Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Reduce sliding frictional resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

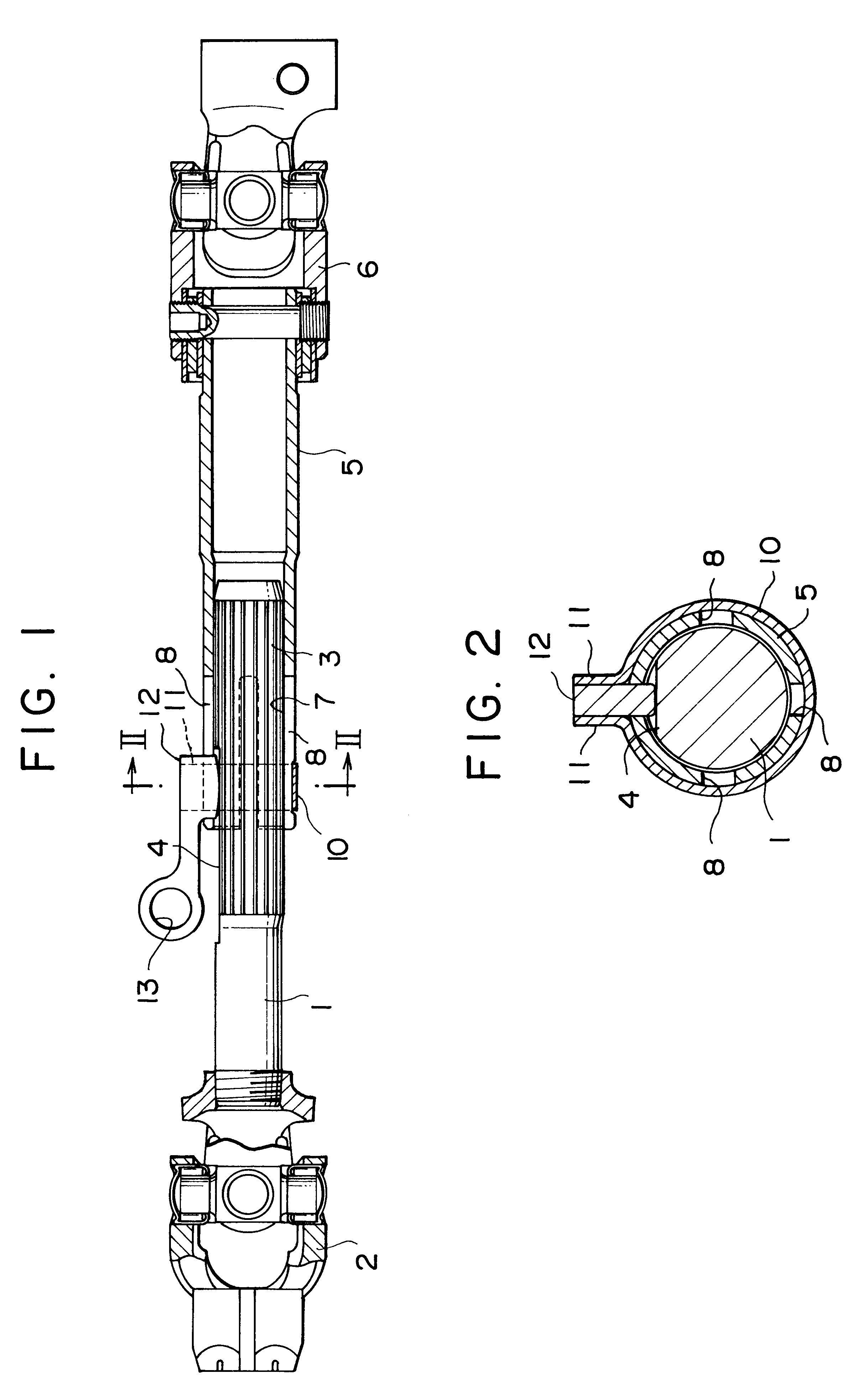

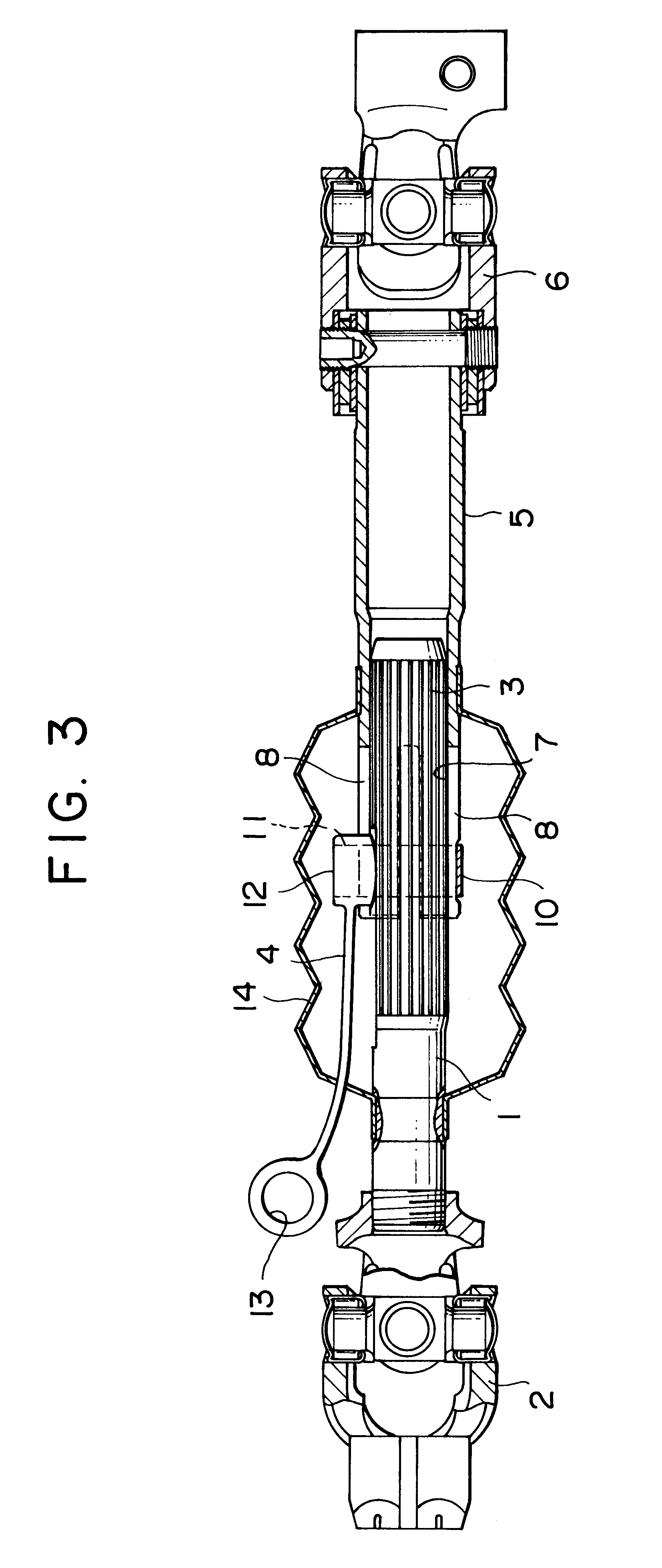

Coupling structure of variable length shaft

InactiveUS6267528B1Reduce pipe resistanceImprove workabilityYielding couplingShaftsCouplingMedial axis

A coupling structure of a variable length shaft, comprises a pipe member having an end formed with a plurality of slits elongated in the axial direction to be capable of expanding and diminishing in diameter, an intermediate shaft spline-fitted in the end of the pipe member, and a ring member fitted on an outer periphery of the end of the pipe member, the intermediate shaft being fastened by the end of the pipe member. A holder is releasably attached to an end of the ring member to expand a diameter thereof and thereby reduce a slide frictional resistance of the pipe member against the intermediate shaft. When the holder is released, the ring member diminishes in diameter, and a fastening force of the pipe member on the intermediate shaft is increased.

Owner:NSK LTD

Pure titanium two-step plastic deformation processing method

The invention relates to a pure titanium two-step plastic deformation processing method in the technical field of metallic material plastic deformation; the method comprises the following steps: level-3 industrial pure titanium block is taken as the raw material, after being coated with graphite lubricant, the material is extruded on a 300KN hydraulic pressure universal experimental machine and then is subjected to rolling treatment at liquid nitrogen temperature to carry out deformation treatment on submicron crystal industrially pure titanium block, thus obtaining the superfine crystal pure titanium. The superfine crystal pure titanium of the invention features a tensile strength of 1218MPa and a specific elongation of 12.6%.

Owner:SHANGHAI JIAO TONG UNIV

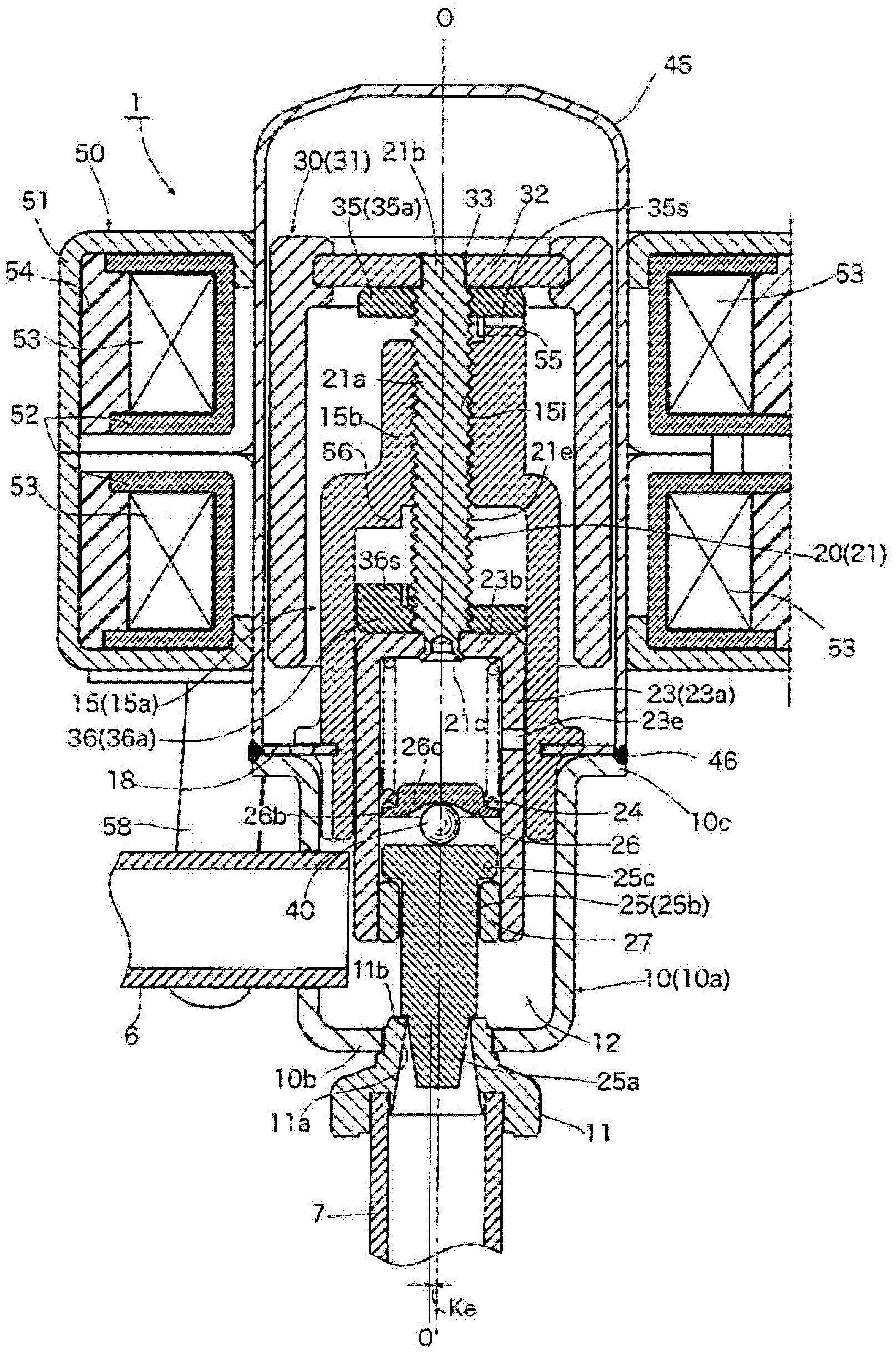

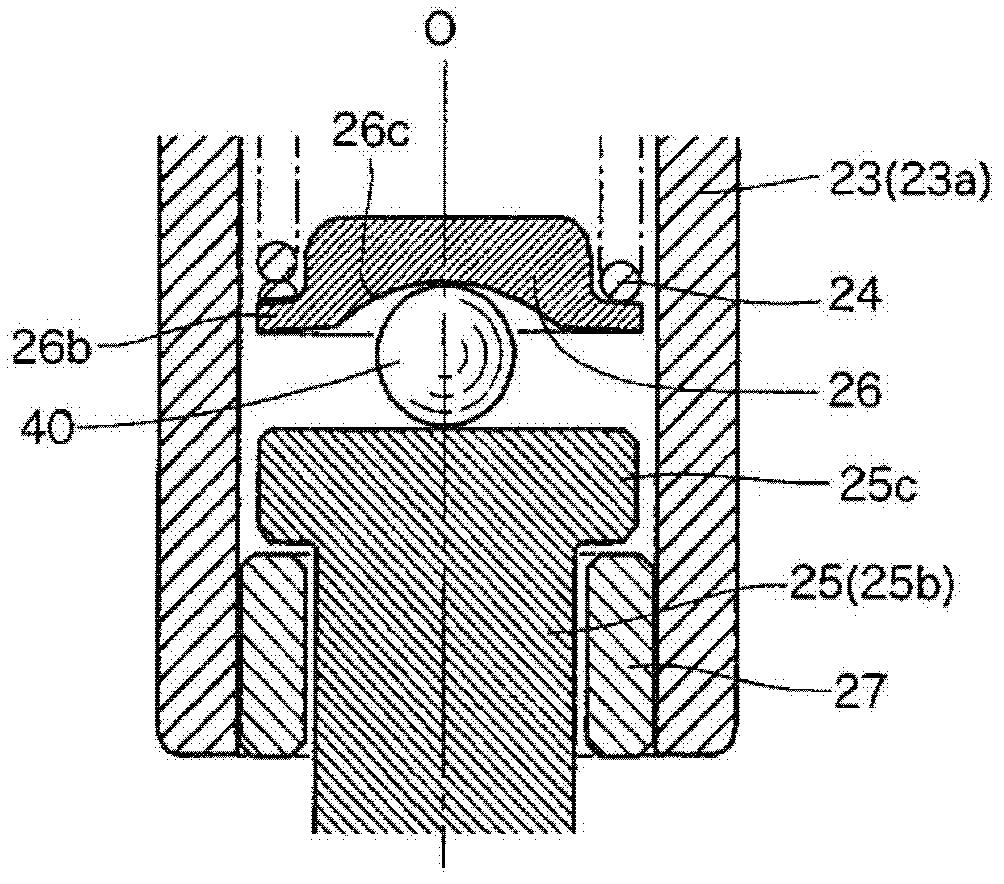

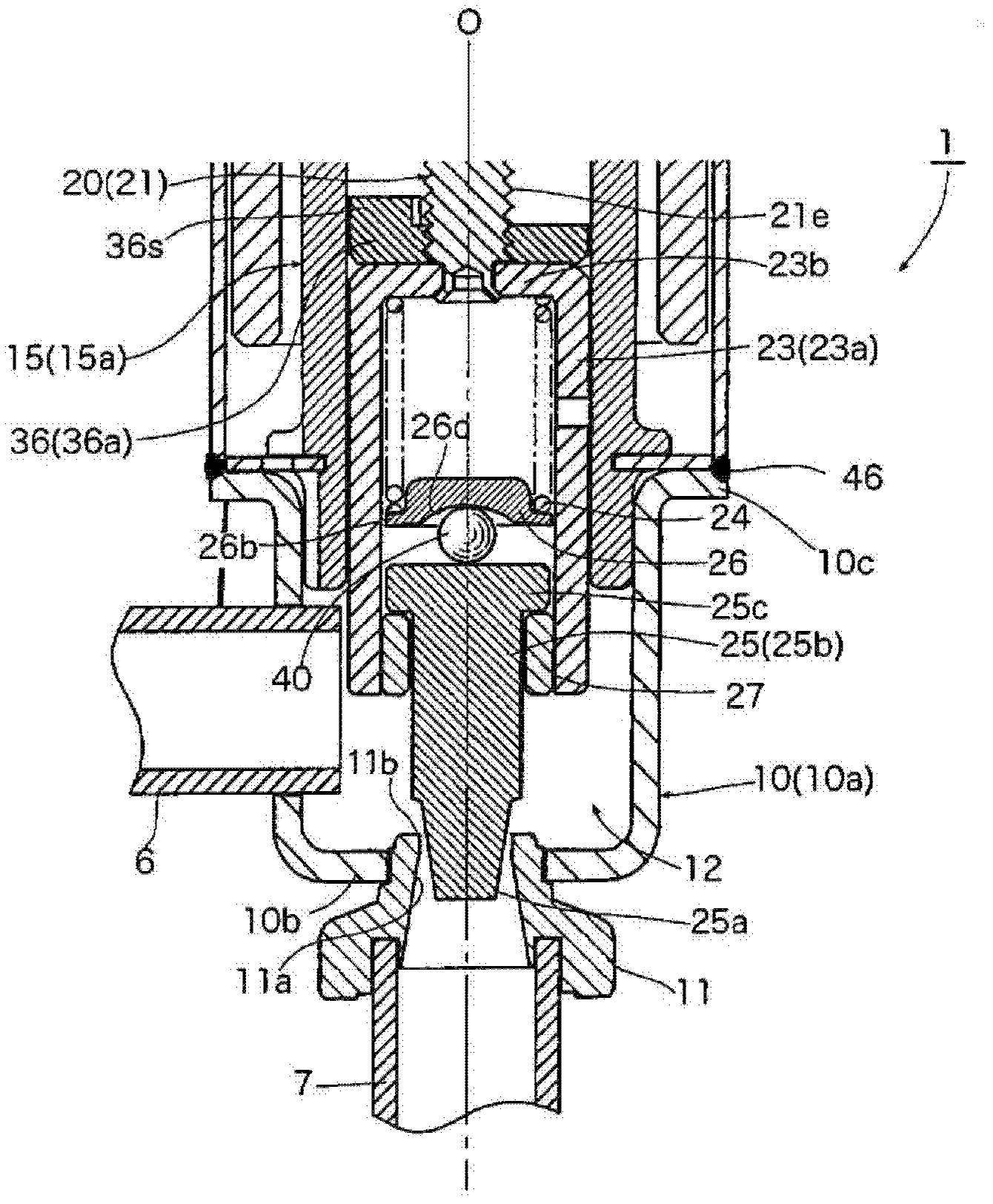

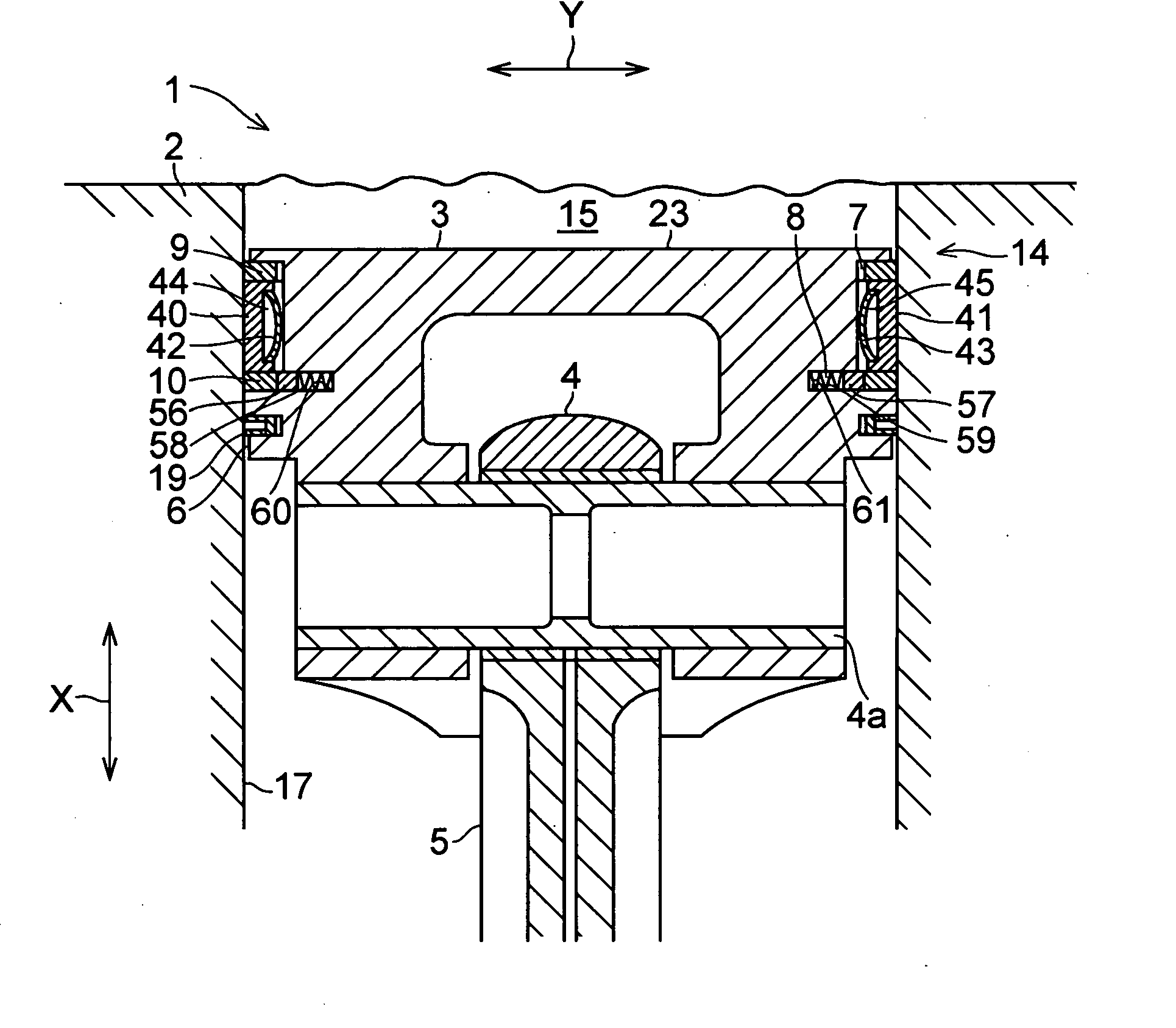

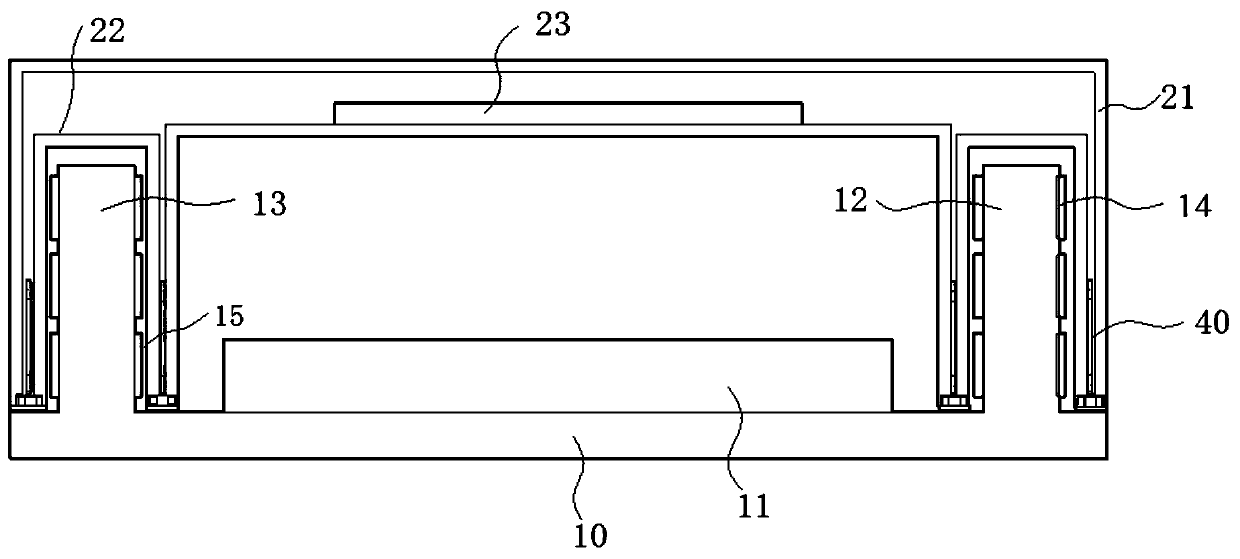

Electric valve

ActiveCN102650336AReduce sliding frictional resistanceImprove the problem of eccentricityOperating means/releasing devices for valvesLift valveEngineeringHelix

The invention provides an electric valve, which can be used to reduce the sliding friction resistance close to the compression spiral spring during the opening and closing of the valve possibly, even when the decentration of the compression spiral spring and the shaft deviation of the valve occur. A coiling end of a lower side of the compression spiral spring (24) is clipped by a spring supporting member (26), and a spherical-shaped object (40) having two parts and the spring supporting member (26) as well as the valve core (25) in a point-contact manner is disposed between the same two members. A concave part (26c) used for adjusting the valve core is formed by a spherical-shaped surface, an ellipsoid-shaped surface, and a cone-shaped surface. The deepest part of the concave part is disposed on an centre of the lower surface of the spring supporting member (26) approximately. By using the concave part (26c) used for adjusting the valve core and the spherical-shaped object (40), the sliding friction resistance can be reduced.

Owner:FUJIKOKI MFG CO LTD

Micro fine-grained titanium-nickel-niobium shape memory alloy block material preparing method

The invention is a manufacturing method for a kind of micron tiny crystal titanium nickel-niobium shape memorizing alloy block materials, 45%-50% titanium, 40%-45% nickel, 5%-10% niobium are melted and produced into titanium nickel-niobium alloy cast ingot, and cuts the titanium nickel-niobium alloy block material into blank, and carries on surface finish process, and paints with glass lubricate, uses isometric curved squeezing mould with 90-120 degrees channel angle, the mould cavity surface is painted with black lead lubricate, the blank and mould are heated and carries on temperature reservation, and takes them out to be squeezed at the same time, finally gets the product. The invention solves the problem that the bad plastic property of titanium nickel-niobium shape memorizing alloy in room temperature, enhances the alloy mechanical performance, and lowers the cost.

Owner:SHANGHAI JIAO TONG UNIV

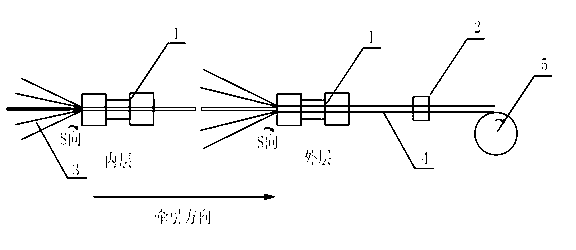

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437AReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

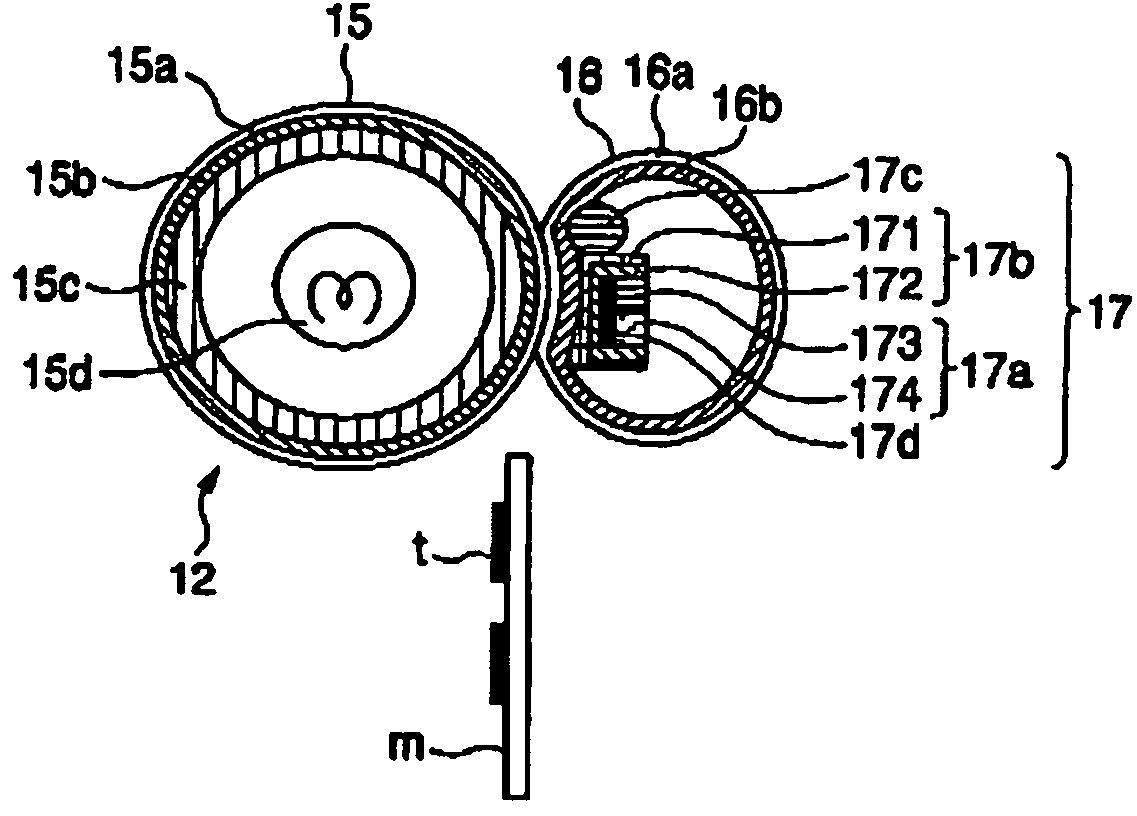

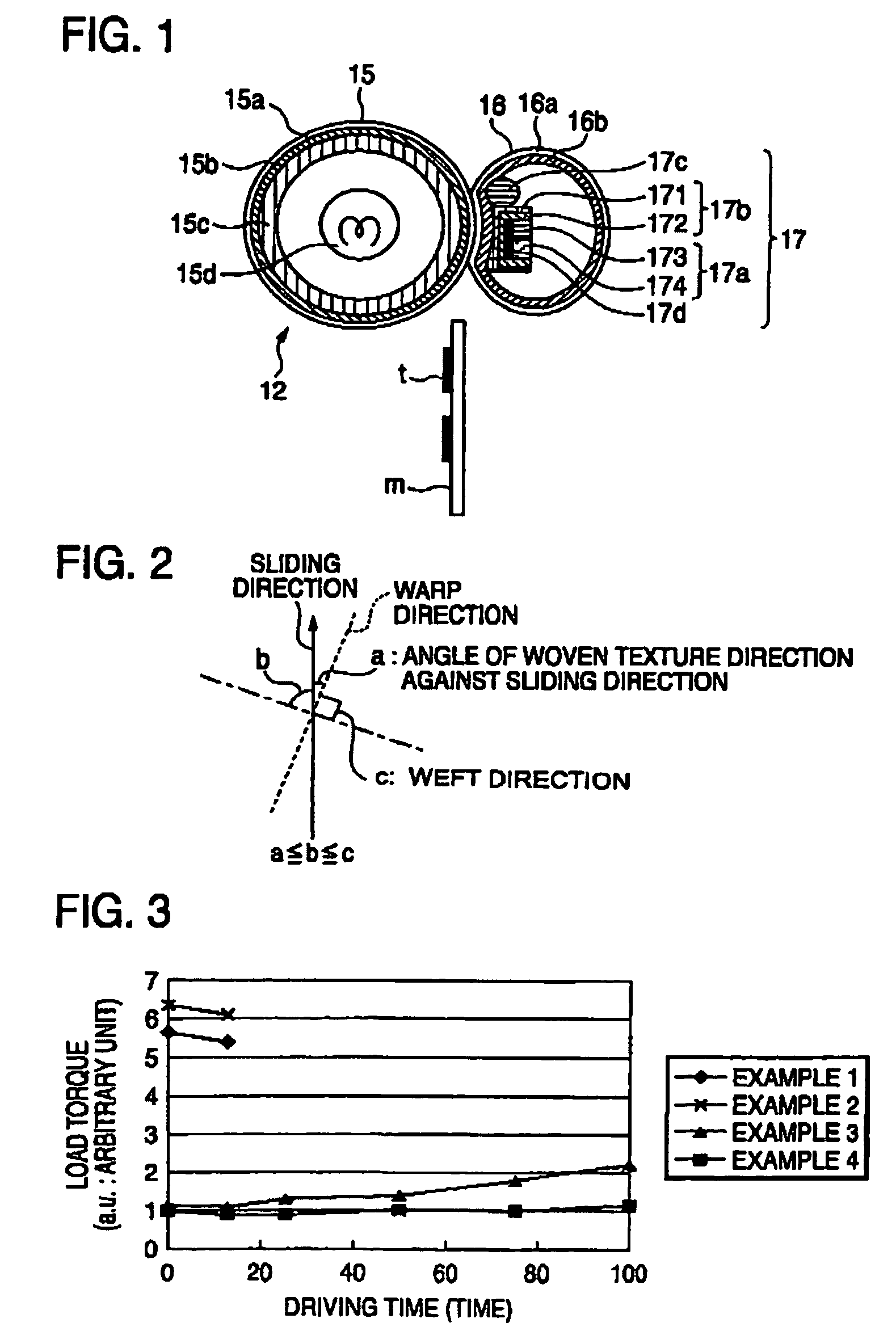

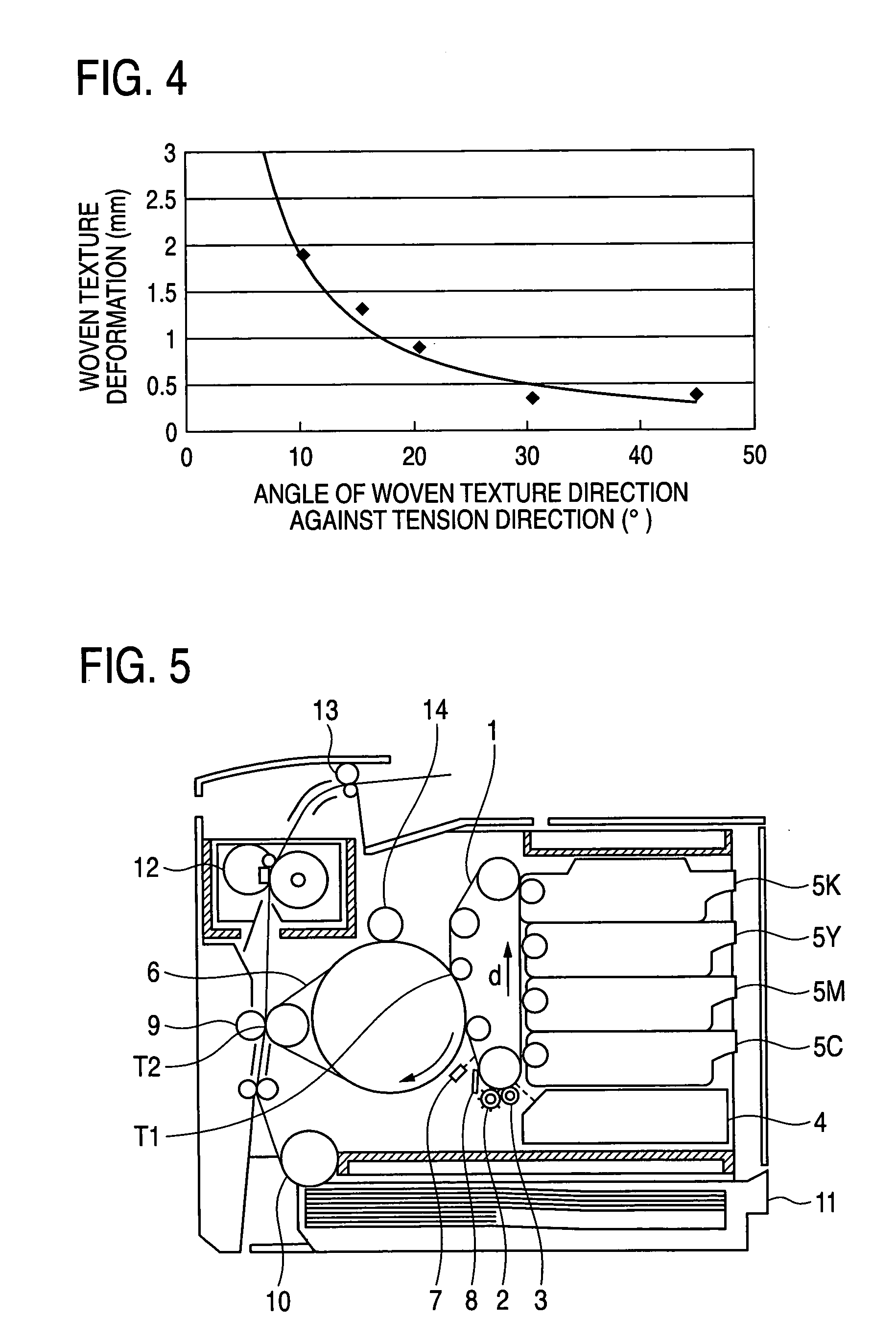

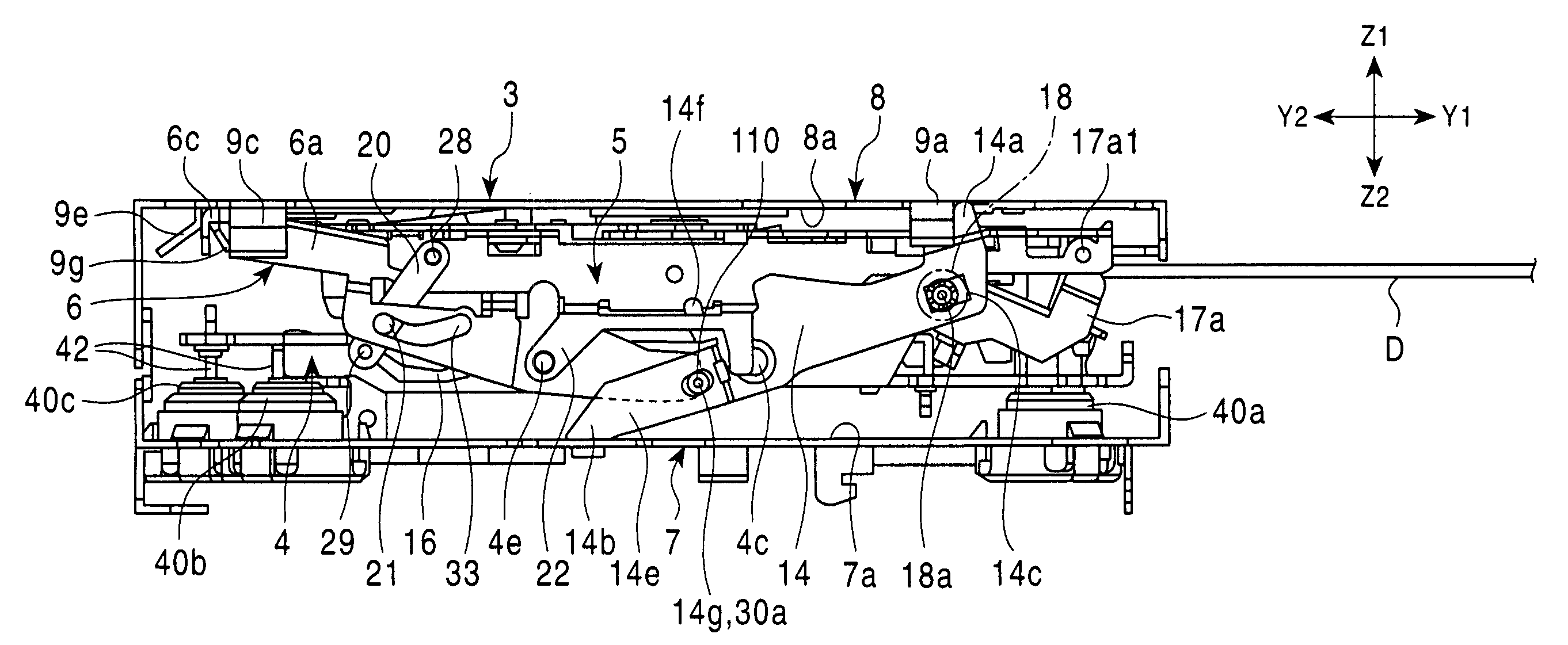

Fixing device and image forming apparatus

InactiveUS7142803B2Reduce sliding frictional resistanceMaintain good propertiesOhmic-resistance heatingElectrographic process apparatusImage formationEngineering

A fixing device includes a roller; an endless belt which is in contact with the roller and rotates with a circulation of the roller in a follower manner; a heating source in at lease one of an inside of the roller and an inside of the endless belt; and a pressure-applying member which is inside the endless belt and presses the endless belt against the roller. A sliding layer is provided on a side on which the pressure-applying member is in contact with the endless belt, and the sliding layer comprises at least two layers and holds a lubricant.

Owner:RICOH PRINTING SYST

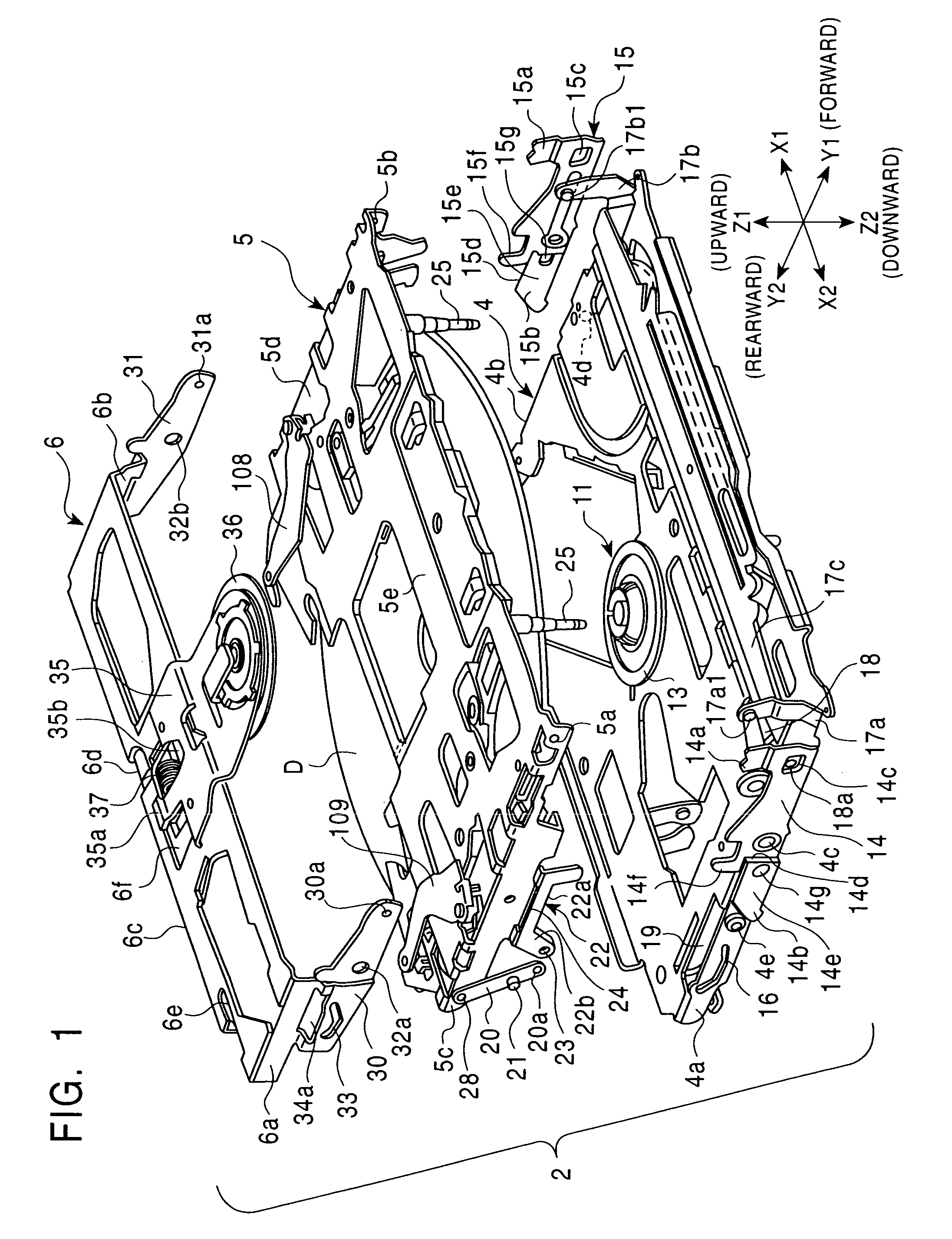

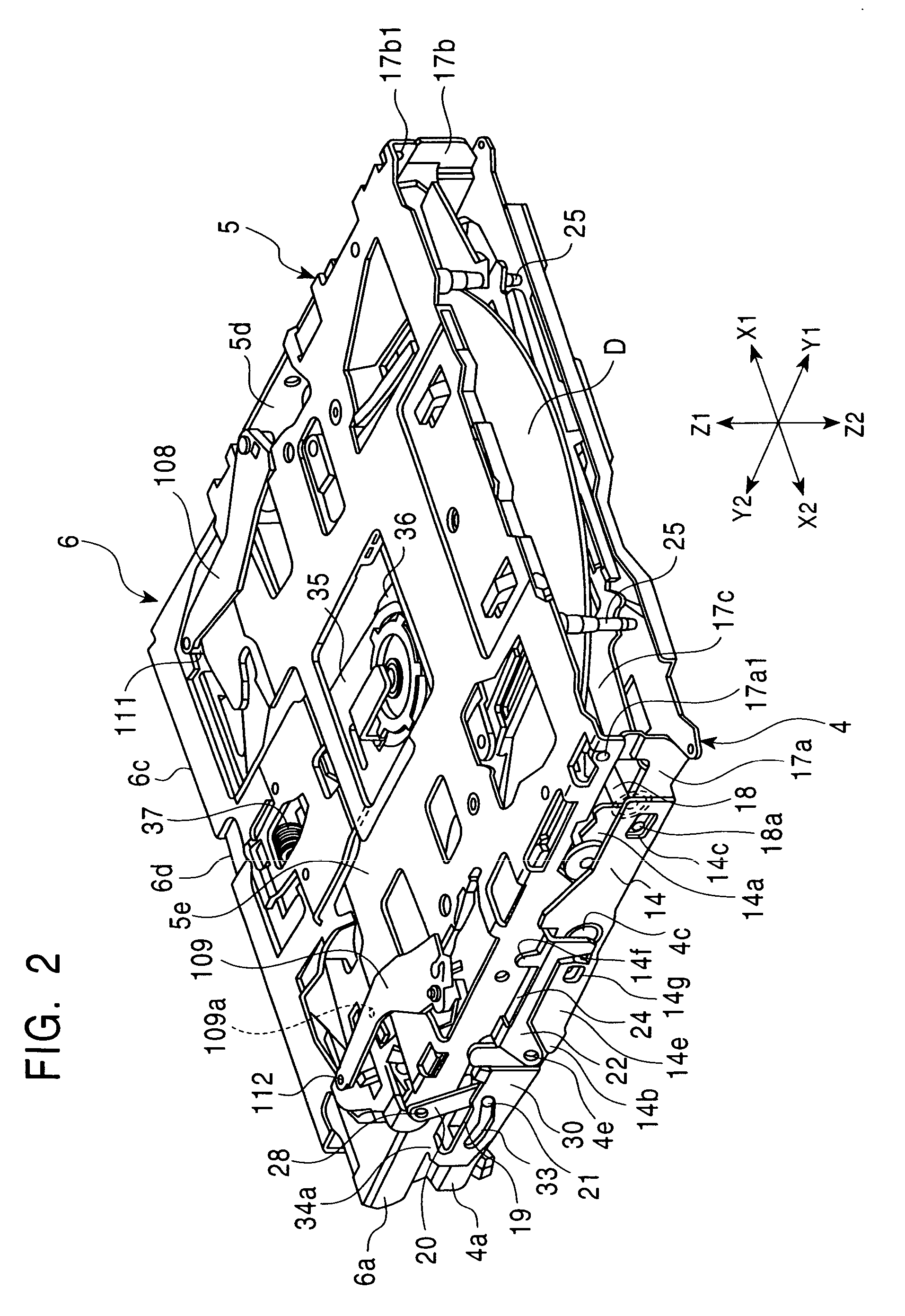

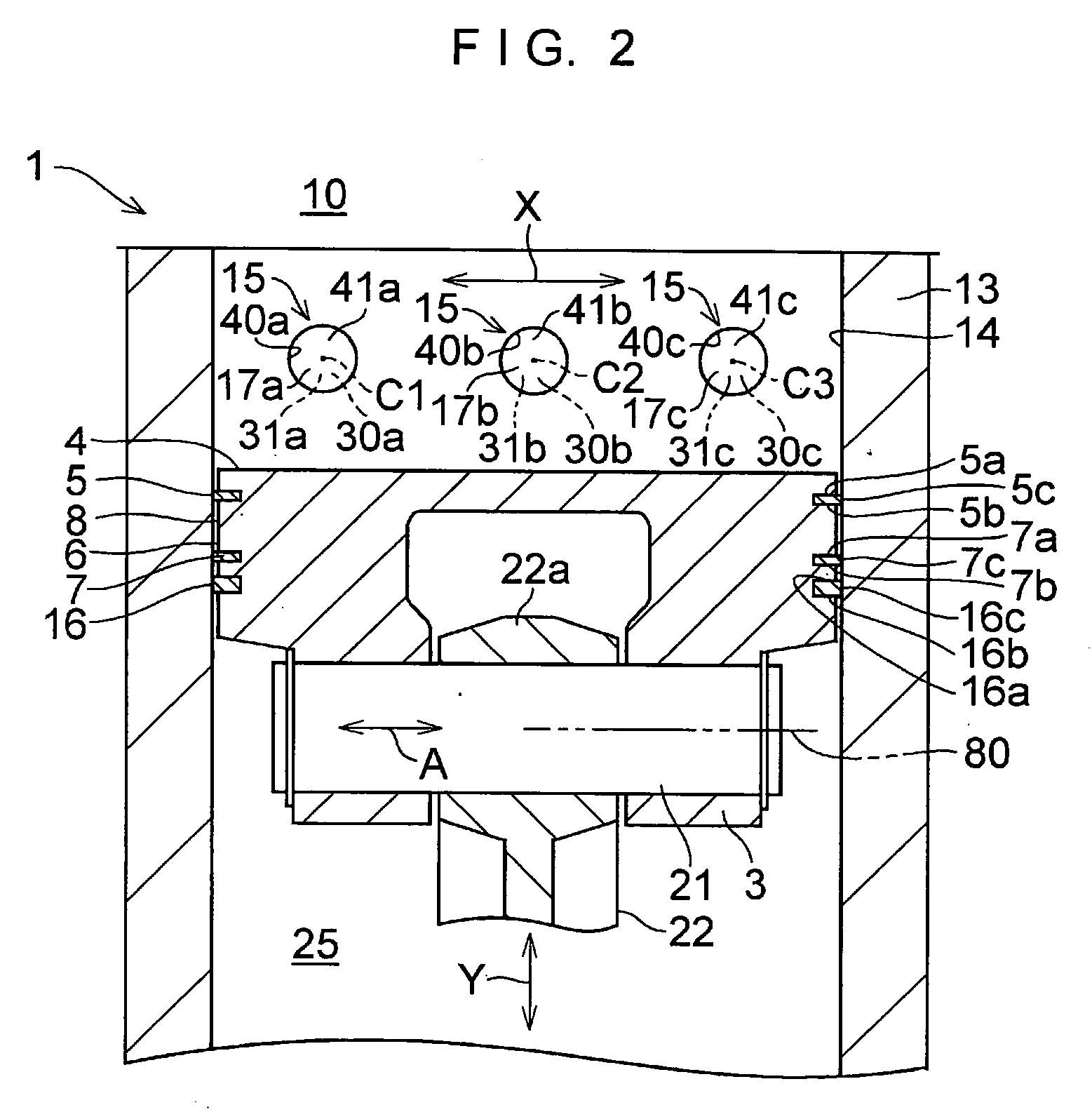

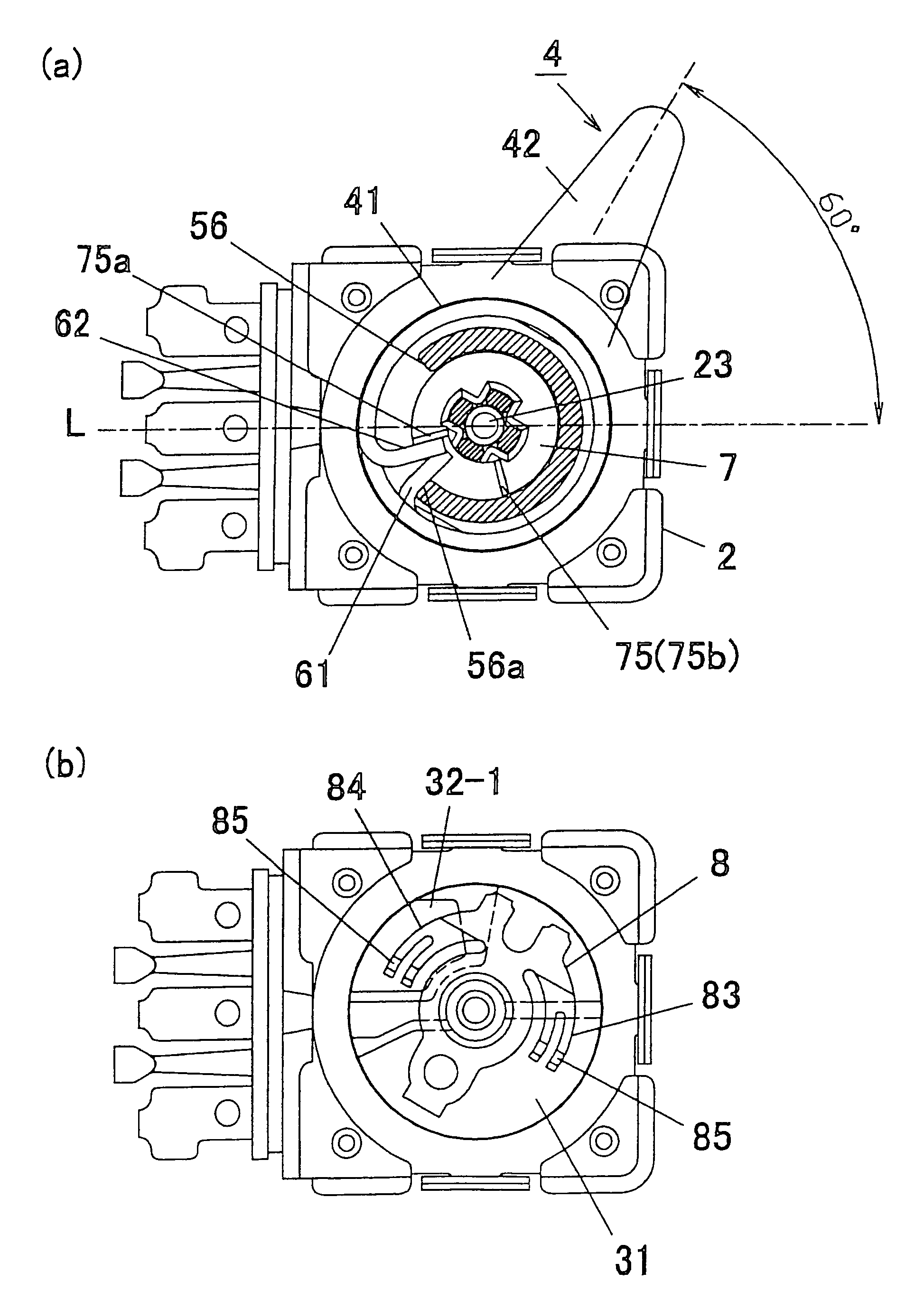

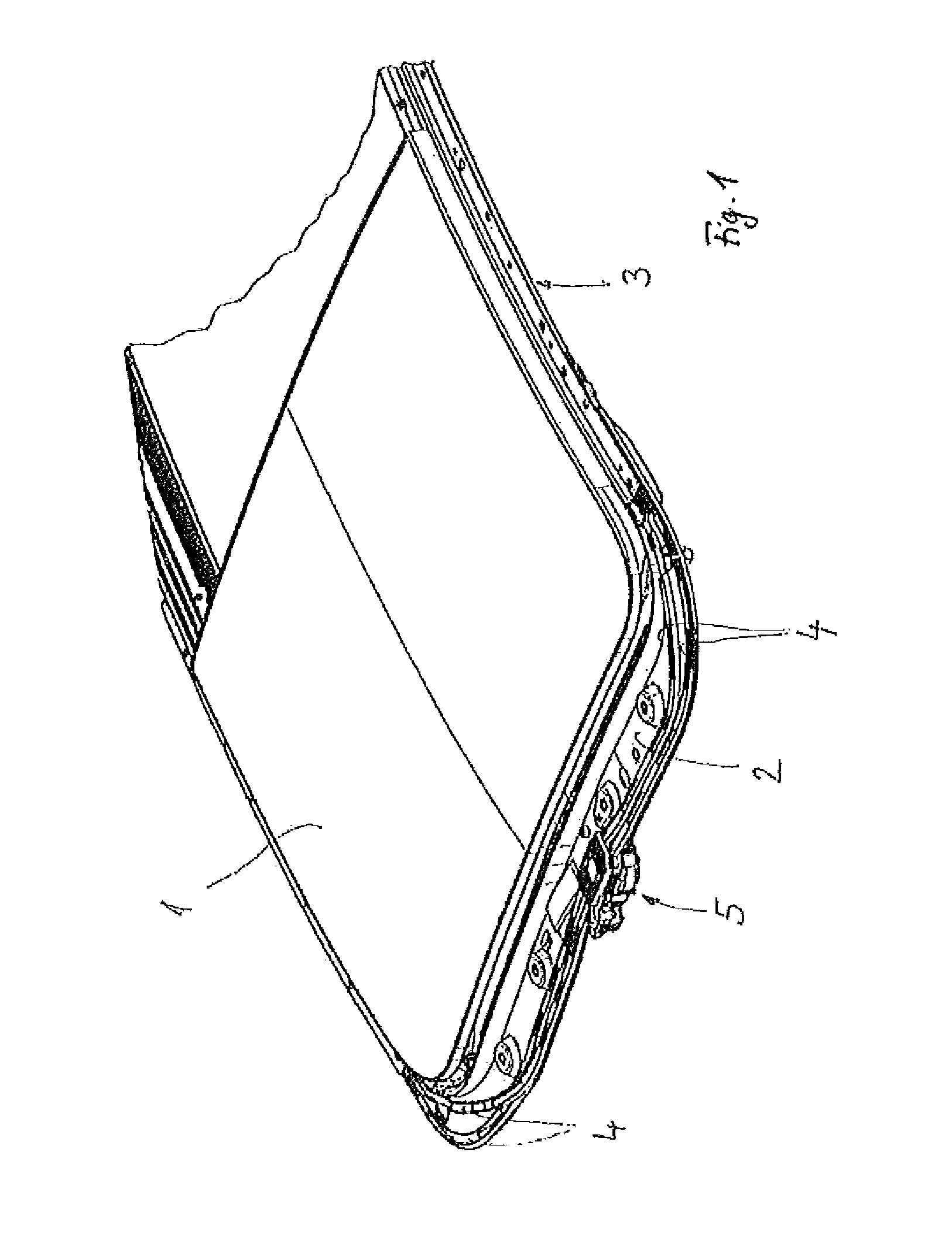

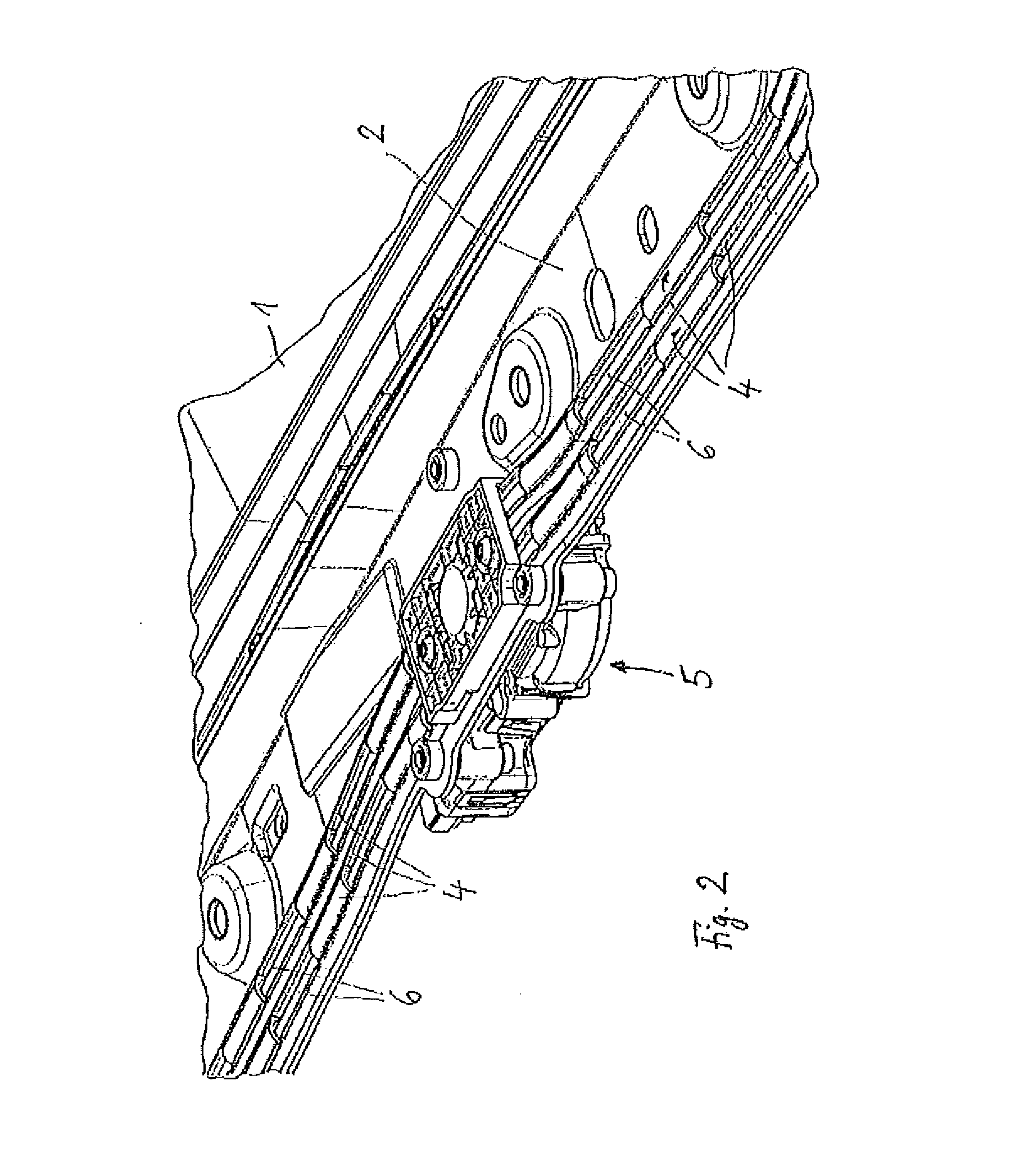

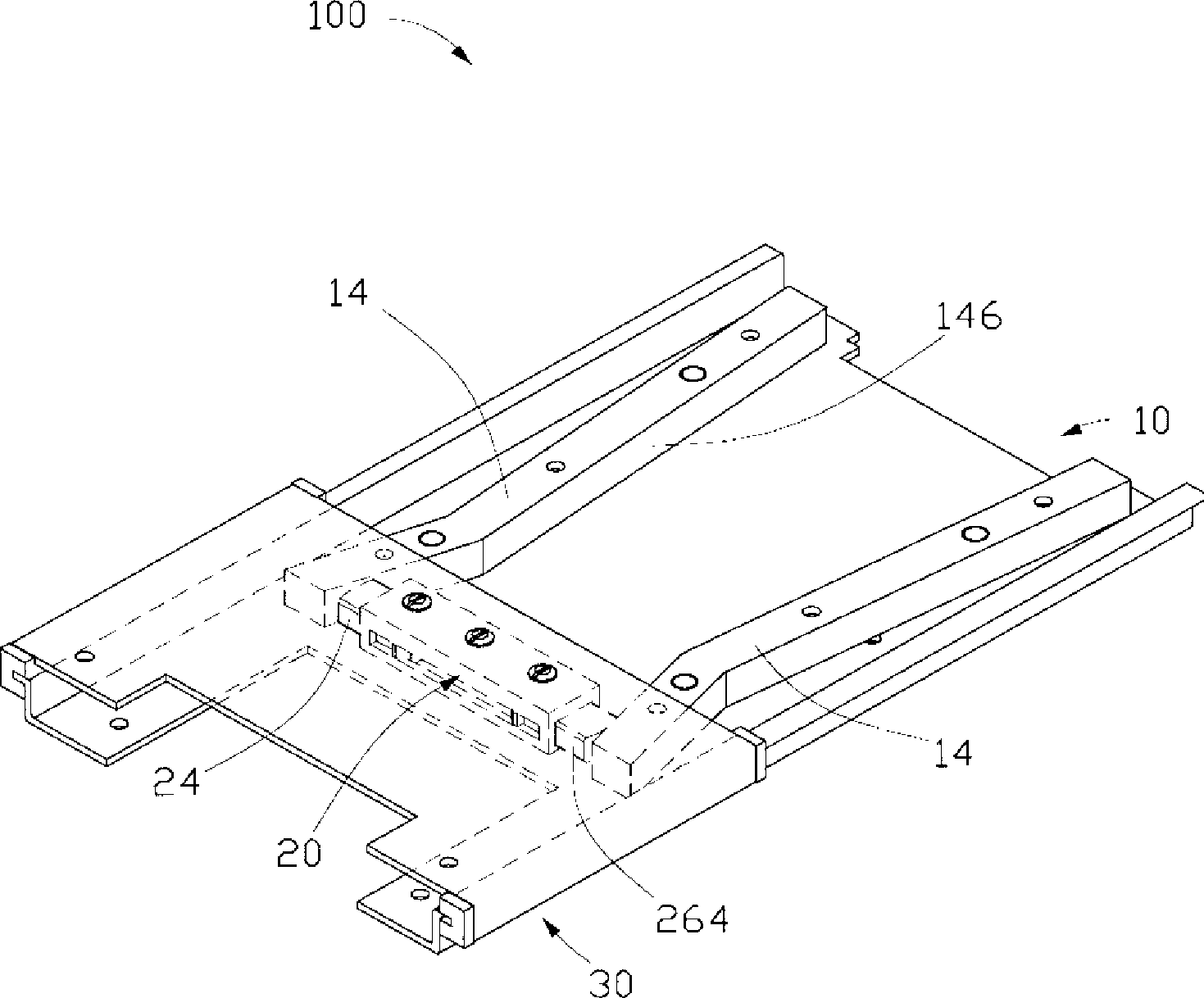

Disk device with clamp mechanism, attitude set-up member and conveying mechanism

InactiveUS7107603B2Reduce loadReduce sliding frictional resistanceRecord information storageRecording on magnetic disksEngineeringMechanical engineering

Owner:ALPINE ELECTRONICS INC

Constant diameter right-angle extruding production of micro/nanometer crustal industrial pure titanium block

An isometric angle squeezing technology for preparing micron / nano-crystal industrial-purity Ti block includes such steps as providing an industrial-purity Ti block, annealing, holding its temp, cutting it to become blanks, polishing the surface of blank, coating glass lubricant, coating graphite lubricant on the inner surface of an isometric angle squeezing die with a squeezing channel angle of 90-120 deg, heating said blank and die, and isometric angle squeezing. Its product has high strength, plasticity, biocompatibility and anticorrosion nature, the elastic modulus similar to that of bone, and low cost.

Owner:SHANGHAI JIAO TONG UNIV

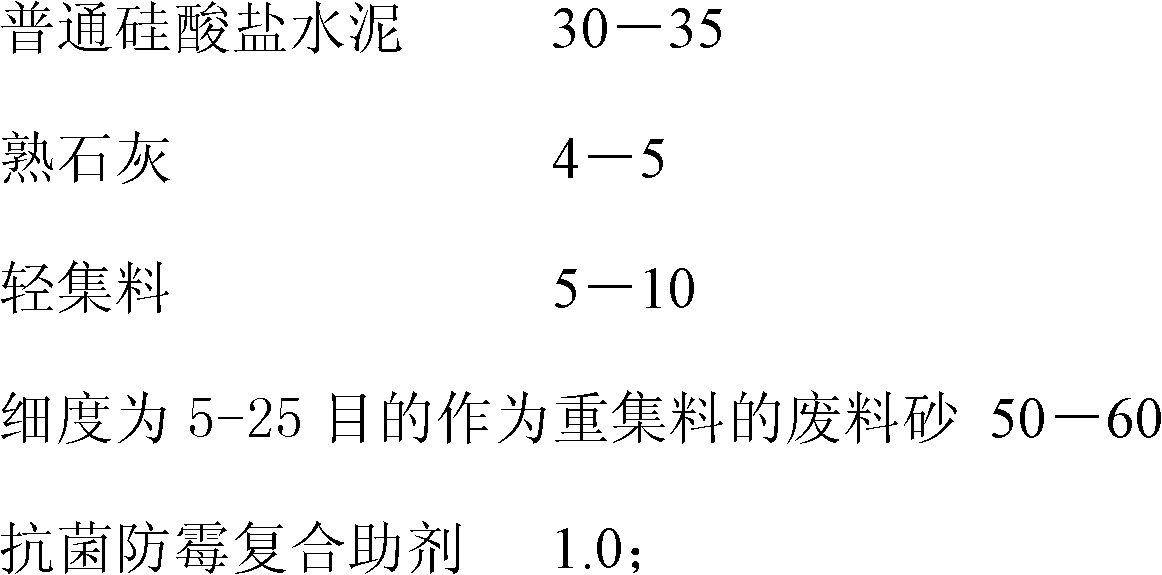

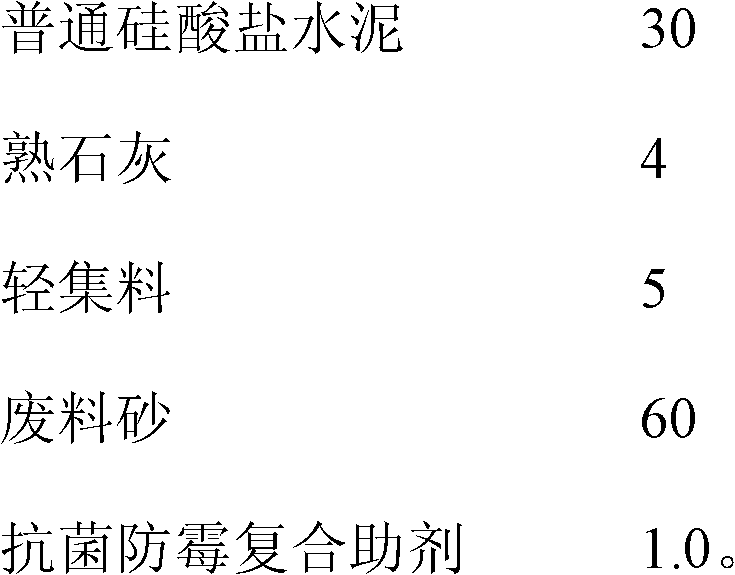

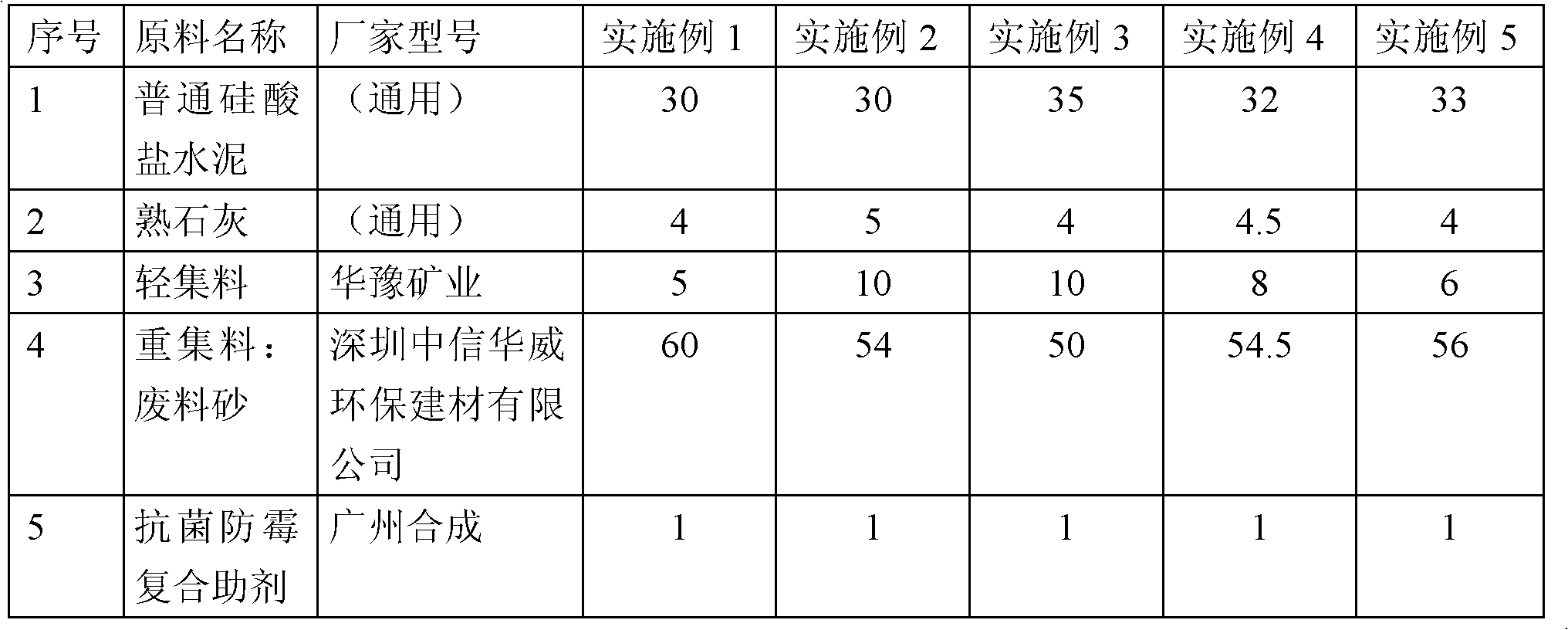

A kind of interior wall plastering mortar and its construction method

A mixed mix of a lightweight inner wall was mixed with the following weight ratio: 30-35 of ordinary silicate cement; 4-5 cooked lime; 5-10 light materials; 5--fineness is 5--The 25th purpose is 50-60 waste sand for heavy materials; 1.0 antibacterial and mold-proof composite agent provided by Guangzhou Synthetic Trade Company, 0.4 kg of antibacterial mold and mold per kilogram, 0.1 kg of water retention, 0.3 kg of diversified latex powder and diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and diversified latex powder and 0.3 kg of diversified latex powder and divergent latex powder and 0.3 kg of divergent latex powder.The composition of the air induction agent is mixed with 0.2 kg; the light collection is the fine -grade -based inorganic vival and short -hole material below 100 destinations.The diluted weight ratio during construction is the inner wall plastering mortar: water = 100: 30-50.The mortar uses waste sand in the construction waste as the mortar. It uses materials to recycled, and the crack resistance is good.The adhesion intensity meets the requirements. It can be used with lightweight walls to prevent air drums, cracking, falling off, and ensuring the quality of the project; low unit area cost; can reduce mold and bacterial breeding.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Micron fine-grained titanium-nickel alloy block material isodiametric corner extrusion preparing method

InactiveCN1528940AReduce temperature dropReduce sliding frictional resistanceMechanical propertyNickel based

The invention is an isometric angle squeezing producing method for a kind of micron tiny crystal titanium nickel alloy block materials. Titanium and nickel whose atom percentage are 45%-52% and 48%-55% are melted in vacuum, produces the titanium nickel base alloy cast ingot, cuts the block materials into blanks, and carries on surface finish process, and paints with glass lubricate, uses squeezing mould with 90-120 degrees angle, the surface of mould cavity is painted with black lead lubricate, the blank, mould are heated, and they are taken out from the stove and carried on with angle squeezing, finally acquires the titanium nickel base alloy block materials with excellent intensity and plasticity. The invention enhances the mechanical property of alloy, and reduces the cost.

Owner:SHANGHAI JIAO TONG UNIV

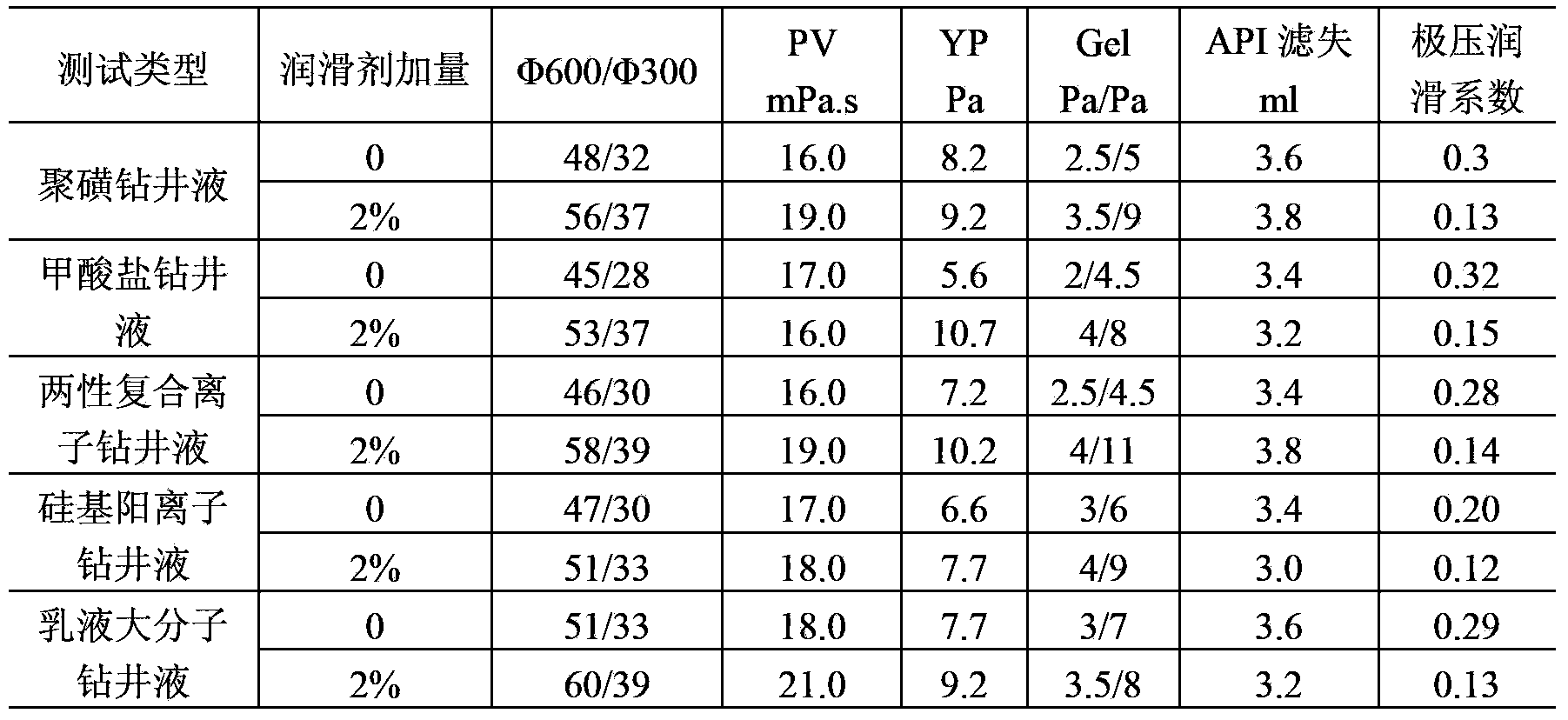

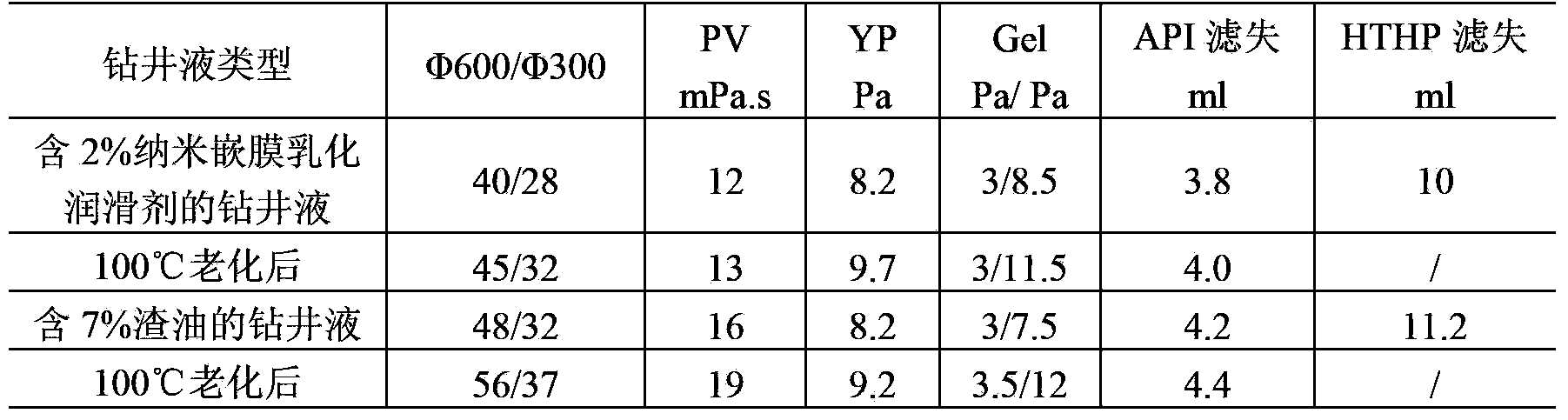

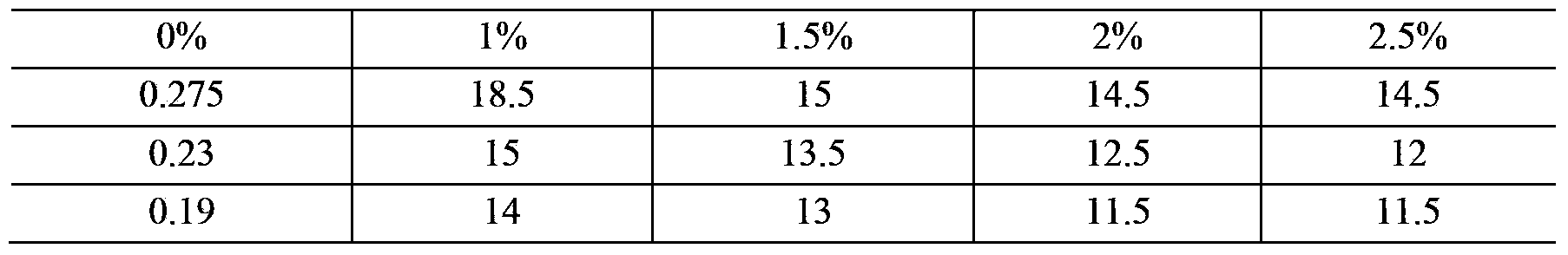

Nano film-embedded emulsion lubricant

ActiveCN103436241AImprove the lubrication effectReduce sliding frictional resistanceDrilling compositionAlkalinityEmulsion

The invention relates to a nano film-embedded emulsion lubricant and mainly solves the problems about high frictional resistance of a horizontal well, serious backing pressure and poor lubricating effect of drilling fluid. The nano film-embedded emulsion lubricant comprises the following components in percentage by weight: 10 to 30 percent of modified paraffin, 3 to 11 percent of a compound emulsifier, 0.5 to 3 percent of an alkalinity modifier, 0.5 to 2 percent of nano graphite powder and the balance of water. The nano film-embedded emulsion lubricant provides an emulsion lubricant which has low fluorescence, is provided with a nano ball material and has capability of forming an anti-adhesion lubricating film between the stratum and a drilling tool; a prepared drilling fluid system has a good lubricating property; a mud cake is fine; the filter loss is low; the class of florescence is low; the nano film-embedded emulsion lubricant has excellent thermal stability and cold-resisting stability; drilling efficiency of the horizontal well is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

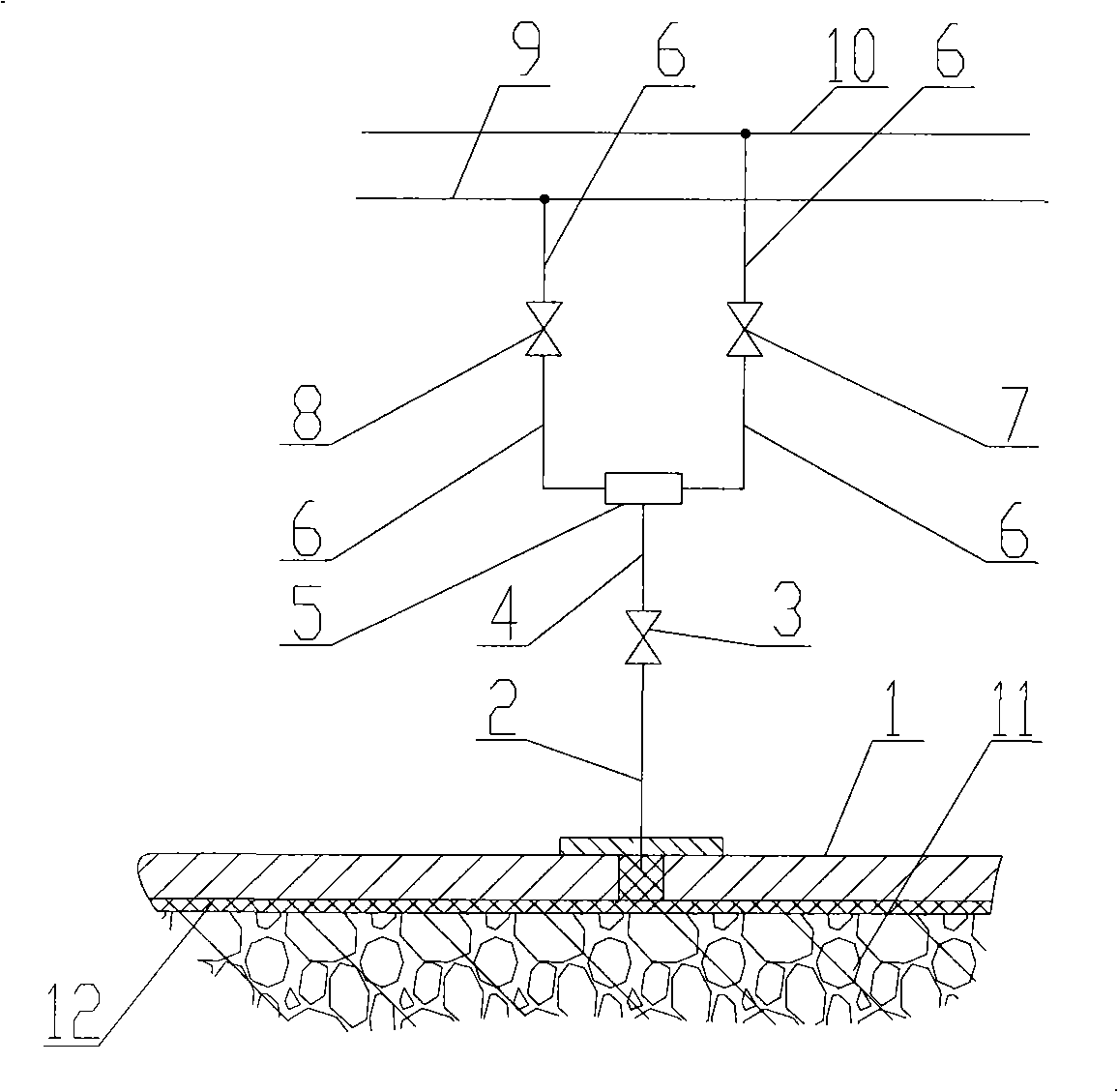

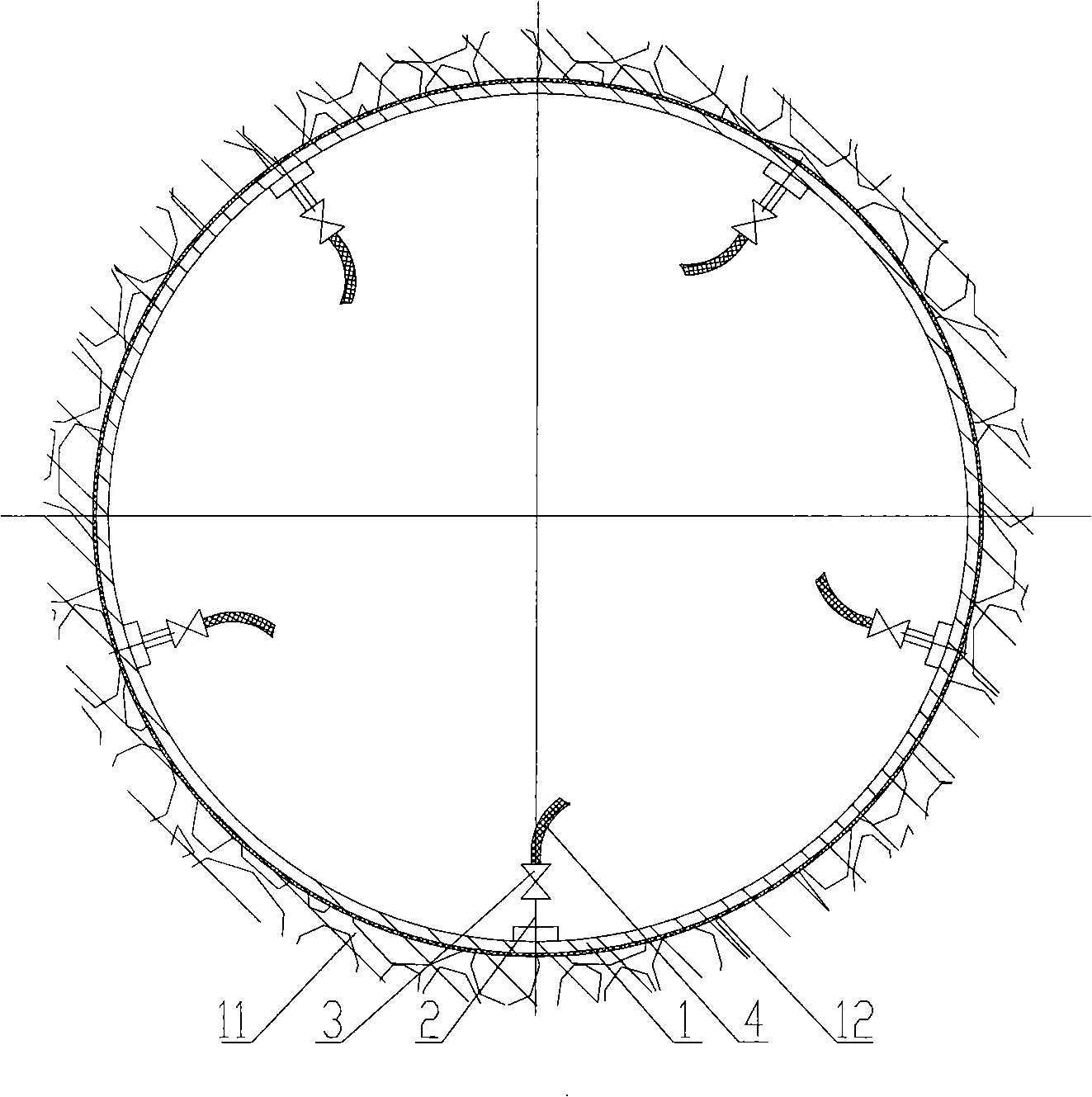

Apparatus for reducing friction resistance between shield machine shield body and tunneling wall

InactiveCN101298837AReduce frictional resistanceReduce sliding frictional resistanceTunnelsTunnel wallEngineering

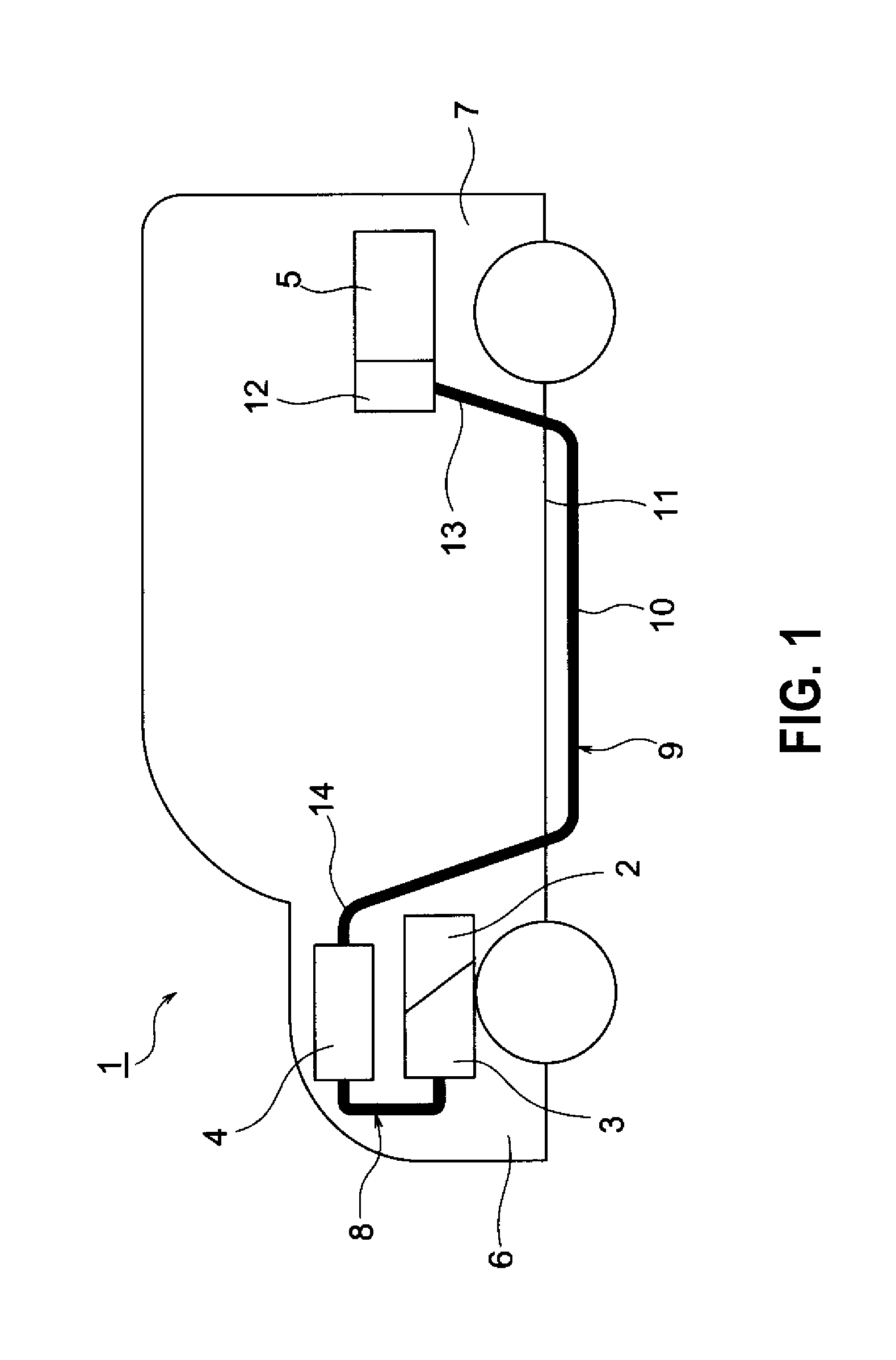

A device for reducing the frictional resistance between the shield machine shield body and tunneling wall applied in the technical field of tunnel driving; the device comprises shield body, steel pipe, valve, lubricant pipeline, distributor, pipeline, first control valve, second control valve, foam system pipeline, bentonite slurry system pipeline, tunnel wall and lubricant; one end of the valve is connected with the steel pile welded in the inside of the shield body and communicated with the tunneling wall; the other end of connected with the lubricant pipeline; the lubricant pipeline is communicated with the foam system pipeline and bentonite slurry system pipeline of the shield machine through the distributor, pipeline, first control valve and second control valve; the steel pipe is communicated with the tunneling wall through the hole of the shield body; the lubricant is injected between the tunnel wall and the shield body; when needs to injecting the lubricant, the valve is opened to inject the lubricant between the shield body and the tunneling wall. The conception of the device is novel and scientific; the device for injecting the lubricant between the shield body and the tunneling wall is able to effectively reduce the sliding friction resistance between the shield body and tunneling wall.

Owner:SHENYANG HEAVY MACHINERY GROUP

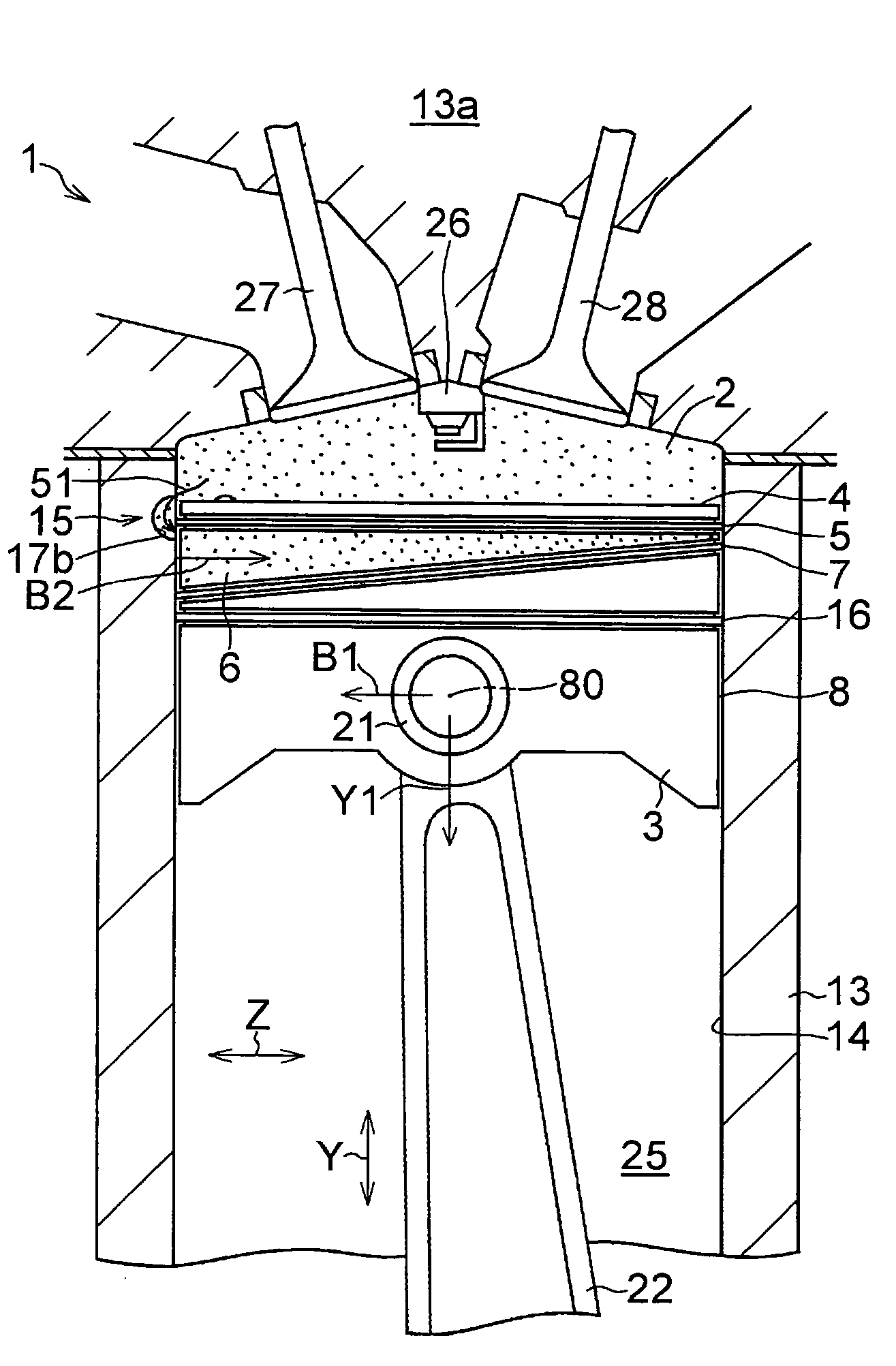

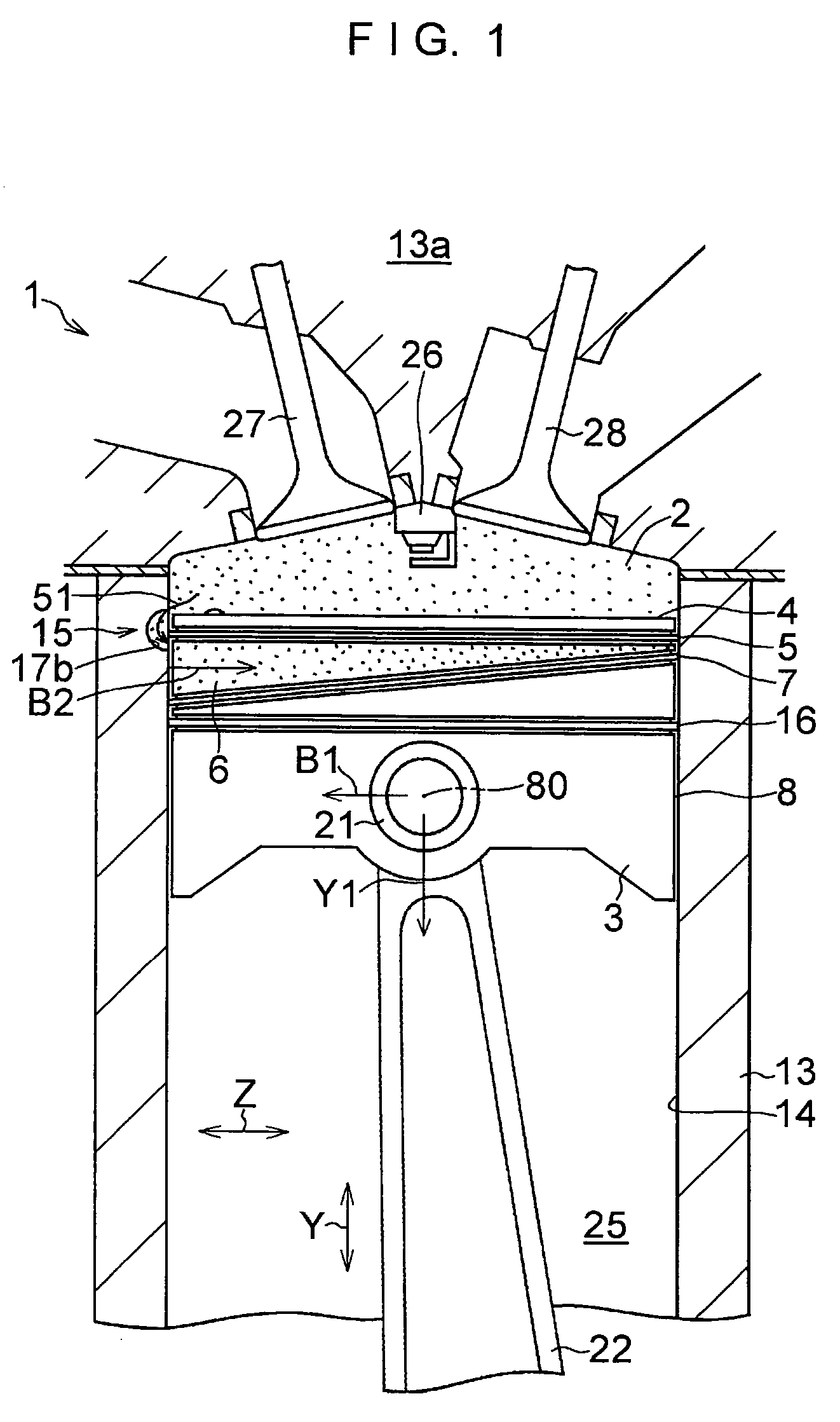

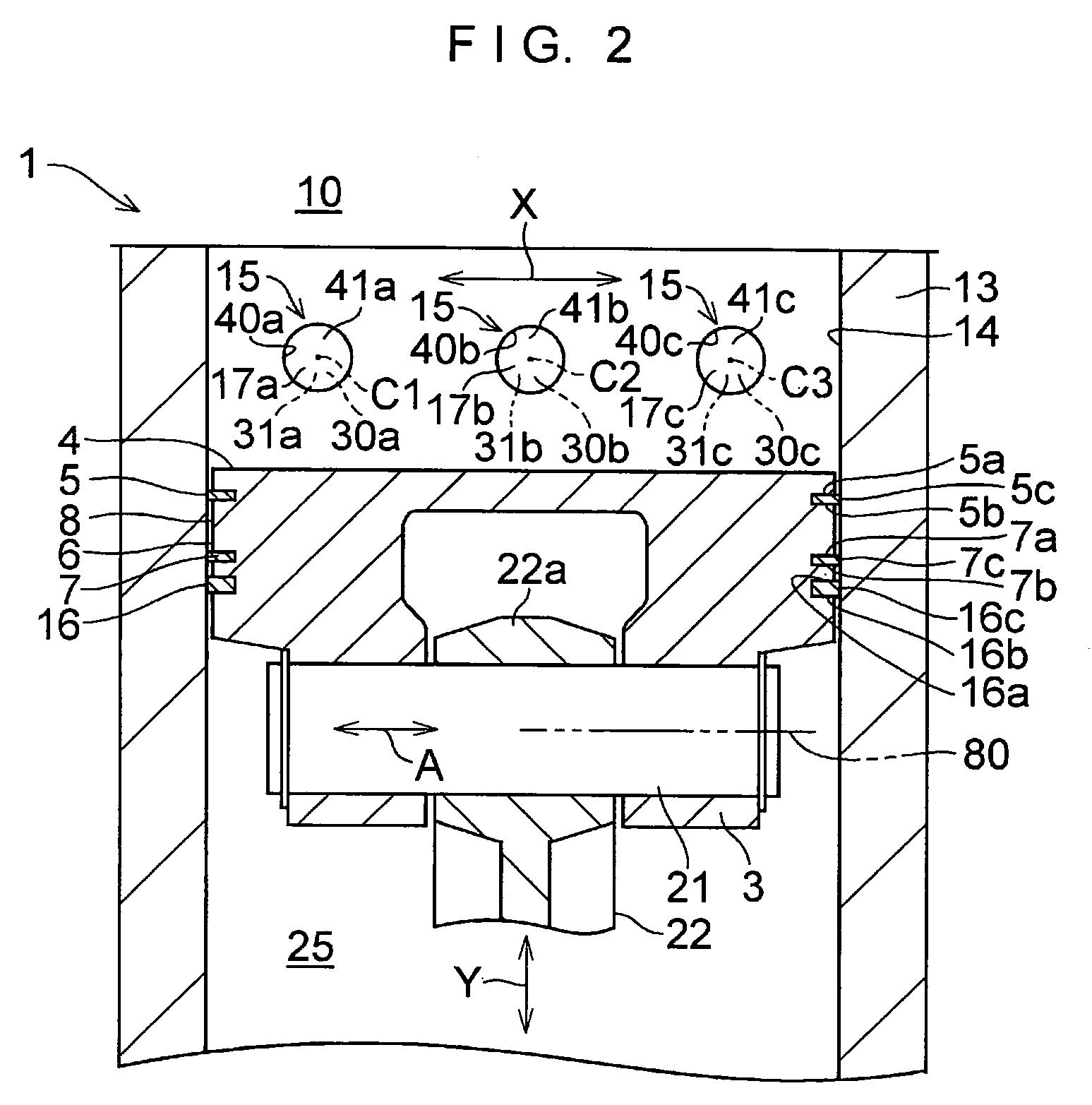

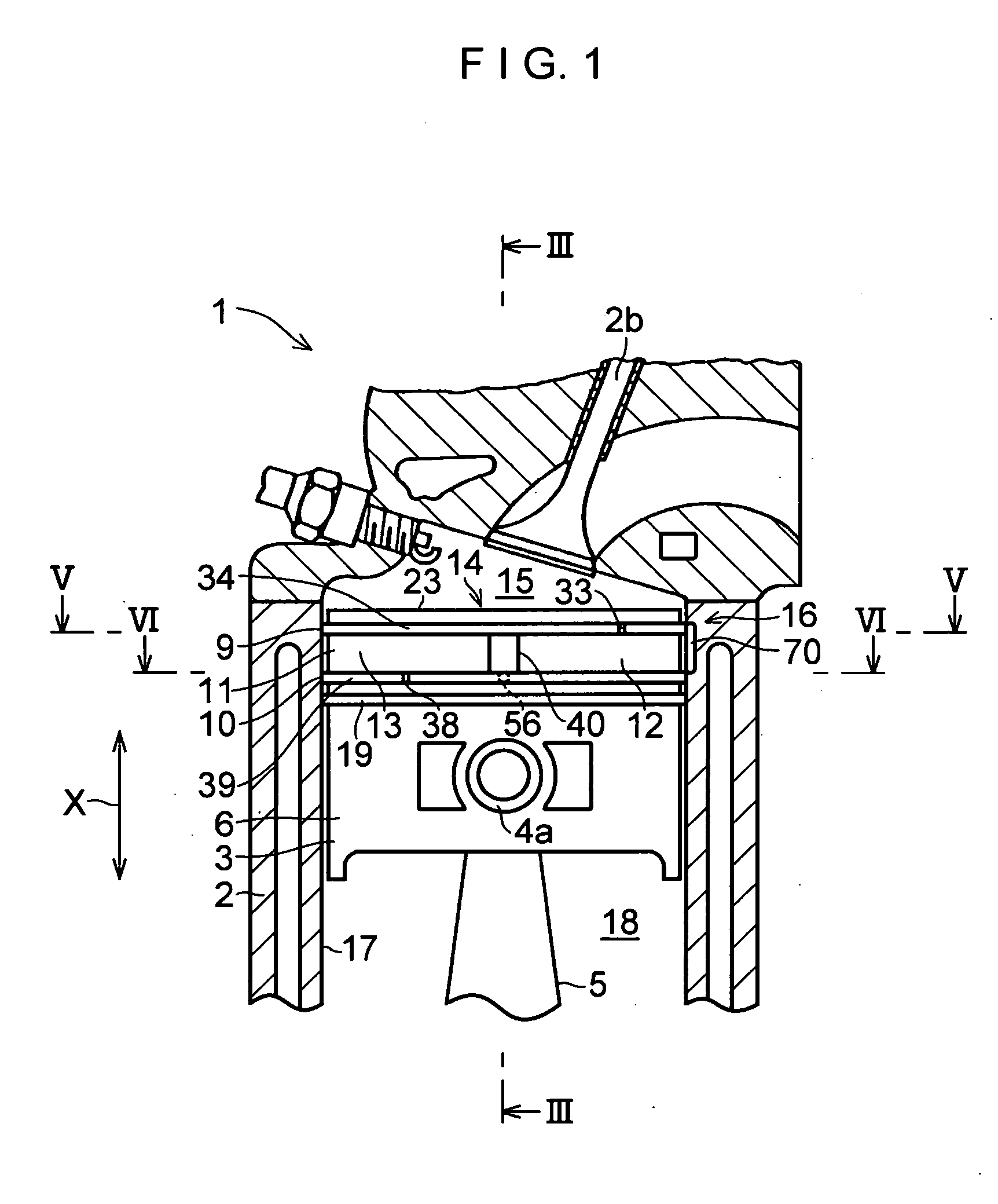

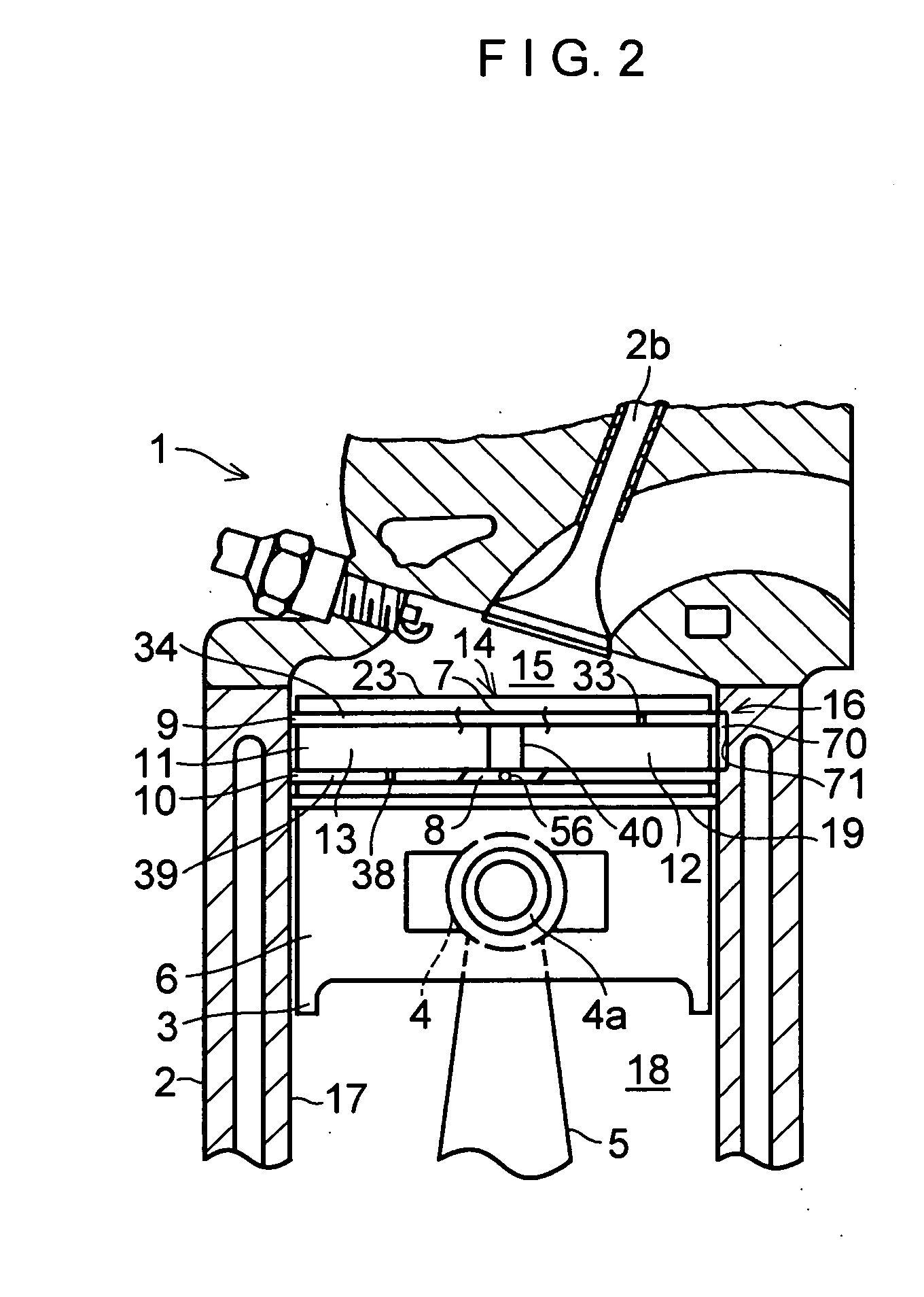

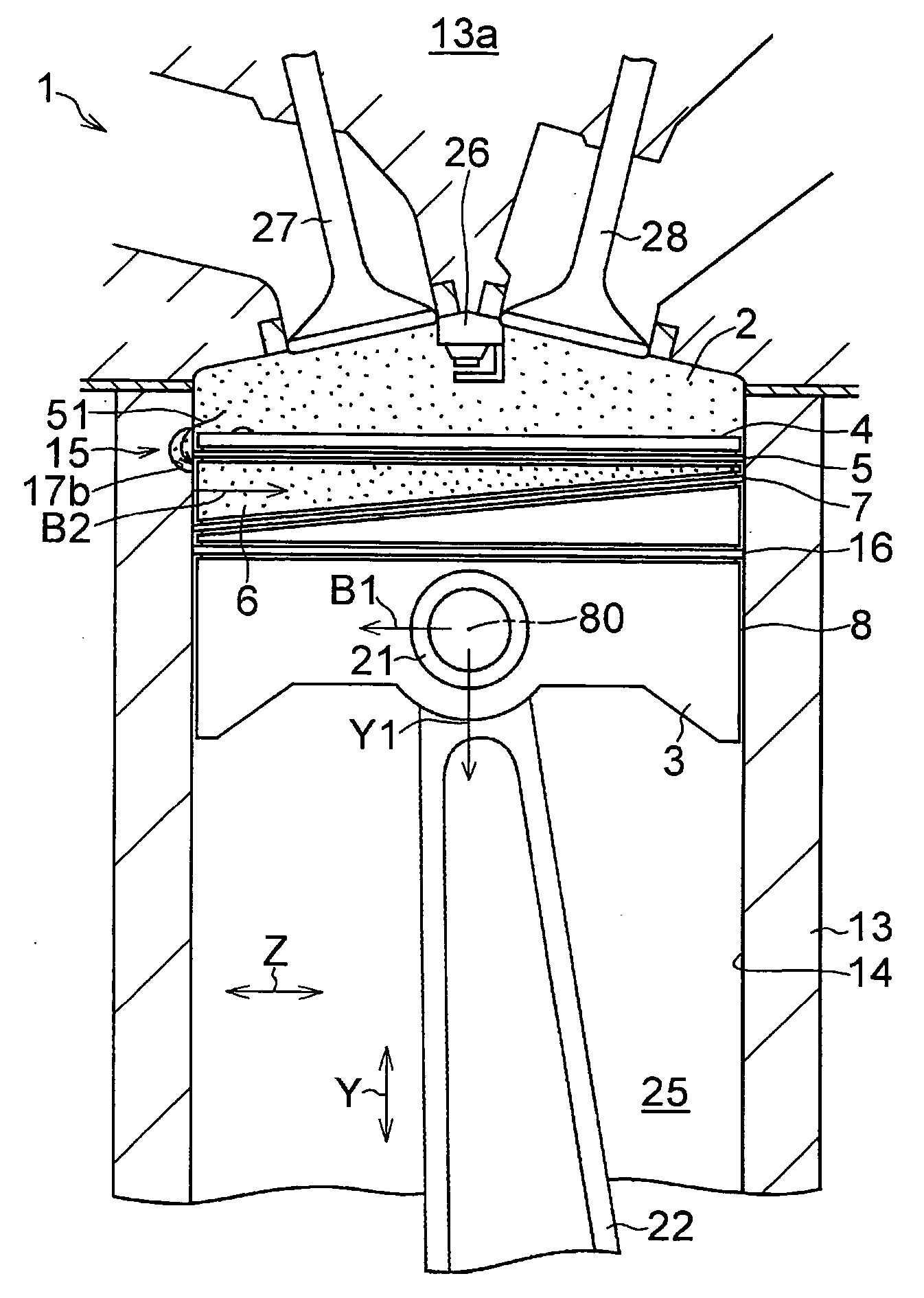

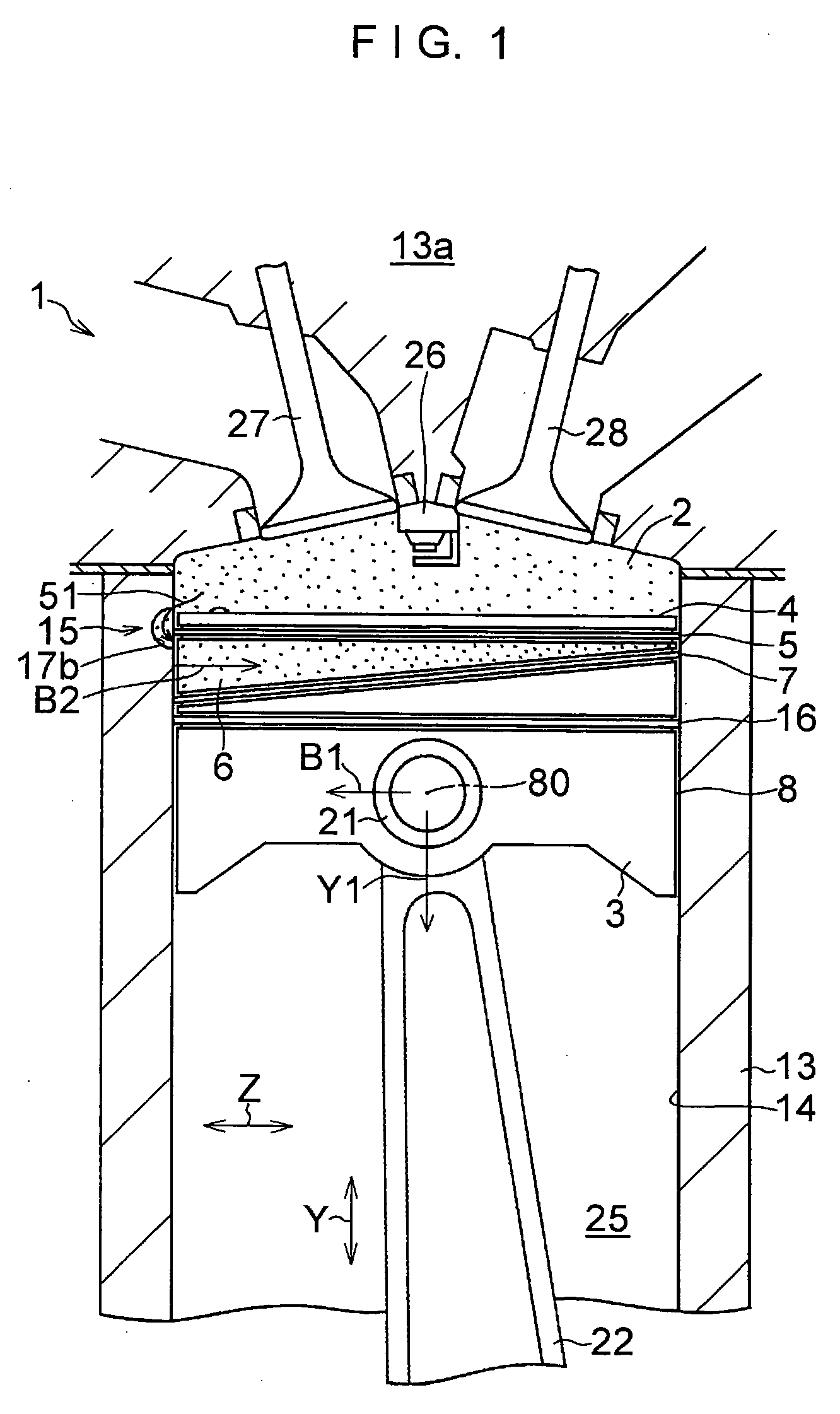

Reciprocating engine

InactiveUS7464683B2Reduce sliding frictional resistanceEliminate distractionsPiston ringsPlungersCombustion chamberPiston ring

A reciprocating engine comprises: a piston ring; a piston ring which defines an annular gas chamber in cooperation with the piston ring and which is adjacent to the piston ring such that a pressure-receiving area of a side surface of a piston in the annular gas chamber becomes greater on a thrust side than on a counter-thrust side of the piston; and gas passages for allowing the annular gas chamber to communicate with the combustion chamber.

Owner:BANDO KIKO CO LTD

Preparation method of aluminum alloy with excellent comprehensive property

InactiveCN103060730AImprove mechanical propertiesImprove tribological performanceMechanical propertyLubricant

The invention discloses a preparation method of an aluminum alloy with excellent comprehensive properties. The preparation method comprises the following steps of cutting the aluminum alloy in the cast state, rolled state or forged state into a blank, wherein the cross section of the blank can be cut into a circular shape or a square shape according to practical demands; carrying out surface machining treatment on the blank; coating a lubricant on the surface of the blank; carrying out equal channel corner extrusion treatment by using an equal channel corner extruding die which is accordant to the cross section of the blank in shape; after each extrusion treatment, carrying out the surface machining treatment again on the surface of the blank; after more than four times of the equal channel corner extrusion treatment, cleaning the surface of the blank; carrying out surface laser fusing treatment, wherein working parameters in the surface treatment can be changed through the laser fusing treatment according to practical application demands; and finally obtaining the aluminum alloy block material of which a substrate has high mechanical property and the surface has high friction property. By utilizing the preparation method, the mechanical property and the friction property of the aluminum alloy can be remarkably improved, the application range of the alloy is widened, and the requirements of practical production on the high-performance aluminum alloy are met better.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

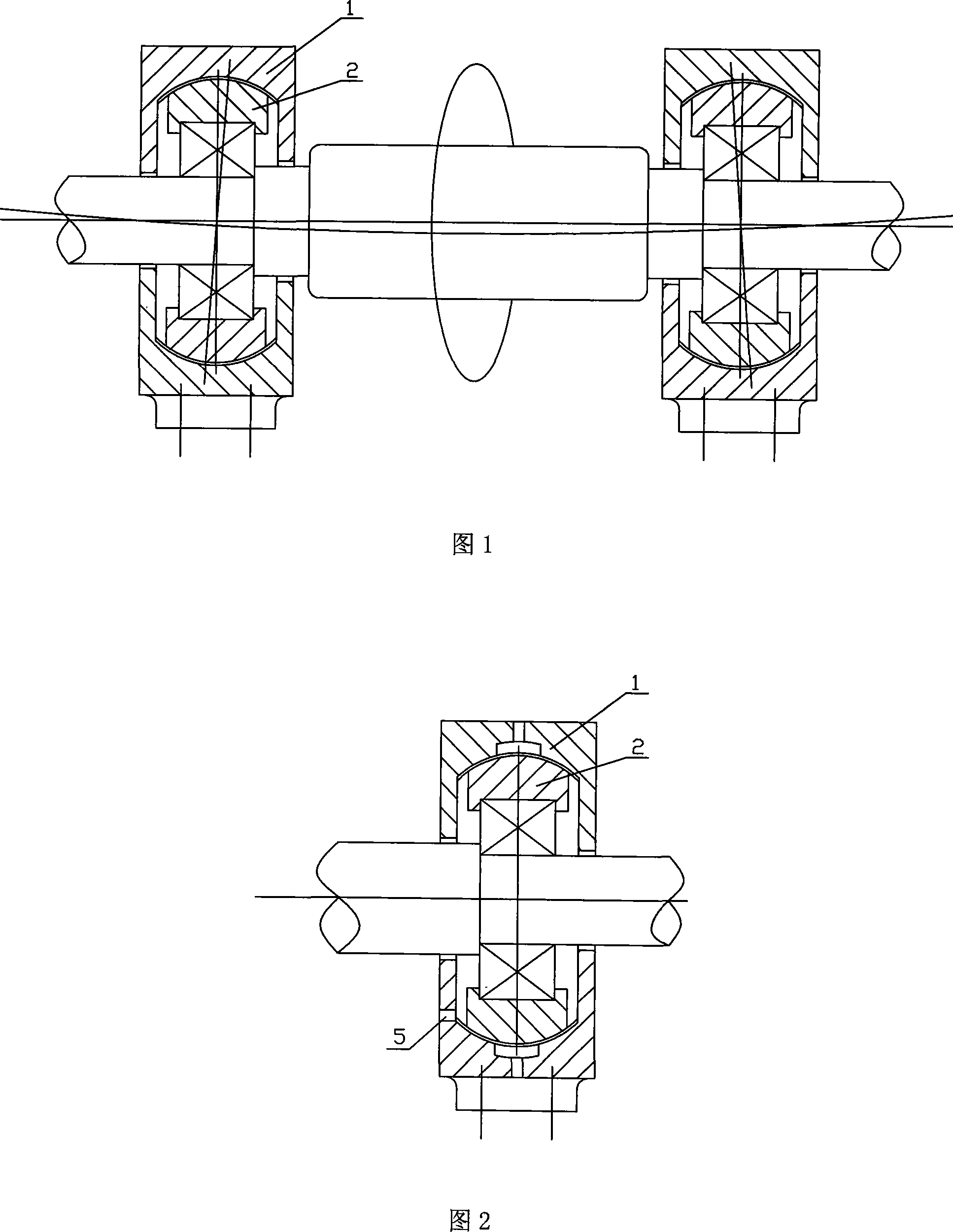

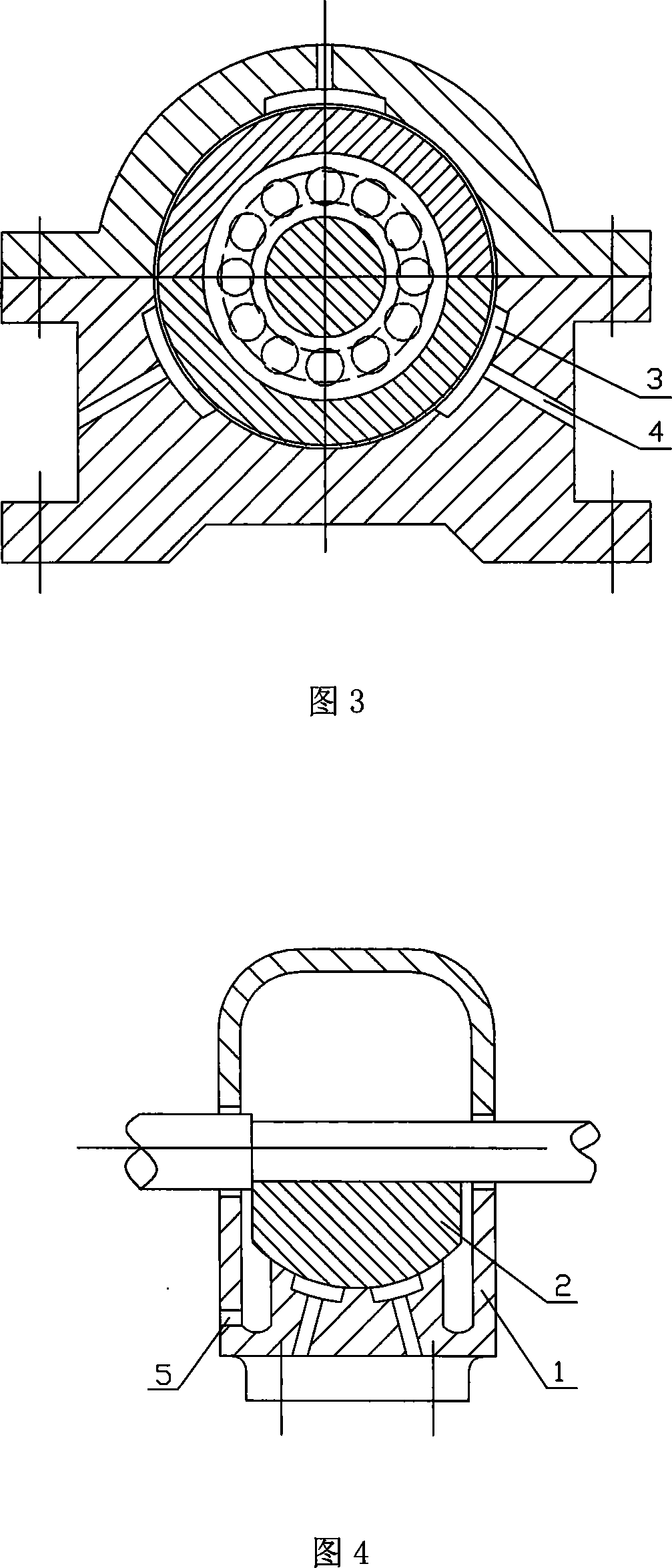

Static-pressure supporting spherical self-aligning bearing seat

InactiveCN101070879AGuaranteed alignmentAchieve lubricationBearing unit rigid supportSpherical bearingEngineering

This invention relates to a rotary equipment housings, specifically is a hydrostatic bearing housings spherical aligning including fixed and dynamic blocks, the blocks in the concave spherical surface cavity with a number of oil, gas chamber connected with external oil source is connected Circuit. There is set to Block Oil, Oil and pipeline connected to. Block set concave spherical ring of 360 degree spherical, aspherical 180 degree partial ring and less than 180 degree partial annular spherical three types. Compared with the existing technology, the benefits of this invention lies: in the sphere aligning the two housings mutual coordination between the spherical form a complete oil film and realized the liquid lubrication, a decrease of sliding friction, thus ensuring that the spherical bearings Block aligning role.

Owner:UNIV OF SCI & TECH LIAONING

Reciprocating engine

InactiveUS20050224038A1Reduce slide friction resistanceReduce hammer soundPiston ringsBraking action transmissionReciprocating engineCombustion chamber

Owner:BANDO KIKO CO LTD

Reciprocating engine

InactiveUS20060070597A1Reduce sliding frictional resistanceEliminate distractionsPiston ringsPlungersCombustion chamberPiston ring

A reciprocating engine comprises: a piston ring; a piston ring which defines an annular gas chamber in cooperation with the piston ring and which is adjacent to the piston ring such that a pressure-receiving area of a side surface of a piston in the annular gas chamber becomes greater on a thrust side than on a counter-thrust side of the piston; and gas passages for allowing the annular gas chamber to communicate with the combustion chamber.

Owner:BANDO KIKO CO LTD

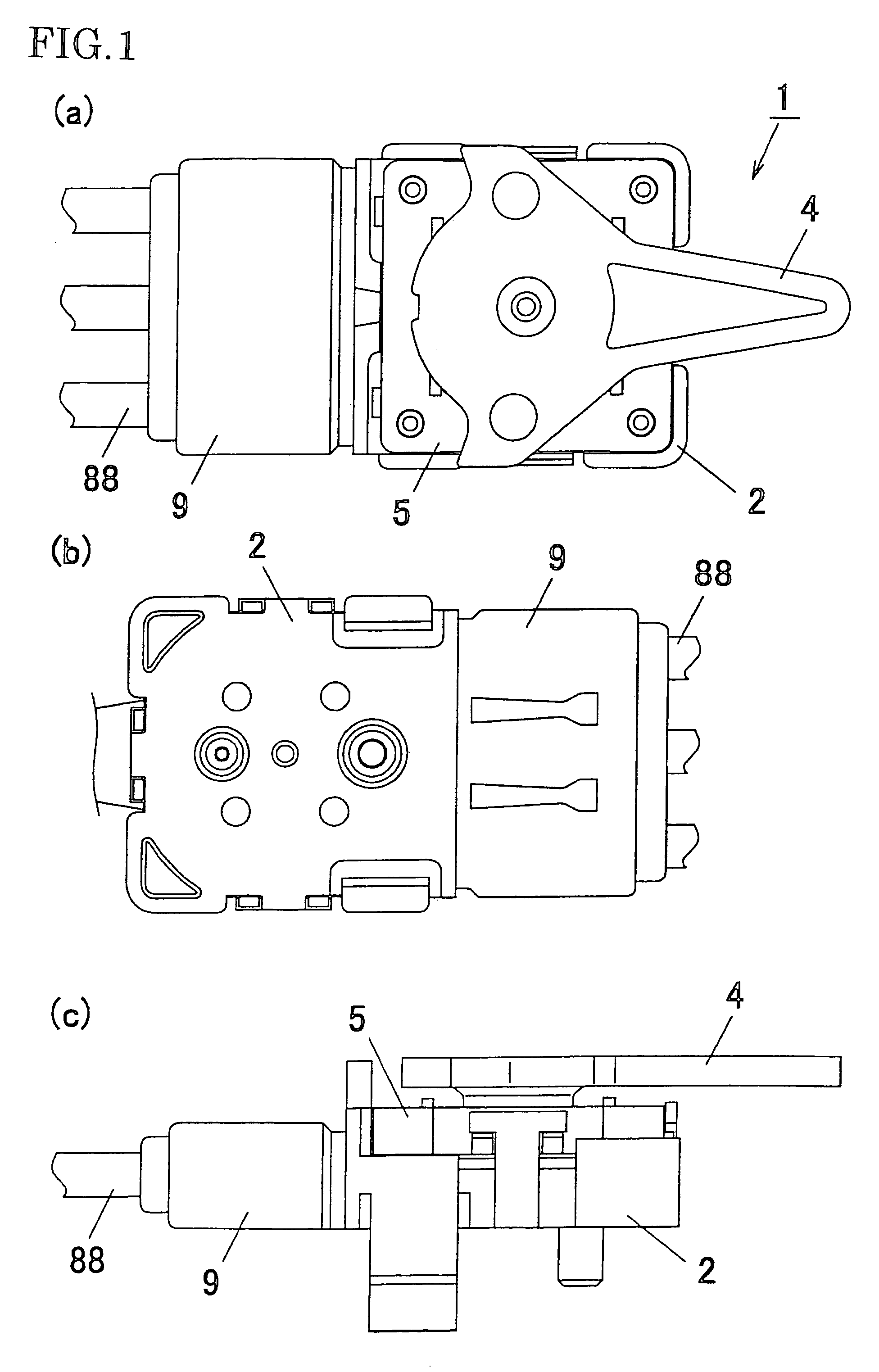

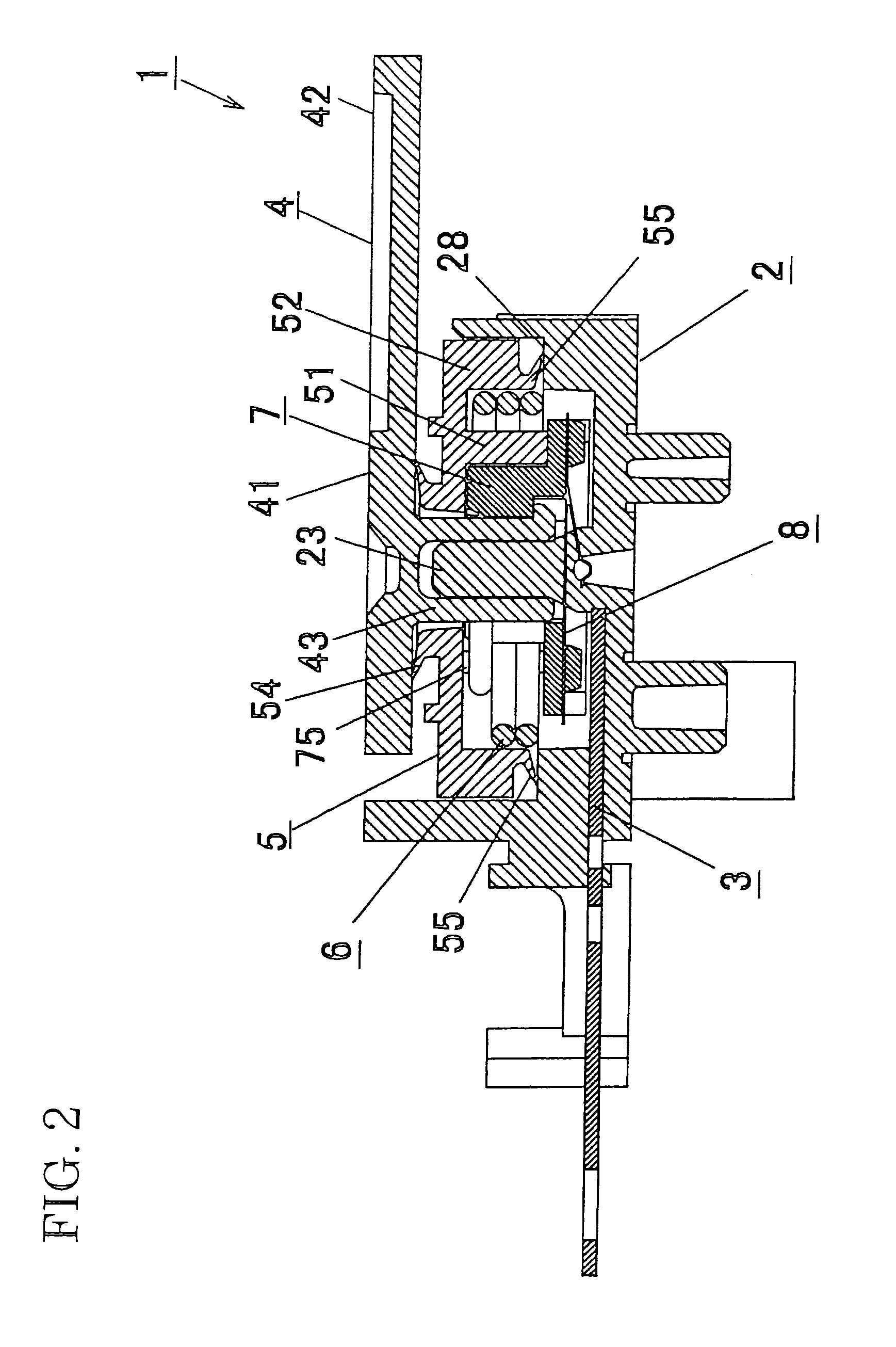

Lever switch

InactiveUS7102091B2Guaranteed uptimeReduce sliding frictional resistanceContact operating partsSpring forceCoil spring

It is an object of the present invention to provide a lever switch capable of reliably preventing intrusion of water or the like into a casing and maintaining smooth operation of a switch mechanism for a long period of time. A lever switch provided with a switch mechanism whereby an operation lever rotates from a neutral position on a base against a spring force of a coil spring to change the position of the switch, a gap between the operation lever and base is filled with a casing, the switch mechanism is accommodated in the casing and a waterproof / dustproof mechanism is provided to seal a sliding surface between the operation lever and casing and a contact surface between the base and casing with an upper lip packing and lower lip packing respectively.

Owner:MIC ELECTRON CO

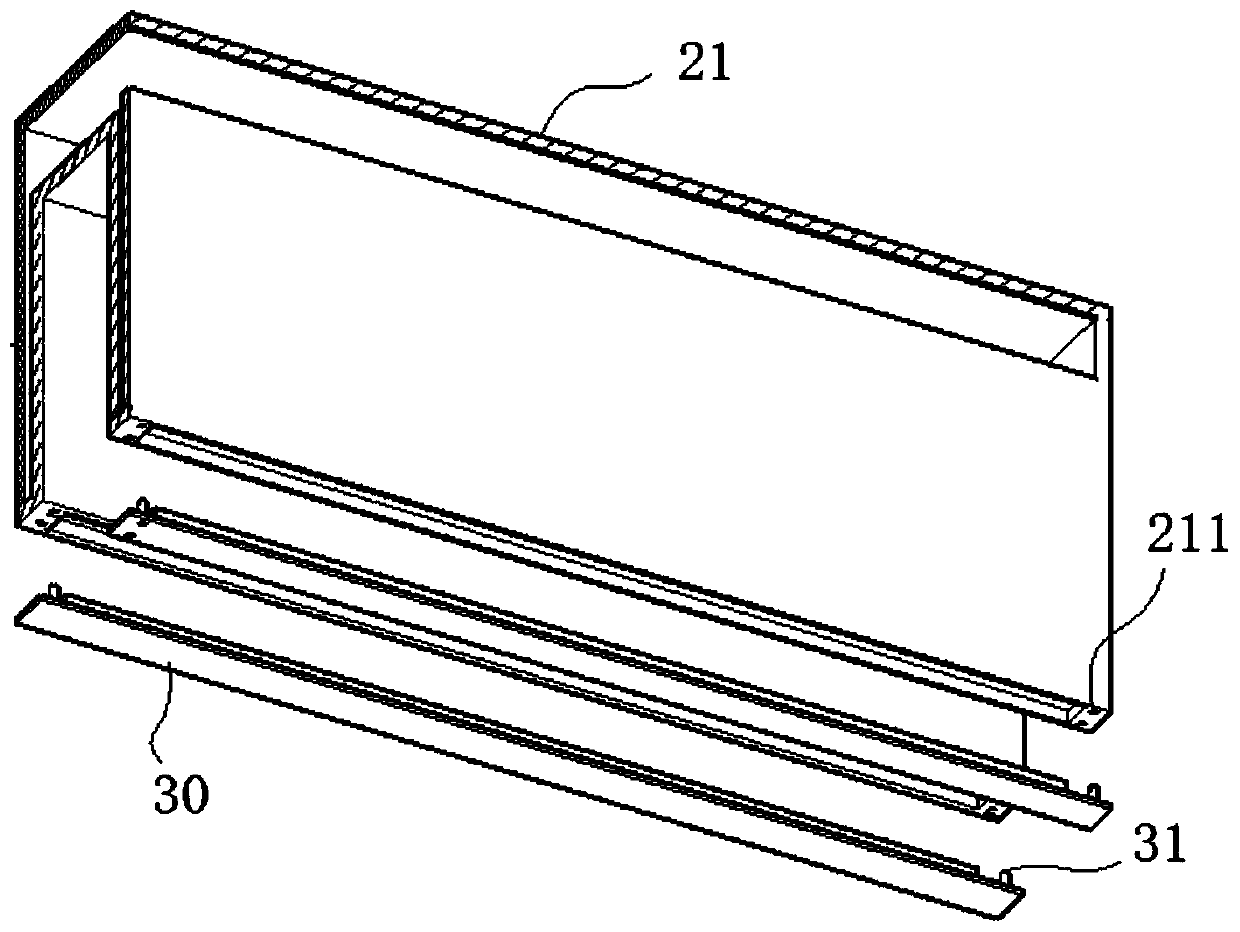

Low-resistance coreless unilateral permanent magnet synchronous linear motor

ActiveCN110707897ARetention orientationReduce positive pressurePiezoelectric/electrostriction/magnetostriction machinesPropulsion systemsElectric machineStructural engineering

The invention relates to the field of permanent-magnet linear motors, and discloses a low-resistance coreless unilateral permanent magnet synchronous linear motor that includes a linear guide rail, wherein permanent magnets are laid on the linear guide rail at intervals in the axial direction. The motor also comprises a mover seat that is in sliding fit with the linear guide rail; a first rail anda second rail are symmetrically arranged on the linear guide rail in parallel in the axial direction. A first guide groove and a second guide groove of which the groove walls are cavities are correspondingly formed in the mover seat; at least one long steel magnet is arranged on at least one axial side wall of each of the first rail and the second rail in the vertical direction; the groove bottoms of the first guide groove, the second guide groove and the long steel magnets on the same side are connected with piezoelectric ceramics; coils are arranged in adjacent groove wall cavities, and thecoils are connected with the piezoelectric ceramics through wires. The guide effect of the guide rail is reserved; when the mover seat bears load and is pressed, the positive voltage effect of piezoelectric ceramic is used for providing current for the coil, so upward lifting force is generated on the mover seat under cutting of a symmetric magnetic field of the long steel magnets, thrust fluctuation is restrained, and the robustness of an advancing system is improved.

Owner:安徽同兴科技发展有限责任公司 +1

Lever switch

InactiveCN1819090APrevent intrusionReduce sliding frictional resistanceElectrical apparatusCoil springSpring force

It is an object of the present invention to provide a lever switch capable of reliably preventing intrusion of water or the like into a casing and maintaining smooth operation of a switch mechanism for a long period of time. A lever switch provided with a switch mechanism whereby an operation lever rotates from a neutral position on a base against a spring force of a coil spring to change the position of the switch, a gap between the operation lever and base is filled with a casing, the switch mechanism is accommodated in the casing and a waterproof / dustproof mechanism is provided to seal a sliding surface between the operation lever and casing and a contact surface between the base and casing with an upper lip packing and lower lip packing respectively.

Owner:MIC ELECTRON CO

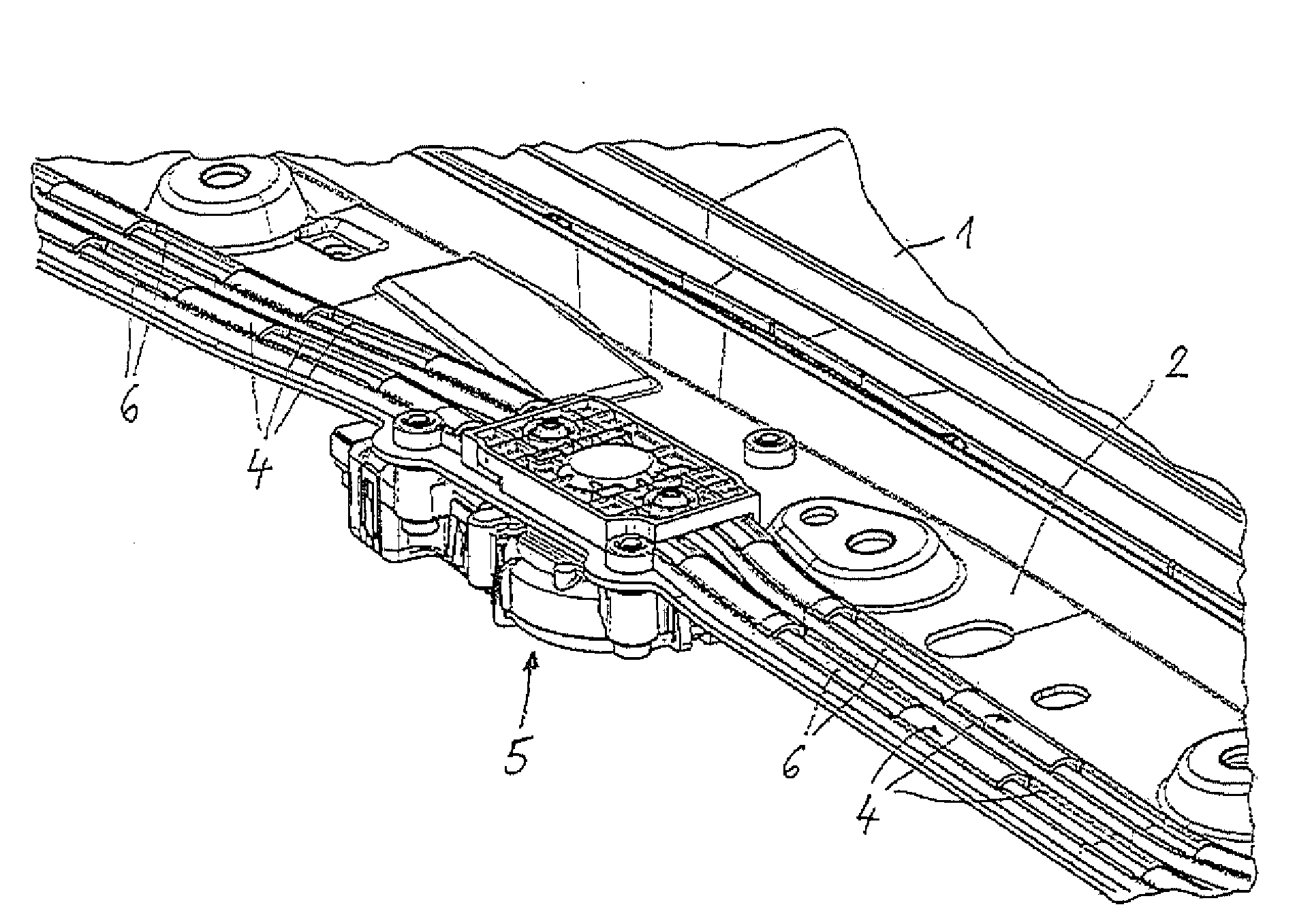

Drive transmission system and method for mounting such a drive transmission system

InactiveUS20140360295A1Easy to set upLow noise operationMetal working apparatusFriction gearingsEngineeringGuide tube

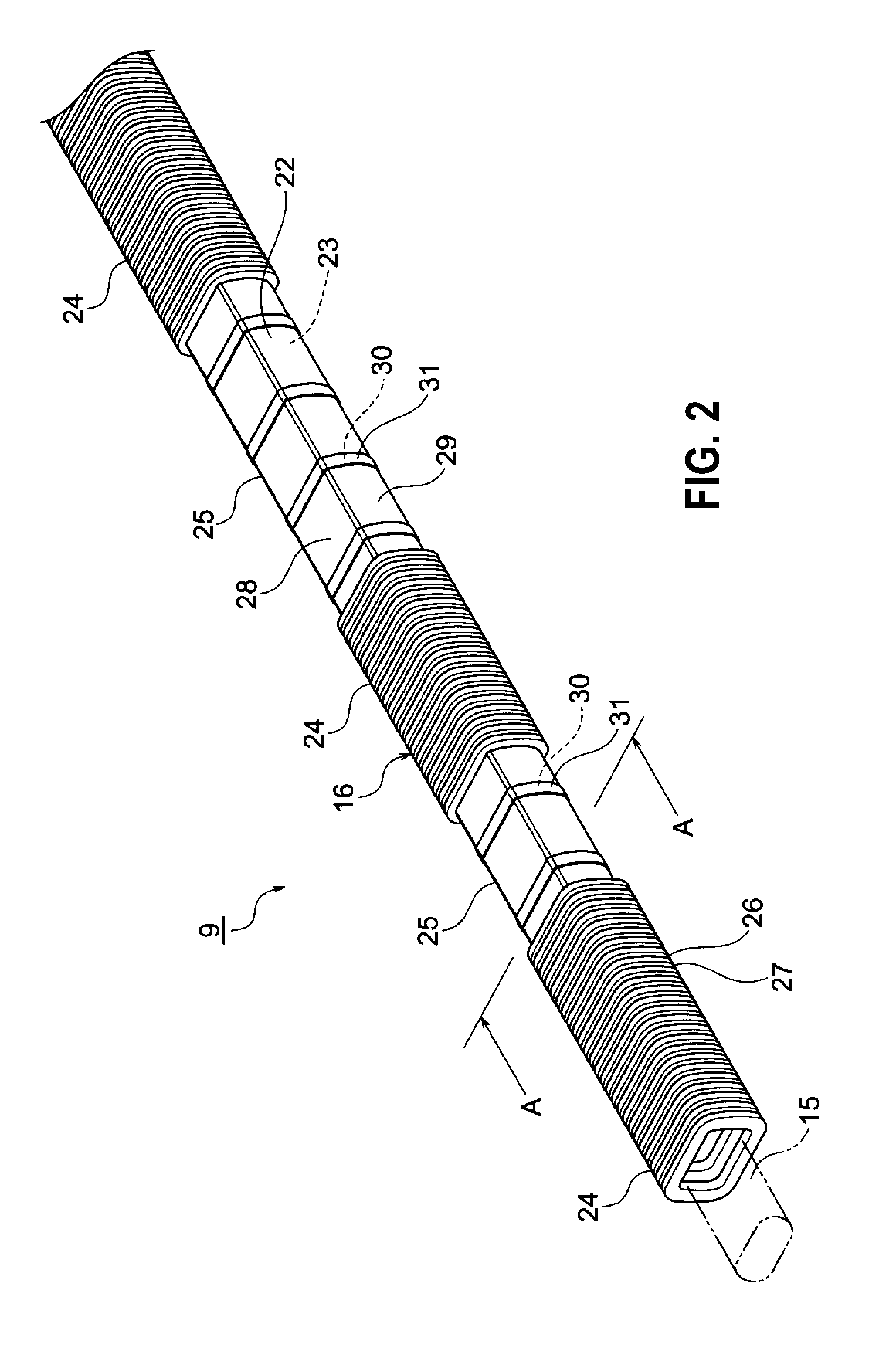

A drive transmission system for a sheet-like structure movable in relation to a vehicle section, with at least one flexible drive cable which can transmit tensile and / or compressive forces, and with at least one stationary dimensionally stable conduit in which the drive cable is laid. The drive cable is guided in a slidably movable manner in a flexible plastic hose which is arranged in the conduit and which is held stationarily in relation to the conduit, the plastic hose having on the inside low sliding friction with respect to the drive cable.

Owner:BOS

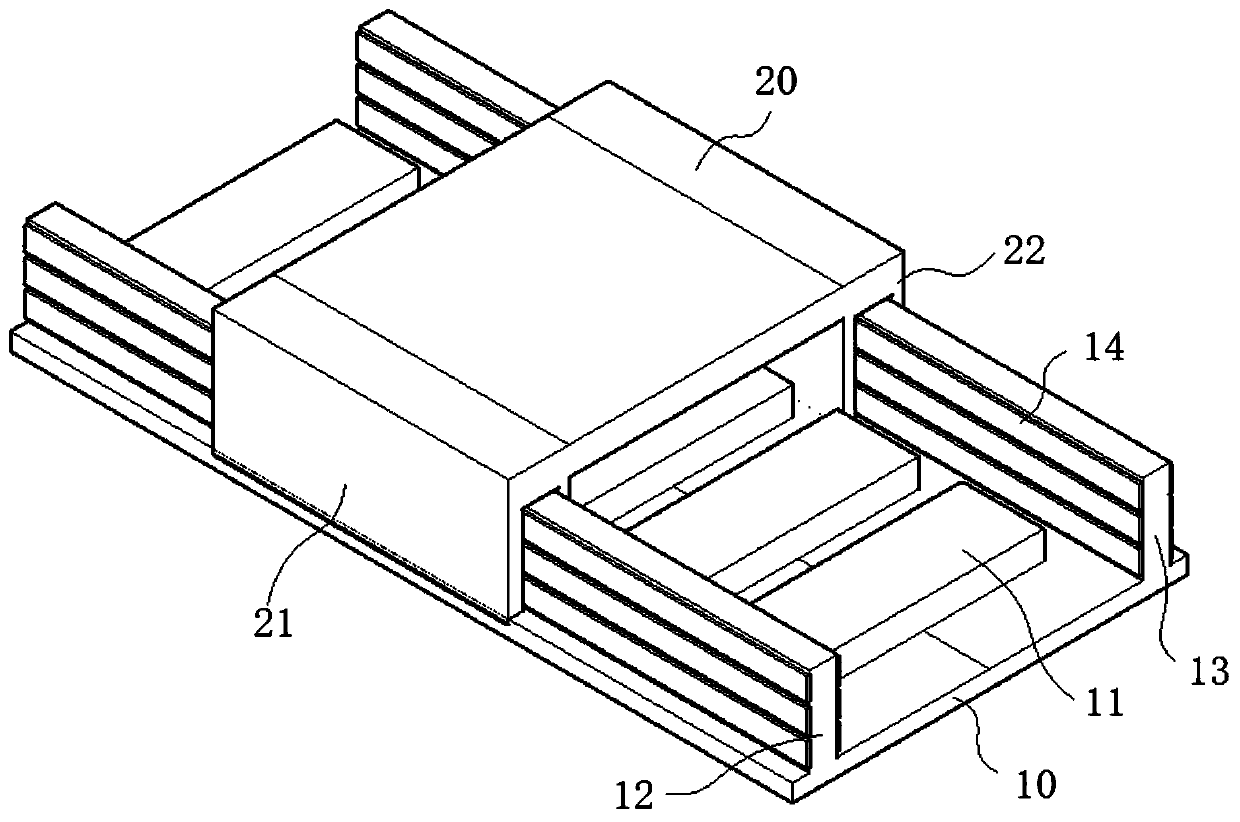

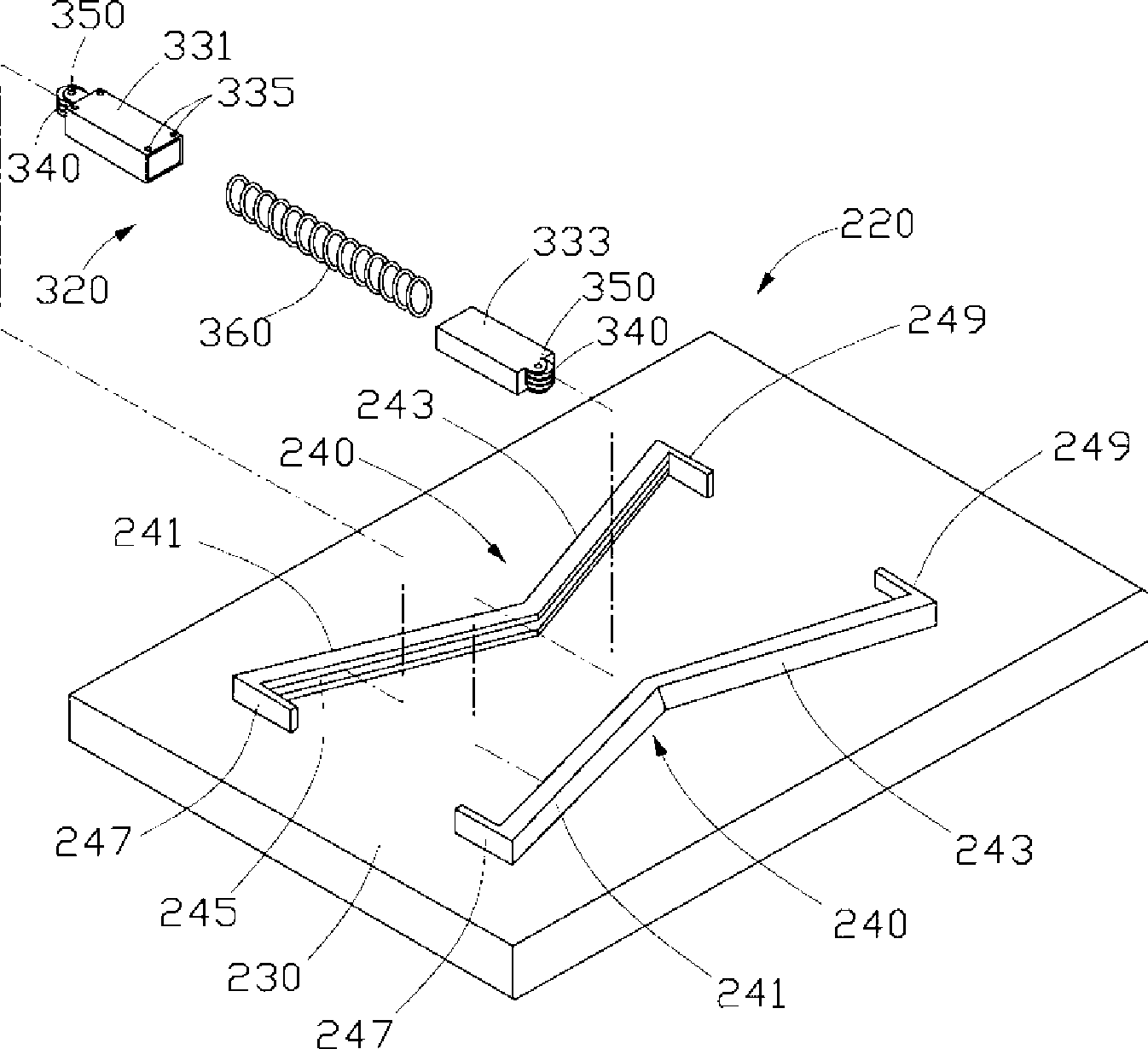

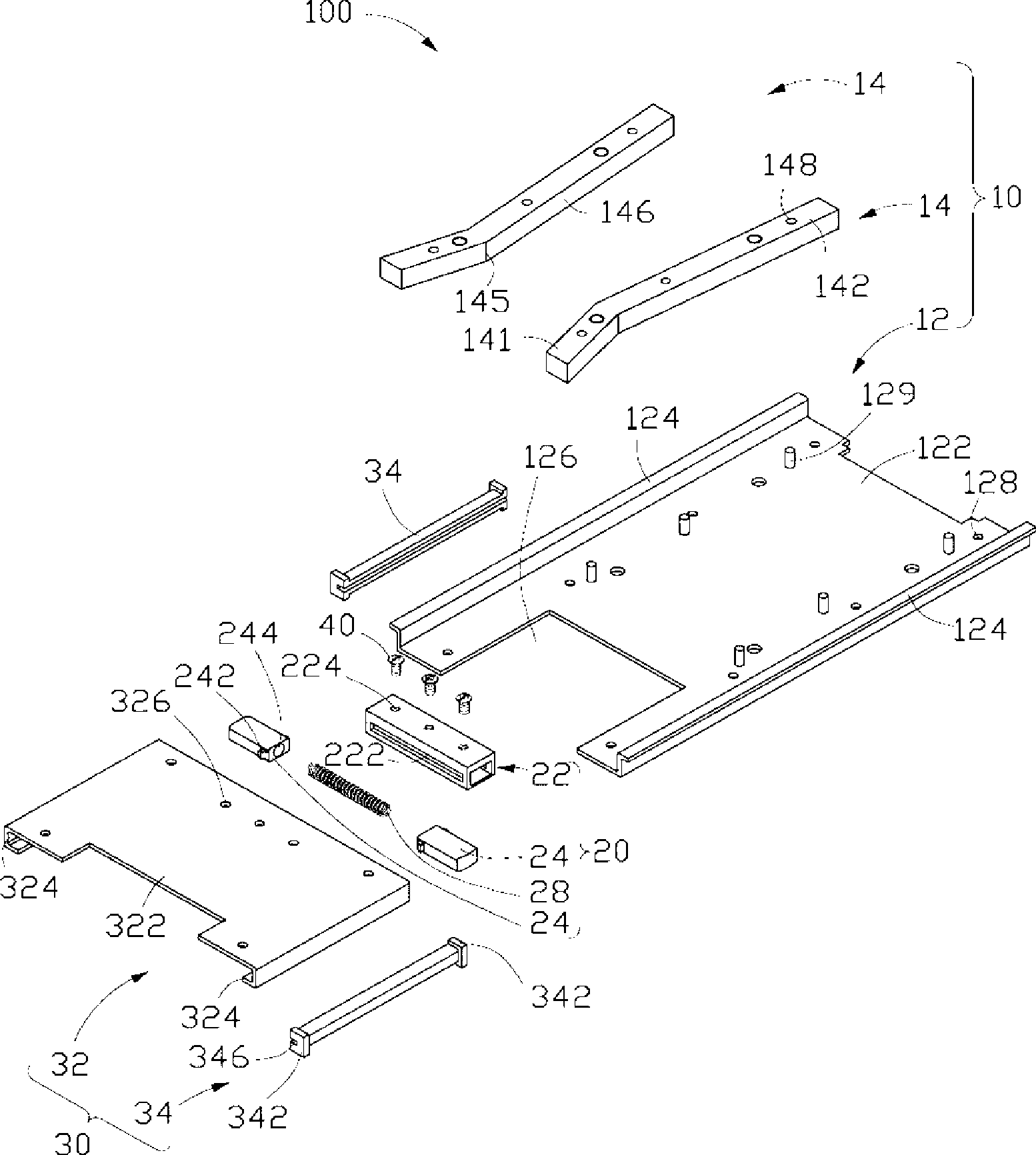

Sliding mechanism

InactiveCN101460023AReduce sliding frictional resistanceExtended service lifeCasings/cabinets/drawers detailsSupport structure mountingClassical mechanicsEngineering

A sliding mechanism comprises a sliding assembly which can relatively slide, a back board assembly and a connection assembly, wherein the sliding assembly comprises a slide cover, the back board assembly comprises a back board and two guide rails which are relatively fixed on the back board, wherein the two guide rail have at least a group of inflexions which are relatively arranged, the connection assembly is connected with the slide cover, and matched with the two guide rails to enable the sliding assembly to semi-automatically slide relative to the back board assembly, the connection assembly comprises two slide blocks matched with the guide rails, wherein the two slide blocks can relatively slide to close or move away, and at least acting force which makes the two slide blocks mutually exclusive exists between the two slide blocks in the sliding process, both the slide block and the guide rail have magnet, and one end of the slide block adjacent to the guide rail has the same magnetic polarity as the inner side of the guide rail. The sliding mechanism of the invention has the advantages of effectively reducing sliding-frictional resistance and extending the service life of the sliding mechanism.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

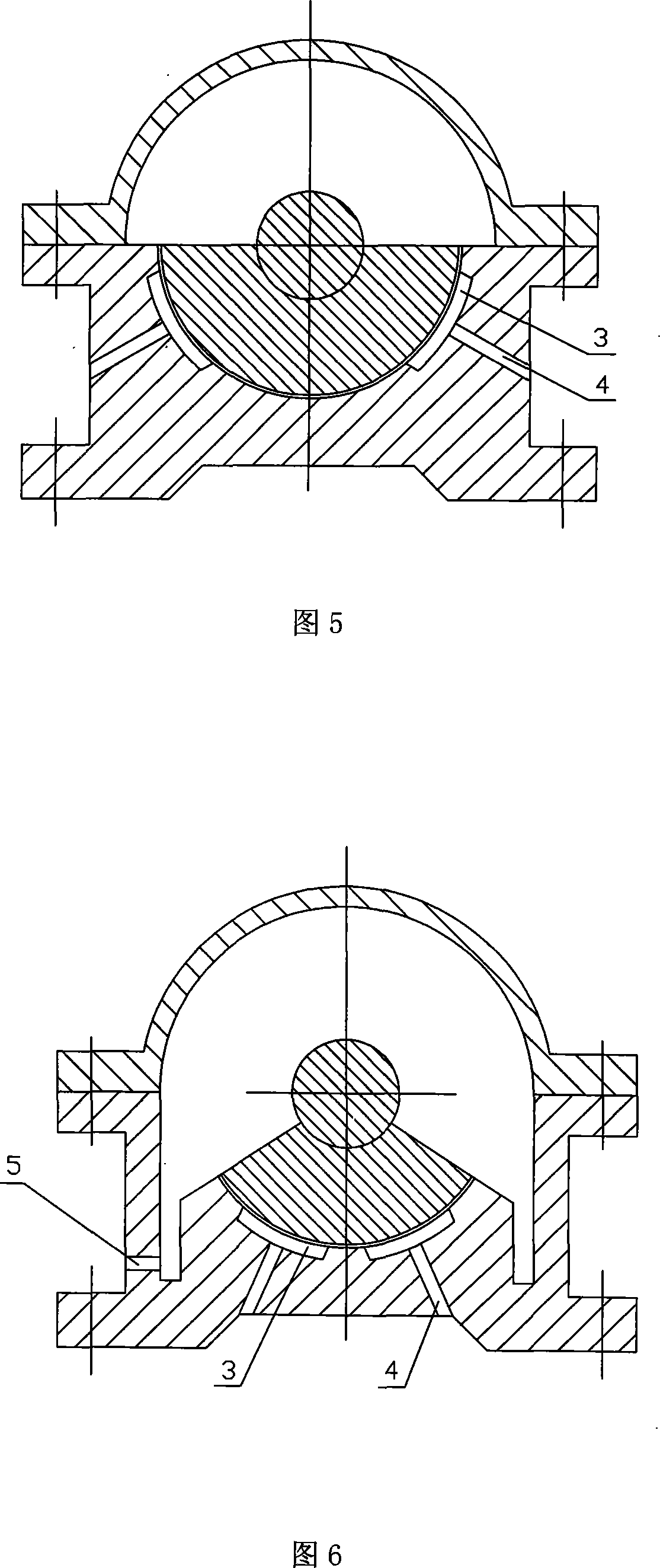

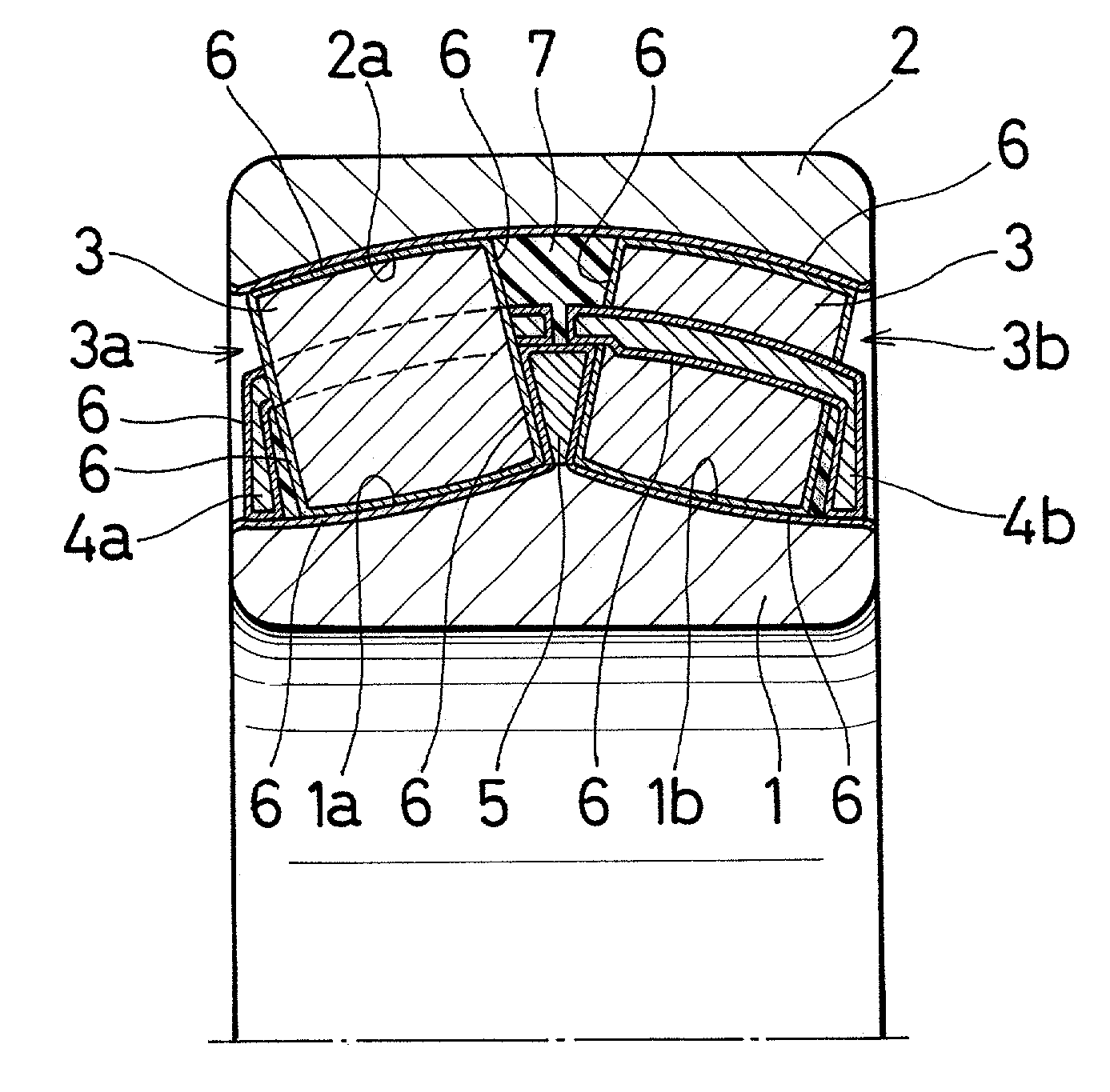

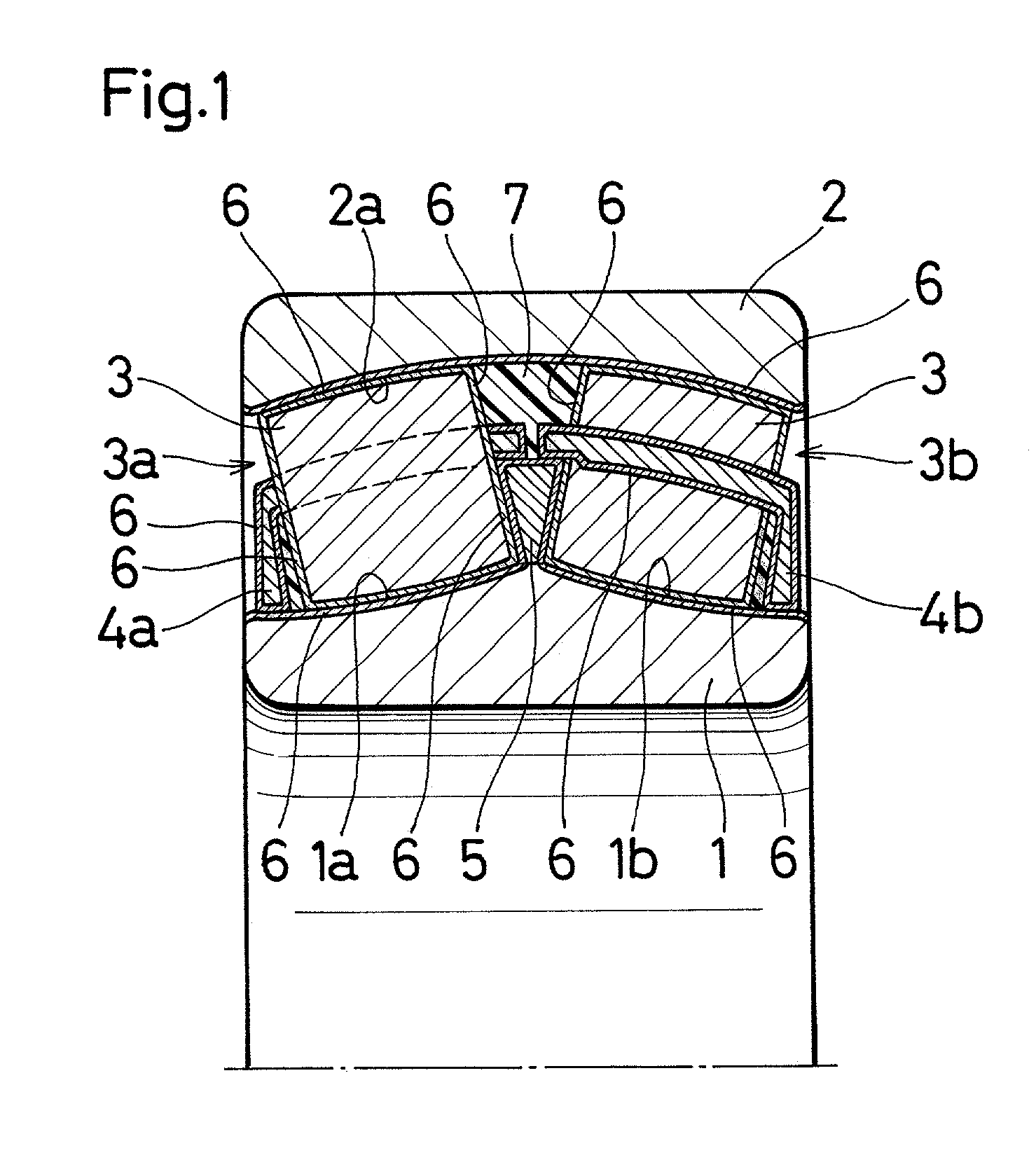

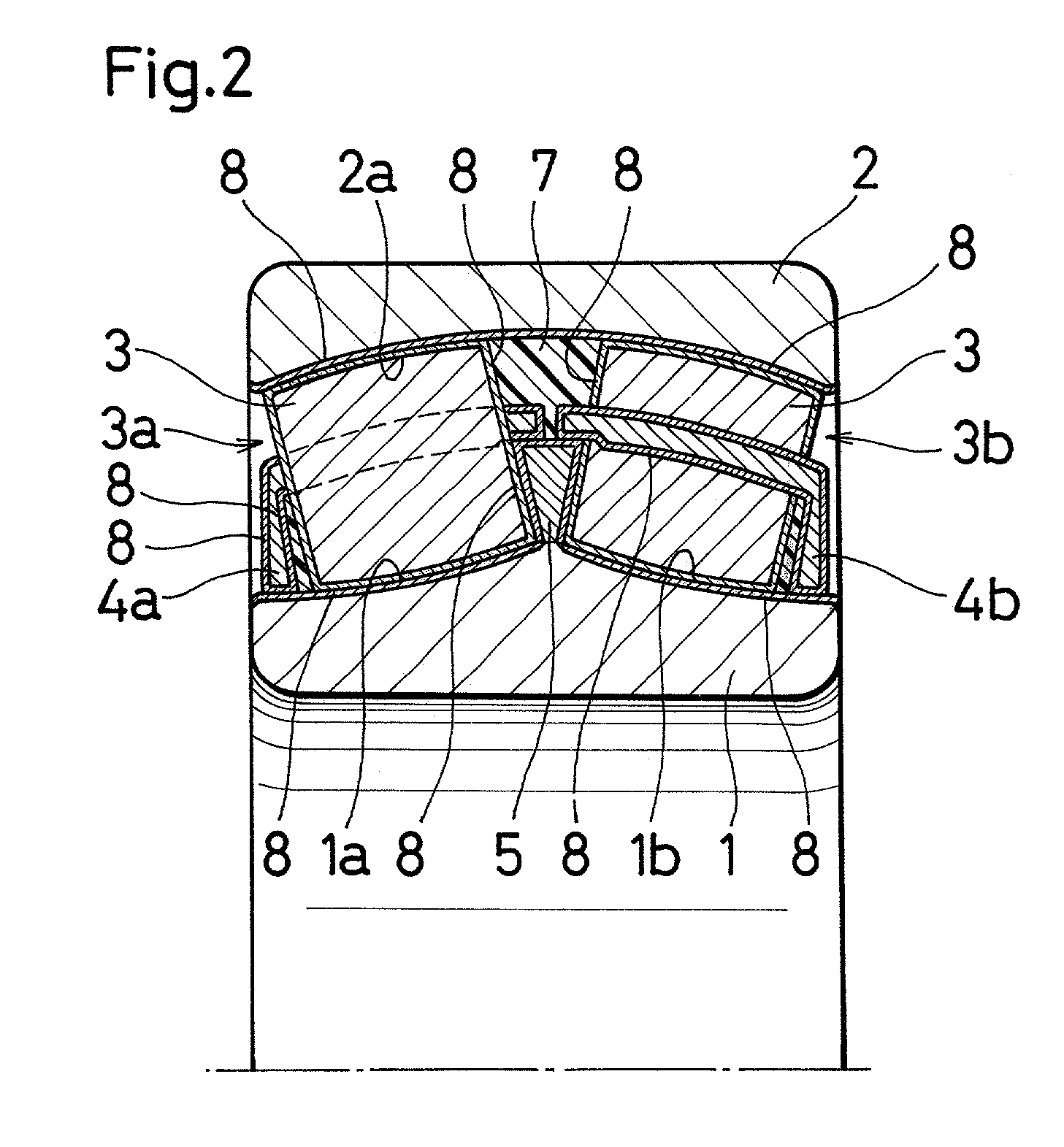

Polymeric lubricant packed bearing and method of producing the same

InactiveUS7008115B2Easily insertSliding frictional resistanceRoller bearingsBearing componentsSolventSpherical roller bearing

A film composed of grease, or a film composed of a thickener for grease, is formed on a portion of the surface of each of components constituting a bearing, the portion being opposed to a polymeric lubricant, whereby sliding frictional resistance between the bearing components and the polymeric lubricant is reduced. In the formation of the film, the assembled bearing in which the film has not yet been formed is immersed into a liquid which is obtained by diluting the grease or the thickener for grease with a solvent, and the solvent is then dried, thereby to highly reproducibly form the film of uniform thickness. In an assembled double-row self-aligning roller bearing wherein an outer race is swingable in a direction perpendicular to the center axis of the bearing, raw materials of a polymeric lubricant are poured into and solidified in two regions of an annular space between the inner and outer races.

Owner:KOYO SEIKO CO LTD

Microcrystal nickel aluminum-manganese shape memory alloy block material preparation method

InactiveCN1546705AReduce temperature dropReduce sliding frictional resistanceManganeseShape-memory alloy

The invention discloses a microcrystal nickel aluminum-manganese shape memory alloy block material preparation method which comprises, preparing the raw materials by the atom percentage of nickel 50%, aluminum 16-20%, manganese 30-34%, smelting under vacuum condition, obtaining nickel-aluminium-manganese alloy cast ingot, cutting the nickel-aluminium-manganese alloy into blanks, carrying out surface smoothness treatment, and coating glass lubricant, using equal diameter curved corner compression die with extruding channel angle being 90-120 degrees, coatint the die molding volume surface with graphite lubricant, subjecting the blank and die arrangement respectively to heating and heat preservation, carrying out equal diameter curved corner extrusion simultaneously after being taken out of the heating-furnace.

Owner:SHANGHAI JIAO TONG UNIV

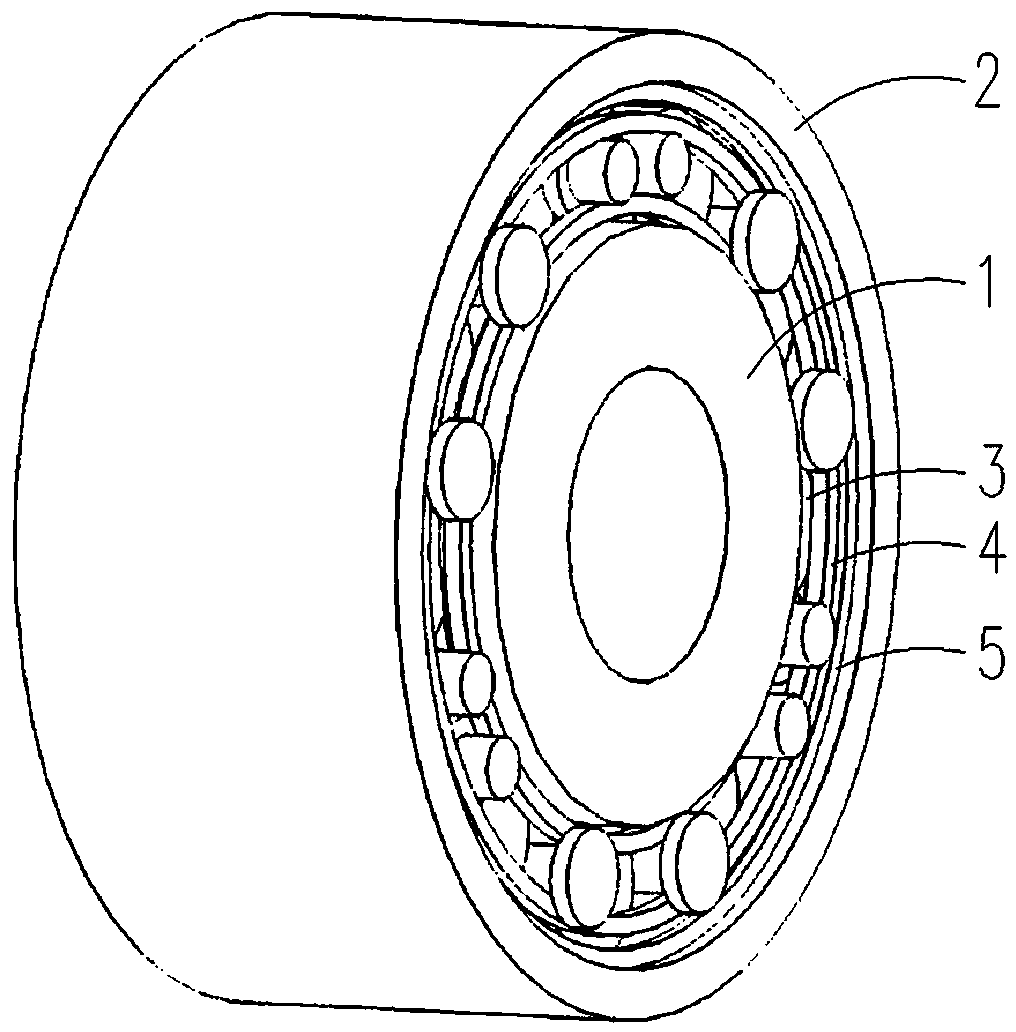

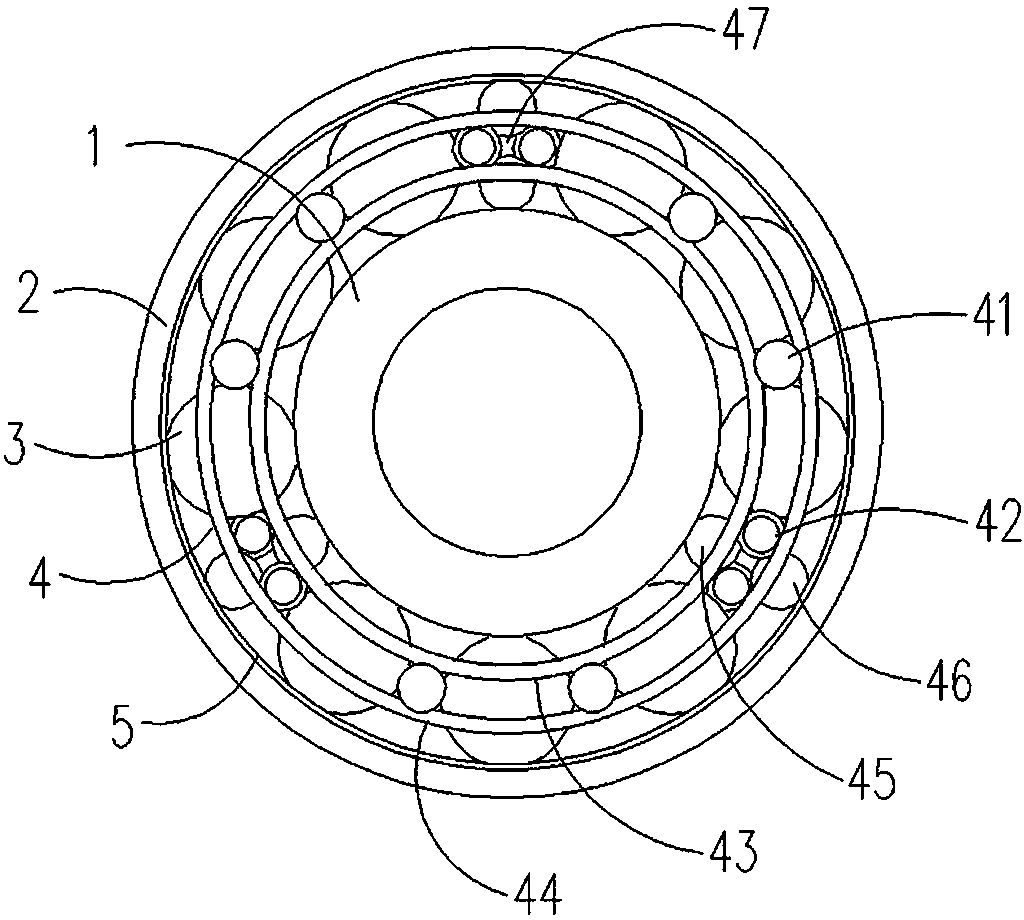

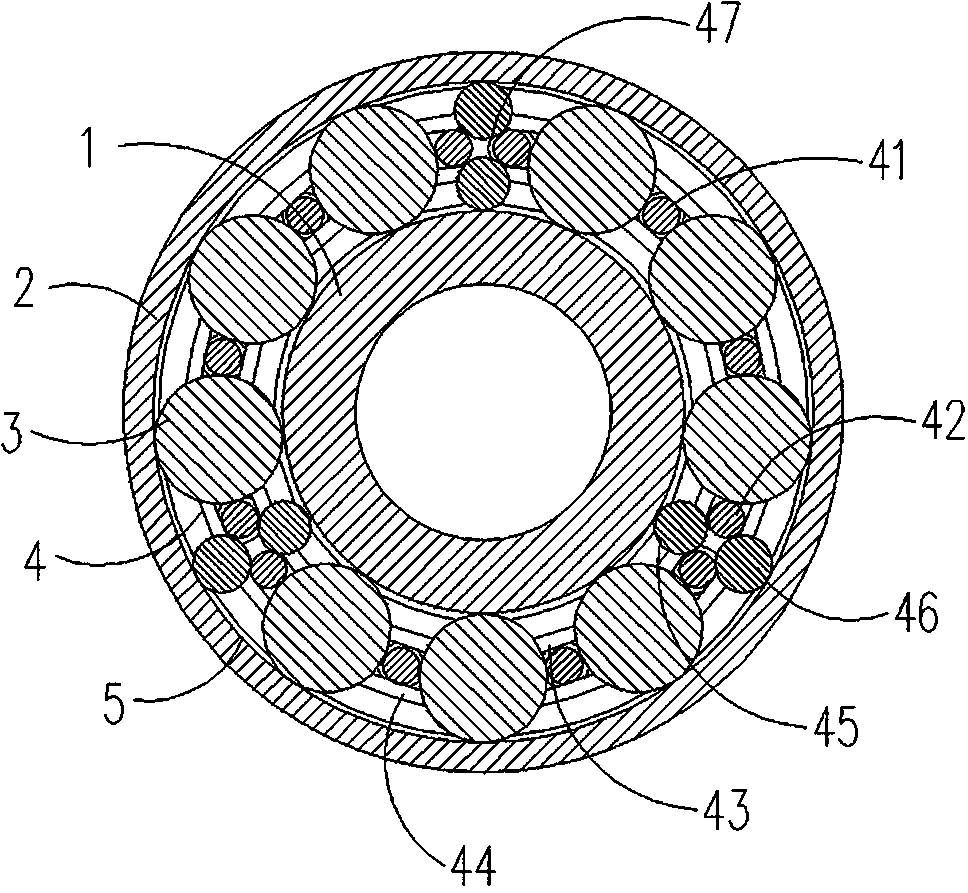

Bearing with rolling-isolation type retainer

InactiveCN104265765AReduce sliding frictional resistanceExtended service lifeBearing componentsMechanical componentsWorking environment

The invention belongs to the field of mechanical parts and particularly relates to a bearing with a rolling-isolation type retainer. The bearing comprises an inner ring, an outer ring, rolling bodies, the retainer and clamp springs, wherein the retainer comprises double-shift isolation rollers, single-shift isolation rollers, an inner auxiliary ring, an outer auxiliary ring, inner supporting rollers and outer supporting rollers; the double-shift isolation rollers and supporting rollers groups on the rolling bodies and the retainer are uniformly arrayed and distributed between the inner ring and the outer ring at intervals; the inner sides of the rolling bodies are mounted by virtue of a roller path between baffling sides of the inner ring, and the outer sides of the rolling bodies are mounted by virtue of a roller path between the clamp springs on the side edge of the inner wall of the inner ring; the inner sides of the inner supporting rollers are mounted by virtue of the roller path between the baffling sides of the inner ring, and the outer sides of the inner supporting rollers cling to the single-shift isolation rollers; the inner sides of the outer supporting rollers cling to the single-shift isolation rollers, and the outer sides of the outer supporting rollers are mounted by virtue of a roller path between the clamp springs on the side edge of the inner wall of the outer ring. The bearing with the rolling-isolation type retainer has the beneficial effects that the frictional resistance between the retainer and each rolling body is low, the bearing can work under a non-lubrication condition, the limit speed is high, and the service life of the bearing is far longer than that of an existing bearing in the equal work environment conditions.

Owner:闫家驹 +1

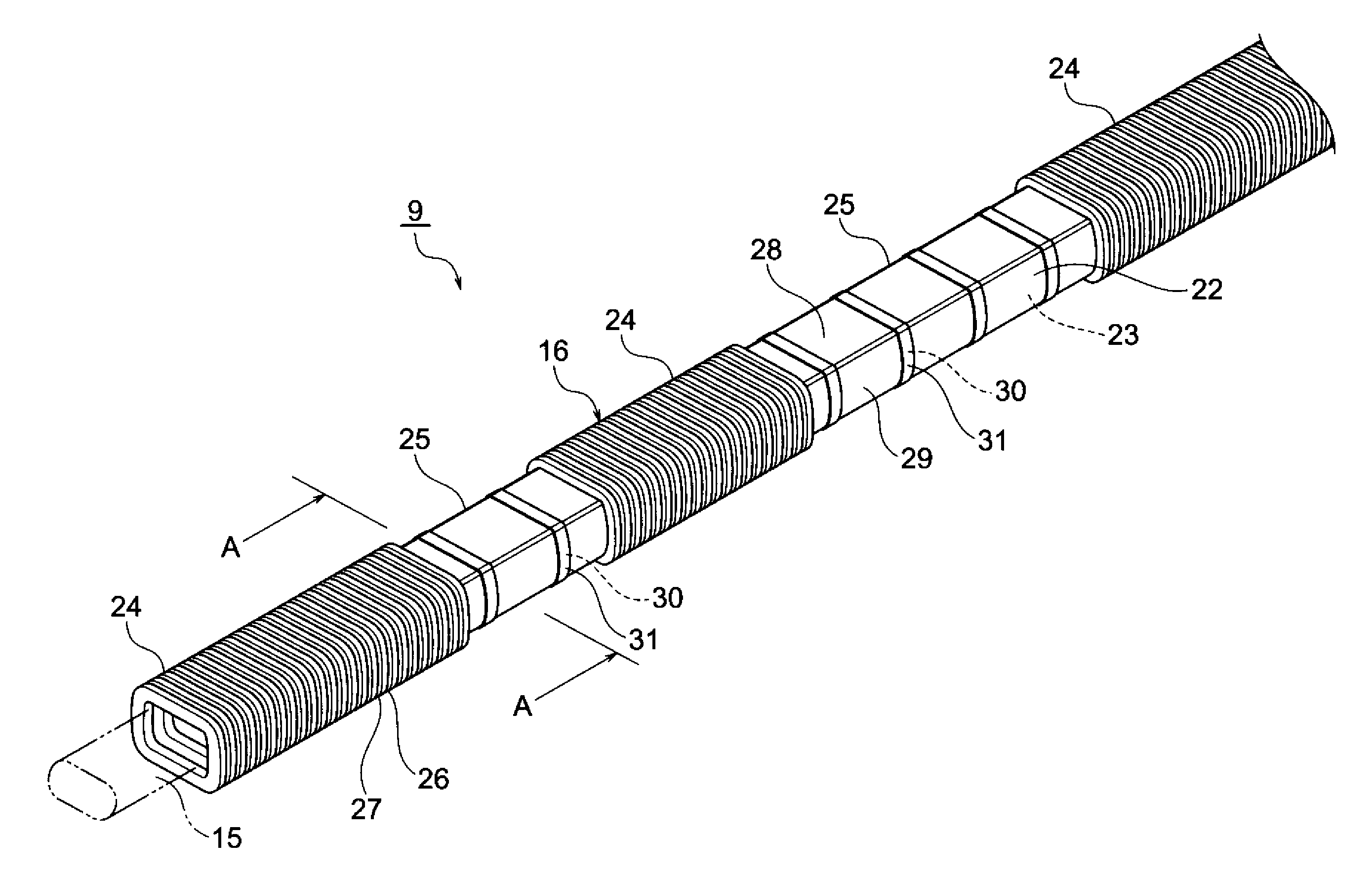

Wire harness

ActiveUS20150375696A1Long distanceEasy to operateElectrical apparatusElectric/fluid circuitEngineeringMechanical engineering

A wire harness includes an electrical pathway and a pipe like exterior member that covers the electrical pathway. The exterior member includes a low rigidity portion which is flelxible and a high rigidity portion which is unflexible and has a rigidity higher than the low rigidity portion, and the low rigidity portion and the high rigidity portion are successively arranged in an extending direction of the electrical pathway.

Owner:YAZAKI CORP

Preparation method of micron-fine-crystal titanium nickel-iron shaped memory alloy block material

InactiveCN1537960AReduce temperature dropReduce sliding frictional resistanceShape-memory alloyMaterials science

A microbe-crystal TiFeNi marmen block is prepared from Ti, Ni and Fe through proportional mixing, vacuum smelting to obtain alloy ingot, cutting, polishing, coating glass lubricant, coating graphite lubricant on the surface of cavity in die, preheating and isometric corner pressing by said preheated die. Its advantages are high strength and plasticity, and low cost.

Owner:SHANGHAI JIAO TONG UNIV

Six-degree-of-freedom spatial position regulating system of rotary part

InactiveCN108621105ACompact designLoad stabilityWork holdersWork benchesSix degrees of freedomEngineering

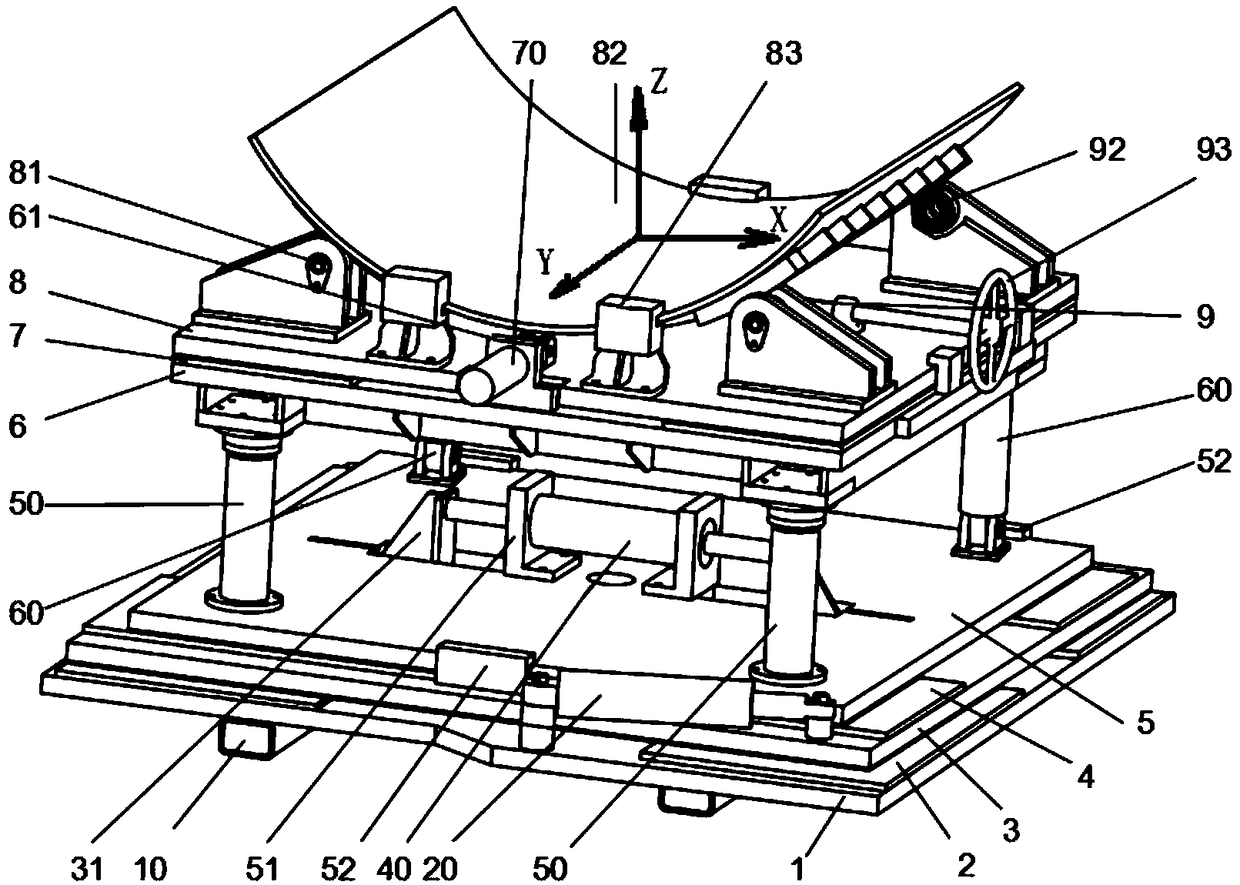

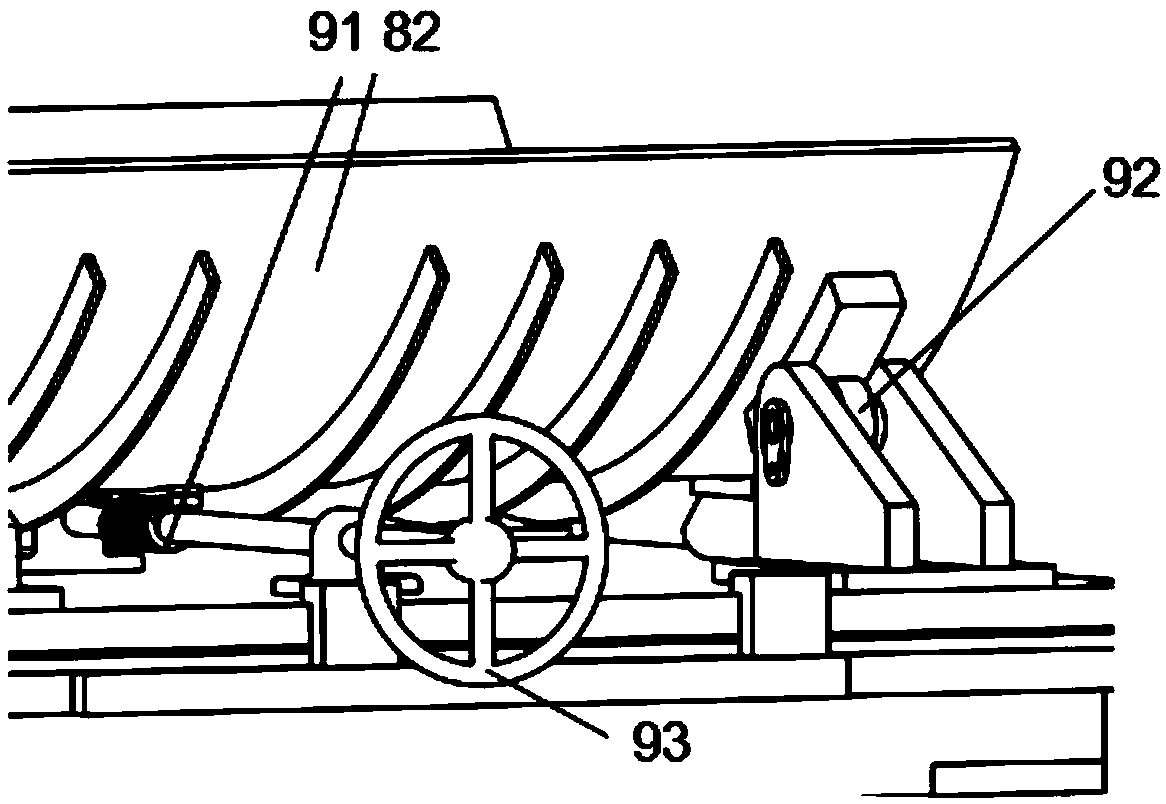

The invention discloses a six-degree-of-freedom spatial position regulating system of a rotary shaft. The six-degree-of-freedom spatial position regulating system comprises a substrate plate with a central shaft, wherein a rotary bottom plate which is matched with the central shaft is arranged above the substrate plate, and the rotary bottom plate can rotate around the Z axis; the rotary bottom plate is matched with an X bottom plate; the rotary bottom plate and the X bottom plate can slide along the X axis; a pair of first jacking oil cylinders which are perpendicular to the X bottom plate and a pair of second jacking oil cylinders are connected on the upper surface of the X bottom plate; a Y bottom plate is connected above the two pairs of the jacking oil cylinders, so that upper perpendicular lifting and pitching around the X axis are realized; a Y sliding bottom plate on a Y bottom plate can slide along the Y axis; a Y rotary mechanism, a bearing frame and a tray are connected on the Y sliding bottom plate; and the tray can be driven by the Y rotary mechanism to rotate around the central shaft thereof. The six-degree-of-freedom spatial position regulating system adopts the oilcylinders to bear main sliding, rotating and jacking drive without middle transmission links, is high in efficiency and is great in load; and through six-degree-of-freedom regulation, rotary parts such as an electric wheel are more flexible, safer and are more reliable in mounting.

Owner:ACTUANT CHINA

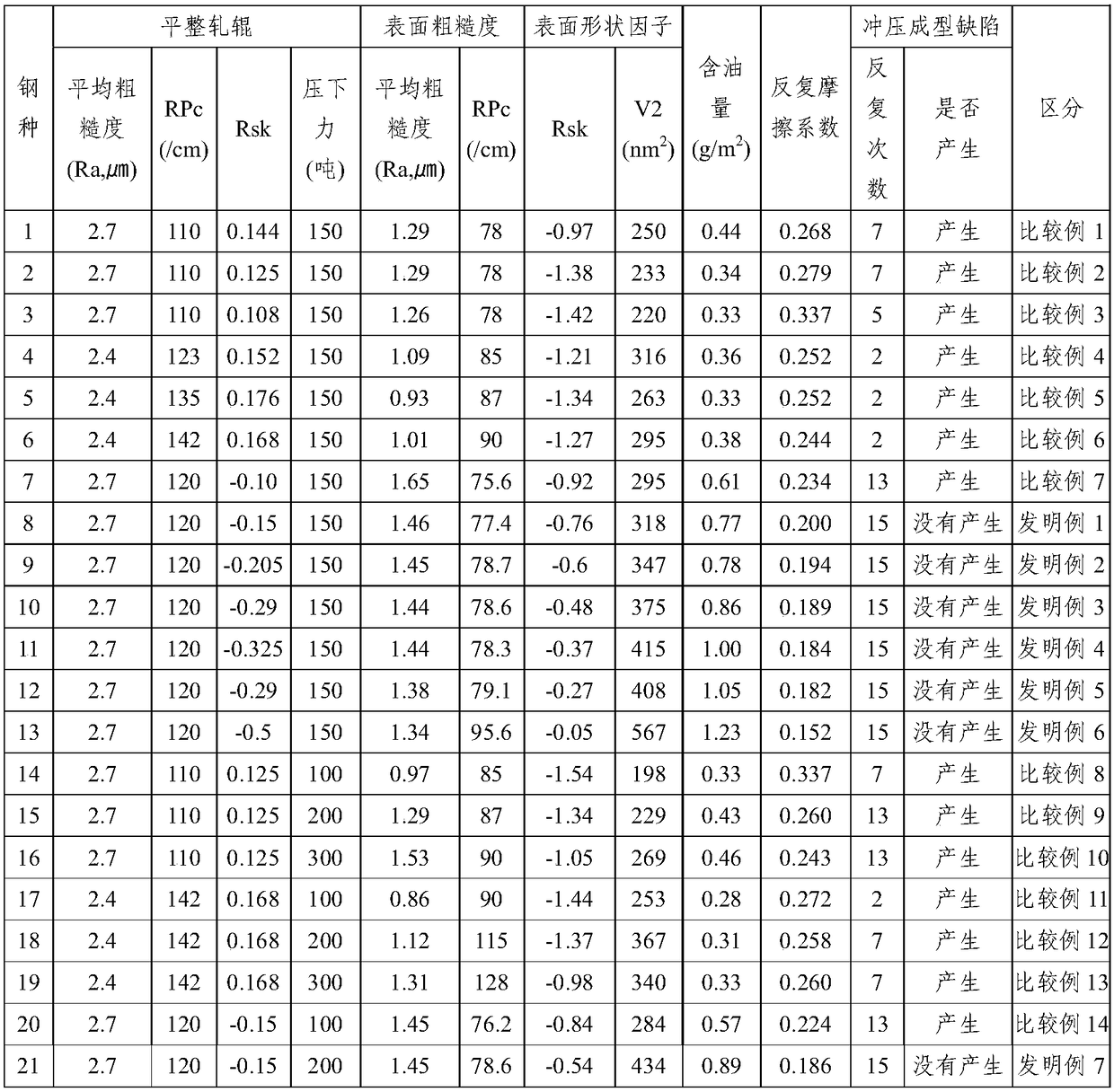

Method for manufacturing plated steel sheet having excellent surface quality and press formability, and plated steel sheet manufactured thereby

ActiveCN108136454APrevent gallingReduce sliding frictional resistanceHot-dipping/immersion processesFurnace typesMetallurgyHot-dip galvanization

The present invention relates to a hot-dip galvanized steel sheet used as an automobile outer panel, etc., and more specifically, to a method for manufacturing a hot-dip galvanized steel sheet havingexcellent surface quality and press formability.

Owner:浦项股份有限公司

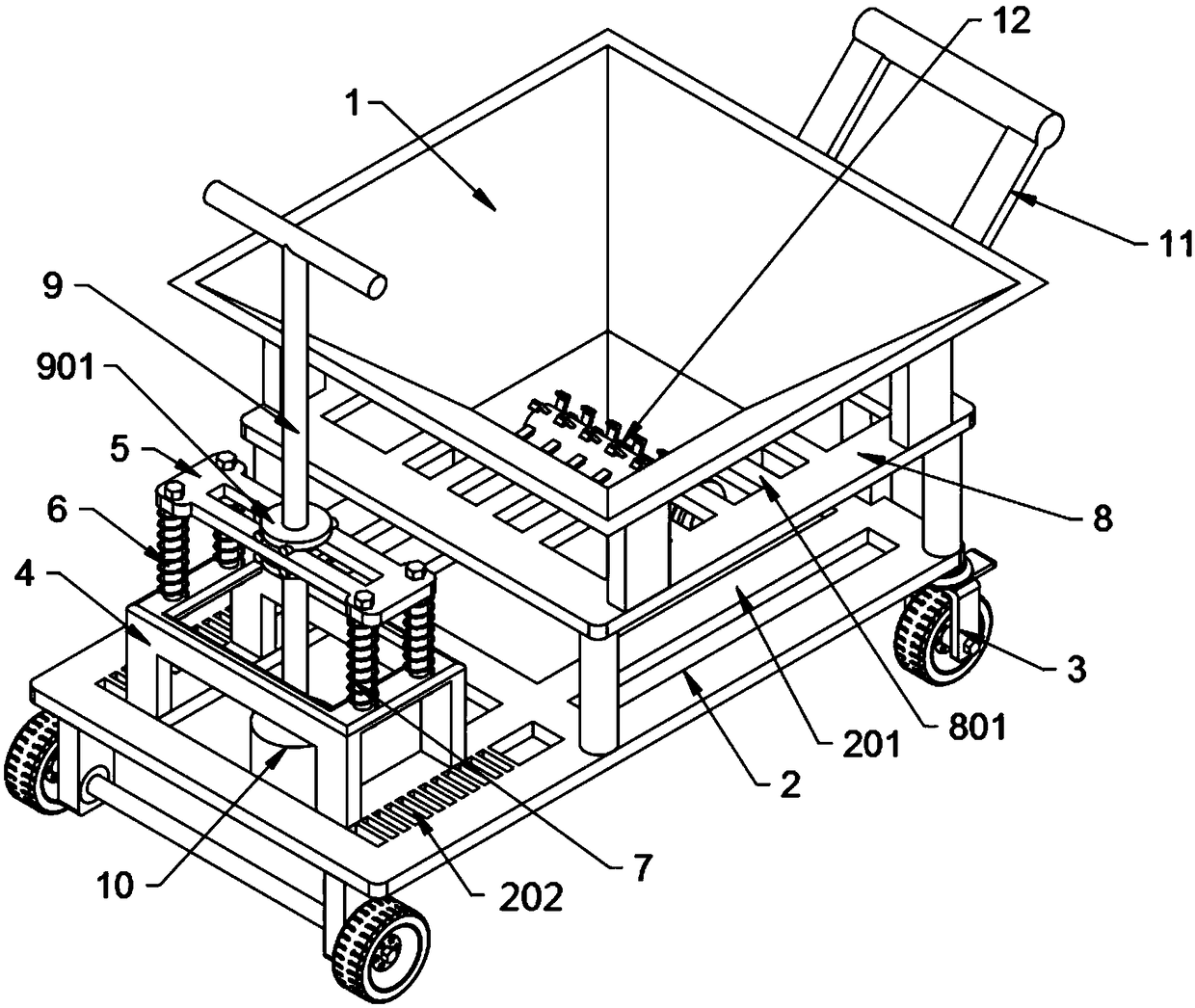

Temporary filling device for pit pavement for municipal road construction

ActiveCN108951393AAvoid unsmooth feedingAvoid bumps and leaksRoads maintainenceEngineeringRoad surface

The invention provides a temporary filling device for pit pavement for municipal road construction, which comprises a push rod, a blanking device, a baffle, a swing handle, a spring fixing buckle, a rotating shaft and a rotating square insertion rod, wherein four supporting frame plates are arranged in equal distance on the intermediate positions of the supporting plates around the supporting frame, and the four rows of supporting frame plates are respectively welded and fixed with the four-side inclined outer wall of the soil holding bucket; The left end of the rotating shaft is welded with aswing handle; The push rod is tilt welded and supported on the rear side of the device body; The blanking device is composed of an insertion sleeve and a plurality of earth-scraping teeth supported on the circumferential surface of the insertion sleeve by equidistant welding in an annular array, and a square shaft hole is formed through the center of the insertion sleeve, that four springs are arranged, the support frame can smoothly slide up and down with the hammering rod under the auxiliary support of the four spring rebound pushing force, the output force of the hand lifting the hammeringrod during the upper and lower reciprocating sliding hammering process is effectively reduced, and the pile hammer is convenient to carry out the hammering operation.

Owner:滁州开顺建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com