Assembly and disassembly device for electric spindle bearing

A technology for dismantling devices and electric spindles, applied in hand-held tools, manufacturing tools, etc., which can solve problems such as bearing damage, inconvenient operation for workers, and high equipment costs, and achieve the effects of low cost, high safety, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

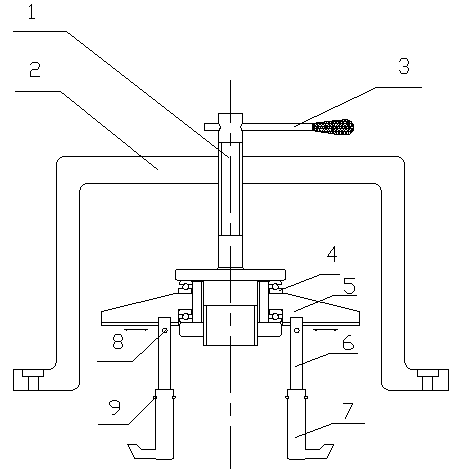

[0014] Such as figure 1 As shown, an electric spindle bearing installation and removal device is characterized in that it includes a threaded shaft frame 1, a support plate 2, a wrench 3, a thrust self-aligning roller bearing 4, a radial length adjustment frame 5, a connecting rod 6, and a claw Hook 7, adjusting pin 8 and cylindrical pin 9; the threaded shaft frame 1 is threadedly matched with the support plate 2, the wrench 3 is installed on the top of the threaded shaft frame 1, and the threaded shaft frame 1 passes through the thrust self-aligning roller bearing 4 Connect the radial length adjustment frame 5, the connecting rod 6 is evenly distributed on the radial length adjustment frame 5 along the circumferential direction, and the position of the connecting rod 6 is adjusted through the adjustment pin 8, and the claw hook 7 is passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com