Imaging module

A technology of camera module and camera element, which is applied in the direction of image communication, TV, color TV parts, etc., and can solve problems such as insufficient thread fastening strength, image quality deterioration, and camera module water resistance decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

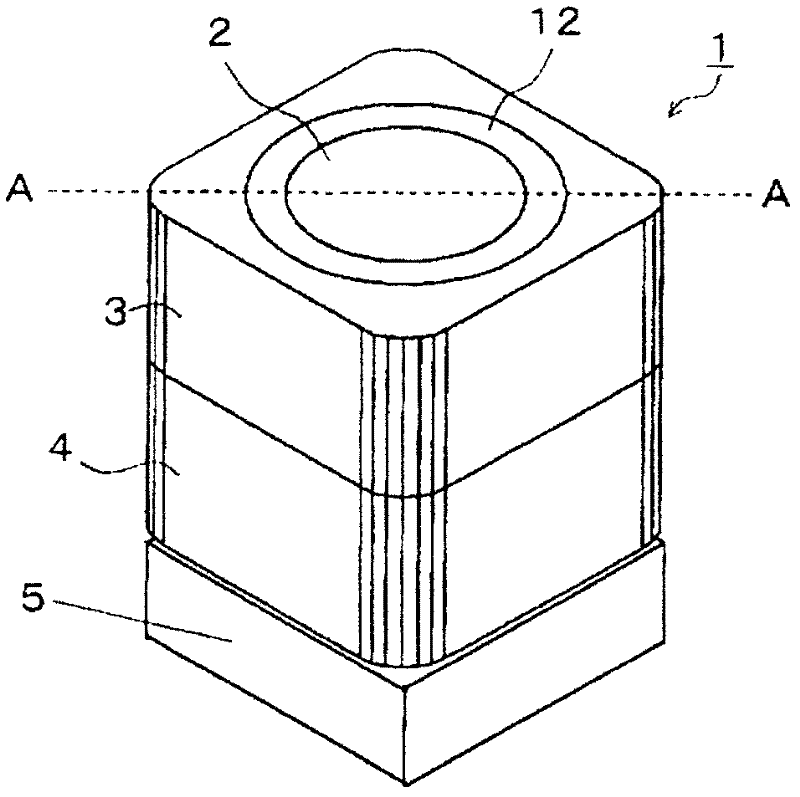

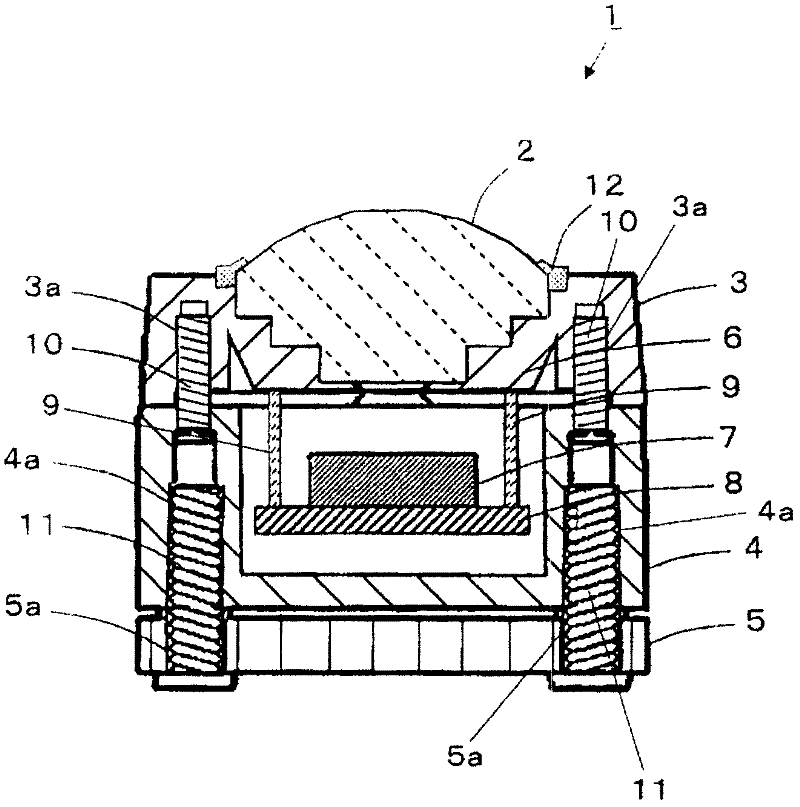

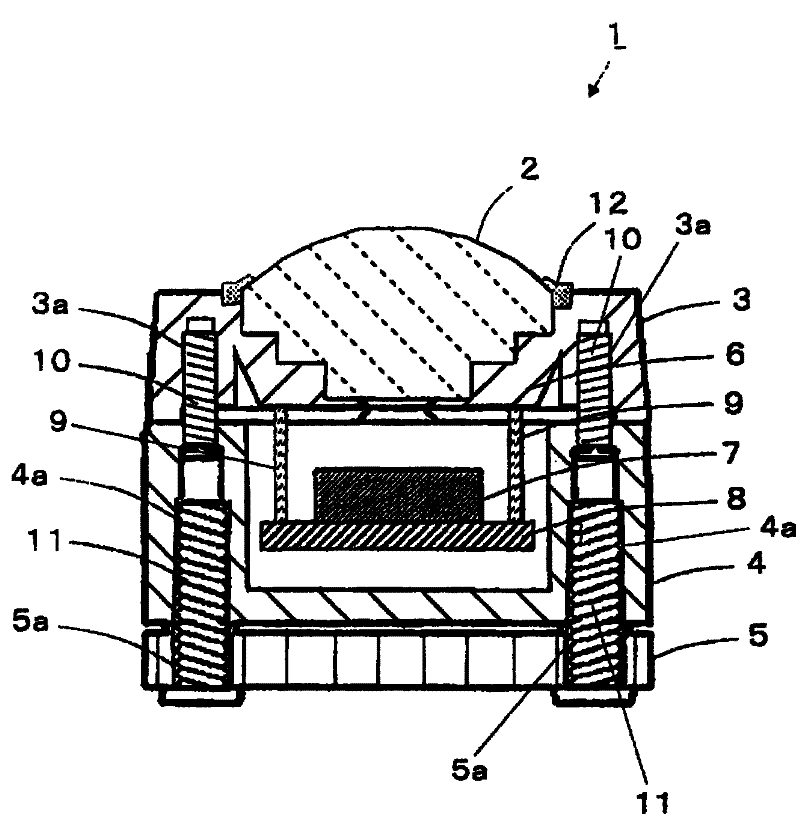

[0055] Hereinafter, an embodiment of the camera module 1 of the present invention will be described.

[0056] figure 1 and figure 2 The camera module of the embodiment of the structure shown is fabricated as follows. First, a rectangular cylindrical front cabinet 3 made of polycarbonate formed by injection molding and a square box-shaped rear cabinet 4 made of polycarbonate formed by injection molding are prepared. In the front case 3, the square cross section has dimensions of 23 mm in length and 23 mm in width and 10 mm in height. In the rear case 4, the square cross section has dimensions of 23 mm in length and 23 mm in width and 13 mm in height. Furthermore, the front case 3 has a cylindrical lens barrel 6 inside.

[0057] Next, the lens unit 2 composed of three lenses is installed on the lens barrel 6 inside the front case 3 , and the lens unit 2 is fixed by the ring-shaped retainer 12 . Moreover, the connection terminal 9 provided on the lens barrel 6 inside the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com