Preparation method and application of lanthanum ion-doped zinc oxide porous hollow sphere

A technology of lanthanum ions and zinc oxide, which is applied in the field of preparation of lanthanum ion-doped zinc oxide porous hollow spheres, can solve the problems that the material properties have not been fully exerted, and achieve the effects of low cost, simple process and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

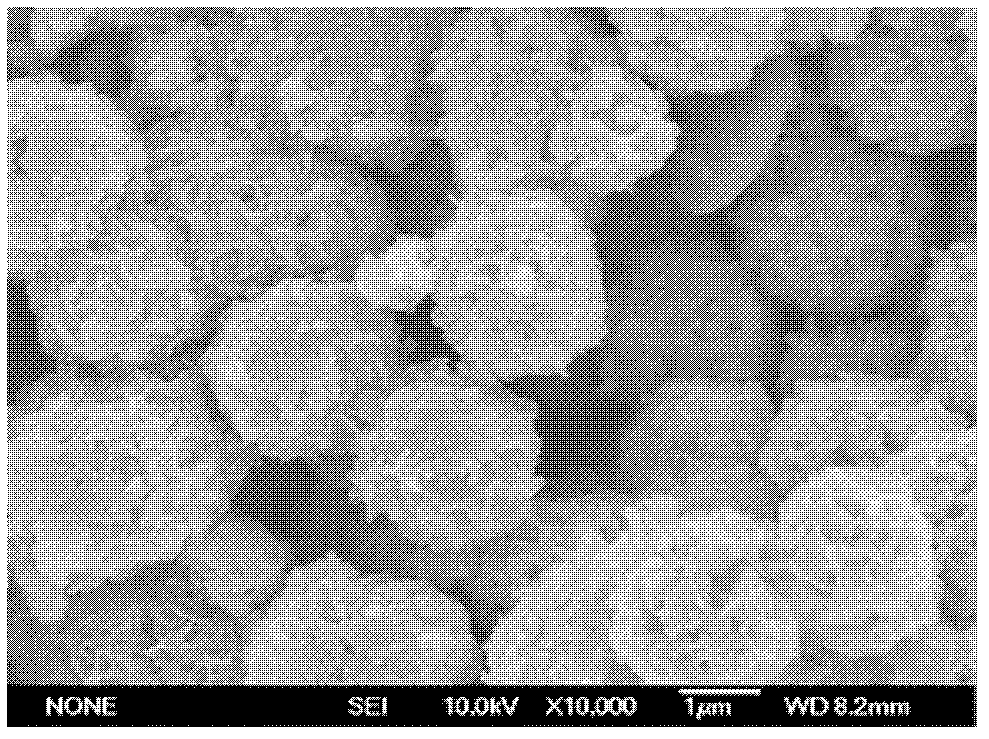

[0021] A kind of preparation method of lanthanum ion doped zinc oxide porous hollow sphere, with lanthanum nitrate La(NO 3 ) 3 , Hexamethylenetetramine (CH 2 ) 6 N 4 and zinc nitrate Zn(NO 3 ) 2 As a raw material, sodium citrate is used as a surfactant, prepared by co-precipitation reaction in water, and the steps are as follows:

[0022] 1) Dissolve 0.7g of hexamethylenetetramine in 200ml of deionized water, ultrasonically dissolve it completely, add 1.49g of zinc nitrate, and then weigh 0.065g of La(NO 3 ) 3 Add to the above solution, ultrasonic vibration for a period of time to make La(NO 3 ) 3 Completely dissolve, finally weigh 0.24g of sodium citrate and add to the above solution, until it dissolves completely;

[0023] 2) Put the mixed solution in a water bath at 95°C, react for 5 hours, and filter to obtain a white precipitate, then wash the precipitate with deionized water and absolute ethanol, filter, and dry in an oven at 60°C to obtain the mixed solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com