A kind of preparation method of monodisperse colloidal particle

A colloidal particle, monodisperse technology, applied in microsphere preparation, microcapsule preparation, etc., to achieve uniform and controllable particle size distribution, adjustable morphology, and adjustable particle chemical composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

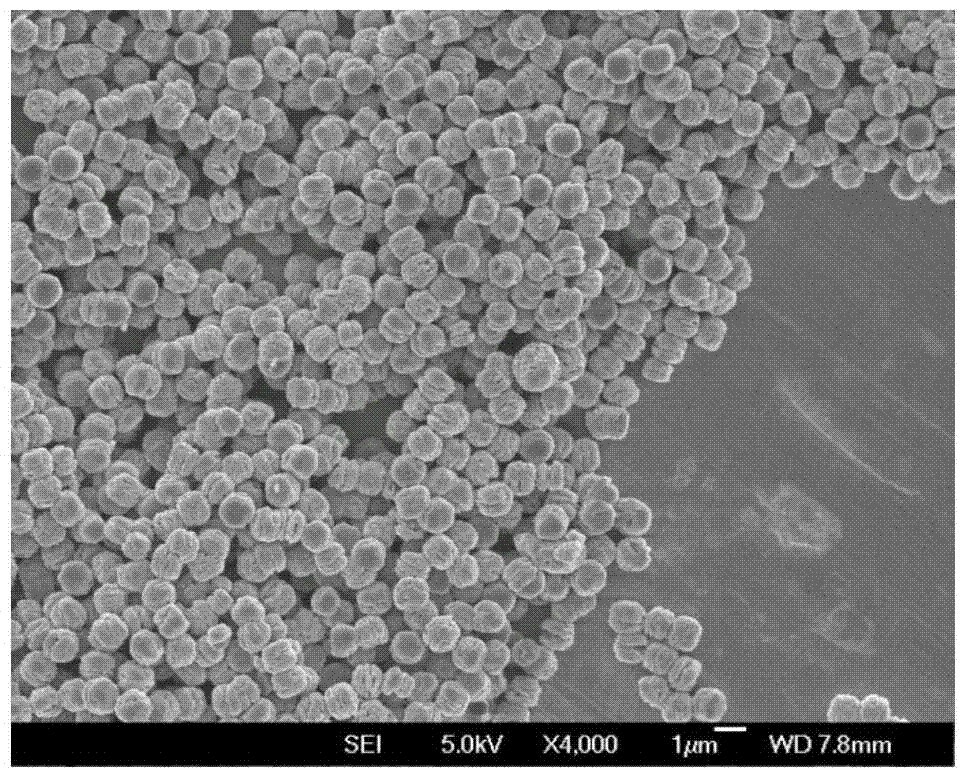

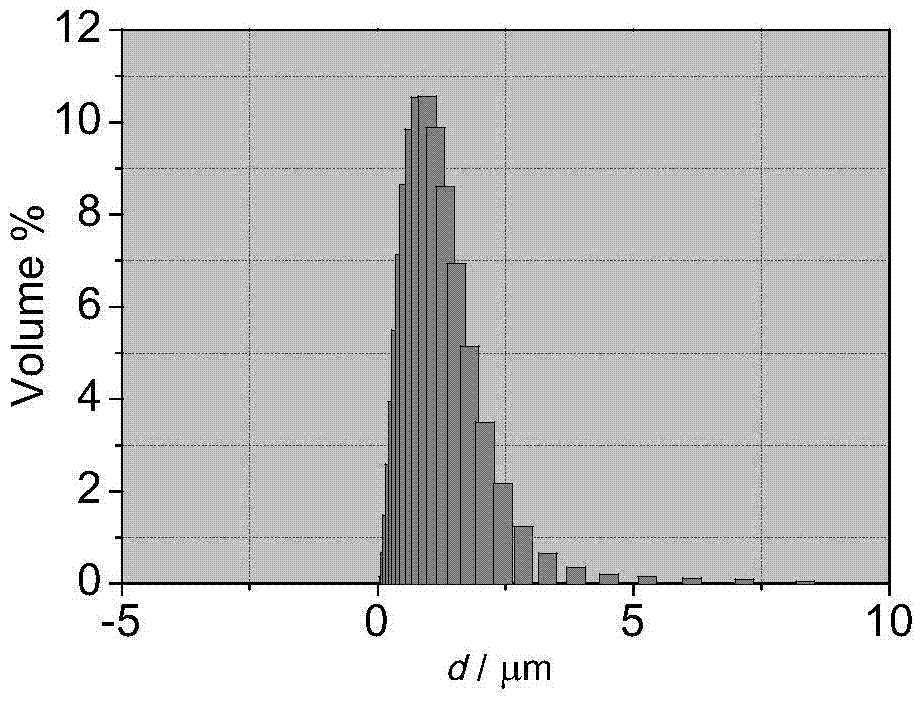

[0035] A certain amount of Al 2 (SO 4 ) 3 18H 2 O dissolved in deionized water to form a clear and transparent solution. This solution was named solution one. Then a certain amount of anhydrous sodium acetate (NaAC) was dissolved in deionized water to form a clear and transparent solution. This solution was named solution two. Solution two was added to solution one to form a clear and transparent solution, and the mixed solution was stirred at room temperature for 1 hour to fully mix the two solutions. The final mixture composition molar ratio is Al 2 (SO 4 ) 3 18H 2 O:NaAC:H 2 O=1:4:247. The mixture was transferred to a stainless steel crystallization autoclave lined with polytetrafluoroethylene, and the crystallization autoclave was placed in an oven at 200 °C for 24 hours for hydrothermal treatment. After the hydrothermal treatment was completed, the solid product in the crystallization tank was centrifuged and washed three times with deionized water, and then t...

Embodiment 2

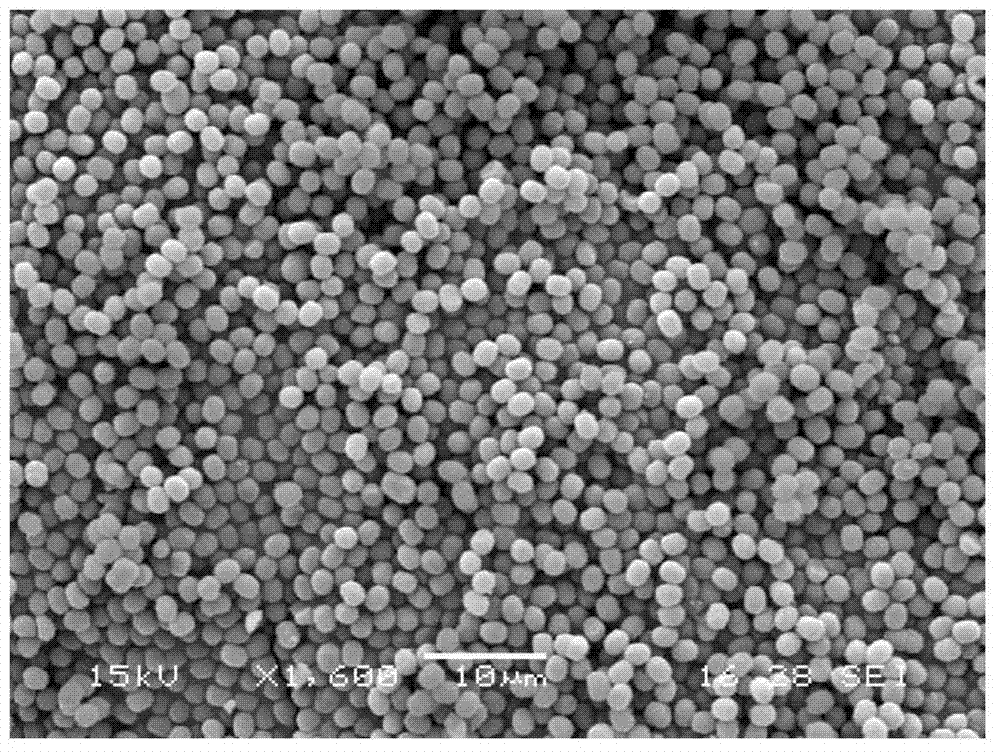

[0038] A certain amount of KAl(SO 4 ) 2 12H 2 O dissolved in deionized water to form a clear and transparent solution. This solution was named solution one. Then a certain amount of anhydrous sodium acetate was dissolved in deionized water to form a clear and transparent solution. This solution was named solution two. Solution two was added to solution one to form a clear and transparent solution, and the mixed solution was stirred at room temperature for 1 hour to fully mix the two solutions. The final mixture composition molar ratio is KAl(SO 4 ) 2 12H 2 O:NaAC:H 2 O=1:2:176. The mixture was transferred to a stainless steel crystallization autoclave lined with polytetrafluoroethylene, and the crystallization autoclave was placed in an oven at 200 °C for 24 hours for hydrothermal treatment. After the hydrothermal treatment was completed, the solid product in the crystallization tank was centrifuged and washed three times with deionized water, and then the solid was ...

Embodiment 3

[0041] A certain amount of Al(NO 3 ) 3 9H 2O dissolved in deionized water to form a clear and transparent solution. This solution was named solution one. Then a certain amount of anhydrous sodium acetate was dissolved in deionized water to form a clear and transparent solution. This solution was named solution two. Solution two was added to solution one to form a clear and transparent solution, and the mixed solution was stirred at room temperature for 1 hour to fully mix the two solutions. The final mixture composition molar ratio is Al(NO 3 ) 3 9H 2 O:NaAC:H 2 O=1:2:139. The mixture was transferred to a stainless steel crystallization autoclave lined with polytetrafluoroethylene, and the crystallization autoclave was placed in an oven at 200 °C for 24 hours for hydrothermal treatment. After the hydrothermal treatment was completed, the solid product in the crystallization tank was centrifuged and washed three times with deionized water, and then the solid was dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com