Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

625 results about "Spherical roller bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

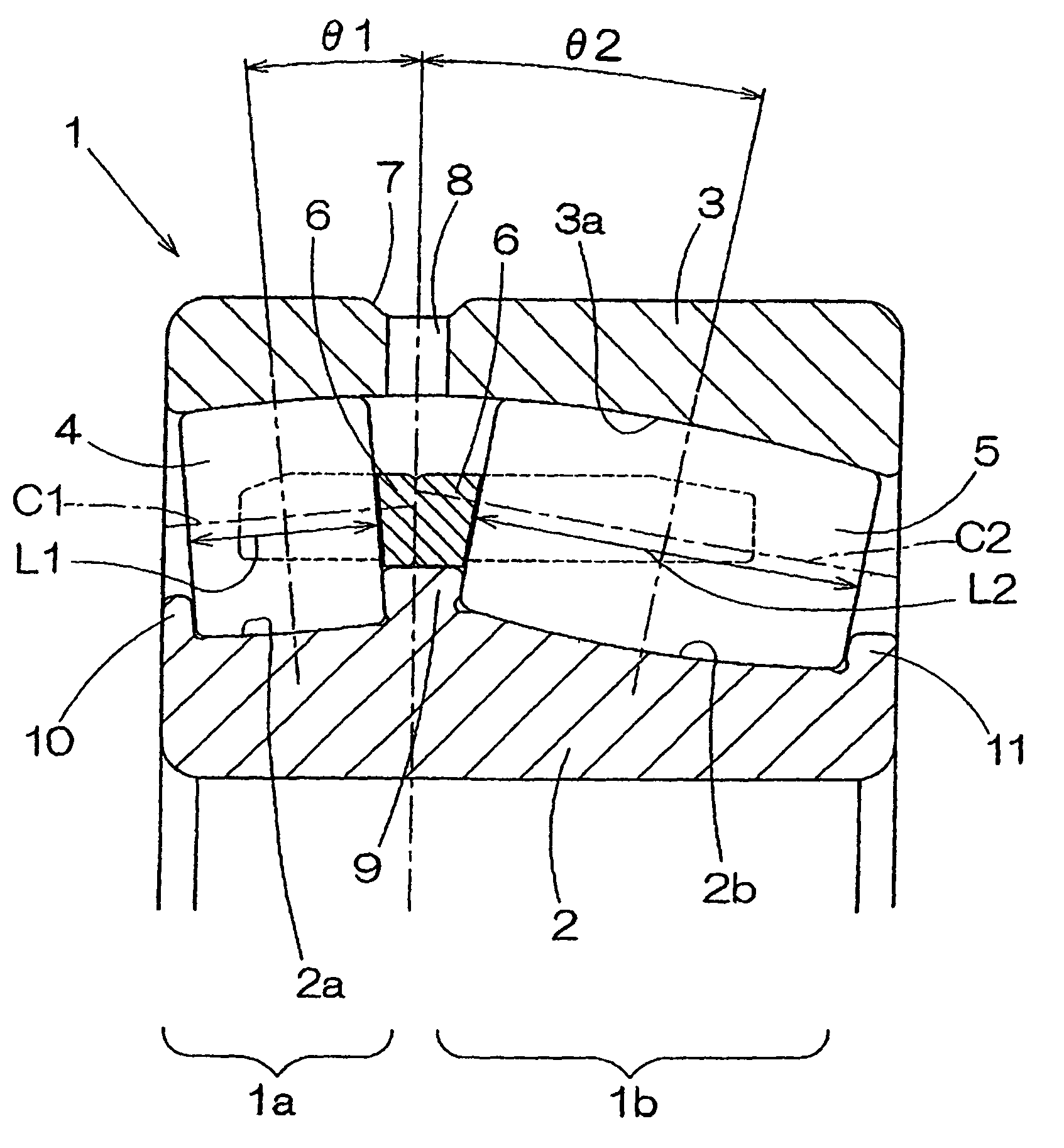

Double-row self-aligning roller bearing and device for supporting wind turbine generator main shaft

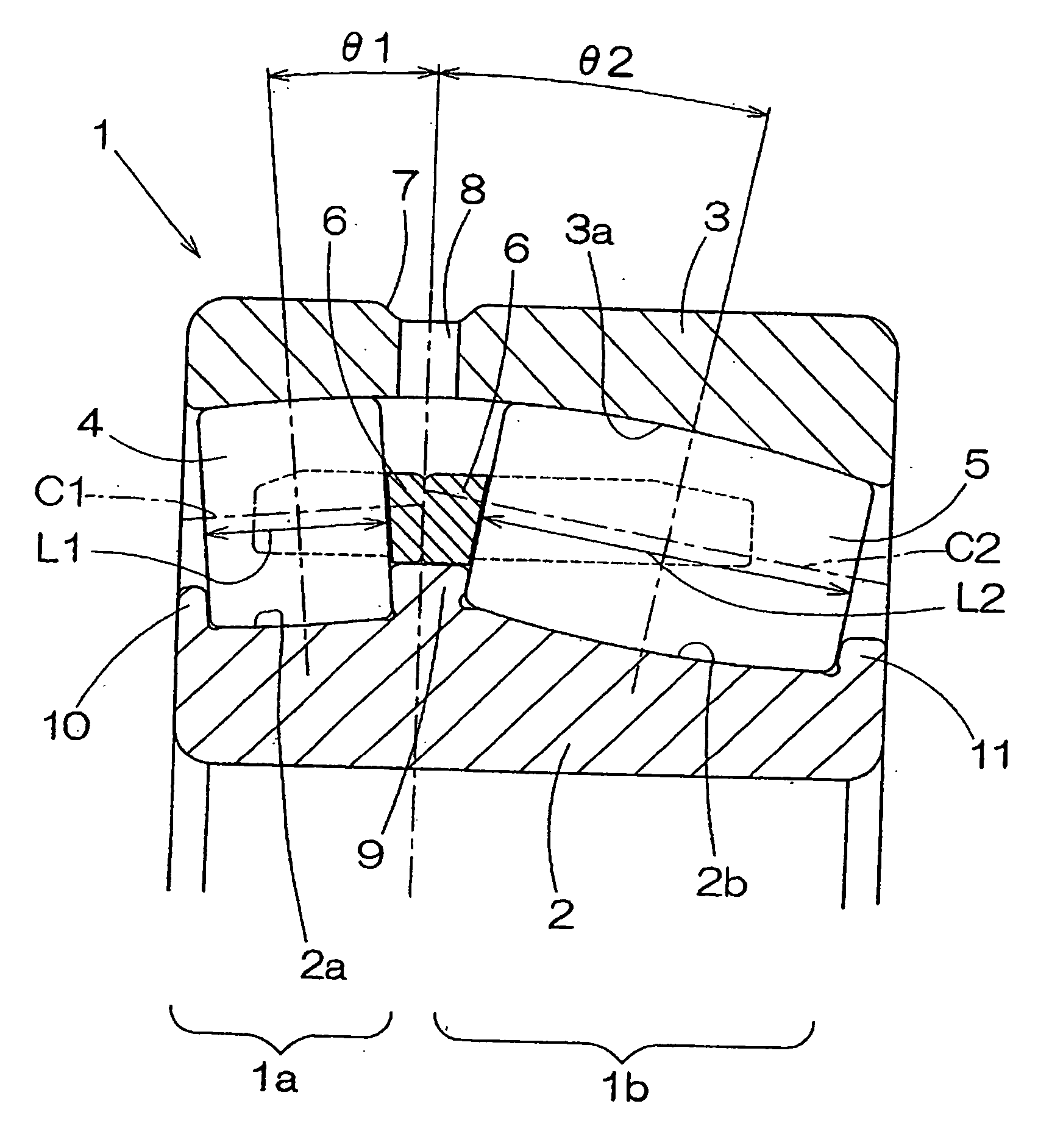

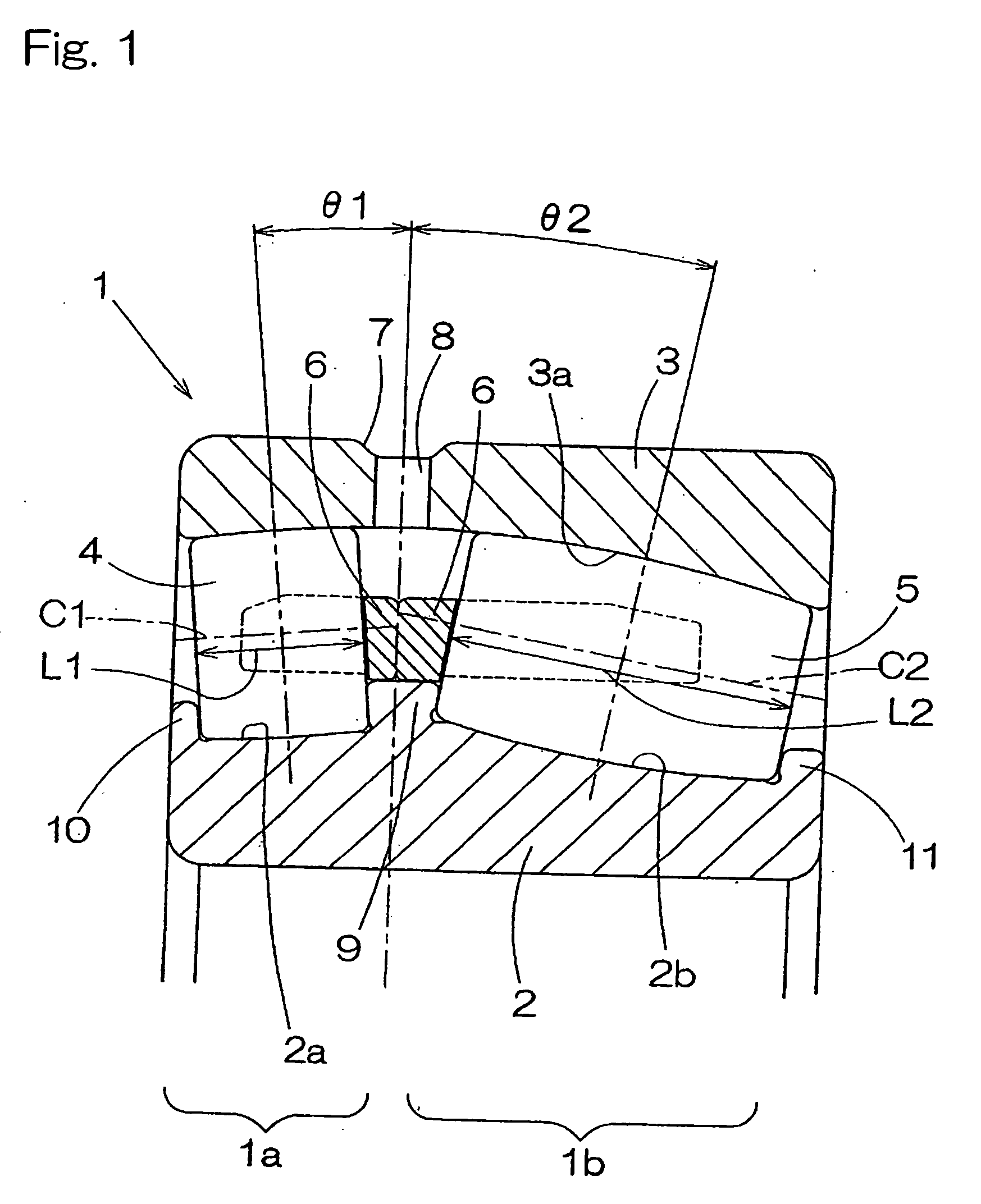

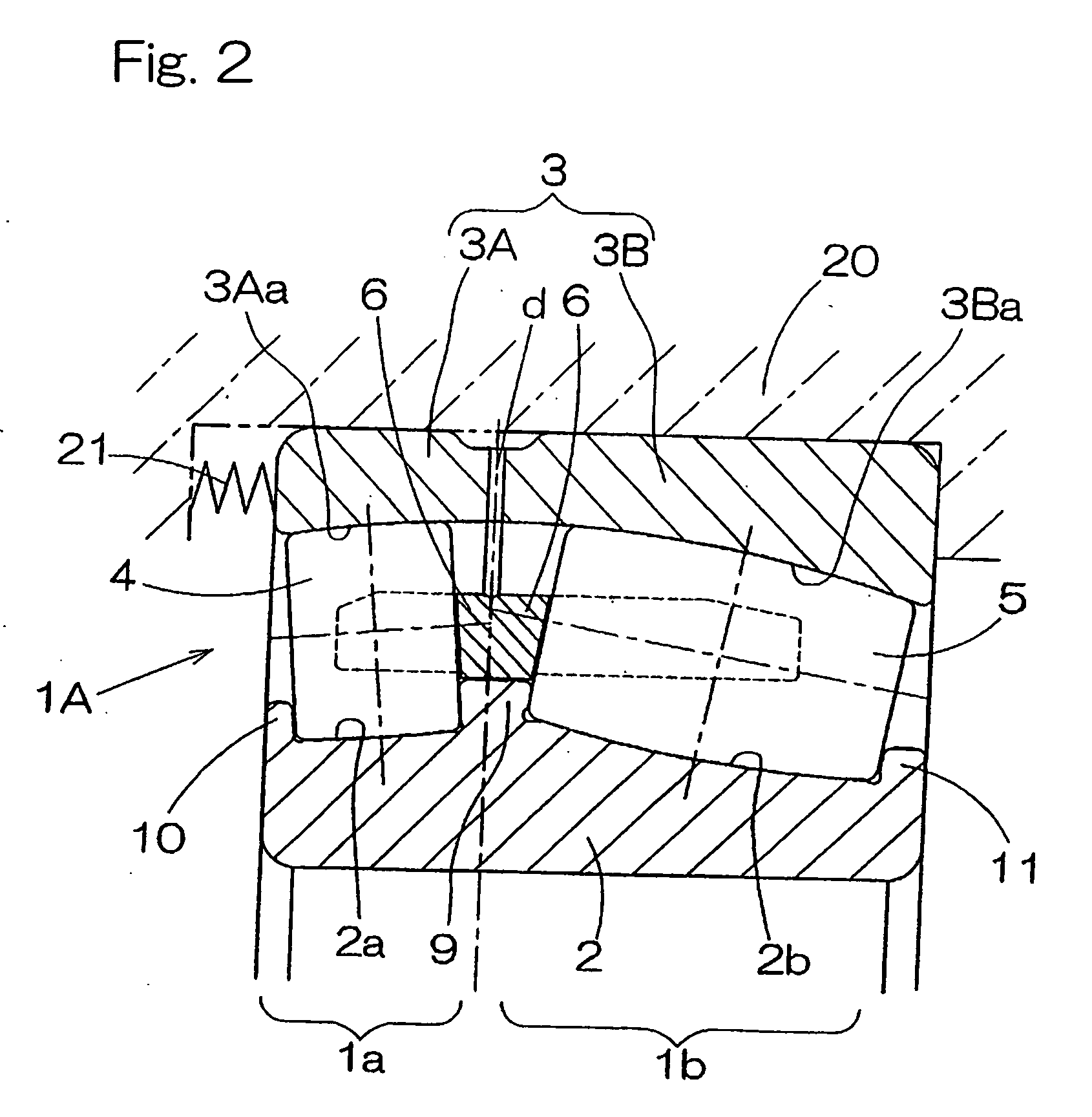

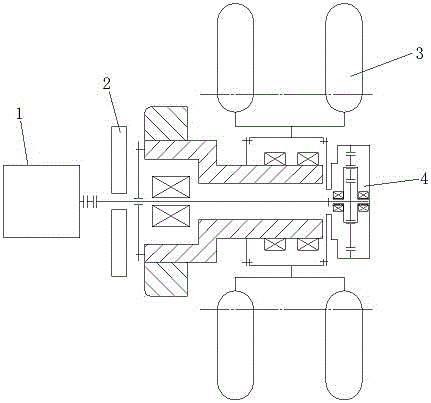

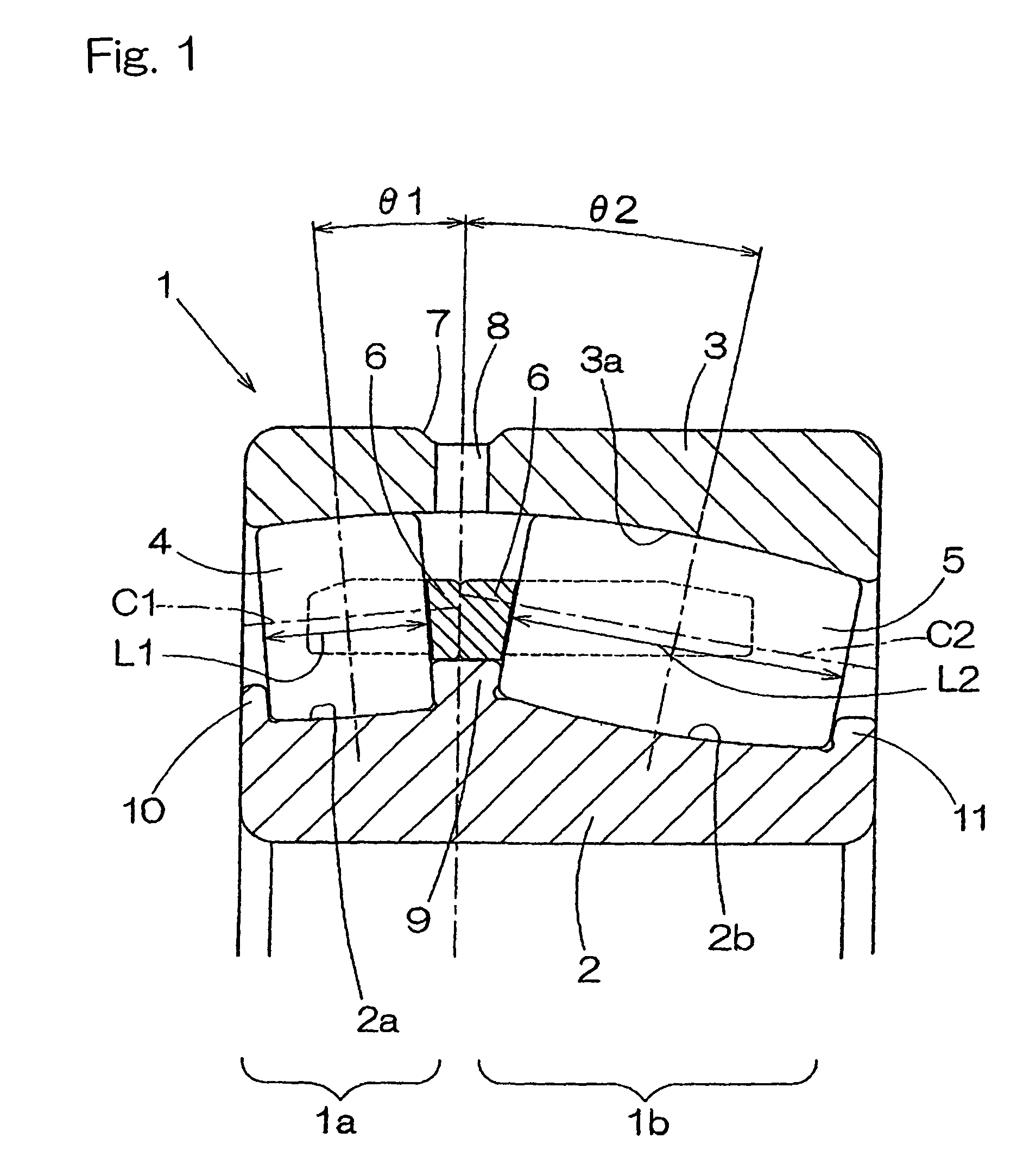

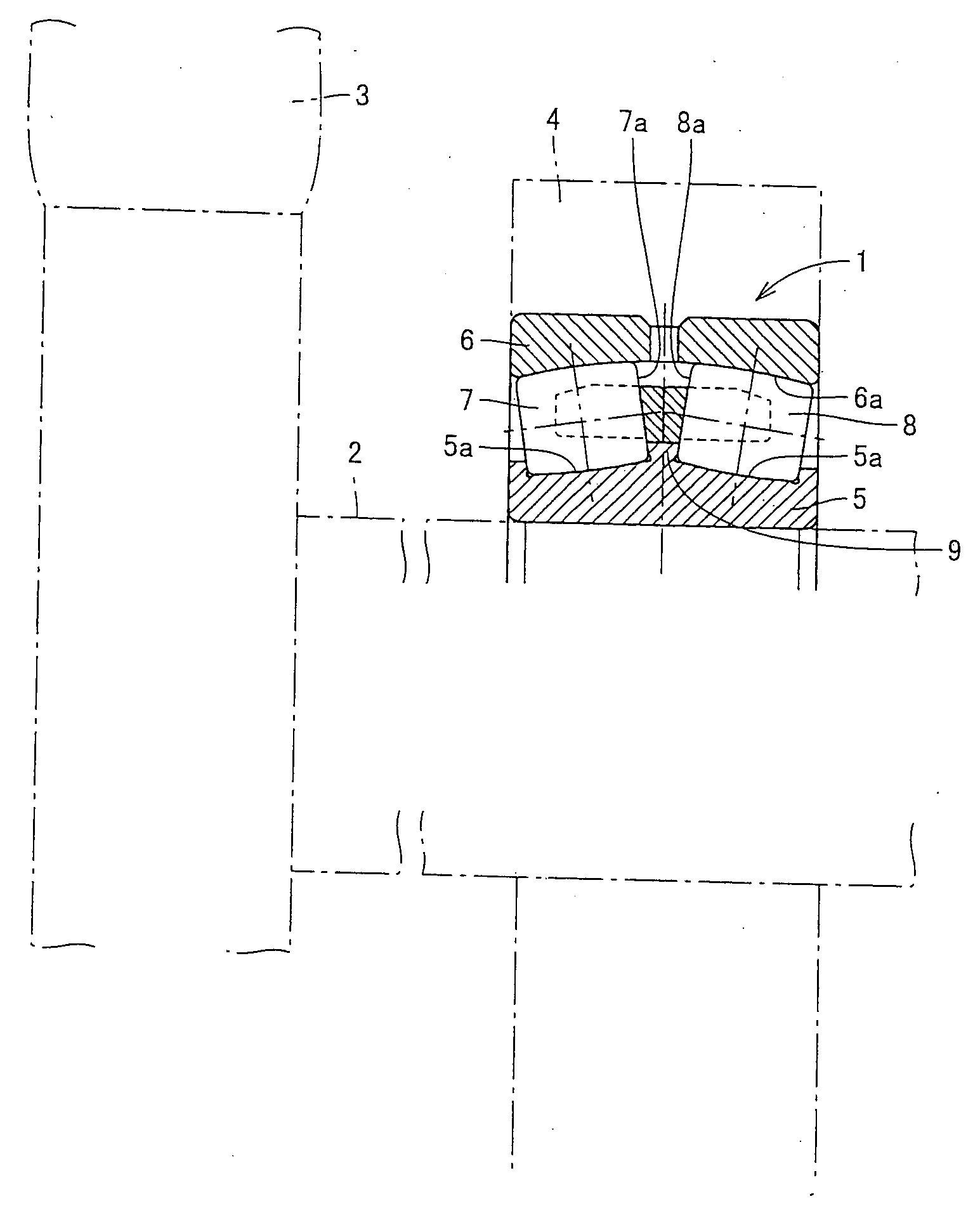

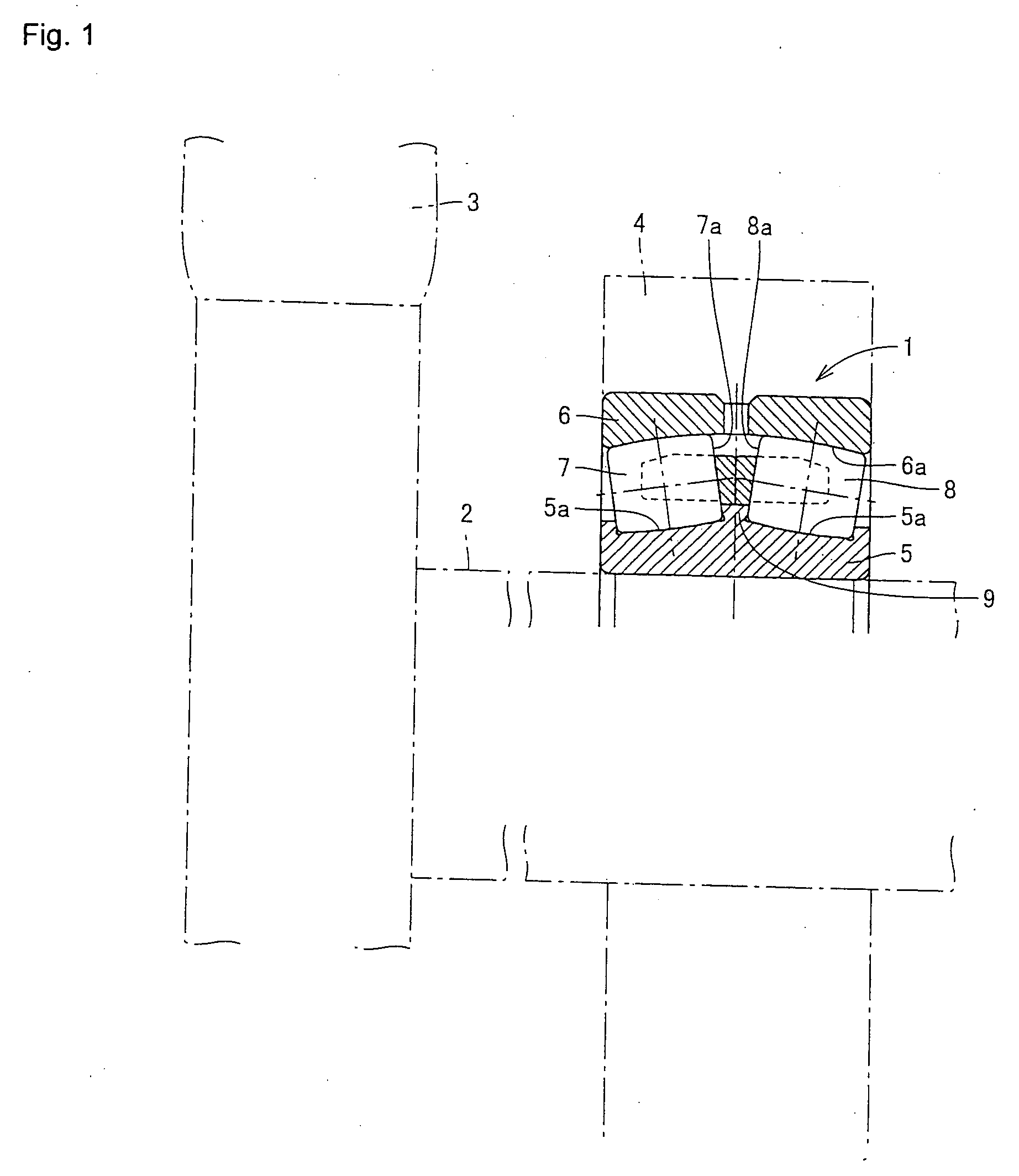

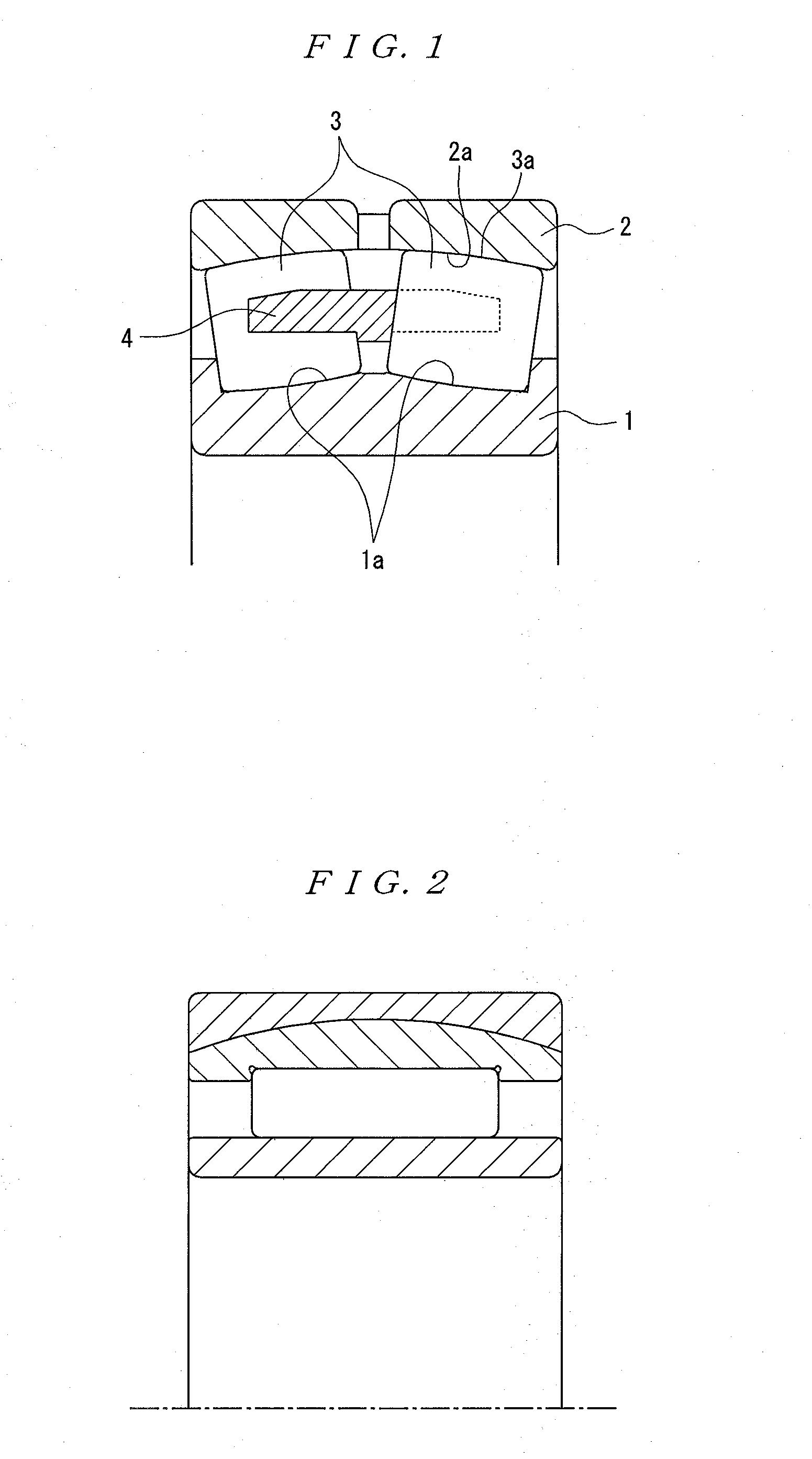

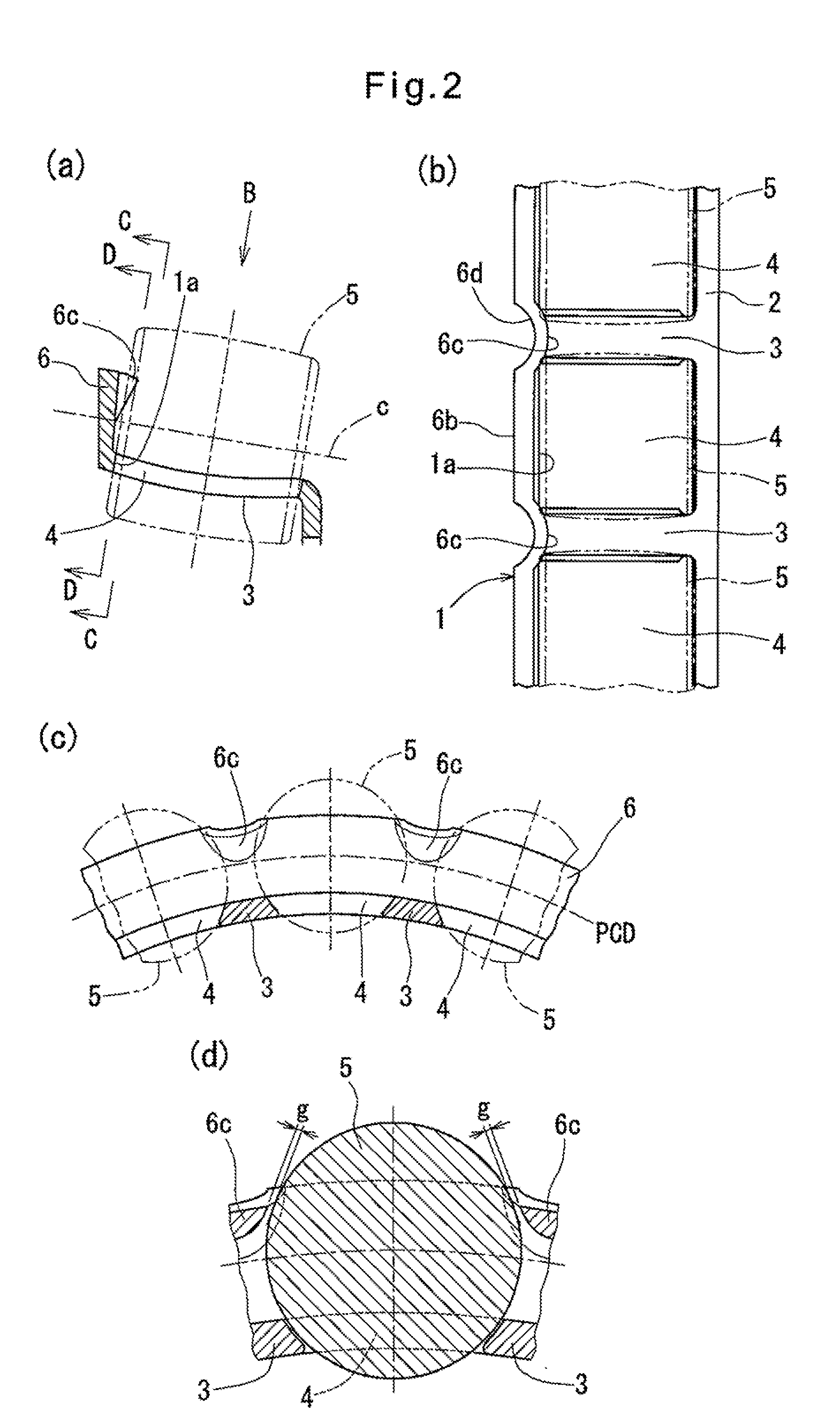

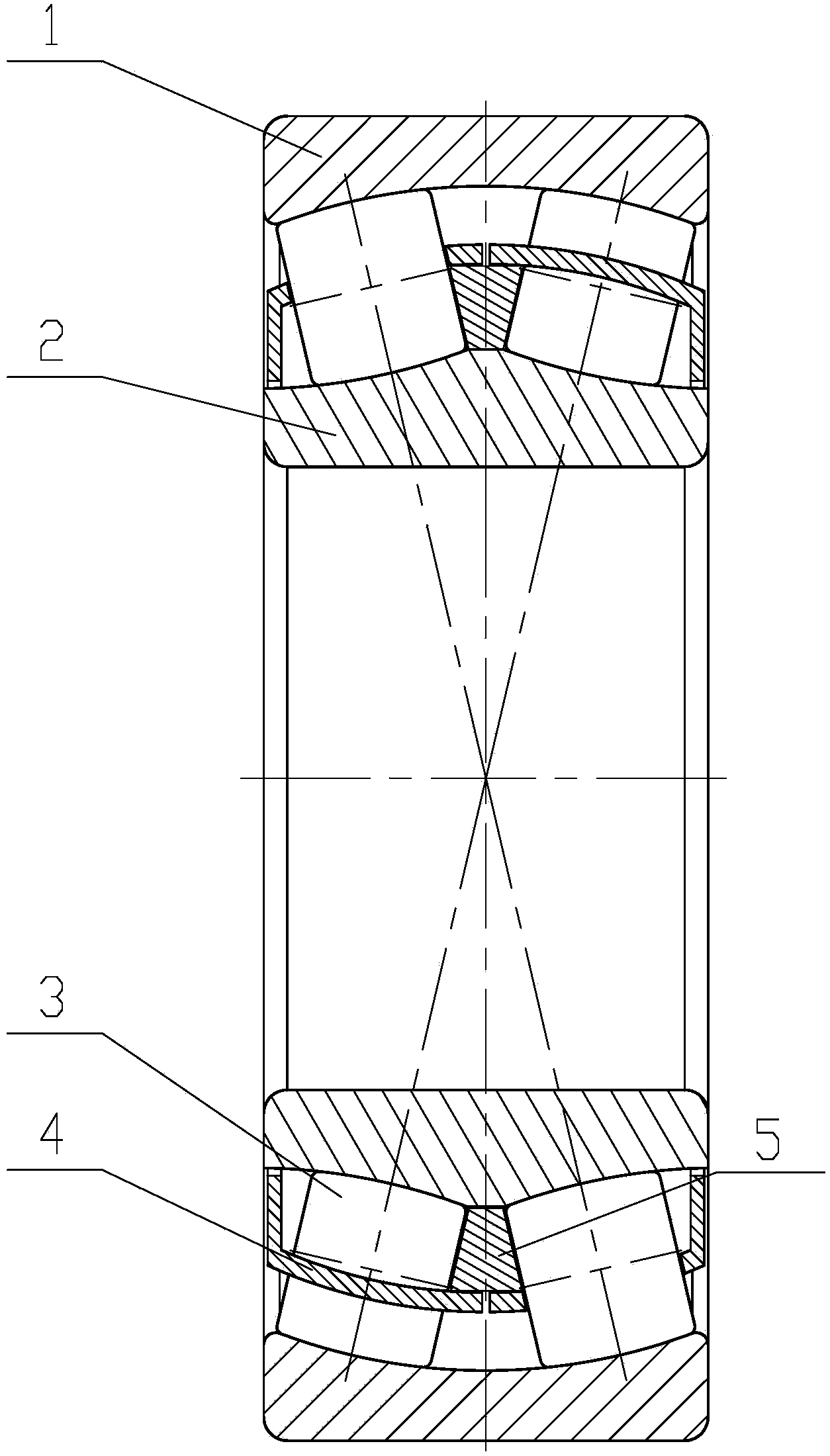

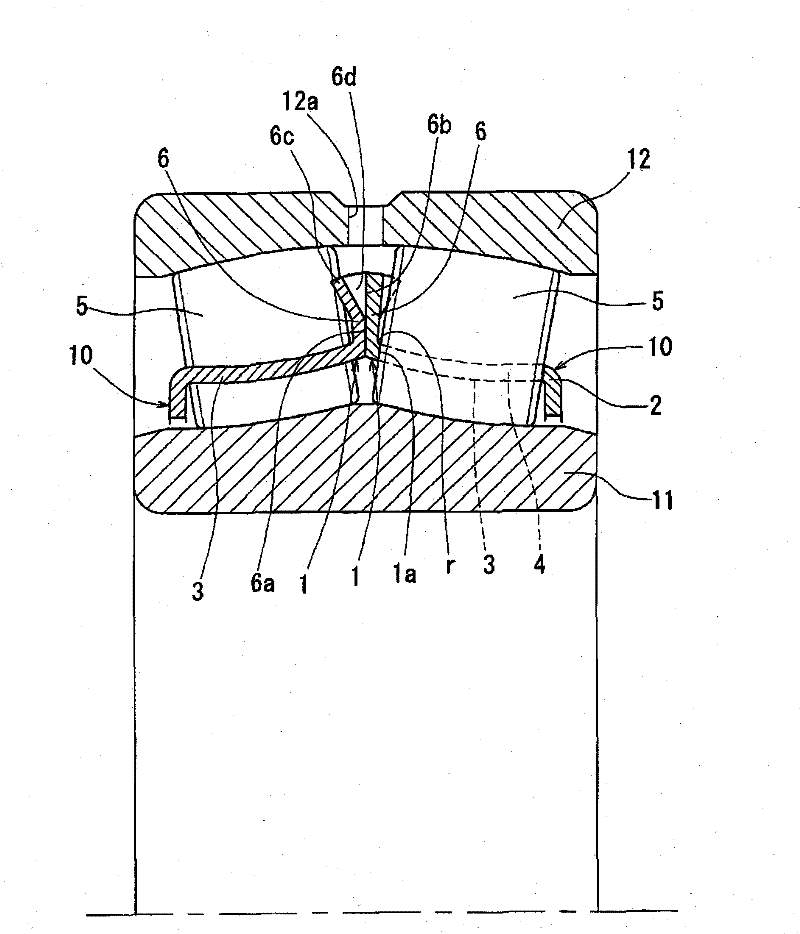

A double-row self-aligning roller bearing includes left and right rows of rollers 4 and 5, arranged between an inner race 2 and an outer race 3. A raceway surface 3a of the outer race 3 represents a spherical shape and the rollers 4 and 5 have an outer peripheral surface following the shape of the raceway surface 3a of the outer race 3. The rollers 4 and 5 of the left and right roller rows have respective lengths L1 and L2 different from each other. Also, the left and right roller rows have respective contact angles θ1 and θ2 different from each other.

Owner:NTN CORP +1

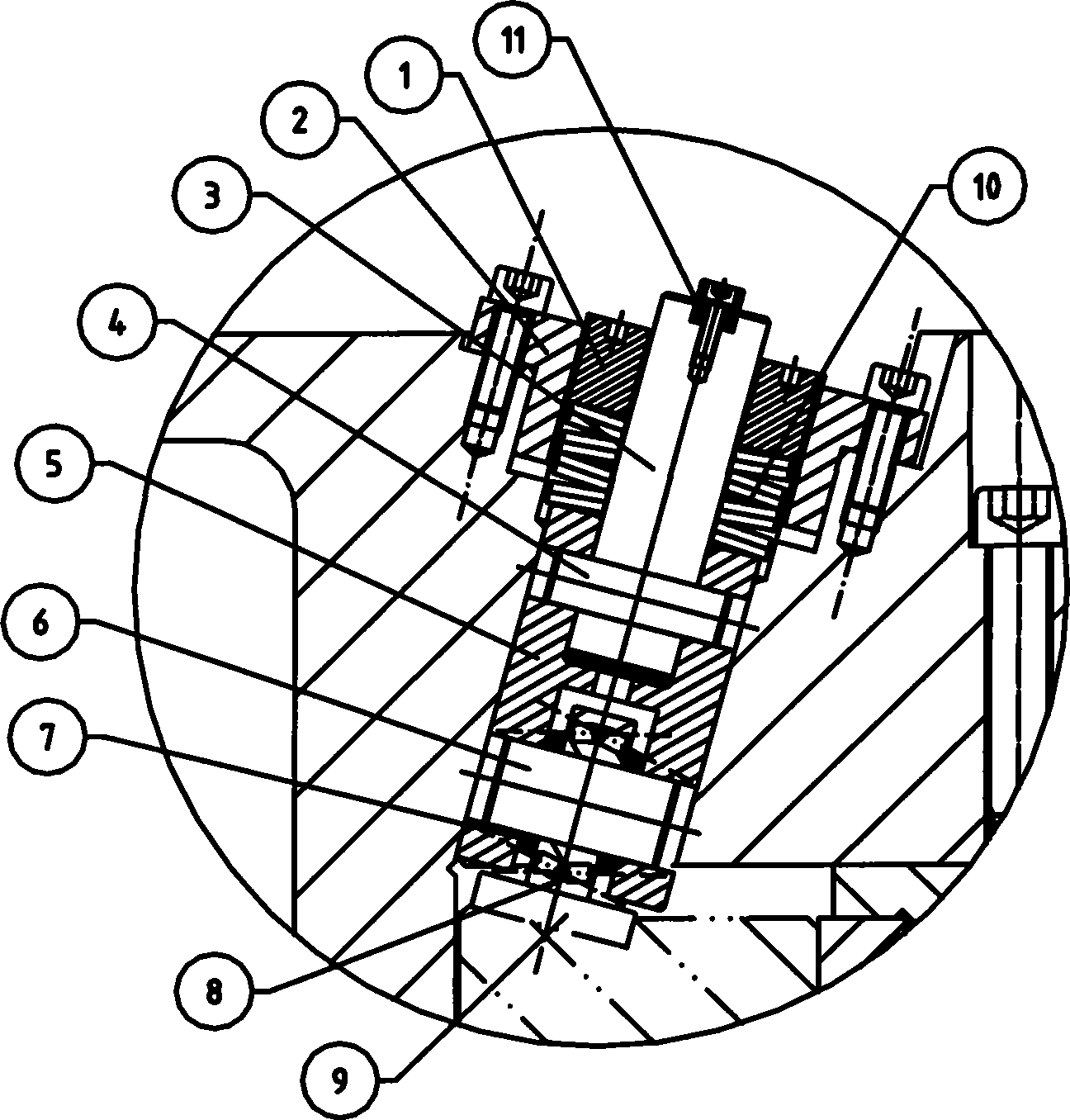

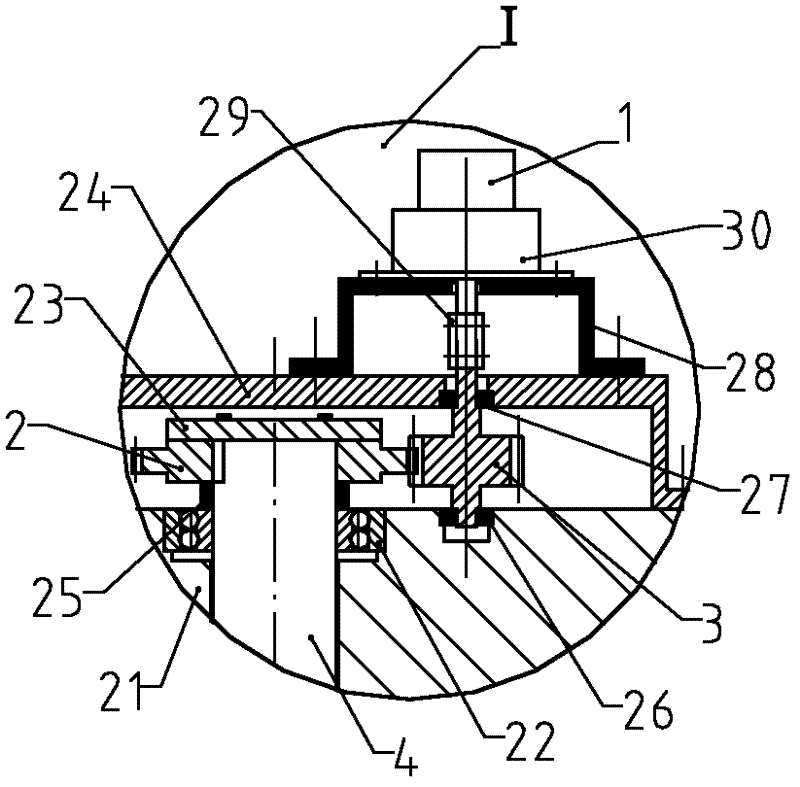

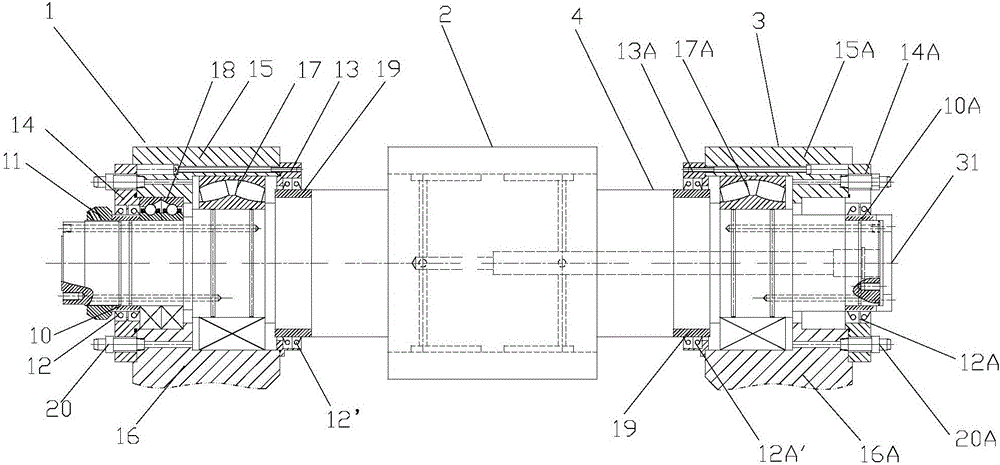

Single axle bogie transmission of straddle-type single rail vehicle

InactiveCN105905120ACompact structureEasy to disassembleElectric motor propulsion transmissionBogieReduction drive

The invention discloses a single axle bogie transmission of a straddle-type single rail vehicle. The transmission is arranged on a bogie frame and used for realizing that walking wheels are driven to walk through the torque of a motor. The transmission comprises the motor, a brake disc, a walking wheel assembly and a reducer. The motor and the brake disc are transversely arranged on the fixed end of an axle, and the walking wheel assembly and the wheel reducer are transversely arranged on the cantilever end of the axle; a walking wheel support shaft is unidirectionally fixed by adopting double fulcrums, one end of the support shaft is fixed on the bogie frame, the other end of the support shaft is suspended, the fixed end of the support shaft is supported by a self-aligning roller bearing, and the cantilever end of the support shaft is supported by a group of tapered roller bearings installed in an axle box in the reverse direction. Longitudinal symmetric planes of the walking wheels are coincided with longitudinal symmetric planes of track beams. The single axle bogie transmission of the straddle-type single rail vehicle has the technical beneficial effects that the bogie is compact in structure, tires are disassembled and assembled easily, and the curve passing performance of the cantilever beam straddle-type single rail vehicle is met.

Owner:SOUTHWEST JIAOTONG UNIV

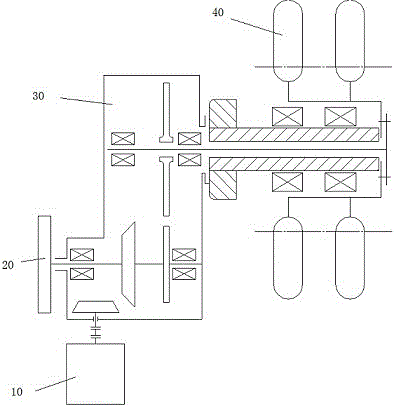

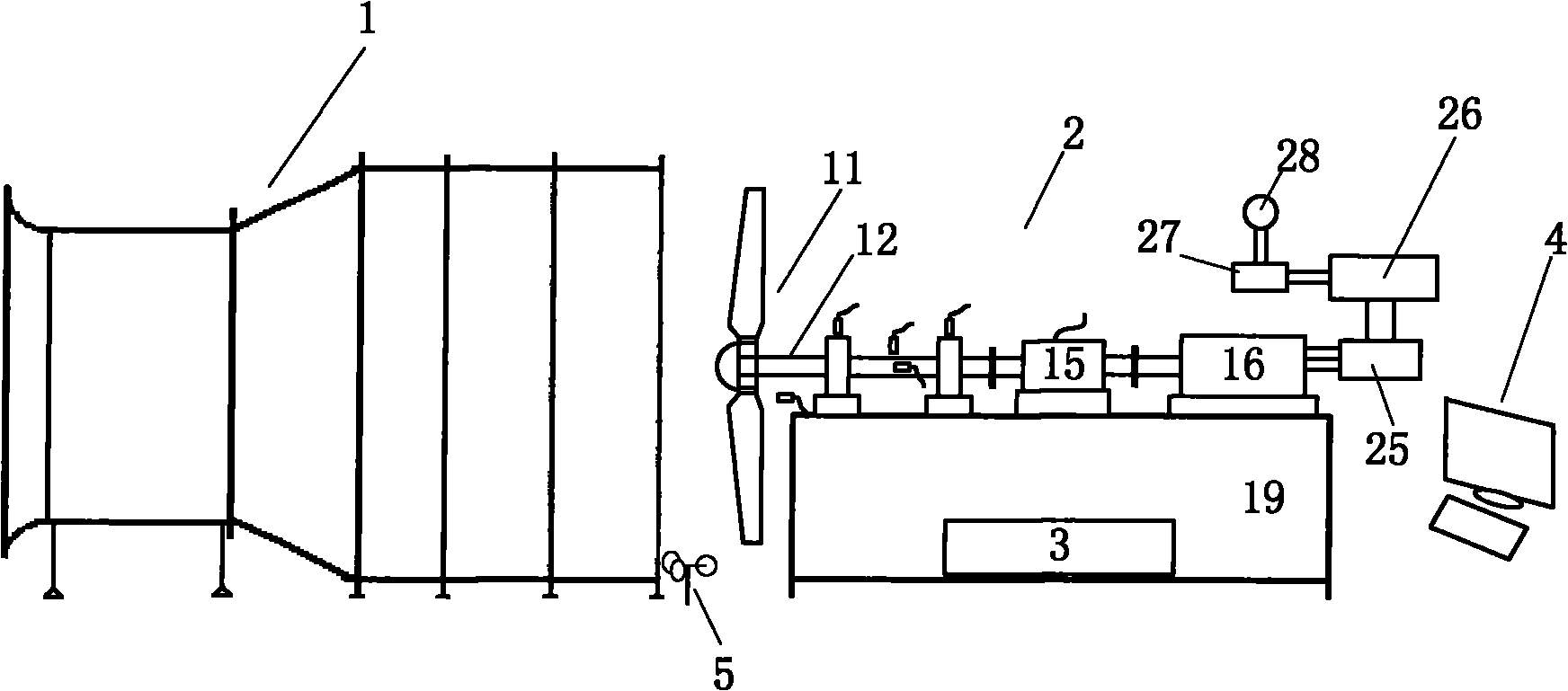

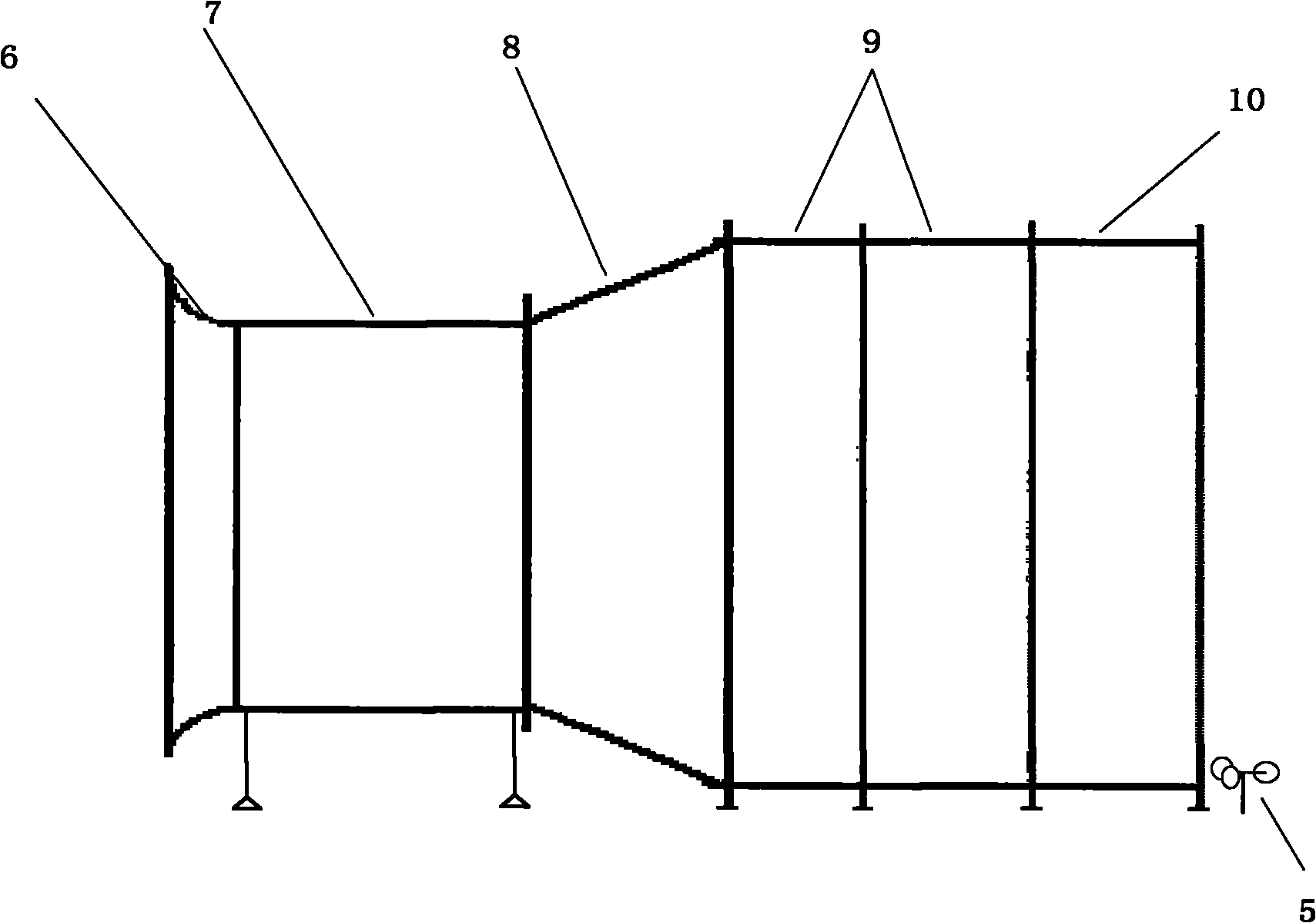

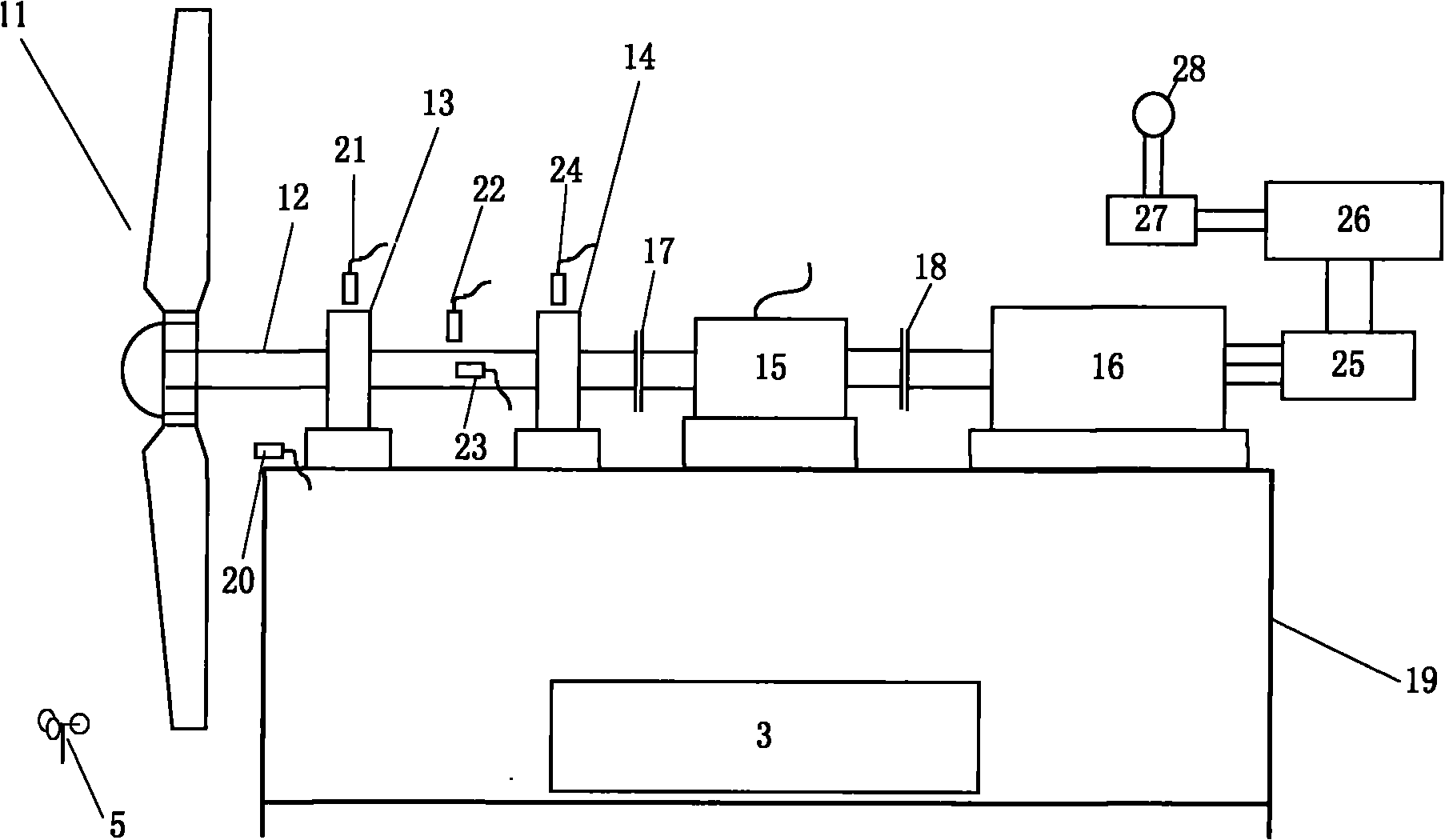

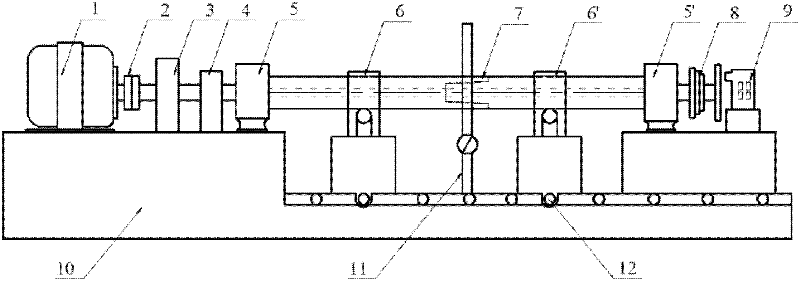

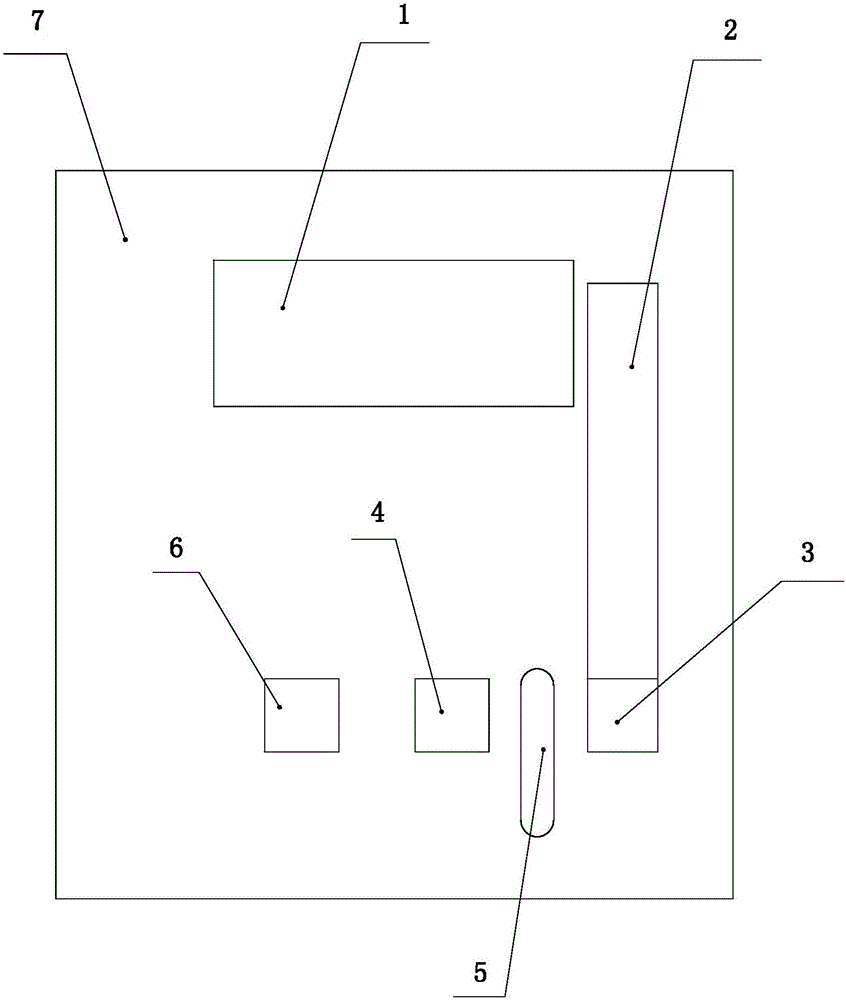

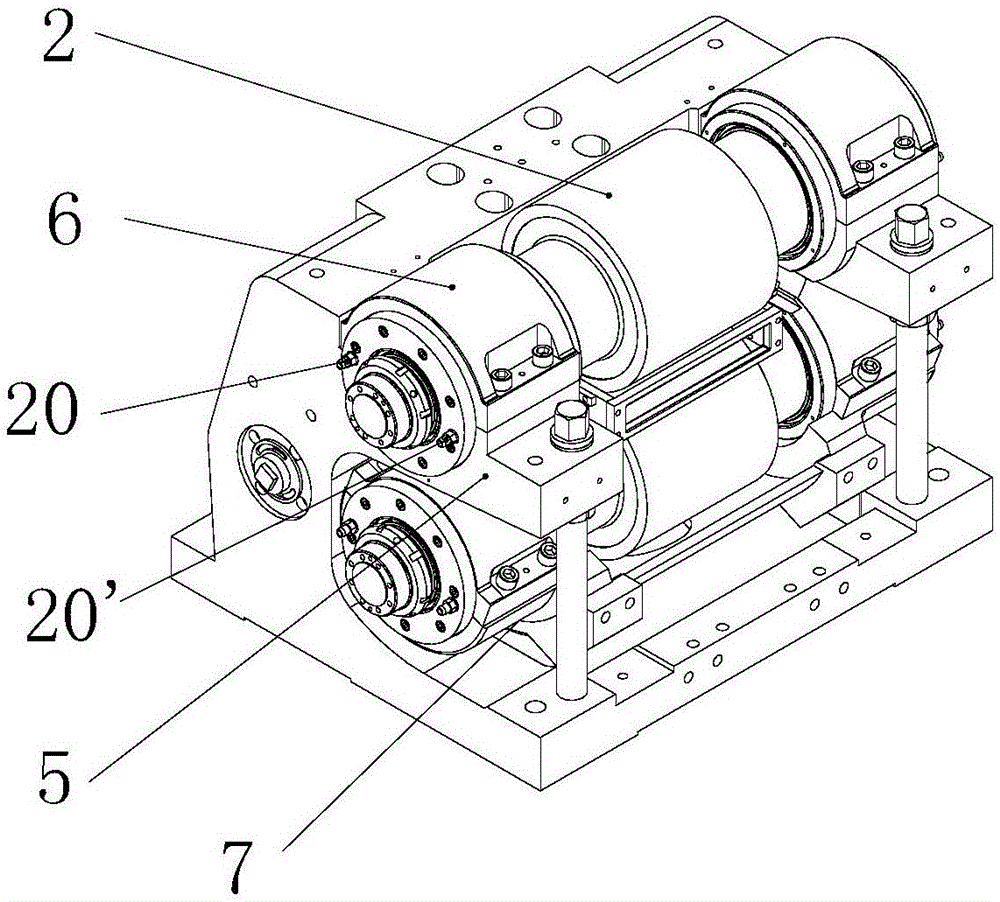

Performance analysis and fault simulation experiment system of wind machine

ActiveCN101871844ASimulation is accurateIncrease opennessAerodynamic testingEngine testingWinding machineReal time analysis

The invention relates to a performance analysis and fault simulation experiment system of a wind machine, belonging to the technical field of wind machine experiment devices. The system comprises a wind tunnel, a wind machine experiment device and a data analysis and processing system, wherein the wind machine experiment device comprises a rack, a wind wheel, a spindle, a generator, a controller and a sensor of torques, wind speed, speed and displacement. The system can be used for researching the influences of different airfoil profiles, wind speeds, wind wheel faults and mechanical faults on the aerodynamic performance of the wind machine, the vibration characteristics and the output force of a shaft system, and the like, and various faults such as unbalanced wind wheel mass, unbalanced pneumatic power, yawing, no shaft system centering, supporting seat loosening, bearing damages, and the like of the wind machine are simulated and analyzed in real time. Through selecting and assembling different types of bearings such as a self-aligning roller bearing, a cylinder roller bearing, a tapered roller bearing, and the like, the performances of the wind machine in different supporting forms can be compared. The system has good openness, dismantlability and expansibility and is mainly suitable for the fields of scientific researches and teaching of the wind machine.

Owner:TSINGHUA UNIV

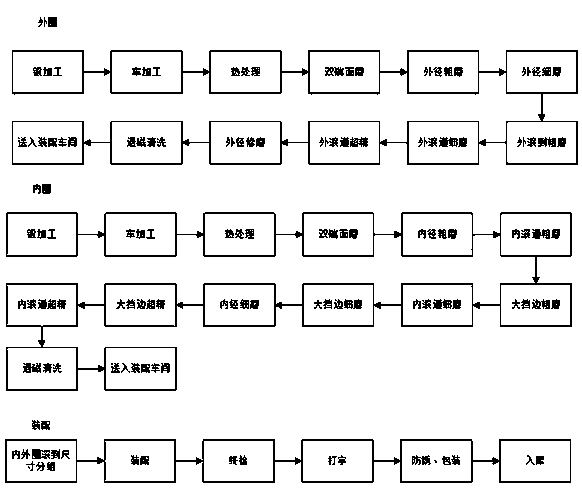

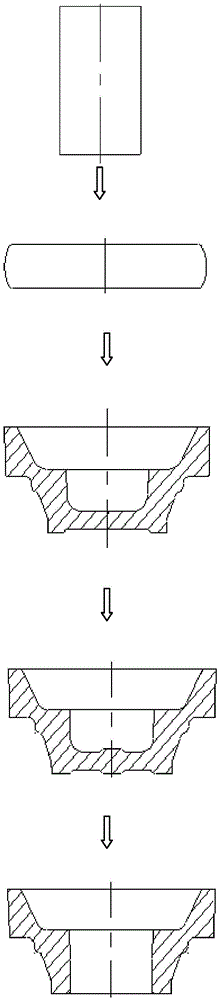

Production process for conical roller bearing

InactiveCN104191170ASimplify complex processing processesImprove processing qualityEngineeringThermal treatment

The invention discloses a production process for a conical roller bearing. The production process includes the following steps of the production technological process of an outer ring, the production technological process of an inner ring and the step that after the inner ring and the outer ring are sent to an assembly workshop, the sizes of an inner ring roller path and an outer ring roller path are grouped, assembling, final inspecting, typewriting, rust protecting and packaging are conducted, and then the conical roller bearing is put in storage. The production technological process of the outer ring includes the steps of forging, lathing, thermal treatment, double end face grinding, outer diameter part coarse grinding, outer diameter part fine grinding, outer roller path coarse grinding, outer roller path fine grinding, outer roller path super-finishing, outer diameter coping and demagnetization cleaning and the step of sending the outer ring to an assembly workshop. The production technological process of the inner ring includes the steps of forging, lathing, thermal treatment, double end face grinding, inner diameter coarse grinding, inner roller path coarse grinding, large flange coarse grinding, inner roller path fine grinding, large flange fine grinding, inner diameter fine grinding, large flange super-finishing, inner roller path super-finishing and demagnetization cleaning and the step of sending the inner ring to the assembly workshop. The production process has the advantages that the complex machining procedures of an ordinary process are simplified, bearing machining quality is improved, production efficiency is greatly improved, and production cost is saved.

Owner:ZHEJIANG HUANYU BEARING

Experiment device for testing fatigue life of threading connector of petroleum drill

InactiveCN102410963AOvercoming the Insufficiency of Fatigue Life TestingMaterial strength using repeated/pulsating forcesStress workingMeasuring instrument

The invention provides an experiment device for testing fatigue life of threading connector of petroleum drill, which comprises a base, a guide rail, a motor, a coupler, a floating bearing, an aligning roller bearing, a fixing end spring clamp, a bending moment applying device, a flexivity measuring instrument, a tail seat and a counter. Bending stress can be applied to the threading connector of the drill by the bending moment applying device based on four-point bending principle. The fixing end spring clamp is driven by the motor to rotate, so the threading connector of the drill can be rotated under certain torsion moment. Therefore, composite alternating stress working conditions of drill under well can be truly simulated. The experiment device is suitable for test research on fatigue life of full-size drill.

Owner:SOUTHWEST PETROLEUM UNIV

Double-row self-aligning roller bearing and device for supporting wind turbine generator main shaft

A double-row self-aligning roller bearing includes left and right rows of rollers, arranged between an inner race and an outer race. A raceway surface of the outer race represents a spherical shape and the rollers have an outer peripheral surface following the shape of the raceway surface of the outer race. The rollers of the left and right roller rows have respective lengths different from each other. Also, the left and right roller rows have respective contact angles different from each other.

Owner:NTN CORP +1

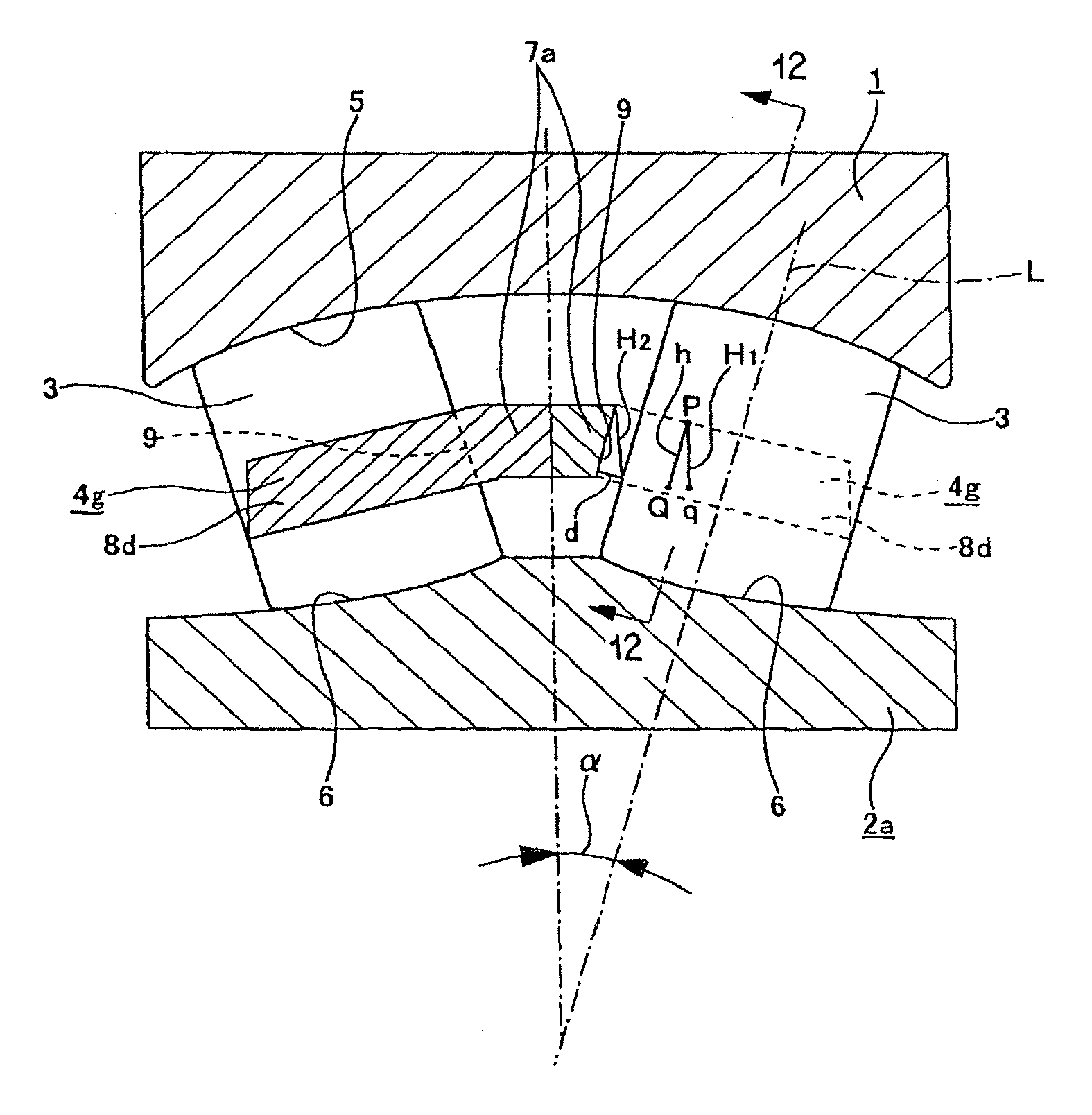

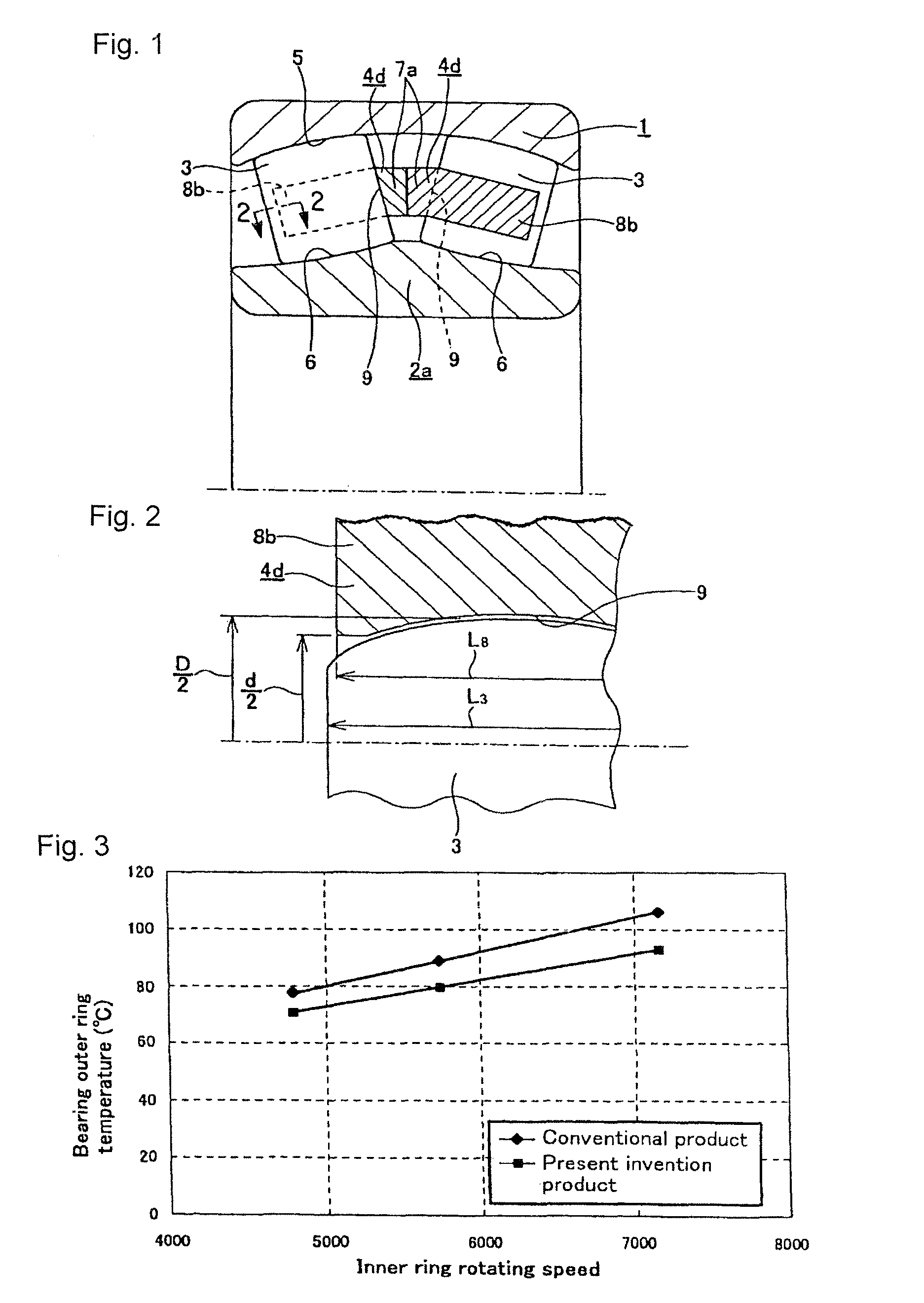

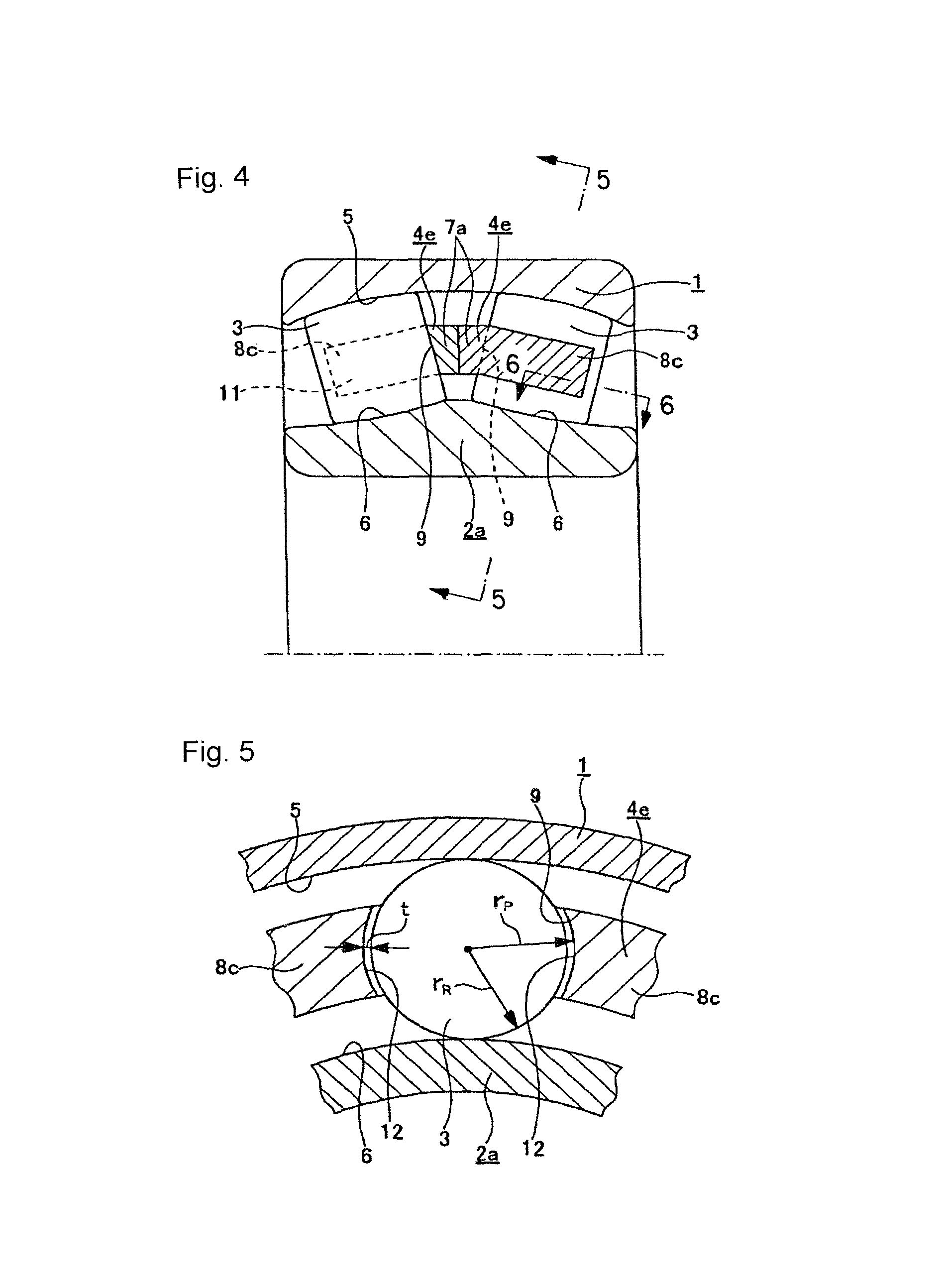

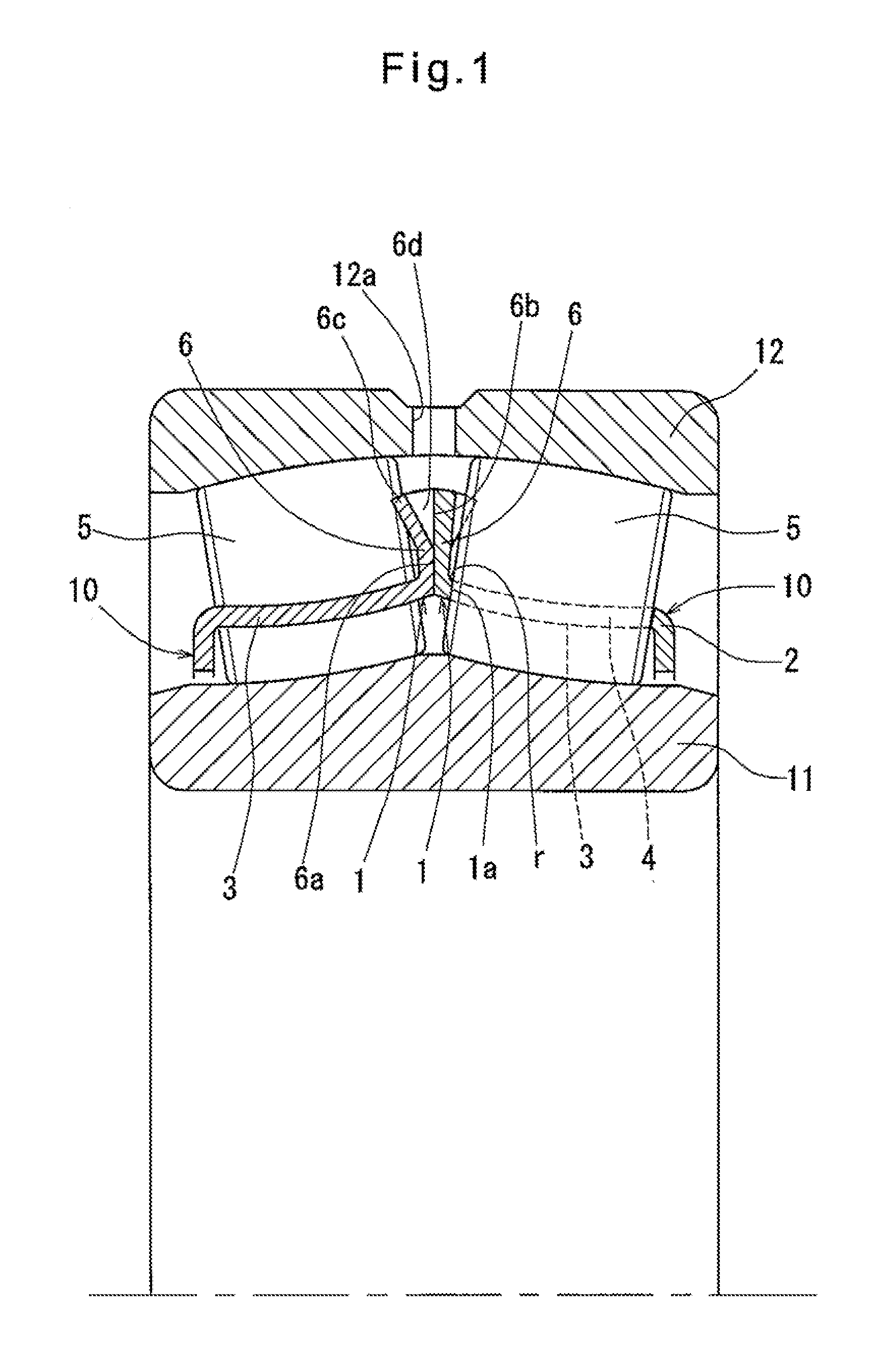

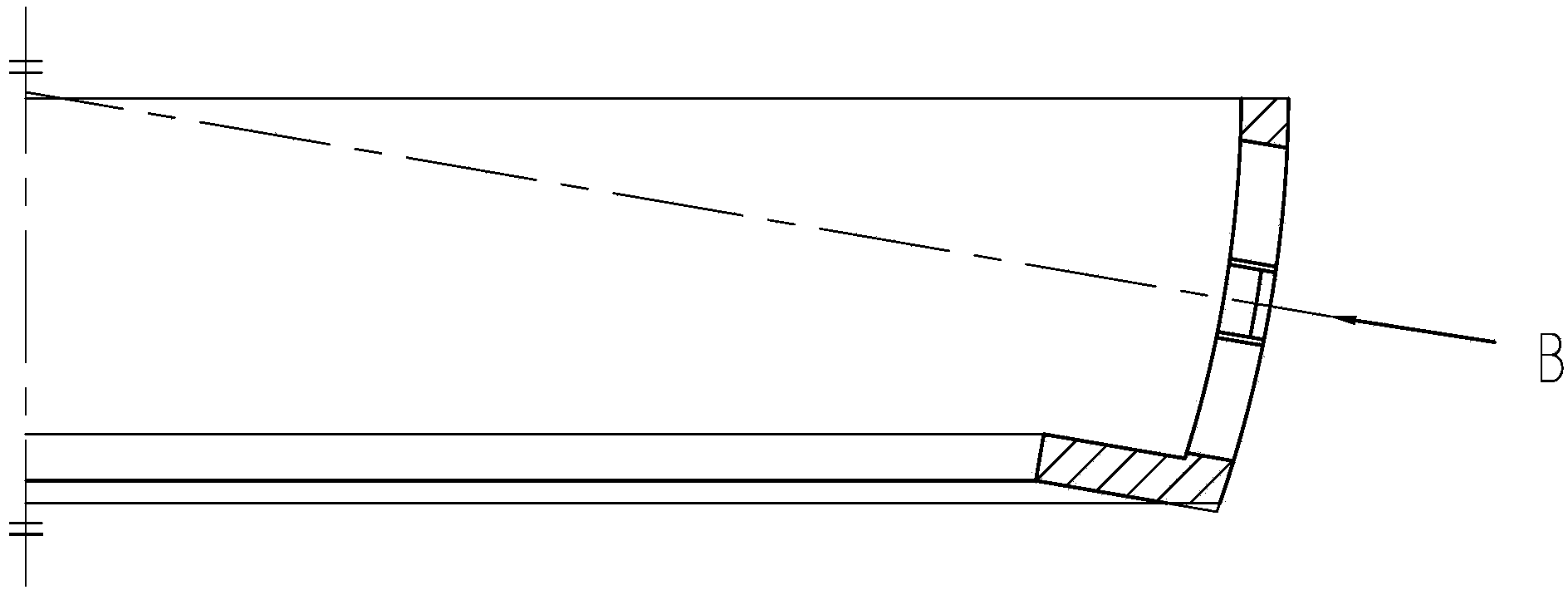

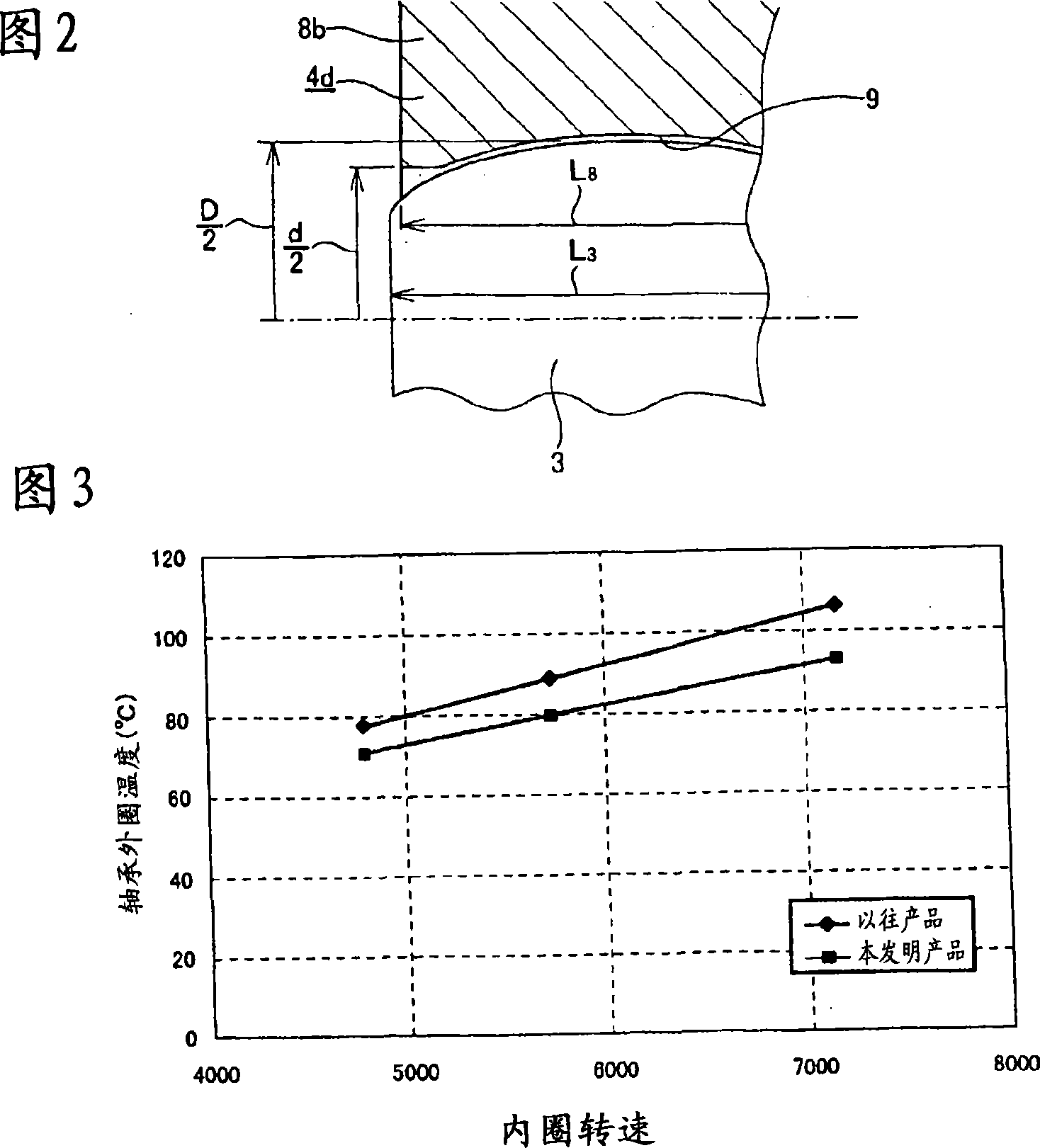

Double Row Self-Aligning Roller Bearing And Main Shaft Support Structure Of Wind Power Generator

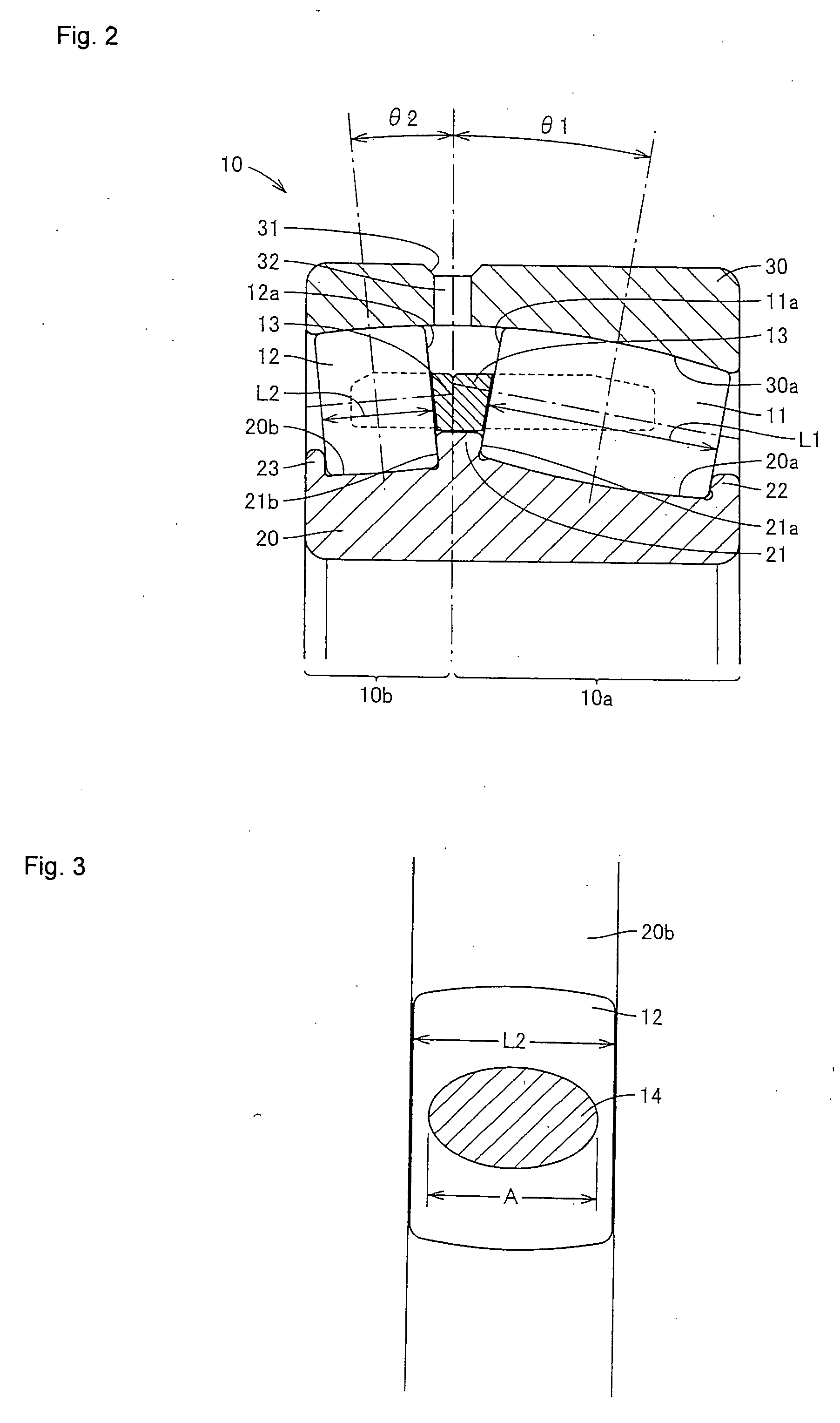

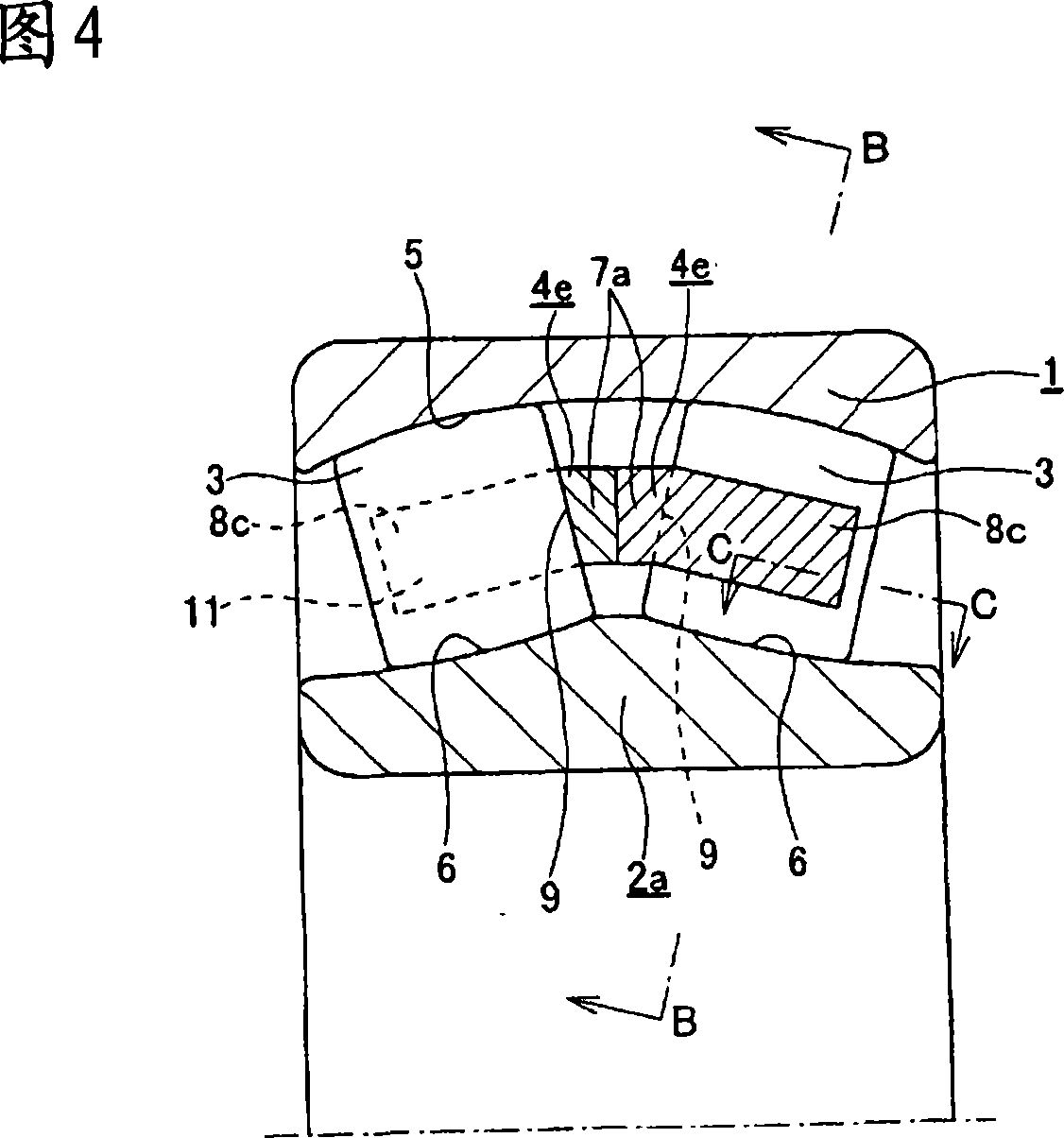

When it is assumed that the length of the spherical roller (11) in one row is L1, the length of the spherical roller (12) in the other row is L2, and the length of the longer axis of a contact ellipse (14) generated on the contact surface between the spherical roller (12) in the other row and a track ring (20b) is A, the relation such thatL2<L1 andL2>Ais satisfied.

Owner:NTN CORP

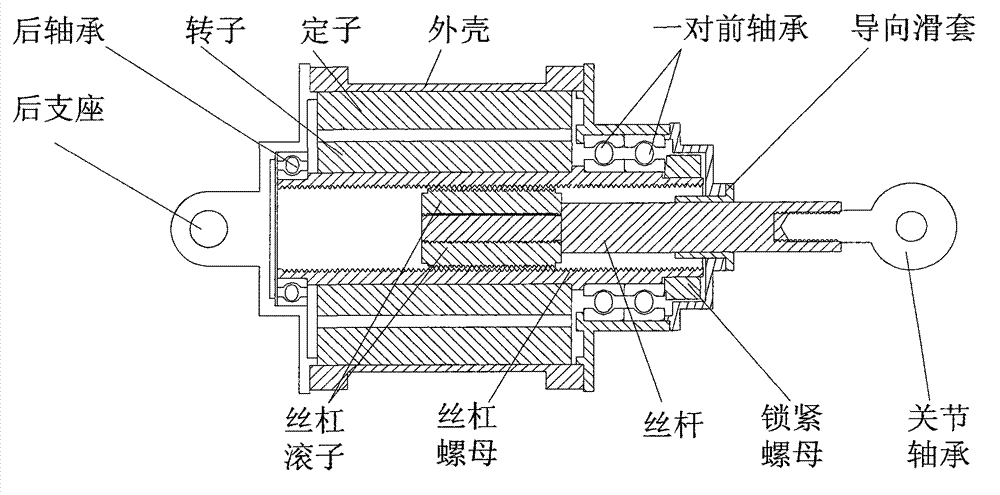

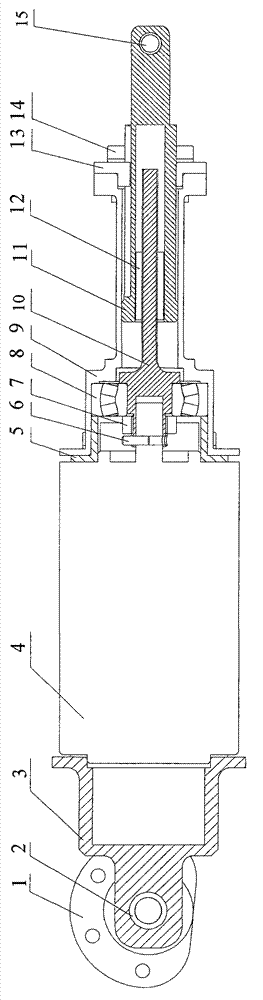

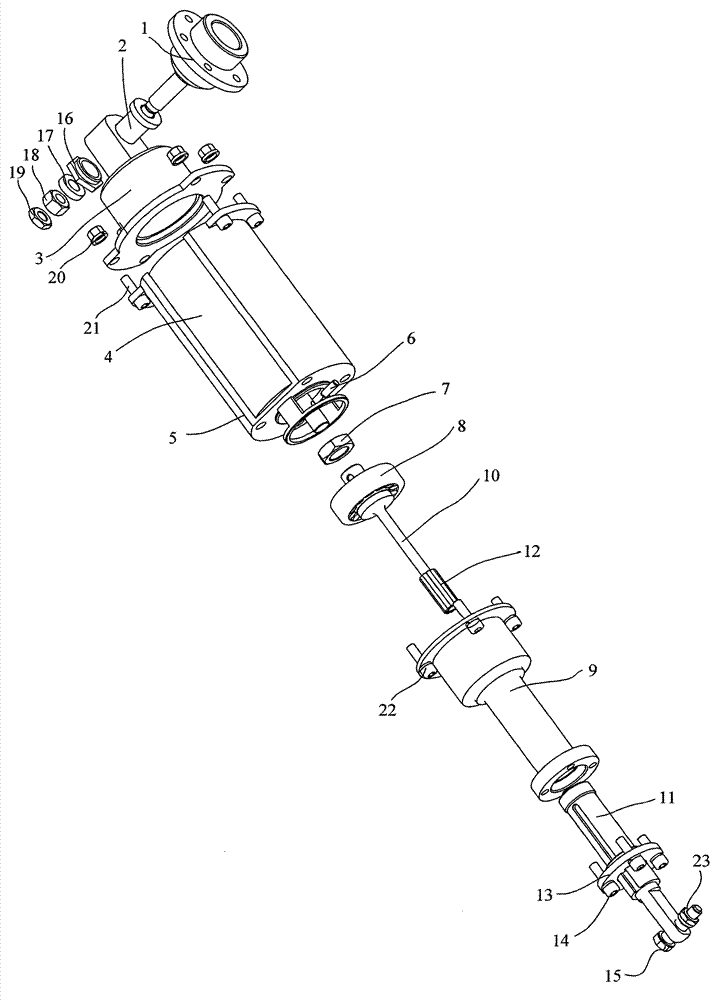

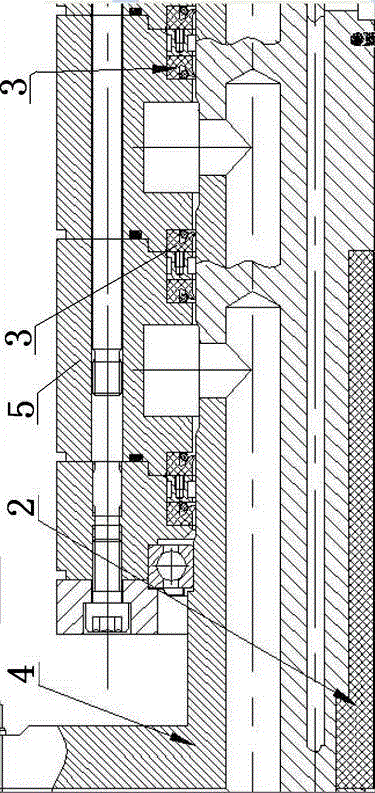

Compact electric servo mechanism for linear displacement

ActiveCN102931760AReduce design difficultyGuaranteed integrityGearingMechanical energy handlingBall screwElectric machine

The invention provides a compact electric servo mechanism for linear displacement. The compact electric servo mechanism comprises a support saddle, a sliding bearing, a motor connector, a motor, a motor shell, a self-aligning roller bearing, a screw support shell, a ball screw, a ball screw nut, a screw roller, a guide element, an output shaft and a sliding bearing end cover. According to the compact electric servo mechanism, the integrity of the motor structure is ensured by a combined design of the screw and the motor; the motor does not need to be independently designed; the design difficulty of the motor is reduced; the motor is directly connected with the ball screw to achieve direct drive, and the screw nut moves forwards and backwards when the motor rotates, so that the screw nut does not need to adopt the structure of a long thread hole, and a guide groove is designed on the screw nut to be used along with the guide element. Therefore, the accurate servo control of linear displacement is achieved, and the linear output of the mechanism does not need the assistance of an external structure.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

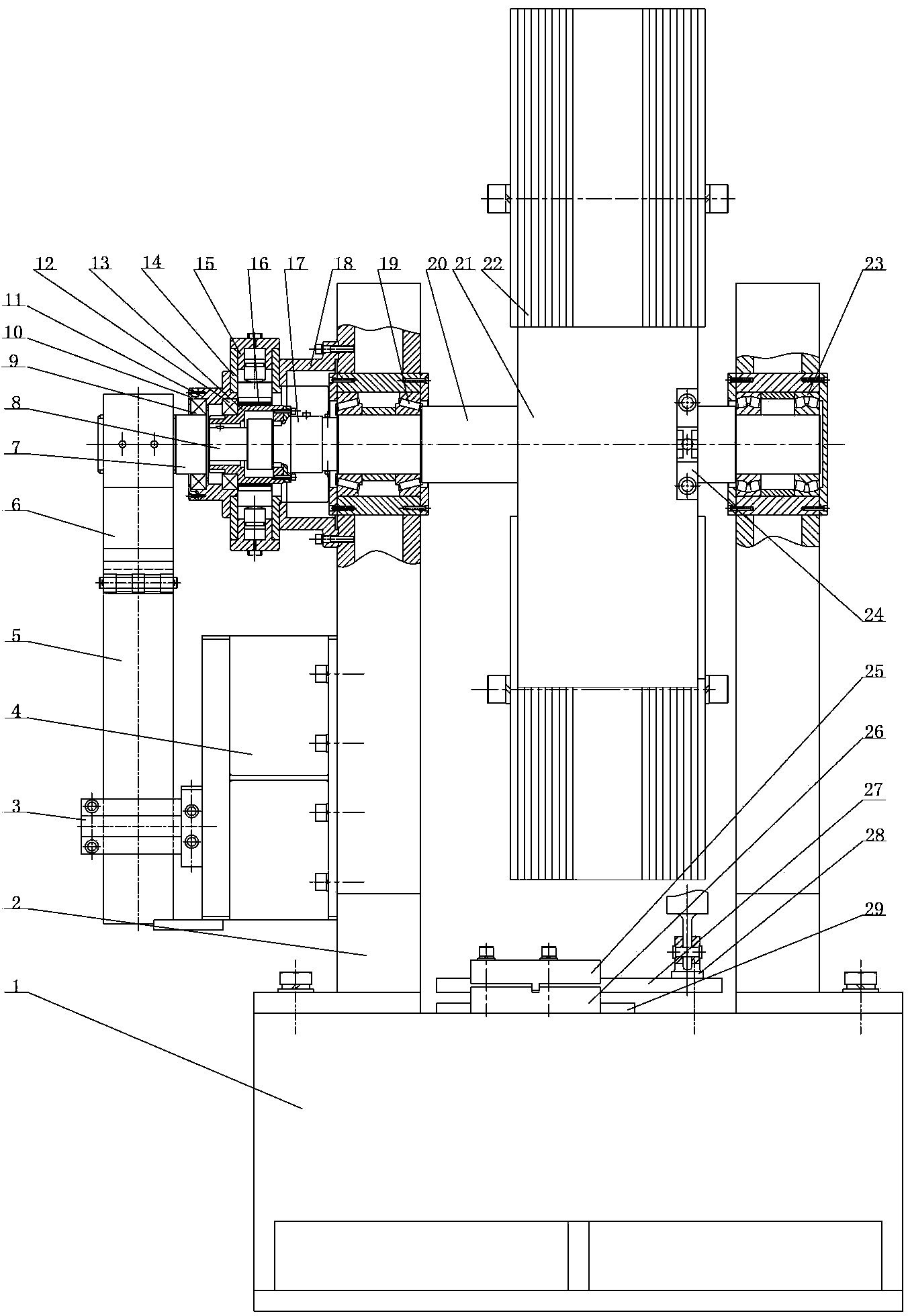

Servo mechanism load simulator

InactiveCN103413474AReal-time monitoring sizeContinuous regulationCosmonautic condition simulationsSimulatorsFriction torqueBall bearing

A servo mechanism load simulator comprises a base, side upright plates, elastic moment spring plate clamping boards, an elastic moment loading support, an elastic moment spring plate, a swing shifting fork, an elastic moment rotary shaft, an elastic moment sensor, ball bearings, a bearing cap, a bearing seat, a friction shaft, a small oil cylinder seat, friction moment loading small oil cylinders, friction sheets, a friction moment sensor, an installation seat, roller bearings, a main shaft, an inertia basic disc, an inertia balance weight disc, self-aligning roller bearings, an upper supporting lug, a supporting spring plate cover plate, a supporting spring plate base, a supporting spring plate, a lower supporting lug, a guide bar and a servo mechanism to be measured. According to the servo mechanism load simulator, the structural characteristics, comprising the inertia load, the elastic moment load, the friction moment load and the supporting rigidity, of a rocket engine tail nozzle can be simulated; the elastic moment and the friction moment can be respectively measured through a torque sensor. The servo mechanism load simulator has the advantages of being simple and compact in structure and capable of enabling the structural characteristics of the actual rocket tail nozzle to well reappear.

Owner:BEIHANG UNIV

Machining method for inner ring and outer ring of conical roller bearing

The invention discloses a machining method for an inner ring and an outer ring of a conical roller bearing, and relates to a bearing machining method. The method is used for solving the problems that in existing bearing machining, detection omission is prone to occurrence in steel material detection, deformation is large after thermal treatment, grinding amount increase exists, grinding efficiency is reduced, product quality can be not ensured easily, and manufacturing cost is increased. The method includes the steps of firstly, conducting nondestructive examination of steel materials; secondly, cutting off examined steel materials; thirdly, forging an inner and outer one-piece sleeve ring; fourthly, conducting annealing; fifthly, lathing the inner and outer one-piece sleeve ring; sixthly, quenching the lathed inner and outer one-piece sleeve ring; seventhly, separating the sleeve ring into an inner ring and an outer ring; eighthly, conducting chamfering; ninthly, grinding the inner ring and the outer ring. The thermal treatment deformation is greatly reduced, the grinding residual amount is decreased, and grinding efficiency is improved; the method is suitable for machining the inner ring and the outer ring of the bearing.

Owner:哈尔滨汽车轴承有限公司

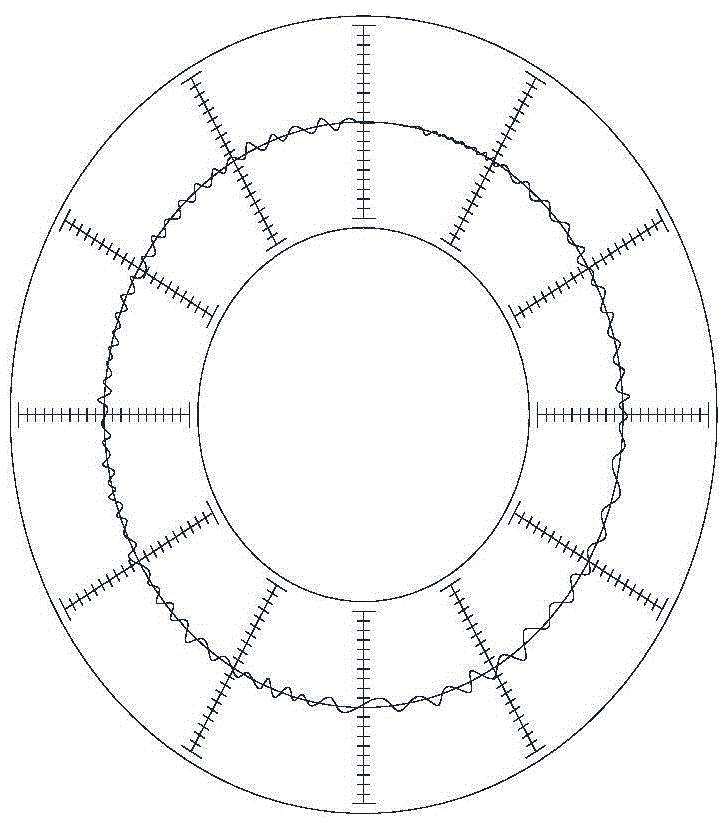

Spherical roller bearing solid cage center-diameter and angle measuring method

InactiveCN101071056AEasy to measureThe measurement method is feasibleAngles/taper measurementsMechanical diameter measurementsCircular coneEngineering

The invention relates to a test way of bearing entity holder center drive and angle, particularly relates to the test way of a sphere roller bearing entity holder center drive and the angle. Its characteristic lies in the method including the following steps: first mash and process the center die, the center die is conical die form and roller; then put said three rollers into any three cage ball pockets of tested sphere roller bearing entity. Observing the match condition between said rollers' outside surface and said die form's circular conical surface shows whether the holder center drive and angle of tested sphere roller bearing entity satisfies the designing requirement. The invention's test way is simple, feasible, and test accuracy is high, defective index is low.

Owner:BAOTA IND CO LTD

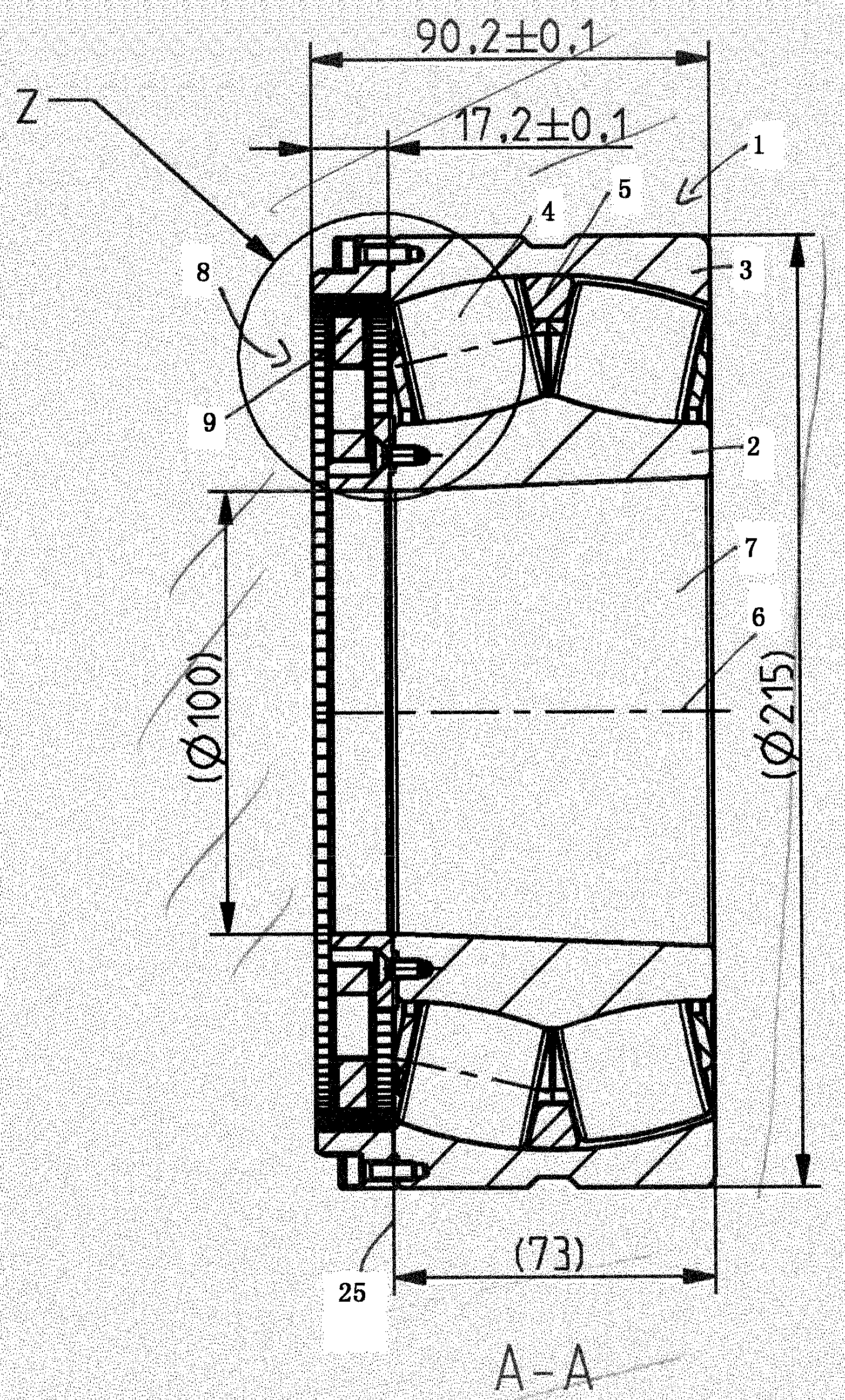

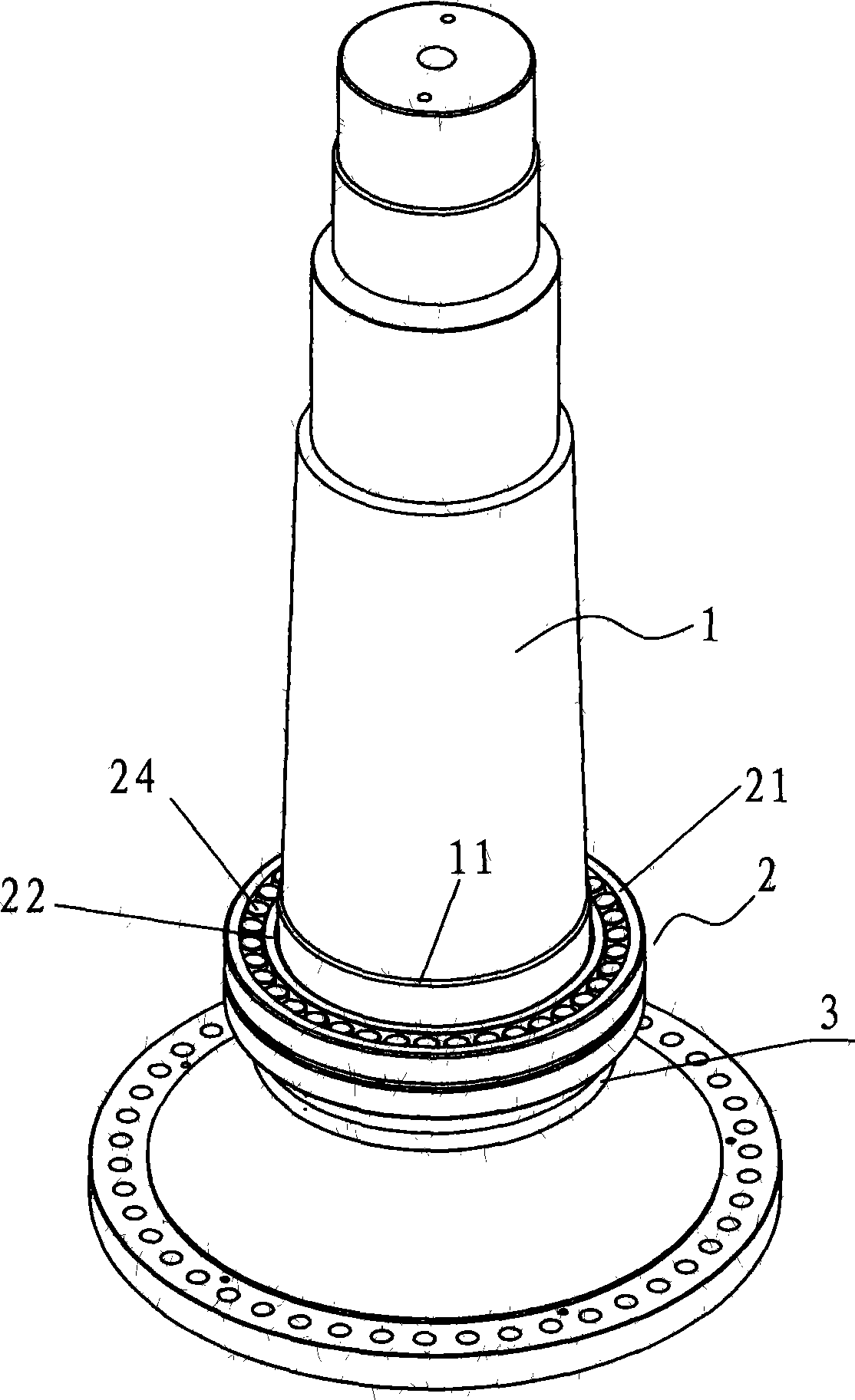

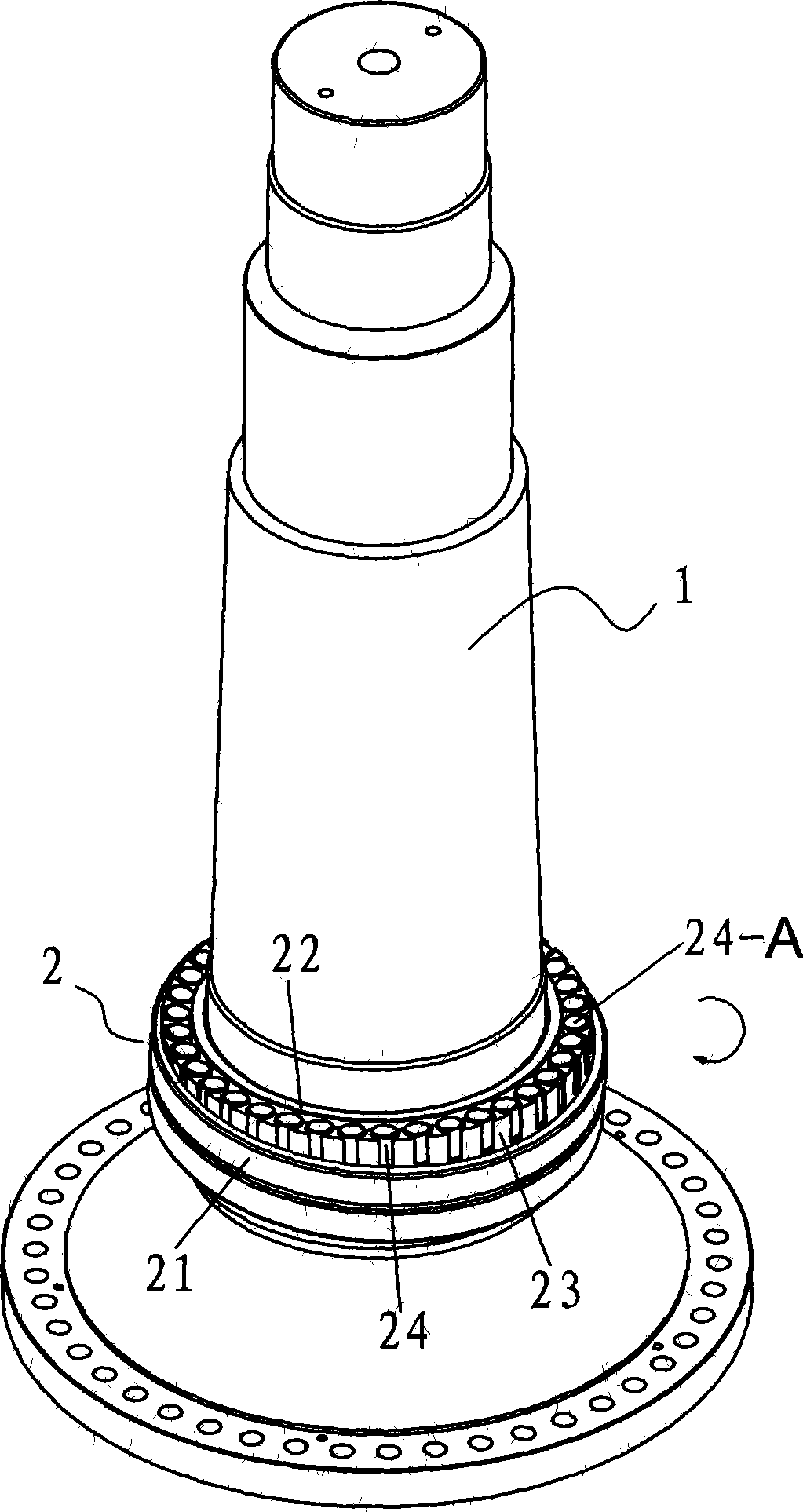

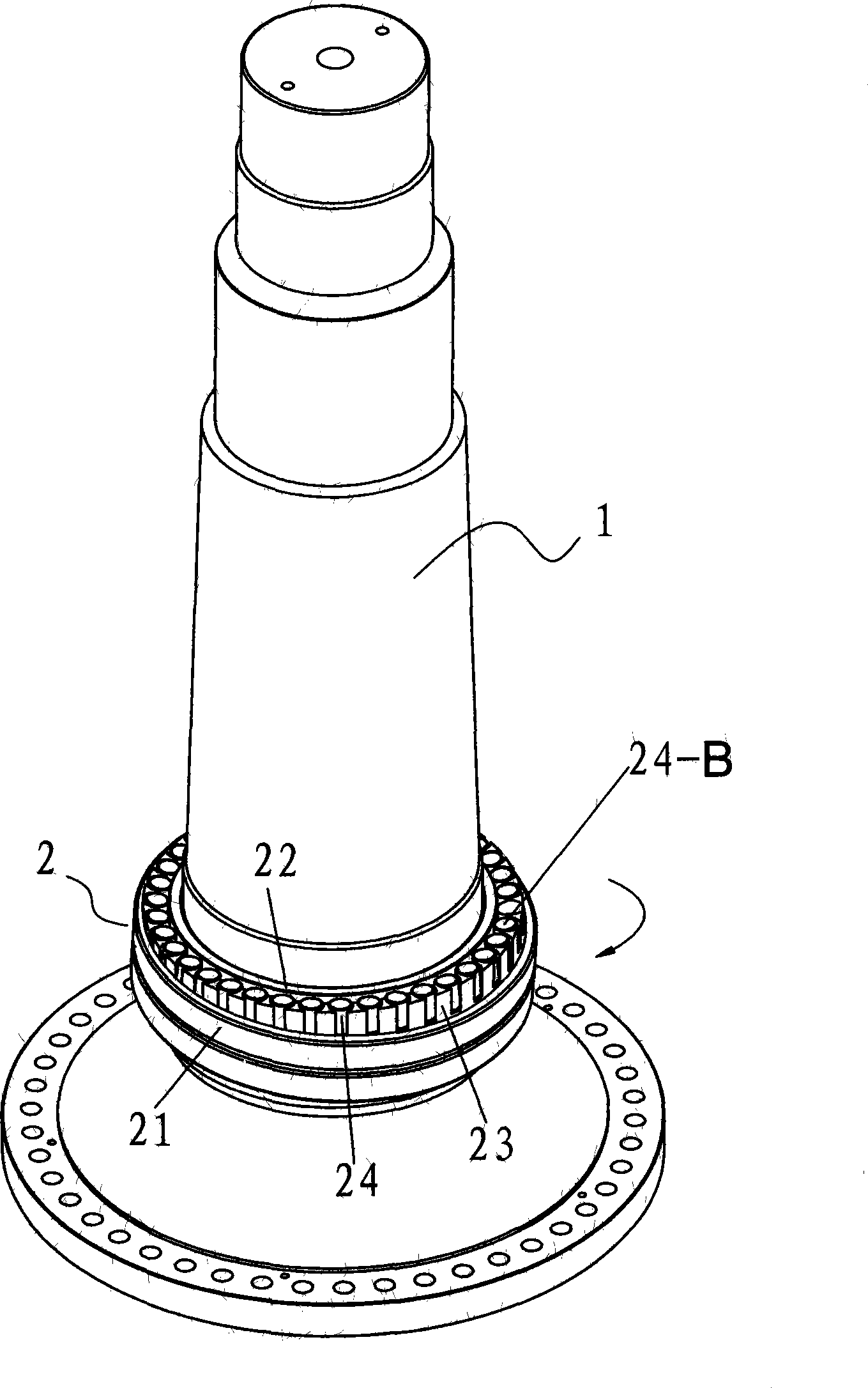

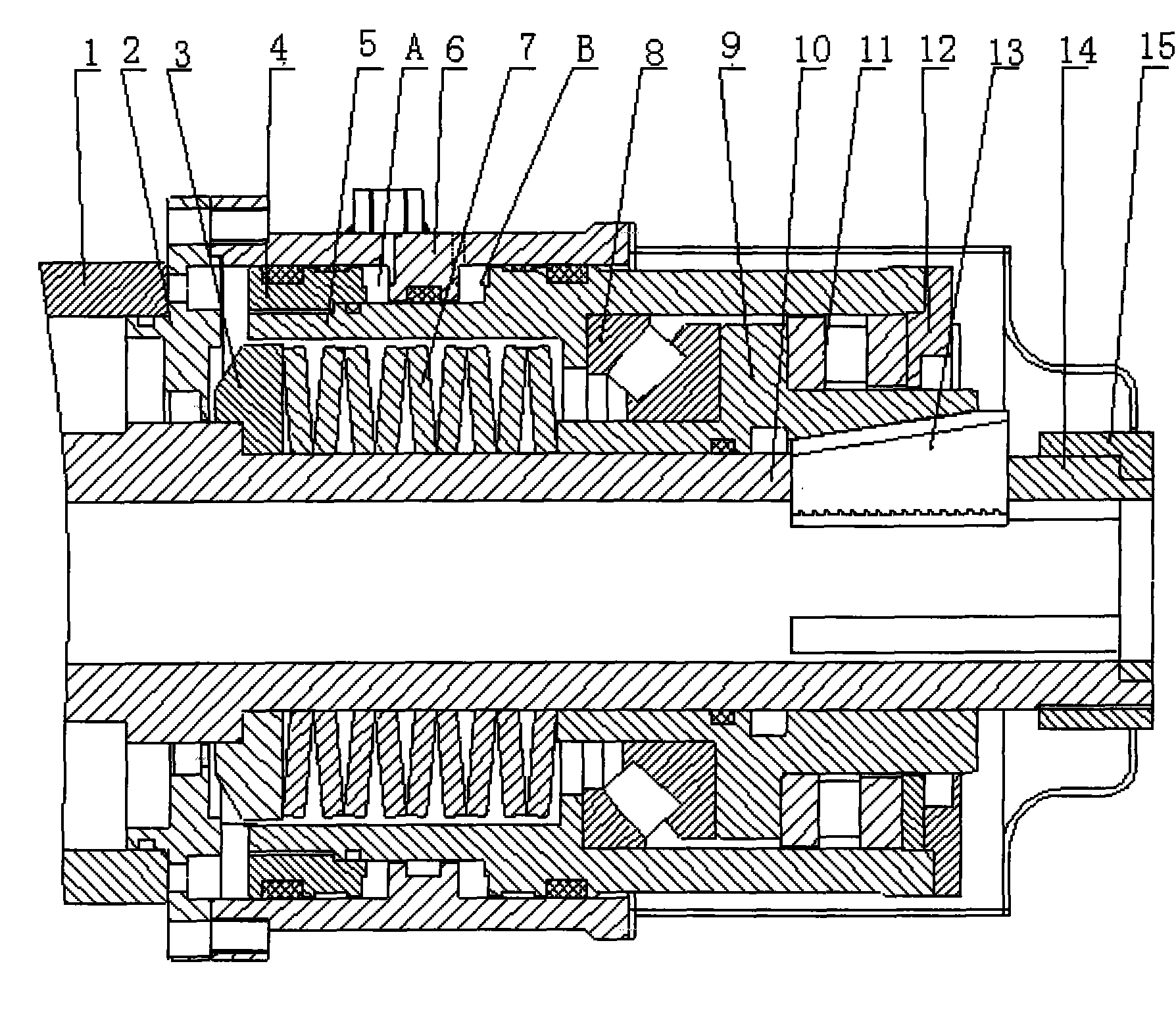

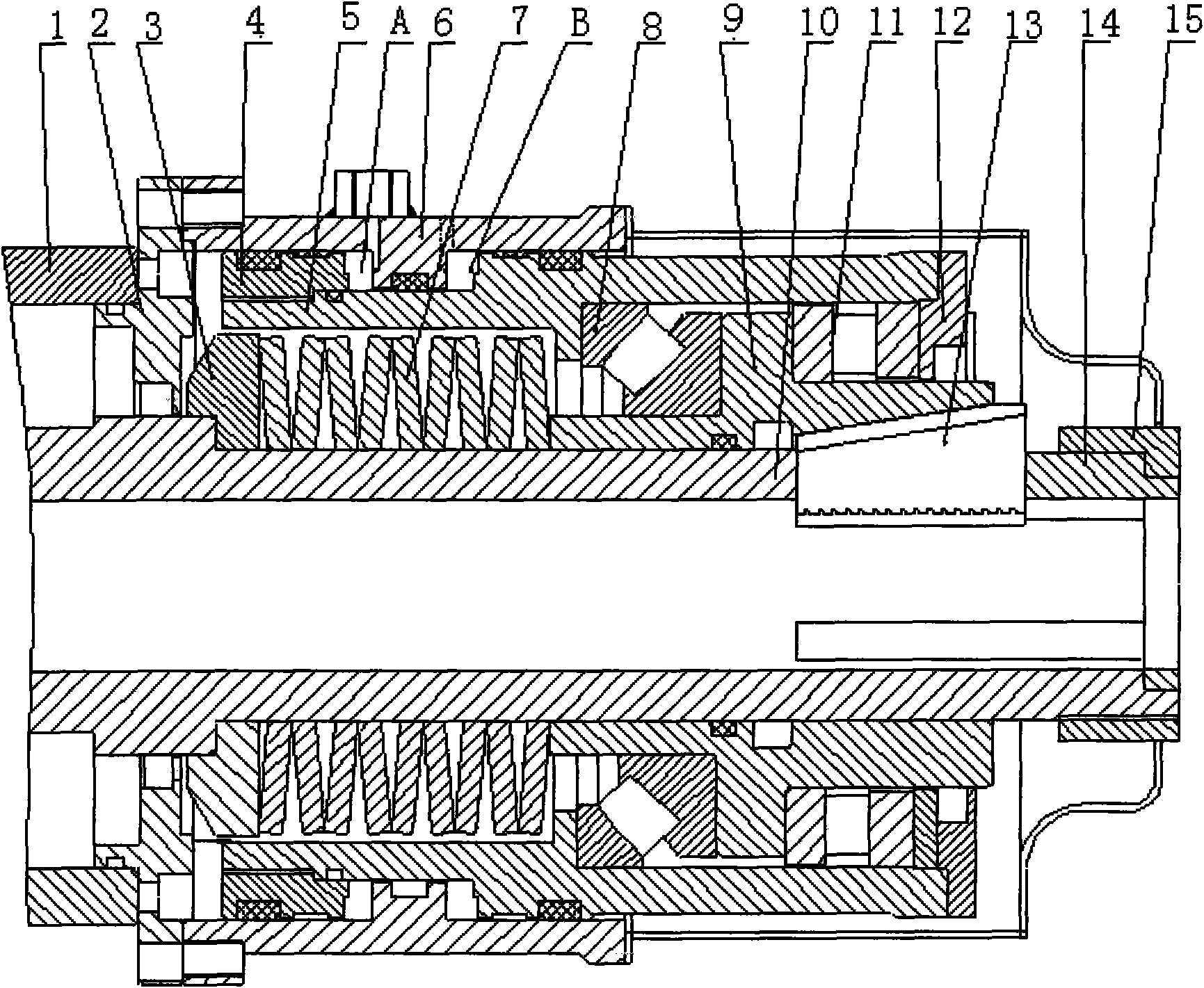

Bearing with an energy production unit, in particular self-aligning roller bearing for the mounting of a roller

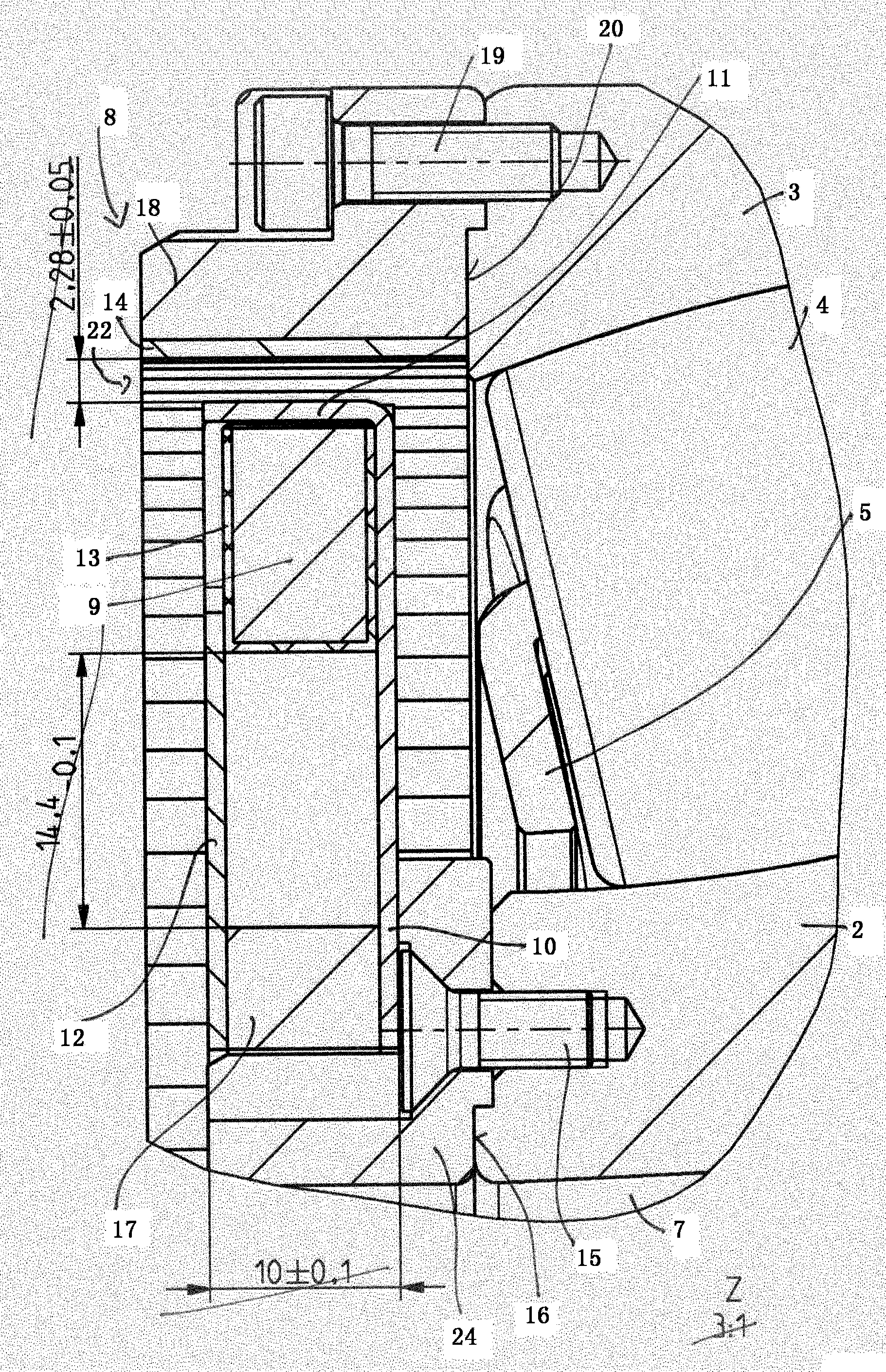

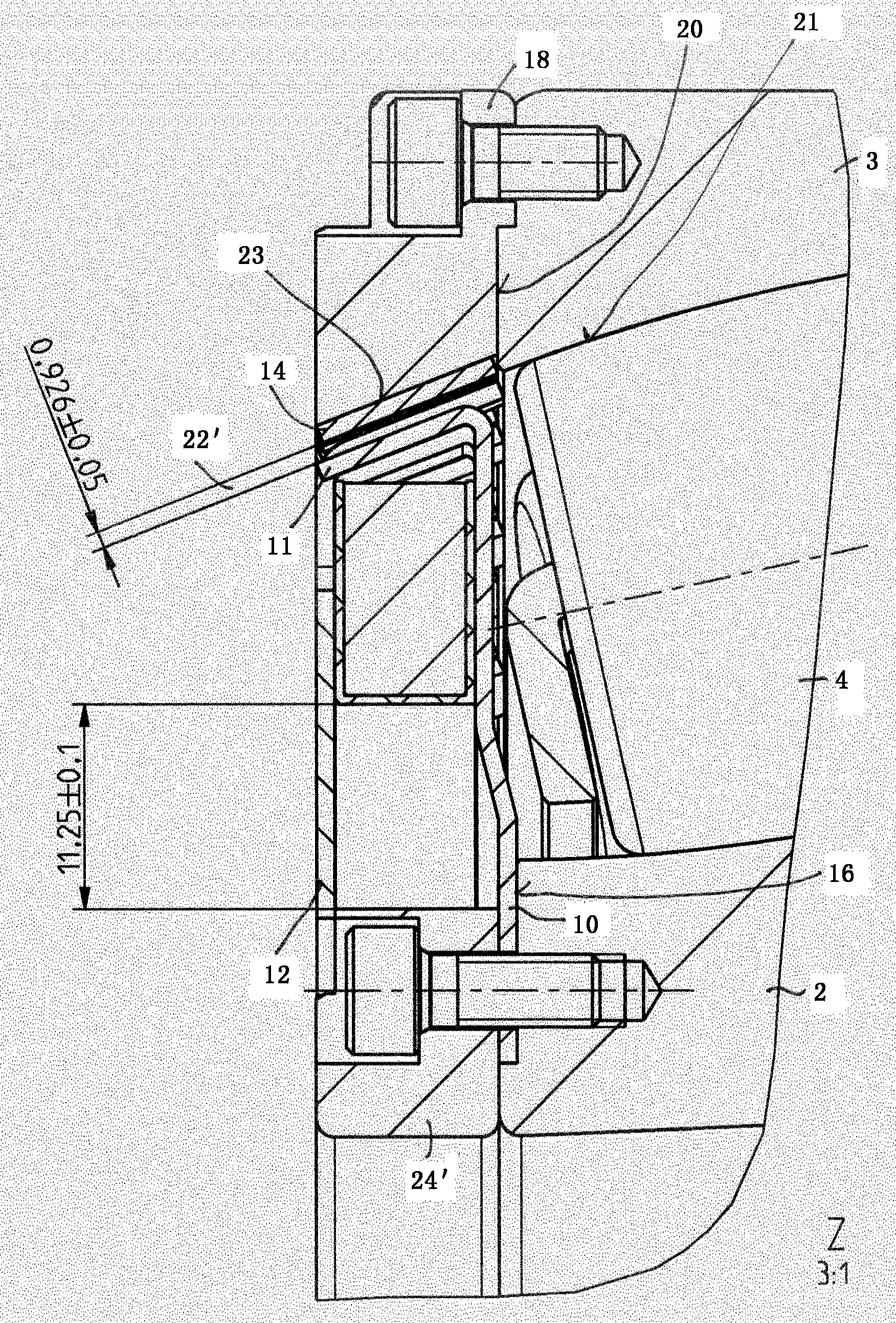

InactiveCN103547821ASave construction spaceMake sure it's closedRoller bearingsBearing assemblyMagnetic polesConductive materials

The invention relates to a bearing, in particular rolling contact bearing (1), comprising a first bearing ring (2), a second bearing ring (3) and an energy production unit (8) designed as a claw pole generator, wherein the claw pole generator (8) comprises a first claw ring (10) with a sequence of first claws (11) and a second claw ring (12) which is offset in the revolving direction of the axis of rotation (6) and has a sequence of second claws, wherein the two claw rings (10, 12) surround an induction coil (9) encircling the axis of rotation (6), wherein the claws (11) of the two claw rings (10, 12) together with a sequence of magnetic poles (14) encircling the axis of rotation (6) form magnetic circuits surrounding the induction coil (9). The problem of providing a bearing which permits retrofitting with a claw pole generator is solved according to the invention in that the claw rings (10, 12) and the induction coil (9) are fastened by a first support ring (24; 24') on an end surface (16) of the first bearing ring (2), in that the magnetic poles (14) are fastened on the end surface (20) of the second bearing ring (3) by means of a second support ring (18), wherein the magnetic poles (14) are connected in a magnetically conductive manner to one another by means of a return-path ring made from a magnetically conductive material, and wherein the two claw rings (10, 12) are connected in a magnetically conductive manner by means of a flux-conducting ring (17).

Owner:SCHAEFFLER TECH AG & CO KG

Self-aligning roller bearing with retainer and manufacturing method for self-aligning roller bearing retainer

ActiveUS8007184B2Prevent disengagementEasy to operateRoller bearingsBearing componentsEngineeringSpherical roller bearing

Owner:NSK LTD

Checking tool for bearing raceways of main shafts

ActiveCN107729597AFull controlShorten the design cycleBearing componentsDesign optimisation/simulationWind drivenDesign cycle

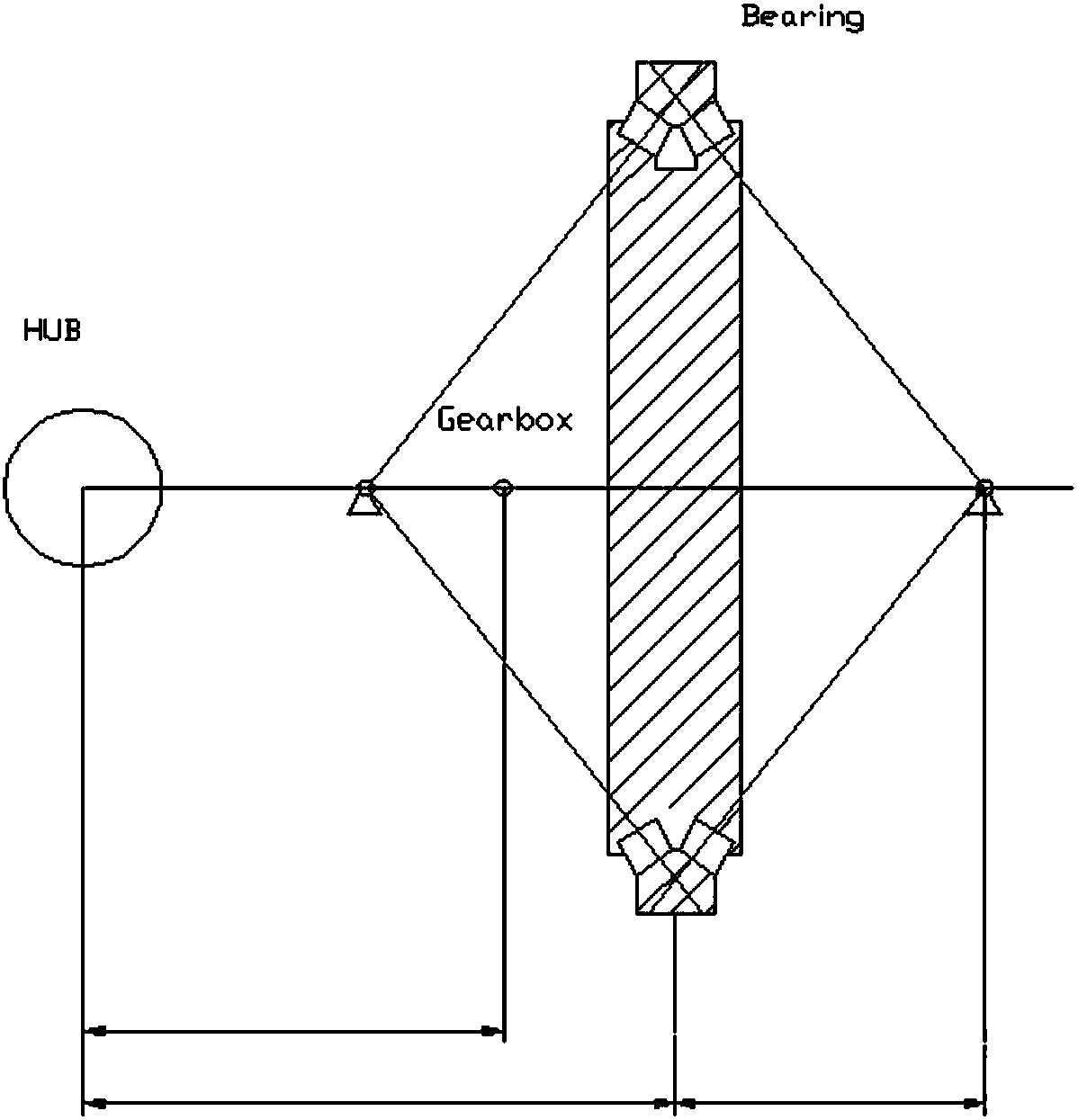

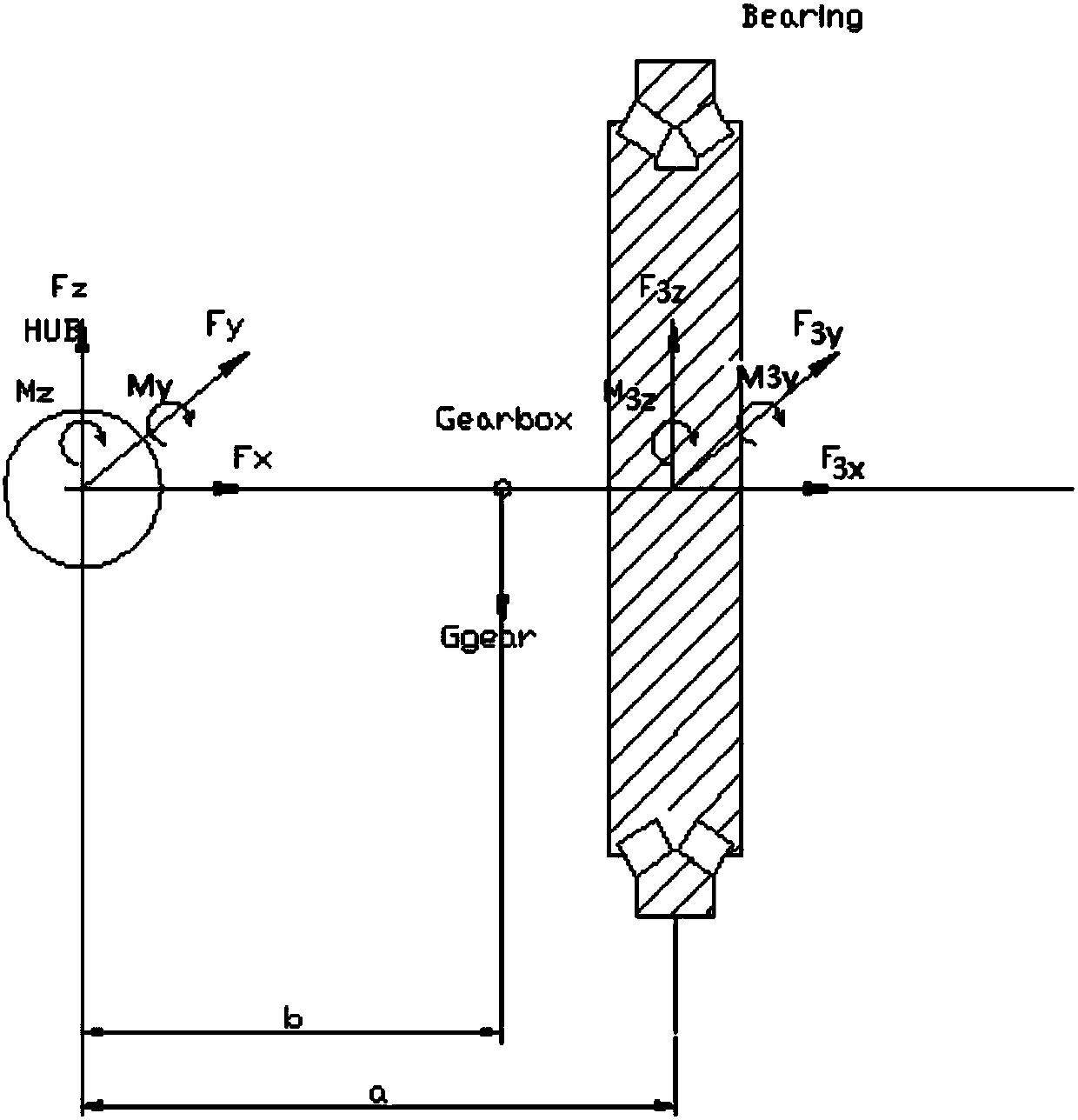

The invention discloses a checking tool for bearing raceways of main shafts. The tool can be used for directly conducting equivalence treatment on time sequence load and LDD load spectrums, each working condition is equivalent to one group of loads, the equivalent loads are loads at the centers of hubs and can be further transmitted to the centers of bearings through a balance relation, and the tool is divided into two modules including the checking module for double-row spherical roller bearing raceways and a checking module for double-row tapered roller bearing raceways according to a bearing structure form; firstly, the static strength safety factors and contact stress of the bearing raceways are solved according to a method provided in ISO76-2006 standards, secondly, the basic rating service life and corrected rating service life of the bearing raceways are solved according to ISO281-2007 standards, and finally, the reference service life of the bearings is solved according to ISO16281-2008 standards. By means of the tool, the starting design cycle of a complete machine can be very effectively shortened, the tool better serves to the design, certification and evaluation of a wind-driven generator, the reliability of the design of a wind-driven generator set is improved, and the cost is saved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

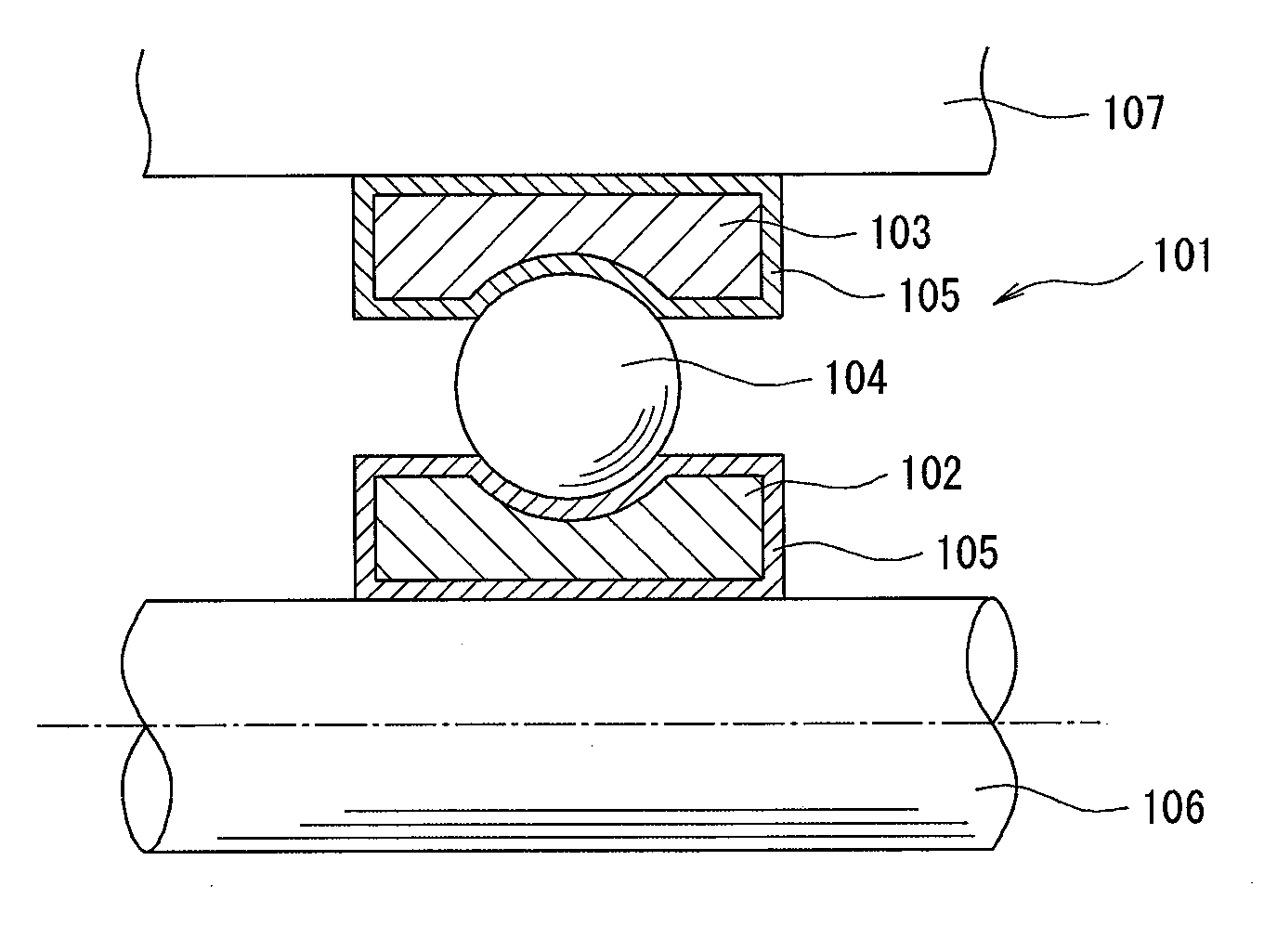

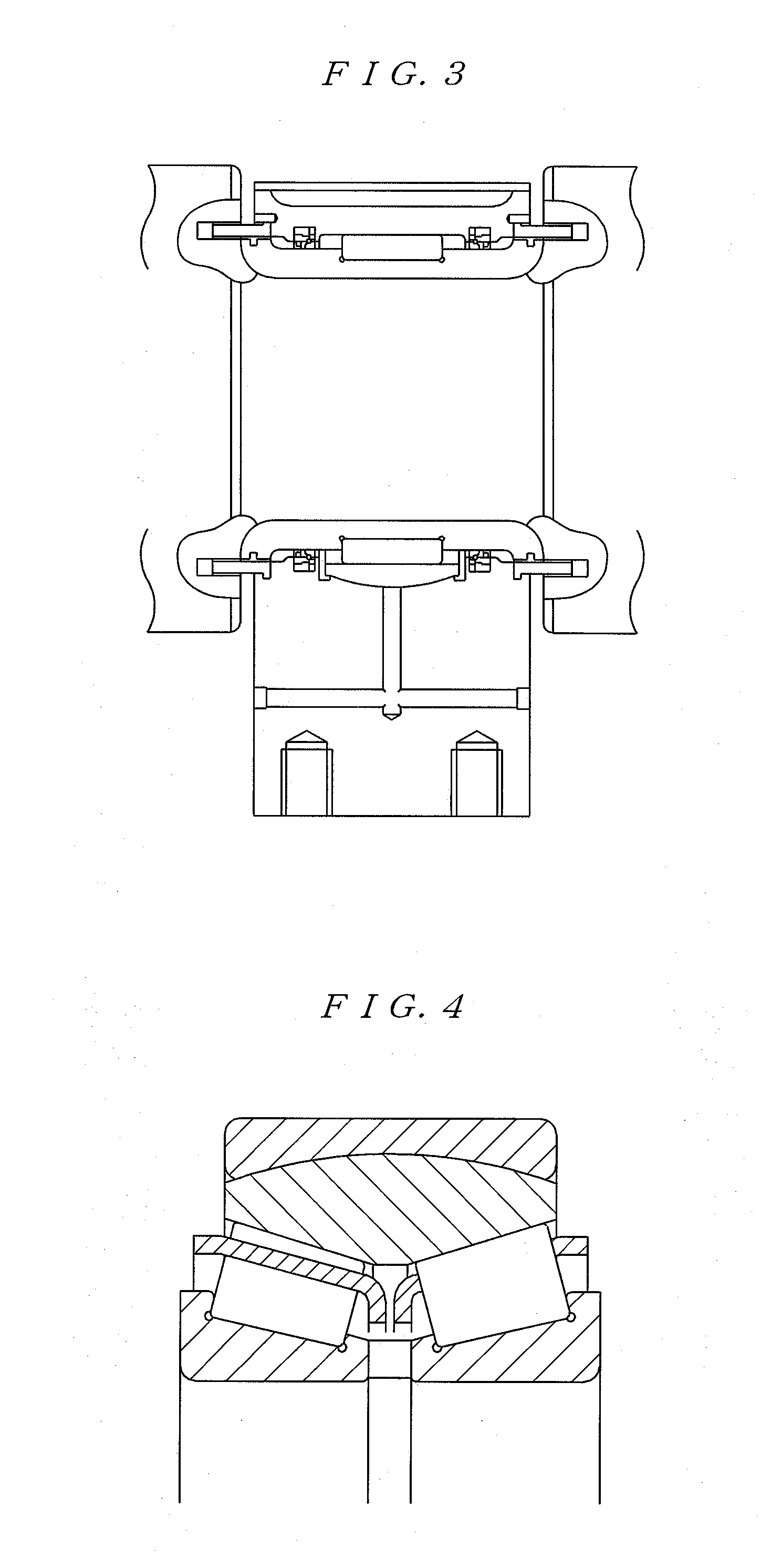

Rolling Device

InactiveUS20100021097A1Good effectImprove wear resistanceRolling contact bearingsShaftsMetal coatingEngineering

A rolling device in which rust development or damage on a raceway surface or rolling surface is hard to occur even if water and the like intrude is provided. A self-aligning roller bearing comprises an inner ring 1, an outer ring 2, and a plurality of rolling elements 3 disposed rotatably between a raceway surface 1a of the inner ring 1 and a raceway surface 2a of the outer ring 2. At least any one of the inner ring 1, the outer ring 2, and the rolling elements 3 is provided with a metal coating formed by shot peening of a powder of metal less noble than iron at least on a part of its surface.

Owner:NSK LTD

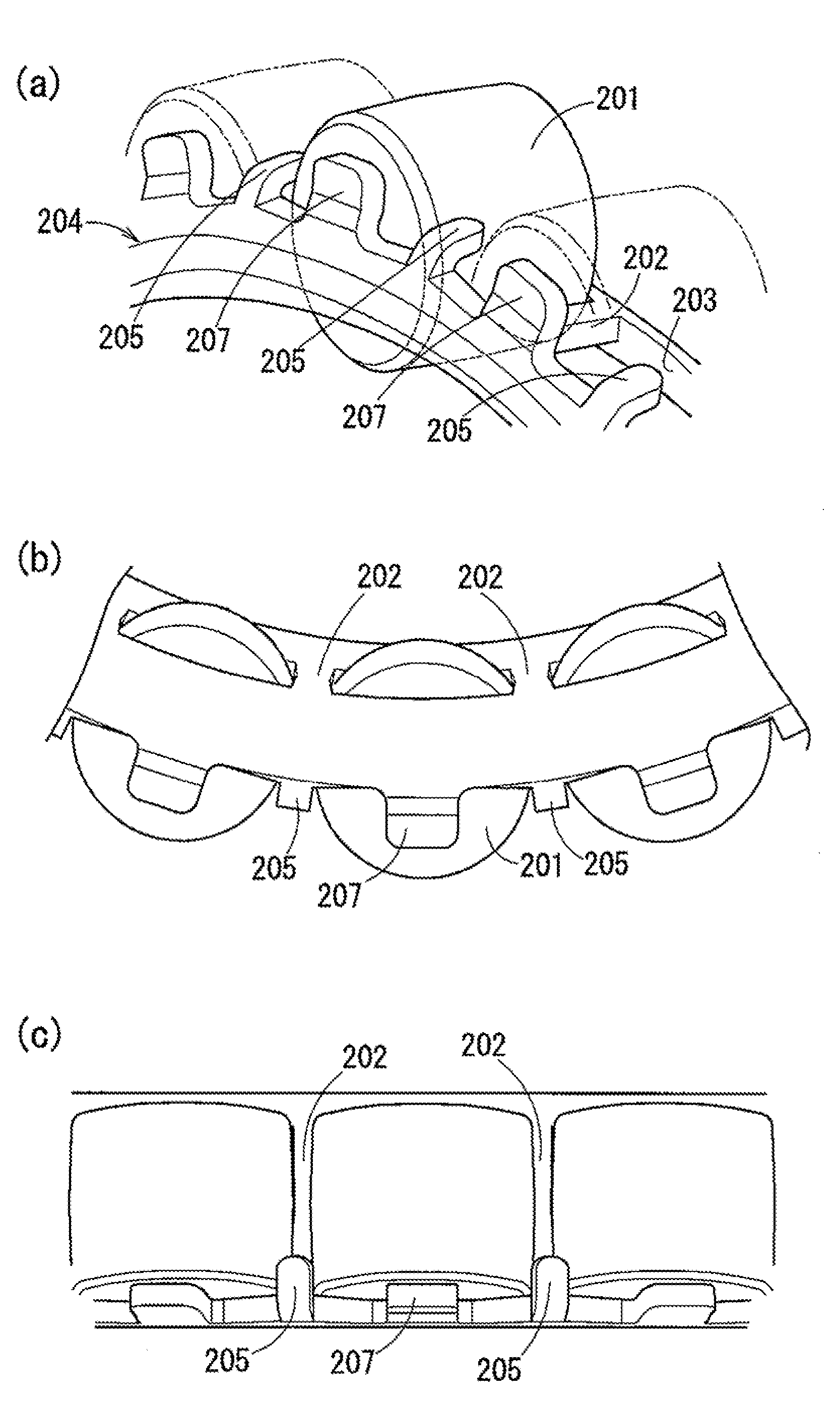

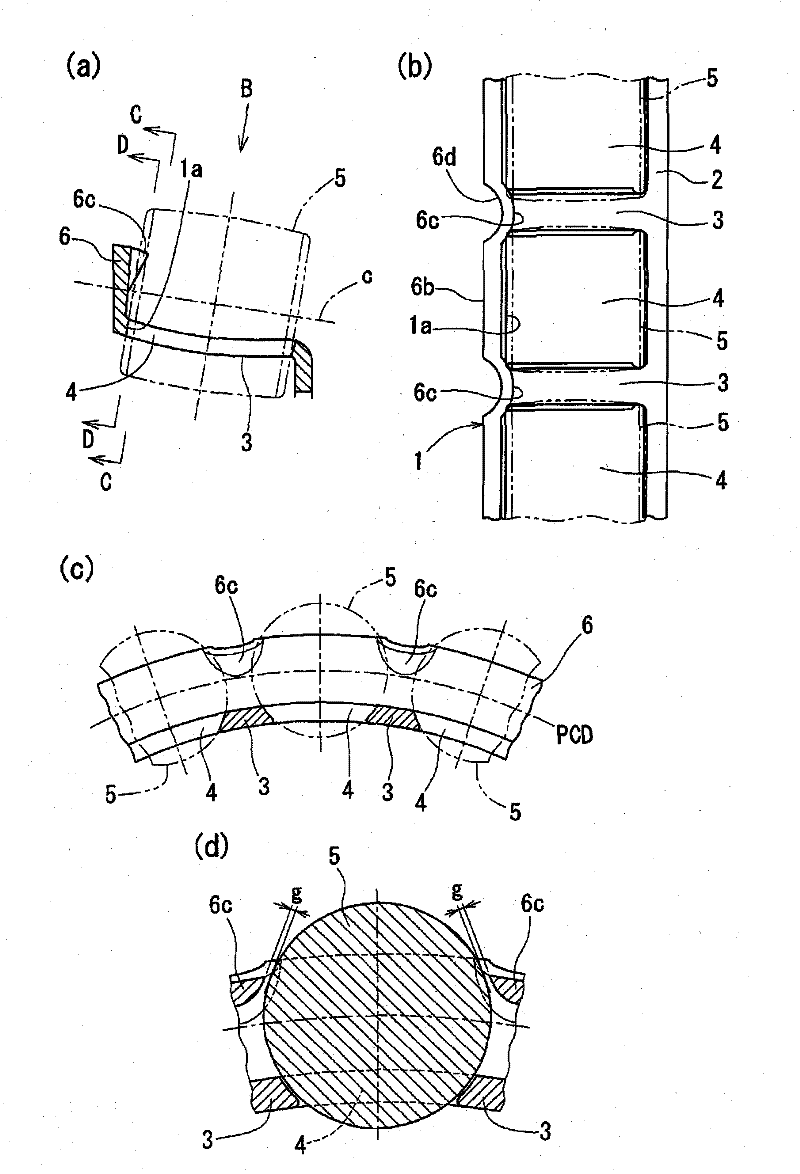

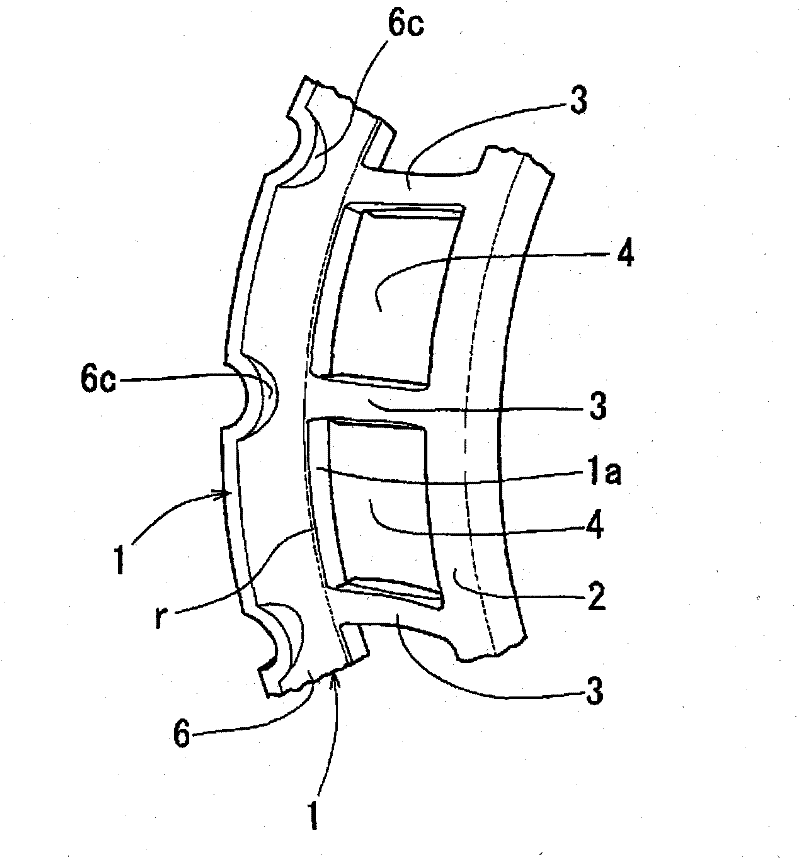

Punched retainer, self-aligning roller bearing, and method of manufacturing punched retainer

InactiveUS20110116734A1Improve accuracyRoller bearingsMetal-working apparatusEngineeringSliding contact

It is desired to form a flange and roller guide surfaces on each retainer of a self-aligning roller bearing easily and with high precision. Each punched retainer include a large-diameter annular portion (1), a small-diameter annular portion (2), a plurality of bridges (3) extending between the annular portions (1) and (2) and defining a plurality of circumferentially separated pockets (4) therebetween, roller guide surfaces (1a) that can be brought into sliding contact with end surfaces of respective convex rollers (5), which revolve around the axis of the bearing, and a flange (6) formed by radially bending the large-diameter annular portion (1). The roller guide surfaces (1a) comprise punched sections formed on the portions of the inner peripheries of the pockets (4) located at the large-diameter annular portion (1), and the flange (6) has a Bent Portion® that extends the entire circumference of the large-diameter annular portion (1). With this arrangement, the roller guide surfaces (1a) can be formed by punching only, which is a essential step. This makes it possible to make uniform the flatness of the back and front surfaces of the flange and its bent angle over the entire circumference thereof.

Owner:NTN CORP

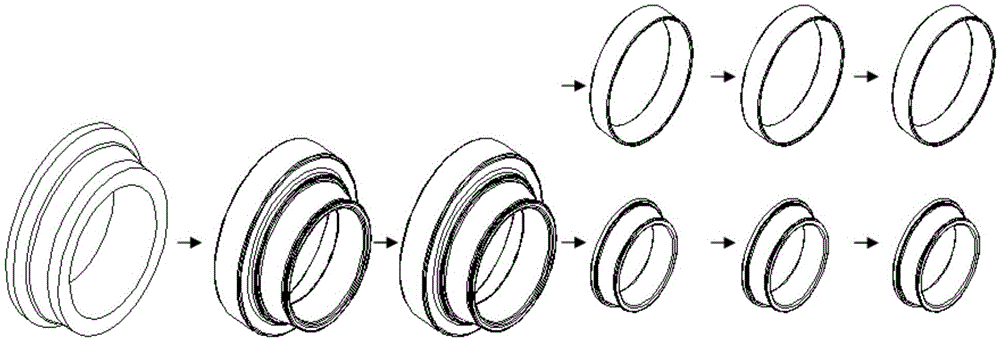

Method for disassembling self-aligning roller bearing matched with long shaft

The invention relates to a method for detaching a spherical roller bearing matched with a long shaft. The method comprises a step of detaching the spherical roller bearing from the long shaft, wherein an outer ring is rotated so that the outer ring swings at a certain angle in the axial direction and at least one roller and part of a holding rack are exposed out of the outer ring; a first roller is taken out; the axial center of the long shaft is used as the axial center of rotation; the outer ring of the bearing is rotated so that a second roller is exposed out of the outer ring; the second roller is taken out; the axial center of the long shaft is used as the axial center of rotation; the outer ring of the bearing is rotated; all residual roller in a rolling track are taken out one by one; the outer ring and the holding rack of the bearing are taken out of the long shaft; an inner ring of the bearing is heated and a shaft journal is frozen or one of the heating of the inner ring and the freezing of the shaft journal is selected; a thermoscope is used to monitor the temperature difference between the shaft journal of the long shaft and the inner ring of the bearing; when the monitoring temperature reaches requirement, heating and freezing are stopped; and the inner ring of the bearing is pushed out of the shaft journal through a jack and is taken out from the long shaft. The method can complete detaching operation and protect the bearing and the shaft from being damaged.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

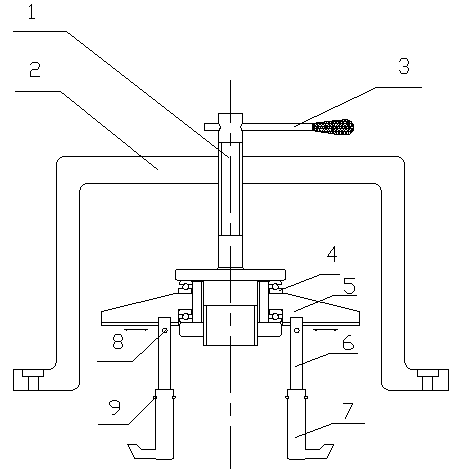

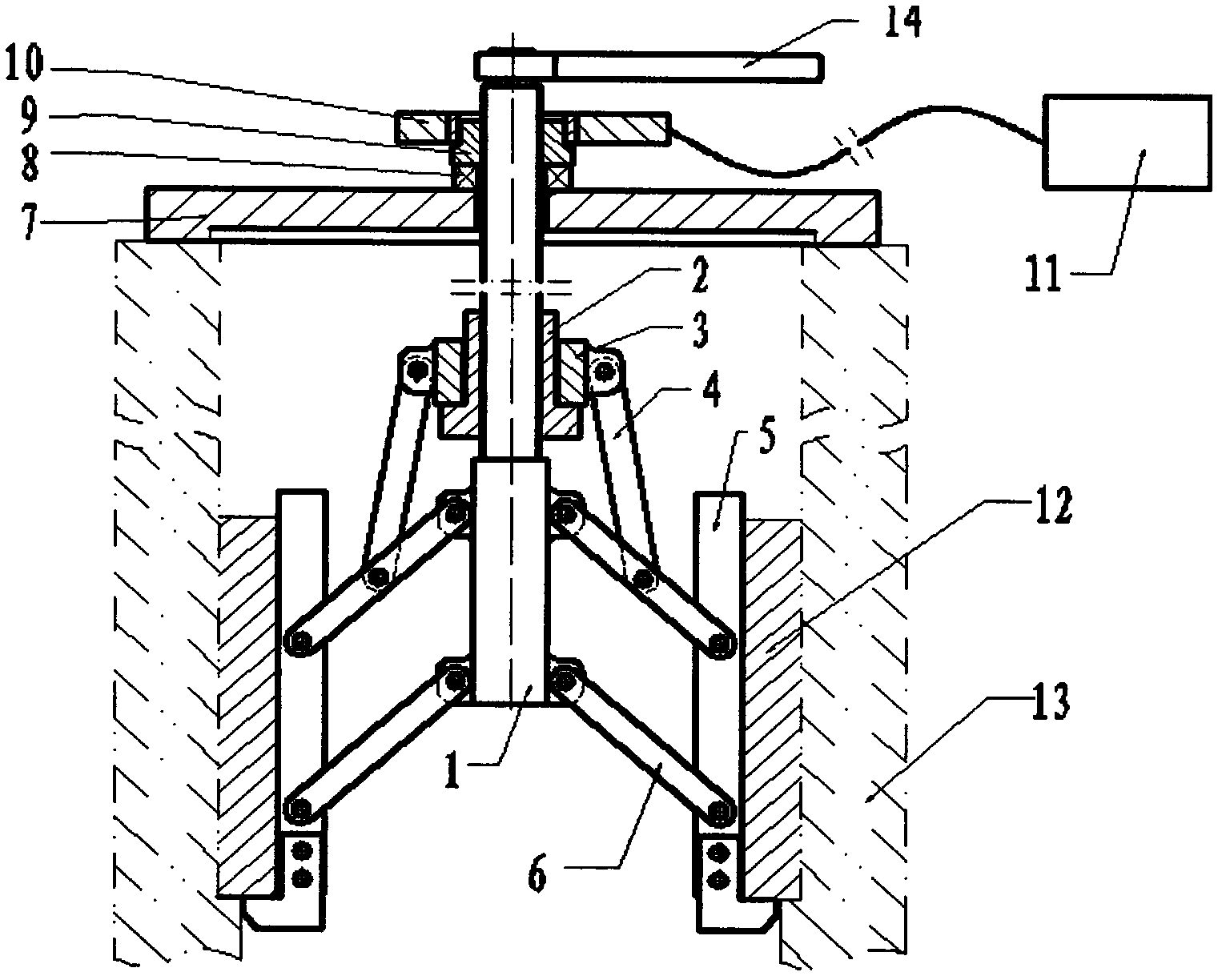

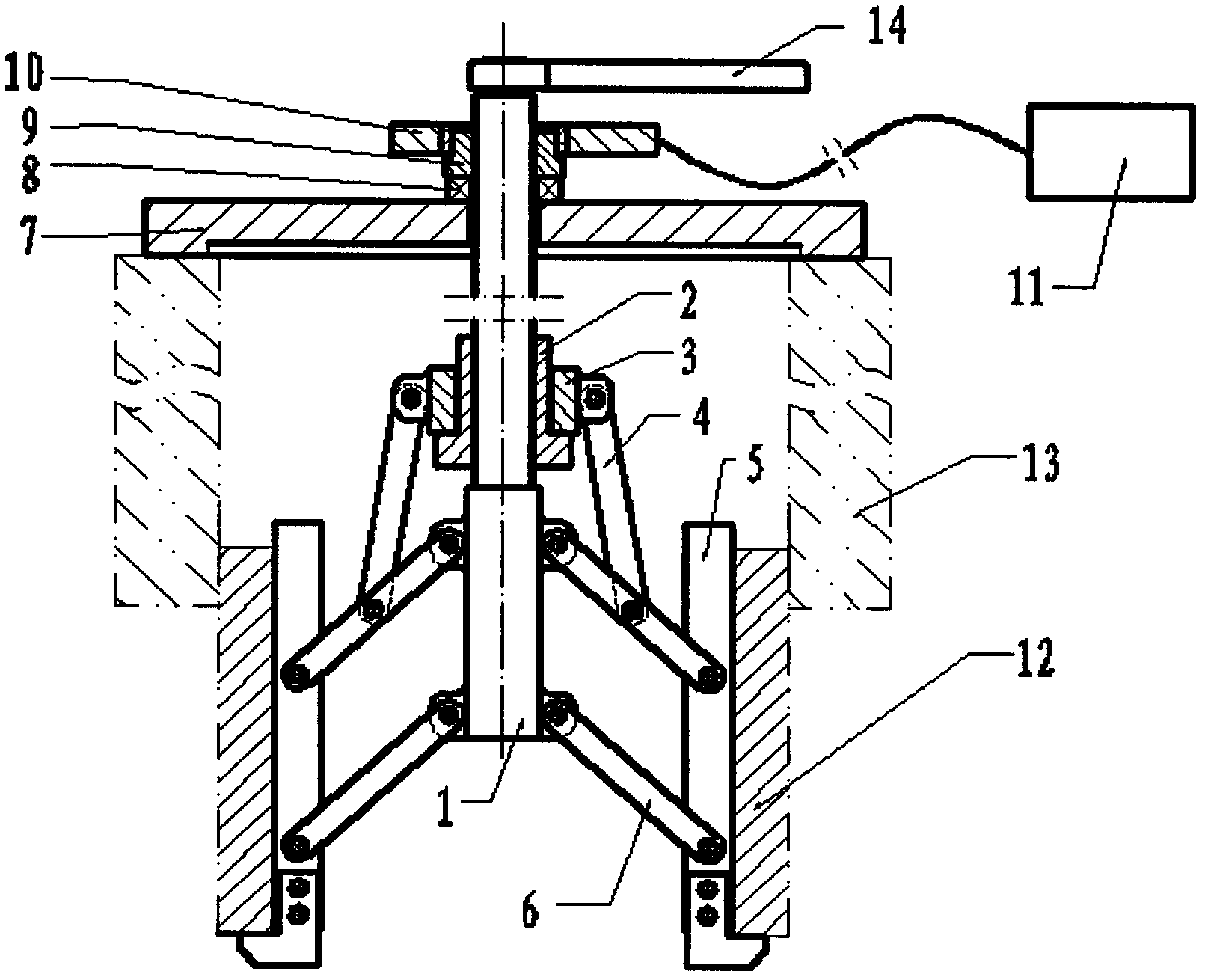

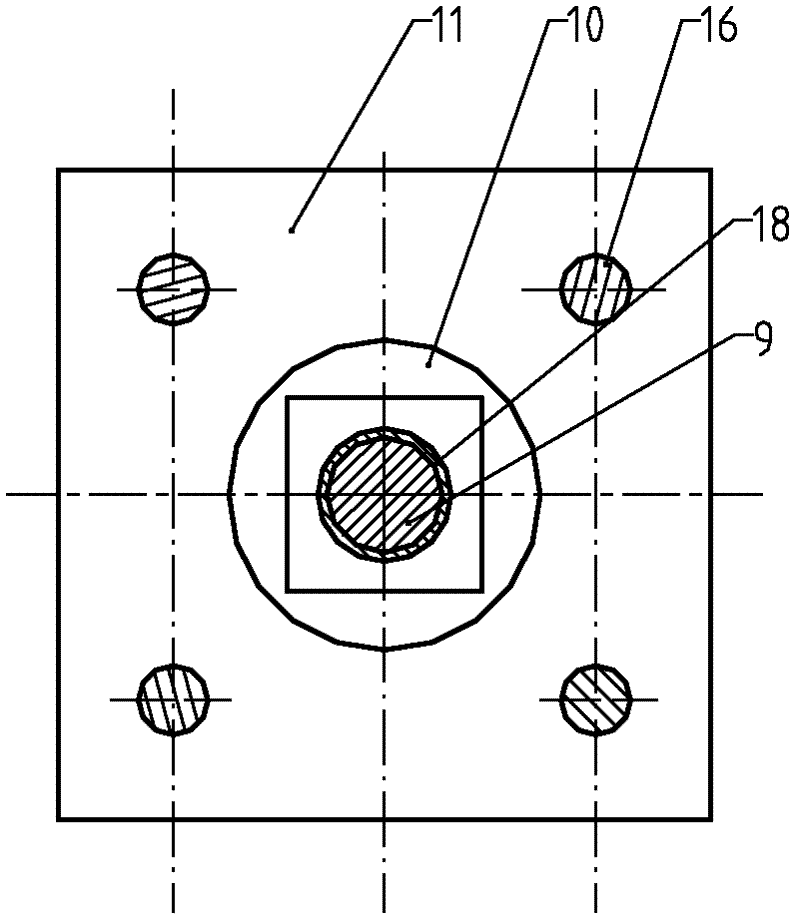

Assembly and disassembly device for electric spindle bearing

InactiveCN104015161AHighlight substantiveEasy to operateMetal-working hand toolsEngineeringSpherical roller bearing

The invention relates to an assembly and disassembly device for an electric spindle bearing. The assembly and disassembly device comprises a thread spindle bracket, a supporting press plate, a wrench, thrust self-aligning roller bearings, a radial length adjustment bracket, connection rods, claw hooks, adjusting pins and cylindrical pins. The thread spindle bracket is matched with the supporting press plate in a threaded mode, the wrench is installed at the top end of the thread spindle bracket, the thread spindle bracket is connected with the radial length adjustment bracket through the thrust self-aligning roller bearings, the connection rods are uniformly installed on the radial length adjustment bracket in the circumferential direction, the adjusting pins adjust the positions of the connection rods, and the claw hooks are connected with the connection rods through the cylindrical pins. The assembly and disassembly device is suitable for manual assembly, can assemble and disassemble bearings of different apertures without damaging the bearings basically, and is compact in structure, convenient to use and low in manufacturing cost.

Owner:SHANGHAI UNIV

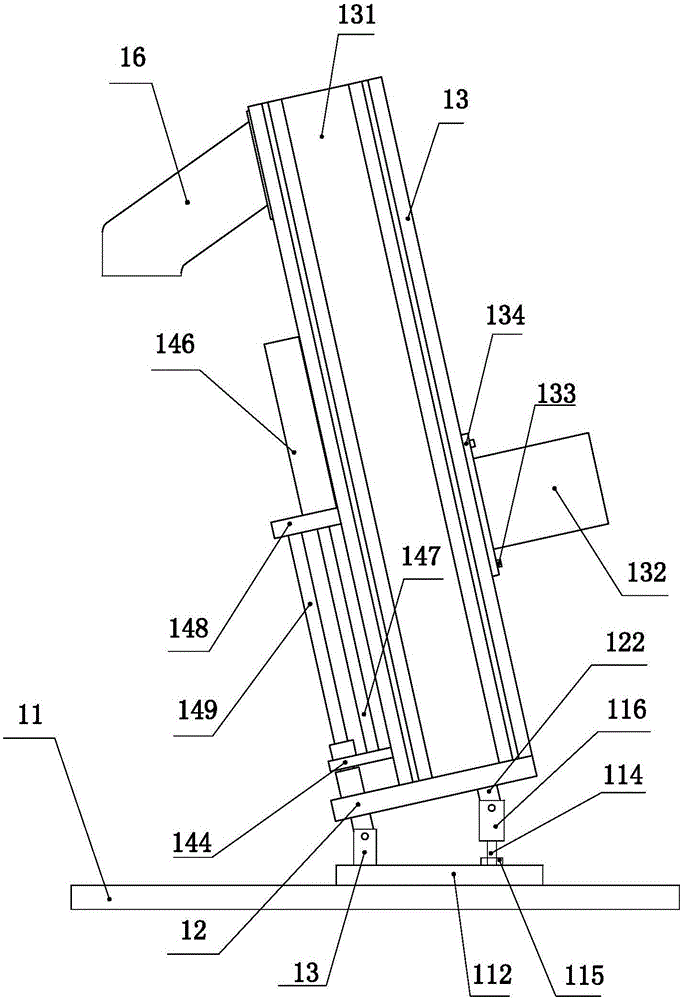

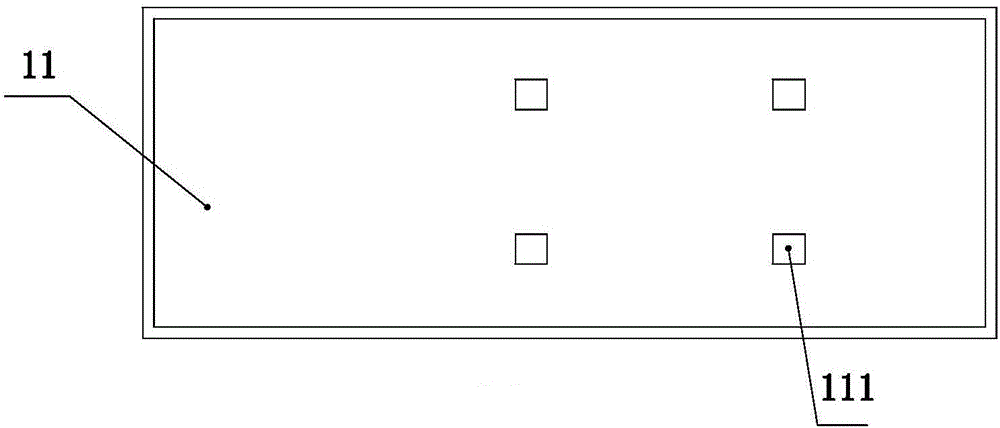

Conical roller bearing assembly device

ActiveCN106736448AHigh degree of automationImprove assembly efficiencyMetal working apparatusEngineeringMechanical engineering

The invention discloses a conical roller bearing assembly device for realizing automatic assembly of a conical roller bearing. The conical roller bearing assembly device comprises a roller loading mechanism, a roller conveying mechanism, a roller assembly table, an outer ring carrying mechanism, an outer ring conveying mechanism and a press fixed on a frame; the roller loading mechanism lifts a roller from a low place to a high place through a lifting mode, and then, the roller falls onto the roller conveying mechanism; the roller conveying mechanism realizes conveying of the roller through conveying rollers for synchronously rotating; the roller on the conveying roller falls into a conveying pipe to enter the roller assembly table, and a cage, an outer ring and the roller are assembled; then, the outer ring carrying device transfers he outer ring into the outer ring conveying mechanism; the outer ring conveying mechanism conveys the outer ring into the press; and the press presses the inner ring into the outer ring. The assembly device can efficiently realize the assembly operation of the conical roller bearing.

Owner:SHANDONG HALIN BEARING IND

Guide rails unloading gear for transverse slide carriage

The invention discloses a guide rail unloading device for a transverse slide carriage, which belongs to the field of machine tools. The guide rail unloading device is provided with a slide carriage and is characterized in that the upper plane of the transverse slide carriage is provided with an inclined hole of 75 degrees, and a retaining nut is connected thereon through screw threads; an inclined guide rail of 15 degrees is machined on a transverse beam and is embedded with a steel strip; a bearing support is arranged in the inclined hole of the slide carriage to play a role in guiding; the lower end of the slide carriage is provided with a self-aligning roller bearing through a pin shaft, and the self-aligning roller bearing rolls on the steel strip of the transverse beam; and a belleville spring piece is arranged between the upper end of the slide carriage and the retaining nut. The guide rail unloading device greatly reduces the pressure on a standard guide rail of the transverse rail, and reduces the gib abrasion between the transverse beam and the transverse slide carriage so that the transverse beam stress is distributed evenly to reduce the deformation of the transverse beam, and the motion form is changed from sliding into rolling to reduce the dragging force of the transverse slide carriage and finally improve the precision of a machine tool.

Owner:WEIHAI HUADONG AUTOMATION

Center rotary joint of earth pressure balance shield machine

The invention discloses a center rotary joint of an earth pressure balance shield machine. The center rotary joint comprises a center stator, wherein the center stator and a rotor are connected through bearings; the center stator is connected with a passive stirring rod and a stop block through splines; the tail part of the center stator is provided with a water spraying joint device; the rotor is connected with a peripheral stator; the rotor is directly connected with a cutter head flange fixedly connected with a cutter head; and the bearings used for connecting the center stator and the rotor comprise a sliding bearing and a self-aligning roller bearing. The center rotary joint adopts an integral design structure; a fluid passage and a hydraulic passage form a whole, so that the structure is more compact; higher processibility is realized; and the manufacturing cost and the maintenance cost are reduced. The center rotary joint adopts a double-stator and single-rotor design; fluid media and hydraulic media can be easily conveyed; the bearings are adopted for rotating supporting; the precision is high; a stirring and center high-pressure flushing system is designed in the center, so that the problem of mud cake forming in the center of the cutter head is solved; and 0.24L / ring of EP2 grease and 0.5L / ring of HBW are saved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Hydraulic chunk with function of compensatory clamping

InactiveCN101956537ASolve the problem of deformation failureSimple structureDrilling rodsDrilling casingsHydraulic cylinderThrust bearing

The invention discloses a hydraulic chunk with function of compensatory clamping, which comprises a piston, a hollow piston rod, a cylinder barrel, a connecting cover, a disc spring, a aligning roller bearing, a slip sleeve, a main shaft, a thrust bearing and a slip. The piston rod and the piston are sleeved in the cylinder barrel, the piston is fixed at the top end of the piston rod, the connection cover and the cylinder barrel are fixedly connected, one end of the disc spring is positioned on the shaft shoulder of the main shaft and the other end is positioned on the slip sleeve, the slip sleeve is arranged at the hollow part of the piston rod and is sleeved on the main shaft, a bearing positioning ring is arranged in the middle of the slip sleeve, the aligning roller bearing and the thrust bearing are respectively arranged at the two ends of the bearing positioning ring on the slip sleeve and positioned at the hollow part of the piston rod, and the slip is arranged in the slip sleeve. By the invention, the requirement of a high-torque drilling machine on great clamp force is met; a ring-shaped double-acting oil cylinder is used for auxiliary clamping so that a problem on deformation failure of a spring can be solved; and hydraulic pressure can be converted into clamping force by utilizing a cavity among the hydraulic cylinder barrel, the piston and the piston rod. The invention has the advantages of simple structure and long service life.

Owner:ZHENJIANG ANDA COAL MINE SPECIAL EQUIP

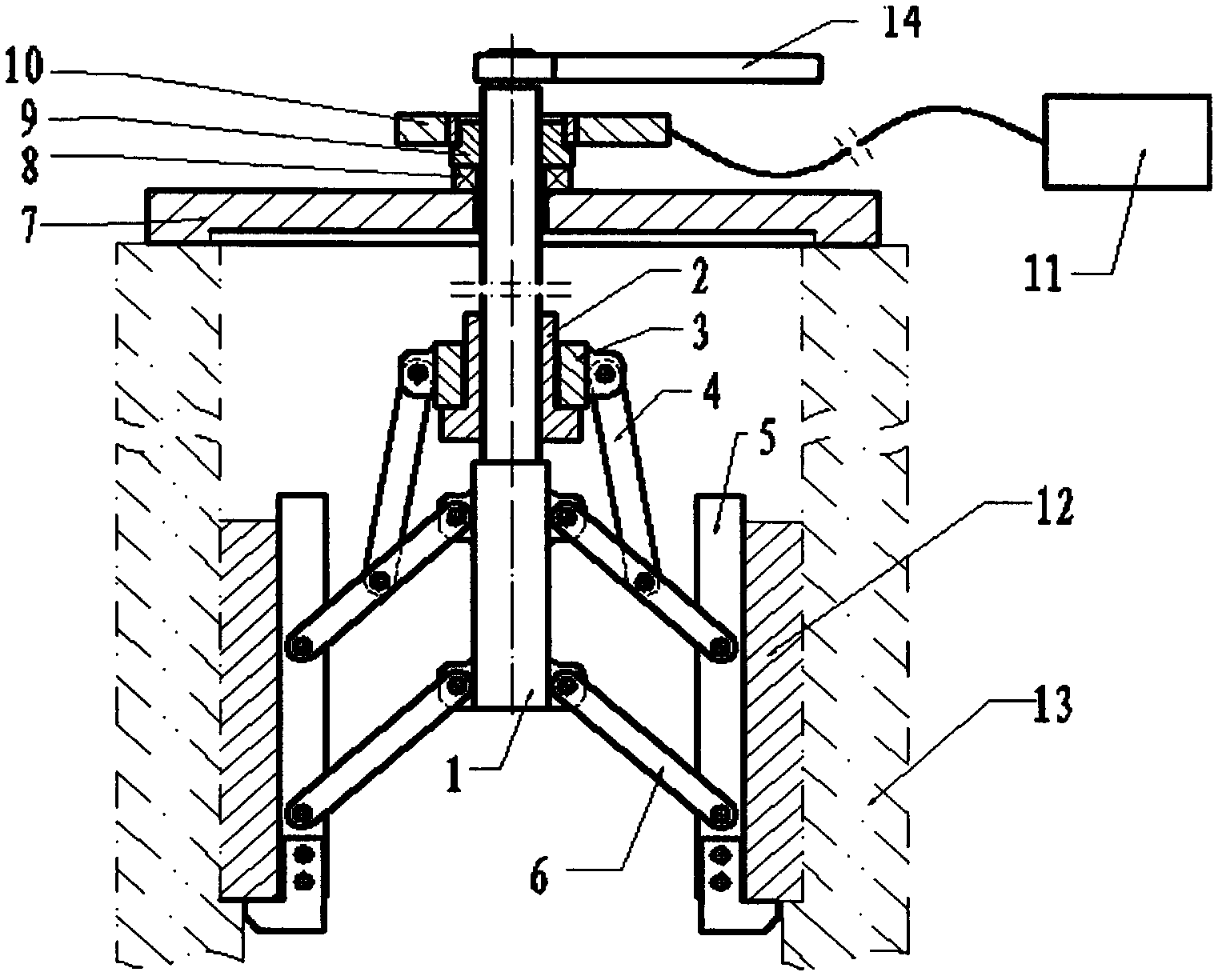

Device for detaching and assembling bearing

InactiveCN102248512ATensile force transmissionAdjust the openingMetal-working hand toolsEngineeringHeavy equipment

The invention discloses a device for detaching and assembling a bearing, which is mainly used for detaching and assembling sliding bearings in hydraulic and pneumatic cylinders and guide sleeves of heavy equipment. The device mainly comprises a central shaft bracket, an adjusting nut, a pull rod connecting sleeve, adjusting pull rods, pull hooks, parallel connecting rods, a support press plate, a thrust aligning roller bearing, a nut, a wrench and the like, wherein three groups of adjusting pull rods, pull hooks and parallel connecting rods are uniformly distributed around the central shaft bracket in the circumferential direction; the central shaft bracket, the adjusting nut, the pull rod connecting sleeve, the adjusting pull rods, the pull hooks and the parallel connecting rods play adapting, axially supporting, connecting and carrying and other roles for sliding bearings with different bore diameters; and the support press plate, the thrust aligning roller bearing, the nut and the wrench are used for fixing the whole device and supplying power for axial extension of the central shaft bracket.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

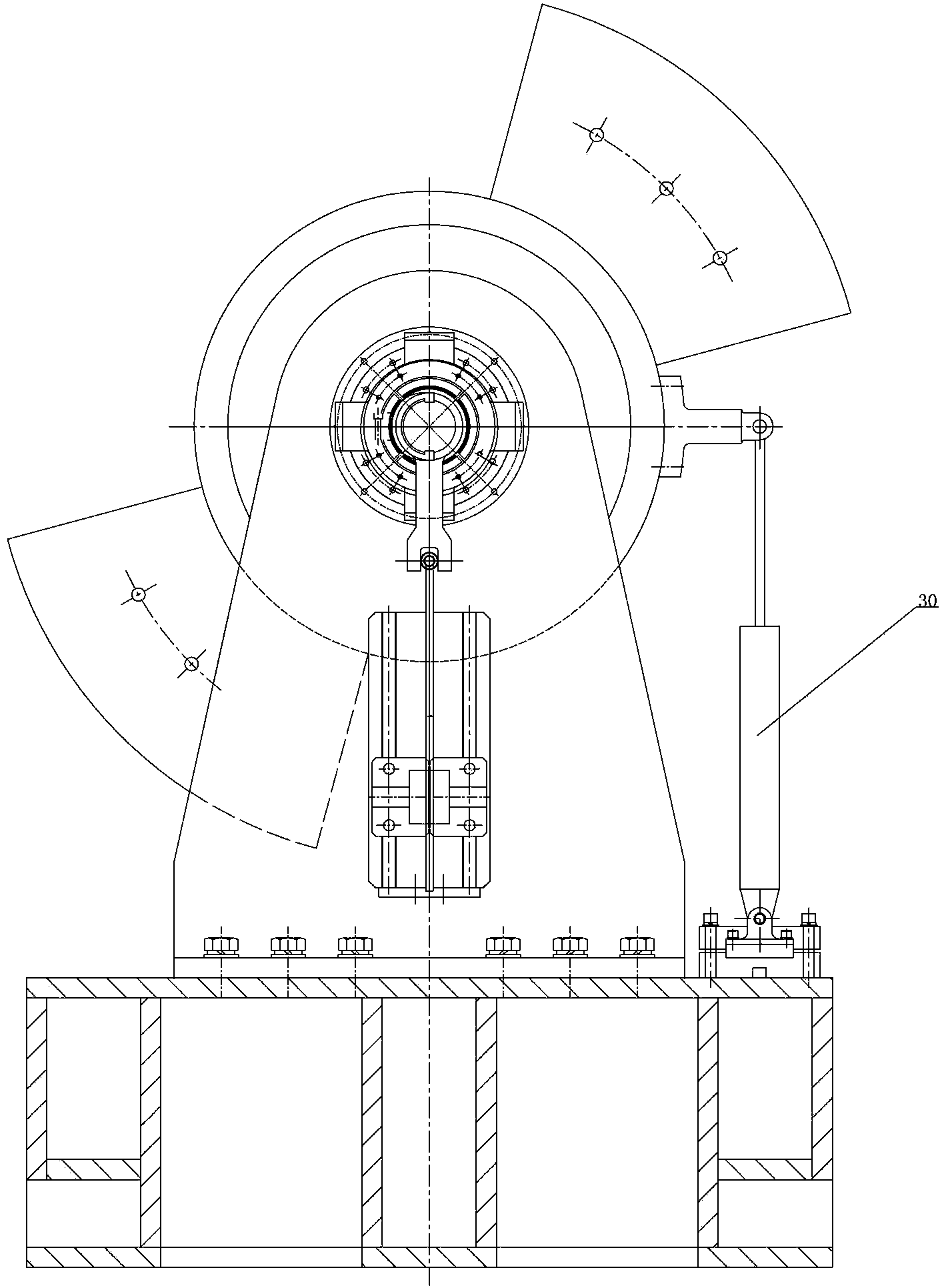

Rotatable rock-soil testing machine

InactiveCN102494951AGuaranteed uniformityConvenient researchMaterial strength using tensile/compressive forcesLine shaftCoupling

A rotatable rock-soil testing machine relates to rock-soil testing machine equipment. A lower flange of a sample cylinder (18) is connected with a downward thrust aligning roller bearing (15) through a pedestal (10) under the cylinder; an upper flange of the sample cylinder (18) is connected with a main shaft (4) through a left side plate and a right side plate (20,16); a bull gear (2) is connected with the main shaft and engaged with a gear on a pinion shaft (3); a motor (1) is connected with the pinion shaft through a reduction box (30) and a shaft coupling (29); and rotation of the main shaft (4) drives the sample cylinder (18) and the pedestal (10) under the cylinder to rotate together, so as to realize rotation of a rock-soil sample (8). The rotatable rock-soil testing machine solvesa rotation problem during axial loading of the rock-soil sample (8), so as to facilitate application of industrial CT continuous scan on internal dynamics of the rock-soil sample during axial loadingand benefit deepening of research on rock-soil mechanics.

Owner:BEIJING JIAOTONG UNIV

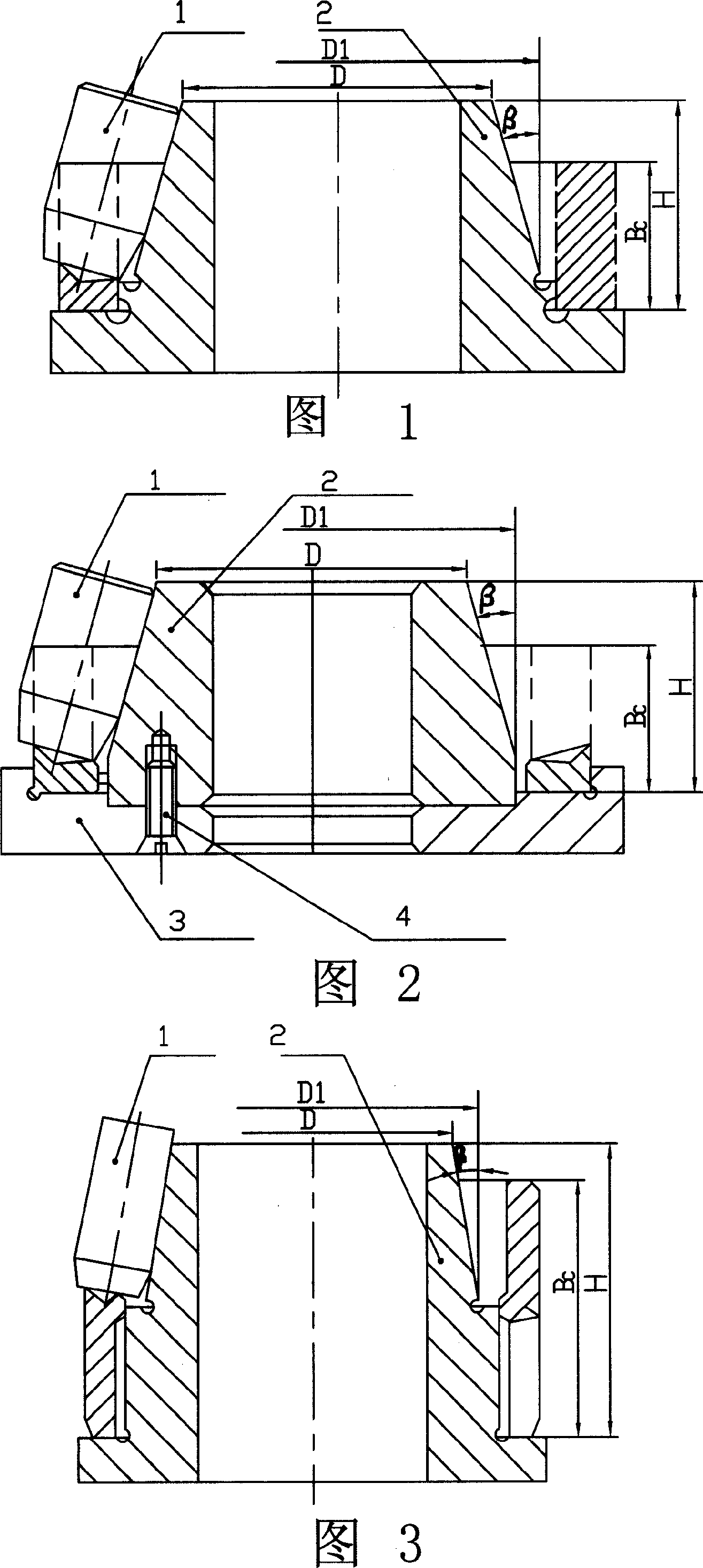

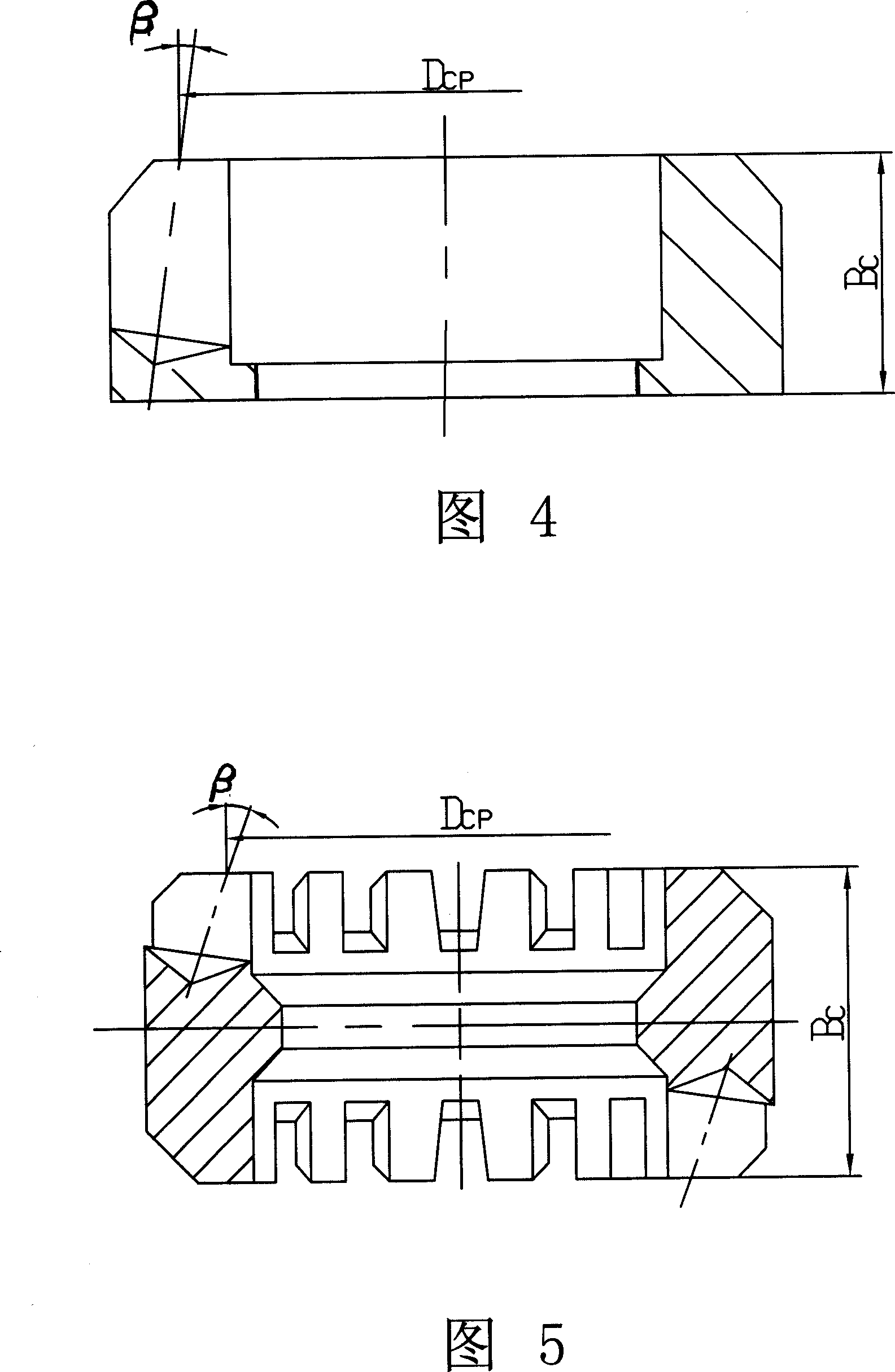

Sealed self-aligning roller bearing for high-speed rail and repair method thereof

InactiveCN103836067AImprove carrying capacityImproves stain resistanceRoller bearingsBearing componentsGlass fiberNylon 66

The invention relates to a sealed self-aligning roller bearing for a high-speed rail and a repair method thereof. The bearing comprises an inner ring, an outer ring, a roller, a holder and a sealed housing, wherein the holder is formed by integral injection moulding of a glass fiber enhanced nylon 66 material and is located on a middle line between the inner and outer rings; the holder is integrally cone-shaped, and the axial section of the single side wall of the holder is / -shaped; roller installation parts are uniformly distributed in the periphery of the holder, and the side face of each roller installation part is a spherical face; the included angle beta between the connecting line of the widest part of each roller installation part and the center of the bearing and the radial section of the bearing is equal to a nominal contact angle. The invention further discloses the repair method of the bearing. According to the structural design, the repaired bearing can be continuously used, so that the maintenance cost of the high-speed rail is effectively lowered, and the service life of the bearing is remarkably prolonged.

Owner:SHANDONG KAIMEIRUI BEARING TECH CO LTD

Self-aligning roller bearing with retainer and method of manufacturing the retainer for the self-aligning roller bearing

ActiveCN101035995AEasy to processLow costRoller bearingsBearing componentsBarrel ShapedSpherical roller bearing

There is realized a self-aligning roller bearing with retainer that stabilizes the orientation of spherical rollers and prevents these spherical rollers from skewing, and which can be rotated at high speed, and furthermore which enables efficient lubricant feed into pockets 9. By rotating a turning tool 14 as it revolves, the surfaces on both sides in the circumferential direction of respective column sections are processed into concave curved surfaces that oppose a rolling surface of the respective spherical rollers across a pocket clearance into which lubricant oil can be fed. The length of the column sections 8c is less than the length in the axial direction of the spherical rollers, and greater than a half of the length, and an end portion of the side surface in the circumferential direction of the respective column sections 8c projects further in the circumferential direction than an intermediate portion thereof, and the spherical rollers are embraced in the pockets 9.A self-aligning roller bearing with a retainer enabling high speed operation by stabilizing the attitude of barrel shaped rollers to prevent the barrel shaped rollers from being skewed and the efficient feeding of a lubricant into pockets (9) and a method of manufacturing the retainer for the self-aligning roller bearing. In the self-aligning roller bearing, the both side faces of each column part (8c) in the circumferential direction are machined to recessed curved faces facing the rolling surface of each barrel shaped roller through pocket clearances allowing the lubricant to feed thereto with a cutting tool (14) revolving while rotating on its axis. Also, the length of each column part (8c) is set equal to or less than the axial length of each barrel shaped roller and more than the half of the axial length thereof, the side face tip portion of each column part (8c) in the circumferential direction are projected from the intermediate portion thereof in the circumferential direction.

Owner:NSK LTD

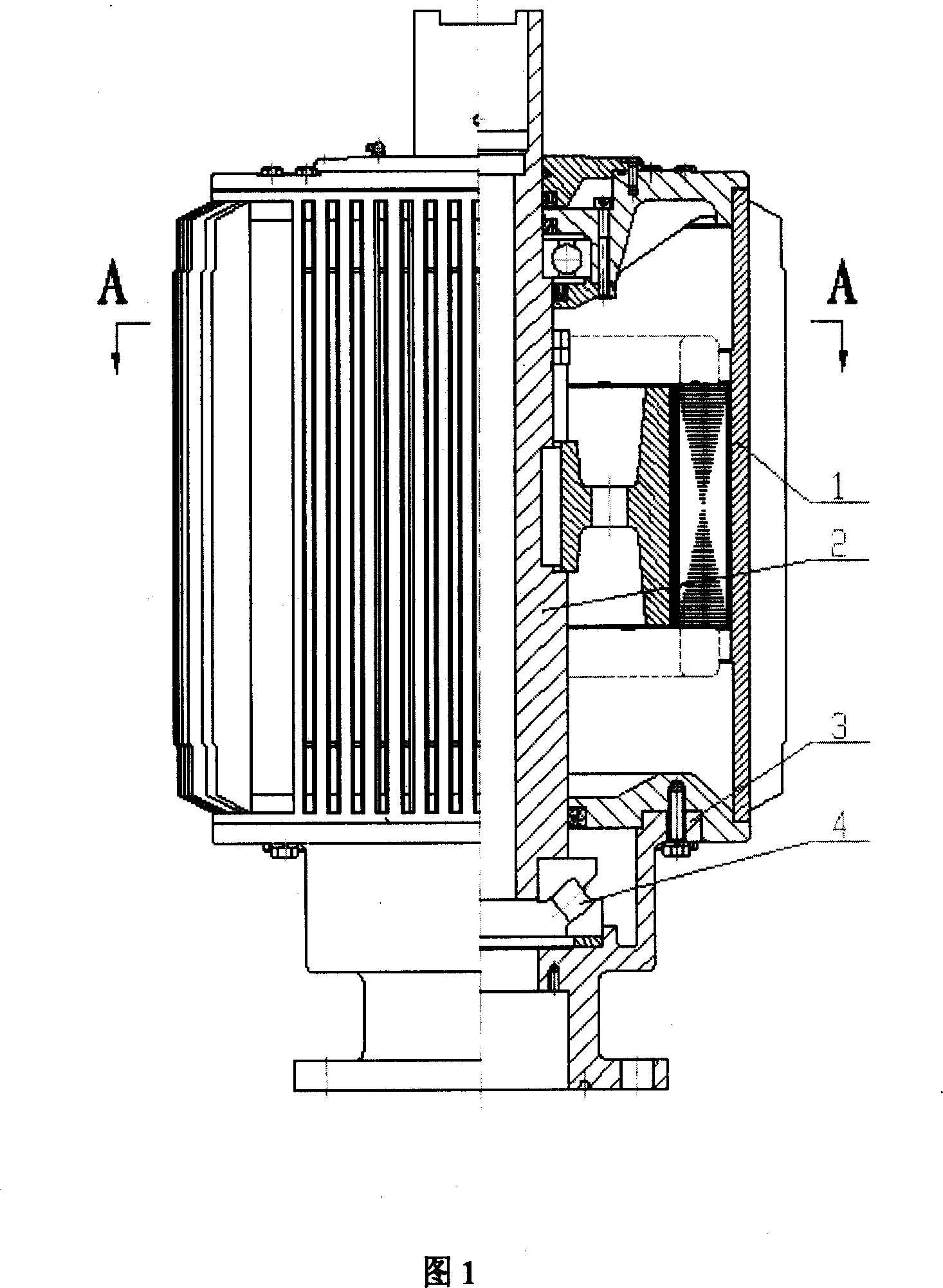

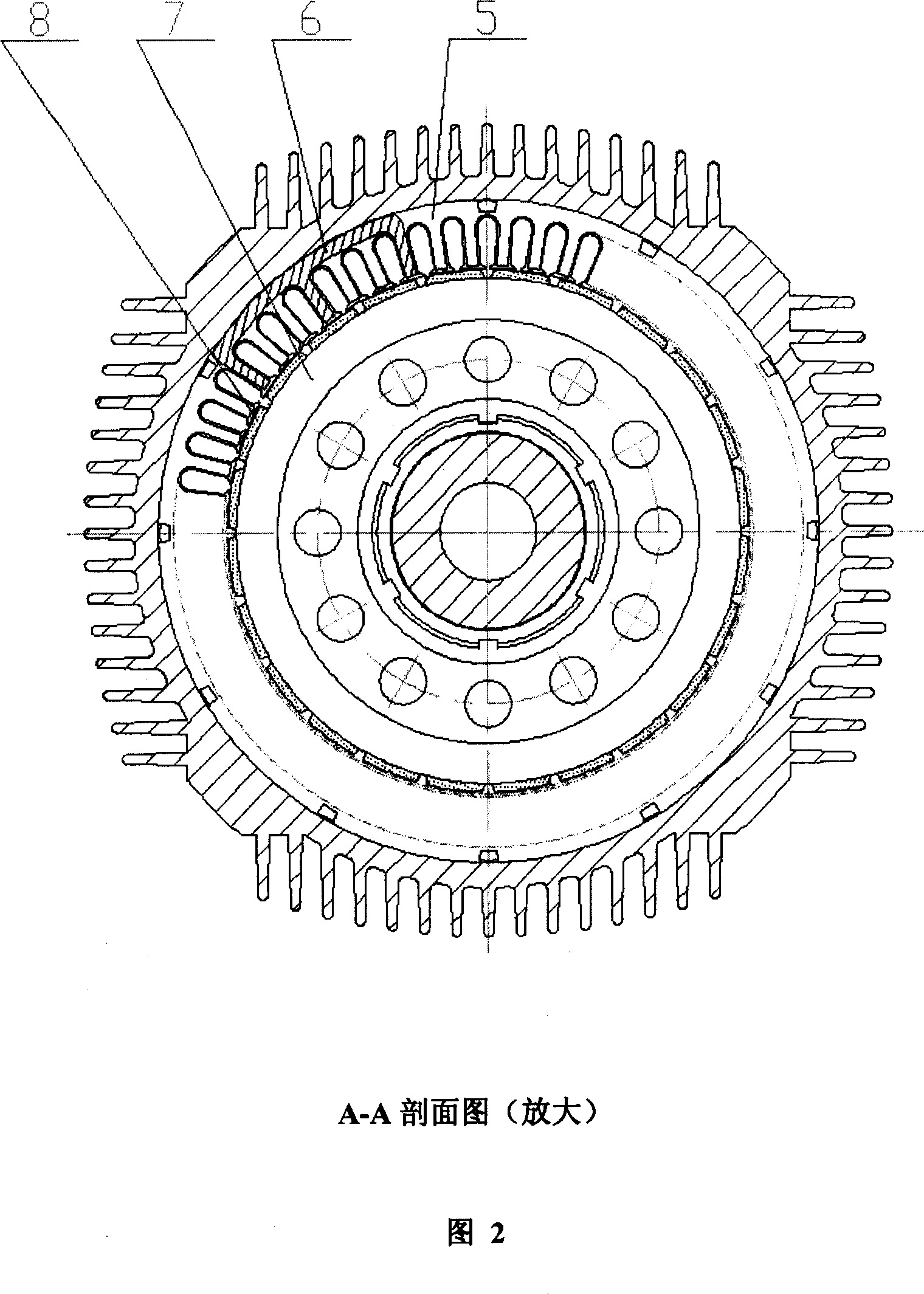

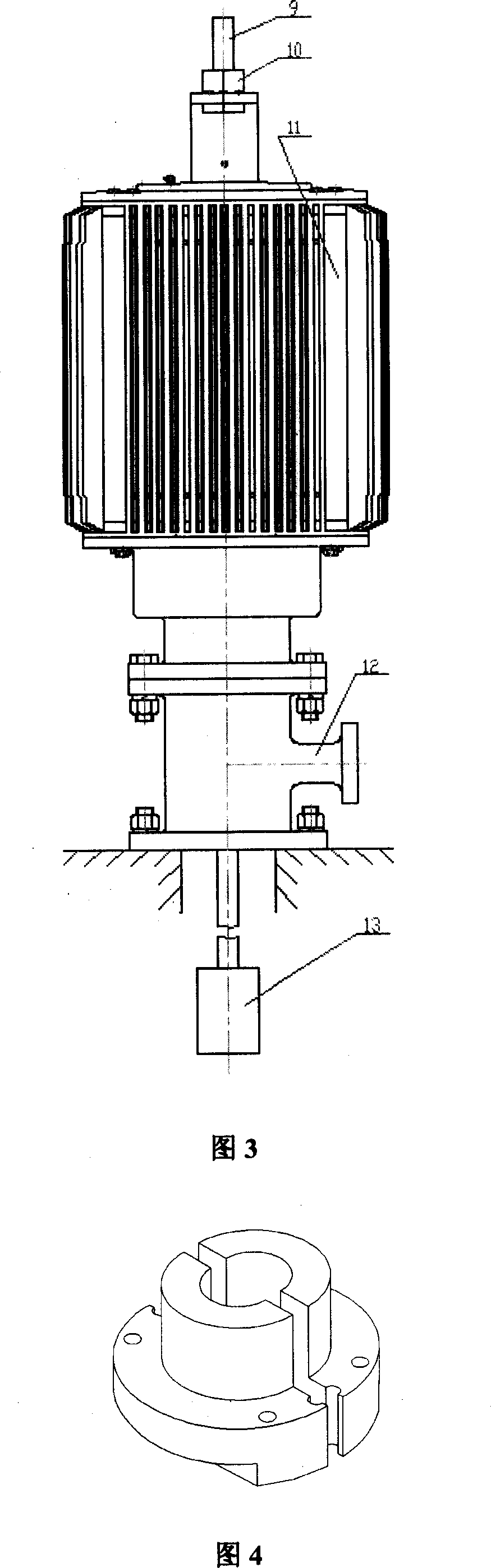

Direct drive permanent magnet synchronous motor for screw pump

ActiveCN1996719ALarge axial loadImprove reliabilityMagnetic circuit rotating partsFluid removalPermanent magnet synchronous motorControl theory

This invention relates to screw bar pump direct drive permanent simultaneous motor in the earth drive mechanic oil sampling device, which comprises permanent magnetic simultaneous motor and the device matched with screw pump, wherein, the invention is characterized by the following: its axis down part uses push force for roller bearing; the drive device uses permanent simultaneous motor matching with connection device meshed with screw bar. This invention saves the band transmission and gear deceleration case to provide torque times more than four times.

Owner:HANGZHOU XO ELEVATOR

Pressed cage, self-aligning roller bearing, and method of manufacturing pressed cage

The invention relates to a pressed cage for a self-aligning roller bearing, wherein a flange and roller guiding surfaces are simply and accurately formed on the cage. A pressed cage has formed thereon pillars (3, 3) extending between a large-diameter ring section (1) and a small-diameter ring section (2), pockets (4, 4) circumferentially separated from each other by the pillars (3), roller guiding surfaces (1a) capable of making sliding contact with end surfaces of revolving convex rollers (5), and a flange (6) formed by raising the large-diameter ring section (1) in the diameter direction. Each roller guiding surface (1a) is a cross-sectional surface of the inner periphery of a pocket (4) which cross-sectional surface is formed in the large-diameter ring section (1) by punching, and flange bend sections (r) of the flange (6) are formed on the entire circumferential periphery of the large-diameter ring section (1). The roller guiding surfaces (1a) can be obtained only by punching, which is an essential step, and this allows the flatness and bending angles of both front and rear surfaces of the flange (6) to be easily and uniformly obtained along the entire circumferential periphery of the flange (6).

Owner:NTN CORP

Pressing-down type crimping machine for short fiber production line

ActiveCN106087155AExtended service lifeGuaranteed accuracyNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveProduction lineFiber

The invention discloses a pressing-down type crimping machine for a short fiber production line. The pressing-down type crimping machine comprises crimping rollers, an engine base and a lower swinging arm; a pair of crimping rollers, which rotate by resultant force, are mounted on the engine base and the lower swinging arm; each crimping roller comprises a crimping roller wheel and crimped rolling shafts arranged on the two sides of the crimping roller wheel; and the crimped rolling shafts at the two ends of the crimping rollers are connected with the engine base and the lower swinging arm through rotary mechanisms. By adopting the pressing-down type crimping machine, the problem of a traditional crimping machine that the service life of equipment is short when short fibers are produced is mainly solved; a self-aligning roller bearing is used as a radial loading bearing of equipment and an angular contact ball bearing is used as an axial positioning bearing, so that precision of the crimping rollers is guaranteed when the crimping machine is operated and the playing is not easy to occur; meanwhile, a bearing base mounting manner is abandoned and the bearing is internally mounted by adopting a bearing bush; and in a mounting process, the bearing bush is directly mounted on a mounting base, so that the subsequent installation and overhauling difficulties of the crimping rollers are reduced and accumulated installation errors are reduced.

Owner:SUZHOU HUIFENG CHEM FIBER MACHINERY

Novel controllable telescopic rod

InactiveCN103711763AStretch smoothlyFlexible and accurate controlRod connectionsMotor driveEngineering

The invention discloses a novel controllable telescopic rod which structurally comprises two sections of hollow telescopic rods, a worm cam, a spherical roller rotating disc, a locking gear, a shaft, a motor, a locating screw and a locking rack switch. The two sections of hollow telescopic rods are nested with each other, the spherical roller rotating disc is arranged on one section of rod through the rotating shaft, the motor is fixed to the other section of rod through the locating screw, and an output shaft of the motor is connected with a worm cam matched with the spherical roller rotating disc. The spherical roller rotating disc is fixedly connected with the locking gear, and the locking rack switch locks the spherical roller rotating disc by being meshed with the locking gear. During internal driving, the spherical roller rotating disc is locked, and the motor drives the worm cam to rotate. During external driving, the spherical roller rotating disc freely rotates, and the worm cam and the spherical roller rotating disc achieve similar movement of the rack and the gear. The novel controllable telescopic rod smoothly extends and retracts, is flexibly and accurately controlled, can achieve switching of internal driving and external driving, and is wide in application range.

Owner:周帅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com