Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

247results about How to "Secure strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

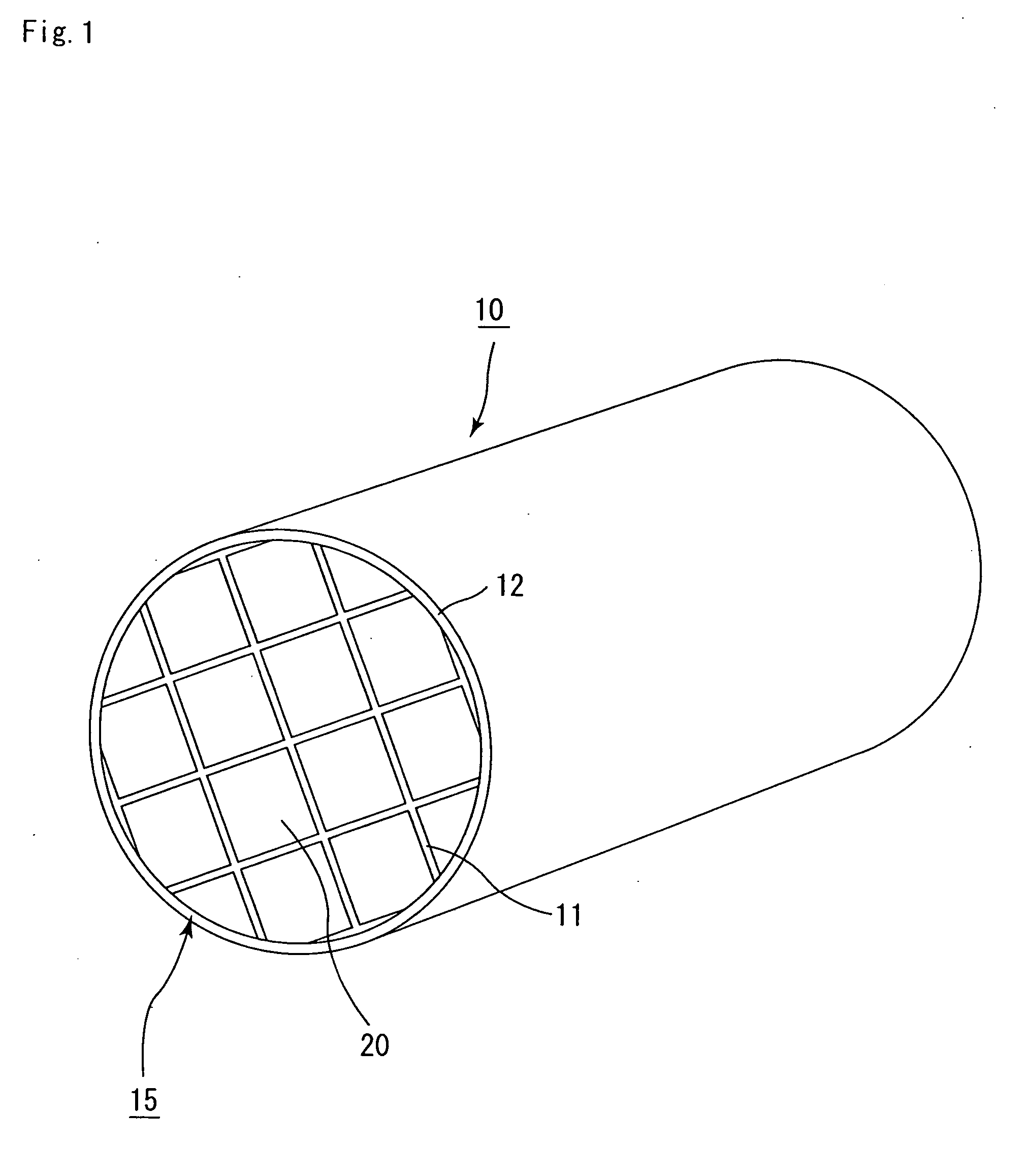

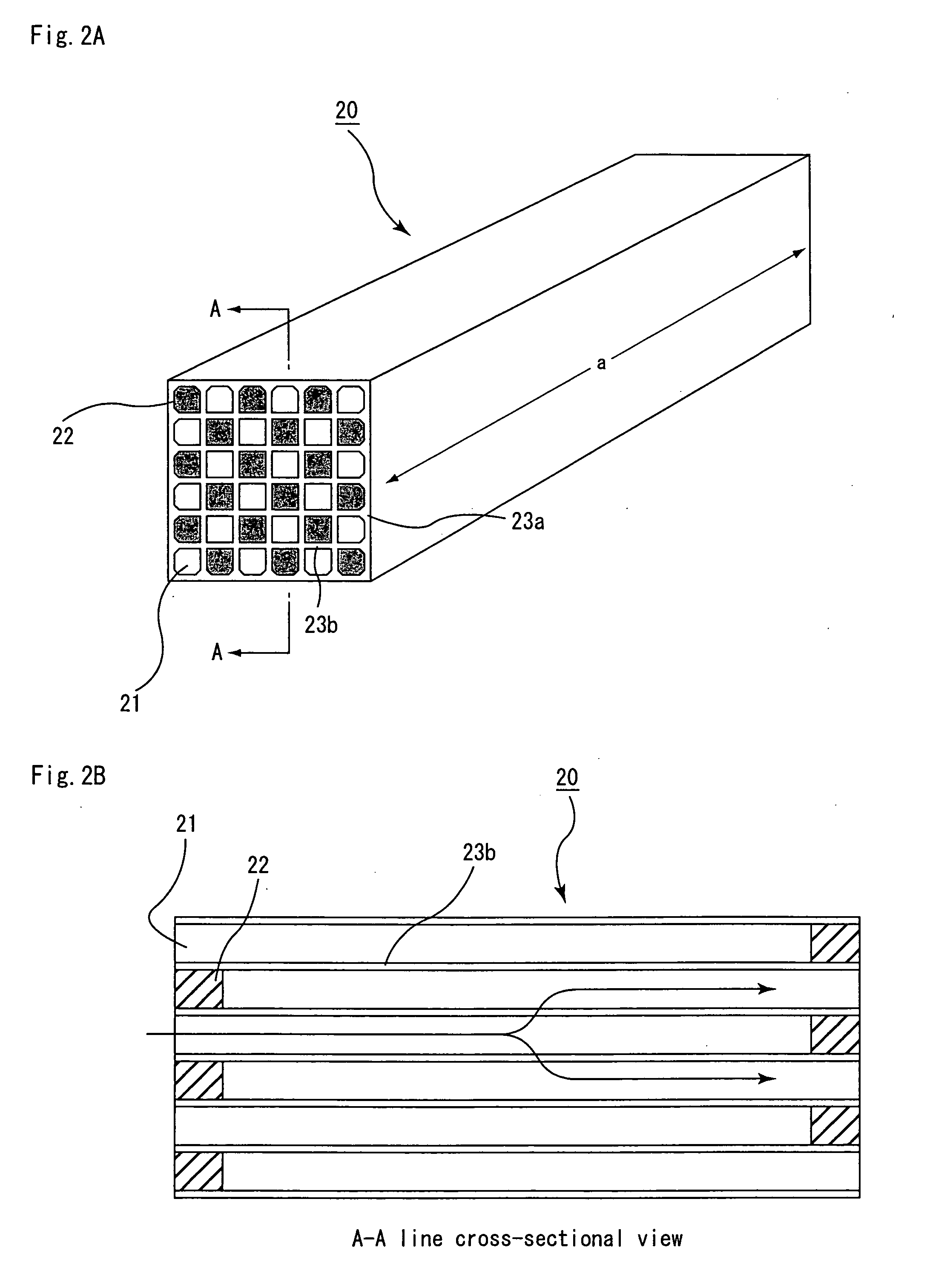

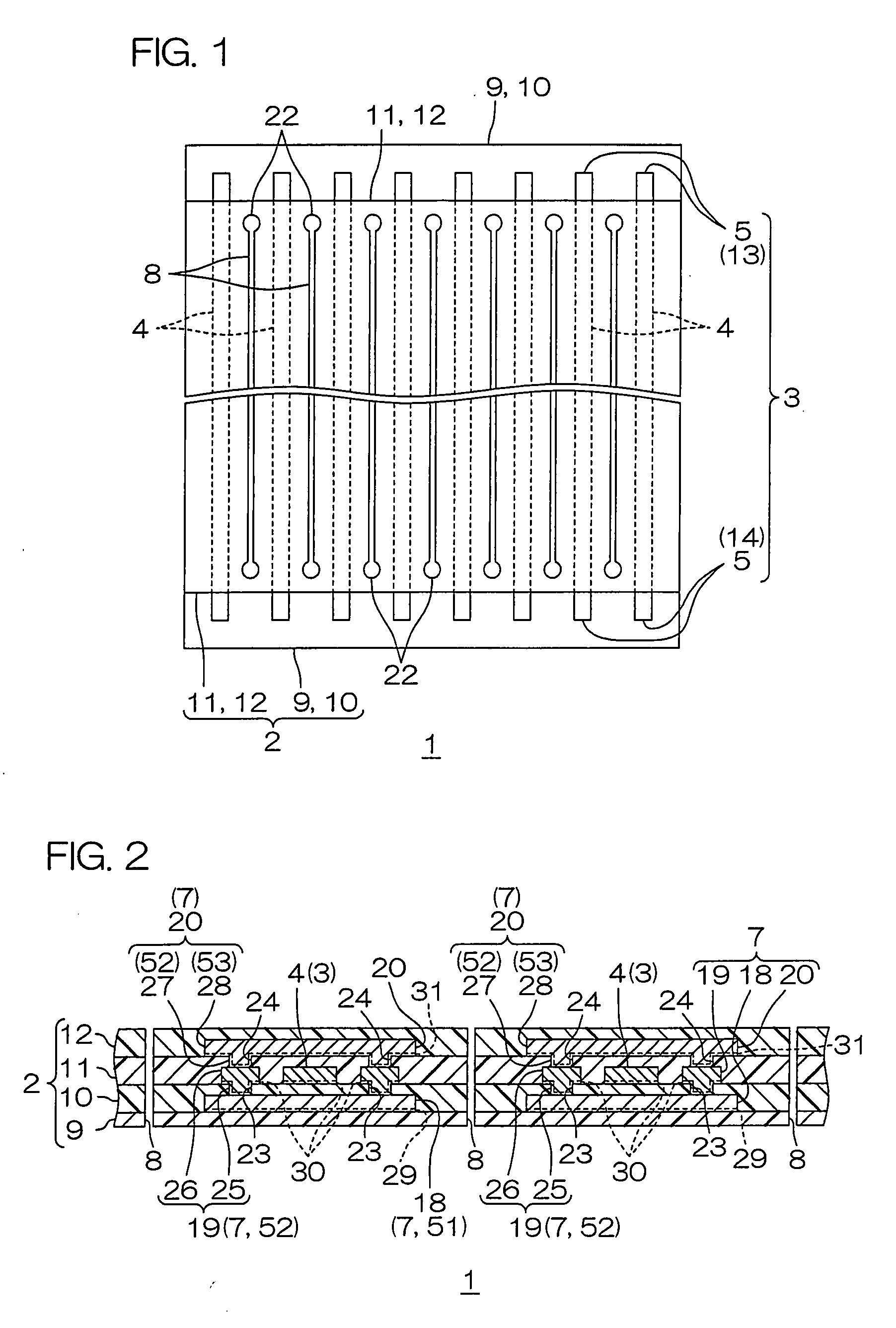

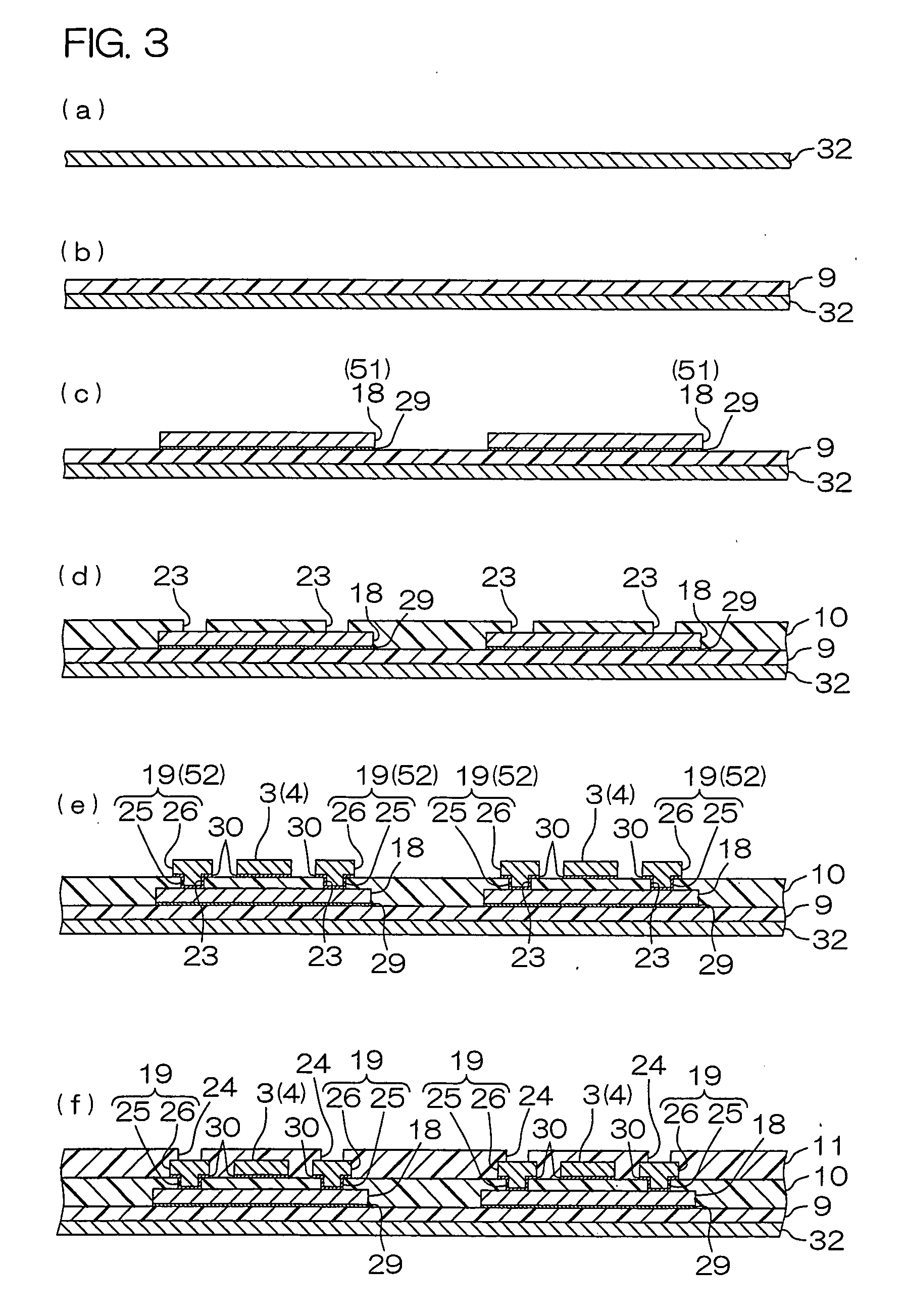

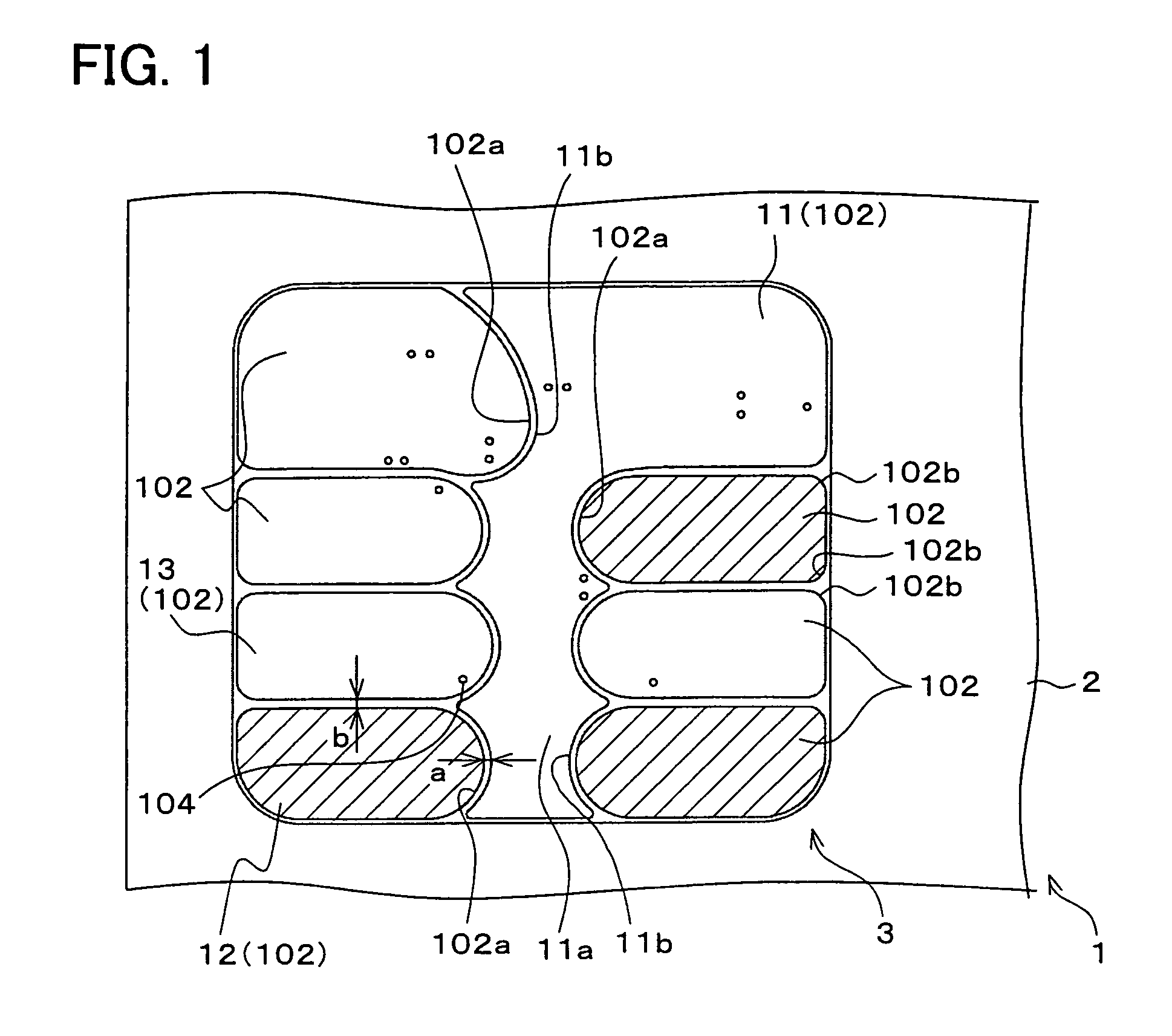

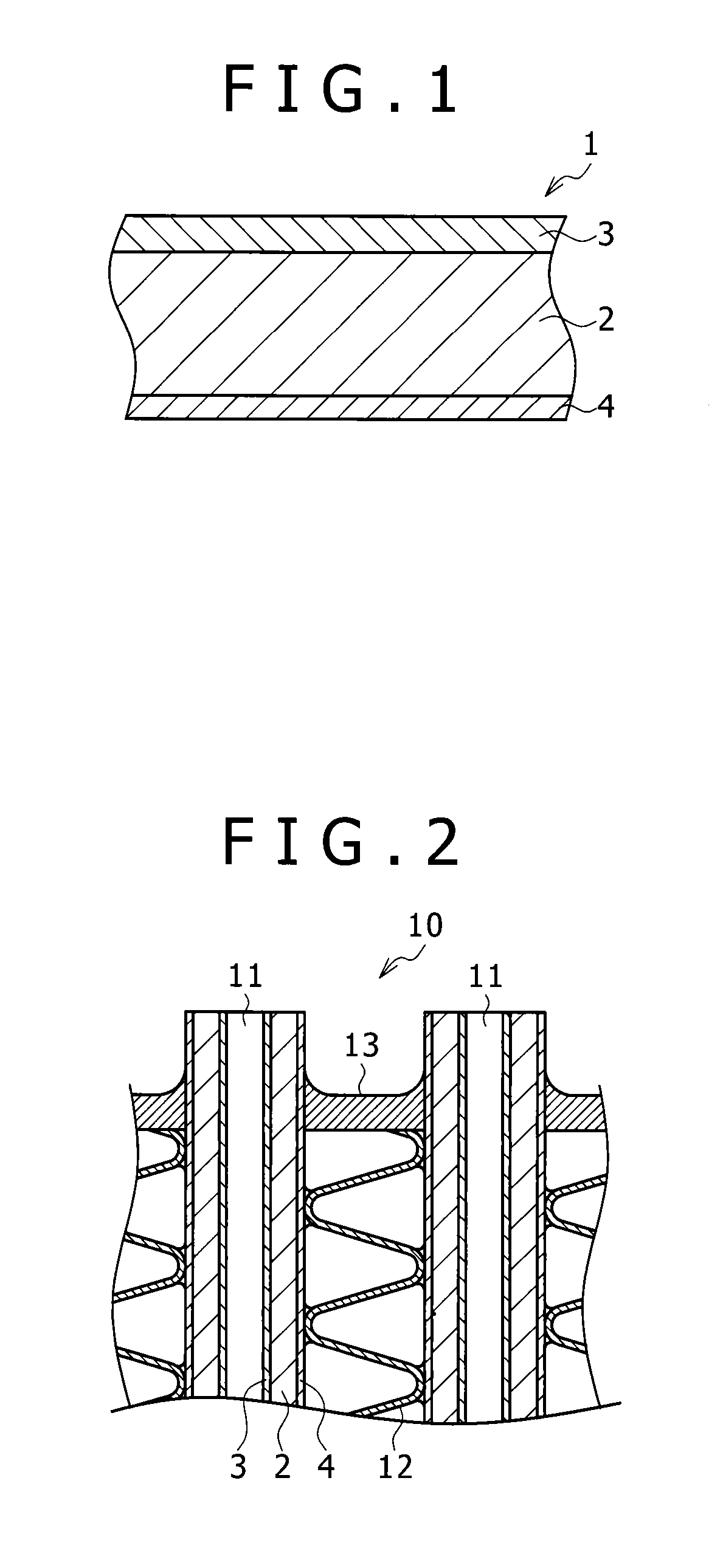

Honeycomb structured body, method for manufacturing honeycomb structured body and exhaust gas purifying device

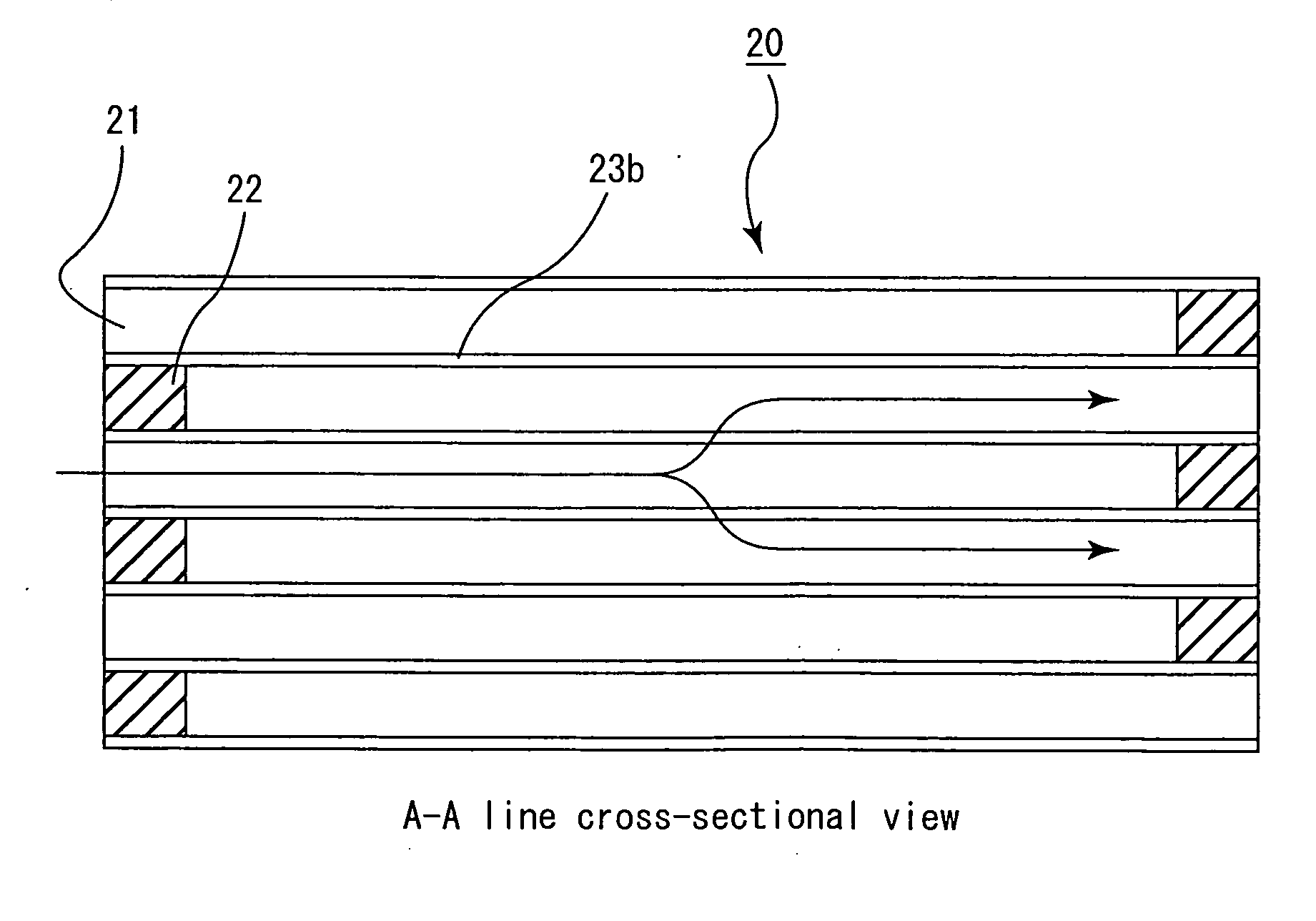

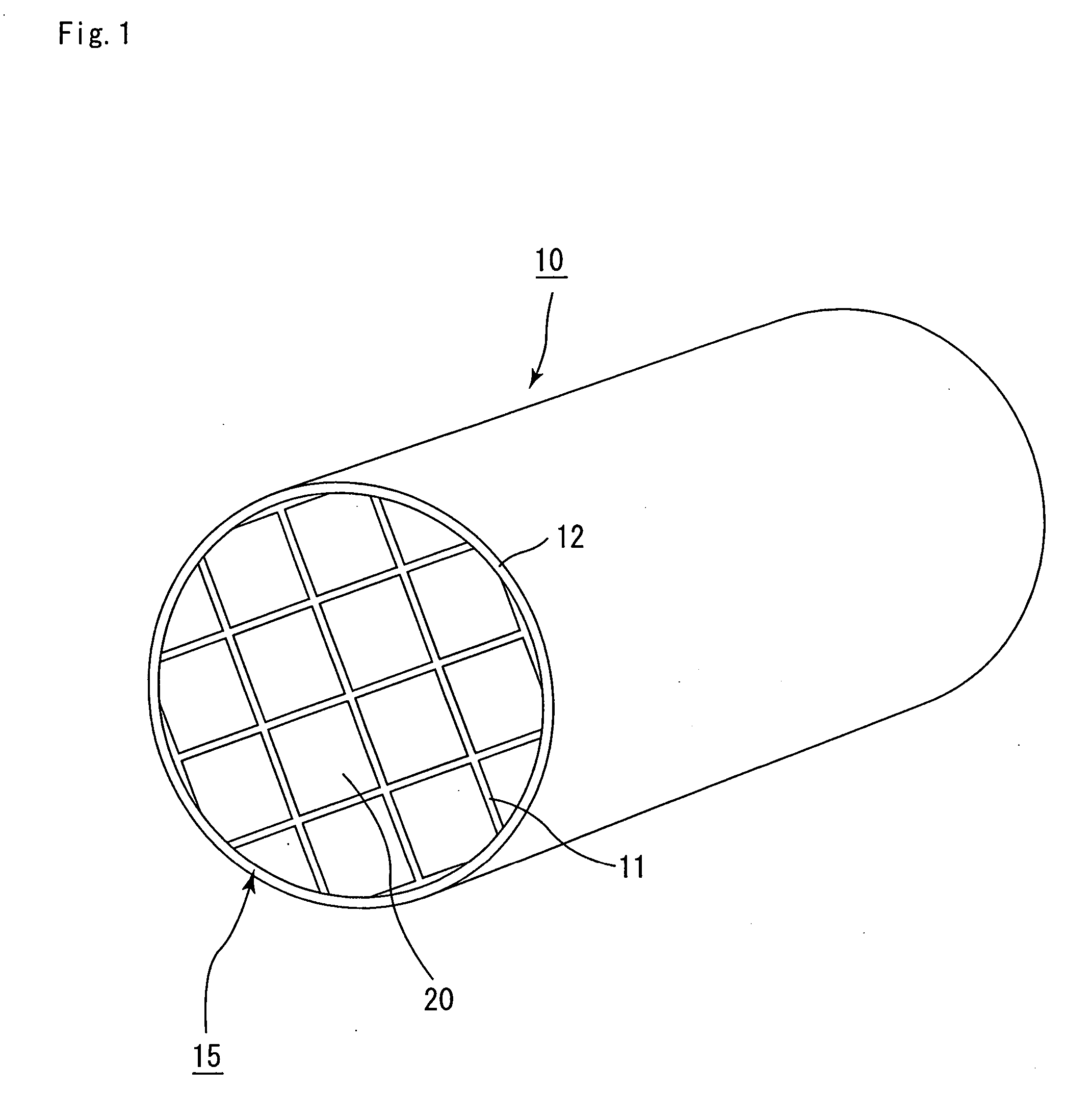

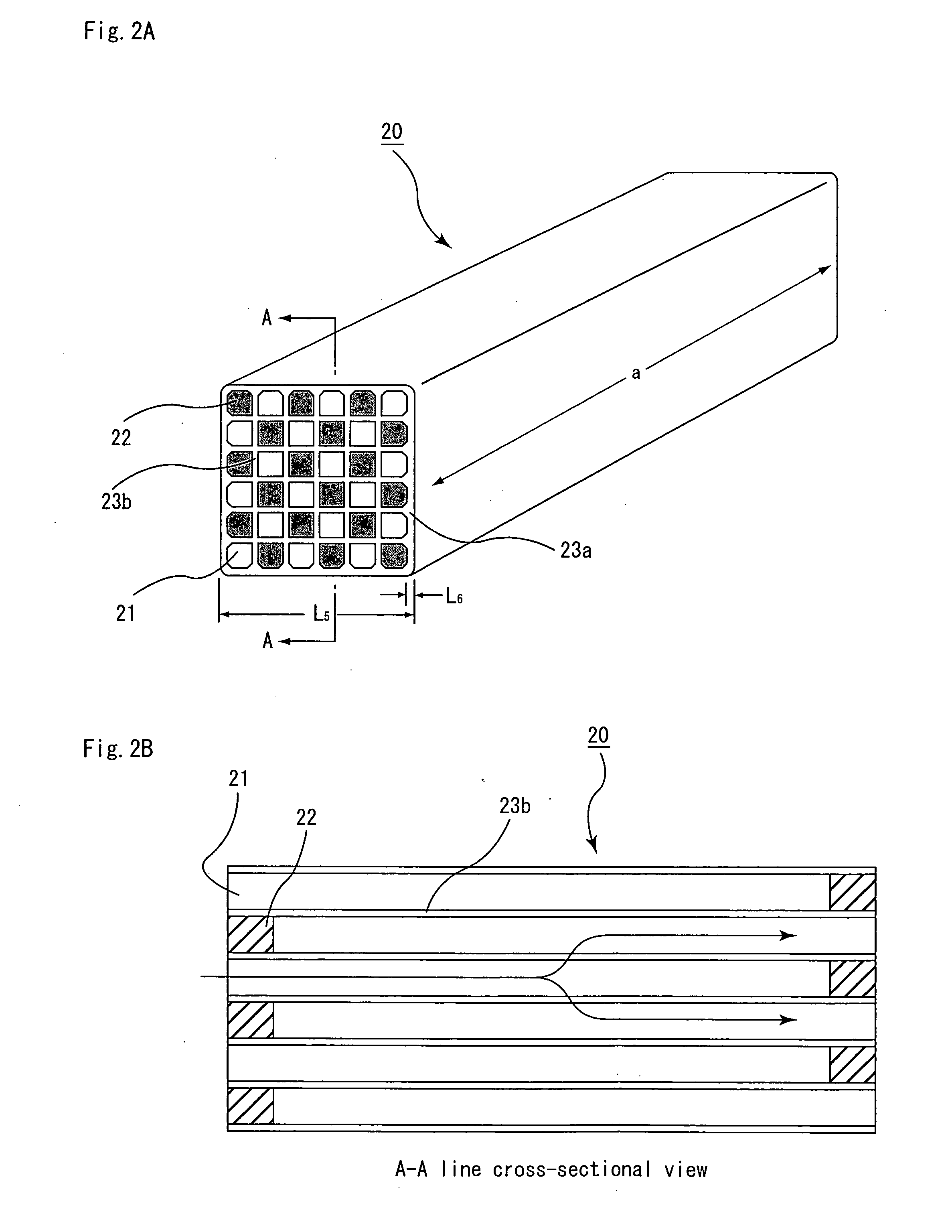

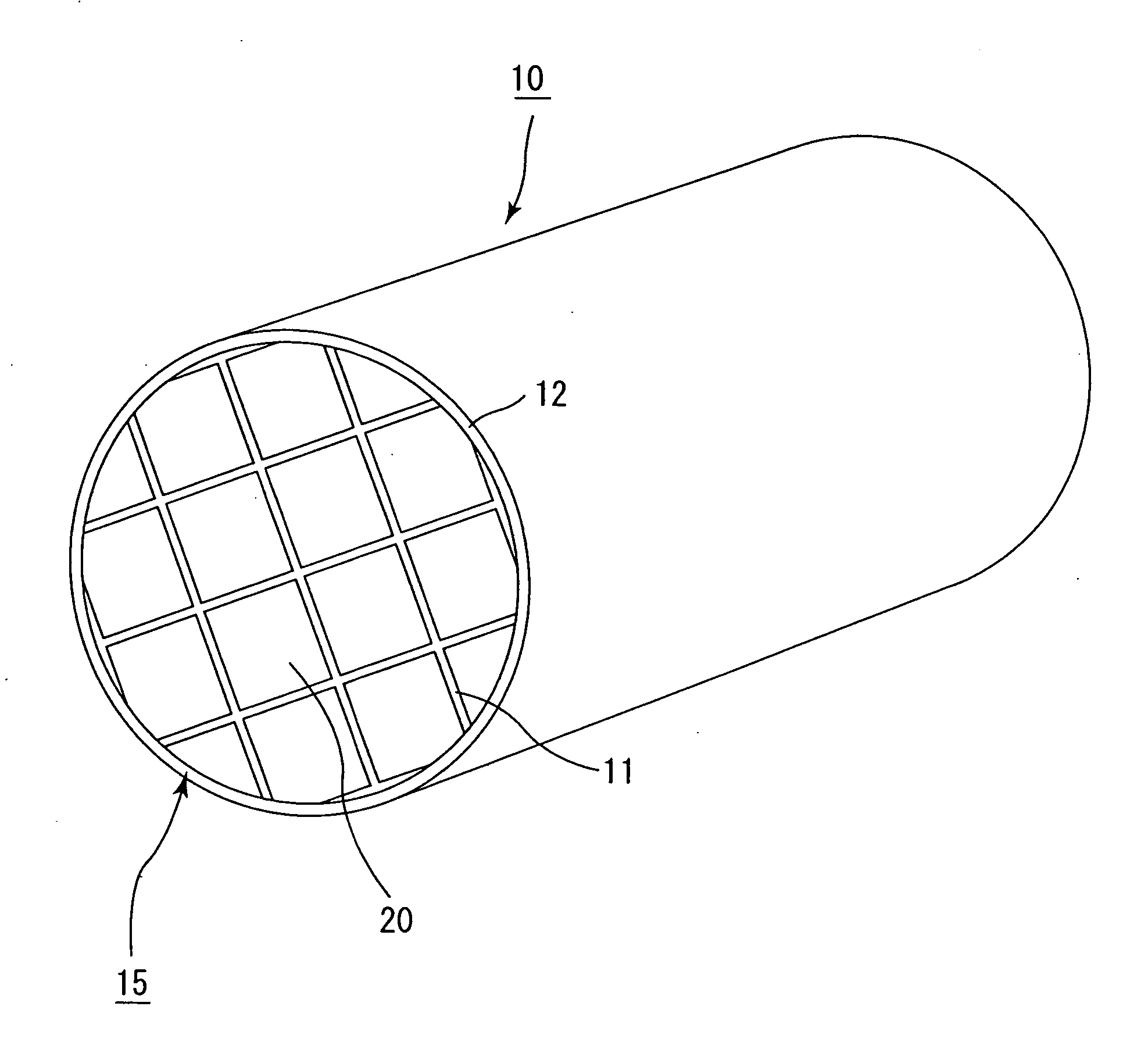

ActiveUS20070128405A1Secure strengthLoss levelingPhysical/chemical process catalystsInternal combustion piston enginesRight triangleEdge surface

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and having an outer edge wall on the outer edge surface thereof, wherein each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members, a cross-sectional shape of the outermost cell at the face orthogonal to the longitudinal direction of the cells is an almost tetragon, and a cross-sectional shape of the filling body at the face orthogonal to the longitudinal direction of the cells is an almost right triangle.

Owner:IBIDEN CO LTD

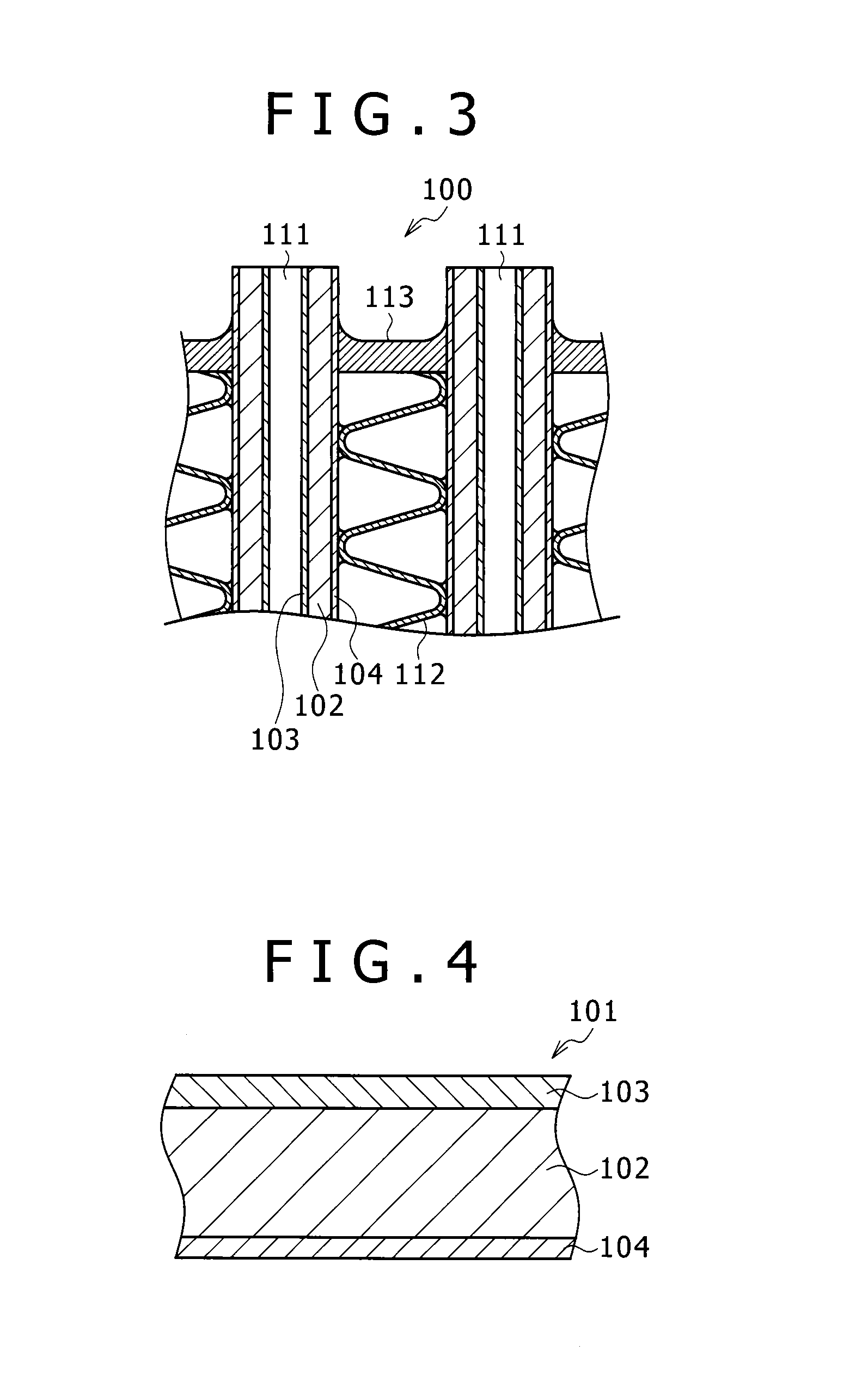

Honeycomb structured body, method for manufacturing honeycomb structured body, and exhaust gas purifying device

InactiveUS20070130897A1Avoid deformationReduce generationPhysical/chemical process catalystsInternal combustion piston enginesEdge surfaceCell wall

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and an outer edgewall on the outer edge surface thereof, wherein the thickness of the outer edge wall of the porous ceramic member is greater than the thickness of the cell wall, and each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members.

Owner:IBIDEN CO LTD

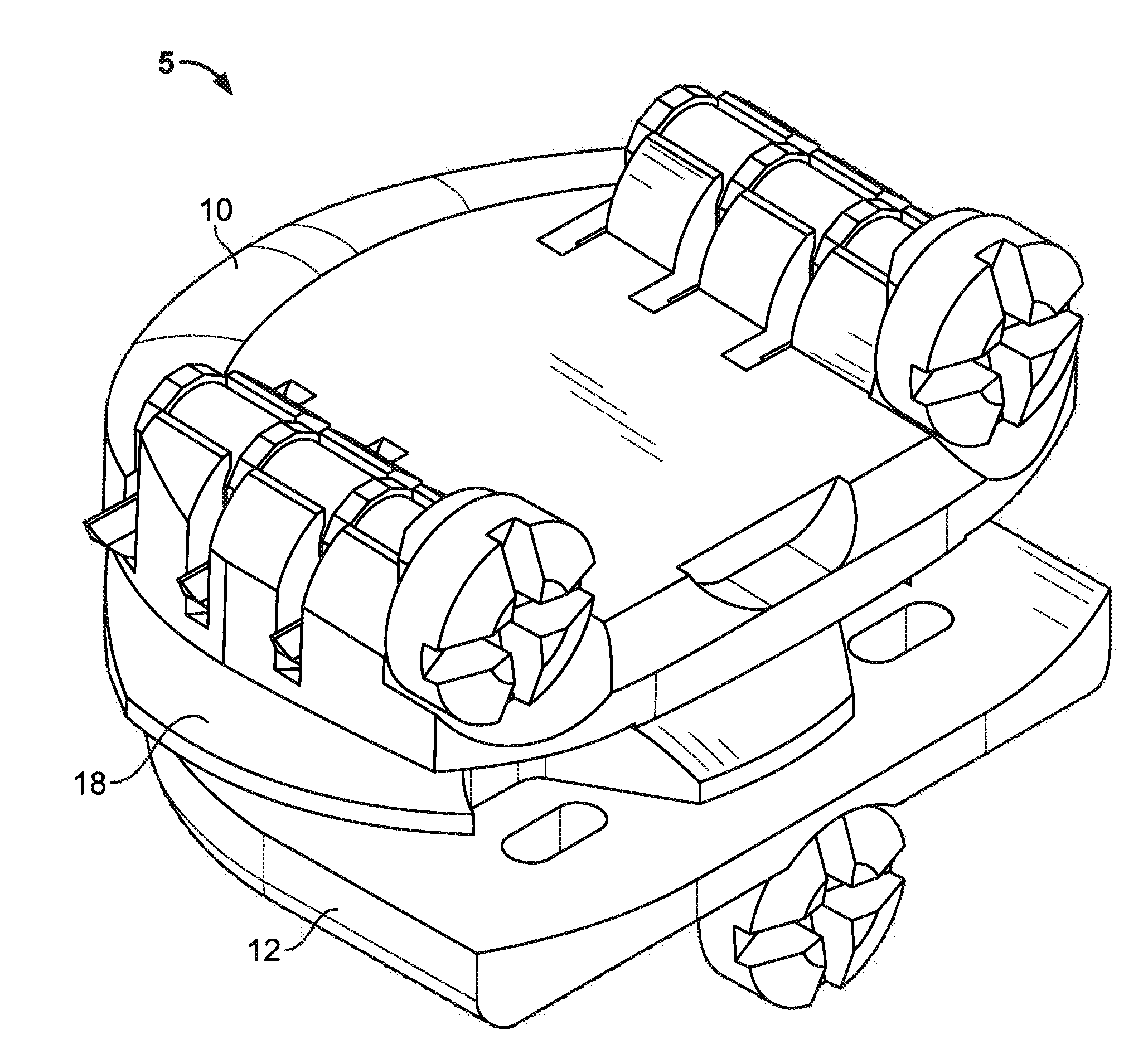

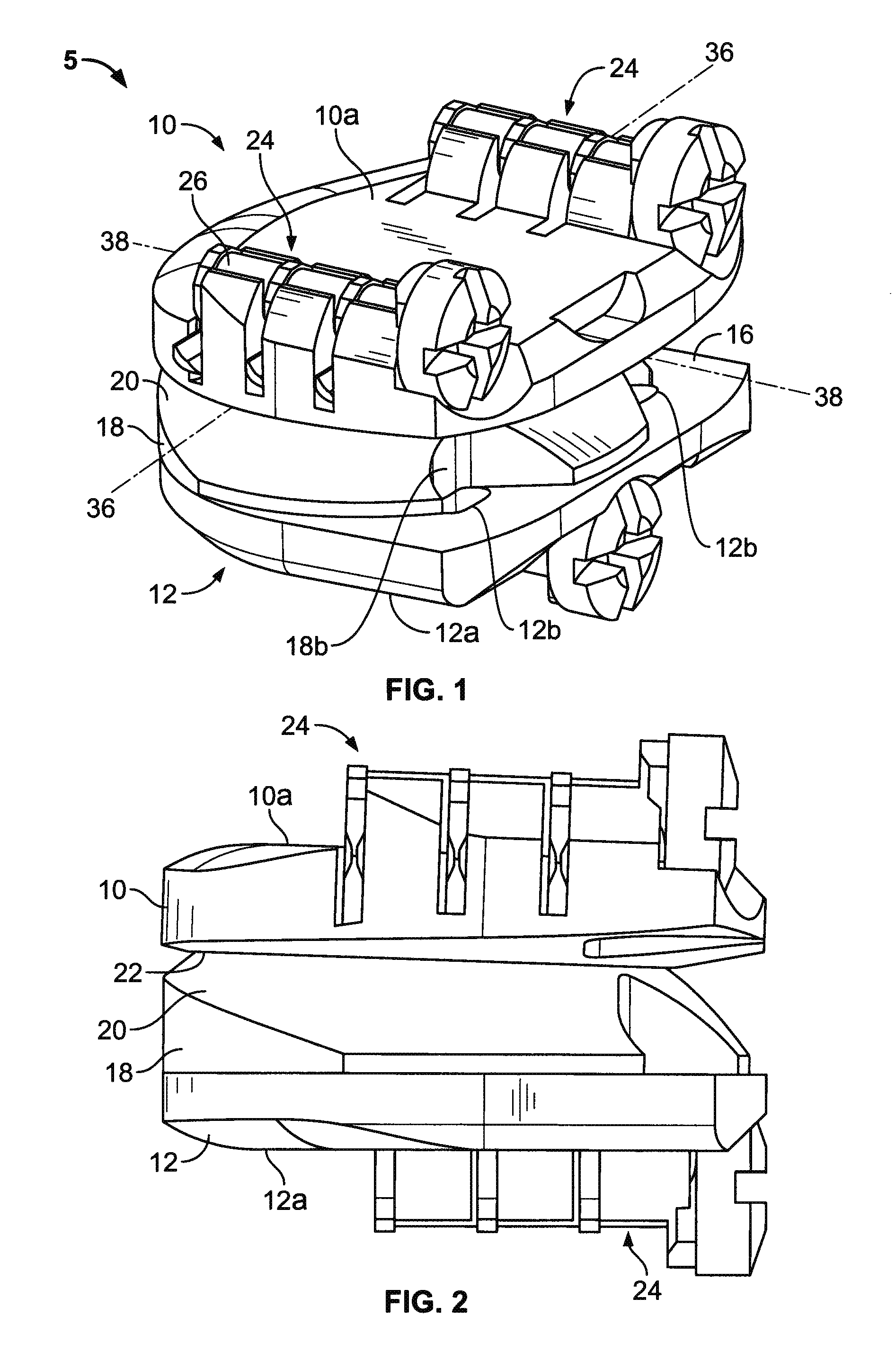

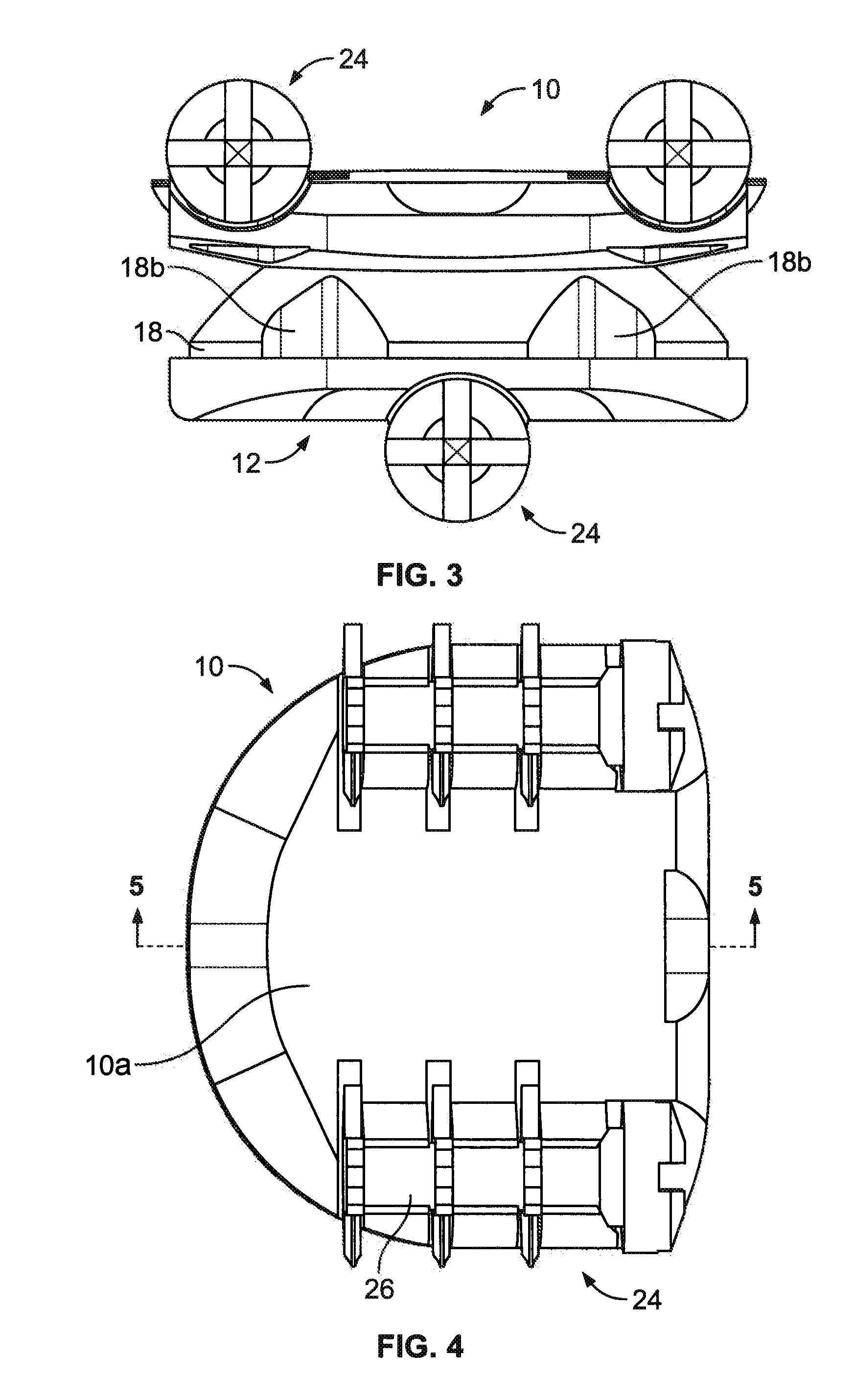

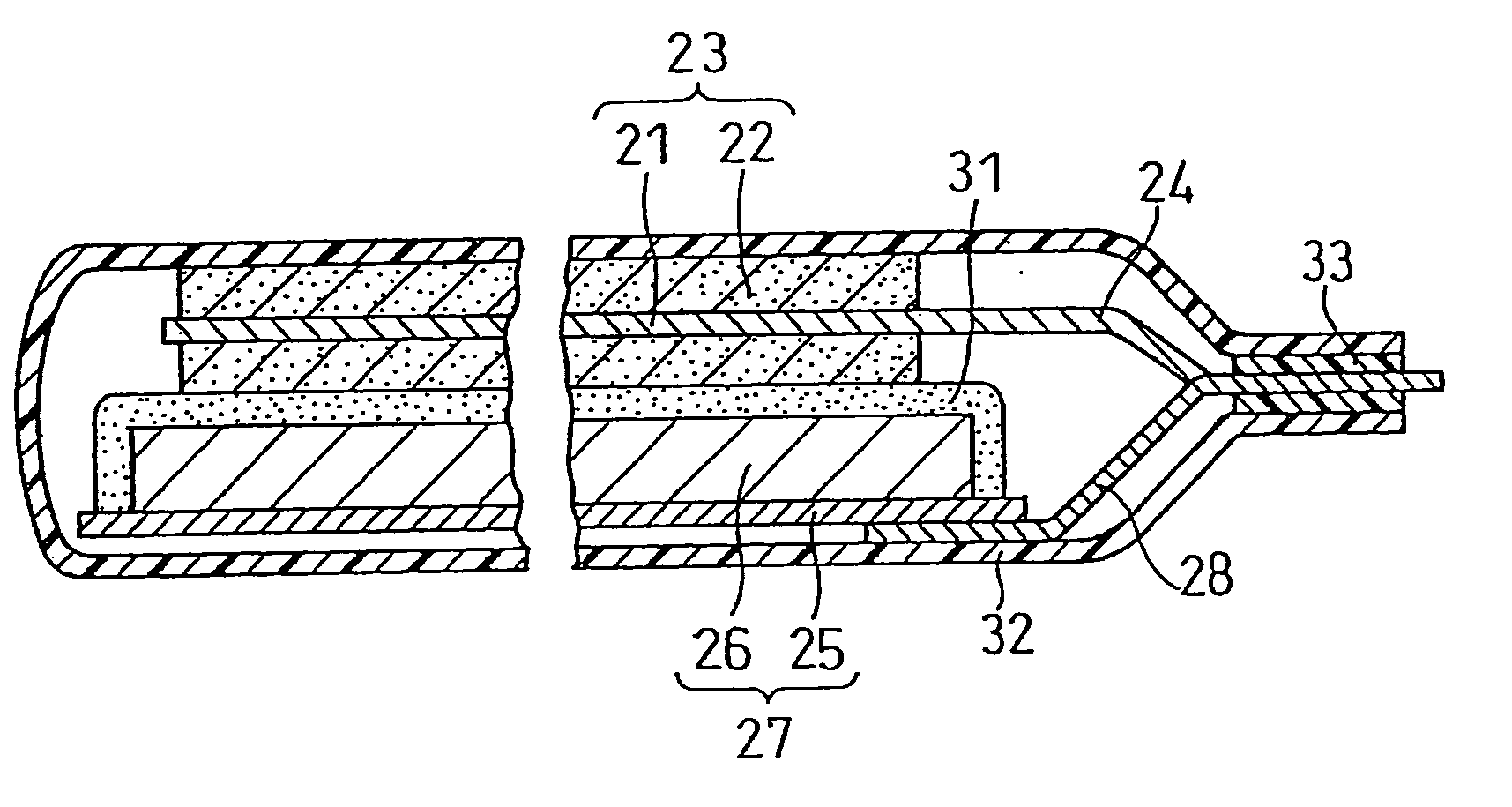

Motion Preserving Artificial Intervertebral Disc Device

InactiveUS20090240333A1Promotes self-centeringExtend the lifespanSpinal implantsCoatingsRelative motionIntervertebral disk

A motion preserving implant having first and second bearing members and a biasing member disposed therebetween operable to provide resistance to the translation of the bodies with respect to one another. An intervertebral implant having first and second bearing members, a translatable member, a resilient connection between the translatable member and one of the bearing members to allow for relative motion therebetween and bearing surfaces of the translatable member and the other bearing member to allow complex, natural motion between the bearing members. A spinal implant having upper and lower bodies and an articulation surface that allows for polyaxial articulation and translation through a concave articulation surface having a first radius of curvature and a second radius of curvature in at least one plane, and a convex articulation surface having the first radius of curvature in the same plane.

Owner:PIONEER SURGICAL TECH INC

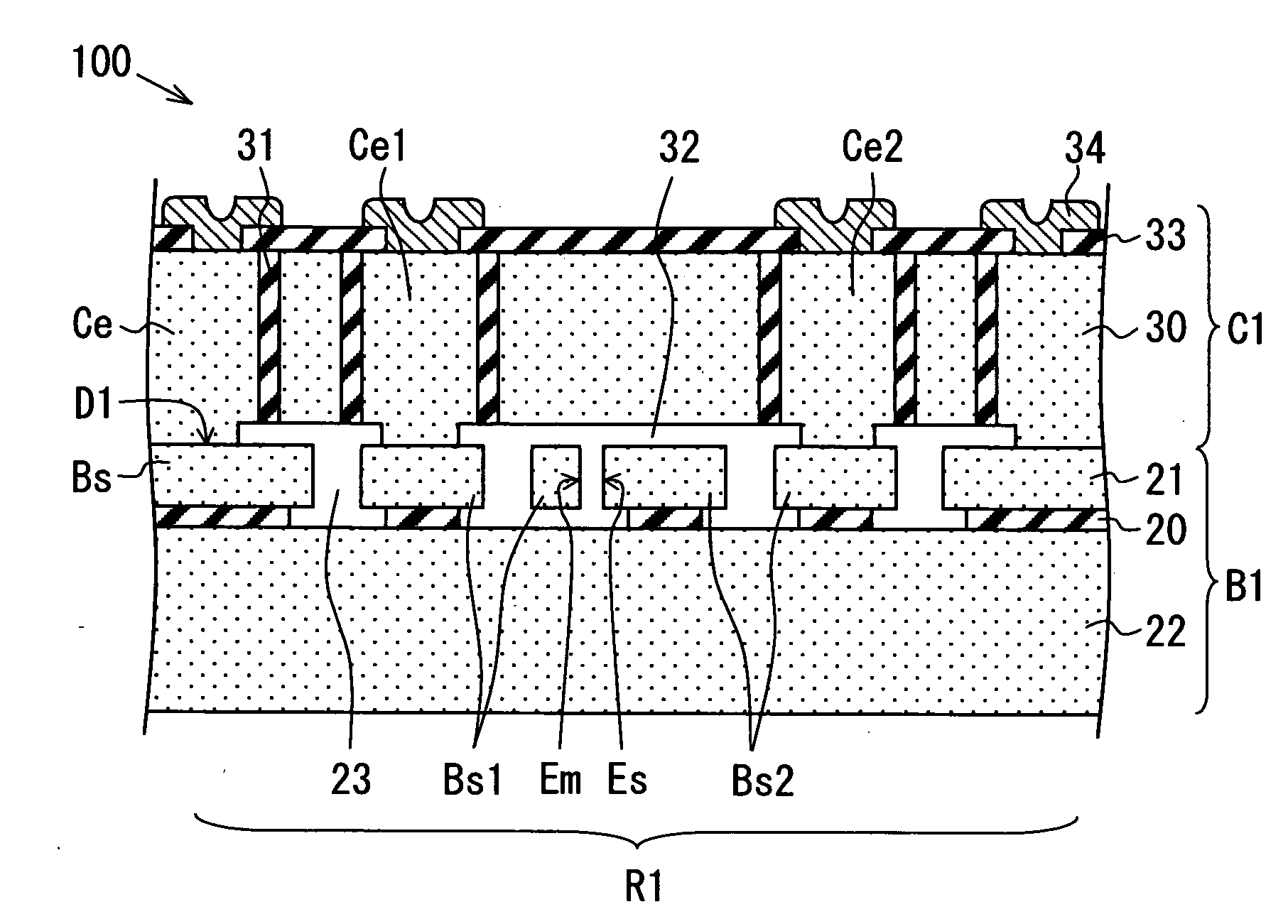

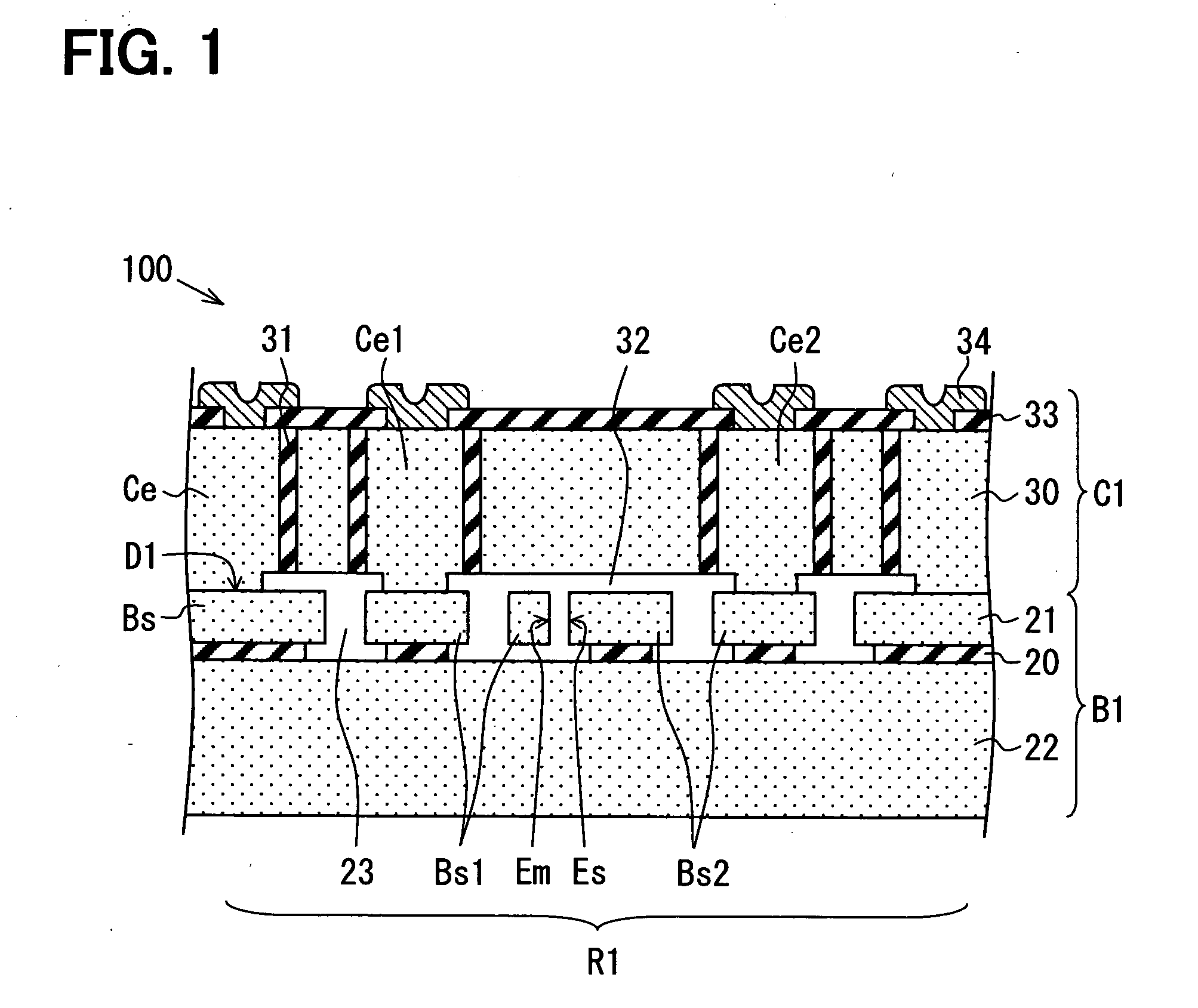

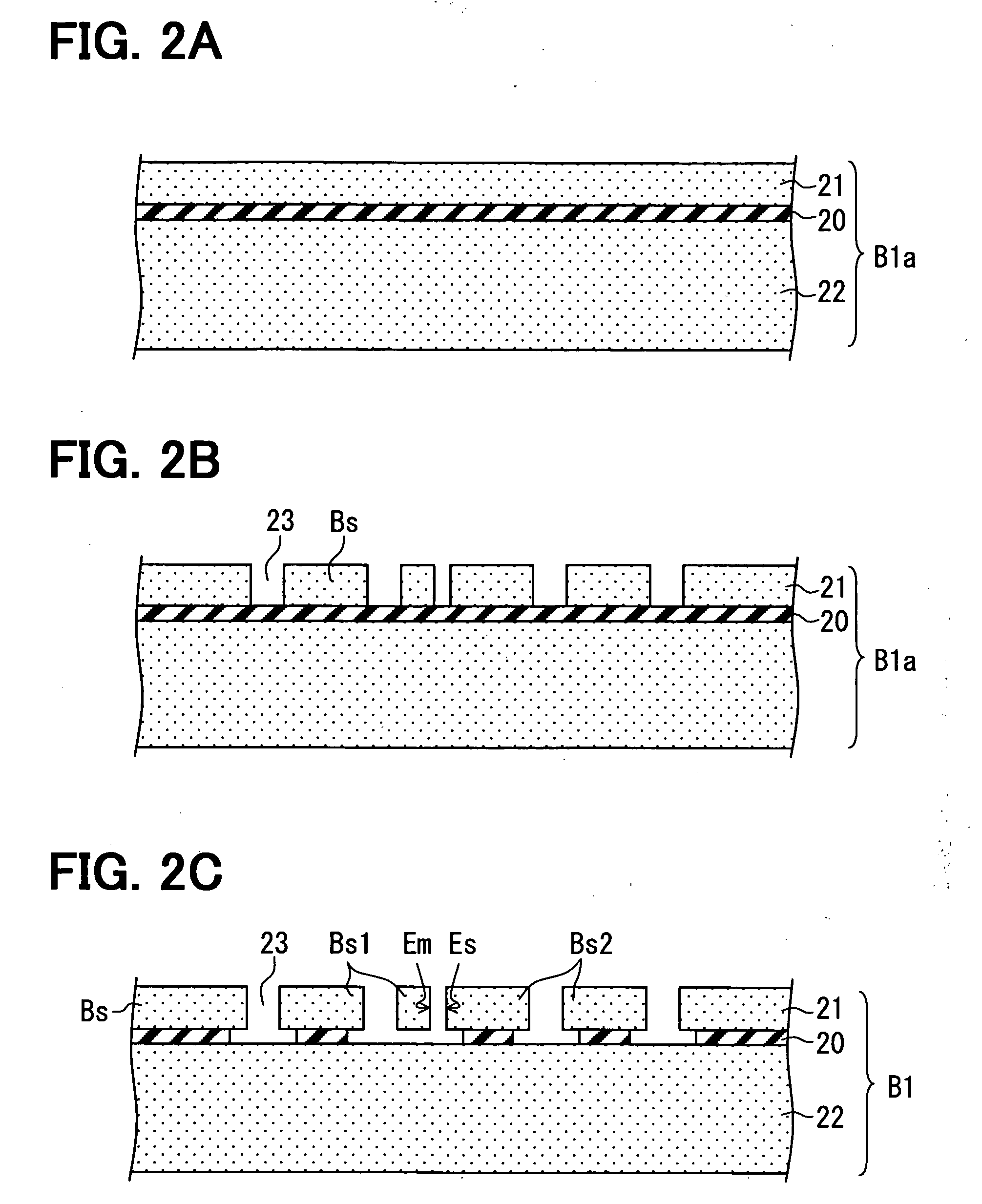

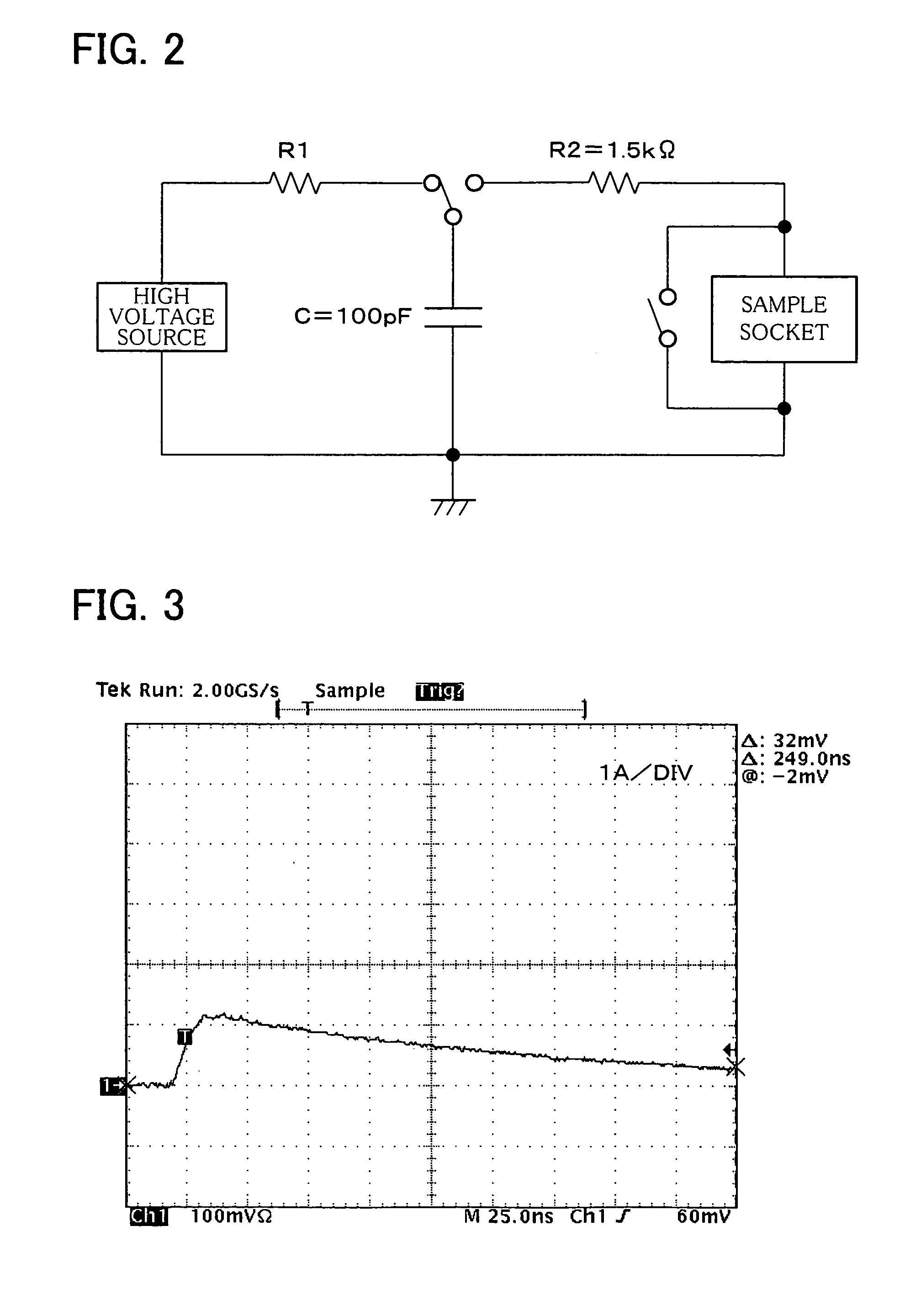

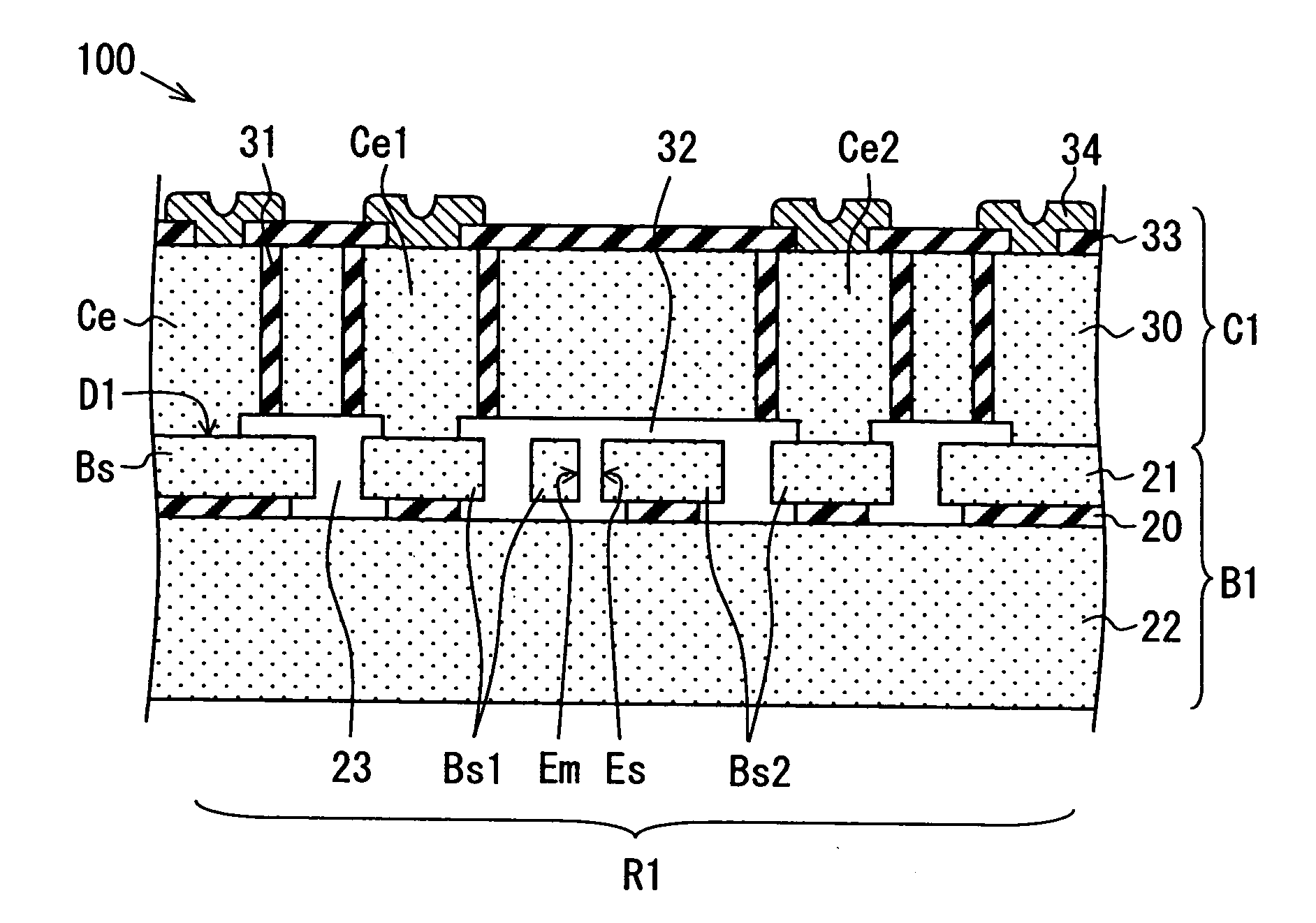

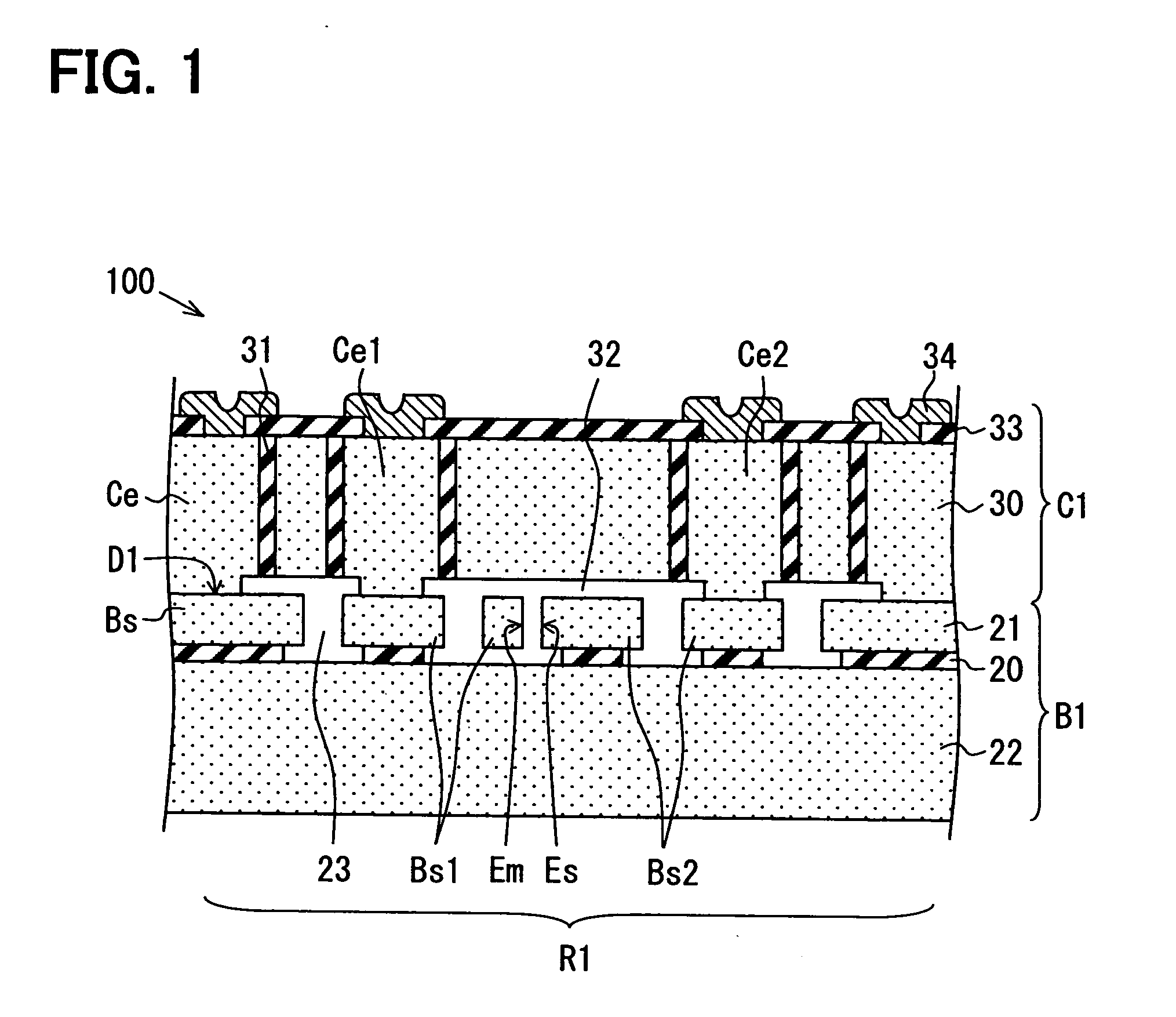

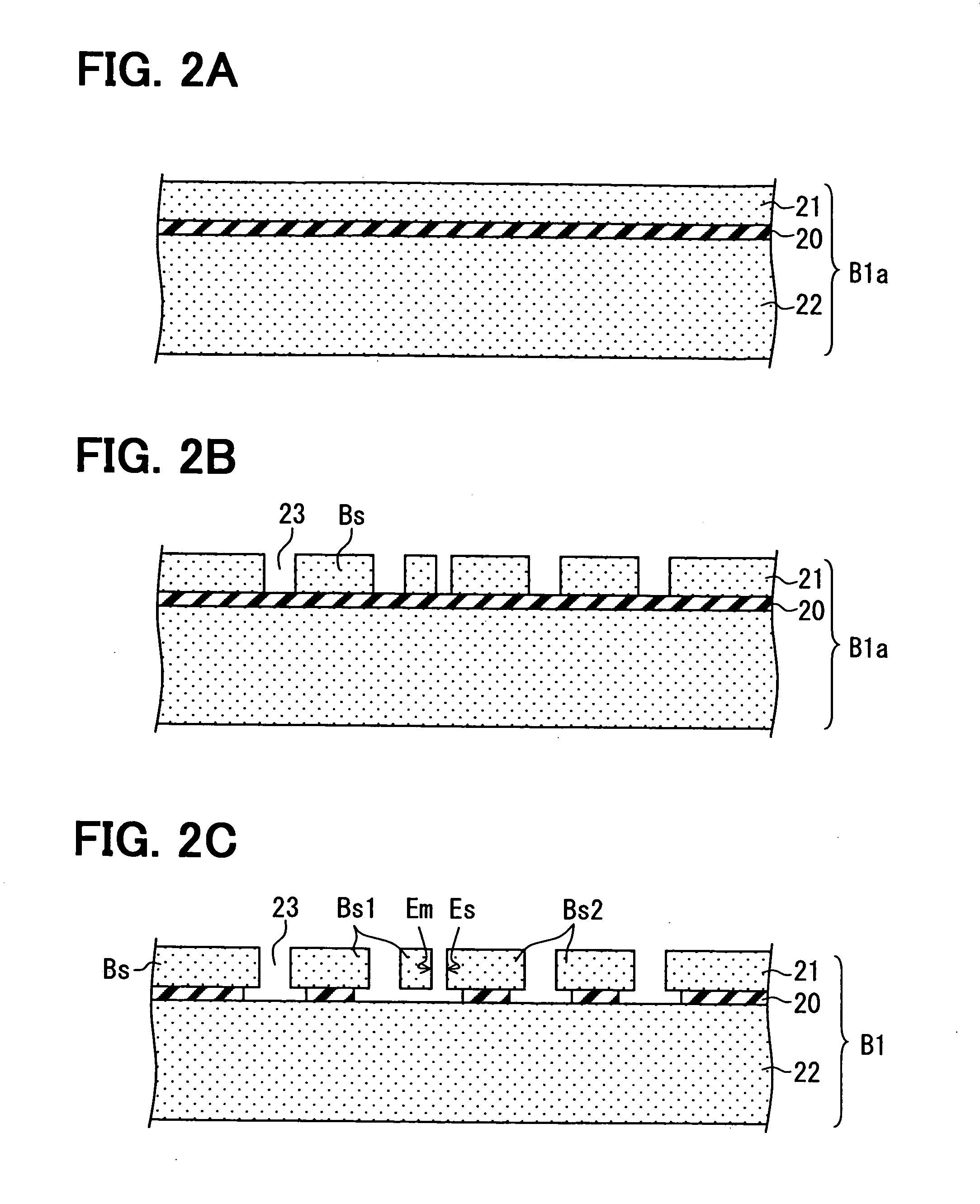

Semiconductor device and method for manufacturing the same

InactiveUS20080290490A1Reduce equipment costsSecure strengthPrecision positioning equipmentSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor device includes: a first substrate made of semiconductor and having first regions, which are insulated from each other and disposed in the first substrate; and a second substrate having electric conductivity and having second regions and insulation trenches. Each insulation trench penetrates the second substrate so that the second regions are insulated from each other. The first substrate provides a base substrate, and the second substrate provides a cap substrate. The second substrate is bonded to the first substrate so that a sealed space is provided between a predetermined surface region of the first substrate and the second substrate. The second regions include an extraction conductive region, which is coupled with a corresponding first region.

Owner:DENSO CORP

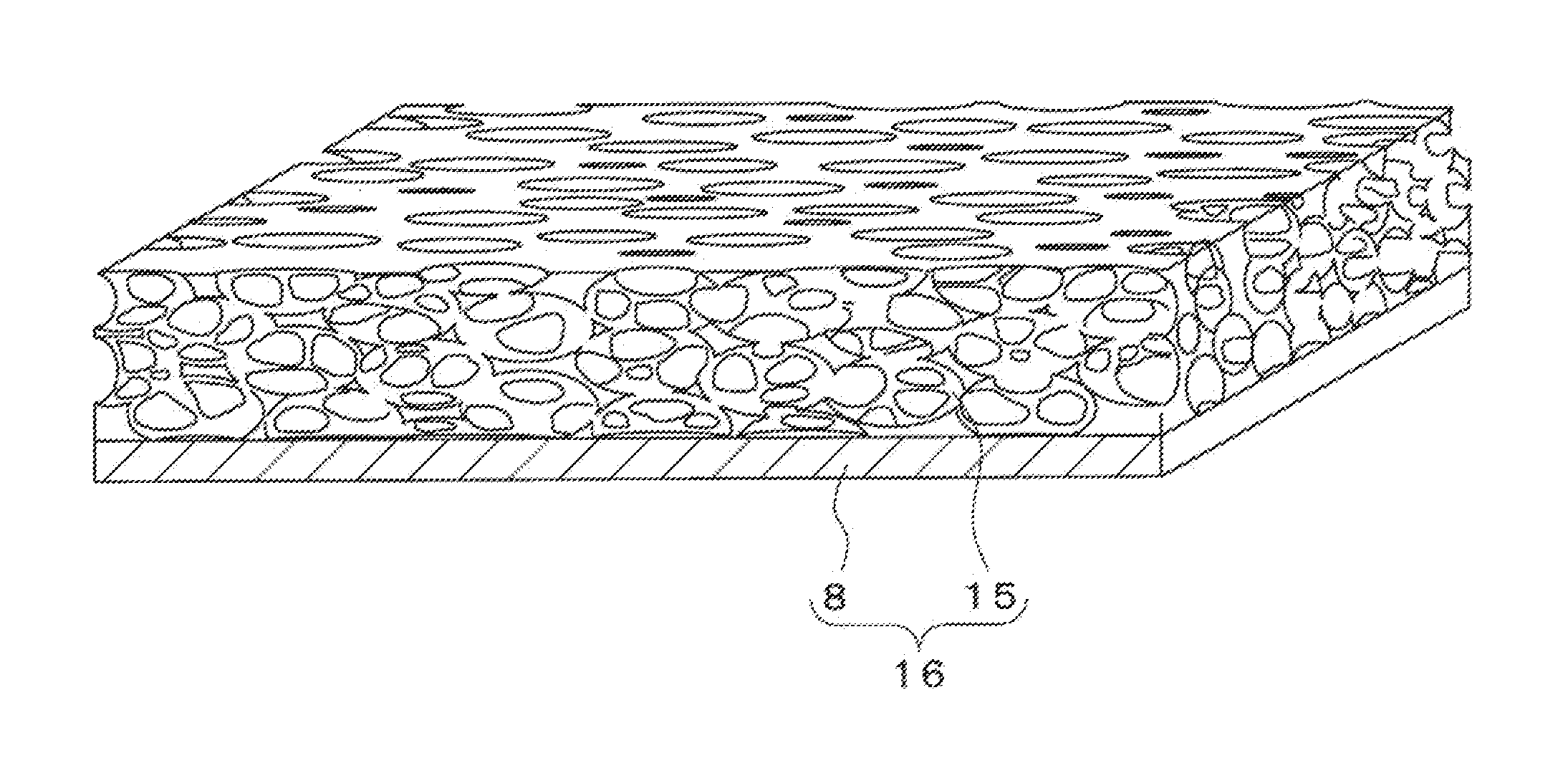

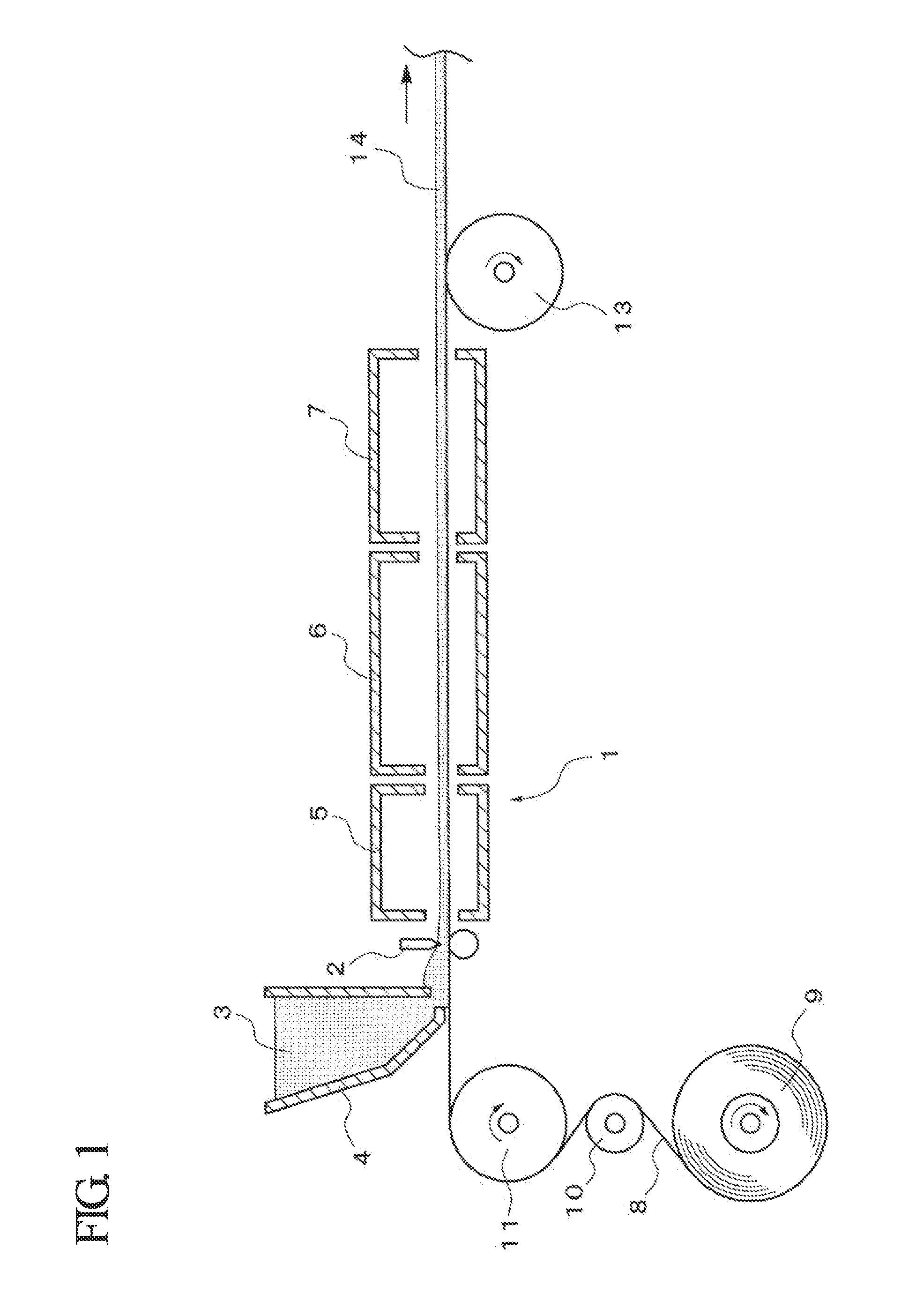

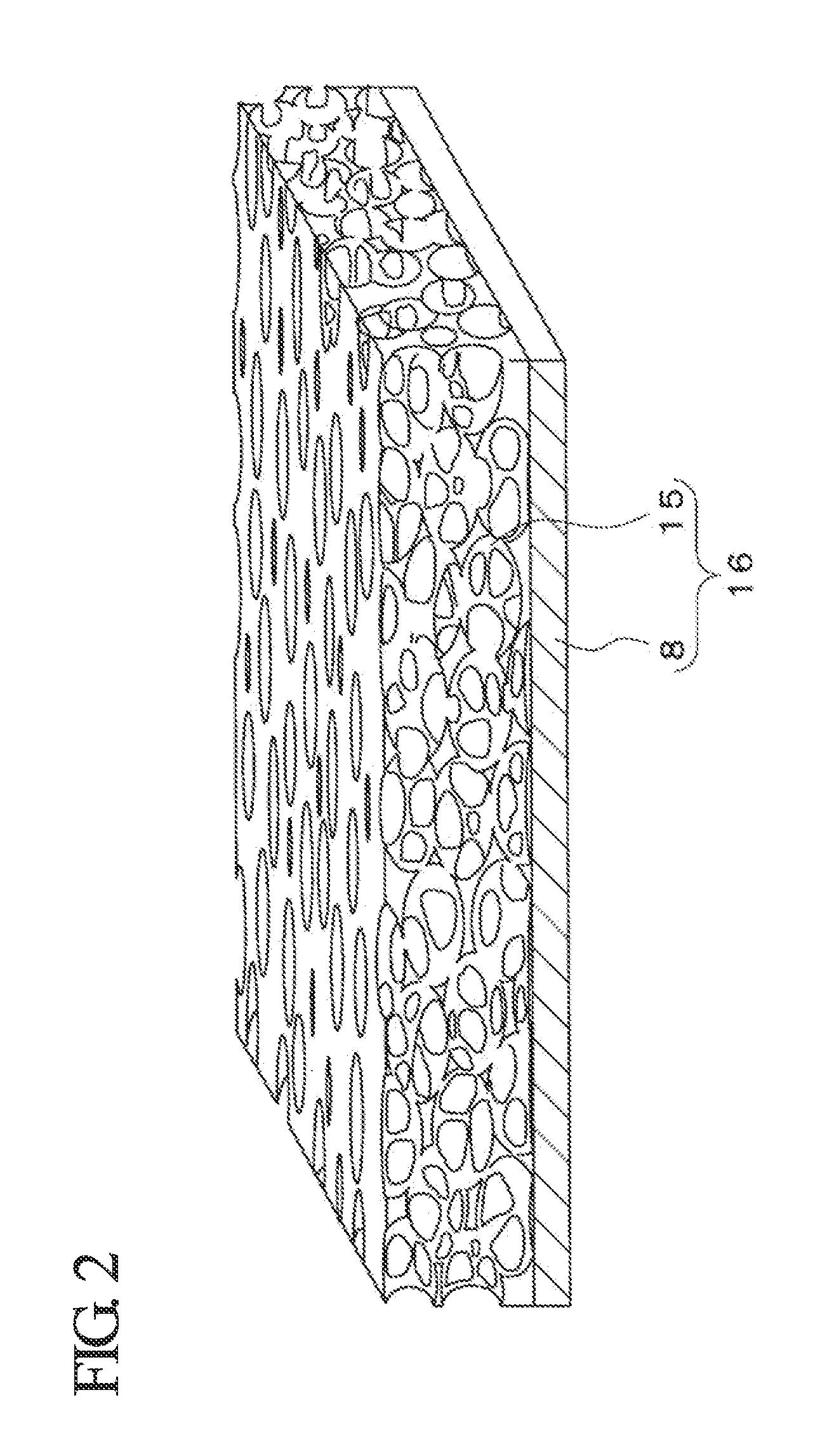

Process for production of aluminum complex comprising sintered porous aluminium body

ActiveUS20120135142A1Reduced strengthAvoid inhibitionTransportation and packagingElectrode carriers/collectorsWater insolubleCoordination complex

This method for producing an aluminum composite including porous sintered aluminum, includes: mixing aluminum powder with a sintering aid powder containing either one or both of titanium and titanium hydride to obtain a raw aluminum mixed powder; adding and mixing a water-soluble resin binder, water, a plasticizer containing at least one selected from polyhydric alcohols, ethers, and esters, and a water-insoluble hydrocarbon-based organic solvent containing five to eight carbon atoms into the raw aluminum mixed powder to obtain a viscous composition; shape-forming the viscous composition on an aluminum foil or an aluminum plate and causing the viscous composition to foam to obtain a formed object prior to sintering; and heating the formed object prior to sintering in a non-oxidizing atmosphere to obtain an aluminum composite which includes porous sintered aluminum integrally joined onto the aluminum foil or the aluminum plate, wherein when a temperature at which the raw aluminum mixed powder starts to melt is expressed as Tm (° C.), then a temperature T (° C.) of the heating fulfills Tm-10 (° C.)≦T≦685 (° C.).

Owner:MITSUBISHI MATERIALS CORP

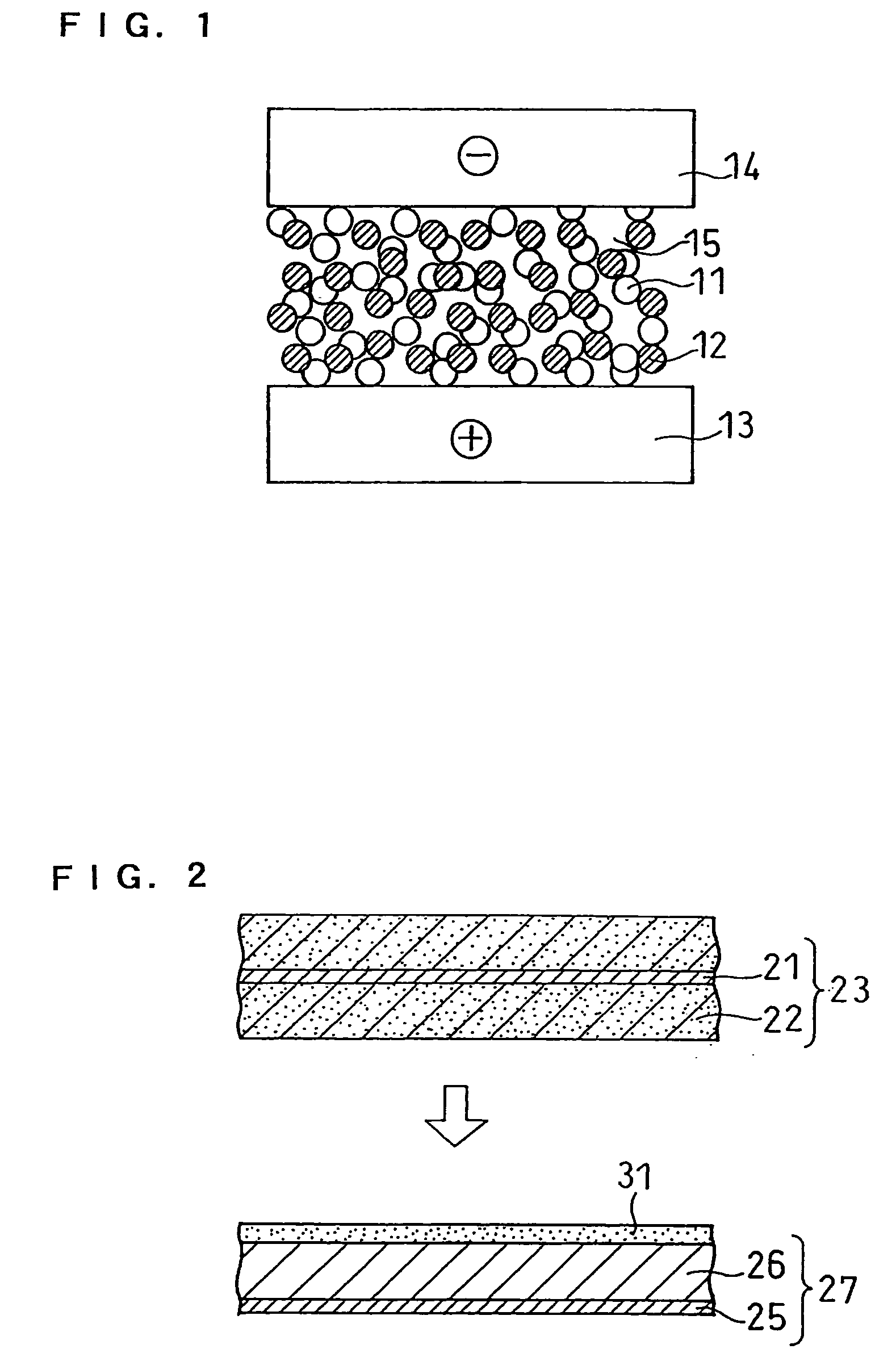

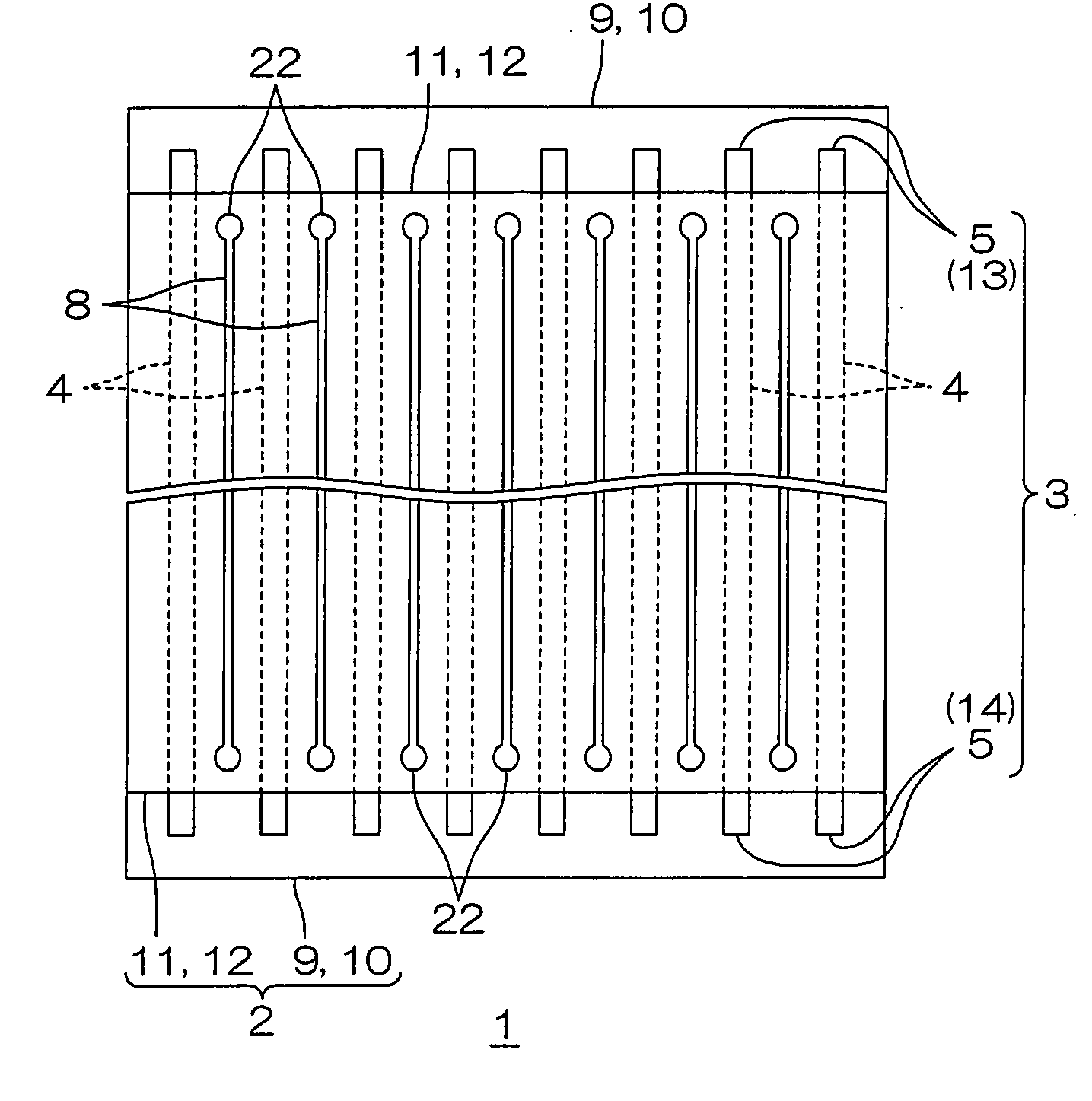

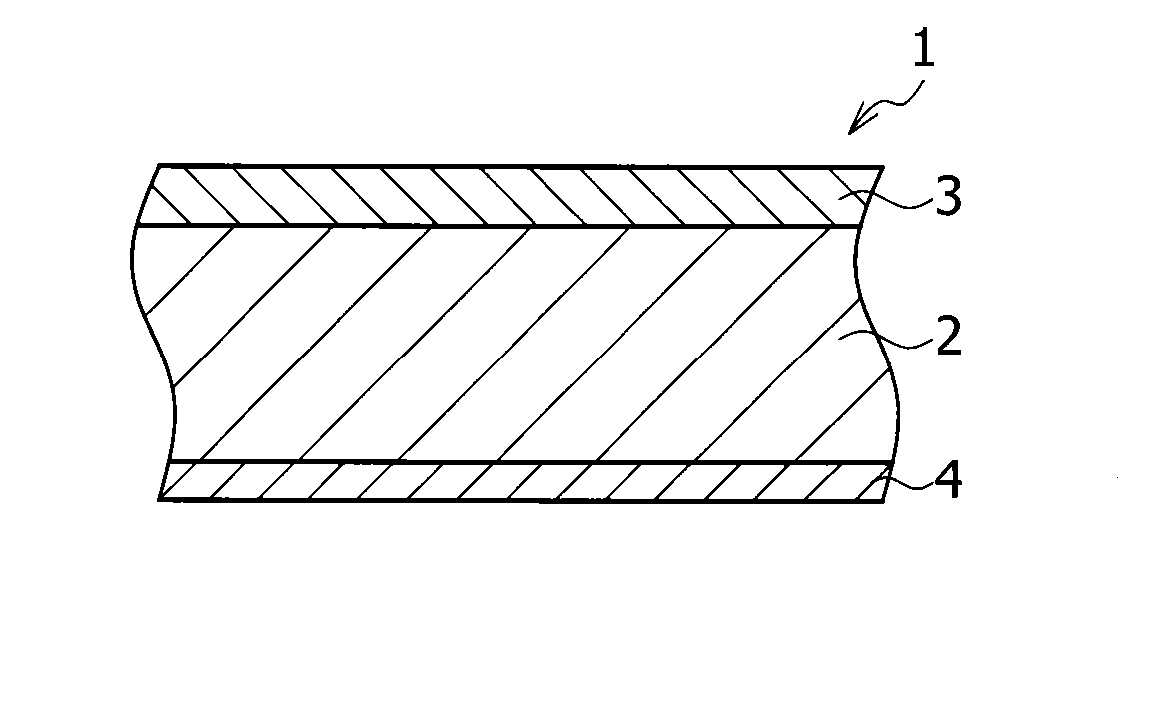

Lithium ion secondary battery

ActiveUS20060216608A1Safety and high-rate characteristicNecessary strengthCell seperators/membranes/diaphragms/spacersFinal product manufactureMethacrylateMaterials science

A lithium ion secondary battery includes a positive electrode capable of absorbing and desorbing lithium ion, a negative electrode capable of absorbing and desorbing lithium ion, a porous film interposed between the positive electrode and the negative electrode, and a non-aqueous electrolyte: the porous film being adhered to a surface of at least one of the positive electrode and the negative electrode; the porous film including a filler and a resin binder; the resin binder content in the porous film being 1.5 to 8 parts by weight per 100 parts by weight of the filler; and the resin binder including an acrylonitrile unit, an acrylate unit, or a methacrylate unit.

Owner:PANASONIC CORP

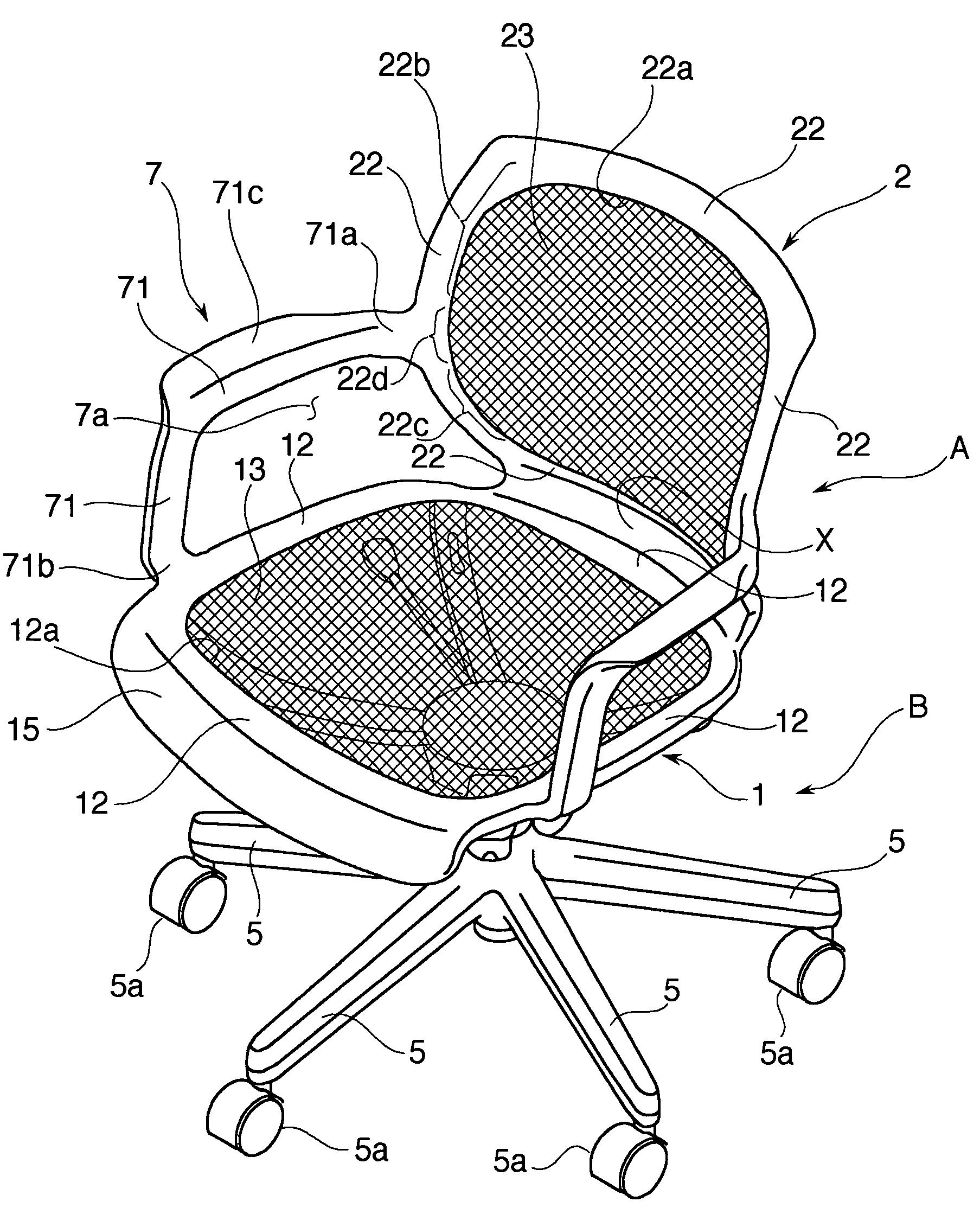

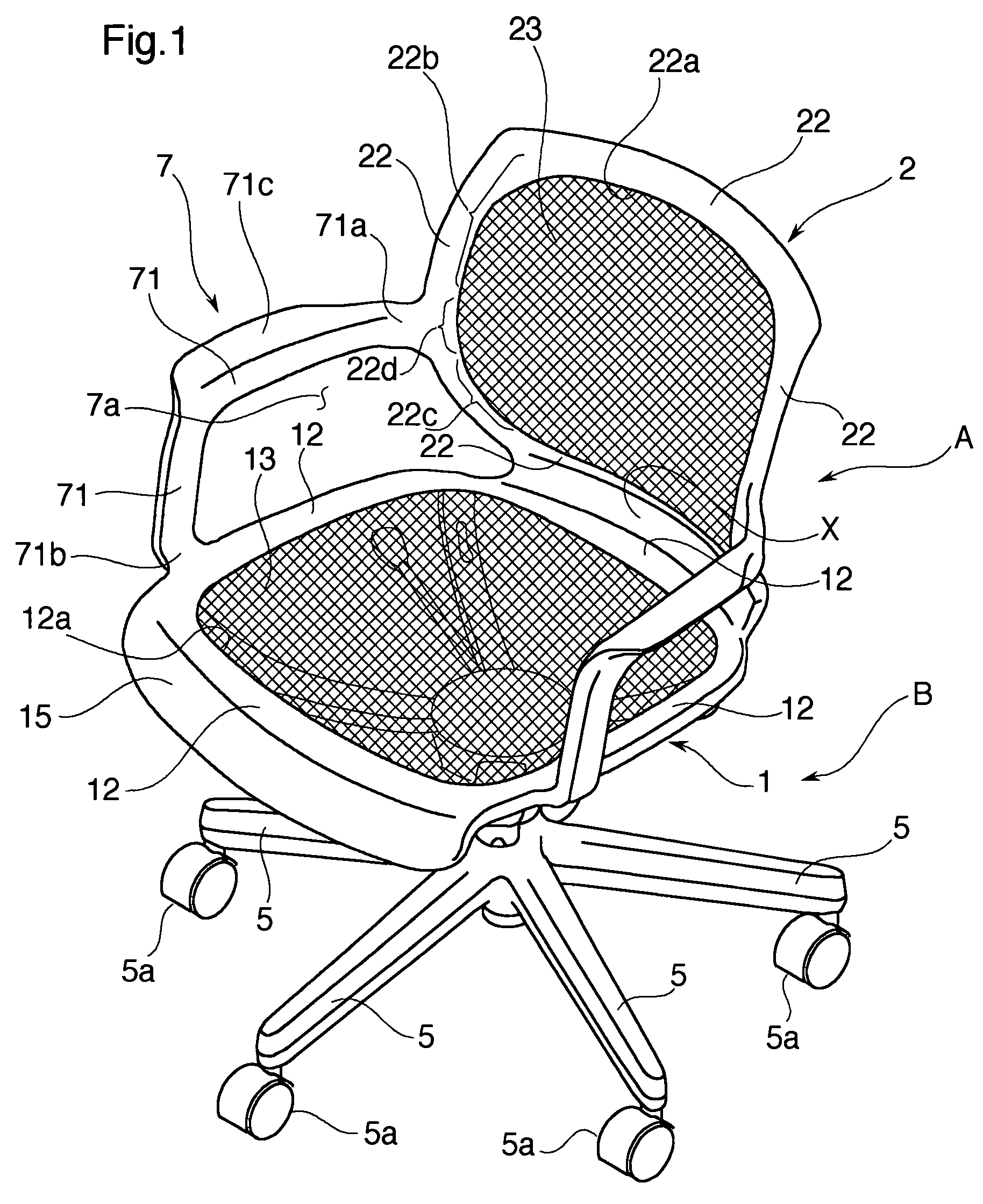

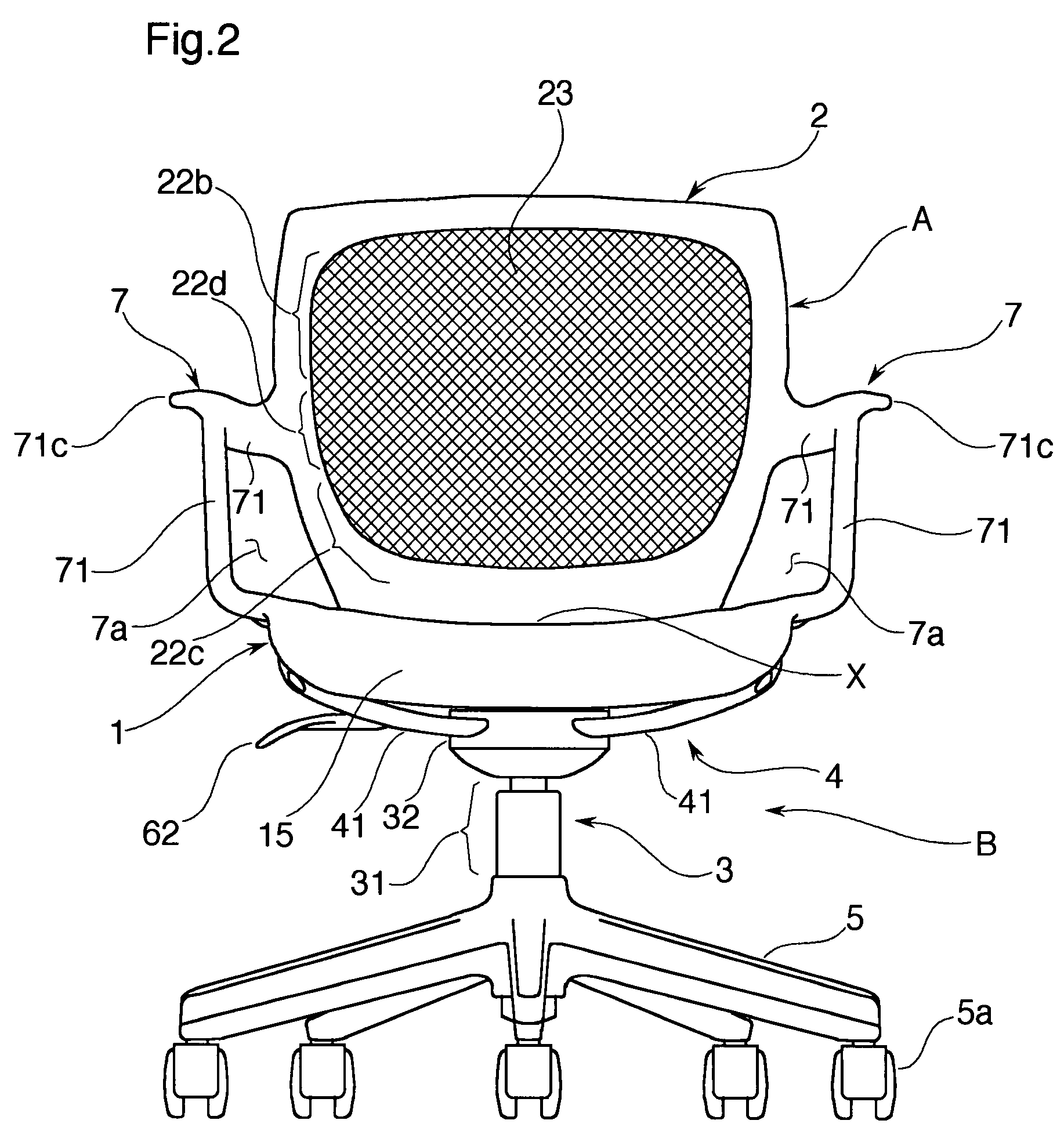

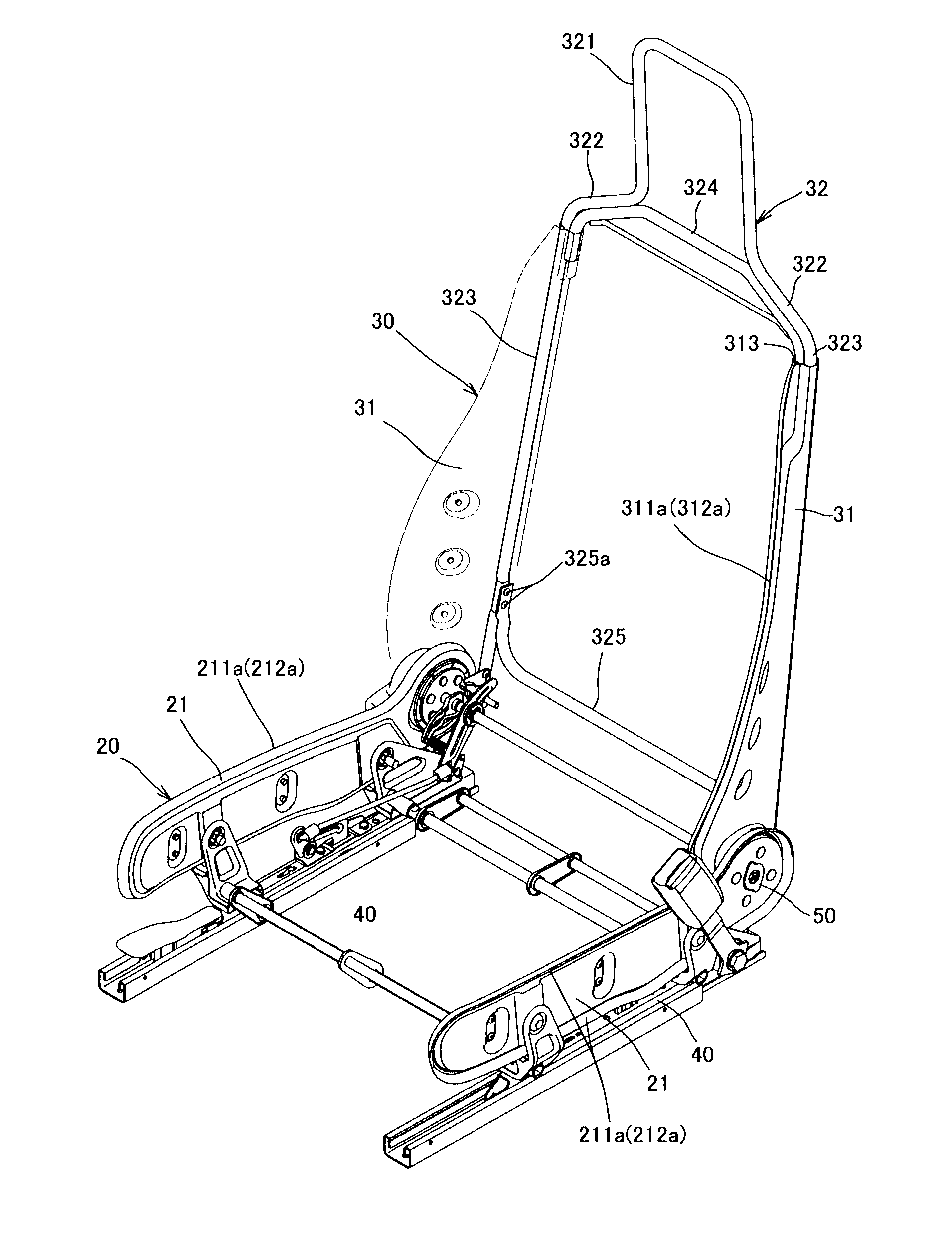

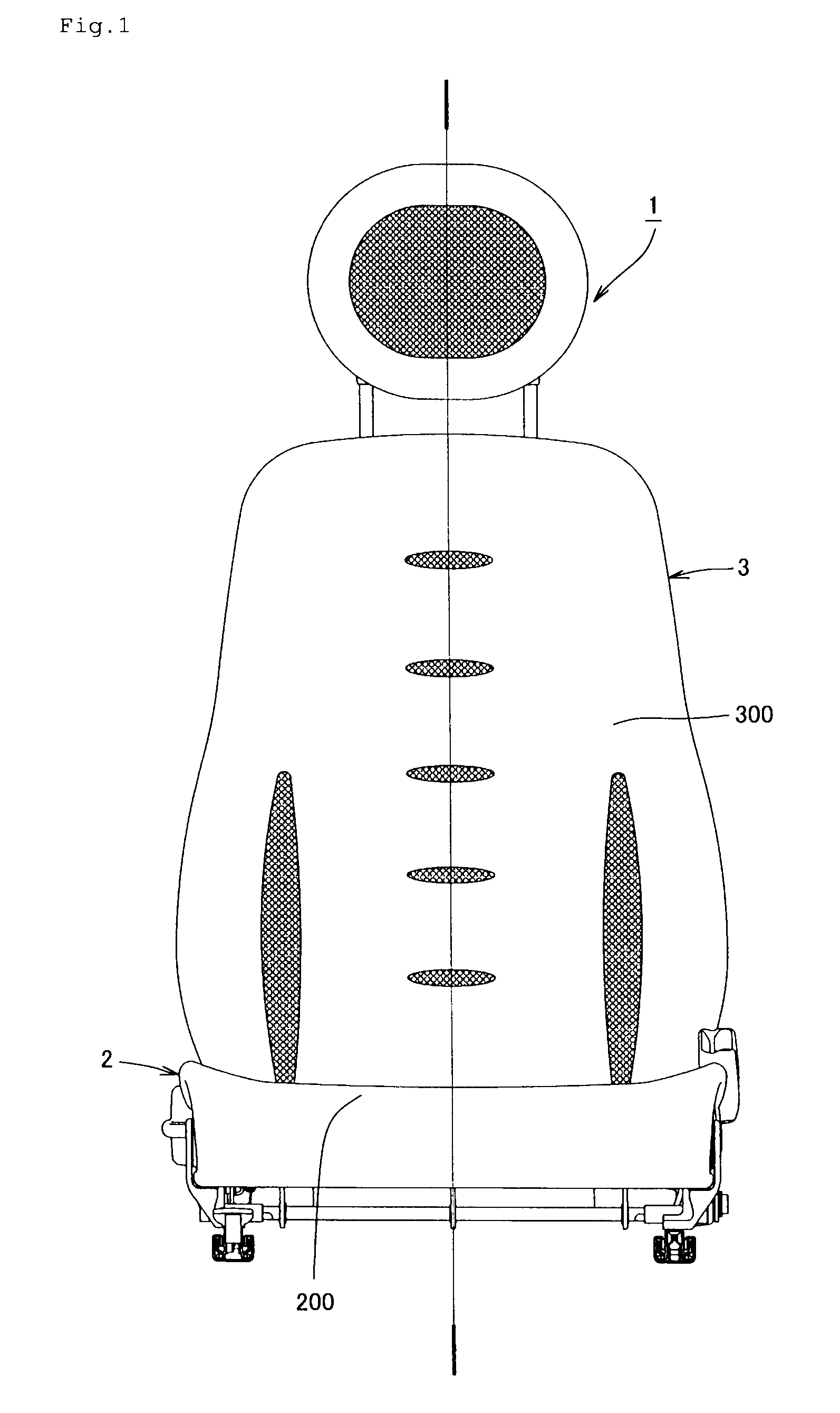

Chair having integrally formed back frame and seat frame

Owner:KOKUYO CO LTD

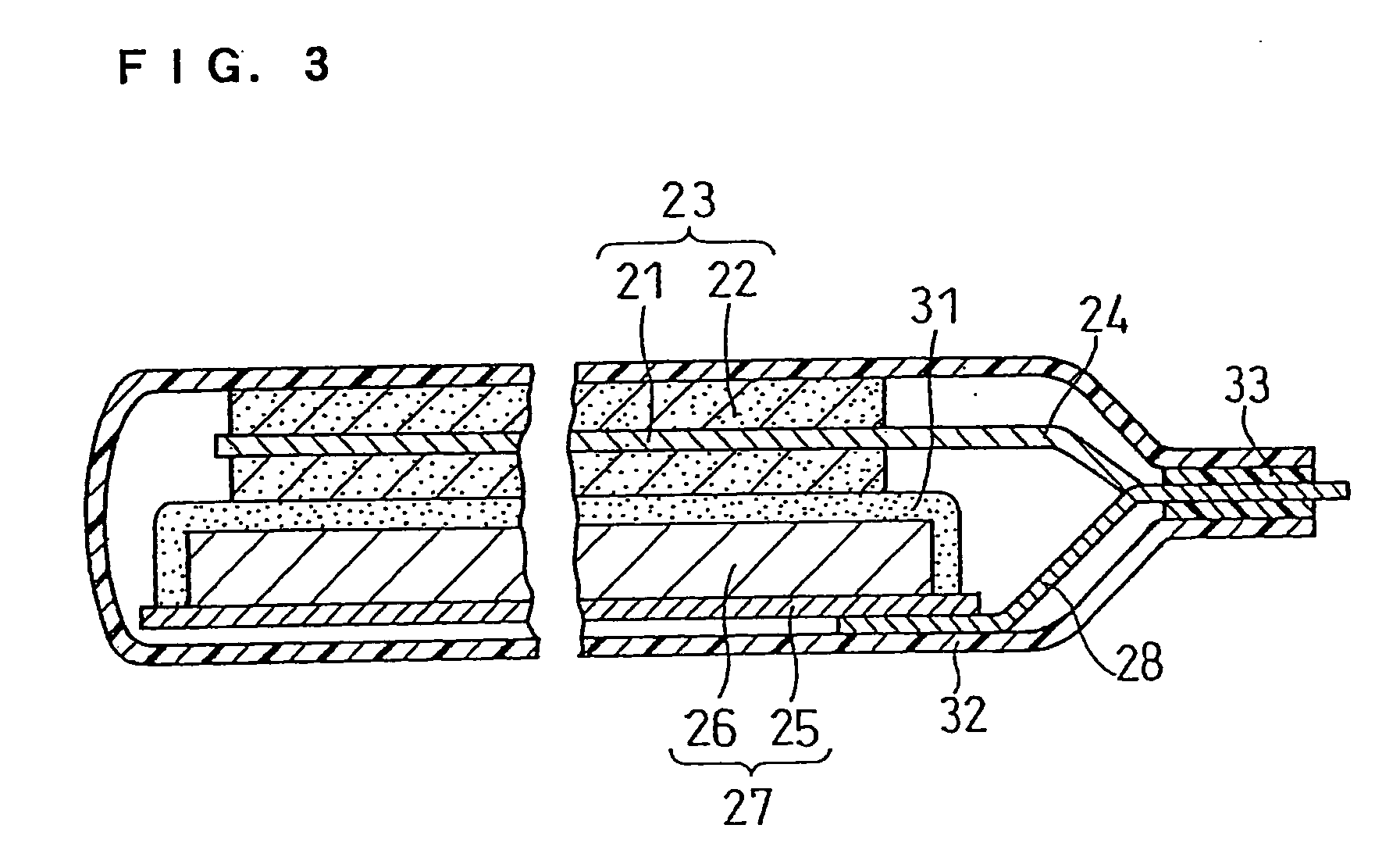

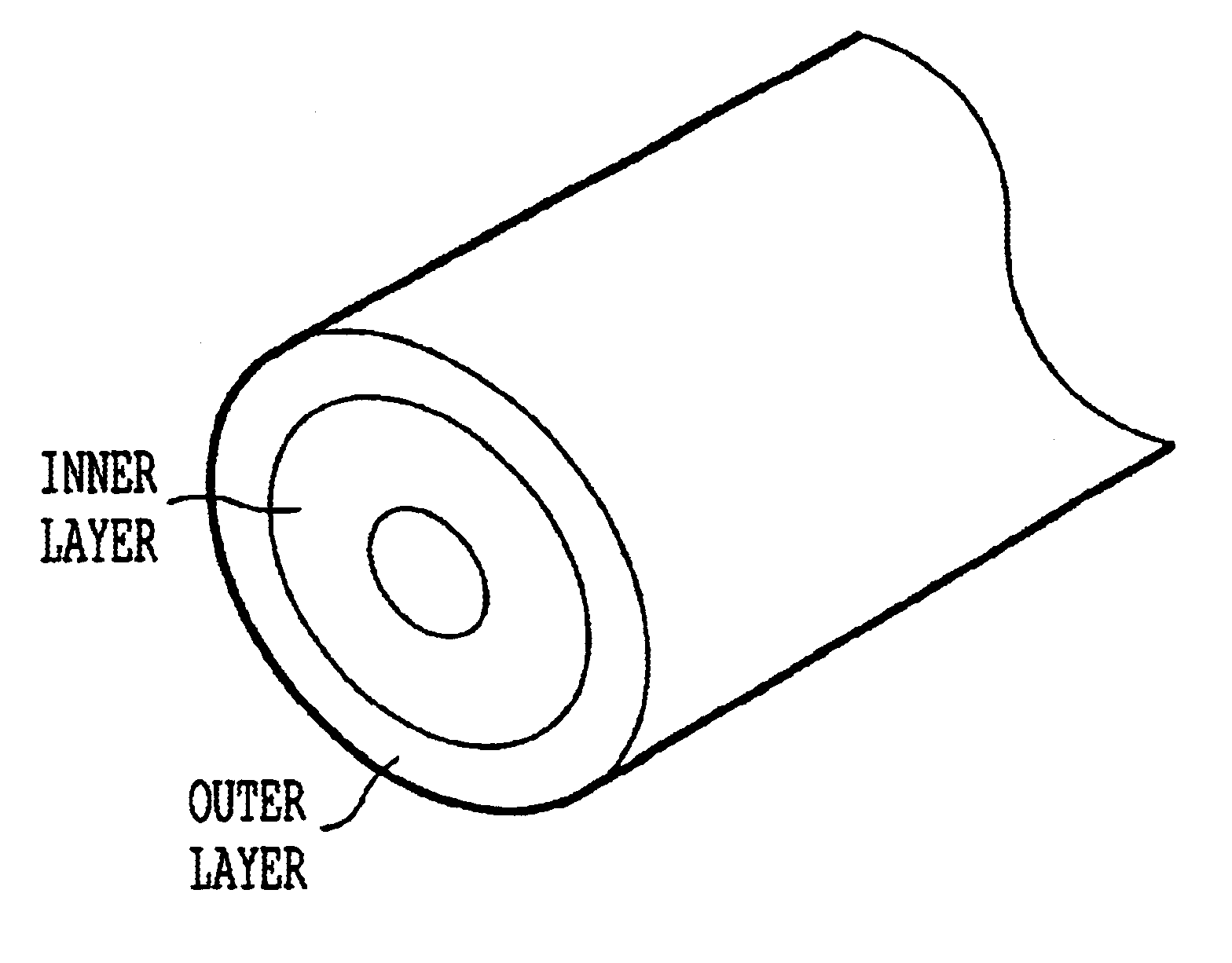

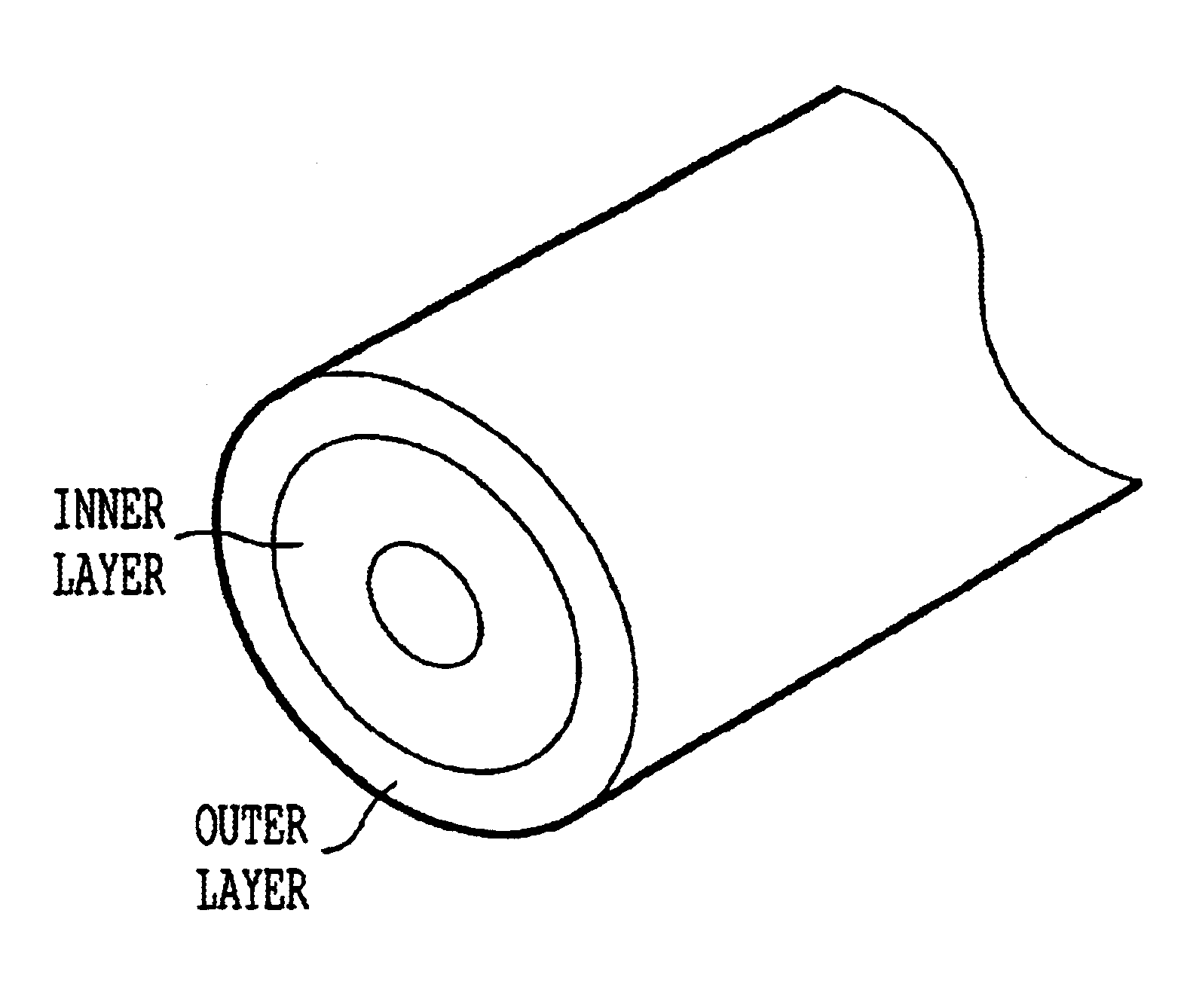

Fuel hose

InactiveUS6655414B2Increase flexibilityIncrease resistanceSynthetic resin layered productsFlexible pipesEngineeringThermodynamics

A fuel hose having a two layer structure comprising an inner layer made of a fluororesin and an outer layer adjacent thereto, made of a thermoplastic resin other than a fluororesin, wherein the fluororesin has a tensile strength at break of higher than 21 MPa, and the fluororesin of the inner layer has a melt adhesiveness with the thermoplastic resin of the outer layer.

Owner:ASAHI GLASS CO LTD

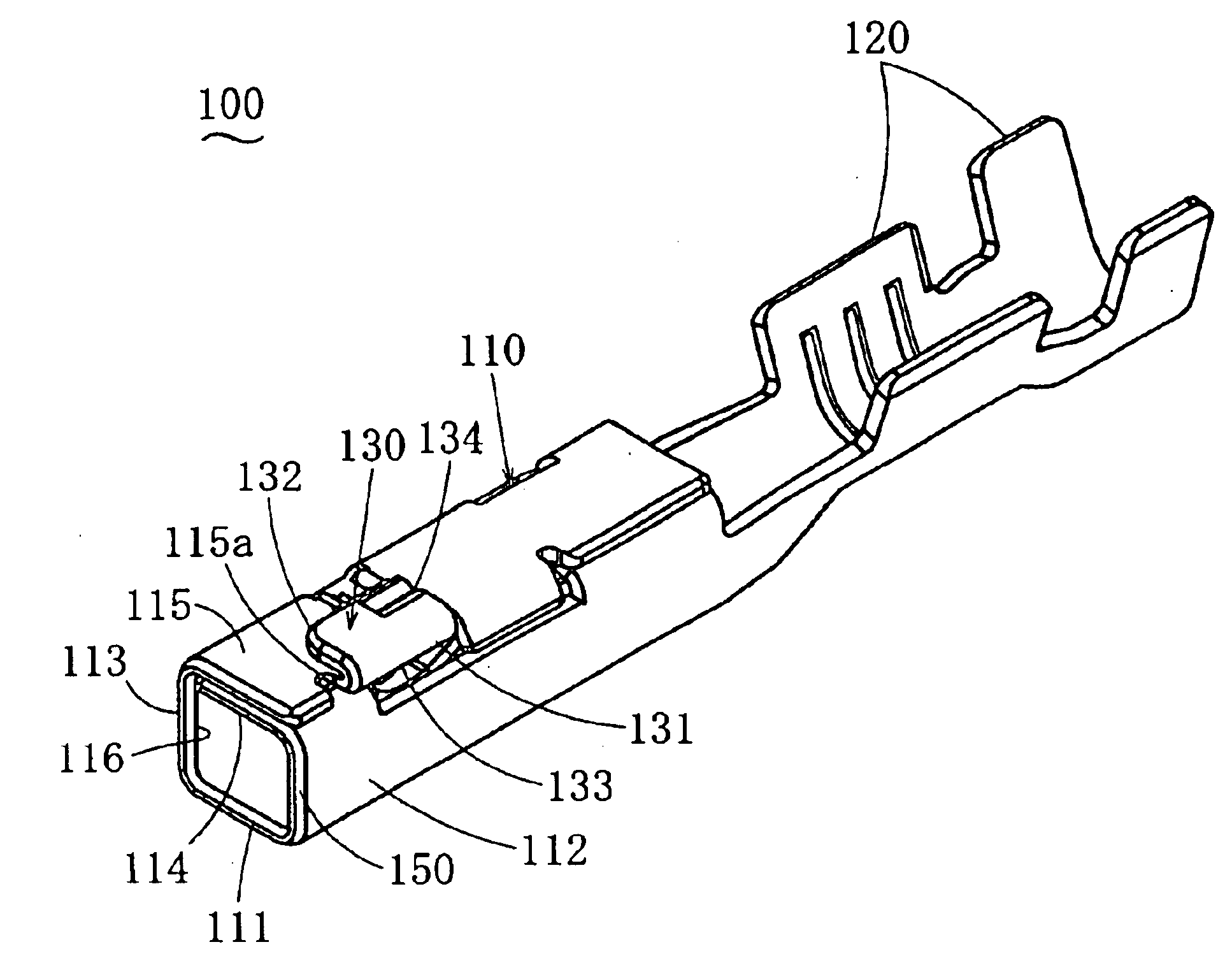

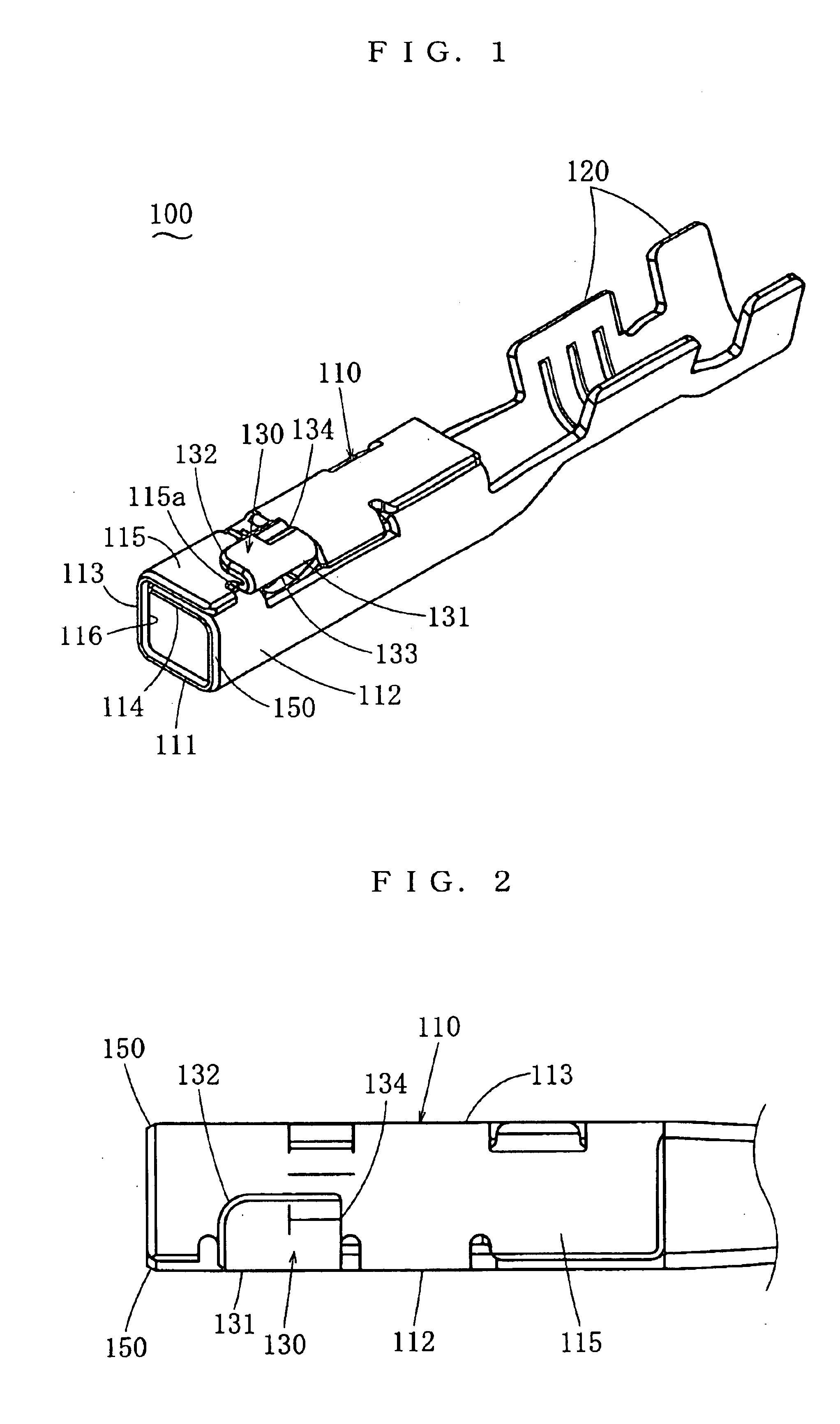

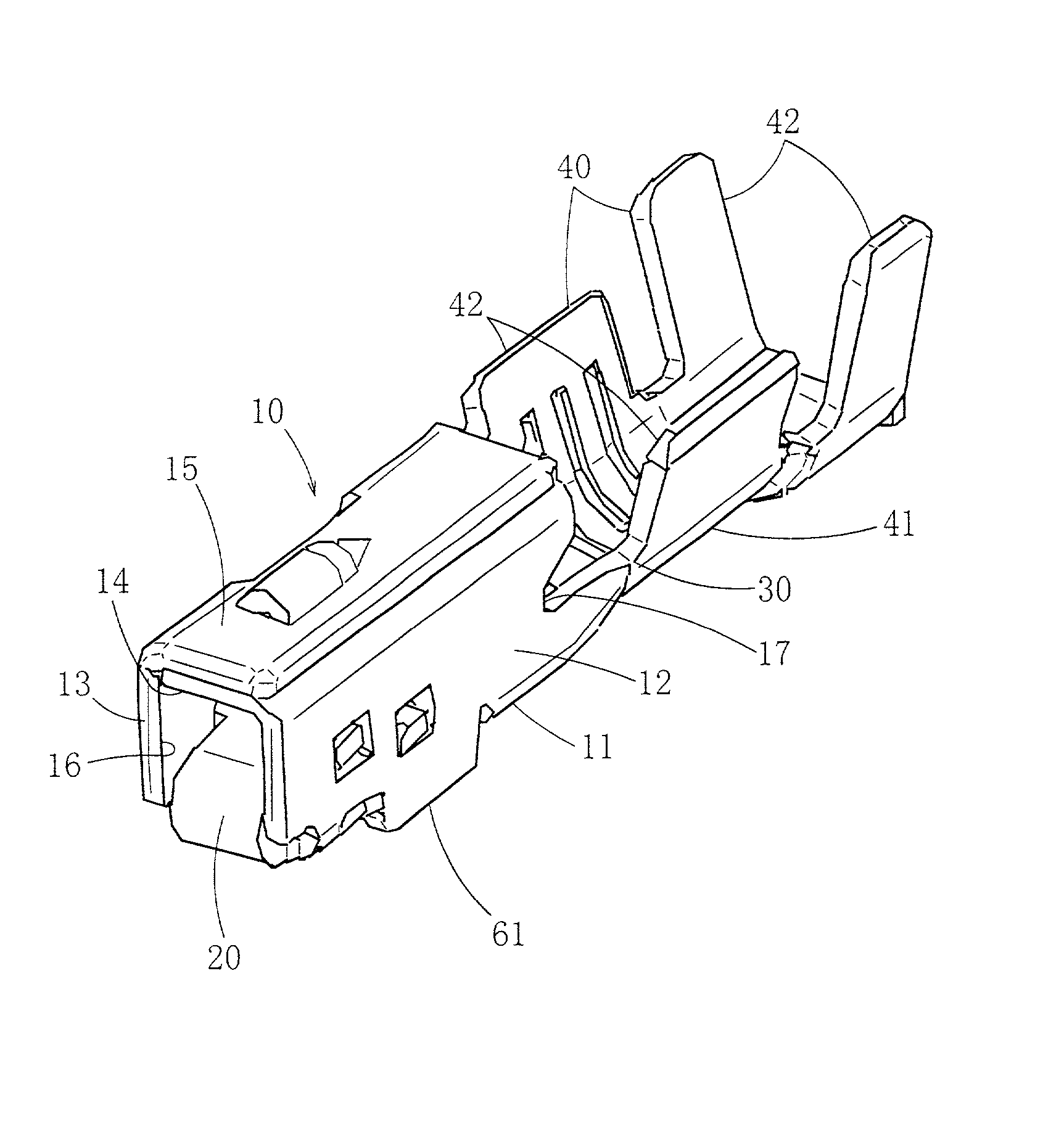

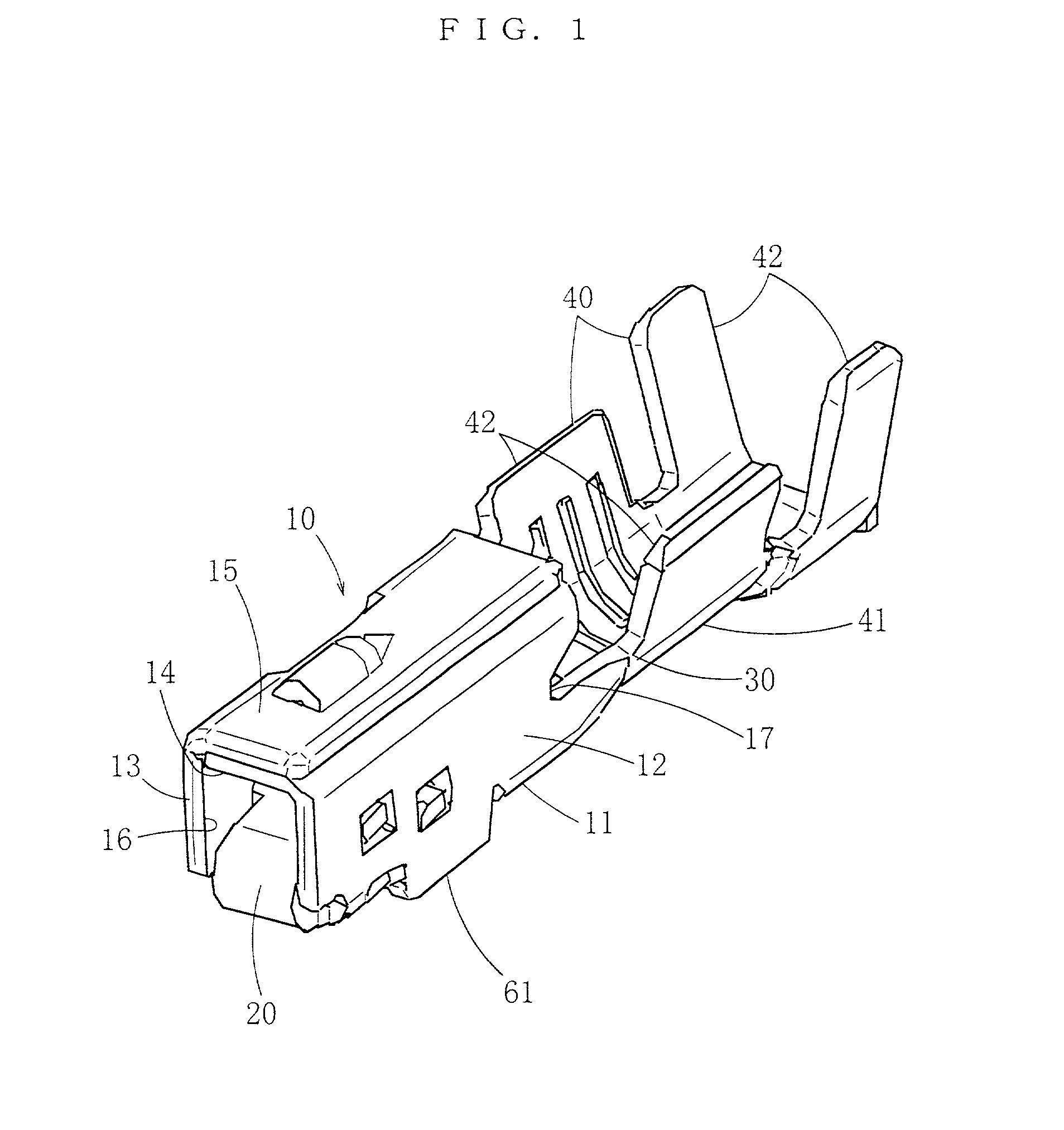

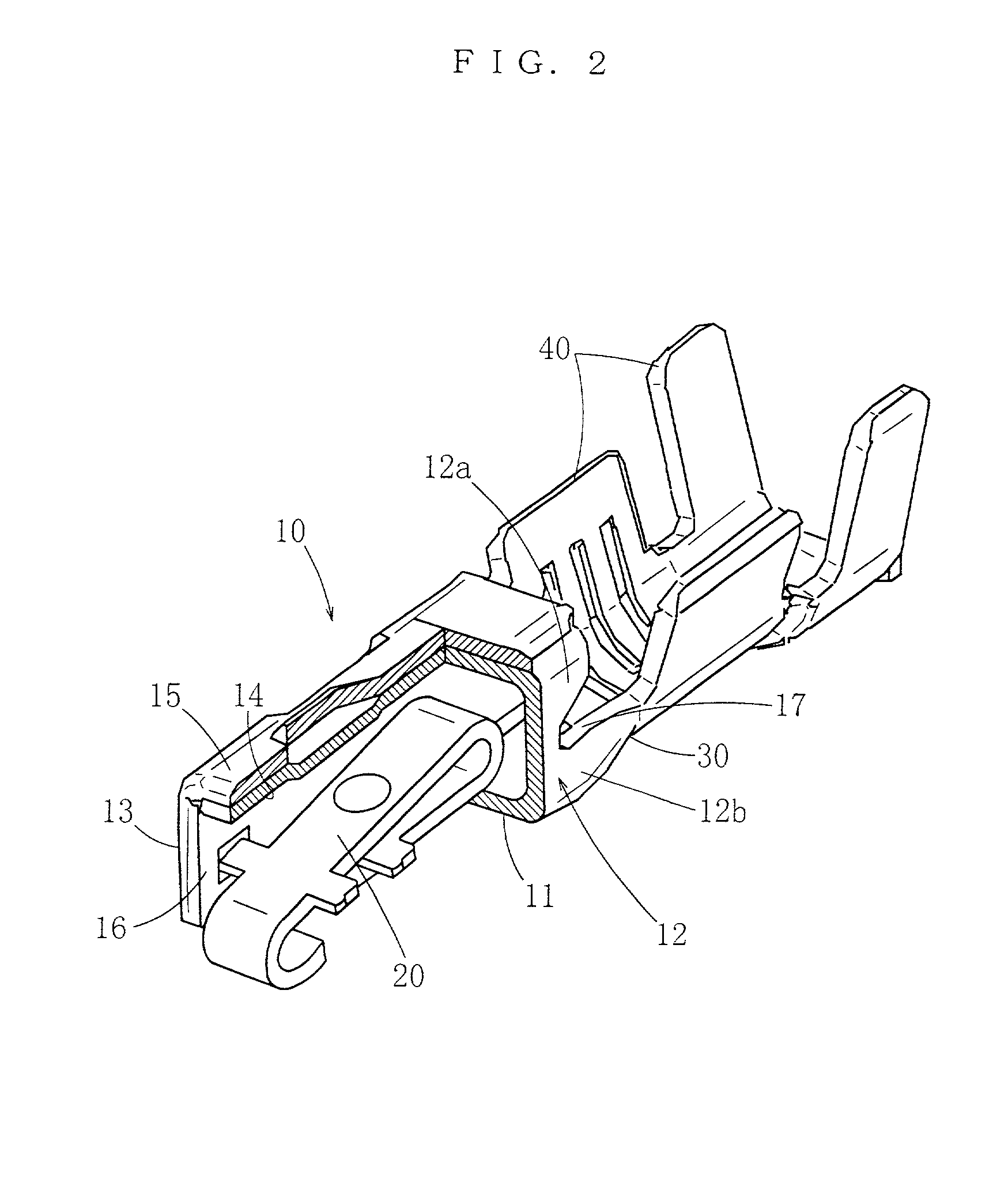

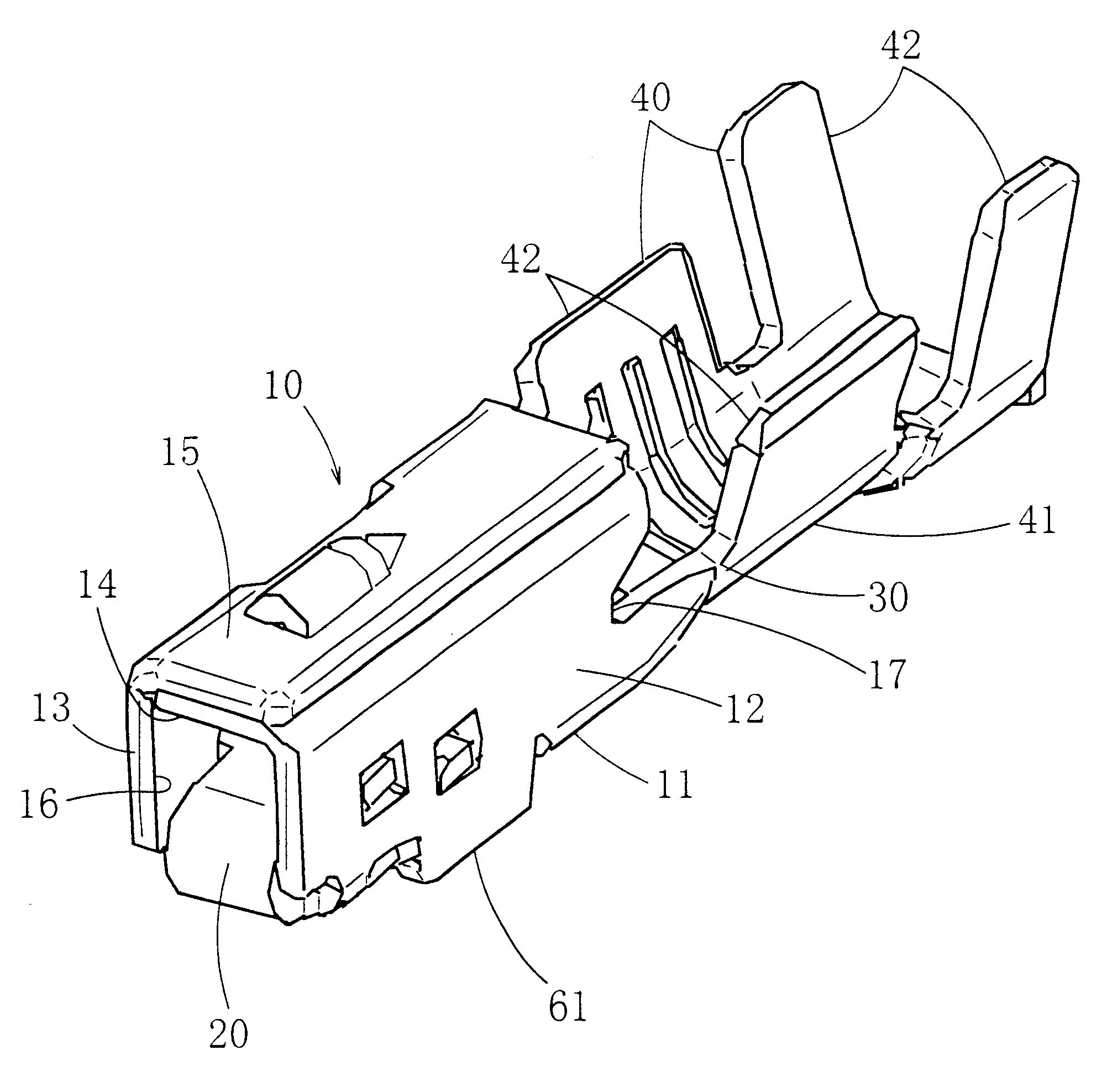

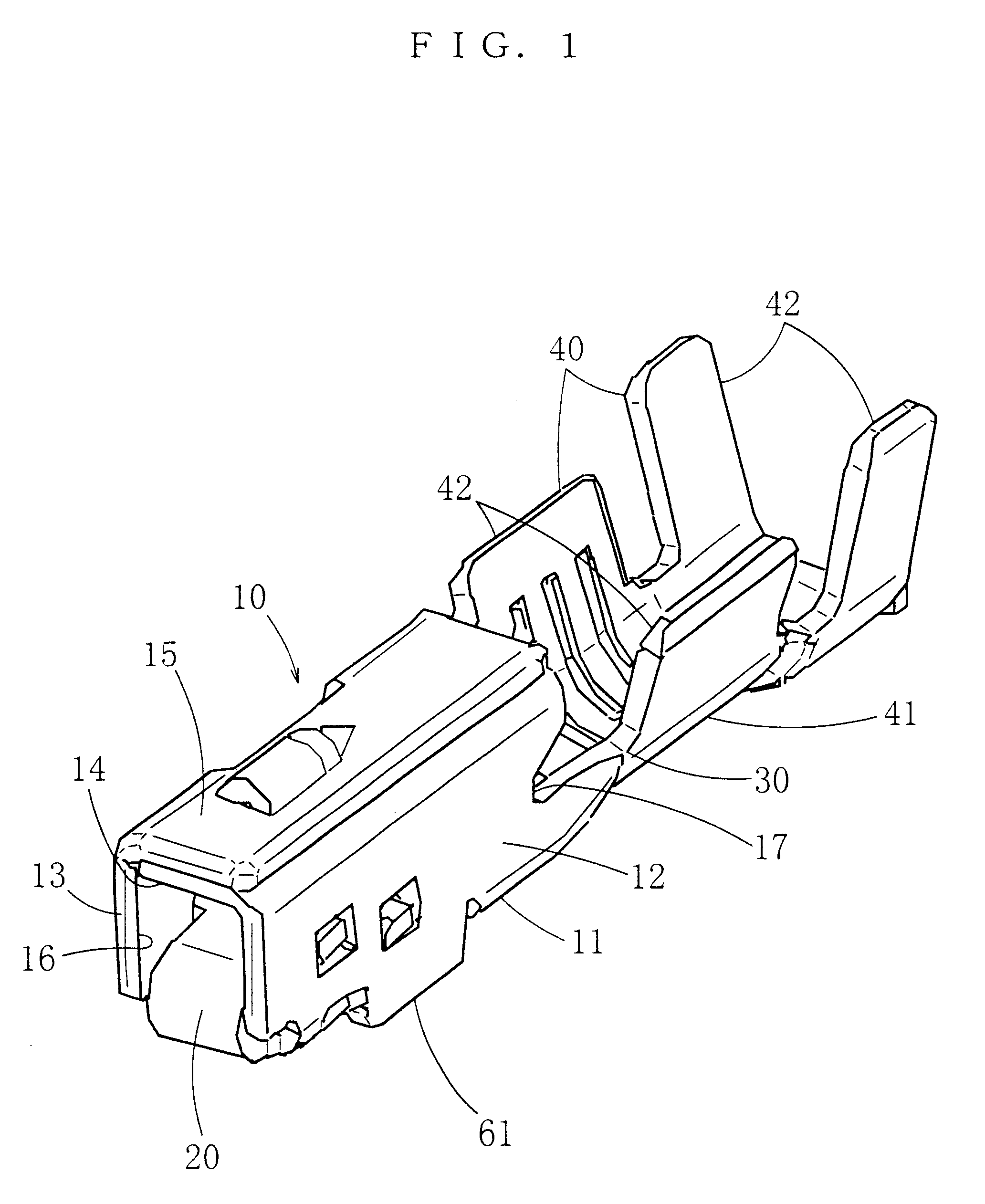

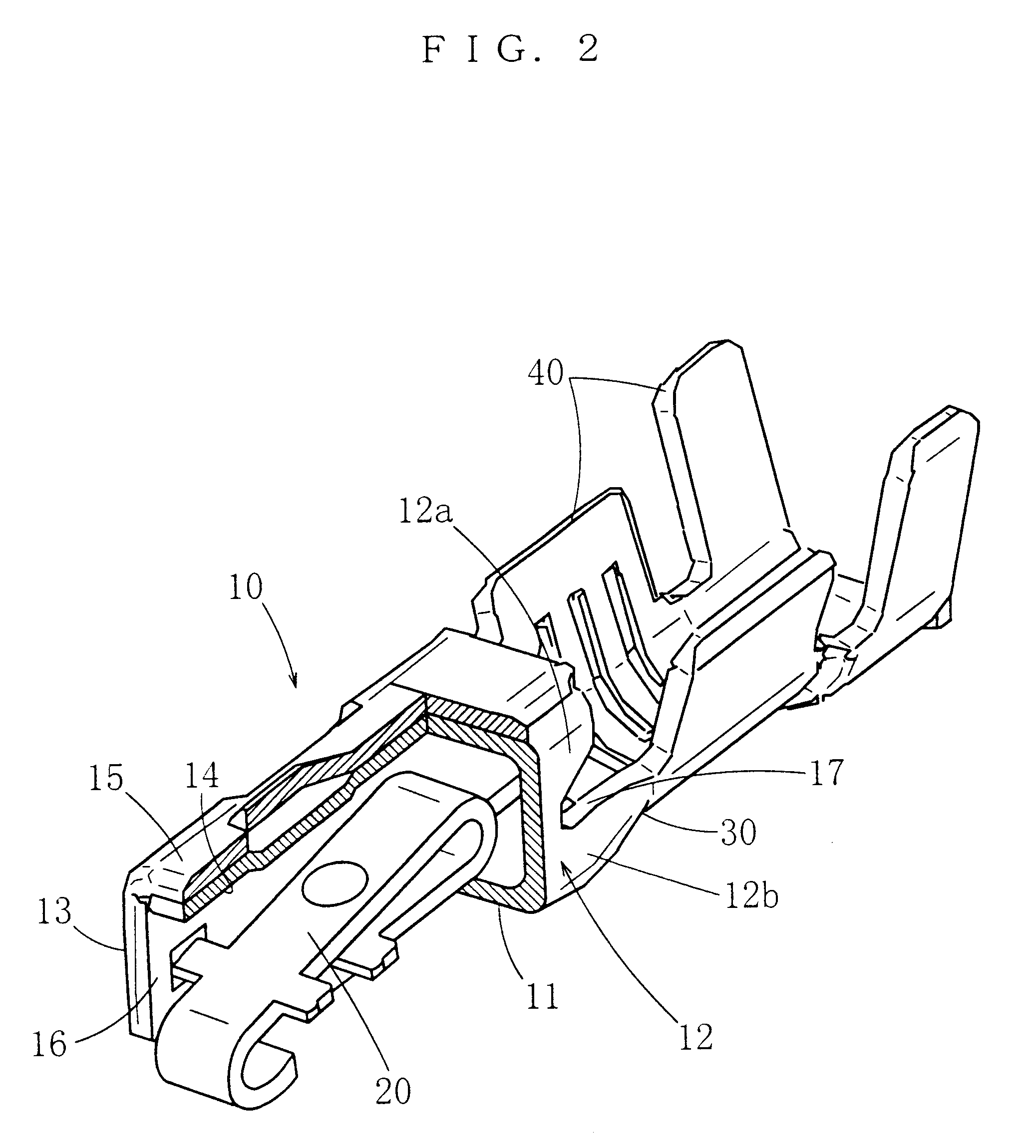

Terminal

ActiveUS6905376B2Reduce loadAvoid deformationSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

Owner:JST MFG CO LTD

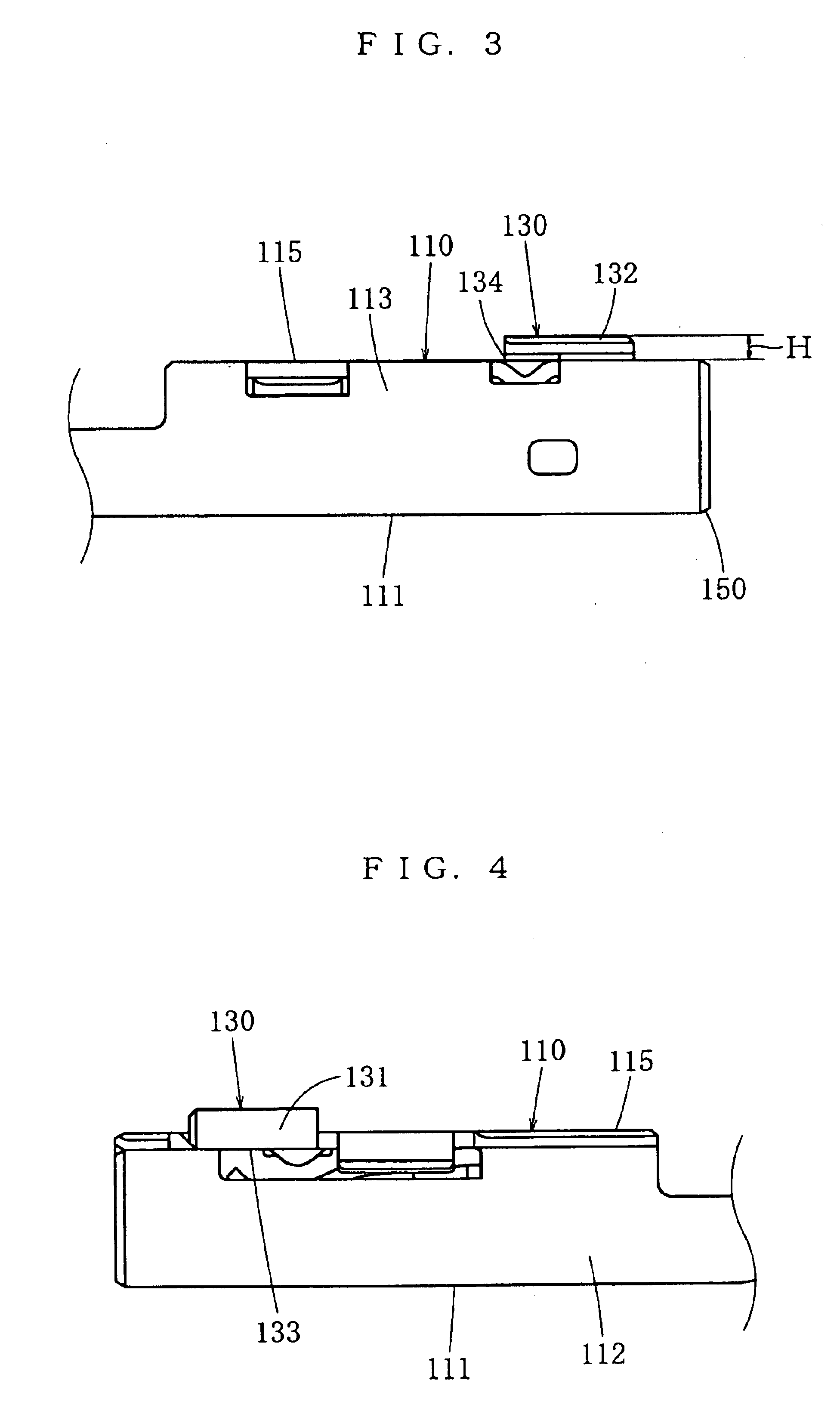

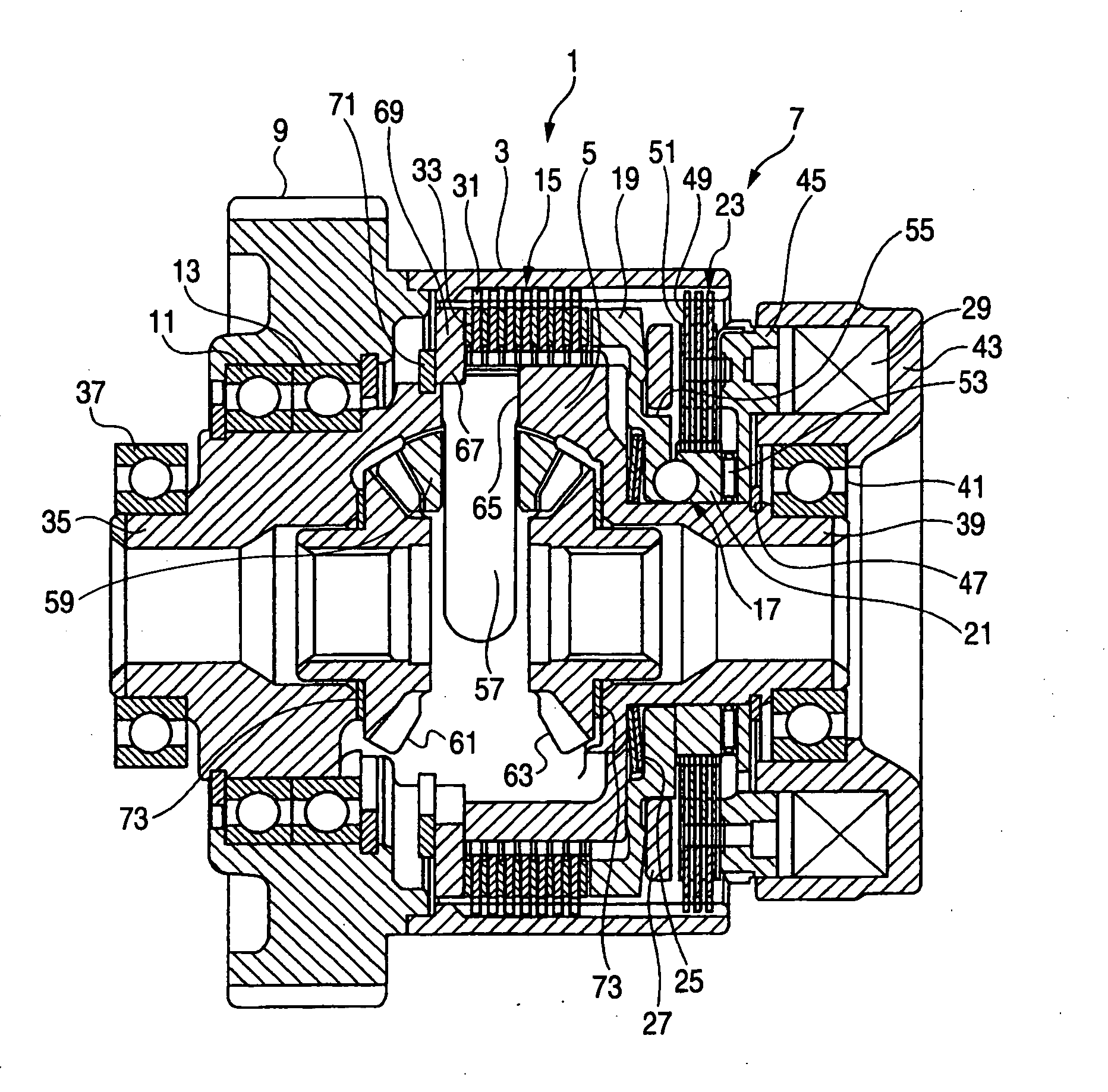

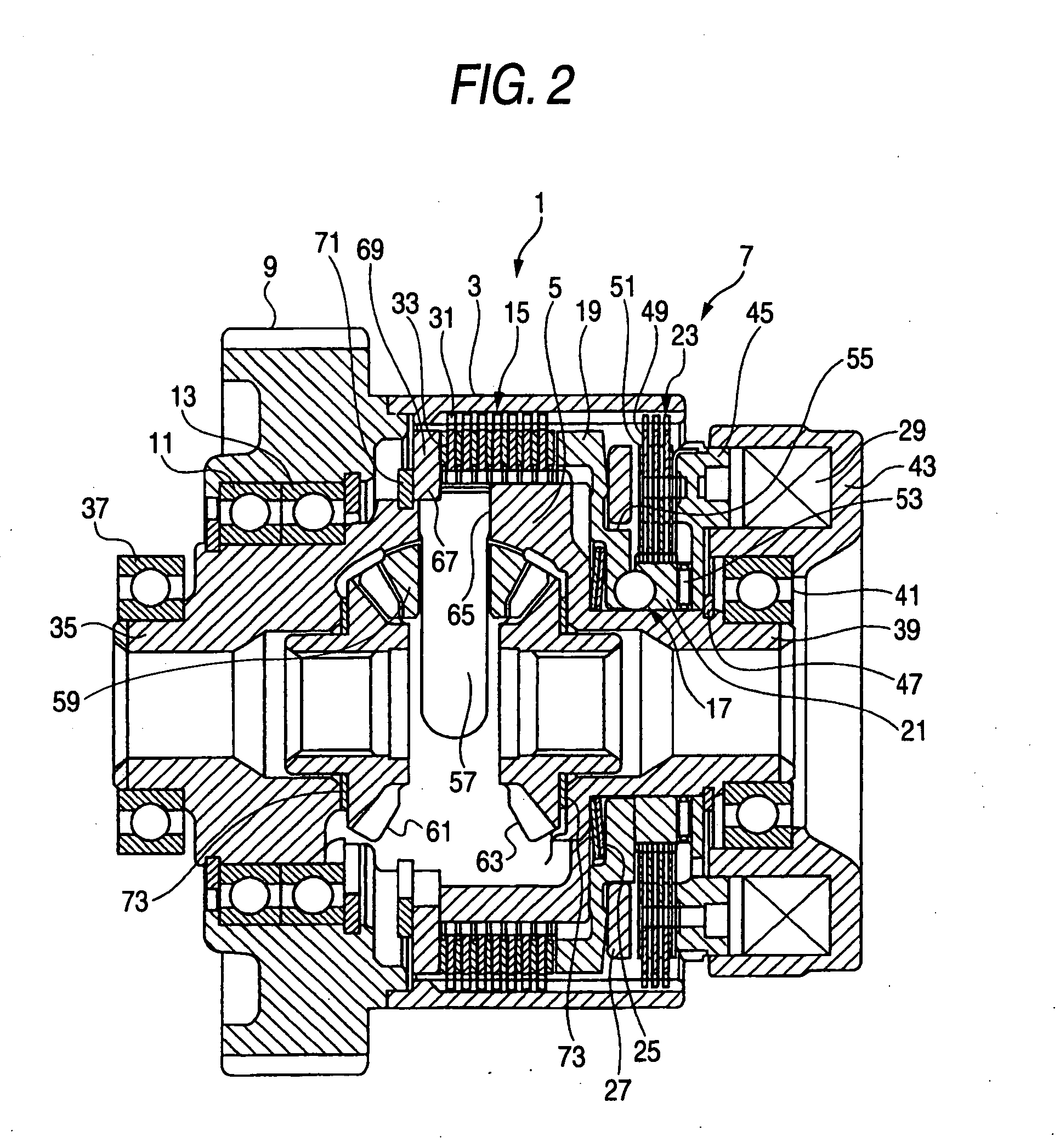

Friction engaging device

InactiveUS20060046890A1Secure strengthReduce and exclude componentMagnetically actuated clutchesDifferential gearingsChemical adsorptionControl theory

An outer plate 31, which is used under a lubricated environment of a differential gear oil including a friction adjuster, is made of a SC tempered material which is subjected to nitriding treatment to suppress chemical adsorption of the friction adjuster. An inner plate 33 has paper on a surface thereof. The outer plate 31 and the inner plate 33 are provided to apply or release the torque between an outer differential case 3 and an inner differential case 5 of a rear differential device 1 having the outer differential case 3 and the inner differential case 5 capable of relatively rotating to the inside and the outside.

Owner:GKN DRIVELINE TORQUE TECHNOLOGY KK

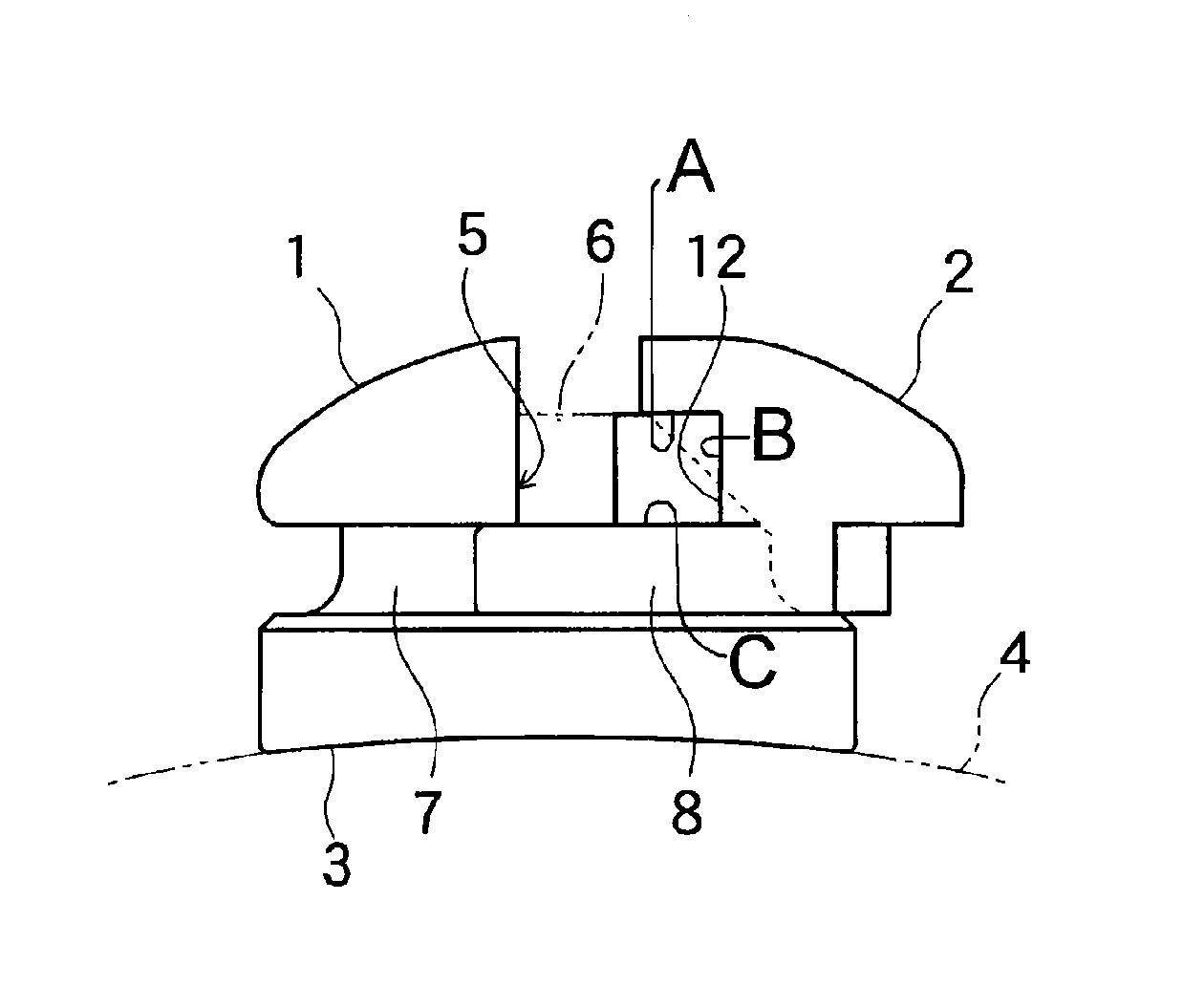

Orthodontic bracket

InactiveUS8297970B2Easy to replaceReliable maintenanceArch wiresBracketsEngineeringTherapeutic effect

Owner:DENTSPLY SANKIN KK

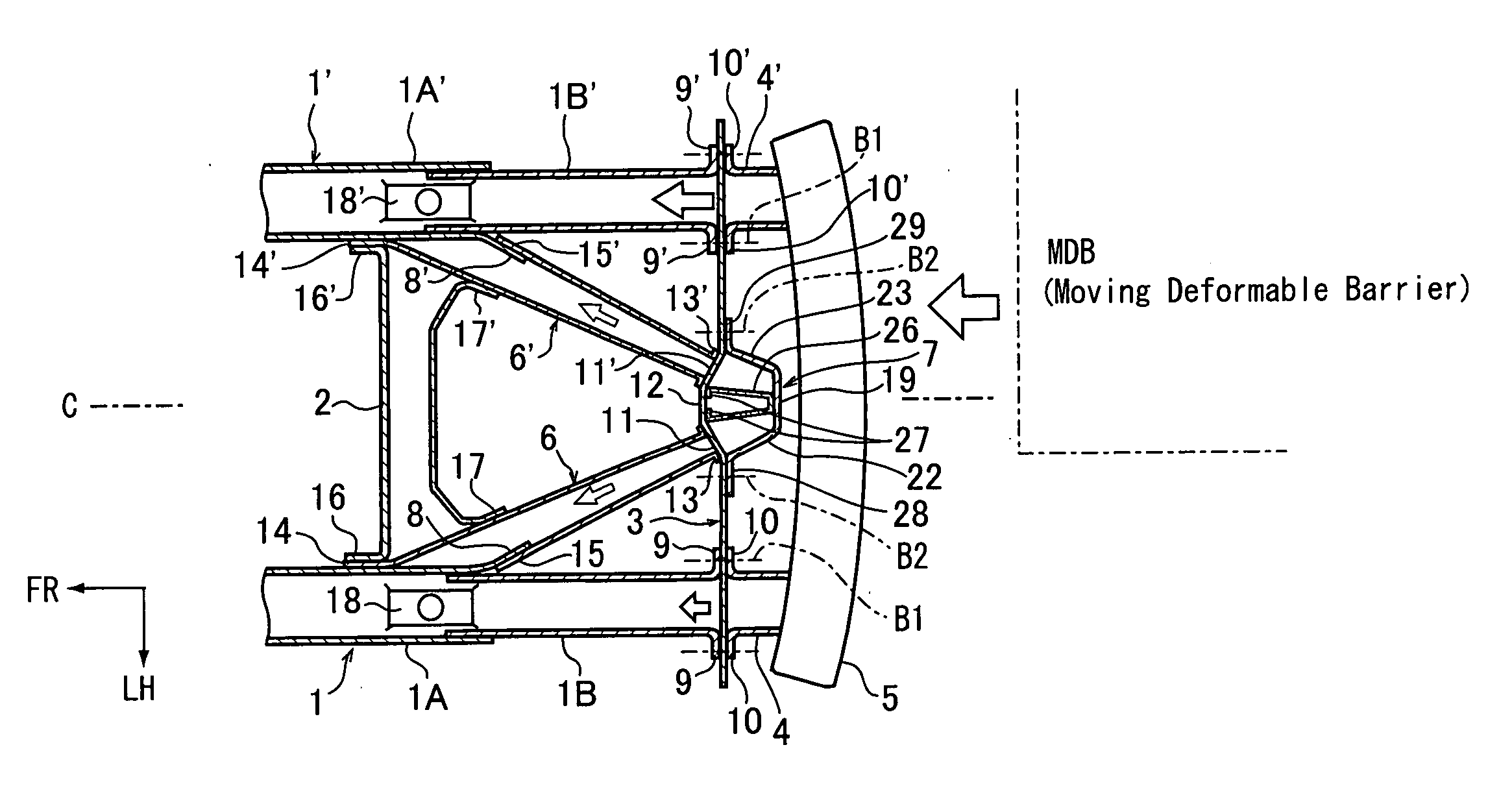

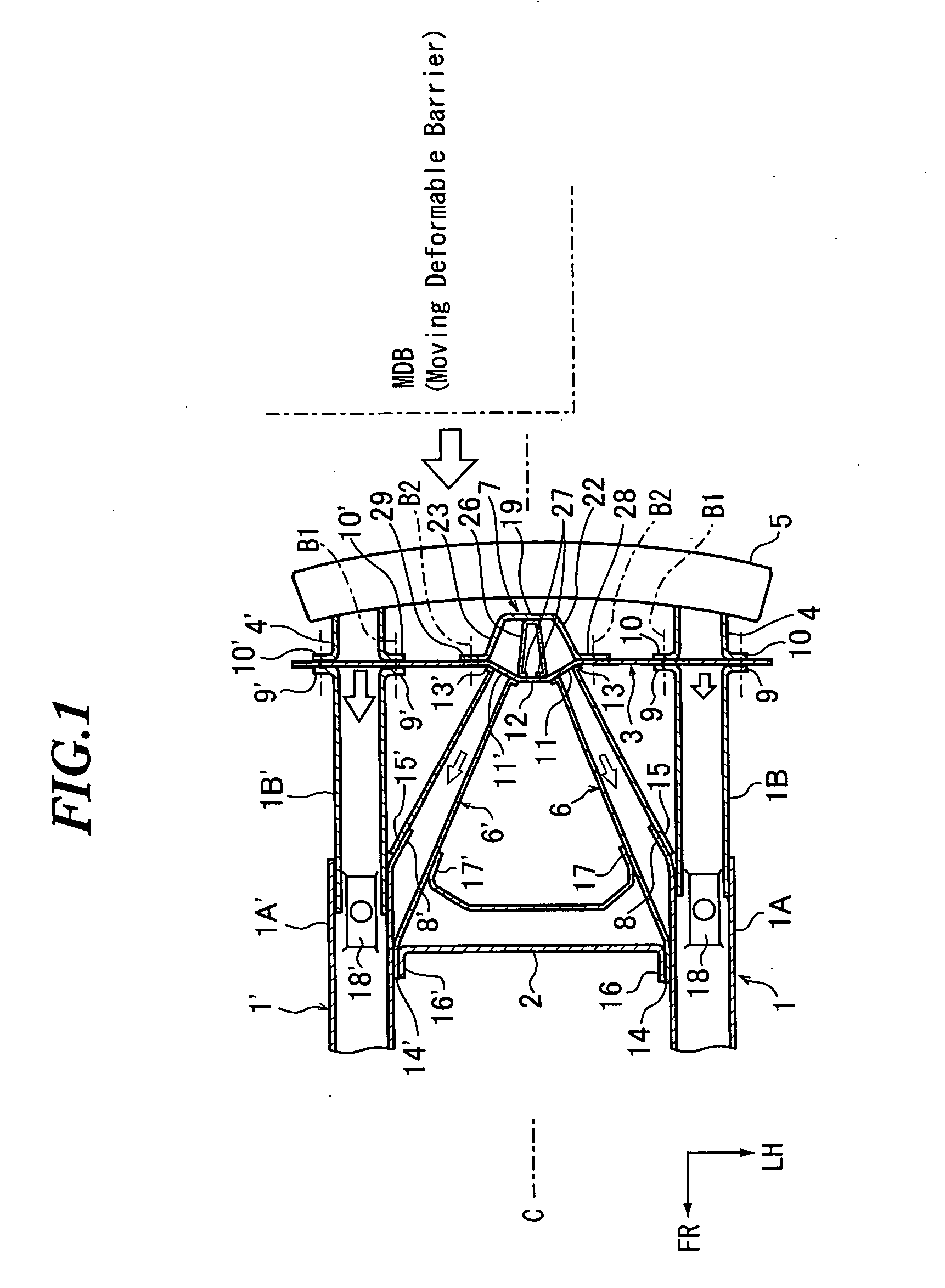

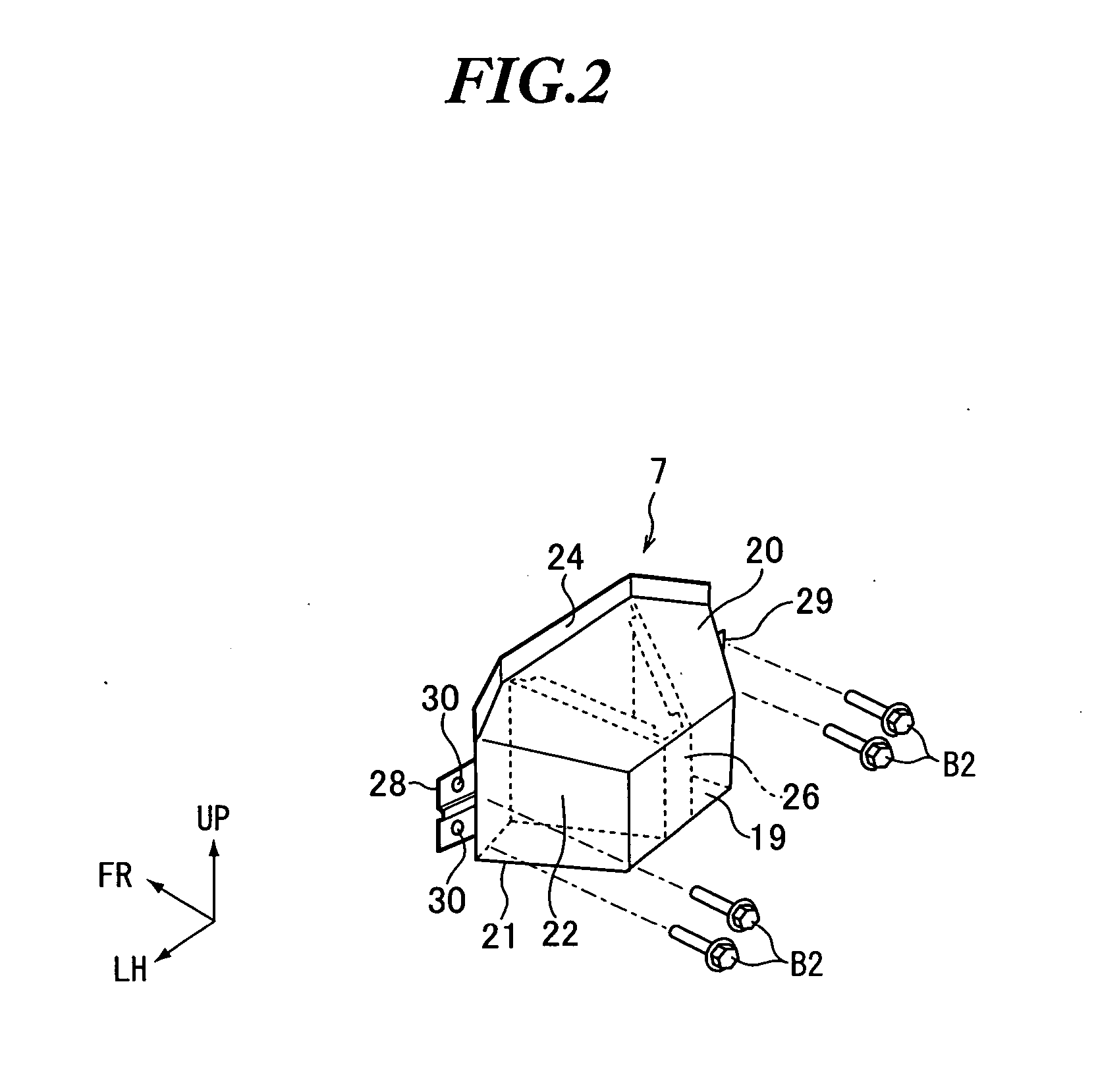

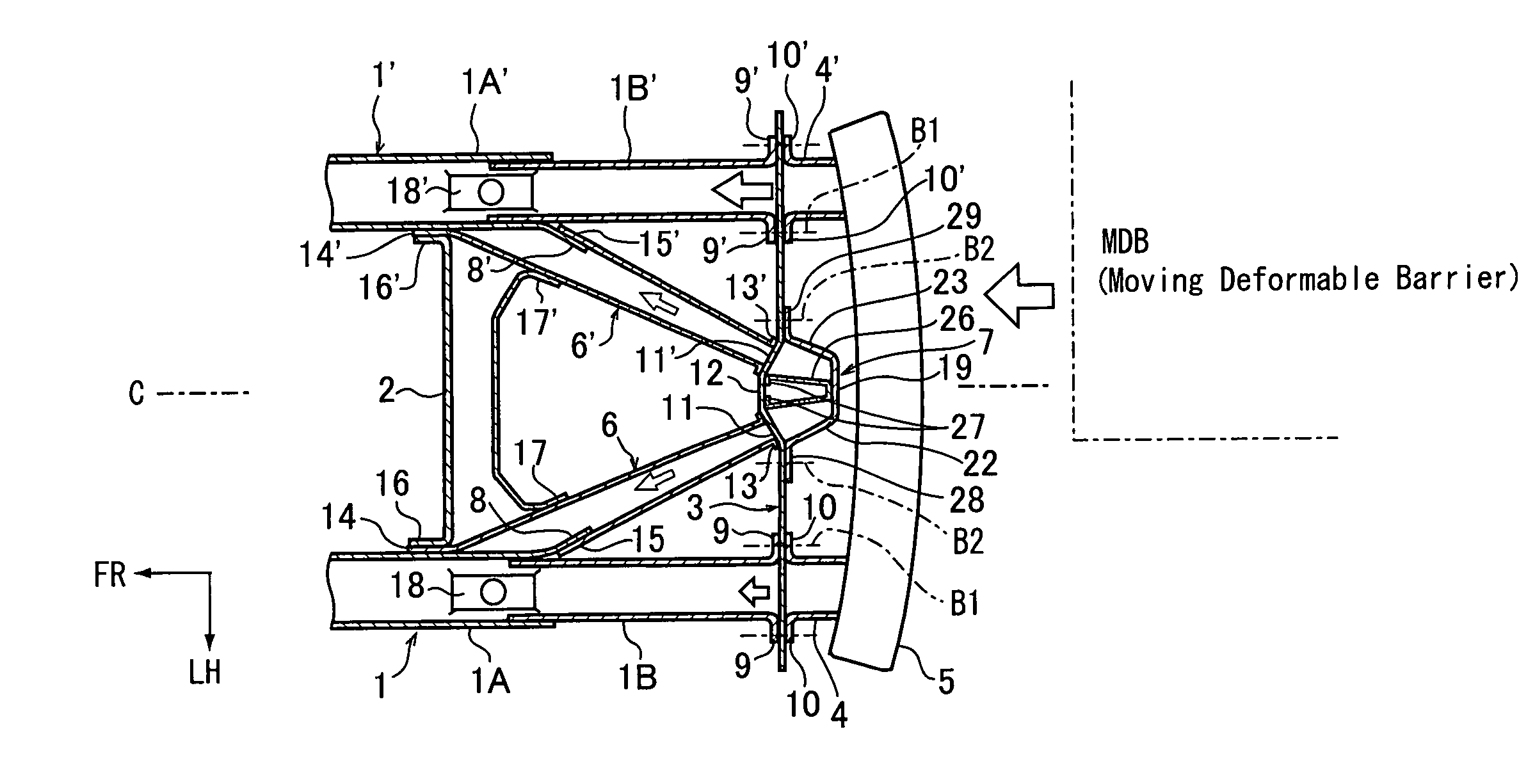

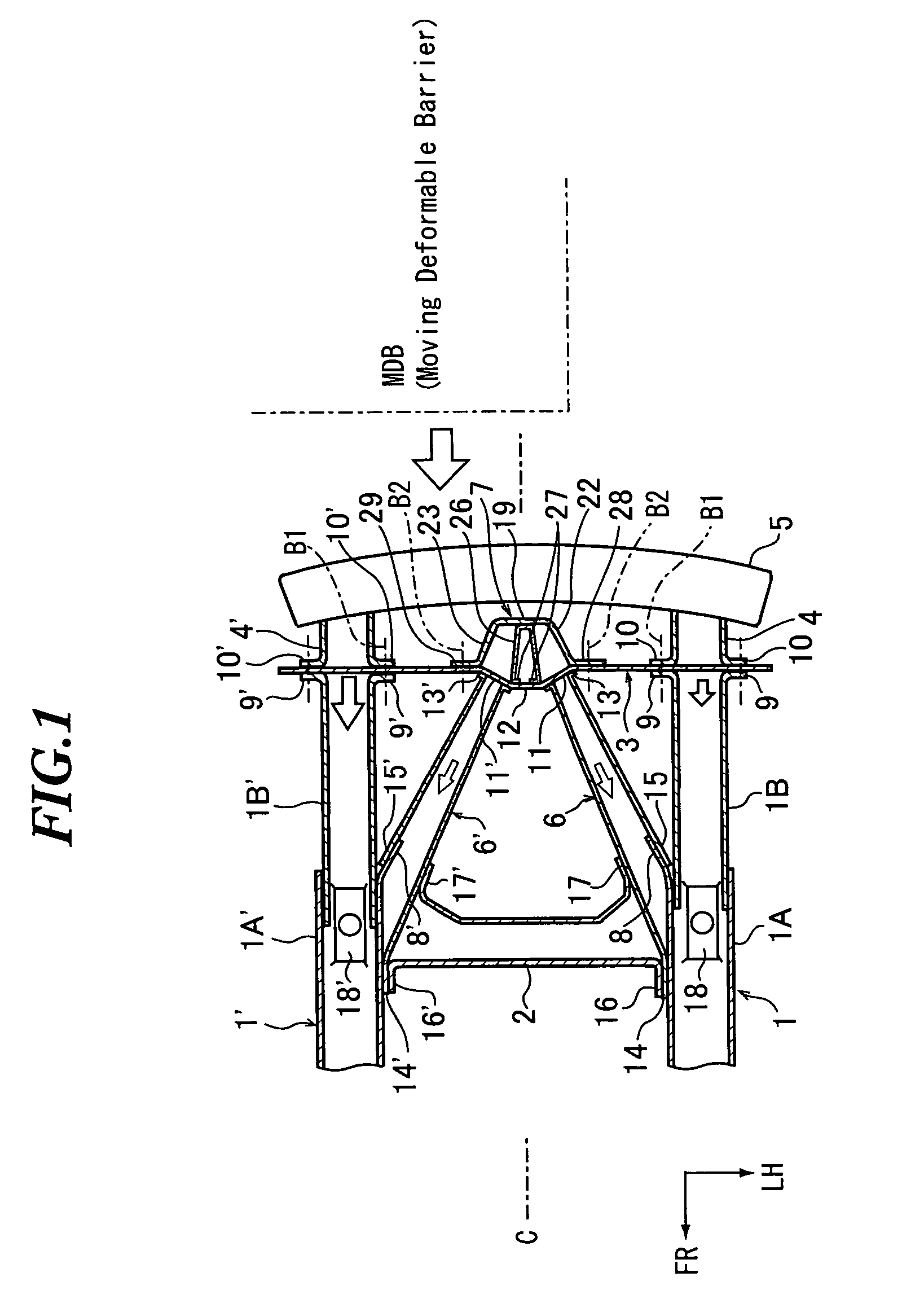

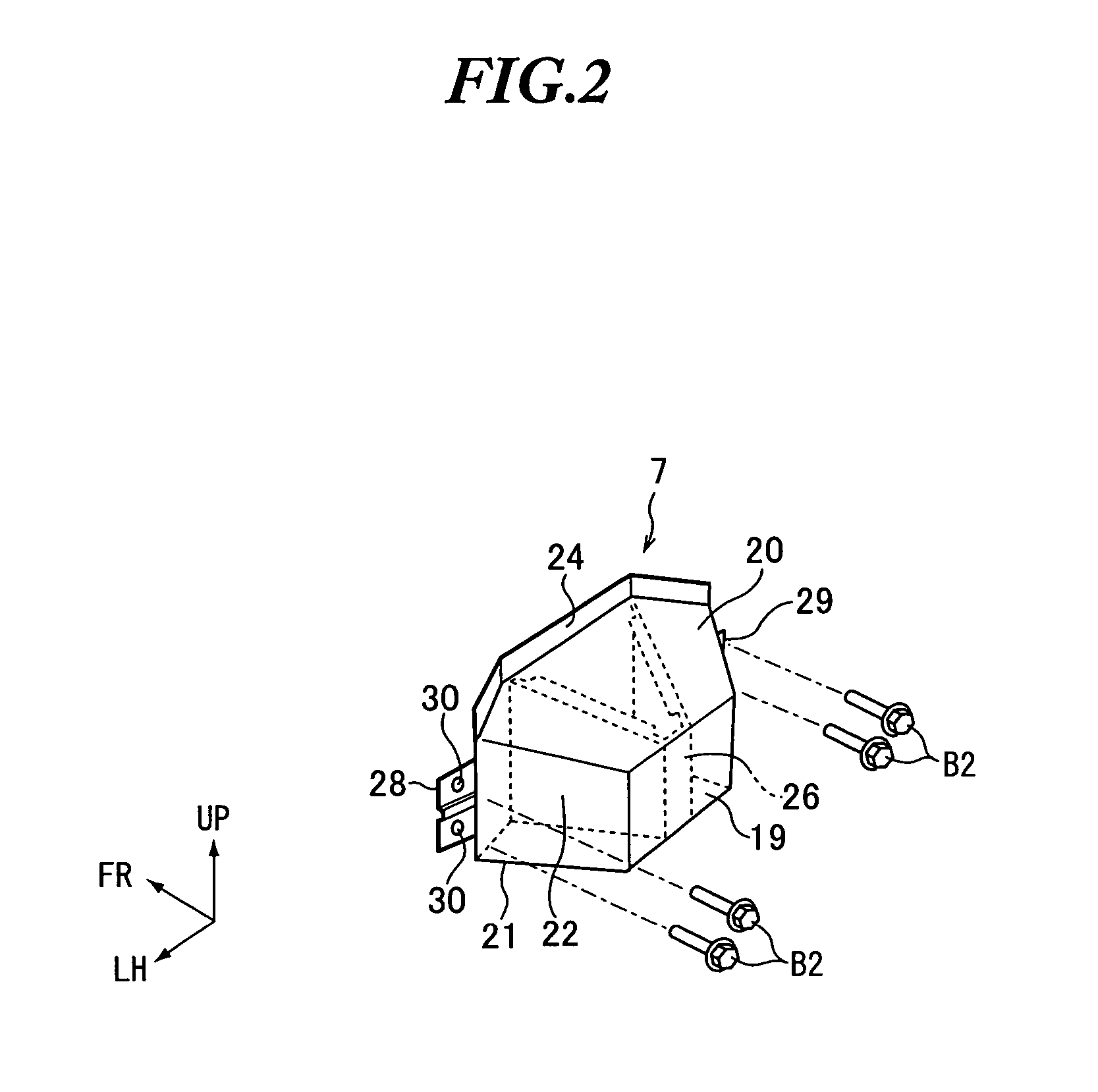

Frame structure for vehicle

ActiveUS20050077756A1Reduced strengthImprove rigidityVehicle seatsUnderstructuresVehicle frameLow speed

A pair of diagonal members are arranged to extend from a substantially central position of a rear end panel extending in a widthwise direction of a vehicle body toward respective junctions of rear frames and a cross member. An end of each of the diagonal members is jointed to the rear end panel, and the other end thereof is jointed to the rear frame together with an end of the cross member. In addition, a guard block protruding toward a bumper beam is detachably fixed to the substantially central position of the rear end panel. Thus, such a frame structure for a vehicle can disperse and absorb an impact load in a low-speed crash or an offset crash.

Owner:SUBARU CORP

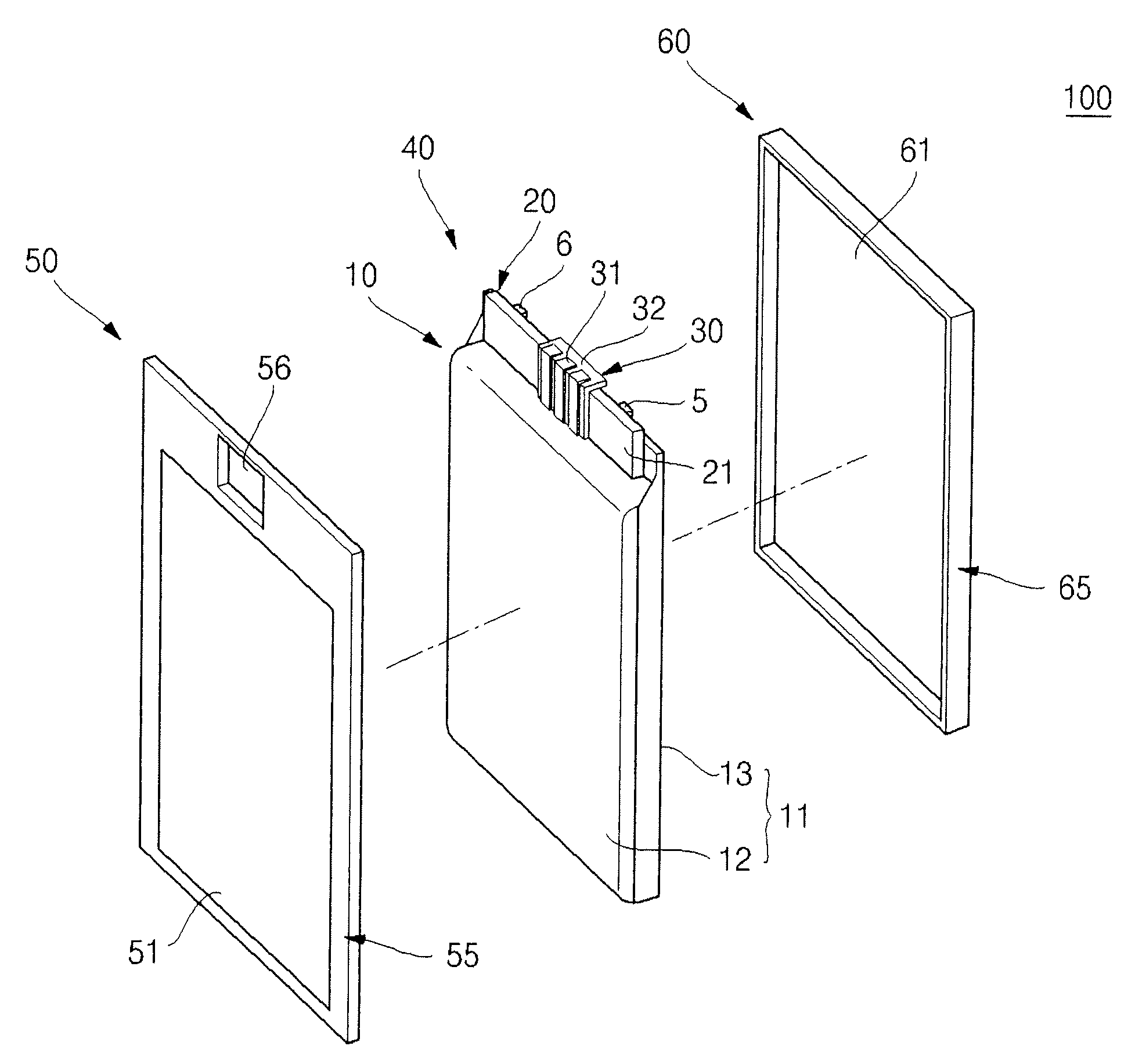

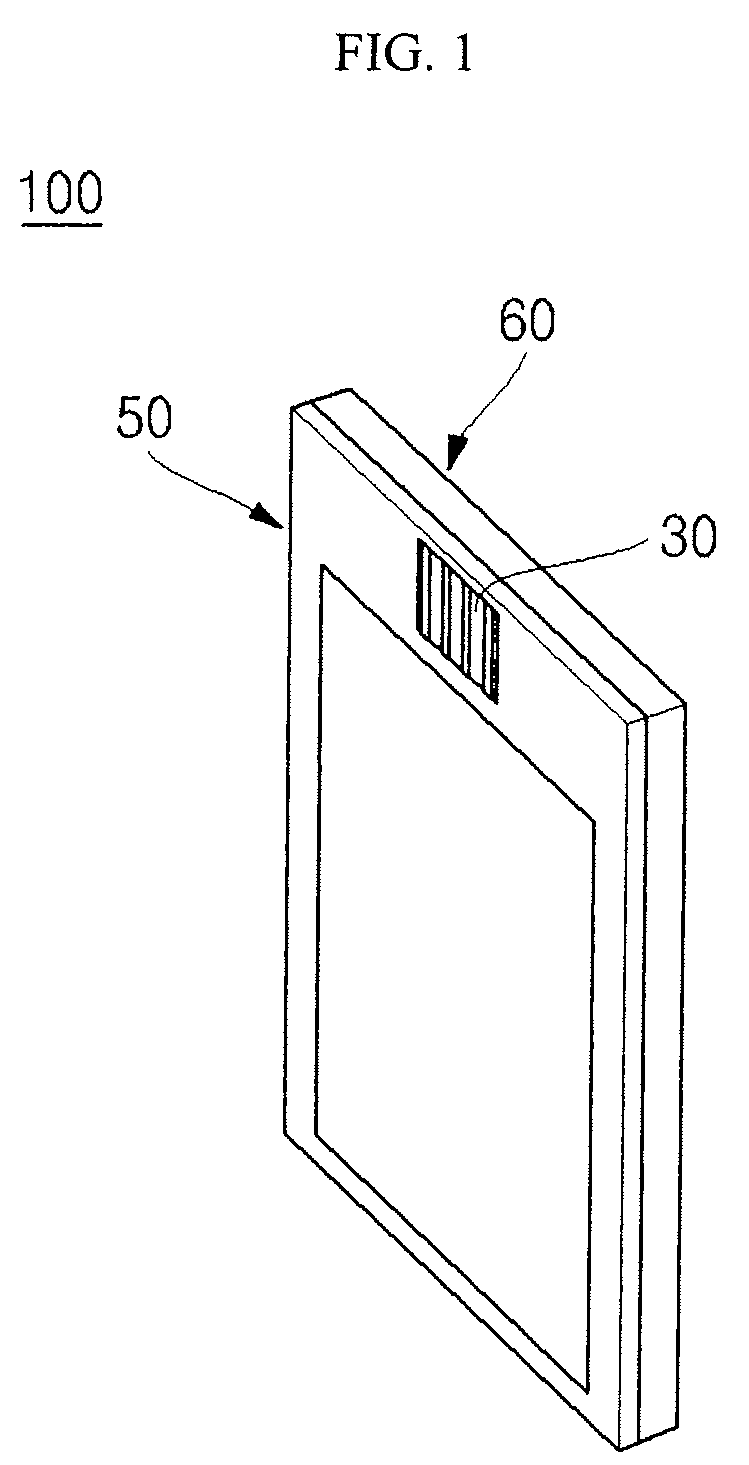

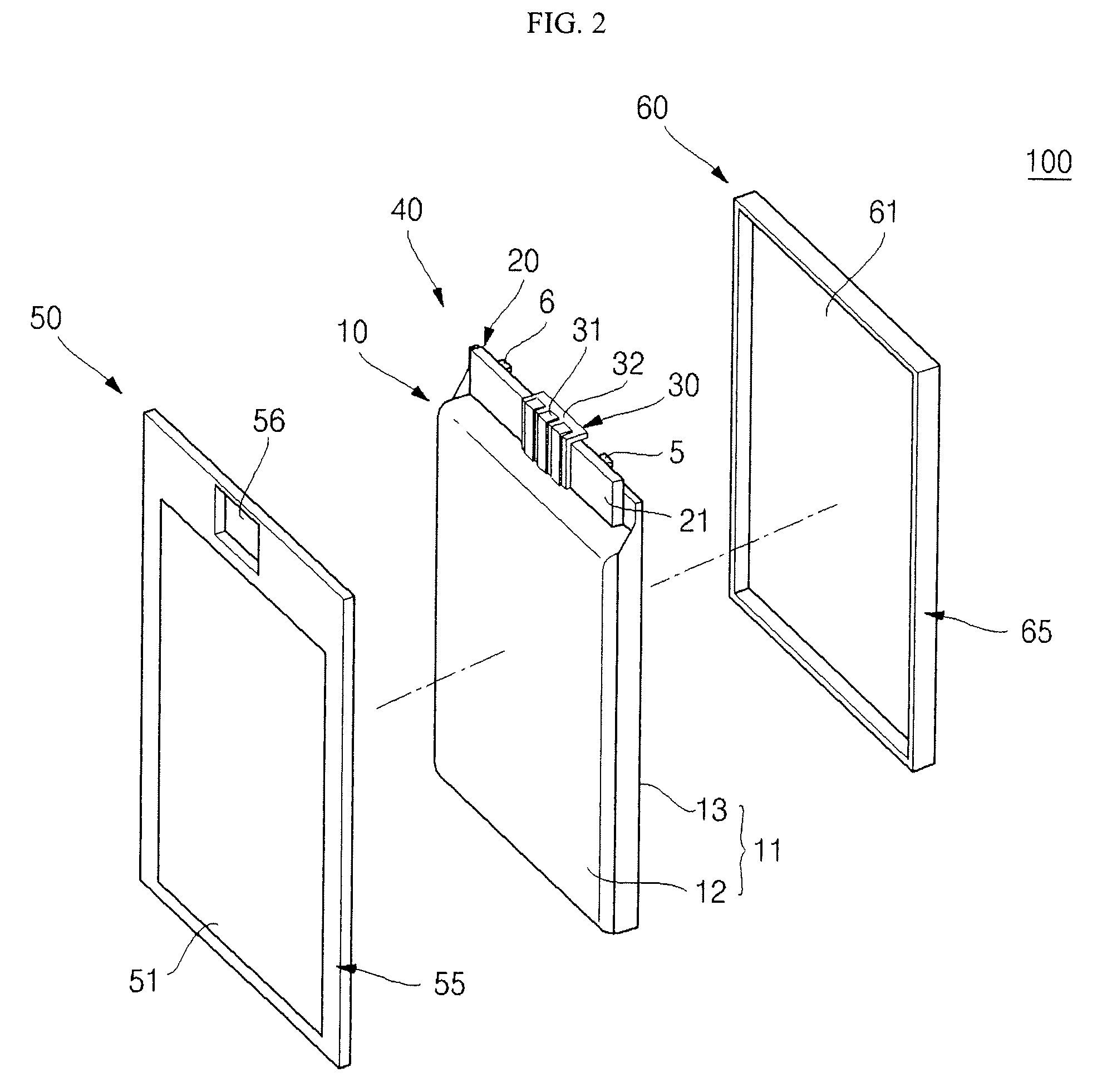

Battery pack

InactiveUS20080081254A1Thickness minimizationMaintaining battery capacityCells structural combinationCell component detailsEngineeringBattery capacity

A battery pack, which can secure the strength of an outer case, minimize the thickness over the whole outer case and ensure a battery capacity of the battery pack, by forming a portion of a main wall of the outer case with a metal plate. The battery pack includes a core pack, a first case, and a second case. The first case has a periphery including a first resin molding part, and is configured to cover a first surface of the core pack. The second case has a periphery including a second molding part, and is configured to cover a second surface of the core pack. The first and second cases are connected with each other by a weld of the first and second molding parts.

Owner:SAMSUNG SDI CO LTD

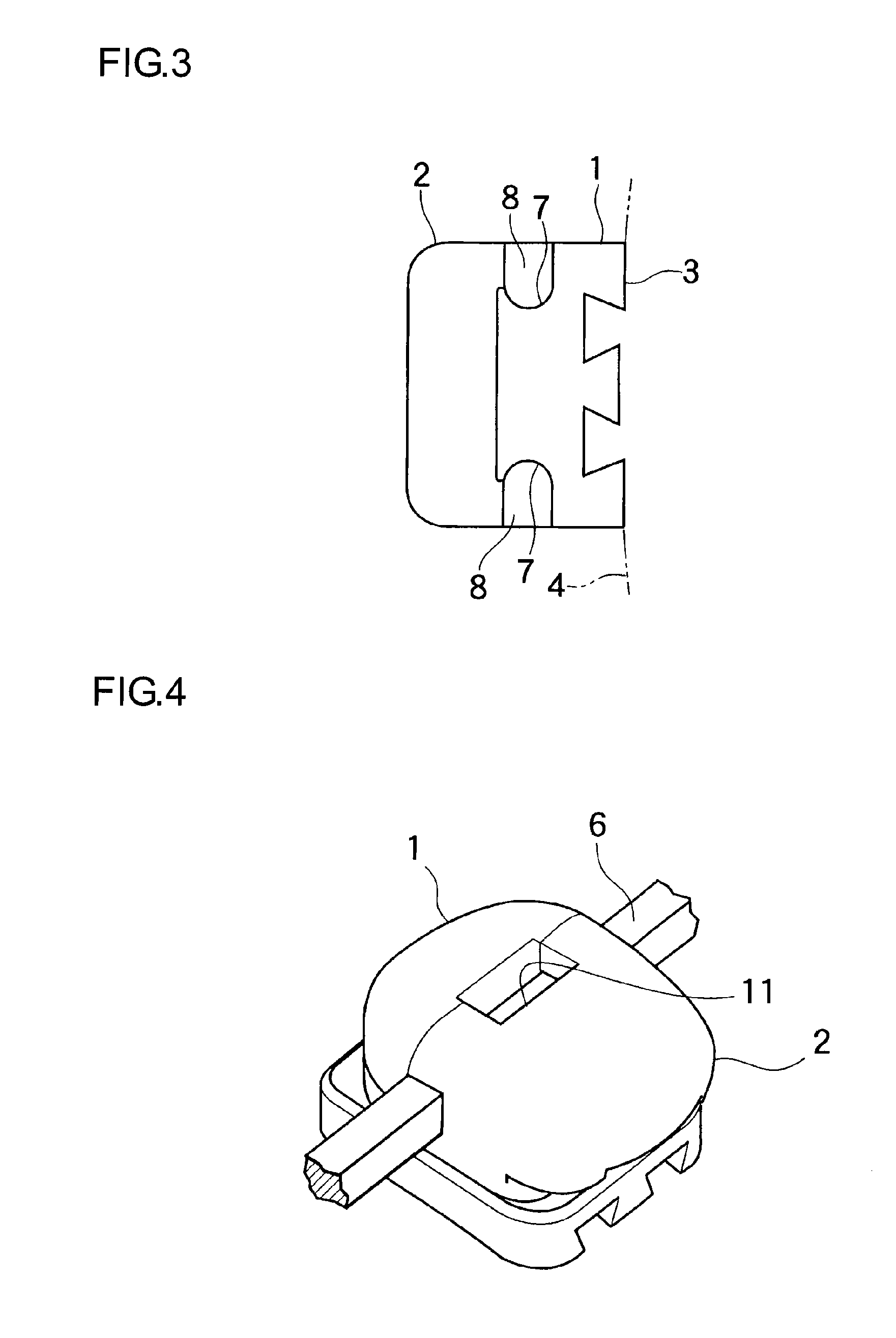

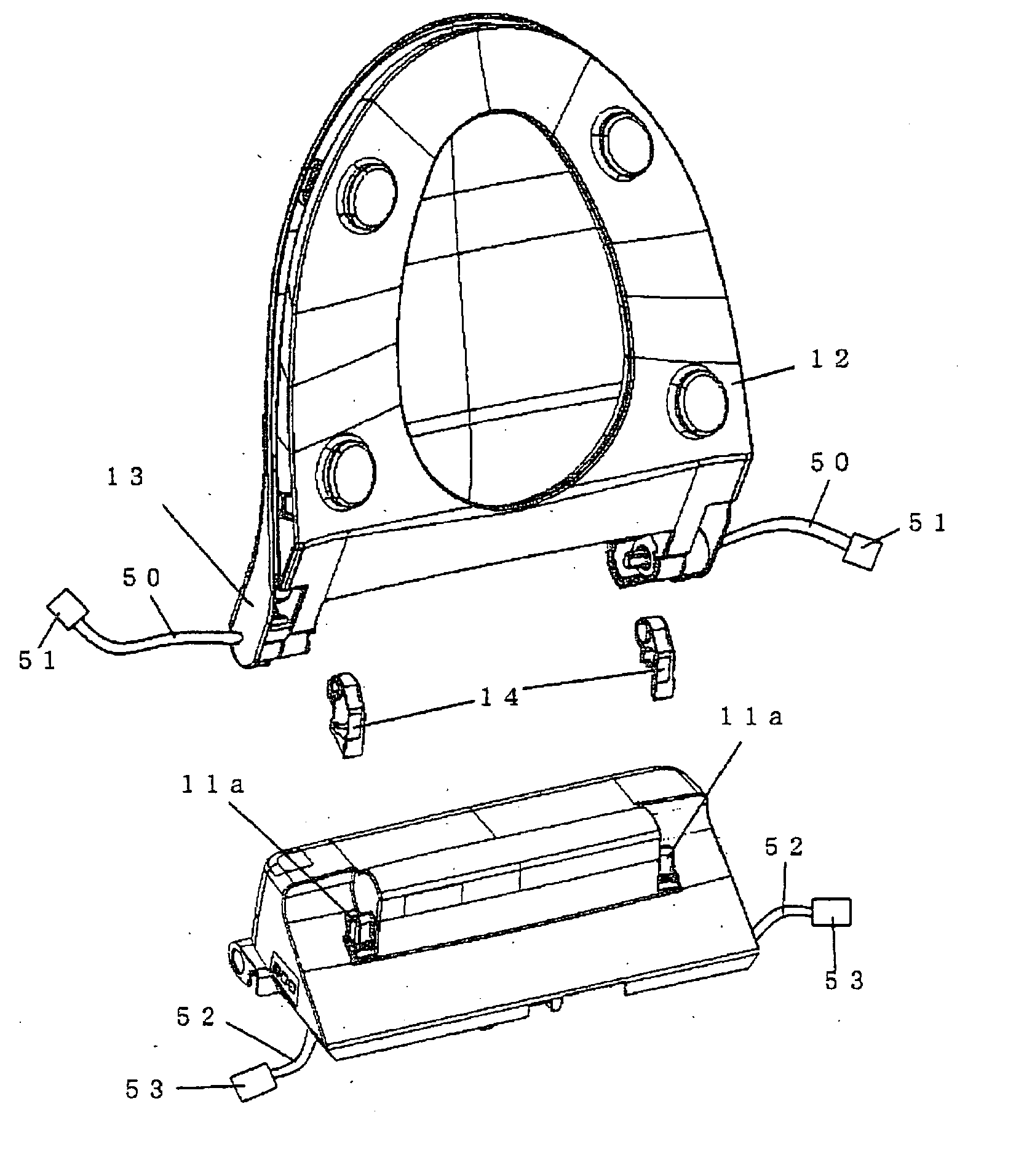

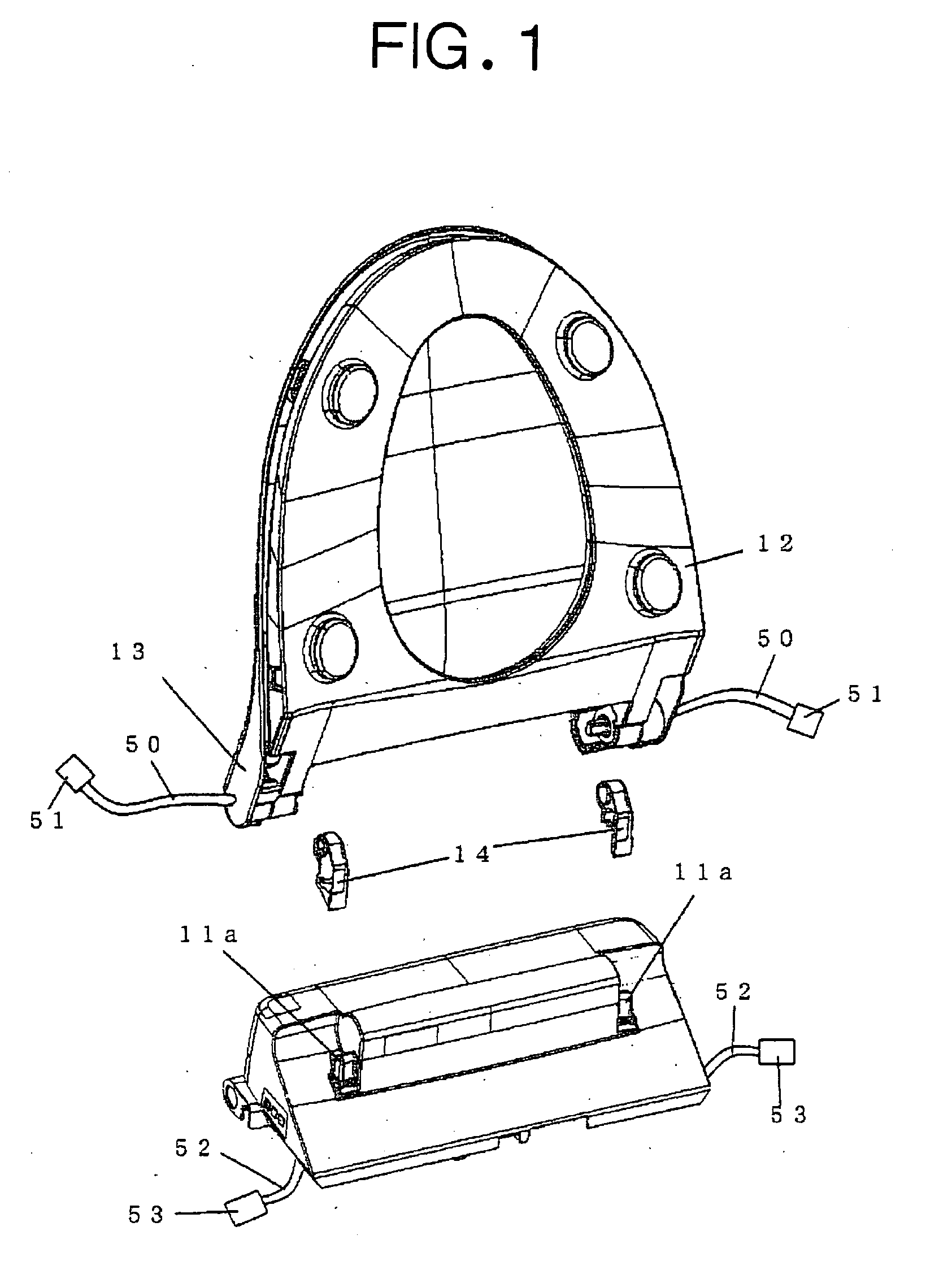

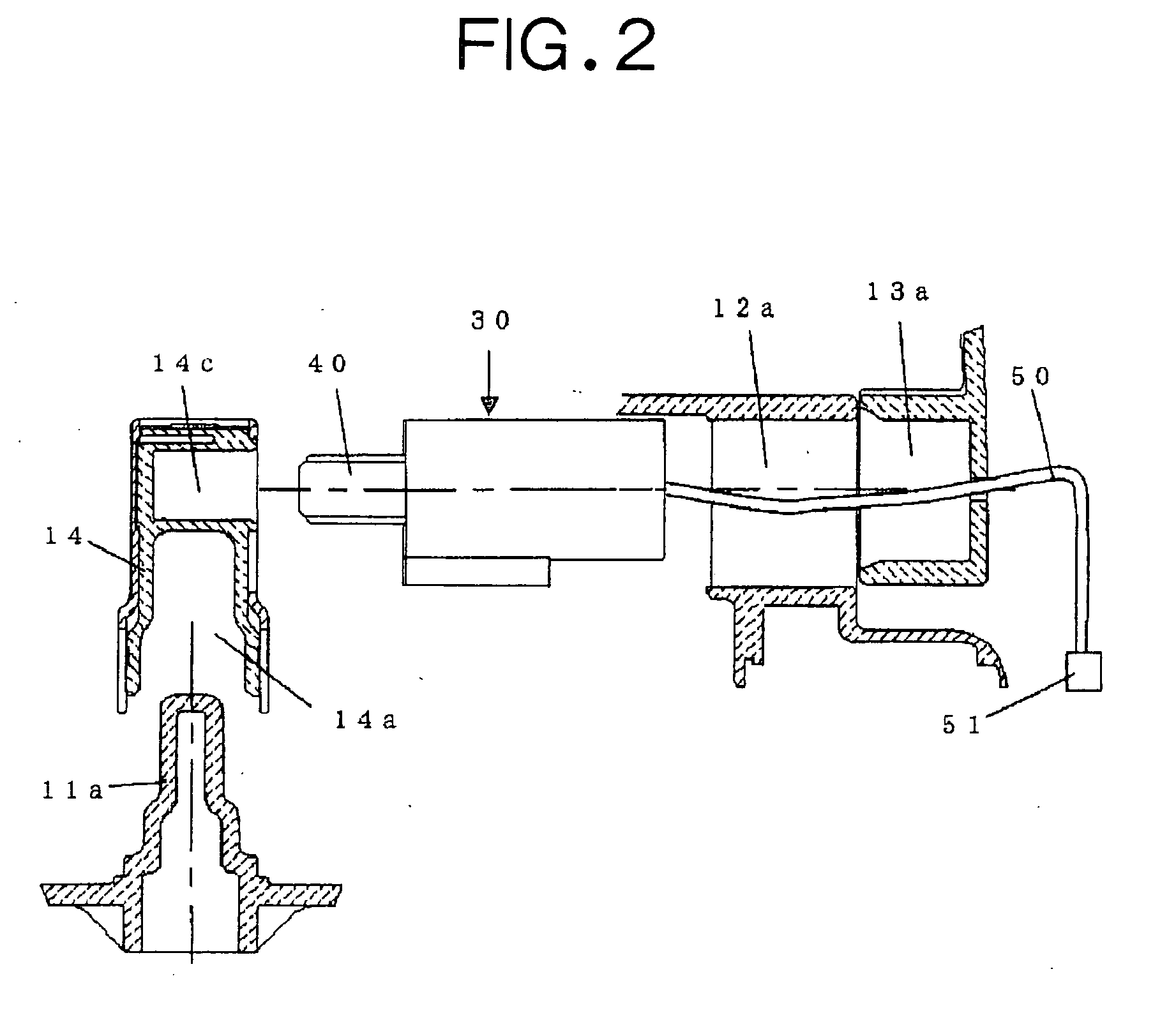

Automatic open/close device for toilet seat or toilet cover

An automatic lifting and lowering device for a toilet seat or a toilet cover usable for a toilet seat provided with a function of washing a body with hot water, which requires reduced size and weight, comprising a rotating shaft (40) rotated together with the toilet seat or the toilet cover, a drive motor (32) rotating the rotating shaft (40) in normal and reverse directions, and a speed reduction gear train (33), wherein the drive force of the drive motor (32) is transmitted to the rotating shaft (40) through the speed reduction gear train (33) to automatically lift and lower the toilet seat or toilet cover, whereby the automatic lifting and lowering device itself can be formed compact by using a planetary gear mechanism for the speed reduction gear train (33).

Owner:TOTO LTD

Frame structure for vehicle

ActiveUS7032961B2Effective dispersionEffective absorptionVehicle seatsUnderstructuresLow speedMechanical engineering

A pair of diagonal members are arranged to extend from a substantially central position of a rear end panel extending in a widthwise direction of a vehicle body toward respective junctions of rear frames and a cross member. An end of each of the diagonal members is jointed to the rear end panel, and the other end thereof is jointed to the rear frame together with an end of the cross member. In addition, a guard block protruding toward a bumper beam is detachably fixed to the substantially central position of the rear end panel. Thus, such a frame structure for a vehicle can disperse and absorb an impact load in a low-speed crash or an offset crash.

Owner:SUBARU CORP

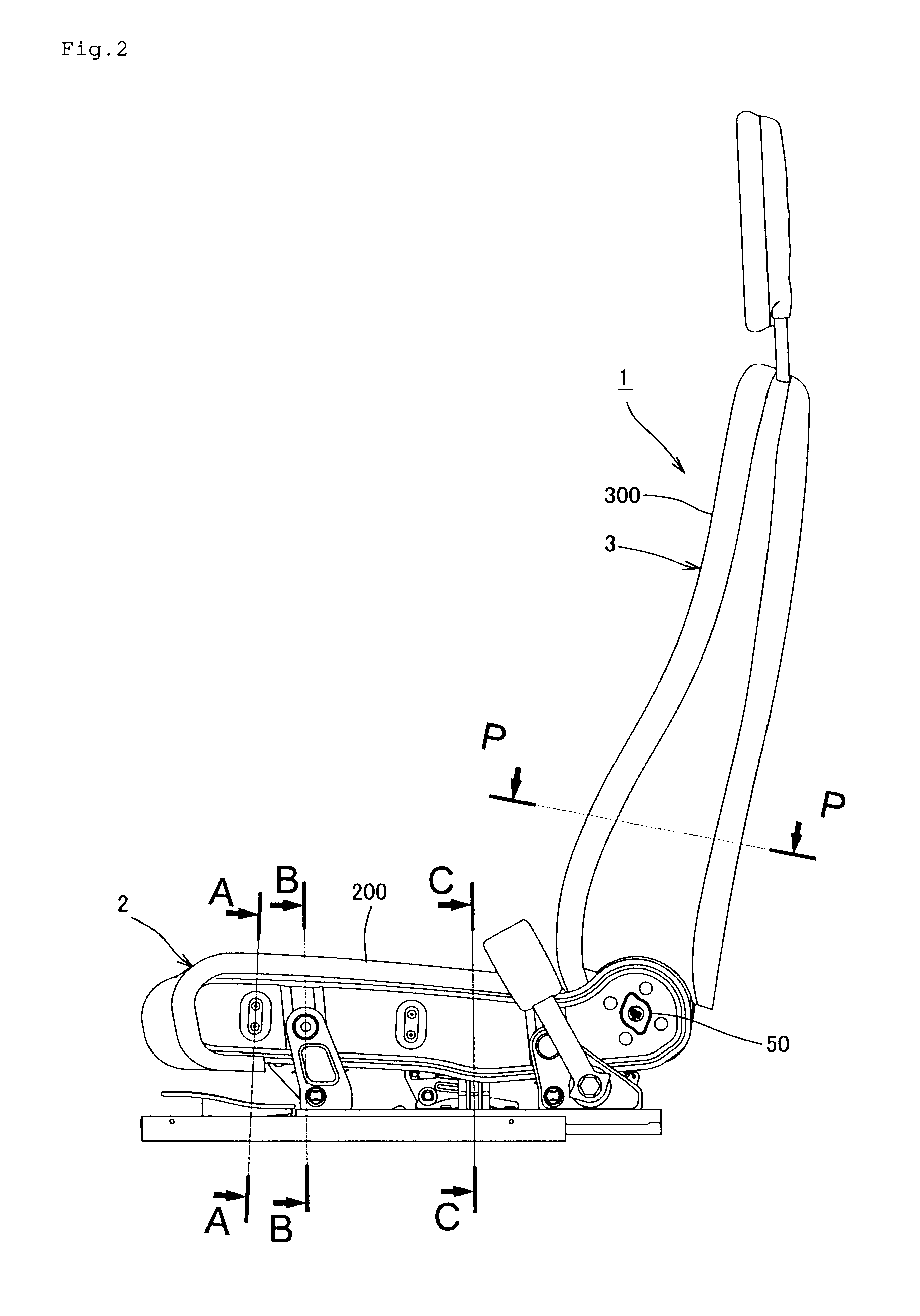

Seat

ActiveUS20110169317A1Reduce weightIncrease the sectionSeat framesStoolsEngineeringUltimate tensile strength

A seat has a configuration in which, in each side frame of a cushion frame, an inner frame and an outer frame which have flanges extending along peripheral edges thereof are faced to each other with a space therebetween at least partially, and the flanges are fixed by hemming process along the entire peripheral edges thereof. Since the entire peripheral edges are hemmed, the inner frame and the outer frame are securely fixed. Additionally, since the inner frame and the outer frame which are thin-plate-shaped are used, reduction in weight of each side frame can be achieved. Further, since the inner frame and the outer frame are faced to each other with a space therebetween at least partially, a compressive / tensile strength required as a side frame can be secured by inserting an expanded bead body into the space.

Owner:DELTA TOOLING CO LTD

Wired circuit board and electronic device

InactiveUS20080078573A1Excellent long-term reliabilityRelieve stressCross-talk/noise/interference reductionPrinted circuit aspectsGround layerPrinted circuit board

A wired circuit board has an insulating layer extending in a longitudinal direction, a conductive layer having a plurality of signal wirings covered with the insulating layer and arranged in mutually spaced-apart and parallel relation in a perpendicular direction to the longitudinal direction and a thickness direction of the insulating layer, and connecting terminals provided on both longitudinal ends of each of the signal wirings and exposed from the insulating layer, and a ground layer covered with the insulating layer and formed to surround each of the signal wirings in a perpendicular direction to the longitudinal direction. A slit along the longitudinal direction is formed between each of the signal wirings in the insulating layer.

Owner:NITTO DENKO CORP

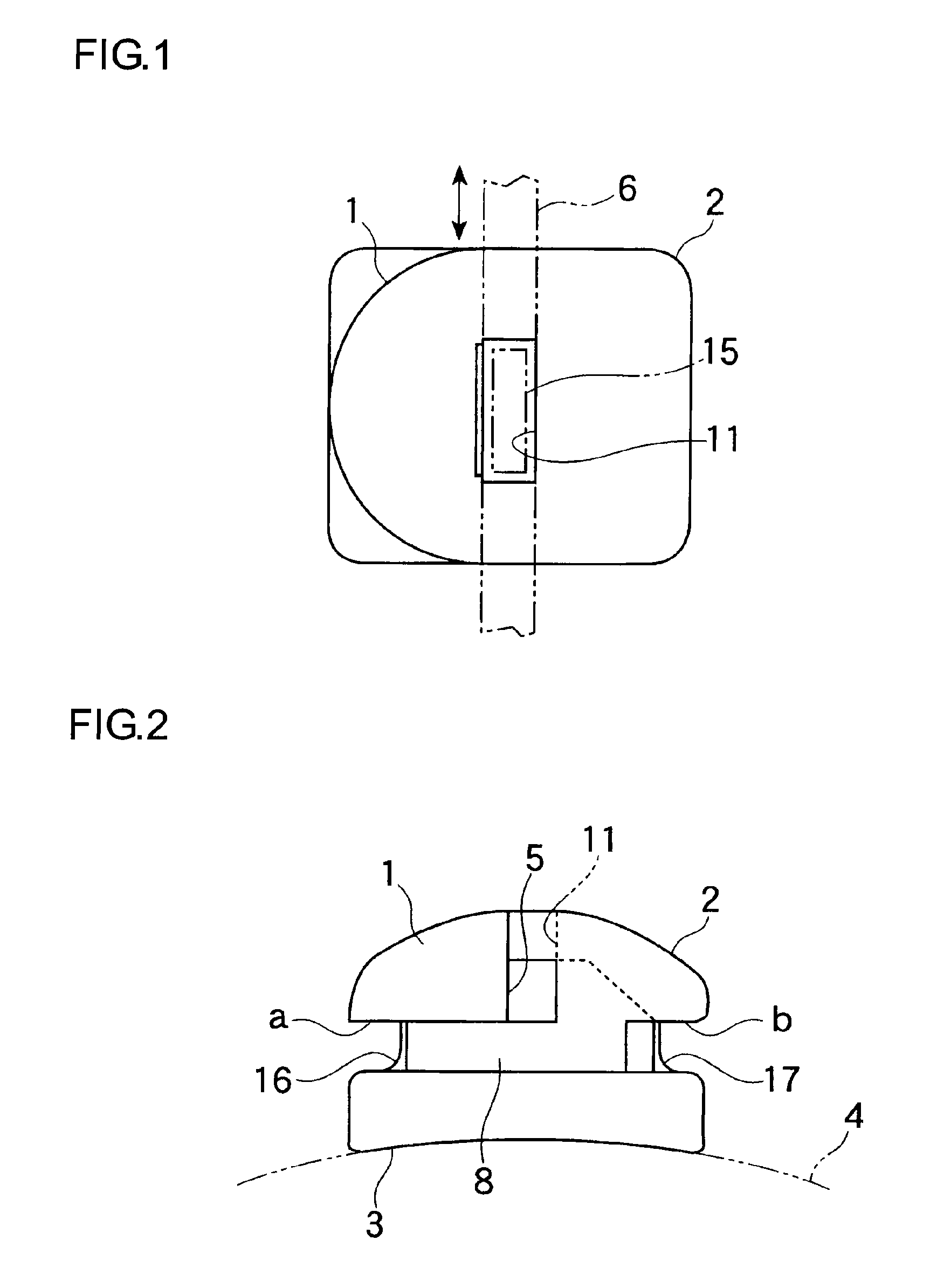

Female crimp terminal

InactiveUS20020077001A1Expansion of the upper wall at the rear end of the bodySecure strengthCoupling contact membersConnections effected by permanent deformationEngineeringLeaf spring

While securing the strength of the neck and securing the function of the leaf spring, bending of the upper parts of the side walls and expansion of the upper walls are prevented, and in turn, smooth insertion of the female crimp terminal into a cell of the housing is assured. As this allows shortening of the longitudinal length of the neck, the female crimp terminal can be compactified. The female crimp terminal comprising a tubular body, a leaf spring being located inside the body and being integrally formed on the front part of the body, a neck being formed approximately into a U shape when seen in the longitudinal direction and being integrally formed on the lower parts of both side walls and the bottom wall at the rear end of the body, and a barrel being formed integrally into a U shape when seen in the longitudinal direction, being integrally formed on the neck and having retainers extending upward high above the neck, and a notch is made in each side wall from the rear end of the body so as to divide the side wall into an upper part and a lower part.

Owner:JST MFG CO LTD

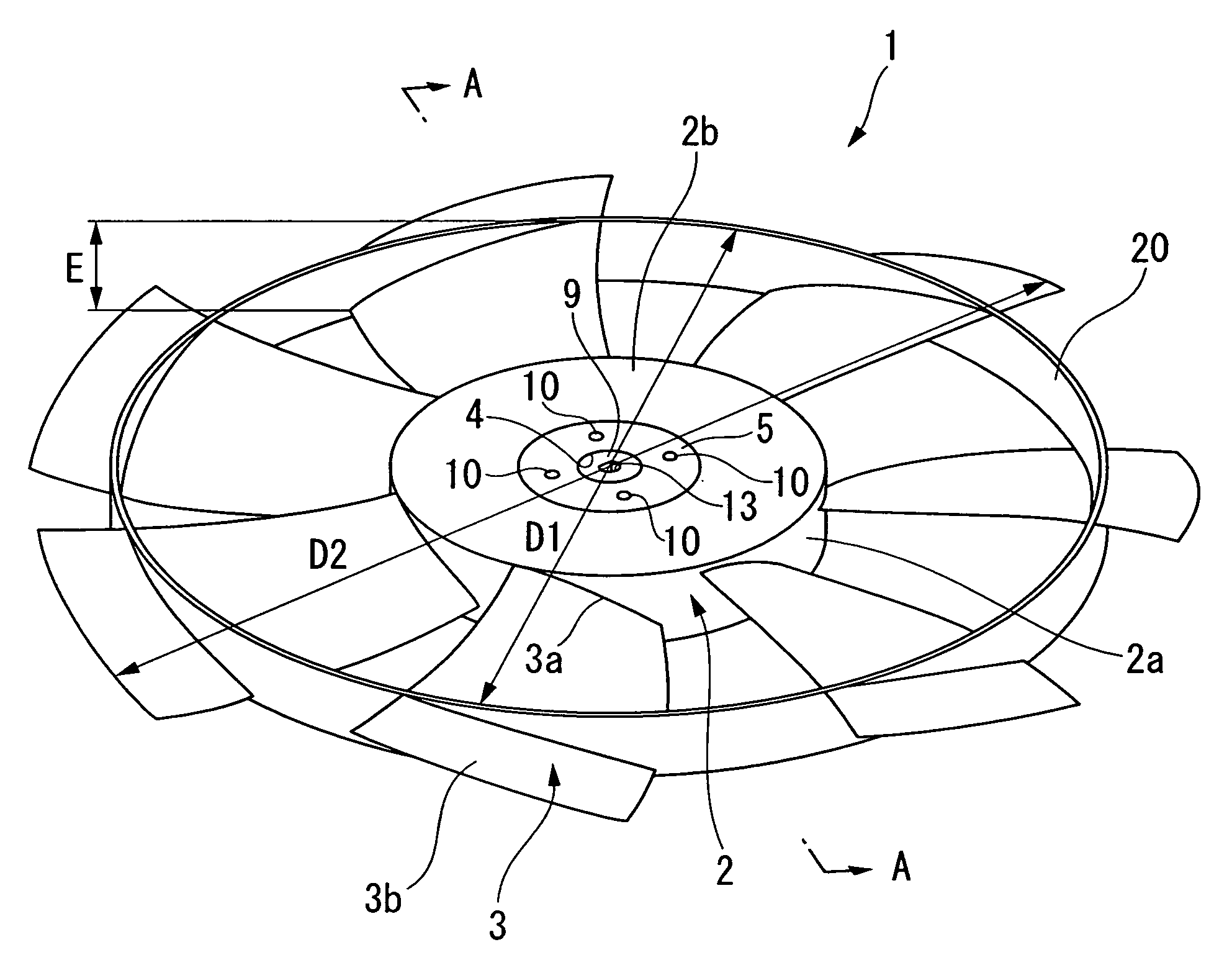

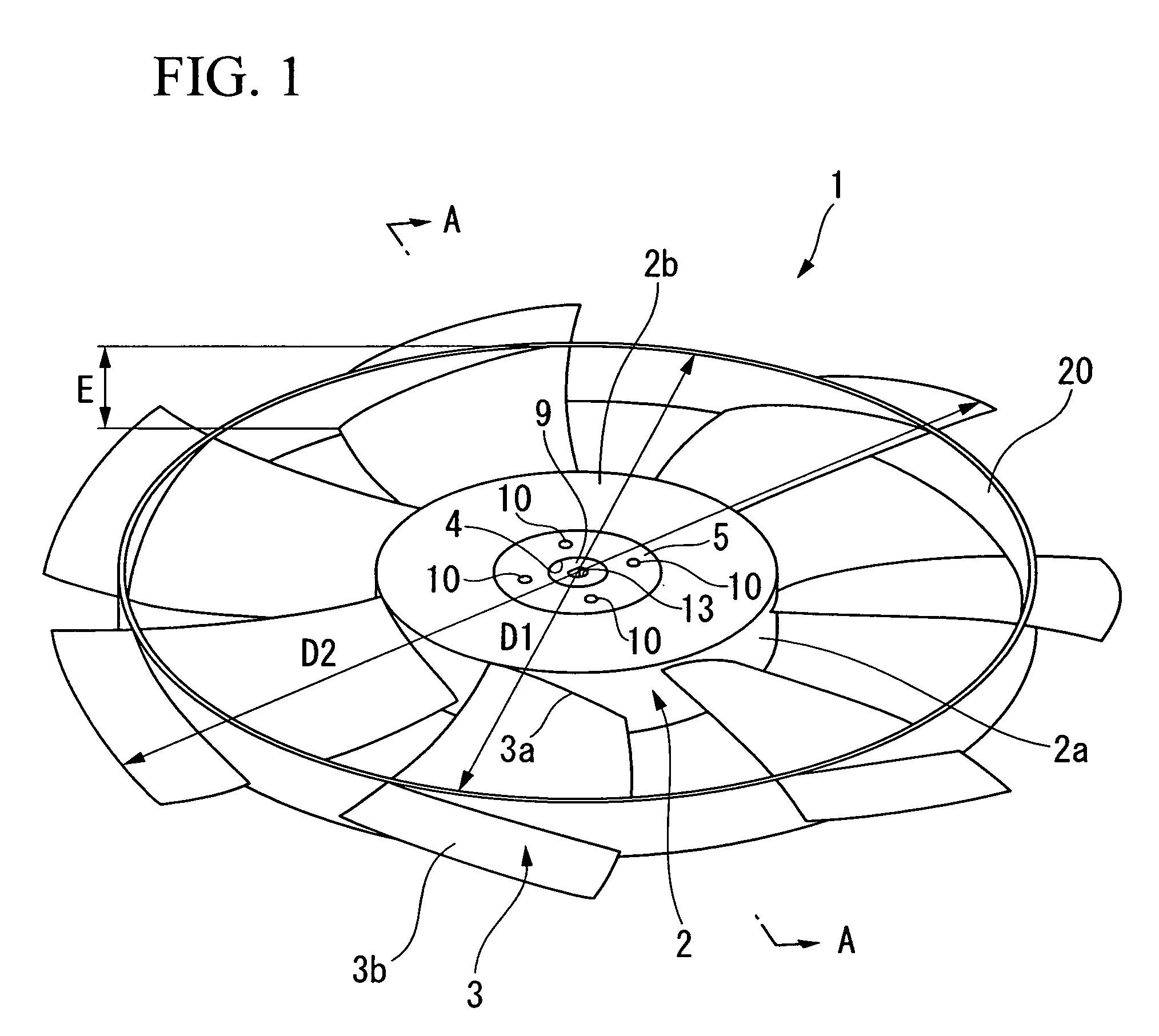

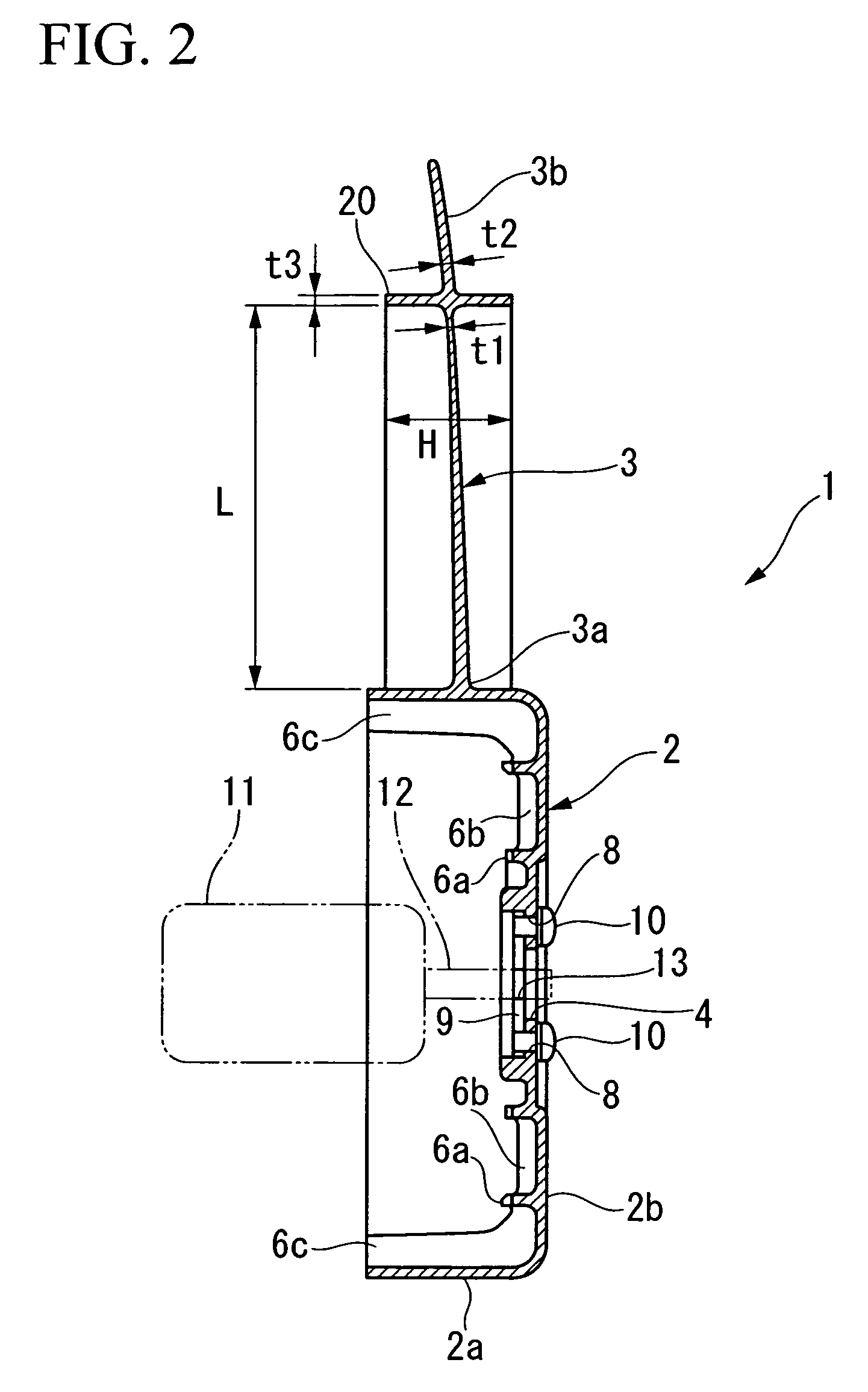

Cooling fan

ActiveUS20100068060A1Excellent in strength balanceReduce weightPropellersPump componentsAerospace engineering

A cooling fan of the present invention includes: a bottomed cylindrical boss portion; and a plurality of blades provided on an outer circumferential surface of the boss portion, the blades radiating in a radial direction, in which a ring member for connecting the blades with each other is provided on a side radially inner from tips of the blades. According to the present invention, it is possible to provide a cooling fan capable of preventing the worsening of the noise characteristic and also of enhancing the versatility even if the blades are made thinner.

Owner:MITSUBA CORP

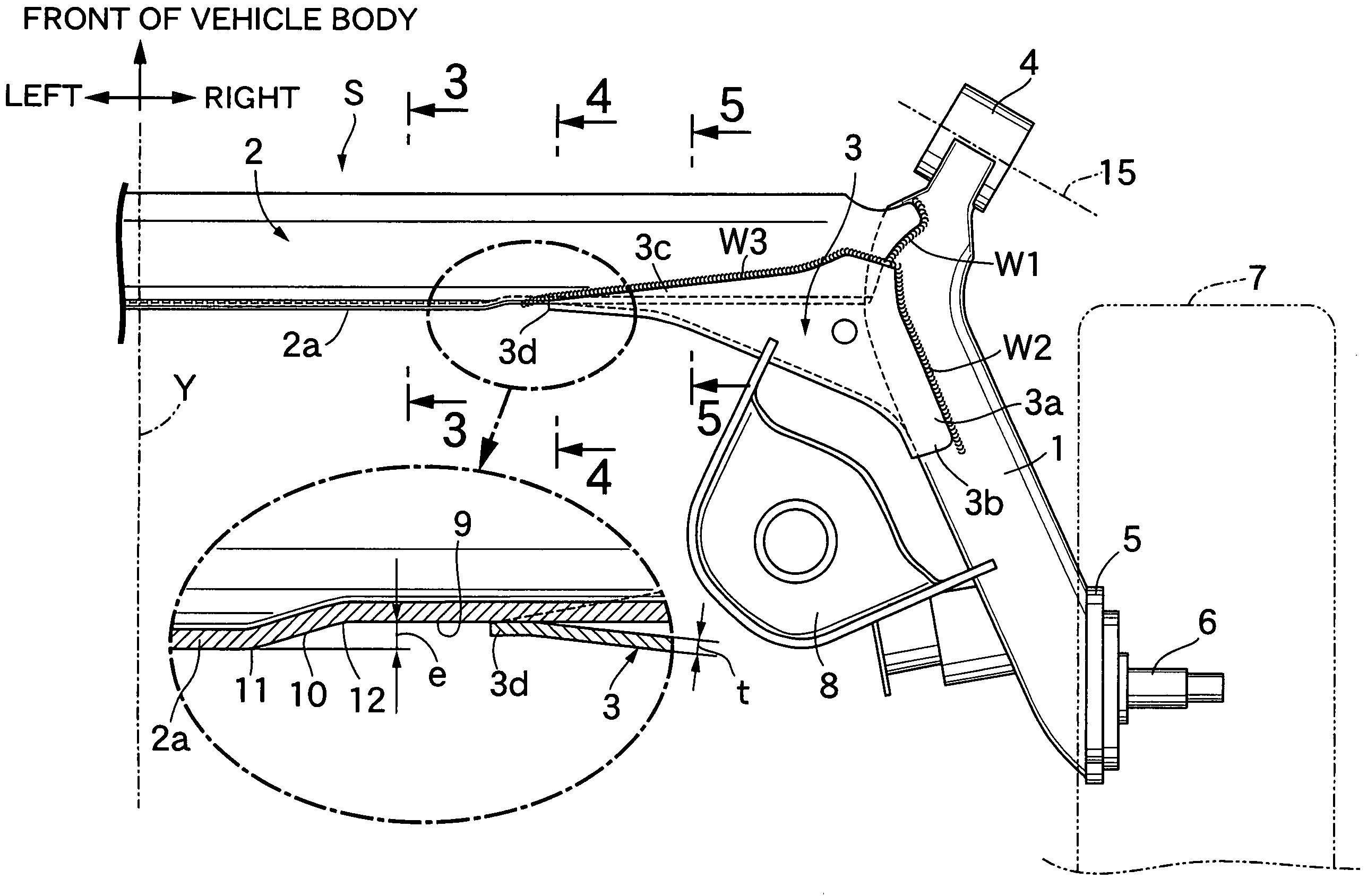

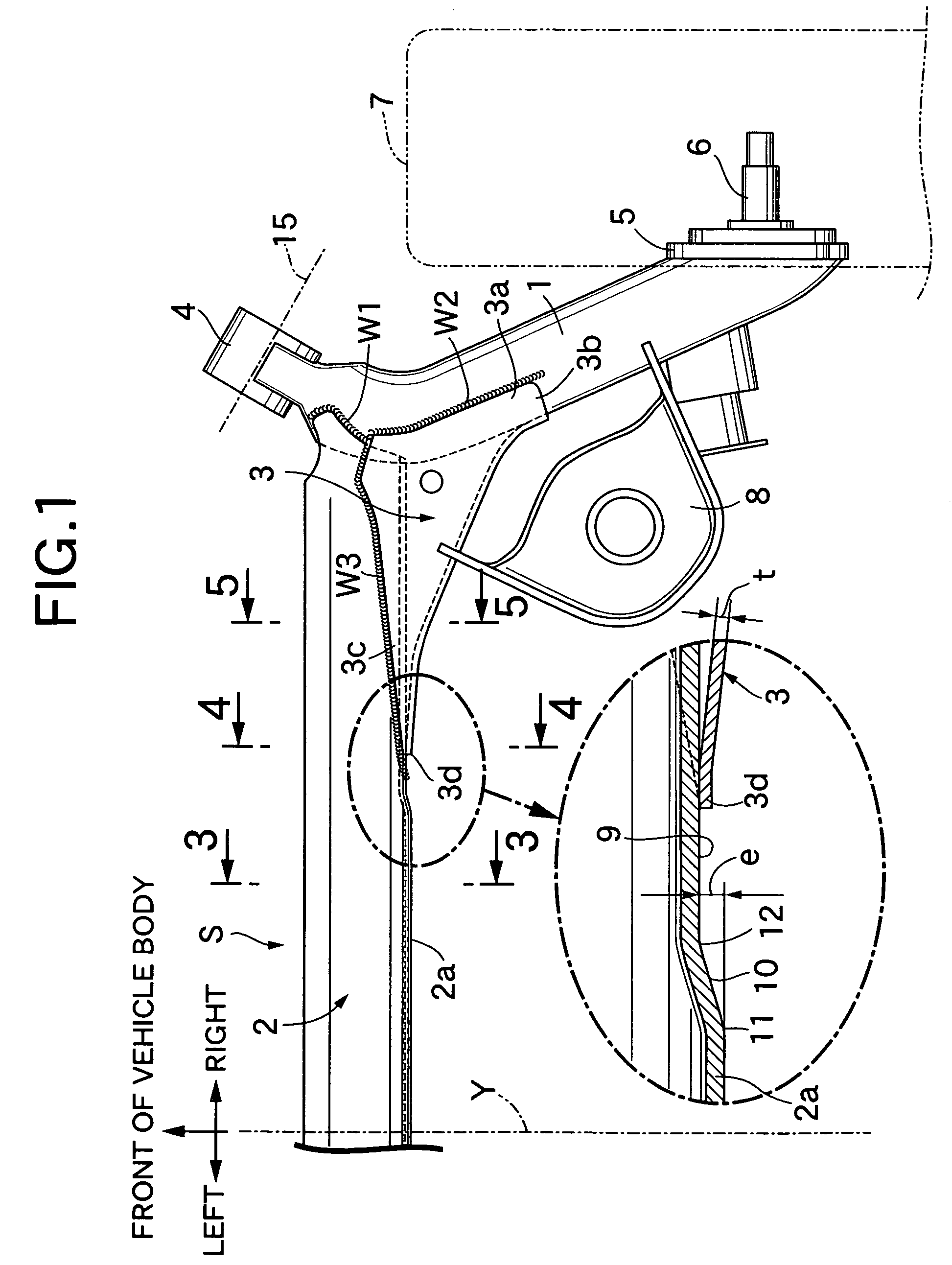

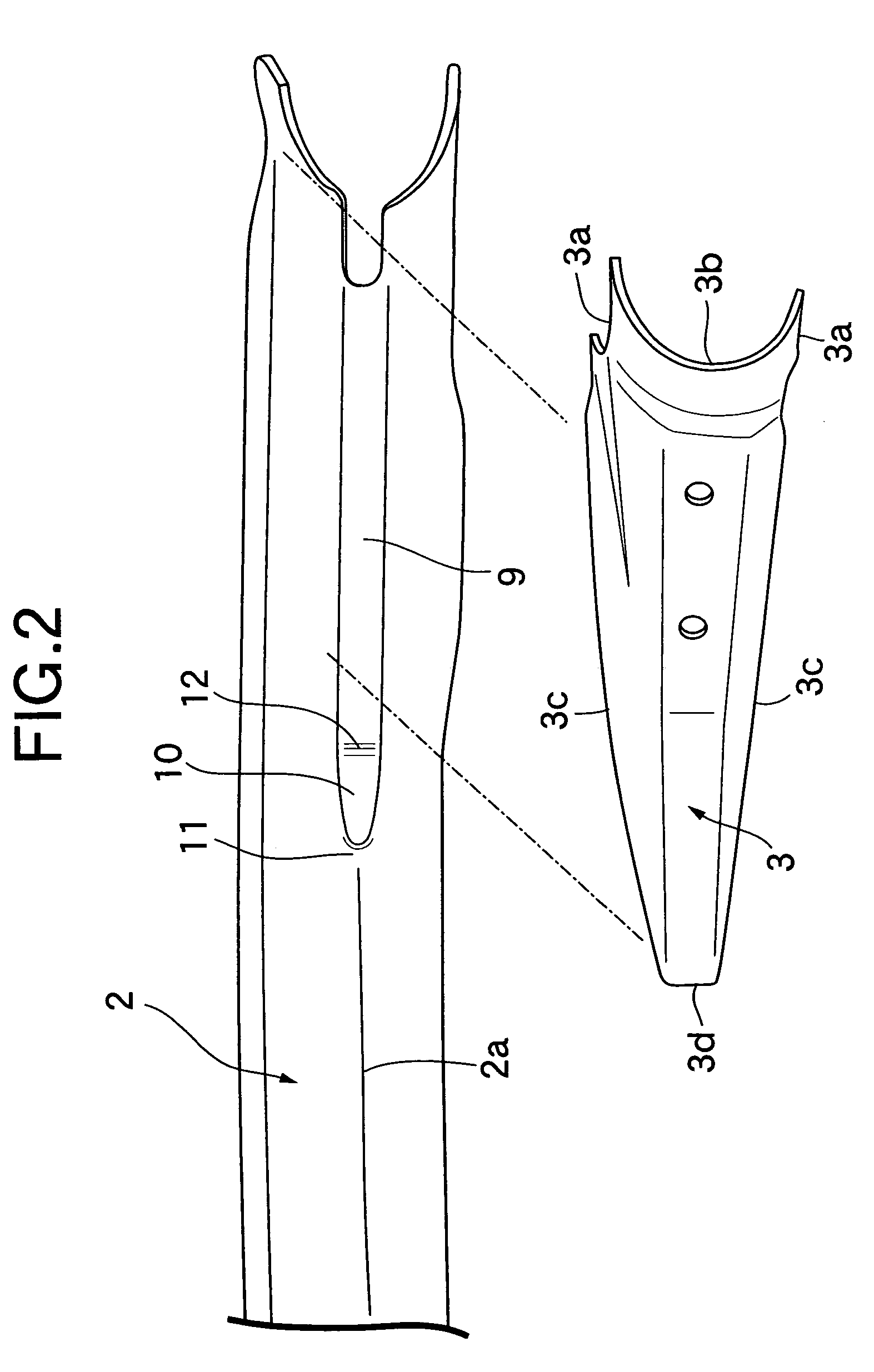

Torsion beam suspension

InactiveUS7284765B1Increased durabilityReduction in weight and costInterconnection systemsResilient suspensionsIn planeStress concentration

In a torsion beam suspension including: a pair of left and right trailing arms 1; a torsion beam 2 providing connection between the trailing arms 1; and gussets 3 which are U-shaped in section and substantially triangular in plane view and which are welded to inner side surfaces of connecting portions between the trailing arms 1 and the torsion beam 2, seat surfaces 9 are formed by crushing at left and right opposite end portions of a rear wall 2a of the torsion beam 2, the seat surfaces 9 being offset forward from a general outer surface of the rear wall 2a by an amount e larger than a plate thickness t of the gussets 3, and each gusset 3 includes an inner end edge portion 3d superposed on an intermediate portion in a lateral direction of the seat surface 9, and upper and lower front edge portions 3c, 3c connected by a weld W3 to upper and lower portions of an outer surface of the torsion beam 2. Thus, in the torsion beam, an abrupt increase in torsional rigidity is suppressed in the gusset inner end portion without reducing strength of the torsion beam to alleviate stress concentration, thereby providing a torsion beam suspension having a high durability.

Owner:F TECH INC

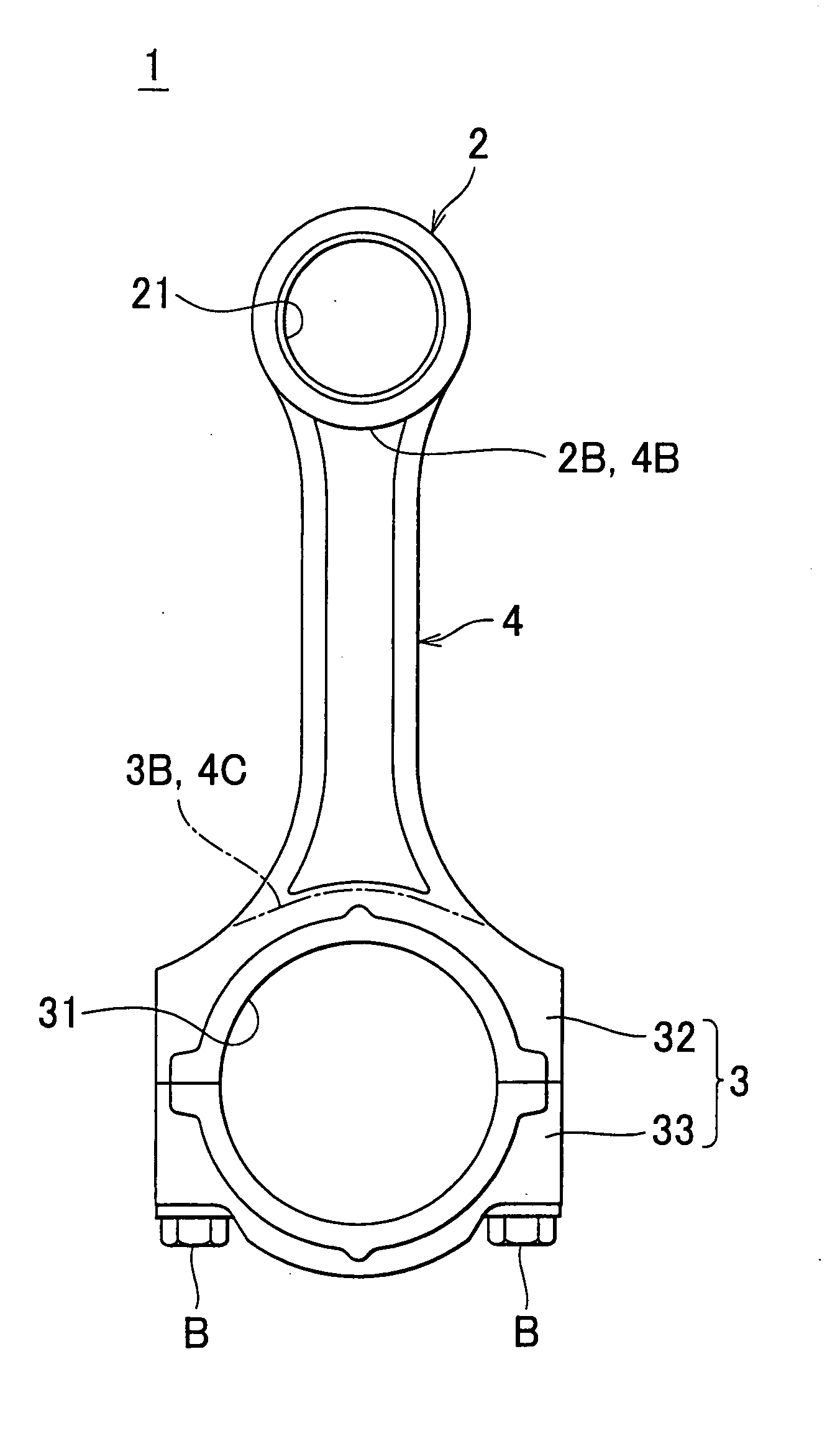

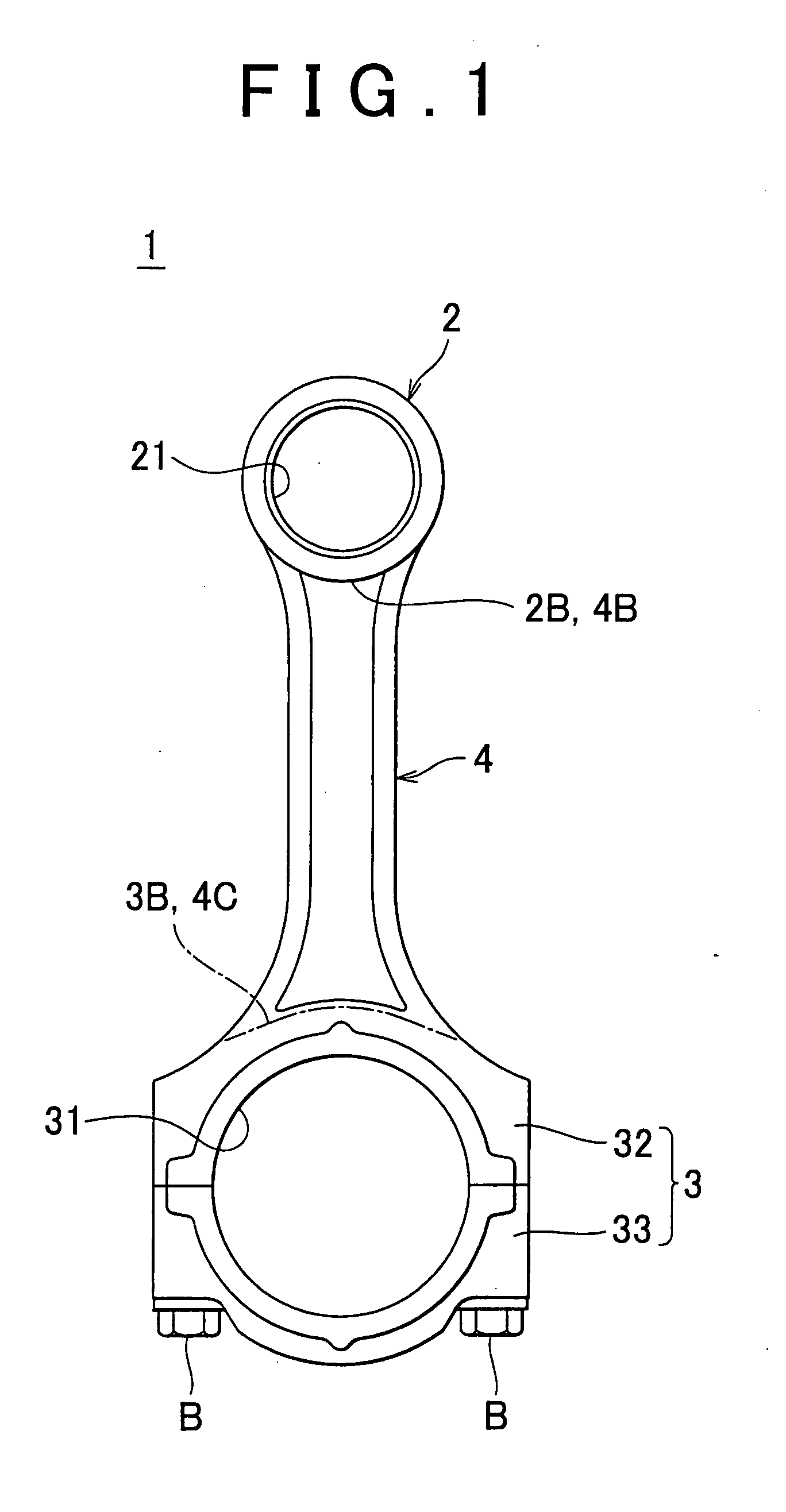

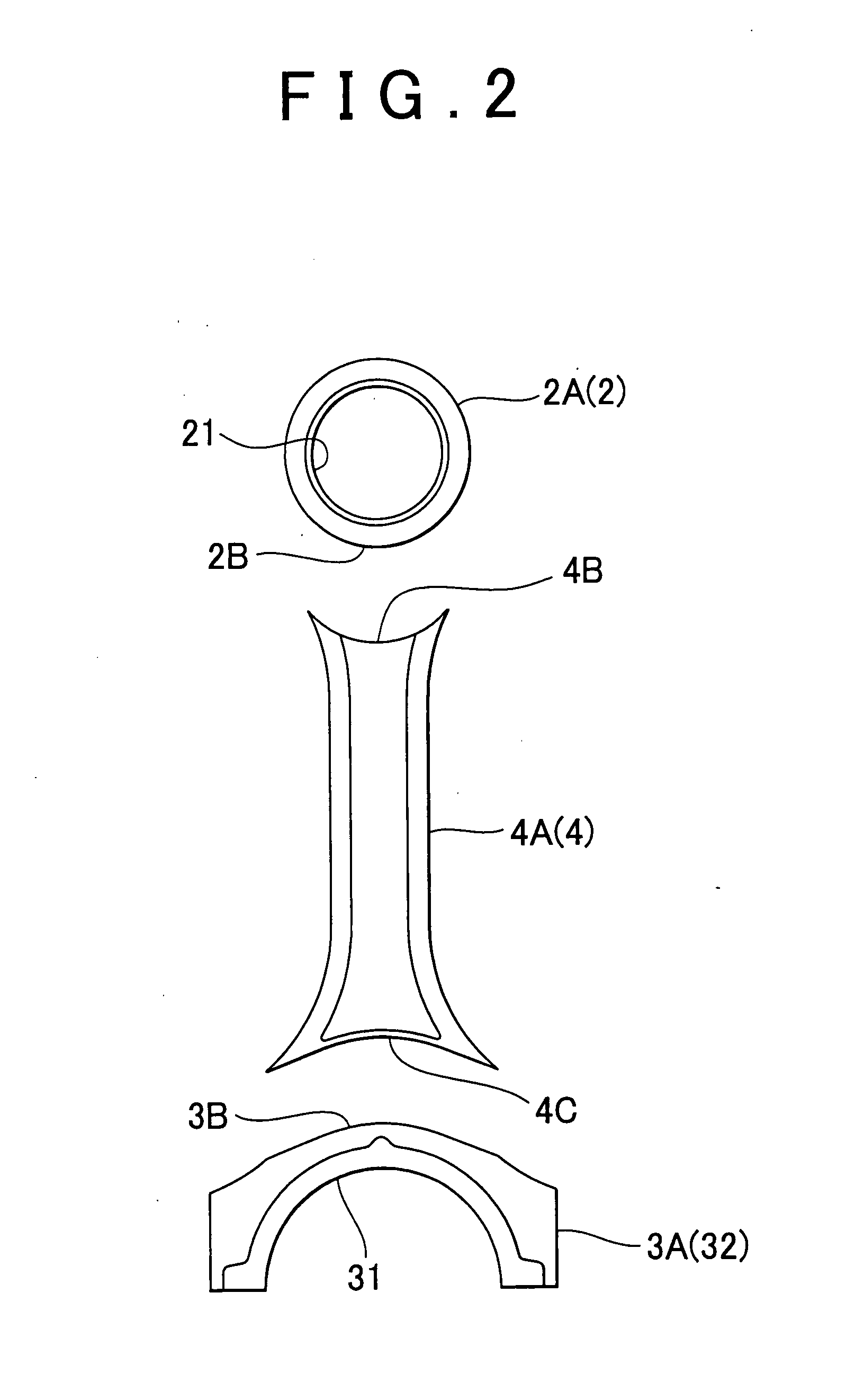

Connecting rod for internal combustion engine and method of manufacturing the connecting rod

InactiveUS20080271562A1Secure rigiditySecure strengthConnecting rodsMetal-working apparatusStress concentrationHigh intensity

A small end member constituting a small end, a column member constituting a column portion, and a big end member constituting a big end of a connecting rod are formed as separate members. In addition, the small end member and the big end member are each made of a high-rigidity material, and the column member is made of a high-strength material. These members are integrally bonded by liquid phase diffusion bonding, thus providing a connecting rod that can achieve suppression of stress concentration.

Owner:TOYOTA JIDOSHA KK

Female crimp terminal

InactiveUS6524143B2Secure strengthAvoid bending forceCoupling contact membersConnections effected by permanent deformationLeaf spring

Owner:JST MFG CO LTD

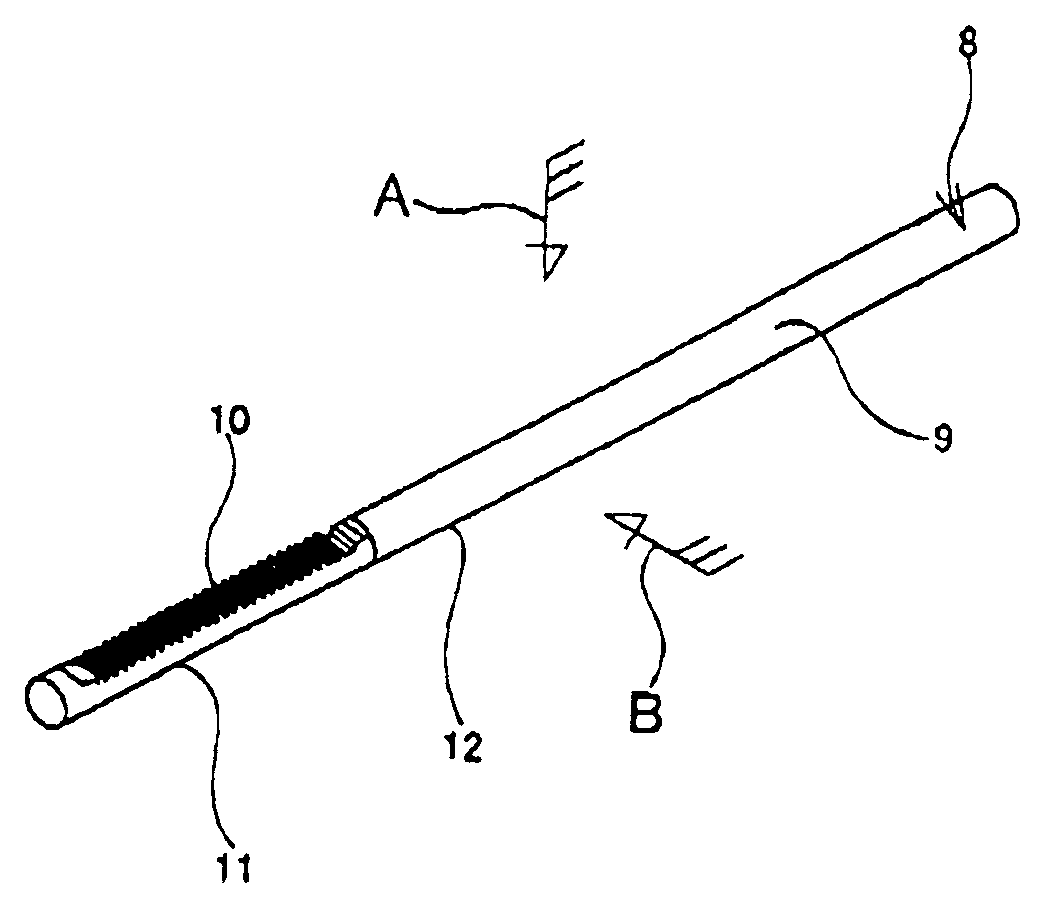

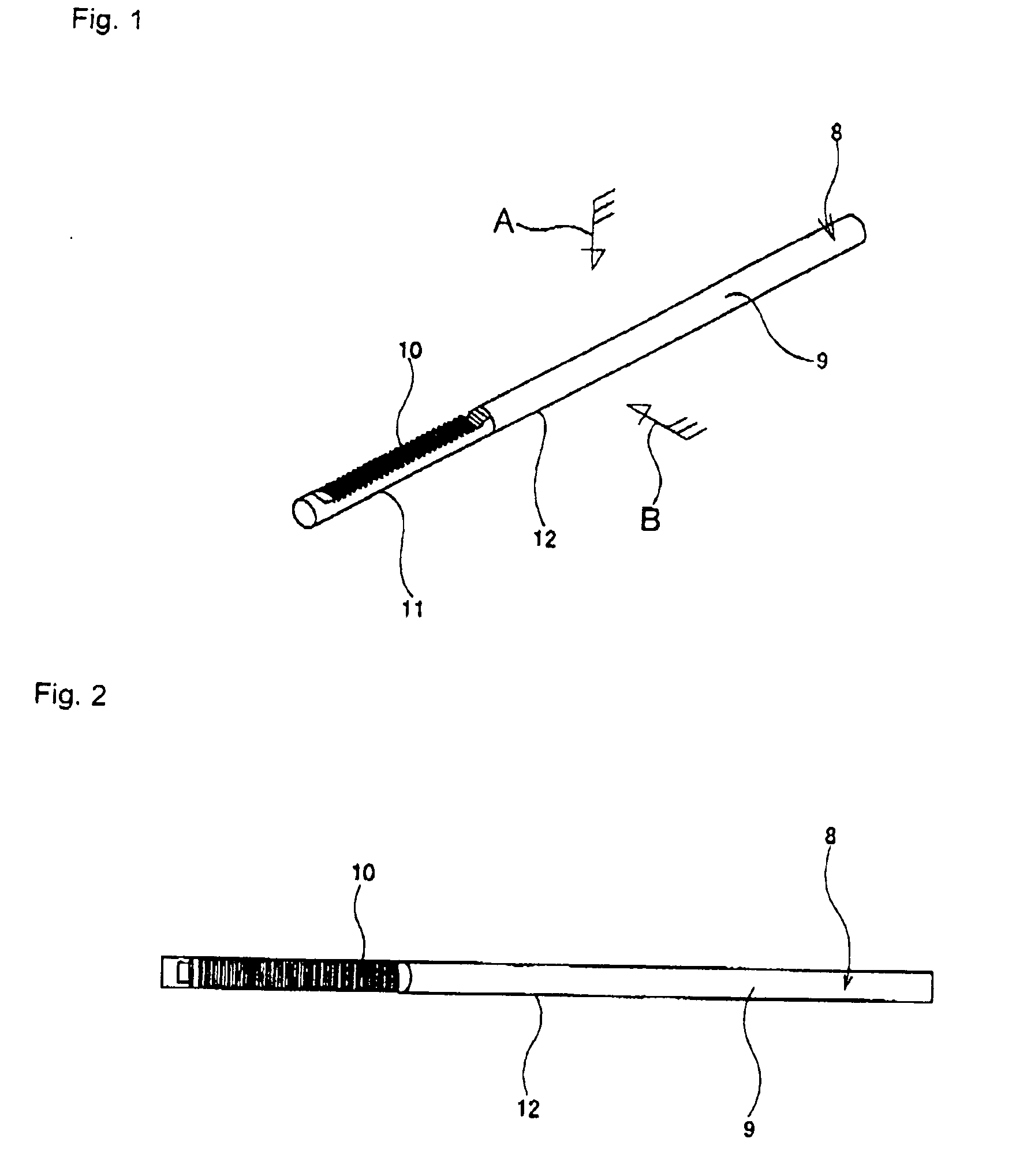

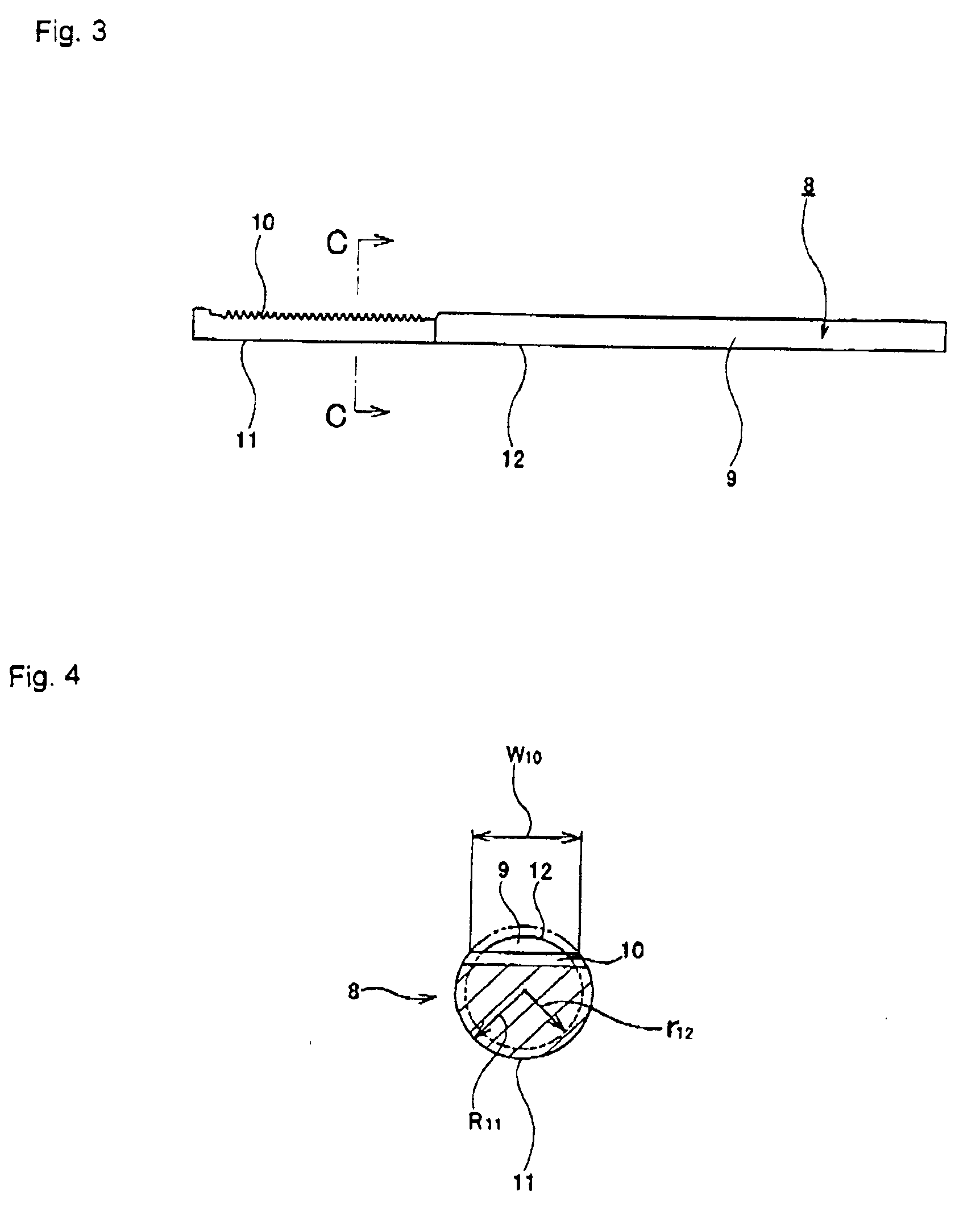

Rack and manufacturing method thereof

InactiveUS20100162843A1Low costSecure strength and rigidityMetal-working apparatusToothed gearingsSizingEngineering

To sufficiently secure the width dimension, strength and rigidity of the rack teeth 10, and to realize the light weight construction and the manufacturing method of the rack 8, the rack teeth 10 is formed by plastic working on one side surface in the radial direction of part in the axial direction of a rod unit 9 having a circular cross-sectional shape, and the curvature radius of the portion which is separated in the radial direction from the portion where the rack teeth 10 is formed, is made greater than that of the cross sectional shape of the outer surface of the axial remaining portion of the rod unit 9. For this purpose, as shown in (A) to (B), while a portion in the circumferential direction of part in the axial direction of a material 13 is compressed, the remaining portion in the circumferential direction of this part in the axial direction is formed into a partial cylindrical surface 17 whose curvature radius is larger than that of the outer surface of the material 13, to form an intermediate material 20. Then, as shown in (C) to (D), the rack teeth 10 are formed on the circumferential portion of the axial part of the intermediate material 20. At last, as shown in (E) to (F), sizing is performed to obtain the rack 8.

Owner:NSK LTD

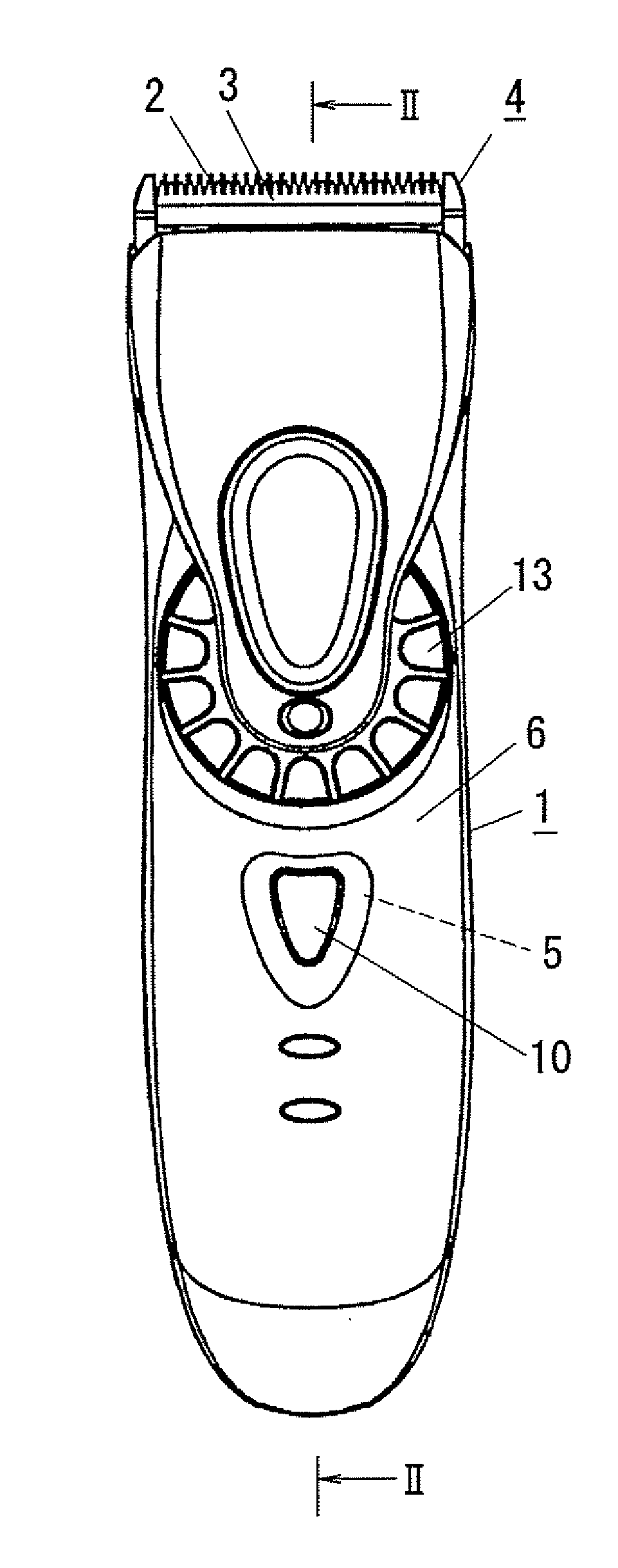

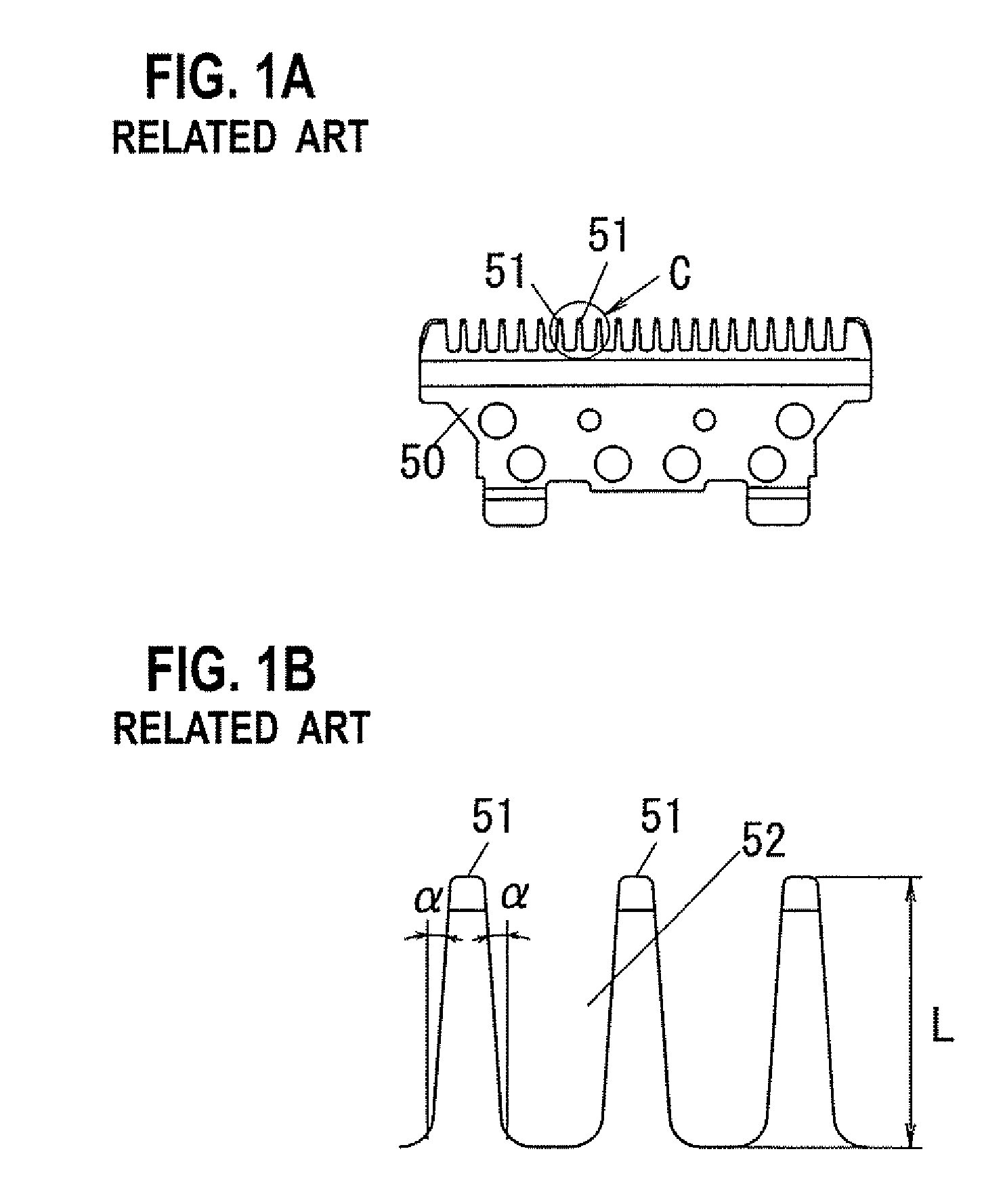

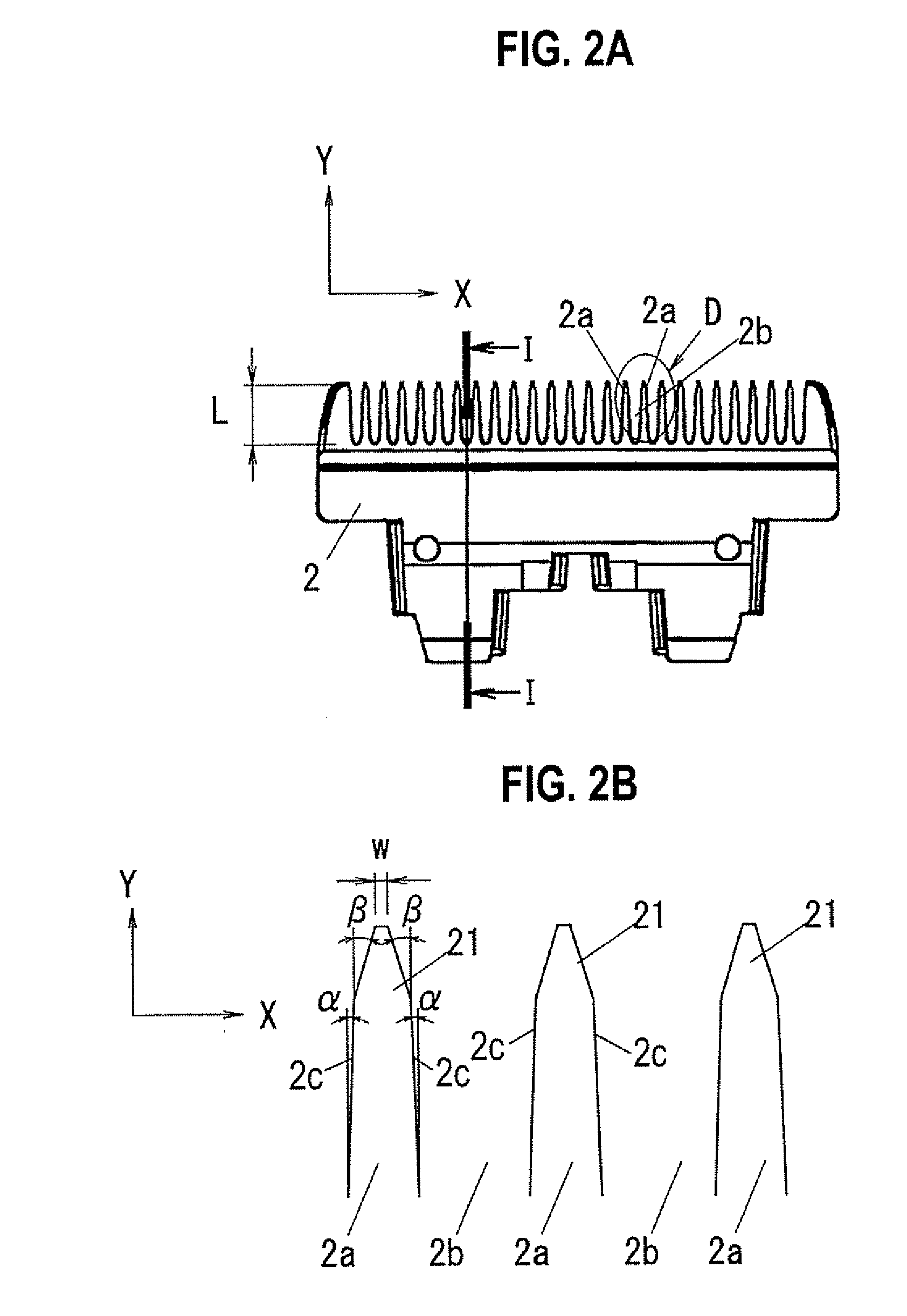

Hair clipper

ActiveUS20070044320A1Efficient introductionSufficient widthMetal working apparatusReciprocating motionEngineering

The hair clipper comprises comb-like fixed blade and movable blade each having a plurality of comb-teeth each provided at its both sides with blades, in which the movable blade is reciprocated with respect to the fixed blade in an arrangement direction of the comb-teeth to cut hair, the fixed blade or the movable blade is slid in a projecting direction of the comb-teeth to adjust cutting height, wherein a tip of each comb-tooth of the fixed blade is provided with a guide projection for introducing hair, the guide projection is tapered with an inclination angle which is larger than an inclination angle of the comb-tooth with respect to projecting direction of blades on both sides of the comb-tooth.

Owner:PANASONIC CORP

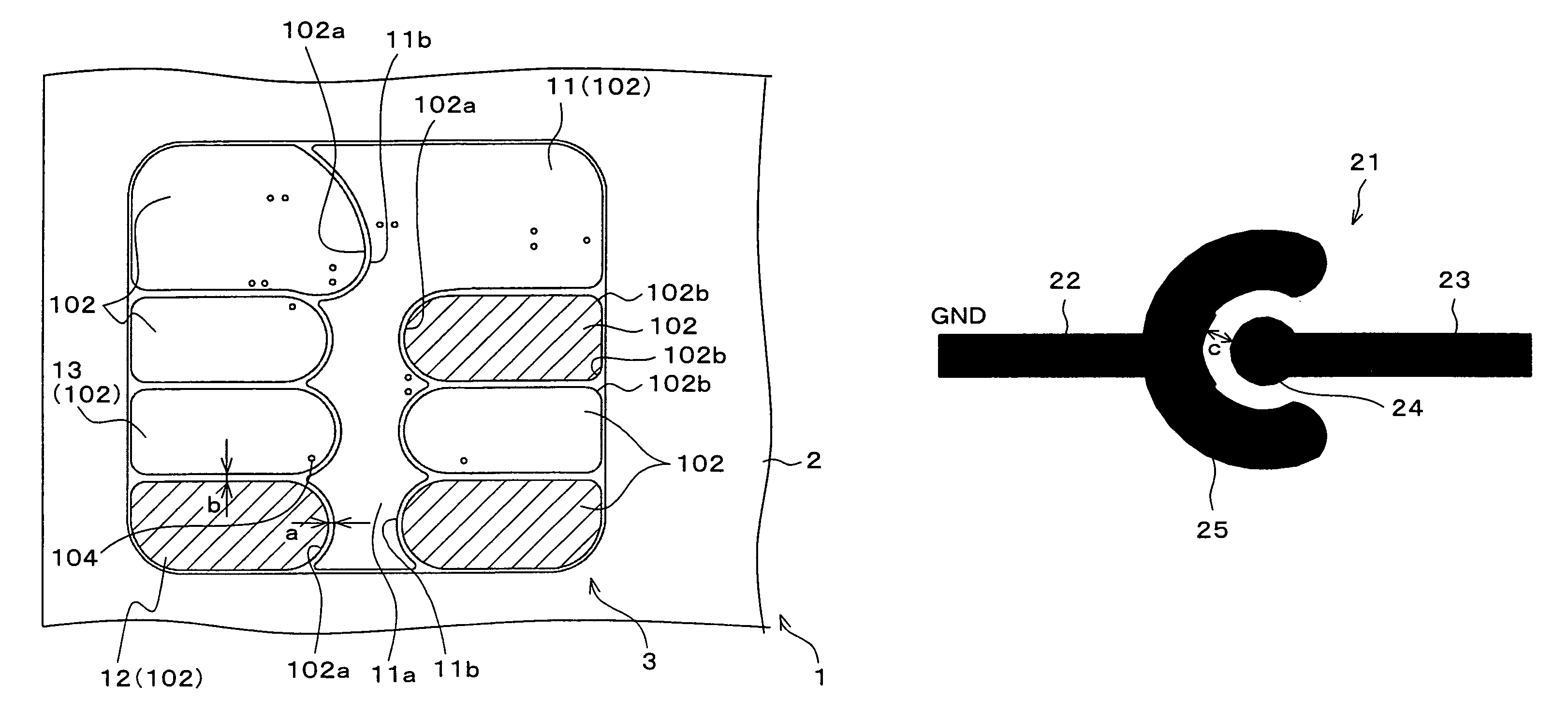

IC module and IC card

InactiveUS7064423B2Enables the IC card's strength with respect to bendingEasy to processSemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

Each of contact terminals, provided on a substrate of an IC module so as to be positioned on a back surface of a surface having an IC chip, which are terminals other than a GND terminal, has a curved convex face, and the GND terminal has a curved concave face as a counter face opposite to the curved convex face of the contact terminal so that there is a constant gap between the curved convex face and the curved concave face, and a gap between the GND and each of the contact terminals other than the GND terminal is narrower than a gap between all the contact terminals other than the GND terminal provided on the substrate so as to be positioned on the back surface of the surface having the IC chip. Thus, it is possible to provide an IC module and an IC card each of which enables the IC card's strength with respect to bending to be secured, and facilitates process thereof, and enables the IC chip to be protected from static electricity.

Owner:SHARP KK

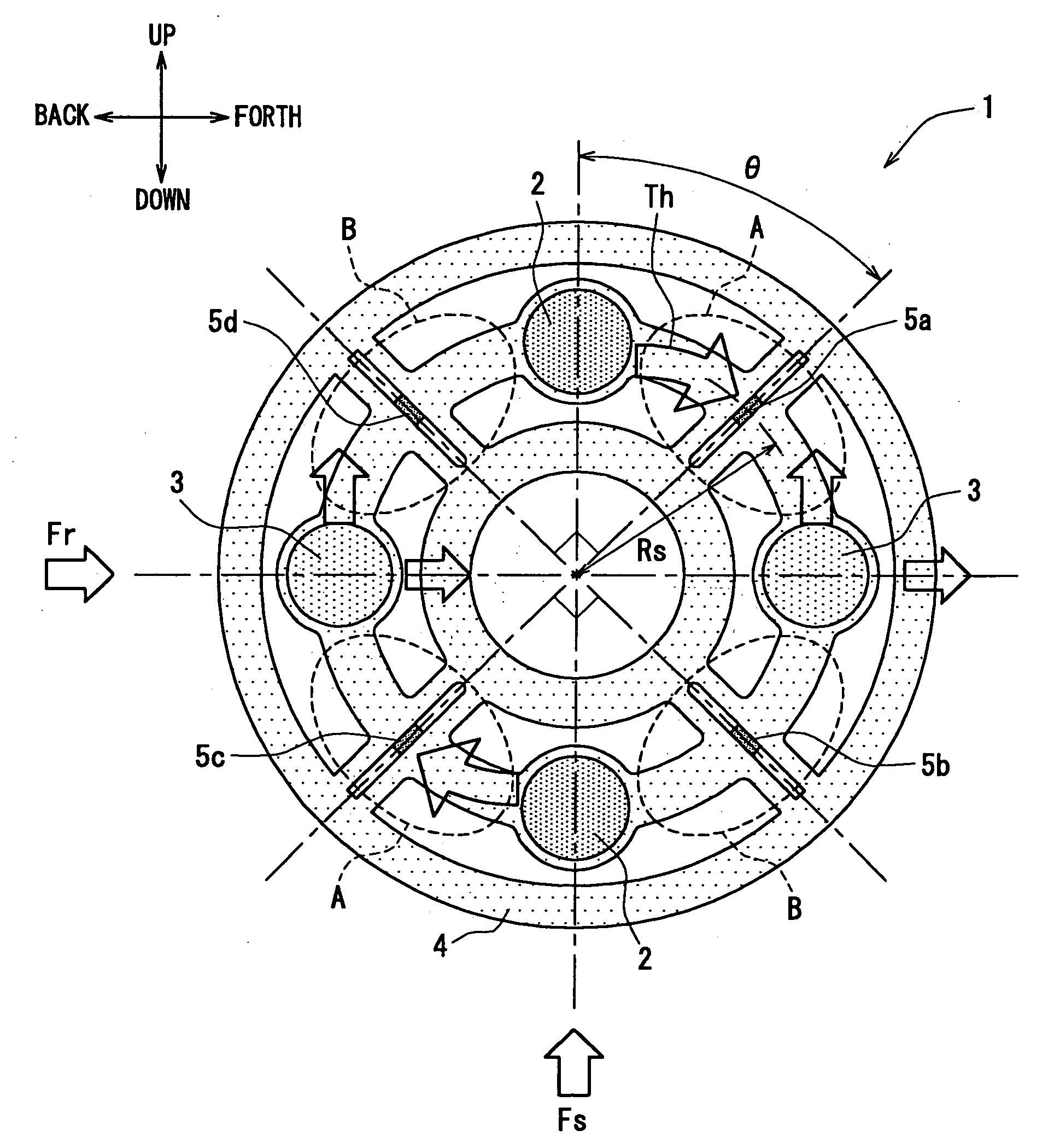

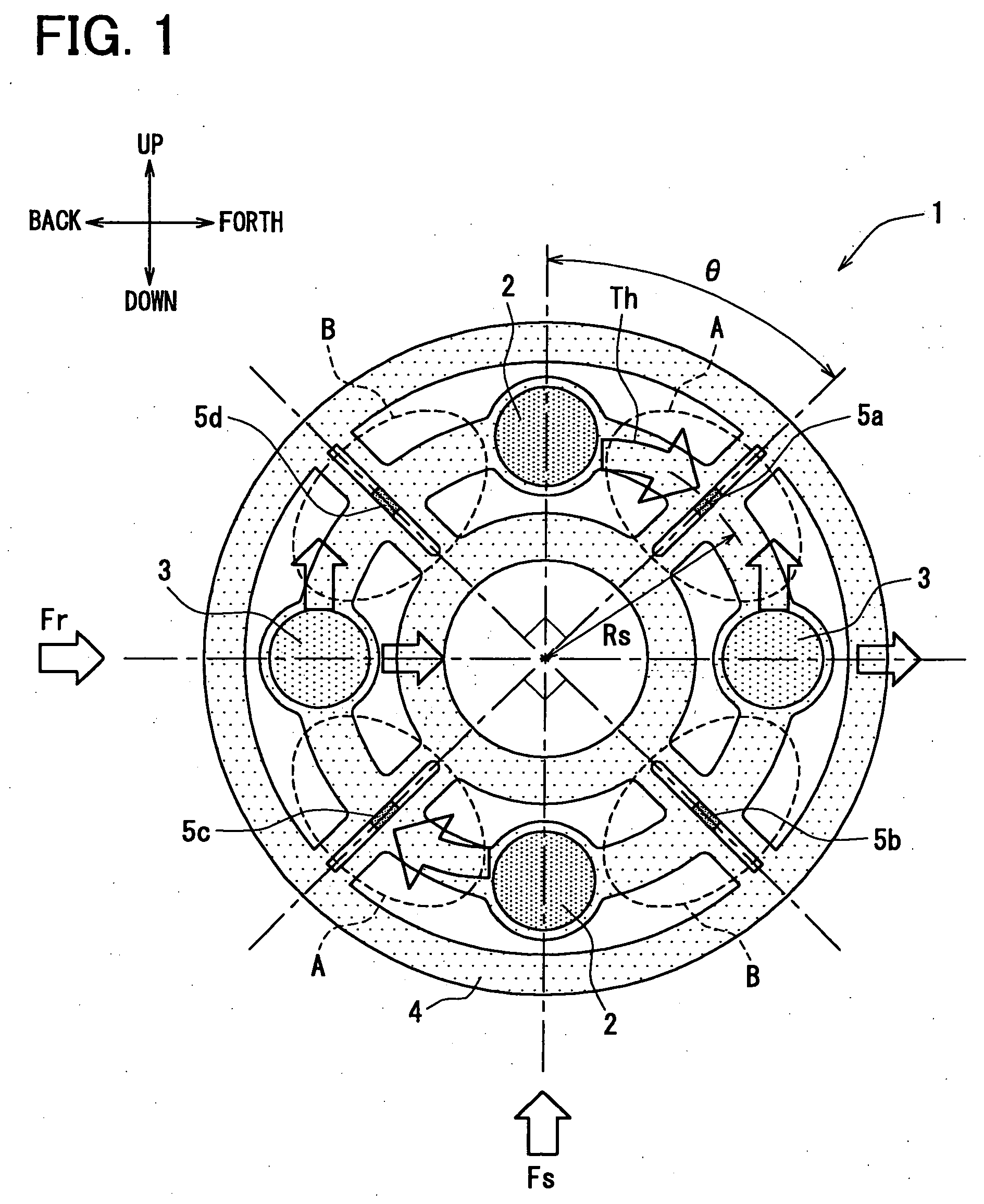

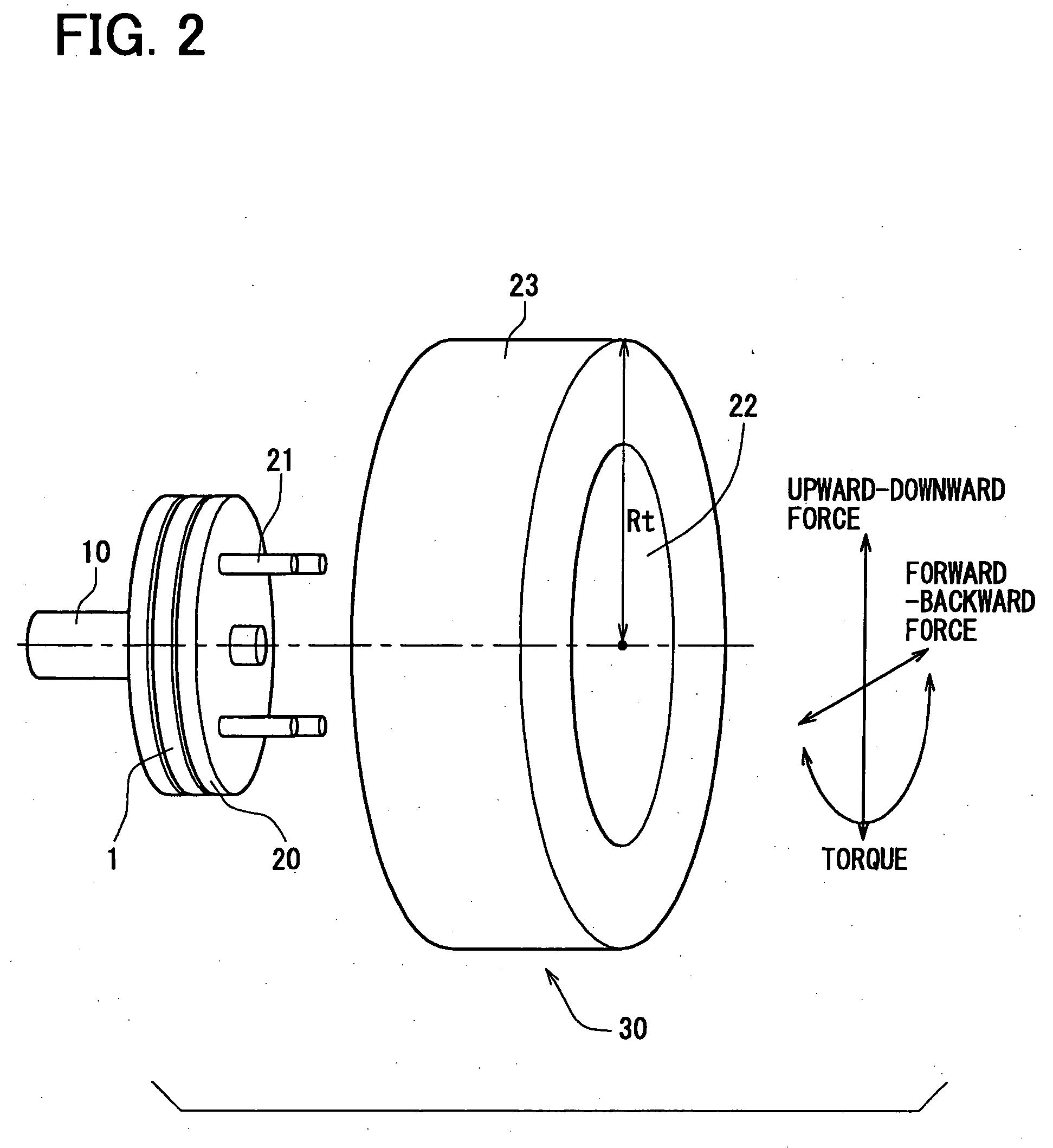

Device and method for detecting force acting on tire

Two axle-side linking portions and two wheel-side linking portions are included in a rotation body. They are alternately arranged in four positions that are disposed, with equal intervals, along a circumference of a coaxial circle within the rotation body. Four regions located between the axle-side linking portions and the wheel-side linking portions are formed by an elastically deformable member. Further, four ceramic load sensors are arranged respectively in middle positions of the four regions along the coaxial circle. Force acting on a tire is thereby detected only from detection values by a load sensor group of the four load sensors.

Owner:DENSO CORP

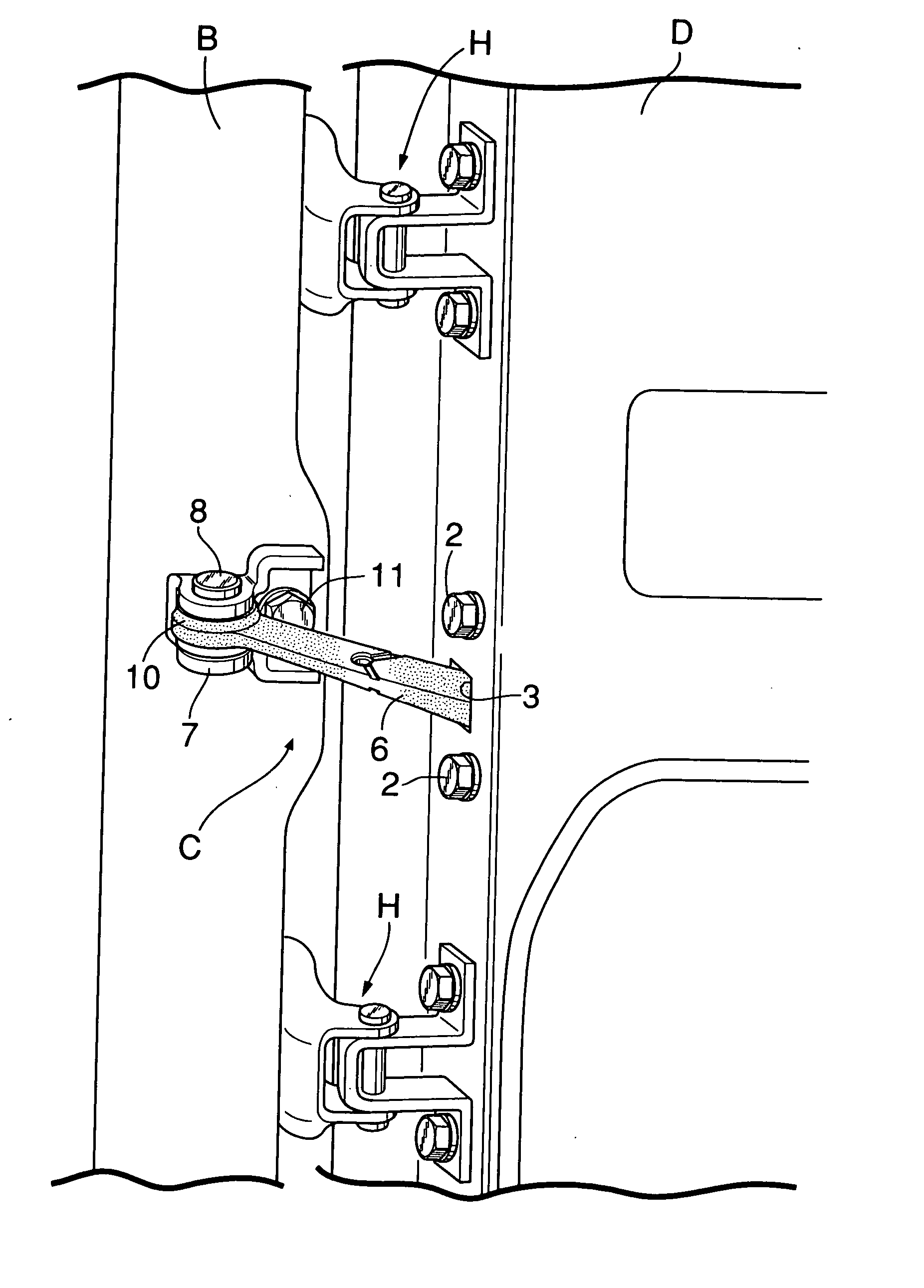

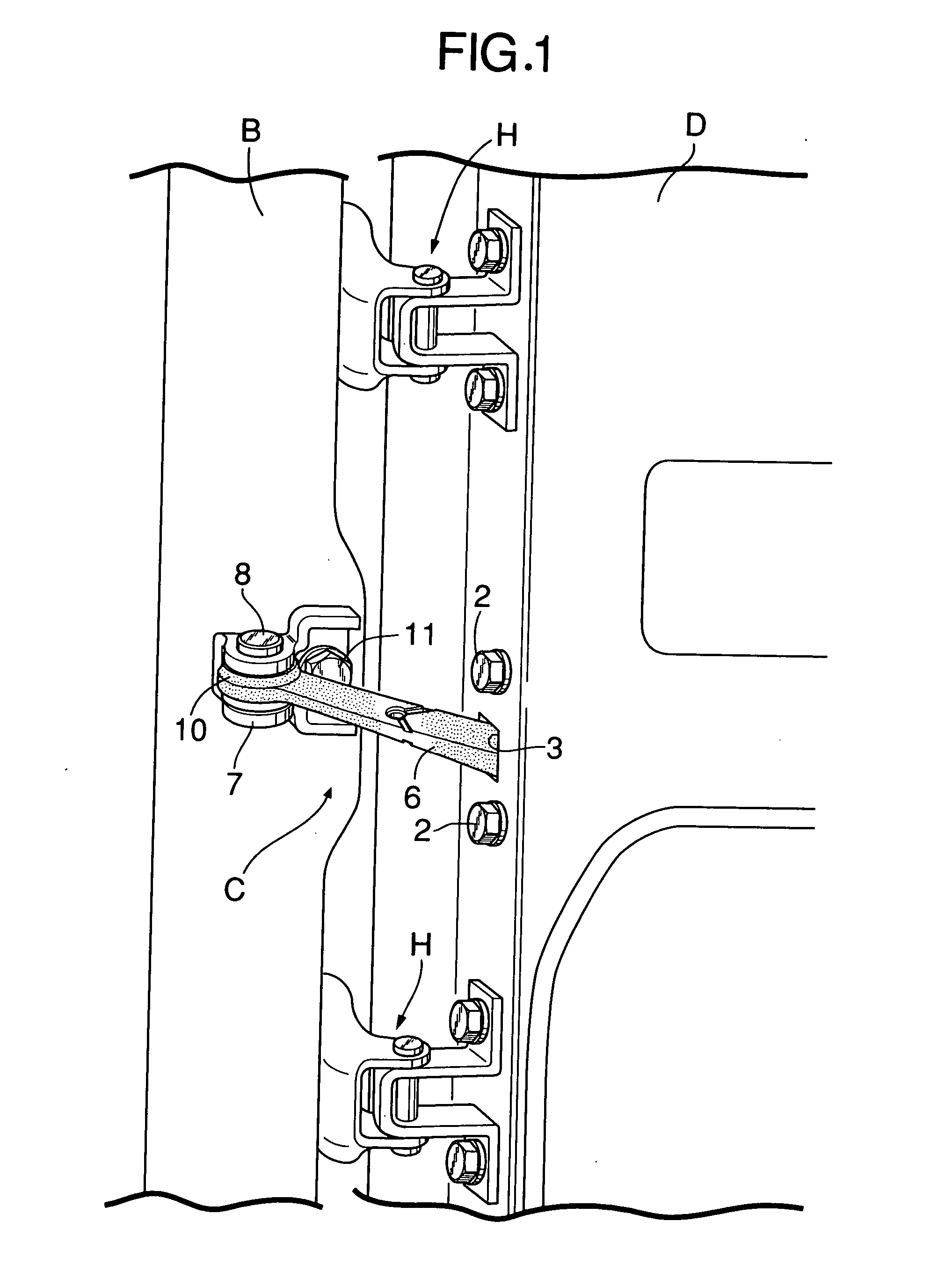

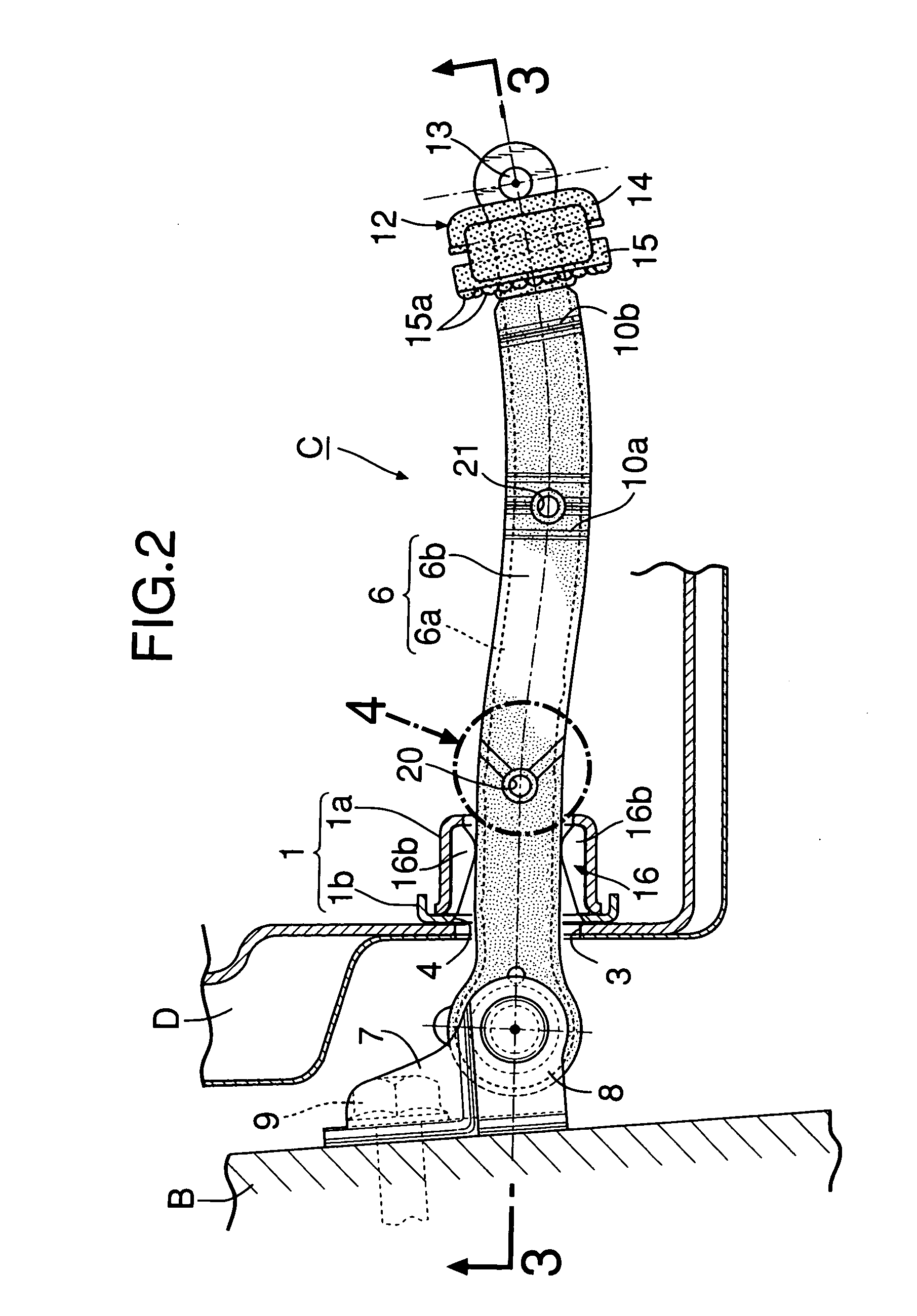

Door checker for automobile

InactiveUS20070040392A1Avoid problemsLow costBuilding locksWing fastenersEngineeringElectrical and Electronics engineering

A door checker for an automobile, includes: a case 1 fixed to a door D; a check plate 6 which movably penetrates the case 1 and is turnably connected to a body B; a pair of upper and lower detent members 16 slidably held in the case 1 to hold the door D at a predetermined opening position in cooperation with a pair of upper and lower detent surfaces 10 of the check plate 6; and an elastic member 17 which is made of an elastic material for generating a detent force between the detent member 16 and the detent surface 10. In this door checker, a drain hole 20 is provided in the check plate 6 in a portion projecting into the door D from the case 1 and at least at a position close to the case 1 as to penetrate the upper and lower detent surfaces 10 when the door is fully closed. Thus, even if rainwater and the like go into the door D and drop onto the upper surface of the check plate 6, it is drained quickly from the check plate 6 and are prevented from flowing into the case 1.

Owner:RIKEN KAKI KOGYO CO LTD

Semiconductor device and method for manufacturing the same

ActiveUS20100270630A1Minimized dimensionReduce equipment costsPrecision positioning equipmentSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor device includes: a first substrate made of semiconductor and having first regions, which are insulated from each other and disposed in the first substrate; and a second substrate having electric conductivity and having second regions and insulation trenches. Each insulation trench penetrates the second substrate so that the second regions are insulated from each other. The first substrate provides a base substrate, and the second substrate provides a cap substrate. The second substrate is bonded to the first substrate so that a sealed space is provided between a predetermined surface region of the first substrate and the second substrate. The second regions include an extraction conductive region, which is coupled with a corresponding first region.

Owner:DENSO CORP

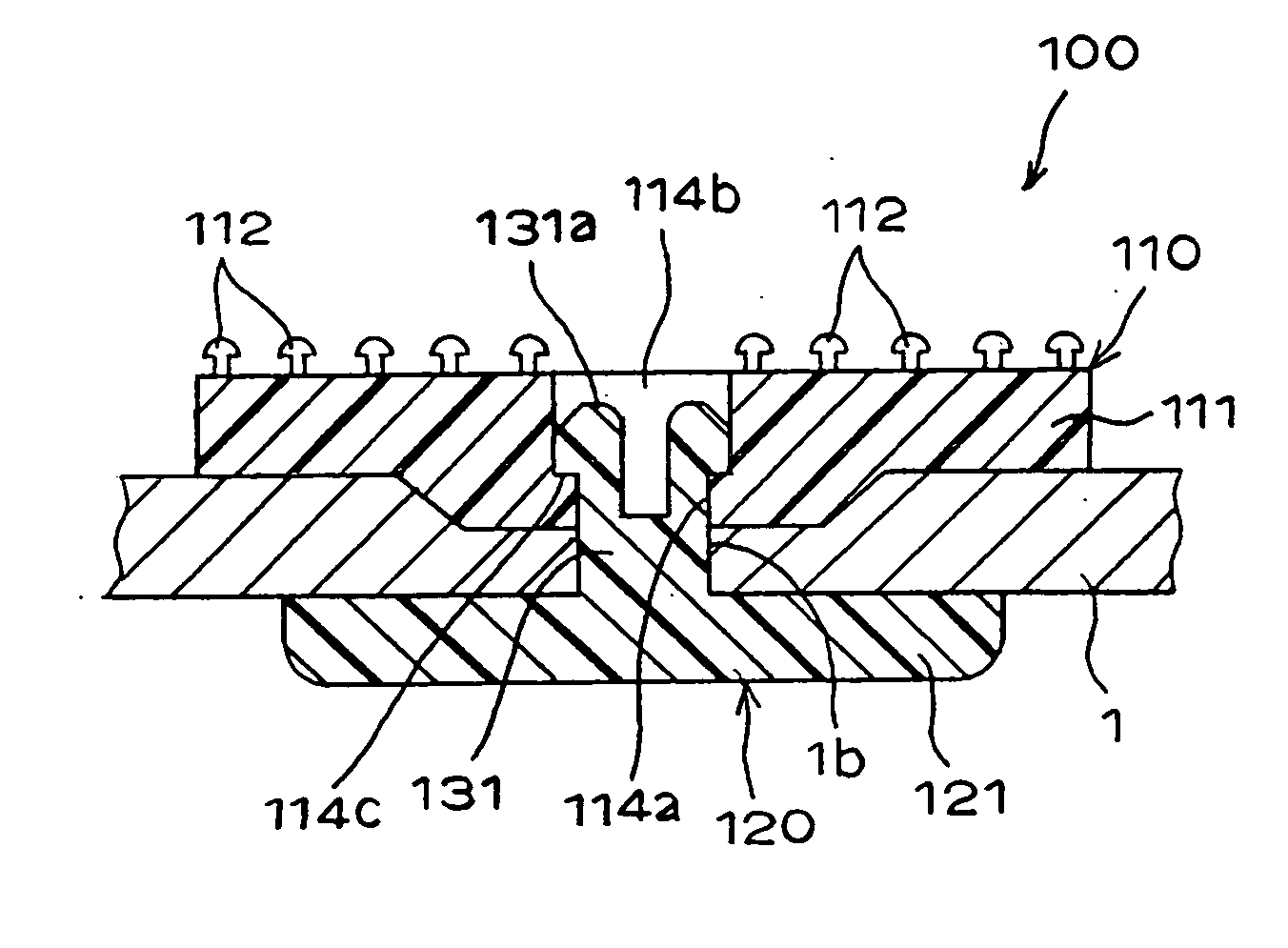

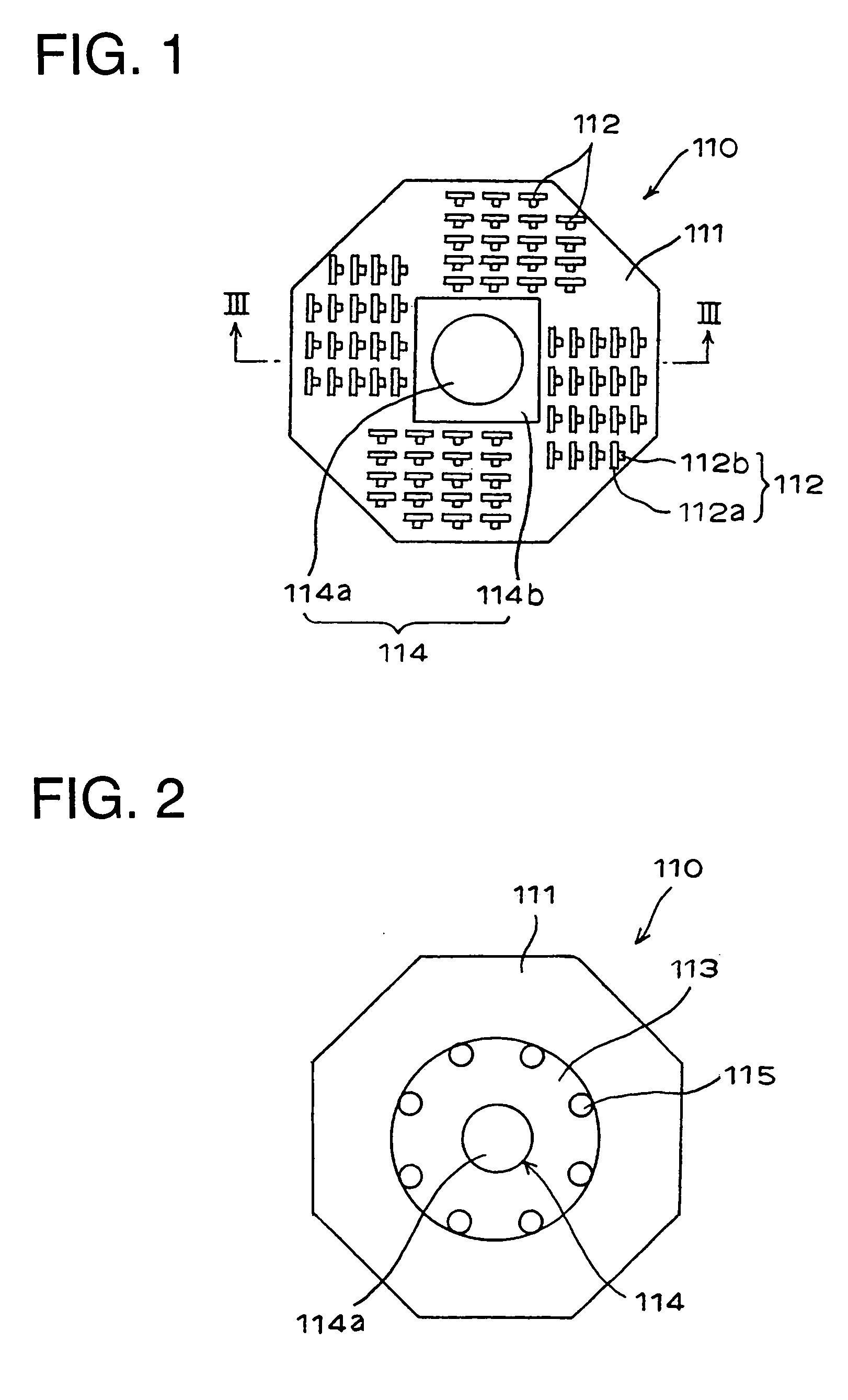

Male fixing member of hook-and loop fastener, and sheet product with the fixing member

InactiveUS20050235462A1Never damage easilyHigh tensile and shear strengthSnap fastenersRopes and cables for vehicles/pulleyFastenerEngineering

A first base material having a number of male engaging elements (112) formed of synthetic resin on a surface thereof and a second base material (121) are jointed and secured each other through a column-like joint portion (131). There is provided a male fixing member for sheets, which facilitates attachment operation to clothes or suspension cloths, has a durability, never loses appearance when it is mounted on clothes and allows even an infant to engage or disengage the male fixing members easily by an engagement / disengagement function of a surface fastener.

Owner:YKK CORP

Aluminum-alloy clad sheet

InactiveUS8932728B2High strengthDegradation in brazabilityWelding/cutting media/materialsHeat exchange apparatusNumber densityUltimate tensile strength

There are provided an aluminum-alloy clad sheet and a clad sheet subjected to heating equivalent to brazing, which each have a high strength and an excellent erosion resistance and thus allow a reduction in thickness of a clad sheet subjected to heating equivalent to brazing such as an aluminum alloy radiator tube, and / or of a clad sheet such as an aluminum-alloy brazing sheet. An aluminum-alloy clad sheet or a clad sheet subjected to heating equivalent to brazing includes at least a core aluminum alloy sheet and an aluminum-alloy sacrificial anti-corrosive material cladded with each other, and is to be formed into a heat exchanger by brazing. The core aluminum alloy sheet includes a specified 3000 series composition. Furthermore, the strength and the erosion resistance of the core aluminum alloy sheet are improved through control of grain size distribution of precipitates having a size in a specified level in the core aluminum alloy sheet, or control of the average number density and the composition of dispersed particles therein.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com