Six-degree-of-freedom spatial position regulating system of rotary part

A technology of spatial position and adjustment system, which is applied to workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of unsatisfactory adjustment results, high personnel dependence, and large safety hazards, and achieves compact structure and high safety. , reliable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

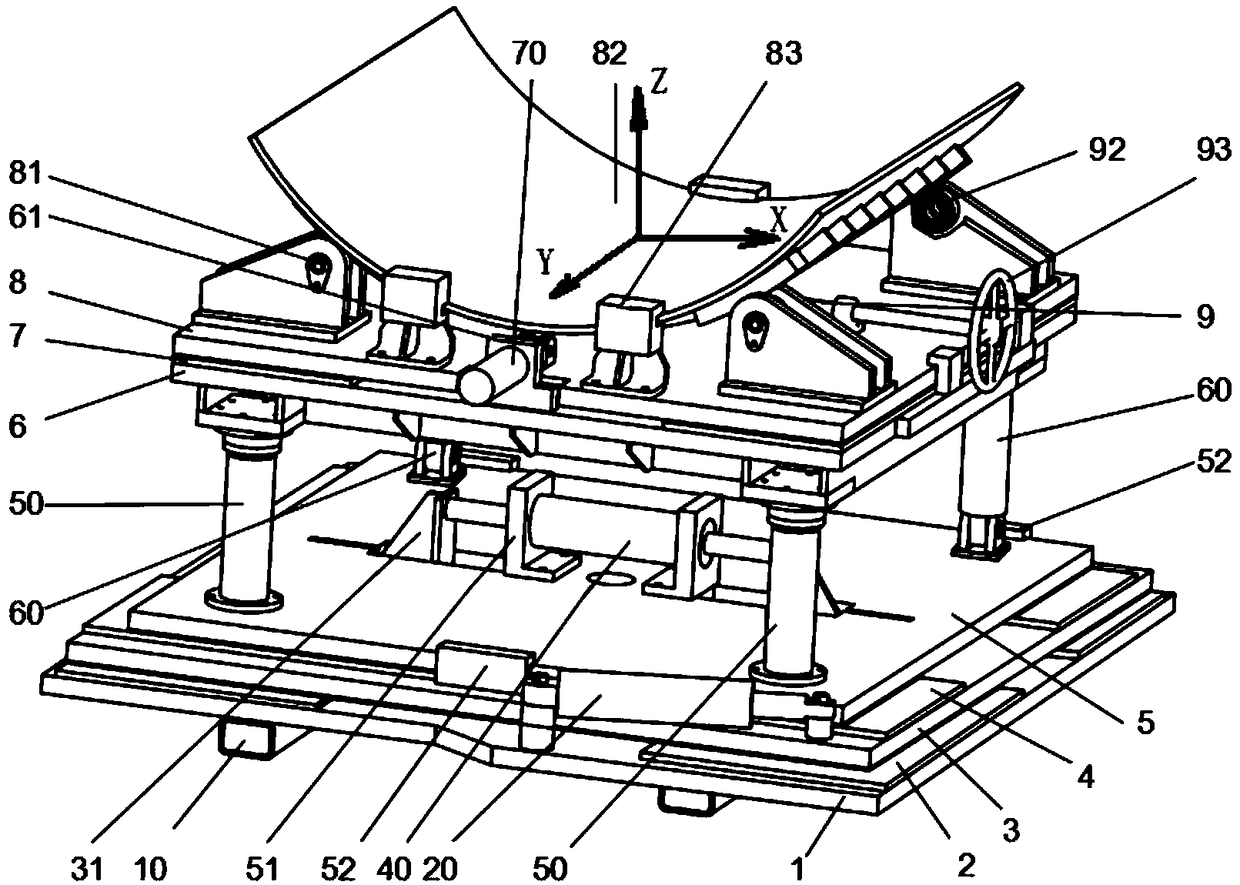

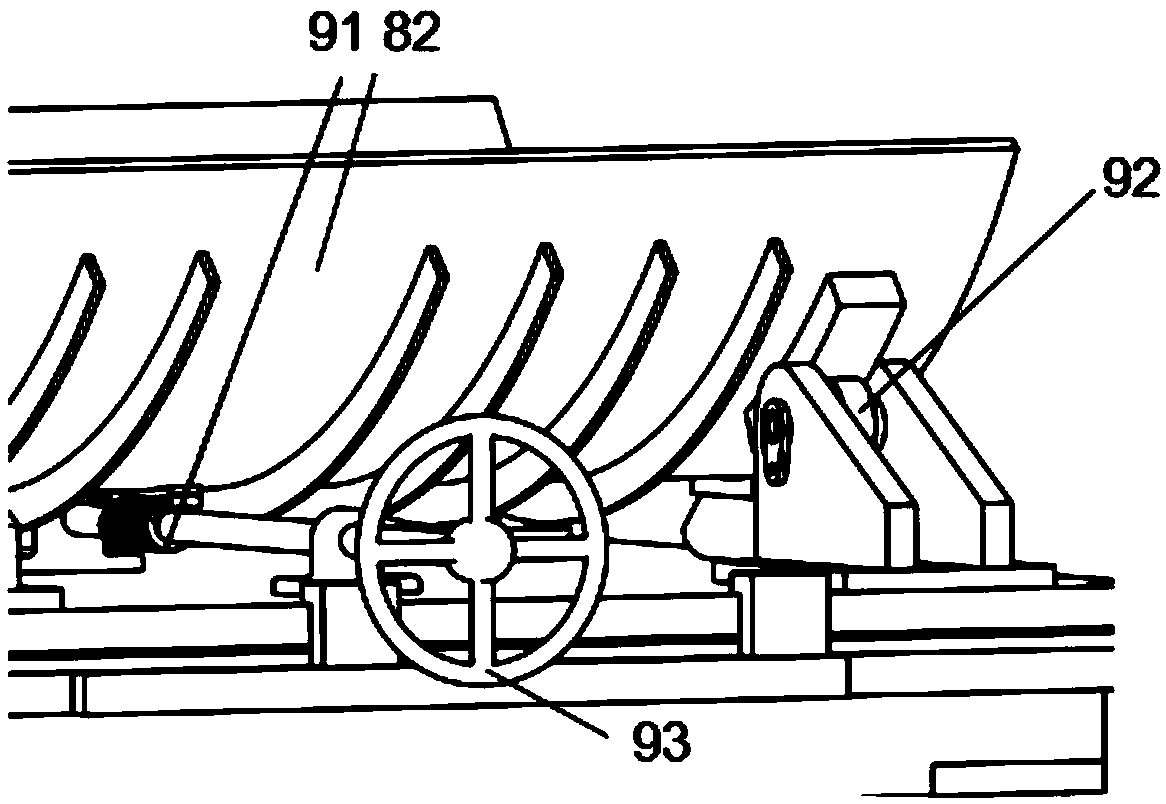

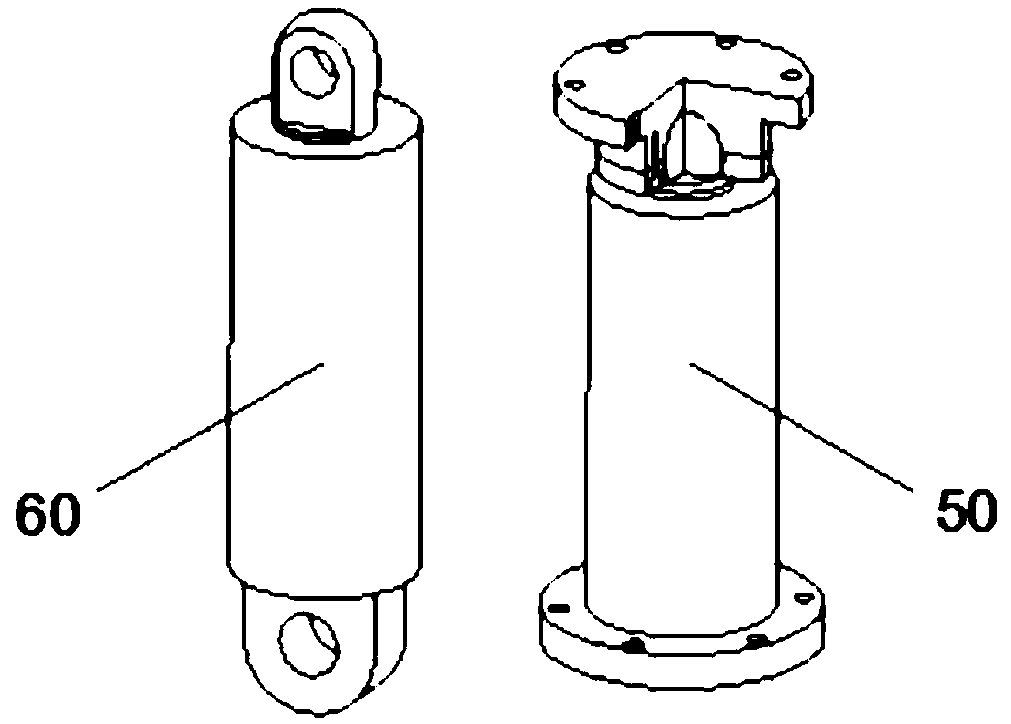

[0029] Such as Figure 1~3 , 6 degrees of freedom rotating parts spatial position adjustment system, including a base plate 1 with a central axis, the plane on which the base plate 1 is located defines mutually perpendicular X-axis and Y-axis, and a Z-axis perpendicular to the XY plane; the base plate 1 The lower end is welded with a square tube 10 for support, and the first anti-friction plate 2 is installed on the base plate 1. There is a rotating bottom plate 3 matching its central axis above the base plate 1. A bright stainless steel sheet is welded under the rotating bottom plate 3. The bright stainless steel sheet Cooperate with the first anti-friction plate 2 to form a moving pair, the rotating bottom plate 3 can be driven by a rotating mechanism 20, and rotate around the Z axis relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com