Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155 results about "Rotor design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

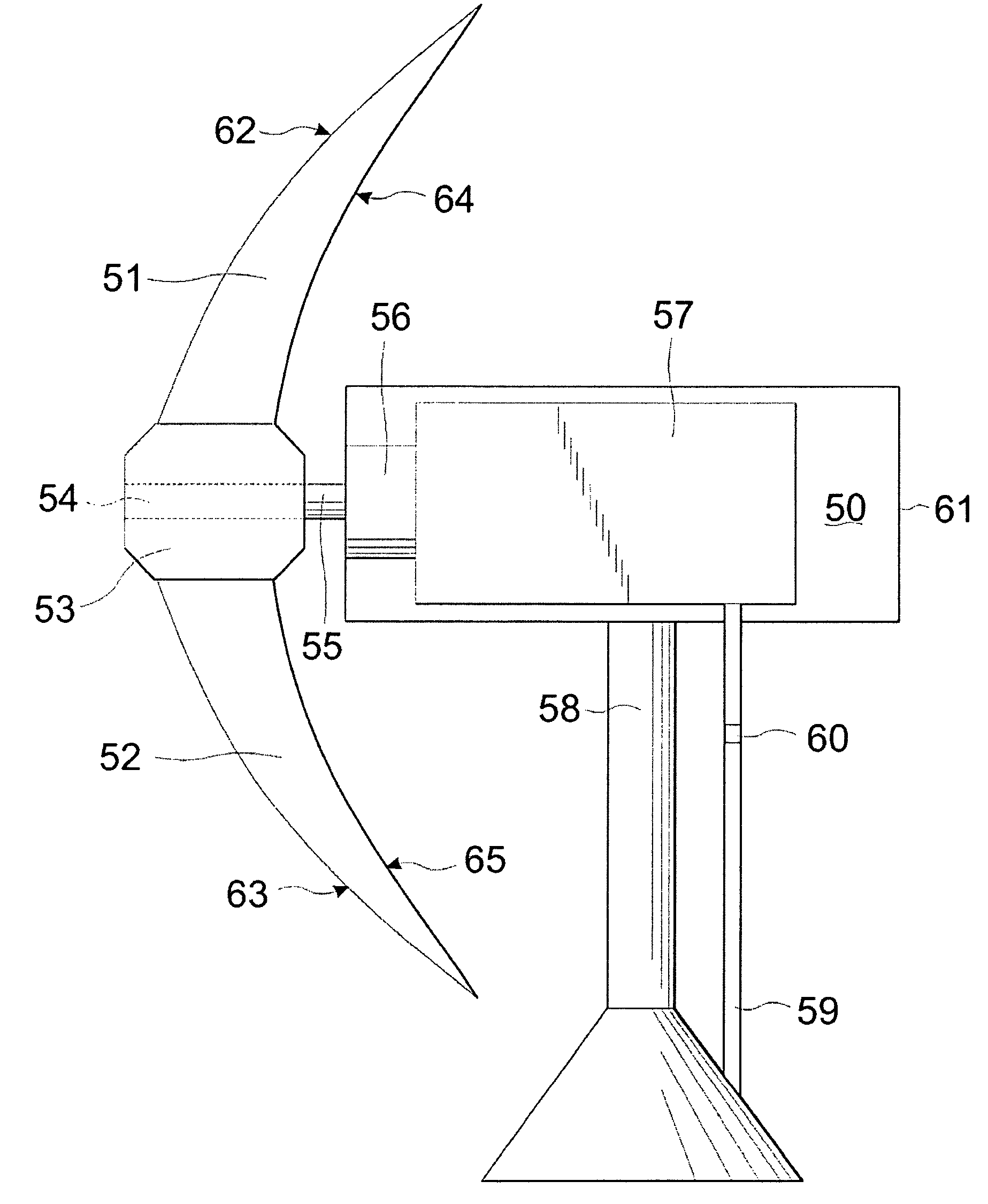

Method of utilization a flow energy and power installation for it

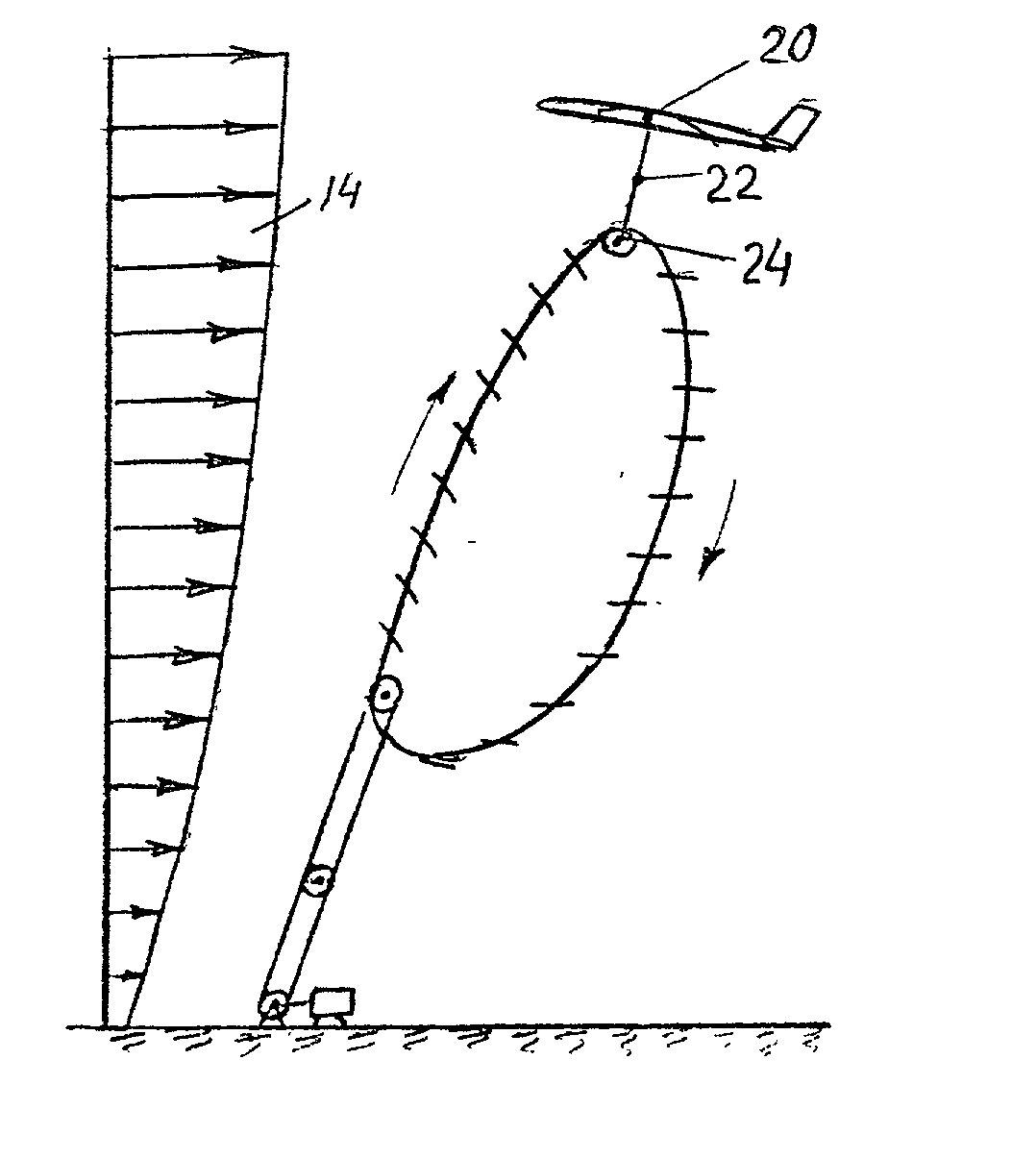

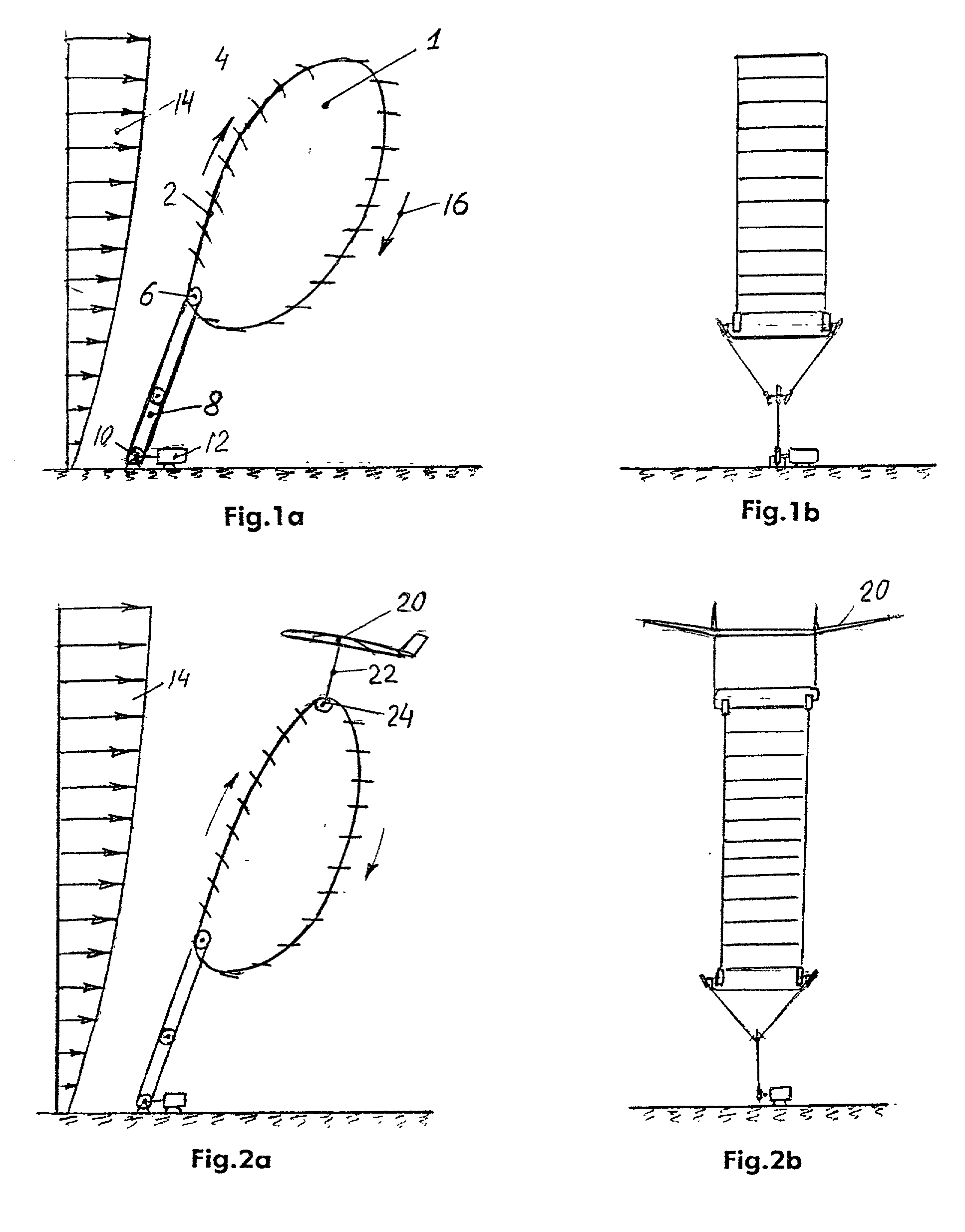

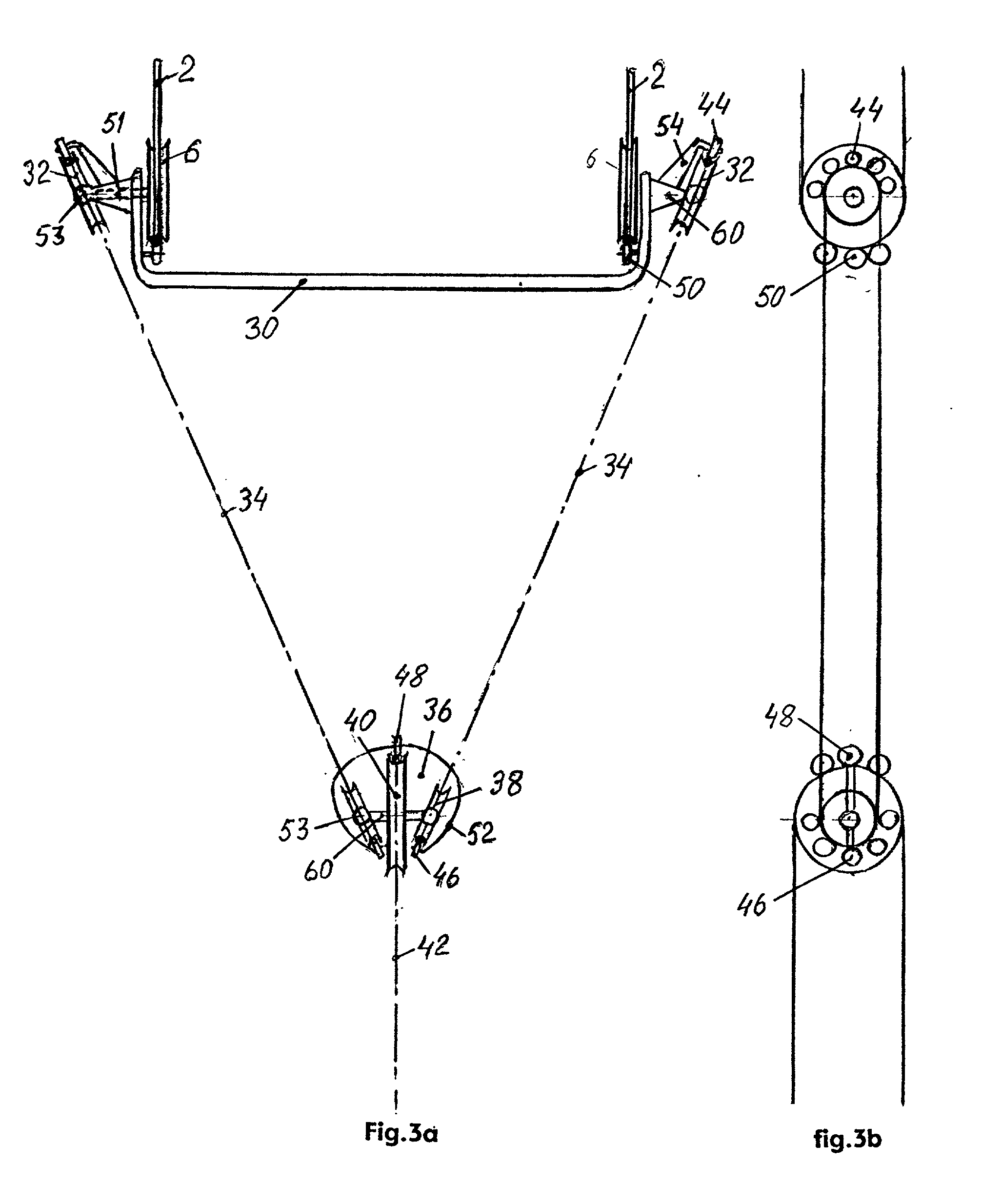

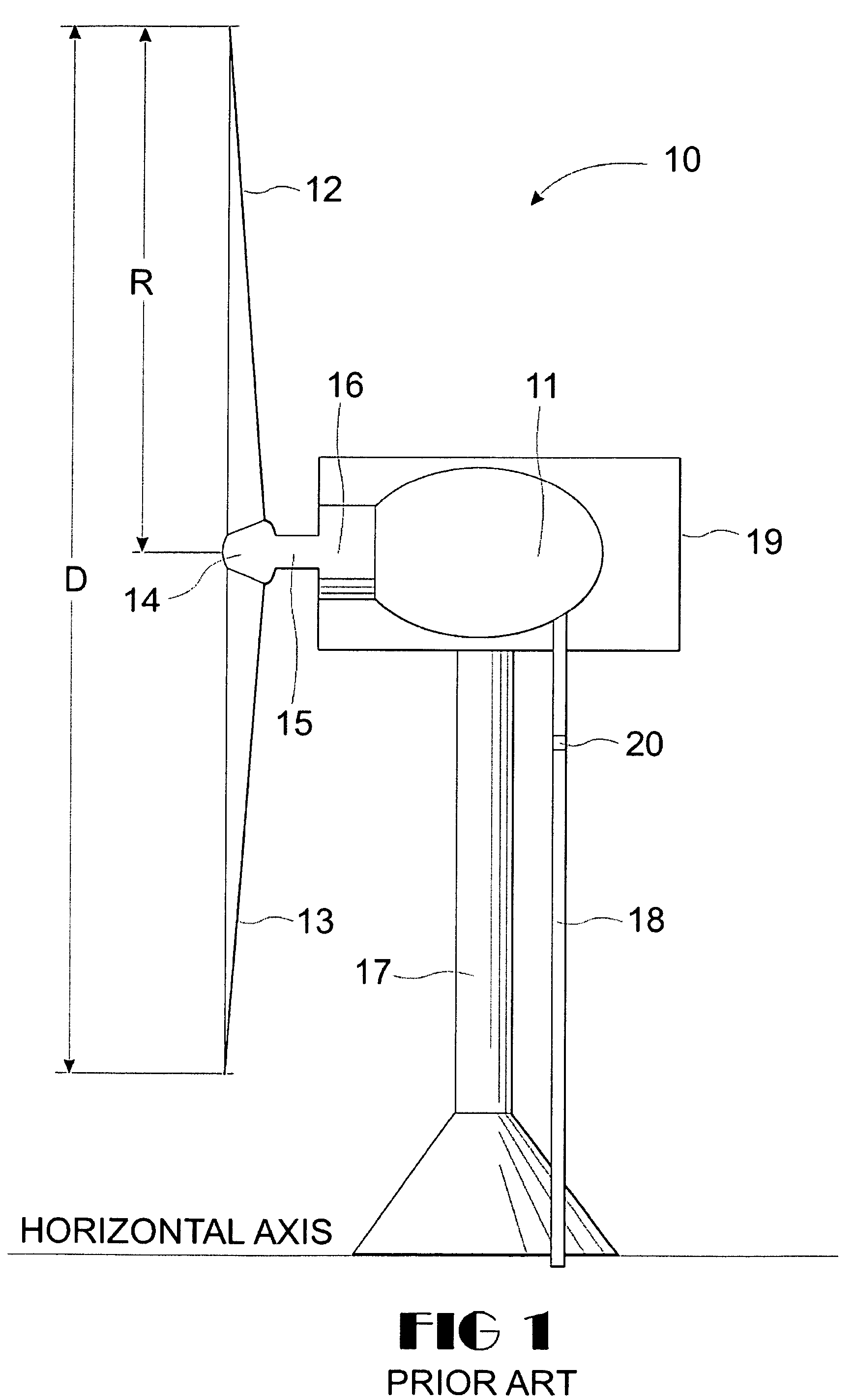

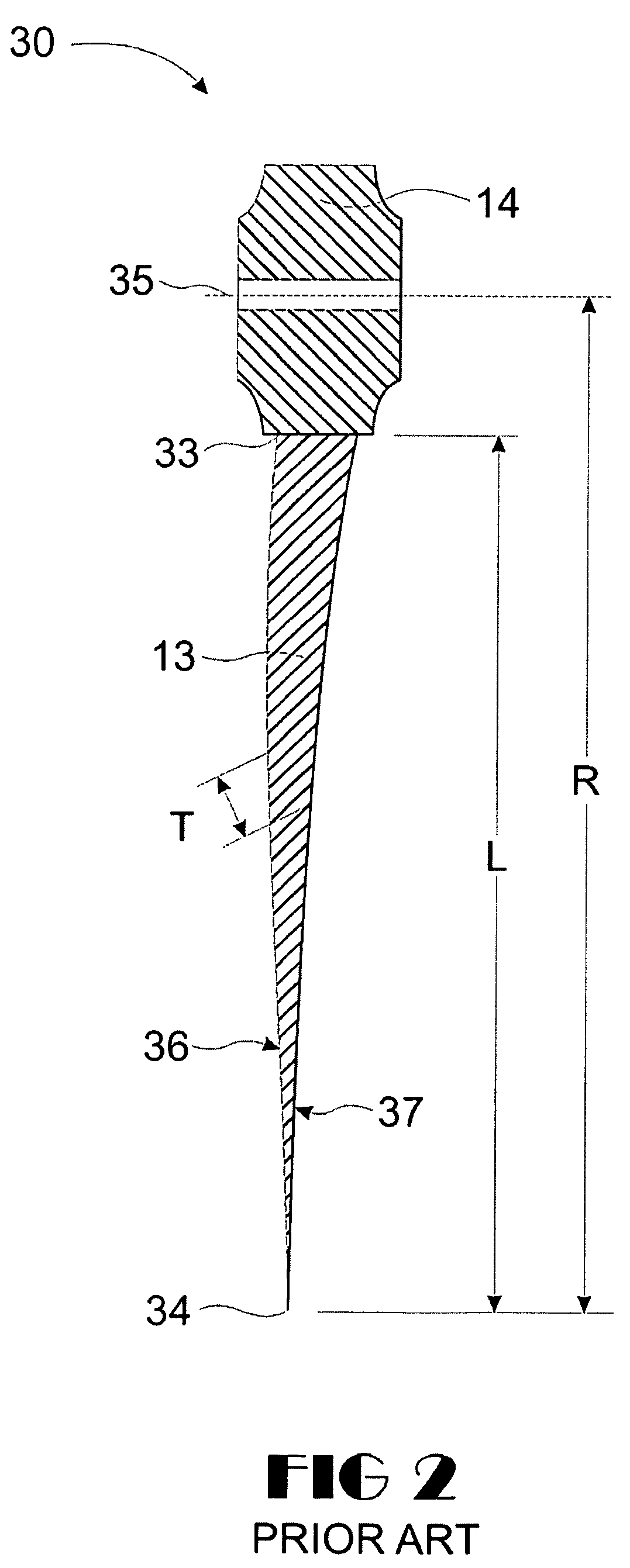

The author suggests a new method and a new inexpensive, large blade-rope type wind rotor, that will be suspended at high altitude and produce huge quantities of energy. The air installation embodiment includes (FIG. 25): propeller 220, wing 226, rope transmission 229, electric generator 12 located at ground. Water rotors can utilize energy of ocean and sea streams. The invention contains 11 projects: 6 for air, 1 for a river, 3 for the sea and ocean, and 1 for ships. They have a power capacity of up to 60 MgW (air), up to 200 MgW (water) for one unit. The suggested installations have the following advantages: 1. Huge power production capacity-up to 5000-10000 times more than conventional ground-based rotor designs. 2. The rotor operates at high altitude of 1-14 kilometers, where wind has high speed and high stability (permanent flows). 3. The installation is much less expensive compared to conventional currently-employed windmills, partly because no tower is necessary to fix the rotor in space. 4. Wind energy is free -environmentally friendly.

Owner:BOLONKIN ALEXANDER ALEXANDROVICH

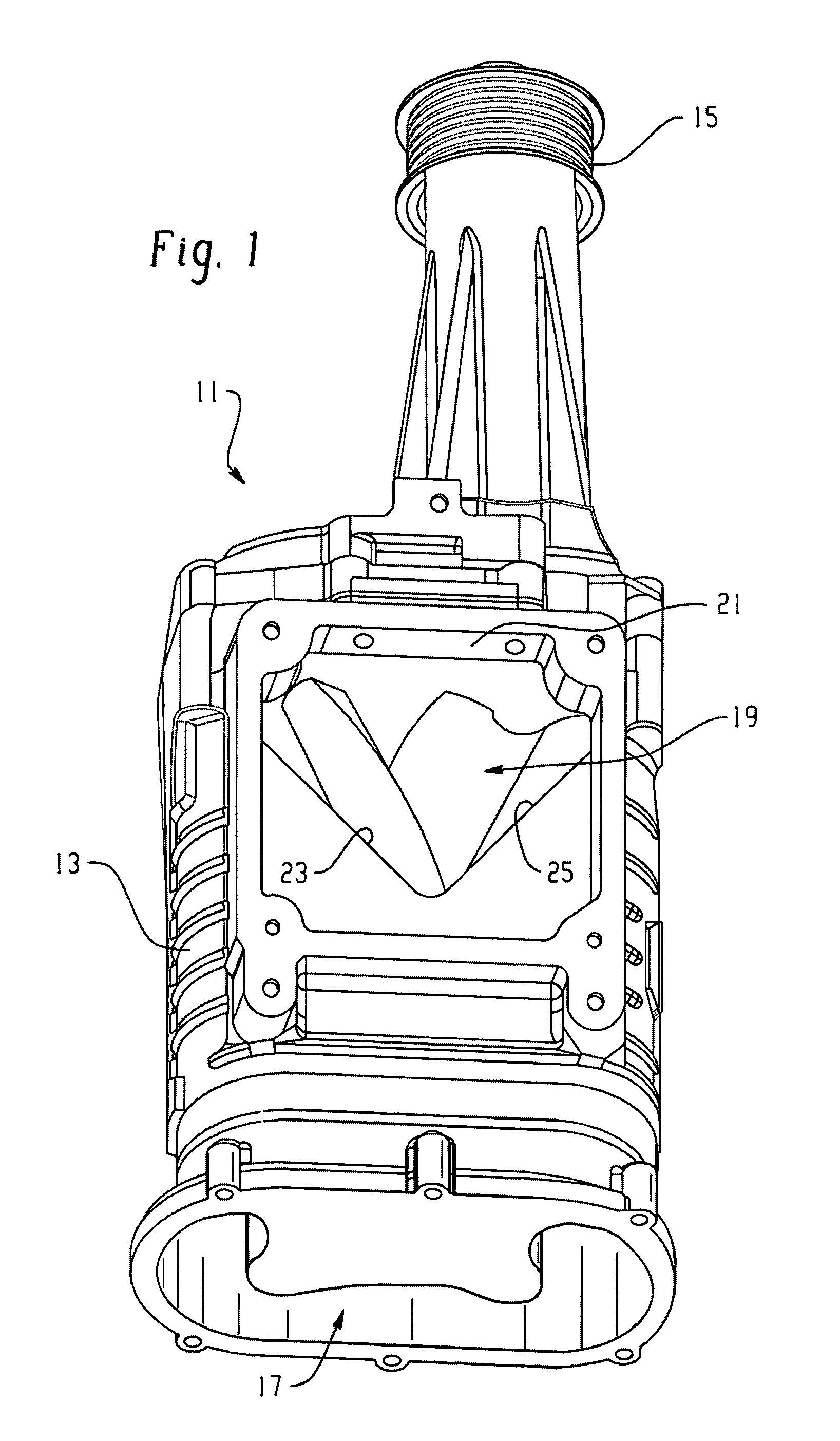

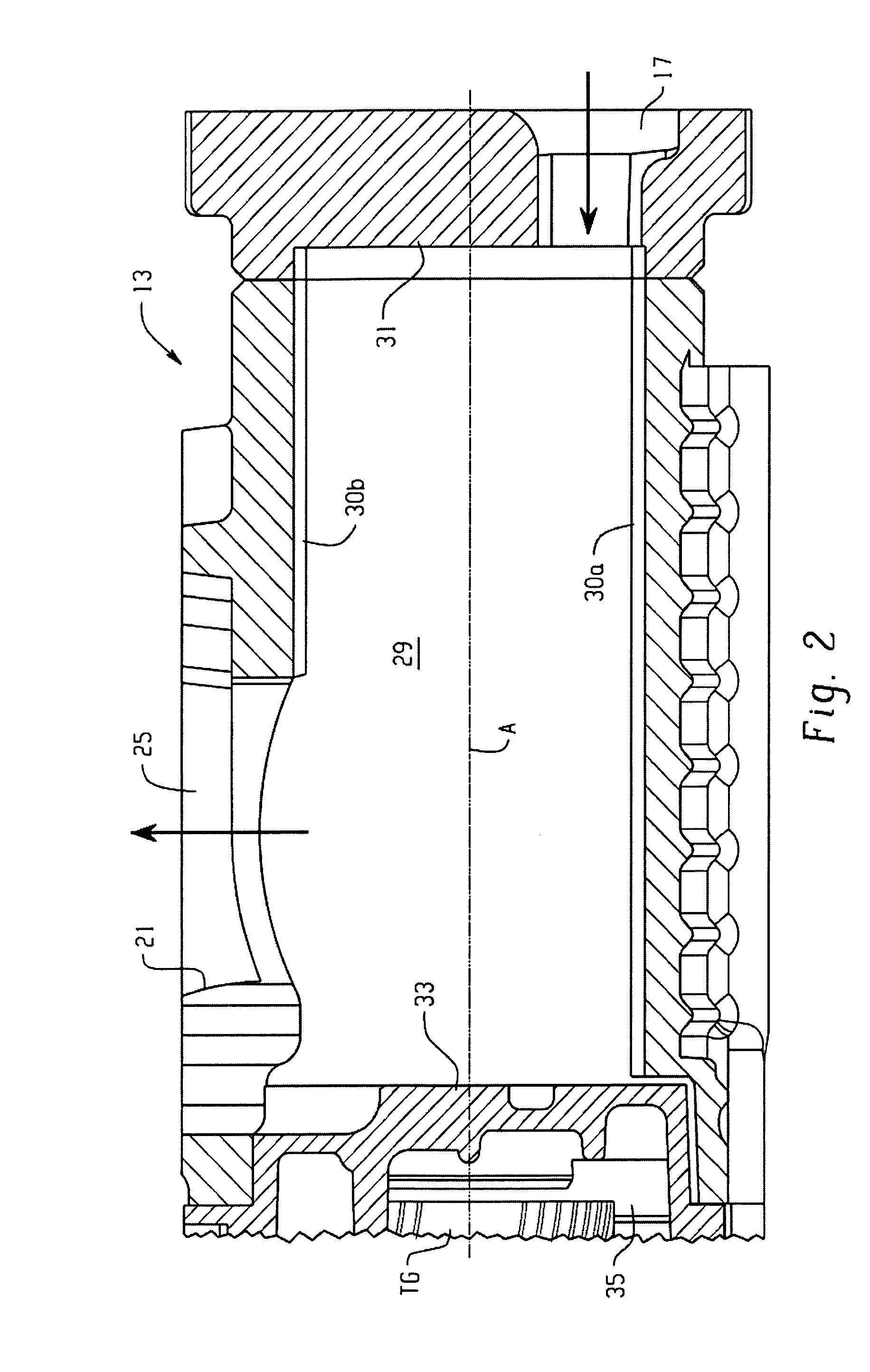

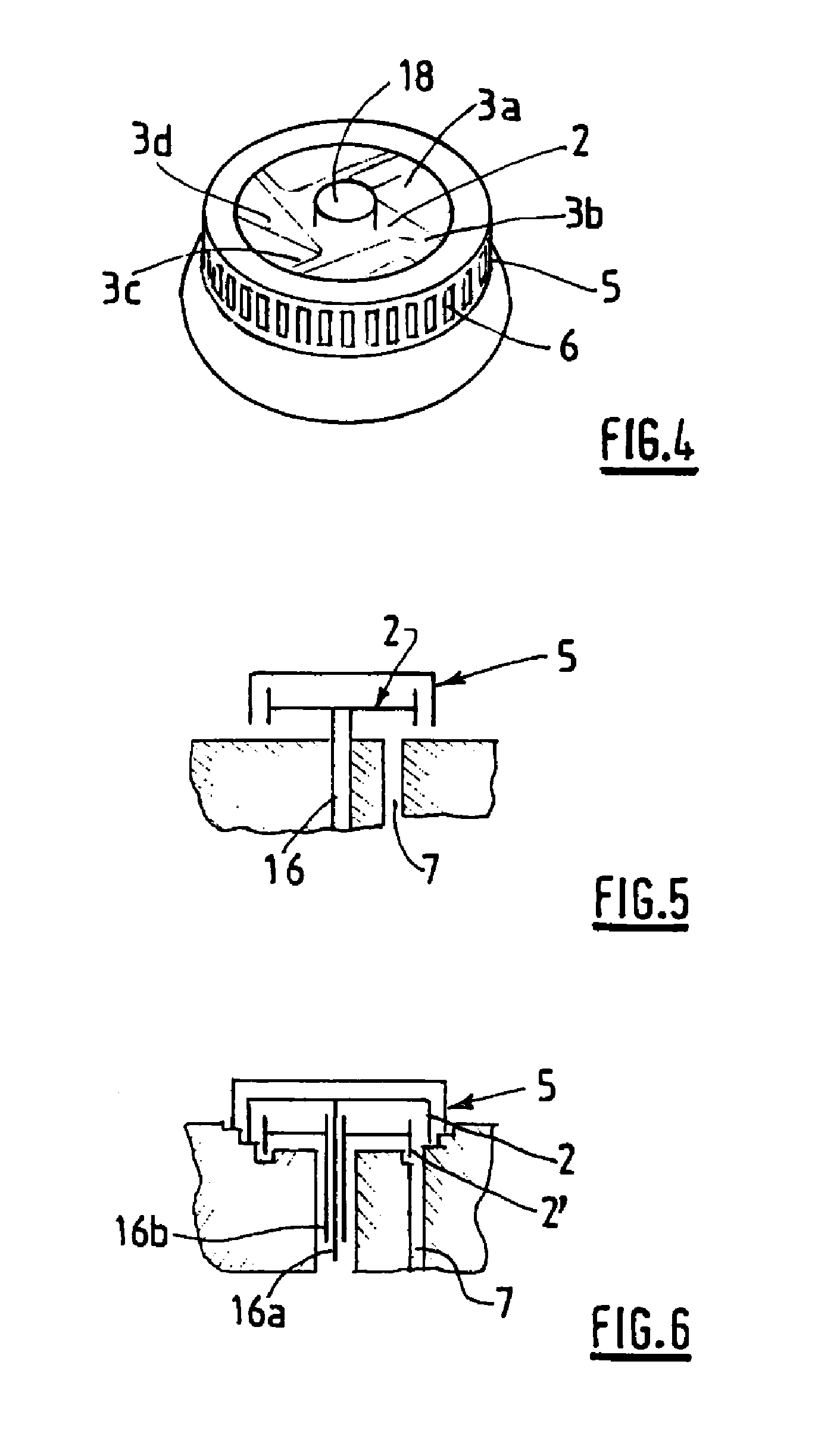

Optimized helix angle rotors for Roots-style supercharger

ActiveUS7488164B2Improve blower efficiencyImprove thermal efficiencyOscillating piston enginesEngine of counter-engagement typeEngineeringHelix angle

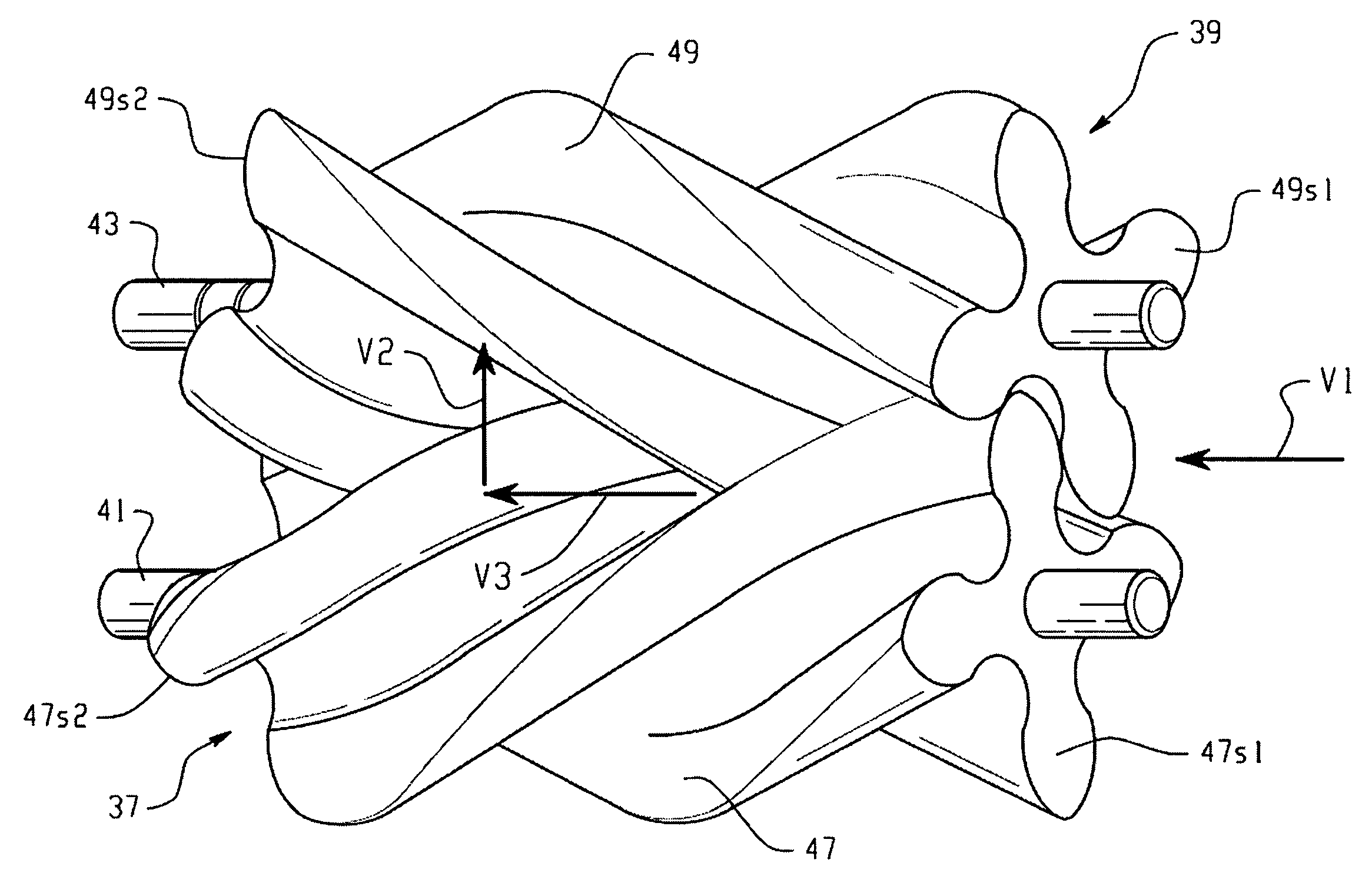

A method of designing rotors for a Roots blower comprising a housing having cylindrical chambers, the housing defining an outlet port (19). The blower includes meshed, lobed rotors (37,39) disposed in the chambers, each rotor including a plurality N of lobes (47,49), each lobe having first (47a,49a) and second (47b,49b) axially facing end surfaces. Each lobe has its axially facing surfaces defining a twist angle (TA), and each lobe defines a helix angle (HA). The method of designing the rotor comprises determining a maximum ideal twist angle (TAM) for the lobe as a function of the number N of lobes on the rotor, and then determining a helix angle (HA) for each lobe as a function of the maximum ideal twist angle (TAM) and an axial length (L) between the end surfaces of the lobe. A rotor designed in accordance with this method is also provided.

Owner:EATON INTELLIGENT POWER LTD

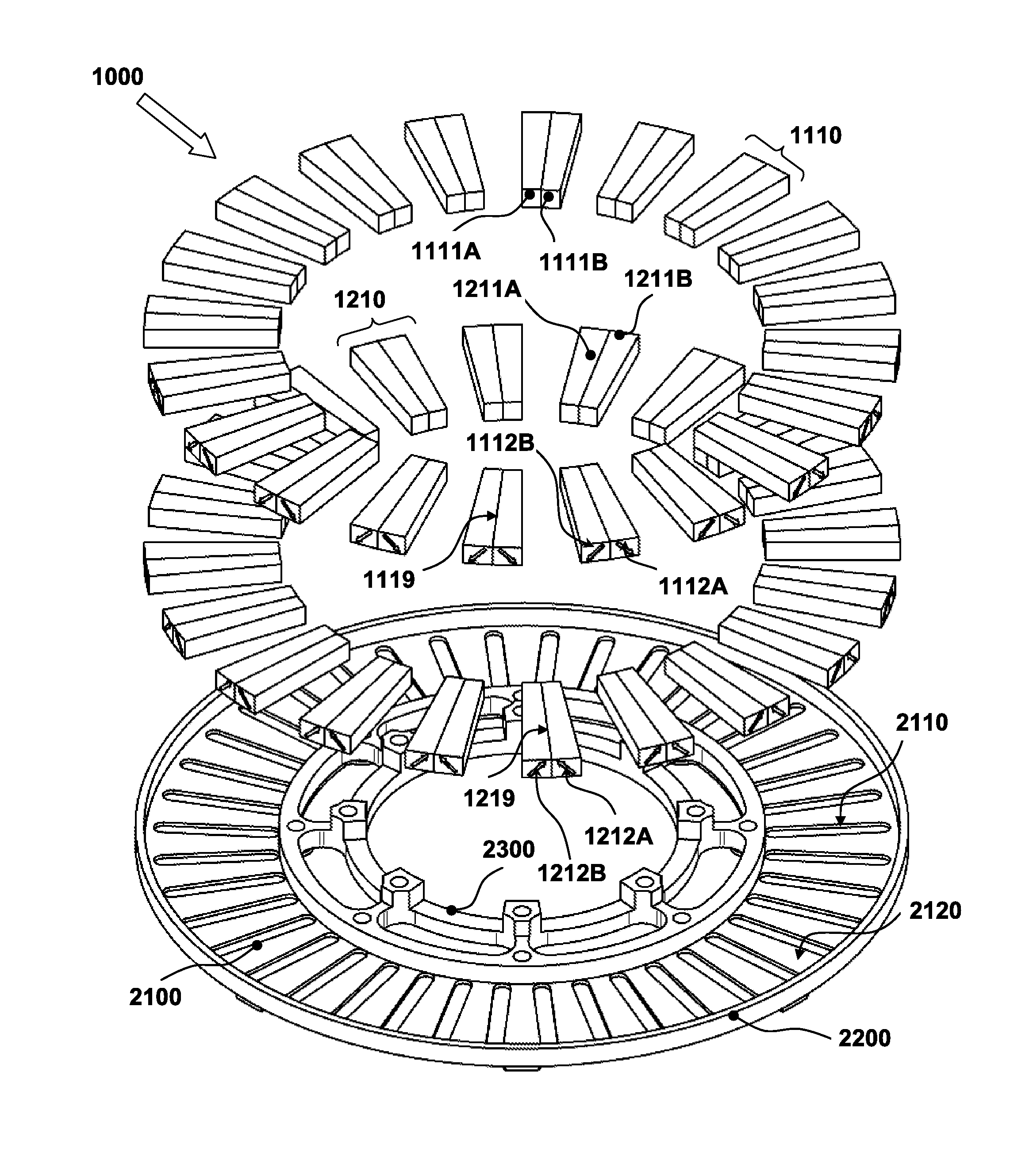

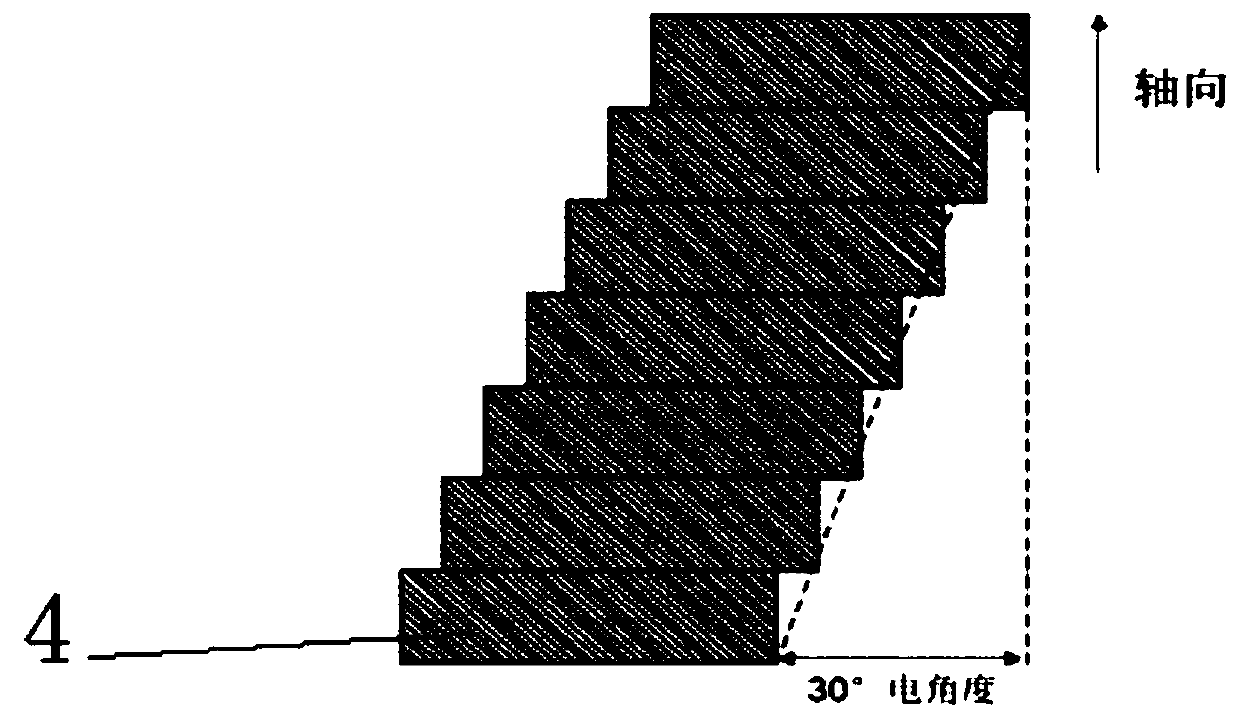

Rotor with magnet pattern

InactiveUS20150229194A1Easy to optimizeDifficult and expensive to manufactureMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnetic poles

Planar rotor designs for axial air-gap electric machines are presented. Some embodiments comprise rotors each of whose magnetic poles comprise a pair of permanent magnets each magnetized in an orientation of about 45° to the direction of the rotor axis. In some embodiments, axial components of the magnetization of each pair of magnets are co-directional, and tangential components of the magnetization of each pair of magnets are opposite.

Owner:ALBUS TECH

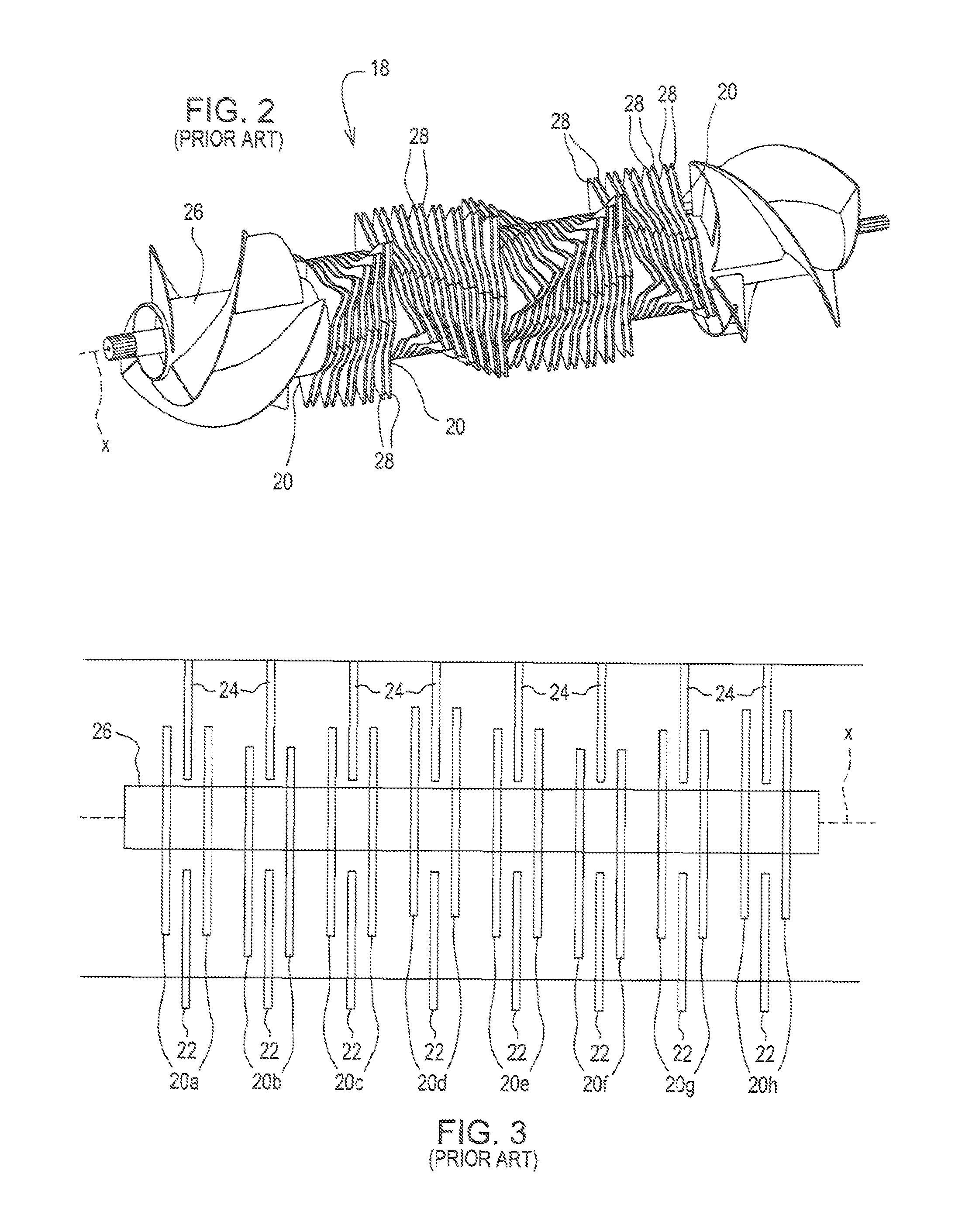

Turbine and compressor employing tubercle leading edge rotor design

ActiveUS20090074578A1Improve the lift-to-drag ratioReduce resistancePropellersHydro energy generationLeading edgeEngineering

Owner:WHALE POWER CORP

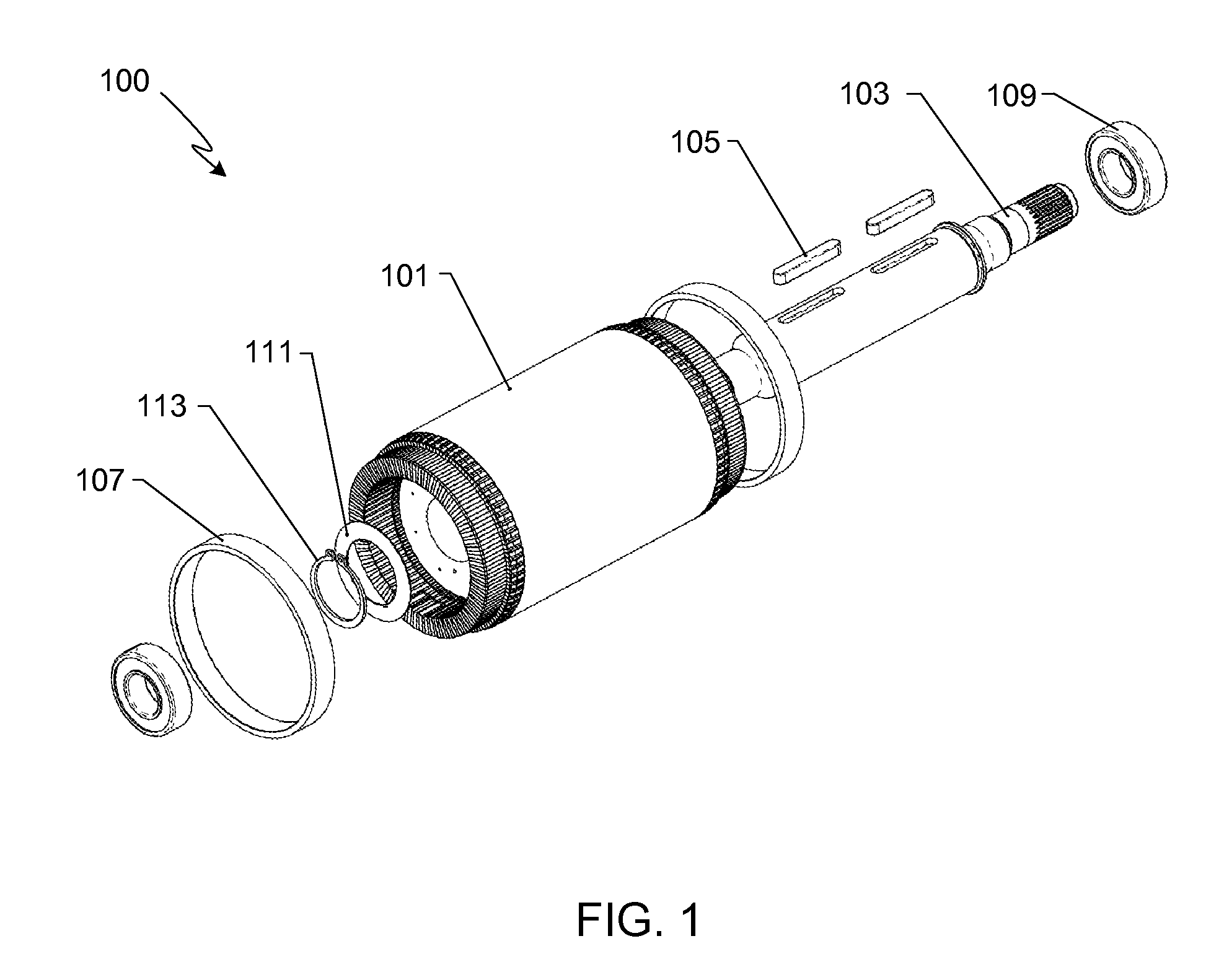

Rotor Design for an Electric Motor

ActiveUS20110062819A1Improve electricityImprove mechanical characteristicsMagnetic circuit rotating partsAsynchronous induction motorsEngineeringRotor design

A rotor assembly and a method for fabricating the same are provided in which a solid rotor ring is formed at either end of a stack of laminated discs, the solid rotor rings yielding improved electrical and mechanical characteristics in a low weight assembly. The solid rotor rings are fabricated by brazing slugs between the end portions of the rotor bars, the braze joints contacting a large percentage (at least 90%) of the rotor bar end portions.

Owner:TESLA INC

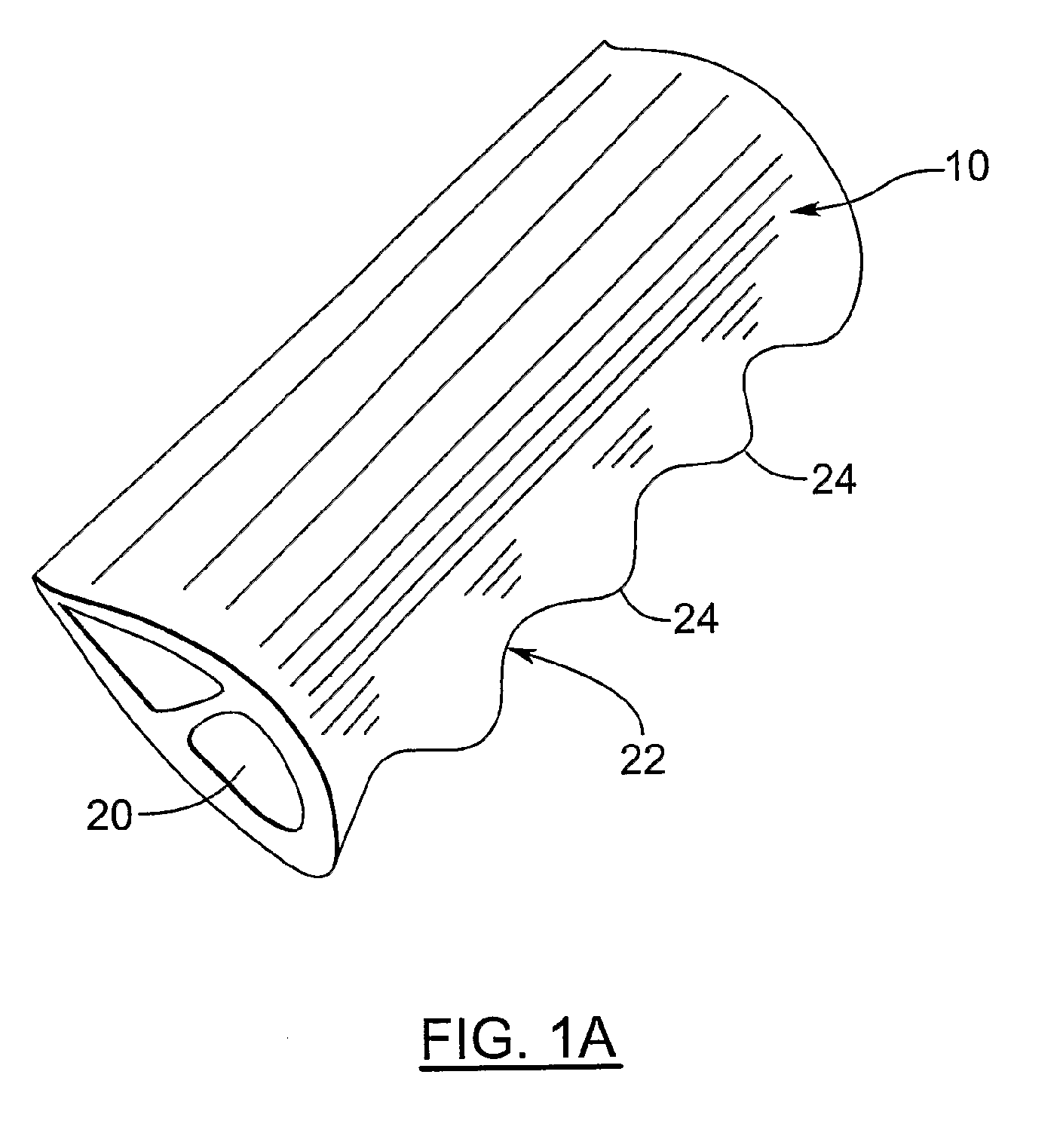

Baler pre-cutter rotor design having reinforced tines

Tines of a baler pre-cutter rotor each include a plate having a plurality of points disposed at equally spaced locations about a rotation axis of the rotor, with each point having a leading region reinforced by a pair of straps fixed in sandwiching relationship to the point. In one embodiment, the pair of straps is also applied to opposite sides of a trailing region bordering a circular mounting hole of the plate. In another embodiment, a second pair of straps abuts each first pair of straps and reinforces a leading region bordering the circular mounting hole. Instead of the second pair of straps, a ramp may be provided on a side surface of the plate for deflecting crop towards a pre-cutter stationary cutting knife. Instead of including separate straps, the tines can be cast or forged as identical sections including a tine point.

Owner:DEERE & CO

Rotor design for submersible electronic generator

InactiveUS7736127B1Avoid serious injuryDecreases the rotor sweep pathPropellersPump componentsElectricityLeading edge

An improved rotor blade used in combination with a submersible electrical generator comprises a rotor base with width W, a leading edge, a tip, and a trailing edge. The leading edge and the trailing edge are defined as elliptical curves having a radius of 8.0(W). A straight line drawn from the front of the base to the lip forms a forty five degree angle with respect to the rotor base. The rotor blade is functionally connected to a rotor shaft through a pivotal support axial which allows the pitch of the blade to be set and maintained. The pitch is set to harness the kinetic energy of flowing water thereby generating electricity.

Owner:CARR FRED K

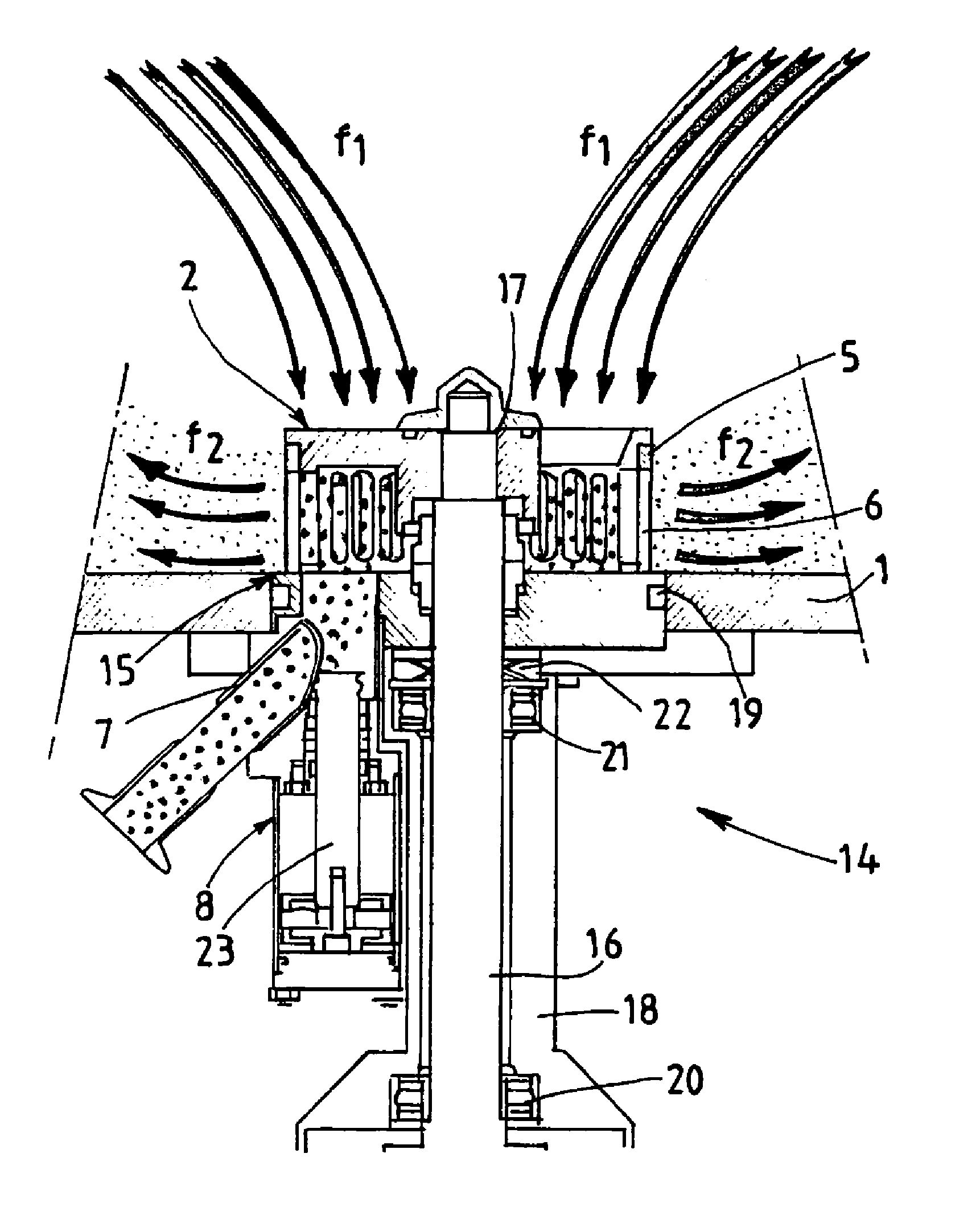

Blender assembly for producing a vacuum inside a vat and method for dispensing particles therein

ActiveUS8960993B2Effective dispersionImprove liquidityFlow mixersTransportation and packagingEngineeringMechanical engineering

Owner:VMI INC

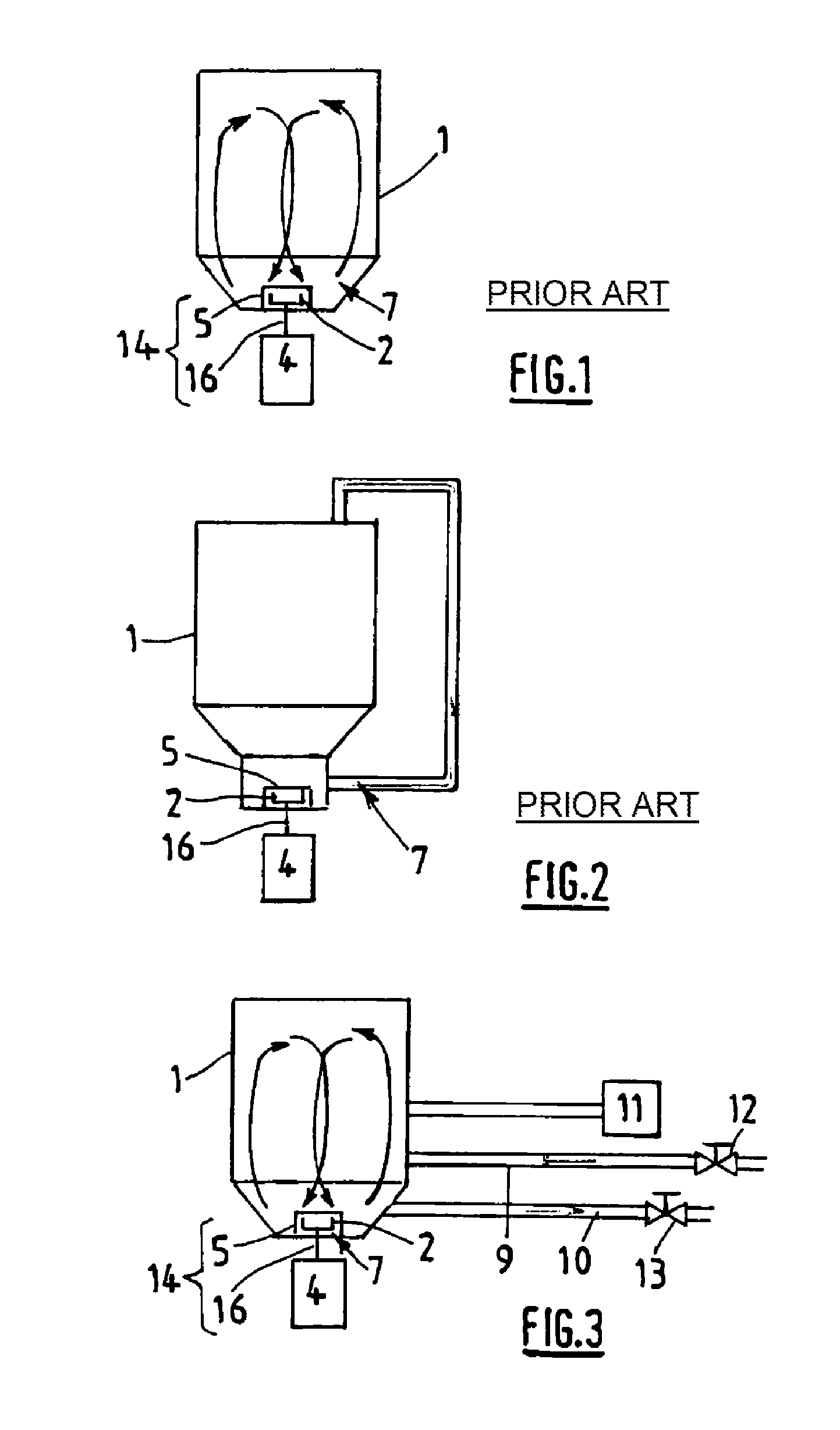

Magnetic mixer drive system and method

InactiveUS20070286015A1Rotary stirring mixersTransportation and packagingMagnetic tension forceHybrid system

An improved magnetic drive for a mixing system and method, wherein stagnation or collection of material in the region of the containment shell and any magnetic rotor are alleviated by the provision of pitched blades provided as radially extending spokes in the inner magnetic rotor. This bladed rotor design may be particularly advantageous in the case of a side entry mixer.

Owner:SPX CORP

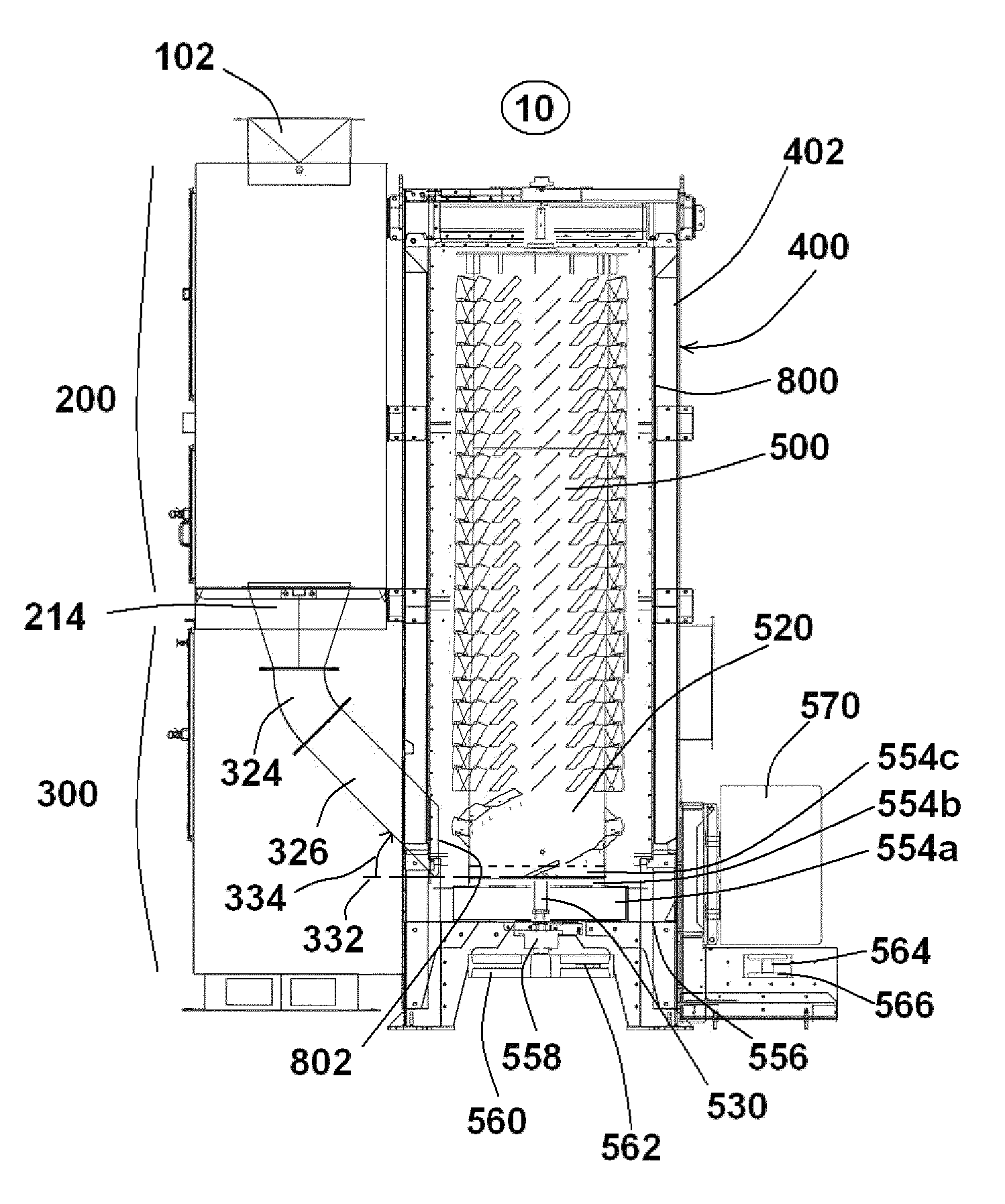

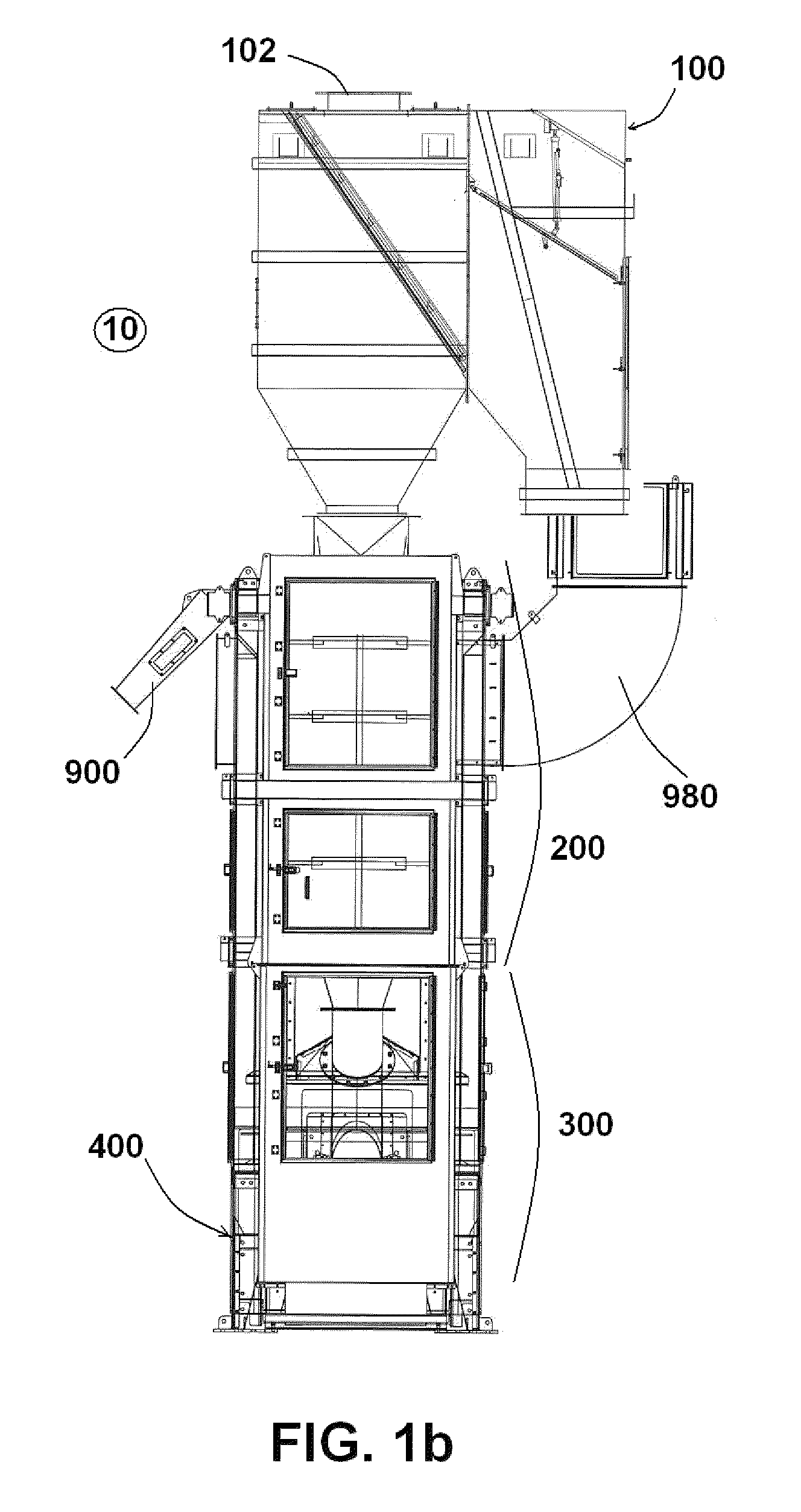

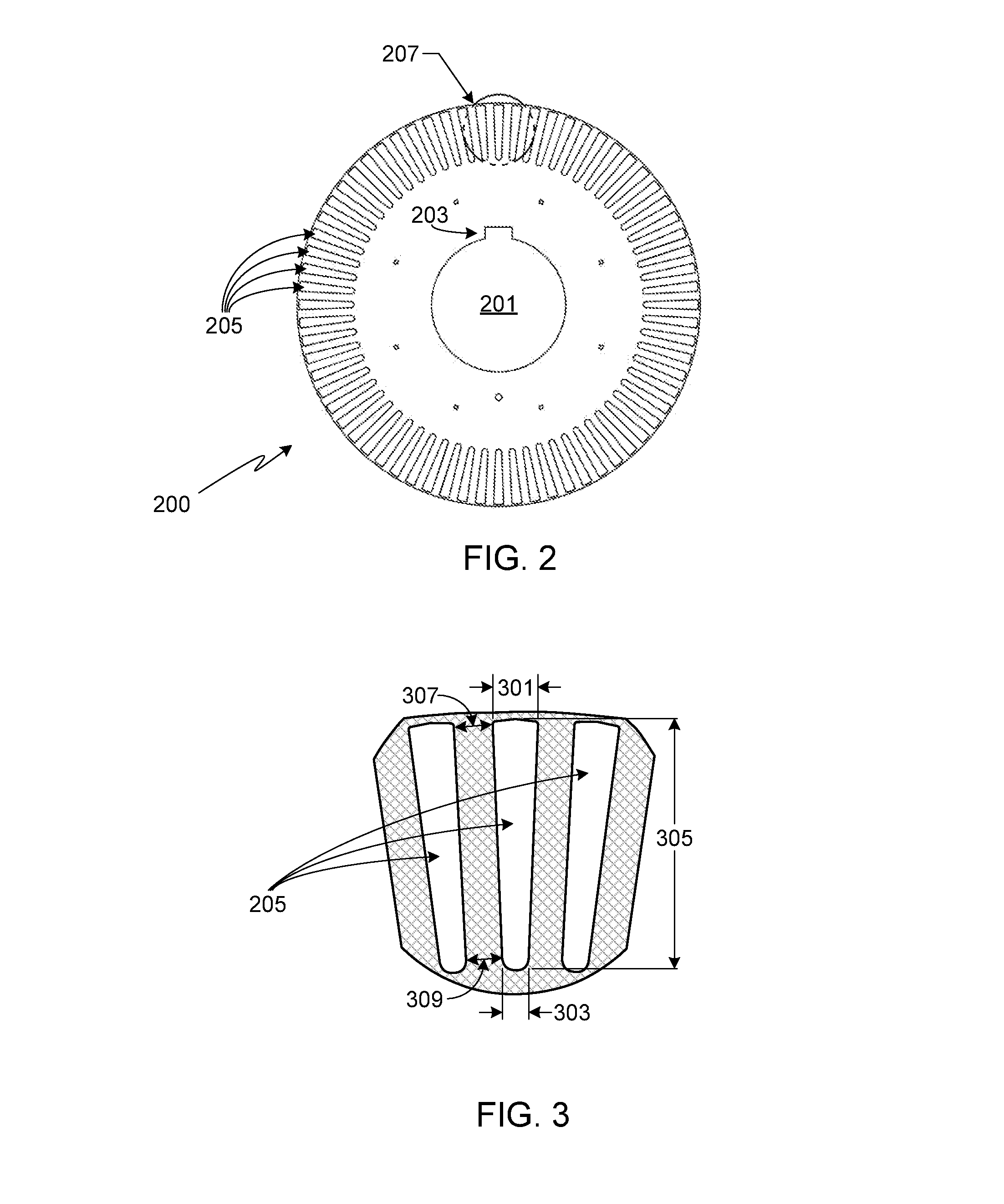

Dryer System With Improved Throughput

InactiveUS20100050458A1Affect velocityIncrease chanceDrying solid materials without heatDrying machinesPulp and paper industryMembrane configuration

A centrifugal dryer that has improved throughput capacity resulting from the combination of a high angle agglomerate catcher with optional overflow, increased dewatering capacity, a cylindrical dewatering feed chute, a modified rotor design with positionally and structurally modified lifters in the feed and dewatering section, the drying and propagating section, as well as the pellet discharge section, and an efficient circumferential foraminous membrane.

Owner:GALA INDUSTRIES INC

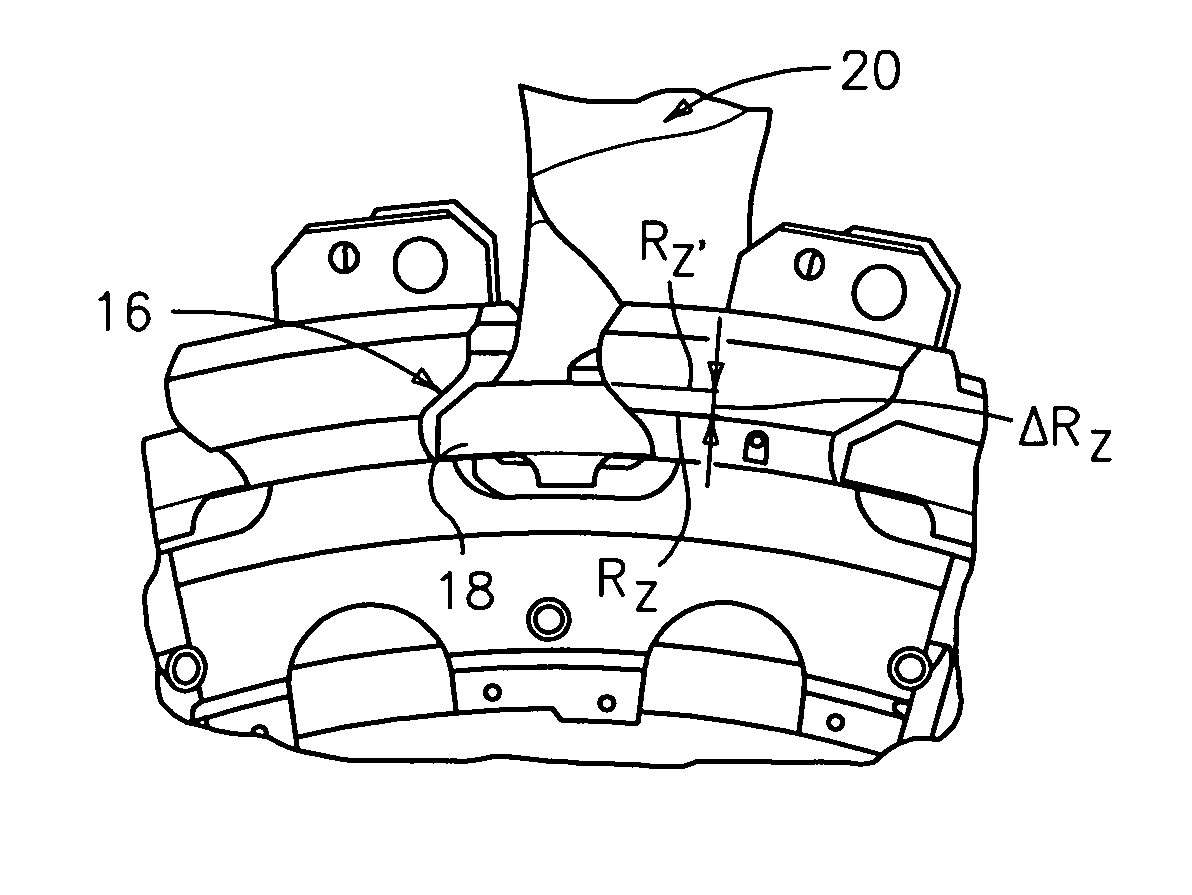

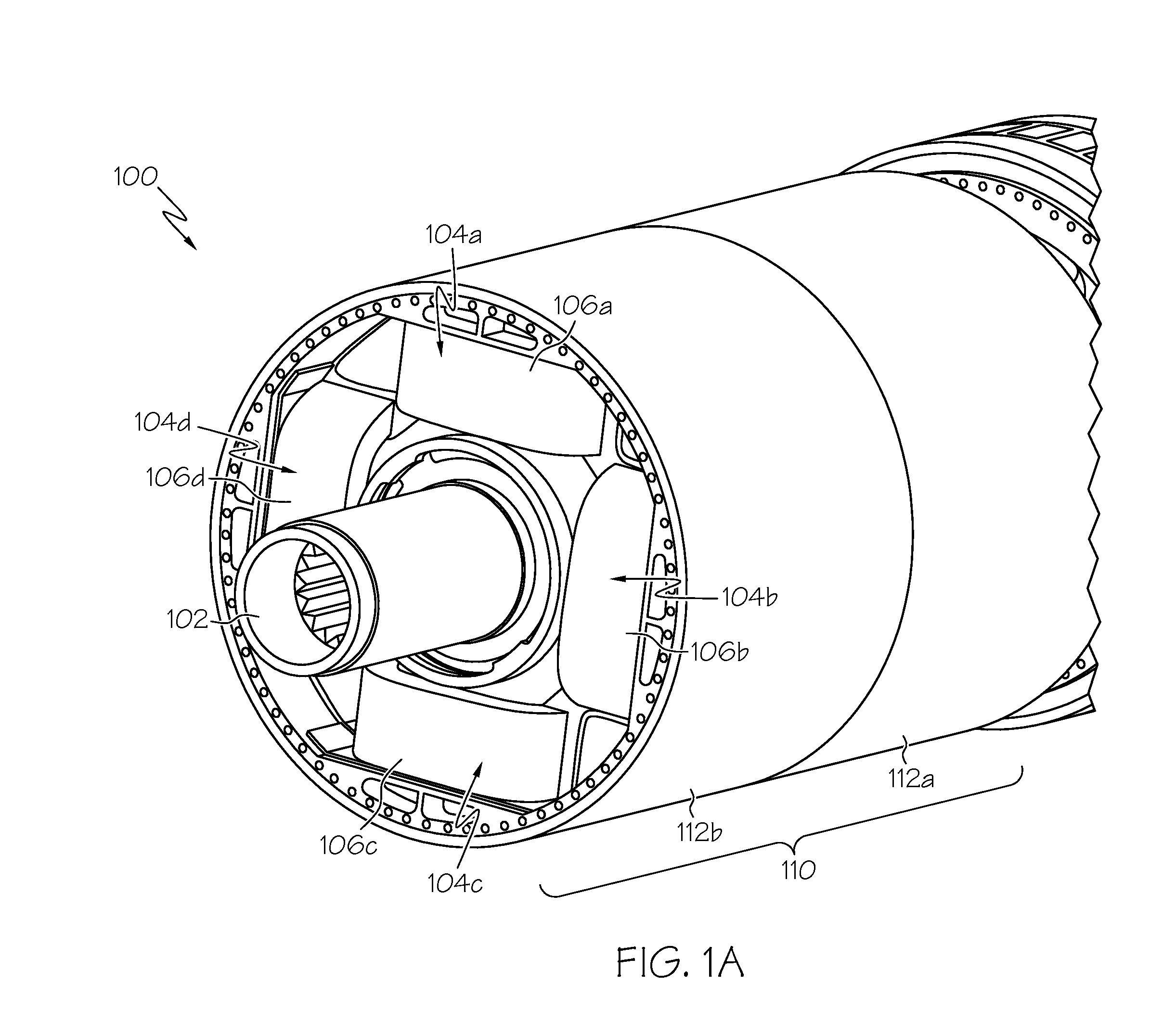

Fan rotor design for coincidence avoidance

A fan rotor capable of avoiding coincidence will include a fan hub comprising one or more slots each designed to receive a fan blade; and one or more fan blades disposed within the slots. One or more slots will comprise an Rz′ baseline and have one or more second fan blades disposed therein while another set of slots will have an Rz baseline having one or more first fan blades disposed therein. The tips of the second fan blades will be positioned at a distance farther from the fan hub than the tips of the first fan blades disposed, which when implemented in a turbofan engine will avoid coincidence occurrences.

Owner:RAYTHEON TECH CORP

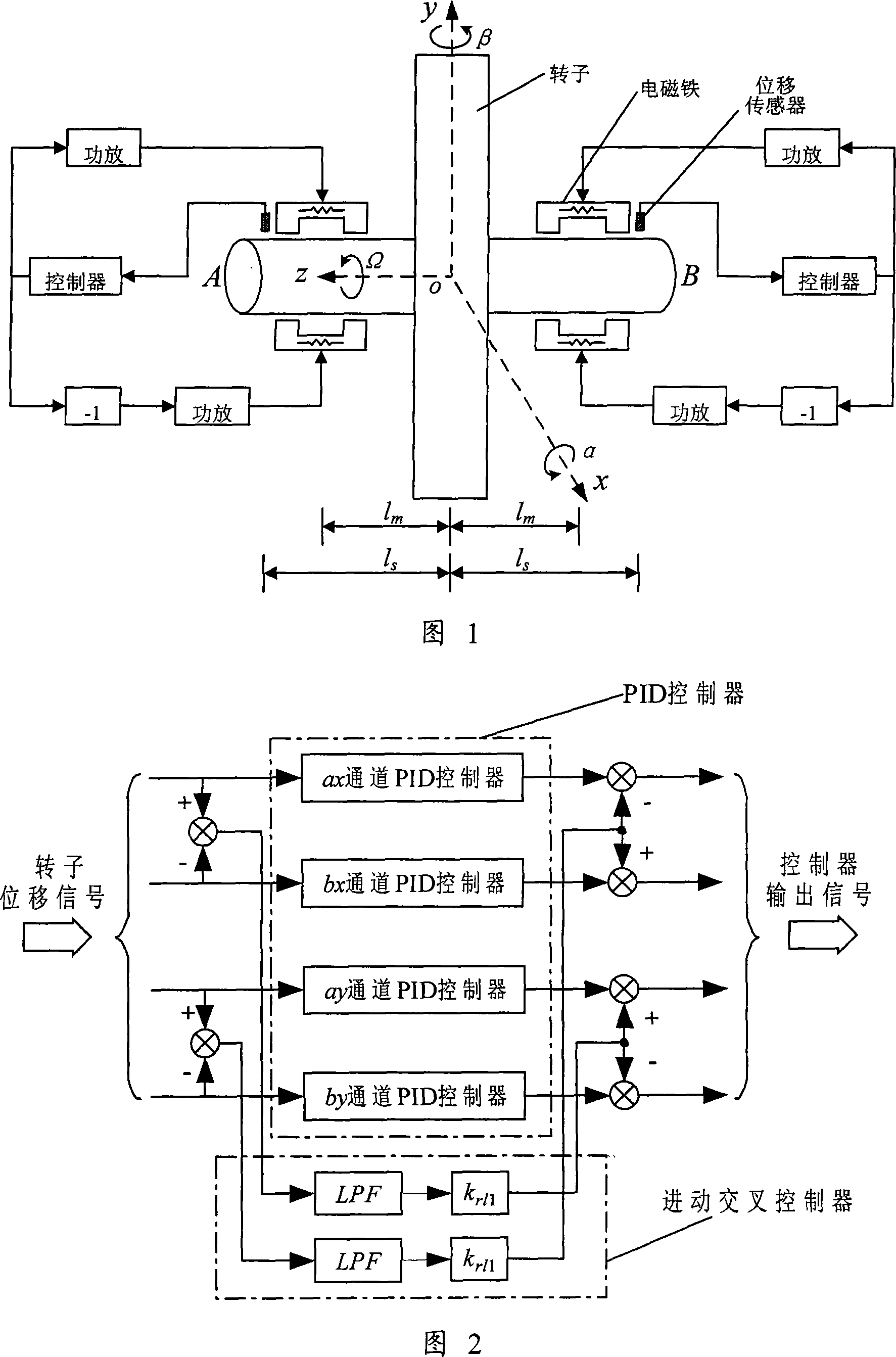

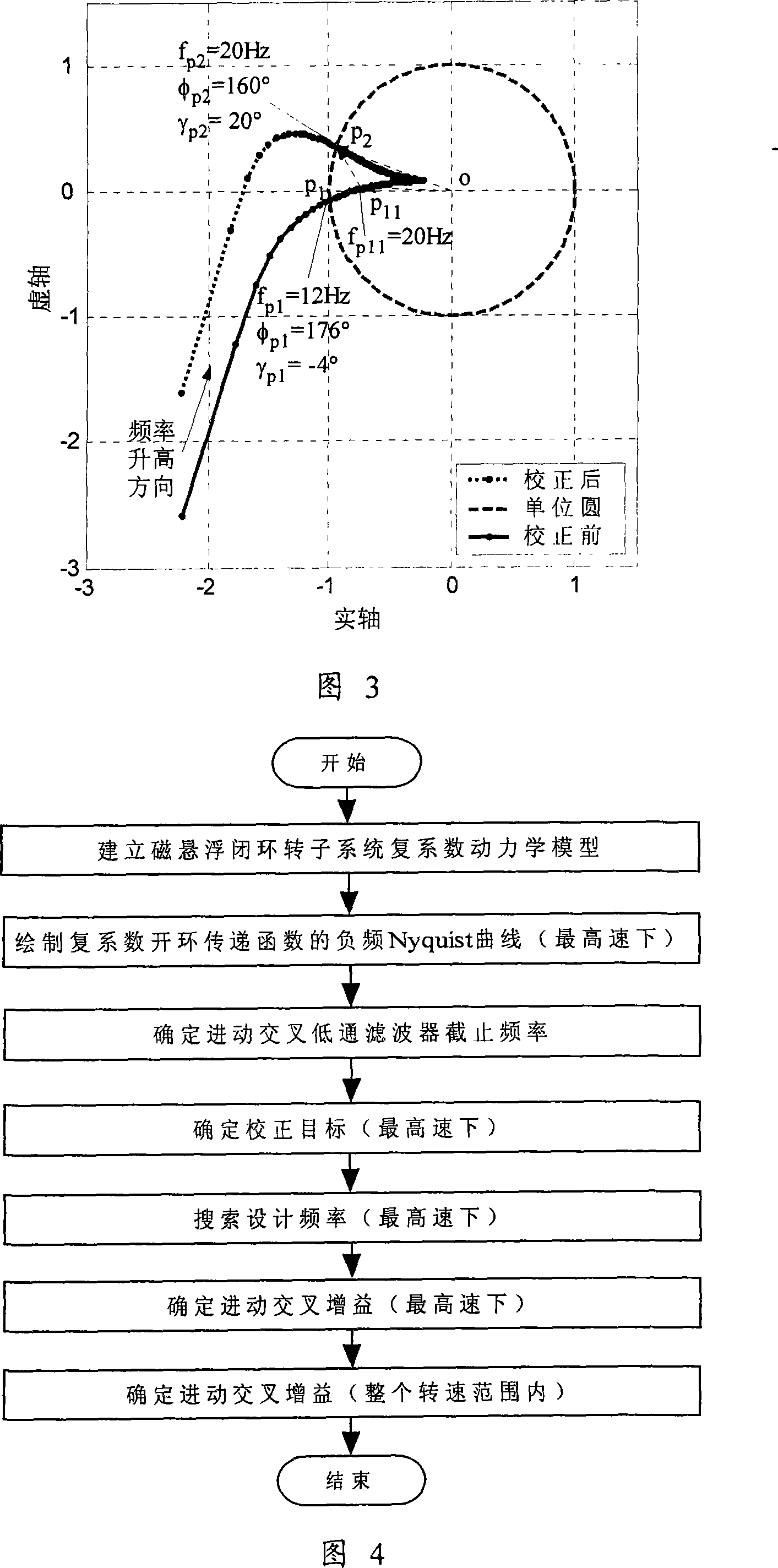

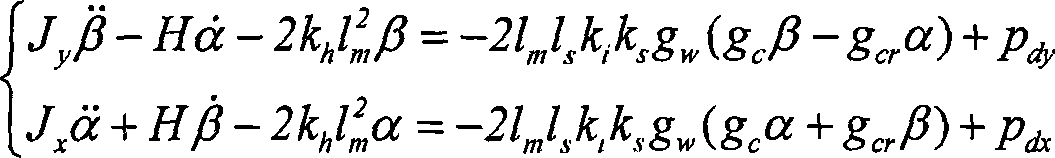

Method for designing precession cross parameter of magnetic levitation high speed rotor

InactiveCN101183241ASolve problems that cannot be directly used for precession cross parameter designIntuitiveAdaptive controlSystems designFlywheel energy storage

A method for designing the precession crossover parameters of the maglev high-speed rotor system, establishing the complex coefficient dynamic model of the maglev closed-loop rotor system, drawing the negative frequency Nyquist curve of the complex coefficient open-loop transfer function at the highest speed and calculating the low-pass cut-off frequency of the precession crossover , and then determine the correction target at the highest speed according to the phase angle margin requirements of the precession mode, search the design frequency and determine the precession cross gain at the highest speed, and then determine the precession cross gain in the entire speed range to ensure that the rotor advances The phase angle stability margin in the whole speed range realizes the robust and stable design of precession cross feedback. Based on the negative frequency Nyquist curve, the present invention proposes a method for designing the precession cross parameters of the maglev high-speed rotor system from the phase angle margin. Compared with the usual multivariable system design method such as the state space analysis method, it is not only very intuitive, but also has good robustness. Rod, so it is more suitable for use in centrifuges, high-precision CNC lathes, turbines, energy storage flywheels, and practical magnetic suspension high-speed rotor systems such as magnetic suspension flywheels and magnetic suspension control torque gyroscopes.

Owner:BEIHANG UNIV

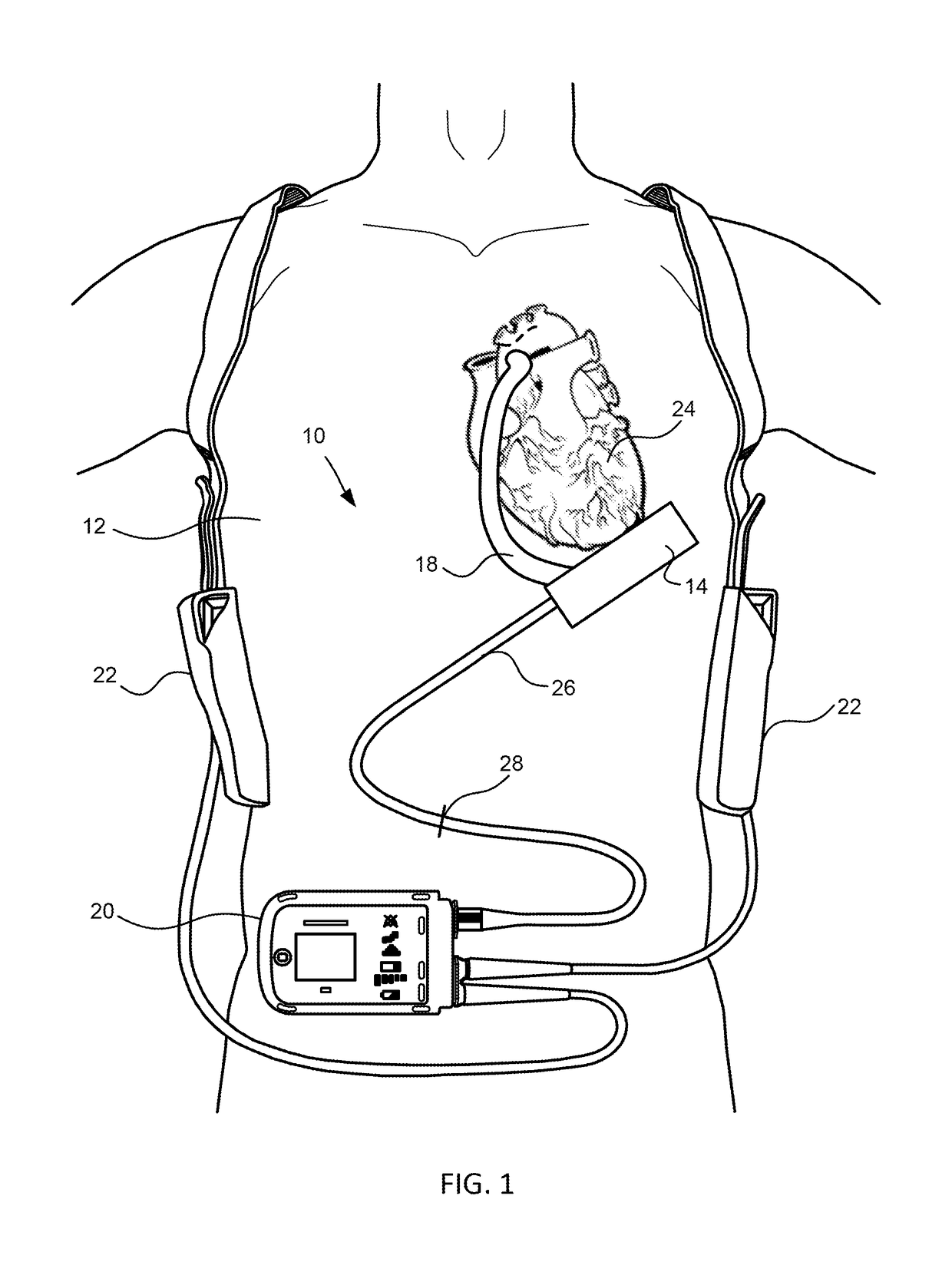

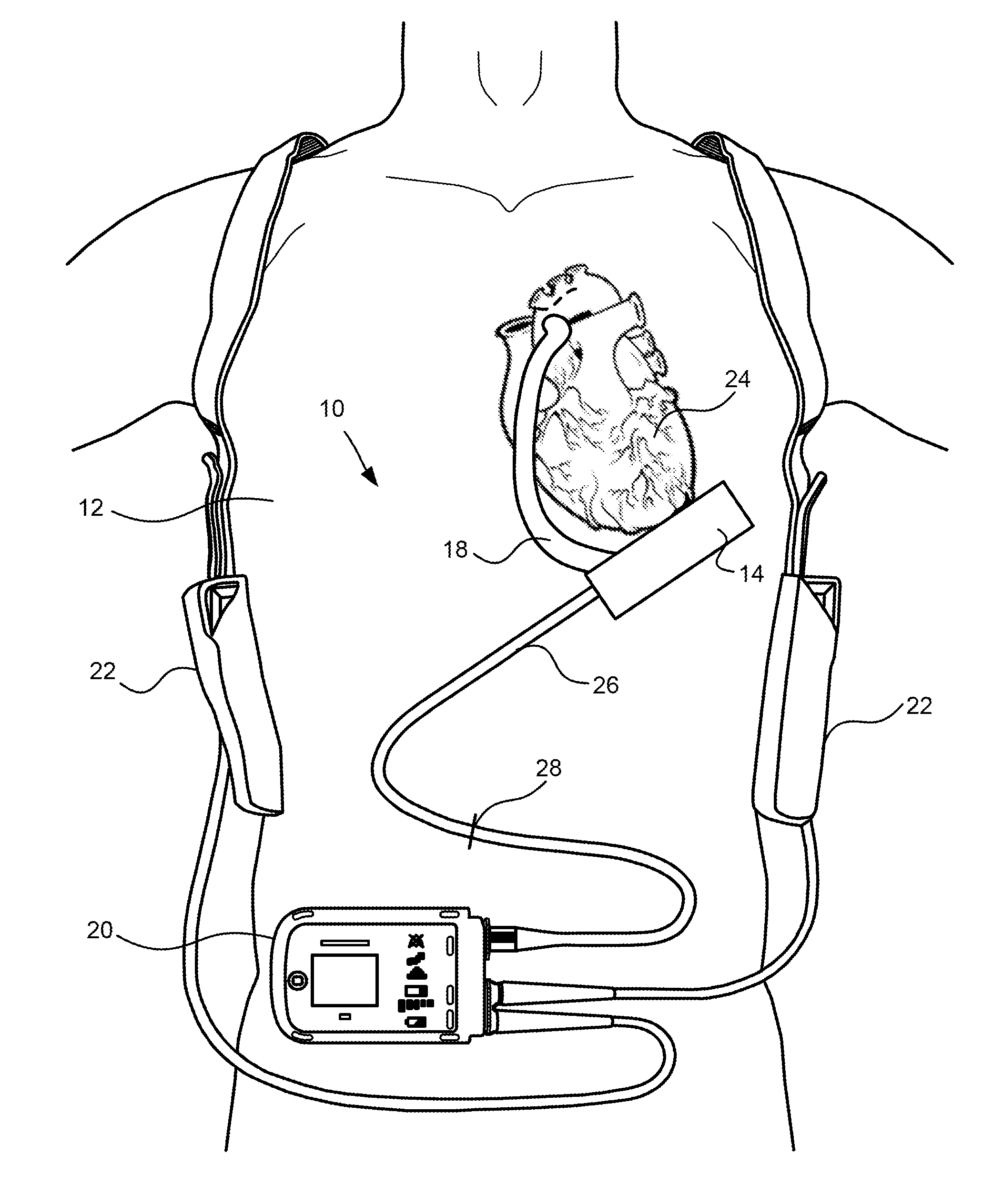

Cantilevered rotor pump and methods for axial flow blood pumping

ActiveUS10029038B2Improved rotor designEasy to moveControl devicesBlood pumpsDistal portionBlood pump

Blood pump devices having improved rotor design are provided herein. Such blood pump devices include rotors having cantilevered support through a sealed mechanical bearing disposed outside a blood flow path of the device so as to avoid thrombus formation caused by blood contact with the bearing. The bearing means can be rotatably coupled with a proximal portion of the rotor shaft extending outside the fluid path, while a stator drives rotation of the rotor shaft so that one or more rotor blades on a distal portion of the rotor force blood flow through the device. The bearing means may include one or more radial bearings on a proximal portion of the rotor shaft that are isolated from the blood flow path by one or more rotary seals.

Owner:TC1 LLC

Wind-driven electricity generation device with savonius rotor

InactiveCN101657636AEasy to handleEasy to assembleMachines/enginesRenewable energy generationWind drivenElectricity

Owner:SAUER ENERGY

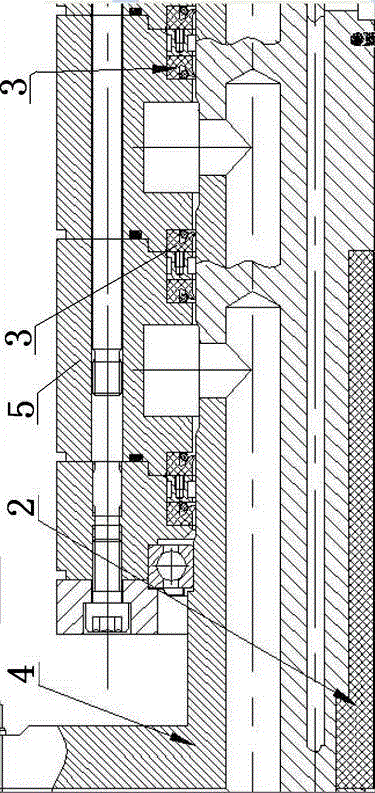

Center rotary joint of earth pressure balance shield machine

The invention discloses a center rotary joint of an earth pressure balance shield machine. The center rotary joint comprises a center stator, wherein the center stator and a rotor are connected through bearings; the center stator is connected with a passive stirring rod and a stop block through splines; the tail part of the center stator is provided with a water spraying joint device; the rotor is connected with a peripheral stator; the rotor is directly connected with a cutter head flange fixedly connected with a cutter head; and the bearings used for connecting the center stator and the rotor comprise a sliding bearing and a self-aligning roller bearing. The center rotary joint adopts an integral design structure; a fluid passage and a hydraulic passage form a whole, so that the structure is more compact; higher processibility is realized; and the manufacturing cost and the maintenance cost are reduced. The center rotary joint adopts a double-stator and single-rotor design; fluid media and hydraulic media can be easily conveyed; the bearings are adopted for rotating supporting; the precision is high; a stirring and center high-pressure flushing system is designed in the center, so that the problem of mud cake forming in the center of the cutter head is solved; and 0.24L / ring of EP2 grease and 0.5L / ring of HBW are saved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Fan rotor design for coincidence avoidance

A fan rotor capable of avoiding coincidence will include a fan hub comprising one or more slots each designed to receive a fan blade; and one or more fan blades disposed within the slots. One or more slots will comprise an RZ′ baseline and have one or more second fan blades disposed therein while another set of slots will have an RZ baseline having one or more first fan blades disposed therein. The tips of the second fan blades will be positioned at a distance farther from the fan hub than the tips of the first fan blades disposed, which when implemented in a turbofan engine will avoid coincidence occurrences.

Owner:RAYTHEON TECH CORP

Active clearance compensation type cycloid pump/ motor device

InactiveCN101865021AImprove efficiencyInternal combustion piston enginesRotary piston pumpsAuto regulationContact pressure

The invention discloses an active clearance compensation type cycloid pump / motor device. A cylinder side plate is provided with symmetrical openings; and each group of rotors consists of separated secondary rotors, an actuated piston and a corresponding piston chamber are arranged between the secondary rotors, the center of the rotors is provided with an inner gear, the tips of the rotors are provided with a sealing sheet, the sealing sheet is provided with a groove, the working face of the rotors is provided with a pressure passage, the pressure passage is communicated with the bottom of the groove of the sealing sheet, and the sealing face of the rotors is provided with a timing groove. The separated secondary rotors are designed to reflect the pressure of the working face or the pre-pressure of an elastic substance so as to automatically adjust the tightness of the sealing face of the rotors and the cylinder side plate and fulfill the purposes of low compression, low friction, high compression and high efficiency; the sealing sheet at the tips of the rotors also reflects the pressure of the working face so as to automatically adjust the contact pressure with the cylinder wall and fulfill the same purpose as the rotor design purpose; and the timing groove is formed on the sealing face of the rotors to allow increasing the overlapped area of the sealing face of the rotors and an inlet / outlet so as to increase the sealing property.

Owner:黄宏志

Designing method of claw type rotor

ActiveCN1904365AImprove performanceIncrease the compression ratioRotary piston pumpsRotary piston liquid enginesTransfer volumeEngineering

There is disclosed a design method of claw rotors, which is used for designing defined rotors conjugate engaged each other and conjugate rotors. Taking the parameterization definition of the motion curvilinears of an ineffective compression to a beginning of the air-intaking and start to end of exhausting of two rotors estimates and seeks out the optimum performance of the rotor. When the rotor designed by the present invention is for use in a vacuum pump, a compressor, a supercharger and the like, it can provide a higher compression ratio and a transfer volume.

Owner:LIUNG FENG INDAL

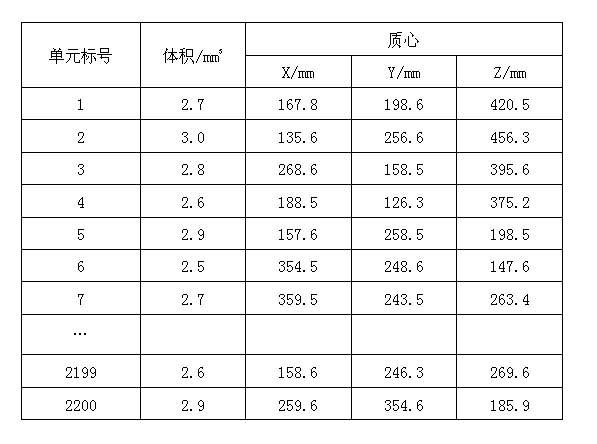

Rigid rotor dynamic balance obtaining method

InactiveCN103257018AHigh precisionImprove accuracyStatic/dynamic balance measurementRigid rotorDynamic balance

The invention belongs to the technical field of rotor design, and provides a rigid rotor dynamic balance obtaining method. The method includes the following steps: (1) an entity model of a rotor part is divided into grids and decomposed into a limited number of unit entities, (2) quality characteristic data of each grid unit are extracted, (3) a dynamic unbalance value of a rotor is obtained, and (4) a dynamic balance result of the rigid rotor is obtained. The method effectively overcomes the defect that obtaining of rigid rotor dynamic balance is not accurate, dynamic balance obtained in the method plays a significant role in the rotor design, vibration of machines can be effectively reduced, so service life of the machines is prolonged, work efficiency is improved, and operation is safe.

Owner:SHANGHAI UNIV OF ENG SCI

Dryer system with improved throughput

InactiveUS8205350B2Easy to disassembleOptimal screen designDrying solid materials without heatDrying machinesPulp and paper industryThroughput

A centrifugal dryer that has improved throughput capacity resulting from the combination of a high angle agglomerate catcher with optional overflow, increased dewatering capacity, a cylindrical dewatering feed chute, a modified rotor design with positionally and structurally modified lifters in the feed and dewatering section, the drying and propagating section, as well as the pellet discharge section, and an efficient circumferential foraminous membrane.

Owner:GALA INDUSTRIES INC

Axial flow fan

A fan or rotor design where the surface profile may be configured to desired dimensions particular to a given operating environment is disclosed.

Owner:PAX SCI +1

Rotor Design for an Electric Motor

InactiveUS20130069476A1Improve featuresSynchronous motorsAsynchronous induction motorsRotor designElectric motor

A rotor assembly is provided in which a solid rotor ring is formed at either end of a stack of laminated discs, the solid rotor rings yielding improved electrical and mechanical characteristics in a low weight assembly. The solid rotor rings are fabricated by brazing slugs between the end portions of the rotor bars, the braze joints contacting a large percentage (at least 90%) of the rotor bar end portions.

Owner:TESLA INC

Design method of seven-segment type straight claw rotor

The invention relates to a design method of a seven-segment type straight claw rotor. The rotor formed by using the design method comprises the following curved segments A1B1, B1C1, C1D1, D1E1, E1F1, E1G1 and G1H1A1, and all the curves are connected to form a shape curve of the rotor, wherein the production mechanism of each segment of curve is as follows: A1B1 is generated by conjugation of F2G2on a conjugated rotor; B1C1 is a segment of arc and is generated by conjugation of D2E2 on the conjugated rotor; C1D1 is a segment of cycloid curve and is generated by conjugation of a C2 point on the conjugated rotor; D1E1 is a segment of arc and is generated by conjugation of B2C2 on the conjugated rotor; E1F1 is a segment of cycloid curve and is generated by conjugation of a B2 point on the conjugated rotor; E1G1 is a segment of straight line envelop curve and is generated by conjugation of A2B2 on the conjugated rotor; and G1H1A1 is segment of arc and is generated by conjugation of G2H2A2on the conjugated rotor. The design method of the seven-segment type straight claw rotor has the beneficial effects that the seven-segment type straight claw rotor can be machined by numerical control machines and can be used for mass production.

Owner:王连智

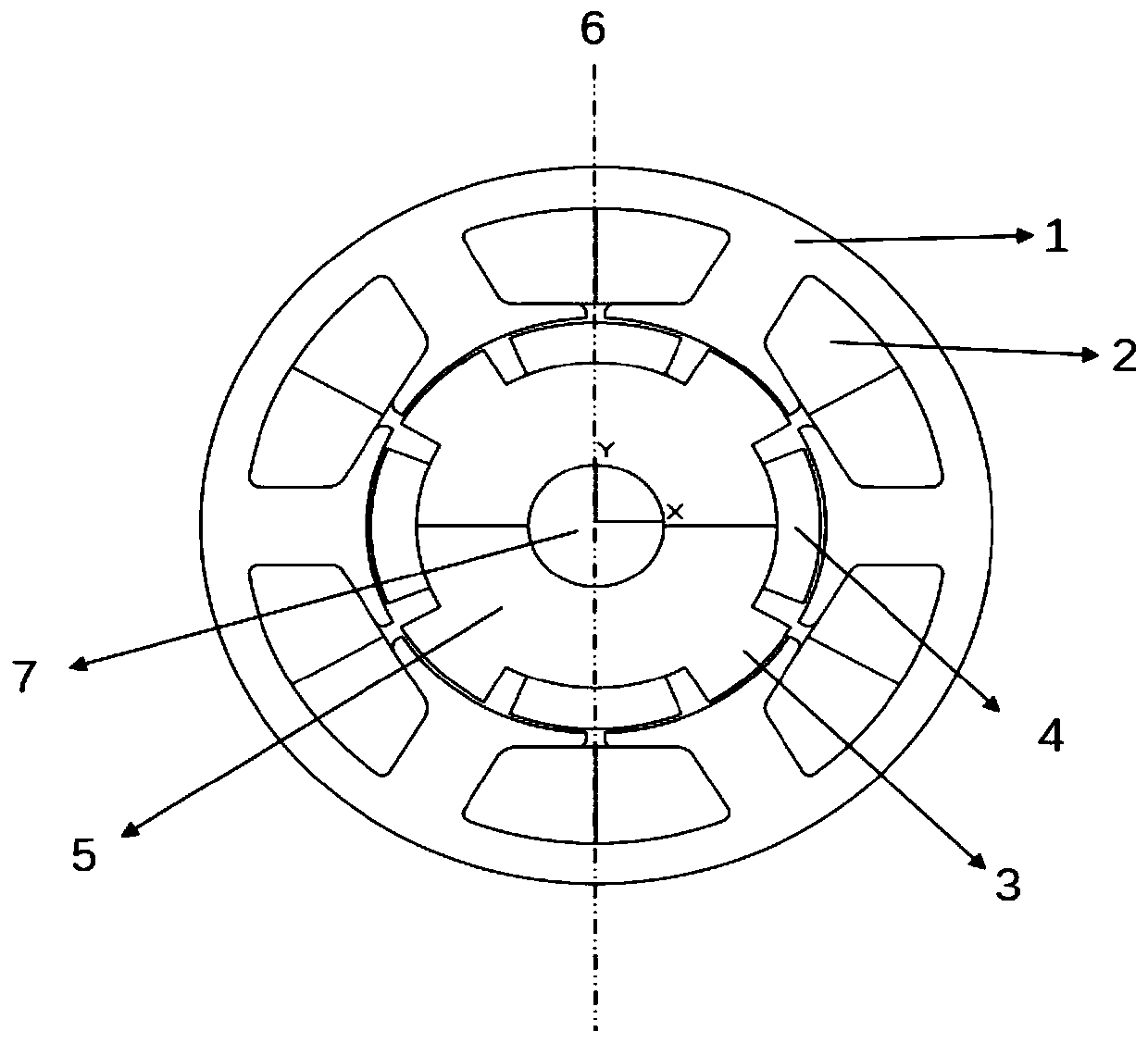

Rotor with inclined magnetic pole and asymmetric salient pole and high-performance permanent magnet motor

ActiveCN110022013ATorque ripple does not dropTorque ripple is reduced without reducing torque densityMagnetic circuit rotating partsElectric machinesUltrasound attenuationMagnetic poles

The invention provides a rotor with an inclined magnetic pole and an asymmetric salient pole and a high-performance permanent magnet motor; the magnetic pole inclined pole is implemented in one magnetic pole polar distance, and the salient pole is arranged on one side of the magnetic pole and has asymmetry in the circumferential direction. According to the rotor design of the high-performance permanent magnet motor, the torque pulsation can be reduced, and the reduction of the output torque after torque pulsation can be effectively avoided, the low-torque pulsation of the motor is realized, the high-torque density operation is achieved, and the performance of the motor is greatly improved; the method specifically comprises the following steps that 1) the torque of a tooth groove is reduced; 2) the sinusoidal or quasi-sinusoidal back electromotive force is generated to reduce the torque pulsation; and 3) the axial direction of the adjacent magnetic poles is not overlapped, so that the overlarge attenuation of the torque density is avoided; and by virtue of the asymmetric salient pole rotor structure, the maximum values of the magnetic resistance torque and the permanent magnet torque are overlapped under the same or similar current phase angles, so that the torque loss caused by the magnetic pole inclined pole is made up by increasing the utilization rate of the two torque components, the low torque pulsation of the motor is ensured, and meanwhile, the high torque density is kept.

Owner:SHANDONG UNIV

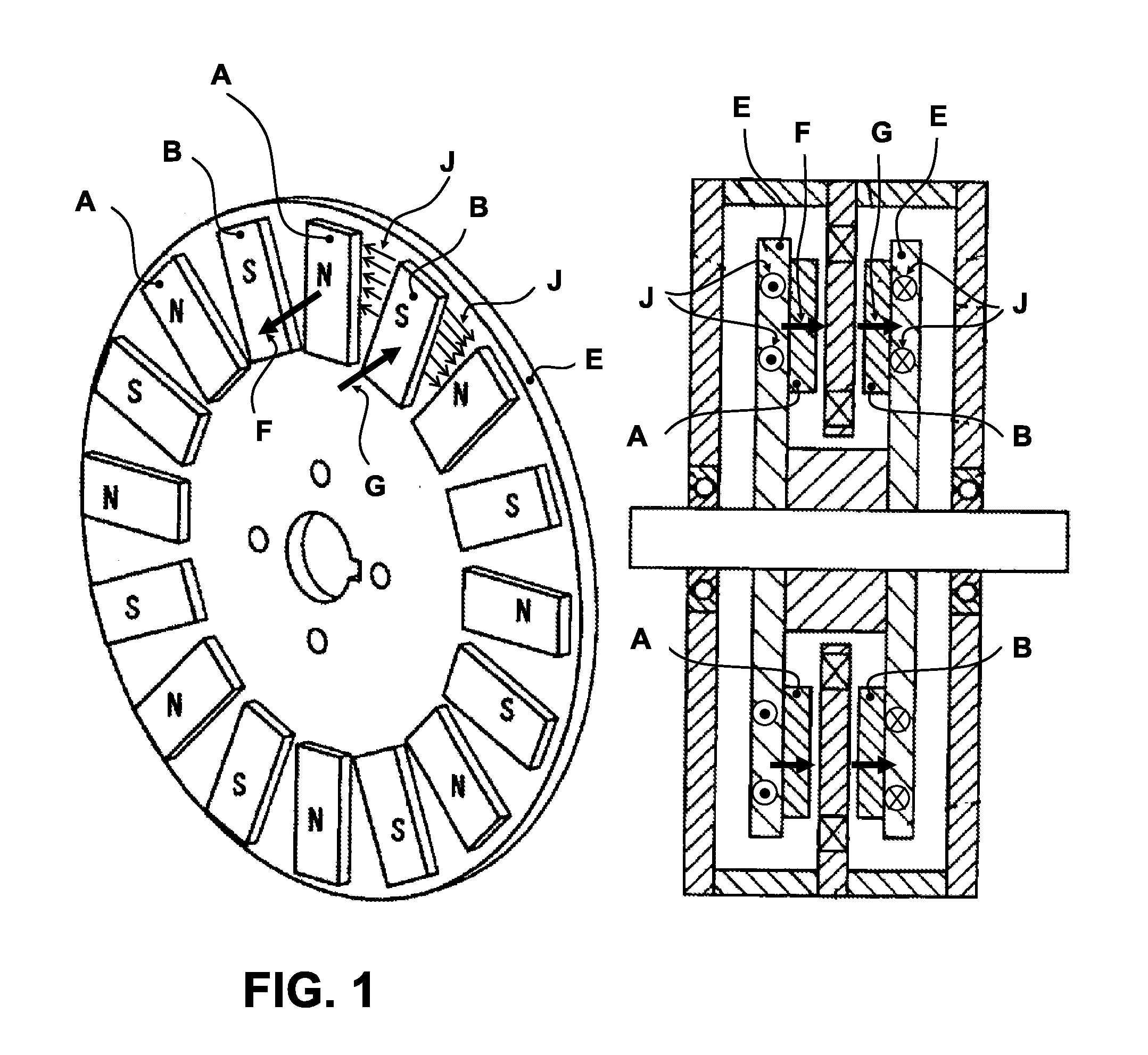

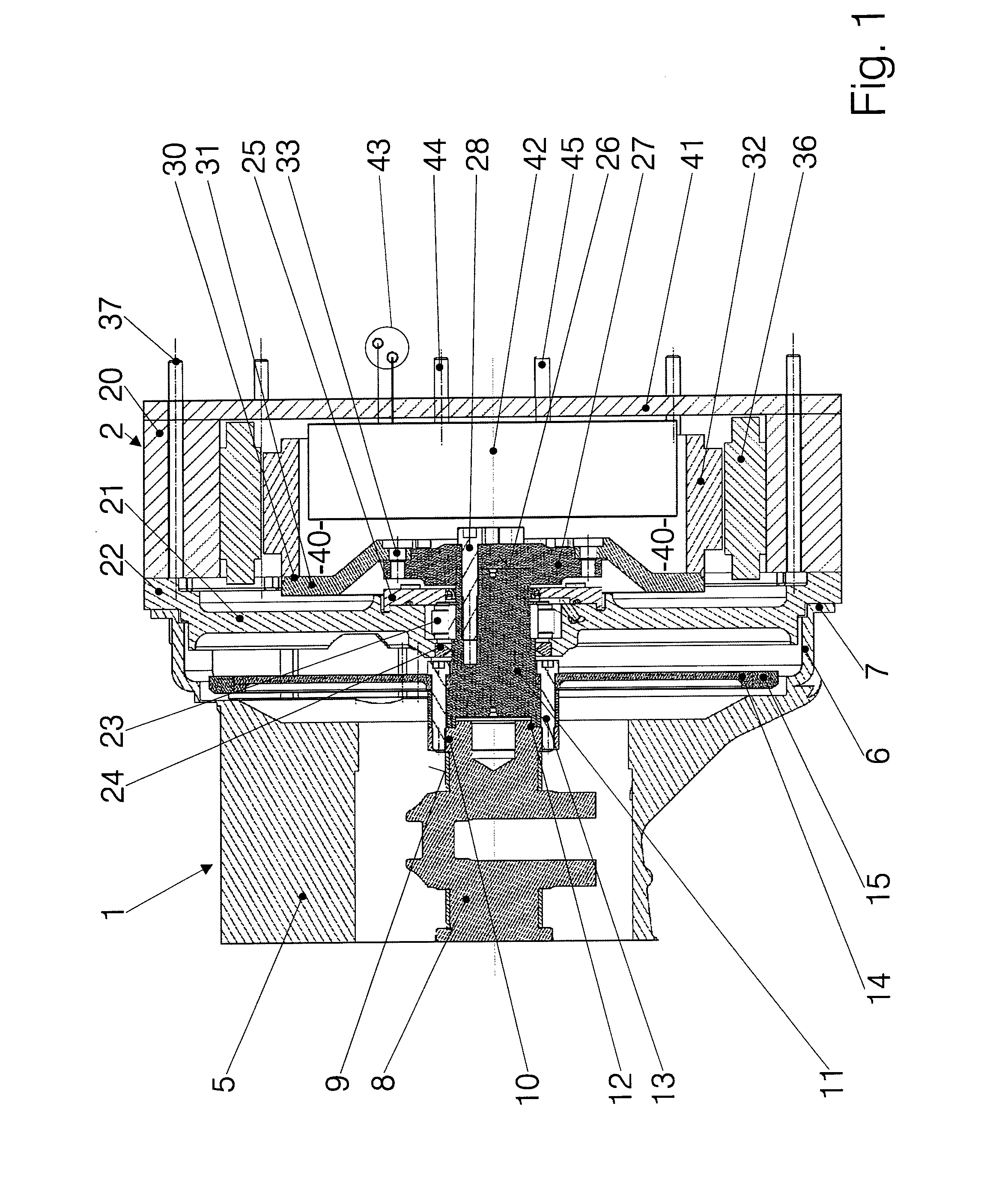

Generating unit comprising a combustion engine and a generator

ActiveUS8227931B2Increase stiffnessEasy accessElectric machinesPropulsion using engine-driven generatorsCombustionCrankcase

A power generating unit consists of an internal combustion engine (1) and a generator (2), the former comprising a crankshaft (8) received in a crankcase (5) and the generator comprising a generator housing (20) connected to the crankcase (5), a stator (36) and a rotor (30) that is connected so as to rotate with the crankshaft (8). The aim is to provide a power generation unit that requires little space and that allows a precise guidance of a rotor designed for the overall unit power. A concentric stub shaft (11) is fixedly connected at the one end to the crankshaft (8) and at the other end to the rotor (30). The generator housing (20), on its side facing the internal combustion engine (1), has a front plate (21) that accommodates a bearing (23) for the sub shaft (11). The rotor (30) is otherwise overhung.

Owner:STEYR MOTORS BETRIEBS GMBH

Multi-purpose vertical take-off and landing unmanned aerial vehicle

InactiveCN105270625AIncrease load capacityHuge potential marketVertical landing/take-off aircraftsRotocraftAviationLevel flight

The invention relates to a multi-purpose vertical take-off and landing unmanned aerial vehicle, which belongs to aviation system technology. A flip-wing V-22 Osprey, in which pitching and heading in a vertical take-off and landing state are controlled through periodical variable pitch, is available for tiltrotor aircrafts internationally. The scheme is not available for the tiltrotor aircrafts in domestic at the present stage. The biggest difficulty for the multi-purpose vertical take-off and landing unmanned aerial vehicle is excessive flight condition of the unmanned aerial vehicle from the vertical take-off and landing state to a level-flight state. The multi-purpose vertical take-off and landing unmanned aerial vehicle can take off and land like a helicopter and can also fly like a fixed-wing aircraft; and through the adoption of a coaxial dual-rotor design, the load capacity of the multi-purpose vertical take-off and landing unmanned aerial vehicle can be improved within a limited rotor diameter space. At present, an unmanned aerial vehicle, which can take off and land vertically and can also fly for a long time, is expected for both military use and civil use.

Owner:QINGAN GRP

Cantilevered rotor pump and methods for axial flow blood pumping

ActiveUS20170021069A1Improved rotor designEasy to moveControl devicesIntravenous devicesDistal portionBlood pump

Blood pump devices having improved rotor design are provided herein. Such blood pump devices include rotors having cantilevered support through a sealed mechanical bearing disposed outside a blood flow path of the device so as to avoid thrombus formation caused by blood contact with the bearing. The bearing means can be rotatably coupled with a proximal portion of the rotor shaft extending outside the fluid path, while a stator drives rotation of the rotor shaft so that one or more rotor blades on a distal portion of the rotor force blood flow through the device. The bearing means may include one or more radial bearings on a proximal portion of the rotor shaft that are isolated from the blood flow path by one or more rotary seals.

Owner:TC1 LLC

Generating unit comprising a combustion engine and a generator

ActiveUS20100127508A1Increase stiffnessEasy accessPropulsion using engine-driven generatorsElectric machinesCombustionEngineering

A power generating unit consists of an internal combustion engine (1) and a generator (2), the former comprising a crankshaft (8) received in a crankcase (5) and the generator comprising a generator housing (20) connected to the crankcase (5), a stator (36) and a rotor (30) that is connected so as to rotate with the crankshaft (8). The aim is to provide a power generation unit that requires little space and that allows a precise guidance of a rotor designed for the overall unit power. A concentric stub shaft (11) is fixedly connected at the one end to the crankshaft (8) and at the other end to the rotor (30). The generator housing (20), on its side facing the internal combustion engine (1), has a front plate (21) that accomodates a bearing (23) fort he sub shaft (11). The rotor (30) is otherwise overhung.

Owner:STEYR MOTORS BETRIEBS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com