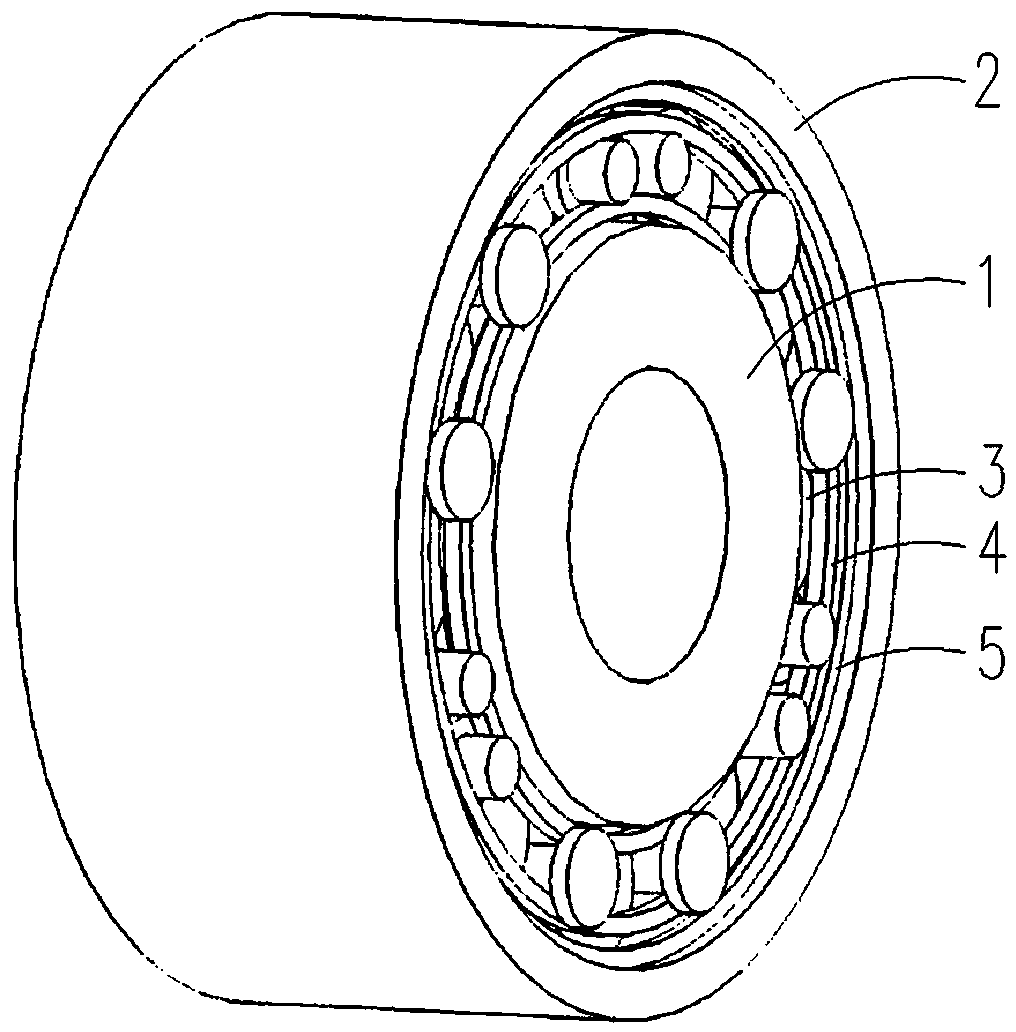

Bearing with rolling-isolation type retainer

A cage and bearing technology, applied in the field of mechanical parts, can solve the problems of low limit speed, short service life, high heat generation, etc., and achieve the effect of high limit speed, small sliding friction resistance and excellent service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

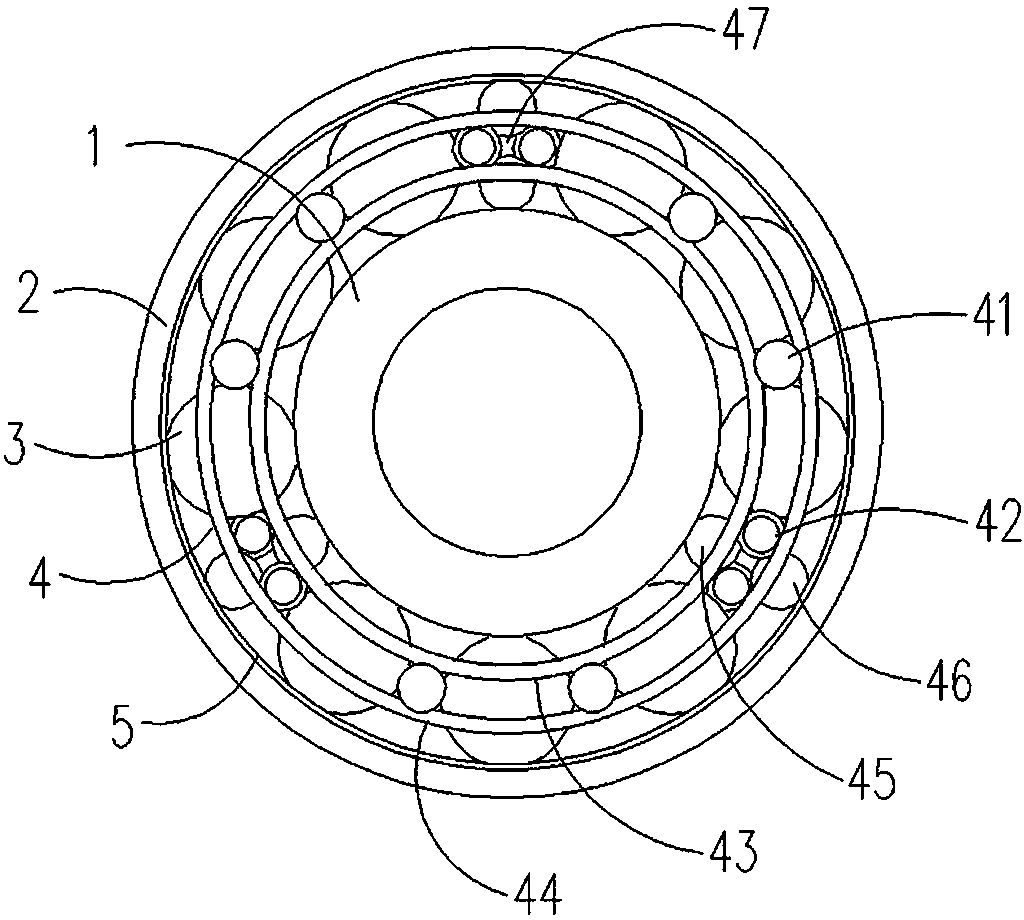

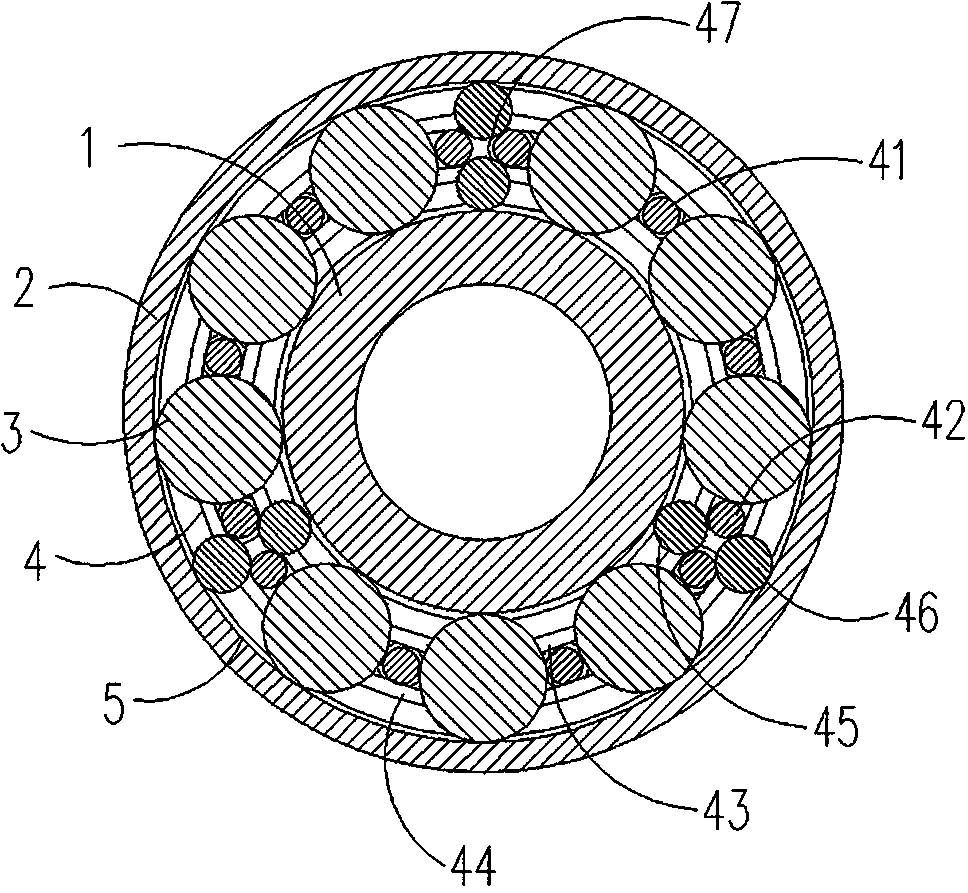

[0031] as attached Figure 1-8 As shown, a rolling isolation cage bearing with a preferred structure, the rolling element 3, the inner support roller 45 and the outer support roller 46 are cylindrical roller structures, the number of rolling elements 3 is 9, and the number of double-block isolation rollers 41 6, the number of supporting roller groups 47 is 3 groups, of which the number of single-block isolation rollers 42 is 6, and the number of supporting rollers is 6; the inner circle of the circlip 5 has inclined surfaces 51 on both sides, and the inclined surfaces 51 and the outer ring 2 The inner wall is at an angle of 100 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com