Underwater noiseless, drag-reducing and antifouling bionic housing

An anti-fouling and shell technology, which is applied in the field of bionic shells and underwater bionic shells, can solve the problems of reducing ship speed, affecting human health, affecting ship waveguide dynamics, economy and safety, etc., to achieve improved anti-fouling Pollution ability and the effect of reducing radiated sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

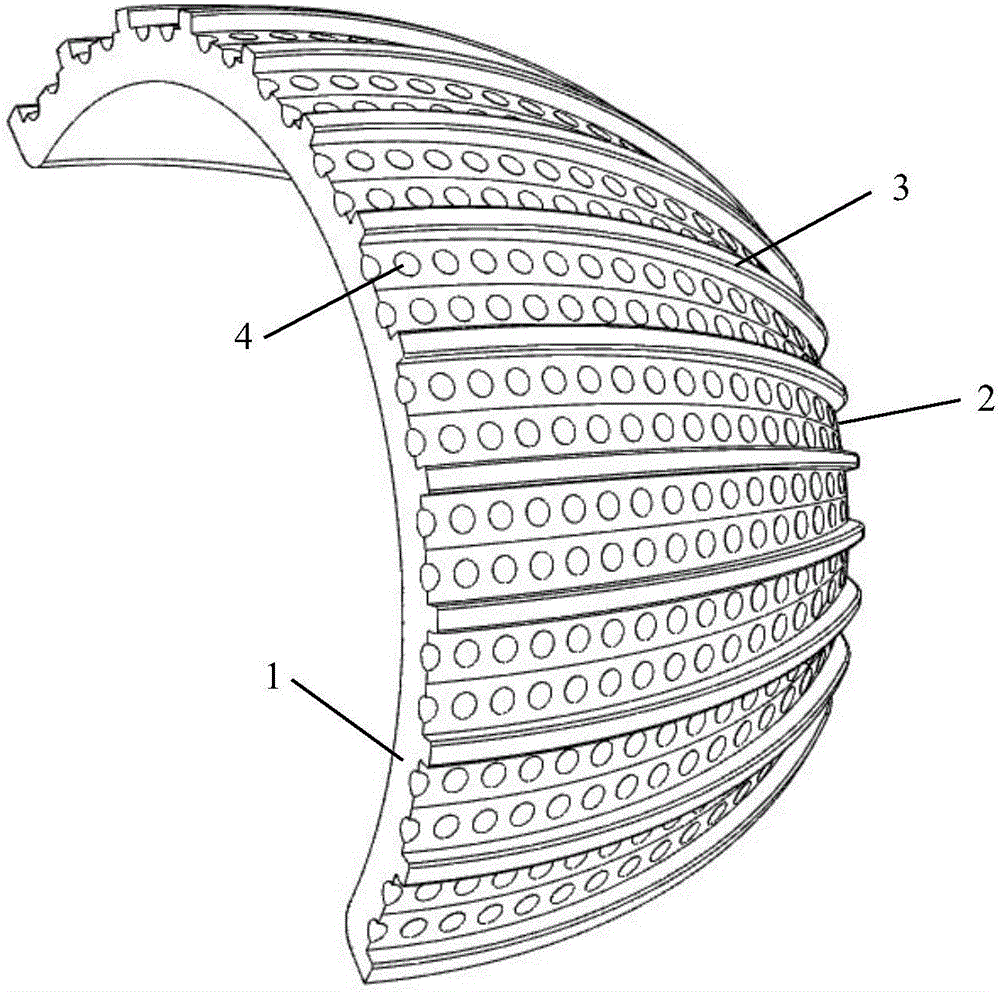

[0021] like figure 1 Shown is a schematic diagram of the radial U-shaped groove bionic shell of the present invention, figure 2 Shown is a partially enlarged schematic diagram of the U-shaped groove. Radial U-shaped grooves 2 are distributed on the outer surface of the substrate 1, and the radial U-shaped grooves 2 are formed by several micro-ridge structures 3 on the outer surface of the substrate 1, and there are regular lattice distributions on the surface of the substrate 1 in each groove 2. The spherical crown-shaped pit 4. The wall thickness of the U-shaped groove 2 is 4 mm, the height of the groove wall is 3 mm, and the maximum width of the U-shaped groove 2 is 15 mm. The diameter of the spherical crown-shaped pits 4 distributed on the outer surface of the substrate 1 in the U-shaped groove 2 is 4 mm, the pitch of the pits 4 is 8 mm, and the depth of the pits 4 accounts for 30% of the thickness of the substrate 1 .

Embodiment 2

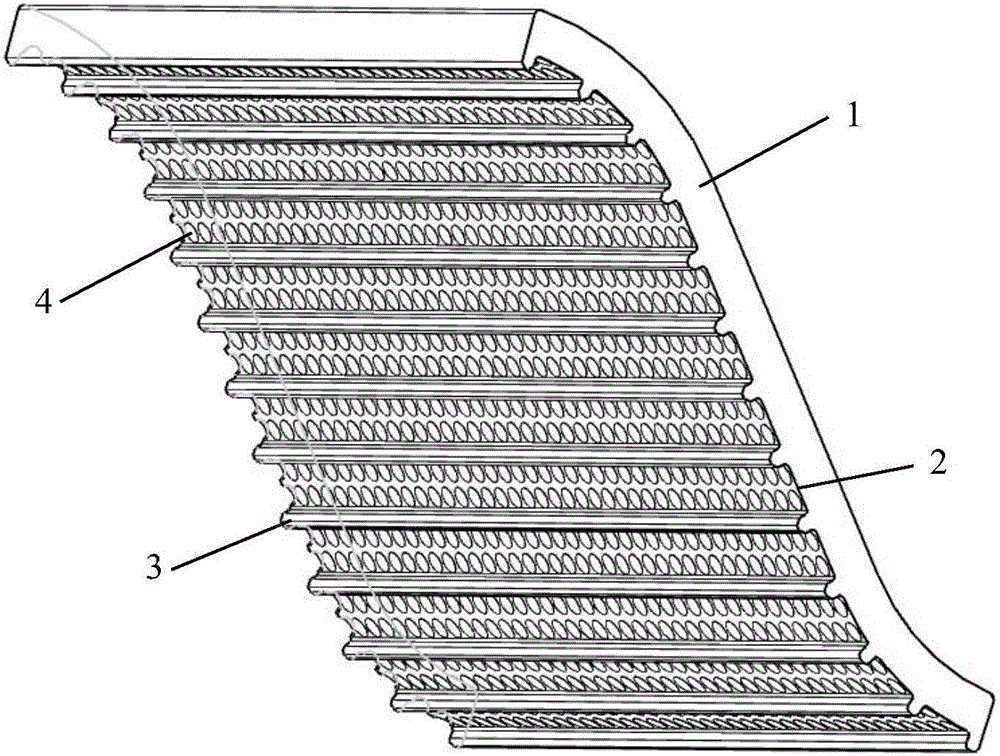

[0023] like image 3 Shown is a schematic diagram of the parallel U-shaped groove bionic shell of the present invention. Parallel U-shaped grooves 2 are distributed on the outer surface of the substrate 1. The parallel U-shaped grooves 2 are formed by several micro-ridge structures 3 on the outer surface of the substrate 1, and there are regular grooves on the outer surface of the substrate 1 in each groove 2. Spherical crown-shaped pits 4 distributed in a lattice. The wall thickness of the U-shaped groove 2 is 4mm, and the height of the groove wall is 3mm. The width of the U-shaped groove 2 is 1 cm. The spherical crown-shaped pits 4 distributed on the outer surface of the substrate 1 in the U-shaped groove 2 have a bottom circle diameter of 3 mm, a pitch of 6 mm between the pits 4, and a depth of the pits 4 accounting for 20% of the thickness of the substrate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com