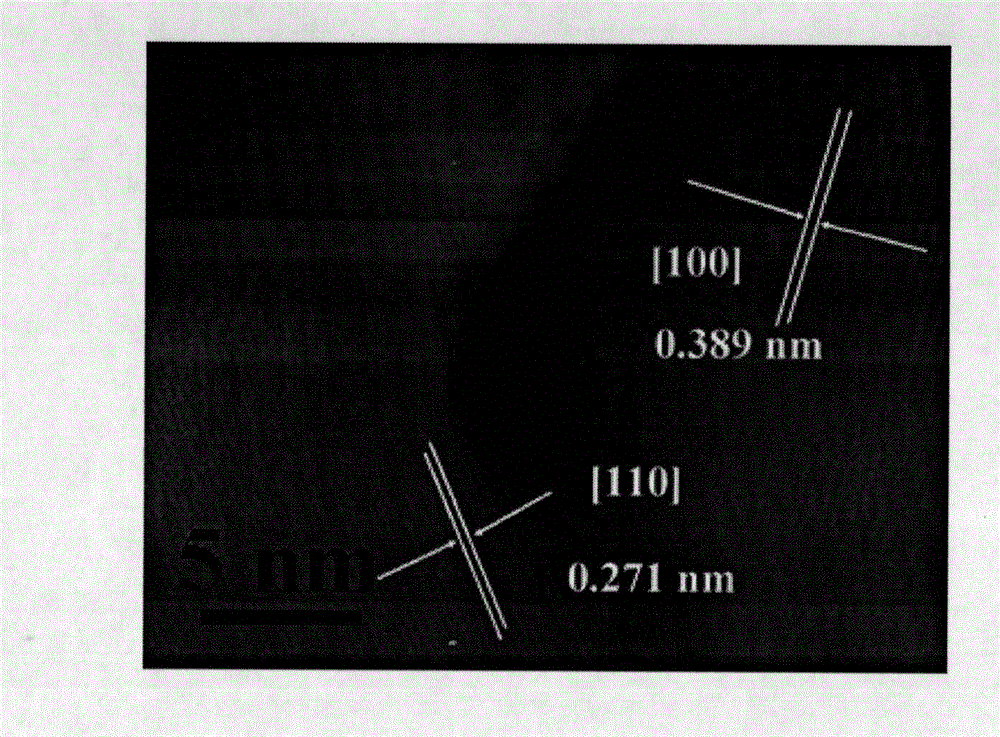

[0027] Embodiment 1: First weigh 0.22g La(NO 3 ) 3 ·6H 2 O, 0.20g Fe(NO 3 ) 3 9H 2 O, 0.3g urea, and 1.773g glucose monohydrate were dissolved in 35ml distilled water to obtain a pale yellow mixed solution. Transfer the above mixed solution to a hydrothermal reaction kettle, seal it well, raise the temperature to 180° C., keep it for 12 hours, and the reaction ends. After natural cooling, the solid product was collected, and the tan product received after washing and drying was the carbon-coated lanthanum iron precipitate nanomaterial. The above-mentioned tan product was calcined at 600°C for 4 hours under air and nitrogen atmosphere respectively, and the reddish-brown solid obtained by calcination under air was LaFeO 3, calcined under nitrogen to get a tan product which is LaFeO 3 C composite nanomaterials.

Embodiment 2

[0028] Embodiment 2: First weigh 0.22g La(NO 3 ) 3 ·6H 2 O, 0.20g Fe(NO 3 ) 3 9H 2 O, 0.45g urea, 1.773g glucose monohydrate were dissolved in 35ml distilled water to obtain a pale yellow mixed solution. Transfer the above mixed solution to a hydrothermal reaction kettle, seal it well, raise the temperature to 180° C., keep it for 12 hours, and the reaction ends. After natural cooling, the solid product was collected, and the tan product received after washing and drying was the carbon-coated lanthanum iron precipitate nanomaterial. The above-mentioned tan product was calcined at 800°C for 3 hours under air and nitrogen atmosphere respectively, and the reddish-brown solid obtained by calcination under air was LaFeO 3 , calcined under nitrogen to get a tan product which is LaFeO 3 C composite nanomaterials.

Embodiment 3

[0029] Embodiment 3: First weigh 0.22g La(NO 3 ) 3 ·6H 2 O, 0.20g Fe(NO 3 ) 3 9H 2 O, 0.6g urea, 1.773g glucose monohydrate were dissolved in 35ml distilled water to obtain a pale yellow mixed solution. Transfer the above mixed solution to a hydrothermal reaction kettle, seal it well, raise the temperature to 200° C., keep it for 12 hours, and the reaction ends. After natural cooling, the solid product was collected, and the tan product received after washing and drying was the carbon-coated lanthanum iron precipitate nanomaterial. The above-mentioned tan product was calcined at 1000°C for 2 hours under air and nitrogen atmosphere respectively, and the reddish-brown solid obtained by calcination under air was LaFeO 3 , calcined under nitrogen to get a tan product which is LaFeO 3 C composite nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com