Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Low fluorescence level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound type vegetable oil lubricating agent for drilling fluid and preparation method thereof

InactiveCN101760186ANon-toxicInhibits hydration swellingDrilling compositionVegetable oilFluorescence

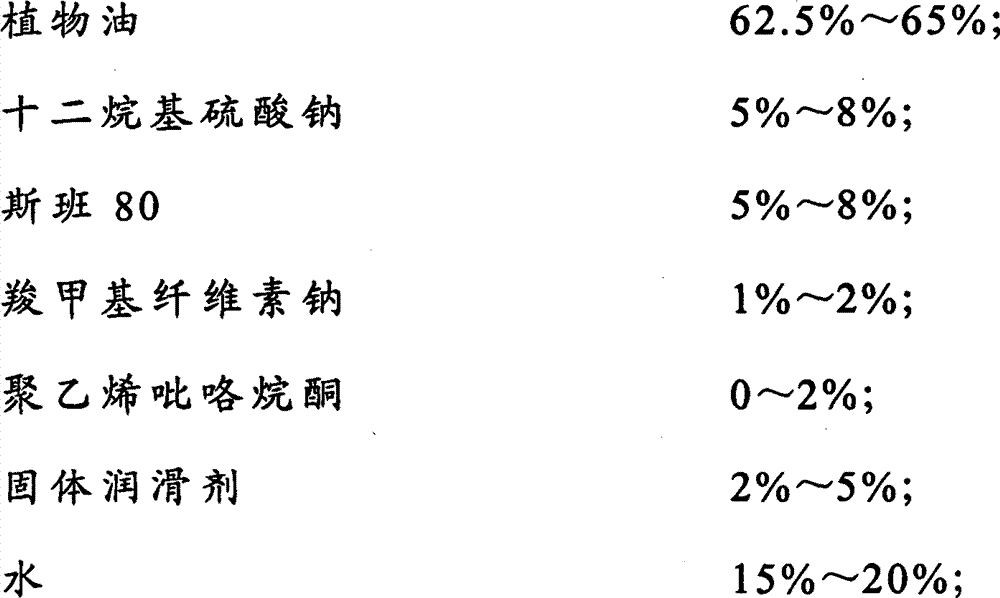

The invention discloses a compound type vegetable oil lubricating agent for a drilling fluid and a preparation method thereof. The compound type vegetable oil lubricating agent for the drilling fluid with favorable oiliness, no toxicity, low fluorescent level and favorable bearing and thermostabilized performance is prepared by taking a vegetable oil leftover which is low in price and easy to obtain, lauryl sodium sulfate, sbane 80, sodium carboxymethylcellulose, polyvinylpyrrolidone and the like as main raw materials, adding a solid lubricating agent which is graphite or serpentine and usinga simple and environment-friendly production method, so that not only the production cost is greatly reduced, but also any toxic and harmful action on the environment is not generated in the production process. The compound type vegetable oil lubricating agent for the drilling fluid is not only applied to drilling, but also can be applied to producing wells, can effectively inhibit the hydrous expansion of mud shale, consolidate the well wall and prevent the sticking accidents and is especially suitable for industrial production on a large scale.

Owner:无锡润鹏复合新材料有限公司

Mud cake adhesion lubricant for water-base drilling fluid

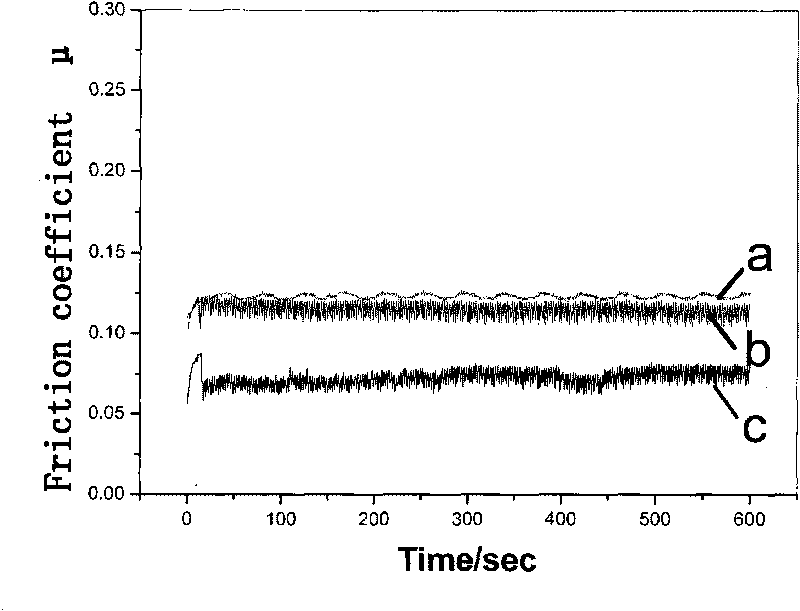

ActiveCN103865498AGood mud cake adhesion and lubricationLow fluorescence levelDrilling compositionWater basedLubrication

The invention discloses a mud cake adhesion lubricant for water-base drilling fluid, and the mud cake adhesion lubricant comprises 0.1-15wt% of mud cake adhesion lubrication improver, 0-4wt% of triethanolamine, 0.01-20wt% of surfactant and the balance of oil, wherein the chemical formula of the mud cake adhesion lubrication improver is (RCO2)[x]M or (RCO2)[x-y](OH)[y]M, wherein the R in the formula is a saturated straight chain or branched chain alkyl group of C8-C20, or an unsaturated straight chain or branched chain alkyl group of C8-C20; M is <+2>, <+3> or <+4> valent metal ions; x is equal to 2-4, y is equal to 0-2, and x is greater than y; the HLB of the surfactant is greater than 8; the oil is mineral oil, plant oil, waste engine oil, plant oil-modified oil or recovered gutter oil. The mud cake adhesion lubricant for water-base drilling fluid has excellent mud cake adhesion lubrication capability, and the reduction rate of the mud cake adhesion lubrication coefficient can achieve more than 70%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-efficient antisticking lubricant for drilling fluid

ActiveCN102344783APlay a lubricating roleLow fluorescence levelDrilling compositionPolymer scienceFluorescence

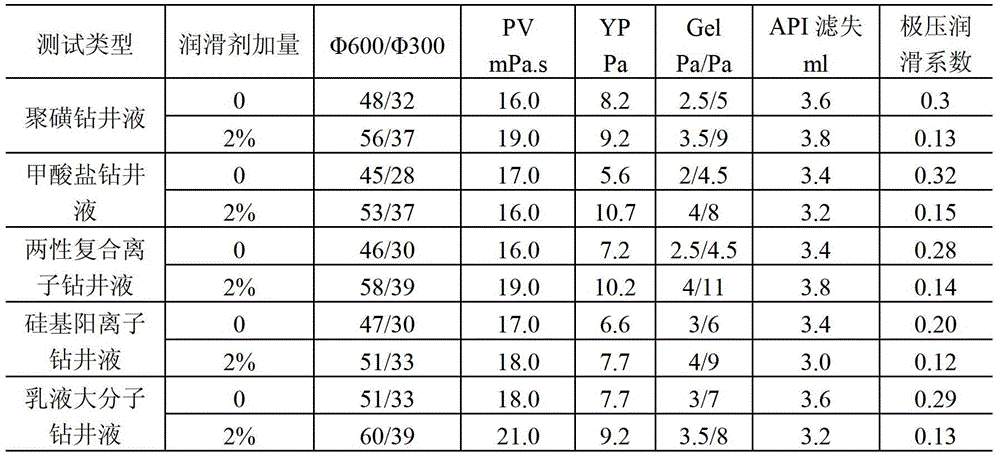

A high-efficient antisticking lubricant for drilling fluid has a technical scheme that the lubricant is obtained by mixing five components of white oil which is used as a main raw material, oleic acid and methyl oleate which are used as auxiliary materials, a defoamer and an extreme pressure agent which are used as regulators, wherein the weight percent ranges of the components are 30%-70% of white oil, 18%-30% of oleic acid, 10%-20% of methyl oleate, 1%-10% of defoamer and 1%-10% of extreme pressure agents. The lubricant of the invention has the advantages of extreme pressure lubrication, sticking resistance, less fluorescence grade, and the like, does not cause index change of drilling fluid, has lubrication effect on hard surface to soft surface (drilling tool to mud cake) and hard surface to hard surface (drilling tool to rock), has good lubrication effect, and thus is a good lubricant for polymer drilling fluid systems.

Owner:石家庄华莱鼎盛科技有限公司

Lubricant and preparation method thereof

InactiveCN104877652ALow fluorescence levelDoes not affect geological loggingDrilling compositionBase oilSURFACTANT BLEND

The invention discloses a lubricant for drilling fluids, which is composed of the following components in percentage by mass: 20-40% of base oil, 40-60% of fatty acid ester, 5-10% of surfactant and 3-10% of defoaming agent. The preparation method of the lubricant comprises the following steps: adding the base oil and fatty acid ester into a reaction kettle, heating to 50-80 DEG C, stirring at high speed for 0.5-1 hour, slowly adding the surfactant, stirring at high speed for 0.5-1 hour, heating to 70-100 DEG C, adding the defoaming agent, continuing stirring for 0.5-1 hour, and cooling.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

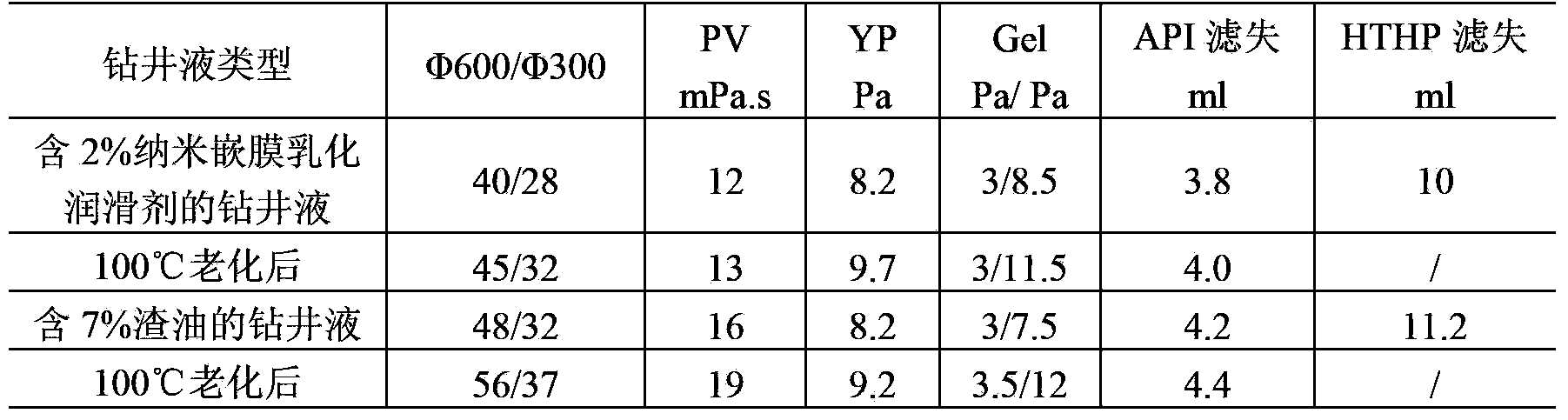

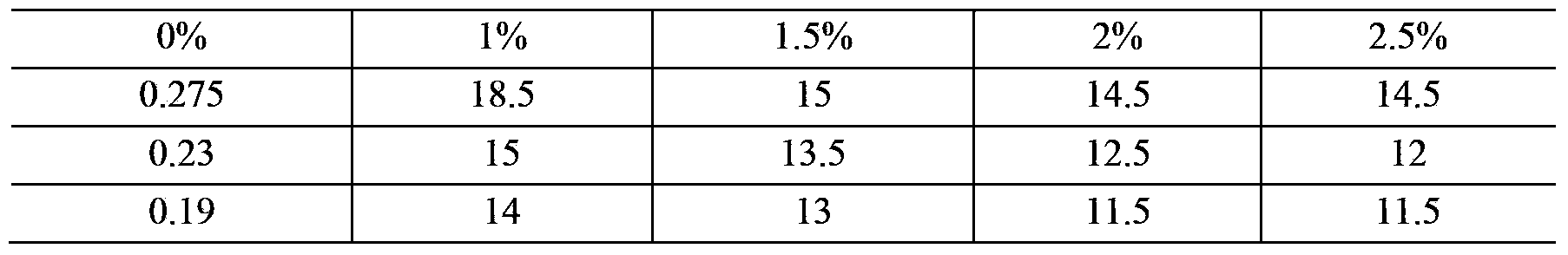

Nano film-embedded emulsion lubricant

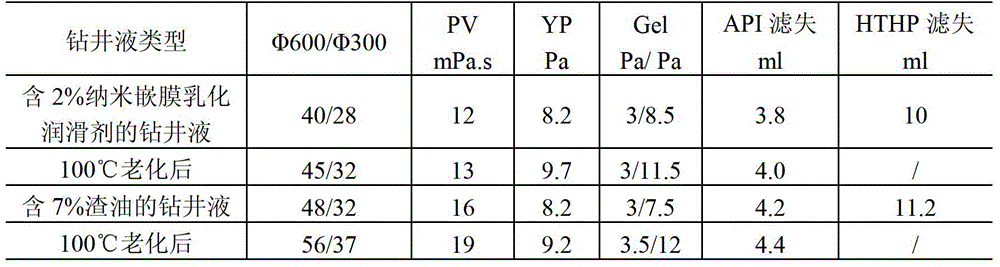

ActiveCN103436241AImprove the lubrication effectReduce sliding frictional resistanceDrilling compositionAlkalinityEmulsion

The invention relates to a nano film-embedded emulsion lubricant and mainly solves the problems about high frictional resistance of a horizontal well, serious backing pressure and poor lubricating effect of drilling fluid. The nano film-embedded emulsion lubricant comprises the following components in percentage by weight: 10 to 30 percent of modified paraffin, 3 to 11 percent of a compound emulsifier, 0.5 to 3 percent of an alkalinity modifier, 0.5 to 2 percent of nano graphite powder and the balance of water. The nano film-embedded emulsion lubricant provides an emulsion lubricant which has low fluorescence, is provided with a nano ball material and has capability of forming an anti-adhesion lubricating film between the stratum and a drilling tool; a prepared drilling fluid system has a good lubricating property; a mud cake is fine; the filter loss is low; the class of florescence is low; the nano film-embedded emulsion lubricant has excellent thermal stability and cold-resisting stability; drilling efficiency of the horizontal well is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

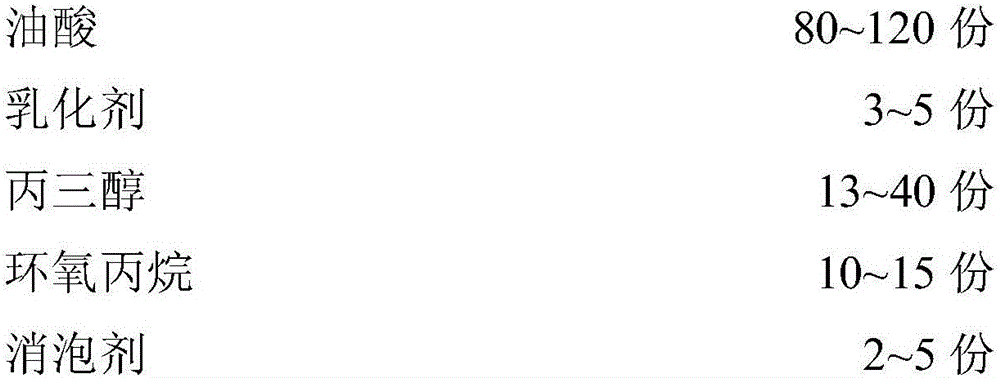

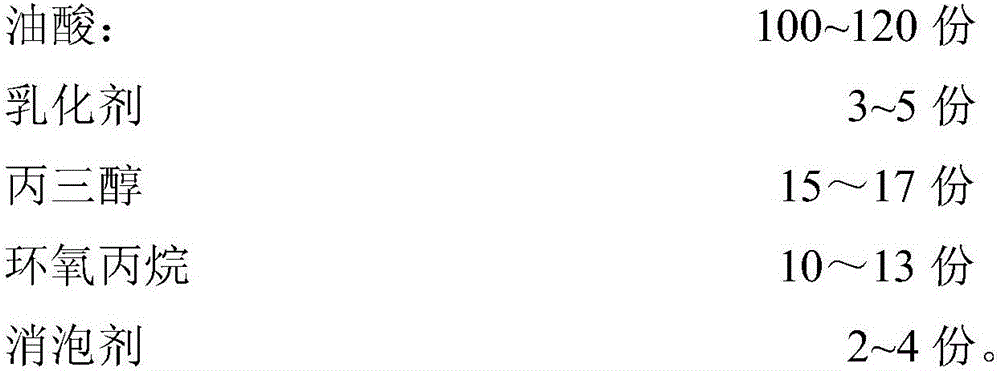

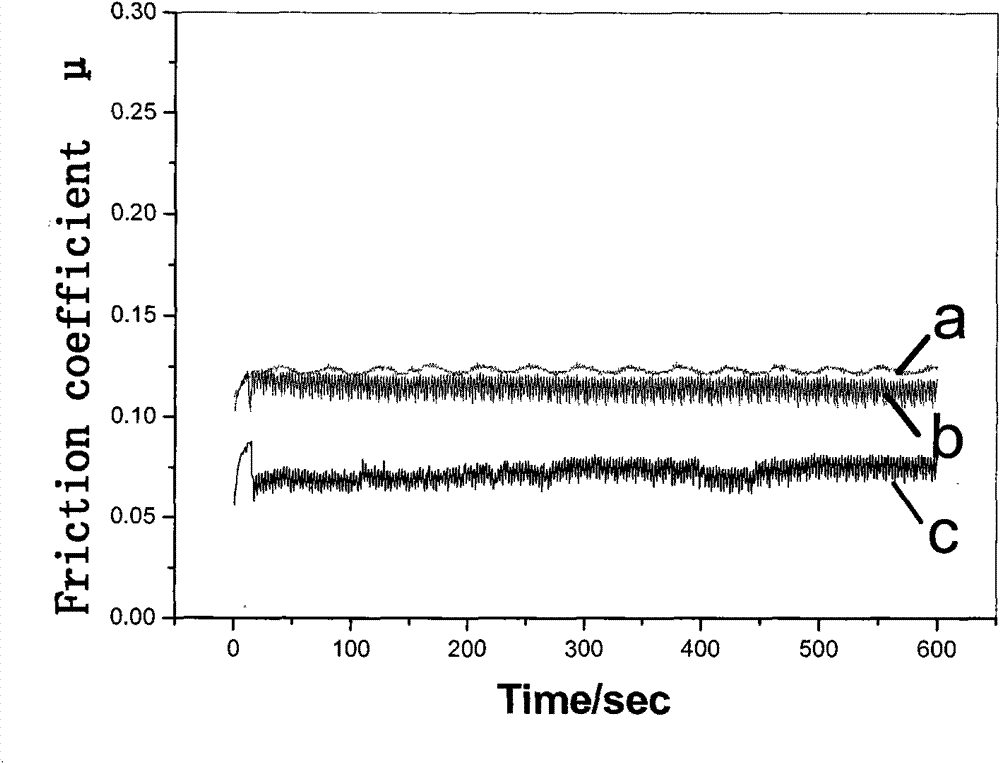

Biomimetic liquid lubricating agent for drilling fluid and preparation method thereof

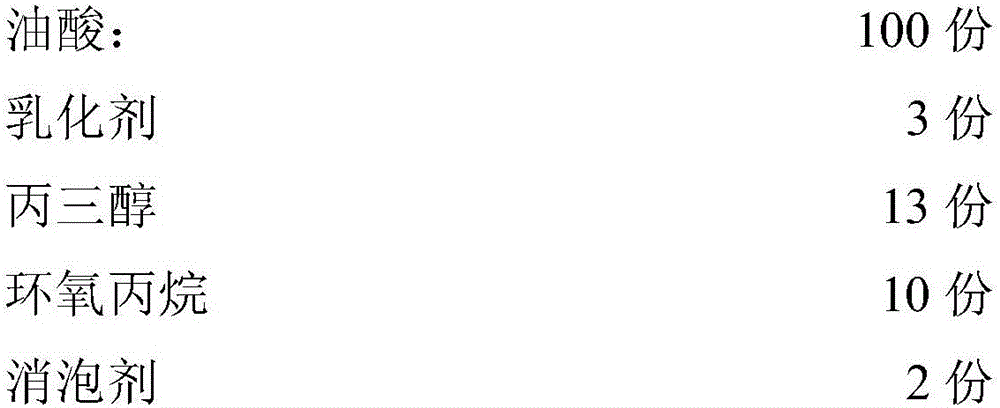

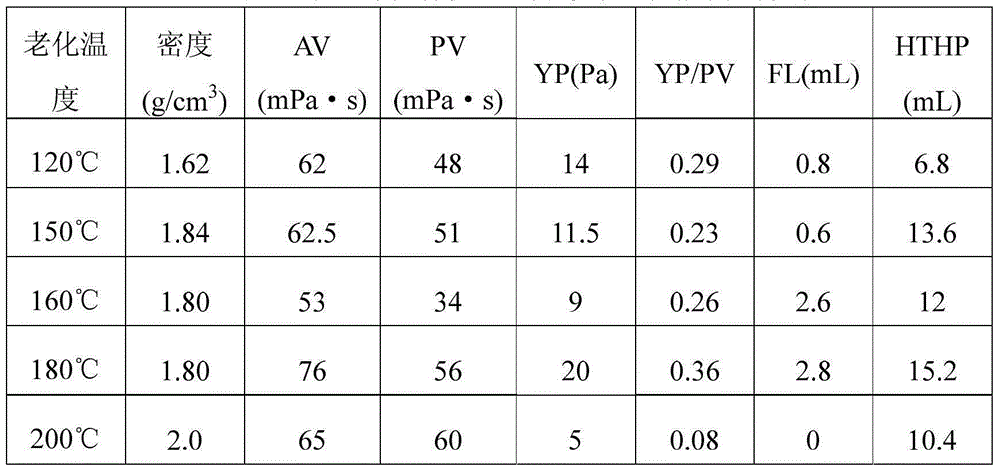

The invention relates to a biomimetic liquid lubricating agent for drilling fluid and a preparation method thereof. The biomimetic liquid lubricating agent is prepared from the following raw materials including oleic acid, emulsifiers, glycerol, epoxy propane and antifoaming agents, wherein the emulsifiers are one or several materials selected from triethanolamine, aluminum stearate and span-80. The preparation method comprises the following technical steps of weight the raw materials of the oleic acid, the emulsifiers, the glycerol and the epoxy propane; adding the raw materials into a reaction kettle so that the raw materials are sufficiently mixed, and a mixed material is obtained; performing an esterification process on the mixed material at the esterification temperature of 200 to 250 DEG C for the esterification time being 1 to 3h; performing cooling to obtain an esterification product; performing an emulsification process on the esterification product at the emulsification temperature of 80 to 100 DEG C for the emulsification time being 1 to 2h; lowering the temperature of a product after completing the emulsification process; adding the antifoaming agents so that the materials are sufficiently and uniformly mixed; discharging the materials after the temperature is lowered to room temperature. The biomimetic liquid lubricating agent can resist high temperature being 200 DEG C or higher; the friction coefficient of the drilling fluid can be reduced; the adhesion coefficient of the drilling fluid can also be reduced; the fluorescence grade is low.

Owner:石家庄华莱鼎盛科技有限公司

Oil-based drilling fluid lubricant and preparation method thereof

ActiveCN104194740AGood extreme pressure lubrication abilityHigh temperature resistanceDrilling compositionFluorescenceExtreme pressure additive

The invention discloses an oil-based drilling fluid lubricant which is prepared from the following components by mass percent: 0.1% to 15% of mud cake adhesion lubricating improver, 0.5% to 30% of extreme pressure additive, 0% to 4% of flow type regulator and the balance of white oil. The invention further provides a preparation method of the oil-based drilling fluid lubricant. The oil-based drilling fluid lubricant has a good extreme pressure lubricating ability and a good mud cake adhesion lubricating ability. When the adding amount of the lubricant in a drilling fluid reaches 0.5% (percent by volume), the mud cake adhesion friction reducing rate is between 56% and 78%, and the extreme pressure friction reducing rate is between 76% and 96%. In addition, the oil-based drilling fluid lubricant is strong in high-temperature resistance and low in fluorescence grade.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Modified kitchen waste grease lubricant for drilling fluid and preparation method thereof

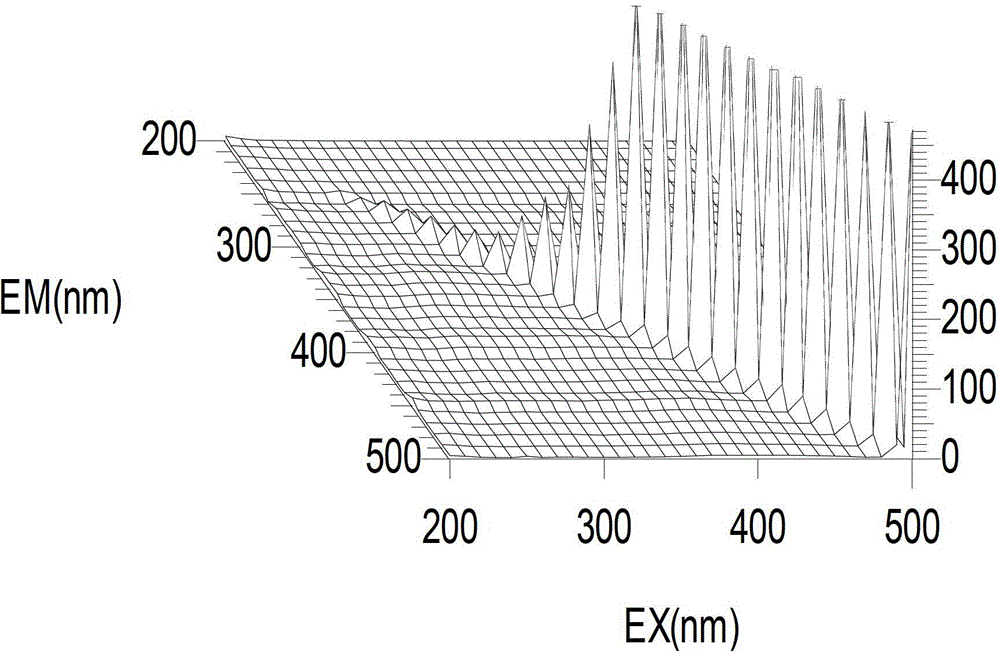

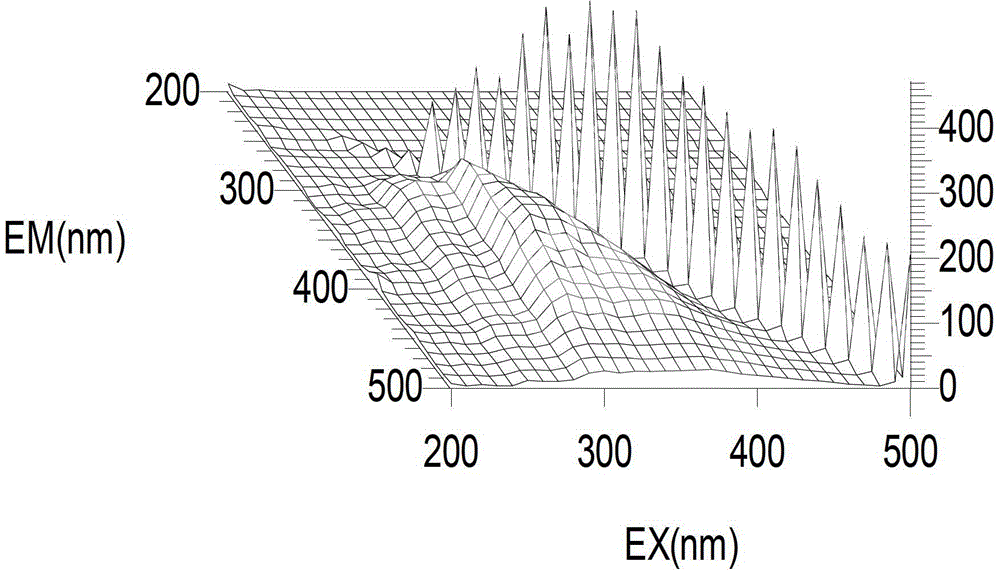

InactiveCN111234787APromote degradationLow fluorescence levelDrilling compositionFluorescenceUltraviolet lights

The invention relates to a modified kitchen waste grease lubricant for drilling fluid and a preparation method thereof, and belongs to the technical field of lubricants. The lubricant comprises the following raw materials in parts by weight: 60-90 parts of kitchen waste grease, 10-40 parts of a sodium hydroxide water solution (30%), 10-30 parts of fuming sulfuric acid, 1-2 parts of an anti-wear agent, 0.5-1 part of an antioxidant, 0.2-0.3 part of an ultraviolet light absorber, 4-6 parts of an extreme pressure additive and 0.2-0.3 part of a preservative. The sulfonated fatty acid lubricant is prepared by chemically modifying the kitchen waste grease, the raw materials are cheap and easily available, the production cost and the fluorescence level of the lubricant are reduced, the preparationmethod is simple, few by-products are produced, no pollution is caused to the environment, and the modified kitchen waste grease has obvious high-temperature resistance and salt resistance effects.

Owner:新乡市振华钻井液材料有限公司

Environmentally-friendly low-fluorescence plugging agent used for drilling fluids, and preparation method thereof

ActiveCN106543993AImprove protectionSmall rheological propertiesDrilling compositionFiberFluorescence

The invention belongs to the field of additives for drilling fluids, and concretely discloses an environmentally-friendly low-fluorescence plugging agent used for drilling fluids, and a preparation method thereof. The plugging agent is prepared from, by weight, 35-45 parts of C1618 fatty alcohol, 40-45 parts of stearic acid, 2-6 parts of polyethylene glycol, 0.5-1.5 parts of p-toluenesulfonic acid, 0.5-1.5 parts of alkylphenol polyoxyethylene, 10-16 parts of lightweight CaCO3 and 10-15 parts of cotton fibers. The plugging agent has the advantages of low fluorescence grade, biodegradability, facilitation of environmental protection, and integration of the excellent plugging and anti-sloughing performances and the oil reservoir protection effect of an asphalt product.

Owner:TIANJIN TIANCHENG TUOYUAN TECH DEV

Anti-sloughing filtrate reducer white asphalt for drilling fluid

PendingCN111925778AAffect normal useLow fluorescence levelDrilling compositionPolymer scienceFiltration

The invention discloses anti-sloughing filtrate reducer white asphalt for drilling fluid. The anti-sloughing filtrate reducer white asphalt is prepared by processing the following raw materials in parts by weight: 3-10 parts of mixed particles, 0.3-2 parts of resin filler and 2-7 parts of copolymerization additive, wherein the mixed particles are used for carrying out surface treatment on light calcium carbonate through a silane coupling agent; then adding the light calcium carbonate subjected to surface treatment into a reaction intermediate of high-carbon fatty acid, high-carbon fatty alcohol and polyhydric alcohol and then performing reaction so that the dispersion and combination effects of the modified light calcium carbonate in the liquid-phase mixture are improved; the resin filleris prepared by taking a resin raw material obtained by reaction of styrene and acrylamide as a coating material to coat cross-linked micro-particles, the effects of lubricating and filling large-aperture gaps are achieved, and early-stage filtration loss is reduced; the high-temperature-resistant resin is used for wrapping so that cross-linked particles can be prevented from being distributed on the side wall of a drilled hole in a centralized manner when the drilling fluid is used, and the normal use of the anti-collapse filtrate reducer is not influenced.

Owner:ANHUI LUHAI PETROLEUM AUX TECH

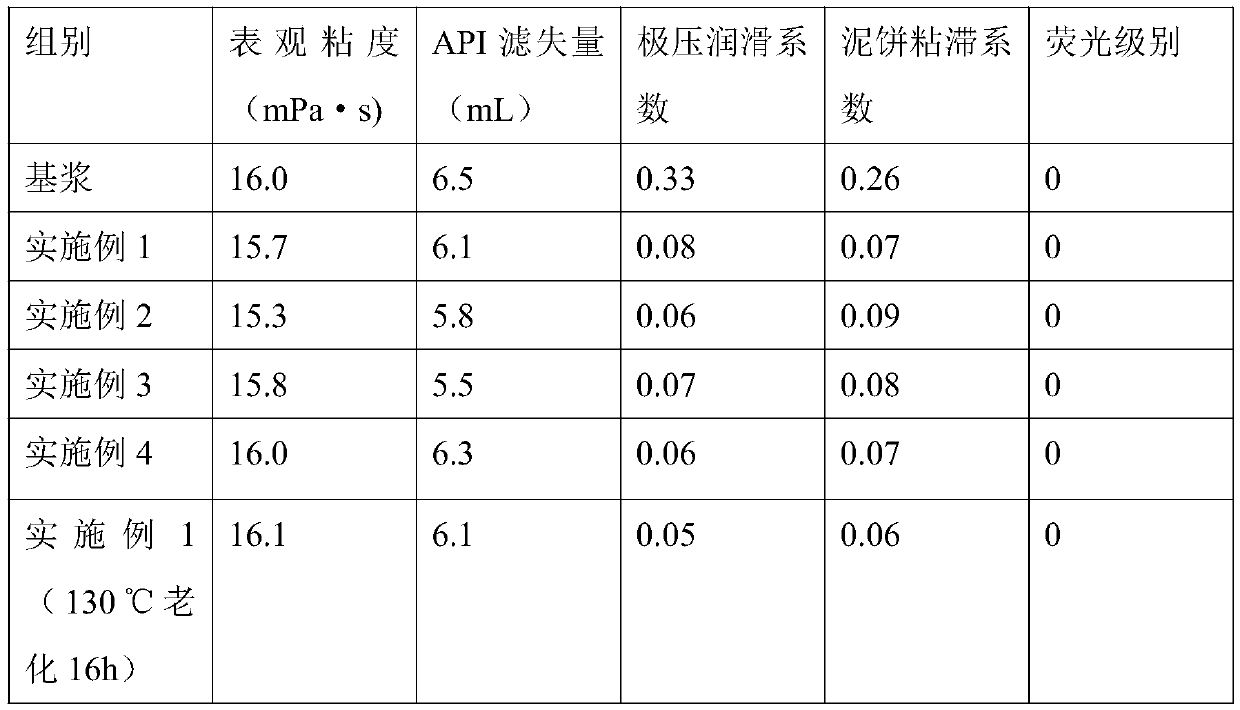

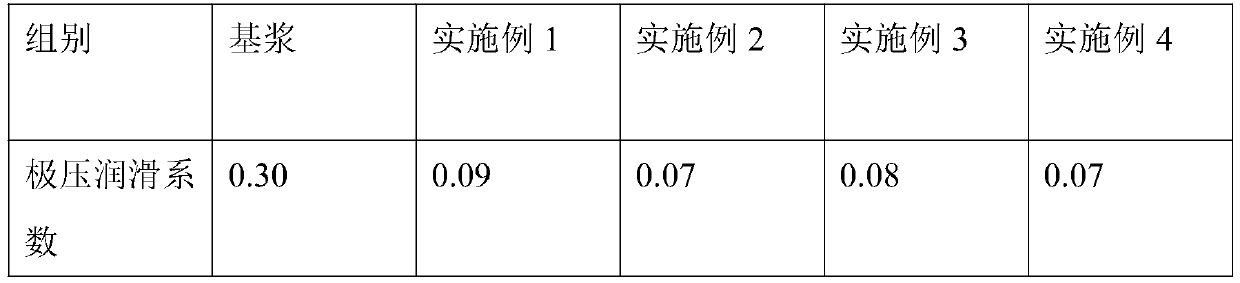

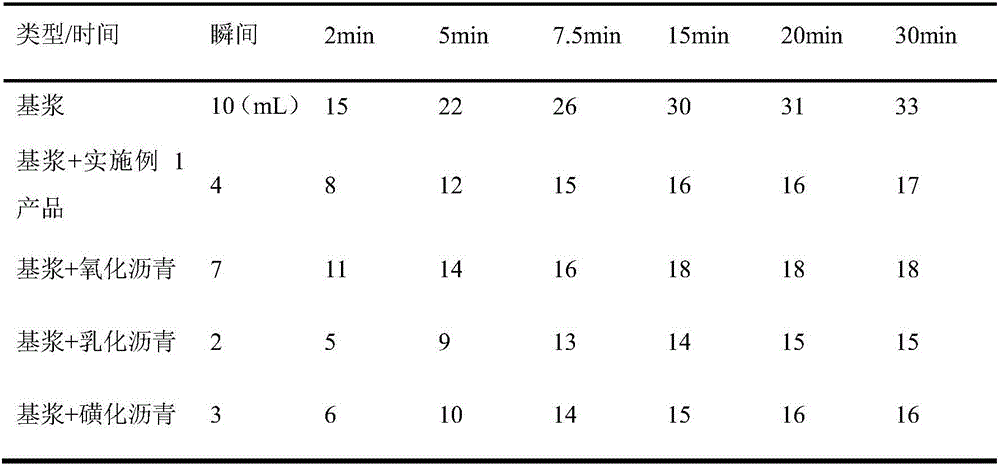

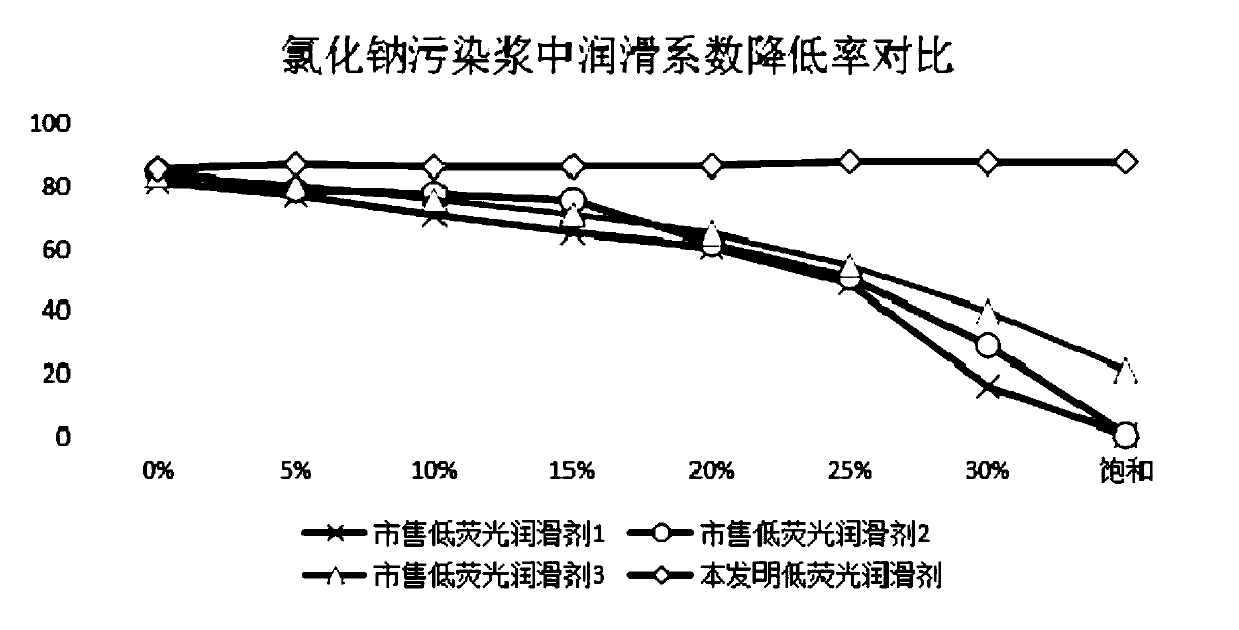

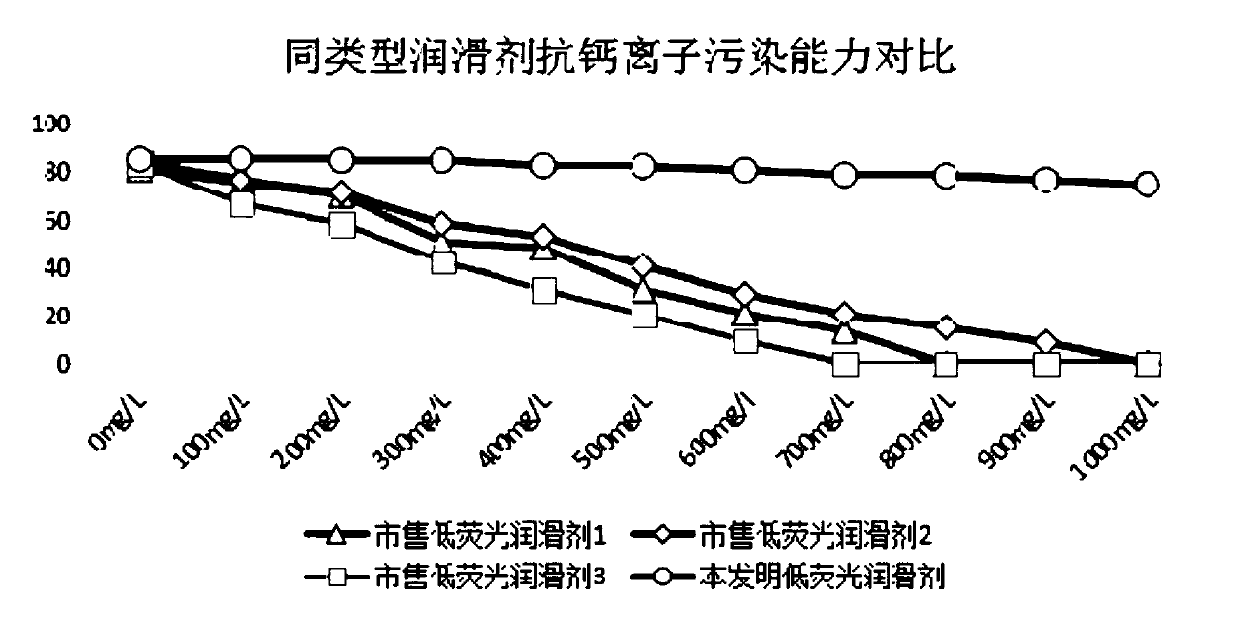

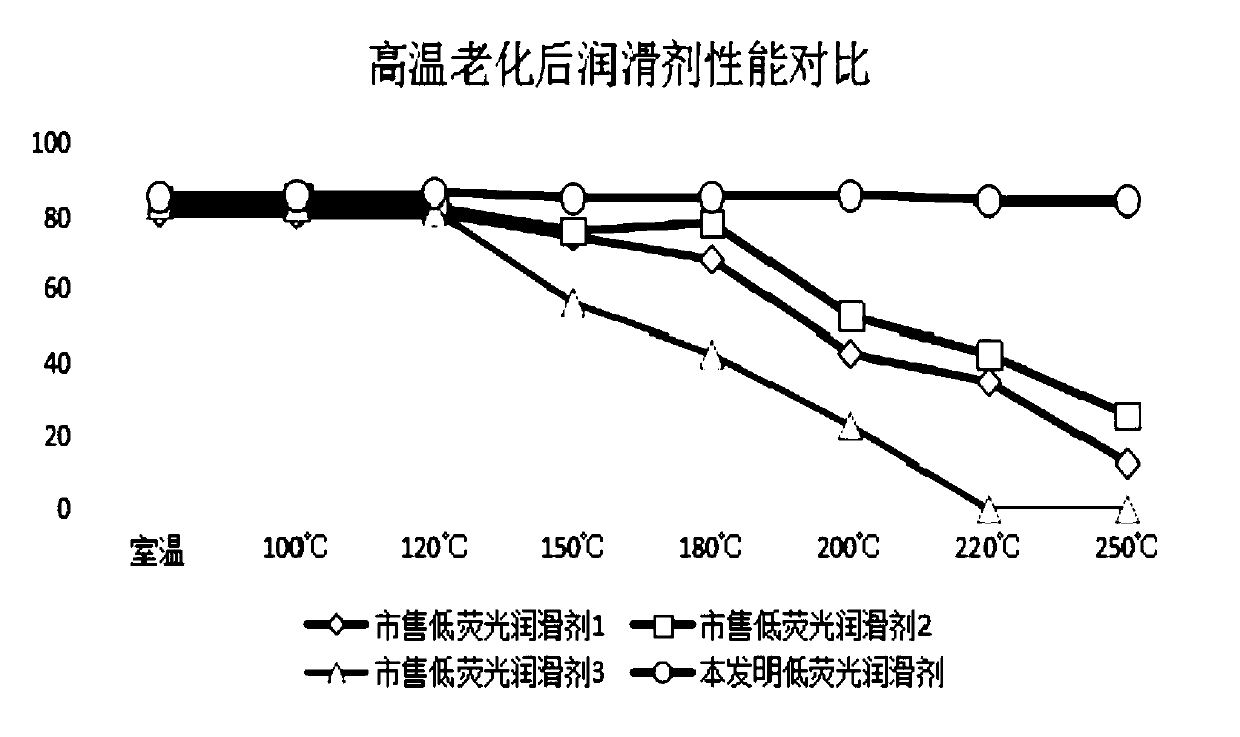

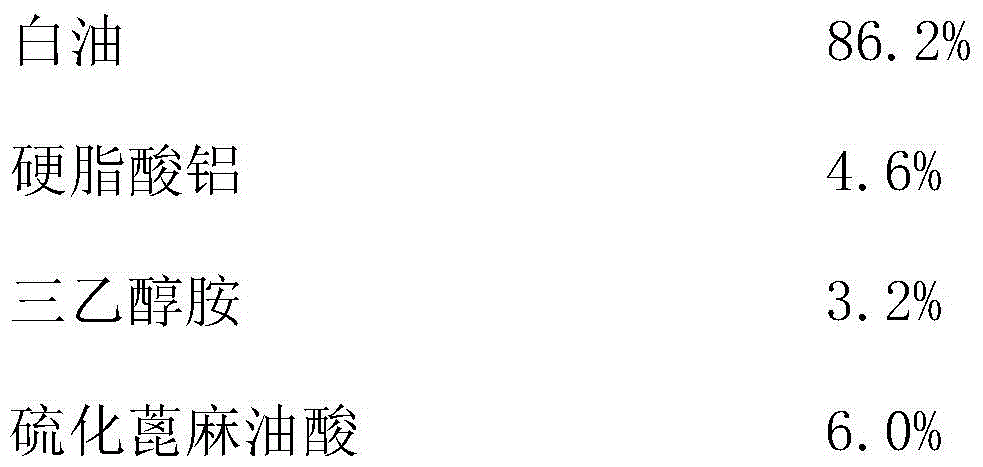

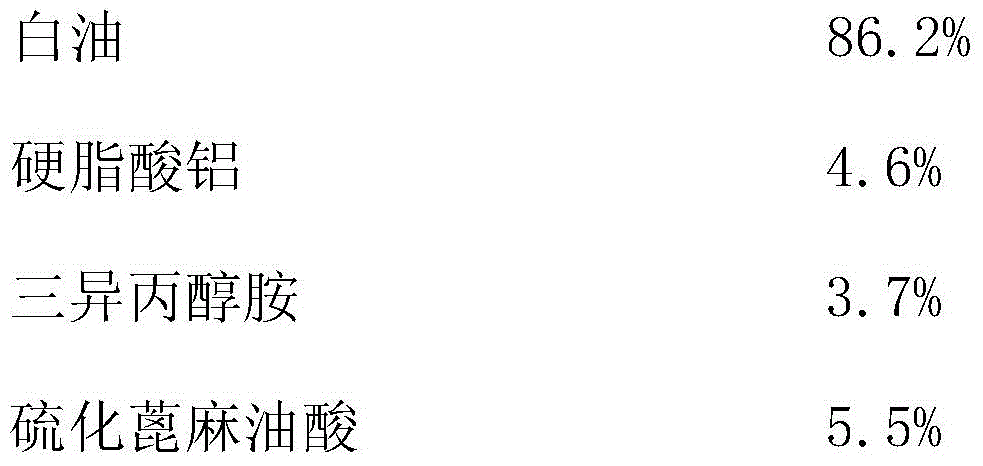

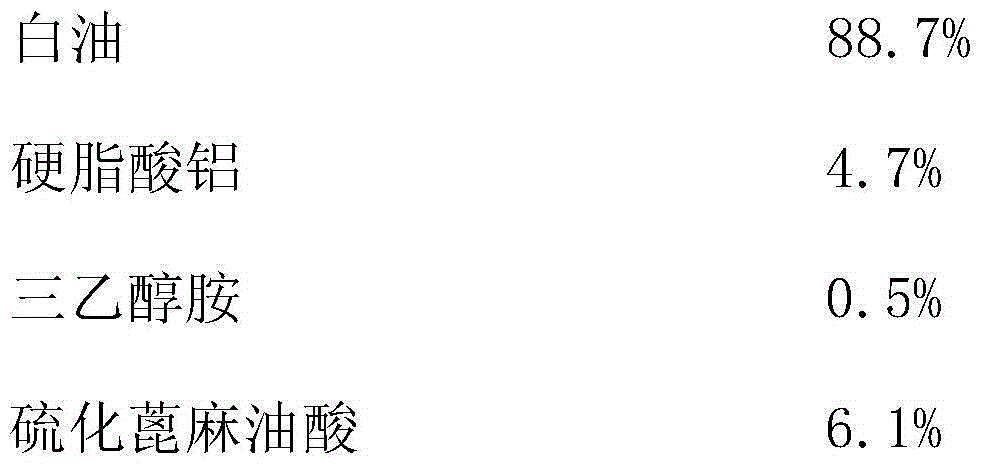

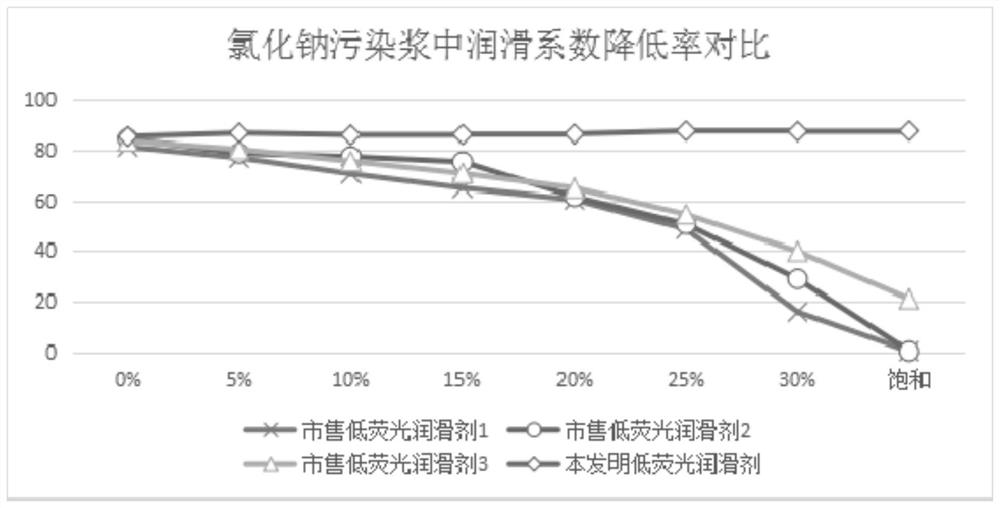

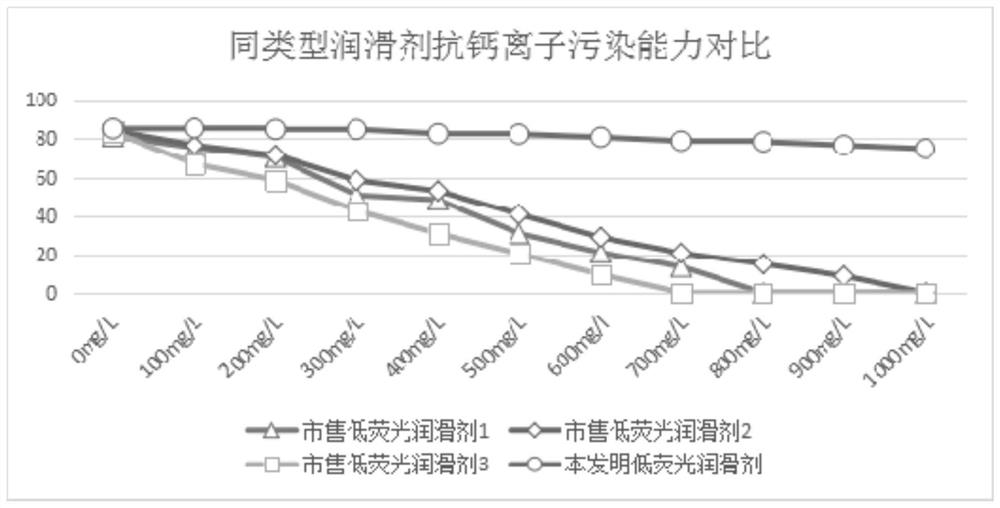

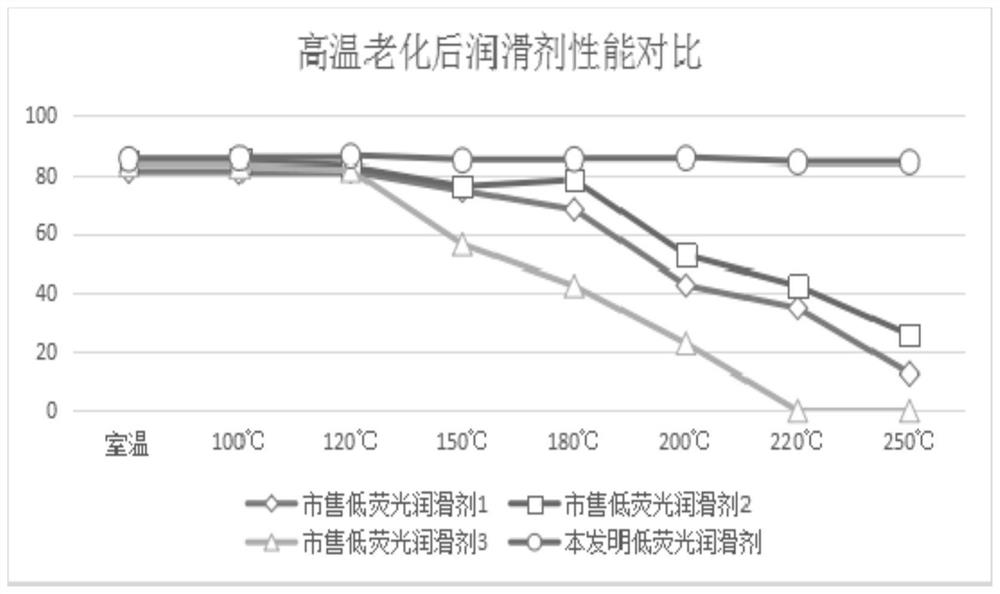

Low-fluorescence lubricant for drilling fluid and preparation method of low-fluorescence lubricant

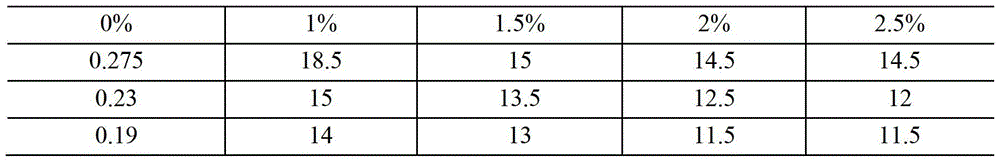

The invention discloses a low-fluorescence lubricant for drilling fluid and a preparation method of the low-fluorescence lubricant, and solves the problems that an existing low-fluorescence lubricanthas poor salt pollution resistance, does not have calcium ion pollution resistance and has greatly reduced lubricating property in a high-temperature environment. The lubricant comprises the raw material of a mixed solution composed of, in parts by mass, 25-30% of industrial oleic acid, 15-20% of industrial coconut oil, 35-45% of industrial white oil, 10% of softened water and 5-10% of an additive.

Owner:XINJIANG TARIM OILFIELD CONSTR ENG

Plant clay oil drilling fluid lubricant, and preparation method thereof

ActiveCN107541194ASolve pollutionRaw materials are cheap and easy to getDrilling compositionFluorescenceOil drilling

The invention discloses a plant clay oil drilling fluid lubricant, and a preparation method thereof, and belongs to the technical field of oil-gas well engineering. The plant clay oil drilling fluid lubricant is prepared from, by mass, 60 to 80% of plant clay oil, 10 to 30% of a fatty acid ester, and 5 to 10% of a surfactant. The plant clay oil drilling fluid lubricant is low in fluorescence grade, and excellent in lubrication performance; and the raw materials are cheap and easily available.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid non-fluorescent lubricant for well drilling

The invention discloses a liquid non-fluorescent lubricant for well drilling. The lubricant is prepared from 50-60 parts of white oil, 6-12 parts of sulfonated palm oil, 4-8 parts of vegetable oil acid, 5-12 parts of octaphenyl polyoxyethyiene-10, 12-18 parts of sorbide oleate, 6-15 parts of chloralkane. The lubricant is prepared by taking the white oil as an oil base, the sulfonated palm oil as asynthesized anionic surfactant and the octaphenyl polyoxyethyiene-10, the sorbide oleate and the like which are taken as a nonionic surfactant are used as auxiliary materials, finally the efficient and environmentally friendly non-fluorescent lubricant capable of resisting salt is obtained, and the extreme pressure lubrication coefficient can reach 98%; the viscosity coefficient of a mud cake canreach 70%; the lubricant can be used for horizontal wells and large inclined wells, the compatibility between the lubricant and other drilling fluid materials is good, and the lubricant has good lubricating performance in the drilling fluid system; the non-fluorescent grade or the fluorescence grade is extremely low, and the lubricant can better cooperate with the specific operation of geologicallogging and the like.

Owner:SICHUAN ZHENGRONG IND +1

Low-fluorescence oil-base pipe-freeing agent and preparation method thereof

The invention discloses a low-fluorescence oil-base pipe-freeing agent and a preparation method thereof. The invention aims at providing the pipe-freeing agent with low filtration loss, good fluidity, good pipe-freeing performance, low solidifying point, and good stability, and a preparation method thereof. The agent is composed of a pipe-freeing liquid and a rapid penetration agent. The pipe-freeing liquid comprises, by weight: 30-40% of diesel oil, 30-40% of engine oil, 4-5% of polyamide, 4-5% of organic earth, 1.5-2% of oil-soluble yellow, and 6-8% of water. The addition amount of the rapid penetration agent is 1.5-2% of the weight of the pipe-freeing liquid. When the pipe-freeing agent provided by the invention is used for treating a pipe-stuck situation, the penetration performance is high, soil cake falling speed is high, and wetting performance is good. A soaking time is commonly 1-2h. A field construction process is simple, pipe-freeing comprehensive cost is low, and pipe-stuck accident can be rapidly and effectively solved.

Owner:天津市宏科泥浆助剂厂(普通合伙)

Clay-free low-density oil-based drilling fluid

The invention relates to drilling liquid for use in the drilling process of oil exploration wells and production wells and belongs to low-density oil-based drilling fluid. The drilling fluid overcomes the drawbacks of serious pollution and strong Jamin effects of the conventional oil-based drilling fluid in hypotonic and water sensitive reservoir strata. The drilling fluid is characterized by containing low-density base oil, oil thickener, oil swelling agent, oil dispersible particle calcium carbonate, calcium oxide and oil soluble high-temperature-resistance fluid loss additive. The drilling fluid does not contain any water phase, the breaking voltage of the drilling fluid is high, the viscosity of the drilling fluid is proper, and the filtration is small (all filtrate is oil). The drilling fluid has the characteristics of high electrical stability, high temperature resistance, high water, soil and salt pollution resistance, excellent emulsification effect at high temperature and the like. The stabilization time of the drilling fluid can reach 20 to 40 hours.

Owner:CHINA PETROCHEMICAL CORP +1

Low-fluorescent-oil-based lubricant for drilling fluid based on reclaimed oil and derivatives thereof

The invention relates to a low-fluorescent-oil-based lubricant for a drilling fluid based on reclaimed oil and derivatives thereof, which is prepared through the following steps: (1) an esterification process and (2) a fluorescence disappearing process. The lubricant has favorable biodegradability and lubrication property, high oxidation resistance, excellent high-temperature-resistant lubrication property and low florescence level, and is less prone to cause fluid loss.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Modified fatty acid ester, preparation method and application thereof

InactiveCN101812374BNo pollution in the processWill not polluteDrilling compositionPetroleumSURFACTANT BLEND

Owner:濮阳市诚信钻采助剂有限公司

Carrier of active ingredient of defoaming agent and preparation method thereof

InactiveCN101831280AReduced stabilityPrevent re-formationDrilling compositionProcess engineeringSlurry

The invention relates to a carrier of an active ingredient of a defoaming agent and a preparation method thereof. The carrier of the active ingredient of the defoaming agent is characterized by comprising the following components in part by weight: 1,000 to 2,000 parts of vegetable fatty acid and 100 to 800 parts of lower fatty alcohol. When in use, the carrier has no side effect on other performance of drilling fluid; the use amount is small; when the addition of the carrier reaches 0.2 percent, the density recovery ratio of the drilling fluid can reach over 98 percent; and the carrier is convenient to use and high in dissolving and dispersing speed and can be added into slurry directly.

Owner:濮阳市诚信钻采助剂有限公司

High-efficient antisticking lubricant for drilling fluid

ActiveCN102344783BPlay a lubricating roleLow fluorescence levelDrilling compositionPolymer scienceLubricant

A high-efficient antisticking lubricant for drilling fluid has a technical scheme that the lubricant is obtained by mixing five components of white oil which is used as a main raw material, oleic acid and methyl oleate which are used as auxiliary materials, a defoamer and an extreme pressure agent which are used as regulators, wherein the weight percent ranges of the components are 30%-70% of white oil, 18%-30% of oleic acid, 10%-20% of methyl oleate, 1%-10% of defoamer and 1%-10% of extreme pressure agents. The lubricant of the invention has the advantages of extreme pressure lubrication, sticking resistance, less fluorescence grade, and the like, does not cause index change of drilling fluid, has lubrication effect on hard surface to soft surface (drilling tool to mud cake) and hard surface to hard surface (drilling tool to rock), has good lubrication effect, and thus is a good lubricant for polymer drilling fluid systems.

Owner:石家庄华莱鼎盛科技有限公司

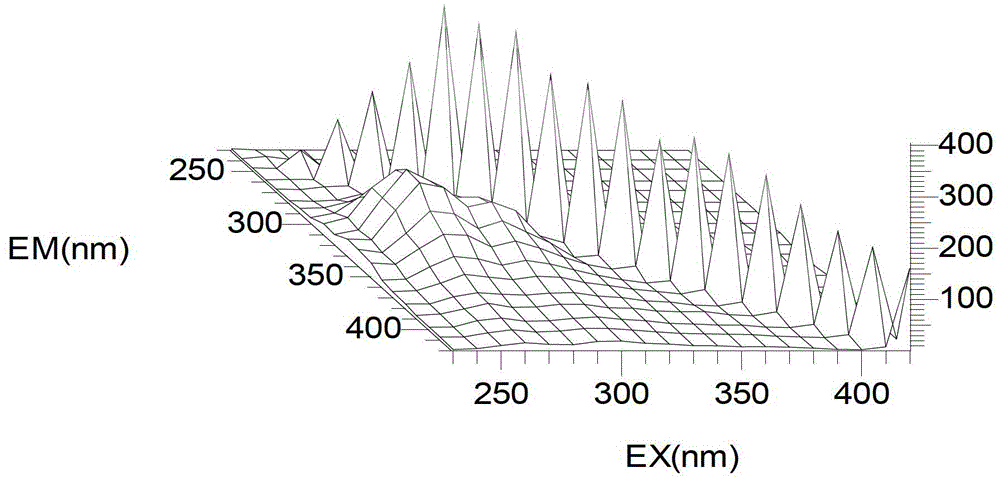

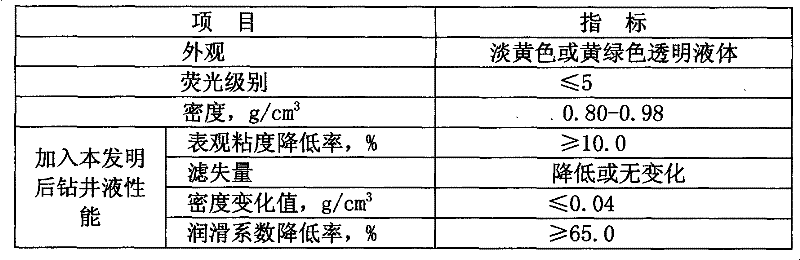

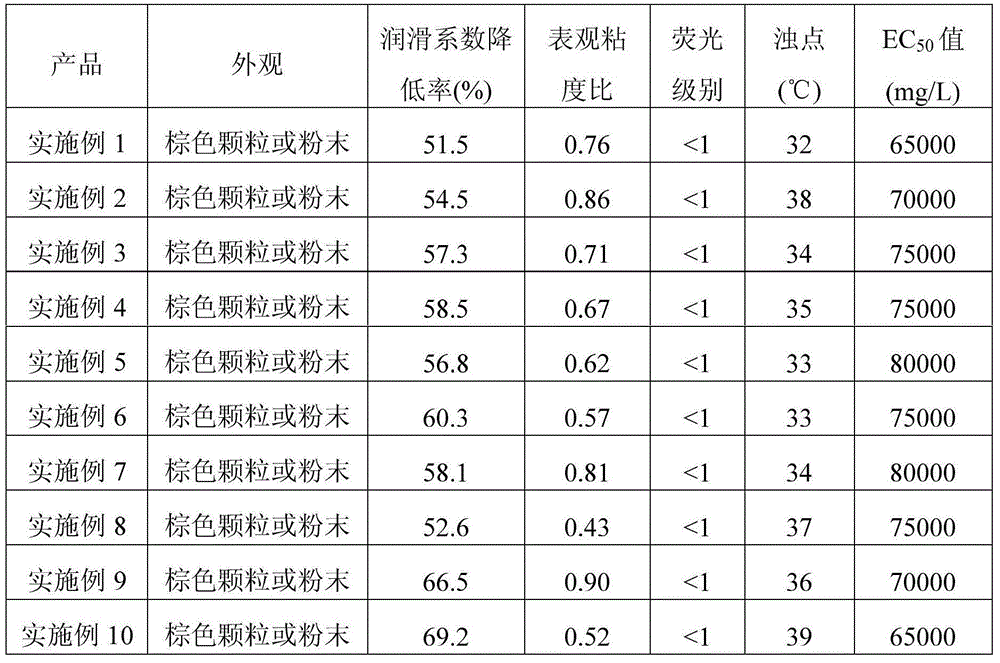

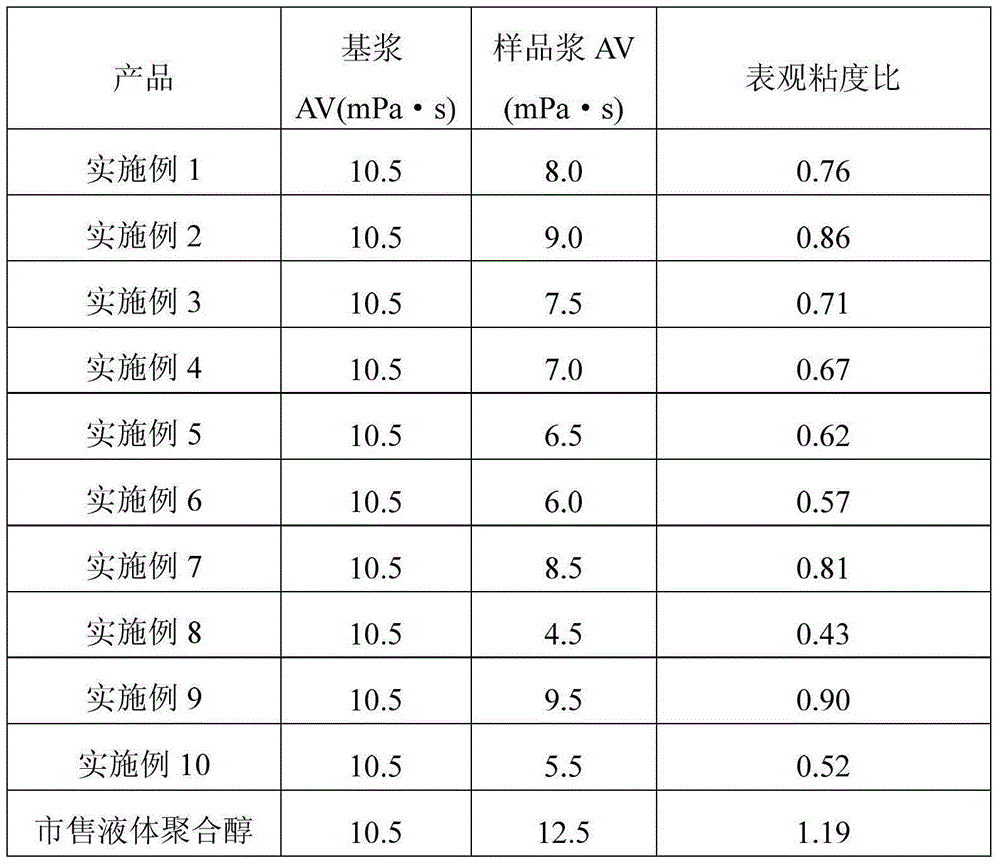

Solid polyalcohol for oil field drilling fluid and its preparation method and application

ActiveCN104341589BImprove the lubrication effectLow cloud pointDrilling compositionAlcoholFluorescence

The invention provides solid polyalcohol for oilfield drilling fluid and a preparation method and application thereof. The method comprises the steps of mixing aliphatic amine, epoxyethane and epoxypropane according to the weight ratio of (1-1.4): (390-450): (260-300), and reacting for 3.5-4.5 hours in the presence of a catalyst at the pressure of 0.2-0.4MPa and the temperature of 155-160 DEG C, thereby obtaining the product, namely the solid polyalcohol for the drilling fluid. The polyalcohol provided by the invention is solid and can be applied to exploratory wells and development wells; compared with the prior art, the polyalcohol has the advantages of good lubricating property, low turbidity point, strong inhibitive ability, low fluorescence level, no biological toxicity, no environmental pollution, convenience in transportation and use, strong compatibility, relatively strong filtration reduction capability and the like.

Owner:北京培康佳业技术发展有限公司

A liquid non-fluorescent lubricant for drilling

The invention discloses a liquid non-fluorescent lubricant for well drilling. The lubricant is prepared from 50-60 parts of white oil, 6-12 parts of sulfonated palm oil, 4-8 parts of vegetable oil acid, 5-12 parts of octaphenyl polyoxyethyiene-10, 12-18 parts of sorbide oleate, 6-15 parts of chloralkane. The lubricant is prepared by taking the white oil as an oil base, the sulfonated palm oil as asynthesized anionic surfactant and the octaphenyl polyoxyethyiene-10, the sorbide oleate and the like which are taken as a nonionic surfactant are used as auxiliary materials, finally the efficient and environmentally friendly non-fluorescent lubricant capable of resisting salt is obtained, and the extreme pressure lubrication coefficient can reach 98%; the viscosity coefficient of a mud cake canreach 70%; the lubricant can be used for horizontal wells and large inclined wells, the compatibility between the lubricant and other drilling fluid materials is good, and the lubricant has good lubricating performance in the drilling fluid system; the non-fluorescent grade or the fluorescence grade is extremely low, and the lubricant can better cooperate with the specific operation of geologicallogging and the like.

Owner:SICHUAN ZHENGRONG IND +1

A kind of solid lubricant and its preparation method and application

ActiveCN113845889BImprove surface activityImprove the lubrication effectDrilling compositionPentaerythritolPolybutylene

Owner:北京培康佳业技术发展有限公司

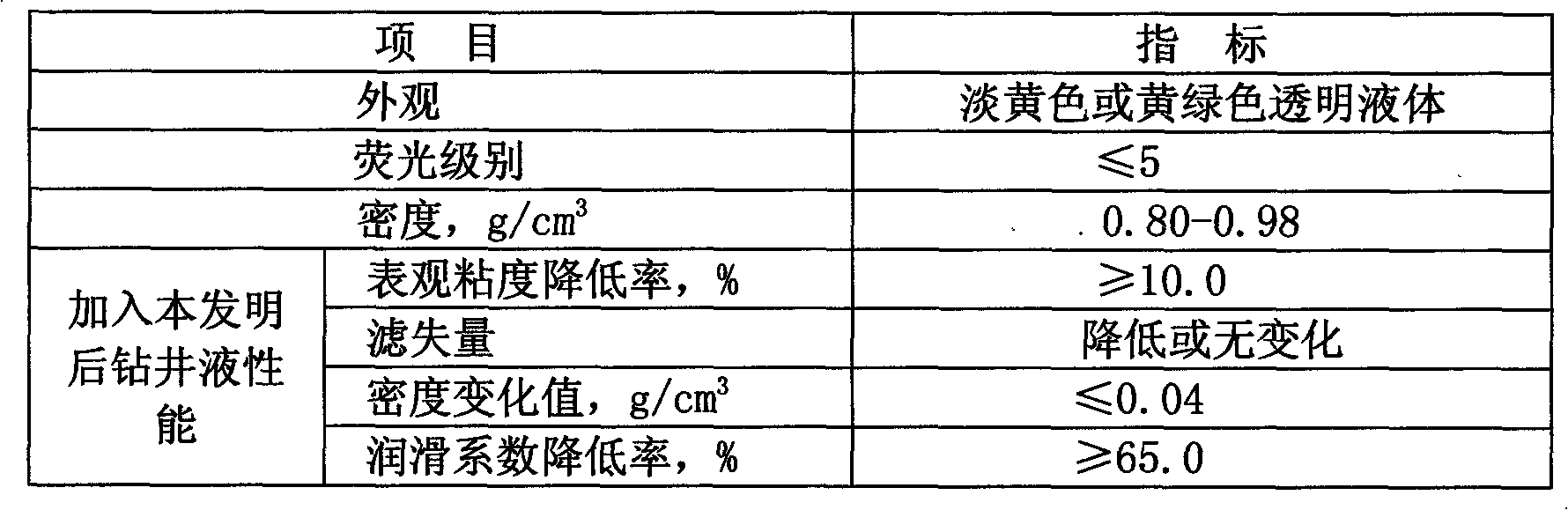

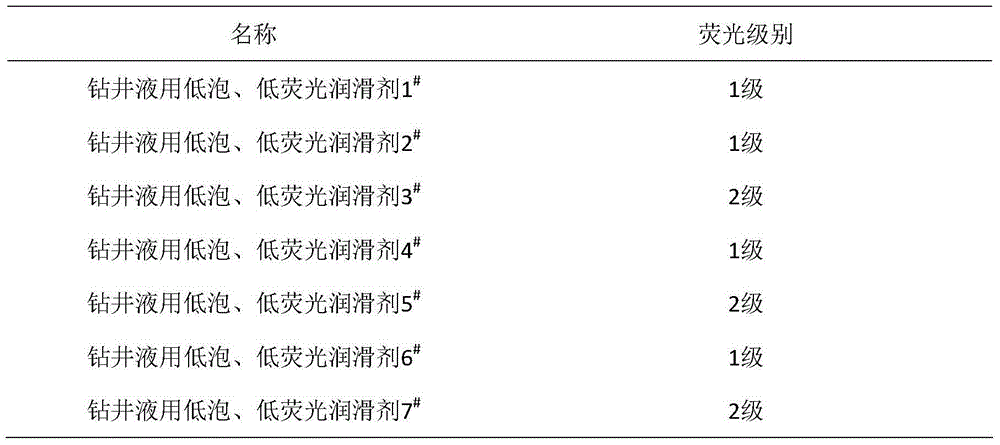

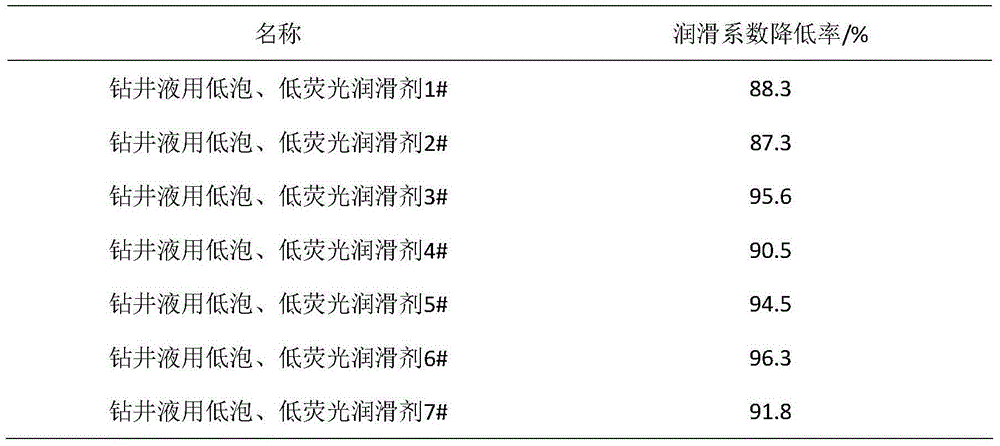

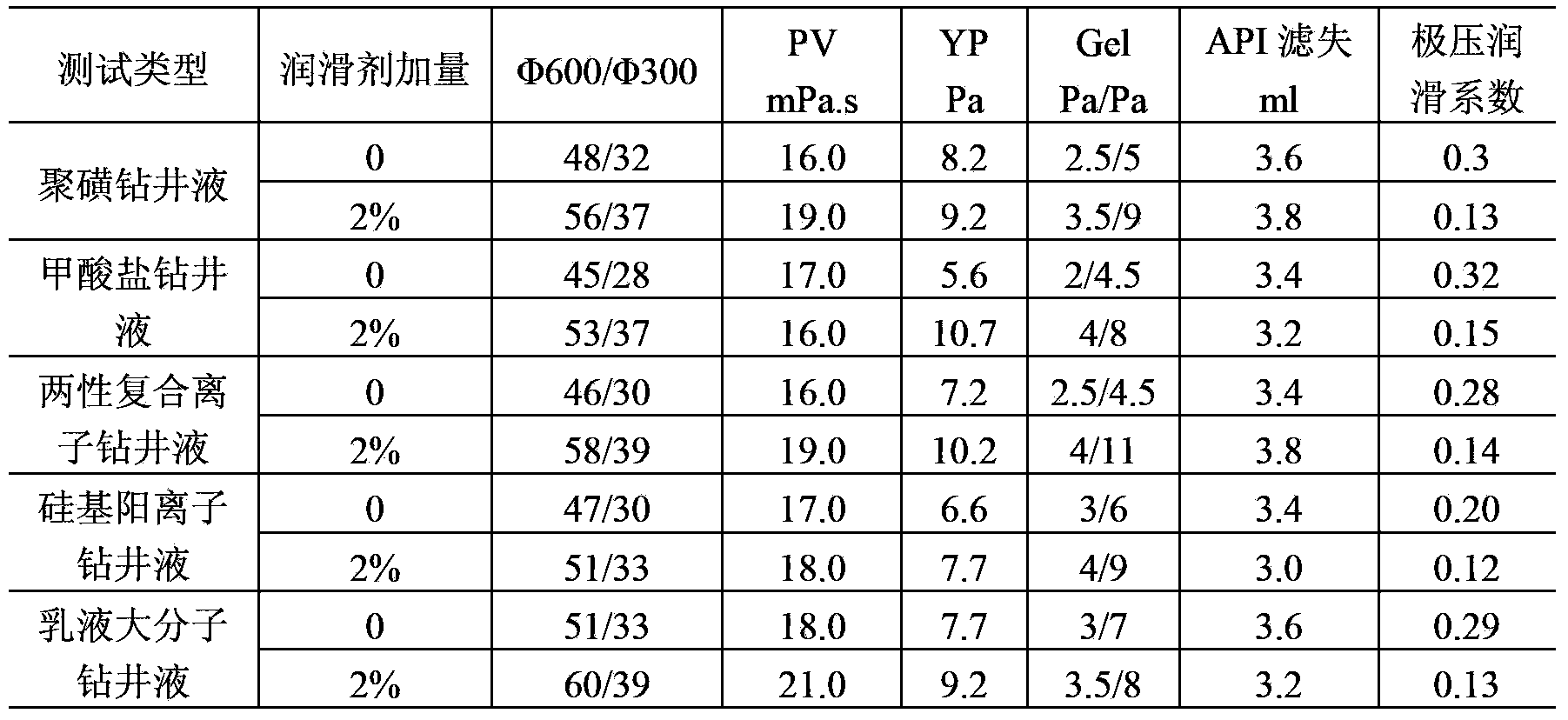

Low-foaming and low-fluorescence lubricant for drilling fluid and preparation method thereof

ActiveCN104559954BLow fluorescence levelDoes not affect geological loggingDrilling compositionWater basedFluorescence

The invention discloses a low-foam low-fluorescence lubricant for a drilling fluid and a preparation method thereof, and relates to the technical field of a lubricant for a water-based drilling fluid. The lubricant is characterized by comprising the following ingredients, by weight, 20-40% of base oil, 40-60% of fatty acid ester, 5-10% of a surfactant and 3-10% of an antifoaming agent. the preparation method of the lubricant comprises the following steps: respectively adding the above base oil and fatty acid ester according to the above ratio into a reaction still, warming to 50-80 DEG C, stirring at high speed for 0.5h, slowly adding the surfactant, stirring at high speed for 0.5h, warming to 70-100 DEG C, adding the antifoaming agent and continuously stirring for 0.5h, and cooling to obtain the low-foam low-fluorescence lubricant for the drilling fluid. As the lubricant has low fluorescence level, the lubricant has no negative effects on geological logging, the condition that real rock debris cannot be dredged out on logging will not happen, and discovery of new hydrocarbon reservoir also will not be influenced. In addition, the lubricant has poor foaming property such that the lubricant has no adverse effects on properties of well mud.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricant for drilling fluid and preparation method thereof

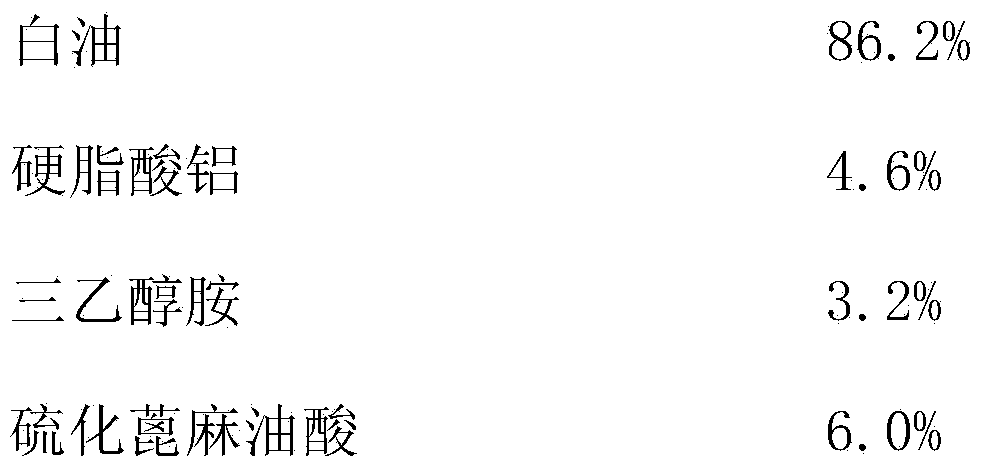

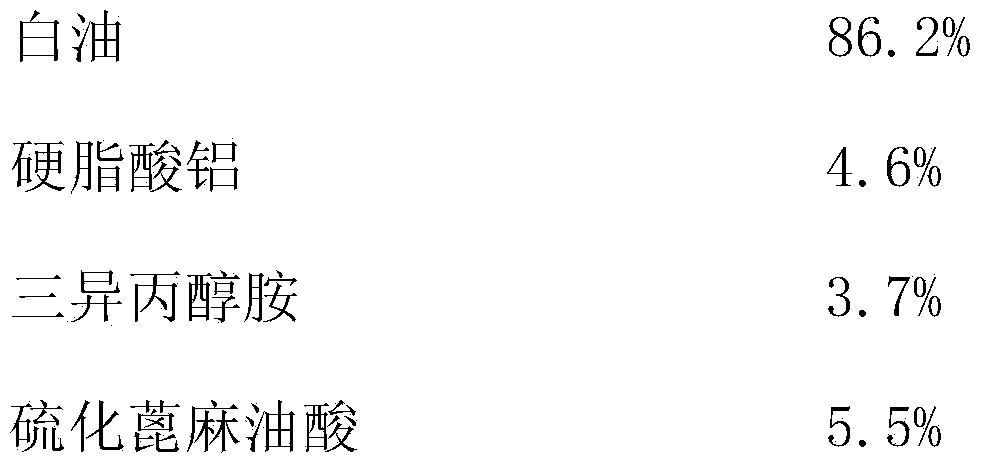

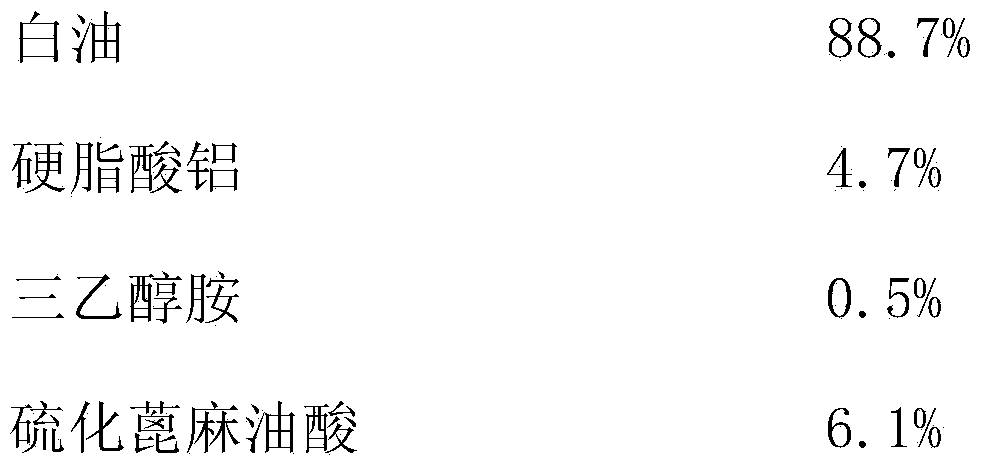

InactiveCN113185954AGood lubricityLow fluorescence levelDrilling compositionLong chain fatty acidMagnesium stearate

The invention discloses a lubricant for drilling fluid and a preparation method thereof. The lubricant for drilling fluid is prepared from long-chain fatty acid, light diesel oil and stearate, the long-chain fatty acid is one or a mixture of at least two of oleic acid, palmitic acid and stearic acid in any proportion, the light diesel oil is one or a mixture of at least two of 5 # diesel oil, 0 # diesel oil and-10 # diesel oil in any proportion, and the stearate is one or a mixture of at least two of aluminum stearate, magnesium stearate, calcium stearate and barium stearate in any proportion. The lubricant for the drilling fluid has the advantages of being good in lubricating property, low in fluorescence level, low in foaming rate and good in compatibility with various common drilling fluid additives, the preparation method of the lubricant is simple, the production cost is low, and industrial production is easy.

Owner:巴州三元石油助剂有限公司

Nano-embedded emulsified lubricant

ActiveCN103436241BImprove the lubrication effectReduce sliding frictional resistanceDrilling compositionAlkalinityFluorescence

The invention relates to a nano film-embedded emulsion lubricant and mainly solves the problems about high frictional resistance of a horizontal well, serious backing pressure and poor lubricating effect of drilling fluid. The nano film-embedded emulsion lubricant comprises the following components in percentage by weight: 10 to 30 percent of modified paraffin, 3 to 11 percent of a compound emulsifier, 0.5 to 3 percent of an alkalinity modifier, 0.5 to 2 percent of nano graphite powder and the balance of water. The nano film-embedded emulsion lubricant provides an emulsion lubricant which has low fluorescence, is provided with a nano ball material and has capability of forming an anti-adhesion lubricating film between the stratum and a drilling tool; a prepared drilling fluid system has a good lubricating property; a mud cake is fine; the filter loss is low; the class of florescence is low; the nano film-embedded emulsion lubricant has excellent thermal stability and cold-resisting stability; drilling efficiency of the horizontal well is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of oil base drilling fluid lubricant and preparation method thereof

ActiveCN104194740BGood extreme pressure lubrication abilityHigh temperature resistanceDrilling compositionFluorescenceExtreme pressure additive

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of low fluorescence lubricant for drilling fluid and its preparation method

The invention discloses a low-fluorescence lubricant for drilling fluid and a preparation method thereof, which solves the problems that the existing low-fluorescence lubricant has poor anti-salt pollution ability, does not have anti-calcium ion pollution ability, and the lubricating performance will be greatly reduced in a high-temperature environment. The raw material of the lubricant is a mixed liquid composed of industrial oleic acid, industrial coconut oil, industrial white oil, demineralized water and additives; the mass fraction of industrial oleic acid is 25-30%; the mass fraction of industrial coconut oil is 15-30%. 20%, the mass fraction of industrial white oil is 35-45%, the mass fraction of demineralized water is 10%, and the mass fraction of additives is 5-10%.

Owner:XINJIANG TARIM OILFIELD CONSTR ENG

A kind of vegetable clay oil drilling fluid lubricant and preparation method thereof

ActiveCN107541194BSolve pollutionRaw materials are cheap and easy to getDrilling compositionActive agentPhysical chemistry

The invention discloses a plant clay oil drilling fluid lubricant, and a preparation method thereof, and belongs to the technical field of oil-gas well engineering. The plant clay oil drilling fluid lubricant is prepared from, by mass, 60 to 80% of plant clay oil, 10 to 30% of a fatty acid ester, and 5 to 10% of a surfactant. The plant clay oil drilling fluid lubricant is low in fluorescence grade, and excellent in lubrication performance; and the raw materials are cheap and easily available.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carrier of active ingredient of defoaming agent and preparation method thereof

The invention relates to a carrier of an active ingredient of a defoaming agent and a preparation method thereof. The carrier of the active ingredient of the defoaming agent is characterized by comprising the following components in part by weight: 1,000 to 2,000 parts of vegetable fatty acid and 100 to 800 parts of lower fatty alcohol. When in use, the carrier has no side effect on other performance of drilling fluid; the use amount is small; when the addition of the carrier reaches 0.2 percent, the density recovery ratio of the drilling fluid can reach over 98 percent; and the carrier is convenient to use and high in dissolving and dispersing speed and can be added into slurry directly.

Owner:濮阳市诚信钻采助剂有限公司

Compound type vegetable oil lubricating agent for drilling fluid and preparation method thereof

The invention discloses a compound type vegetable oil lubricating agent for a drilling fluid and a preparation method thereof. The compound type vegetable oil lubricating agent for the drilling fluid with favorable oiliness, no toxicity, low fluorescent level and favorable bearing and thermostabilized performance is prepared by taking a vegetable oil leftover which is low in price and easy to obtain, lauryl sodium sulfate, sbane 80, sodium carboxymethylcellulose, polyvinylpyrrolidone and the like as main raw materials, adding a solid lubricating agent which is graphite or serpentine and usinga simple and environment-friendly production method, so that not only the production cost is greatly reduced, but also any toxic and harmful action on the environment is not generated in the production process. The compound type vegetable oil lubricating agent for the drilling fluid is not only applied to drilling, but also can be applied to producing wells, can effectively inhibit the hydrous expansion of mud shale, consolidate the well wall and prevent the sticking accidents and is especially suitable for industrial production on a large scale.

Owner:无锡润鹏复合新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com