Preparation method of enhanced UO2 nuclear fuel pellet

A nuclear fuel and enhanced technology, which is applied in nuclear engineering, nuclear power generation, manufacturing reactors, etc., can solve the problems of large pellet grains, achieve scientific design, improve capacity, and meet technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

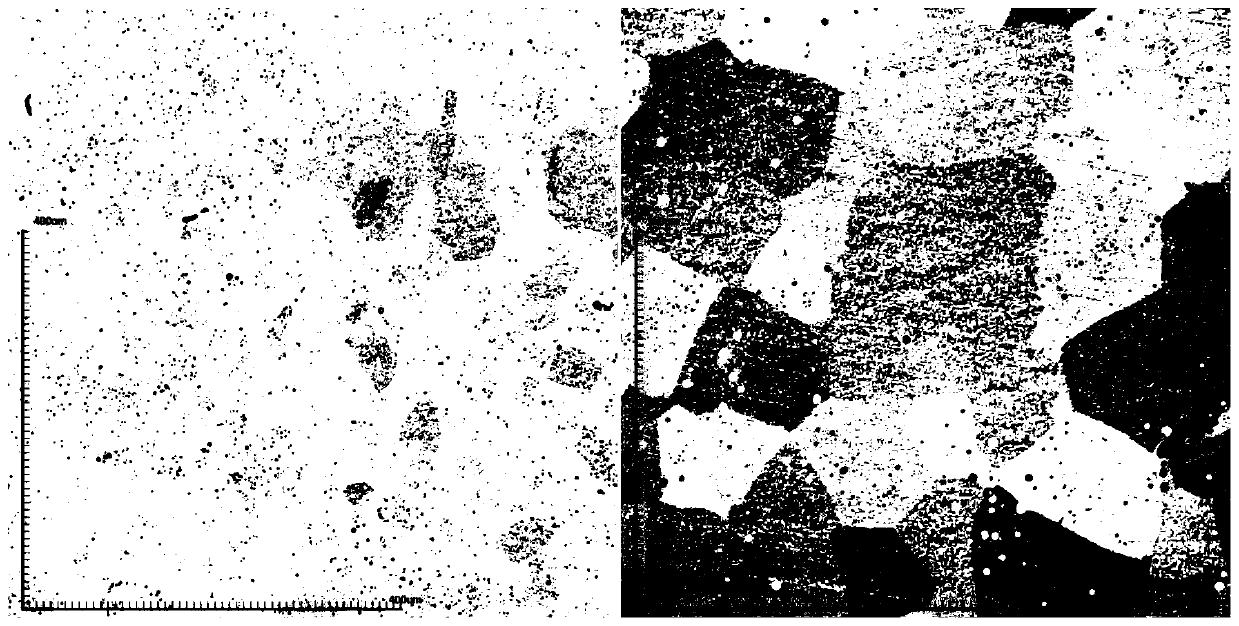

Image

Examples

Embodiment 1

[0039] This embodiment provides the enhanced UO of the present invention 2 A method for preparing nuclear fuel pellets, specifically:

[0040] UO with a particle size of 50nm 2 The powder was mixed with 0.05wt.% of the reinforcing phase TiC, 0.05wt.% of the lubricant zinc stearate for 24 hours to obtain UO 2 Mixture powder with TiC. Press it into UO under 400MPa pressure with powder metallurgy pre-pressing mold 2 - TiC mixture pre-compacts. The pre-press is crushed and sieved to obtain UO with a particle size of 200 mesh 2 - TiC composite particles. Put the composite particles into spheroidization equipment for grinding and spheroidization for 8 hours to obtain UO with good sphericity 2 - TiC composite particles.

[0041] Spherified UO 2 -TiC composite particles are loaded into a powder metallurgy forming mold and pressed to a density of 5.8g / cm 3 nuclear fuel pellets. Put the obtained nuclear fuel pellet blank into an atmosphere sintering furnace, and carry out low-...

Embodiment 2

[0044] This embodiment provides the enhanced UO of the present invention 2 A method for preparing nuclear fuel pellets, specifically:

[0045] UO with a particle size of 5 μm 2 The powder was mixed with 1.5wt.% reinforcing phase VC, 0.2wt.% lubricant Akewax for 18 hours to obtain UO 2 Mixture powder with VC. Press it into UO with a cold isostatic press under a pressure of 500MPa 2 -VC mixture pre-compact. The pre-press is crushed and sieved to obtain UO with a particle size of 100 mesh 2 -VC composite particles. Put the composite particles into the spheroidization equipment for grinding and spheroidizing for 12 hours to obtain UO with good sphericity 2 - VC complex particles.

[0046] Spherified UO 2 -VC composite particles are loaded into powder metallurgy forming molds and pressed to a density of 6.5g / cm 3 nuclear fuel pellets. Put the obtained nuclear fuel pellet blank into an atmosphere sintering furnace, carry out low-temperature degreasing and high-temperature ...

Embodiment 3

[0048] This embodiment provides the enhanced UO of the present invention 2 A method for preparing nuclear fuel pellets, specifically:

[0049] UO with a particle size of 500 μm 2 powder with 0.5wt.% reinforcing phase Cr 3 C 2 , 0.5wt.% lubricant Akewax was mixed for 6 hours to obtain UO 2 with Cr 3 C 2 mixture powder. Press it into UO under 50MPa pressure with powder metallurgy pre-pressing mold 2 -Cr 3 C 2 The mixture is pre-compacted. The pre-compact was crushed and sieved to obtain UO with a particle size of 20 mesh 2 -Cr 3 C 2 Composite particles. Put the composite particles into spheroidization equipment for grinding and spheroidization for 1 hour to obtain UO with good sphericity 2 -Cr 3 C 2 Composite particles.

[0050] Spherified UO 2 -Cr 3 C 2 The composite particles are loaded into a powder metallurgy forming mold and pressed to a density of 5.0g / cm 3 nuclear fuel pellets. Put the obtained nuclear fuel pellet blank into an atmosphere sintering f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com