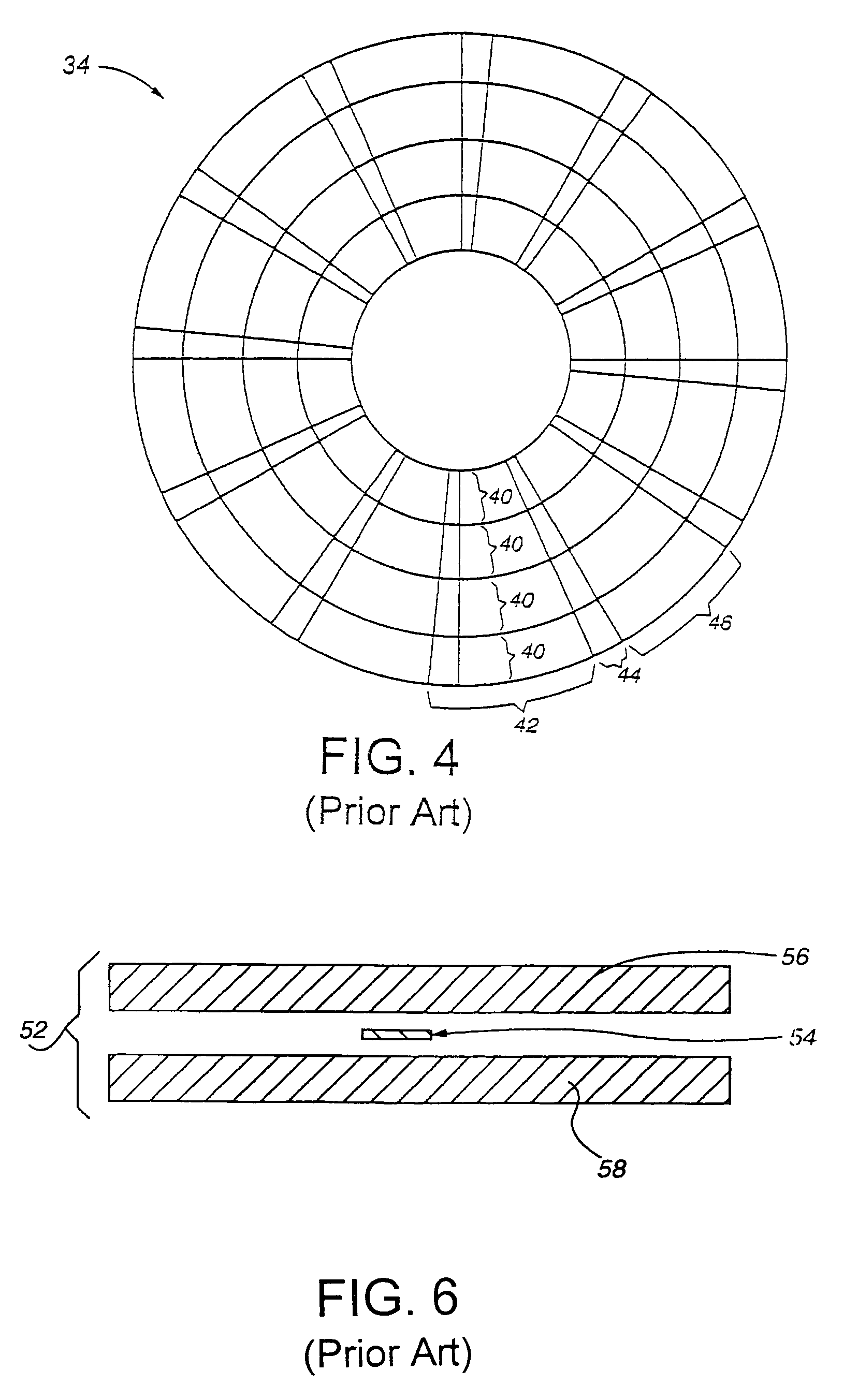

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

675 results about "Magnetic polarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic polarity describes the magnetic field around almost any magnetic object. Almost every magnet has a north pole and a south pole that are oriented with Earth’s magnetic field.

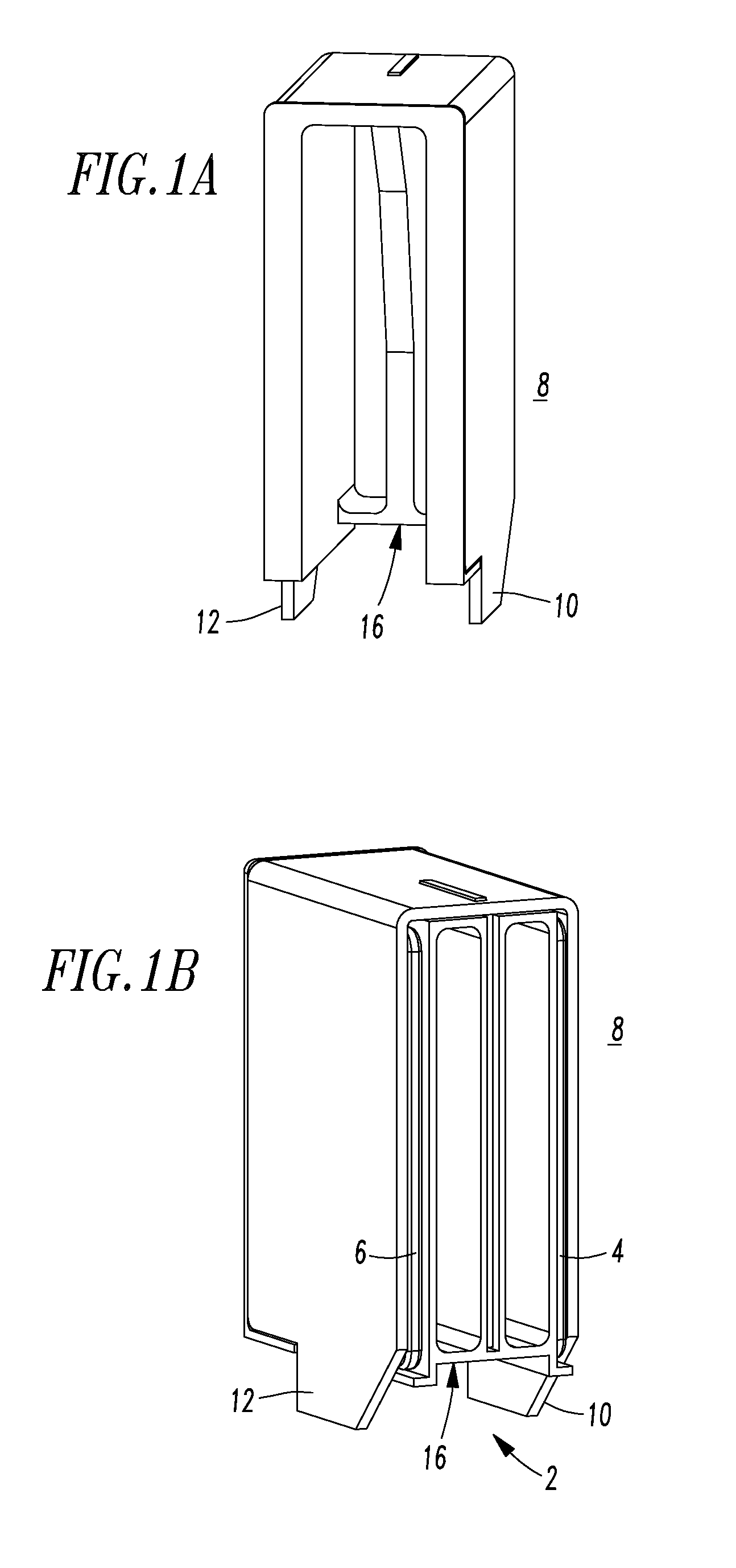

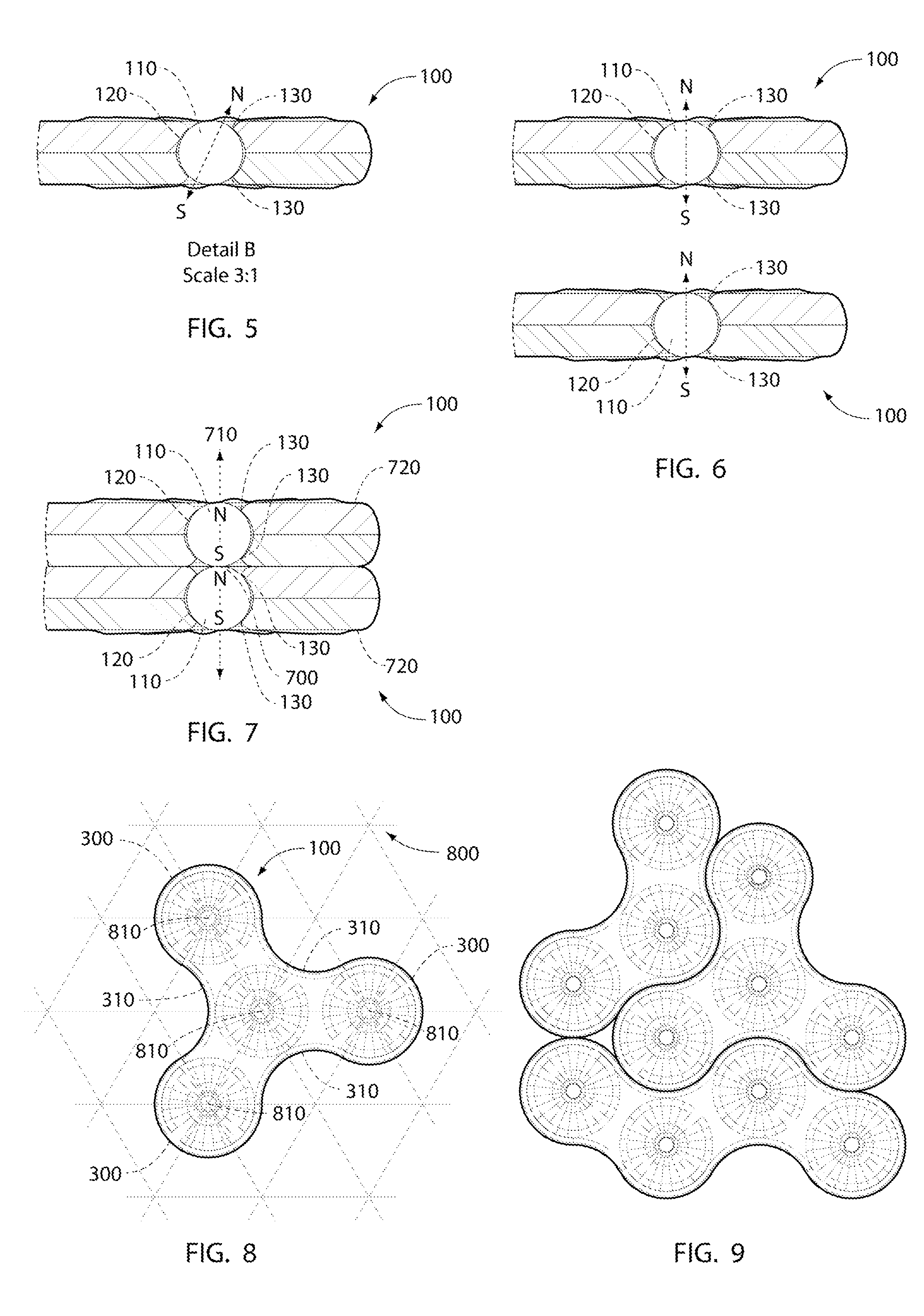

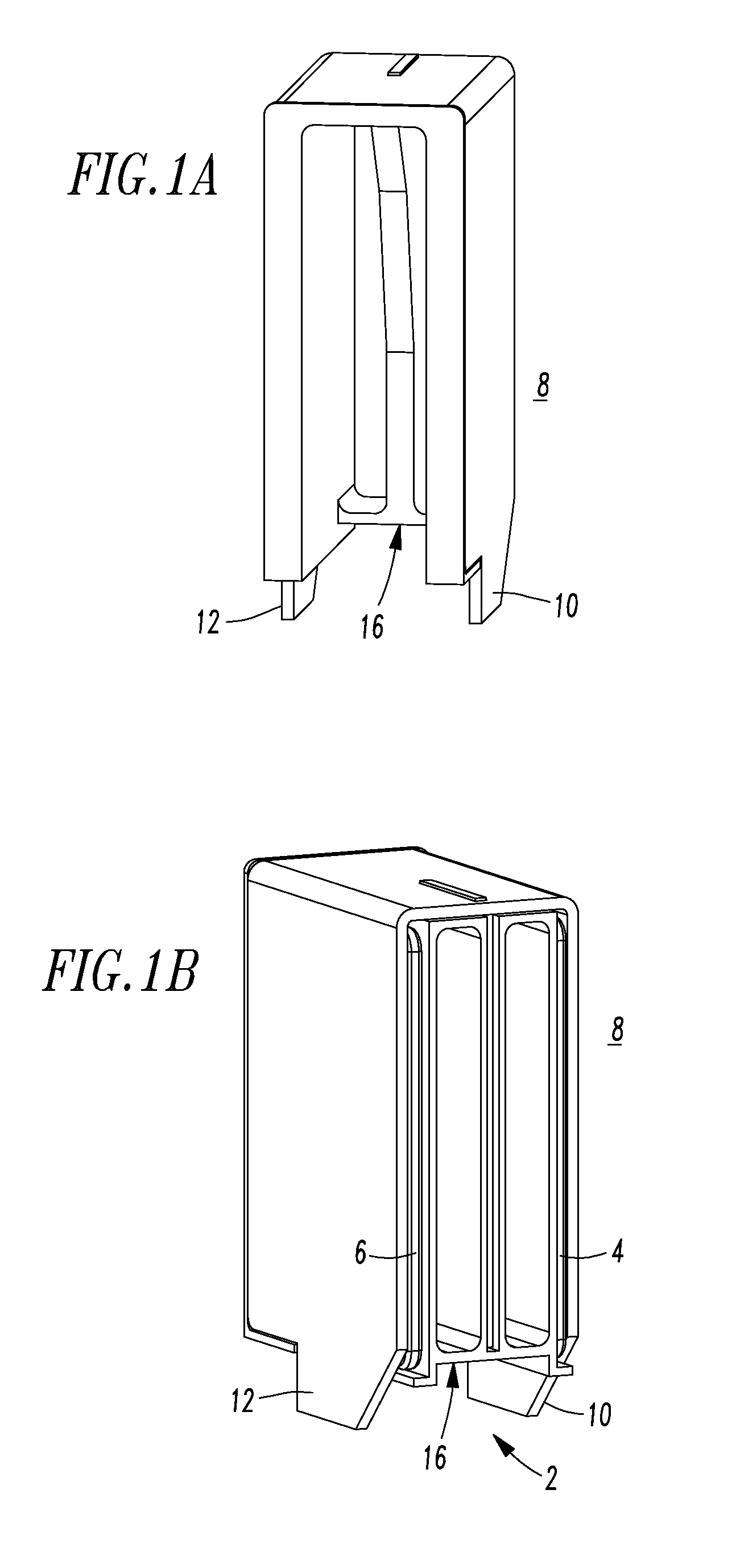

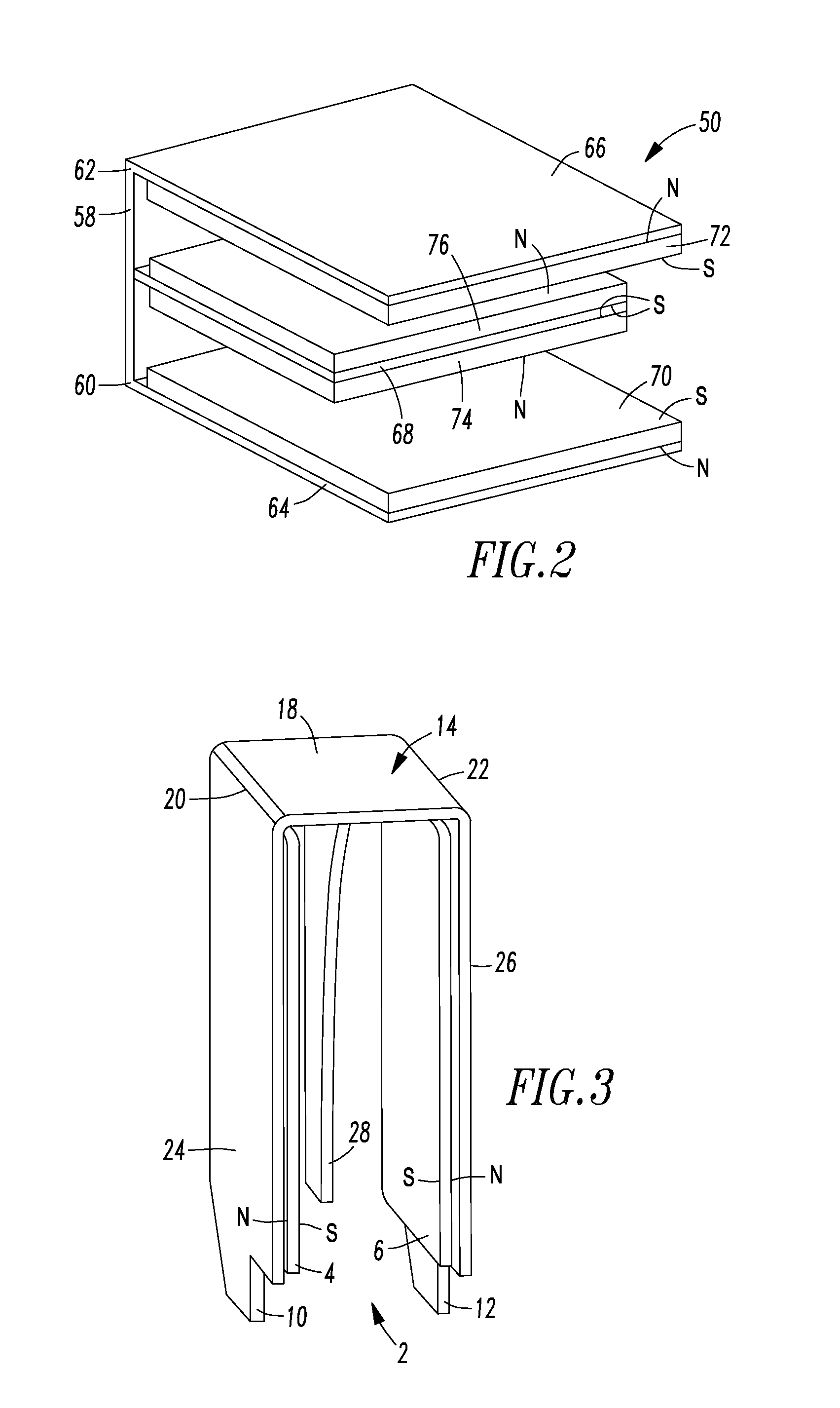

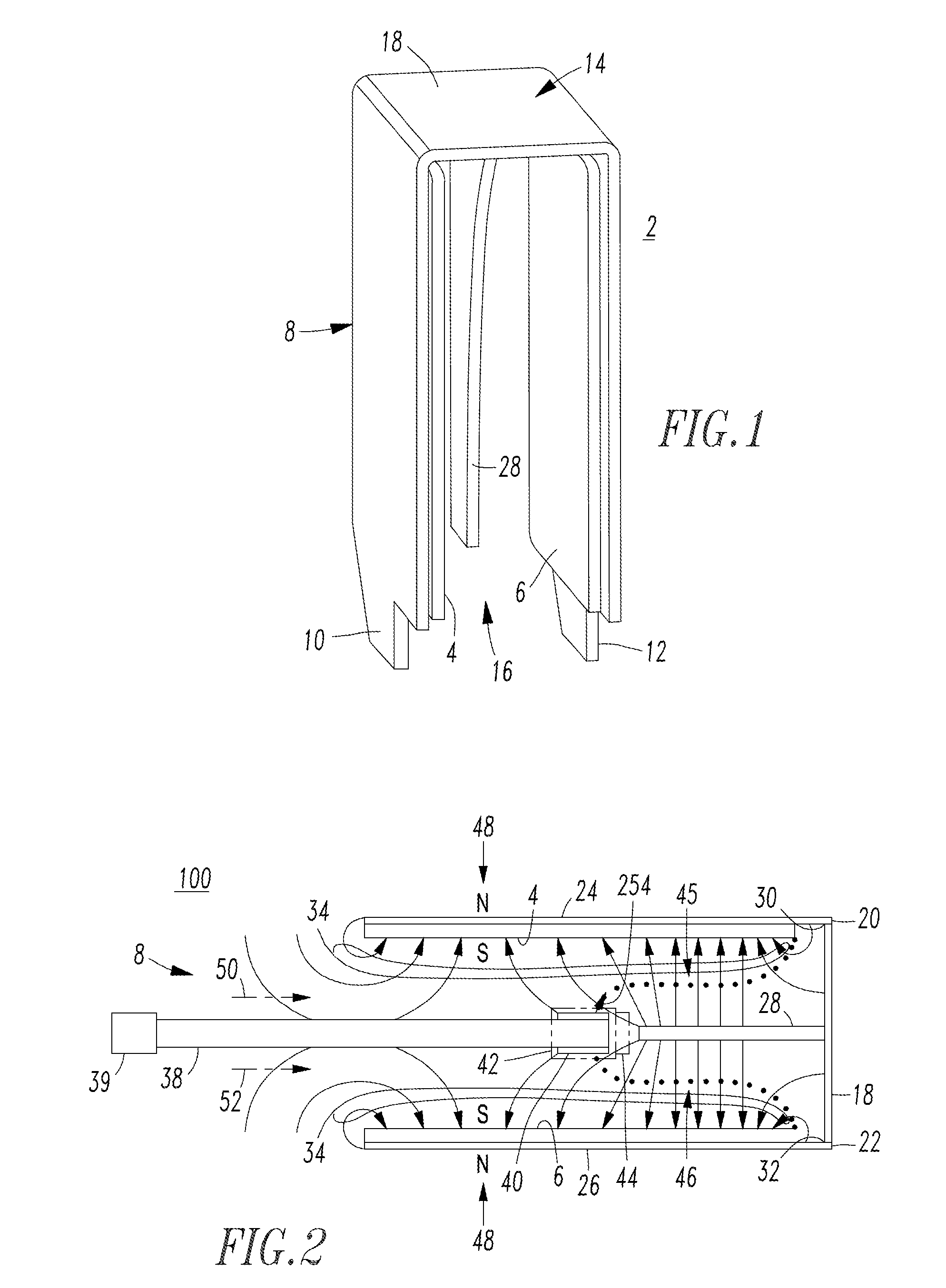

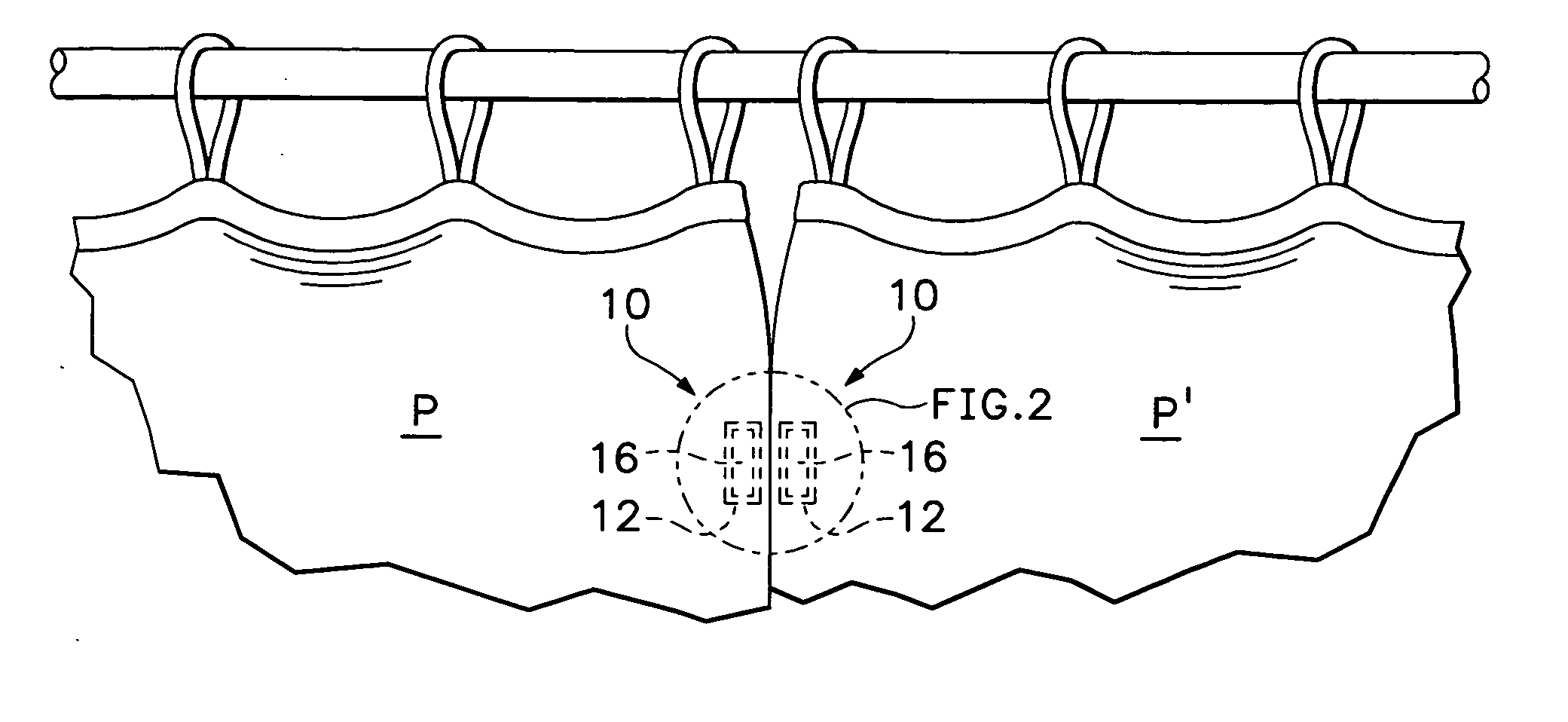

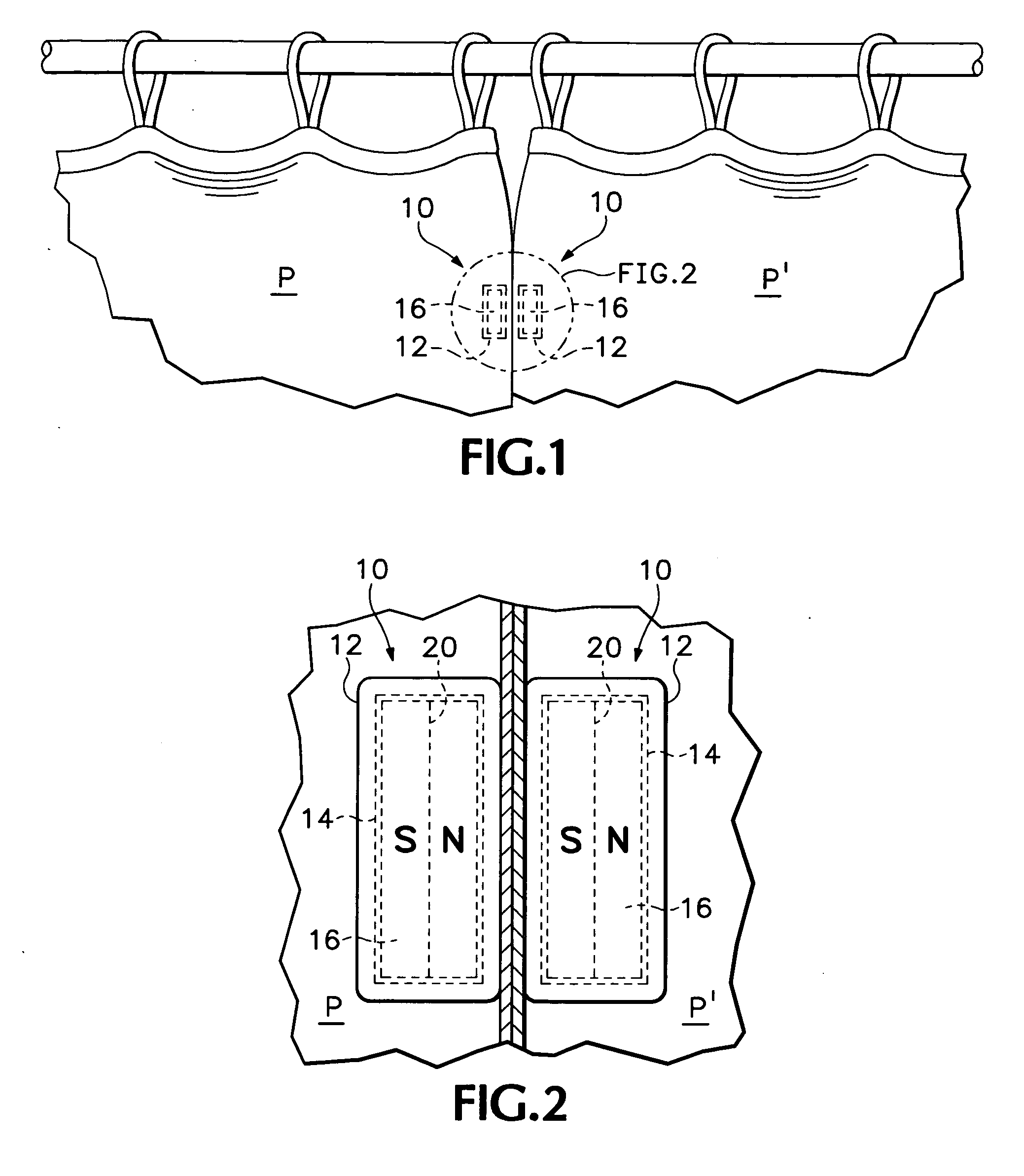

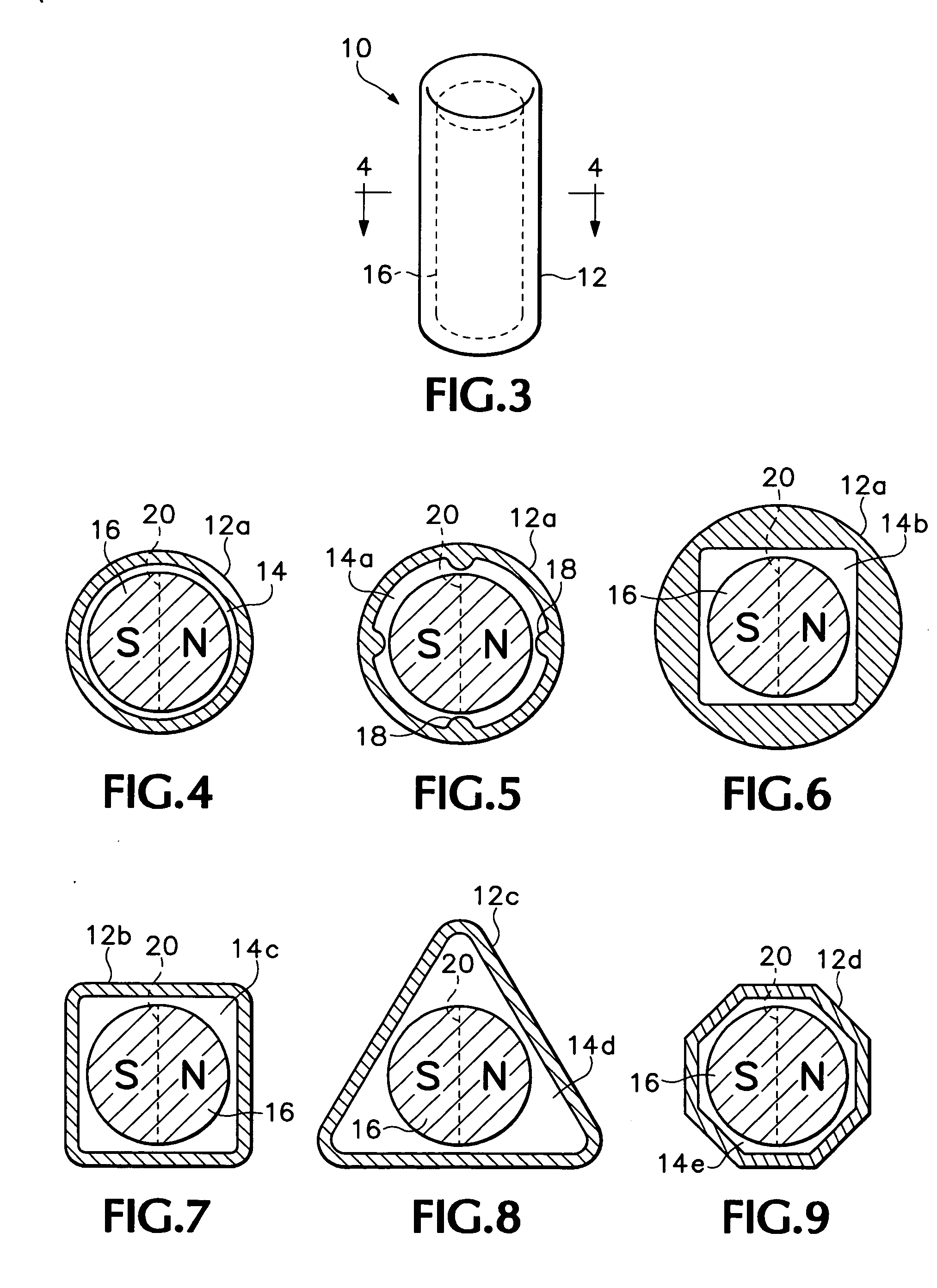

Magnetic connector apparatus

ActiveUS7154363B2Reduce manufacturing costSimple structureSnap fastenersElectromagnets without armaturesEngineeringMagnetic polarity

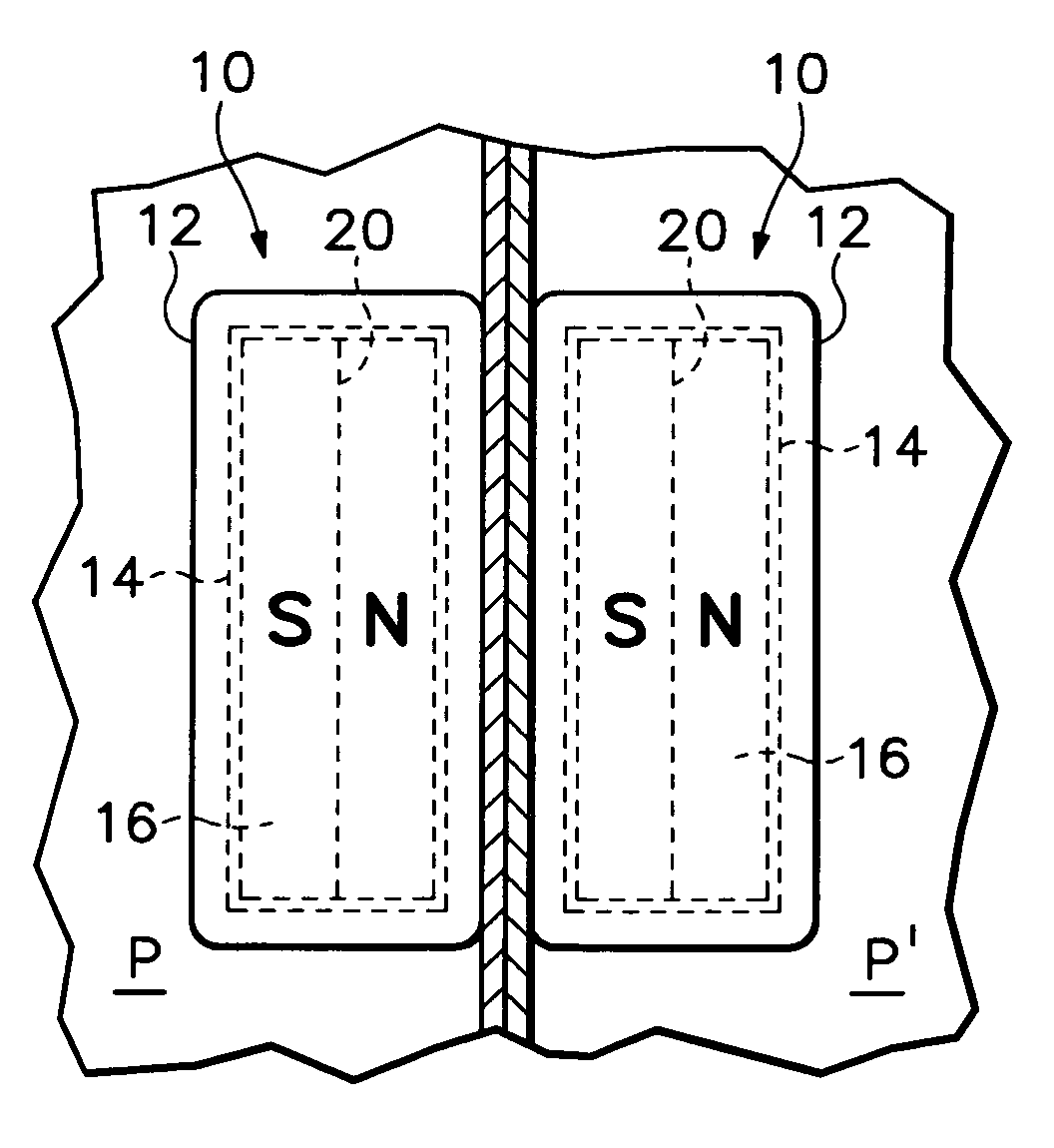

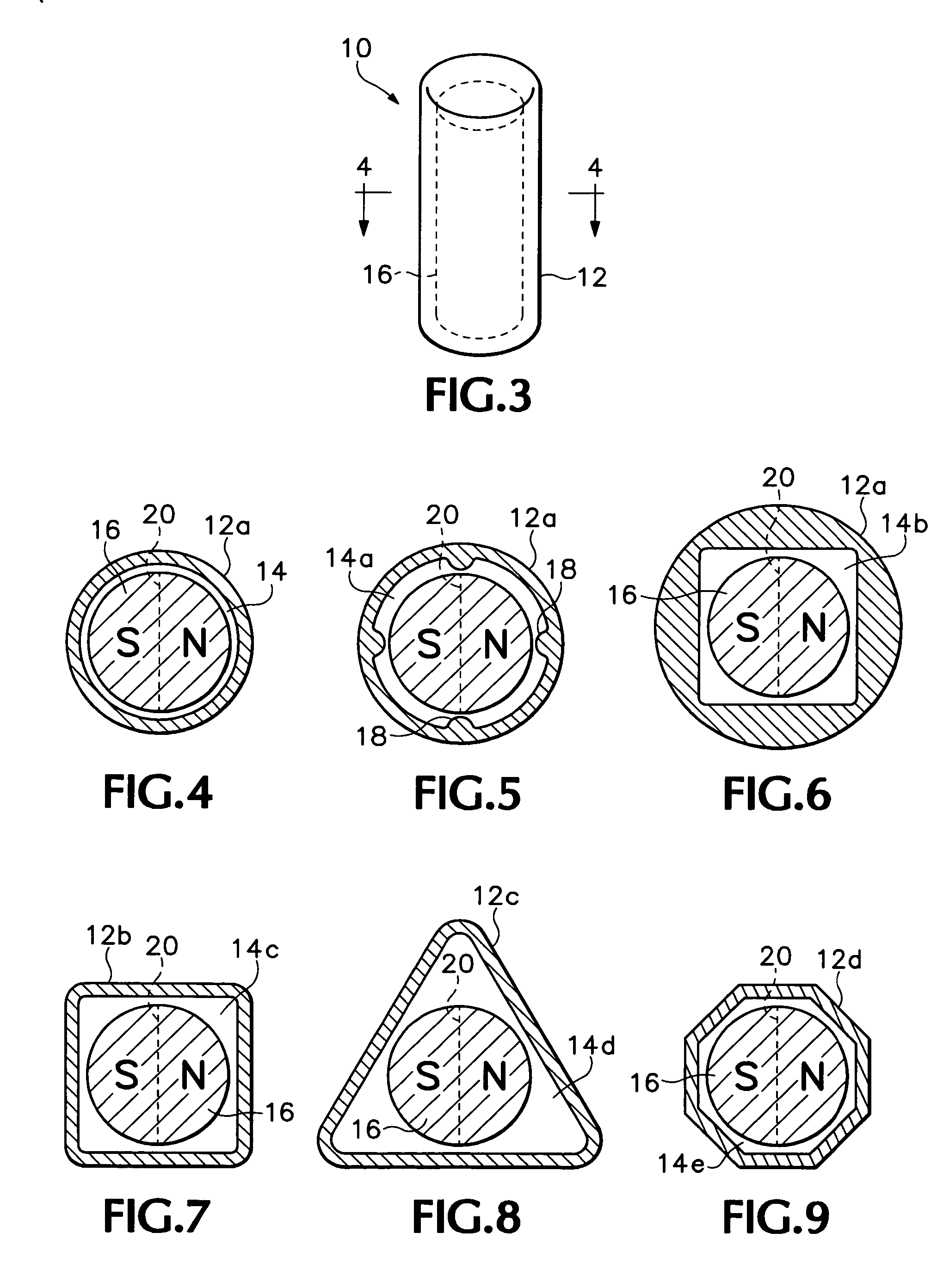

A magnetic connector apparatus provides a plurality of magnetic connector bodies in various different forms for magnetic connection of two or more bodies together along mutually-confronting, longitudinally-elongated, linear peripheral border edges, each linear peripheral border edge having at least one particularly-configured longitudinally elongated, cylindrical magnet supported adjacent thereto for rotation of the magnet adjacent said peripheral edge of each connector body for orientation of the magnetic polarity of magnets of confronting connector bodies for mutual magnetic attraction along, mutually confronting, linear peripheral border edges of magnetic connector bodies.

Owner:GYMWORLD

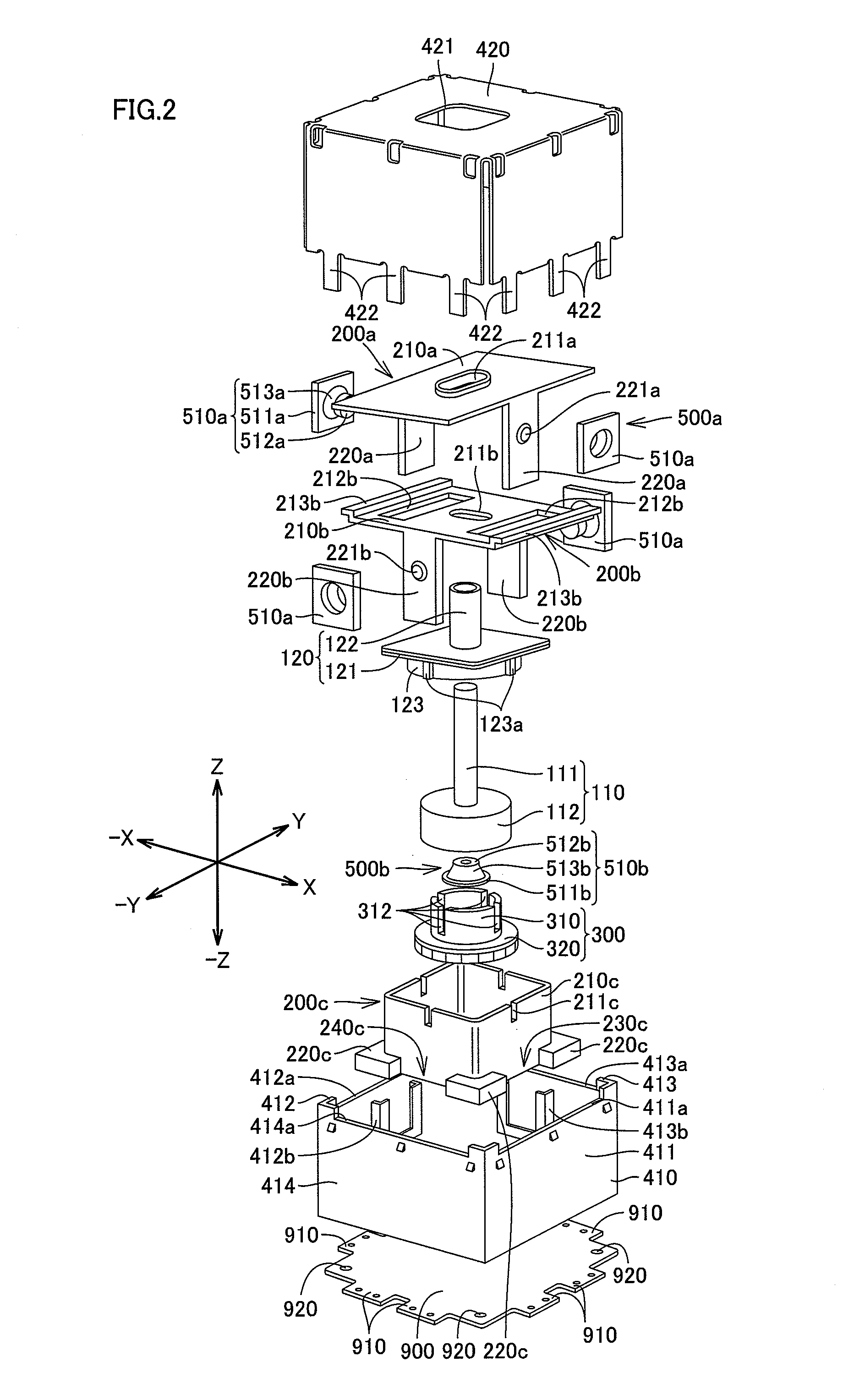

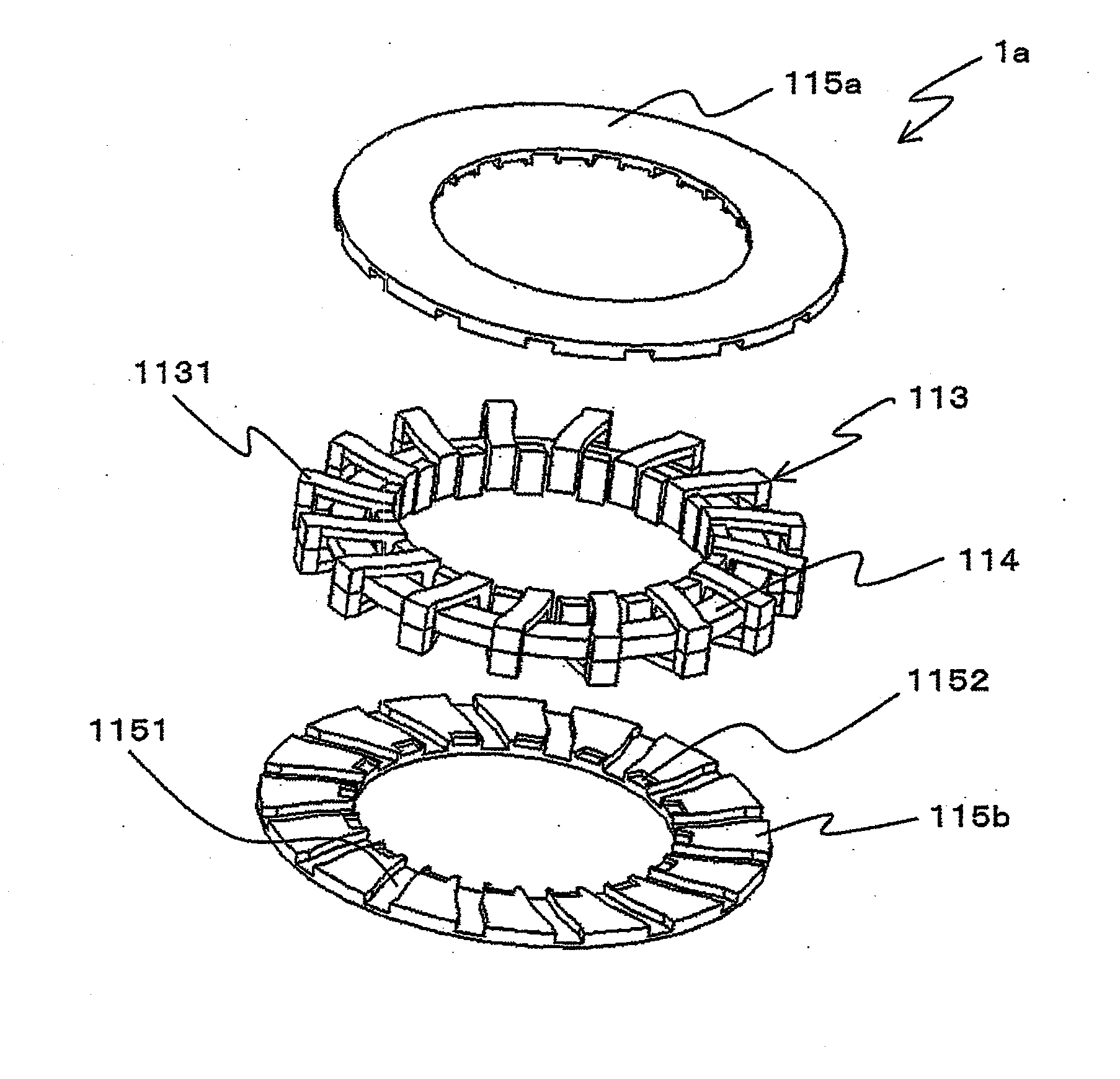

Input apparatus

InactiveUS8344834B2Increase the number ofReduce in quantityInput/output for user-computer interactionCathode-ray tube indicatorsEngineeringMagnetic polarity

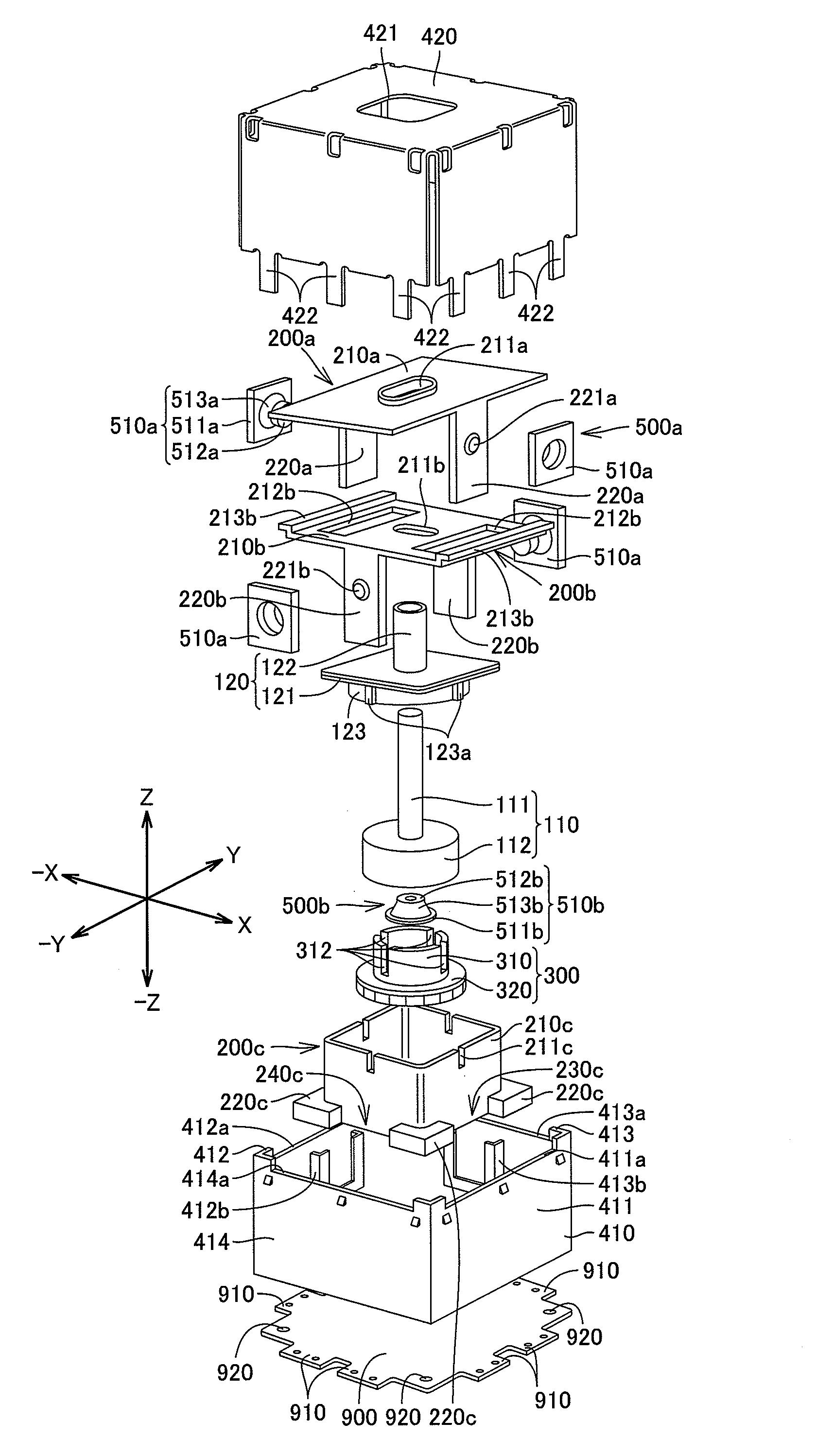

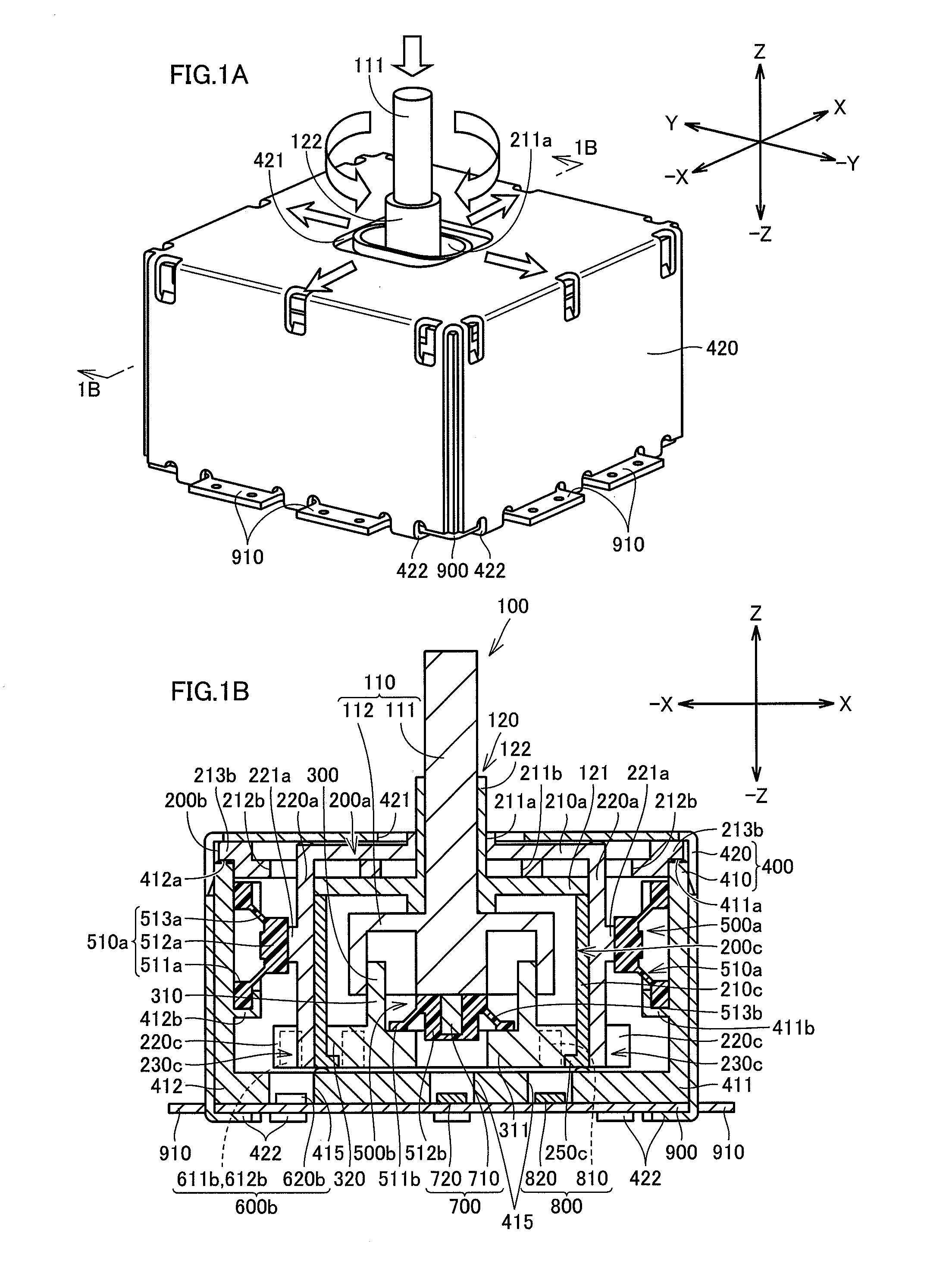

The invention provides an input apparatus An input apparatus according to the present invention includes: an operating member, operable to move in at least X and −X directions from a neutral position; first and second magnets, being arranged with spacing along an X and −X direction and having opposite magnetic polarities to each other, wherein when the operating member moves in either one of the two directions, the first and second magnets moves in the same direction as the operating member; and a first magnetic sensor, provided at a position displaced from a middle point between the two magnets when the operating member is located in the neutral position, the position being equidistant from the two magnets. When the operating member moves in one of the two directions, the first magnetic sensor outputs a signal in accordance with the magnetic polarity of one of the first and second magnets.

Owner:HOSIDEN CORP

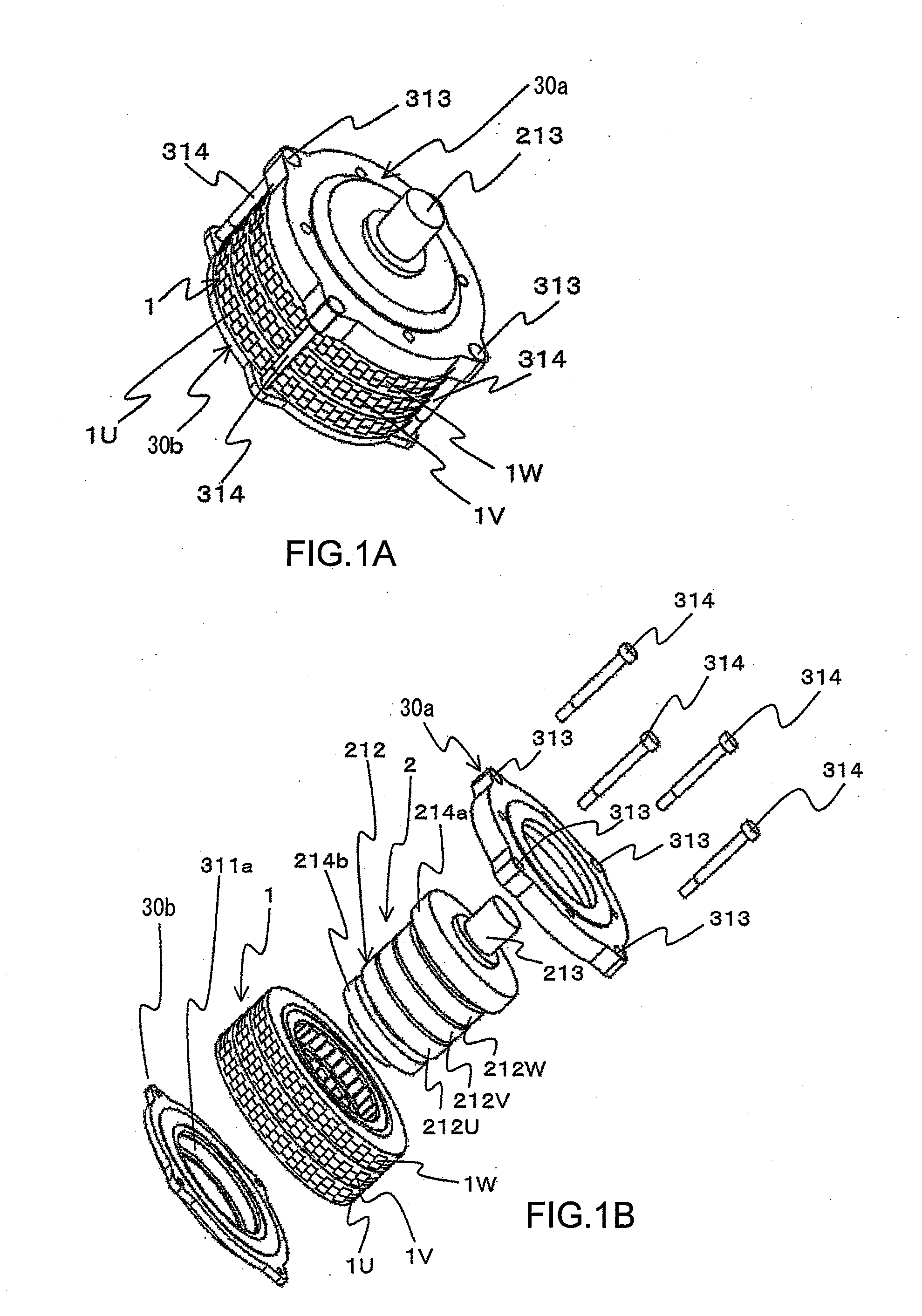

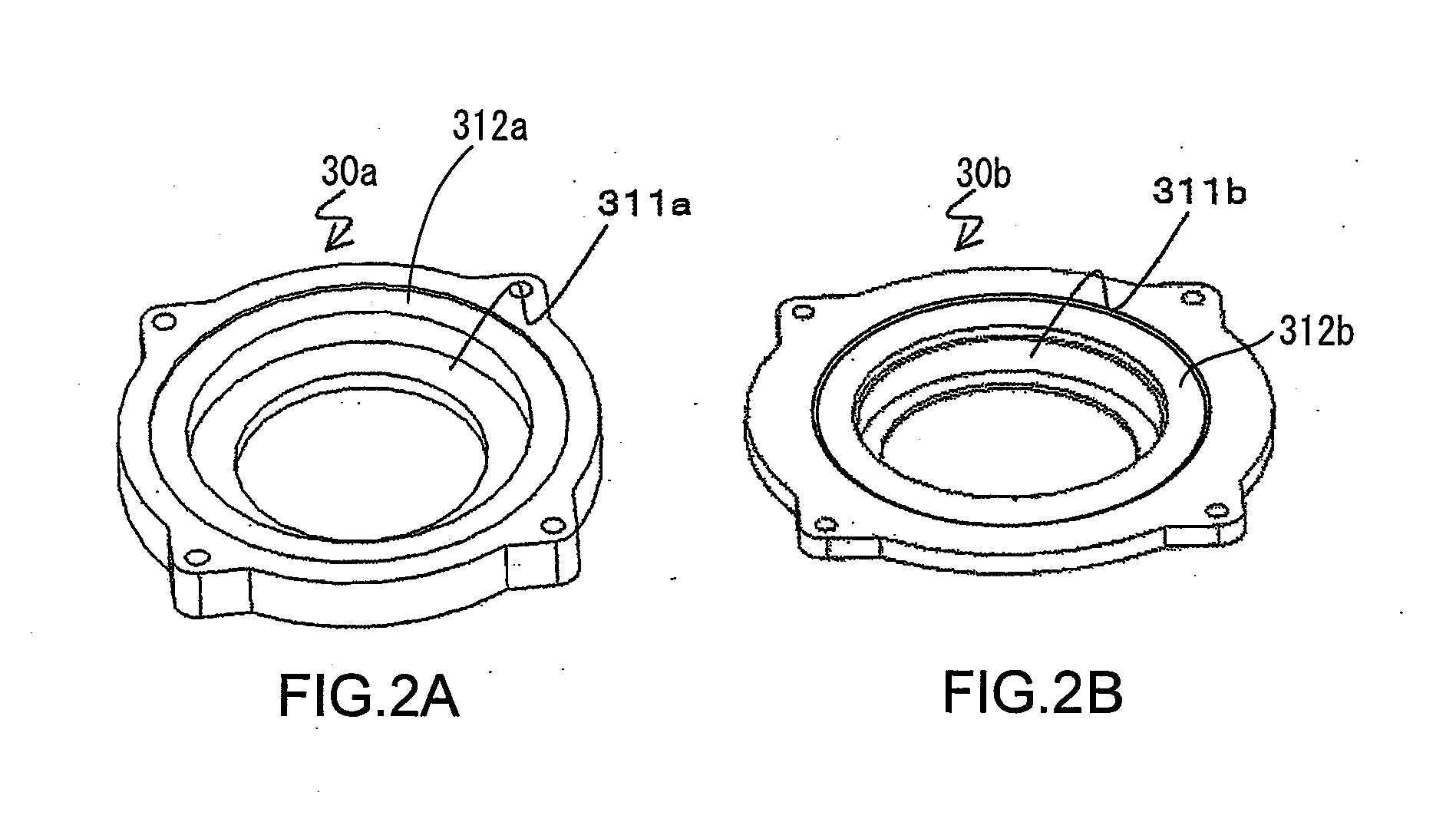

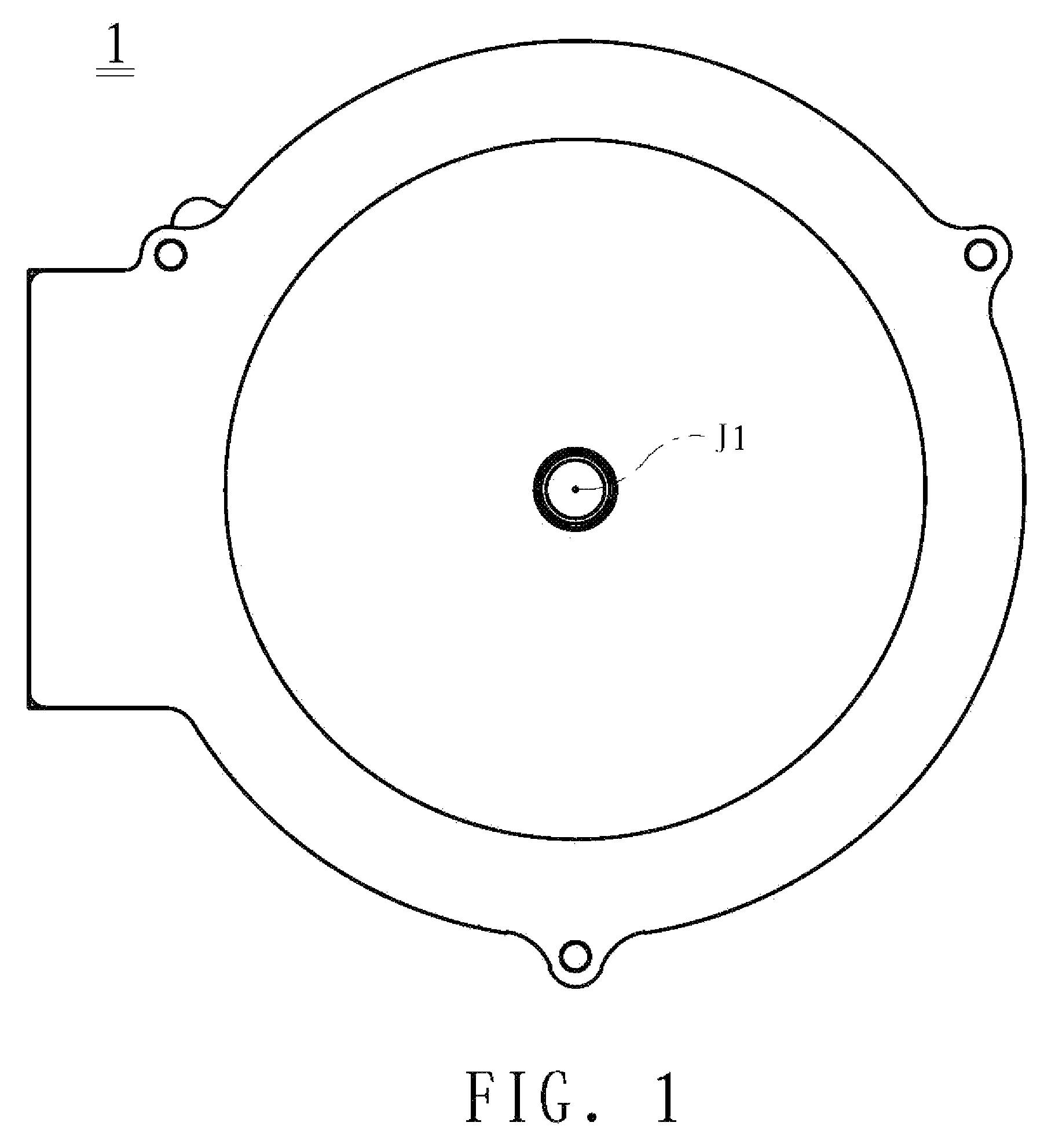

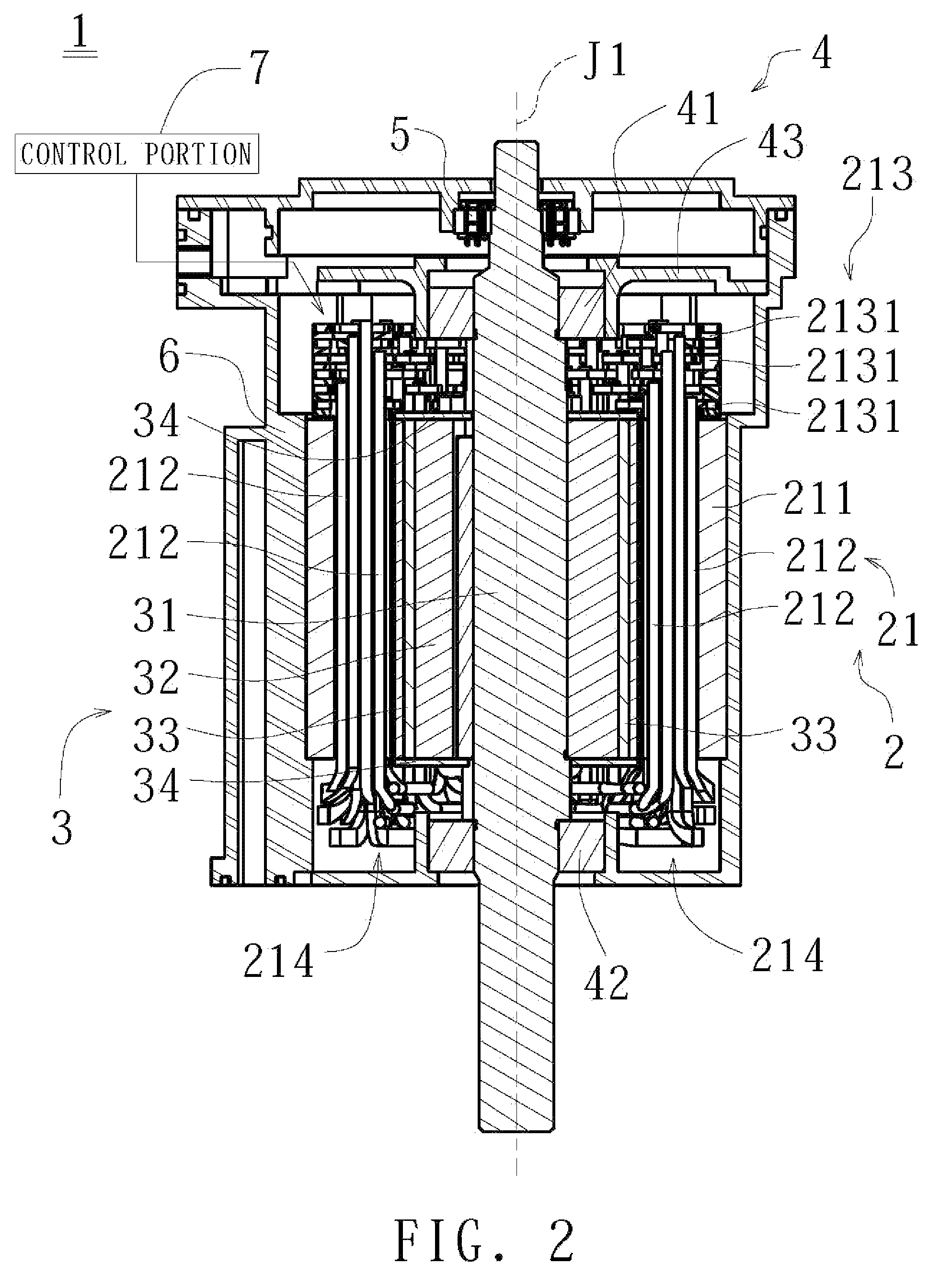

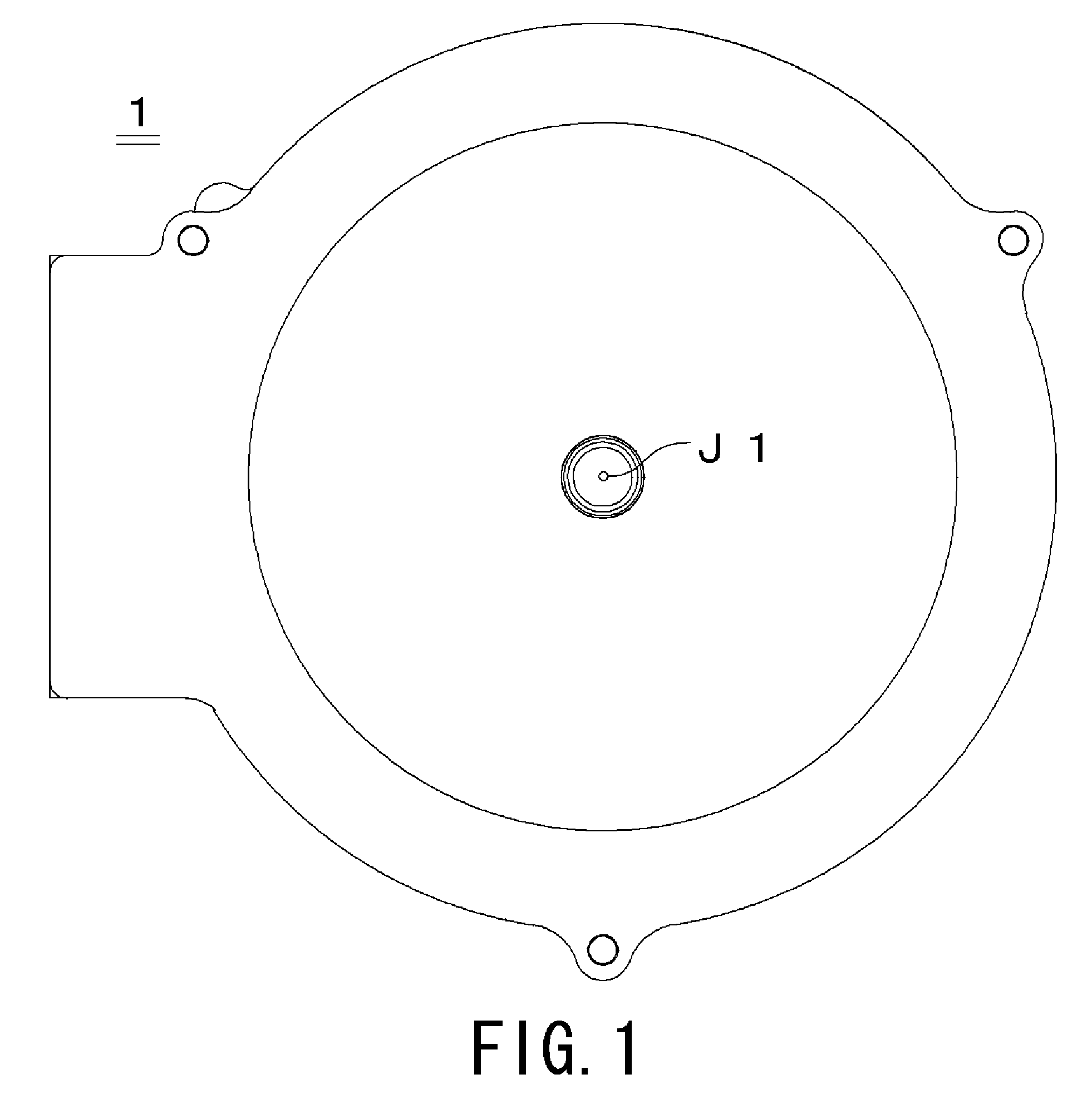

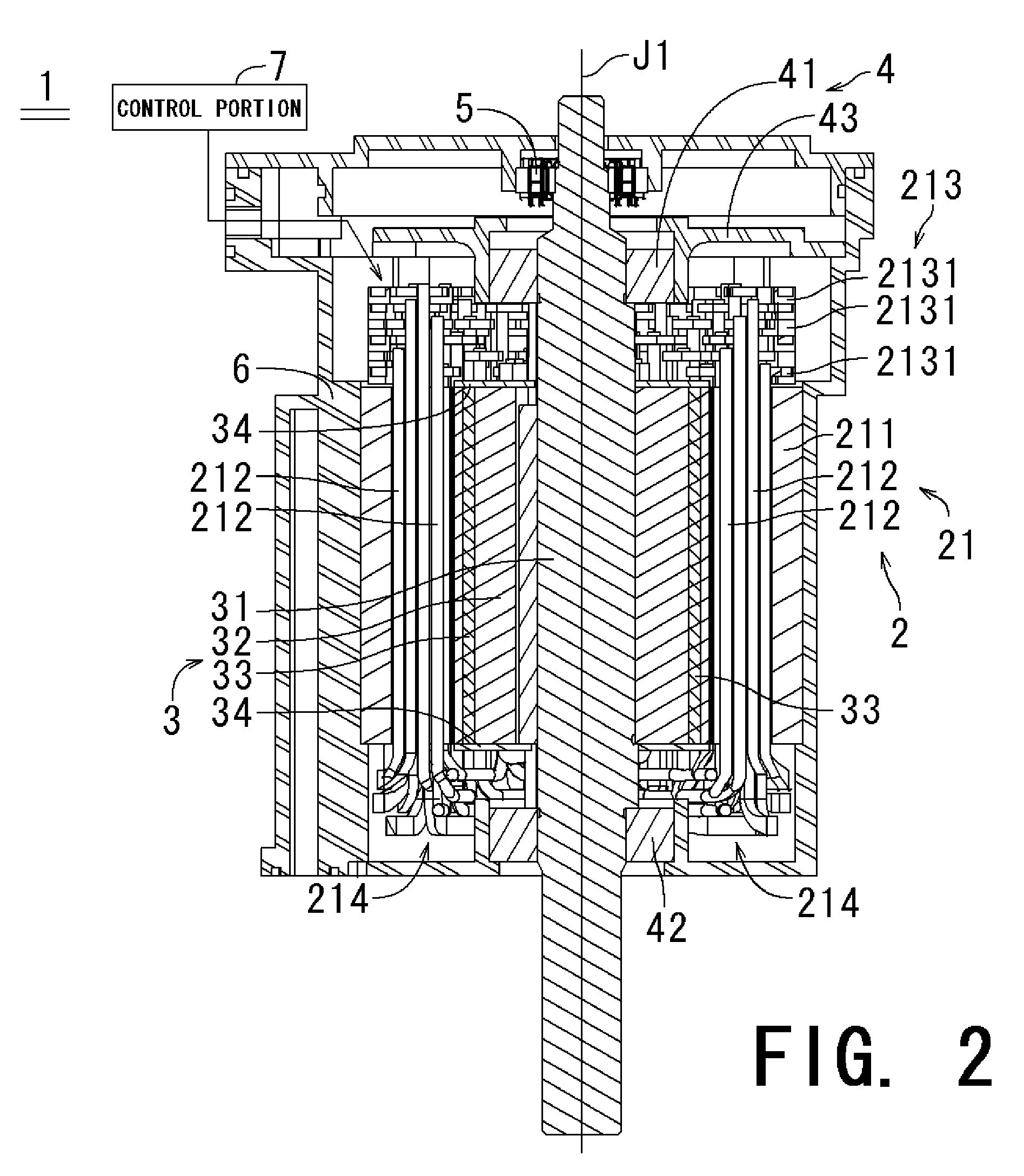

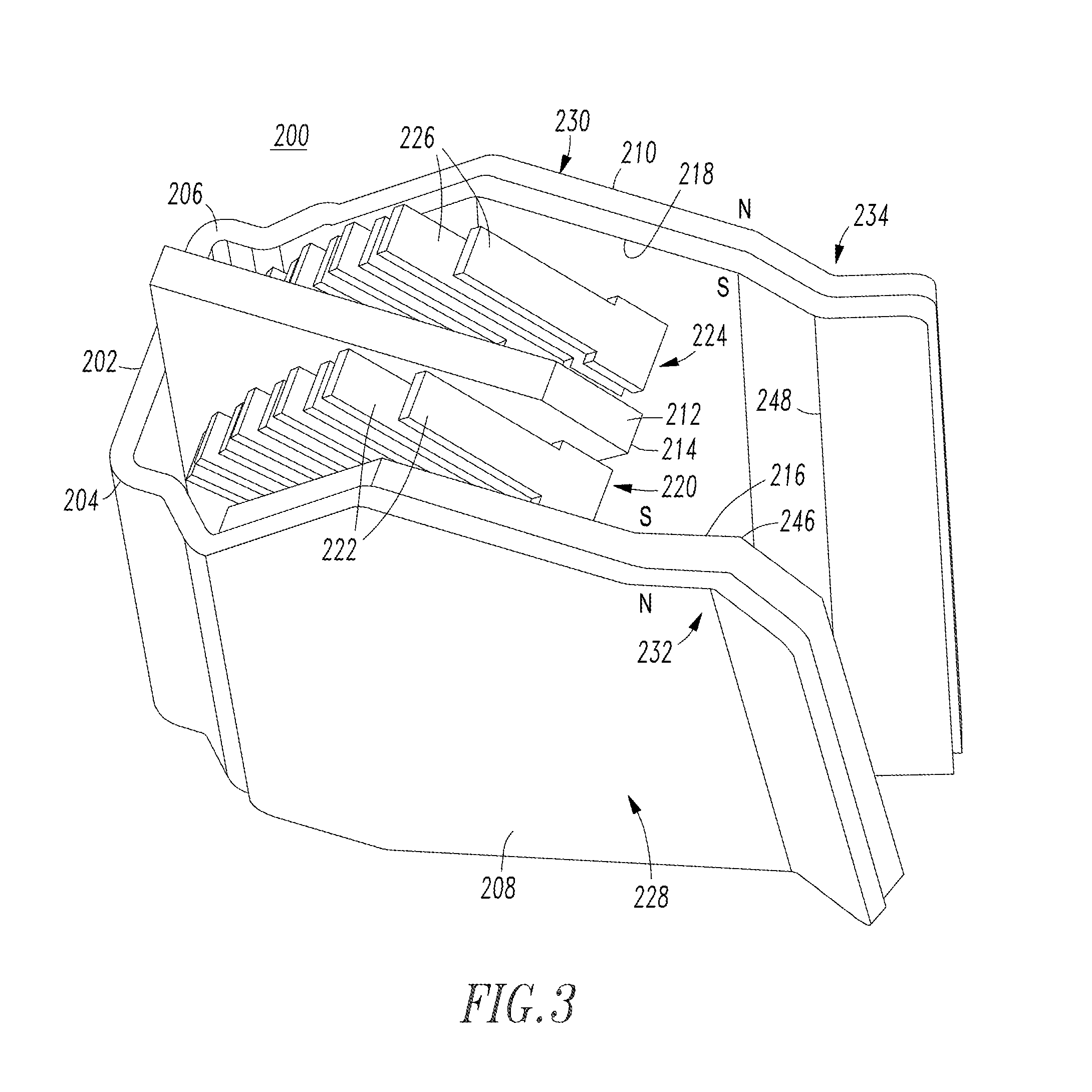

Rotating electrical machine

InactiveUS20090001843A1Increase productivityImprove efficiencyMagnetic circuit stationary partsSupports/enclosures/casingsMagnetic polesStator coil

A rotating electrical machine includes: a claw pole stator constituted with a stator core that includes a plurality of claw poles and a stator coil wound inside the stator core; and a rotor rotatably disposed at a position facing opposite the claw poles. The stator core is constituted of split blocks each corresponding to at least one of magnetic pole pairs each made up with two claw poles assuming different magnetic polarities when an electric current is supplied to the stator coil.

Owner:HITACHI LTD

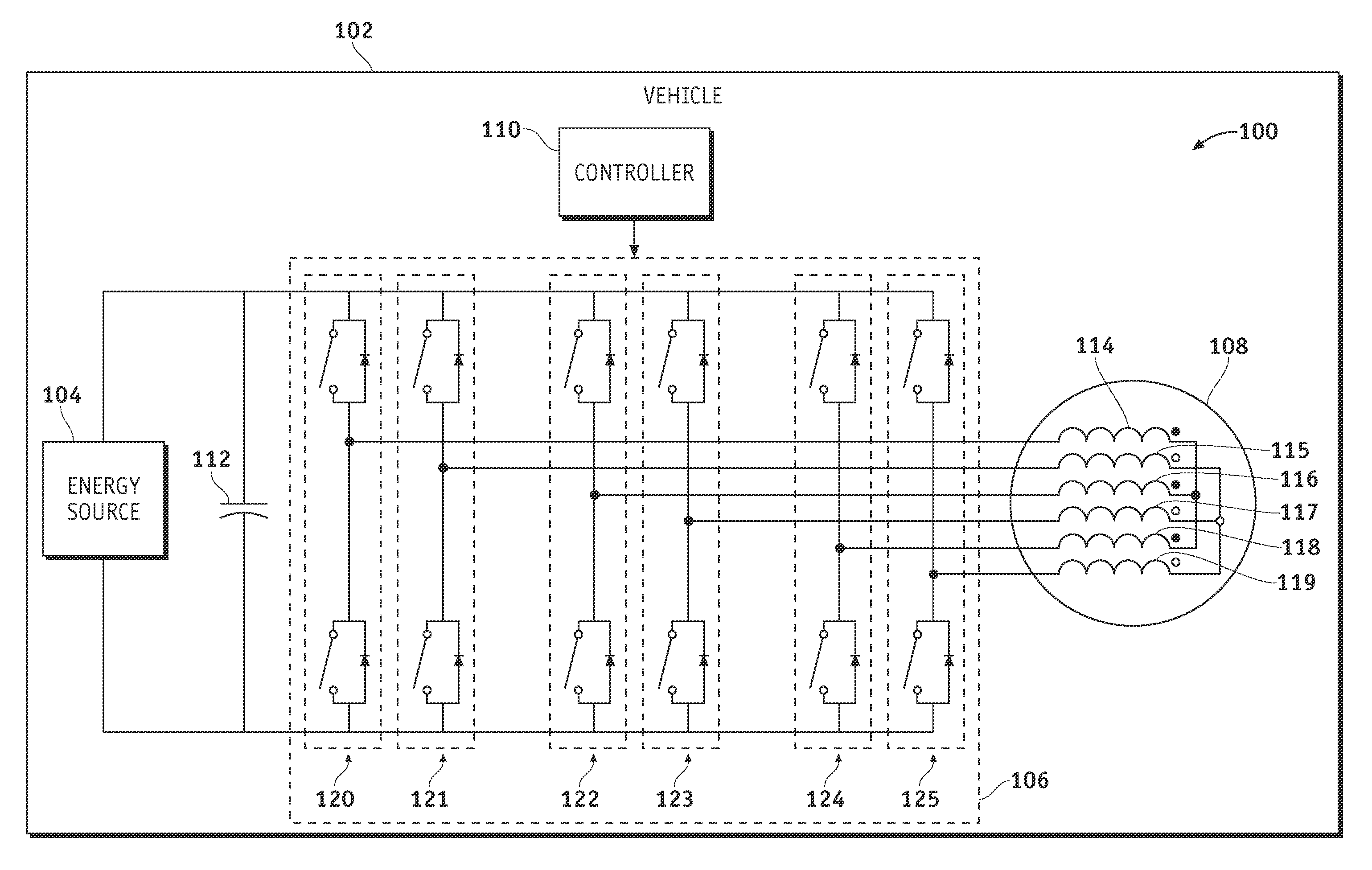

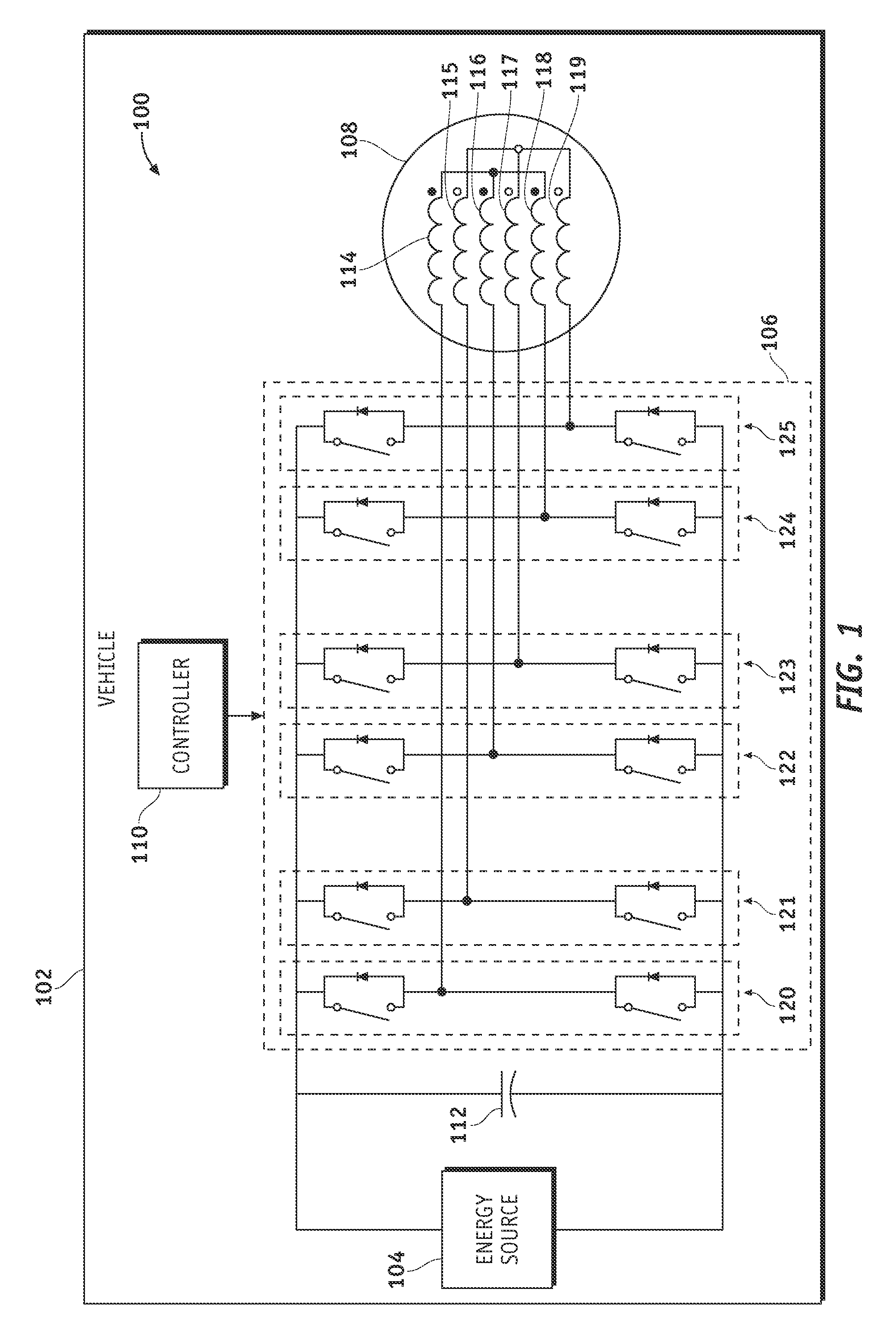

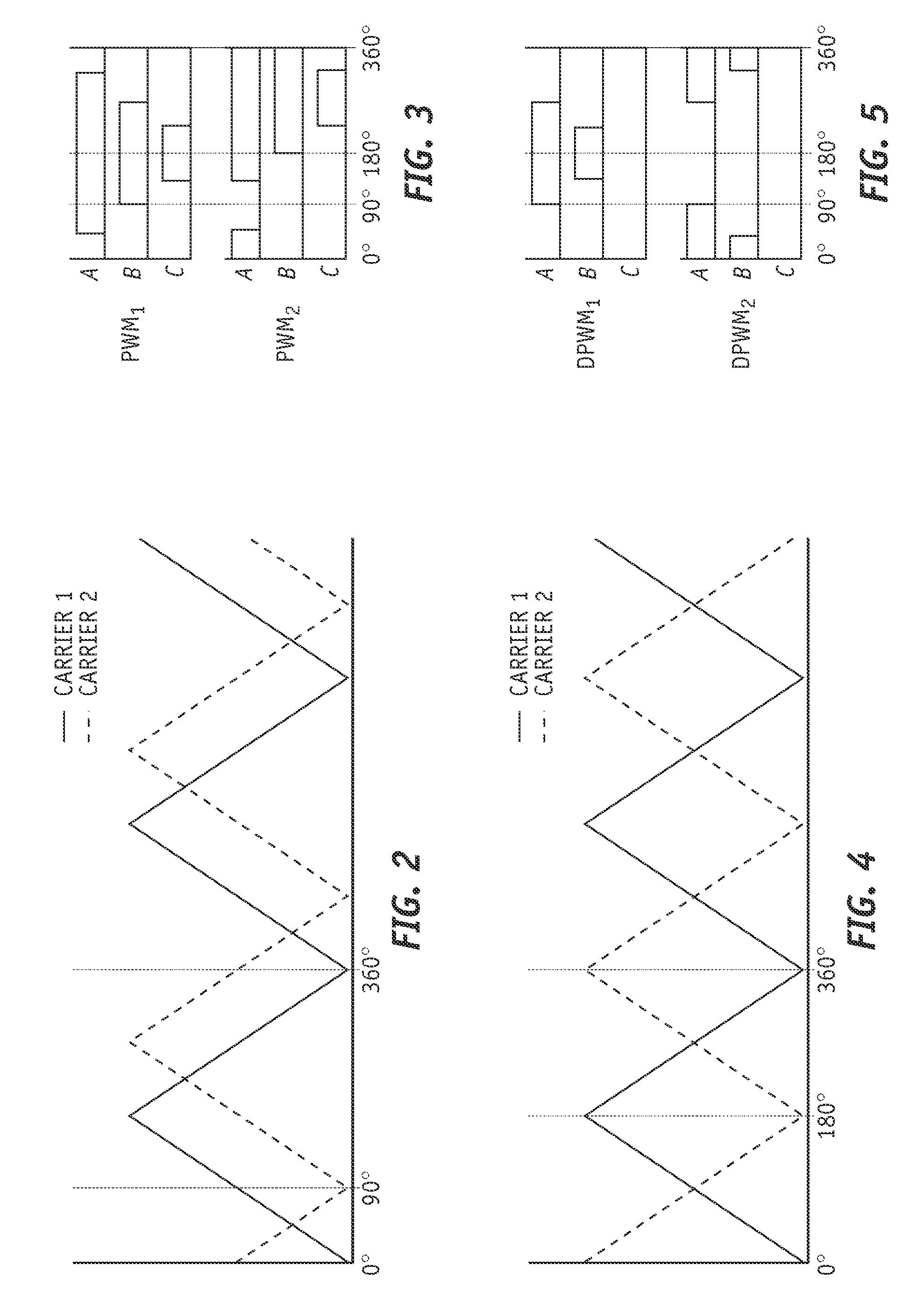

Electrical system using phase-shifted carrier signals and related operating methods

An automotive drive system and methods for making the same are provided. The system includes a three-phase motor and an inverter module. The three-phase motor includes a first set of windings each having a first magnetic polarity; and a second set of windings each having a second magnetic polarity that is opposite the first magnetic polarity. The first set of windings being electrically isolated from the second set of windings. The inverter module includes a first set of phase legs and a second set of phase legs. Each one of the first set of phase legs is coupled to a corresponding phase of the first set of windings, and each one of the second set of phase legs is coupled to a corresponding phase of the second set of windings.

Owner:GM GLOBAL TECH OPERATIONS LLC

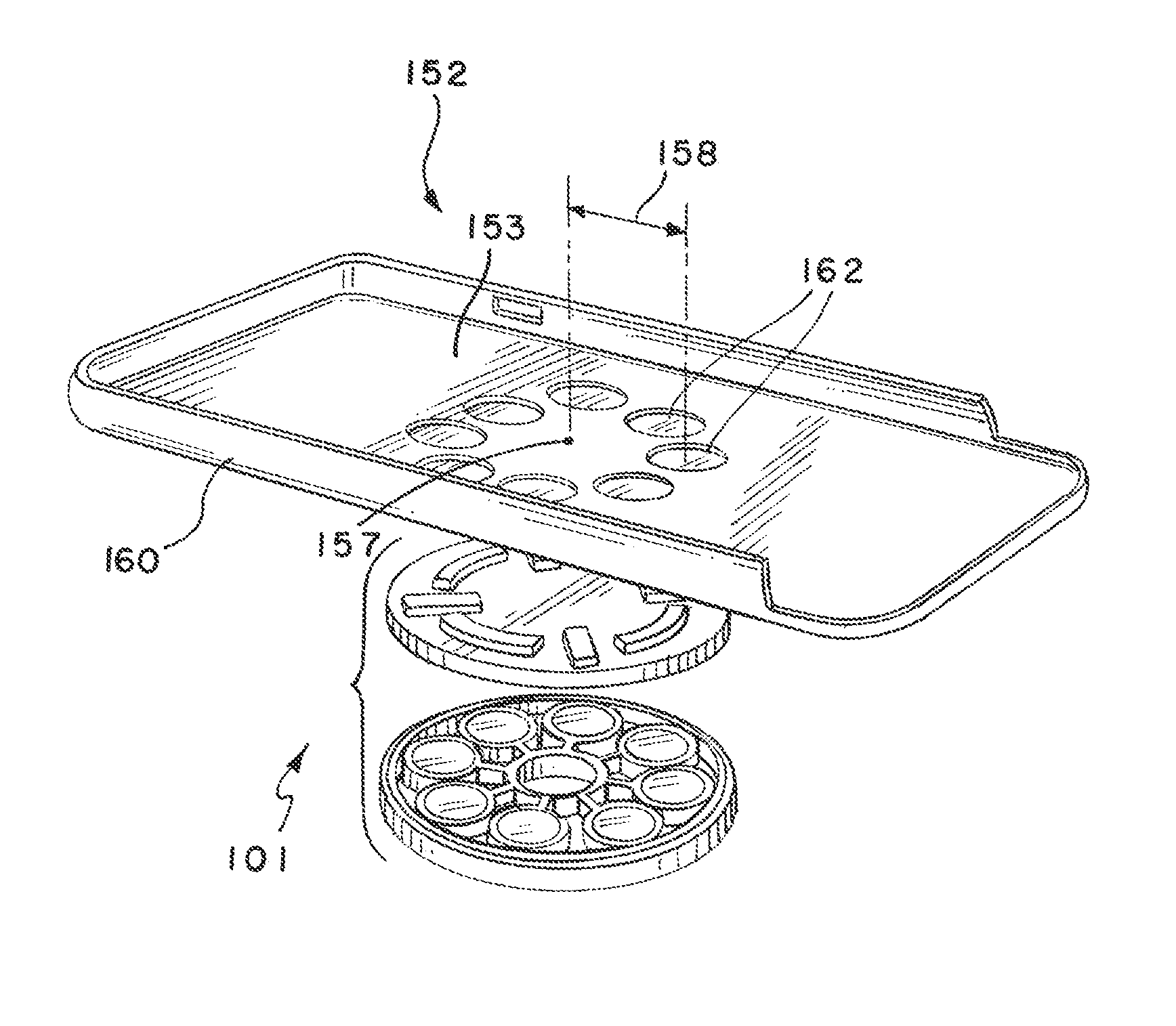

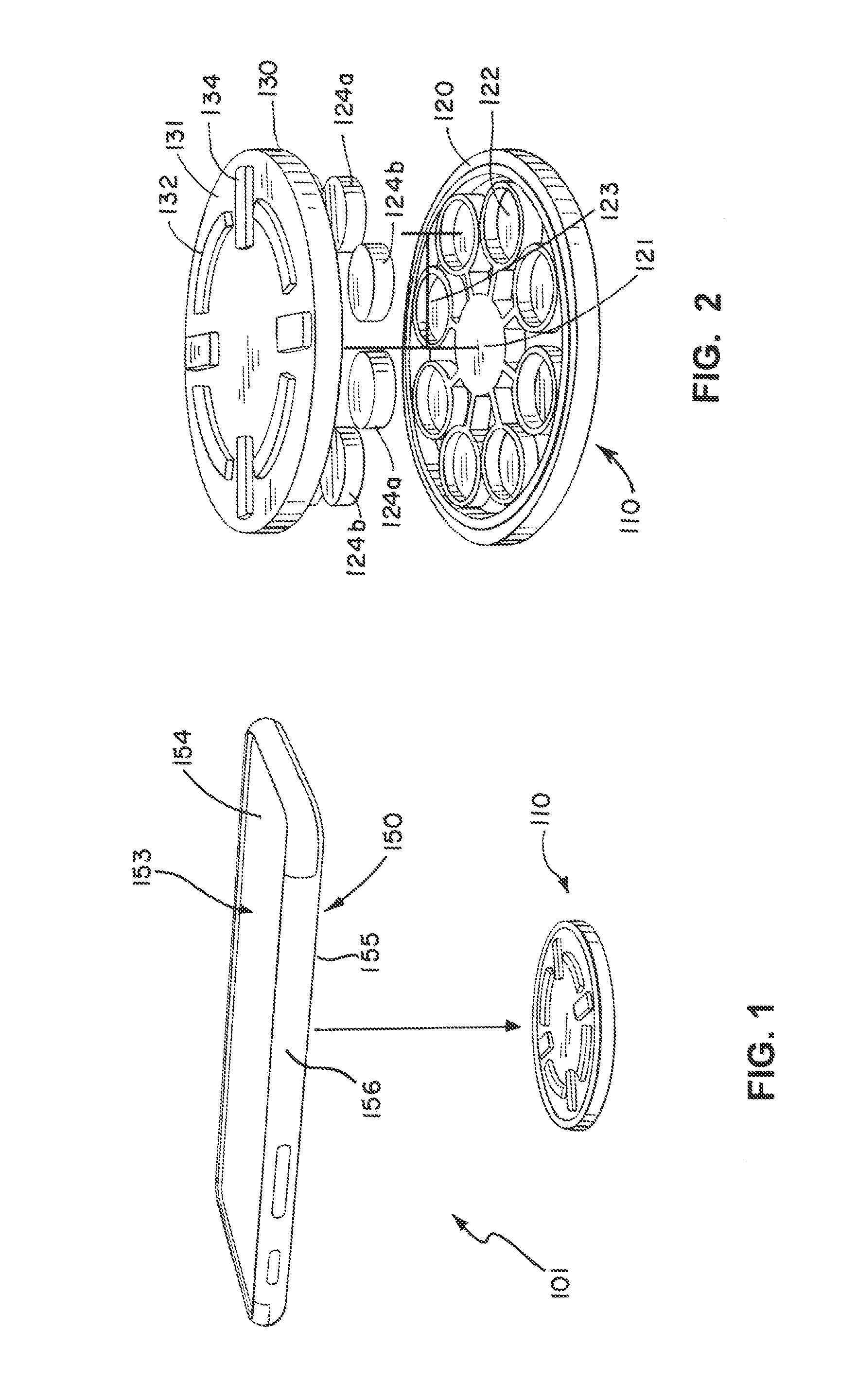

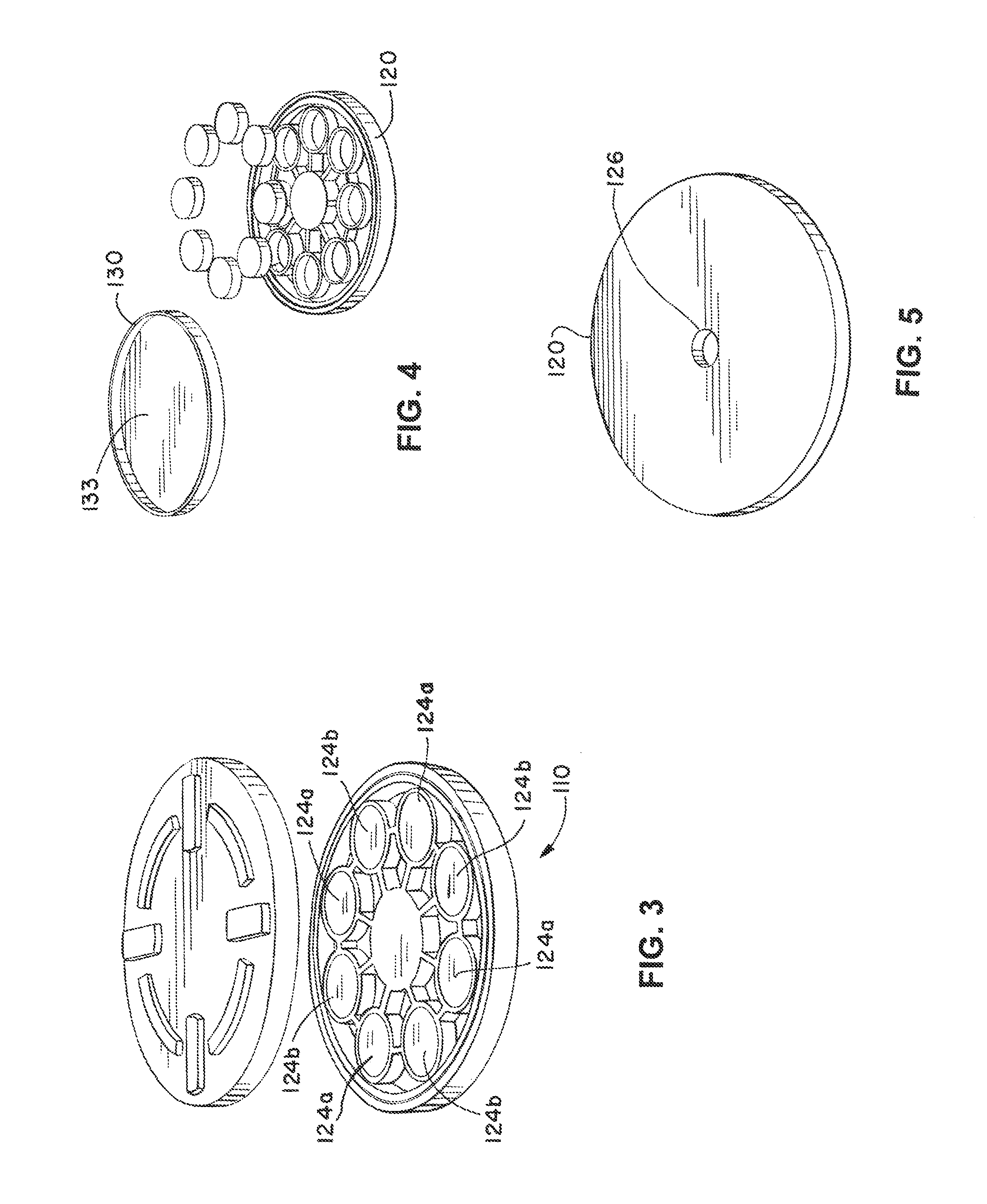

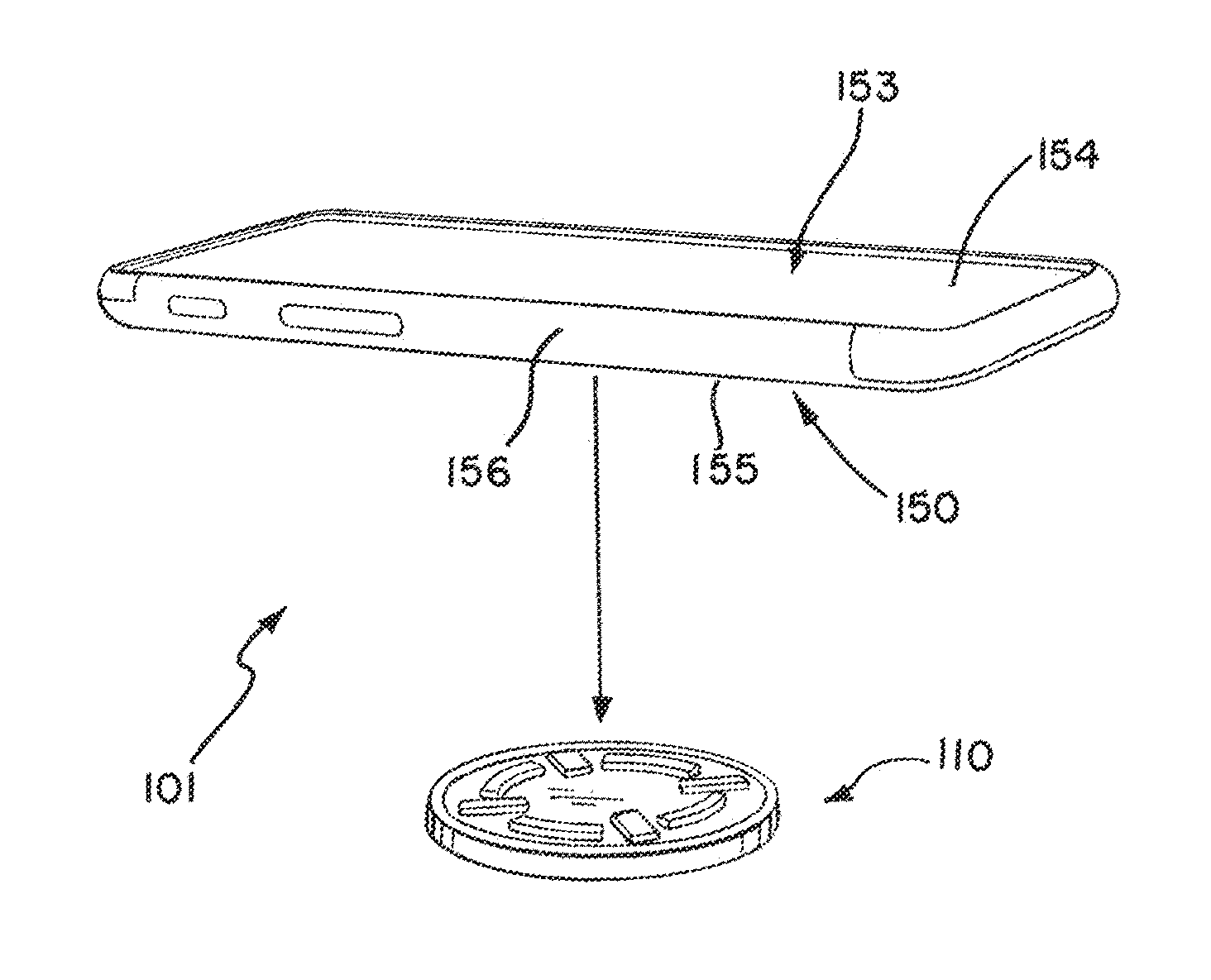

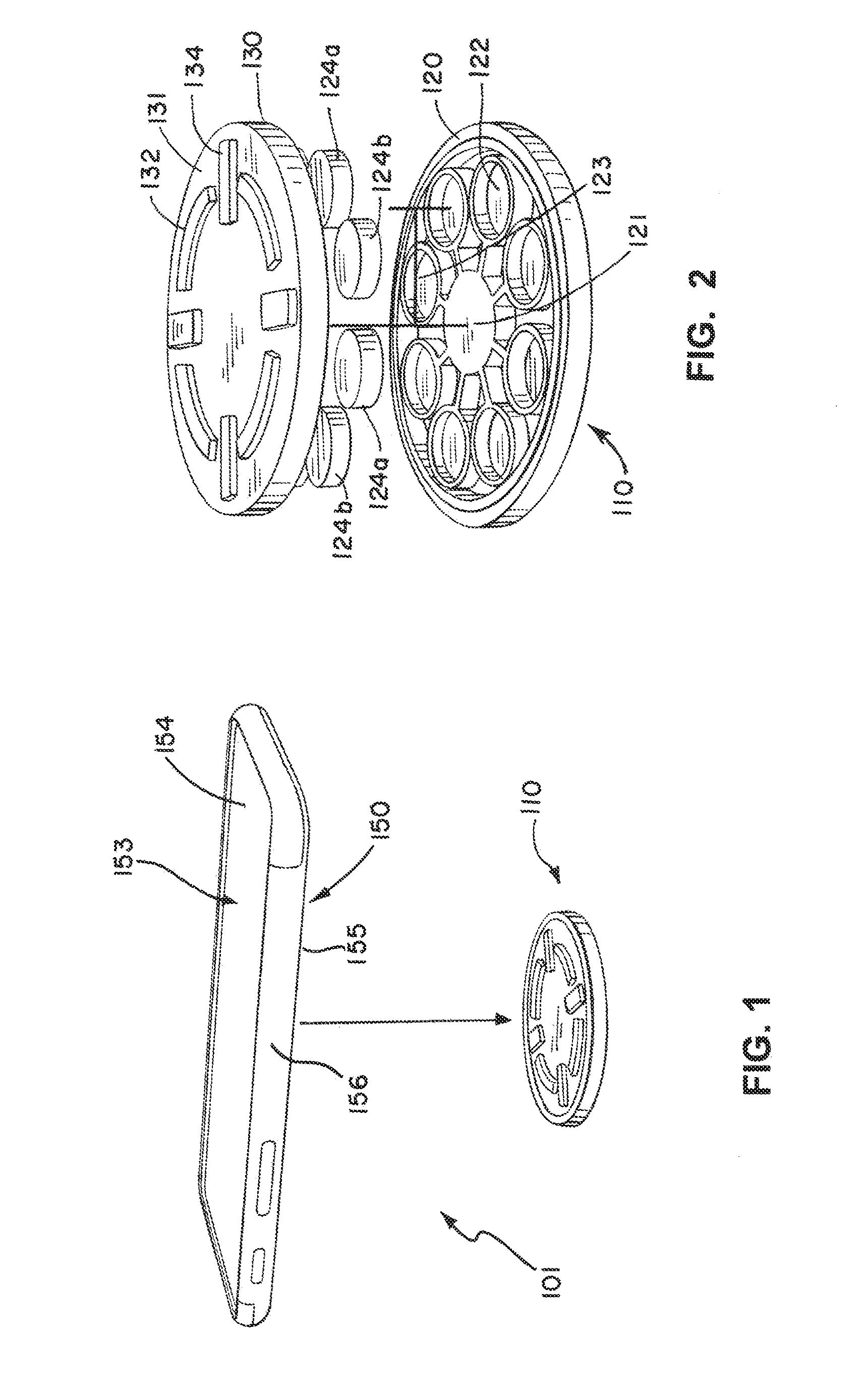

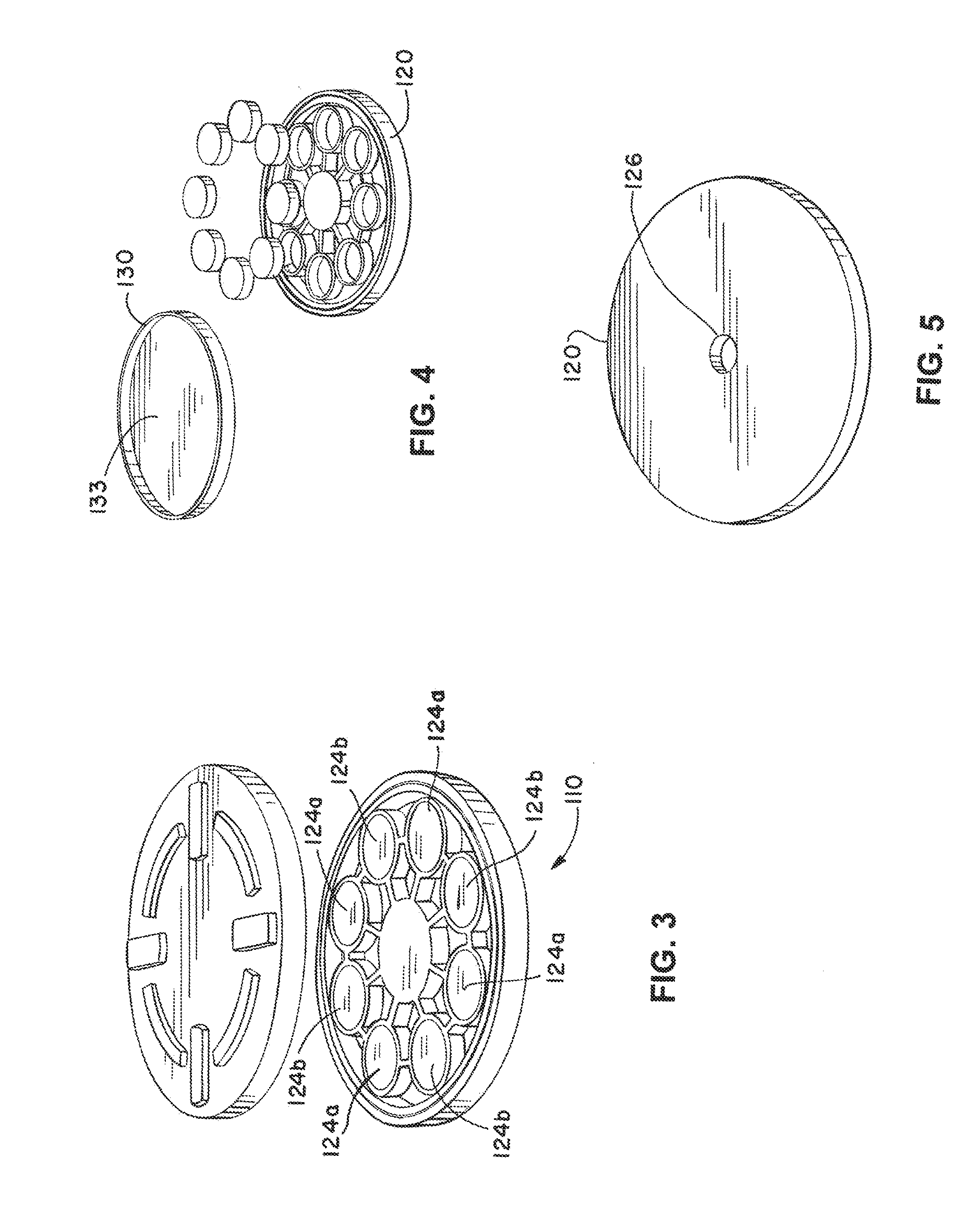

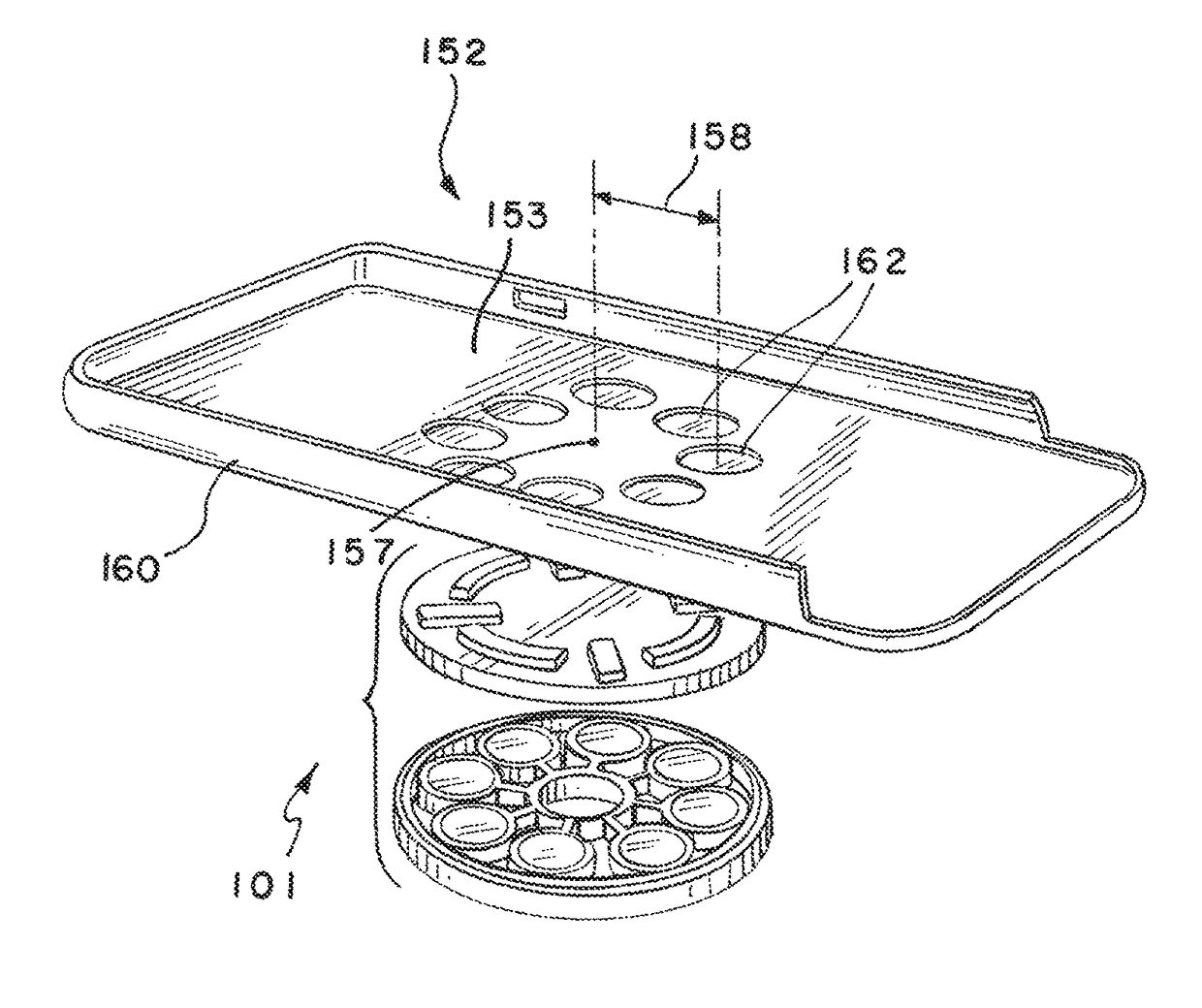

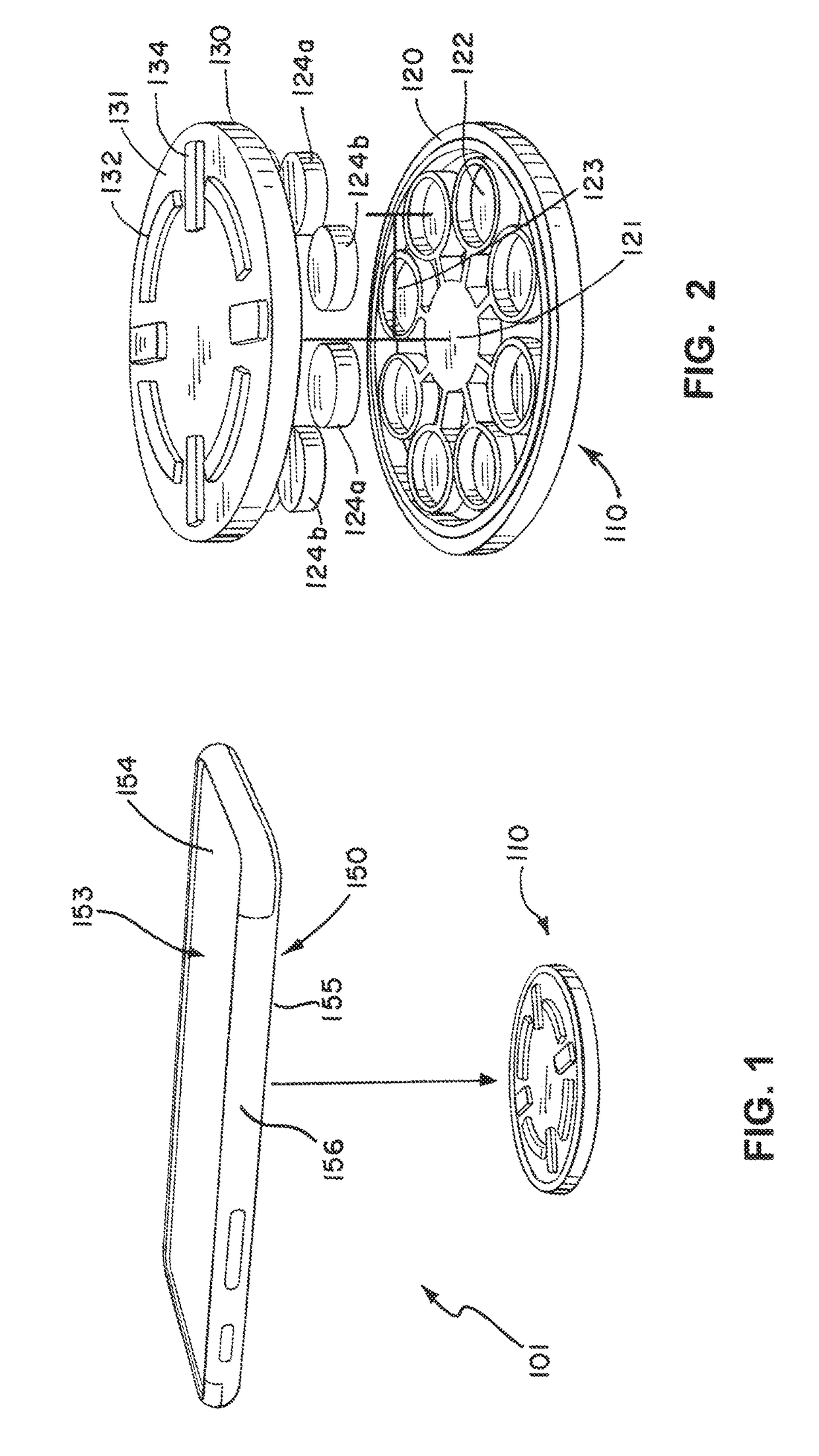

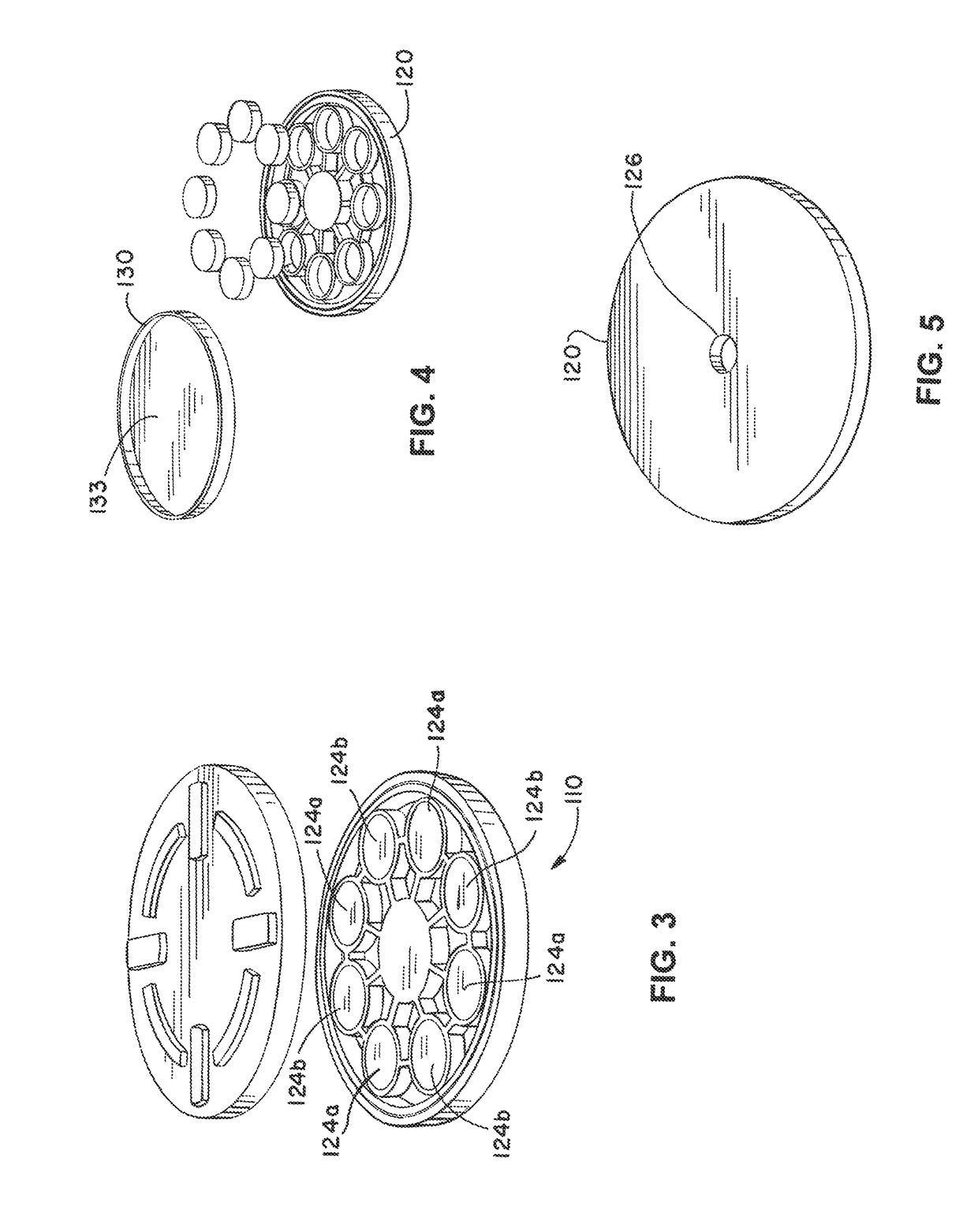

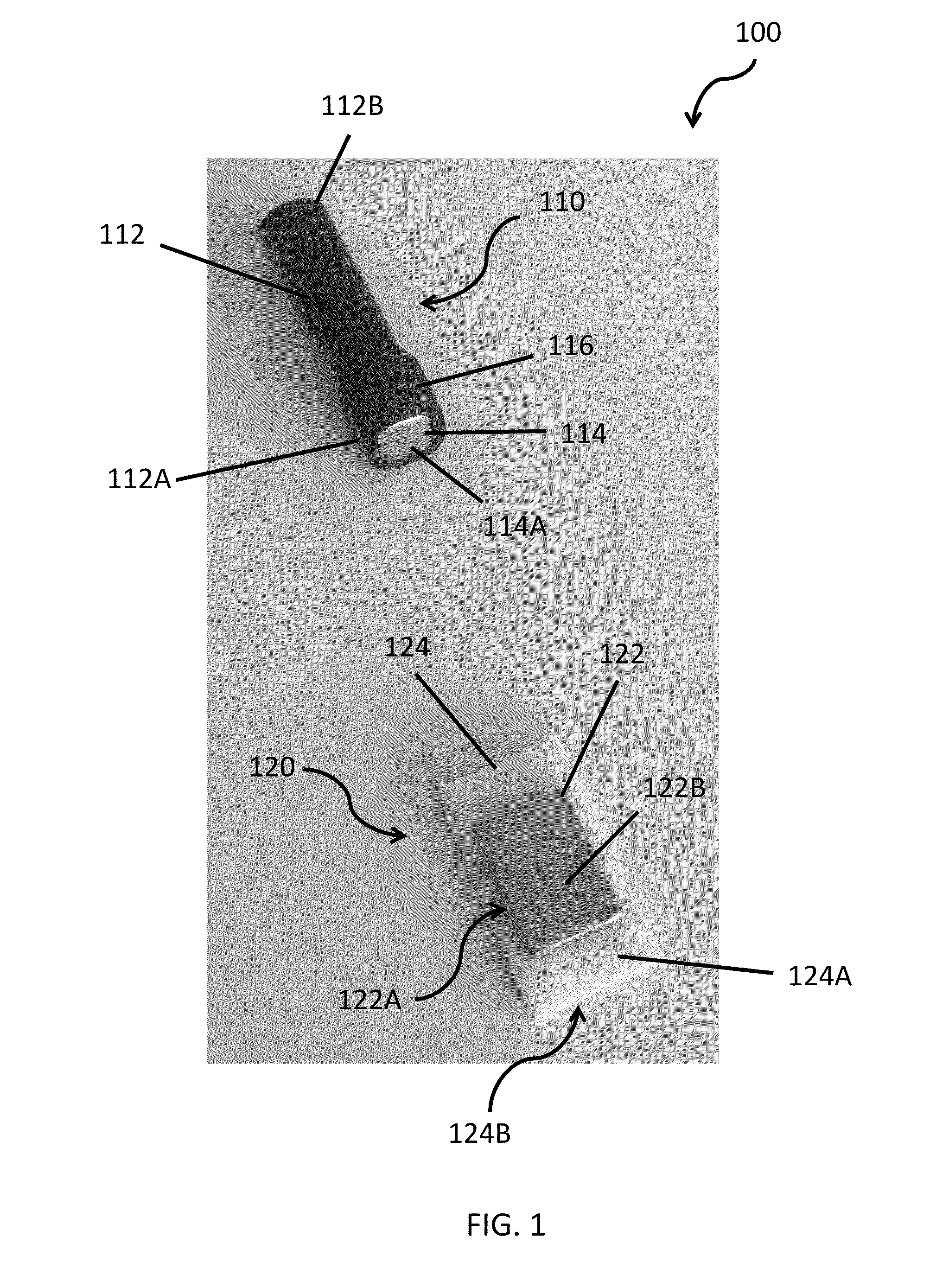

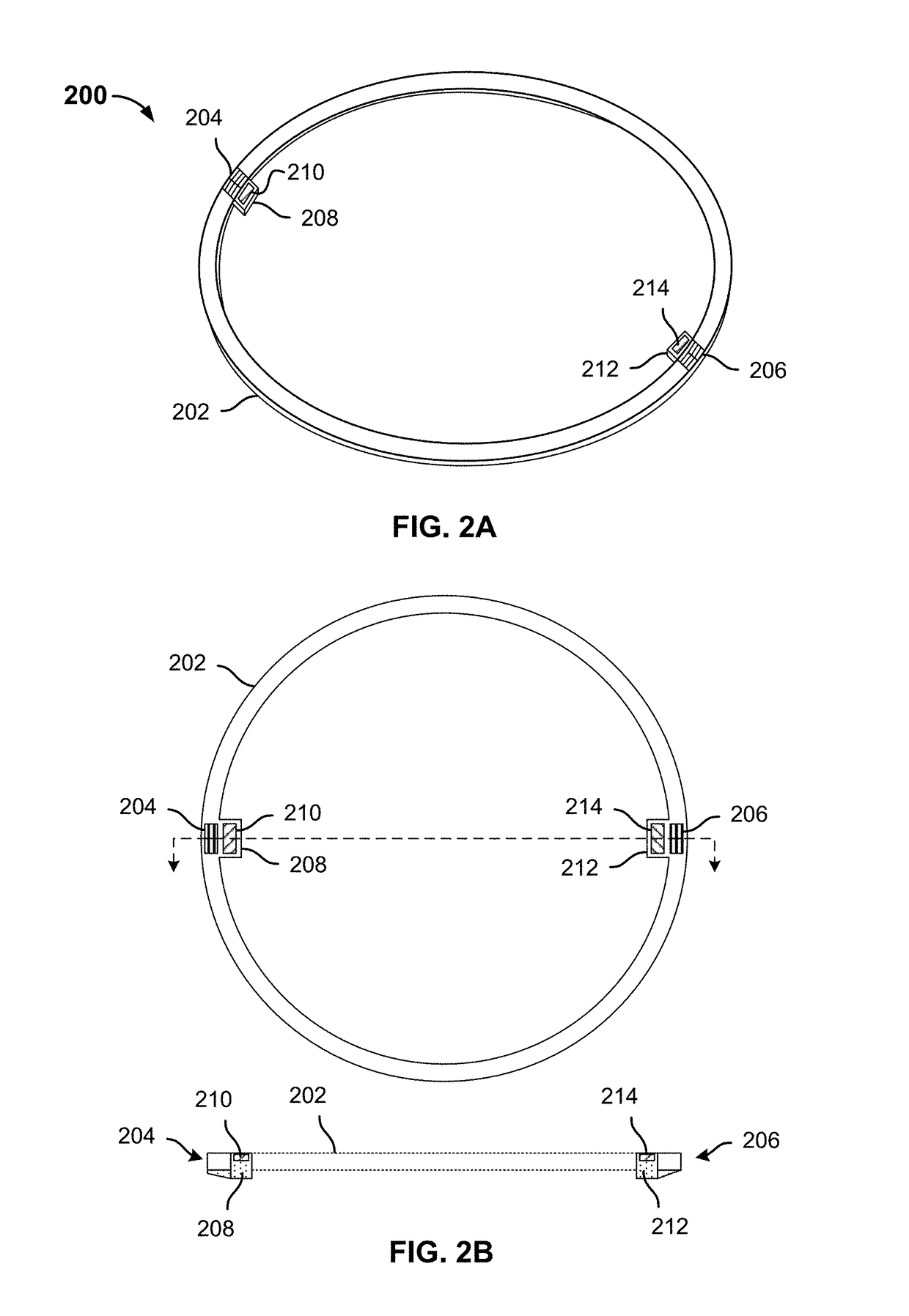

Mobile device holder

A two-piece mobile device holder having a case assembly and a mounting assembly is disclosed. The case assembly is configured to receive and secure a mobile device such as a smart phone. The mounting assembly is configured to be detachably coupled to other objects. Sets of permanent magnets are arranged in a circular pattern in the case assembly and the mounting assembly. The magnets in both the first and second set of magnets are arranged with alternating magnetic polarity. As the case assembly is placed on top of the mounting assembly, the magnets in the mounting assembly will attract magnets with opposite polarities in the case assembly. A user may detach the case assembly from the mounting assembly by rotating the case assembly such that the magnets in the case assembly are now adjacent to magnets in the mounting assembly of the same polarity.

Owner:AIRO COLLECTIVE INC

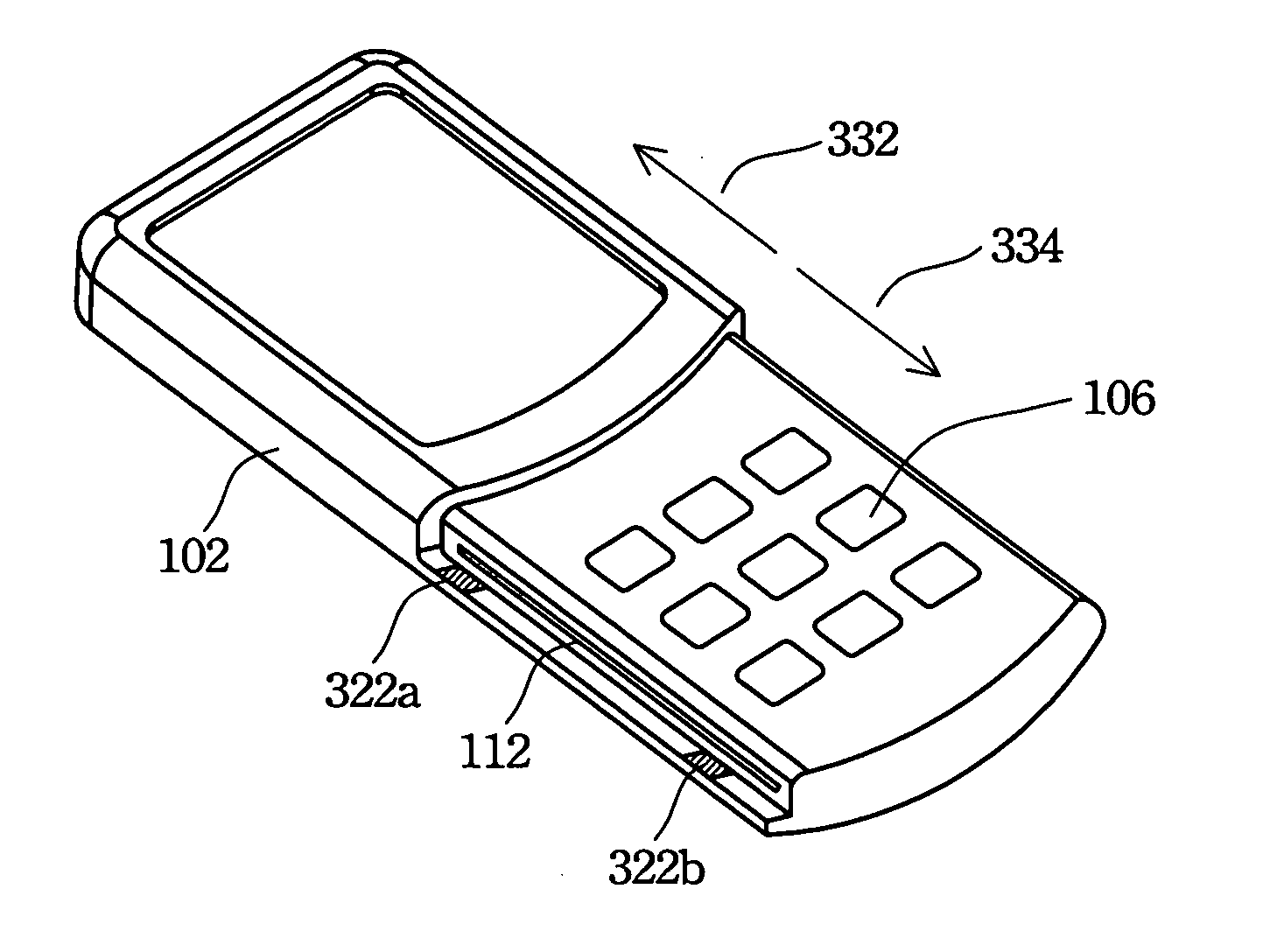

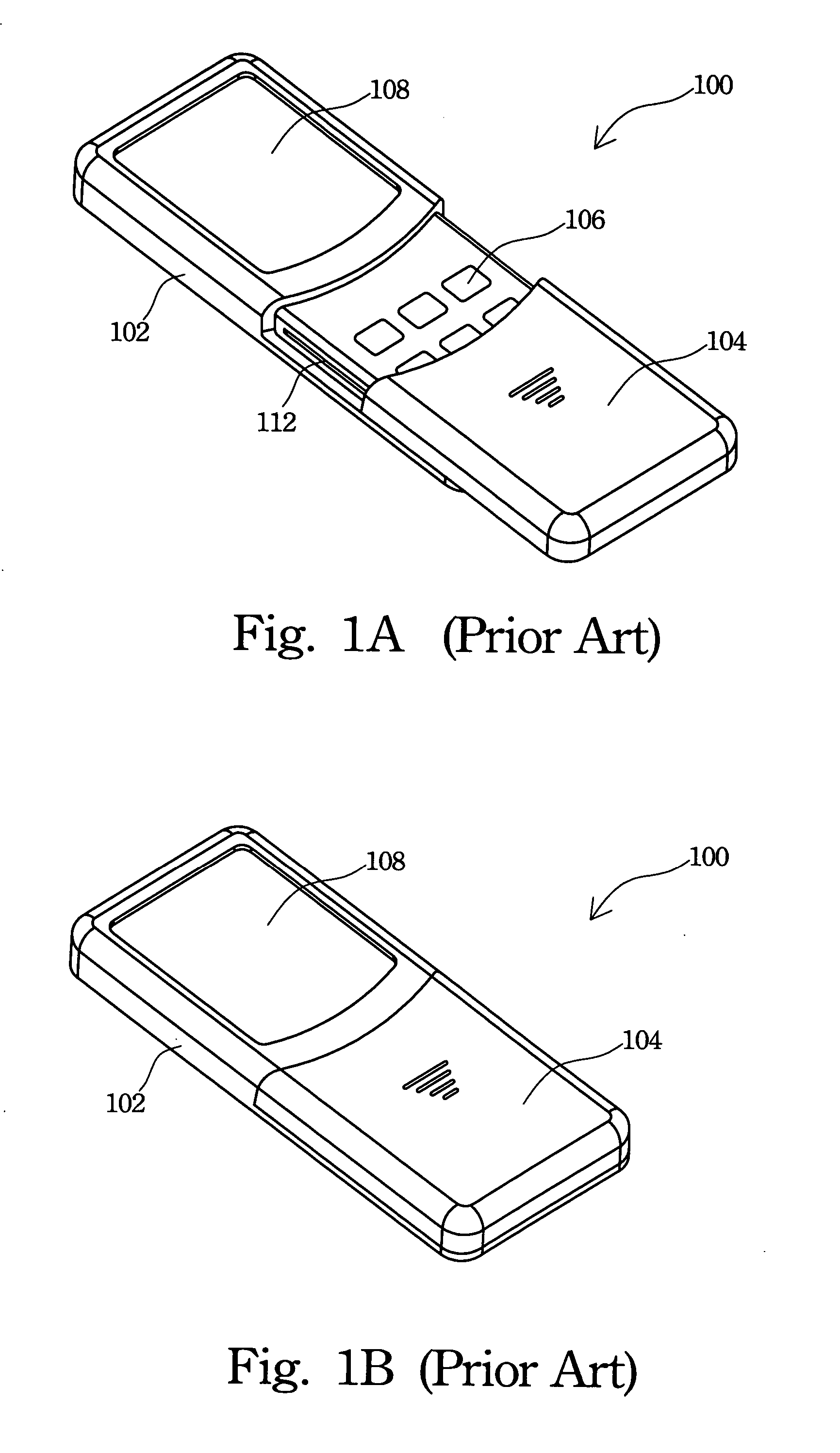

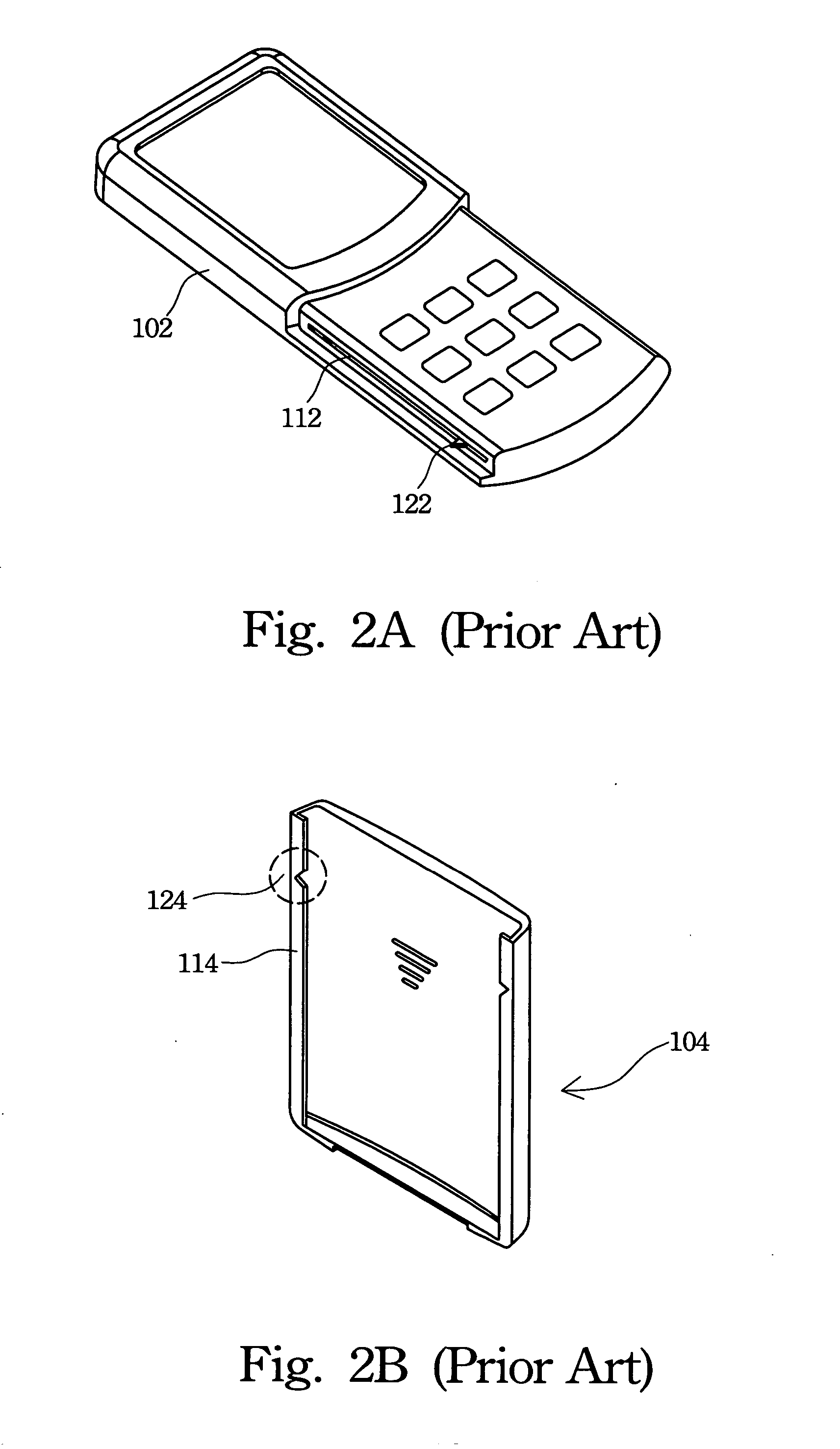

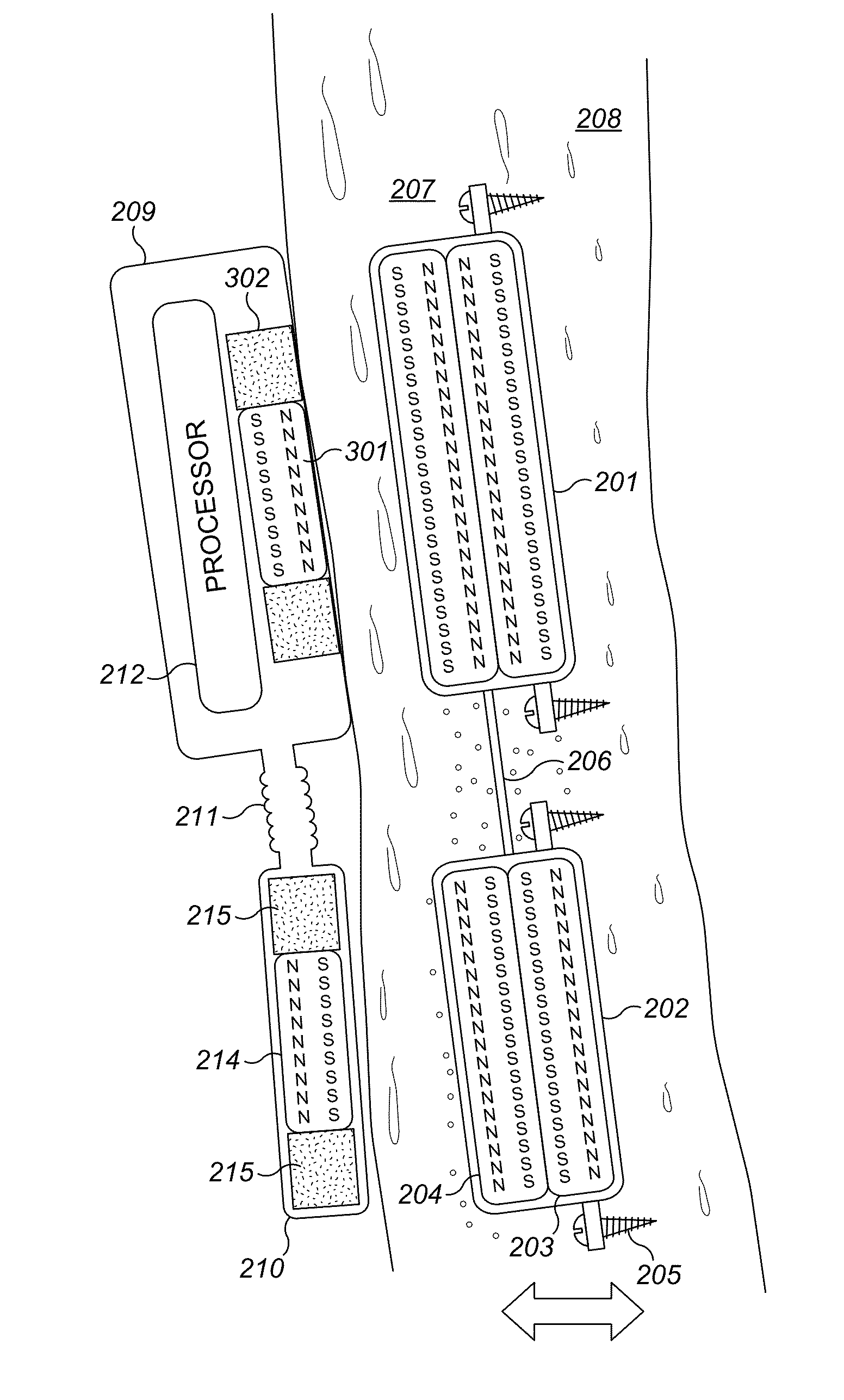

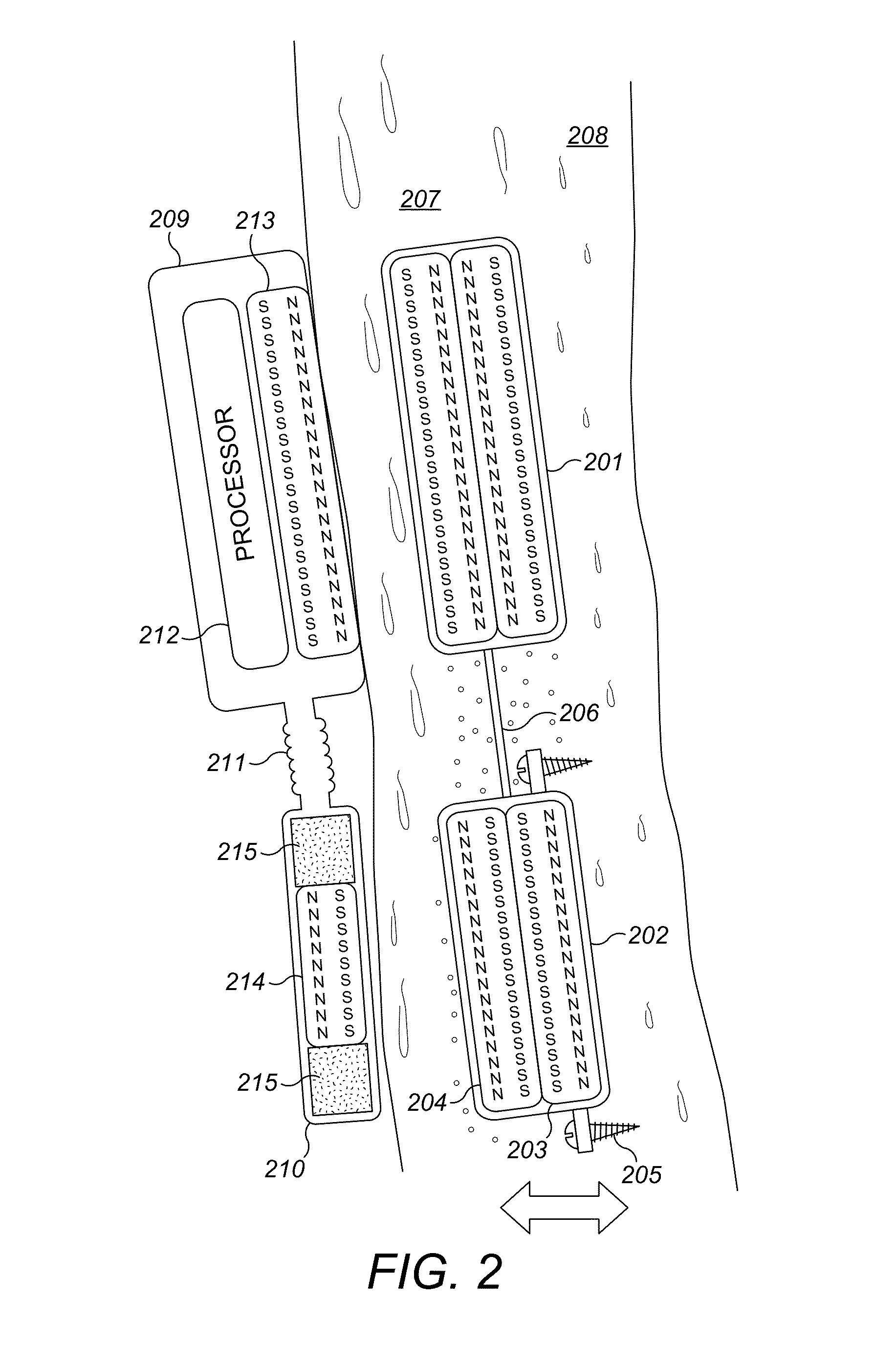

Positioning apparatus and method for a slide cover

InactiveUS20050079902A1Improve positionStrengthen the relative fixedTelephone set constructionsEngineeringLocation Equipment

The positioning apparatus has a first magnetic component, a second magnetic component, and a third magnetic component. The first magnetic component and the second magnetic component are of a first magnetic polarity, and the third magnetic component is of a second magnetic polarity. The first magnetic component and the second magnetic component are configured together on a device body or a slide cover, and these two magnetic components are located at two different places along with a sliding direction of the slide cover. The third magnetic component is oppositely configured on the slide cover or the device body, which lacks the first and the second magnetic components.

Owner:ARIMA COMM CORP LTD

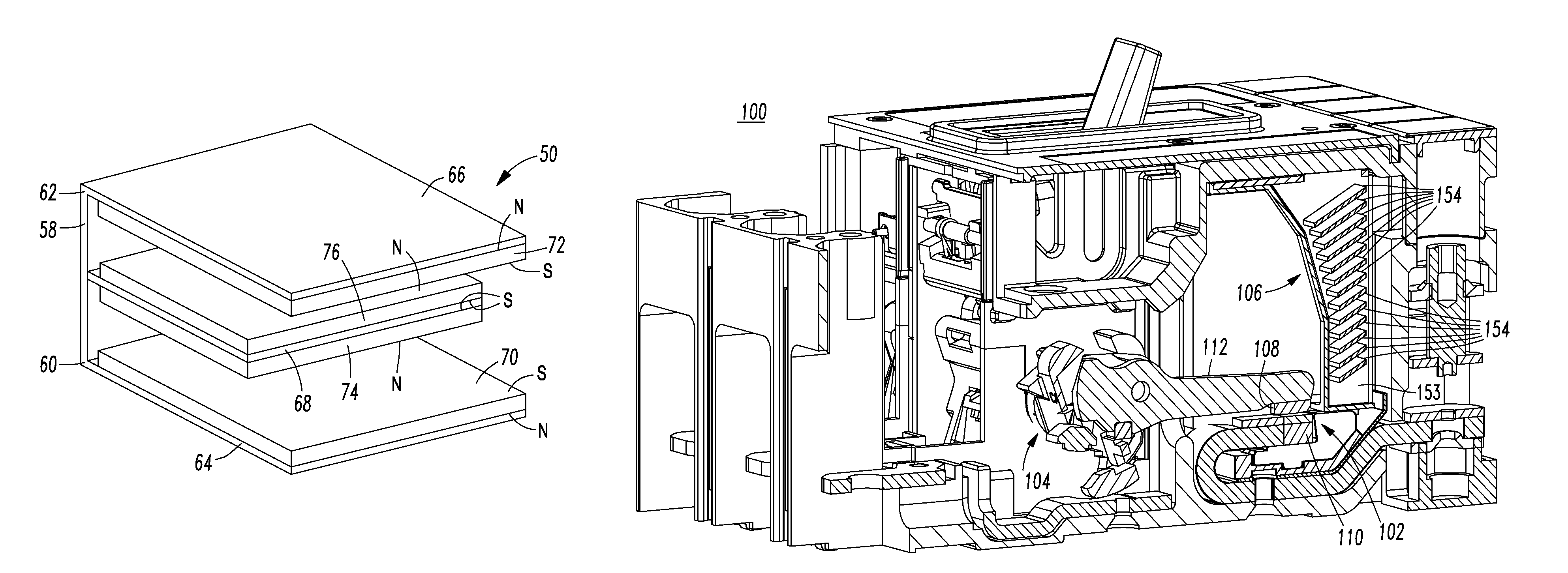

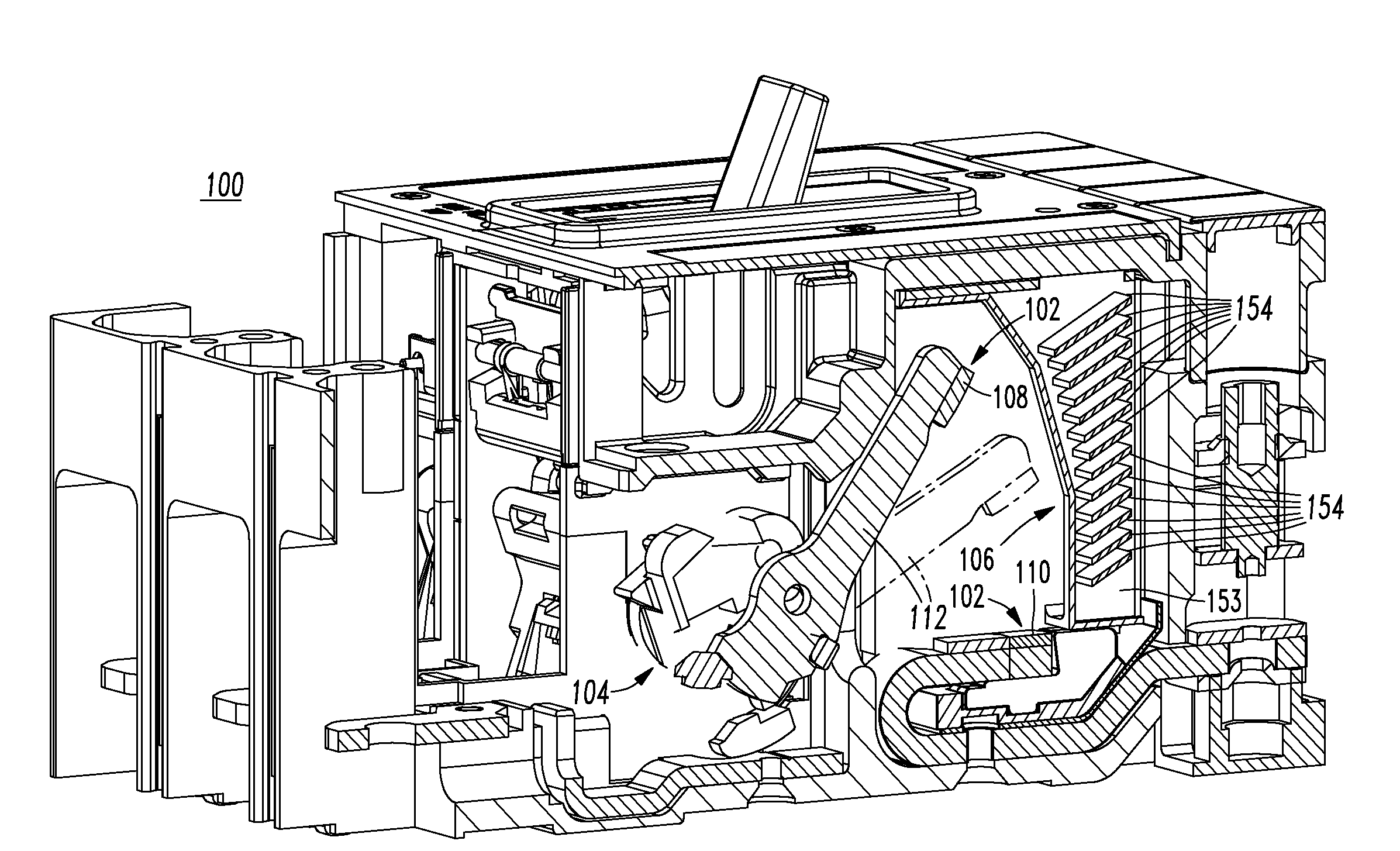

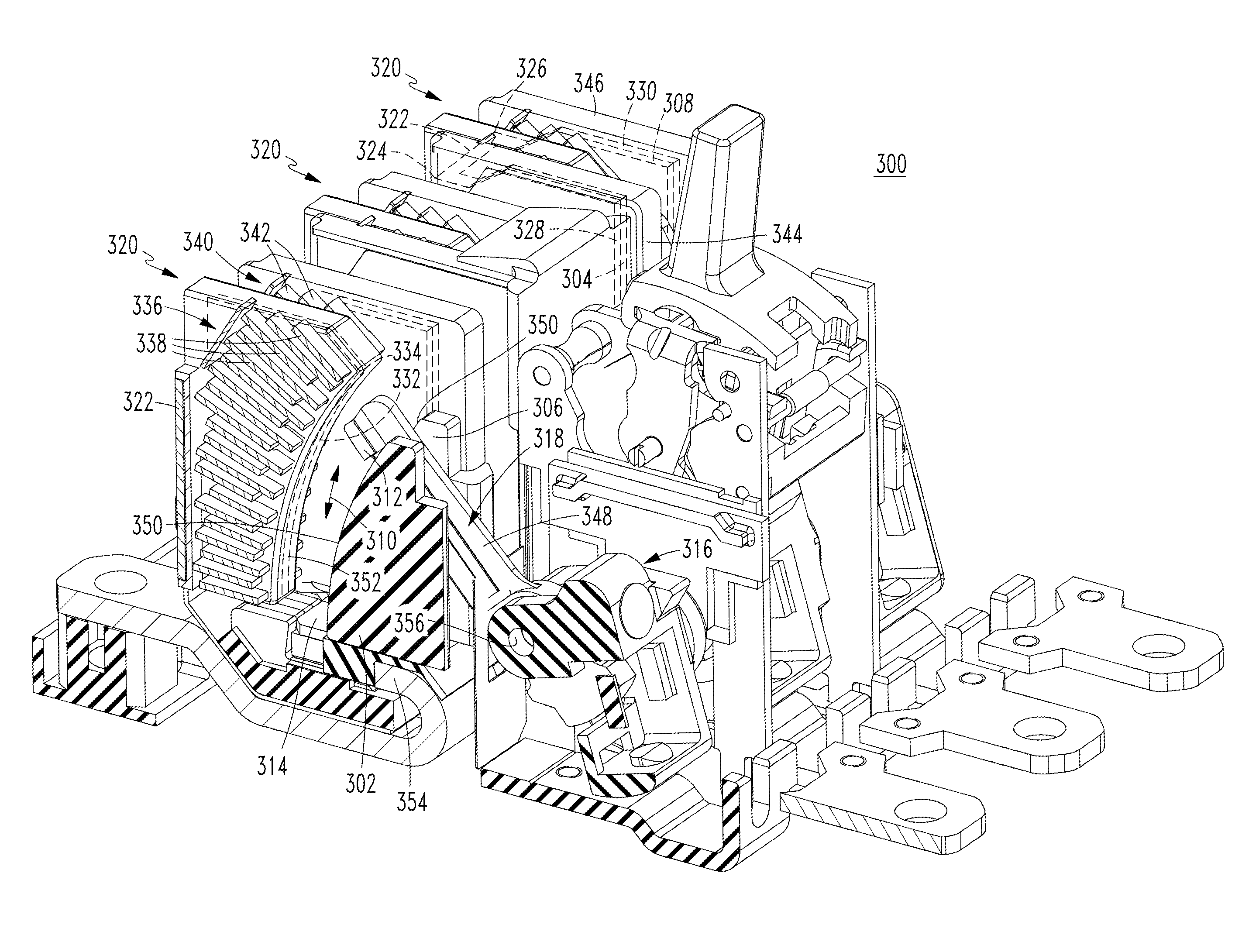

Single direct current arc chamber, and bi-directional direct current electrical switching apparatus employing the same

A single direct current arc chamber includes a ferromagnetic base having first and opposite second ends, a first ferromagnetic side member disposed from the first end, a second ferromagnetic side member disposed from the opposite second end, a third ferromagnetic member disposed from the ferromagnetic base intermediate the ferromagnetic side members, a first permanent magnet having a first magnetic polarity disposed on the first ferromagnetic side member and facing the third ferromagnetic member, and a second permanent magnet having the first magnetic polarity disposed on the second ferromagnetic side member and facing the third ferromagnetic member.

Owner:EATON INTELLIGENT POWER LTD

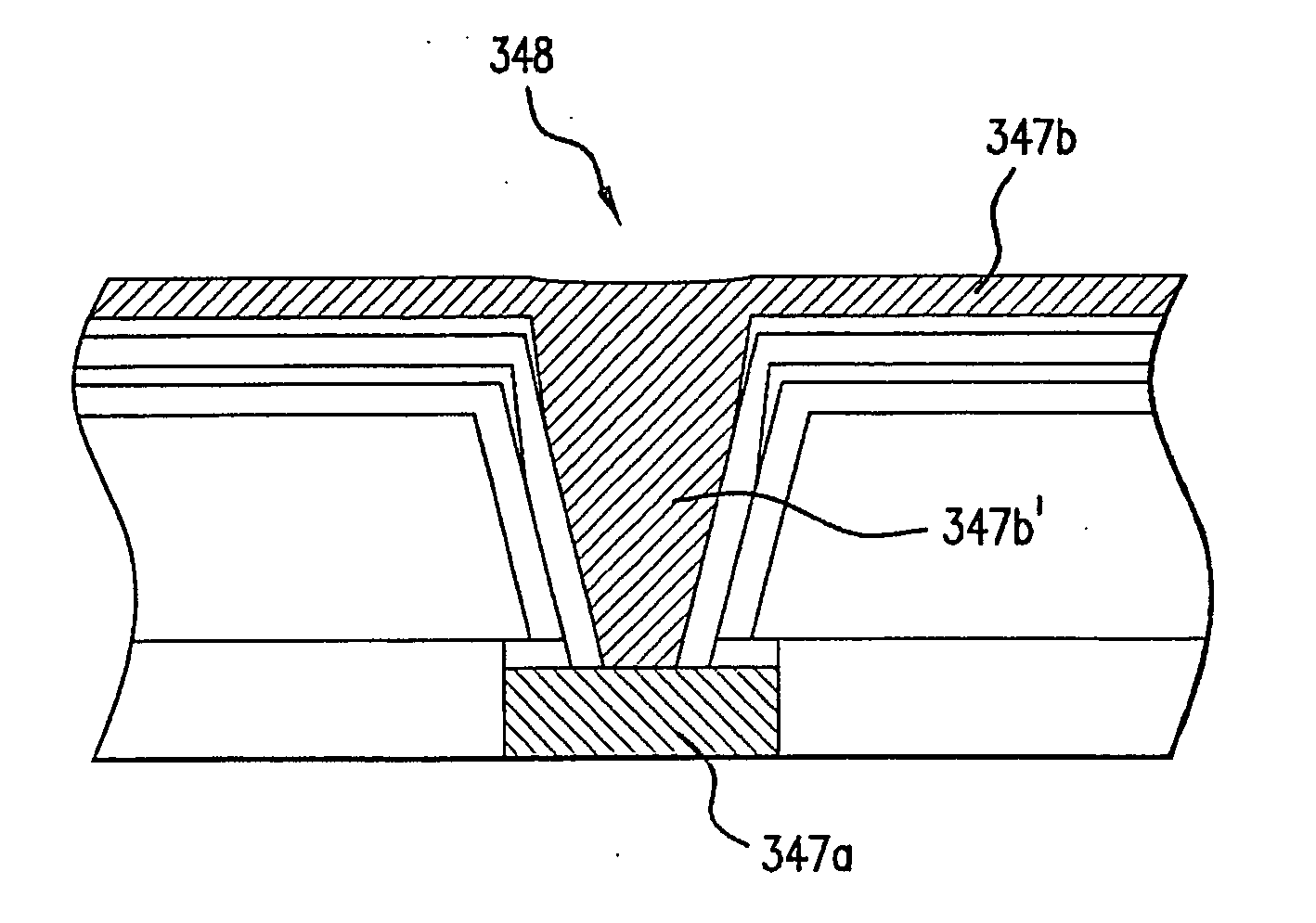

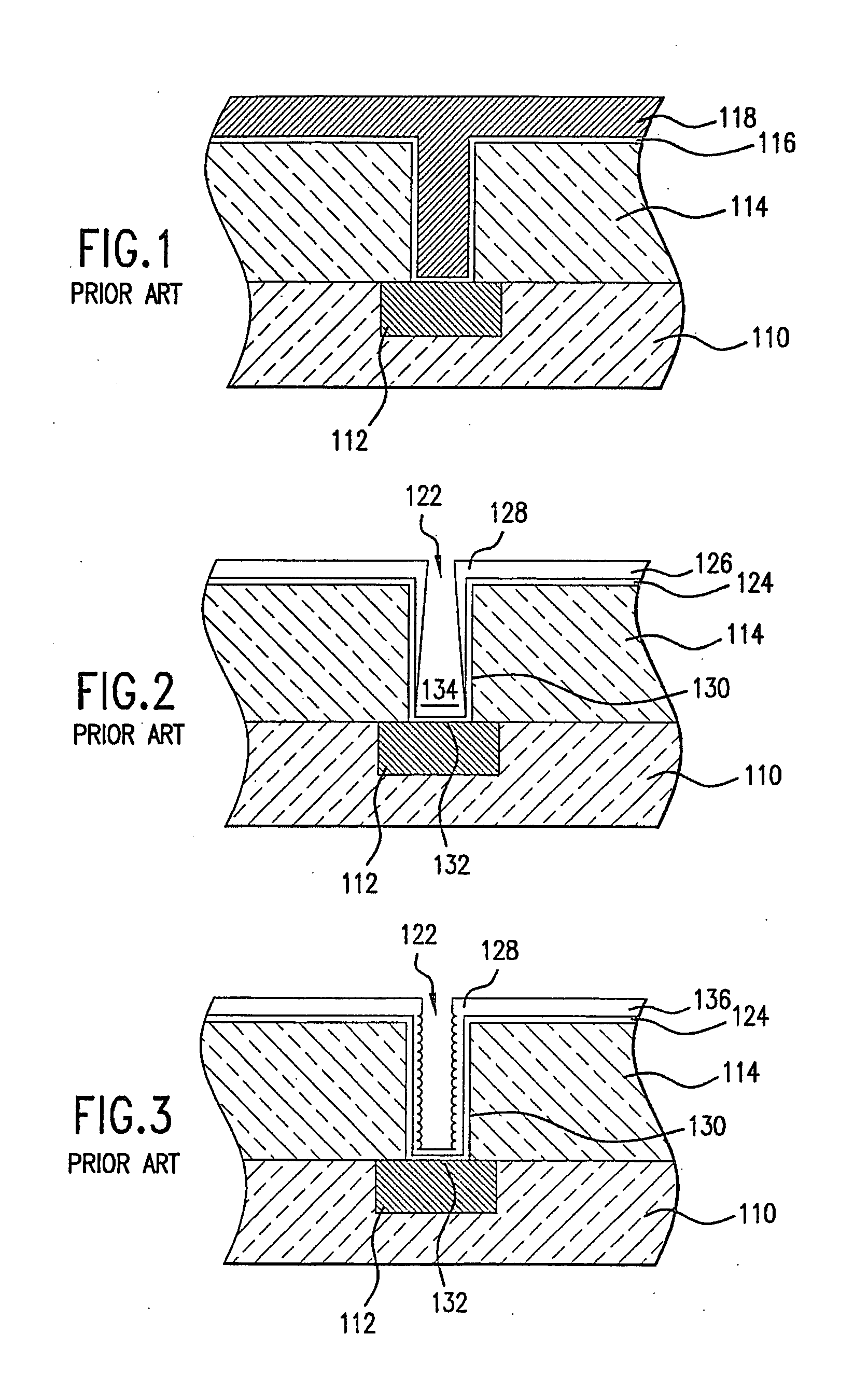

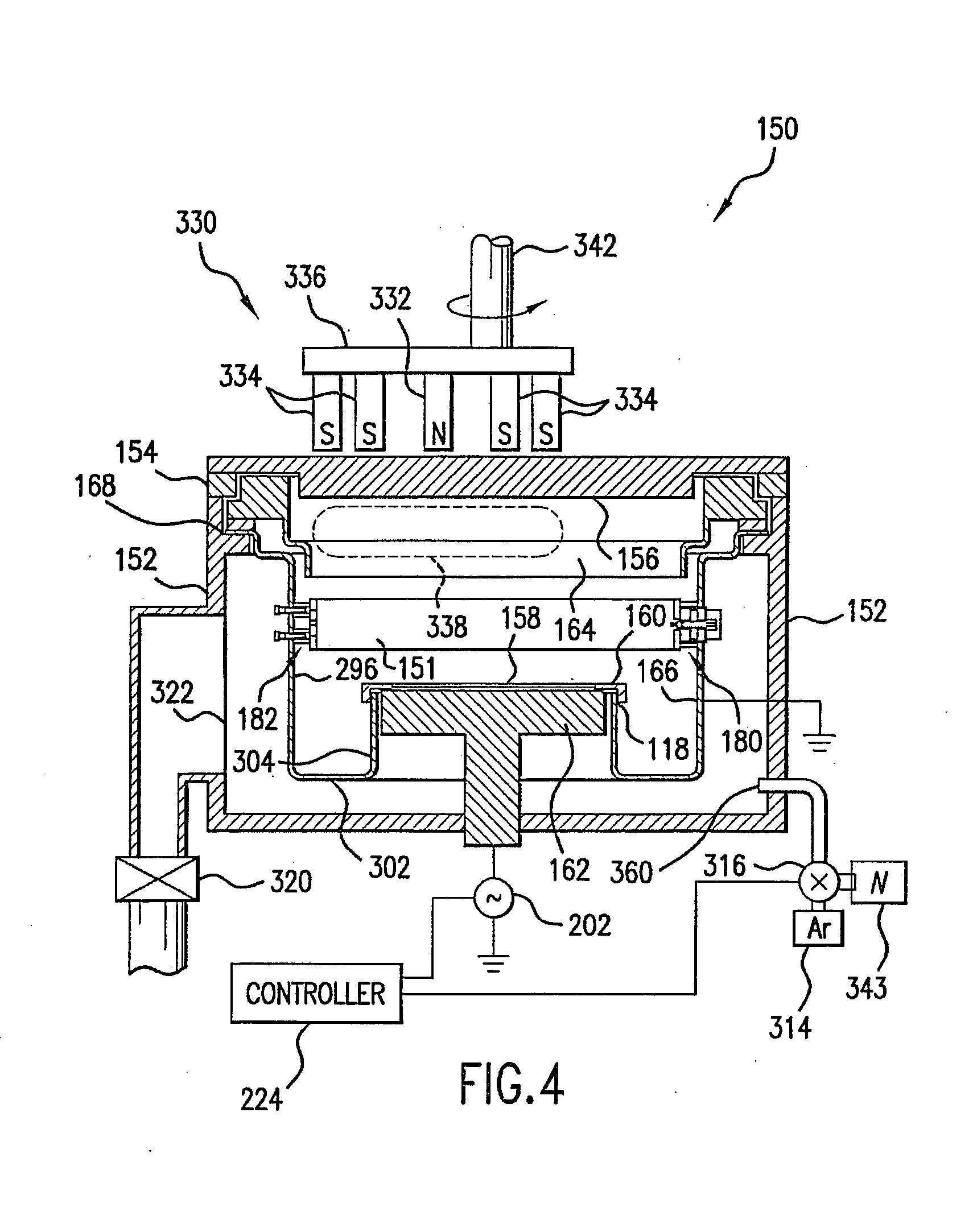

Self-ionized and inductively-coupled plasma for sputtering and resputtering

InactiveUS20050255691A1Raise the ratioReduce layer thicknessElectric discharge tubesSolid-state devicesRadio frequency energyMagnetic poles

Owner:APPLIED MATERIALS INC

Mobile device holder

A two-piece mobile device holder having a case assembly and a mounting assembly is disclosed. The case assembly is configured to receive and secure a mobile device such as a smart phone. The mounting assembly is configured to be detachably coupled to other objects. Sets of permanent magnets are arranged in a circular pattern in the case assembly and the mounting assembly. The magnets in both the first and second set of magnets are arranged with alternating magnetic polarity. As the case assembly is placed on top of the mounting assembly, the magnets in the mounting assembly will attract magnets with opposite polarities in the case assembly. A user may detach the case assembly from the mounting assembly by rotating the case assembly such that the magnets in the case assembly are now adjacent to magnets in the mounting assembly of the same polarity.

Owner:AIRO COLLECTIVE INC

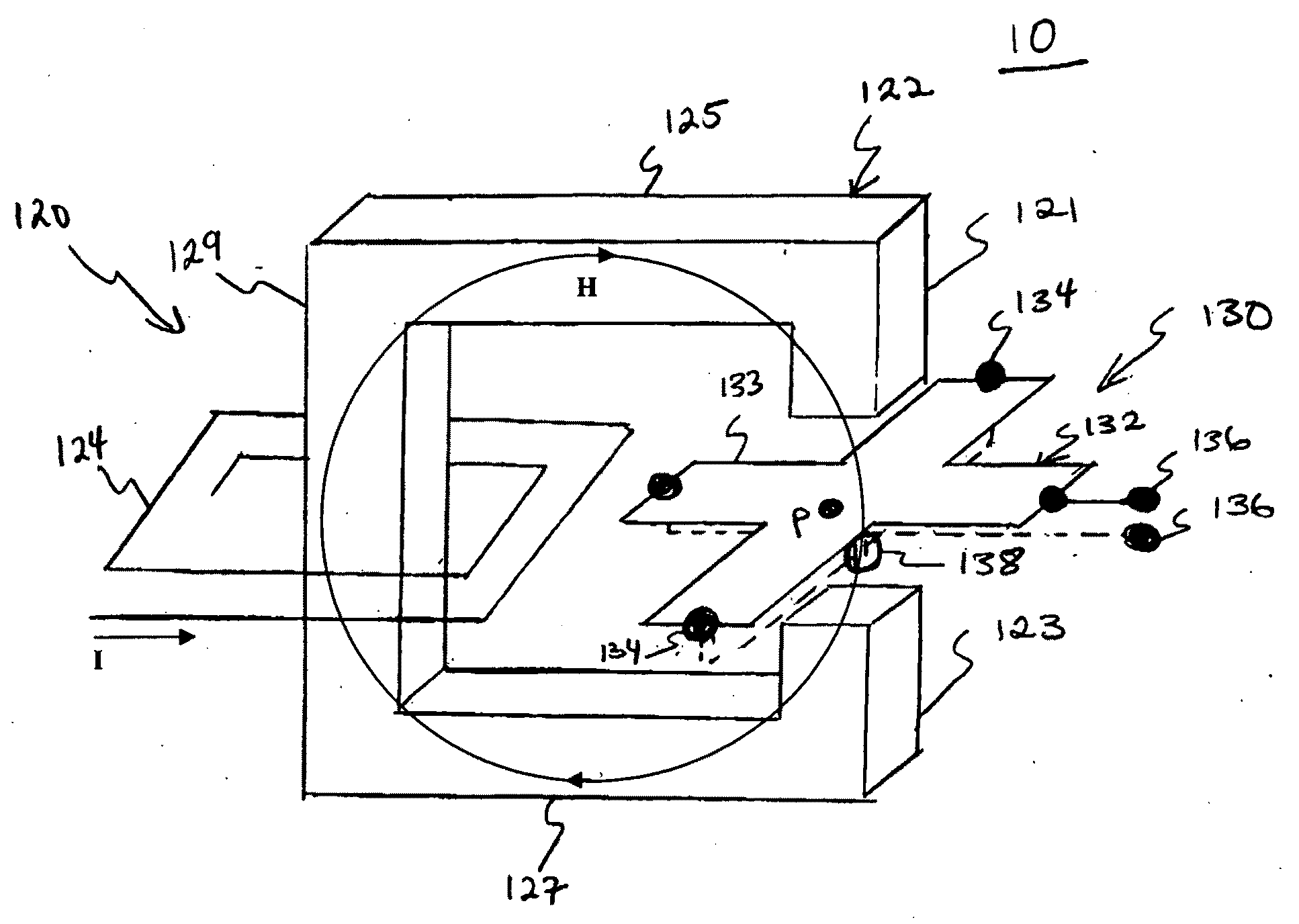

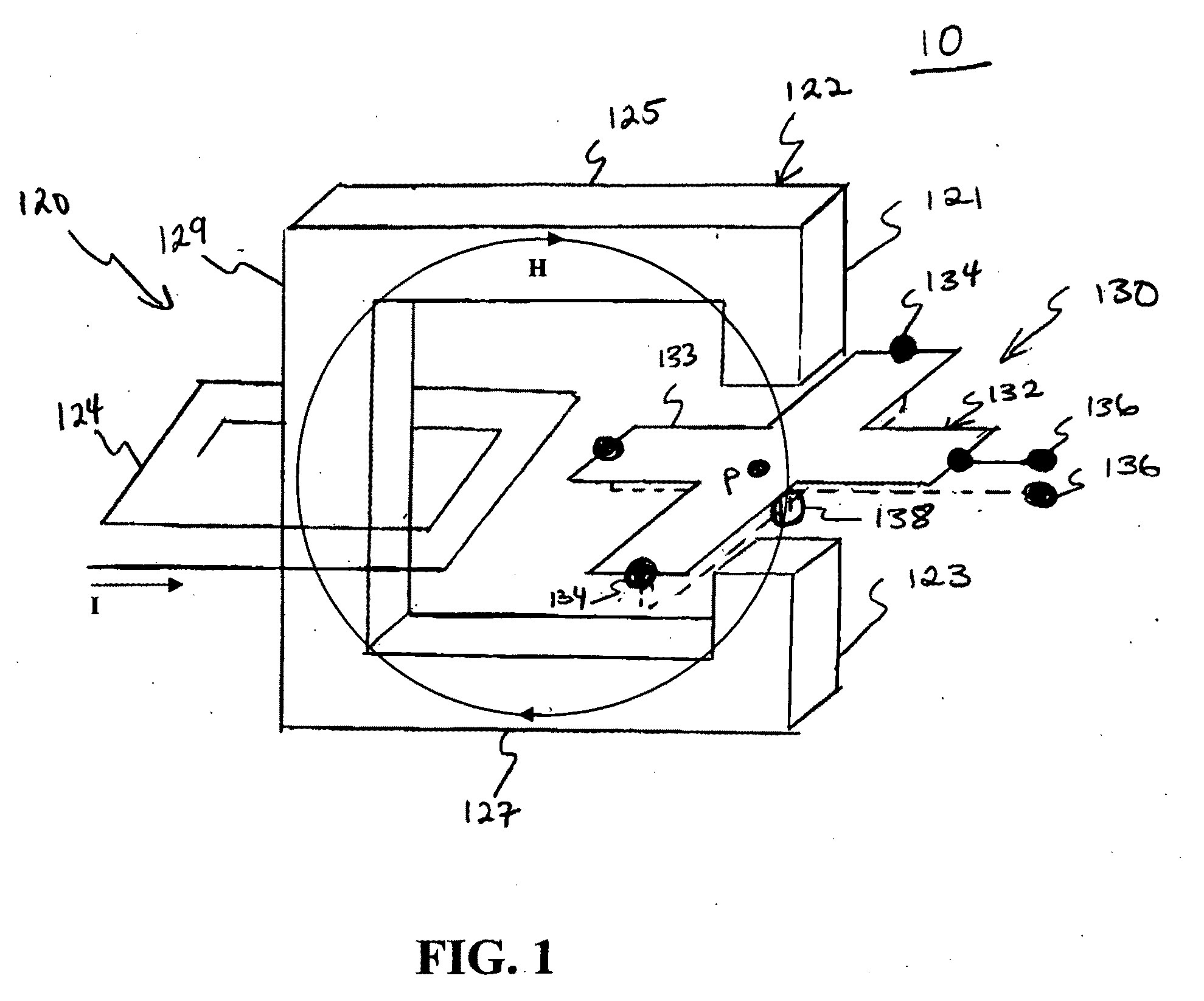

Magnetic memory device having a C-shaped structure and method of manufacturing the same

InactiveUS20090146231A1Simple methodMagnetic measurementsSemiconductor/solid-state device manufacturingMagnetic memoryMagnetic switch

A non-volatile magnetic memory device having one or more memory cells, each of the memory cells includes a magnetic switch including a C-shaped magnetic component and a write coil located proximate the magnetic component, the write coil coupled to receive a current sufficient to create a remnant magnetic polarity in the magnetic component, and a Hall sensor, positioned proximate the magnetic component, to detect the remnant magnetic polarity indicative of a stored data bit.

Owner:MICROMEM TECH

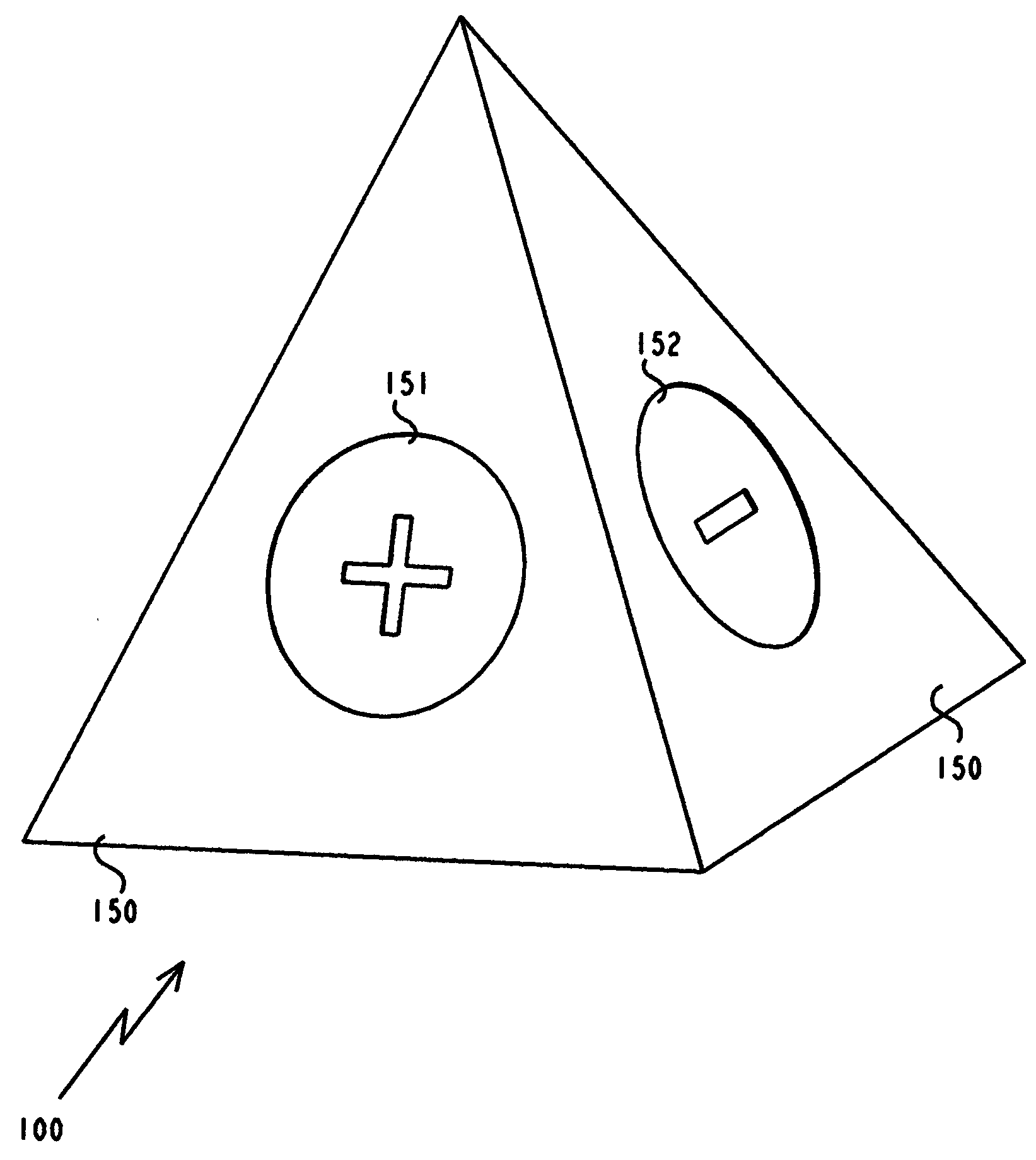

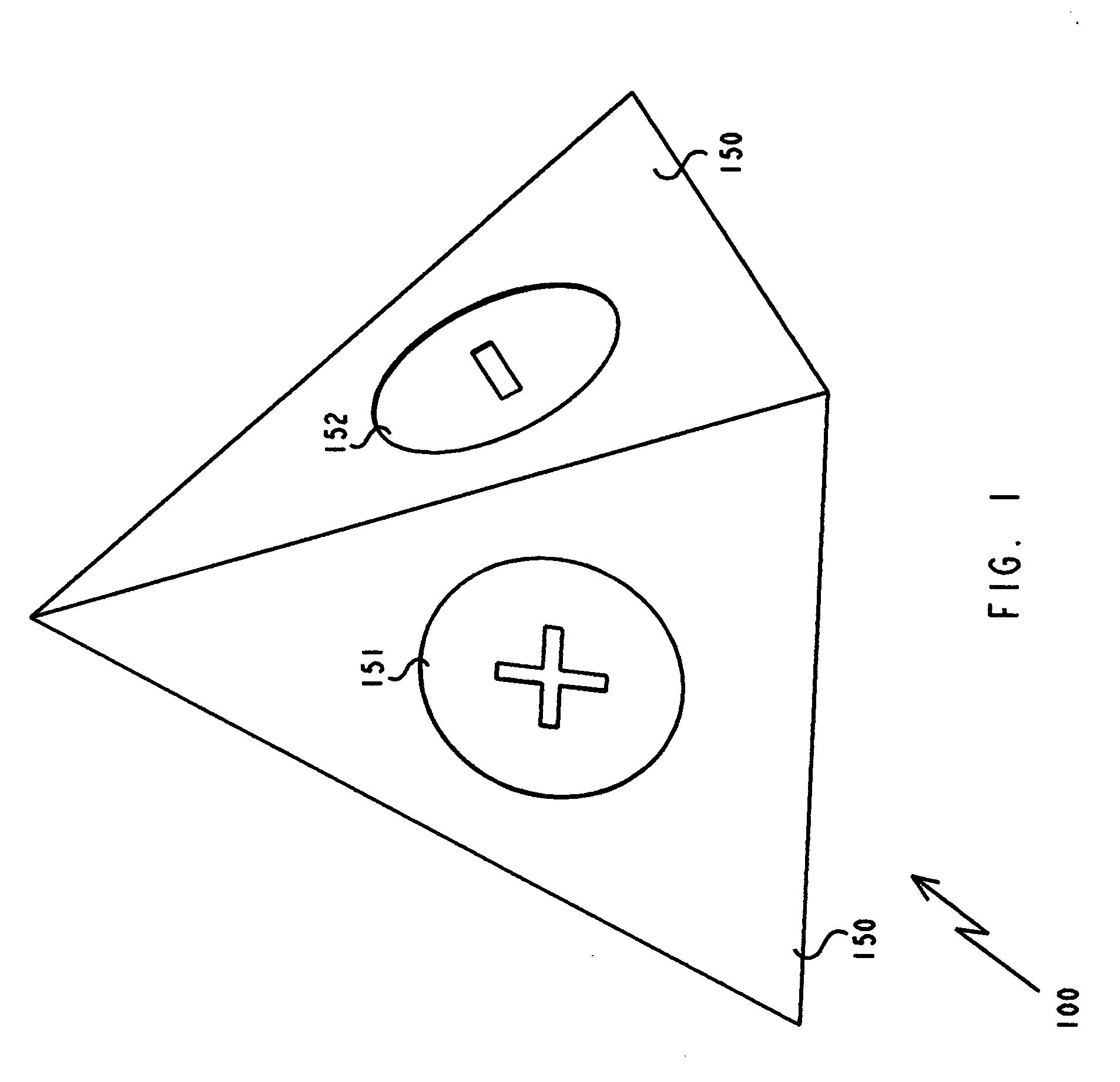

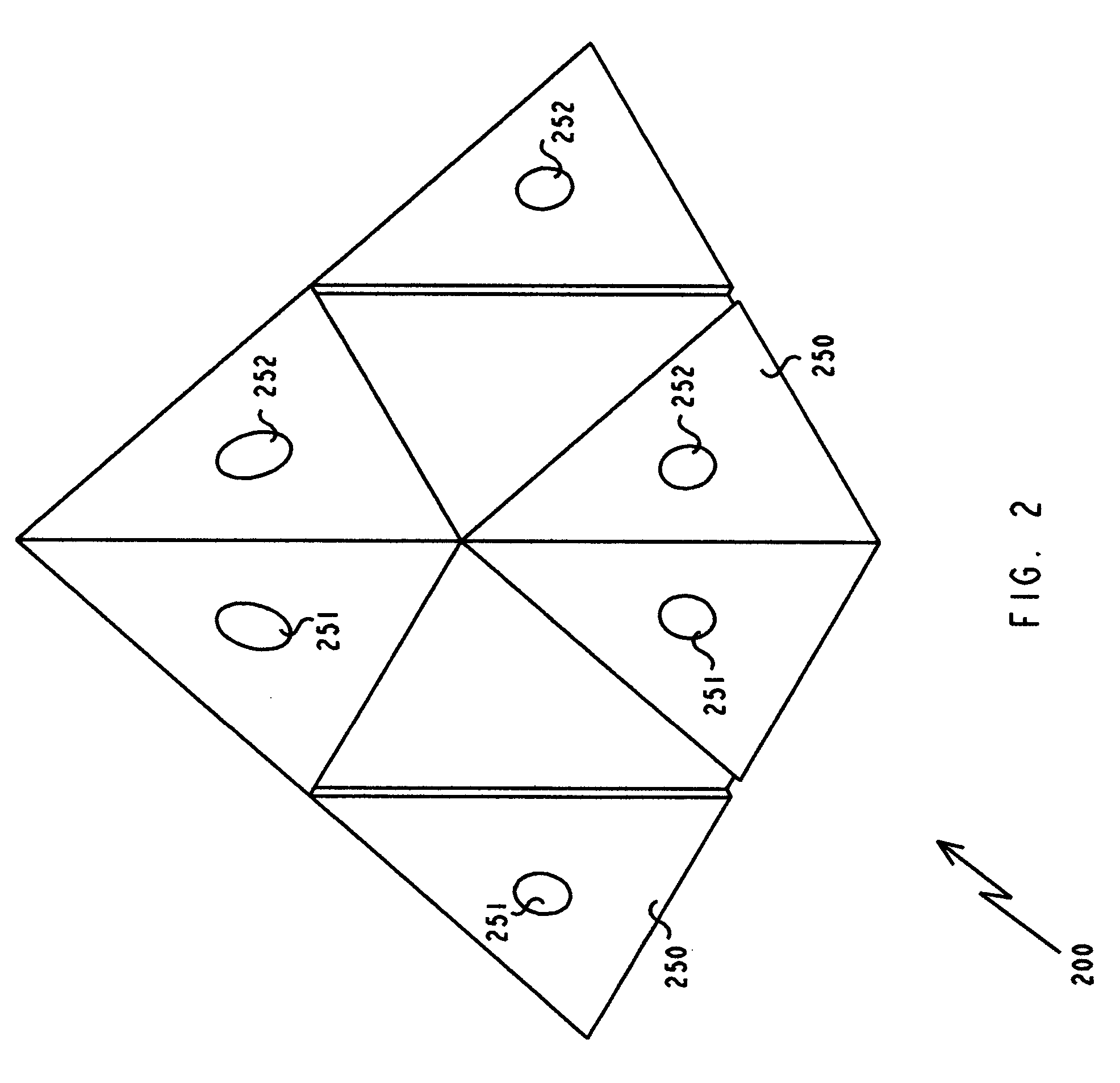

Sacred geometry educational entertainment system

Methods, devices and systems for teaching, learning and understanding sacred geometry concepts through magnetic modular toys comprising a plurality of triangular modular members assembled to form multidimensional hedrons and where in each triangular member includes a magnet such that adjacent members have opposite magnetic polarity facing each triangular member. Platonic solid shapes with interior magnets to hold forms together for construction of larger Platonic solids, geometry learning, and puzzle solving skills. Multidimensional hedrons include simple and small as ell as stellated tetrahedrons, octahedrons, icosahedrons and dodecahedrons.

Owner:FENTRESS WARREN SCOTT

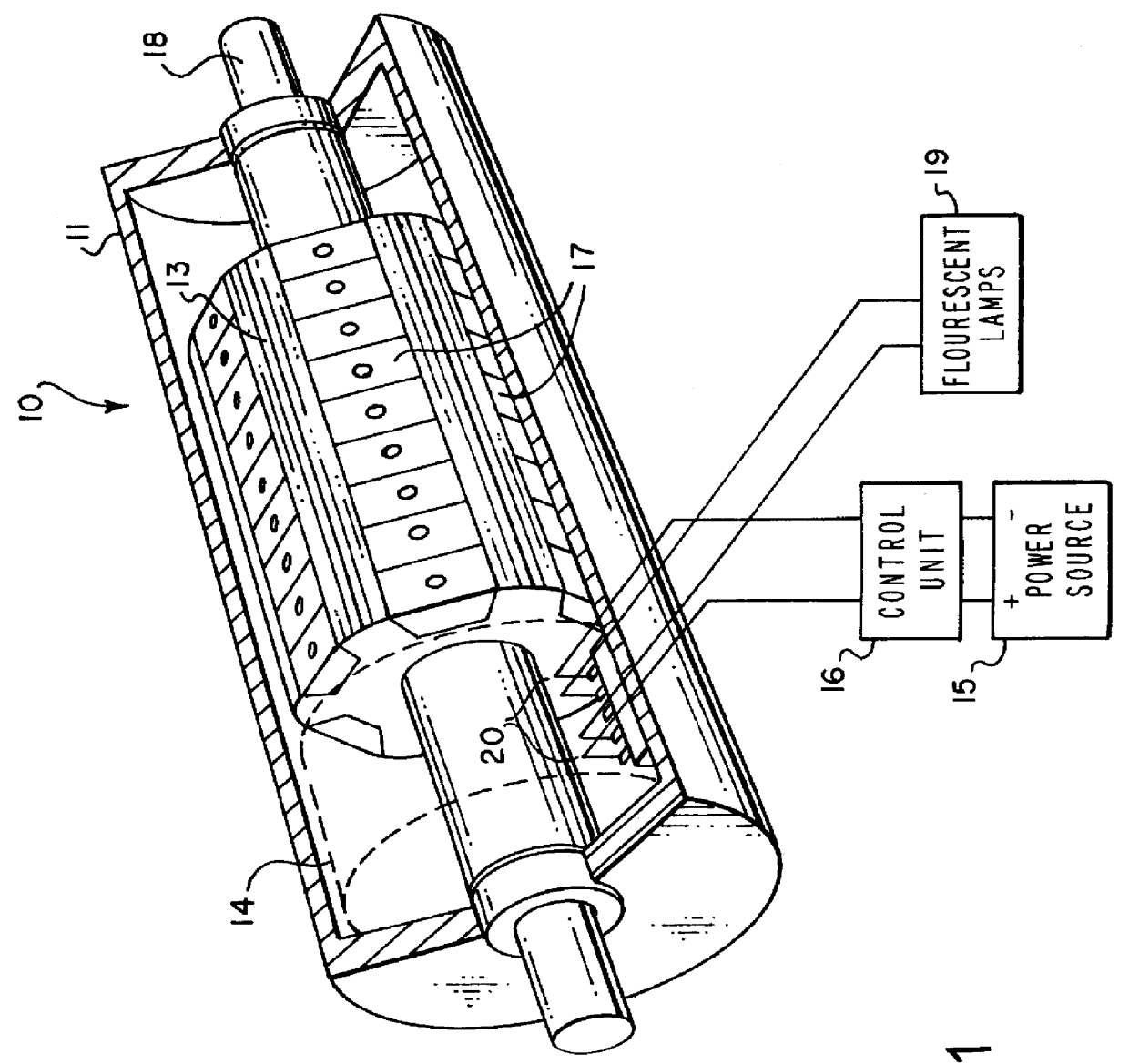

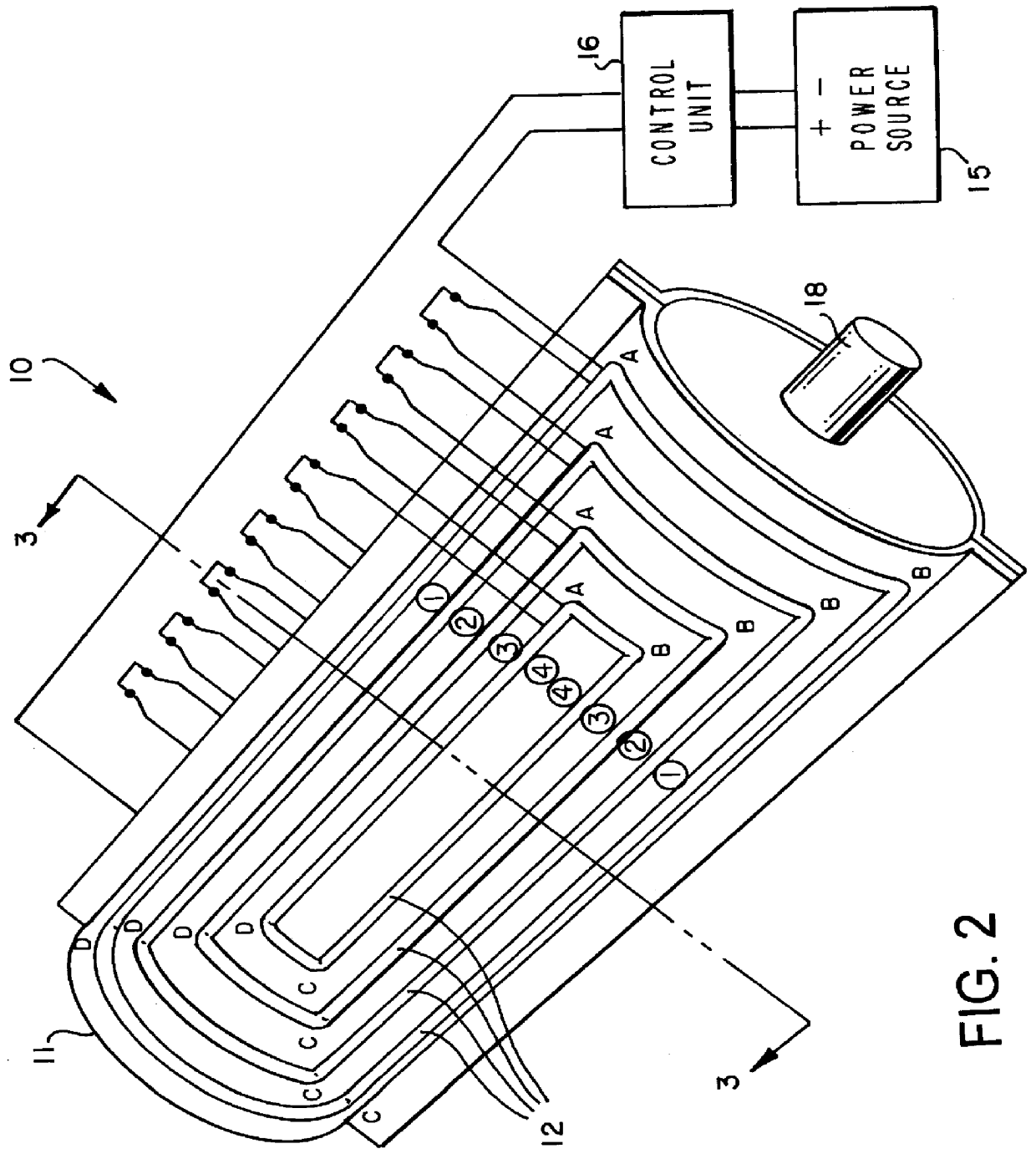

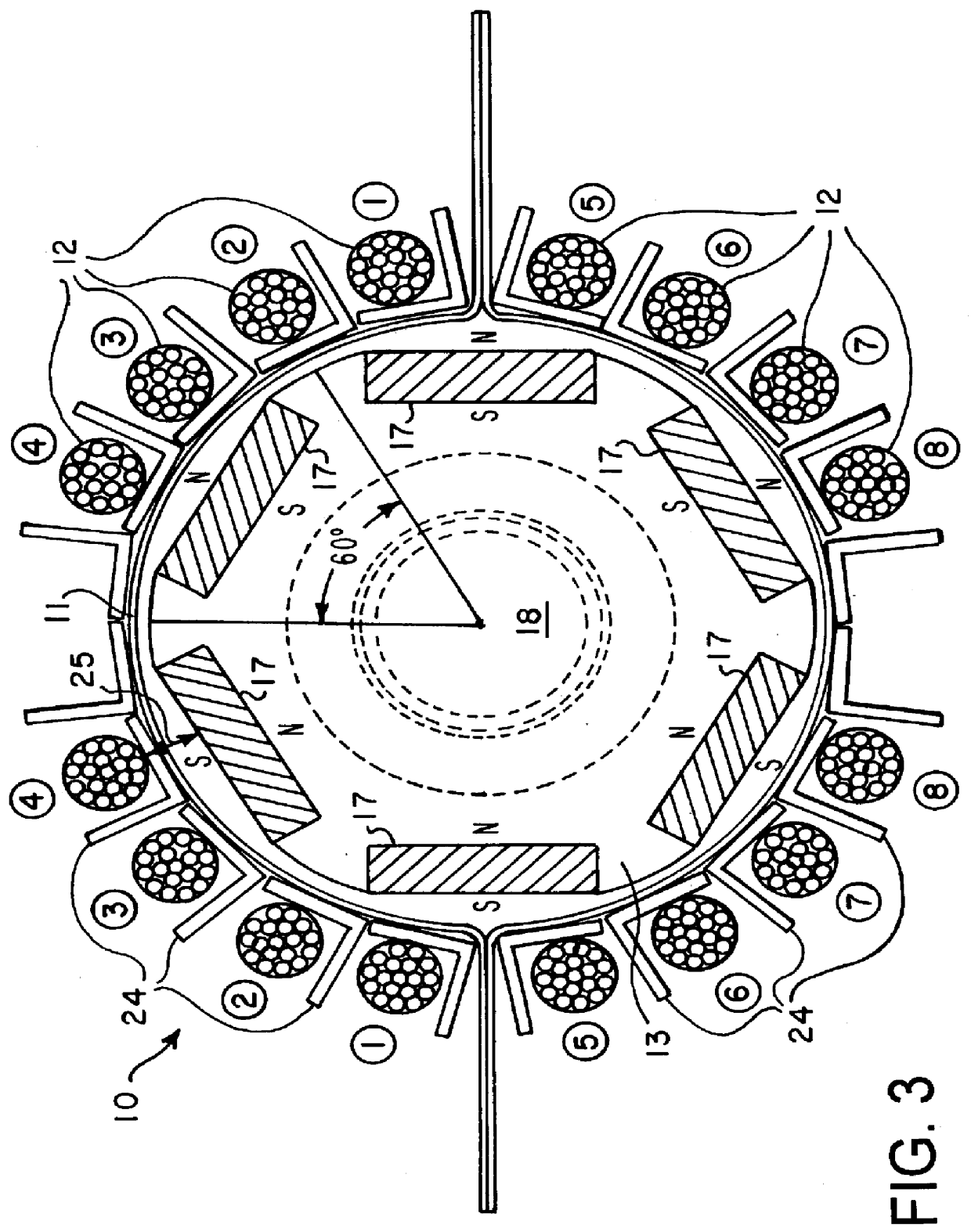

High efficiency electro-mechanical energy conversion device

An Electro-Mechanical Energy Conversion (EMEC) device and a method of electro-magnetically converting electrical energy to mechanical energy and electrical energy. The EMEC device comprises a stator; a rotor; a direct current power source; a commutator, and flourescent lamps acting as a non-linear, capacitive, voltage-limiting load. Four armature coils of a first magnetic polarity are concentrically mounted on a first side of the outer surface of a non-magnetic cylindrical stator casing, and four armature coils of an opposite polarity are concentrically mounted on an opposite side of the stator casing. Each coil is wound with an average of 6,650 turns of 34 AWG gauge teflon-coated wire. The rotor is constructed of non-magnetic material, and is rotationally mounted in the stator casing. A plurality of neodymium iron-boron permanent magnets are circumferentially mounted on the rotor. The magnets on a first side of the rotor are mounted with a first outward polarity, and the magnets on an opposite side of the rotor are mounted with an opposite outward polarity. The power source is connected to the coils and produces an output of 0-5,000 volts at 30 to 40 milliamperes maximum. The flourescent lamps are connected to the coils for rapidly dumping magnetic energy from the coils when the polarity is reversed. The commutator reverses the polarity of the first and second coils every 180 DEG of rotor rotation, and guides the magnetic energy from the coils to the load.

Owner:EMEC ENERGY L L C

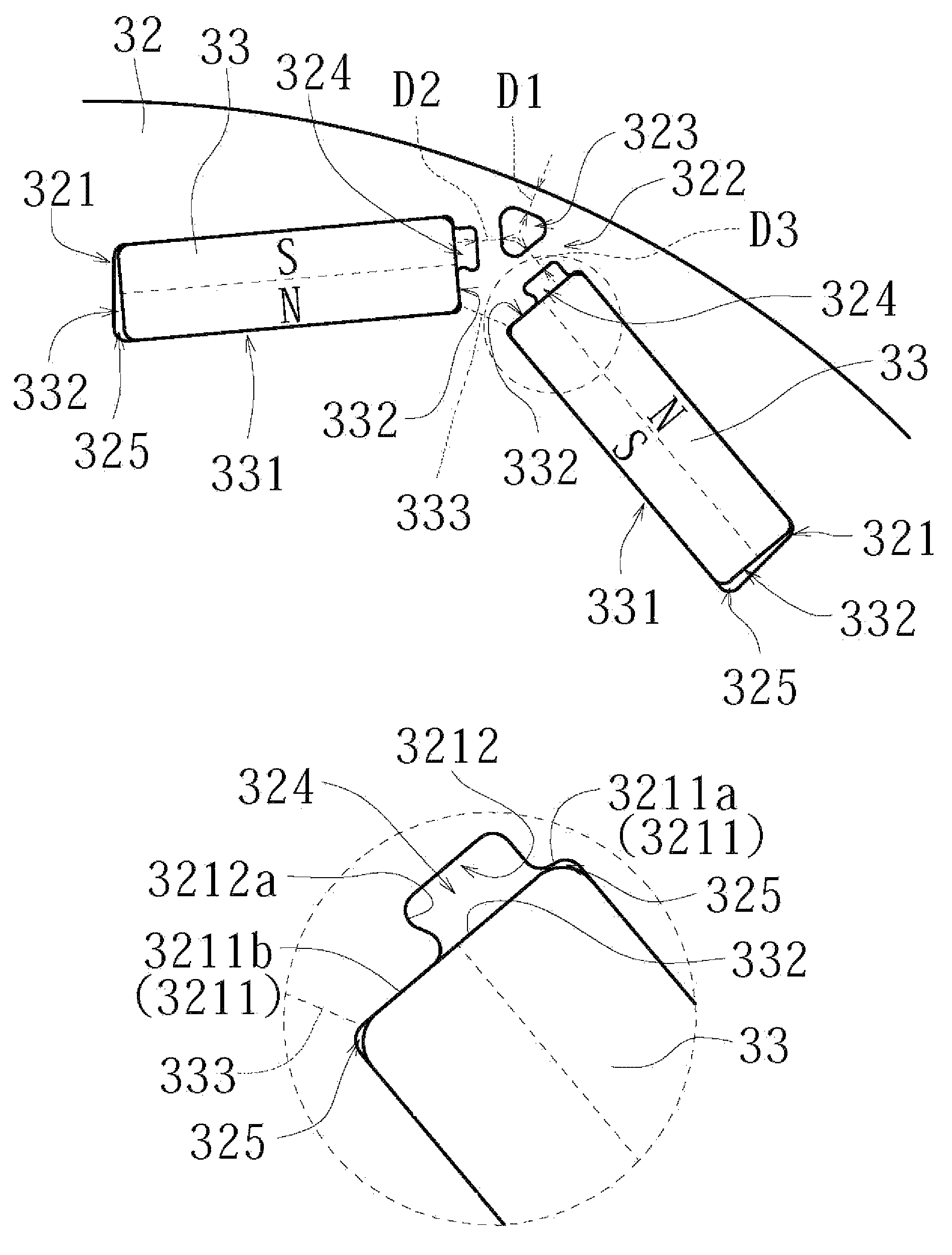

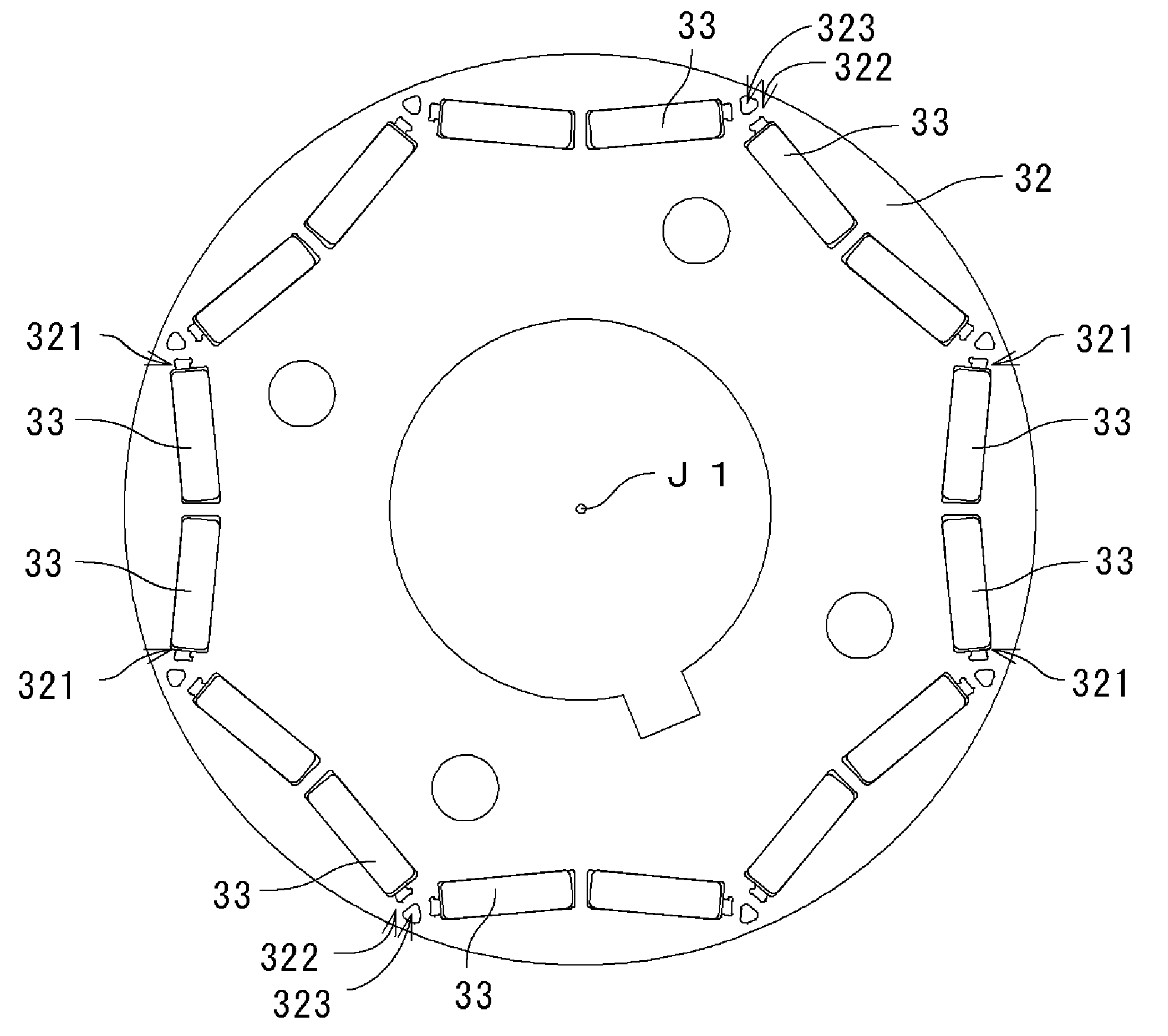

Interior permanent magnet motor

ActiveUS7612480B2Magnetic circuitSynchronous machines with stationary armatures and rotating magnetsPermanent magnet motorMagnetic polarity

A rotor portion of a motor includes a rotor core and a plurality of field magnets arranged in a circumferential direction at the rotor core. The rotor core includes at a flux barrier portion thereof arranged between a pair of field magnets of opposite magnetic polarities arranged next to one another a flux barrier hole. The flux barrier hole is independent of a magnet retaining hole in which the field magnet is retained. The magnet retaining hole includes a concave portion extending from a side thereof nearest to the flux barrier hole toward the corresponding flux barrier hole.

Owner:NIDEC CORP

Mobile device holder

A two-piece mobile device holder having a case assembly and a mounting assembly is disclosed. The case assembly is configured to receive and secure a mobile device such as a smart phone. The mounting assembly is configured to be detachably coupled to other objects. Sets of permanent magnets are arranged in a circular pattern in the case assembly and the mounting assembly. The magnets in both the first and second set of magnets are arranged with alternating magnetic polarity. As the case assembly is placed on top of the mounting assembly, the magnets in the mounting assembly will attract magnets with opposite polarities in the case assembly. A user may detach the case assembly from the mounting assembly by rotating the case assembly such that the magnets in the case assembly are now adjacent to magnets in the mounting assembly of the same polarity.

Owner:AIRO COLLECTIVE INC

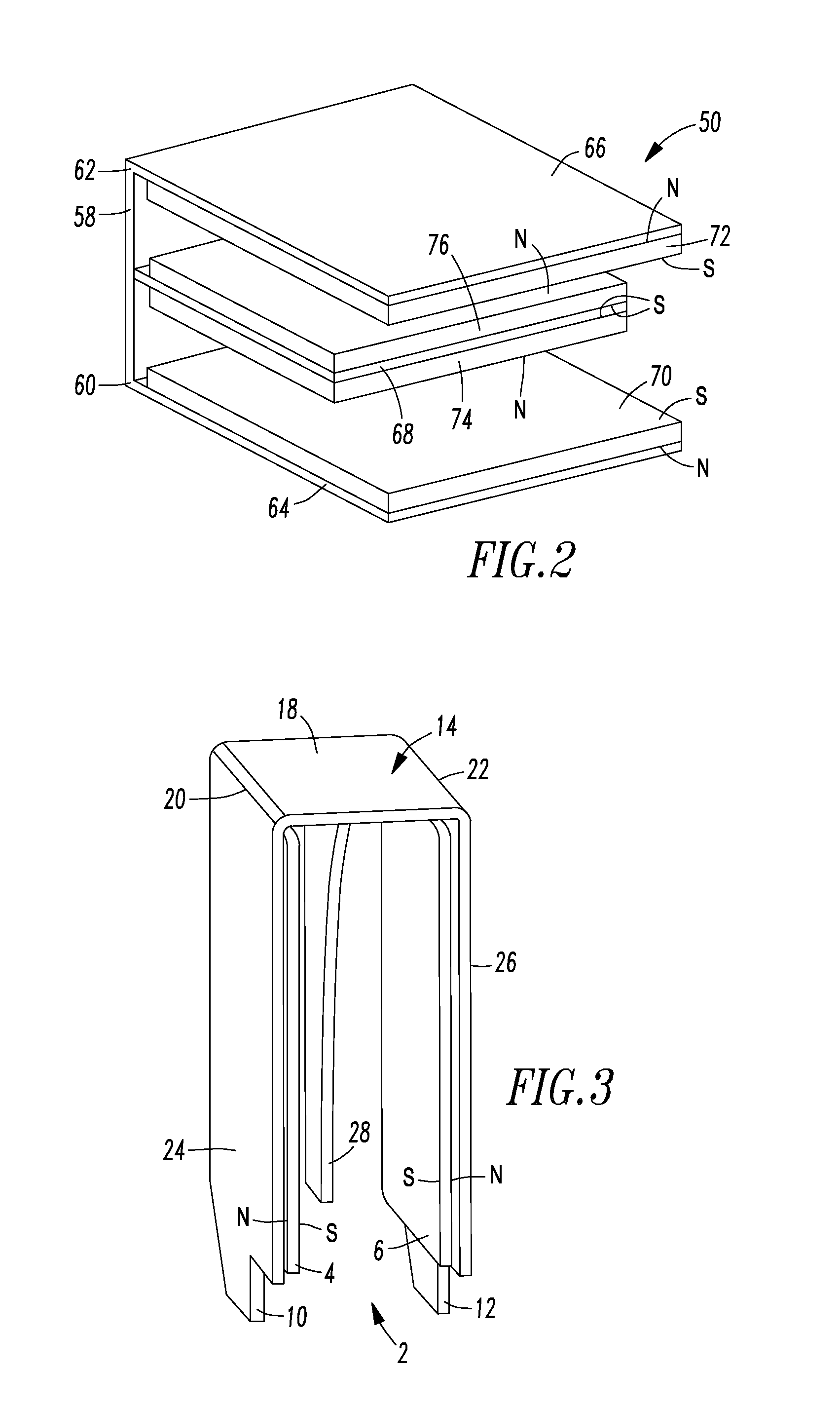

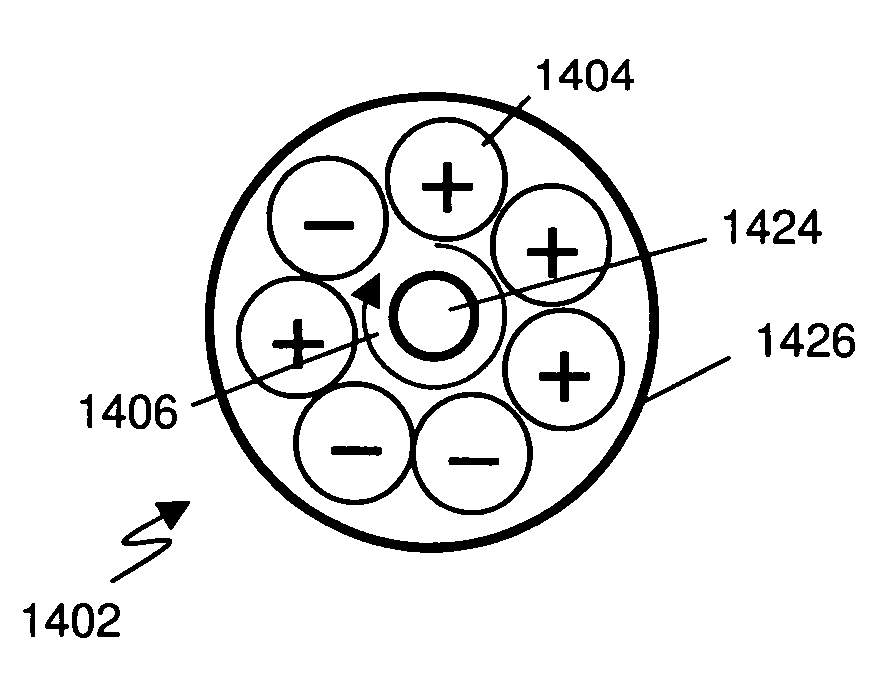

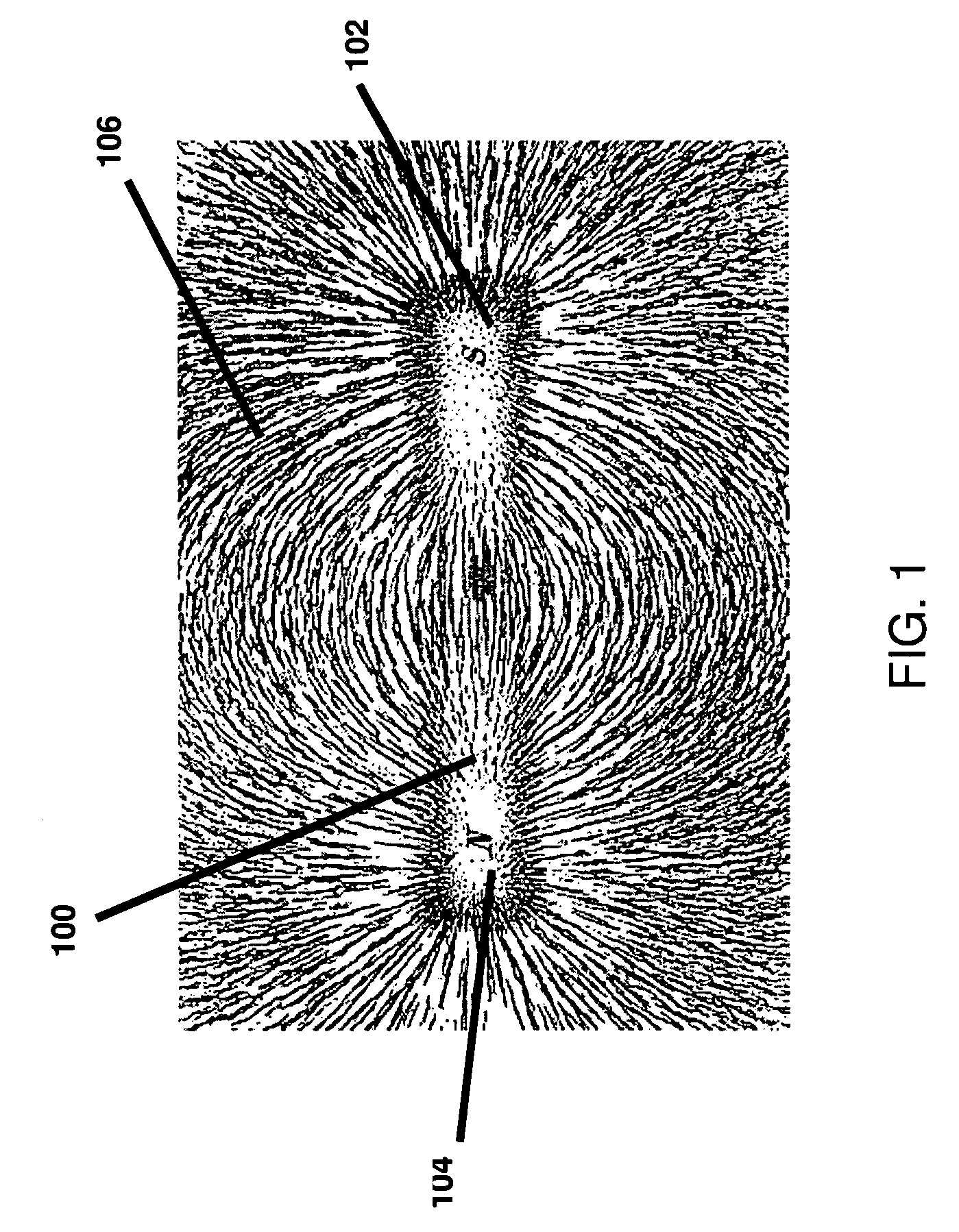

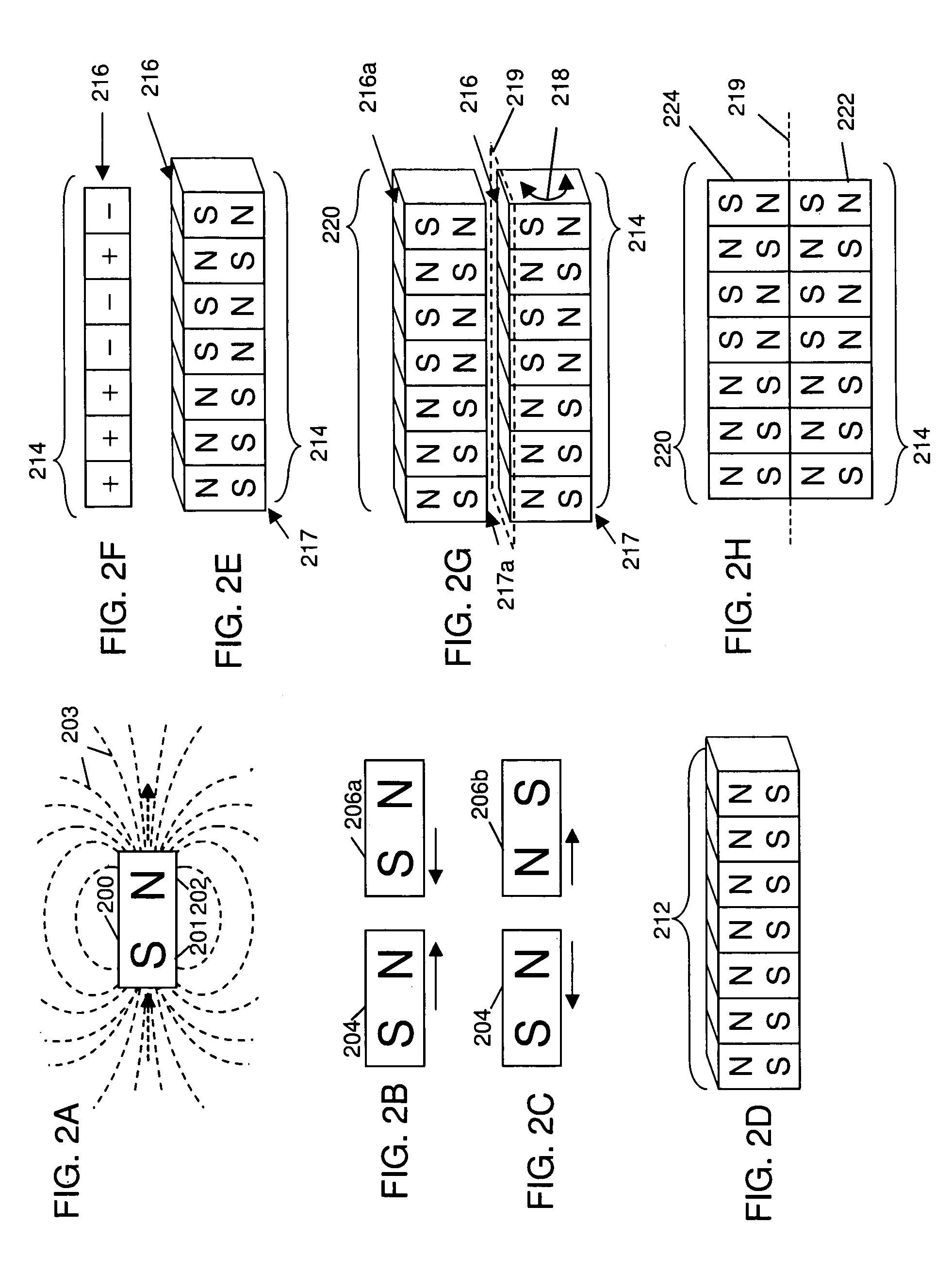

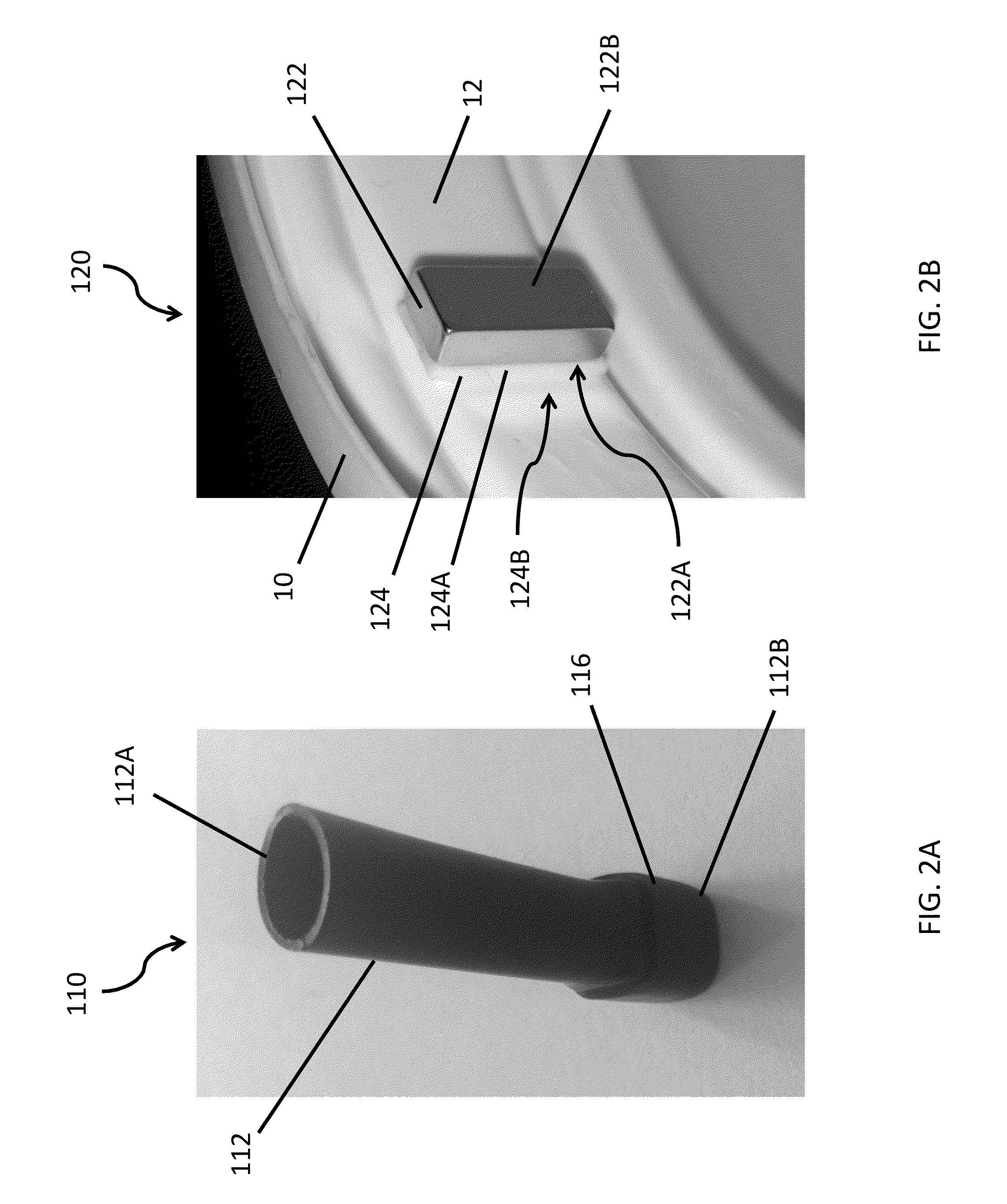

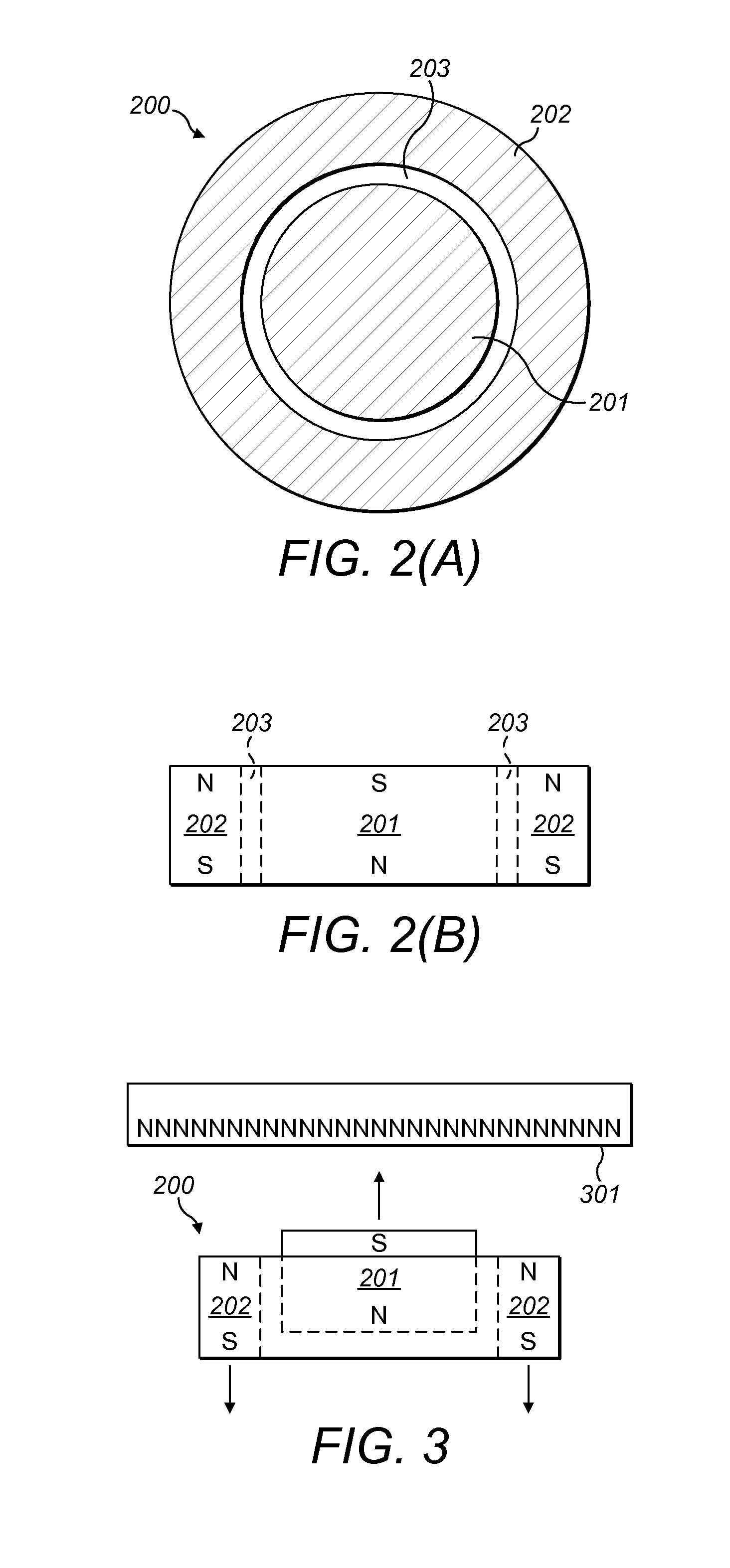

Ring magnet structure having a coded magnet pattern

InactiveUS7755462B2Electromagnets without armaturesPermanent magnetsMagnetic polarityCondensed matter physics

Field emission structures comprising a plurality of electric or magnetic field sources having magnitudes, polarities, and positions corresponding to a desired spatial force function where a spatial force is created based upon the relative alignment of a field emission structure and a complementary field emission structure. The magnetic field sources may be arranged according to a code having a desired autocorrelation function. Specific exemplary embodiments are described with magnetic field sources arranged in a ring structure. The ring structure may include one or more concentric rings of component magnets. Additional magnets may be included. Magnet polarities and / or spacings may be defined by the code Mechanical constraints may be employed to limit lateral motion. Exemplary codes are described and applied to magnetic field source arrangements. Specific codes found by the inventors are described.

Owner:CORRELATED MAGNETICS RES LLC

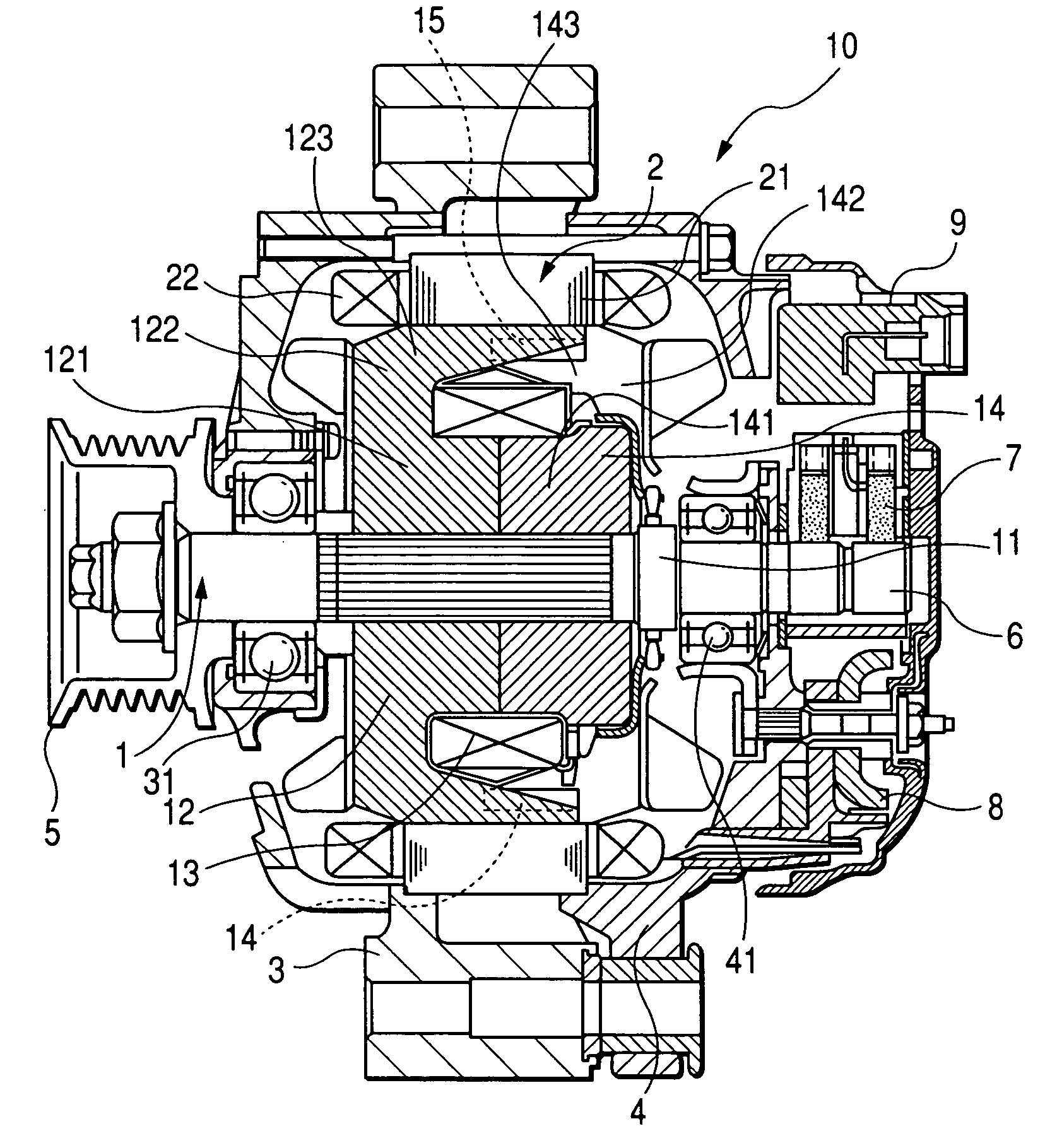

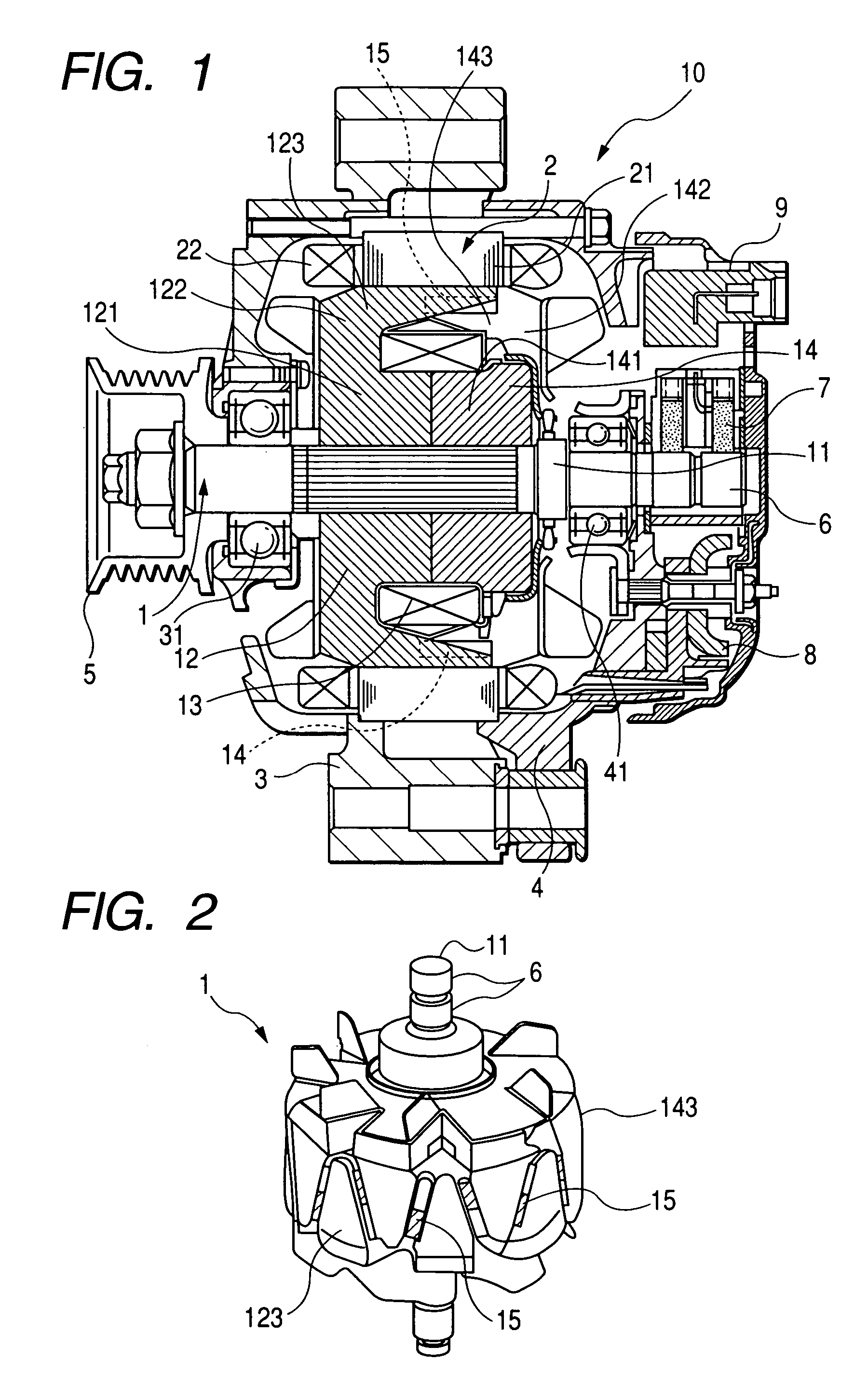

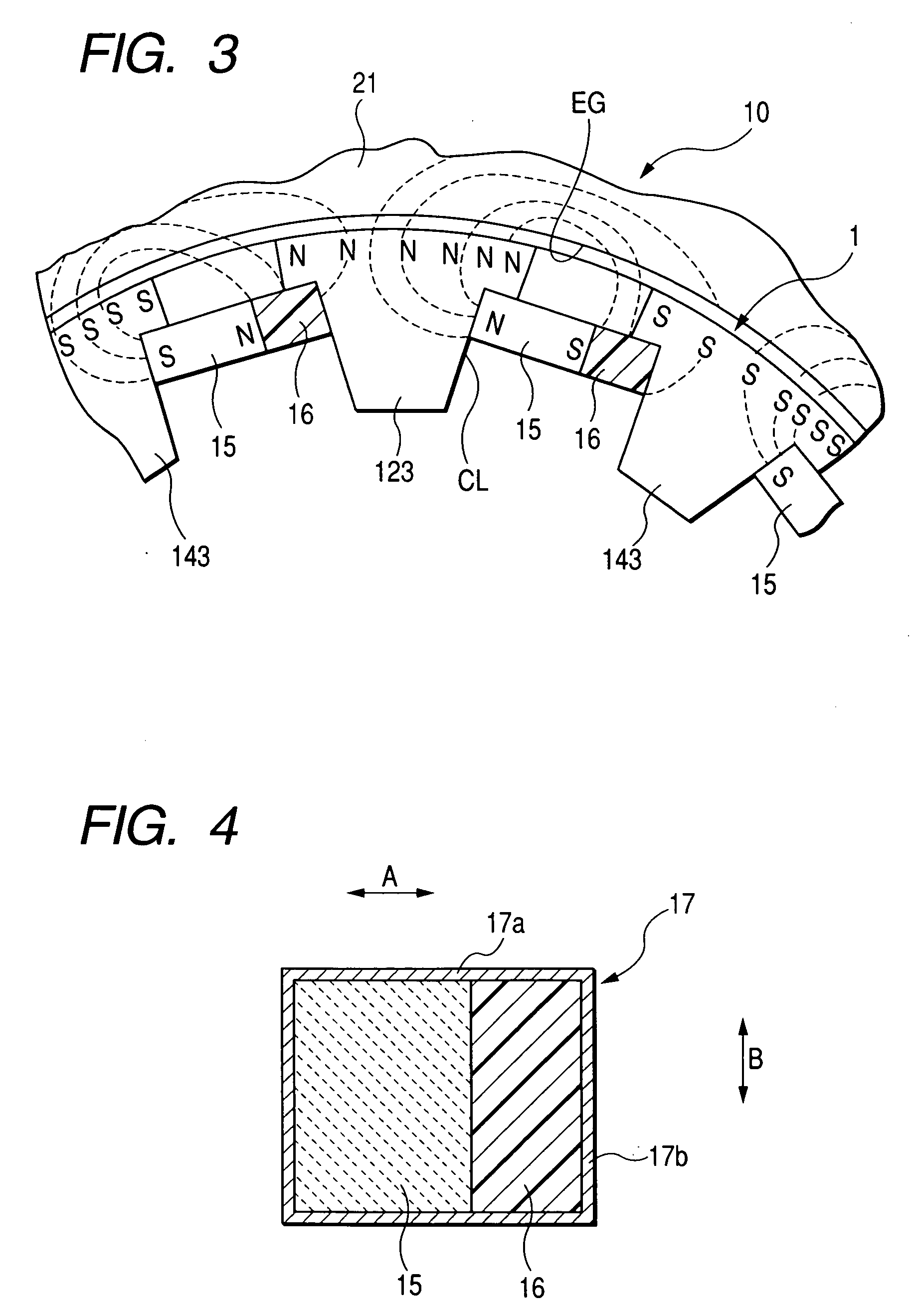

Lundell type rotor core structure and rotary electric machine employing the same

InactiveUS20070046139A1Suppression of magnetic soundSimple structureMagnetic circuit rotating partsElectric machineHarmonic

A Lundell type rotor core structure and an electric rotary machine employing the same are disclosed. The rotor core structure has first and second claw pole portions alternately placed in a circumferential direction to define clearances each having a magnet mount position deviated from an axial center of each clearance and permanent magnets alternately disposed in the magnet mount positions of the clearances with respect to the axial direction of the rotor core structure for magnetizing the first and second claw pole portions in first and second magnetic polarities, respectively, wherein each of the permanent magnets allows a greater amount of magnetic fluxes to pass through one of the first and second claw pole portions than those passing through the other one of the first and second claw pole portions for minimizing harmonic component to suppress the magnetic sound.

Owner:DENSO CORP

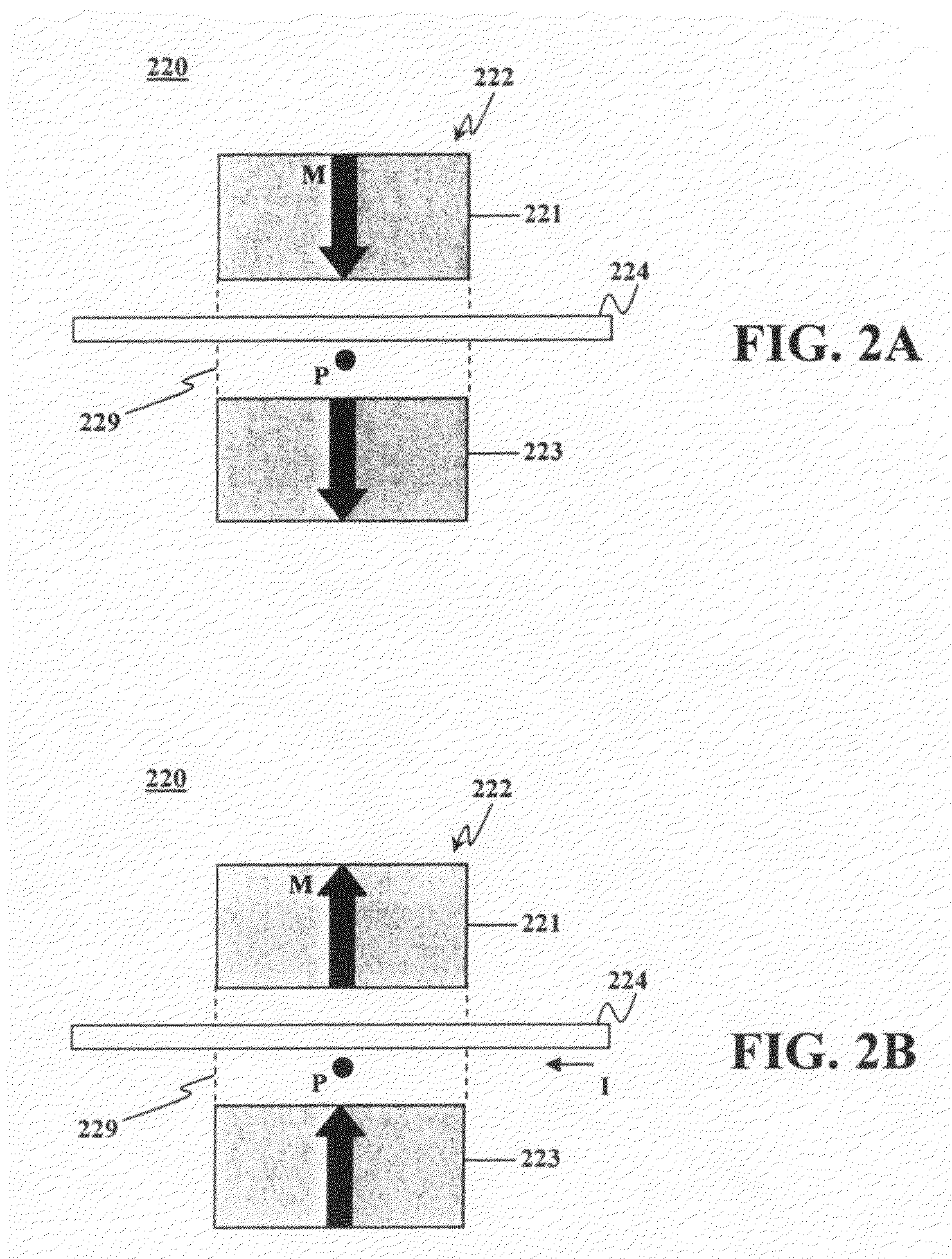

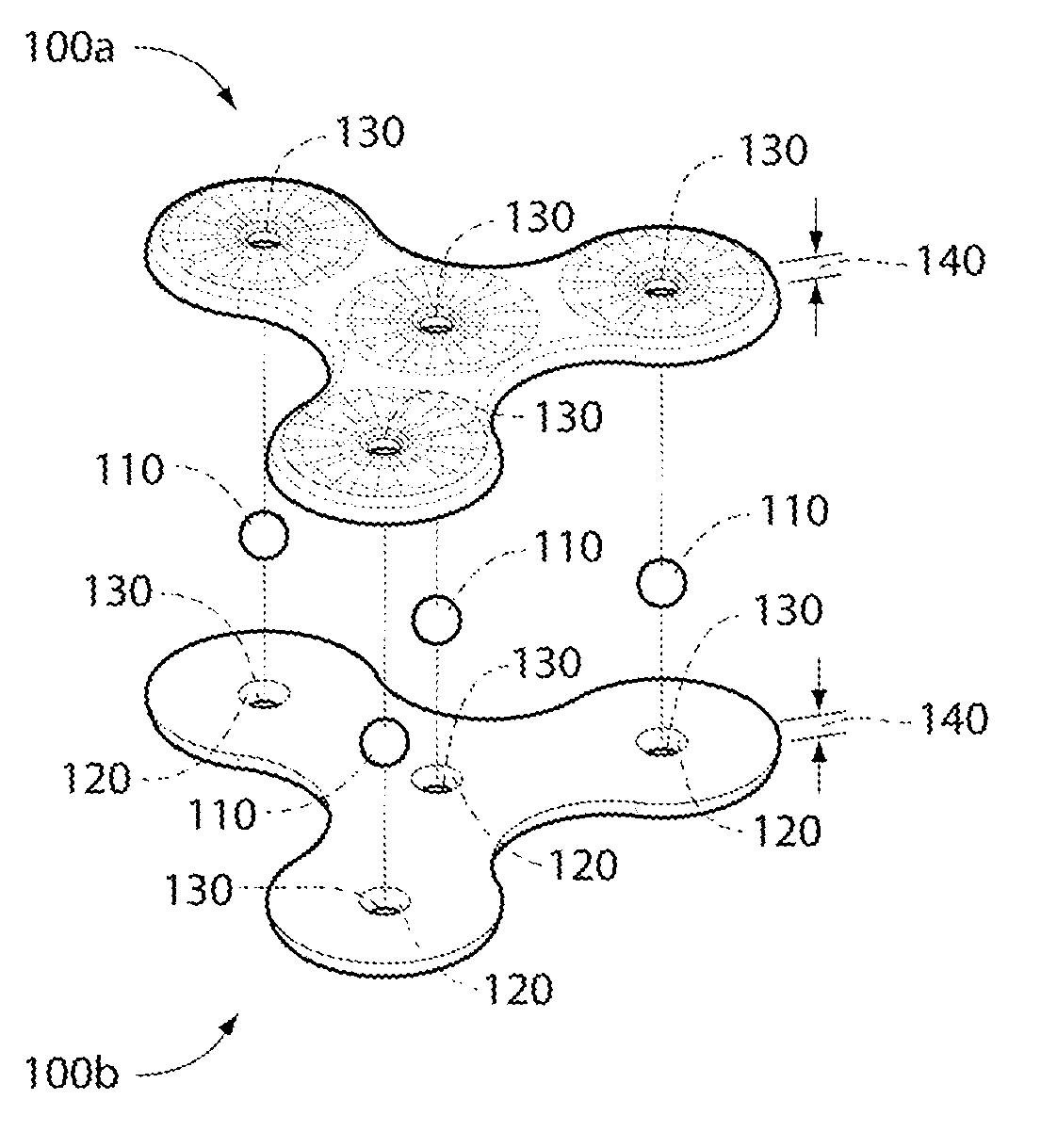

Magnetic construction system and method

ActiveUS20140213139A1Increasing magnetic coupling forceImprove abilitiesToy vehiclesMagnetic tension forceRotational stability

A magnetic construction system comprised of plural multi-shaped structural bodies each containing one or more captured magnets, wherein each magnet is free to rotate within its respective retaining pocket to align in magnetic polarity with rotatable magnets in adjacent structural bodies. Surface geometry around each magnet may include a radial detent feature which provides lateral and rotational stability between magnetically coupled structural bodies, or a radial recess which allows free rotation of respective structural bodies about the polar axis of magnetic coupling.

Owner:FERGUSON JOSHUA WILLARD

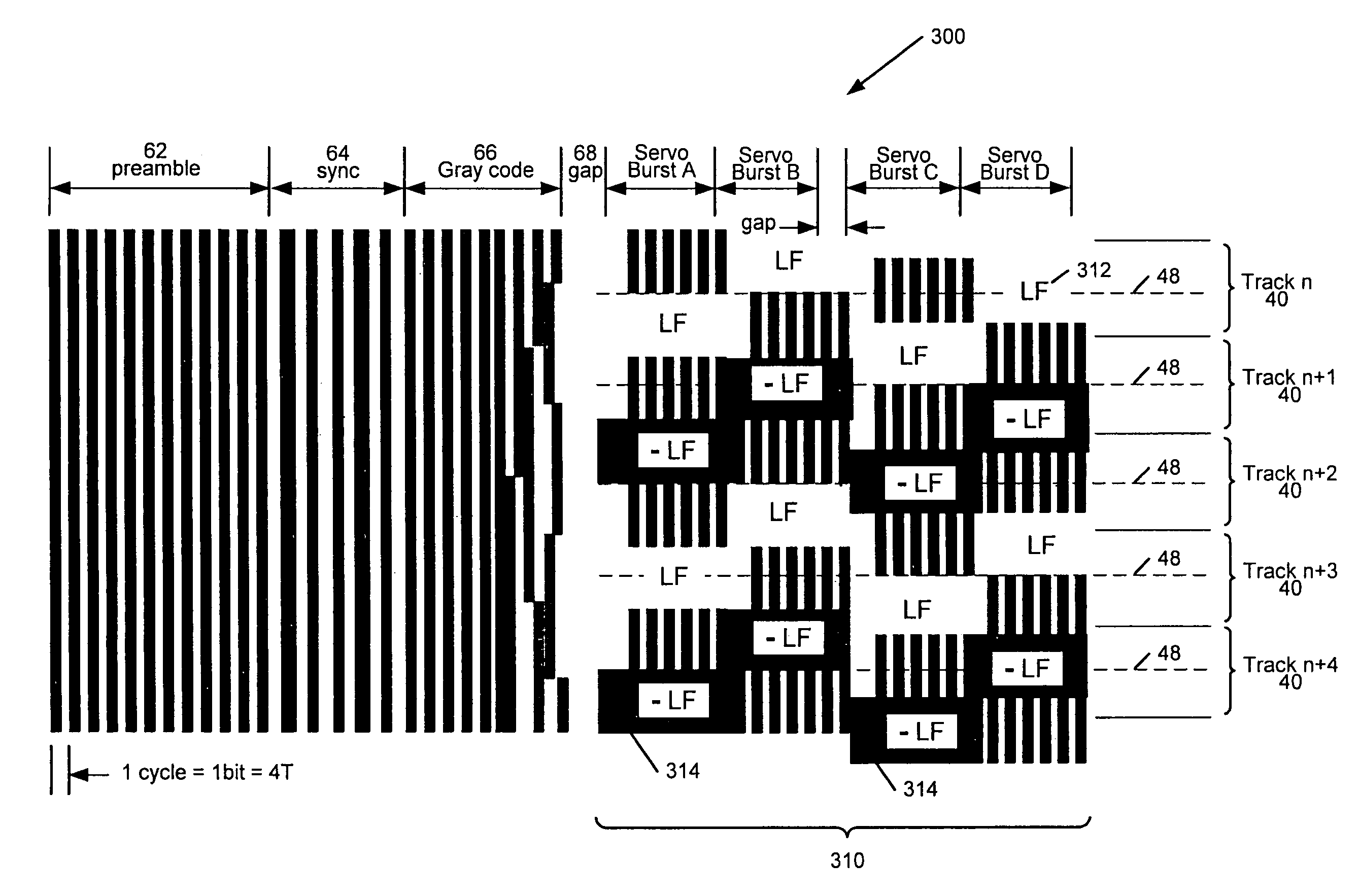

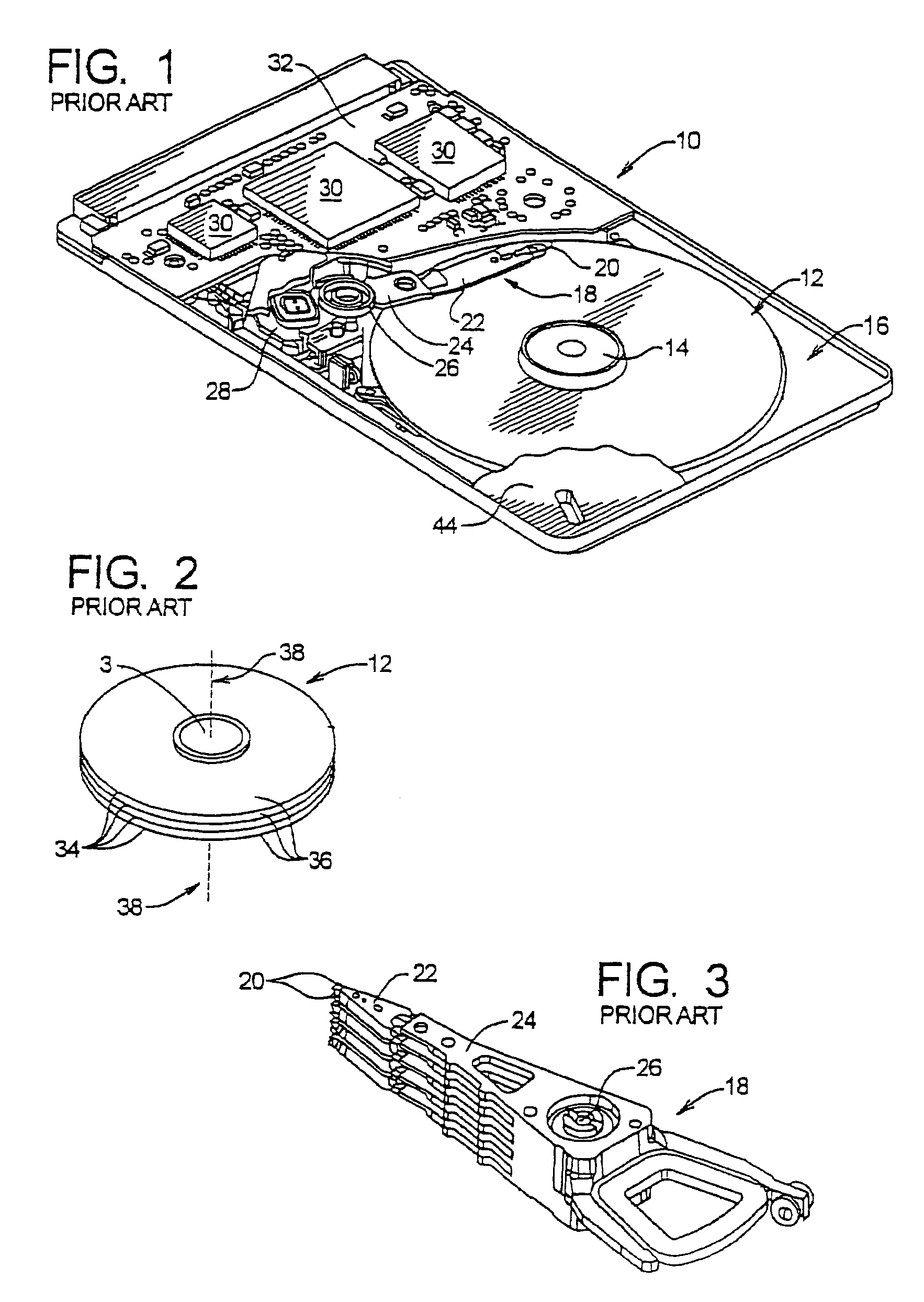

Magnetic disk drive with servo bursts and alternating magnetic polarity regions therebetween

InactiveUS7230790B1Record information storageAlignment for track following on disksMagnetic polesControl theory

A disk drive includes a data storage disk that has servo information thereon which includes first servo bursts and second servo bursts. The first servo bursts are at least substantially radially aligned with each other, and have low frequency regions therebetween. Adjacent ones of the low frequency regions between the first servo bursts have magnetic polarities that are opposite to one another. The second servo bursts are at least substantially radially aligned with each other and have low frequency regions therebetween. The first and second servo bursts are in a single servo region.

Owner:MAXTOR

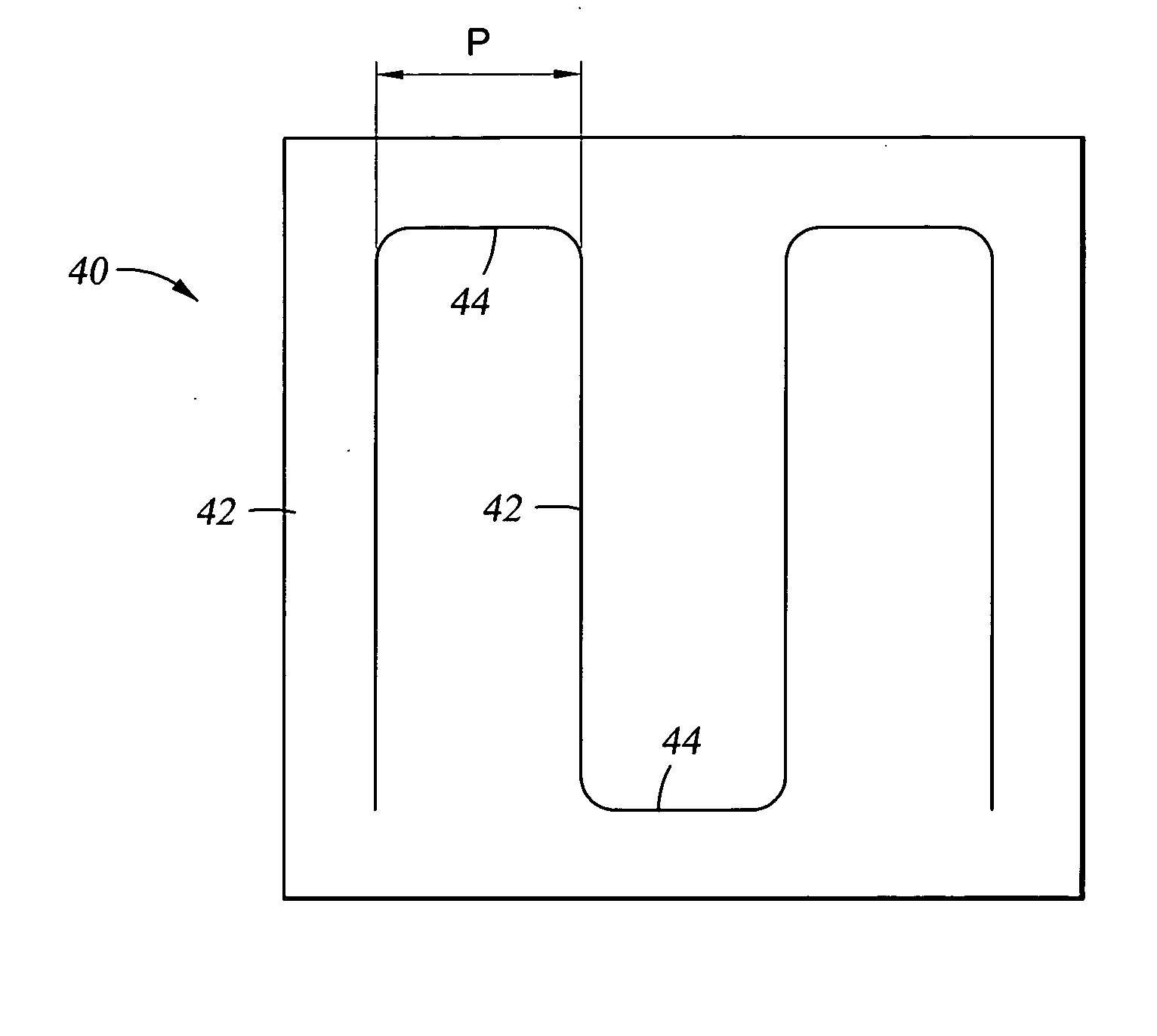

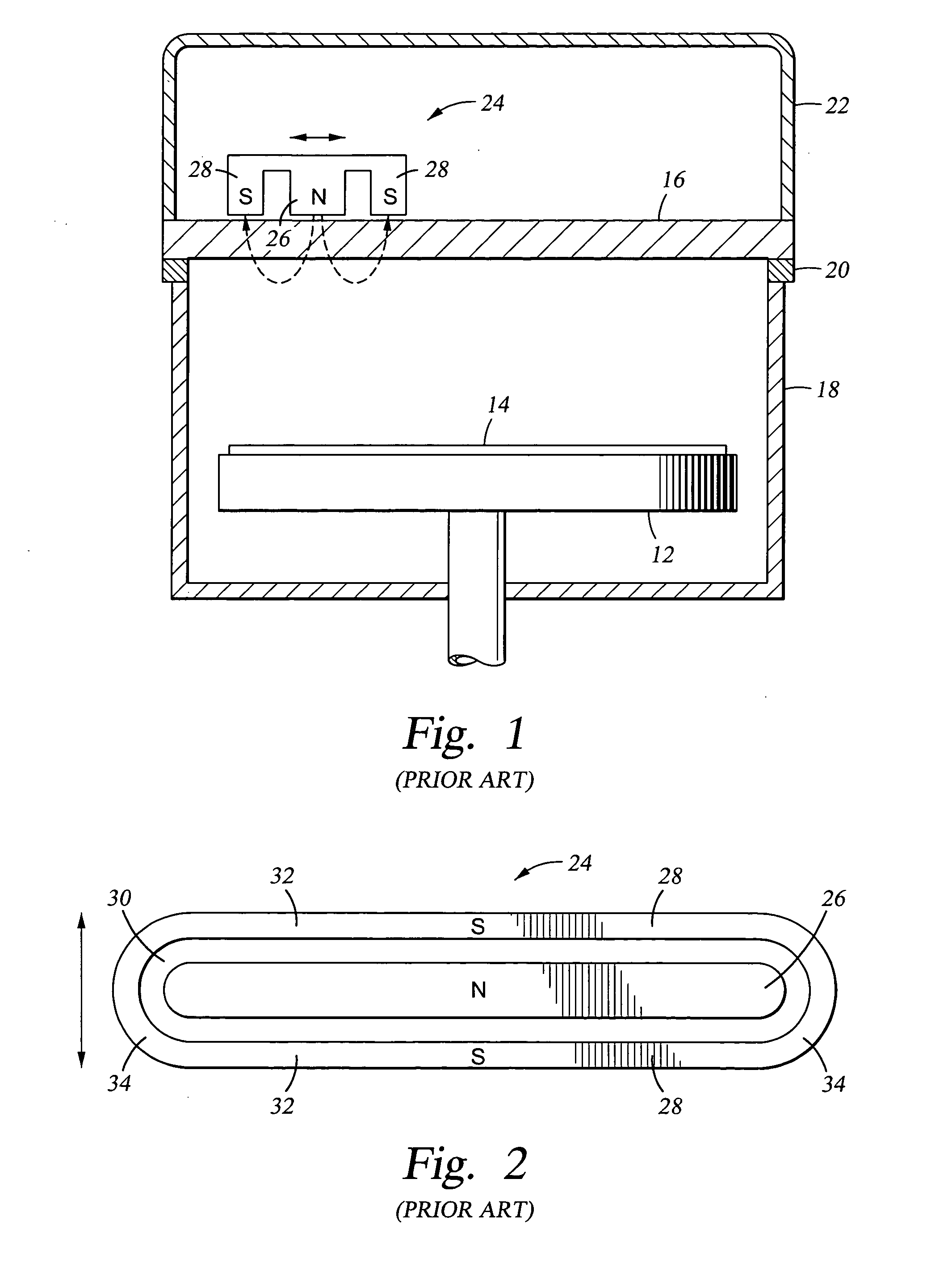

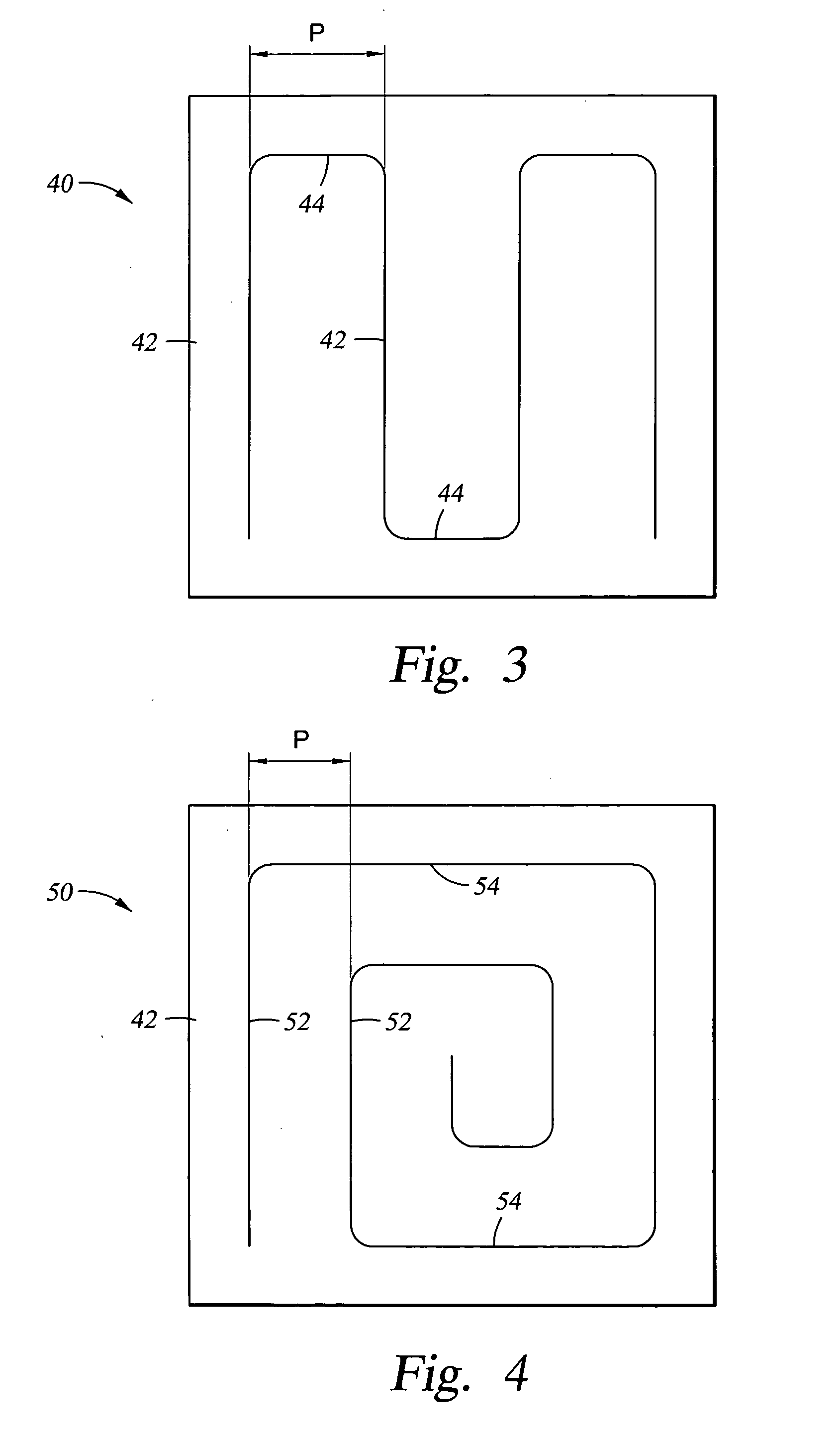

Two dimensional magnetron scanning for flat panel sputtering

InactiveUS20050145478A1Uniformity of sputter erosionImprove uniformityCellsElectric discharge tubesSputteringDiagonal

A generally rectangular magnetron placed at the back of a rectangular target to intensify the plasma in a sputter reactor configured for sputtering target material onto a rectangular panel. The magnetron has a size only somewhat less than that of the target and is scanned in the two perpendicular directions of the target with a scan length of, for example, about 100 mm for a 2 m target. The scan may follow a double-Z pattern along two links parallel to a target side and the two connecting diagonals. The magnetron includes a closed plasma loop formed in a convolute shape, for example, serpentine or rectangularized helix with an inner pole of nearly constant width extending along a single path and having one magnetic polarity completely surrounded by an outer pole having the opposed polarity.

Owner:APPLIED MATERIALS INC

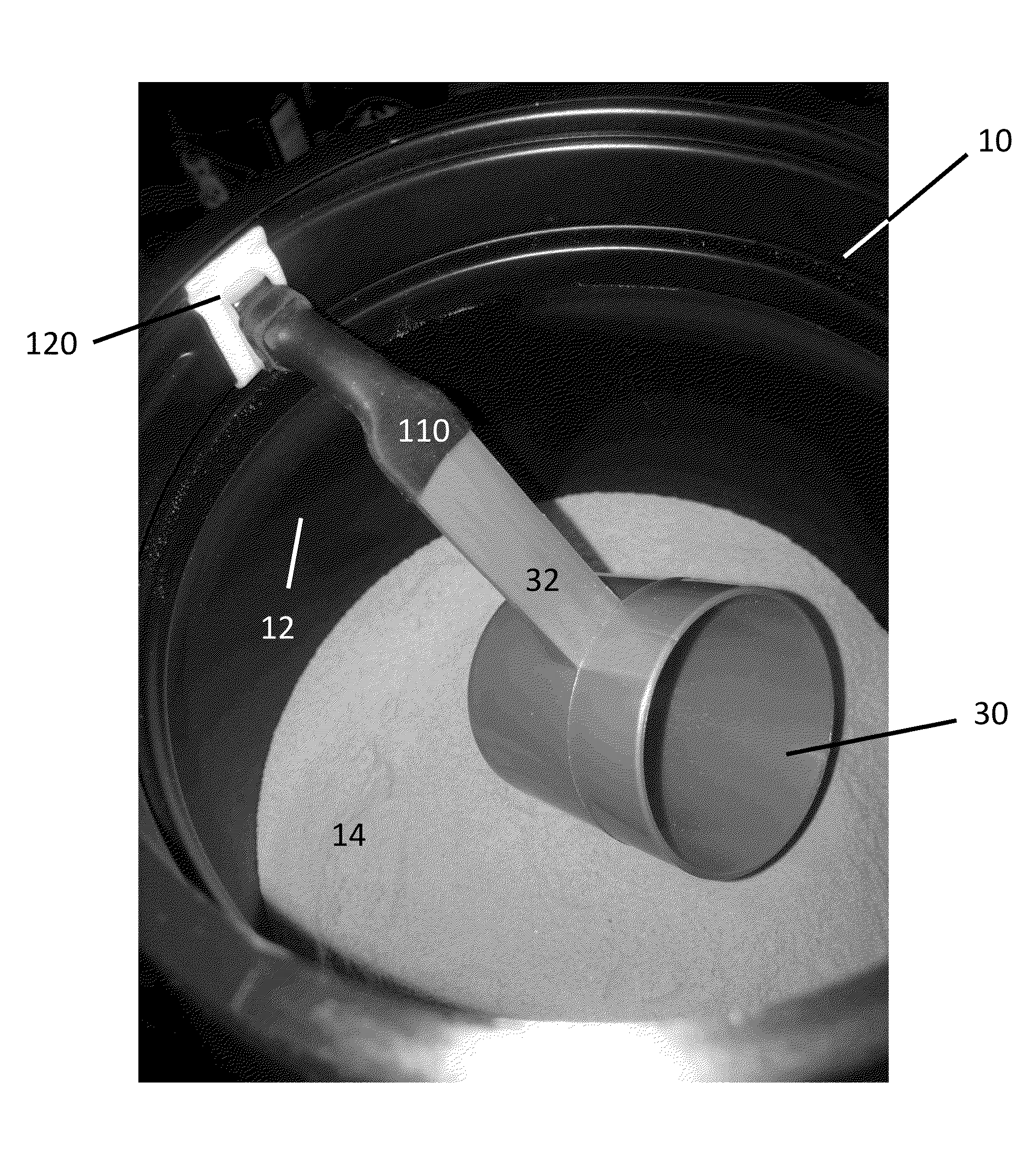

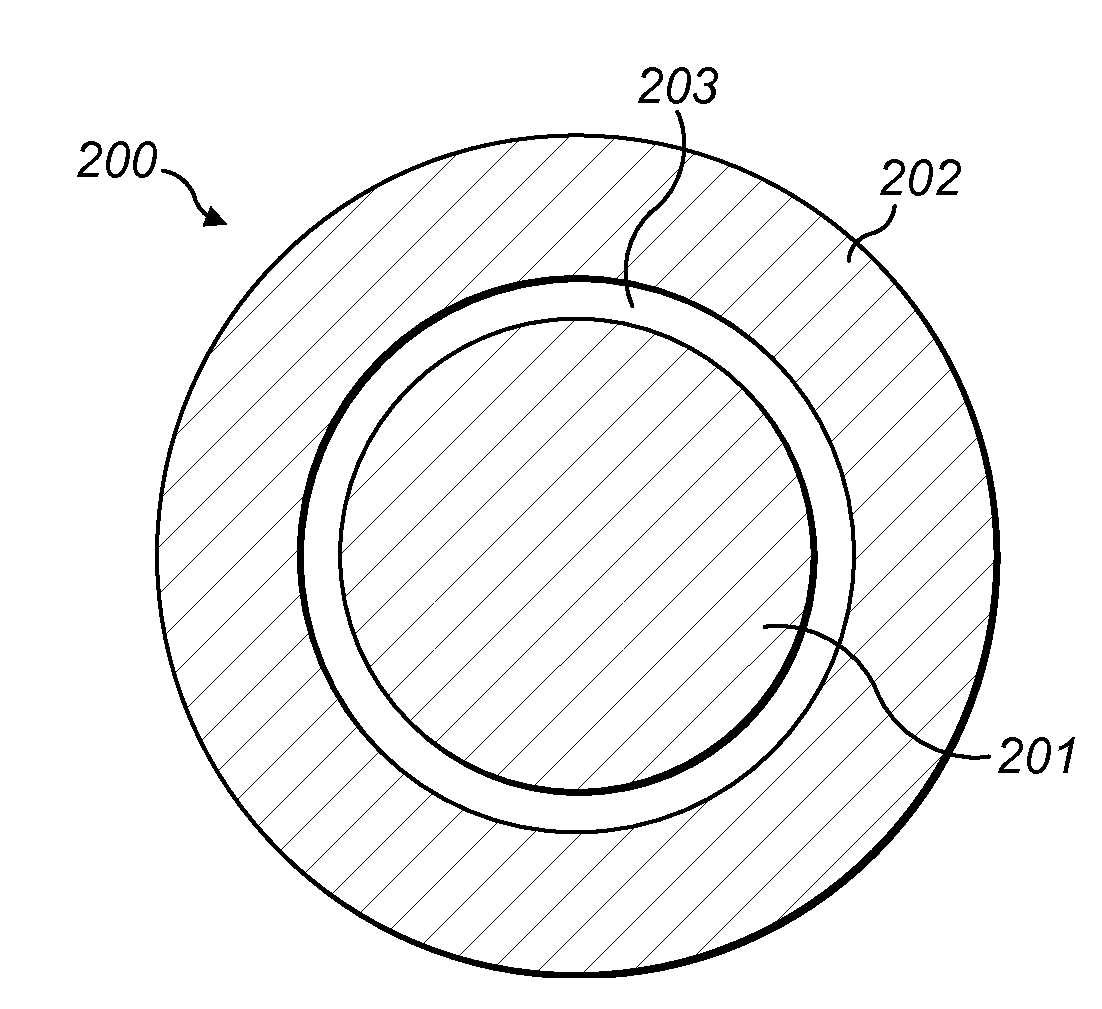

Scoop retention device

A scoop retention device is provided, comprising: a first length of flexible tubing having openings at each of first and second ends, the first length of tubing being configured to receive and retain a handle of a scoop within the first opening; a first magnet secured within the opening at the second end of the first length of tubing and having an exposed surface associated with a first magnetic polarity; and a second magnet securable to the inside of a container having a surface associated with a second magnetic polarity opposite the first polarity and facing the inside of the container; whereby, the scoop is removably secured to the inside of the container by magnetic attraction between the first and second magnets.

Owner:THE MENTALITY

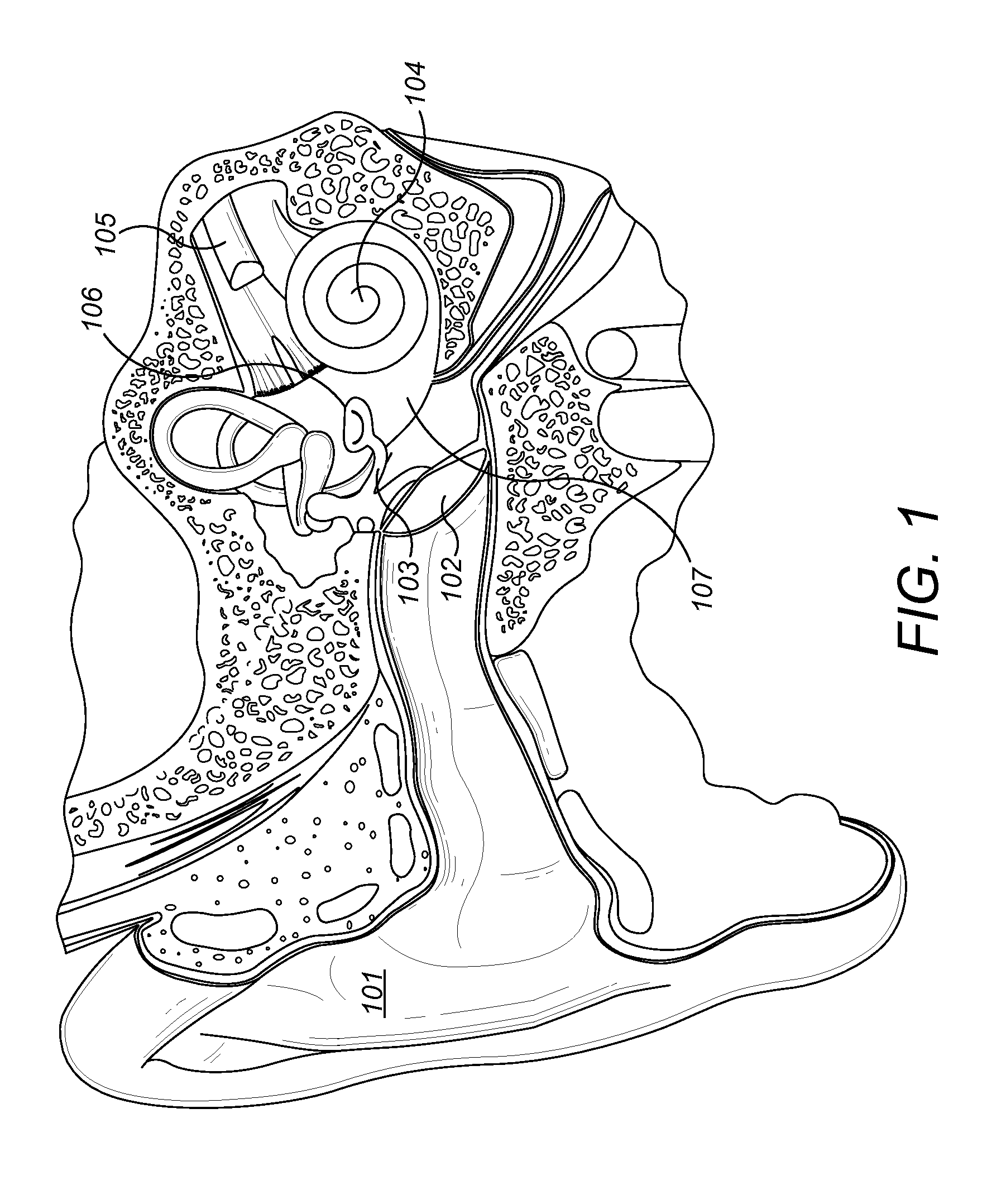

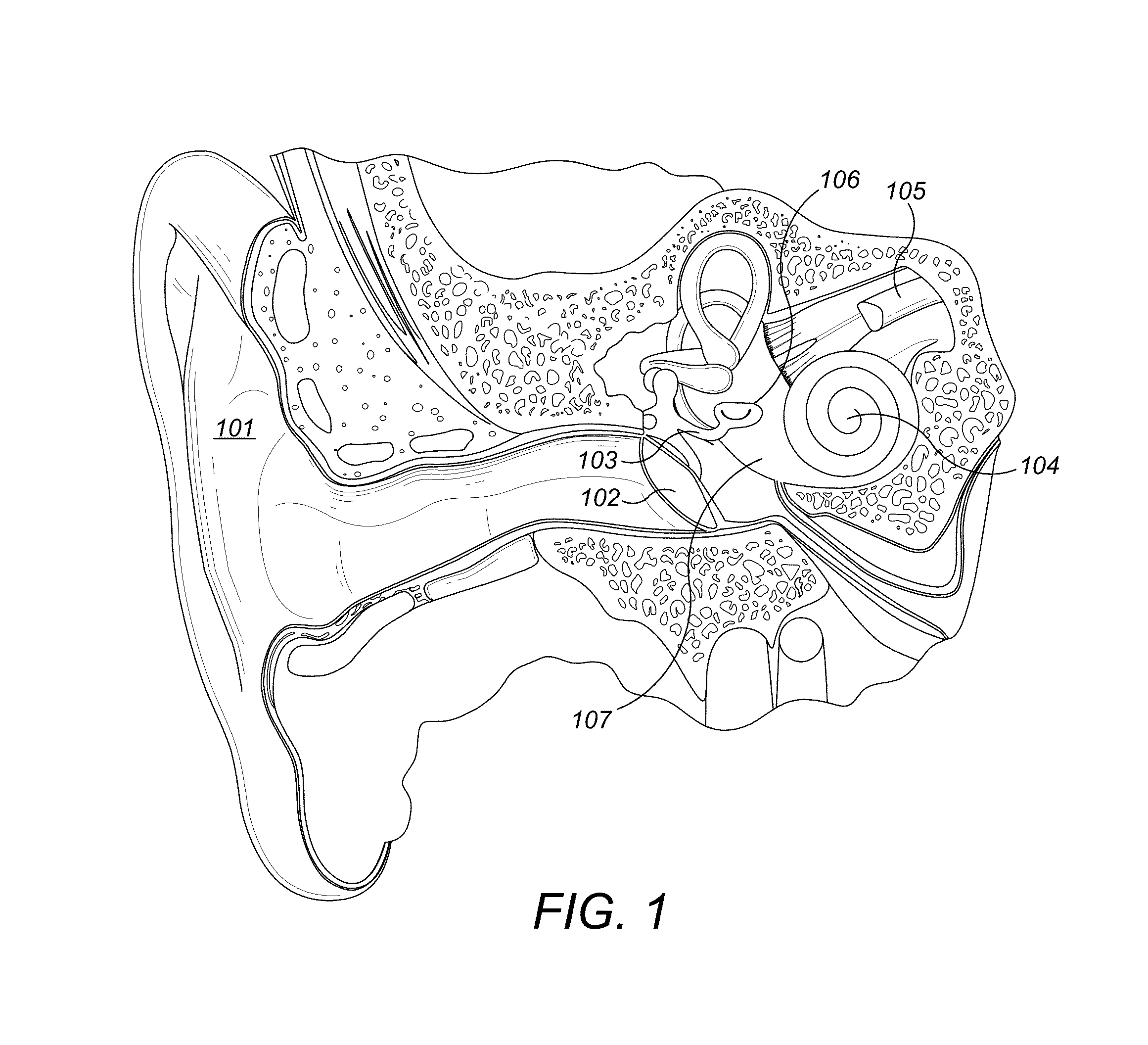

Magnet Arrangement for Bone Conduction Hearing Implant

An implantable magnetic transducer arrangement is described for a hearing implant in a recipient patient. An implant housing hermetically encapsulates an interior housing volume and is fixedly attached to skull bone beneath the skin of the patient. A magnetic transducer is located within the housing volume and includes multiple permanent magnets wherein adjacent magnets have opposite magnetic polarities, and one or more suspension elements that resiliently couple adjacent magnets to allow their relative movement. The magnetic transducer forms a coupled oscillating system with an external magnetic drive component above the skin of the patient to develop a mechanical stimulation signal to the implant housing for delivery by bone conduction of the skull bone as an audio signal to the cochlea of the patient.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

Motor

ActiveUS20080136281A1Magnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polarityPhysics

A rotor portion of a motor includes a rotor core and a plurality of field magnets arranged in a circumferential direction at the rotor core. The rotor core includes at a flux barrier portion thereof arranged between a pair of field magnets of opposite magnetic polarities arranged next to one another a flux barrier hole. The flux barrier hole is independent of a magnet retaining hole in which the field magnet is retained. The magnet retaining hole includes a concave portion extending from a side thereof nearest to the flux barrier hole toward the corresponding flux barrier hole.

Owner:NIDEC CORP

Single direct current arc chamber, and bi-directional direct current electrical switching apparatus employing the same

ActiveUS20120145675A1High-tension/heavy-dress switchesAir-break switchesEngineeringMagnetic polarity

A single direct current arc chamber includes a ferromagnetic base having first and opposite second ends, a first ferromagnetic side member disposed from the first end, a second ferromagnetic side member disposed from the opposite second end, a third ferromagnetic member disposed from the ferromagnetic base intermediate the ferromagnetic side members, a first permanent magnet having a first magnetic polarity disposed on the first ferromagnetic side member and facing the third ferromagnetic member, and a second permanent magnet having the first magnetic polarity disposed on the second ferromagnetic side member and facing the third ferromagnetic member.

Owner:EATON INTELLIGENT POWER LIMITED

Magnet arrangement for bone conduction hearing implant

An implantable magnet arrangement is described for a hearing implant in a recipient patient. A pair of implant magnets are fixable in a common plane beneath the skin of the patient to underlying skull bone. At least one of the magnets is adapted to transform a magnetic drive signal from an external signal drive coil into a corresponding mechanical stimulation signal for delivery by bone conduction of the skull bone as an audio signal to the cochlea. Each implant magnet includes a pair of internal magnets lying in parallel planes which meet along a common junction with repelling like magnetic polarities facing towards each other, and the magnetic polarities of each implant magnet are reversed from each other.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

Single direct current arc chute, and bi-directional direct current electrical switching apparatus employing the same

ActiveUS20140061160A1High-tension/heavy-dress switchesAir-break switchesEngineeringMagnetic polarity

A direct current arc chute includes a ferromagnetic base having first and second ends; first and second ferromagnetic side members disposed from the respective first and second ends; a third ferromagnetic member disposed from the base intermediate the side members and having an end portion opposite the base; and first and second magnets on the respective first and second members have a magnetic polarity facing the third member. A first arc chamber is between the first and third members; and a second arc chamber is between the second and third members. The first magnet and first member extend away from the first end and beyond the end portion, and toward the second magnet and second member after the end portion. The second magnet and second member extend away from the second end and beyond the end portion, and toward the first magnet and first member after the end portion.

Owner:EATON INTELLIGENT POWER LIMITED

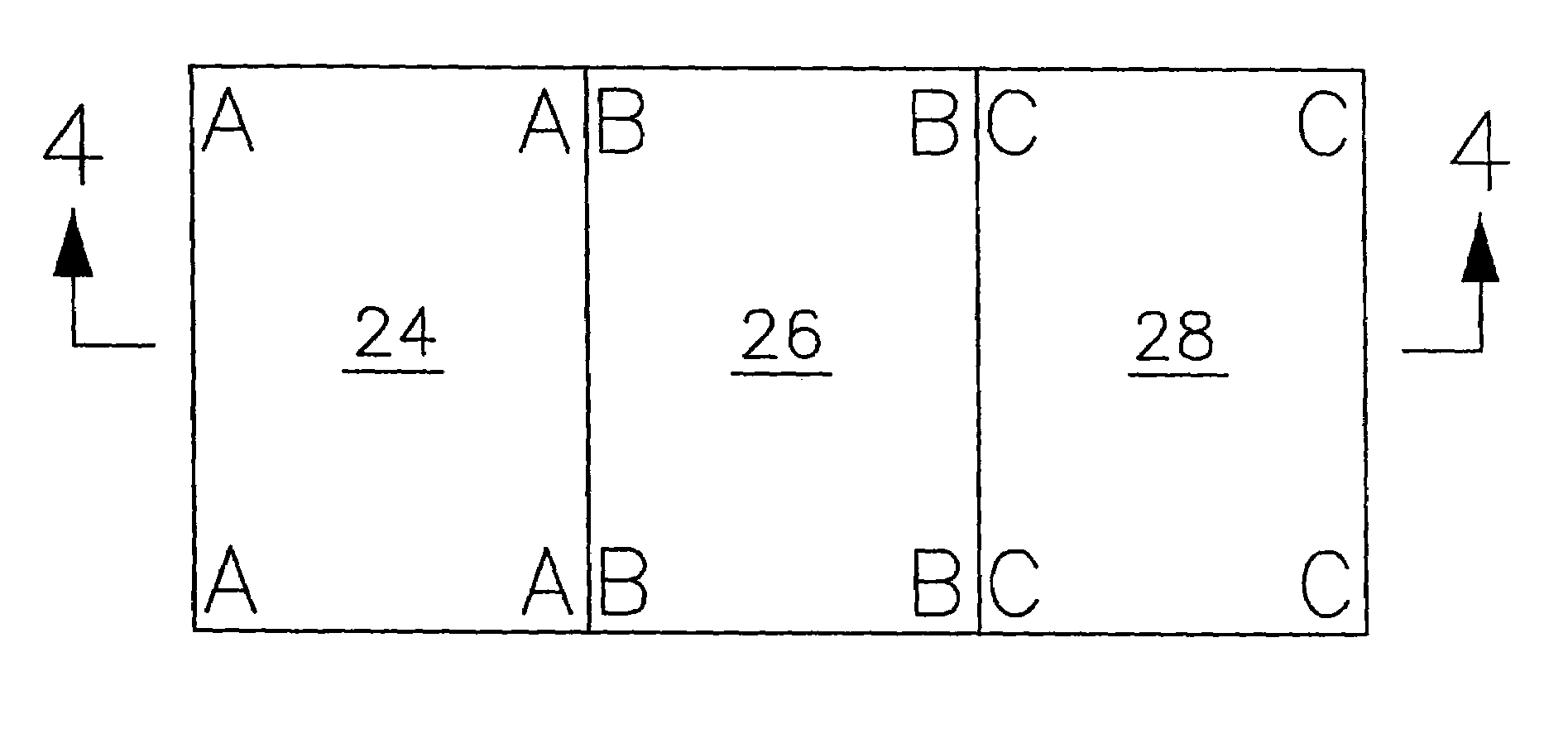

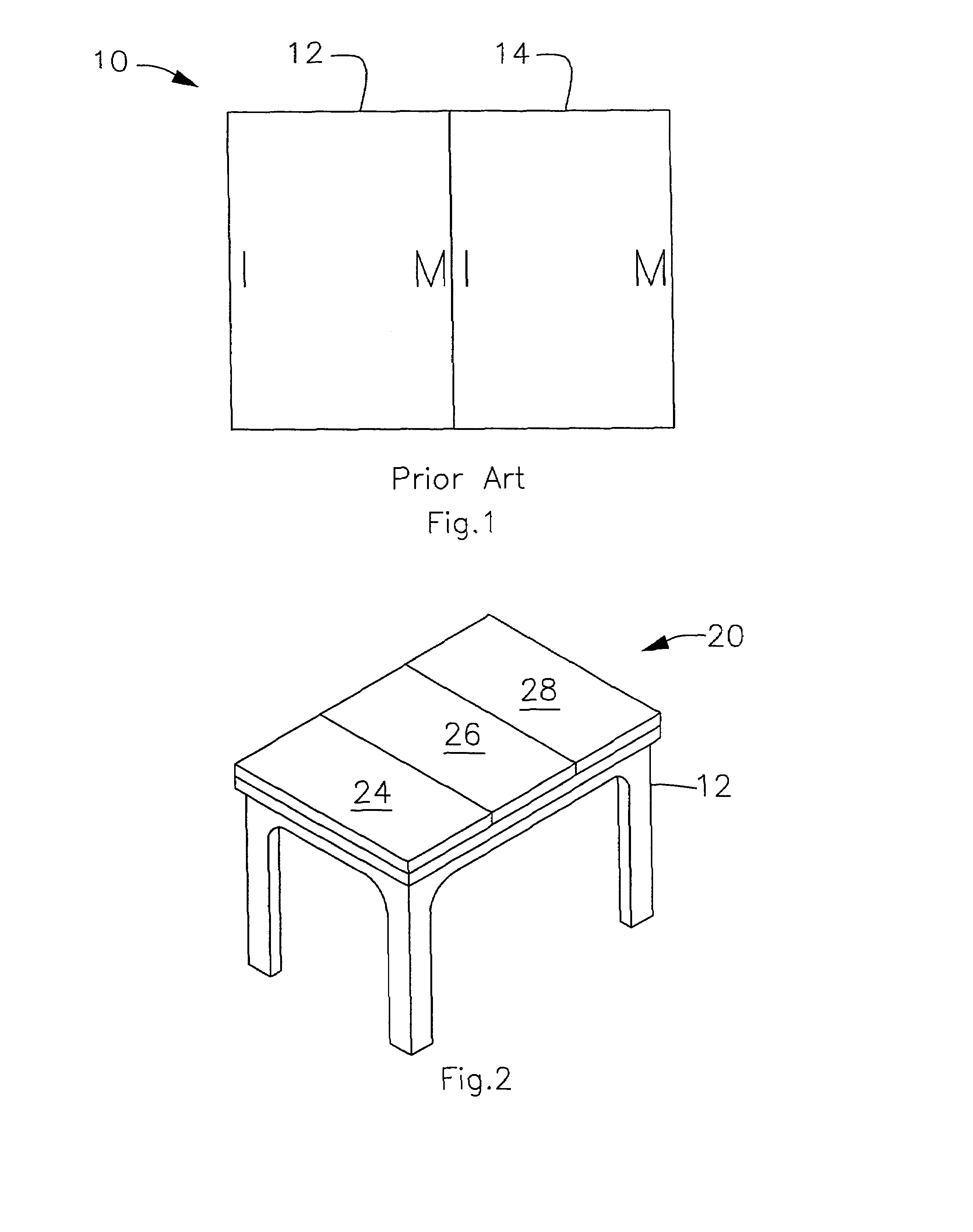

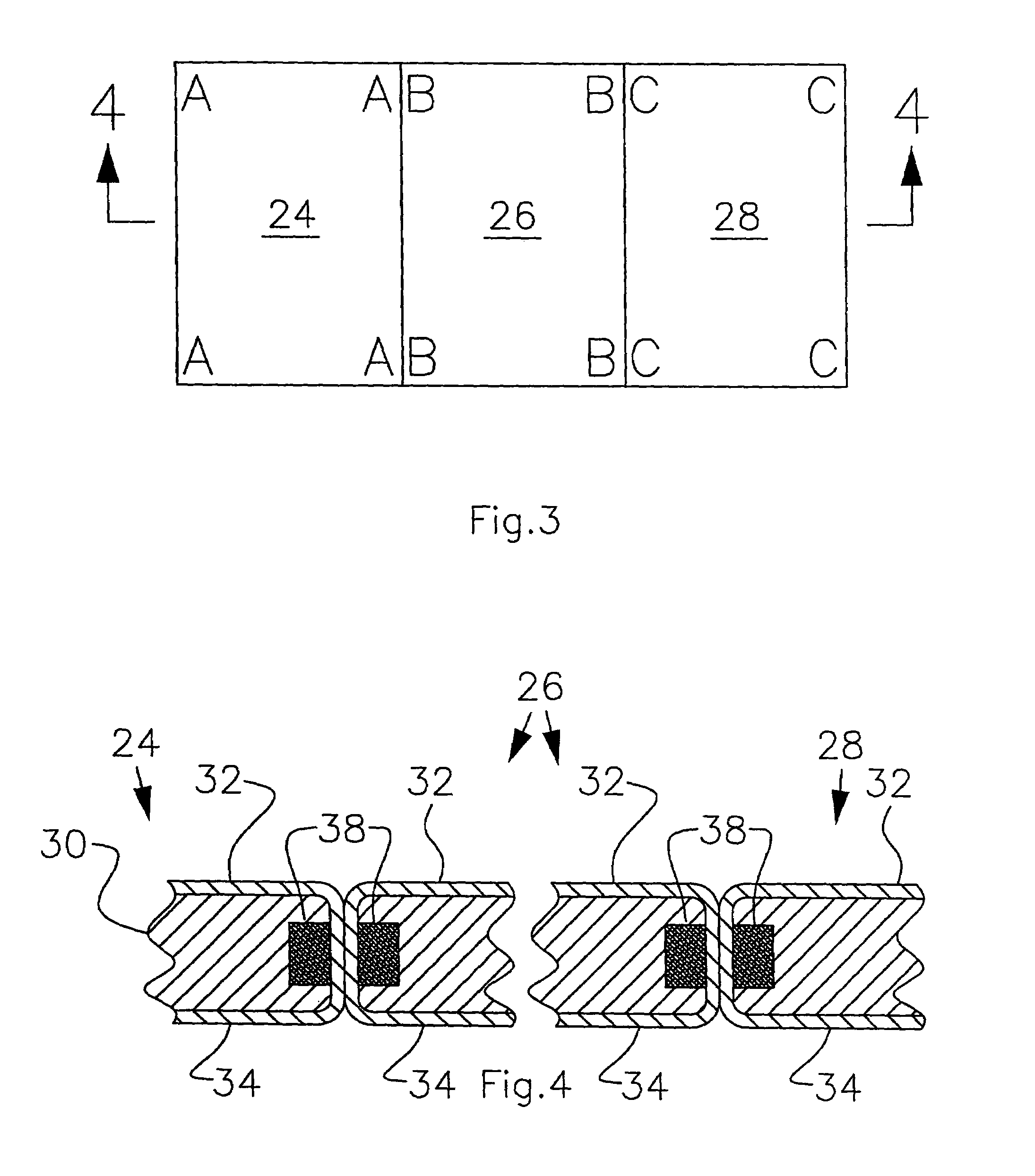

Table pad coupling system

InactiveUS7250207B1Enhanced Magnetic CouplingCellulosic plastic layered productsStands/trestlesCoupling systemMagnetic polarity

A table pad coupling system including a first table pad and a second table pad. The first table pad having a plurality of peripheral surfaces including a first peripheral surface and a second peripheral surface, the first peripheral surface opposite the second peripheral surface. The first table pad additionally including a plurality of magnets positioned within the first table pad, the plurality of magnets including a first magnet associated with the first peripheral surface and a second magnet associated with the second peripheral surface, the first and second magnets having a surface of a same magnetic polarity, the surface of the first magnet and the surface of the second magnet outwardly oriented proximate the respective first and second peripheral surfaces. The second table pad having a plurality of peripheral surfaces including a first peripheral surface and a second peripheral surface, the first peripheral surface opposite the second peripheral surface, the first peripheral surface of the first table pad disposed adjacent the first peripheral surface of the second table pad.

Owner:OHIO TABLE PAD COMPANY THE

Magnetic connector apparatus

ActiveUS20060139134A1Reduce manufacturing costSimple structureSnap fastenersElectromagnets without armaturesMagnetic polesEngineering

A magnetic connector apparatus provides a plurality of magnetic connector bodies in various different forms for magnetic connection of two or more bodies together along mutually-confronting, longitudinally-elongated, linear peripheral border edges, each linear peripheral border edge having at least one particularly-configured longitudinally elongated, cylindrical magnet supported adjacent thereto for rotation of the magnet adjacent said peripheral edge of each connector body for orientation of the magnetic polarity of magnets of confronting connector bodies for mutual magnetic attraction along, mutually confronting, linear peripheral border edges of magnetic connector bodies.

Owner:GYMWORLD

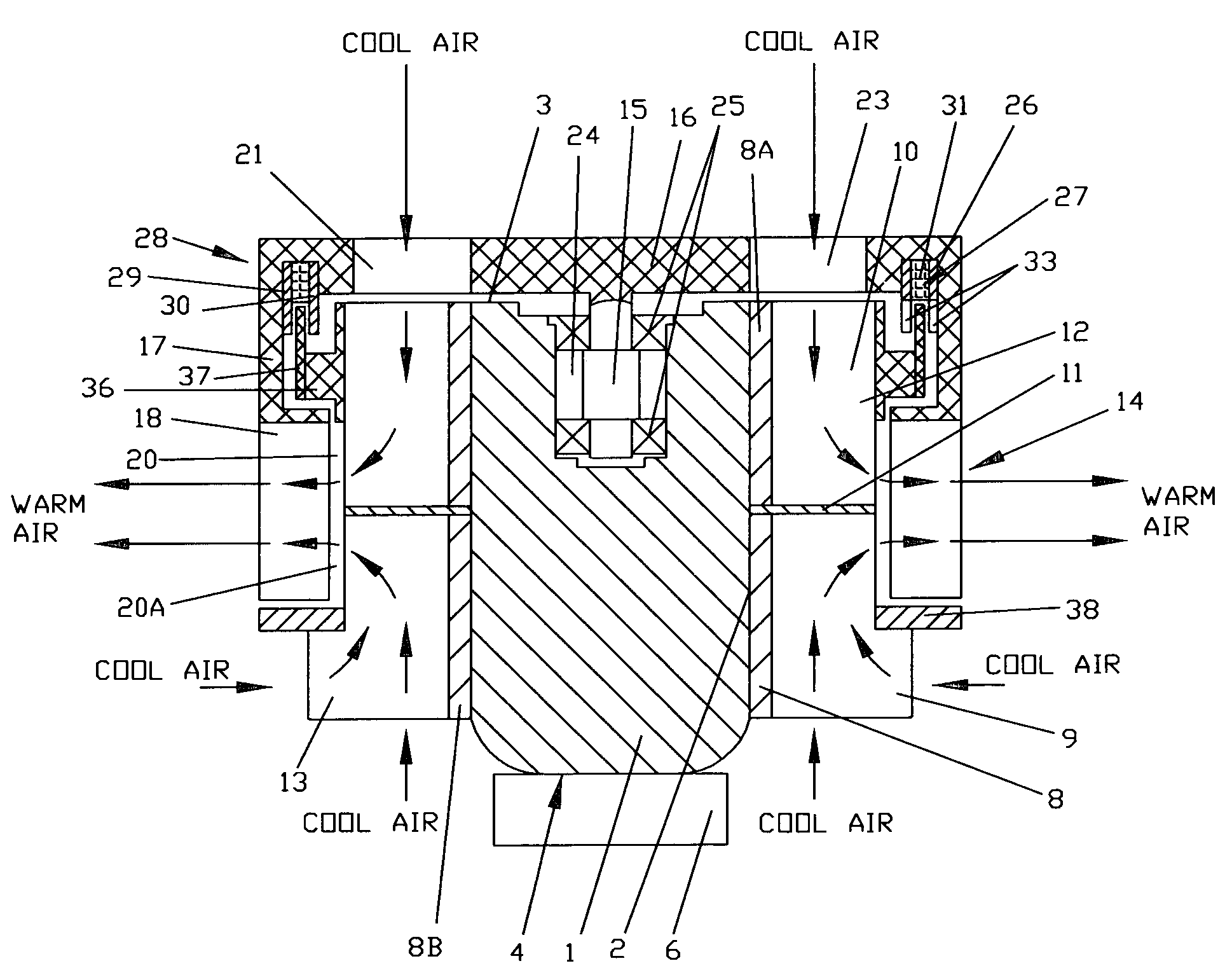

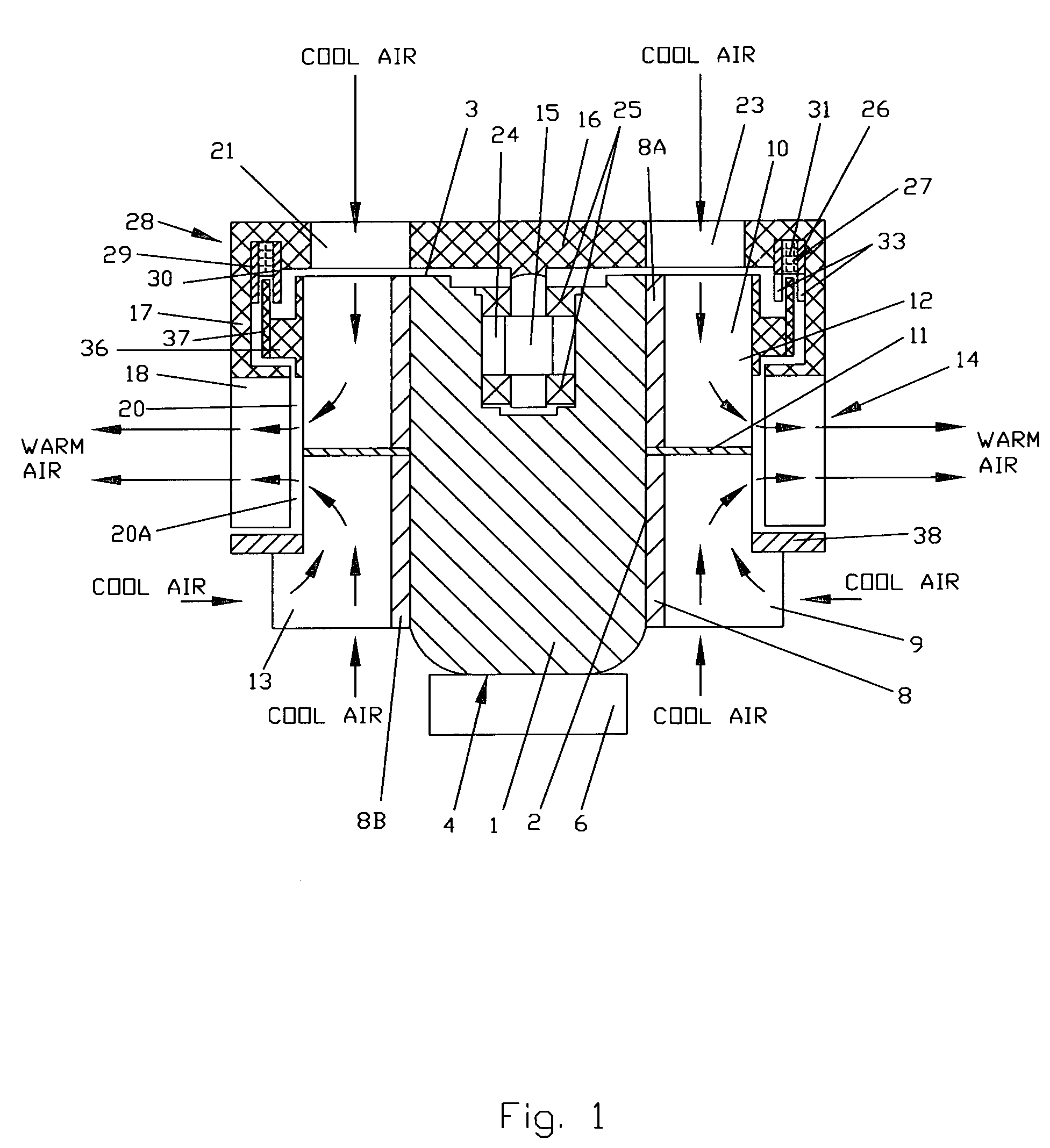

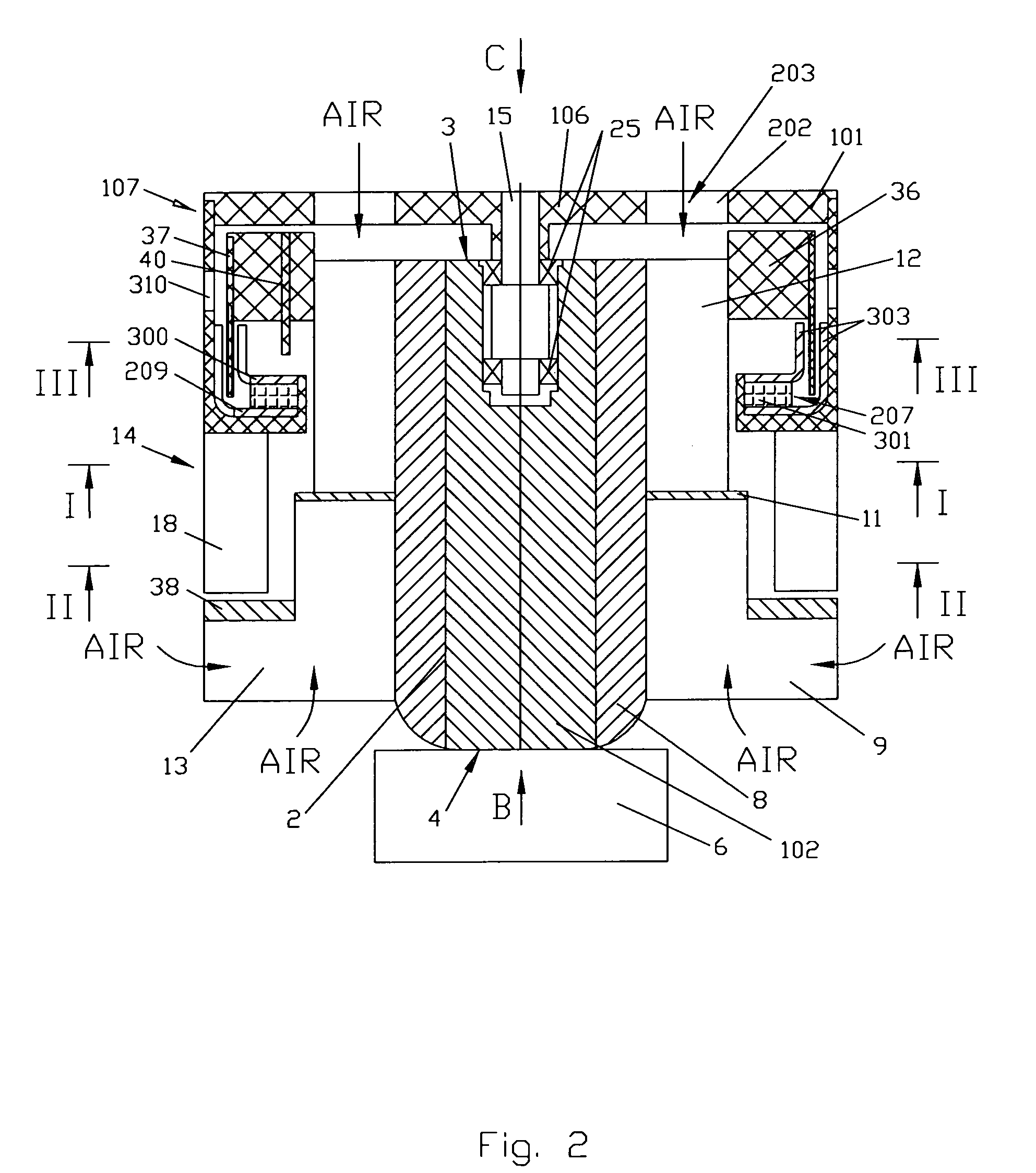

Cooler for electronic devices

InactiveUS7044202B2Improve cooling effectIncrease temperature differenceSemiconductor/solid-state device detailsSolid-state devicesCold airPath length

A cooler for electronic devices provides cool air to the inlet sides of the heat sink by using a radial blower with blades located around air outlets of the heat sink. This blower is driven by a brushless DC electric motor. The motor has an opening in the center allowing for the transfer of incoming air to the center of the heat sink. The rotors outer circumferential arrayed poles are rigidly secured to the frame of the radial blower. The stator of the motor is rigidly secured to the heat sink and has an opening in its center. The stator comprises circumferential arrayed coils on circuit board material. When the current flows through the stator coils, the coils acquire a magnetic polarity. The poles of the rotor and stator coils attract and repel depending on the polarities. The cool air comes simultaneously from opposite sides of the heat sink. For this reason the heat sink has a divider located approximately in the middle of the heat sink fins. The blades of the radial blower are located around the air outlets on the heat sink. Because the ambient air is drawn in from both sides of the heat sink the air path length through the heat sinks channels is effectively halved. This results in an increased cooling ability for the heat sink because of the increase in temperature differentials.

Owner:ADVANCED ROTARY SYST

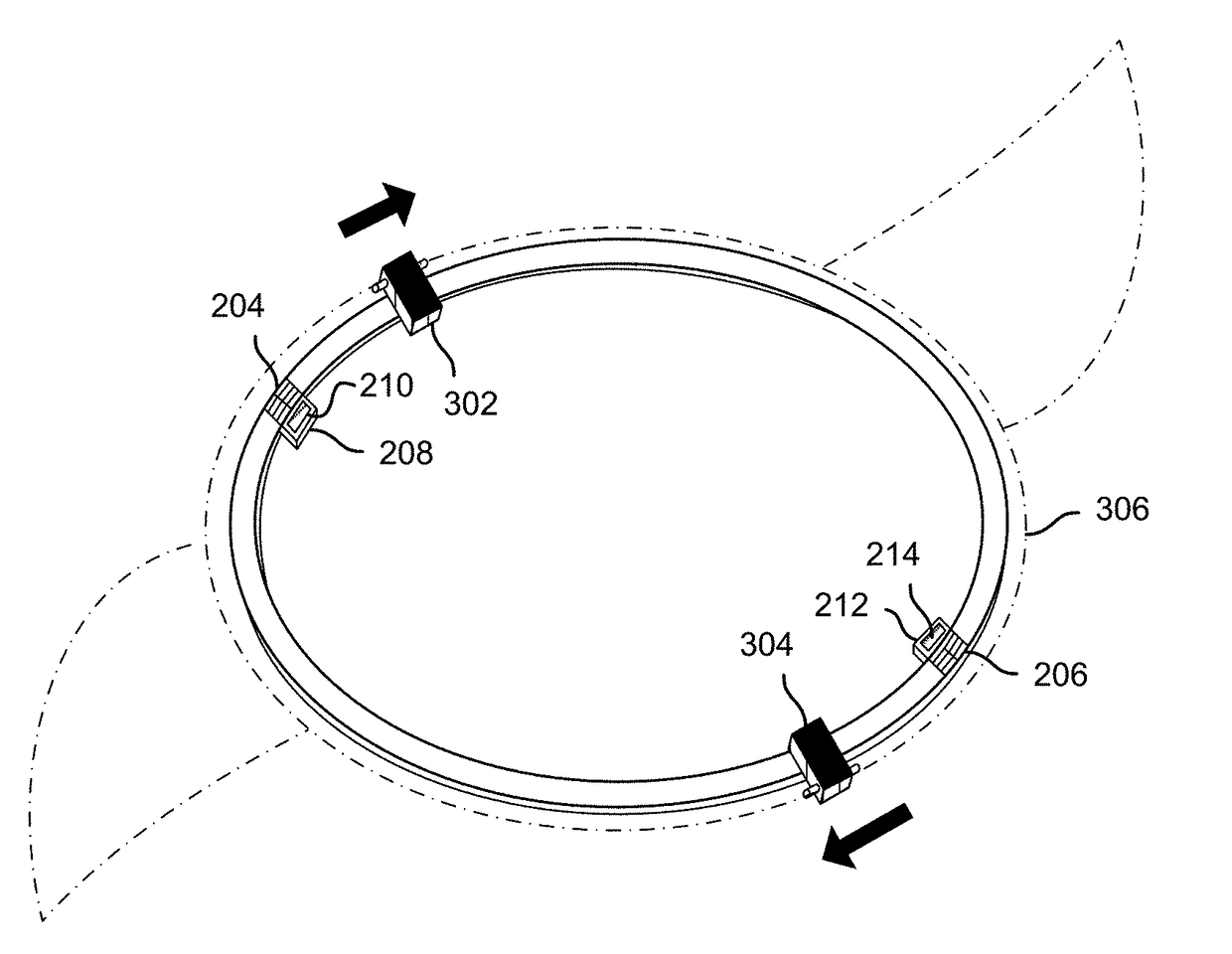

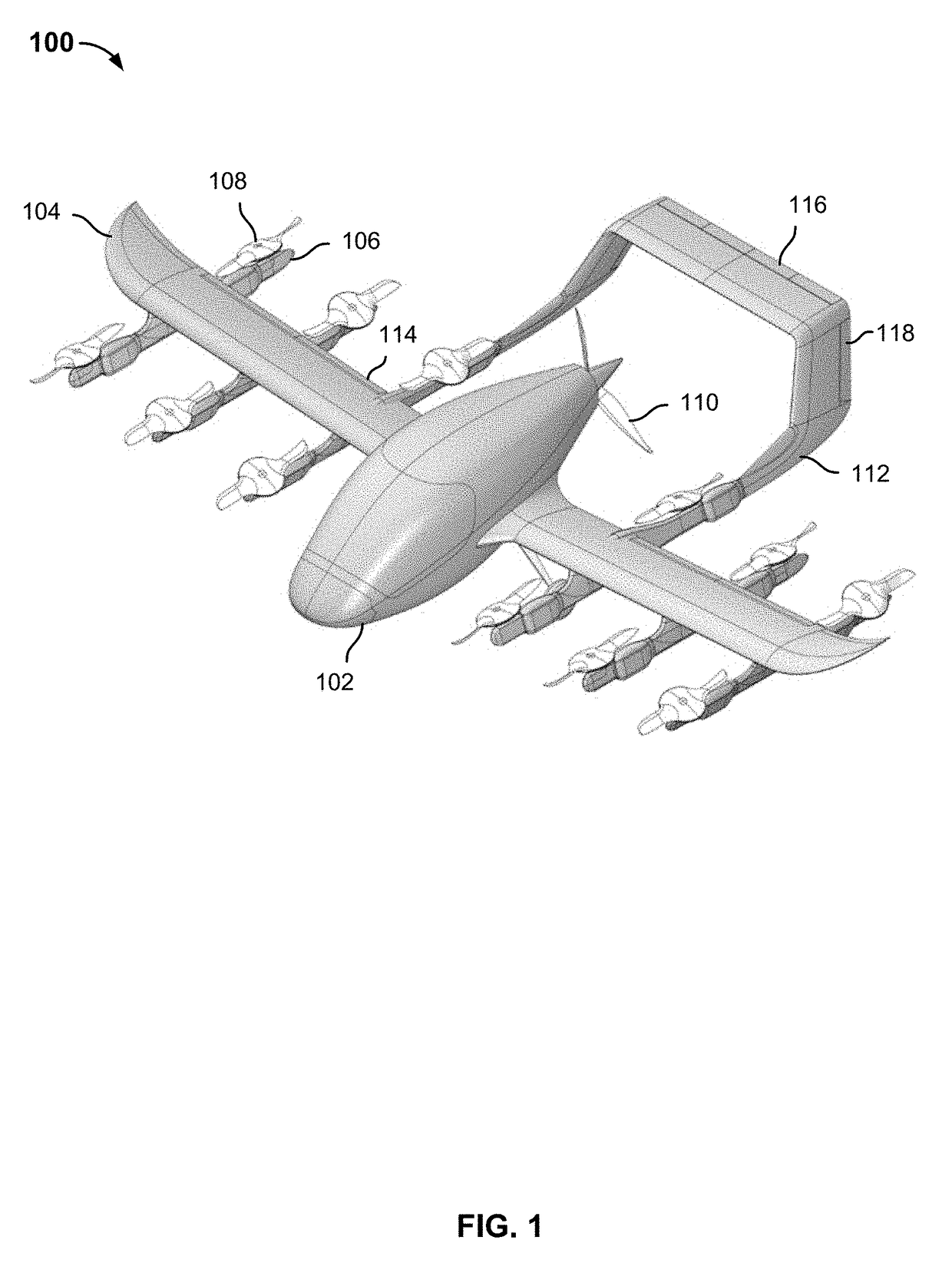

Lift fan position lock mechanism

A lift fan position lock mechanism is disclosed. In various embodiments, a position lock mechanism includes a ring structure having a first surface, the ring structure including one or more detents defined in the first surface of the ring structure. For each detent, the lock mechanism includes a stationary magnet coupled fixedly to the ring structure at a location adjacent to the detent. The lock mechanism further includes a rotating magnet assembly comprising a magnet of opposite magnetic polarity to at least one of the stationary magnets and a mechanical stop structure of a size and shape to fit into a corresponding detent and engage mechanically with a surface defining at least one extent of said corresponding detent when the rotating magnet assembly is in a locked position.

Owner:WISK AERO LLC

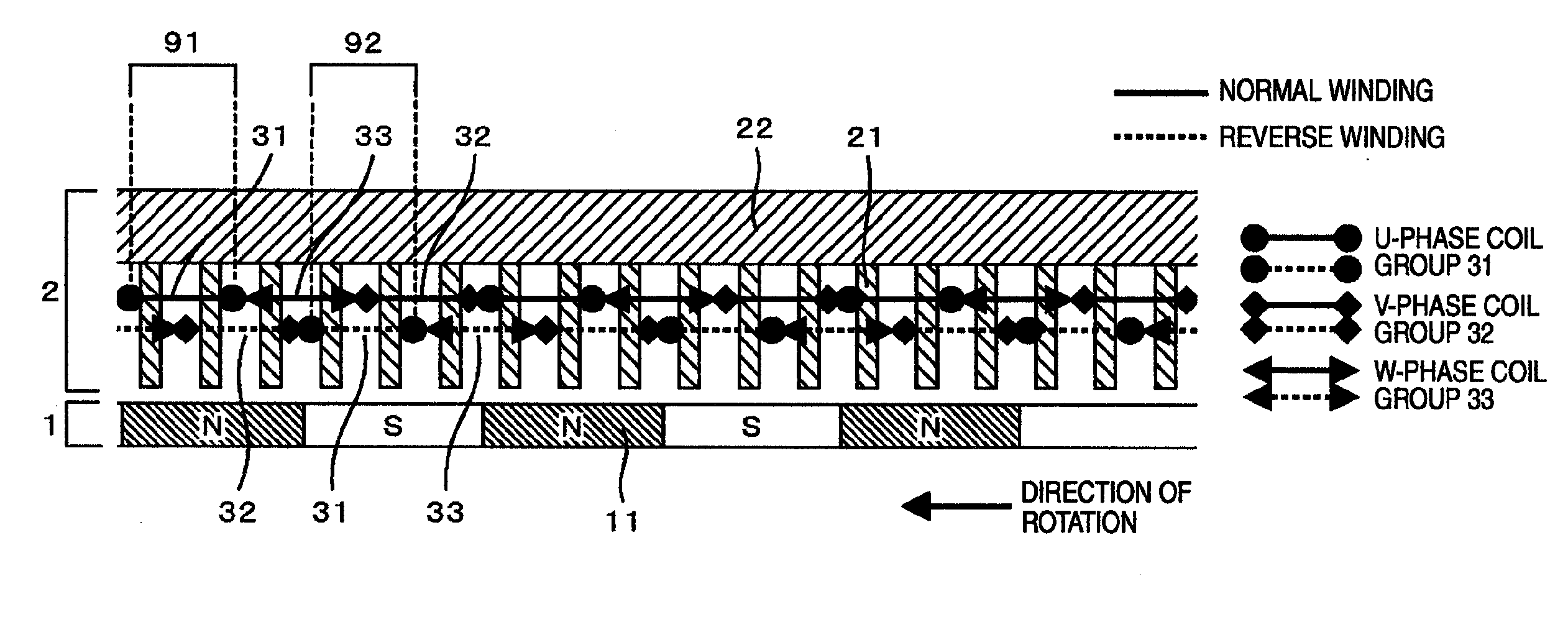

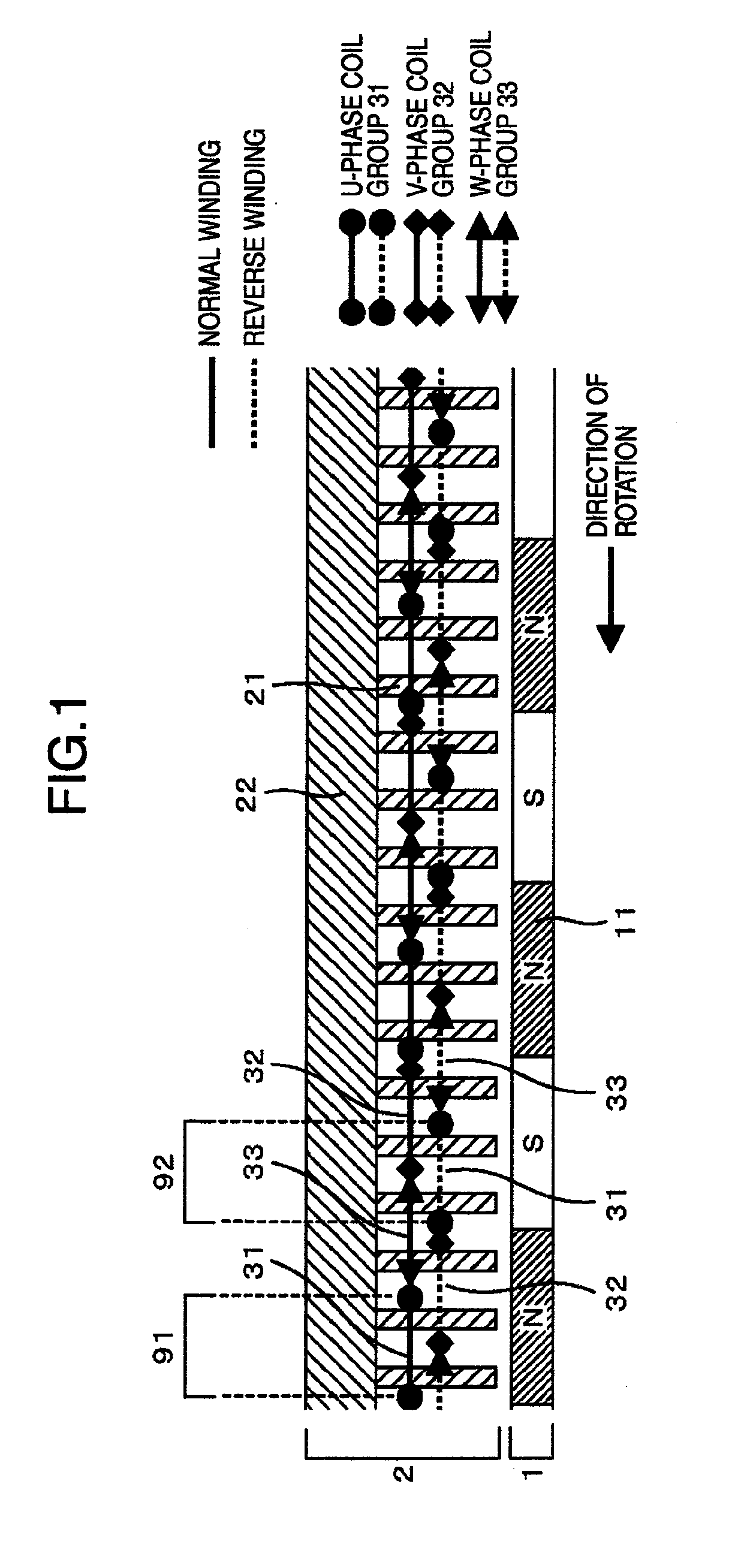

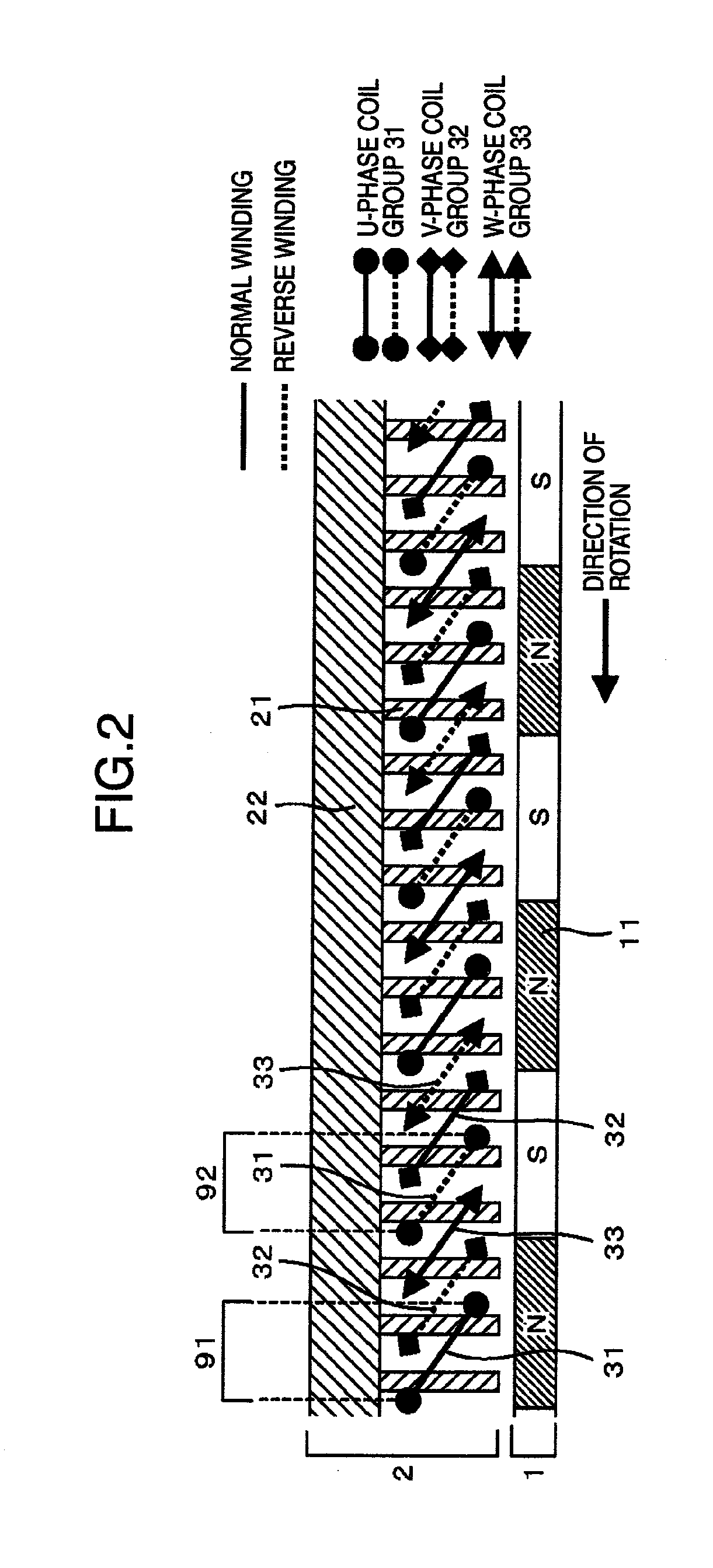

Electric motor

ActiveUS20090230806A1Improve featuresSynchronous generatorsSynchronous motorsElectrical conductorMagnetic poles

An electric motor comprising a rotor having plural magnetic poles in the circumferential direction; and a stator whose teeth are disposed opposite to the periphery of the rotor, with an air gap interposed between the rotor and the stator, wherein the coil conductors are wound on the stator so that two stator magnetic poles may be formed by two coil units of a phase wound around stator teeth within the range of 360 electrical degrees subtended by the magnetic poles of the rotor; each of the two coil units forming the stator magnetic poles spans an electrical angle less than 180 electrical degrees; the two coil turns forming the two stator magnetic poles are laid out so that they may not overlap each other; and the coil conductors are so wound that the adjacent stator magnetic poles exhibit opposite magnetic polarities.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com