Absorbent used in sewage phosphorus removal, and preparation method thereof

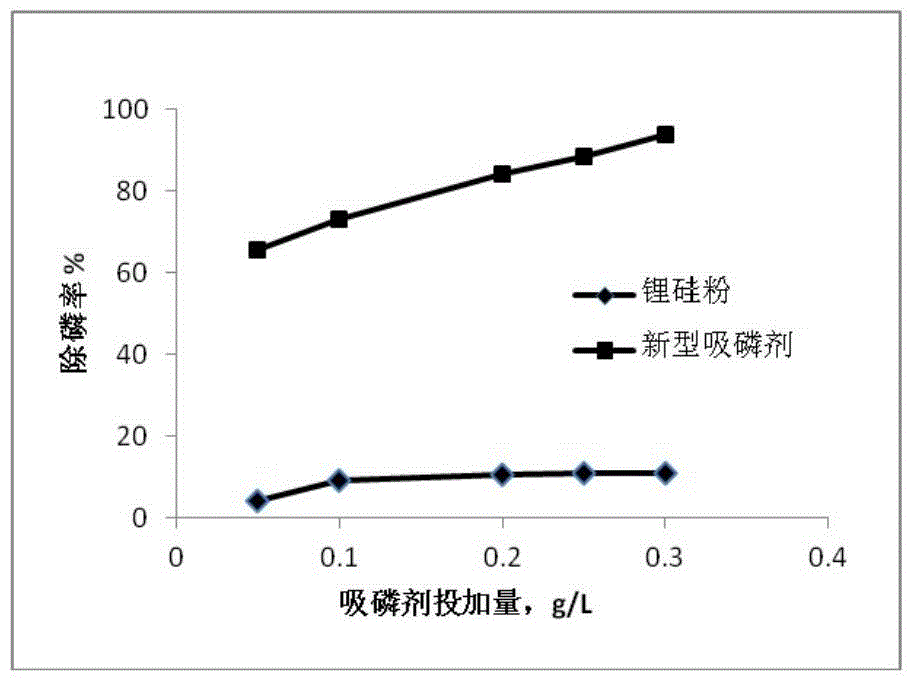

A phosphorus adsorbent and adsorbent technology, applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve problems such as the popularization and use of unfavorable phosphorus-absorbing agents, the high cost of molecular sieve preparation, and the complicated operation steps. , to achieve strong market competitiveness and promotion value, good phosphorus absorption effect, and high phosphorus removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dry industrial lithium-silicon powder waste slag after 150 mesh sieving; then prepare La 3+ A solution with an ion concentration of 0.12mol / L, and then add the dried industrial lithium silicon powder waste residue to the prepared La 3+ ionic solution, and use 1M NaOH dilute lye to adjust the pH of the mixed solution to 9, and then stand at room temperature for 8 hours for impregnation reaction after fully stirring; perform solid-liquid separation of the lithium silicon powder-lanthanum mixture after the impregnation reaction, and collect solid powder, and the obtained solid powder is repeatedly washed to neutrality, and then dried.

Embodiment 2

[0033] After passing through 200 mesh sieves, the industrial lithium silicon powder waste residue is dried for later use; then the lanthanum nitrate is prepared into La 3+ A solution with an ion concentration of 0.10mol / L, and then add the dried industrial lithium silicon powder waste residue to the prepared La 3+ ionic solution, and use 1M NaOH dilute lye to adjust the pH of the mixed solution to 8, and then stand at room temperature for 7 hours of impregnation reaction after being fully stirred; perform solid-liquid separation of the lithium silicon powder-lanthanum mixture after the impregnation reaction, and collect solid powder, and the obtained solid powder is repeatedly washed to neutrality, and then dried.

Embodiment 3

[0035] After passing through 250 mesh sieves, the industrial lithium silicon powder waste residue is dried for later use; then the lanthanum sulfate is prepared into La 3+A solution with an ion concentration of 0.04mol / L, and then add the dried industrial lithium silicon powder waste residue to the prepared La 3+ ionic solution, and use 1M NaOH dilute lye to adjust the pH of the mixed solution to 11, after fully stirring, stand at room temperature for 10 hours of impregnation reaction; perform solid-liquid separation of the lithium silicon powder-lanthanum mixture after the impregnation reaction, and collect solid powder, and the obtained solid powder is repeatedly washed to neutrality, and then dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com