Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

364results about How to "Improve fastening force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

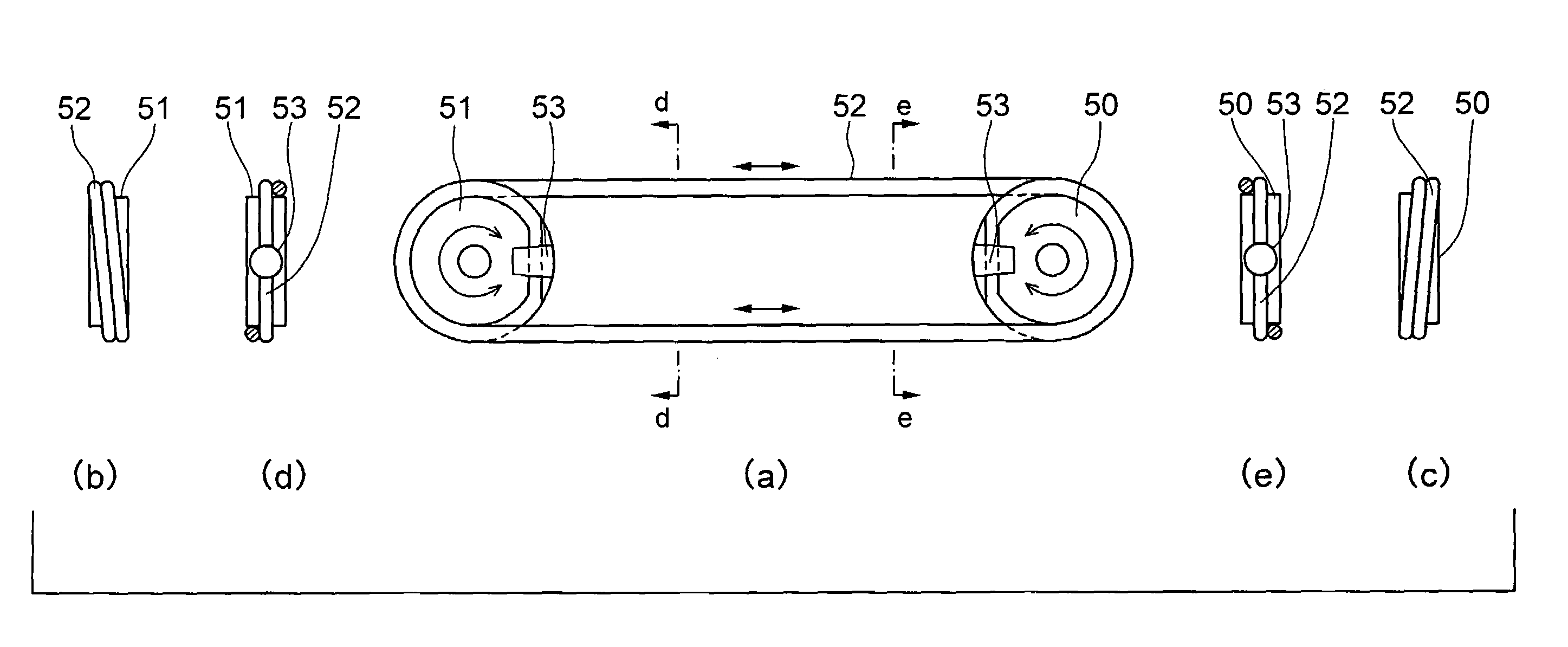

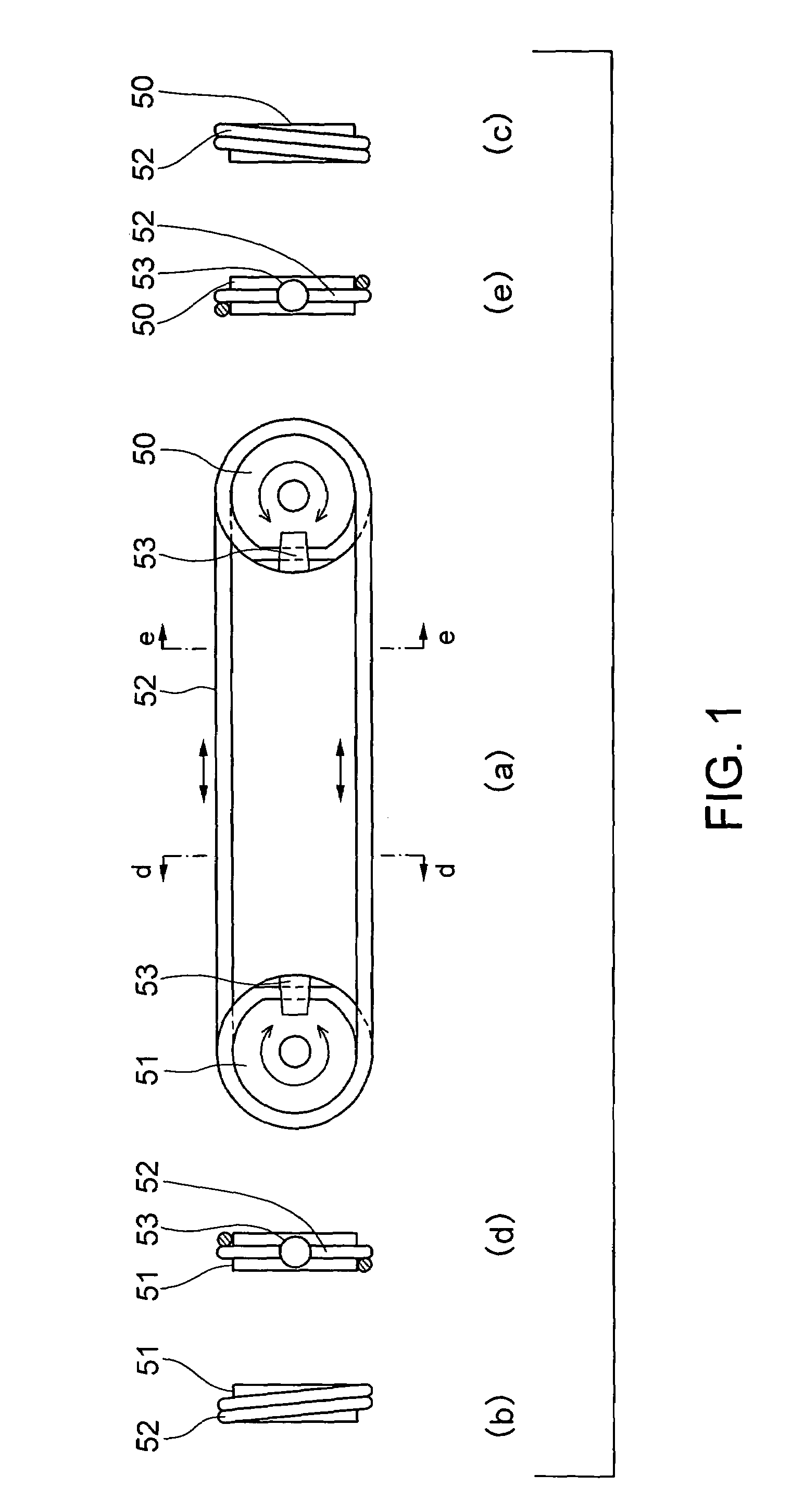

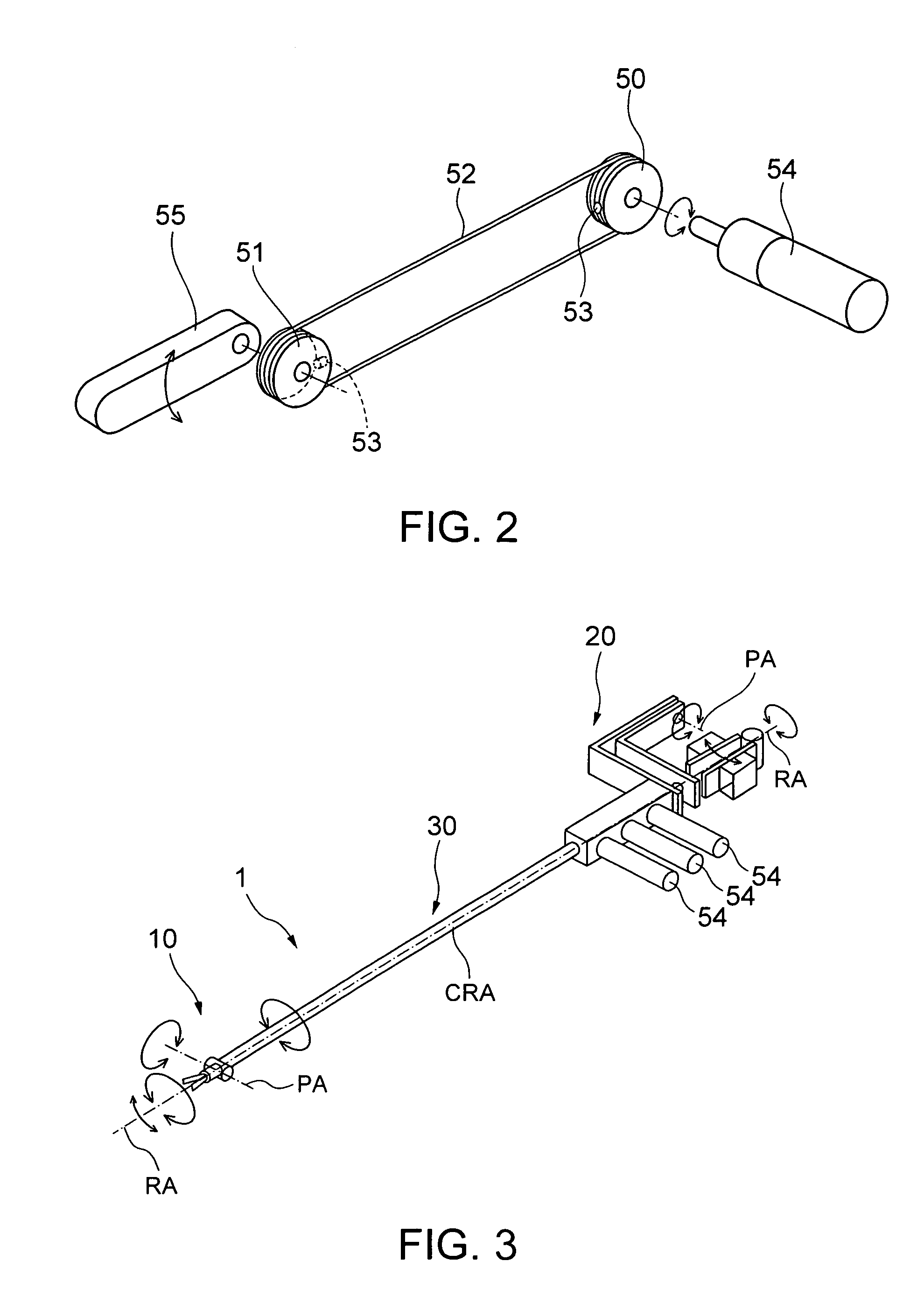

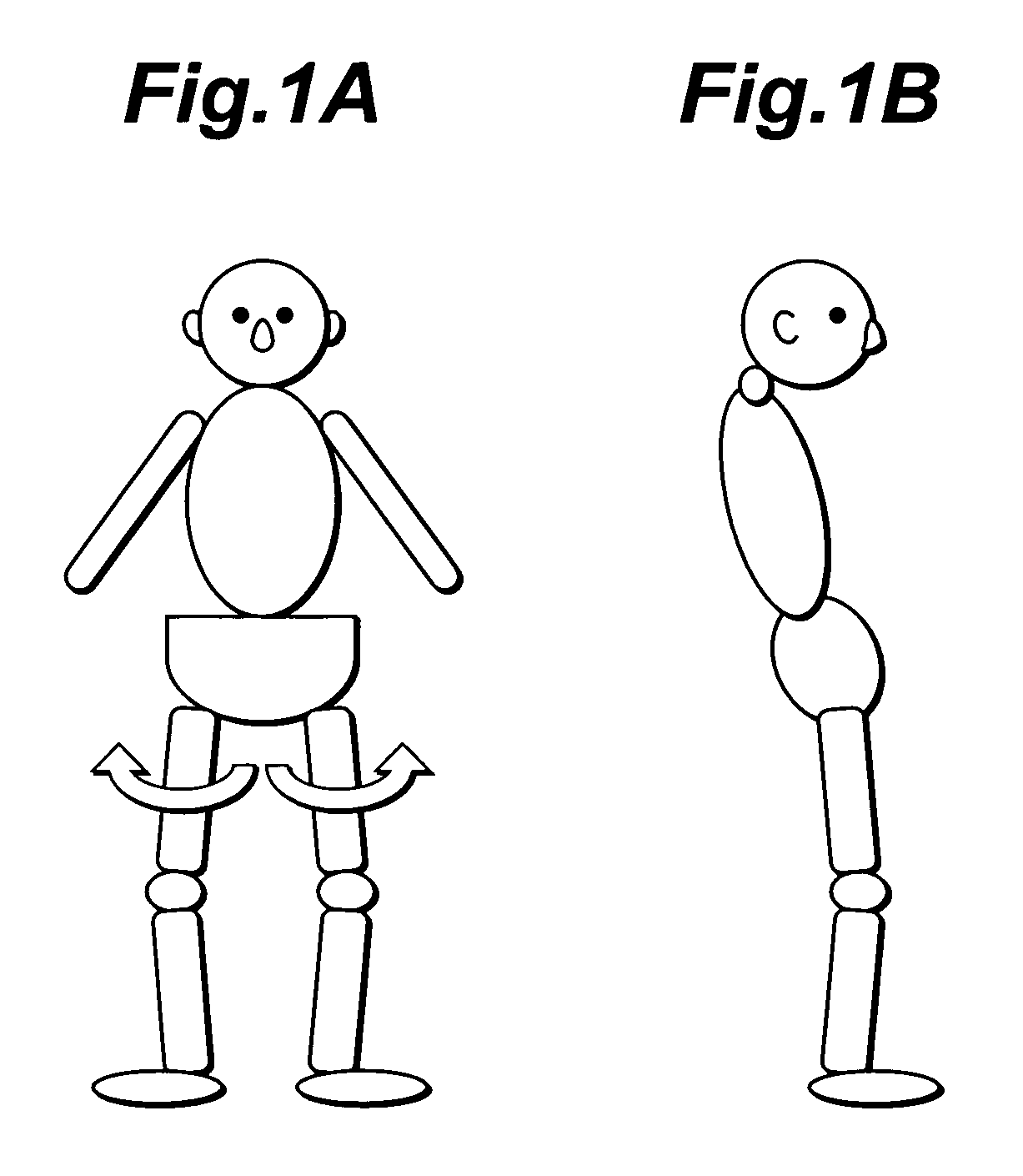

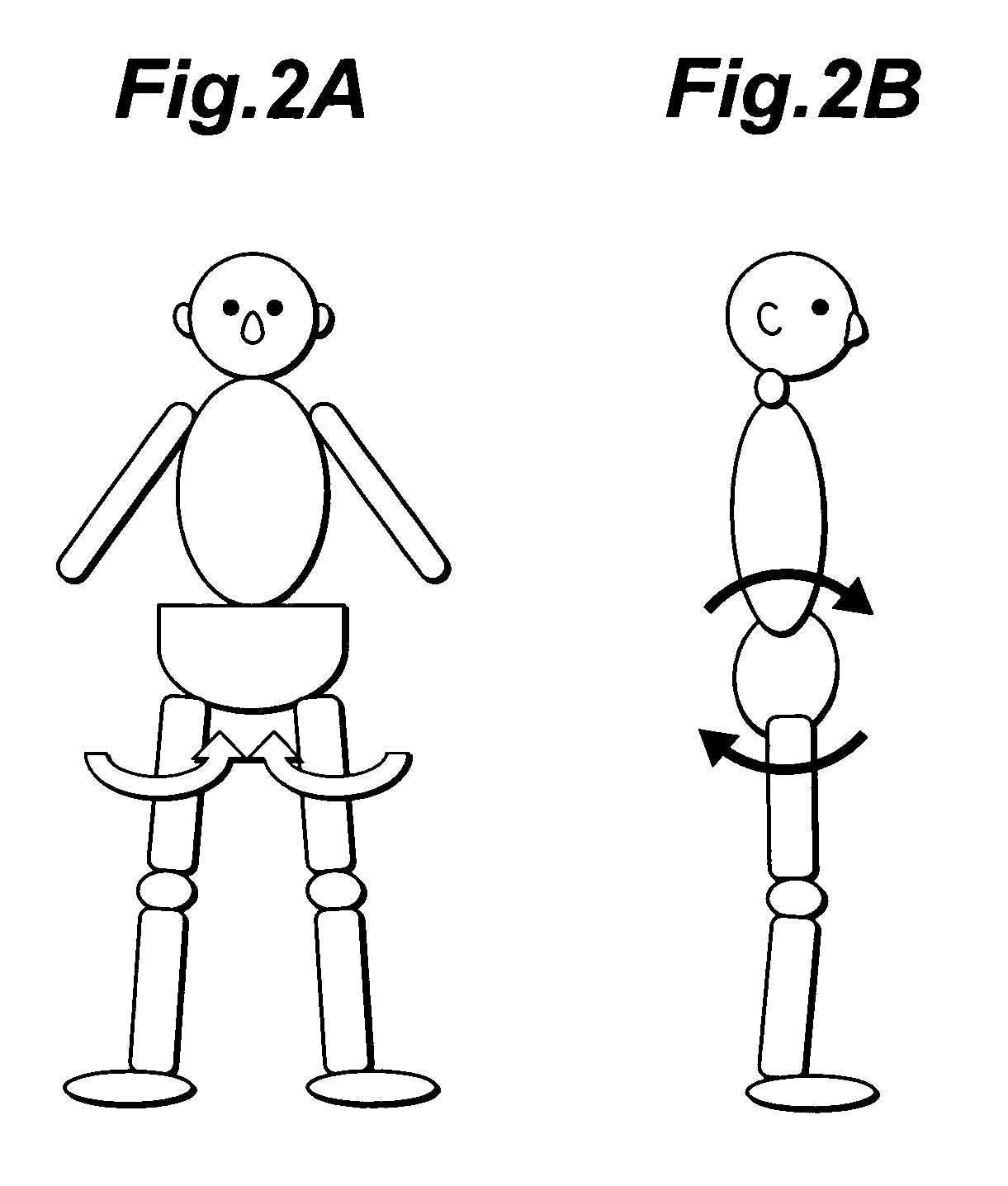

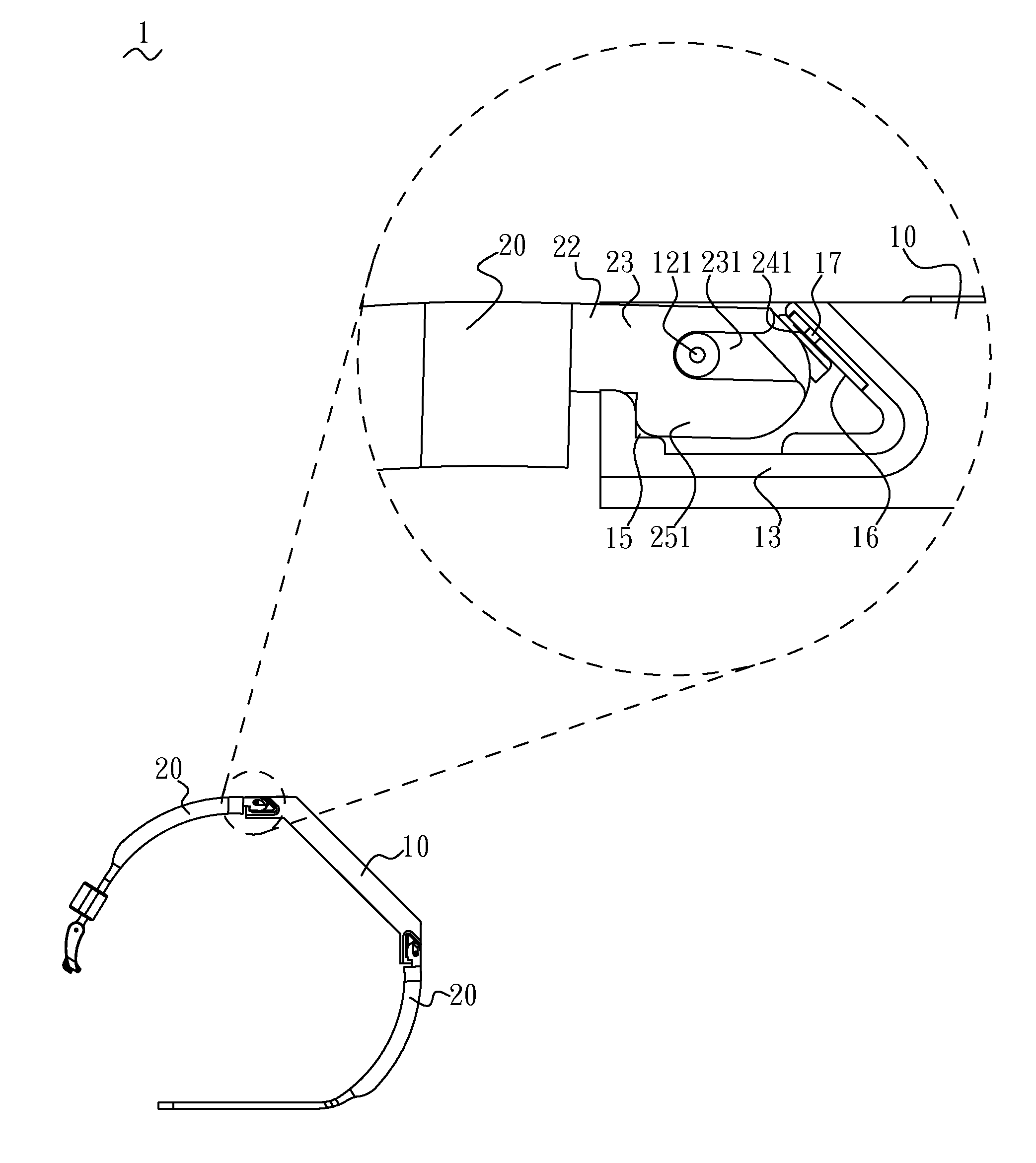

Power transmission mechanism and manipulator

ActiveUS7300373B2Small sizeEnhance reliability and rigidity and controllabilitySuture equipmentsProgramme-controlled manipulatorElectric power transmissionEngineering

A power transmission mechanism comprising: a flexible power transmission element; a pair of a drive pulley and a driven pulley on which the flexible power transmission element is wound, each the pulley having a pin-embedding hole formed to extend from the outer circumferential thereof toward the center thereof, and a slit elongated in the circumferential direction of the pulley to extend to opposite sides of the embedding hole and communicating with the embedding hole; and a pair of columnar or tapered anchor pins each having a path hole penetrating the anchor pin across the lengthwise direction thereof to receive the flexible power transmission element inserted therein, wherein each the anchor pin receiving the flexible power transmission element in the path hole thereof is embedded in the embedding hole of the associated pulley under pressure, and the flexible power transmission element is thereby held on the pulley.

Owner:TERUMO KK

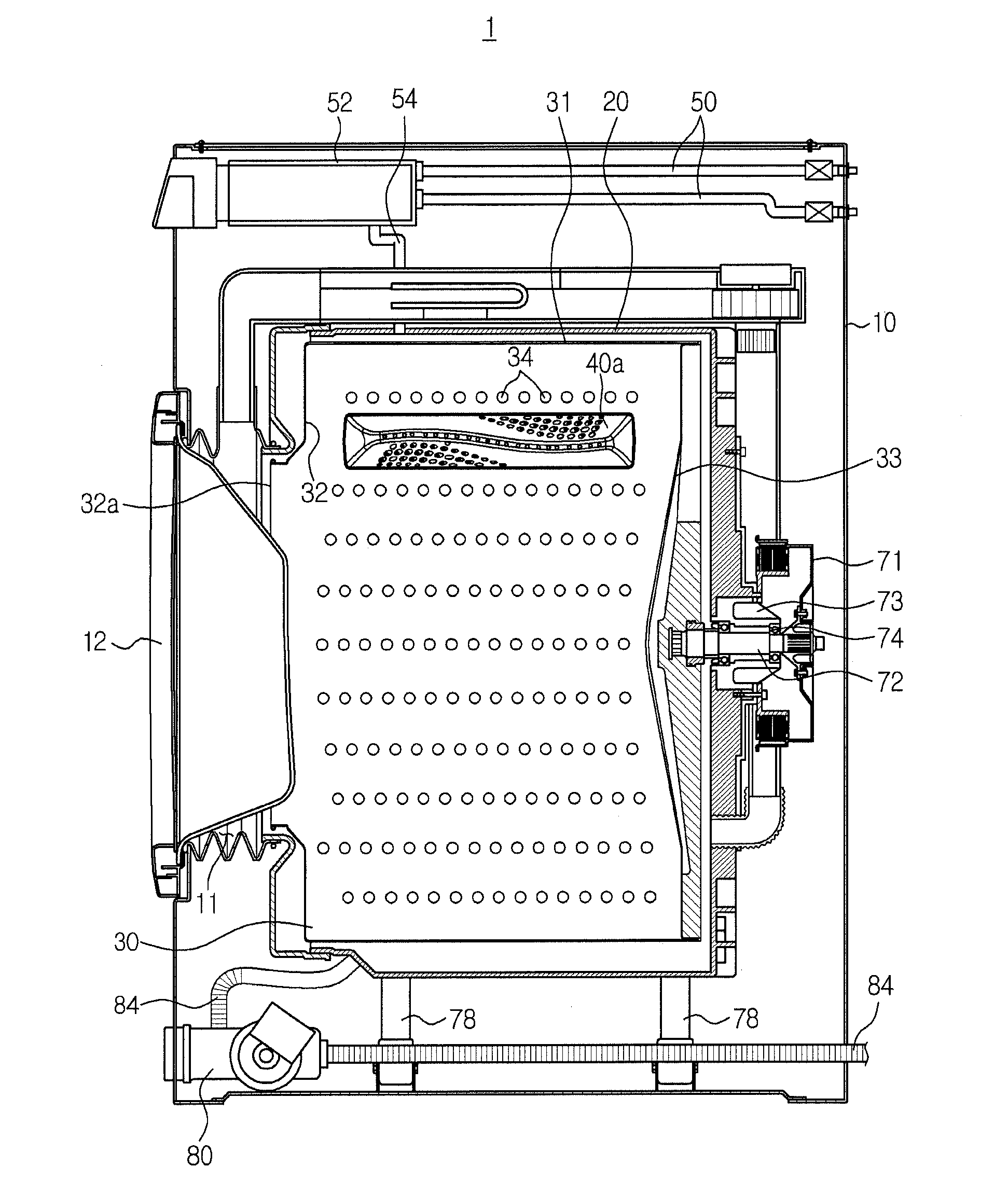

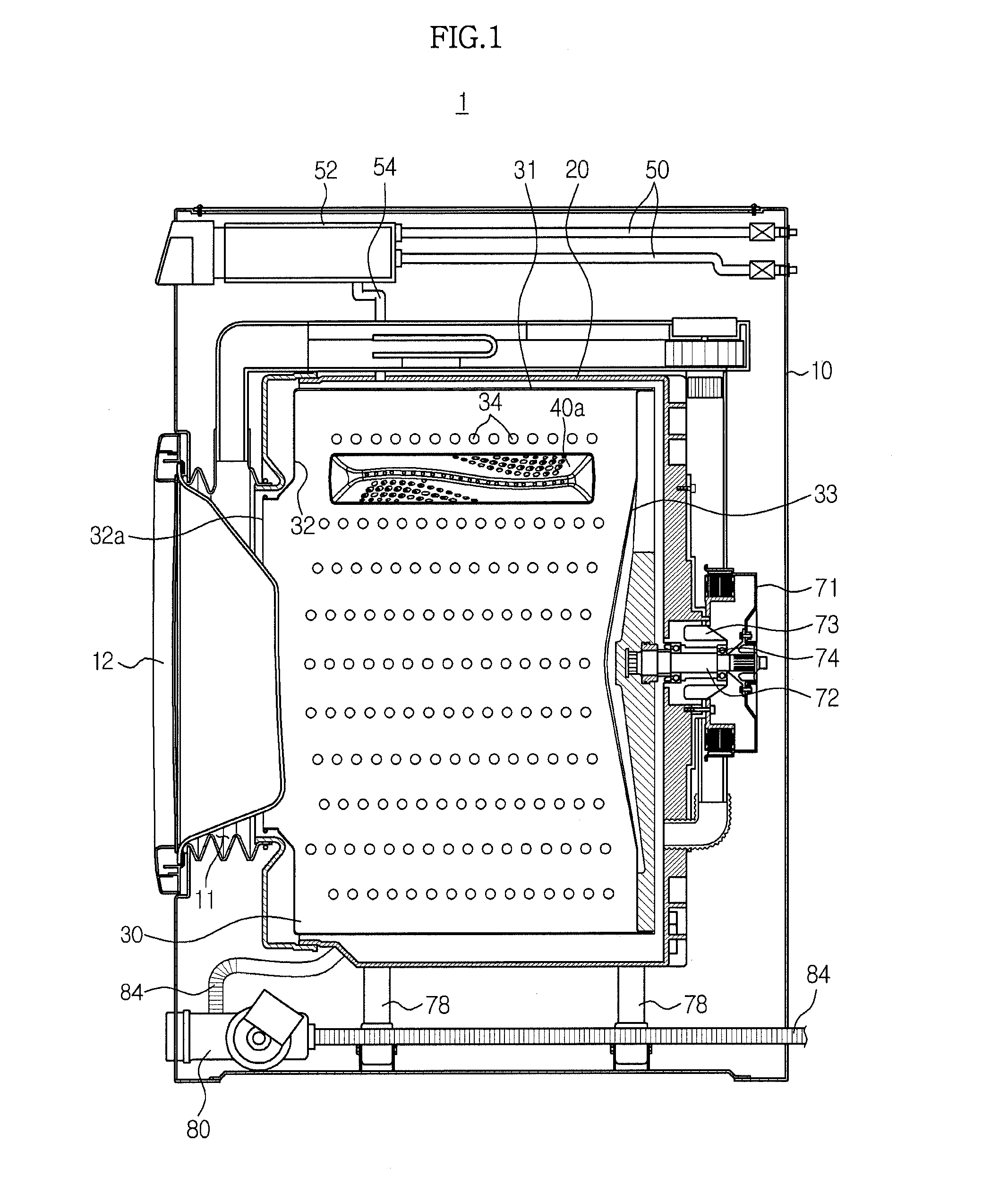

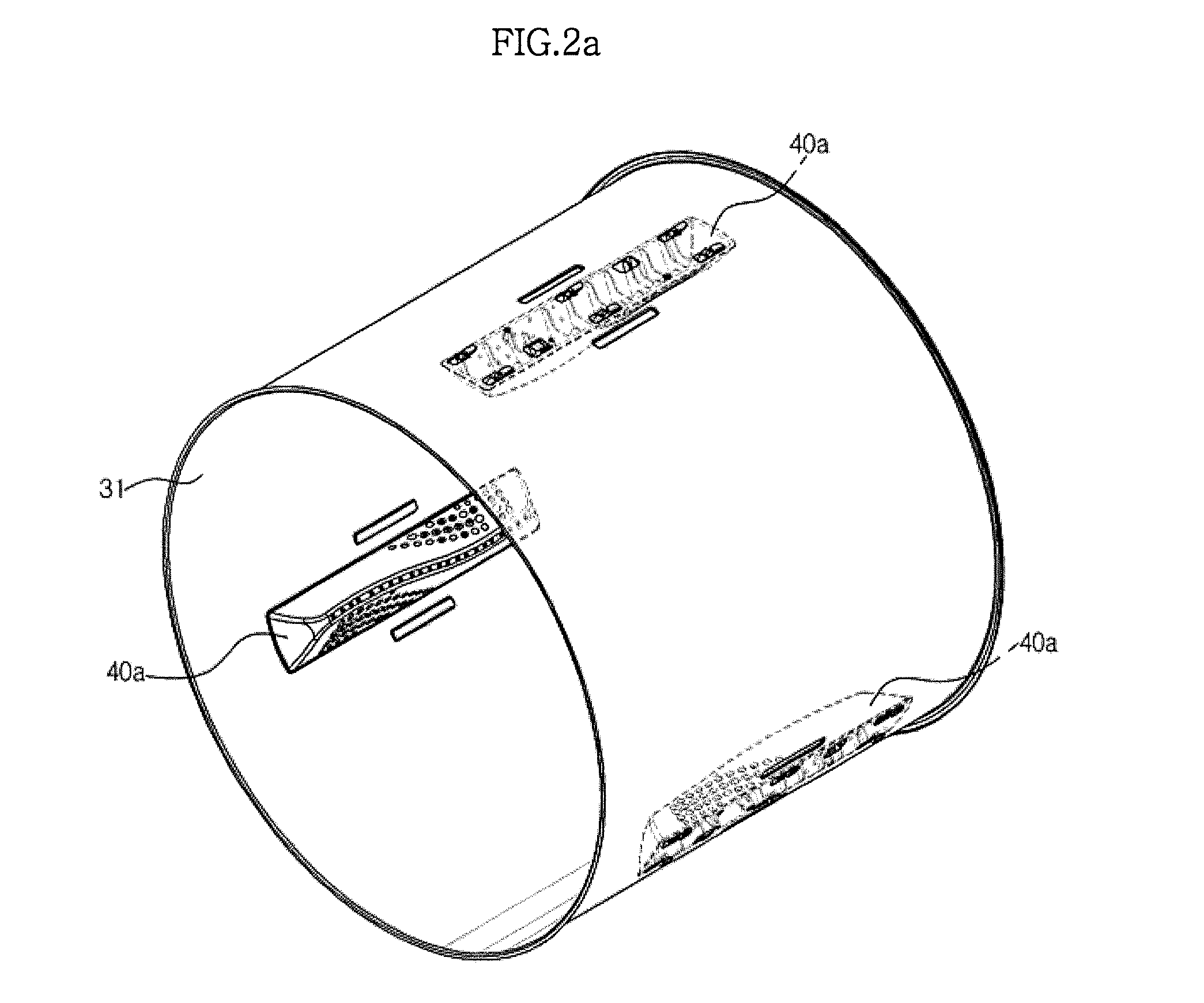

Lifter and washing machine having the same

InactiveUS20130081432A1Improve washing efficiencyImprove fastening forceOther washing machinesWashing machine with receptaclesLaundryMechanical engineering

A lifter simply mounted on a drum and a washing machine having the same. The washing machine includes a cabinet, a tub arranged within the cabinet, a drum arranged within the tub to accommodate laundry and rotated by rotary force transmitted from a driving source, and a plurality of lifters provided on the inner circumferential surface of the drum to move the laundry within the drum. Each of the plurality of lifters includes a plurality of hooks provided along a frame formed at the lower end of each of the plurality of lifters so as to allow each of the plurality of lifters to be hung to the drum, and at least one protrusion protruding from the lower end of each of the plurality of lifters so as to allow each of the plurality of lifters to be fixed to the inner circumferential surface of the drum.

Owner:SAMSUNG ELECTRONICS CO LTD

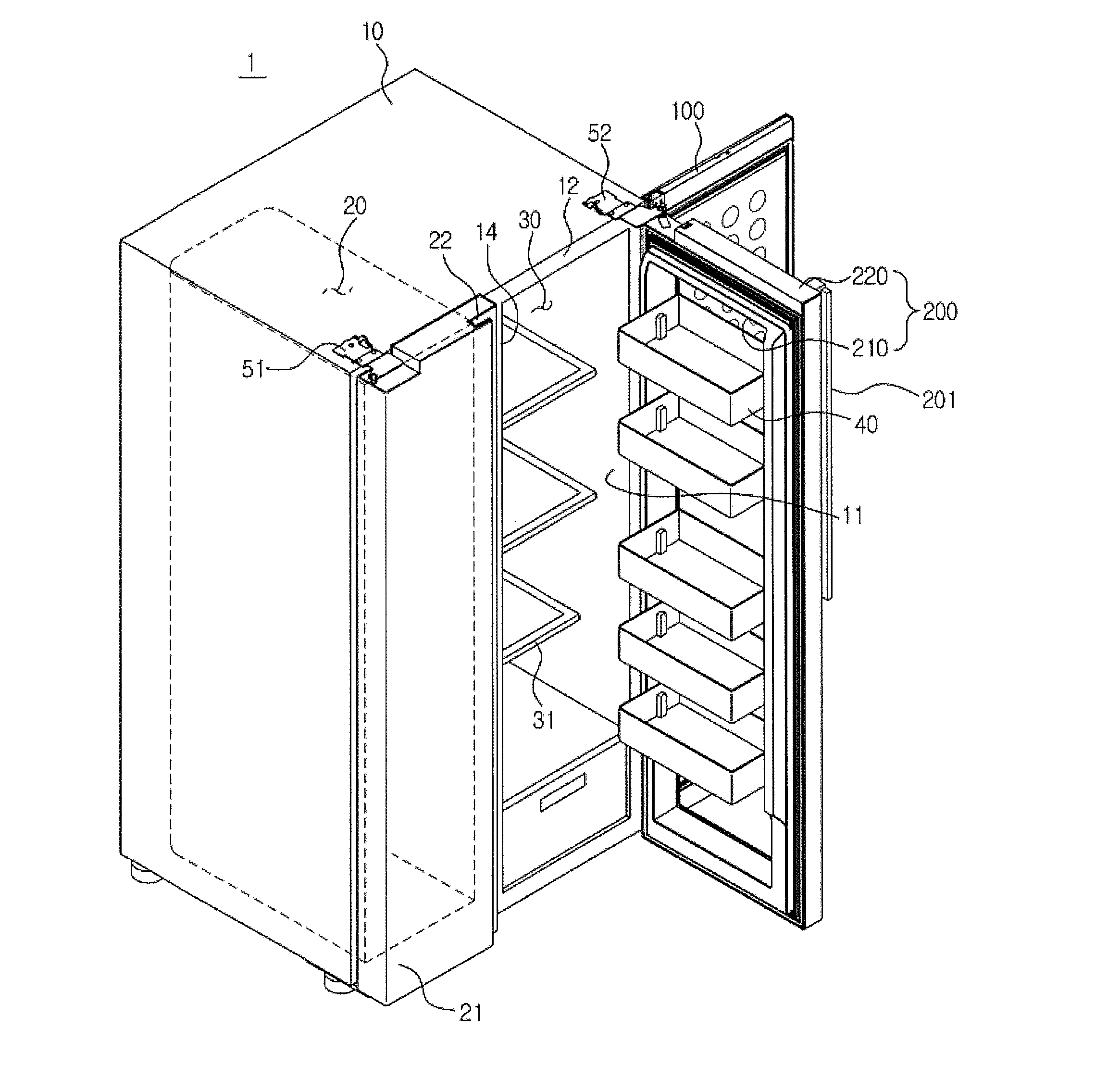

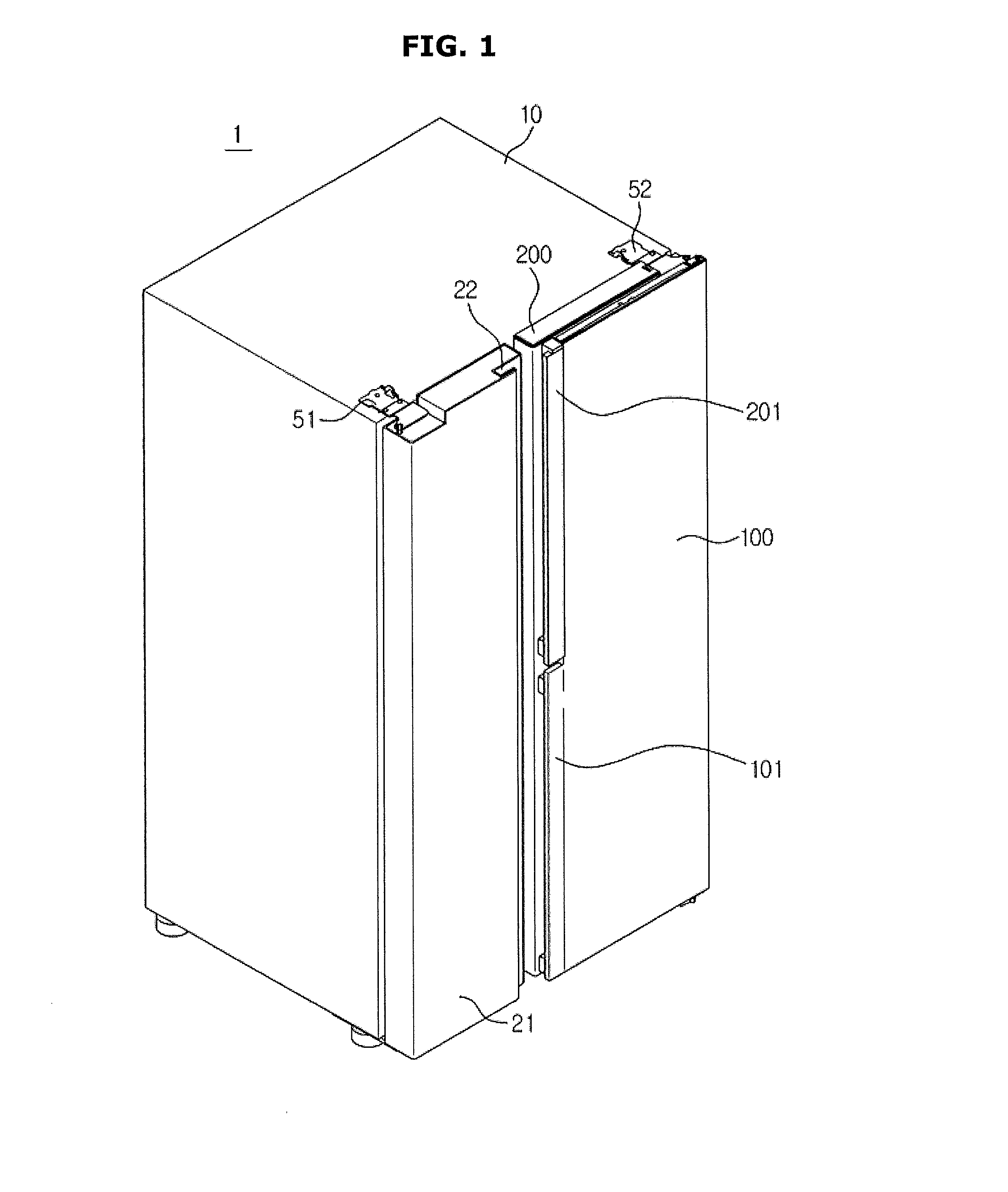

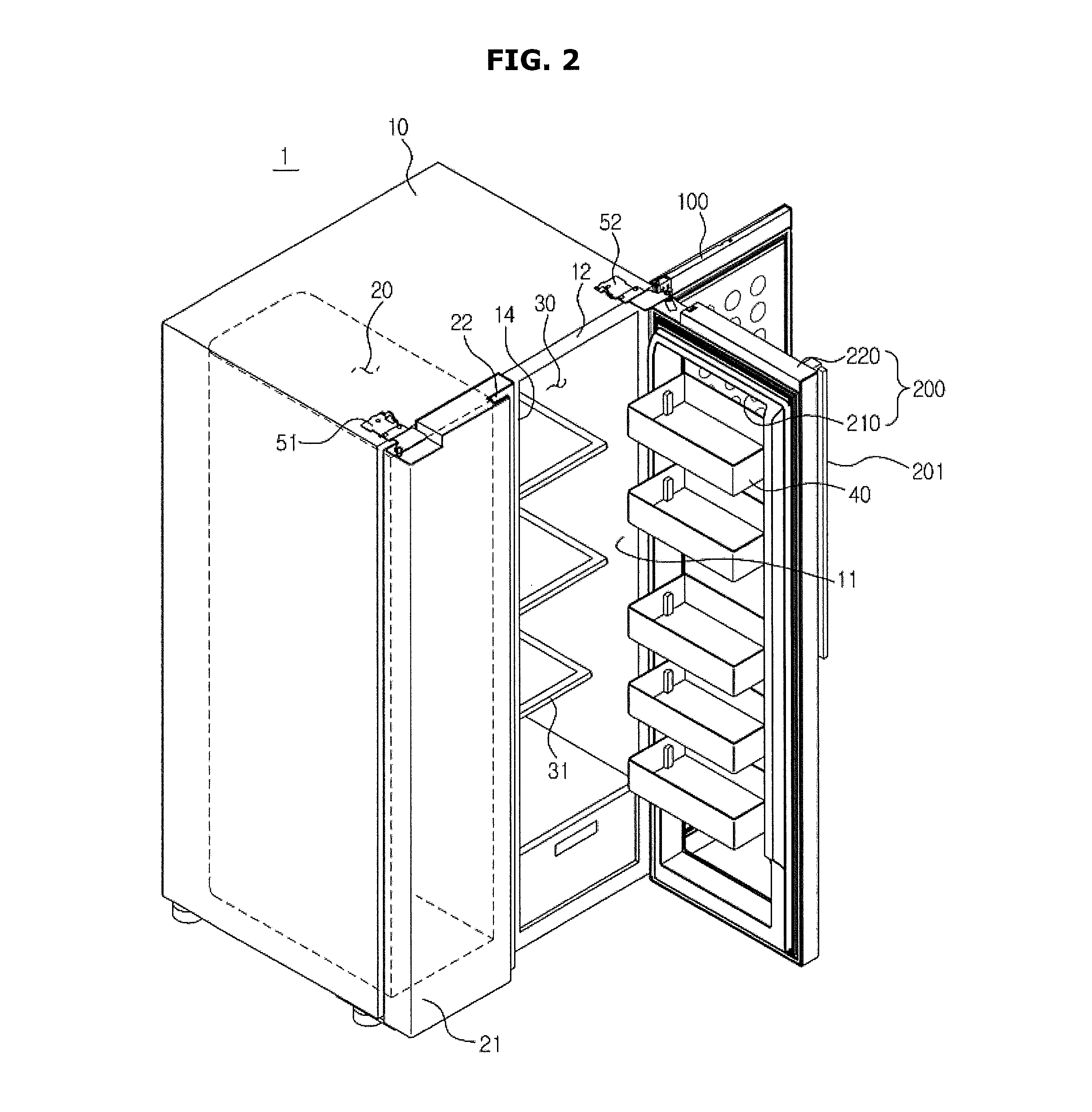

Refrigerator and method of manufacturing inner door thereof

ActiveUS20140132146A1Improve fastening forceAvoid distortionLighting and heating apparatusFurniture partsRefrigerated temperatureHolding room

Owner:SAMSUNG ELECTRONICS CO LTD

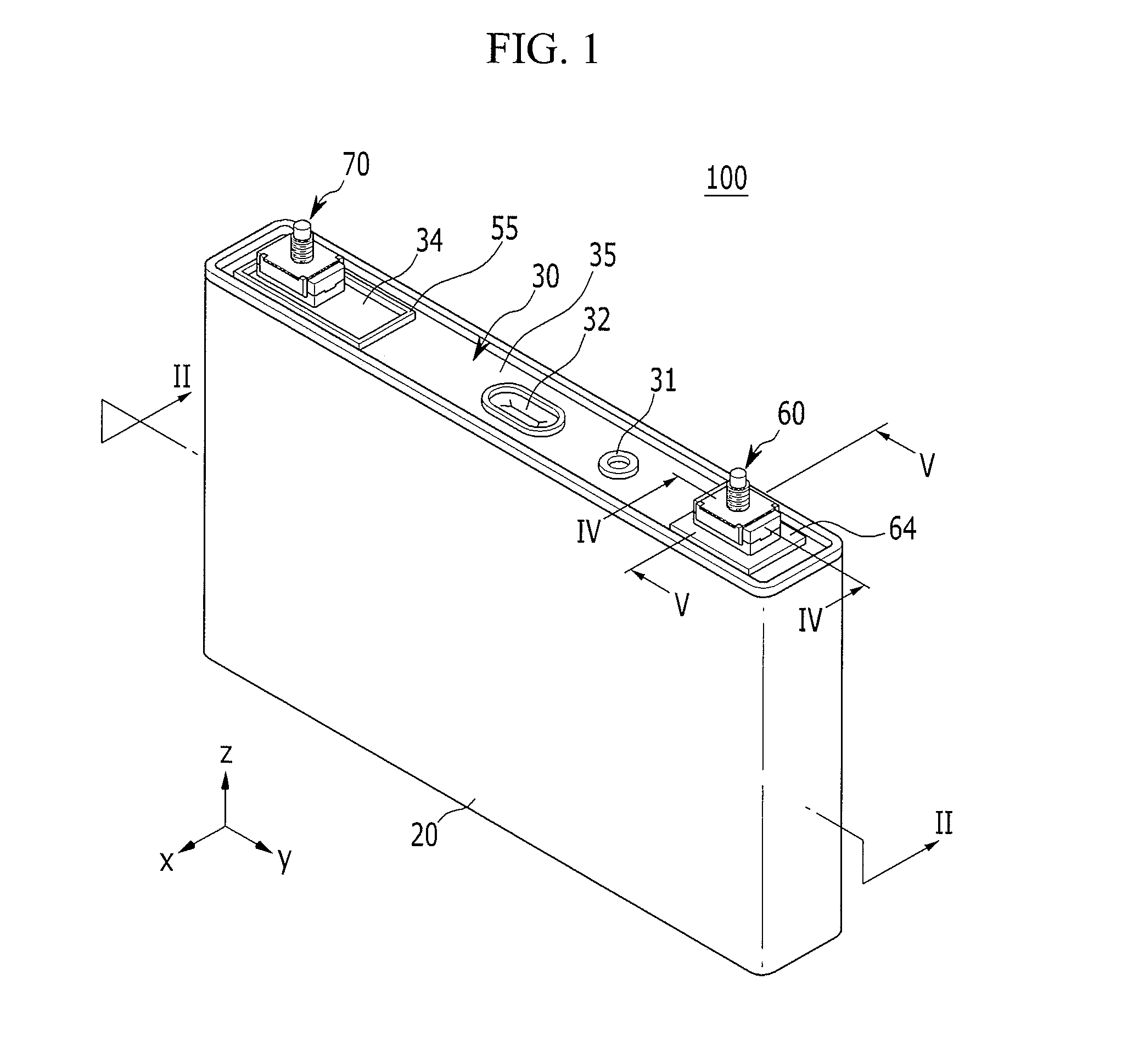

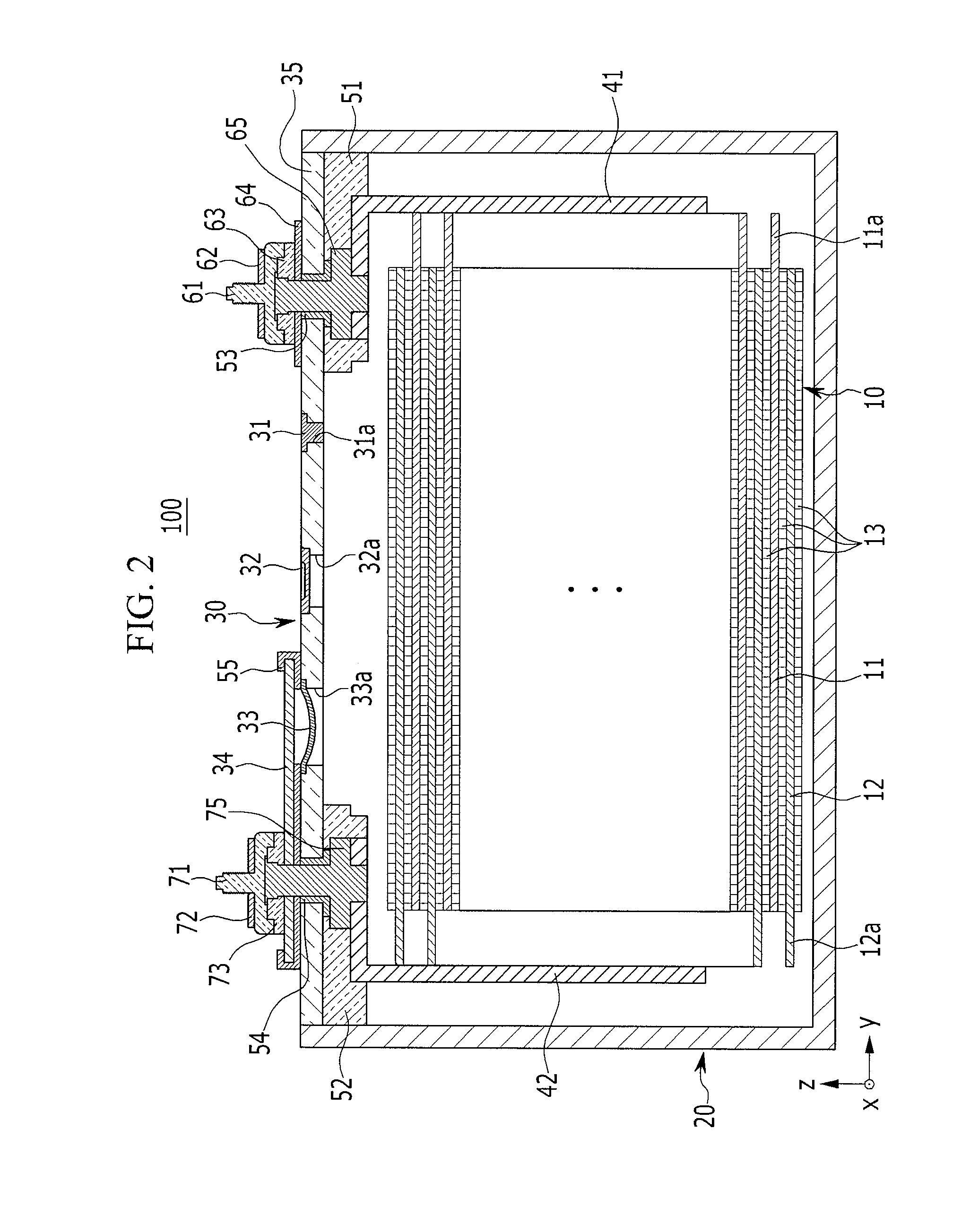

Rechargeable Battery

ActiveUS20110244310A1Improved electrode terminal structureImprove fastening forcePrimary cell to battery groupingLarge-sized flat cells/batteriesRechargeable cellEngineering

A rechargeable battery includes an electrode assembly including a positive electrode, a negative electrode, and a separator therebetween; a case that has an opening that houses the electrode assembly; a cap assembly including a cap plate that covers the opening of the case; and an electrode terminal that is electrically connected to the electrode assembly and protrudes through the cap plate to the outside of the case. The electrode terminal includes a lower terminal plate that is connected to the electrode assembly, an upper terminal plate that covers an upper part of the lower terminal plate, and a terminal fastener that is housed in a space between the lower terminal plate and the upper terminal plate that protrudes through an upper surface of the upper terminal plate.

Owner:ROBERT BOSCH GMBH +1

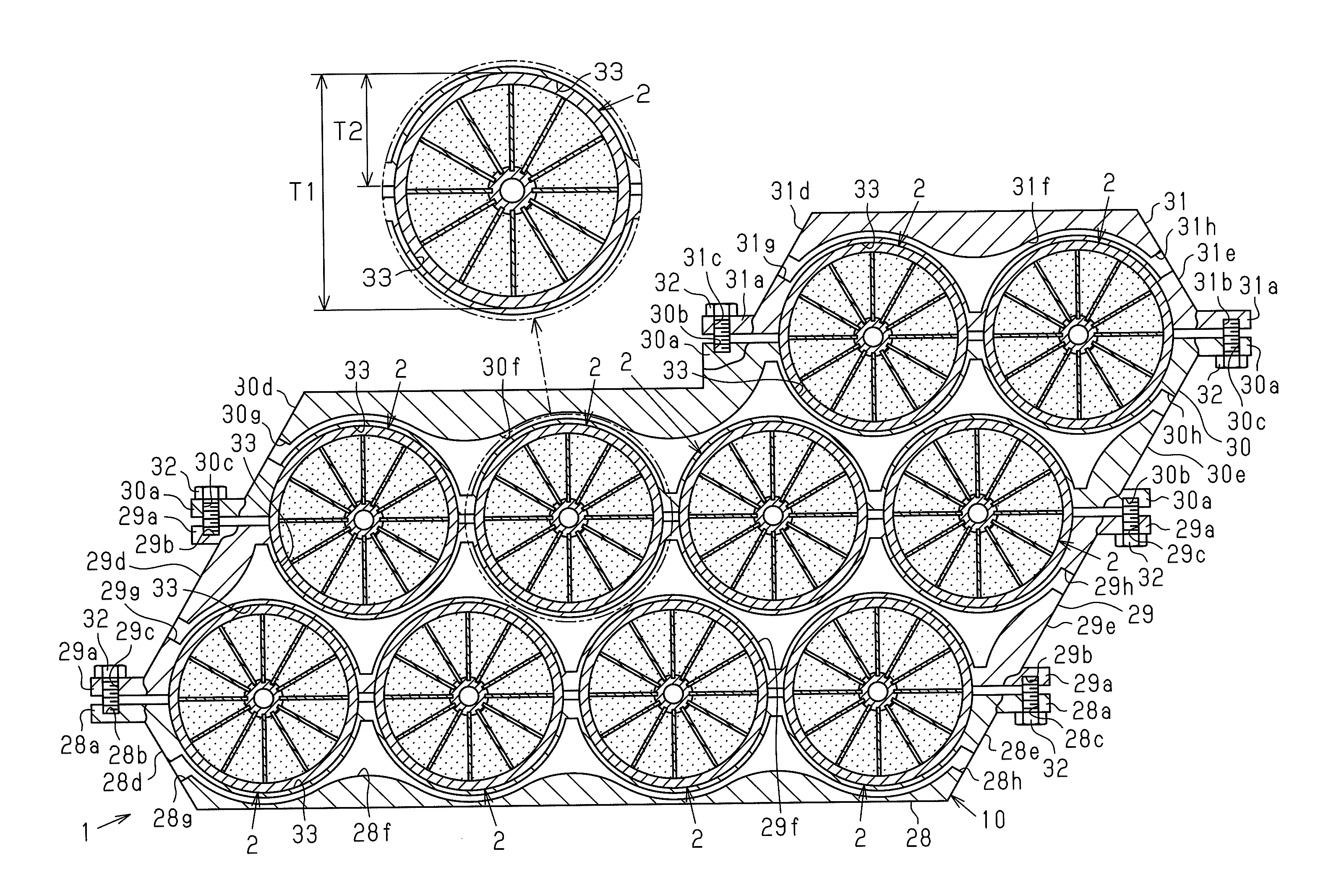

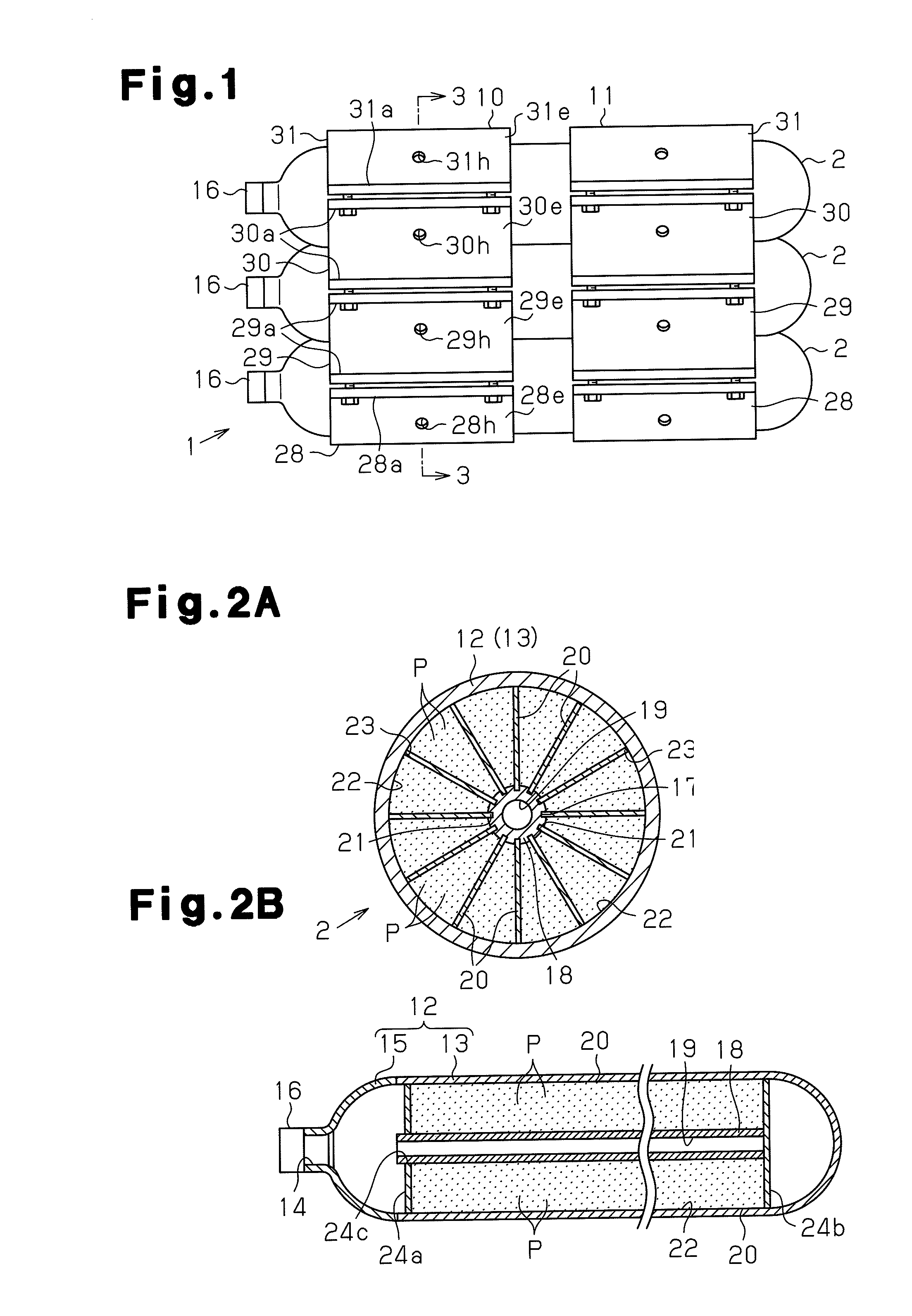

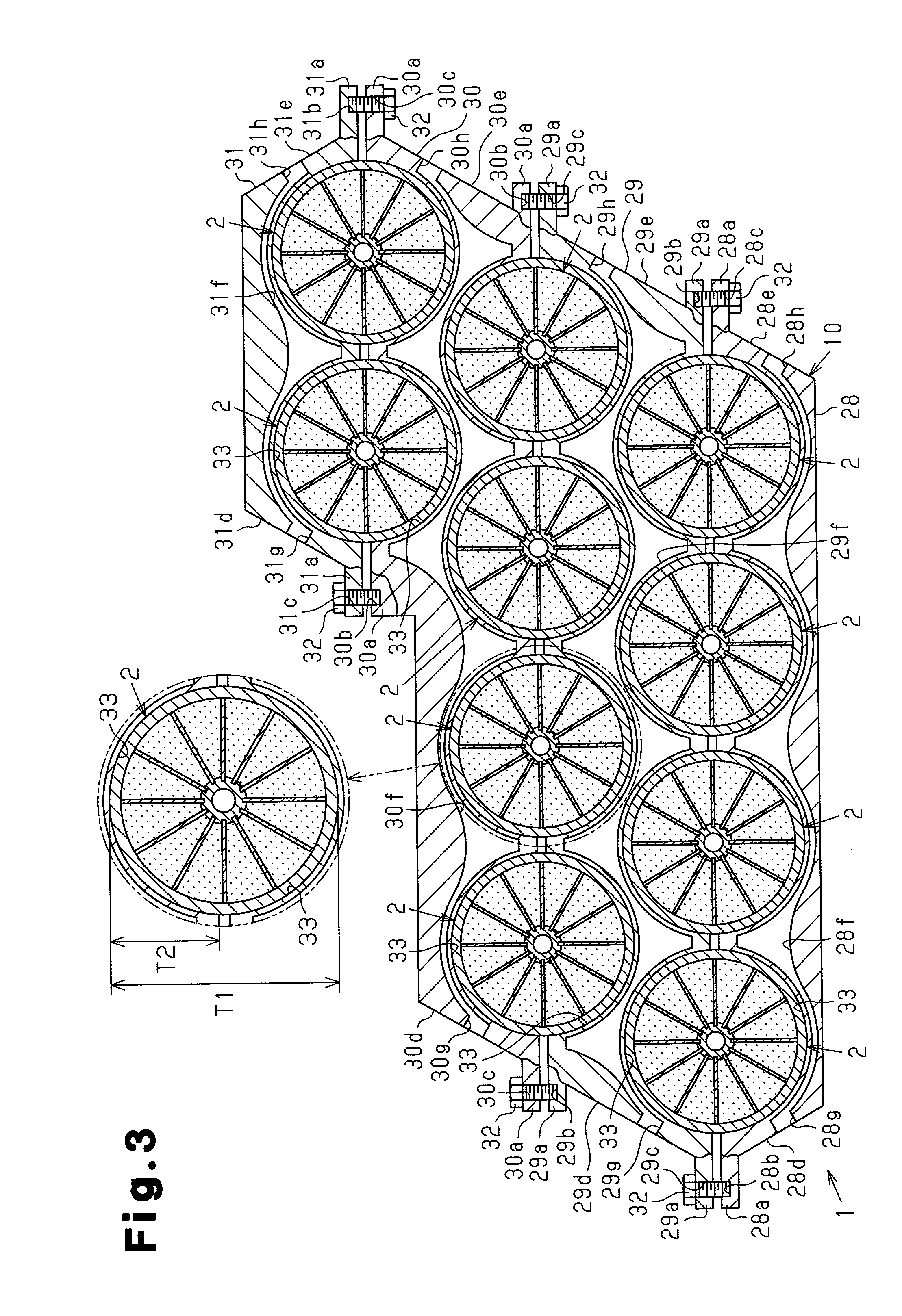

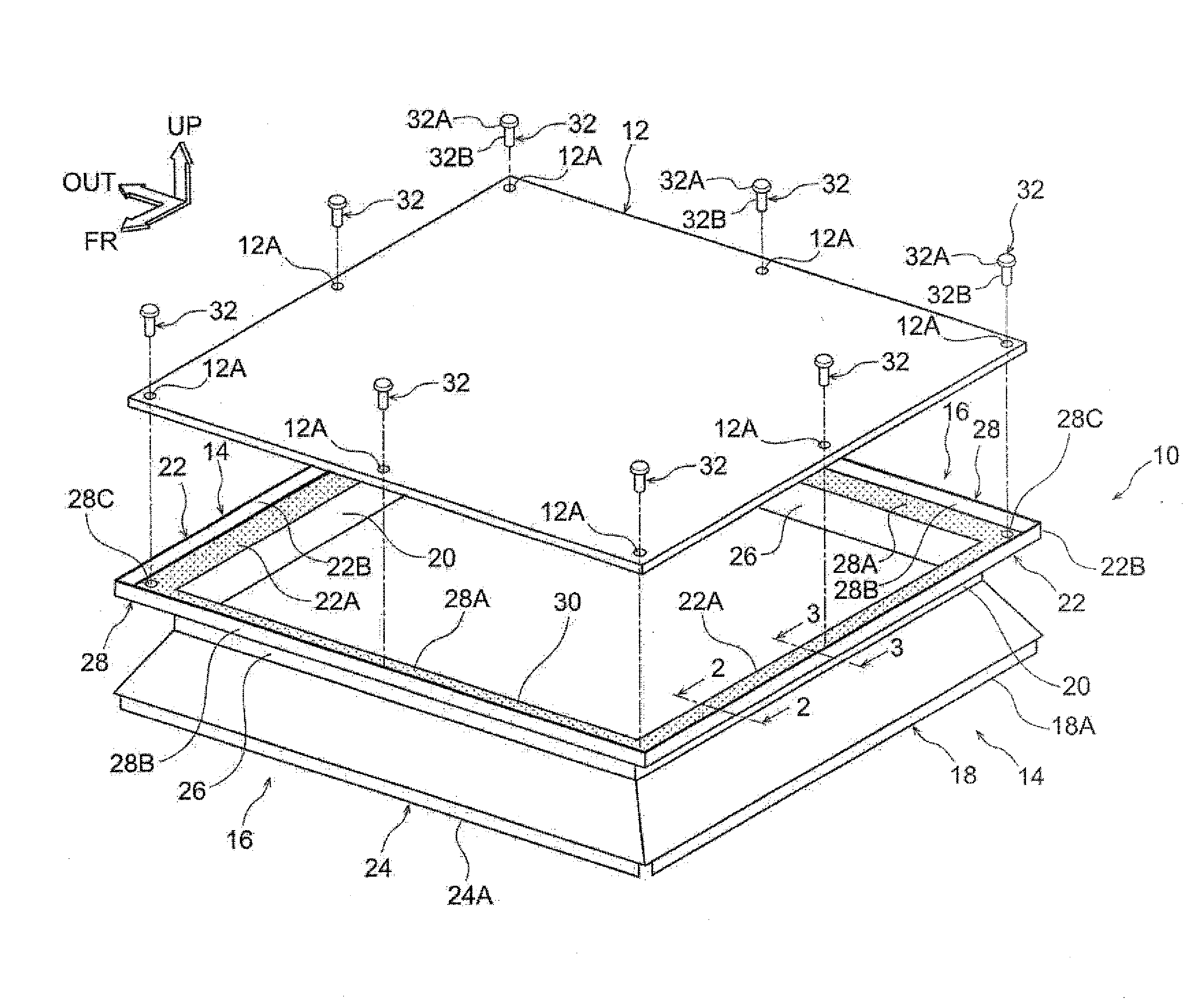

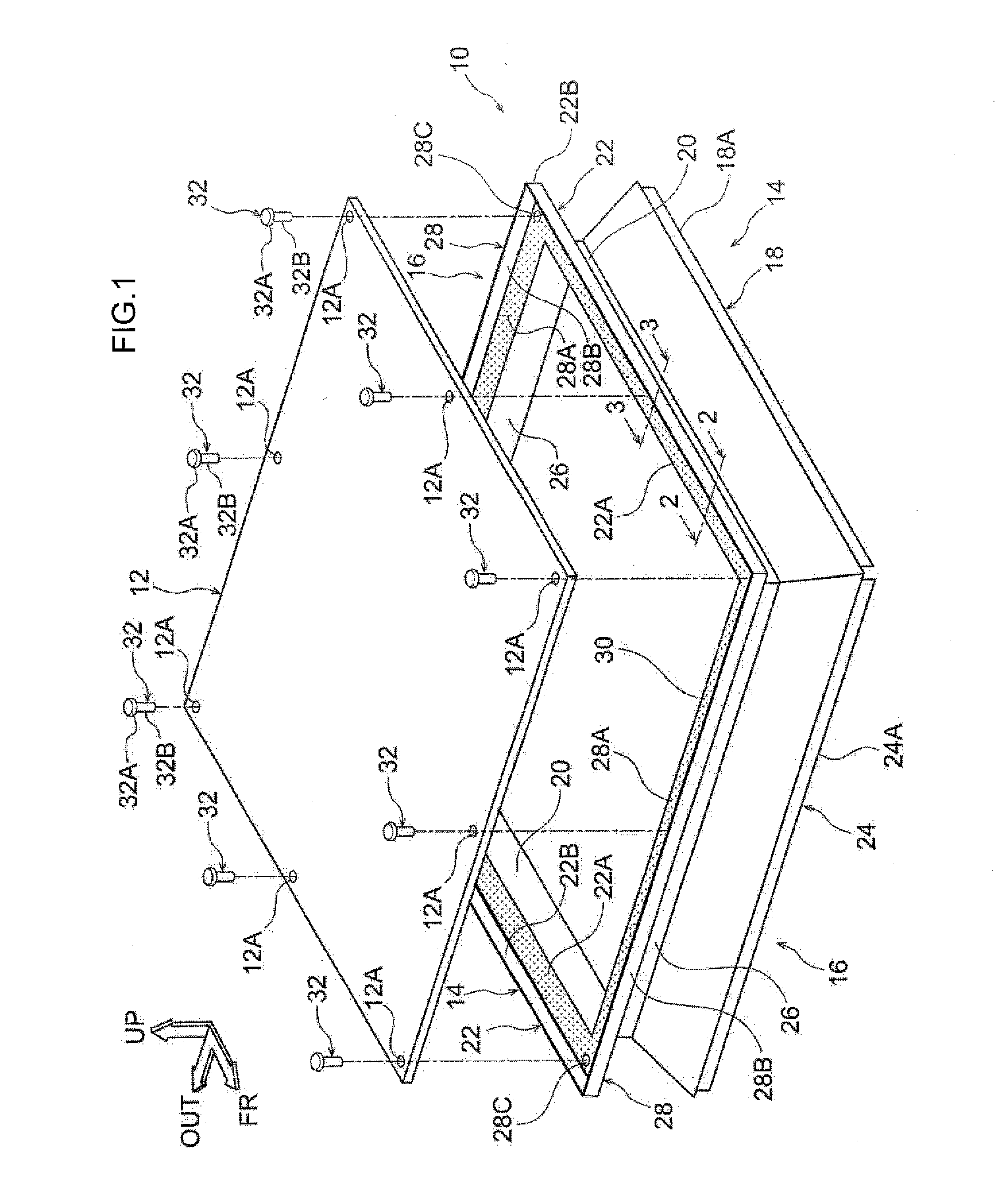

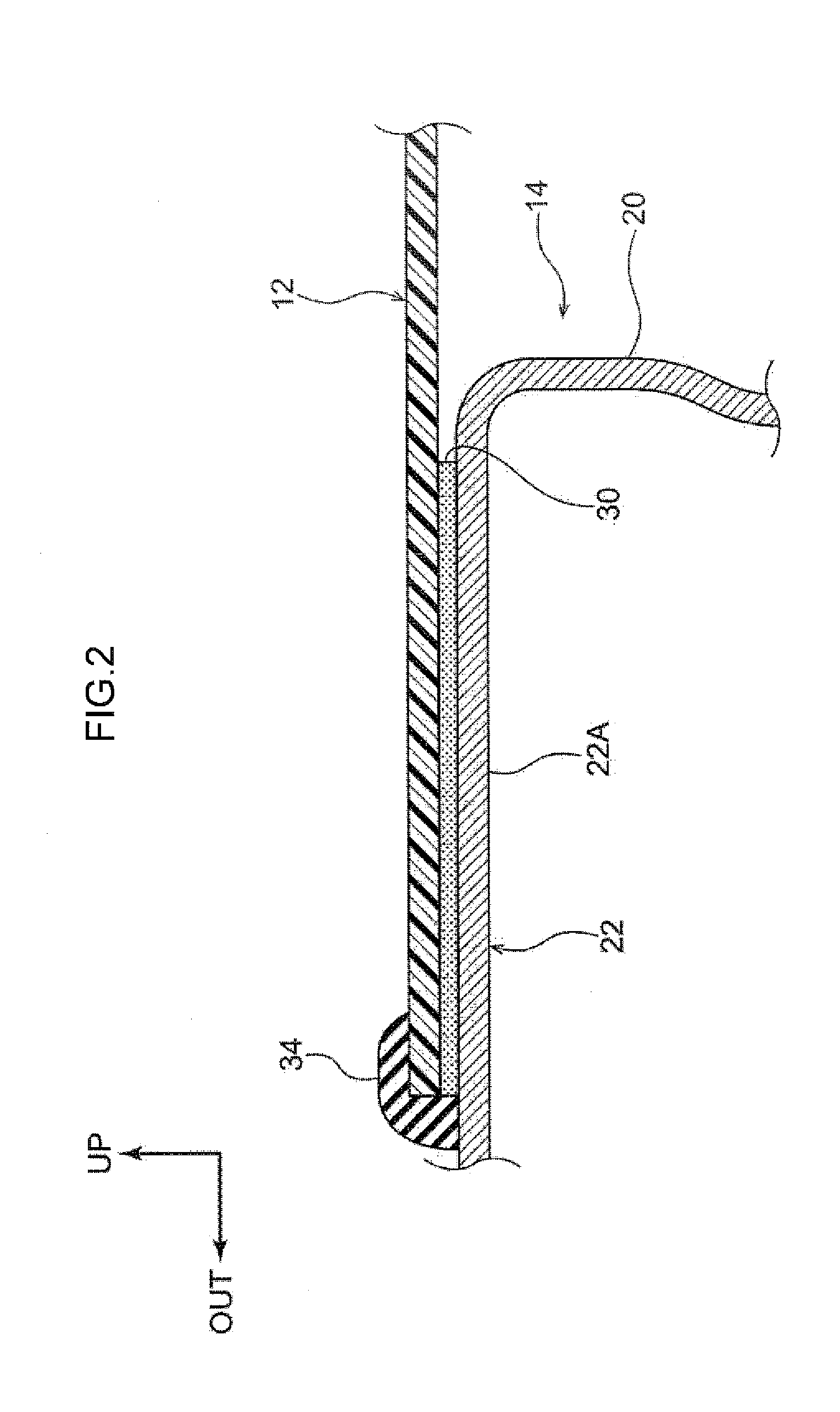

Hydrogen gas storage device

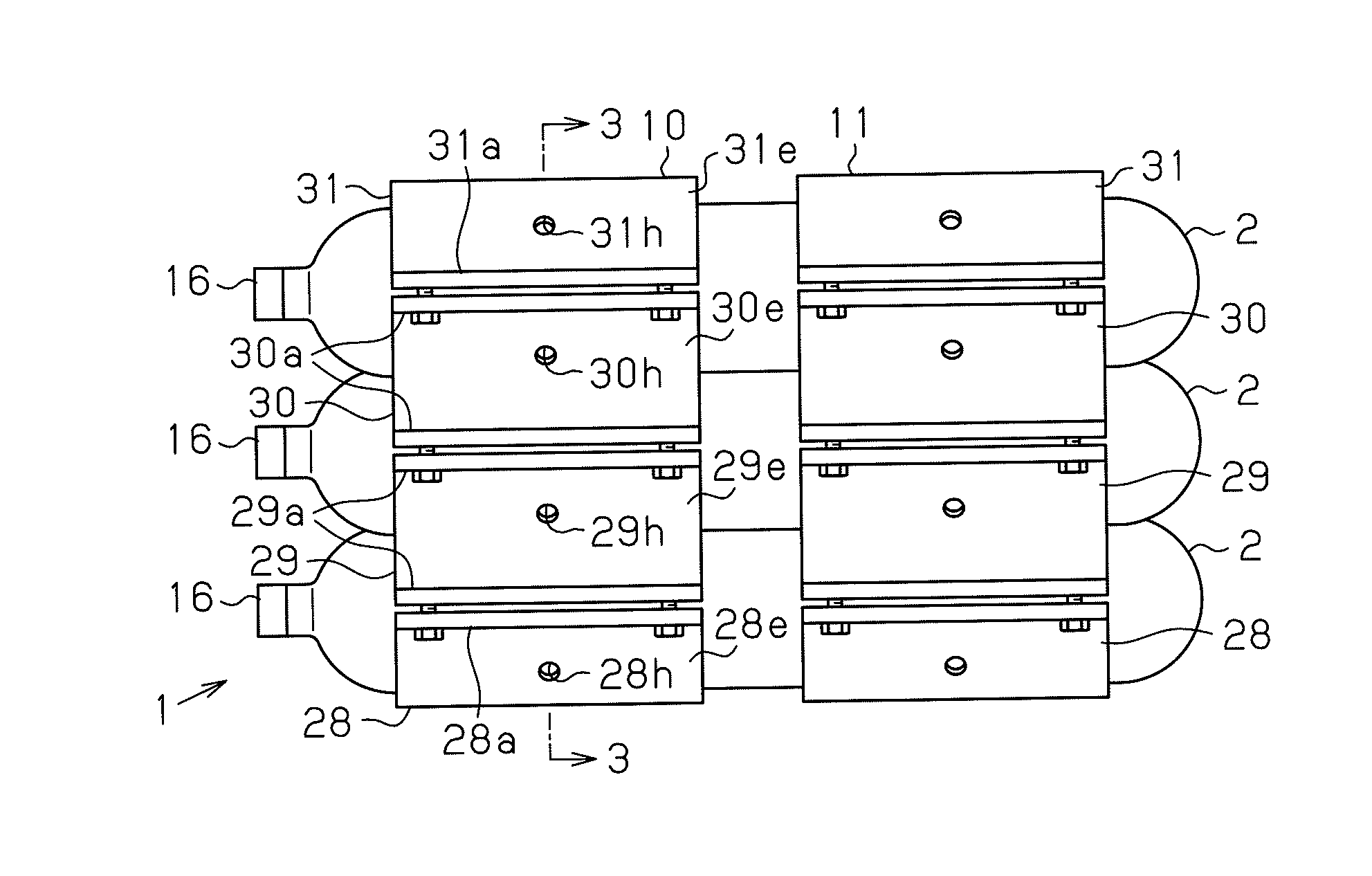

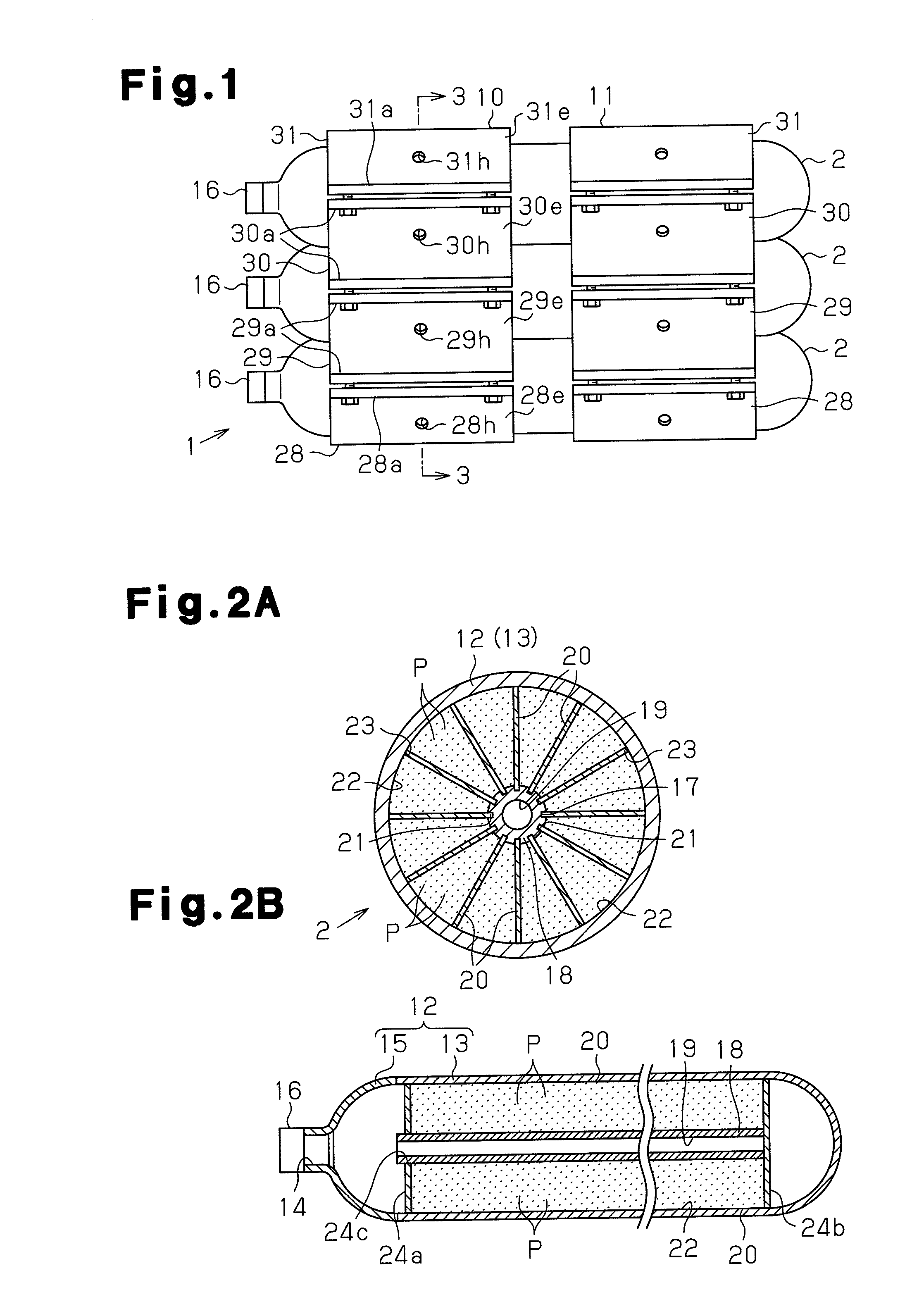

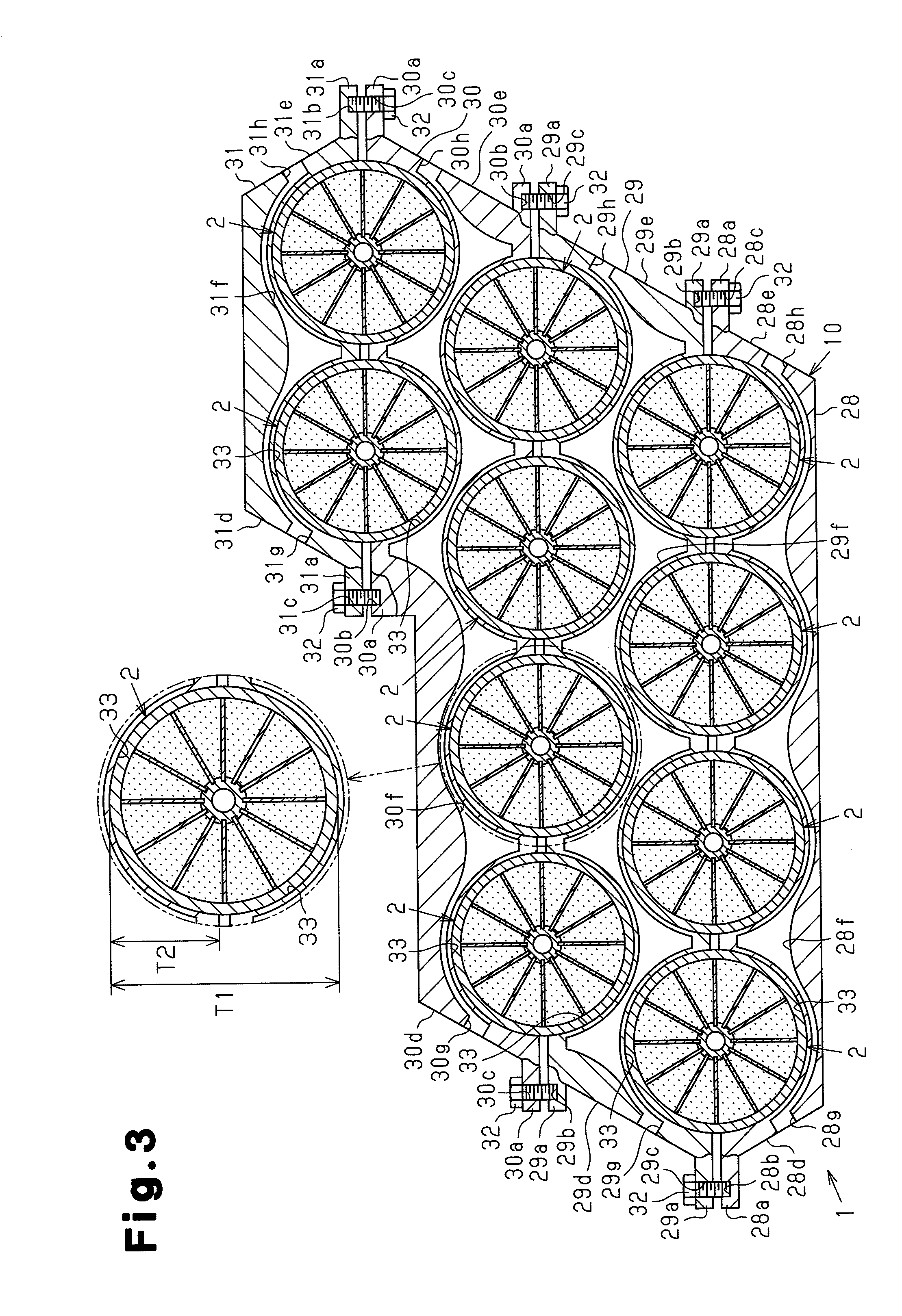

InactiveUS8287629B2Improve fastening forceReactant parameters controlIsotope separationHydrogenEngineering

An MH tank module 2 has a hollow outer shell portion 12 formed of metal. The outer shell portion 12 has a plurality of MH powder retaining chambers 22 defined by a plurality of fins 20. A plurality of MH tank modules 2 are bound together by a first tank holder 10 and a second tank holder 11. The tank holders 10, 11 are each configured by fastening and fixing first, second, third, and fourth holder components 28-31, which are separate from one another. The first to fourth holder components 28-31 each have a heat medium passage 28f-31f. The first to fourth holder components 28-31 each have recessed portions 33 each corresponding to the shape of a side portion of each MH tank module 2. The MH tank modules 2 are held individually by the corresponding recessed portions 33.

Owner:TOYOTA JIDOSHA KK

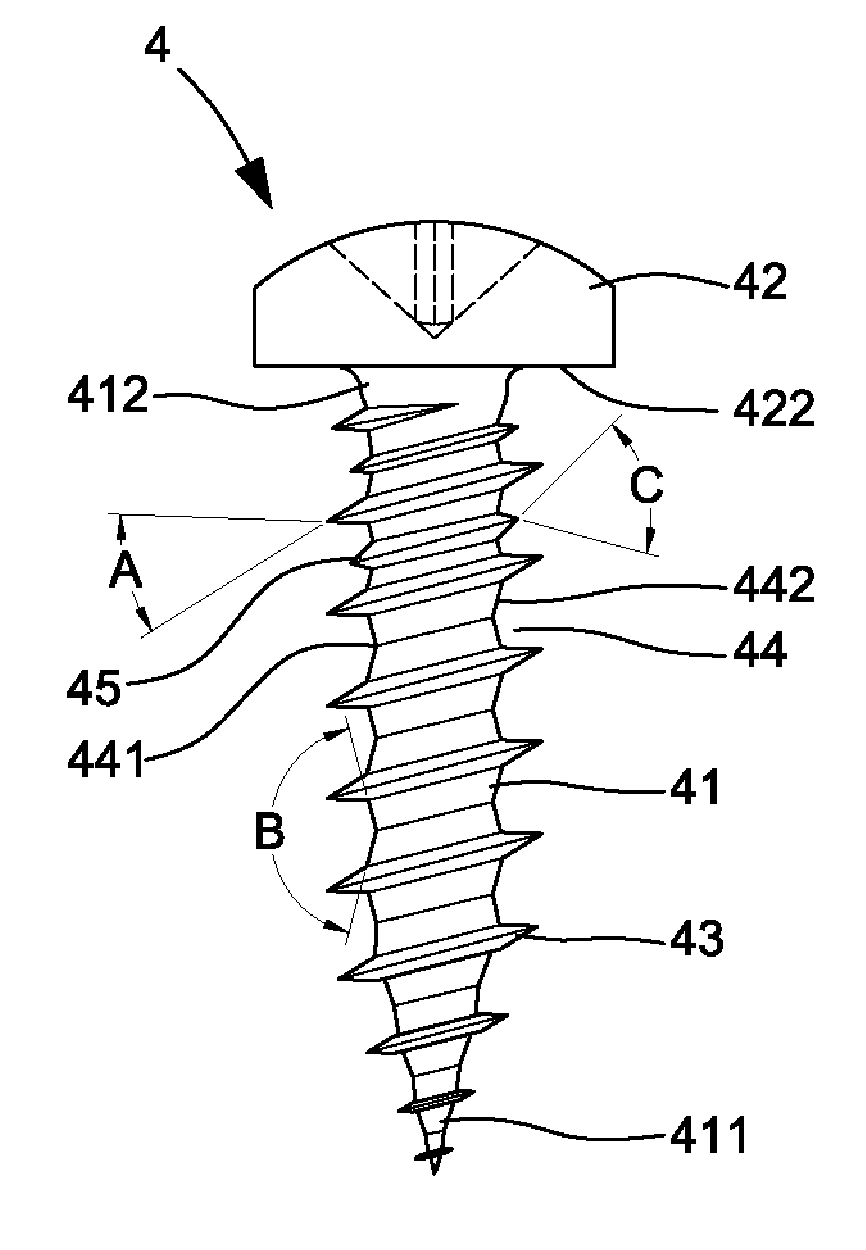

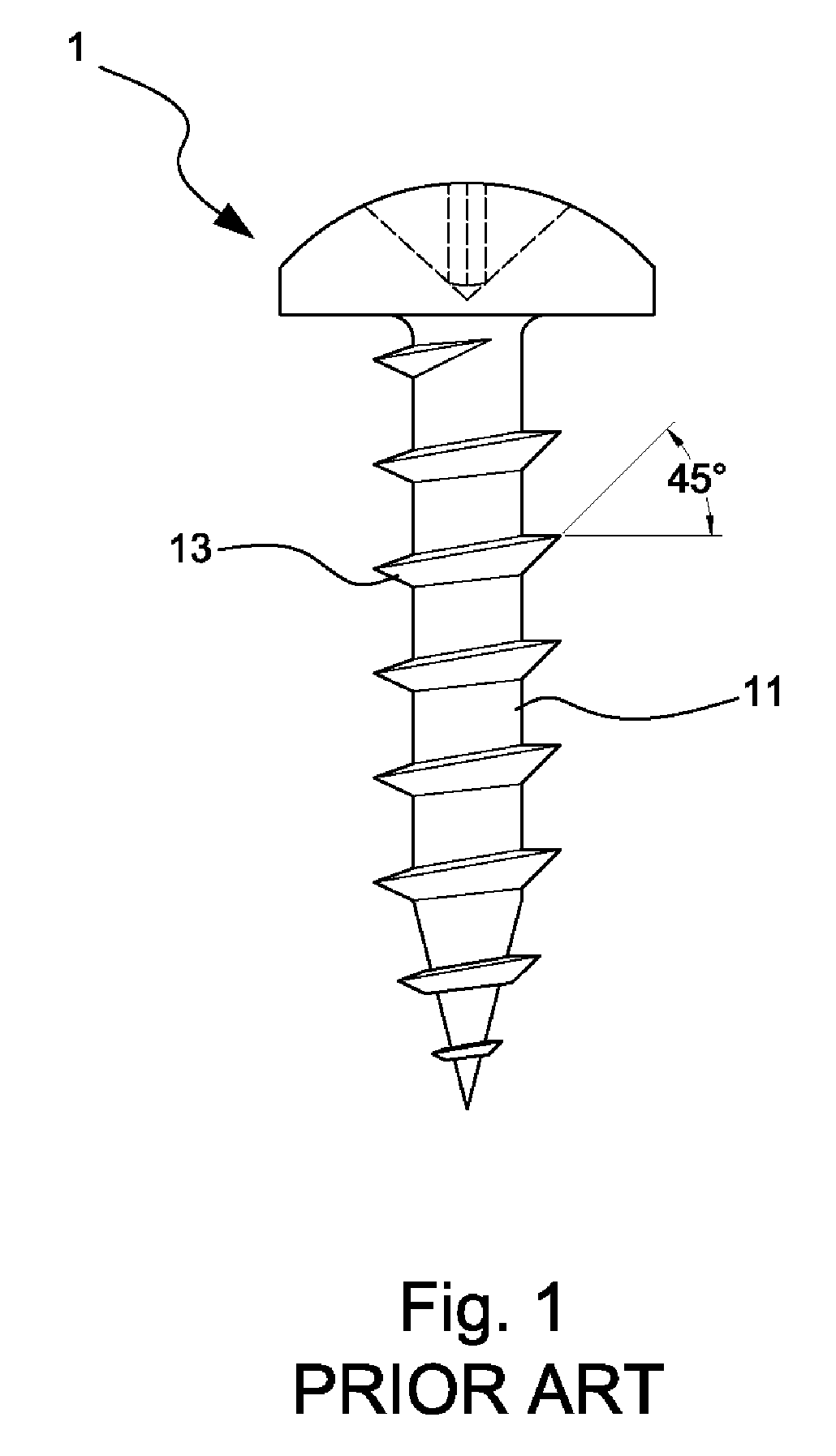

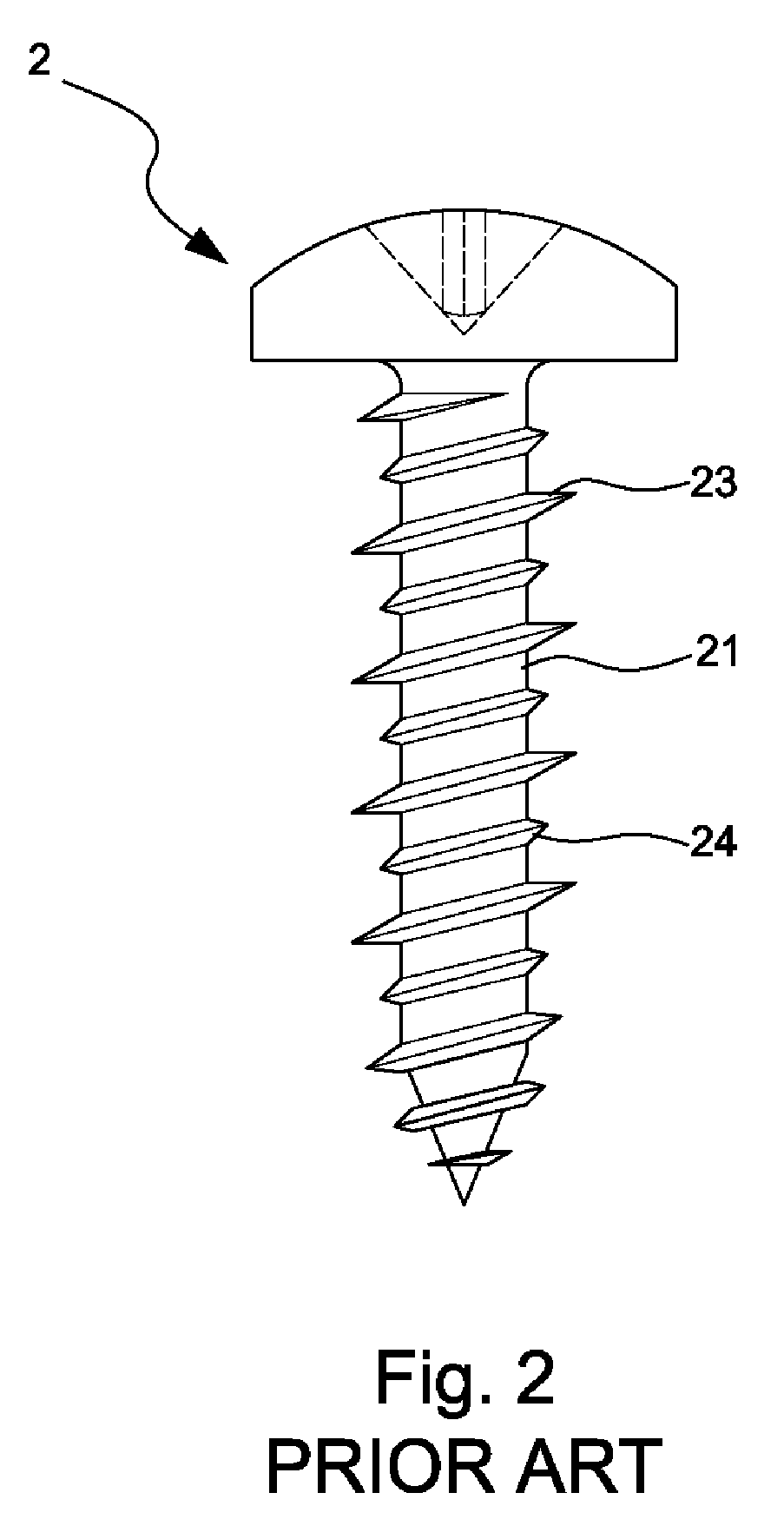

Screw for plastic articles

A screw for plastic articles includes a head, a shank having an insertion end and a coupling end adjacent to a bottom face of the head, a first thread, and a second thread. The first thread is formed on the shank and extends from the insertion end through the coupling end of the shank. The first thread includes a plurality of convolutions. The second thread is formed on the coupling end of the shank and intermediate the convolutions of the first thread. The second thread has a major diameter smaller than that of the first thread. The first thread includes a plurality of crests. A root is defined between two adjacent crests of the first thread outside the coupling end and has a profile defined by two straight lines that forms an angle of 120-160 degrees therebetween.

Owner:M & W FASTENER

Hydrogen gas storage device

InactiveUS20100219087A1Improve fastening forceReactant parameters controlIsotope separationHydrogenEngineering

An MH tank module 2 has a hollow outer shell portion 12 formed of metal. The outer shell portion 12 has a plurality of MH powder retaining chambers 22 defined by a plurality of fins 20. A plurality of MH tank modules 2 are bound together by a first tank holder 10 and a second tank holder 11. The tank holders 10, 11 are each configured by fastening and fixing first, second, third, and fourth holder components 28-31, which are separate from one another. The first to fourth holder components 28-31 each have a heat medium passage 28f-31f. The first to fourth holder components 28-31 each have recessed portions 33 each corresponding to the shape of a side portion of each MH tank module 2. The MH tank modules 2 are held individually by the corresponding recessed portions 33.

Owner:TOYOTA JIDOSHA KK

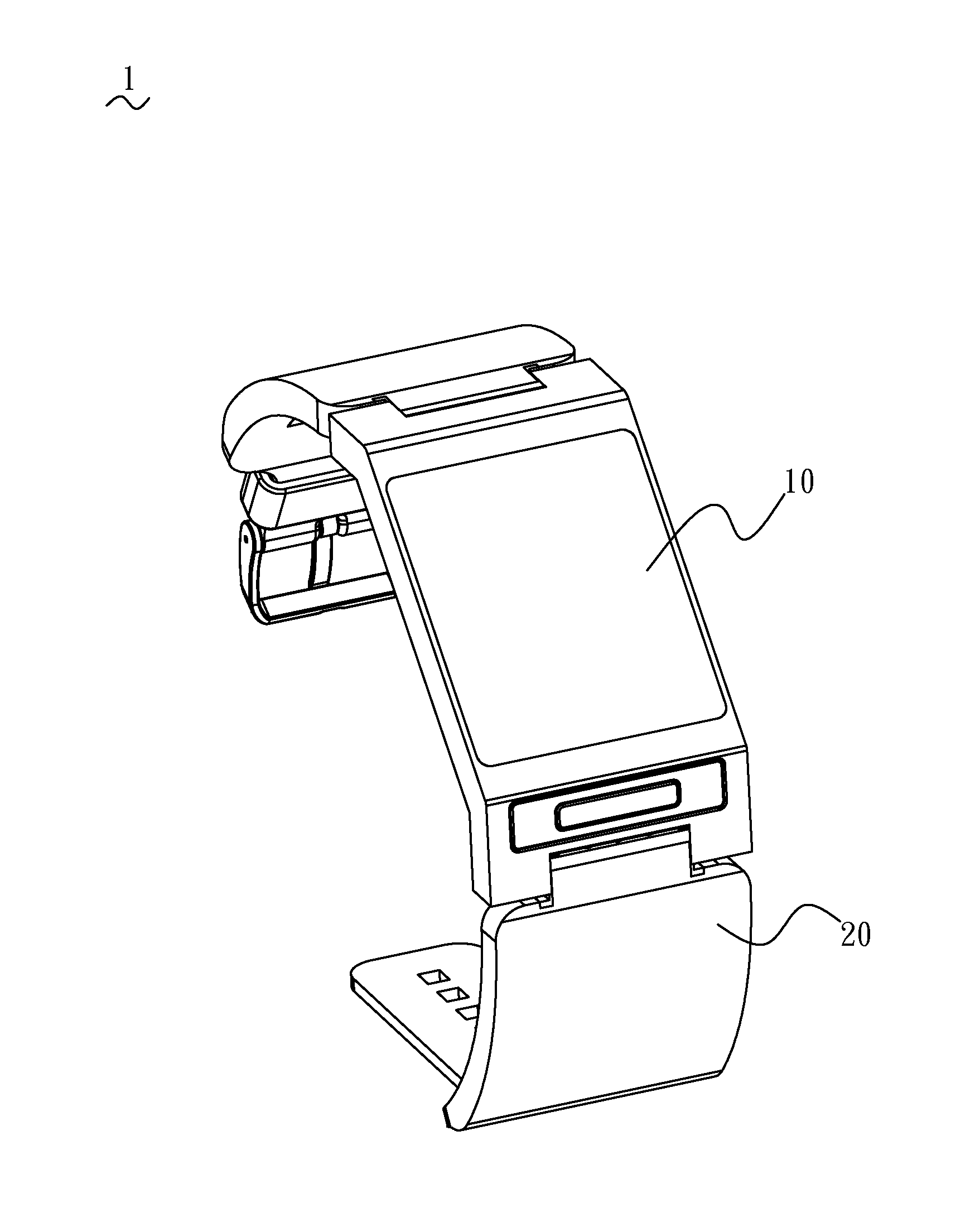

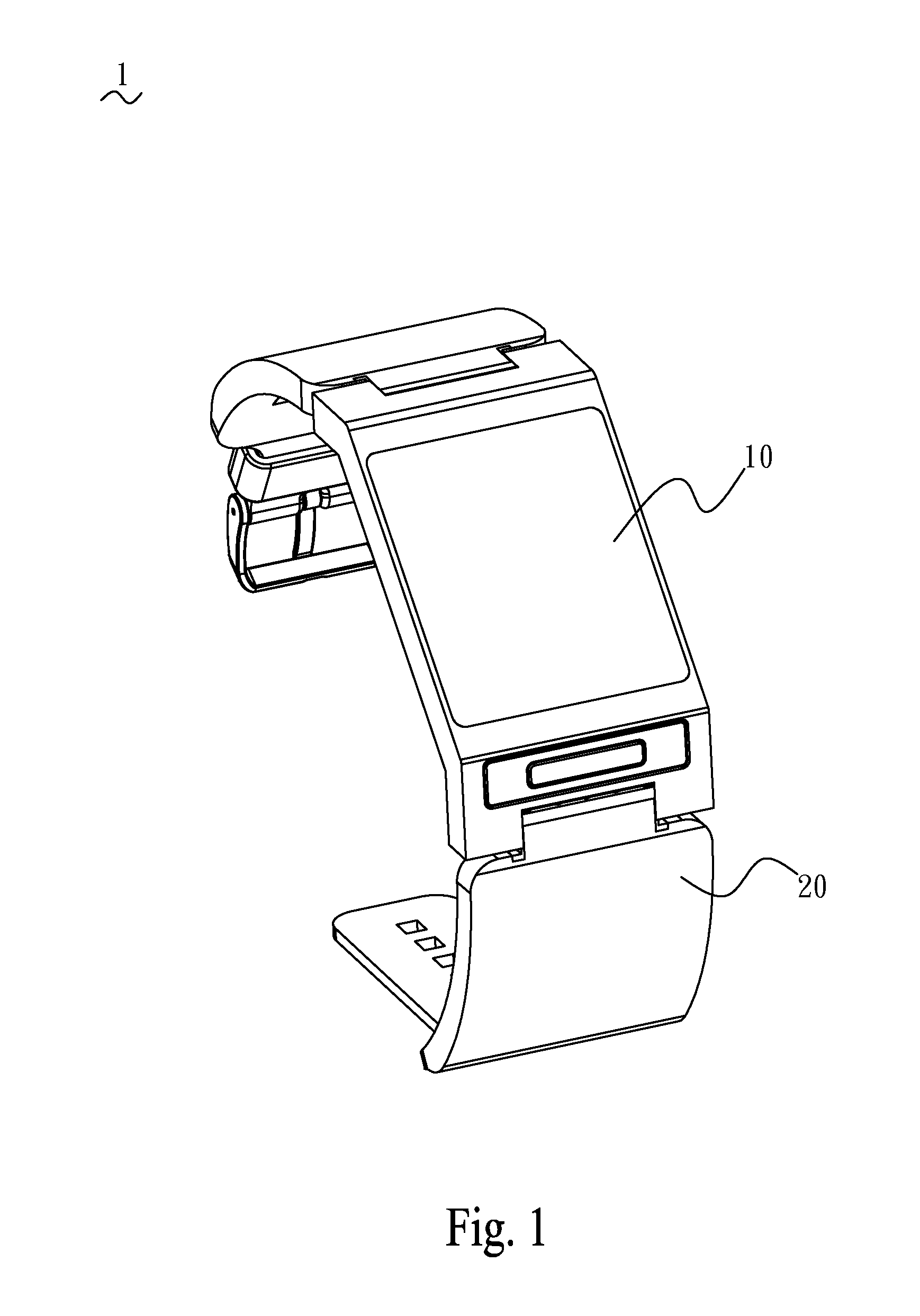

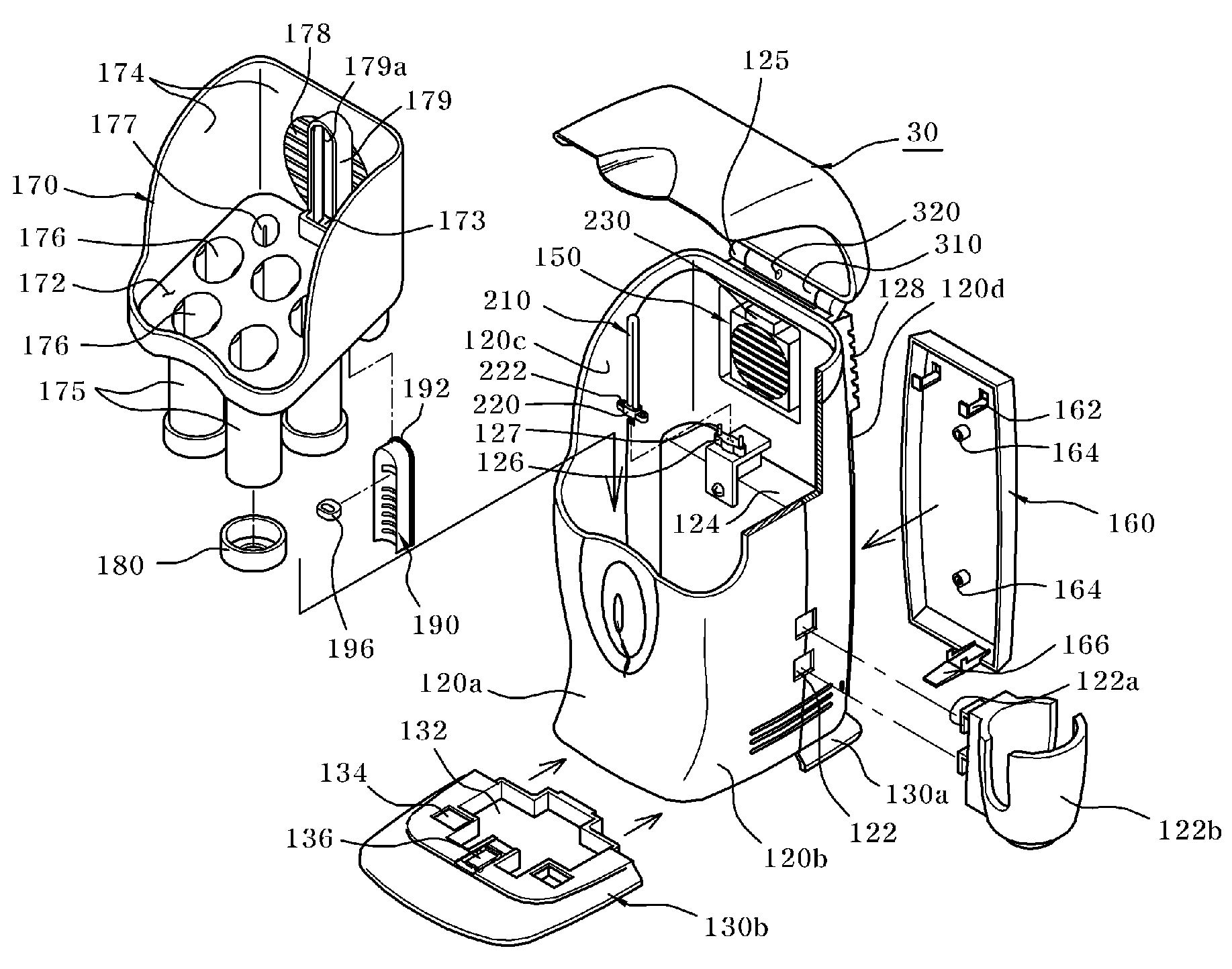

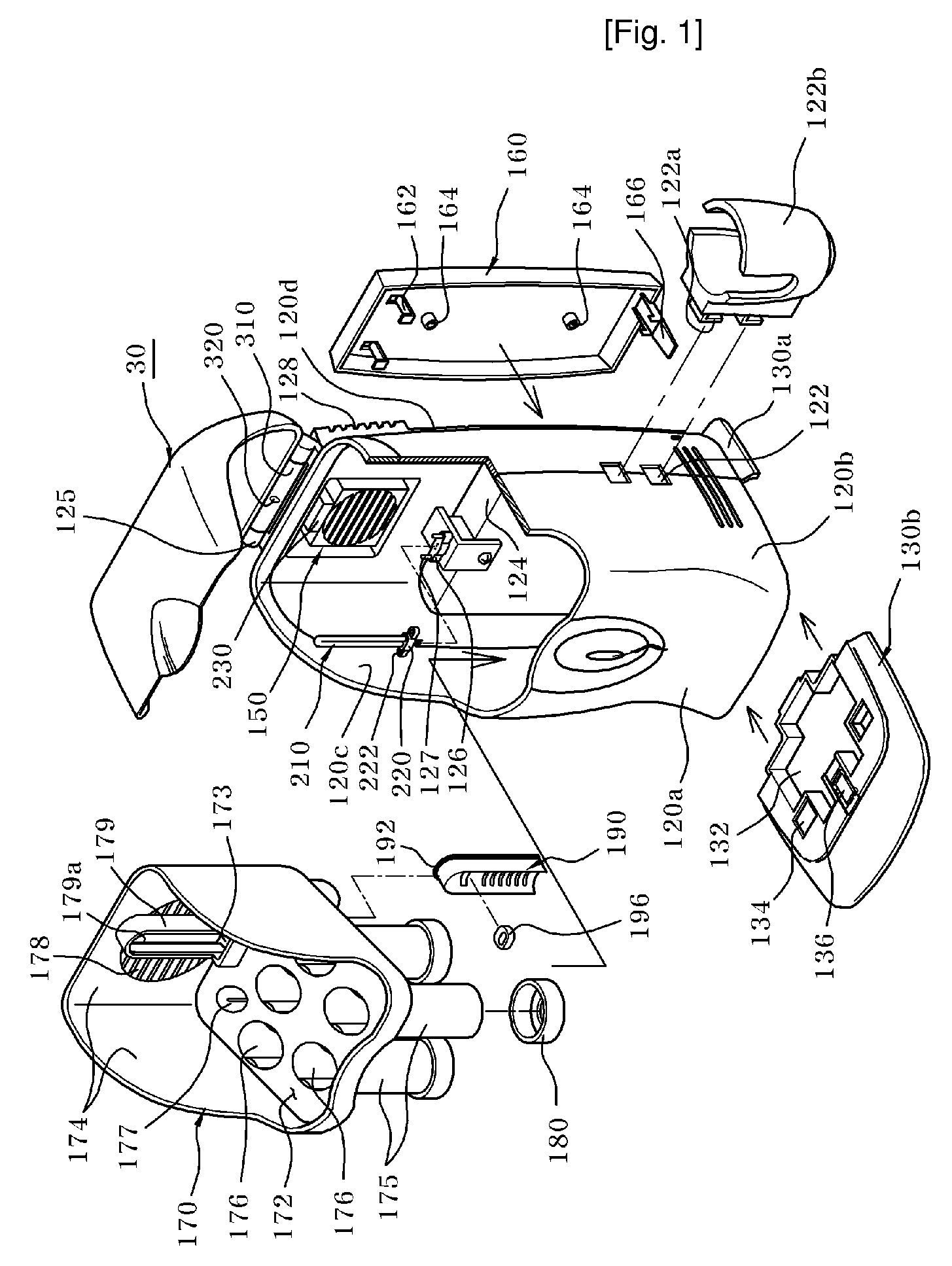

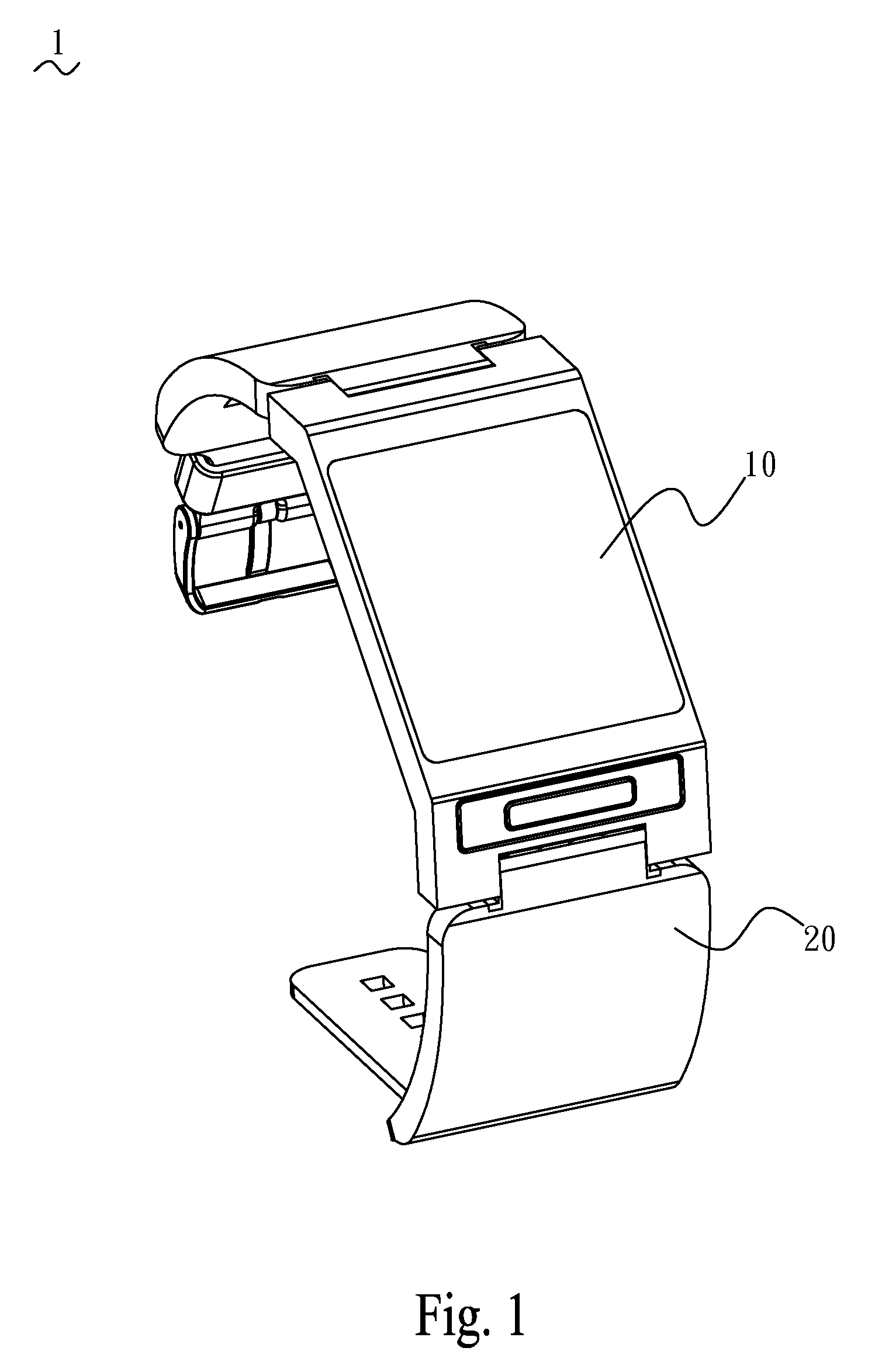

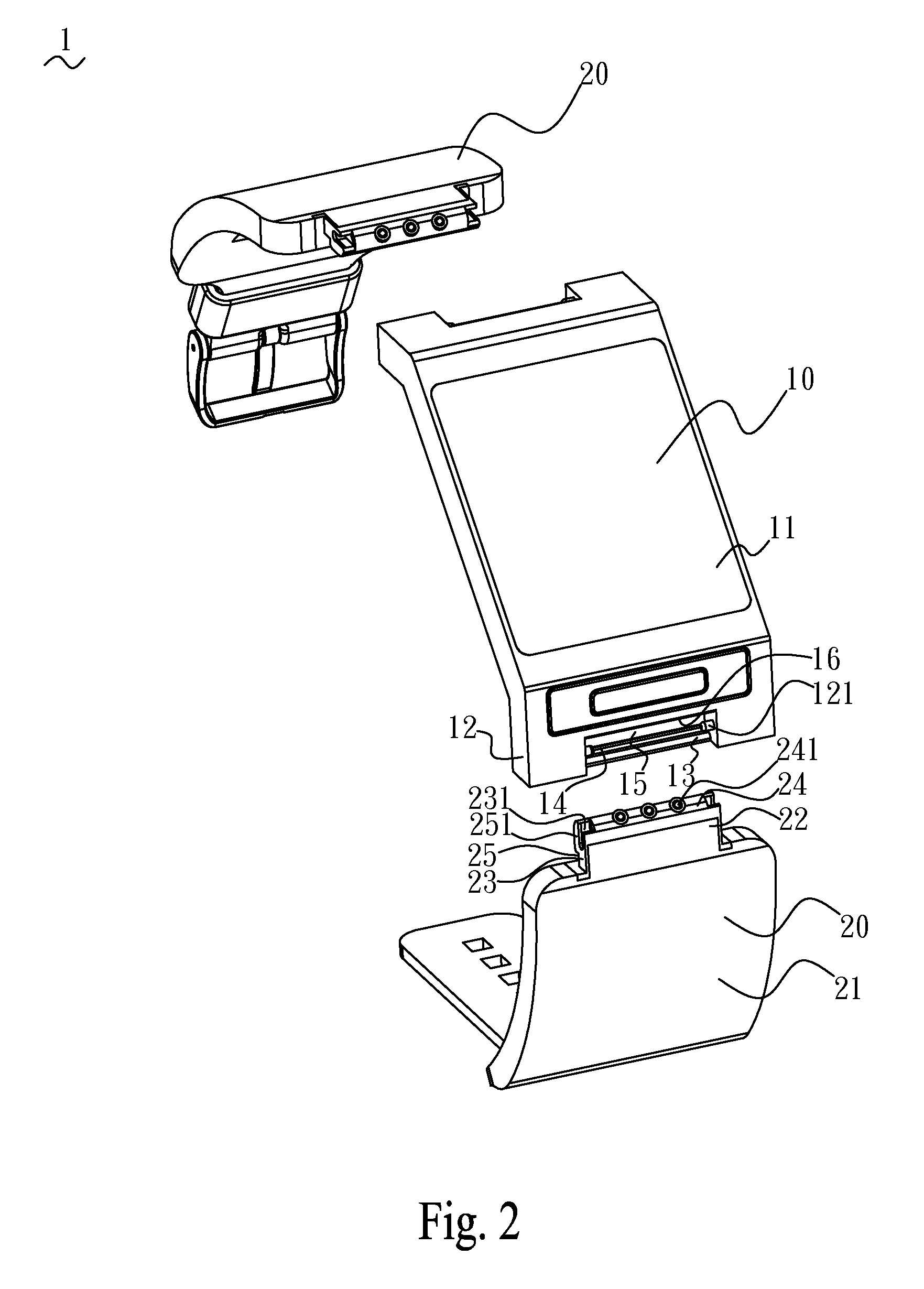

Wearable electronic device

ActiveUS20150212541A1Improve fastening forceEasy to changeElectronic time-piece structural detailsMachine supportsWearable Electronic DeviceMetal

A wearable electric device includes a main body with a circuit module inside and at least a detachable battery strap with a battery module inside, the main body and the detachable battery strap are detachable fastened together. A female buckle member is formed on the edge of the main body and includes a receiving chamber, a pair of locking notch arranged on the respective sides of the receiving chamber and plurality of metal conductive points connected with the circuit module. A male buckle member is attached on the front part of the detachable battery strap to be fastened with the female buckle member, a plurality of pogo pin connectors for connecting with the metal conducting points, and a locking block for fastening with the receiving chamber.

Owner:CHENG UEI PRECISION IND CO LTD

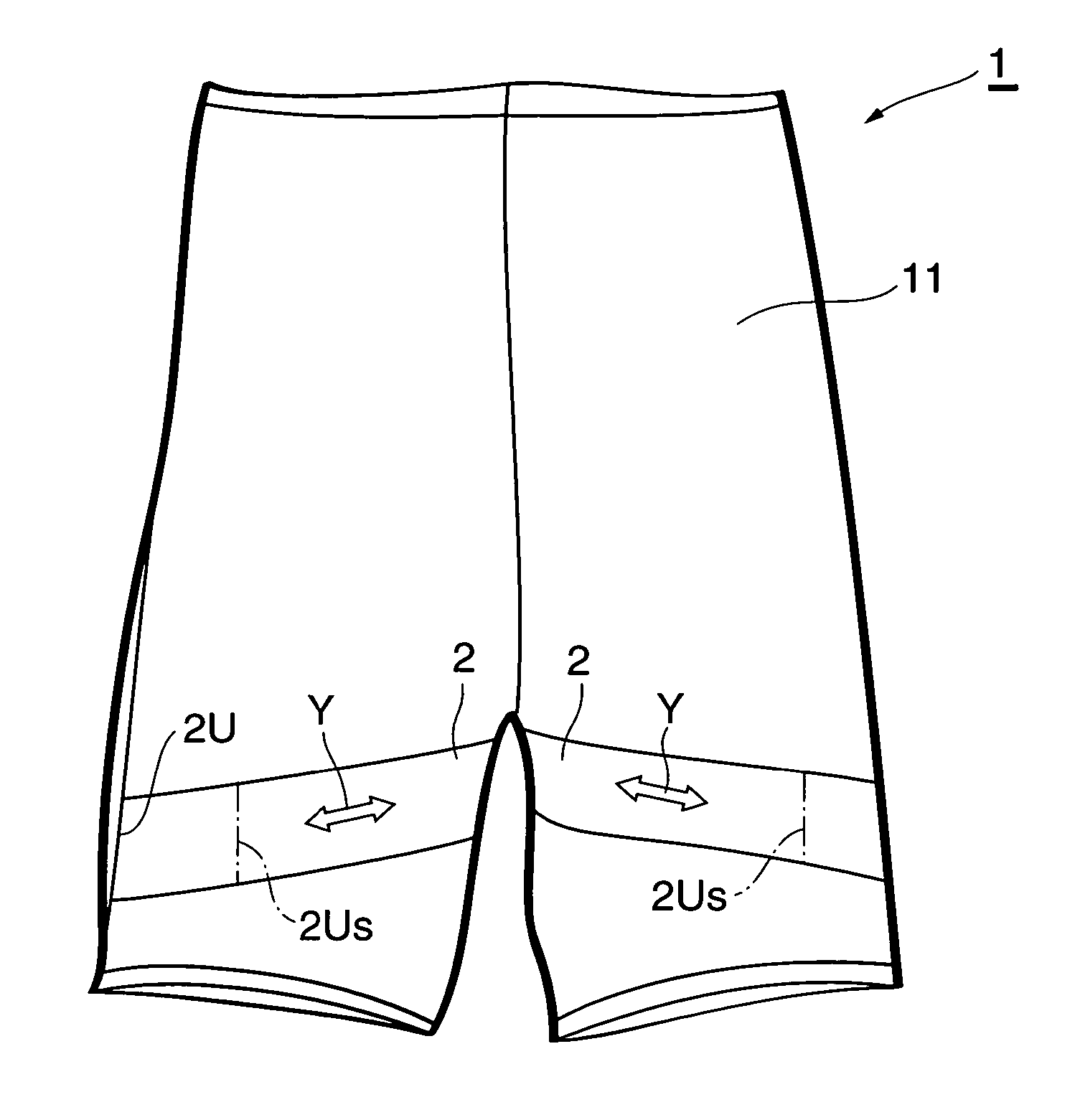

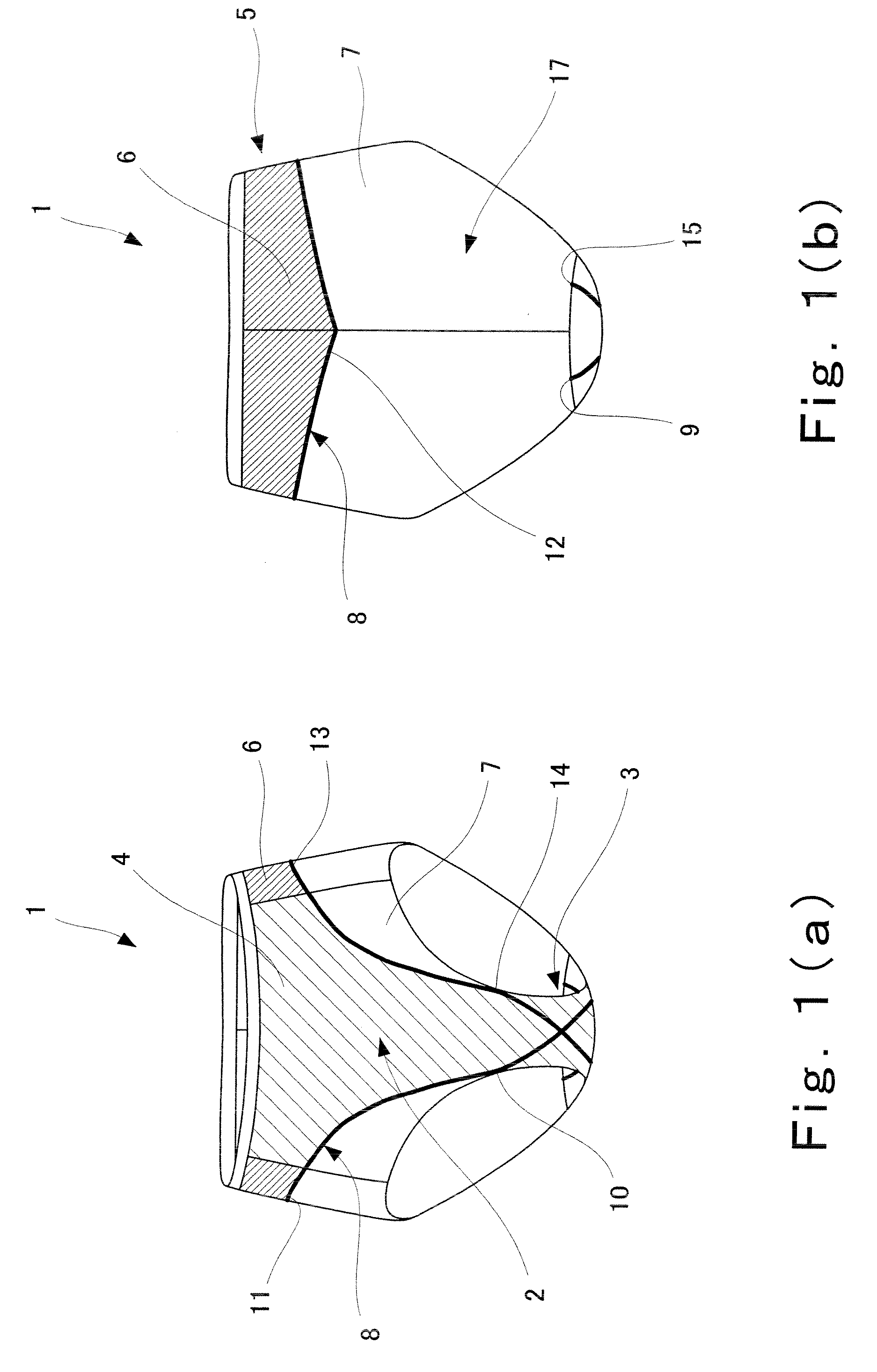

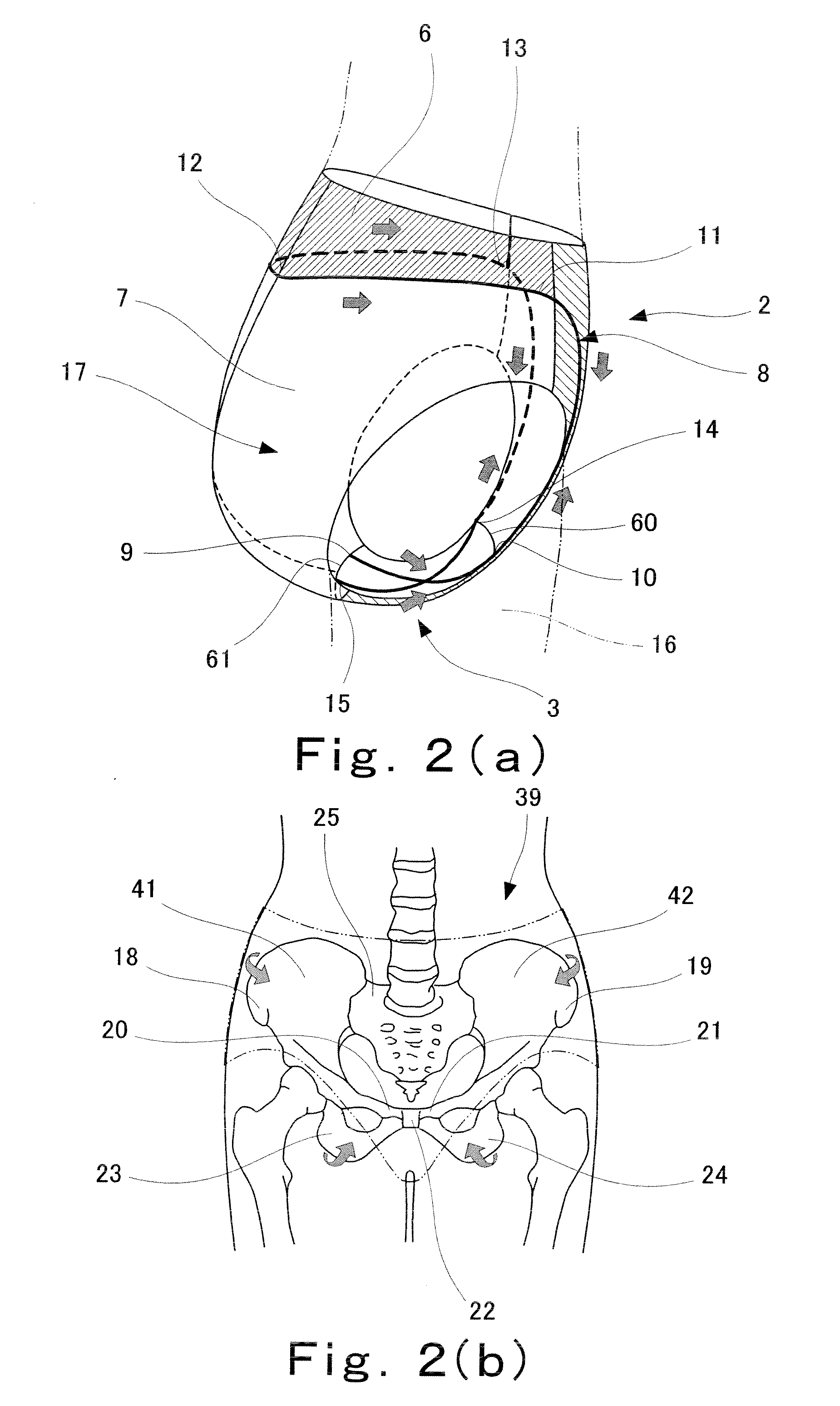

Crotch-possessing garment

InactiveUS20070067892A1Strong tightening forceSecure supportGarment special featuresTrousersThighEngineering

A long girdle substantially comprises a main body part 1 covering from a lumbar to an upper part of a thigh, and a support line part 2 stitched on a part of the main body part 1. The support line part 2 has a lower end 2U at a part of a connecting line L that connects the front main body part 11 and rear main body part 12, and an upper end 2T at a part of the connecting line L. The support line part 2 is arranged from the lower end 2U to the upper end 2T through the front side of the thigh and a section which is located at the rear side of the thigh and the lower section of the rump-cleft, in a spiral. Specifically, the support line part 2 continues from the lower end 2U to the upper end 2T in a spiral so as to cover, in the form of a band, a region where the great adductor muscle of the thigh is located. The main body part 1 and the support line part 2 are configured with a stretchable material, and the tightening force of the support line part 2 is stronger than that of the main body part 1.

Owner:WACOAL

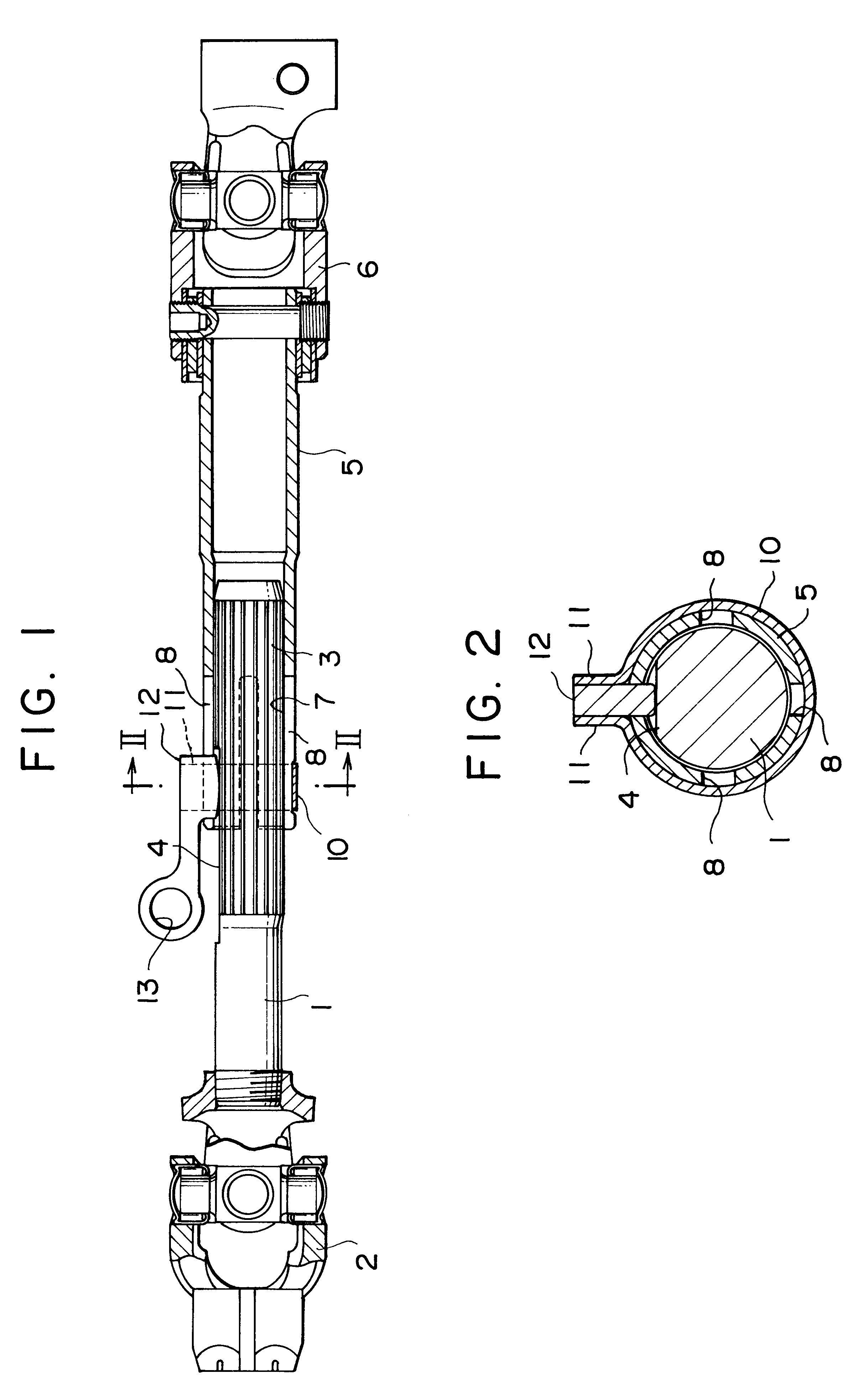

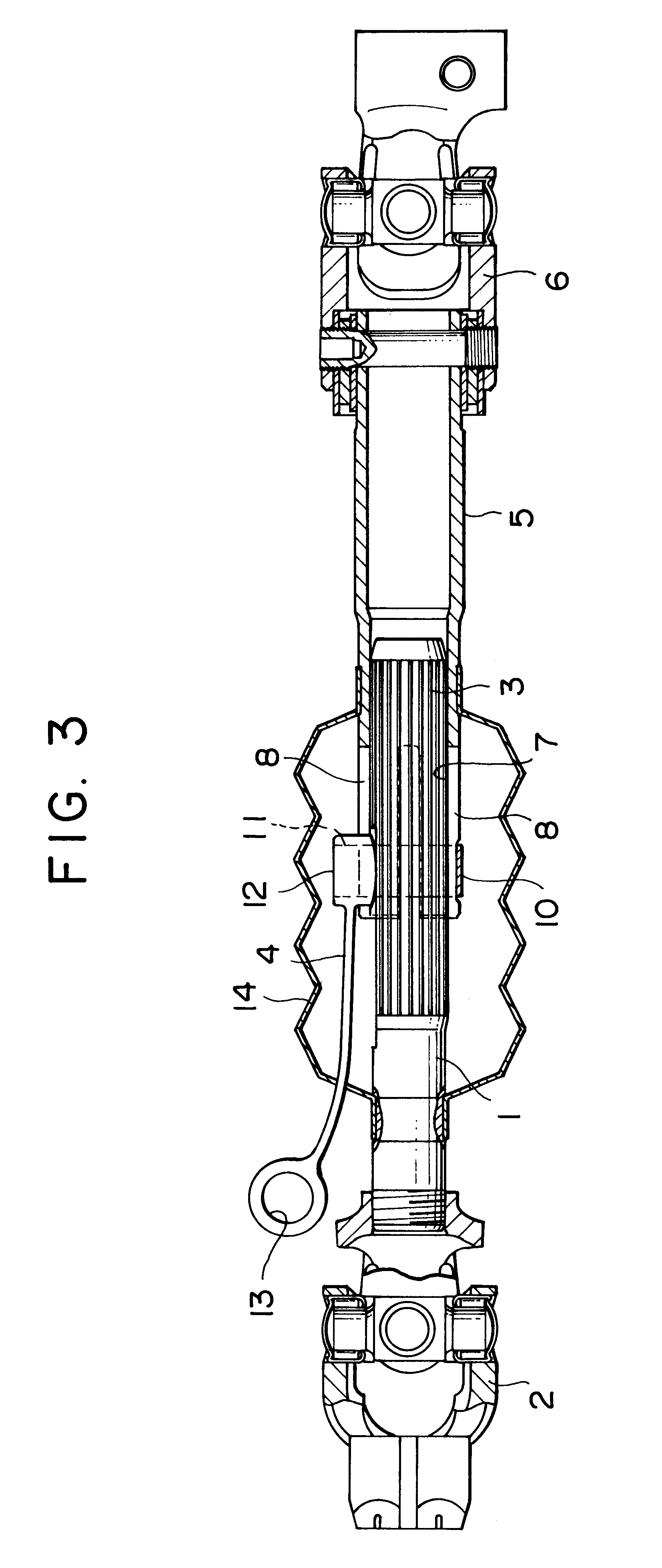

Coupling structure of variable length shaft

InactiveUS6267528B1Reduce pipe resistanceImprove workabilityYielding couplingShaftsCouplingMedial axis

A coupling structure of a variable length shaft, comprises a pipe member having an end formed with a plurality of slits elongated in the axial direction to be capable of expanding and diminishing in diameter, an intermediate shaft spline-fitted in the end of the pipe member, and a ring member fitted on an outer periphery of the end of the pipe member, the intermediate shaft being fastened by the end of the pipe member. A holder is releasably attached to an end of the ring member to expand a diameter thereof and thereby reduce a slide frictional resistance of the pipe member against the intermediate shaft. When the holder is released, the ring member diminishes in diameter, and a fastening force of the pipe member on the intermediate shaft is increased.

Owner:NSK LTD

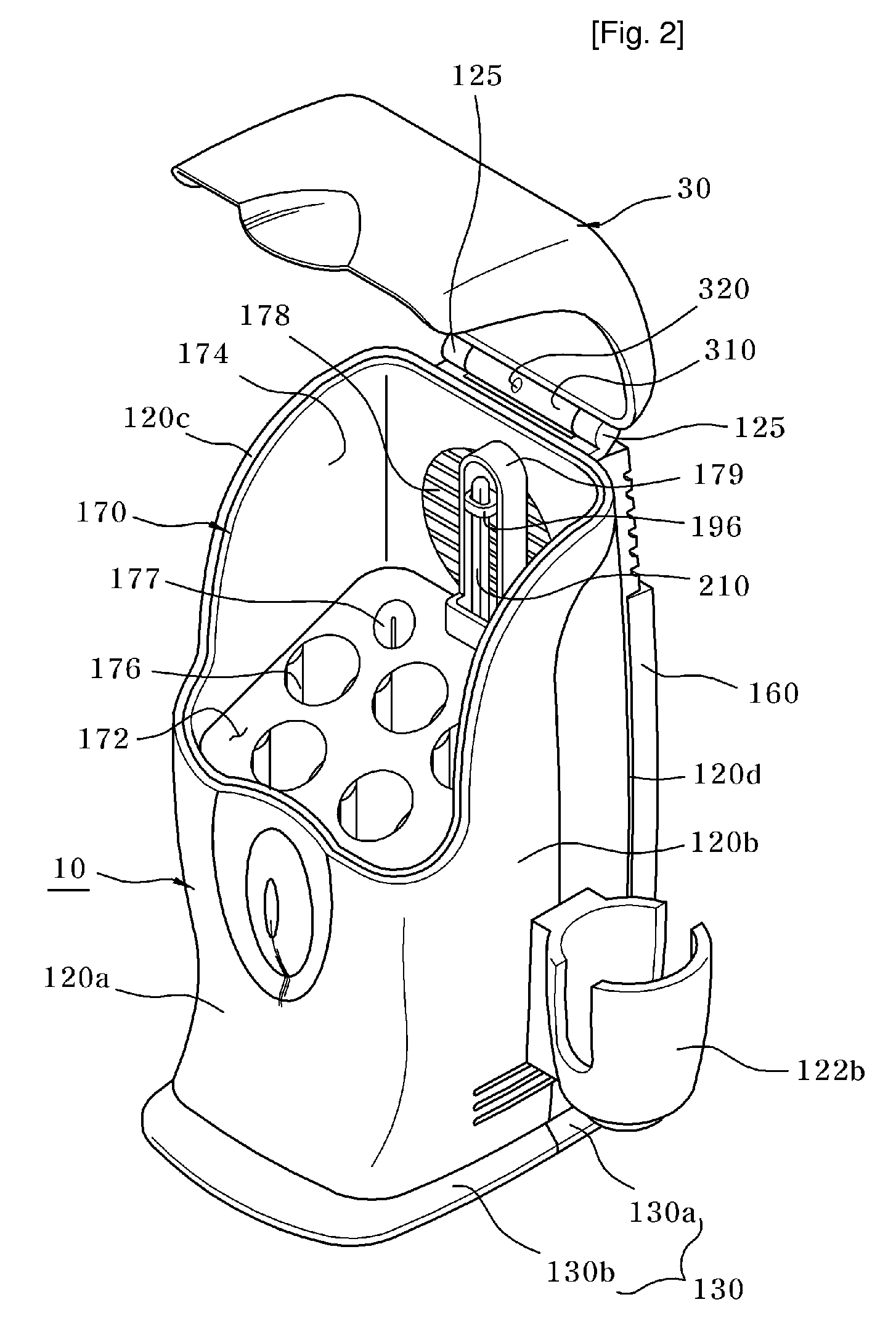

Toothbrush Sterilizer

InactiveUS20090010826A1Improve fastening forceGood adhesionLavatory sanitoryPin hingesEngineeringBiomedical engineering

A toothbrush sterilizer is provided. The toothbrush sterilizer employs a magnet on its pivoting cover and a lead switch on its main body opposite the cover to illuminate its sterilizing lamp only when the cover is closed, has a detachable toothbrush storage compartment, has a lamp holder that allows easy replacement of the sterilizing lamp and a detachably mounted stand with a water receiving area, and is easy to use and maintain in a hygienic state. The toothbrush sterilizer includes a storage compartment detachably attached inside the main body. The storage compartment has a plate, a side wall erected around a perimeter of the plate, and a plurality of insert holes formed in and extending a predetermined distance down from the plate, for storing the toothbrushes therein.

Owner:ESENCIA

Holder for conductive contact

InactiveUS20050225313A1High strengthHigh mechanical strengthMeasurement leads/probesIndividual semiconductor device testingPlastic materialsCoil spring

A holder supported by an arm comprises a metallic reinforcing member and a plastic holder hole forming member filled in an opening formed in the reinforcing member. Holder holes are formed in the holder hole forming member, and a coil spring and electroconductive needle members are installed in each holder hole to thereby provide a contact probe having two moveable ends. Because the holder is essentially made of the metallic member, the mechanical strength of the holder can be improved over that formed strictly from plastic material. Therefore, the contact probe holder would not suffer from dimensional changes of the holder owing to aging compounded by temperature changes for testing (tests under high temperature conditions) and residual stress so that the change in the pitch of the holder holes can be avoided, and a high level of precision can be ensured. Therefore, the contact probe allows tests to be conducted in a stable manner over an extended period of time.

Owner:NHK SPRING CO LTD

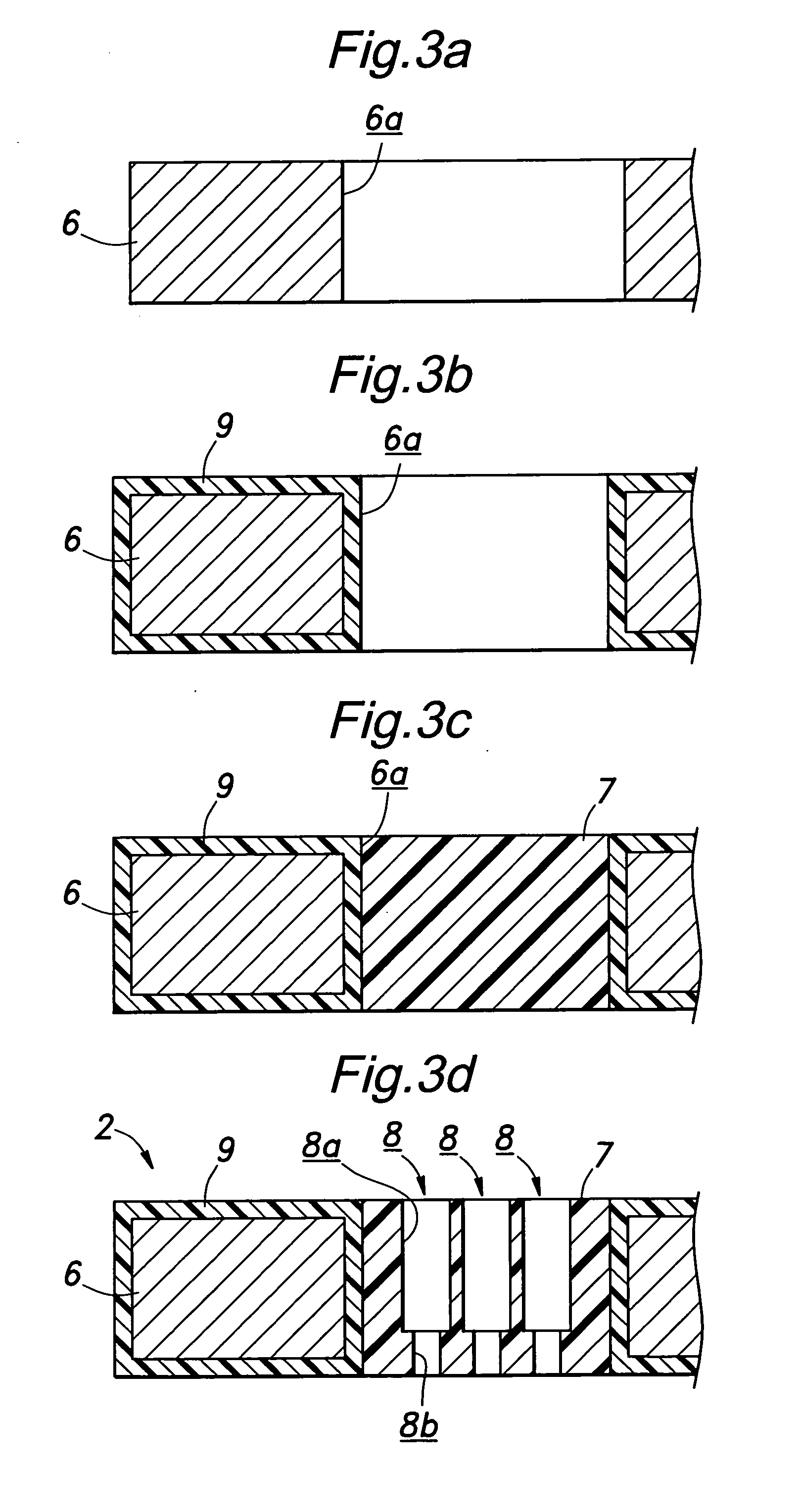

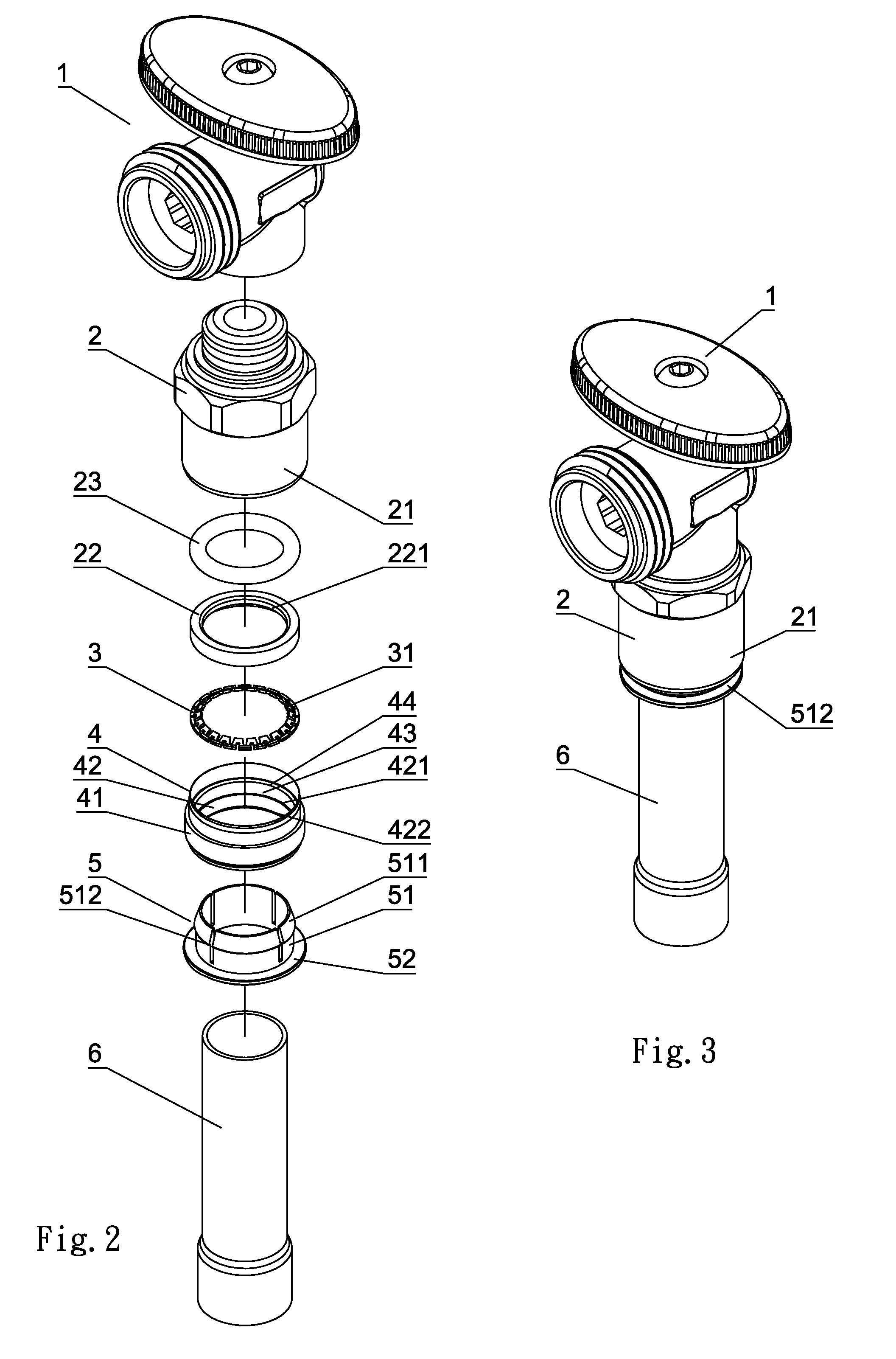

Pipe joint structure

A pipe joint structure for an upright valve includes a pipe joint, a resilient ring, a connection cylinder and an inner sleeve. The pipe joint includes a first chamber to receive a positioning ring and a seal ring. The resilient ring, the connection cylinder and the inner sleeve are inserted in the pipe joint in sequence. When a connection pipe is inserted in the pipe joint, the connection pipe will be inserted in a one-way direction and fastened by fastening talons of the resilient ring. To disengage the connection pipe, top push flanges of resilient claws of the inner sleeve are pushed to an inner limit inclined surface of the positioning ring to disengage the connection pipe from the fastening talons, such that the connection pipe can be pulled out. The present invention provides a quick connection and can prevent the connection pipe from being pulled out unexpectedly.

Owner:SING ENTERPRISES CO LTD

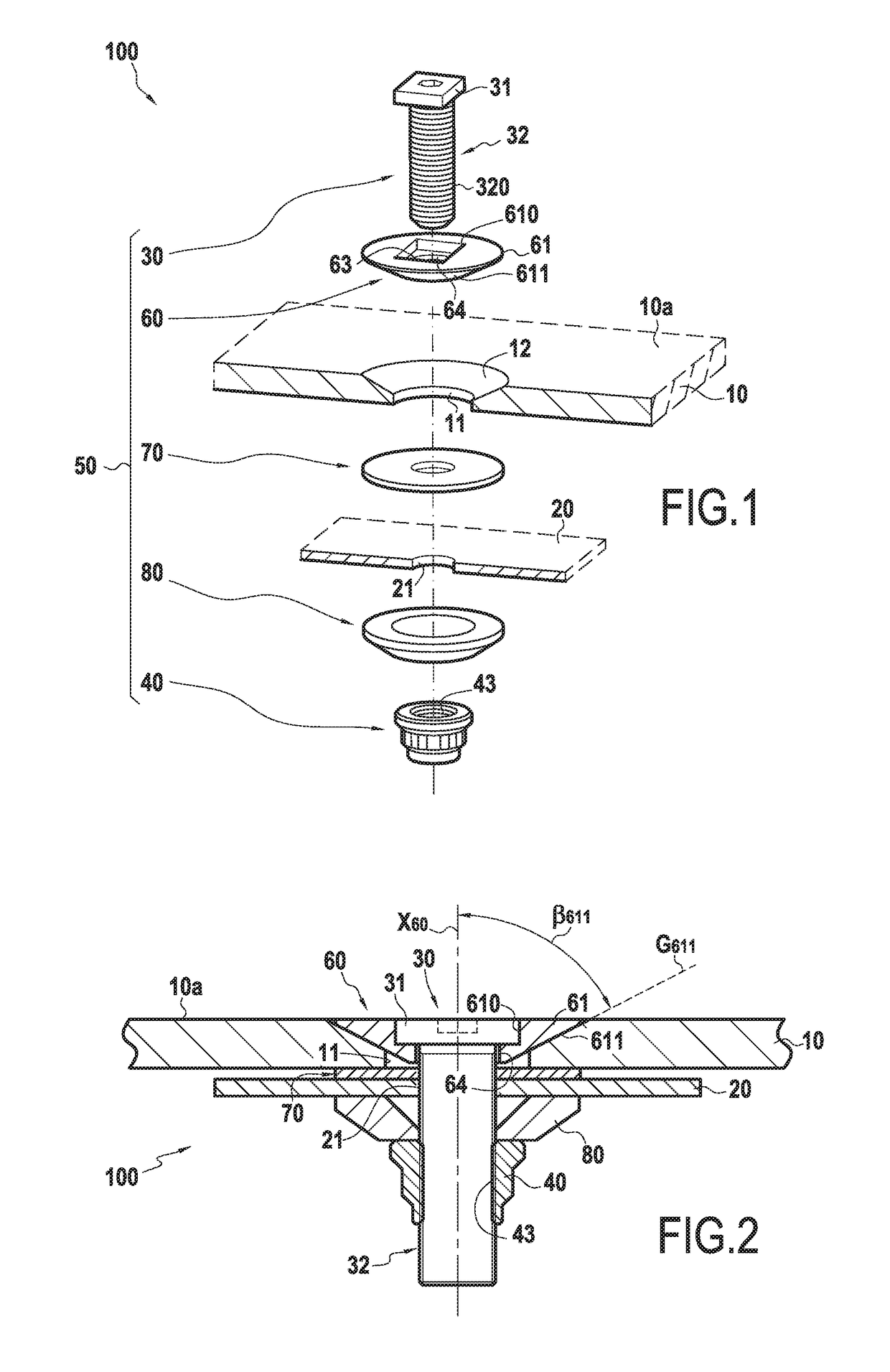

An assembly by mechanical connection including at least one part made of composite material

An assembly includes a first part made of composite material and a second part, which parts are held one against the other by at least one fastener system having a fastener element with a head from which there extends a shank. The fastener system further includes a bushing, the bushing including a collar presenting an inside face and an outside face of conical shape. The head of the fastener element bears against the inside face of the collar, while the outside face of the collar bears against a countersink formed in the first part.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

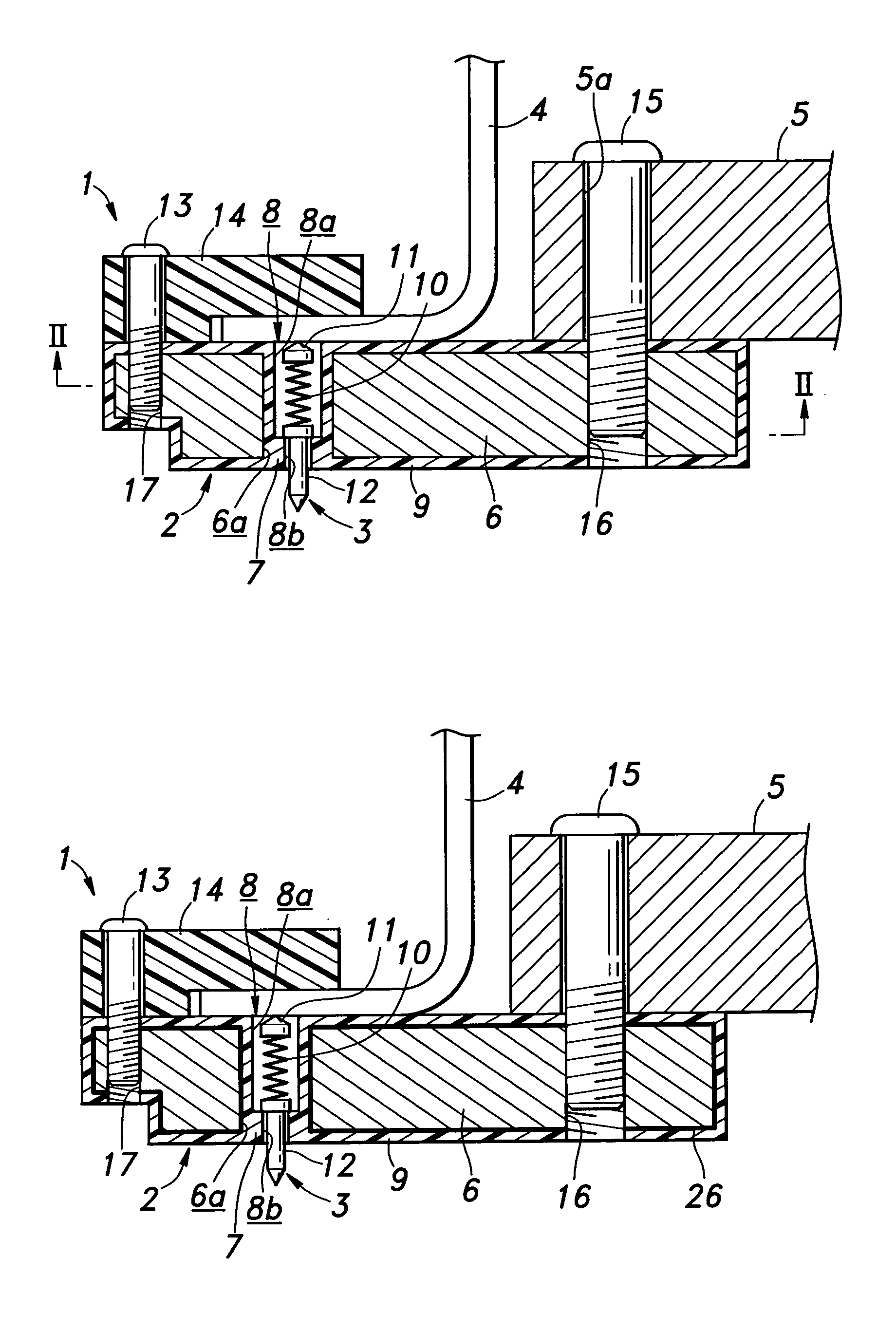

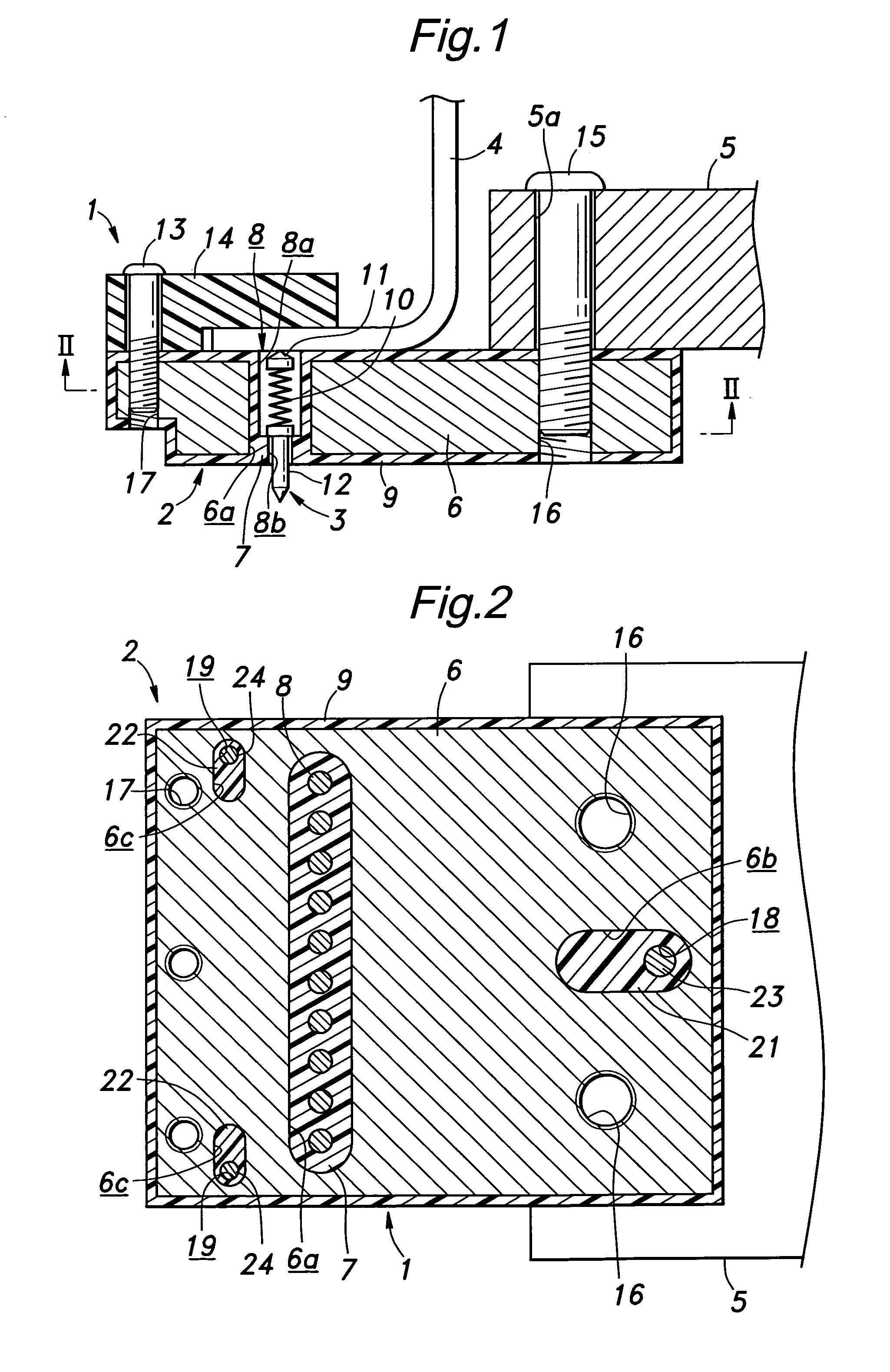

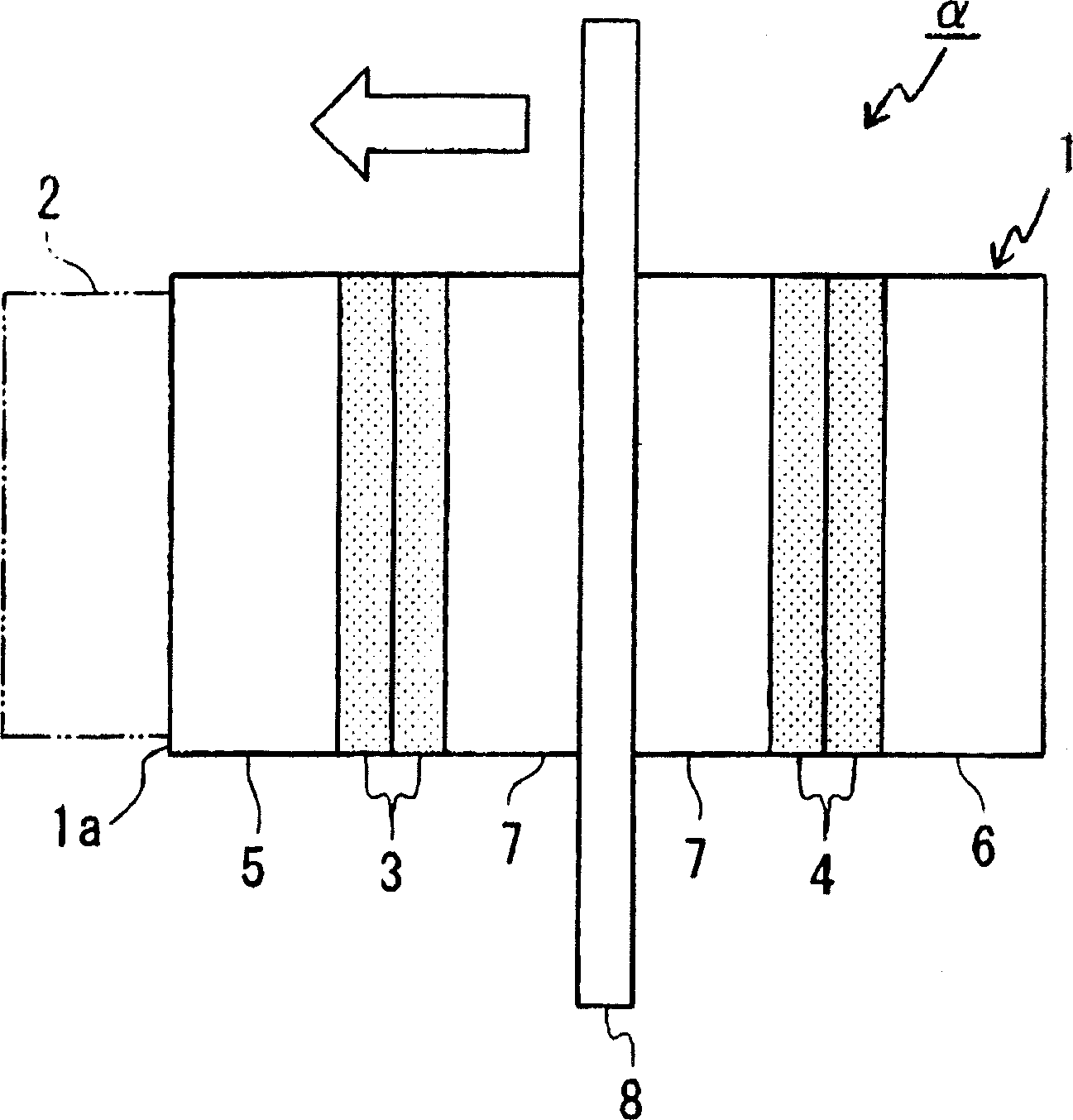

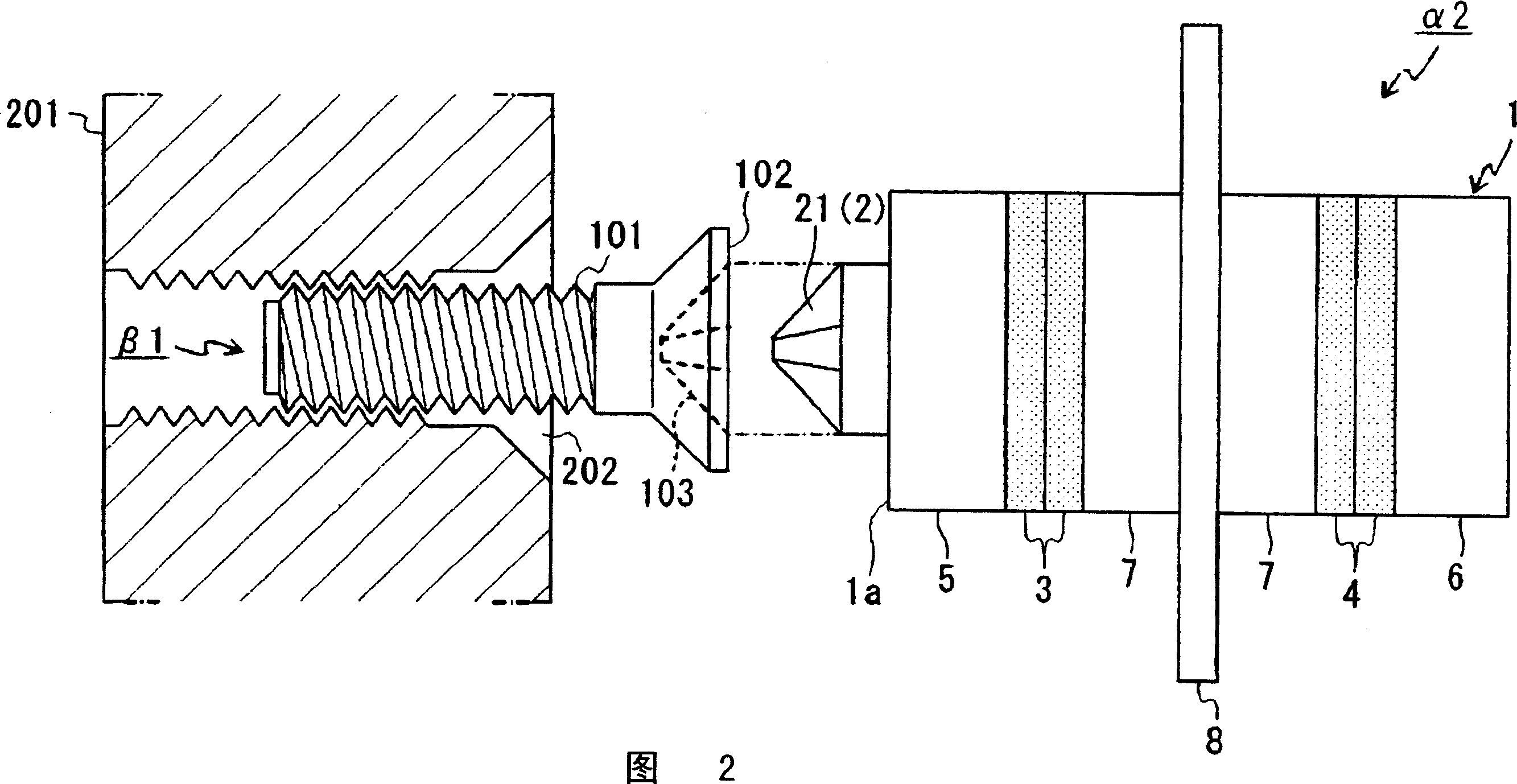

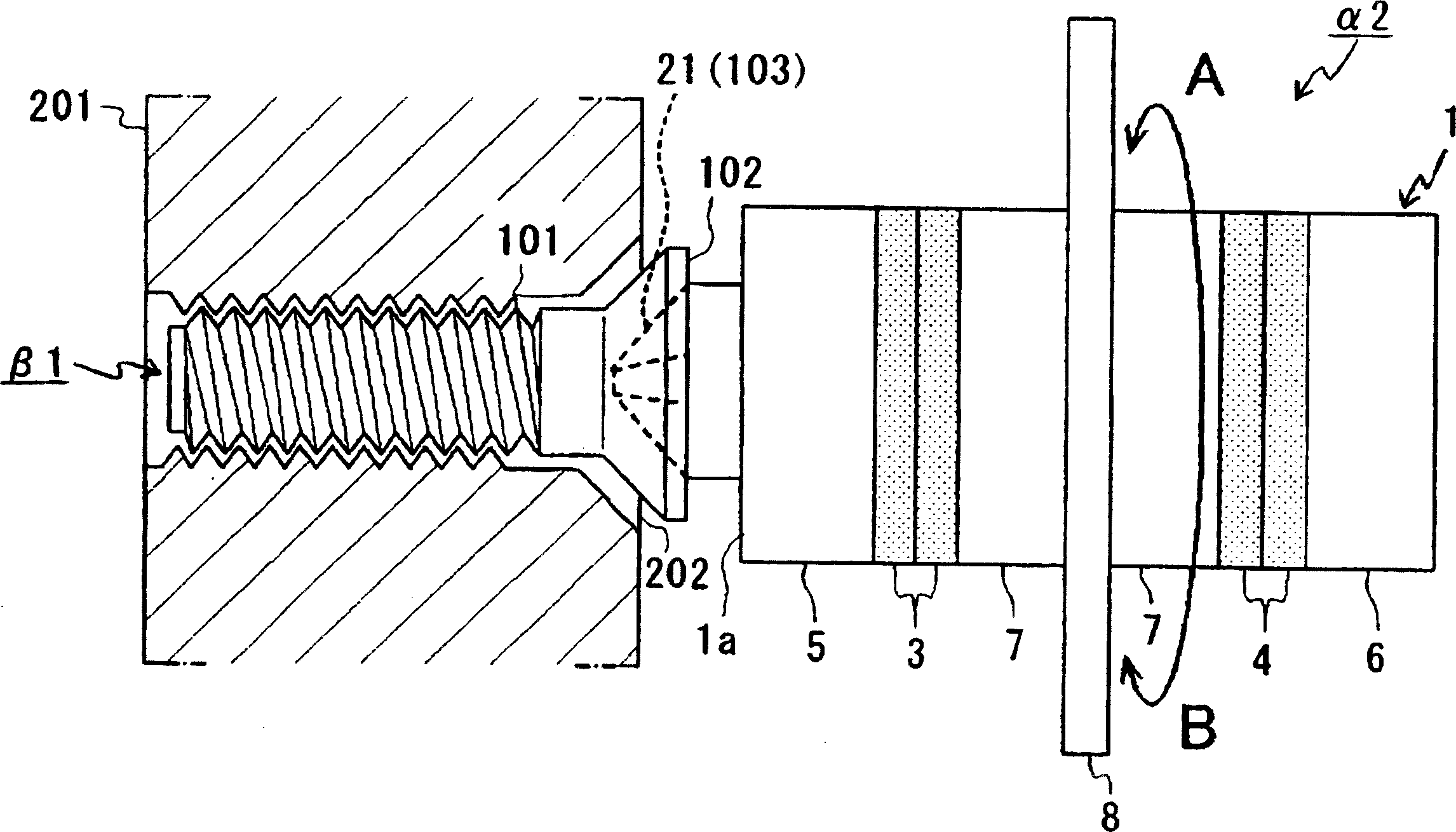

Screwdriver device and screw

ActiveCN1910015AImprove fastening forceRotational torque reliefWashersLoad modified fastenersPower flowEngineering

A screwdriver device where rotational torque directly applied to the device by an external force can be drastically reduced in screw tightening operation. The screwdriver device has characteristic construction means having a device body (1) and a male-type head section (21). The device body (1) is constructed by layering over each other piezoelectric elements (3, 4) in a screwdriver device (alpha2), the piezoelectric elements (3, 4) generating predetermined ultrasonic vibration with application of a predetermined AC voltage, and based on the ultrasonic vibration, the device body (1) excites mechanical vibration in a predetermined direction on a vibration end surface (1a) of the device body (1). The male-type head section (21) is formed so that it can fit in a female-type engraved marking (103) in a screw (beta1) and is integrally fixed with the device body (1) on the vibration end surface (1a) of the device body (1). The male-type head section (21) applies rotational torque, directly applied to the screwdriver device (alpha2) by an external force, to the screw (beta1) in which the female-type engraved marking (103) is fitted and contact, and also the male-type head section (21) transmits to the screwdriver device (alpha2) mechanical vibration in a predetermined direction excited by the device body (1).

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

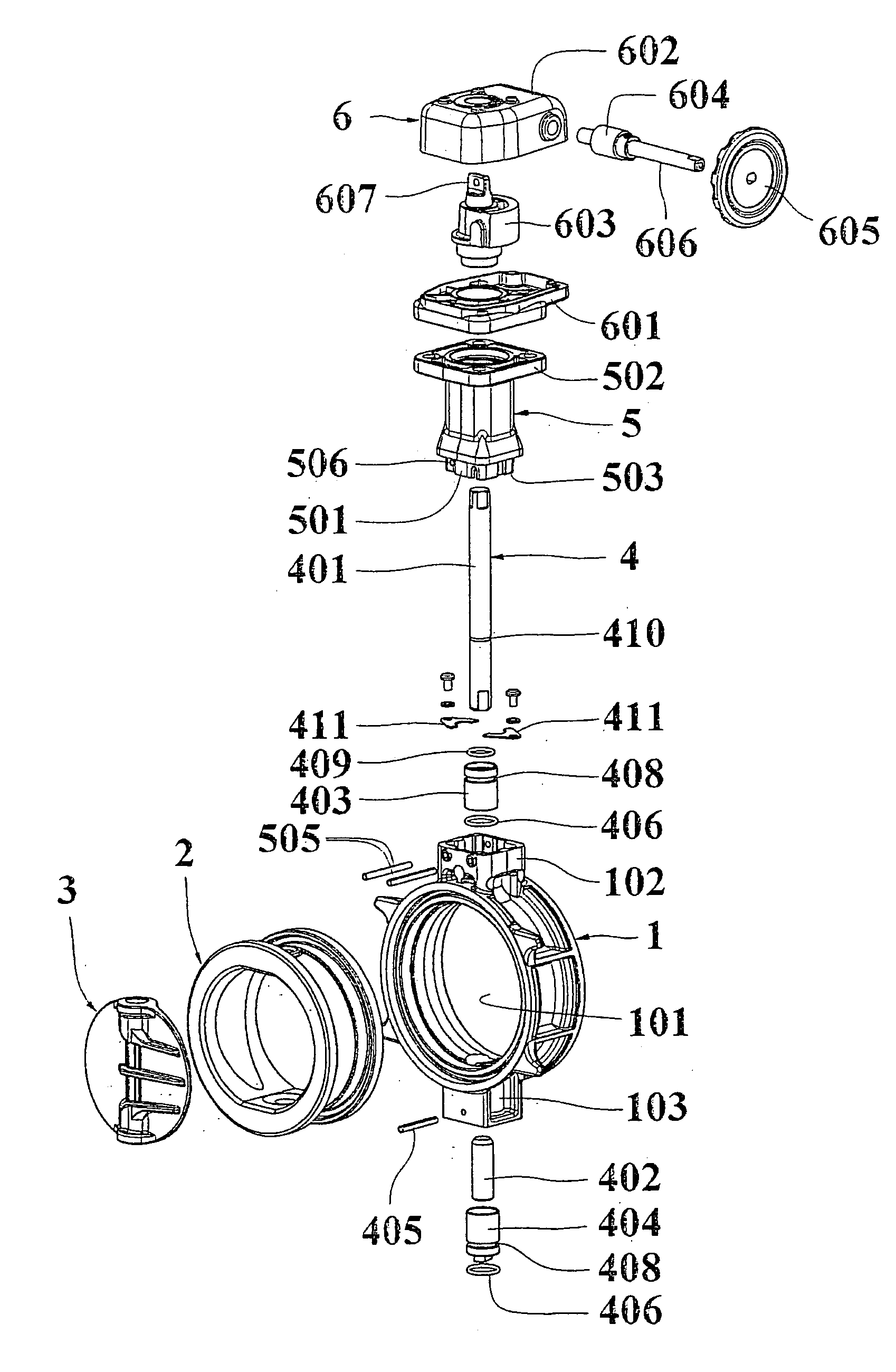

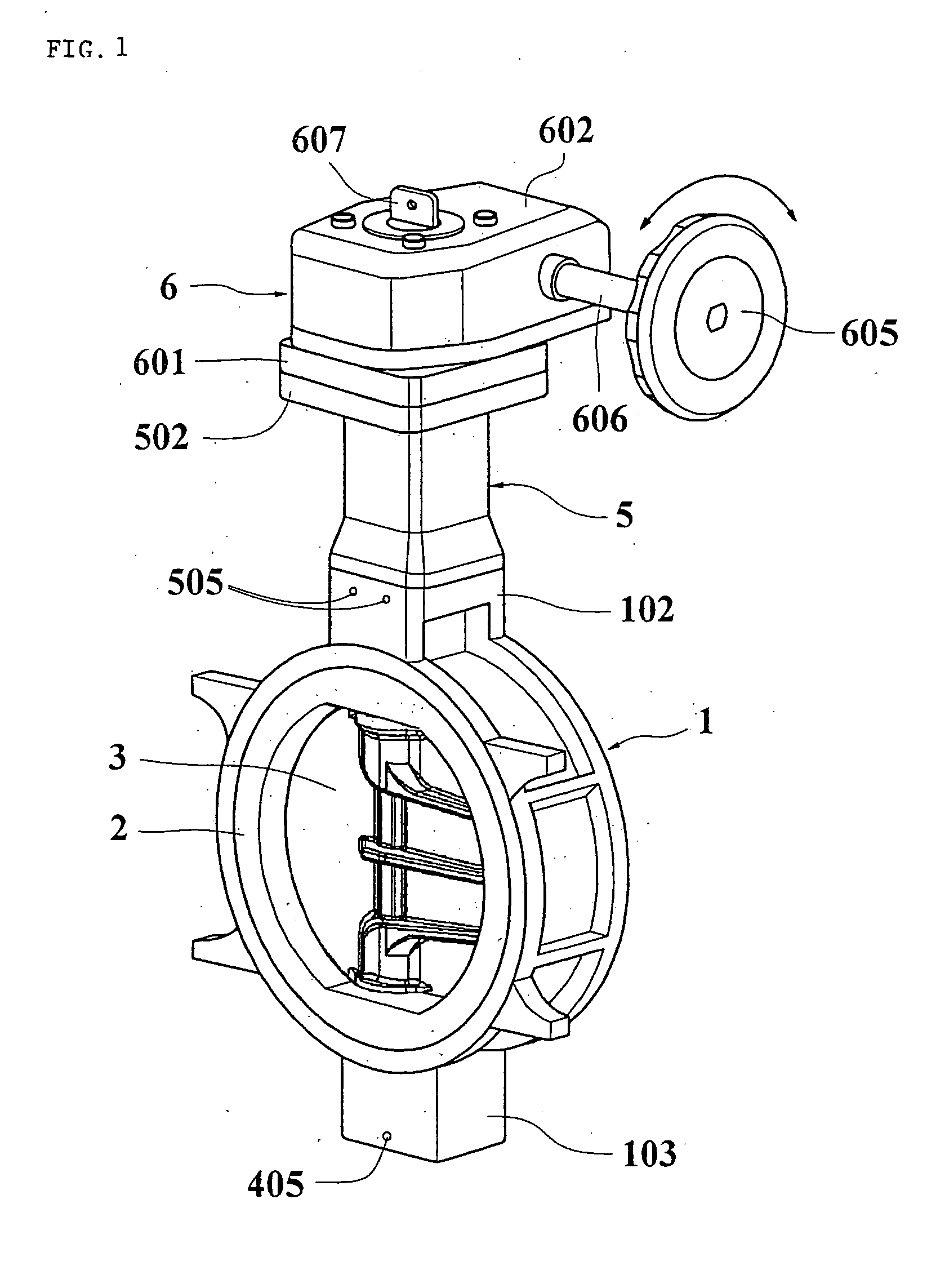

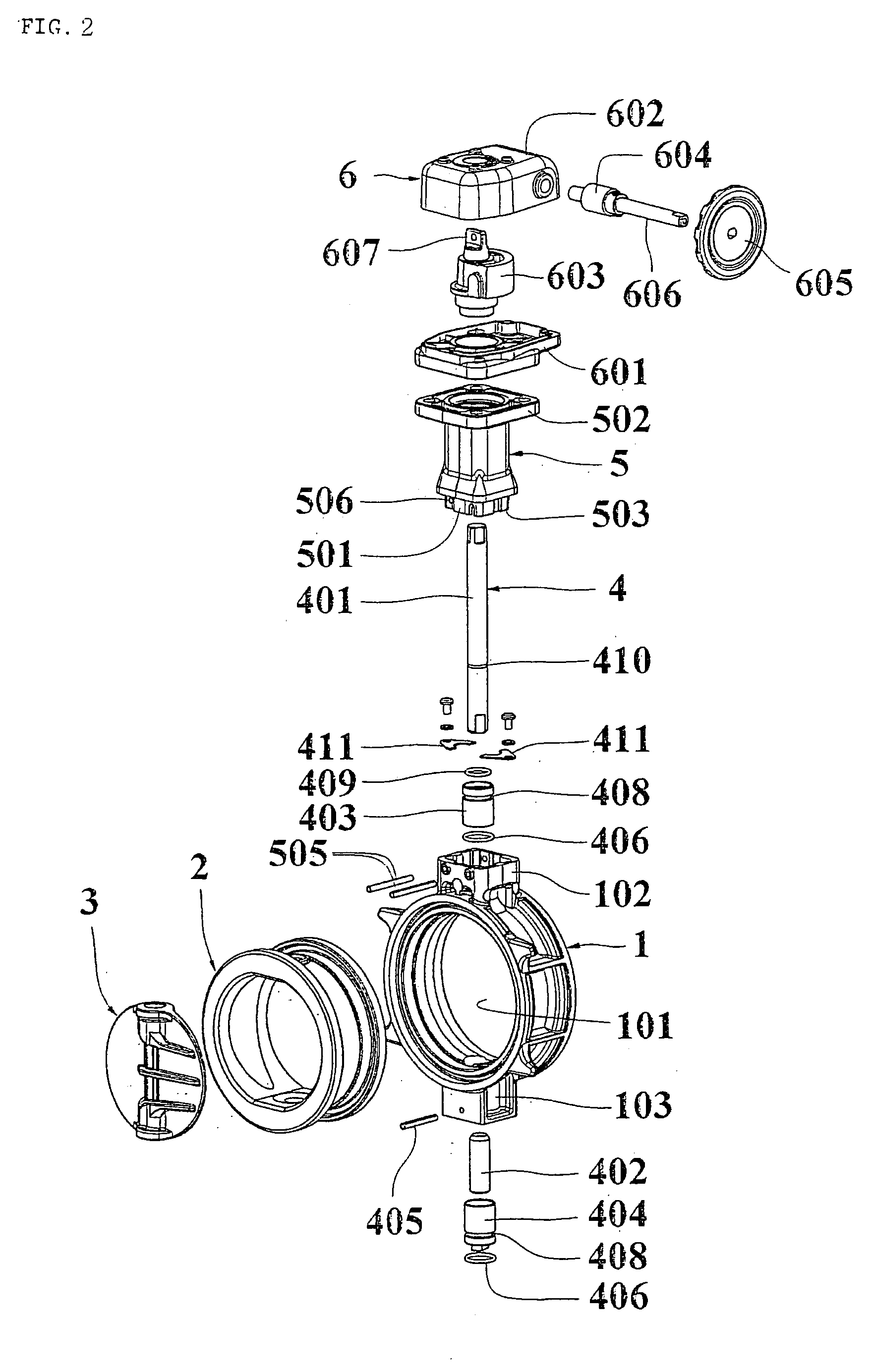

Butterfly valve

InactiveUS20050184267A1High strengthReliable preventionLift valveValve housingsButterfly valveVALVE PORT

A portion of the one valve rod which extends outward is pivotally supported, the valve shaft cylindrical portion which is connected to the valve rod shaft supporting portion is made of material different from that of the valve body, a slanting surface is formed between the inner peripheral surface and the outer peripheral surface of the sheet ring, an angle and a width formed by the slanting surface and the outer peripheral side surface are the greatest at a position intersecting with the valve shaft at right angles and are the smallest at a position of the valve shaft, a central portion of an inner peripheral surface of the valve body is allowed to project inward to form an engaging projection, the sheet ring is brought into contact with the inner peripheral surface of the valve body under pressure in the opposite sides of the recess groove, the cylindrical bush whose one end is closed is mounted to the other valve rod which pivotally supports the valve element, and the other valve rod is sealed.

Owner:TOMOE TECH RES CO LTD

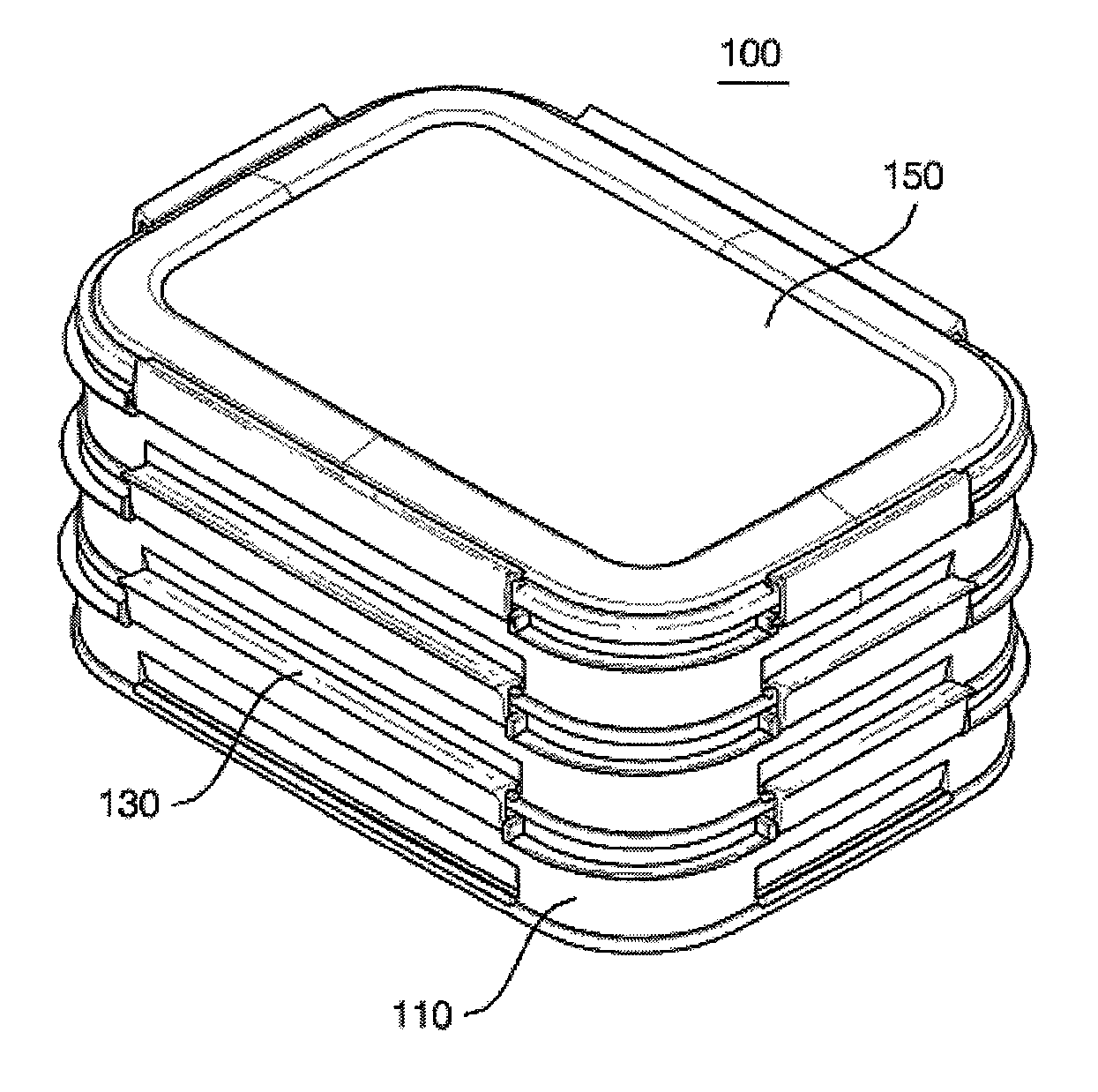

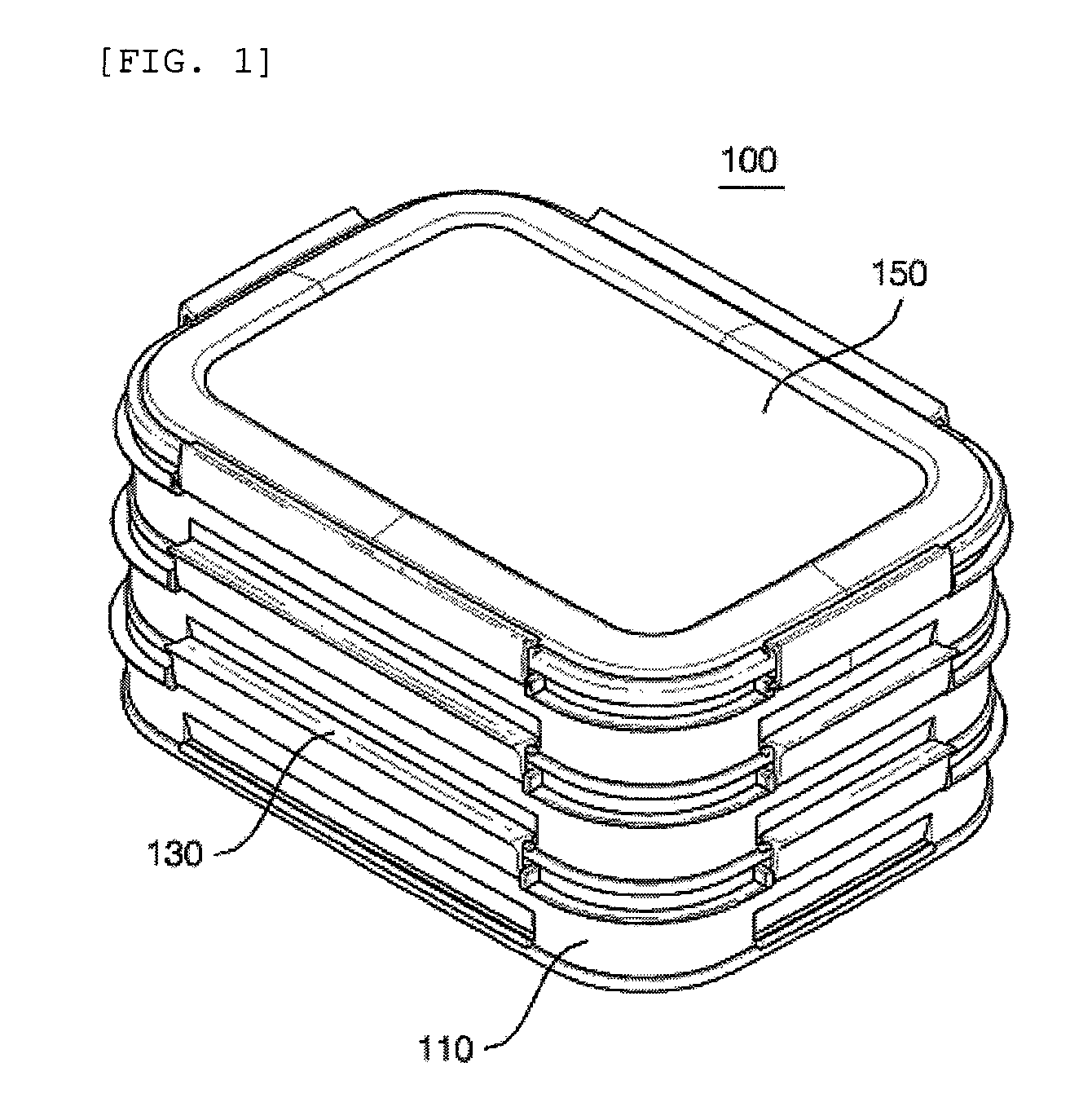

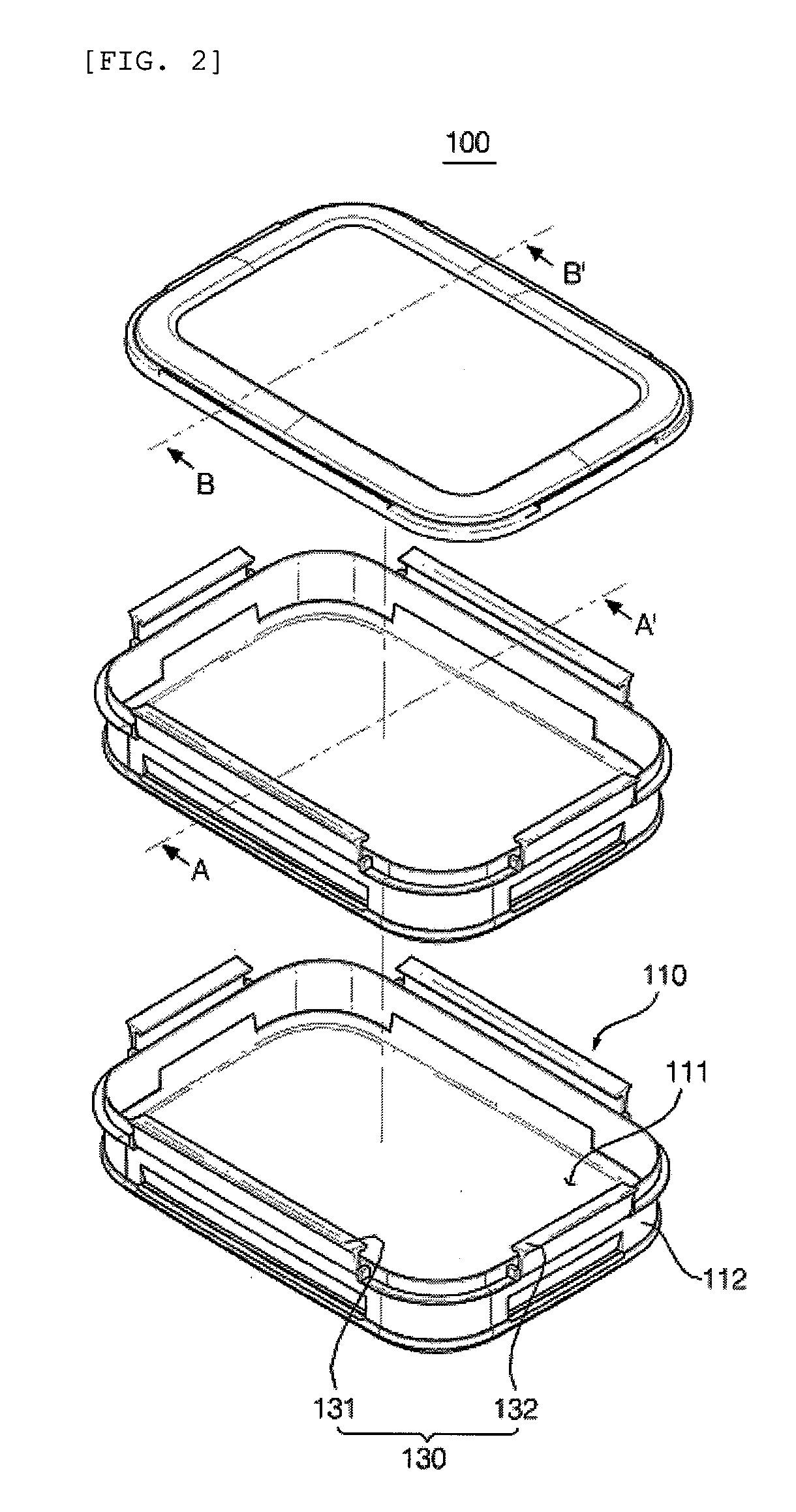

Interlocking container

InactiveUS20090223853A1Improve fastening forceExtend lifespanRemovable lids/coversBoxesHinge angleEngineering

The present invention relates to an interlocking container that has a wing provided on the exterior wall of a container body containing contents and fixes the other container body interlocked above the container body by means of the wing. The interlocking container includes a container body that includes a projecting portion bent downward, which is provided at the circumference of an exterior wall, a first groove grooved at an upper end of the projecting portion in a predetermined depth, and a hill portion that is provided at an entrance of the first groove and projects from an upper end of the projecting portion; a wing that includes a pair of hinges projecting at one side of the exterior wall, a support body hinge-coupled with the hinge, and a fixation projecting piece projecting on one end of the support body to form a predetermined angle to the support body, which fits in the first groove through the fixation projecting piece; and a cover that includes the projecting portion provided at the circumference of the exterior wall and the hill portion provided on the top surface of the projecting portion, which covers the upper part of the container body. According to the present invention, fastening force between interlocked containers is improved, contents stored in the container are prevented from being leaked to the outside, and a lifespan is also increased.

Owner:HANA COBI PLASTIC

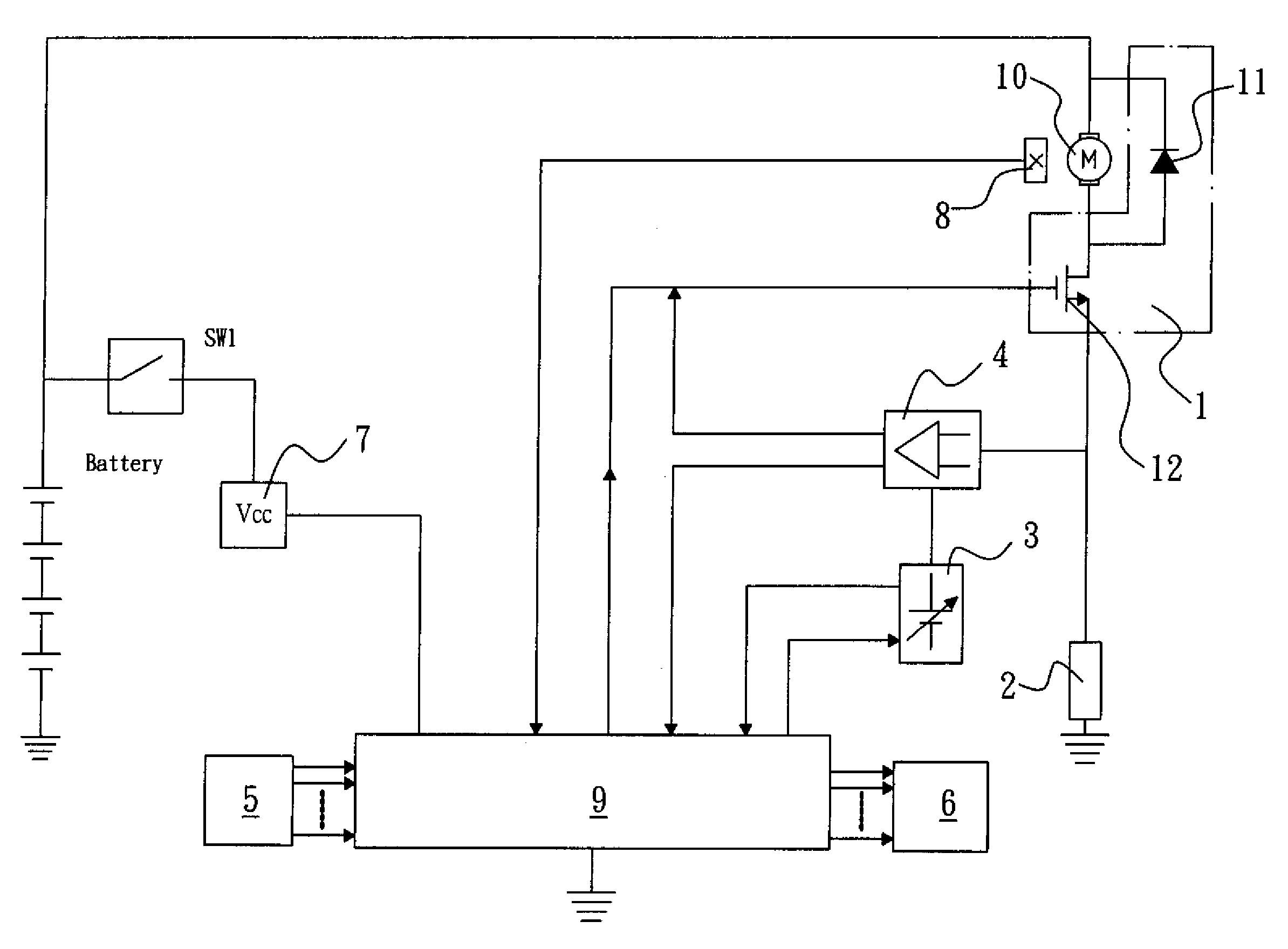

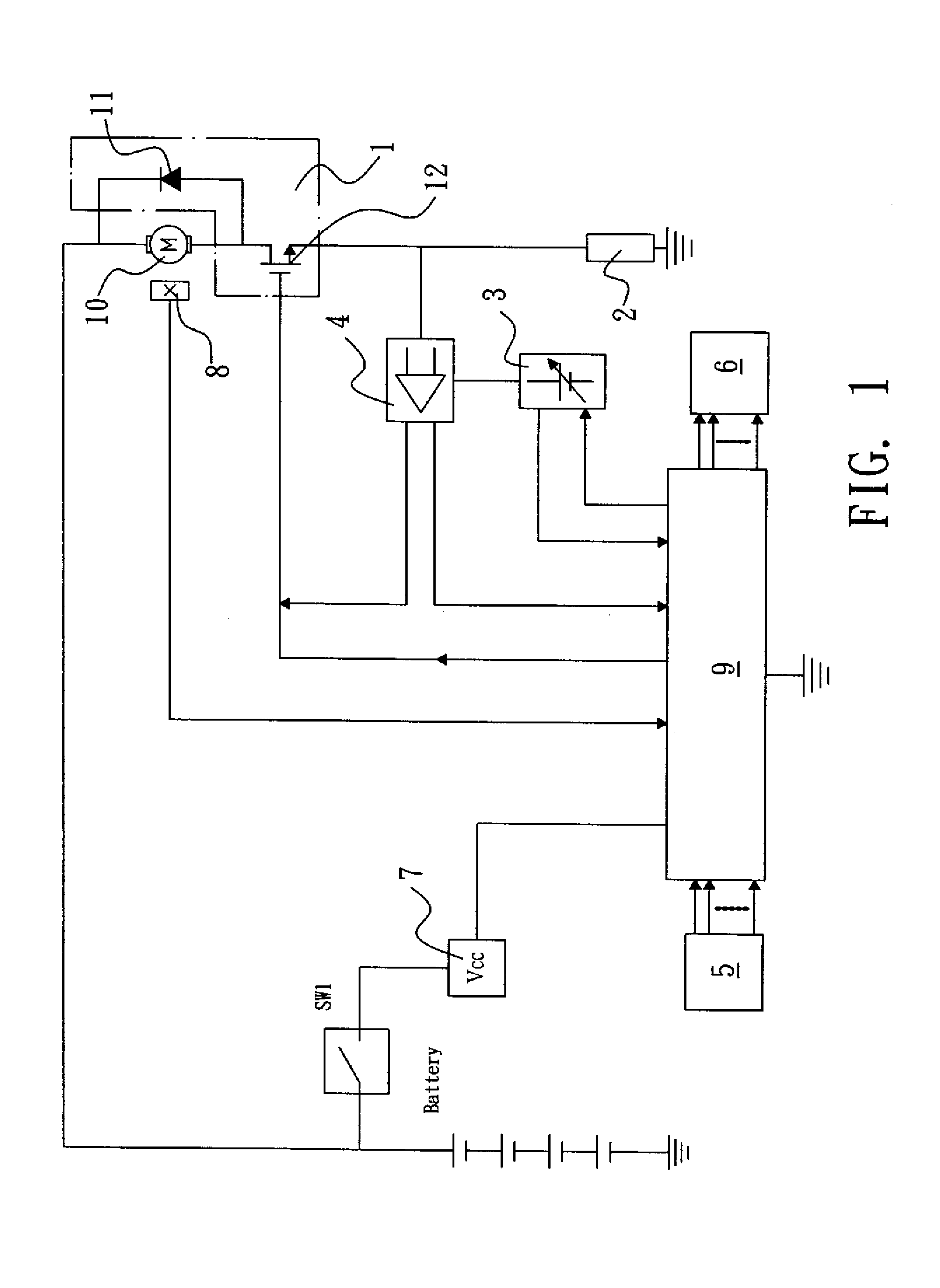

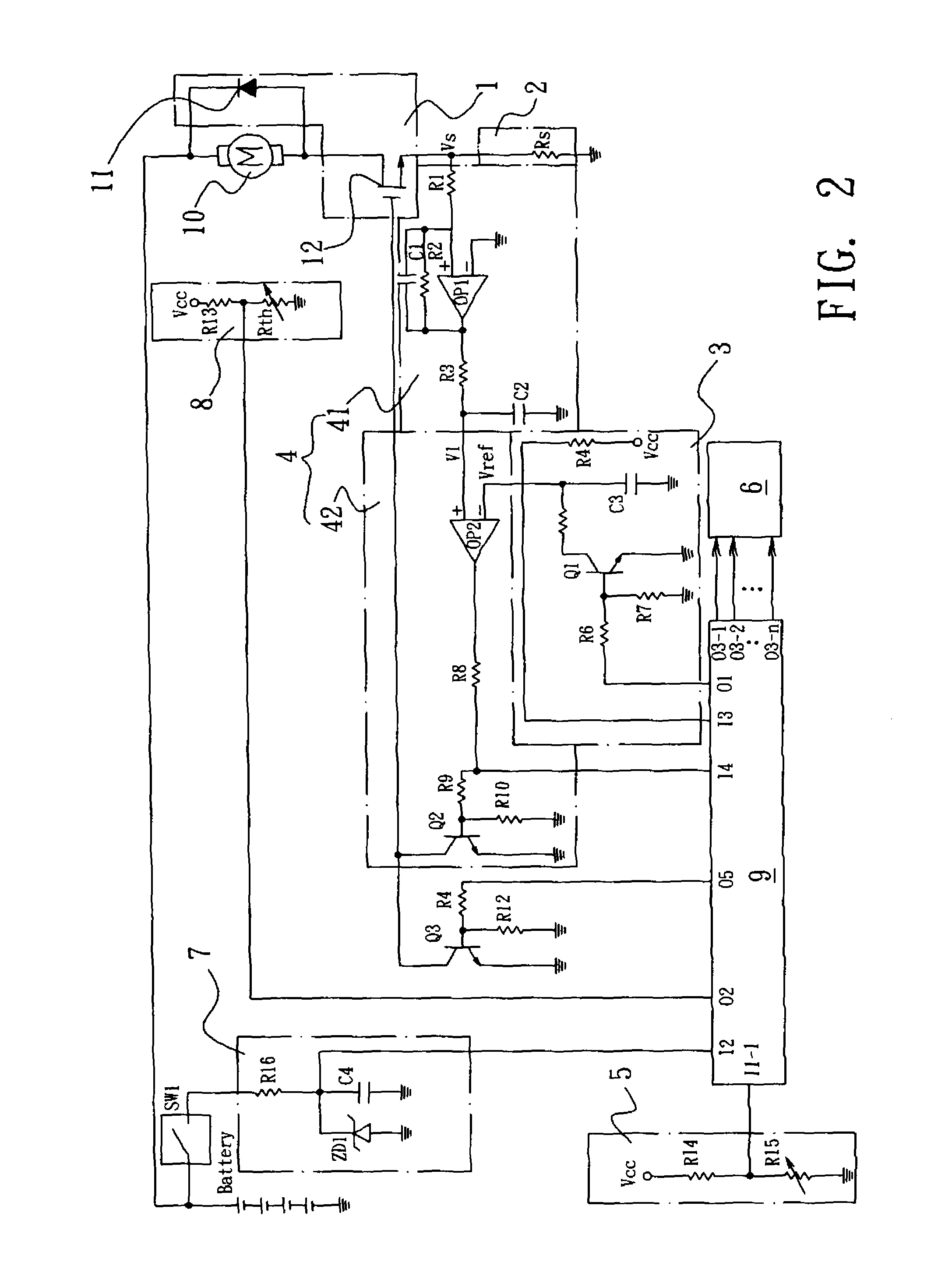

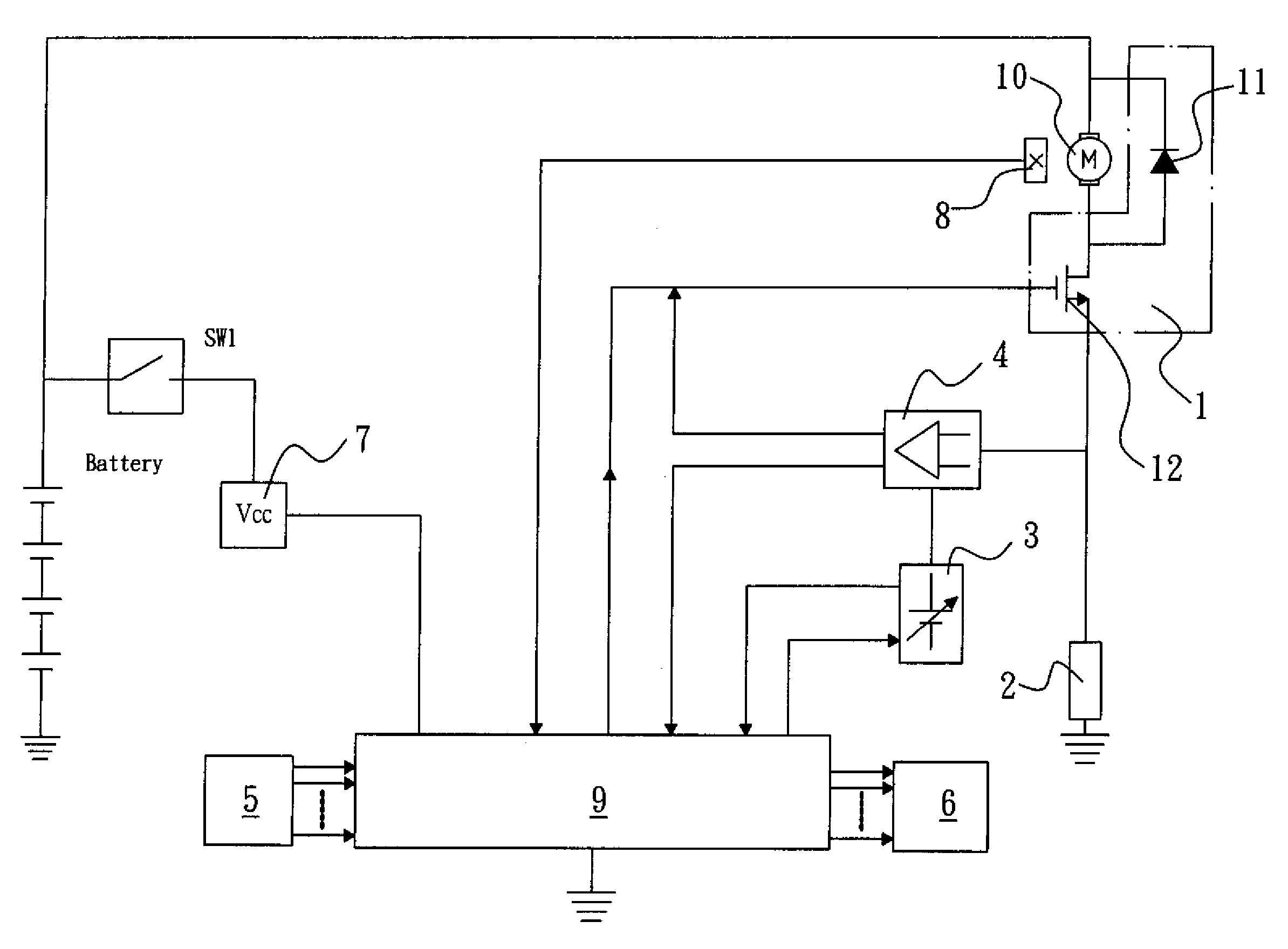

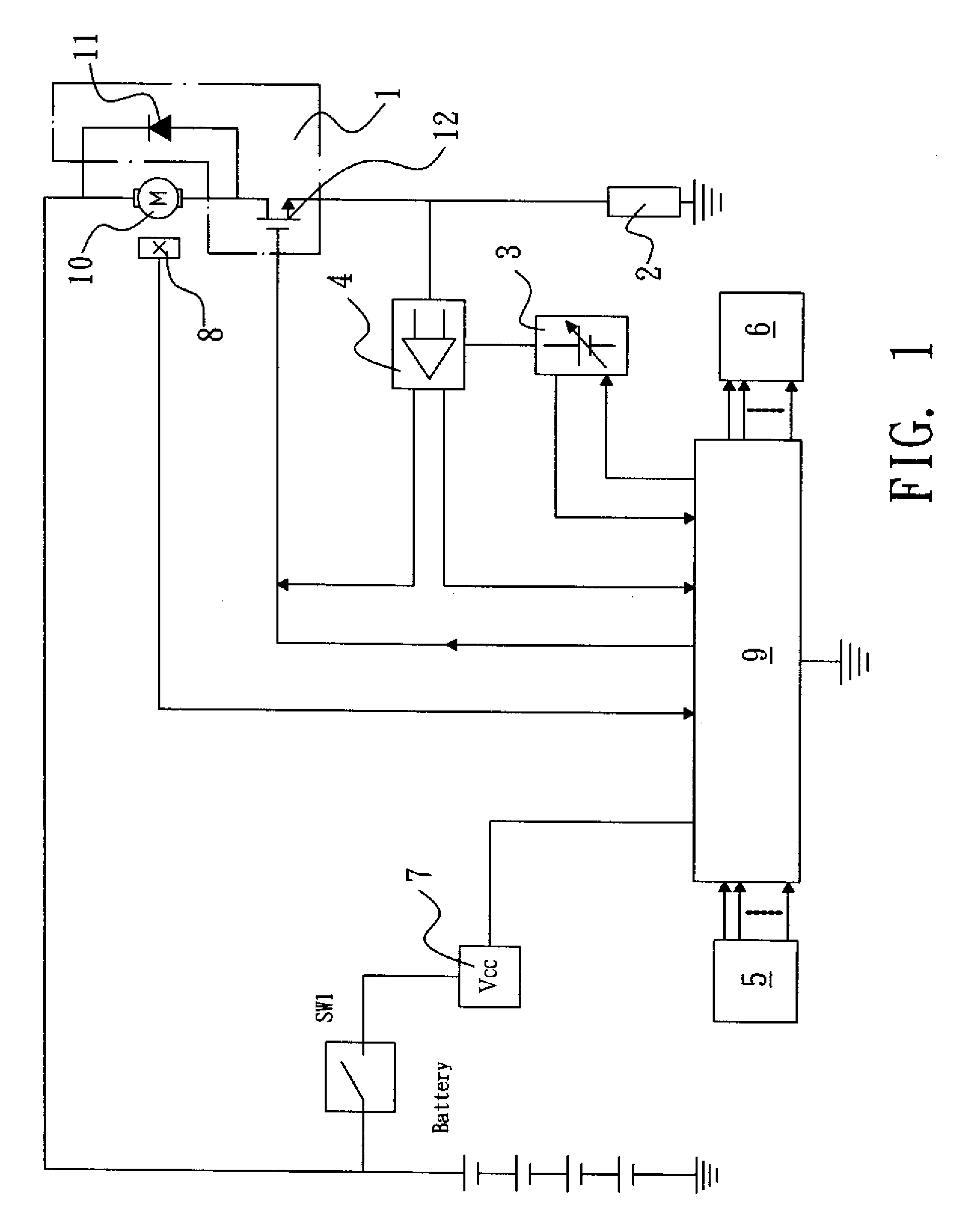

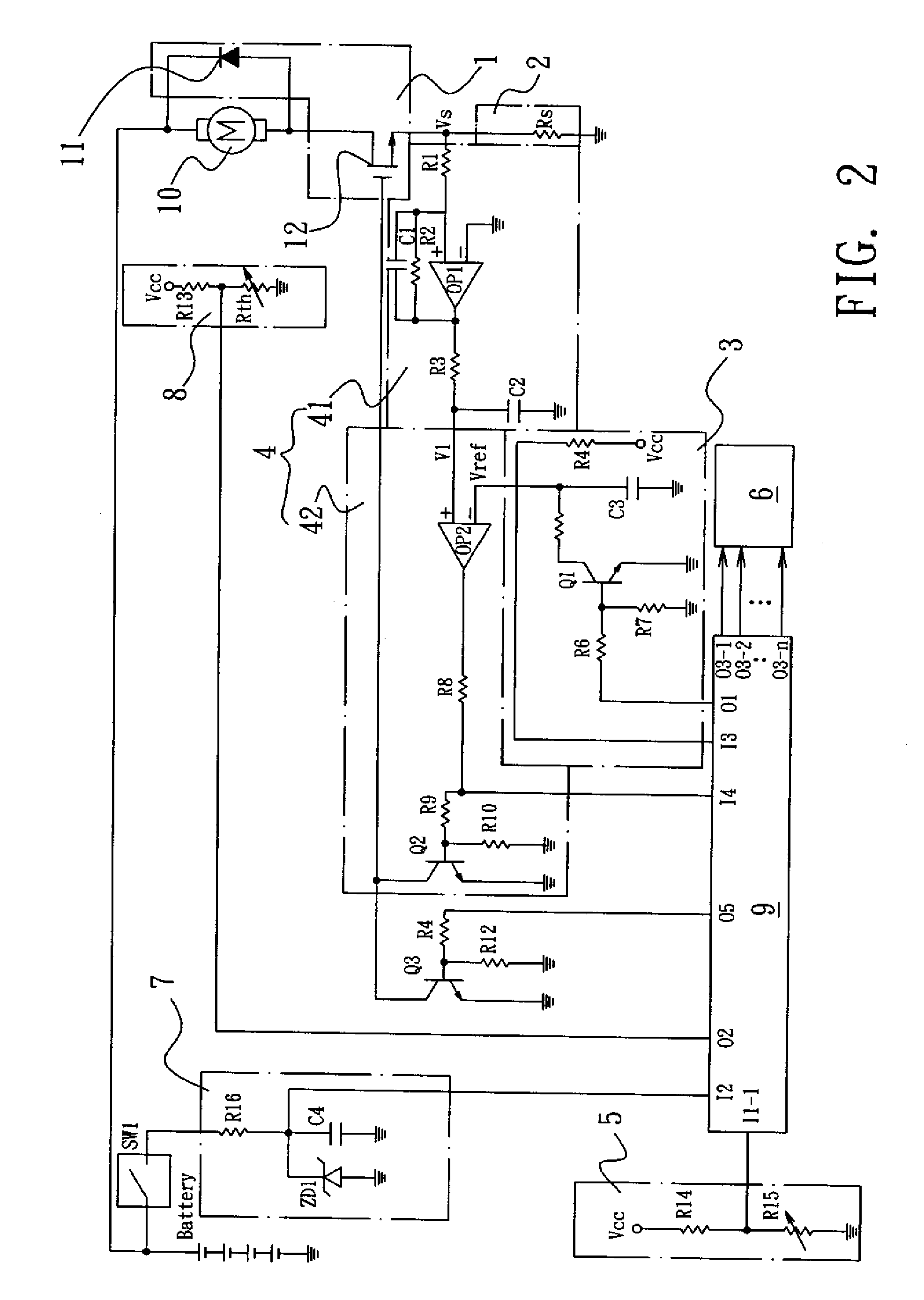

Torque control circuit for impact tool

InactiveUS7839112B2Less degree of tighteningSave powerDC motor speed/torque controlSimulator controlMotor driveElectric machine

A torque control circuit includes a motor driving circuit, a motor operating current detection circuit, a reference voltage generation circuit, a maximum motor current setting circuit, a torque setting circuit, an information output circuit, a regulated-voltage power supply circuit, a motor operating temperature detection circuit, and a control circuit. The control circuit includes an integrated circuit to carry out functions of reading information detection sources, processing, and instruction for execution of torque control and output terminals of the reference voltage generation circuit, the maximum motor current setting circuit, the motor operating temperature detection circuit, and the motor impedance torque setting circuit are respectively connected to corresponding input terminals of the integrated circuit to carry out desired control of torque supplied to the impact tool.

Owner:MOBILETRON ELECTRONICS

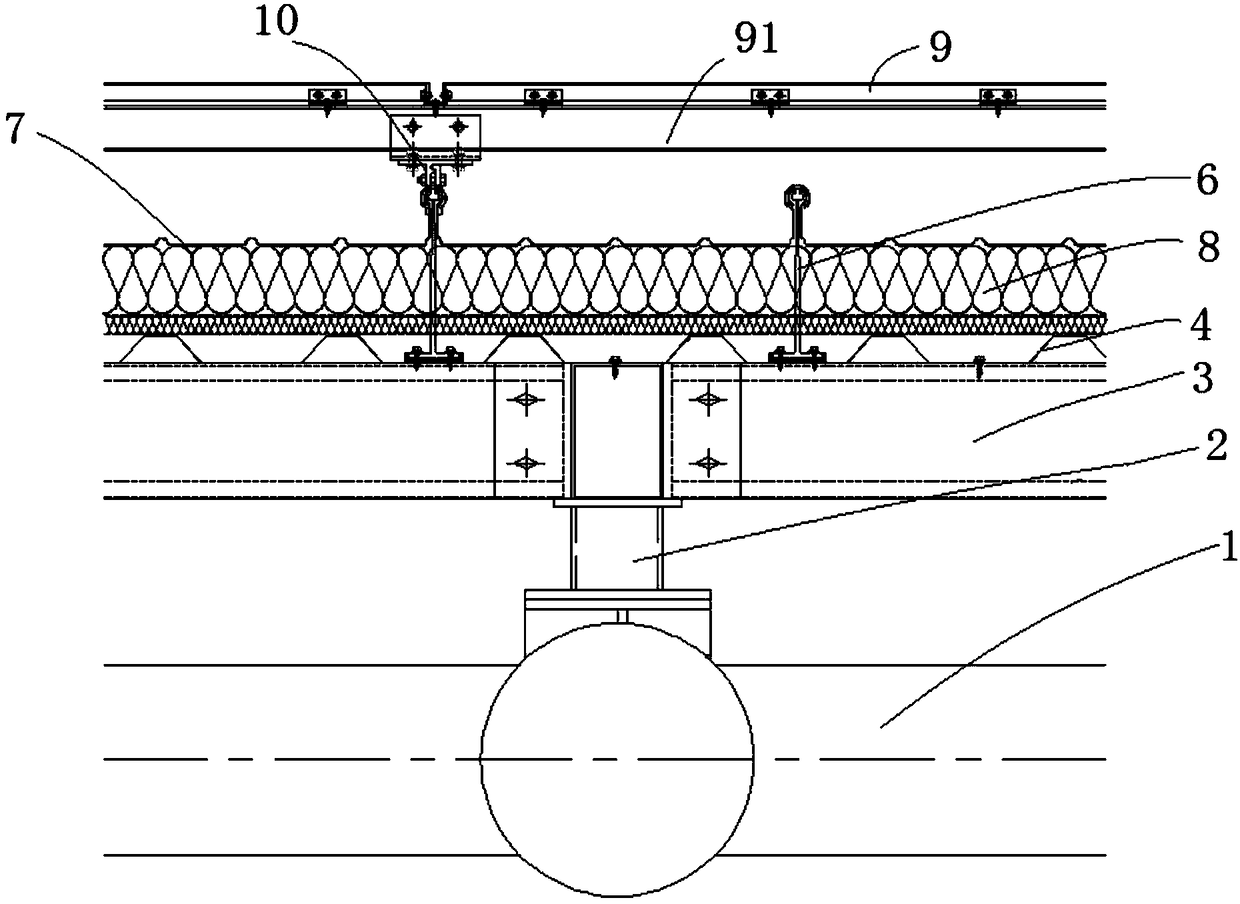

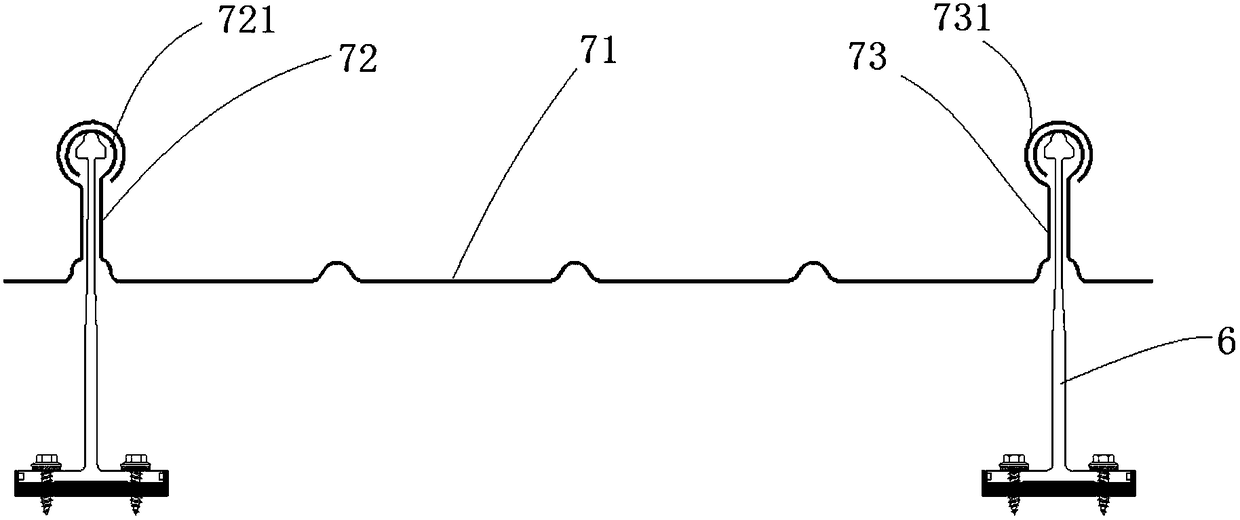

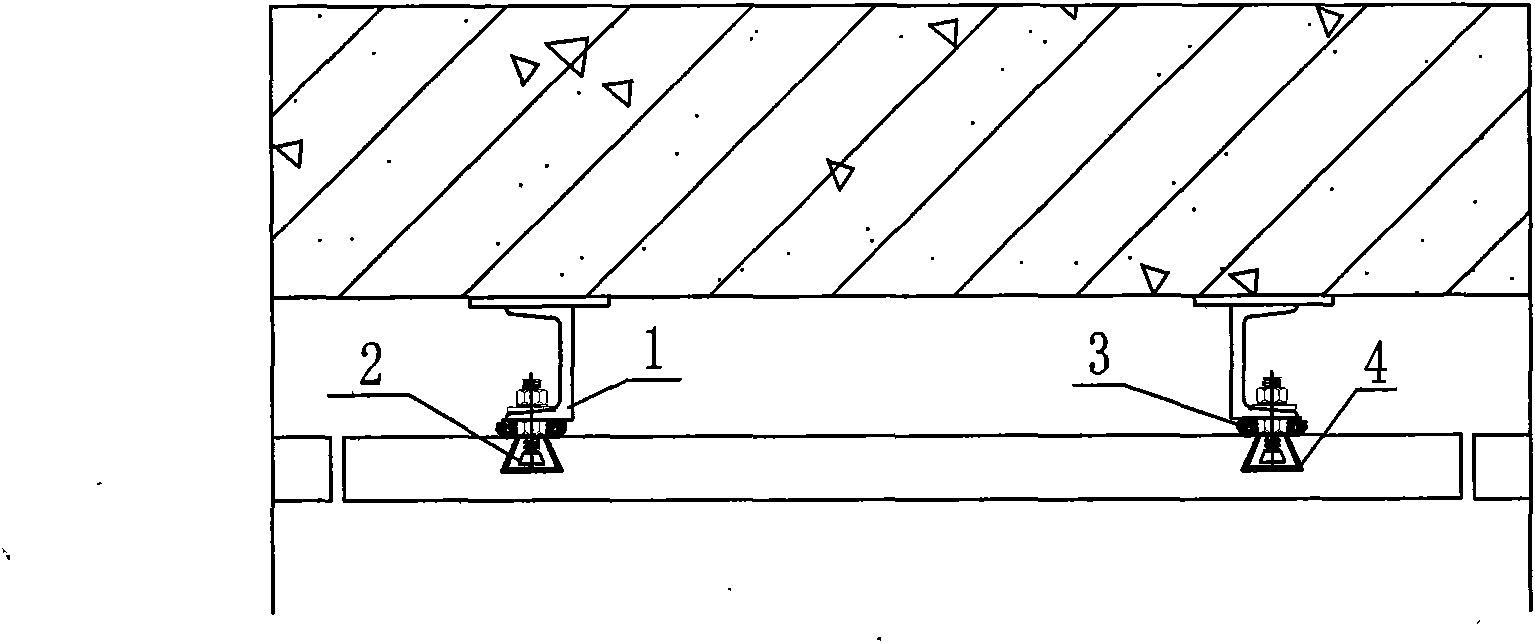

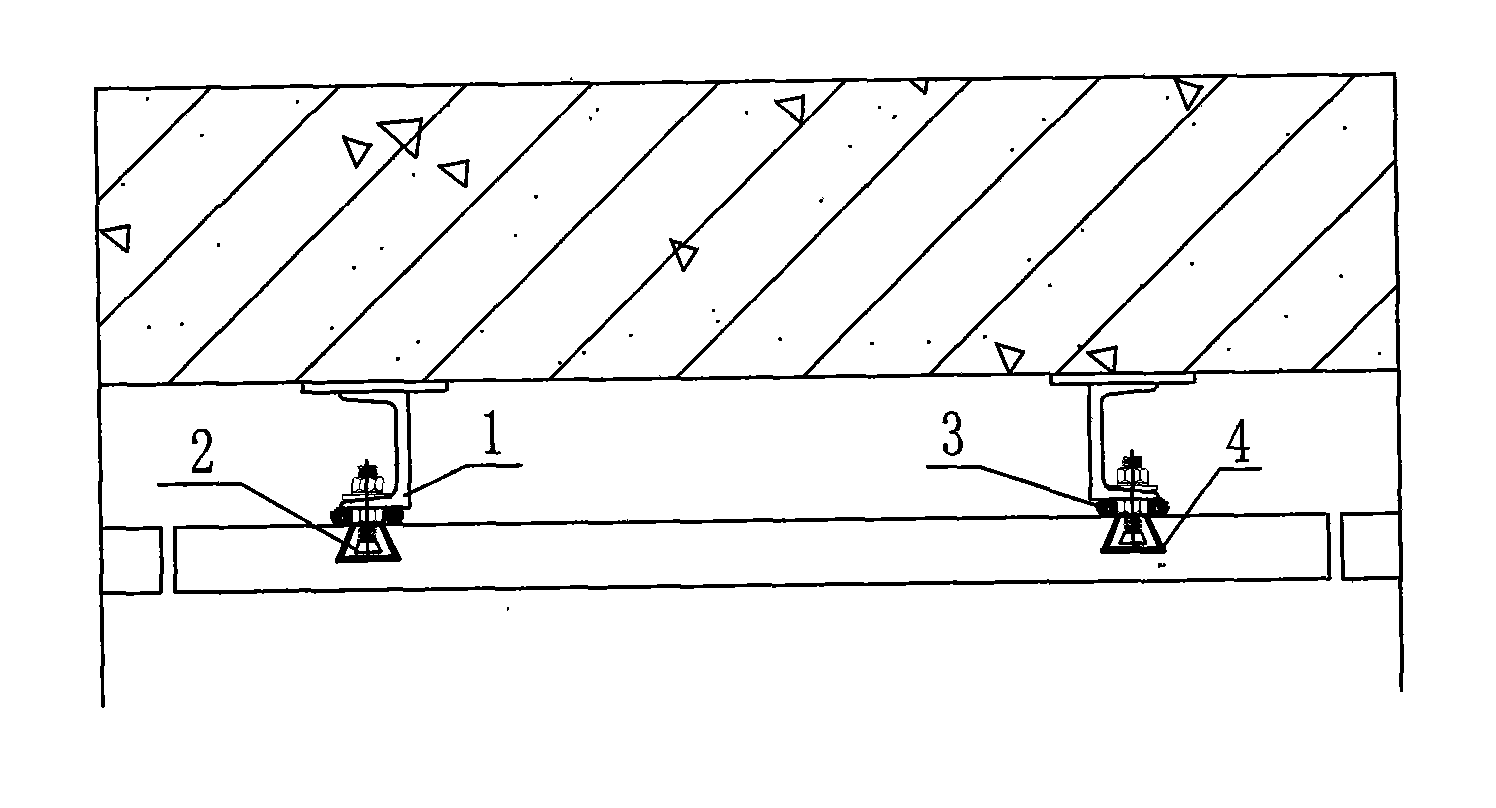

Anti-typhoon and anti-leakage metal roof system

PendingCN108590007AAvoid fatigue damageNo stress concentration problemsBuilding roofsRoof covering insulationsThermal insulationEngineering

The invention discloses an anti-typhoon and anti-leakage metal roof system. The metal roof system sequentially comprises a main steel structure, main roof purline, secondary roof purline, pressed steel bottom plates and purline laid on the pressed steel bottom plates from top to bottom. A plurality of fixed seats are fixed to the purline at intervals, concave roof plates which are engaged with thefixed seats are arranged between the fixed seats, and multiple layers of sound-insulation and vapor-proof thermal insulation materials are laid on the pressed steel bottom plates. The fixed seats include fixed supporting seats and panel engaging plates, wherein the purline is fixedly connected with the lower ends of the fixed supporting seats; the panel engaging plates are fixedly connected withthe fixed supporting seats, and small angles are formed between the panel engaging plates and the fixed supporting seats in the length direction of the roof plates so that the panel engaging plates and the fixed supporting seats can rotate relatively; and panel engaging parts are formed in the upper parts of the panel engaging plates, and the panel engaging parts and both side edges of the roof plates form engaging connection. The anti-typhoon and anti-leakage metal roof system solves the problems that a traditional metal roof system with vertical lockrands has low wind resistance, and is prone to leaking and prone to producing expansion deformation damage, and the safety of upper supporting facilities is affected.

Owner:CENT INT GROUP +1

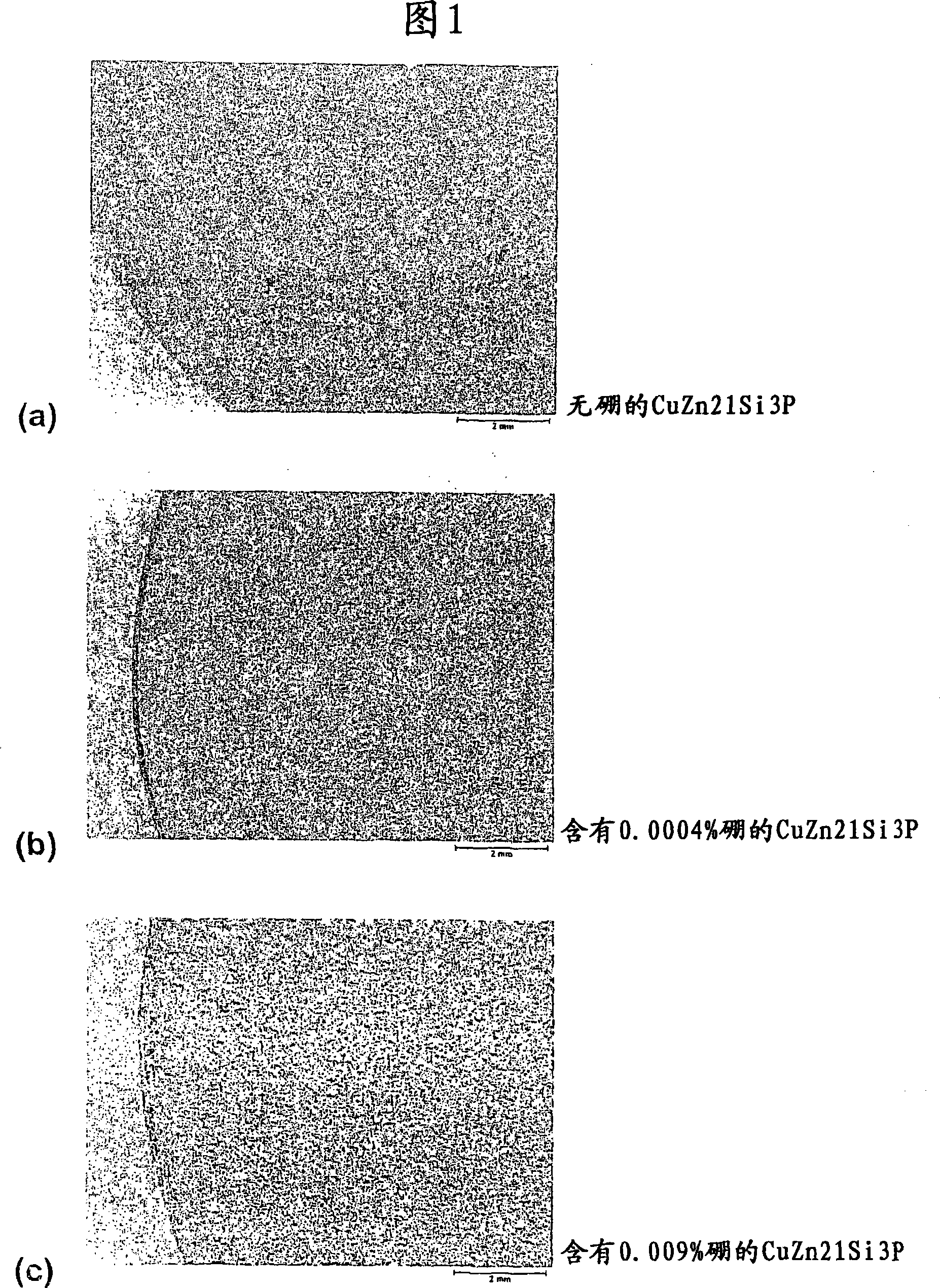

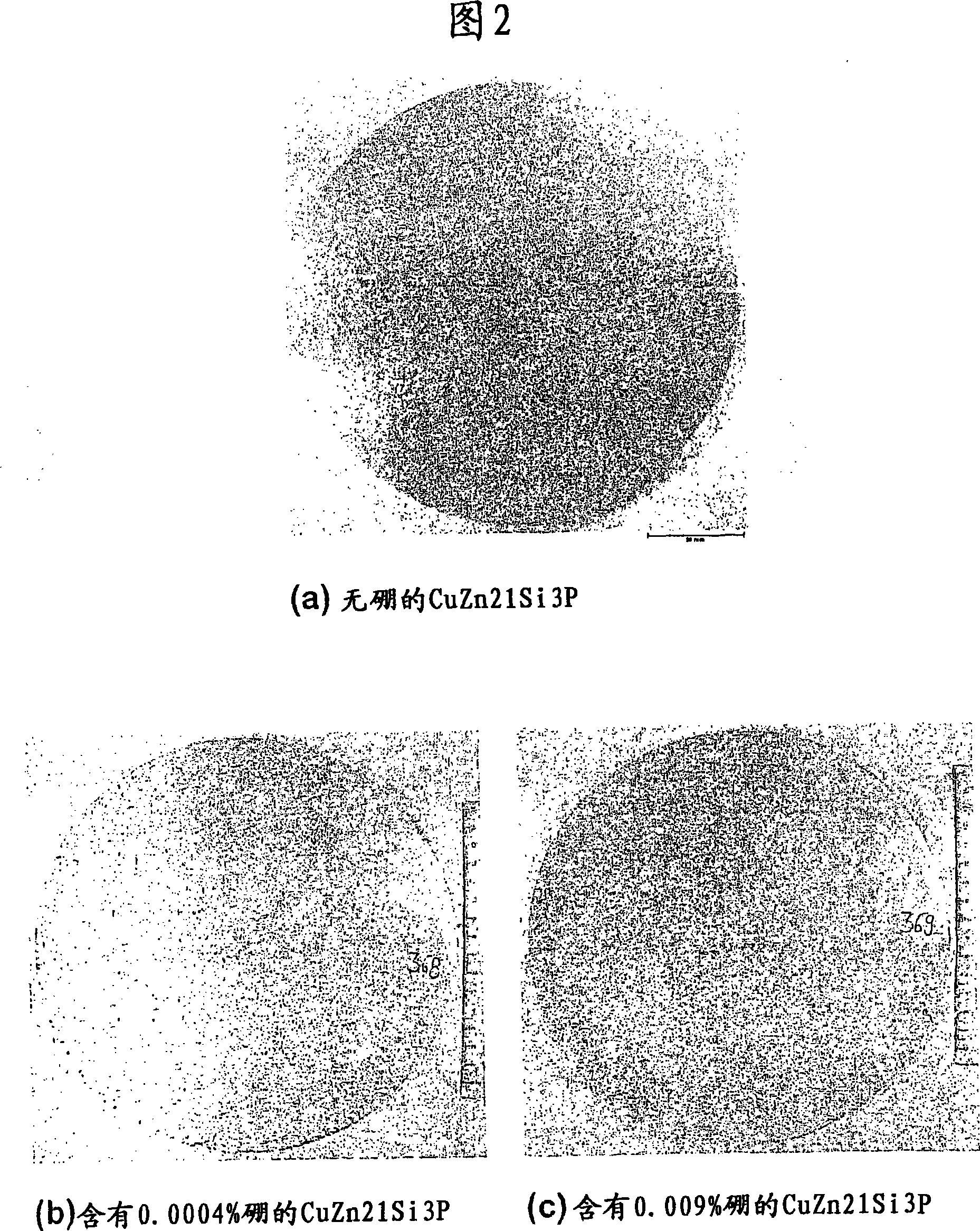

Copper/zinc/silicon alloy, use and production thereof

A Cu-Zn-Si alloy includes, in % by weight, 70 to 80% of copper, 1 to 5% of silicon, 0.0001 to 0.5% of boron, up to 0.2% of phosphorus and / or up to 0.2% of arsenic, a remainder of zinc, plus inevitable impurities. Products using the alloy and processes for producing the alloy are also provided. The alloy is distinguished by an improved resistance to oxidation and by uniform mechanical properties.

Owner:DIEHL METAL STIFTUNG & CO KG

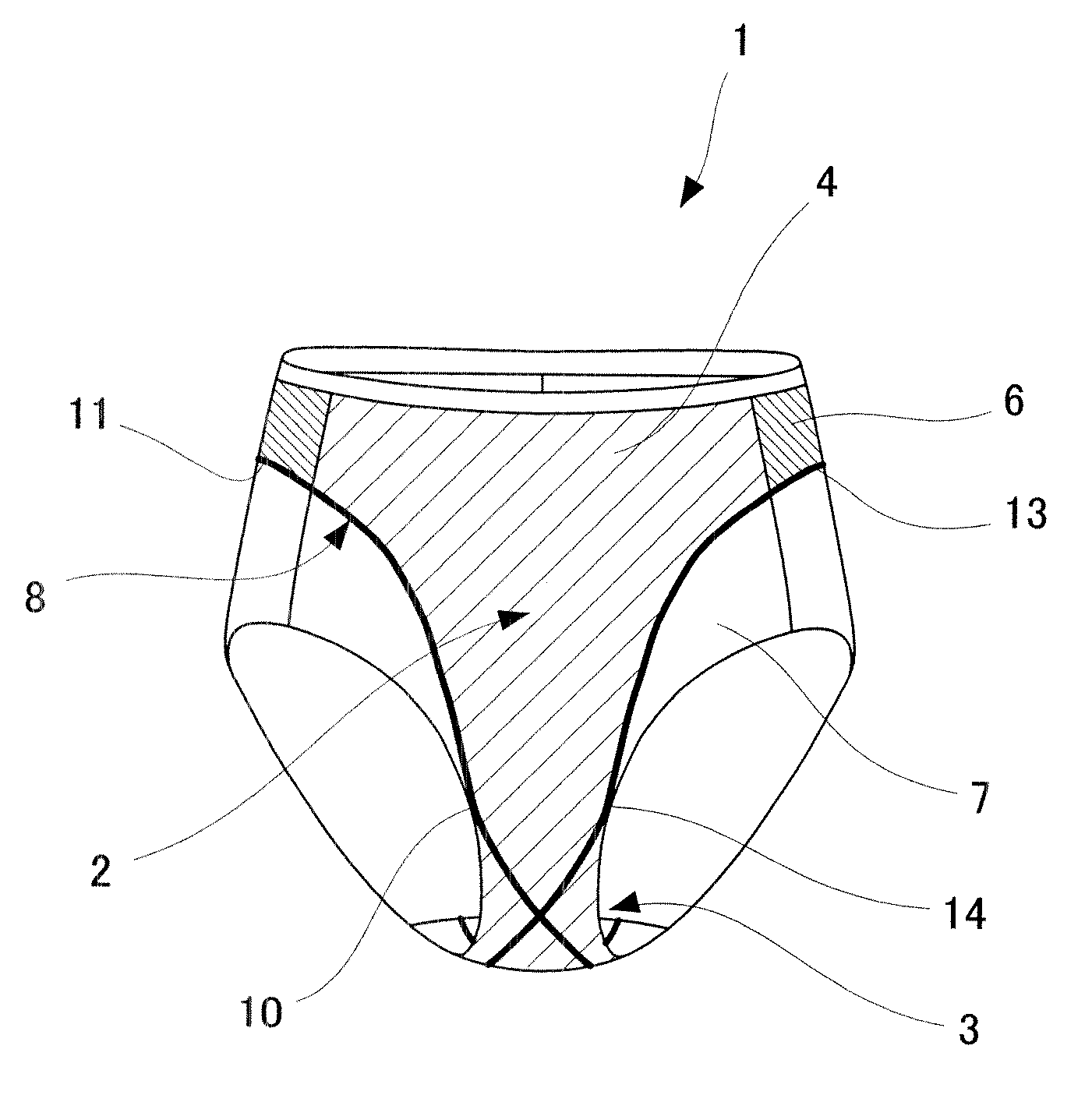

Underwear for lower parts

ActiveUS8092273B2Correct distortionExcessive distortionBrassieresGirdlesRight anteriorPhysical medicine and rehabilitation

Owner:INDY & ASSOC

Torque control circuit for impact tool

InactiveUS20090302798A1Reduce output voltageTorque set range narrowDC motor speed/torque controlSimulator controlOperating temperatureIntegrated circuit

A torque control circuit includes a motor driving circuit, a motor operating current detection circuit, a reference voltage generation circuit, a maximum motor current setting circuit, a torque setting circuit, an information output circuit, a regulated-voltage power supply circuit, a motor operating temperature detection circuit, and a control circuit. The control circuit includes an integrated circuit to carry out functions of reading information detection sources, processing, and instruction for execution of torque control and output terminals of the reference voltage generation circuit, the maximum motor current setting circuit, the motor operating temperature detection circuit, and the motor impedance torque setting circuit are respectively connected to corresponding input terminals of the integrated circuit to carry out desired control of torque supplied to the impact tool.

Owner:MOBILETRON ELECTRONICS

Vehicle member joining structure and vehicle member joining method

ActiveUS20160347377A1Inhibit thermal strainImprove joint strengthMaterial gluingVehicle sub-unit featuresAdhesiveEngineering

A vehicle member joining structure has: a metal member that is part of a vehicle; a resin member that is adjacent to the metal member; and an adhesive that is provided between the metal member and the resin member and joins the metal member to the resin member, the adhesive having an elastic modulus that is lower than elastic moduli of the metal member and the resin member, wherein, given that (i) ΔL is a difference in linear expansions of the metal member and the resin member at a time of heating in a drying process after application of the adhesive, (ii) T0 is a thickness of the adhesive and (iii) T1 is a length of an end surface of the adhesive, the following predetermined relational expression is satisfiedT12=T02+ΔL2.

Owner:TOYOTA JIDOSHA KK

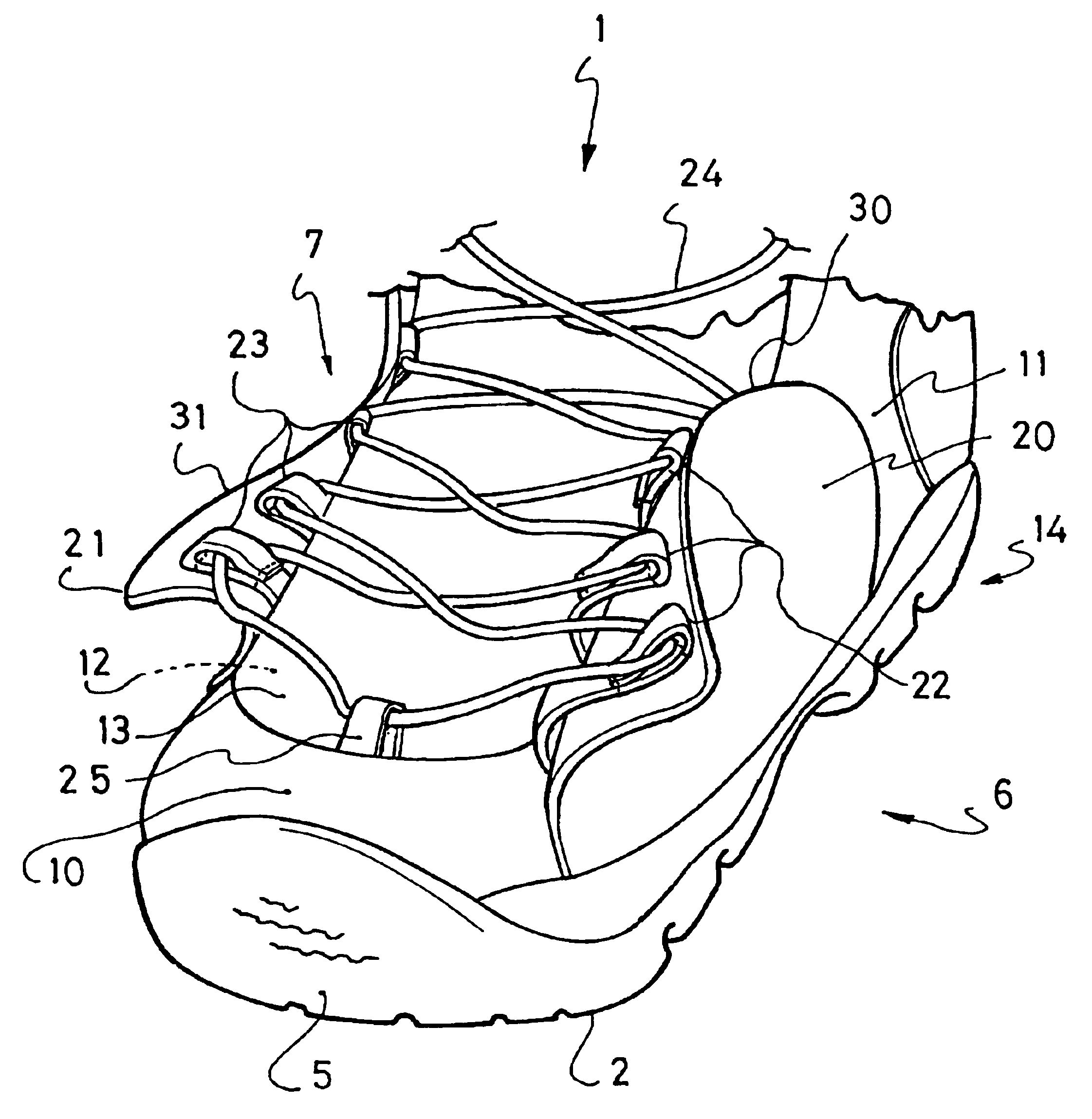

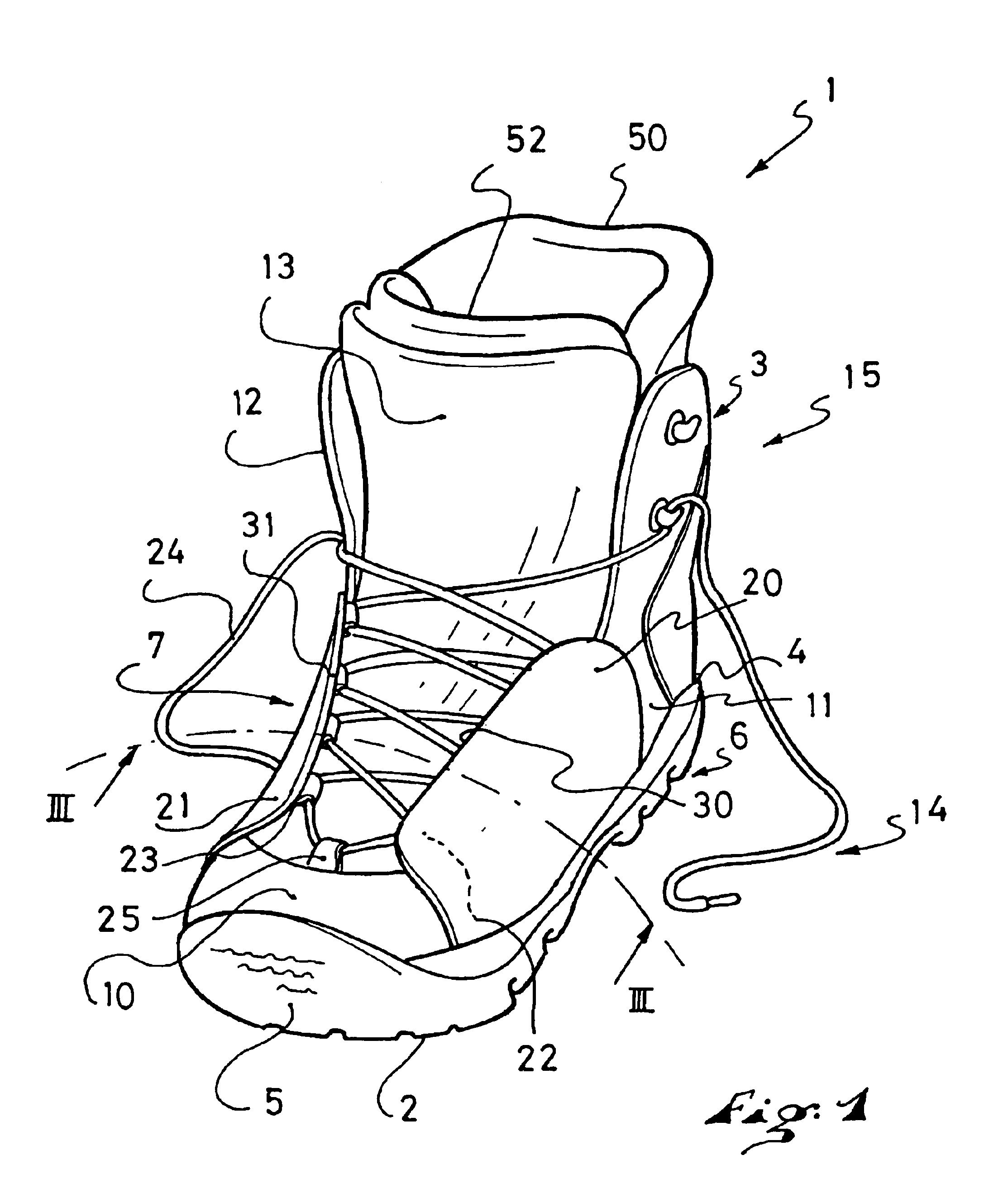

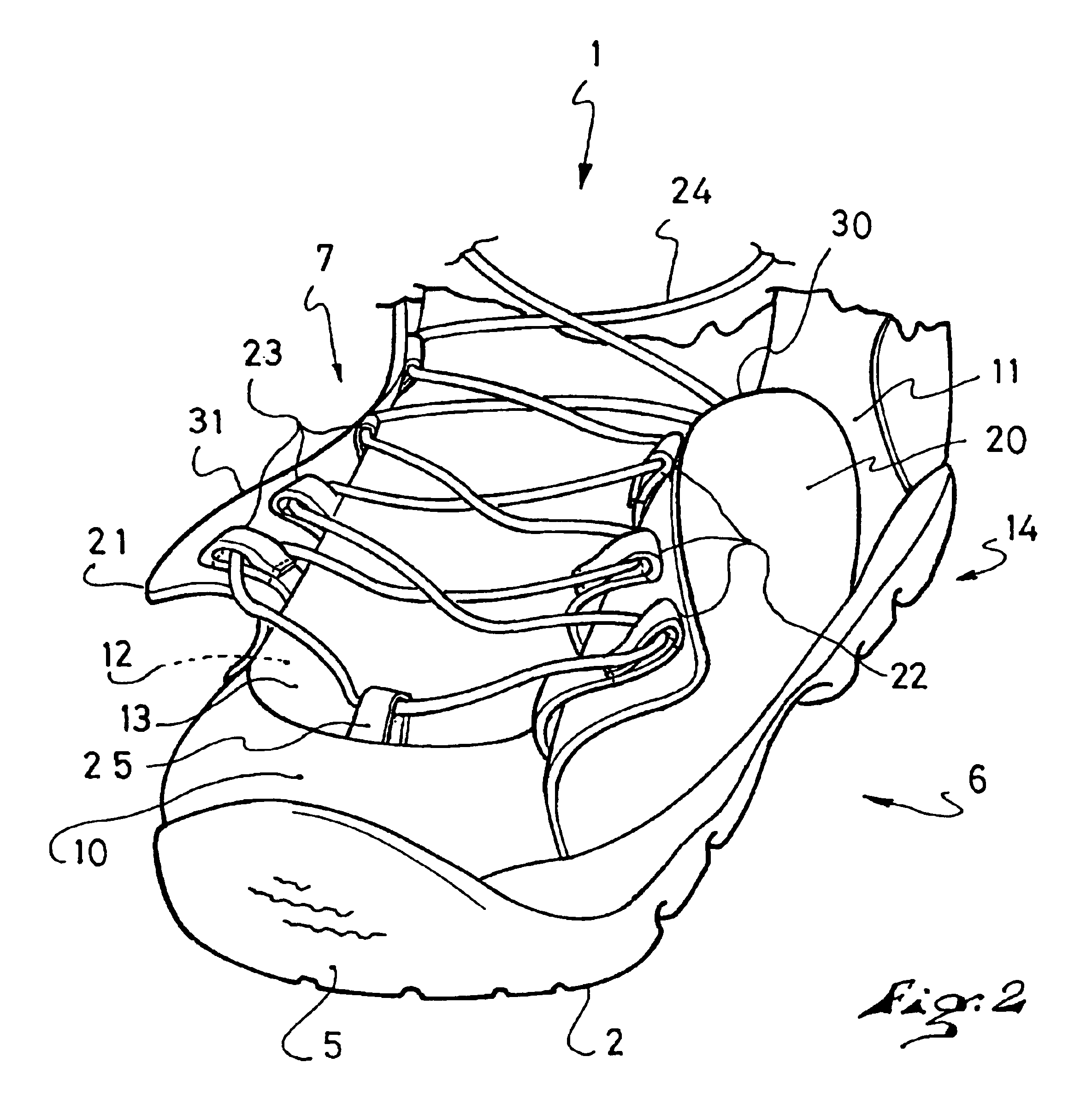

Sports boot

InactiveUS6954996B2Reduce wearImprove fastening forceShoe lace fasteningsEngineeringMechanical engineering

Owner:SALOMON SA

Wearable electronic device

ActiveUS9274506B2Improve fastening forceBe detached or fastened quicklyElectronic time-piece structural detailsDigital data processing detailsComputer moduleWearable Electronic Device

A wearable electric device includes a main body with a circuit module inside and at least a detachable battery strap with a battery module inside, and the main body and the detachable battery strap are detachably fastened together. A female buckle member is formed on the edge of the main body and includes a receiving chamber, a pair of locking notches arranged on the respective sides of the receiving chamber and a plurality of metal conductive points connected with the circuit module. A male buckle member is attached on the front part of the detachable battery strap to be fastened with the female buckle member and includes a plurality of pogo pin connectors for connecting with the metal conducting points, and a locking block for fastening with the receiving chamber.

Owner:CHENG UEI PRECISION IND CO LTD

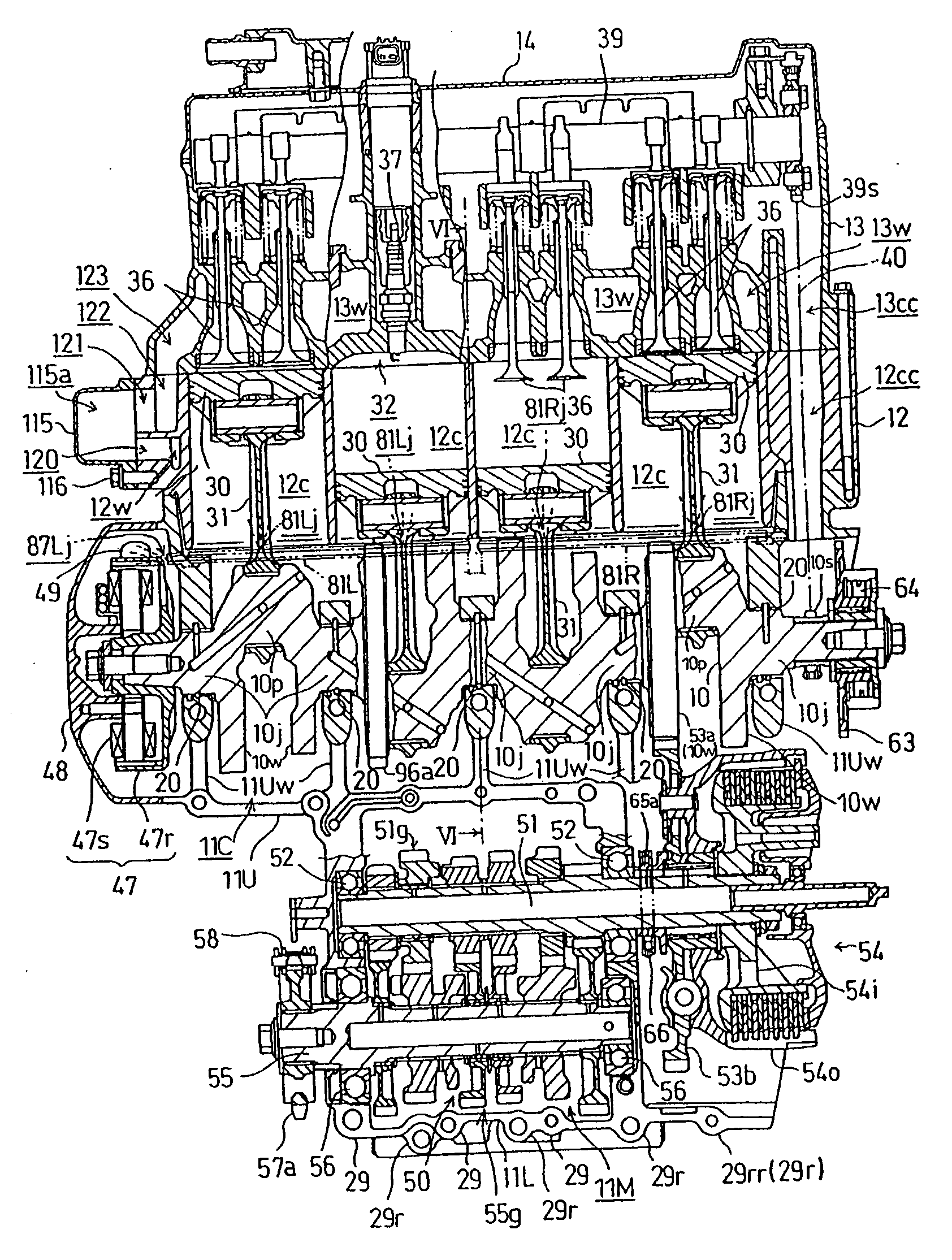

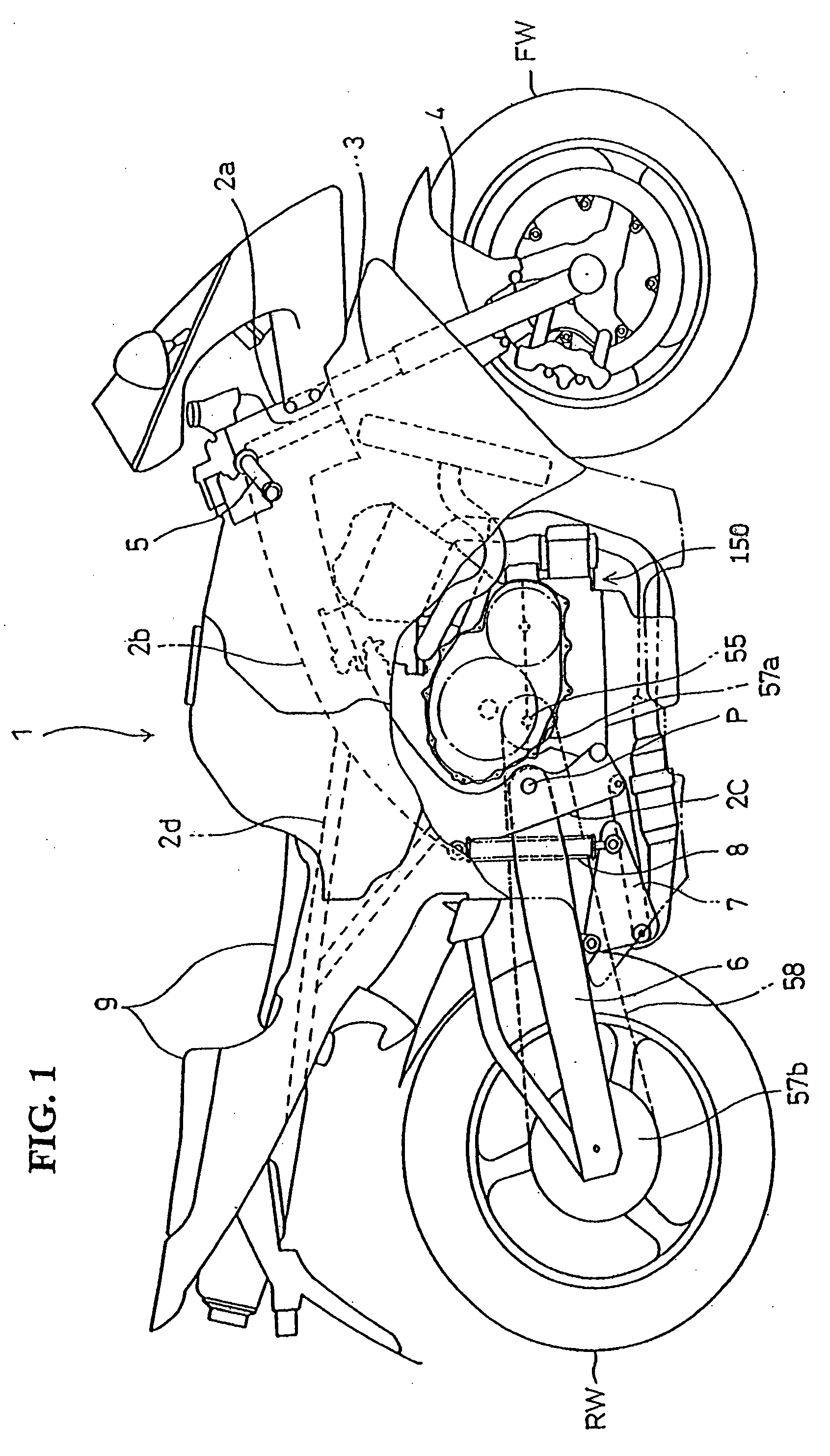

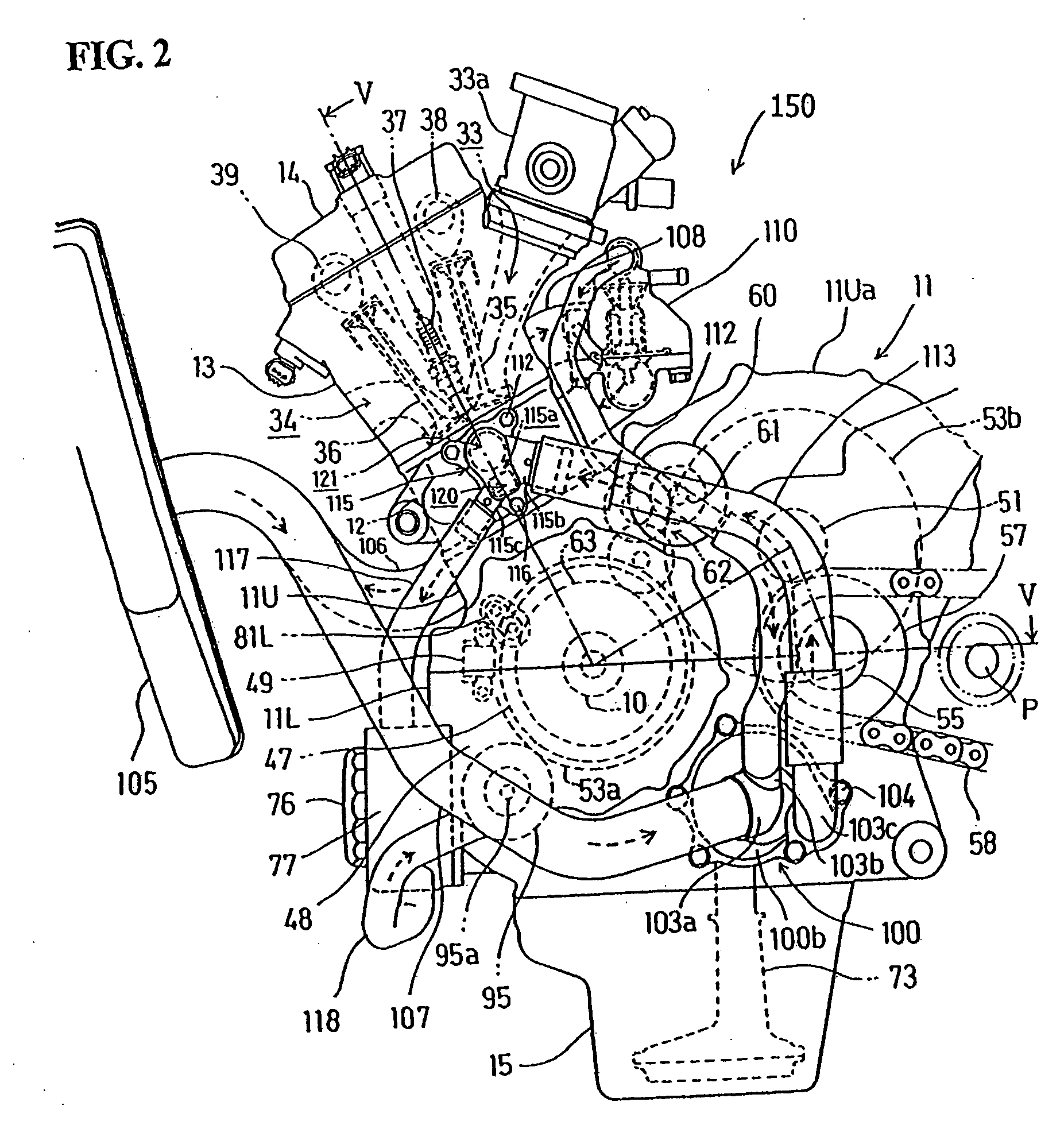

Integrated power unit including split crankcase with reinforced fastening arrangement, and vehicle including same

InactiveUS20070221160A1Shorten the lengthCompact designCasingsMachines/enginesDrive shaftEngineering

An integrated power unit for a small vehicle is configured to permit a compact engine design in a power unit having a crankcase that is split into upper and lower portions. The power unit includes a crankshaft supported by the crankcase and oriented transverse to the running direction of the vehicle. A transmission shaft is rotatably supported in a transmission chamber formed on the rear side of the crank chamber. The respective split surfaces of the upper and the lower crankcase portions are provided plural fastening boss portions arranged as vertically opposed pairs. The plural fastening boss portions are respectively joined using fastening bolts to integrate the upper crankcase and the lower crankcase, thereby forming the crankcase. A clutch is disposed at one end of the transmission shaft, and the rearmost fastening boss portions overlap with a rear portion of the clutch in the front-rear direction of the vehicle.

Owner:HONDA MOTOR CO LTD

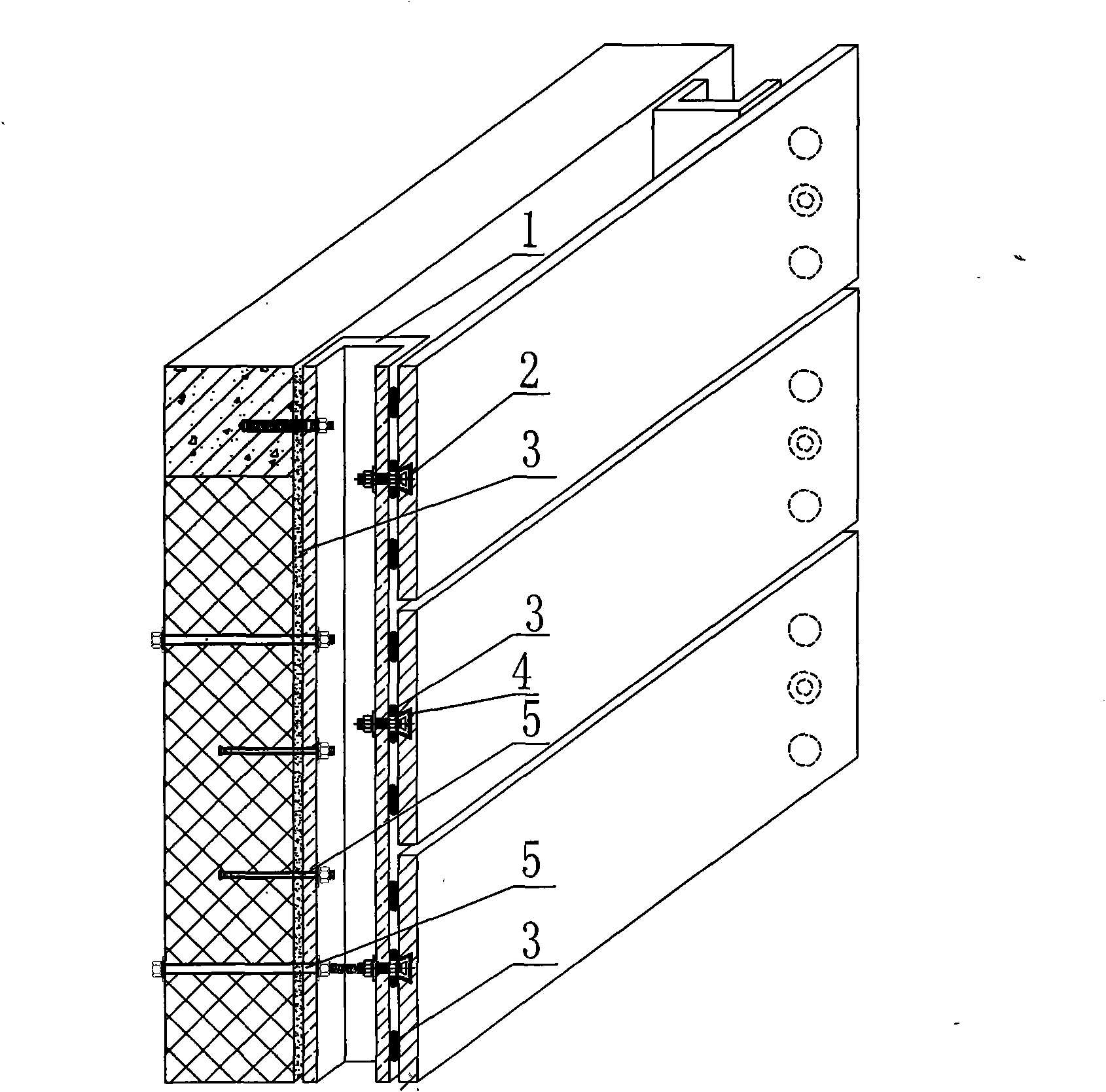

Structure member for dry hanging of veneer on wall surface steel joist and application method thereof

The invention relates to a structure member for dry hanging of a veneer on a wall surface steel joist and an application method thereof. The structure member comprises a steel joist, adhesive, a pendant, a hole slot and bolts and is characterized in that both ends of a steel joist are fixed with a wall body according to routine, and the middle thereof is connected with the wall body through a plurality of bolts so as to lead the bearing capacity and stability of the joist to be multiplied compared with the original method. The veneer is directly fixed on the joist through the pendant and the adhesive and is not conventionally fixed on a pull rod made of angle iron; after the adhesive is solidified, the veneer becomes the pull rod between the joists and replaces the pull rod made of angle iron while realizing the decorative effect at the same time. The pull rods can be greatly reduced, even one pull rod in the prior art is not needed, therefore, a large amount of steel can be saved, the construction is simpler and faster compared with the prior art, the manufacturing cost is reduced, and the structure member has practical value.

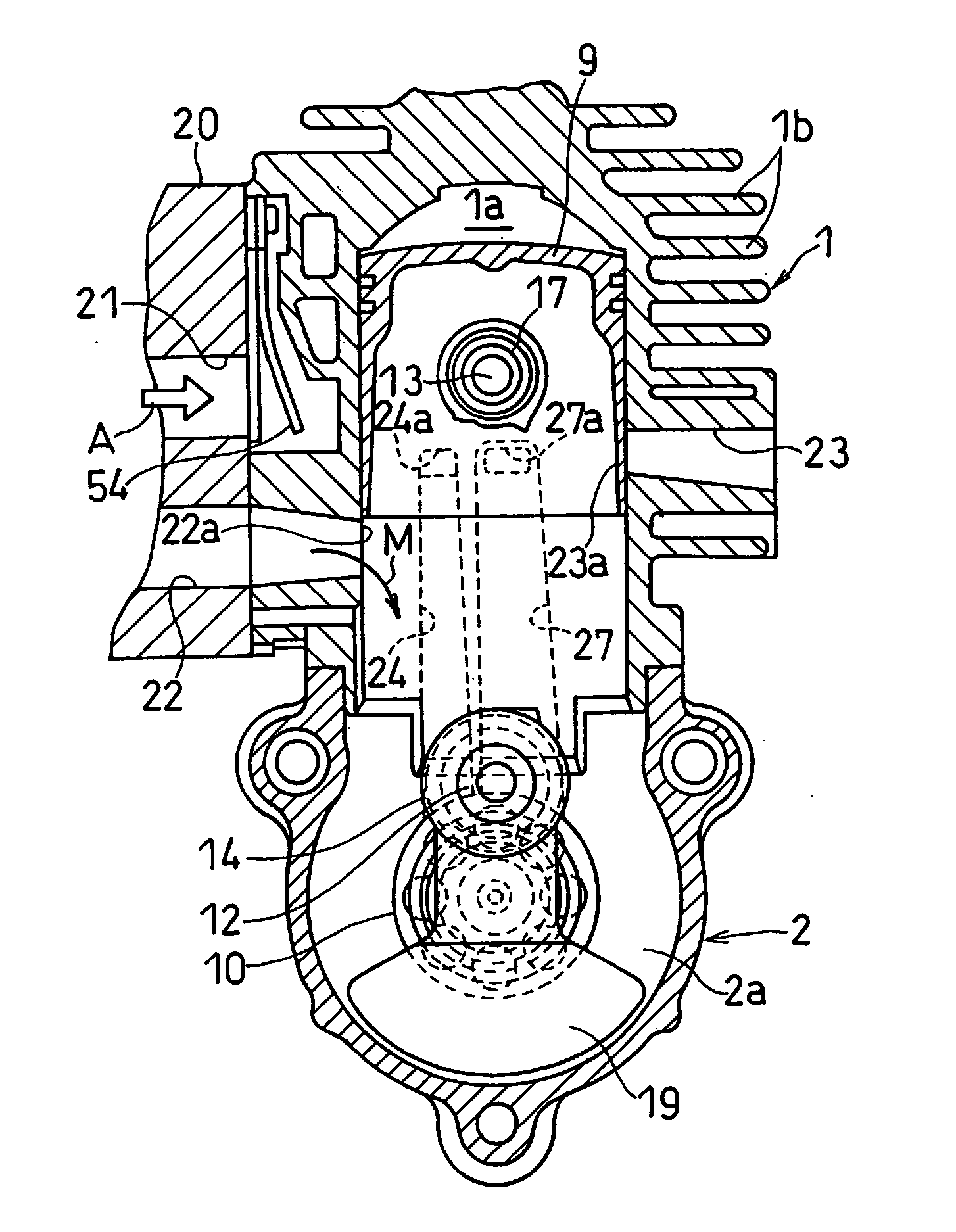

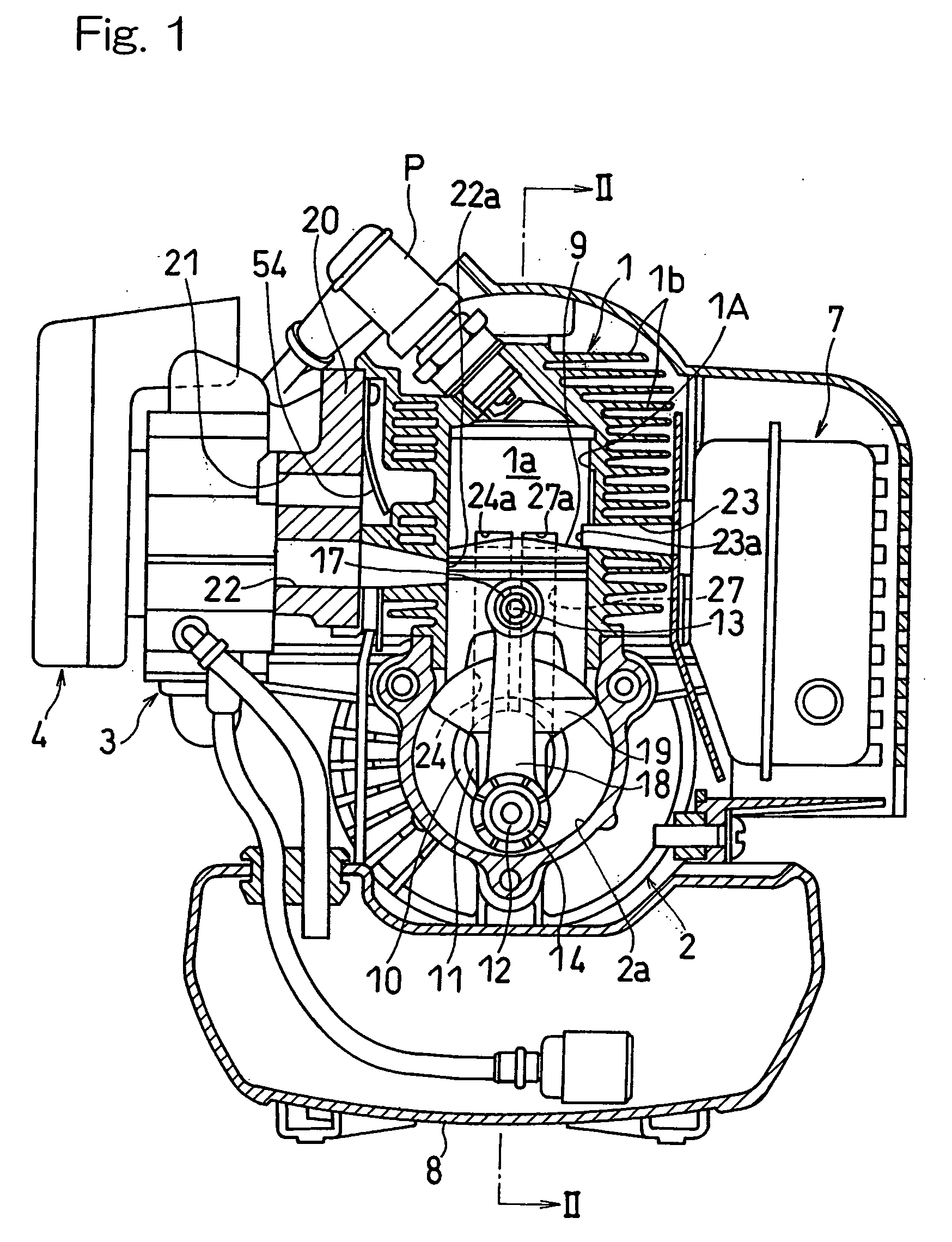

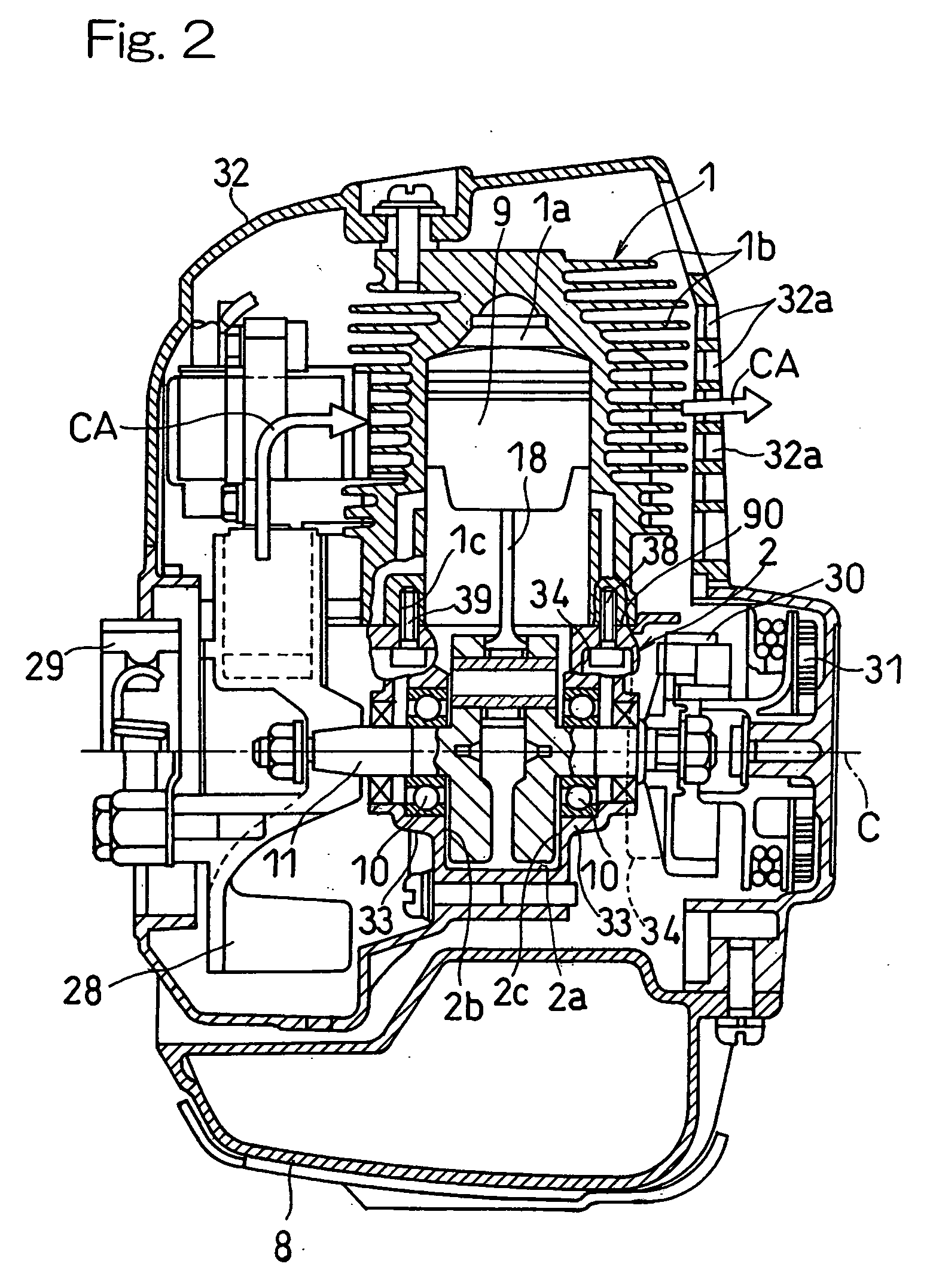

Two-cycle combustion engine

ActiveUS20070119404A1Simplify connection structureFirm connectionCasingsCylinder headsCylinder blockCombustion

To provide a two cycle combustion engine utilizing a connecting structure of a shape that can be formed inexpensively with a simple process to enable the efficiency of cooling of the cylinder block to be maintained at a high level and, also, that can firmly connect the cylinder block with the crankcase with fastening forces exerted by the fastening bolts, the two cycle combustion engine includes a crankcase 2 including first and second crank casings 2A and 2B that are split in a direction conforming to a crank axis C for operatively supporting a crankshaft 11, and a cylinder block 1 having a cylinder bore 1a defined therein and fixedly mounted atop the crankcase 2 by means of a plurality of fastening members 38 and 39 fitted in a direction upwardly from a crankcase-side.

Owner:KAWASAKI MOTORS LTD

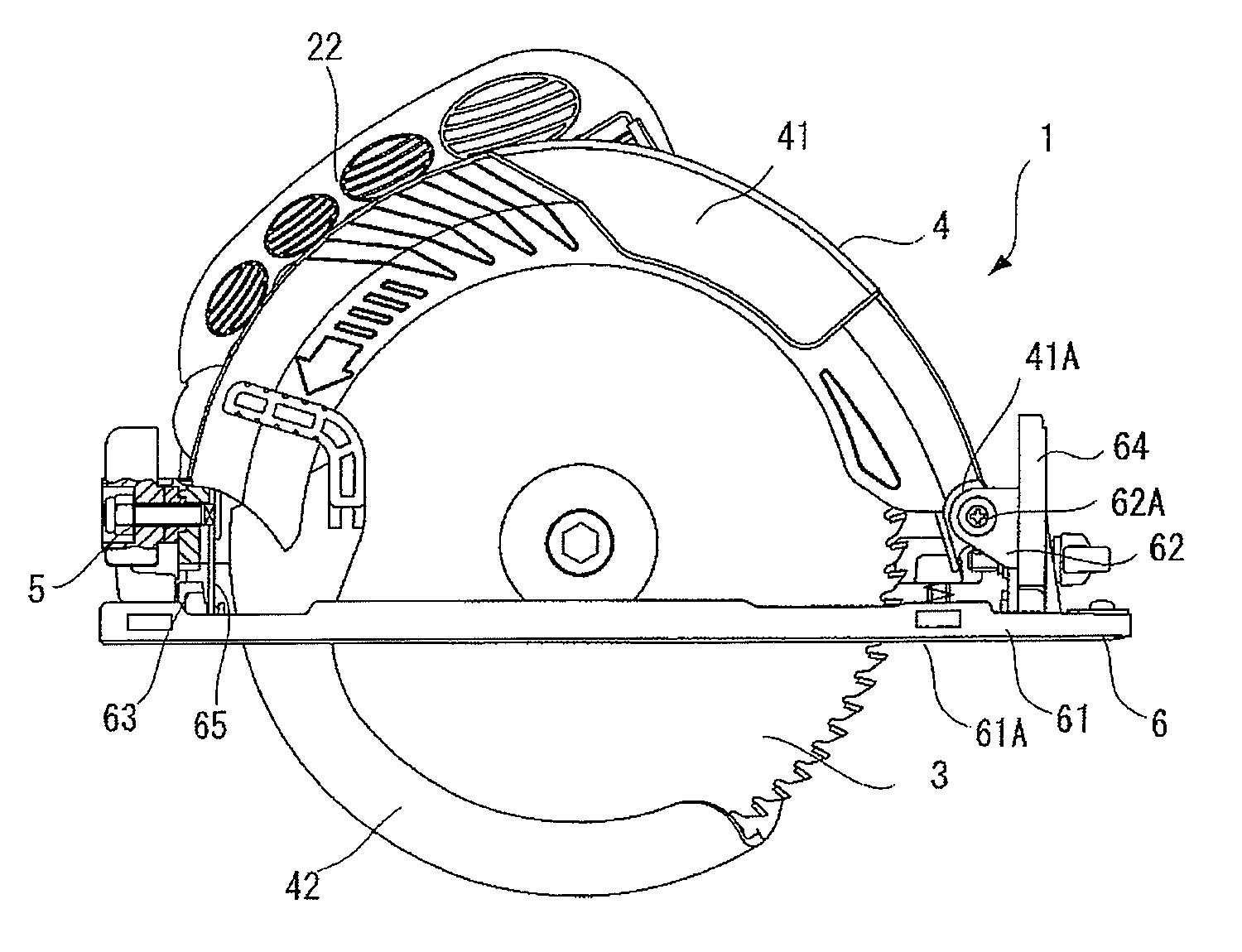

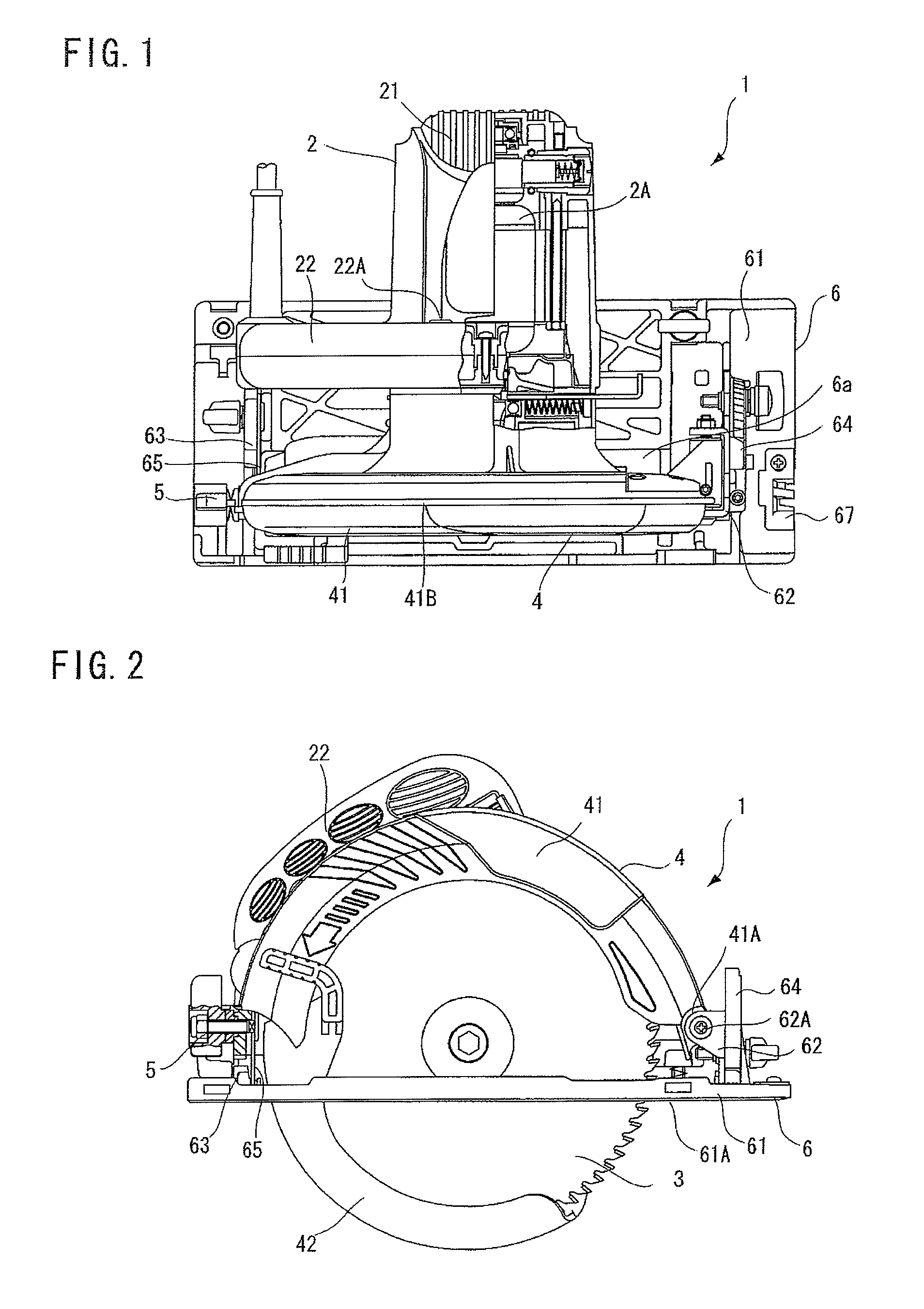

Portable cutting device capable of adjusting cutting depth

ActiveUS8104183B2Less laborImprove fastening forceMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

A portable cutting device capable of changing and adjusting a cutting depth of a circular saw blade relative to a base with lesser labor. A saw cover is pivoted on the base to change the cutting depth. An adjustment guide extends from the base in a pivotally moving direction of the saw cover in a superposed relation to the saw cover. A tightening unit is disposed to the saw cover at a position superposed with the adjustment guide and the saw cover for providing a selective tightening between the saw cover and the adjustment guide. The tightening unit includes a shaft part extending through the saw cover and the adjustment guide, a pivot operation part pivotally movable about an axis of the shaft part, and an urging part disposed over the shaft part and movable by the pivot operation part in the axial direction of the shaft part.

Owner:KOKI HLDG CO LTD

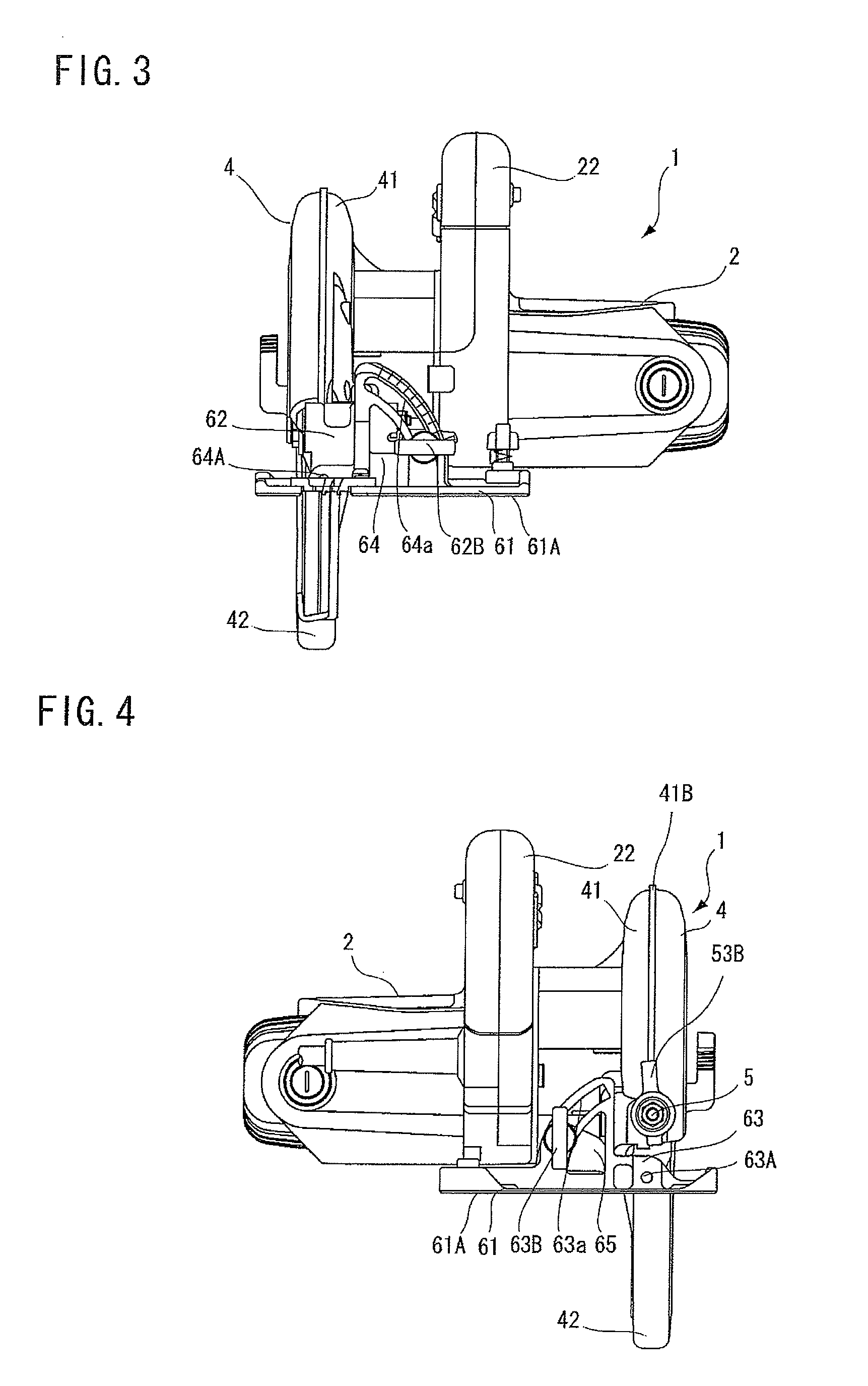

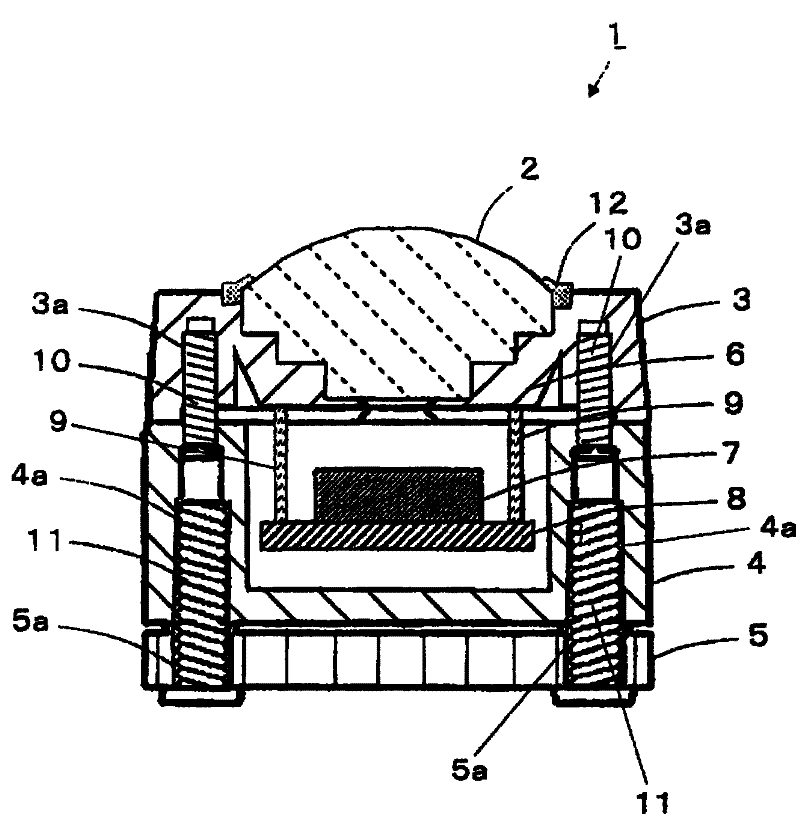

Imaging module

ActiveCN102308571ASuppresses weakening of tightening forceSuppression of Image Quality DeteriorationTelevision system detailsColor television detailsOptical axisEngineering

Screw-fastening sections for attaching a front case, a back case, and a bracket can be made smaller, high screw-fastening strength can be maintained, and when the bracket is installed on an automobile or the like using screws, changes in the length of the optical axis between a lens unit and an imaging element and shifting of the optical axis can be prevented. An imaging module (1) is provided with a front case (3) that has a lens unit (2) installed on the photographic subject side, a back case (4) that is attached to the front case (3) such that an imaging substrate (8) is sealed inside an inner space formed with the front case (3), and a bracket (5) that is attached to the back case (4). The back case (4) is attached to the front case (3) by means of screw holes (3a) and first screws (10) that are screwed into first screw-fastening through-holes (4a), and the bracket (5) is attached to the back case (4) by means of the first screw-fastening through holes (4a) and second screws (11) that have a diameter larger than that of the first screws (10) and are screwed into second screw-fastening holes (5a).

Owner:KYOCERA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com