Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Large axial load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

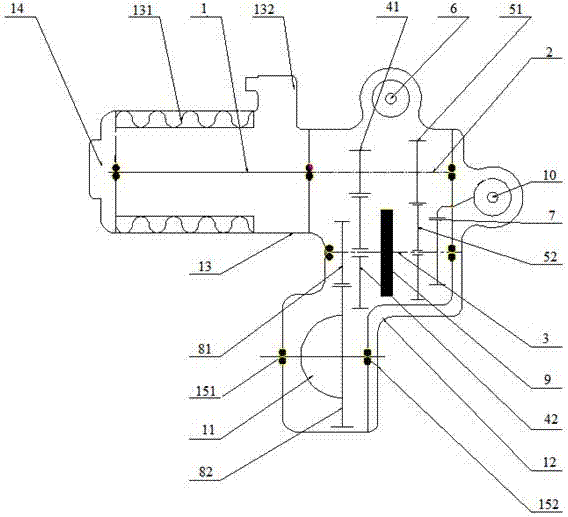

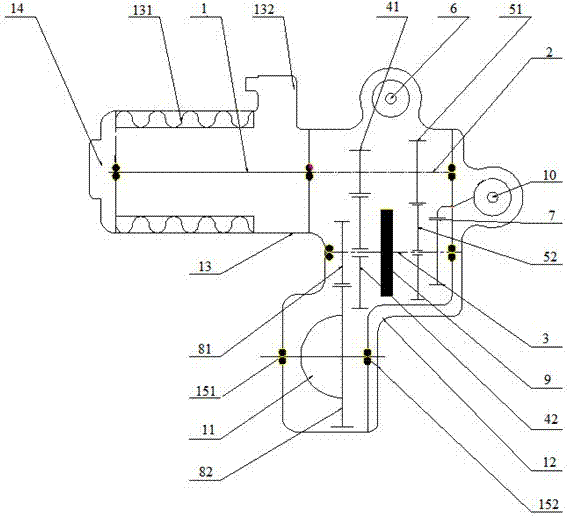

Motor-AMT (automated mechanical transmission) coupling mechanism

InactiveCN102518780AImprove efficiencyImprove battery lifeGearboxesElectric machinesReduction driveElectric machine

The invention relates to a motor-AMT (automated mechanical transmission) coupling mechanism. An AMT speed reducer portion is characterized in that a first driving gear and a second driving gear are connected onto an input shaft through splines to jointly form an input shaft assembly, a parking gear, a synchronizer mechanism, a first driven gear, a second driven gear, an output shaft and a main reduction driving gear form an output shaft assembly, and a main reduction driven gear and a differential shell form a main reduction assembly. A motor portion comprises a motor shaft and a motor body on the outer side of the motor shaft. Occupied space of a front cabin is greatly reduced after a motor is coupled with an AMT. A gear selecting and shifting controller automatically selects two corresponding transmission ratios of a first gear or a second gear according to actual road conditions, so that the motor continues running with better use efficiency, endurance mileage is increased, the space of the front cabin occupied by a power assembly is saved, and the motor-AMT coupling mechanism is provided with a parking gear so that an electric vehicle runs on a ramp more safely and reliably.

Owner:CHERY AUTOMOBILE CO LTD

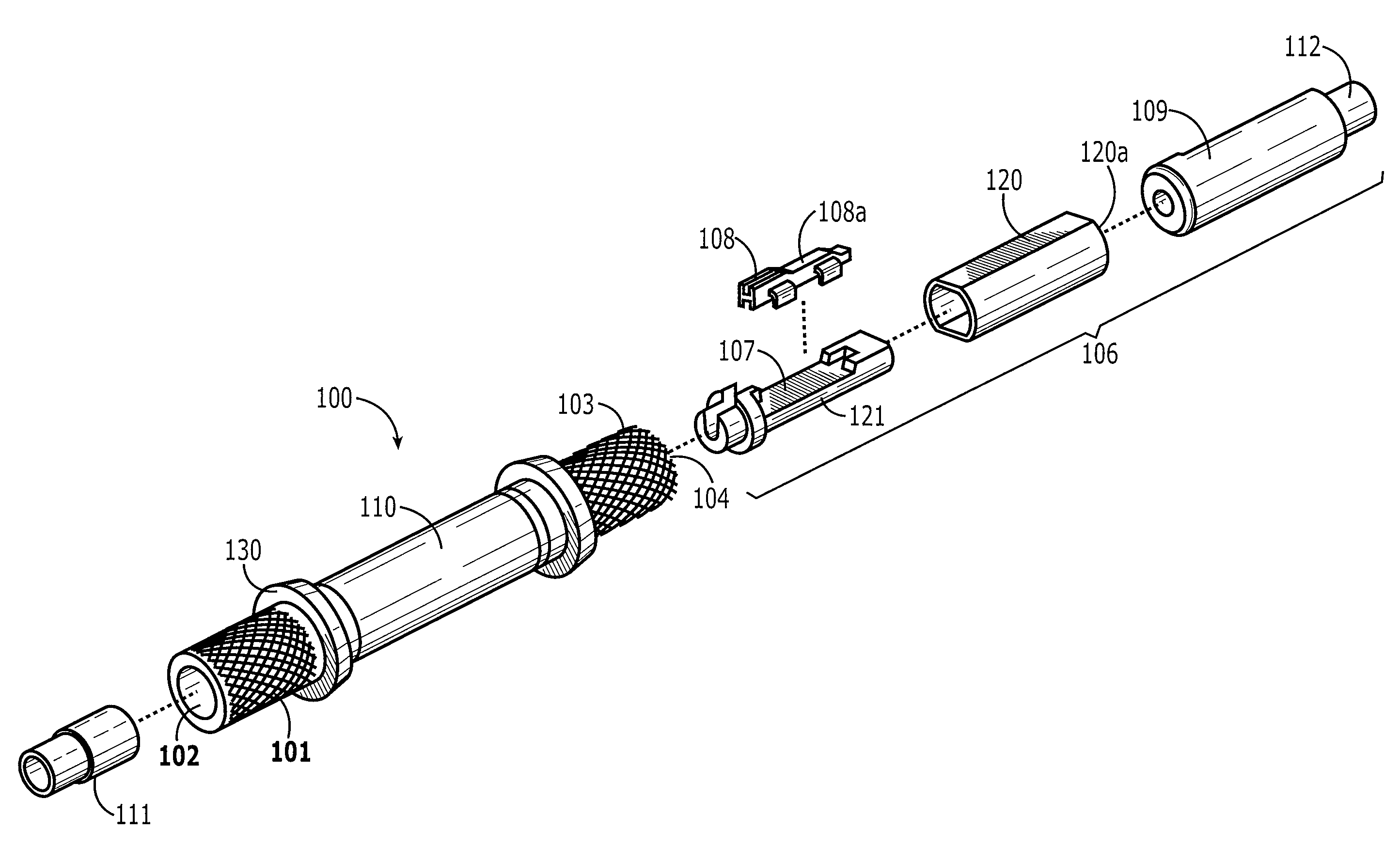

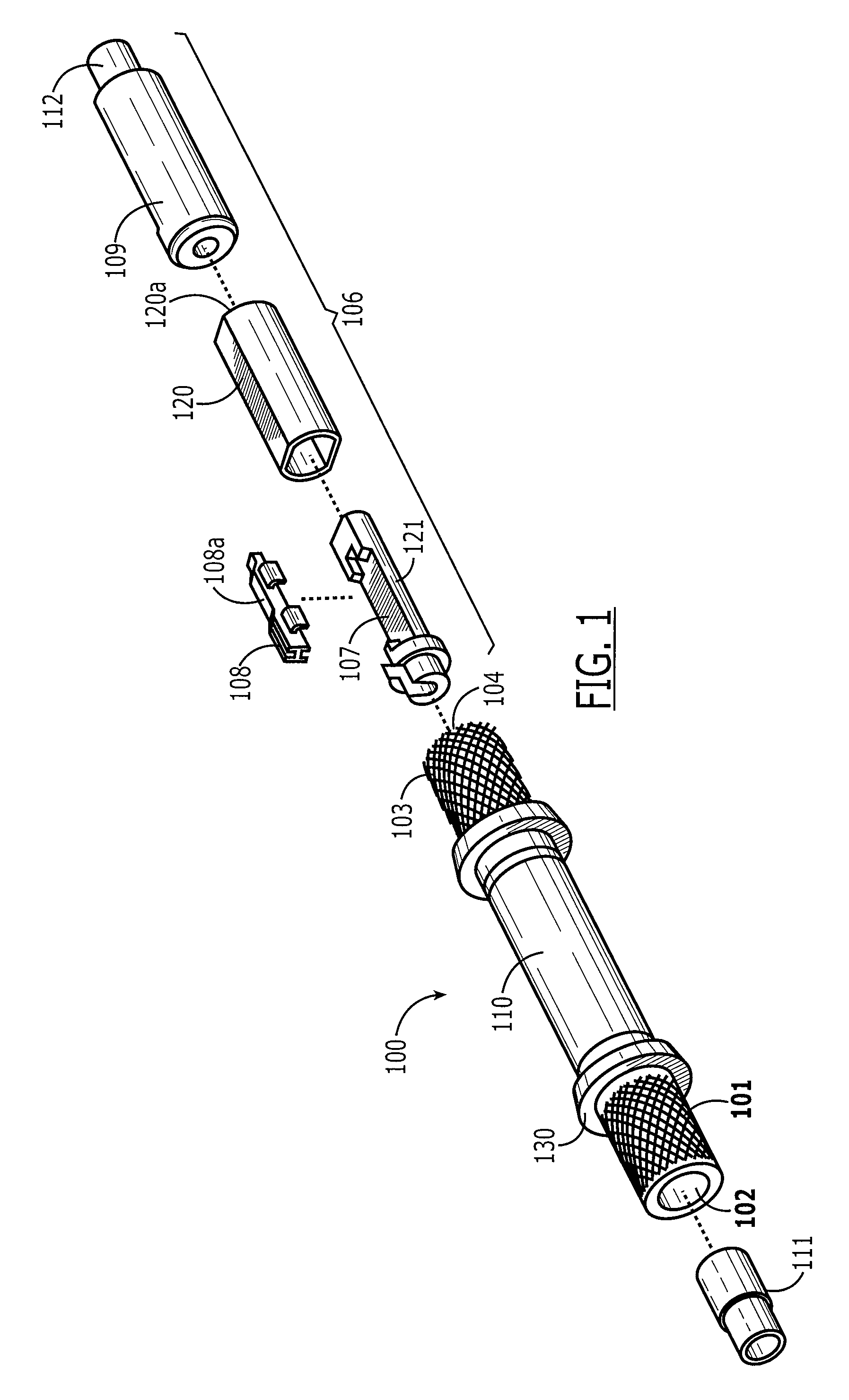

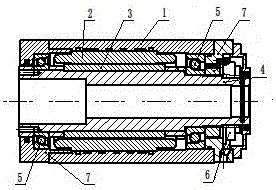

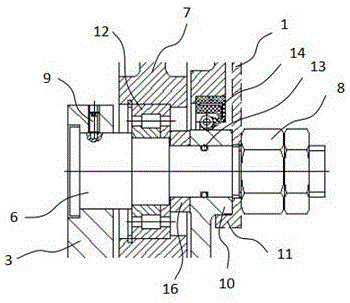

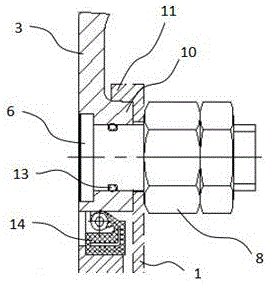

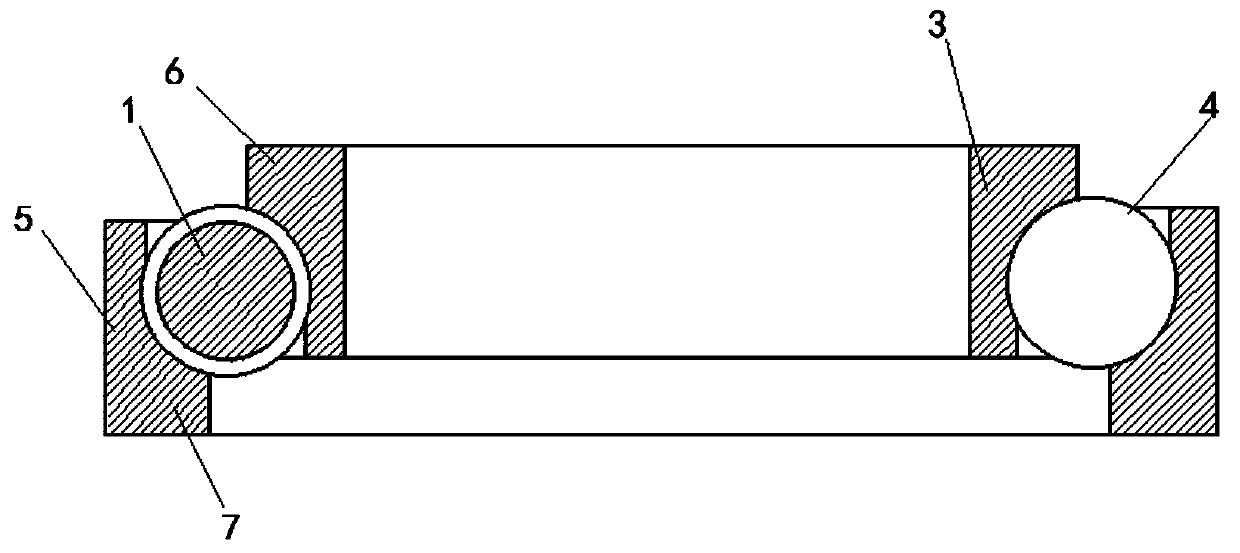

Field-installable optical splice

A splice for connecting two segments of optical fiber cable, the splice comprising: (a) an elongated housing having a first end with a first opening, a second end with a second opening, and a central cavity, the housing being essentially seamless between the first and second ends; (b) a clamping mechanism disposed in the central cavity and comprising at least a platform defining a fiber-receiving channel open to both first and second openings, a first member adjacent to the fiber-receiving channel and having at least one cam surface, and a second member having a second cam surface, the first and second cam surfaces cooperating such that relative movement of the first and second members toward the first end causes the first member to move toward the fiber-receiving channel and an actuator to cause relative movement of the first and second members toward the first end; (c) a first buffer crimp disposed at the first opening; and (d) a second buffer crimp disposed at the second opening.

Owner:TE CONNECTIVITY CORP

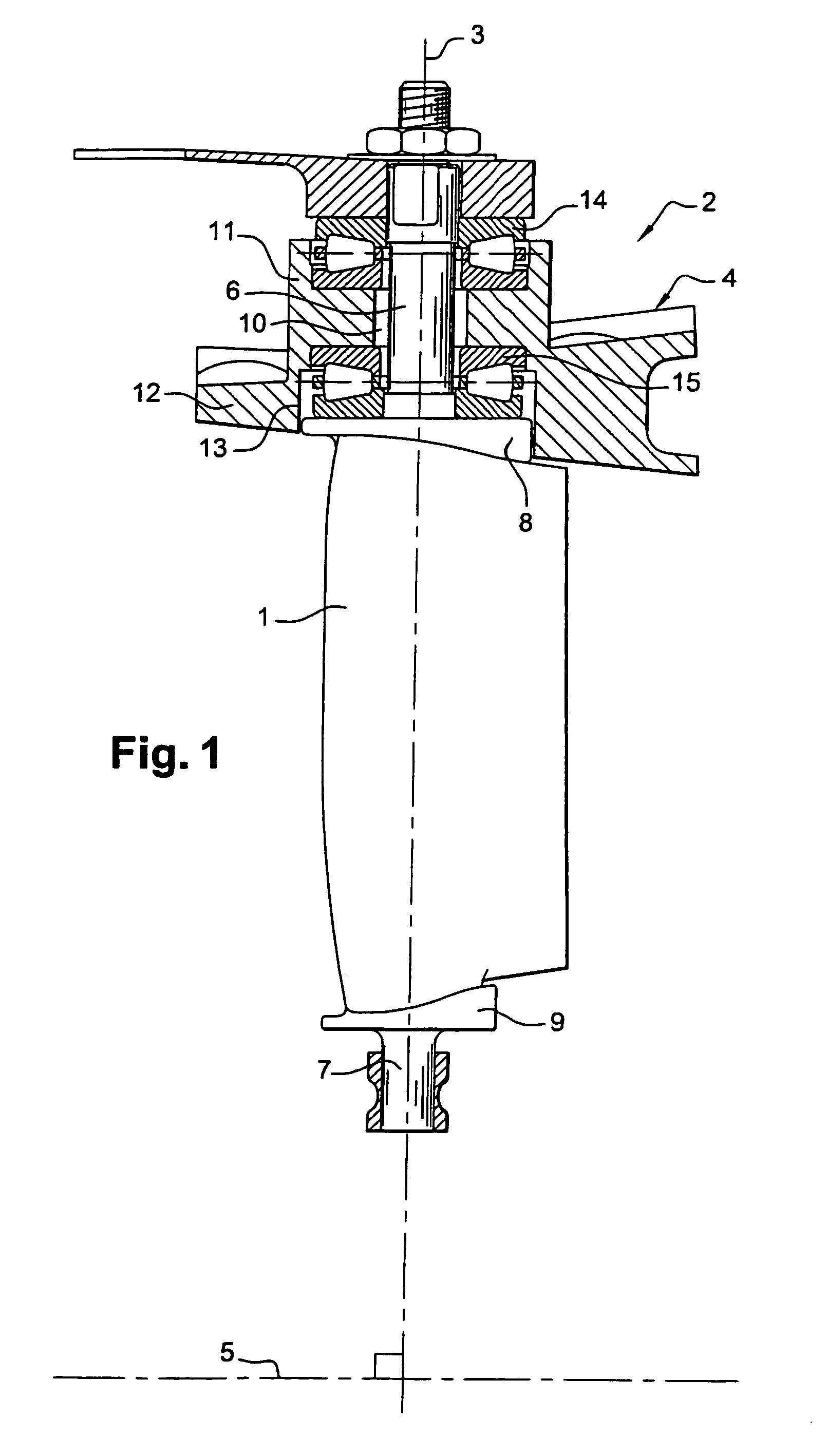

Method of guiding a blade having a variable pitch angle

ActiveUS7112040B2Avoid premature wearReduce maintenanceRoller bearingsPump componentsMechanical engineeringEngineering

A guide device for guiding a variable-pitch blade, in particular in a turbomachine compressor, the blade having a pivot formed by a cylindrical axial shank mounted in a cylindrical housing of a casing and pivotally guided about an axis in said housing by bearings, where the bearings are abutment bearings with conical rollers, the axes of the rollers being substantially perpendicular to the pivot axis of the blade.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

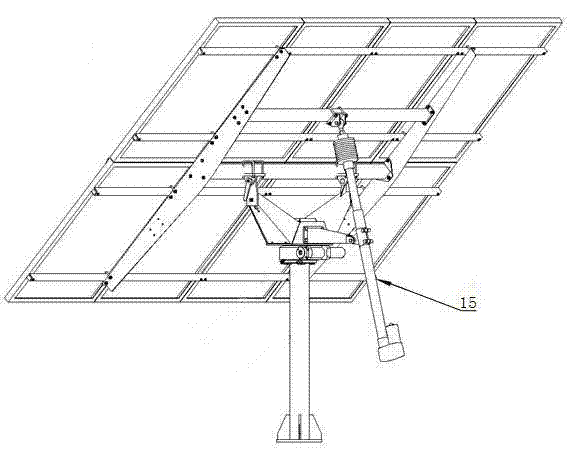

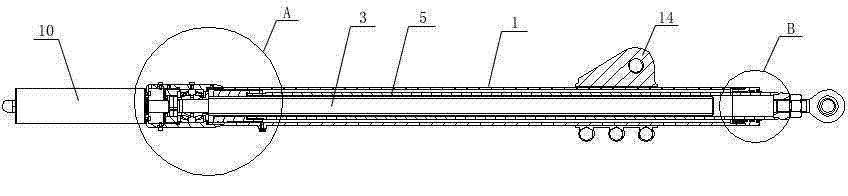

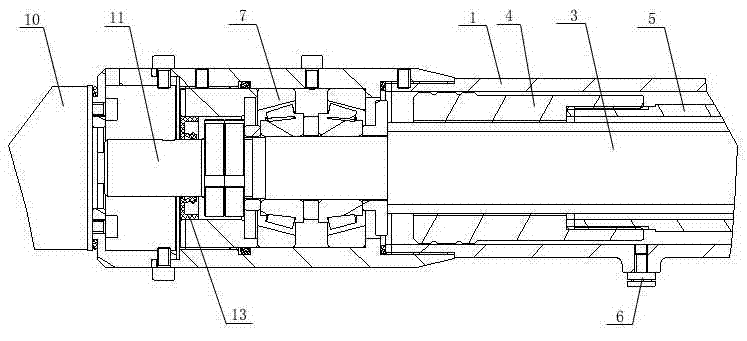

Linear driving device and controlling and using method of linear driving device for solar tracker

ActiveCN102968127AGuaranteed uptimeImprove load resistancePhotovoltaic supportsSolar heating energyLoad resistanceEngineering

The invention discloses a linear driving device and a controlling and using method of the linear driving device for a solar tracker. The linear driving device comprises an outer tube and a sealing end cover arranged at the end portion of the outer tube. A screw is arranged in the outer tube, one end of the screw is connected with a drive mechanism, a transmission nut in threaded match with the screw is arranged on the screw, and a telescopic rod is arranged between the outer tube and the screw. One end of the telescopic rod is connected with the transmission nut, the other end of the telescopic rod penetrates through the sealing end cover, a sealing assembly is arranged between the telescopic rod and the sealing end cover, and a waterproof oil-proof vent plug is arranged on the outer tube. The linear driving device is mainly used on the solar tracker, corresponding structural design is performed on the aspects of deflection, load resistance and protection of the device according to the using environment of the solar tracker, and the linear driving device applied in the solar tracker is reliable and stable in operation and strong in deflection and load resistance and accordingly improves the tracking accuracy of the solar tracker effectively.

Owner:CHENGDU ZSUN SCI & TECH DEVING

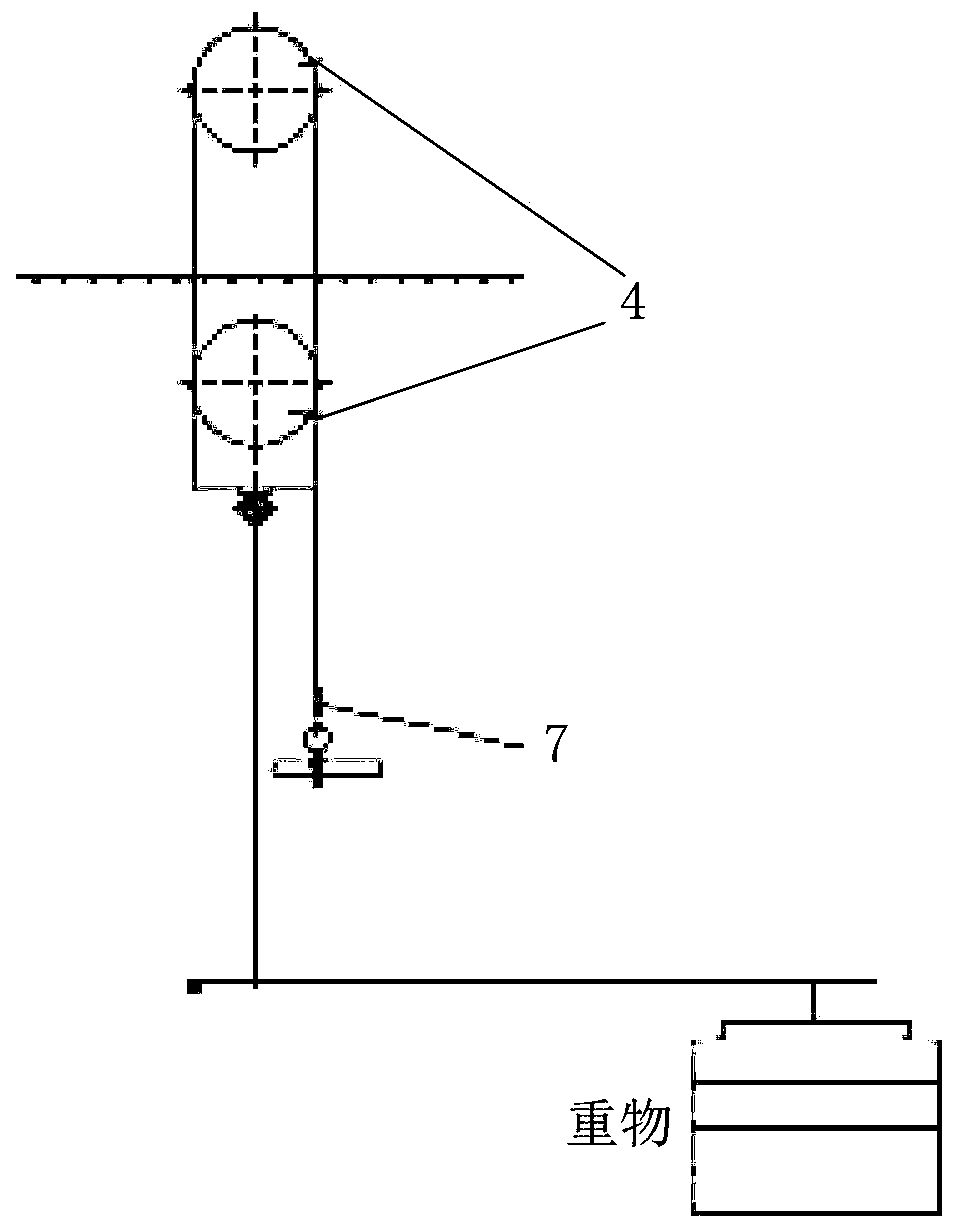

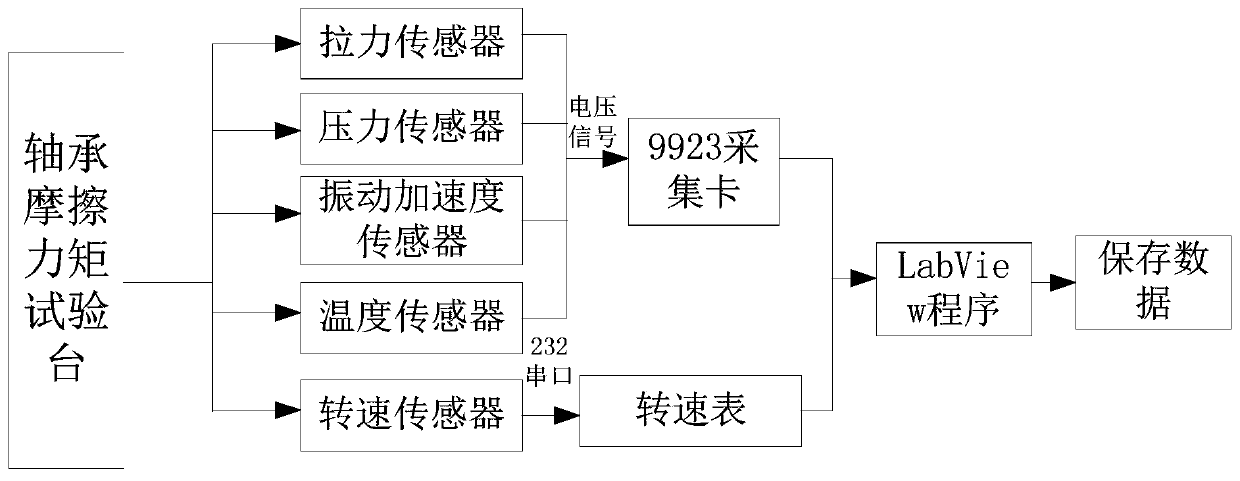

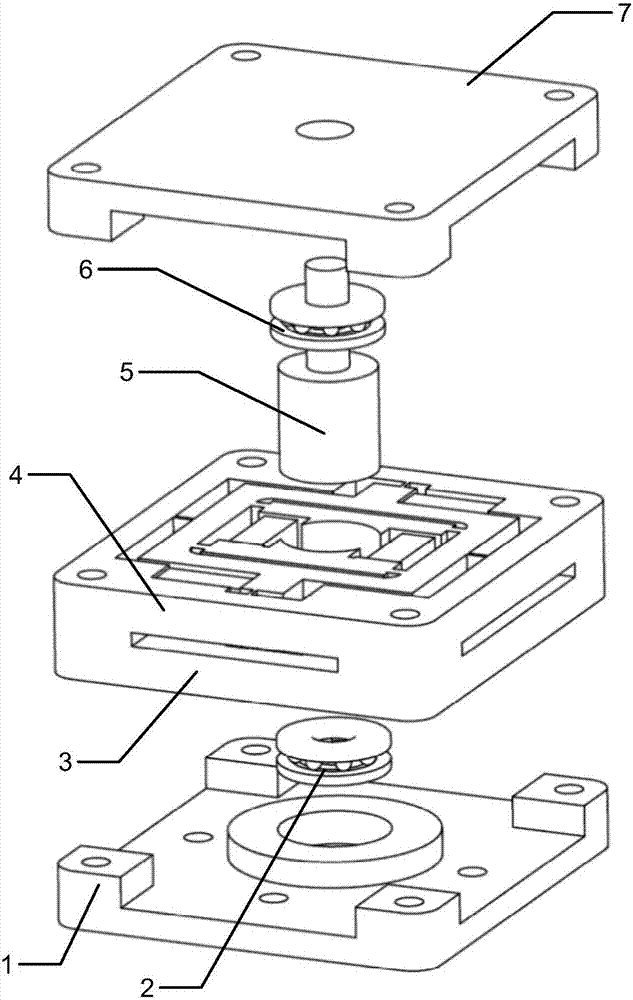

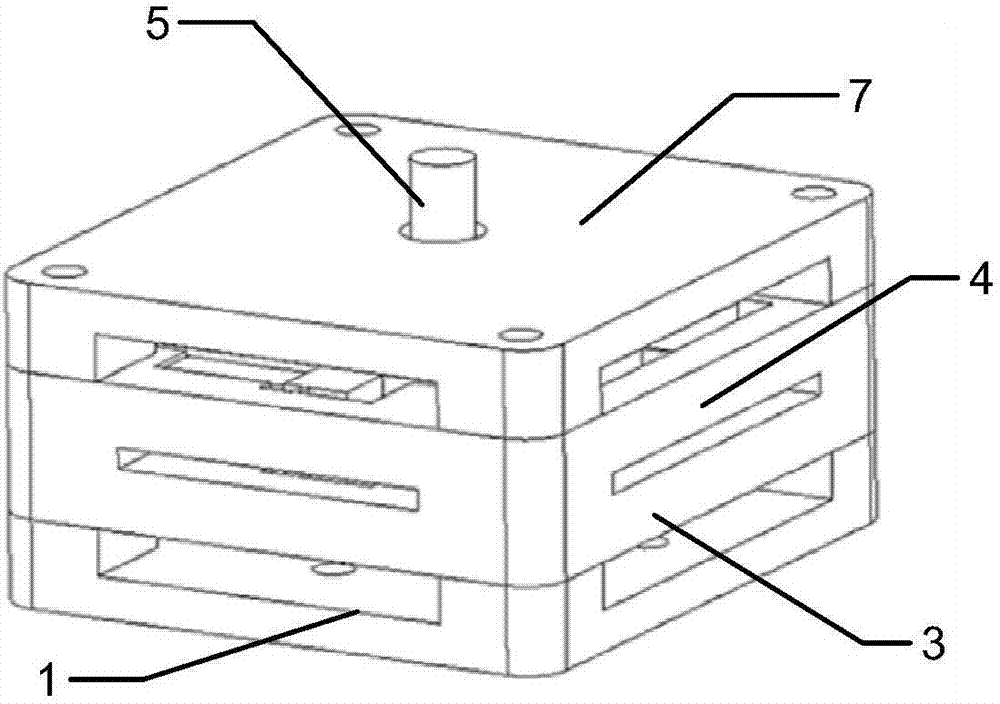

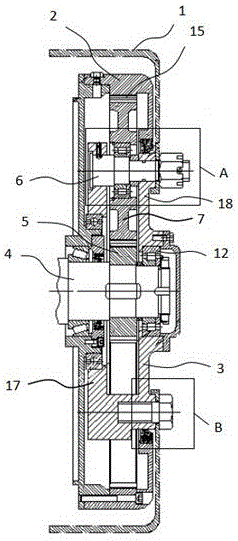

High speed bearing friction torque measuring system

InactiveCN110186678ALarge axial loadReduce difficultyMachine bearings testingWork measurementFriction torqueControl theory

The present invention discloses a high speed bearing friction torque measuring system, and relates to the field of bearing performance testing. The system solves the problem that a test bench used formeasuring a bearing friction torque is limited by a bearing structure and bearing capacity in the prior design, an axial load applied to the bearing cannot reach a high level, and finally the bearingfriction torque cannot be accurately measured. A limiting step is provided on a main shaft for limiting axial position of the first bearing to be tested, an axial load measuring device is used to measure the axial load force applied to the two bearings under testing, an axial load applying device is used for squeezing and applying the axial load to the second bearing to be tested, a sleeve is sleeved on the axial load measuring device and outside of the two bearings to be tested at the same time, a tension sensor is connected to outer wall of the sleeve through a wire rope, the tension sensoris used to pull the sleeve, when the main shaft rotates, the sleeve is at an equilibrium position to measure the frictional torque of the two bearings to be tested under the axial load. The system isused to measure the frictional torque of the bearings under the axial load.

Owner:HARBIN INST OF TECH

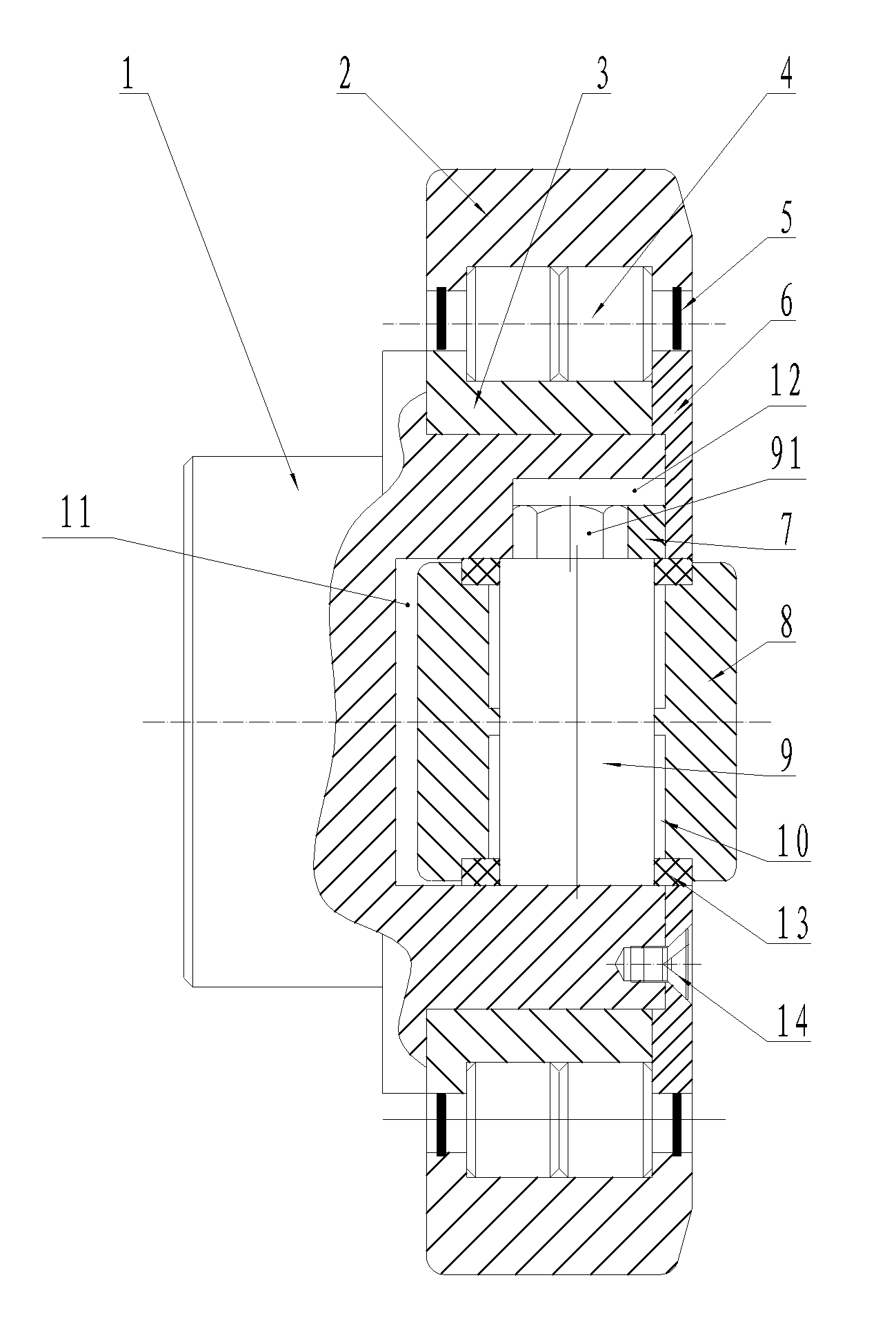

Clamp-driven integrated type piezoelectric-drive high-precision rotary actuator and method thereof

ActiveCN106887971AHigh precision torque outputReduce standby power consumptionPiezoelectric/electrostriction/magnetostriction machinesElectricityBall bearing

The invention provides a clamp-driven integrated type piezoelectric-drive high-precision rotary actuator and method thereof. The actuator comprises an actuator pedestal, a lower thrust ball bearing being installed at the pedestal and being capable of bearing an axial load, a lower drive structure arranged above the pedestal, an upper drive structure connected with the lower drive structure 3 into one, an output shaft being capable of being clamped and limited by the lower drive structure and the upper drive structure after installation, an upper thrust ball bearing installed above the output shaft, and a top cover installed above the thrust ball bearing. In addition, the invention also discloses an actuating method for the actuator. Piezoelectric ceramic units are driven according to a certain order to realize bidirectional large-angle rotation driving. The upper drive structure and the lower drive structure have completely identical geometric dimensions; and with slow feeding, one-time processing moulding is realized, the processing and assembling flow is simplified, and the implementation is high. Moreover, the actuator employs the piezoelectric ceramic units as driving elements. The actuator has characteristics of large output stroke, high output resolution, and power-off self-locking.

Owner:西安朗威科技有限公司

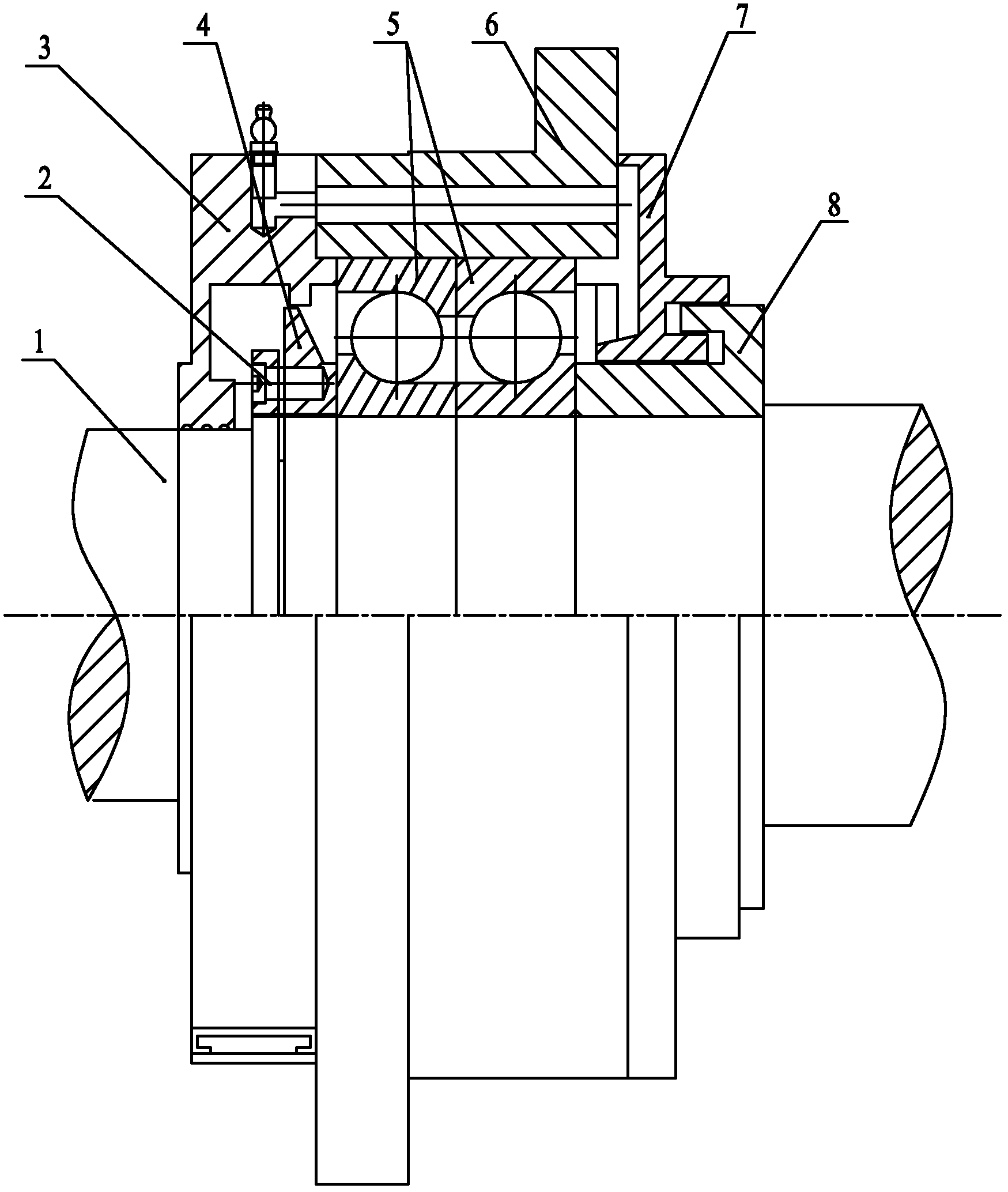

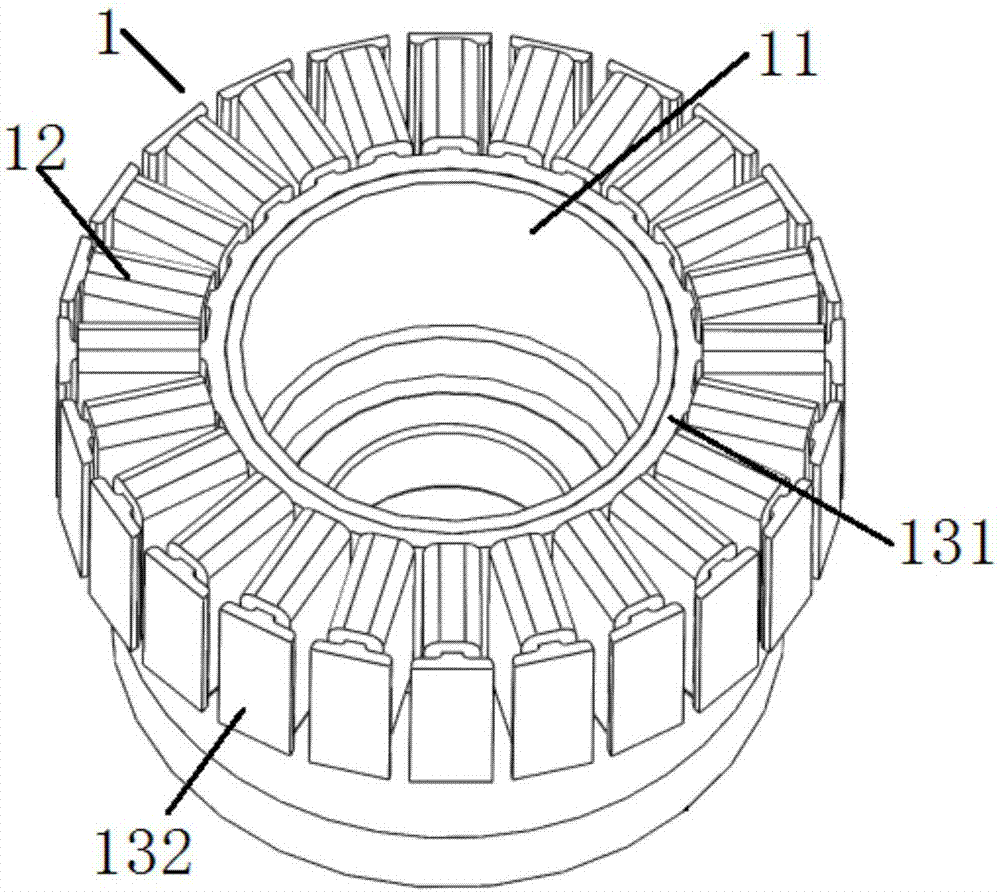

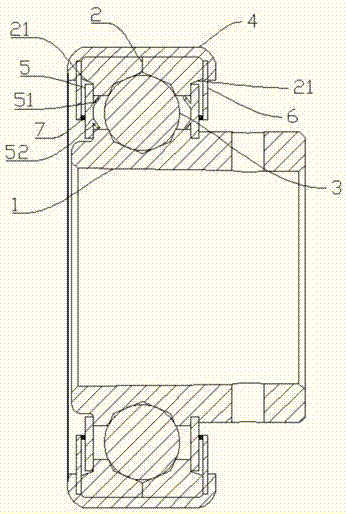

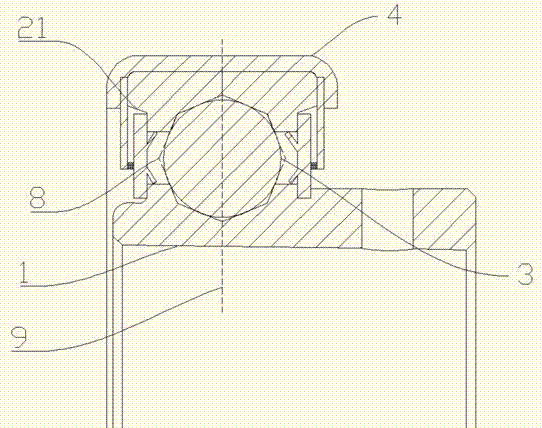

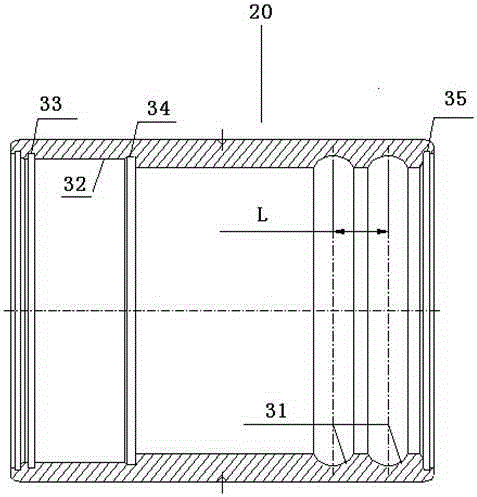

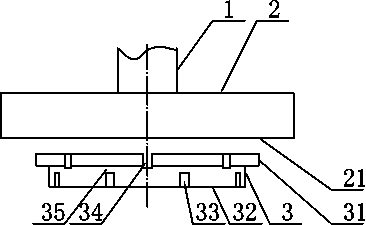

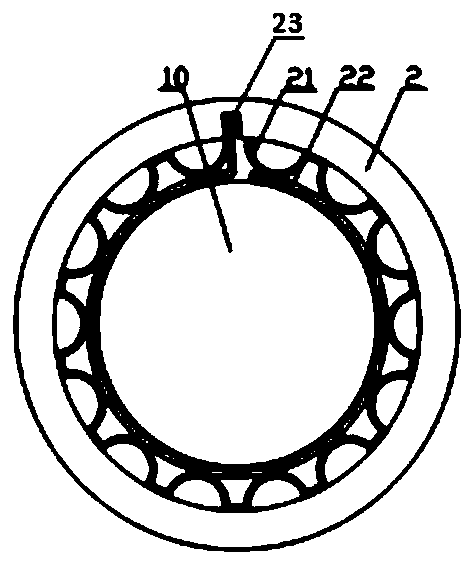

Integral shaft-connect type fan clutch bearing

The invention discloses an integral shaft-connect type fan clutch bearing. The bearing adopts a row of rollers and double-row steel balls, the double-row steel balls adopt an angular contact structure in a geometric form, the bearing comprises a bearing outer ring, a mandrel, a steel ball holder, a roller holder and a seal ring, wherein channels and a raceway are machined on the bearing outer ring and used for bearing the rolling elements and guiding the rotation of rolling elements, the rolling elements comprise the steel balls and the cylindrical rollers, the mandrel is inserted into the bearing outer ring in the axial direction, inner channels are machined on the outer diameter of the mandrel and used for bearing the steel balls and guiding the rotation of the steel balls, an inner raceway is further machined on the outer diameter of the mandrel and used for bearing the cylindrical rollers, the steel ball holder is arranged between the bearing outer ring and the mandrel and makes the steel balls distributed in the channels at equal intervals, the roller holder adopts a design of a cylinder-shaped structure and a spring collar structure, a spring collar is assembled on the bearing outer ring in a matched mode to prevent the cylindrical rollers from springing out in the axial direction, and the sealing ring is installed in a seal groove formed in the end of the bearing outer ring in a pressed mode and remains still with the bearing outer ring.

Owner:长沙优力电驱动系统有限公司

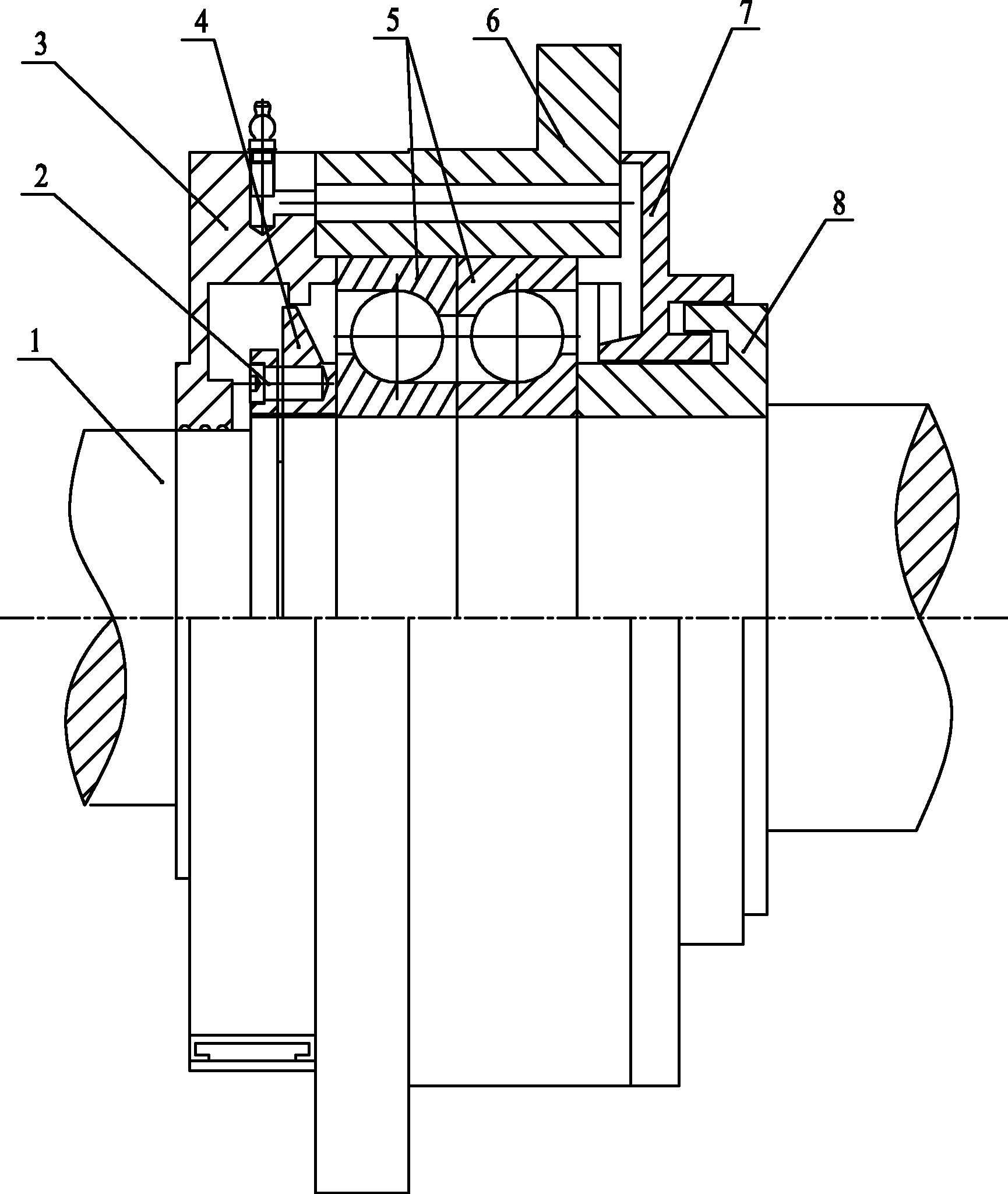

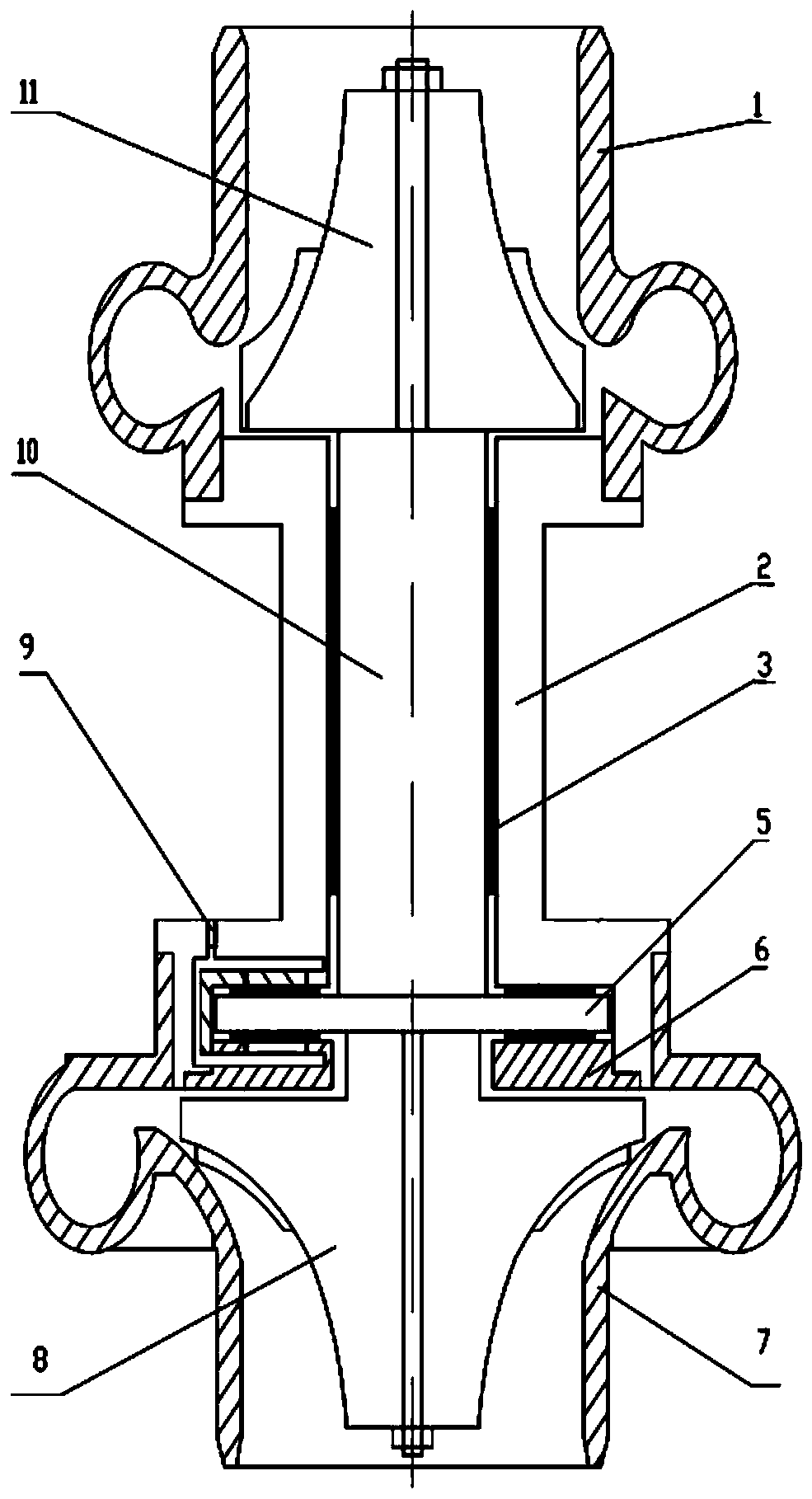

Bearing device of direct current vertical motor

The invention relates to a bearing device of a direct current vertical motor, which comprises a rotating shaft, a bearing outer cover, a bearing sleeve, a bearing group and a bearing inner cover; the bearing sleeve is supported and assembled on to the rotating shaft through the bearing group; the bearing inner cover is assembled on the inner side of the bearing group in a sealing way, and the bearing outer cover is assembled on the outer side of the bearing group in a sealing way. The bearing device of the direct current vertical motor is characterized in that: the bearing group mainly comprises two single row angular contact bearings which are arranged back to back. The bearing device of the direct current vertical motor has a simple and reasonable structure, good sealing performance, high reliability and low manufacturing cost, can bear quite large axial load in an upward direction and a downward direction when the safety and the reliability of the motor are ensured, has higher rigidity, can meet the use requirements of the vertical motor, and has an obvious effect.

Owner:SEC ELECTRIC MACHINERY

Motor capable of directly driving rotating shaft

InactiveCN106160332AReduce volumeLarge torqueStructural associationMechanical energy handlingEngineeringEncoder

The invention provides a motor capable of directly driving a rotating shaft, and aims to solve the problem that when an existing motor is used, safe power output and accurate mechanical positioning cannot be implemented in limited mounting space. According to the technical scheme, the motor comprises a motor shell, wherein a motor stator, a motor rotor and a hollow shaft are successively arranged in the motor shell from outside to inside; lead screw bearings respectively penetrate through two ends of the hollow shaft; each lead screw bearing and the hollow shaft are fixed together through an end cap; and an encoder is fixed at one end of the hollow shaft. The motor capable of directly driving the rotating shaft has the advantages of simple structure, simplicity and convenience in operation, high reliability and high feasibility.

Owner:郑先道

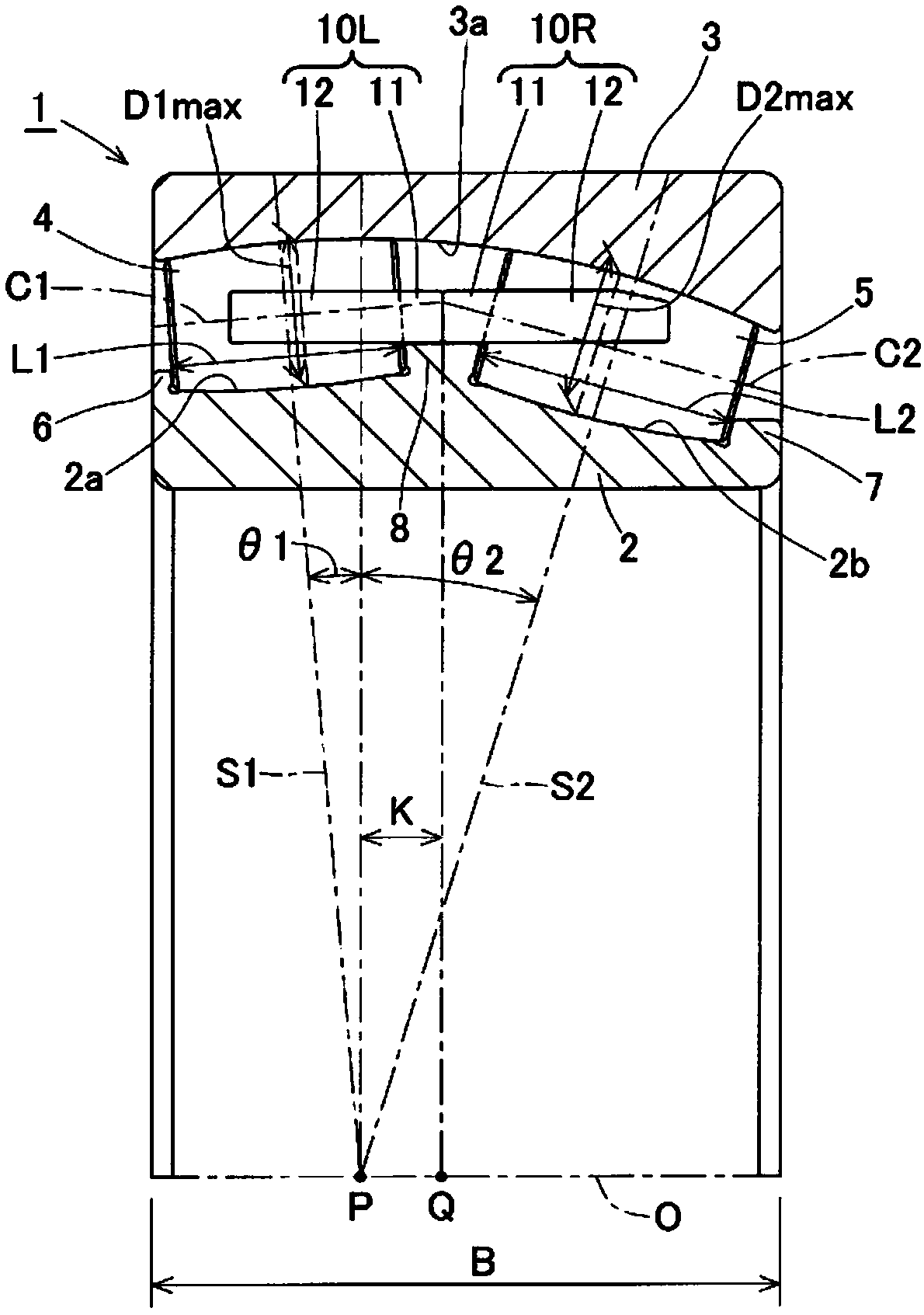

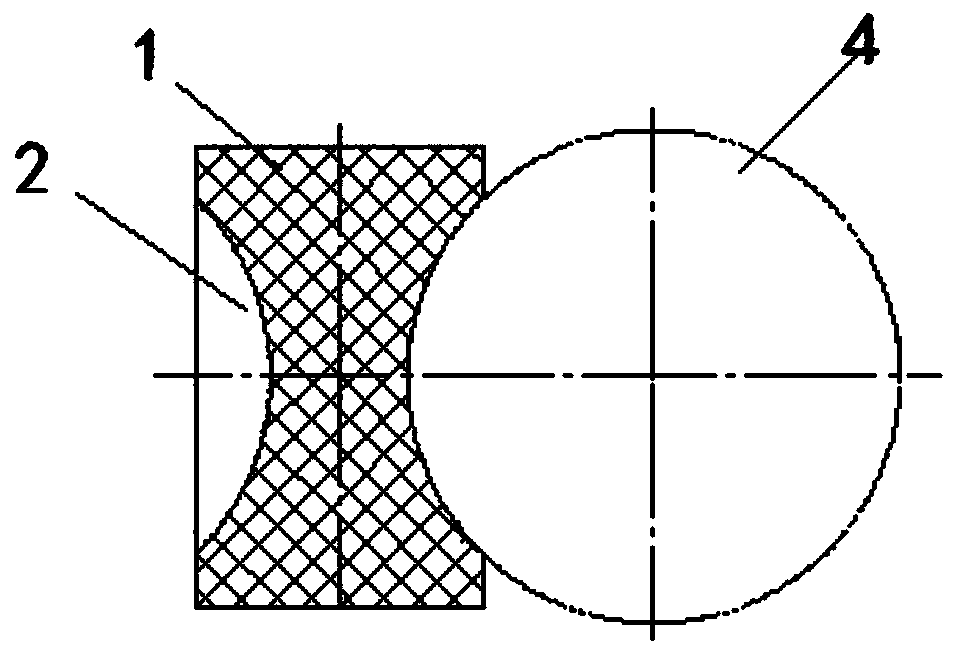

Double-row self-aligning roller bearing

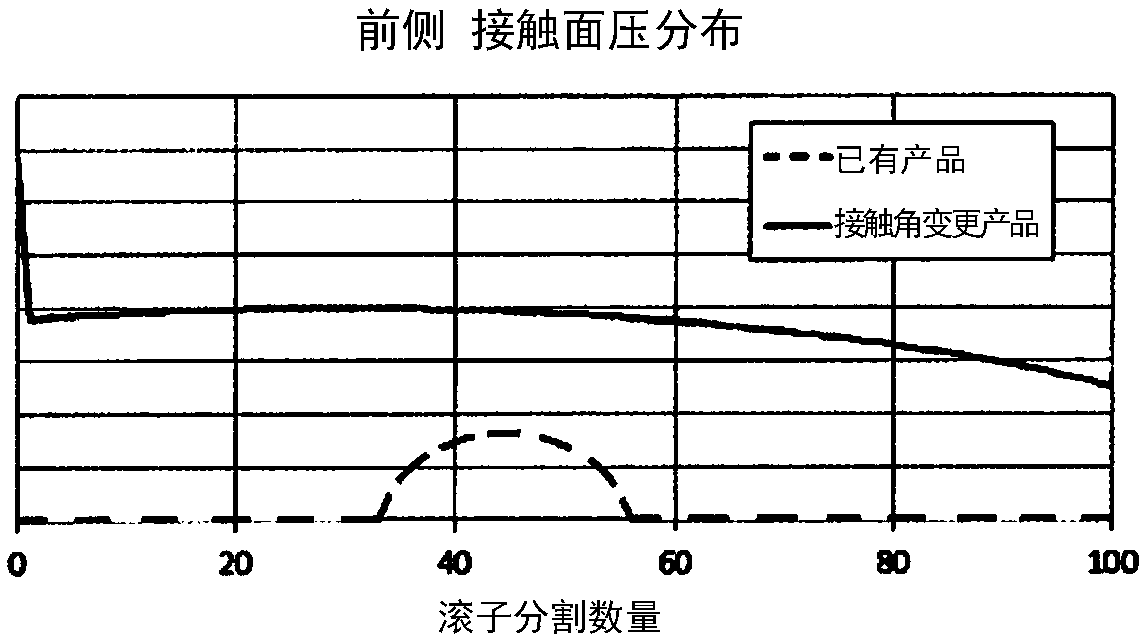

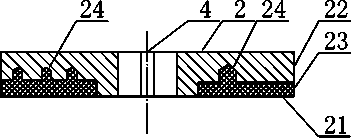

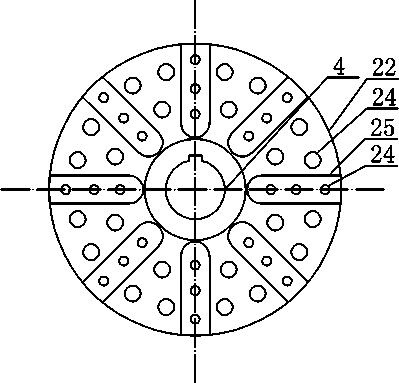

ActiveCN108884867AIncrease the burdenLarge axial loadRoller bearingsShaftsMechanical engineeringLoad capacity

In this double-row self-aligning roller bearing (1), rollers (4, 5) are interposed, between an inner race (2) and an outer race (3), in two rows beside each other in the axial width direction of the bearing, a raceway surface (3a) of the outer race (3) is spherical, and the outer peripheral surfaces of the two rows of rollers (4, 5) have a cross-sectional shape that conforms to the raceway surface(3a) of the outer race (3). The two rows of rollers (4, 5) have different lengths (L1, L2) and the length (L1) of the long roller (5) is at least 39% of the bearing width (B). The ratio of the contact angle (theta1) of the short roller (4) to the contact angle (theta2) of the long roller (5) is within the range 1:2 to 1:4. Thus, the present invention can simultaneously receive both axial load andradial load, can be used in applications in which loads of different sizes act on two rows of rollers beside each other in the axial direction, and makes it possible to sufficiently increase, withinthe constraints of boundary dimensions, the load capacity of the roller in the row that receives the axial load.

Owner:NTN CORP

Pressure buffering device for foot end

InactiveCN112943847AAccelerateLarge adjustment rangeSpringsVibration dampersPhysicsEnvironmental geology

The invention provides a pressure buffering device for a foot end. The foot end comprises a foot joint upper part, a foot joint middle part and a foot sole. The device comprises a pressure sensor, a first hydraulic cylinder, a second hydraulic cylinder and a controller, wherein the foot joint upper part is in non-contact connection with the foot joint middle part; cylinder bodies of the first hydraulic cylinder and the second hydraulic cylinder are detachably and symmetrically installed on the two sides of the foot joint upper part; hydraulic rods of the first hydraulic cylinder and the second hydraulic cylinder are detachably and symmetrically installed on the two sides of the foot joint middle part; the pressure sensor is detachably connected with the foot joint middle part and the foot sole respectively and is used for collecting a pressure value when the foot sole is in contact with the ground; and the controller is used for receiving the pressure value collected by the pressure sensor and controlling the stretching amount of the first hydraulic cylinder and the stretching amount of the second hydraulic cylinder according to the pressure value. According to the buffering device provided by the invention, buffering force is provided through the first hydraulic cylinder and the second hydraulic cylinder, the corresponding speed is high, and the adjusting range is wide.

Owner:常州龙源智能机器人科技有限公司

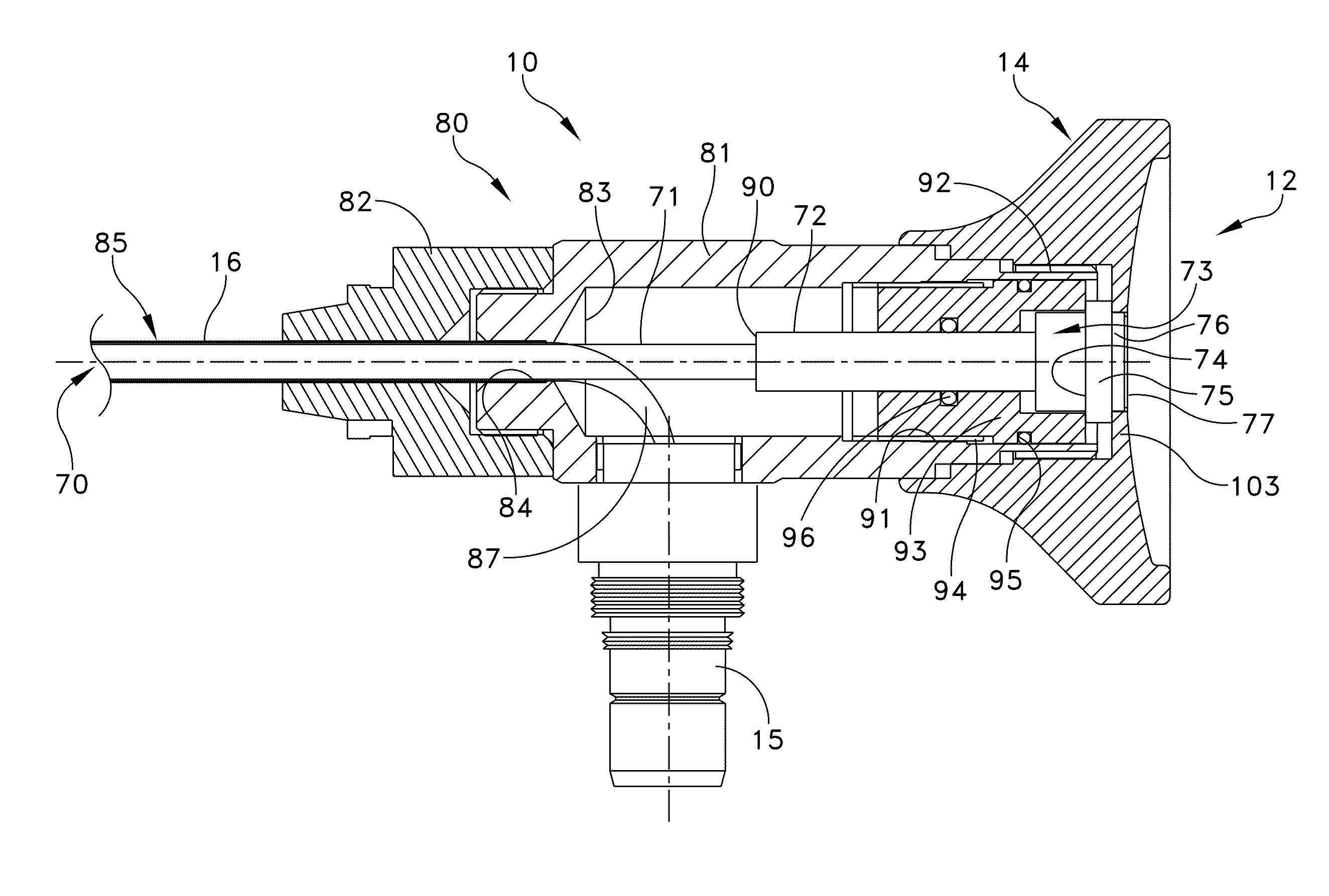

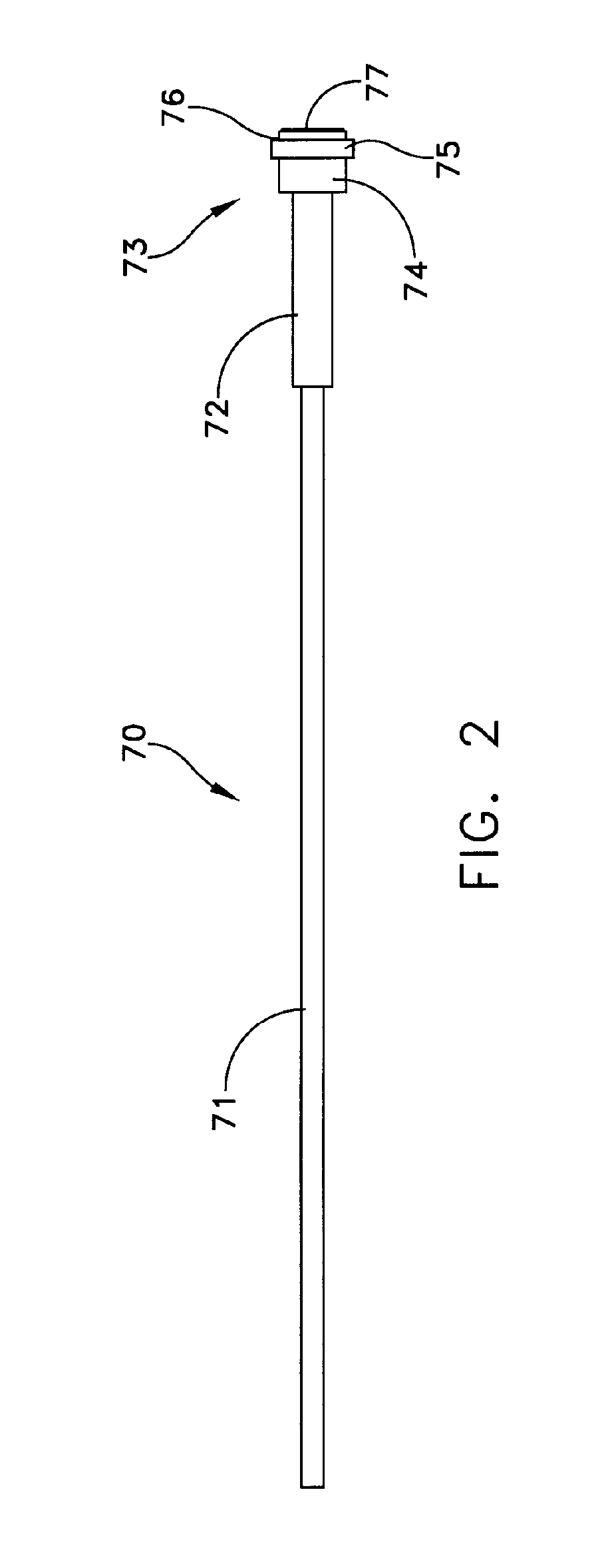

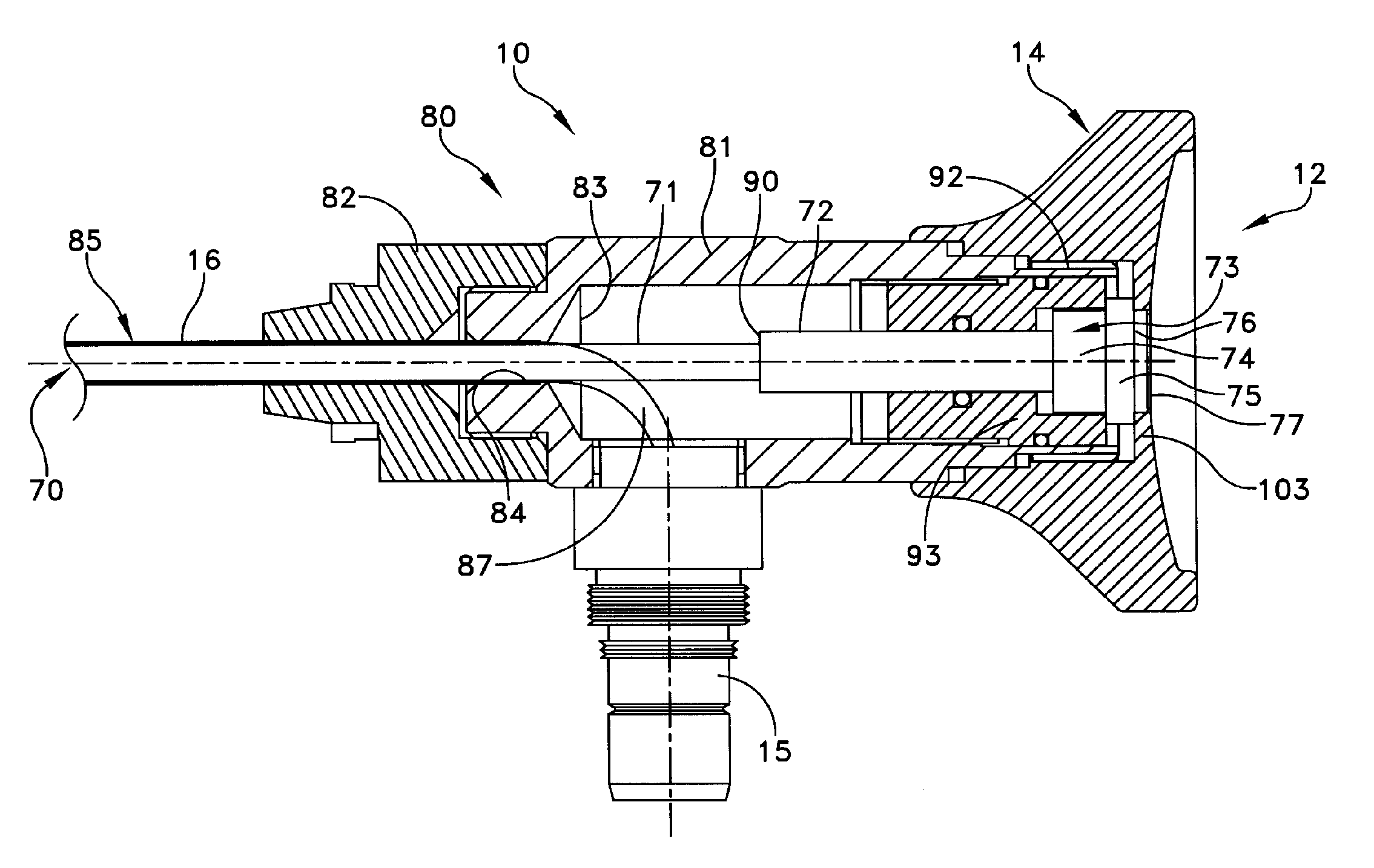

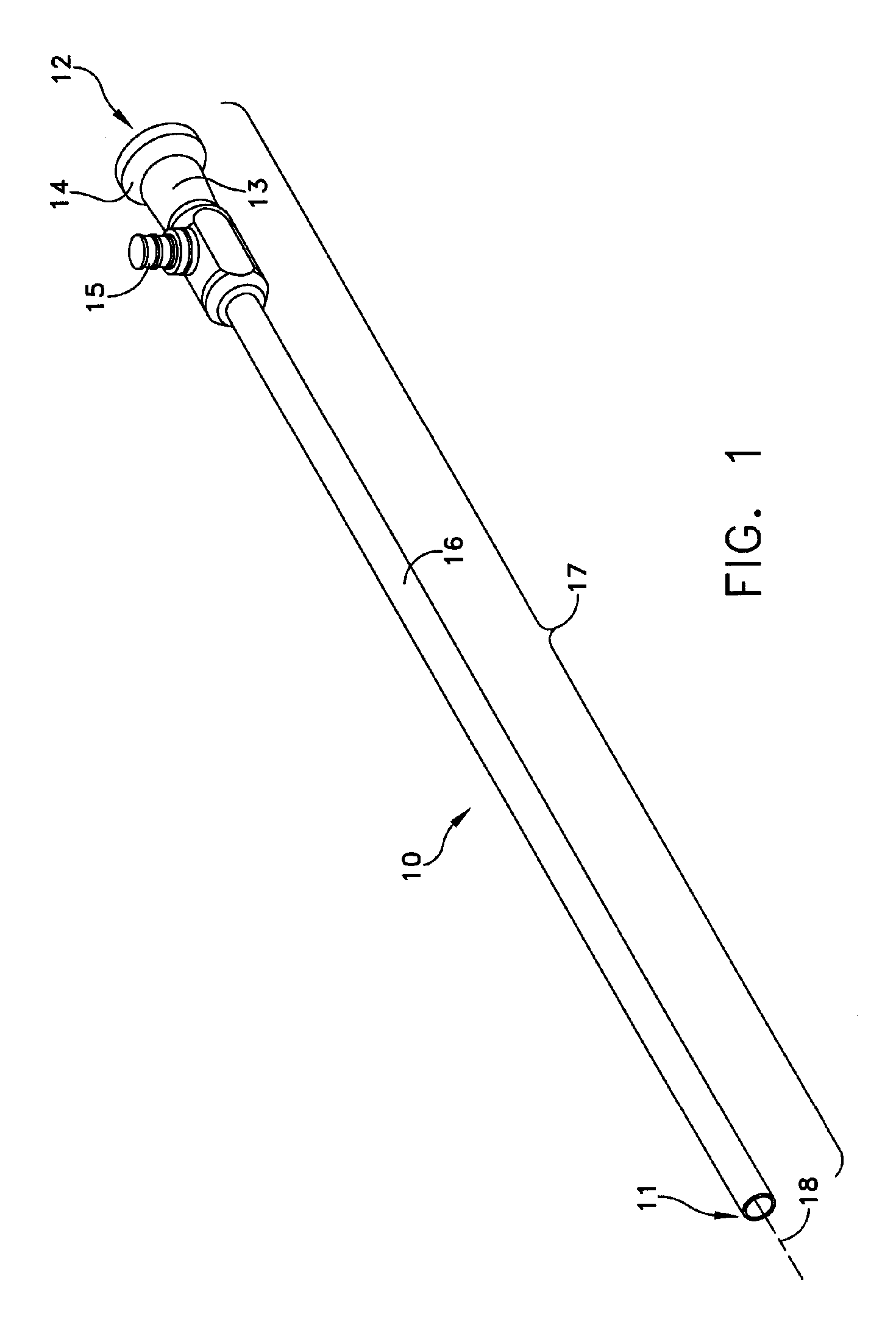

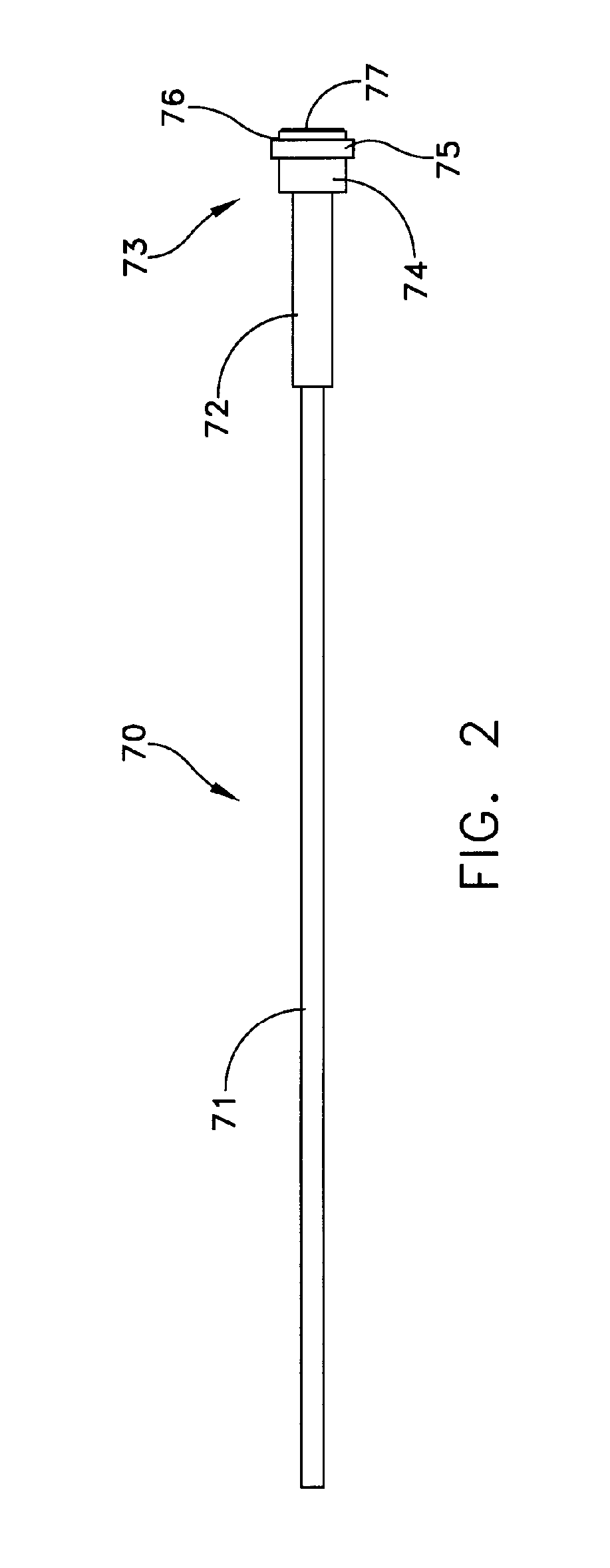

Endoscope with relief of axial loading

Owner:INTUITIVE SURGICAL OPERATIONS INC

Endoscope with relief of axial loading

A rigid endoscope includes an outer housing subassembly that supports an optics subassembly. The outer housing subassembly includes concentric tubes with optical fiber for providing object illumination. The optics subassembly includes a tubular sheath sealed at both ends for carrying lenses and other optical elements. First and second positioners associated with the optics subassembly and the outer housing subassembly, respectively, limit the transfer of axial forces from the proximal end of the endoscope to the tubular sheath.

Owner:INTUITIVE SURGICAL OPERATIONS INC

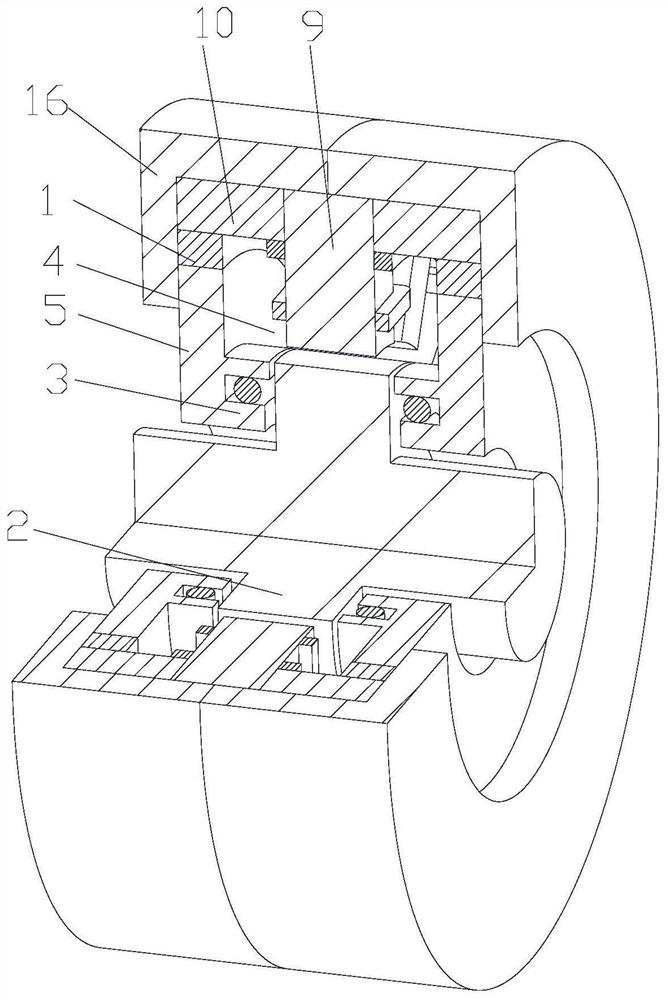

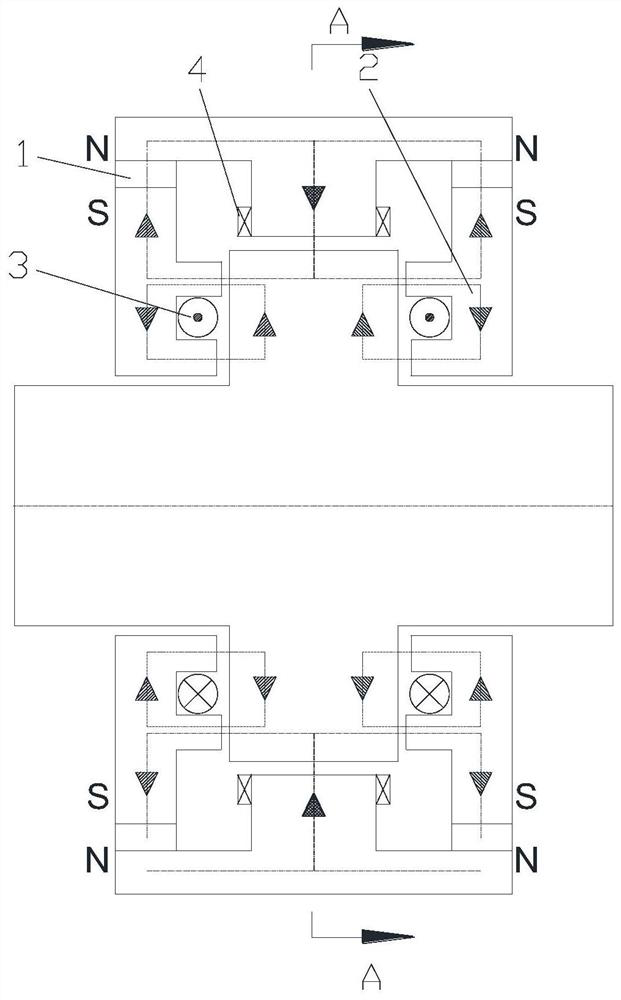

Magnetic suspension bearing, motor, compressor and air conditioner

PendingCN113586609AResolve mutual interferenceAchieve independenceBearingsControl systemElectric machinery

The invention provides a magnetic suspension bearing, a motor, a compressor and an air conditioner. The magnetic suspension bearing comprises an axial magnetic field control part, a radial magnetic field control part and a rotor assembly, the rotor assembly comprises a rotor iron core, the axial magnetic field control part comprises an axial control end opposite to the end face of the rotor iron core, the axial control end is provided with an axial control winding, each radial magnetic field control part comprises a radial control end arranged opposite to the peripheral surface of the rotor iron core, each radial control end is provided with a radial control winding, permanent magnets are arranged between the axial magnetic field control parts at the two ends and the radial magnetic field control parts respectively, the permanent magnets provide bias magnetic fields for the axial magnetic field control parts at the ends where the permanent magnets are located, the permanent magnets at the two ends jointly provide the bias magnetic field for the radial magnetic field control part. According to the magnetic suspension bearing, front and rear axial control magnetic fields can be mutually independent and do not interfere with each other, front and rear axial control systems are independent, the control logic is simplified, and the system stability is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Needle roller and cylindrical roller combination bearing

InactiveCN102829077AIncrease the amount of sticking outImprove wear resistanceRolling contact bearingsBearing unit rigid supportNeedle roller bearingEngineering

The invention discloses a needle roller and cylindrical roller combination bearing. The bearing comprises a bearer, the outer peripheral surface of the bearer is a cylindrical surface, the outer peripheral surface of the rear end of the bearer is provided with a cylindrical roller bearing, the position of the rear end of the bearer corresponding with the providing position of the cylindrical roller bearing is provided with a counter bore, a needle bearing assembly is arranged in the counter bore, the needle bearing assembly comprises a fixing shaft, two ends of the fixing shaft are fixed on the side wall of the counter bore, a needle bearing outer ring is sleeved on the outer peripheral surface of the middle part of the fixing shaft, a needle roller is arranged between the fixing shaft and the needle roller outer ring, and the two ends of the fixing shaft are arranged in the U-shaped locking slots on the two side walls of the counter pore at the rear end of the bearer in a side arranging manner. In the invention, the fixing shaft is arranged into the U-shaped locking slots from the rear end of the bearer in a side arranging manner and then is fixedly arranged between the two side walls of the counter pore after the needle bearing assembly is fixed on the fixing shaft during installation, so the needle roller and cylindrical roller combination bearing does not damage the needle roller and the fixing shaft in the installation and dismounting processes.

Owner:LUOYANG BEARING SCI & TECH CO LTD

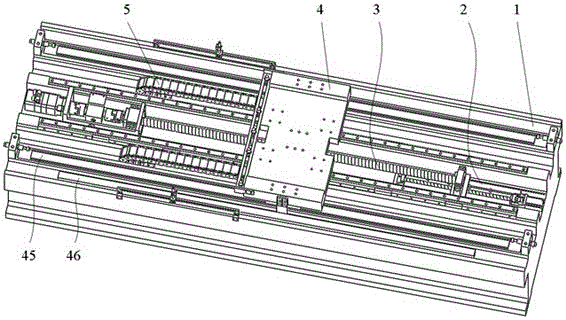

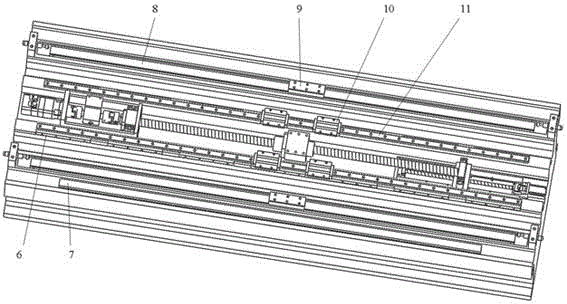

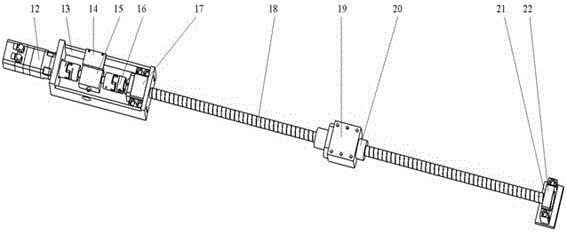

Ball screw performance test bench based on motor servo loading

InactiveCN104266837BIncrease stiffnessNo wearMachine gearing/transmission testingFriction torqueBall screw

The invention relates to a ball screw performance testing testbed based on motor servo loading. Rolling guide rails are arranged on a bed body, a movable pair is formed by the rolling guide rails and guide rail sliding blocks, the guide rail sliding blocks are fixedly connected with a workbench, a load ball screw pair is arranged in a middle groove in the bed body, a load nut seat is fixedly connected with the workbench, linear motor permanent magnet guide rails are arranged in outer inner grooves symmetrically formed in the bed body, a movable pair is formed by the linear motor permanent magnet guide rails and linear motor sliding blocks, and the linear motor sliding blocks are fixedly connected with the workbench. The ball screw performance testing testbed can simulate static or dynamic loads through a rotary servo motor or a linear servo motor, meanwhile, the locating precision, repeated locating precision, reverse errors, temperature rise and friction torque of the load ball screw pair are examined, the feasibility of the ball screw performance testing testbed in practical work is verified, the testbed has the advantages of being flexible in loading mode, high in loading precision and stable in loading process, and load lead screws of different lengths and the identical specification can be used for tests on the same performance testbed.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Special speed reducer for hub motor

InactiveCN106402281AGuaranteed uptimeFacilitate modular productionGearboxesToothed gearingsReducerControl theory

The invention provides a special speed reducer for a hub motor and belongs to the technical field of speed reducers. The special speed reducer for the hub motor comprises an outer hub, a bracket, a planetary mechanism, an input shaft and a frame. The frame is arranged in the outer hub. The input shaft is arranged in the middle of the frame and is sleeved with the bracket through a bearing. The planetary mechanism is arranged between the input shaft and the frame. The input shaft is sleeved with a sun gear. A planetary shaft is fixedly arranged on the bracket and sleeved with a planetary gear. An independent unit is arranged to facilitate later modular production, and the production cost is lowered. A spigot is arranged on the bracket. The spigot has the taper. The spigot is matched with a spigot matching position of the outer hub and is connected with the planetary shaft through a compression nut. Torque is output through the planetary shaft, so that the output torque is larger. As the spigot and the spigot matching position both have the tapers, and the two tapers are matched with each other, so that locating is more accurate, mounting is faster and firmer, and higher axial load can be borne.

Owner:宁波东力股份有限公司

Ball cage and angular contact ball bearing

PendingCN110778606AReduce weightSmall starting torqueBearing componentsBall bearingStructural engineering

The invention provides a ball cage and an angular contact ball bearing. The ball cage comprises a plurality of frame bodies, the end faces of the two sides of each frame body are provided with ball pockets, the surface of each ball pocket is used for contacting with bearing balls, a straight-line distance between any two points on any cross section of one frame body is smaller than the diameter ofthe bearing balls, one frame body is arranged between two adjacent bearing balls, so that the lives of the bearing balls are prolonged, the weight of bearings and the starting torque of the bearingsis reduced; and the angular contact ball bearing comprises bearing inner rings, bearing balls, bearing outer rings and the above-mentioned ball cage, ball sliding ways are arranged between the bearinginner rings and the bearing outer rings, the ball cage is used for separating the bearing balls and prevent the bearing balls from falling off, the number of the bearing balls is multiple, the numberof bearing balls is the same as that of the frame bodied, each bearing ball can slide in the ball sliding ways, and the ball cage does not affect the arranging of the bearing inner rings and the bearing outer rings, so that the contact angle of the bearings is increased.

Owner:SHANDONG BOTE BEARING

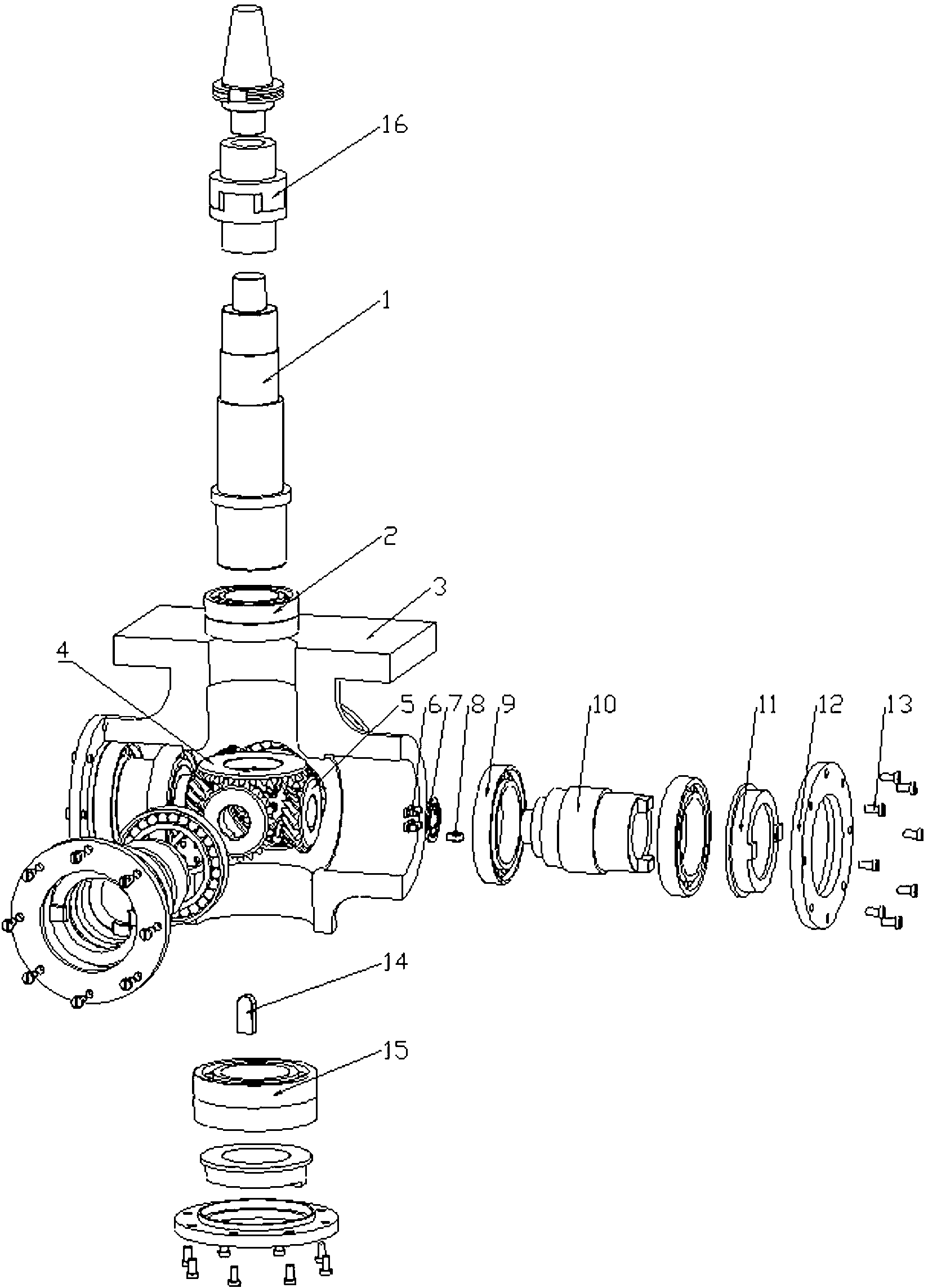

Polyhedron milling head

The invention relates to a polyhedron milling head. The polyhedron milling head comprises a main shaft and a shell body. The main shaft is provided with a first gleason spiral bevel gear. Four second gleason spiral bevel gears are uniformly arranged around the first gleason spiral bevel gear in a 90-degree mode and meshed with the first gleason spiral bevel gear. Each second gleason spiral bevel gear is connected with a transmission shaft, one end of the transmission shaft is located through a round end cover shaft axially, and the other end of the transmission shaft is located through a flange plate axially. A snap ring is connected between the transmission shaft and the flange plate through fine threads. The polyhedron milling head has the advantages of being capable of being used on various standard milling machines in a supporting mode, safe, reliable, convenient to disassemble and assemble, strong in adaptability, and capable of improving dimensional accuracy of machined parts greatly.

Owner:NINGBO VICTORY PRECISION MACHINERY

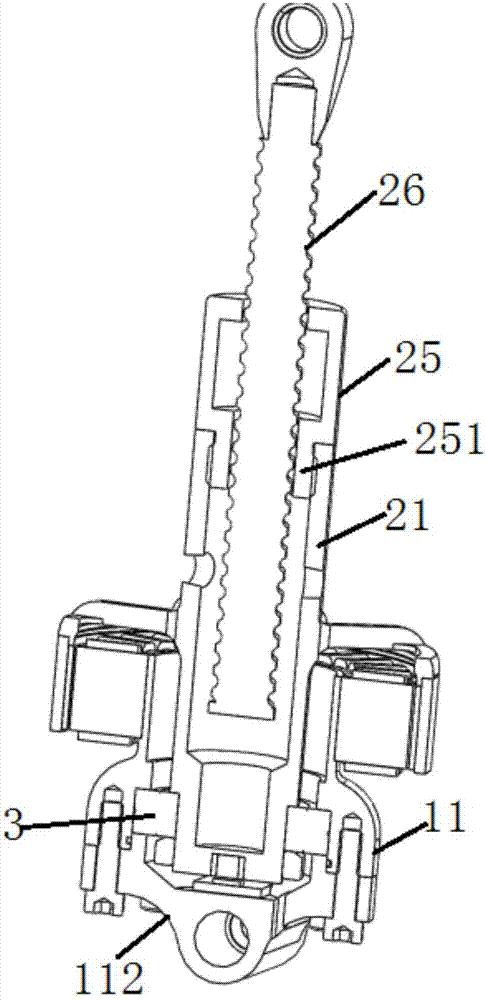

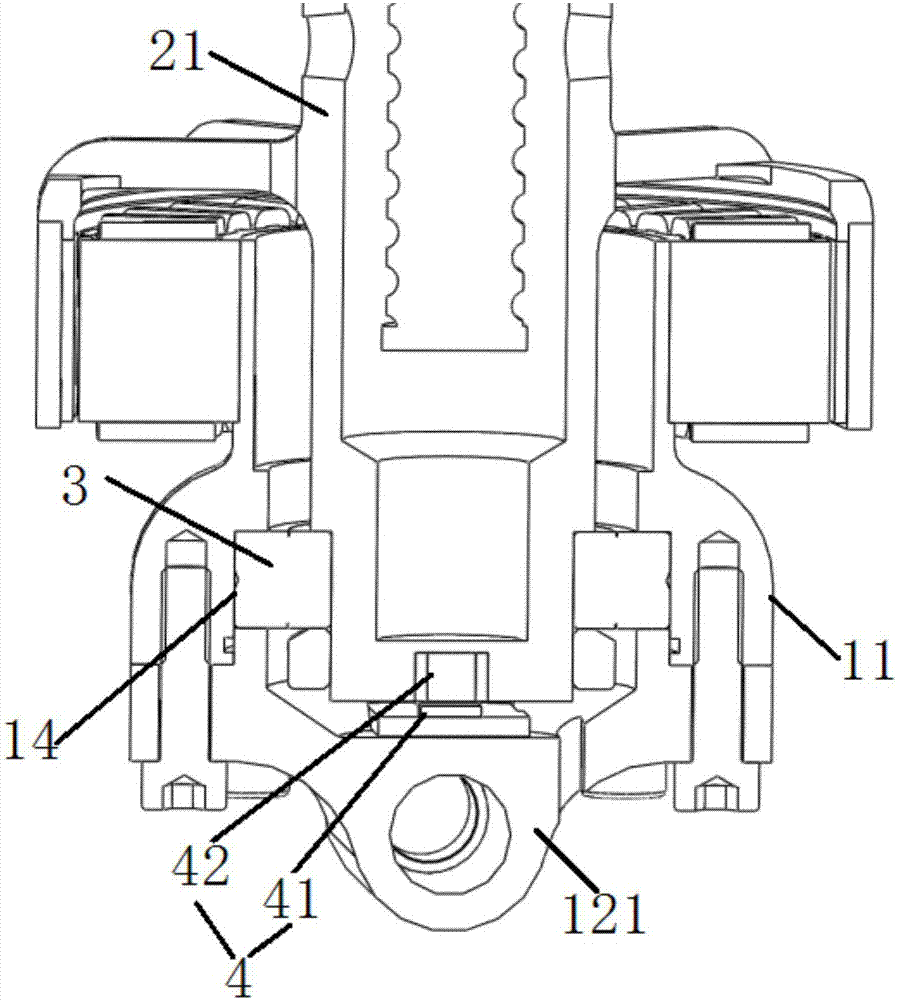

Straight-line servo driver and robot

PendingCN107317427AReduce weightReduce in quantityMechanical energy handlingControl engineeringAxial load

The invention discloses a straight-line servo driver and a robot. The driver comprises a stator assembly, a rotor assembly, a detection assembly and at least one bearing, wherein the stator assembly is provided with a first shell; the rotor assembly is provided with a second shell and a lead screw arranged inside the second shell in a penetrating manner; the end, stretching into the interior of the first shell, of the second shell is rotatably arranged on the first shell through the at least one bearing; a detected part and a detecting piece in the detection assembly are fixed on the second shell and the first shell respectively and are close to the bearing. The robot comprises a first arm, a second arm and the driver for driving the first arm to rotate on the second arm. According to the driver, the rotation points, relative to the first shell, of the detection assembly and the second shell are both concentrated on the position of the bearing, the bearing can bear the radial and axial load of the rotor assembly and guarantees relative position of the detection assembly, a plurality of bearings do not need to be arranged, the quantity of components is reduced, the driver is convenient to process and mount, and the self weight of the driver is reduced, so that the frictional resistance is reduced, and the transmission efficiency is improved.

Owner:苏州瑞步康医疗科技有限公司

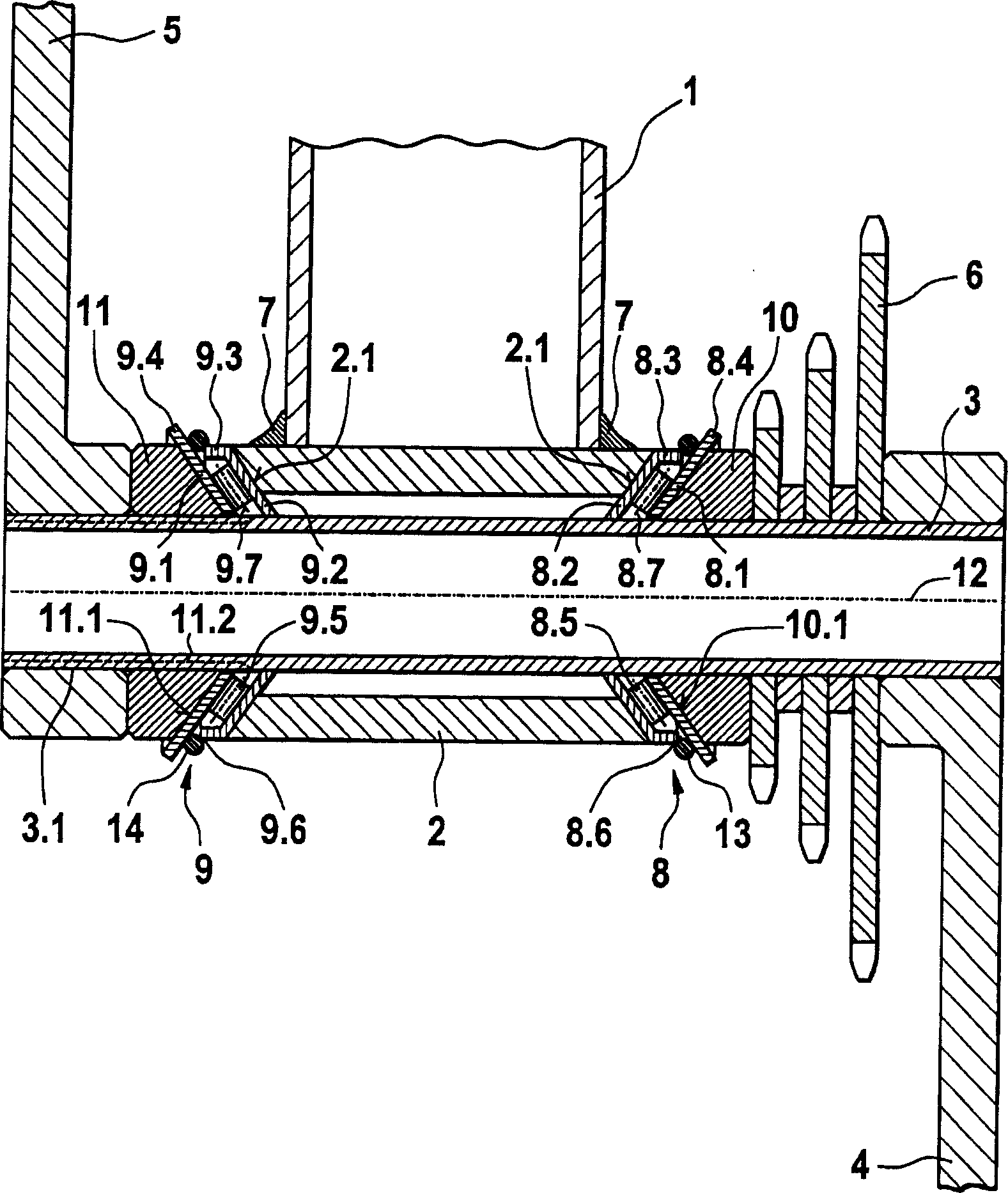

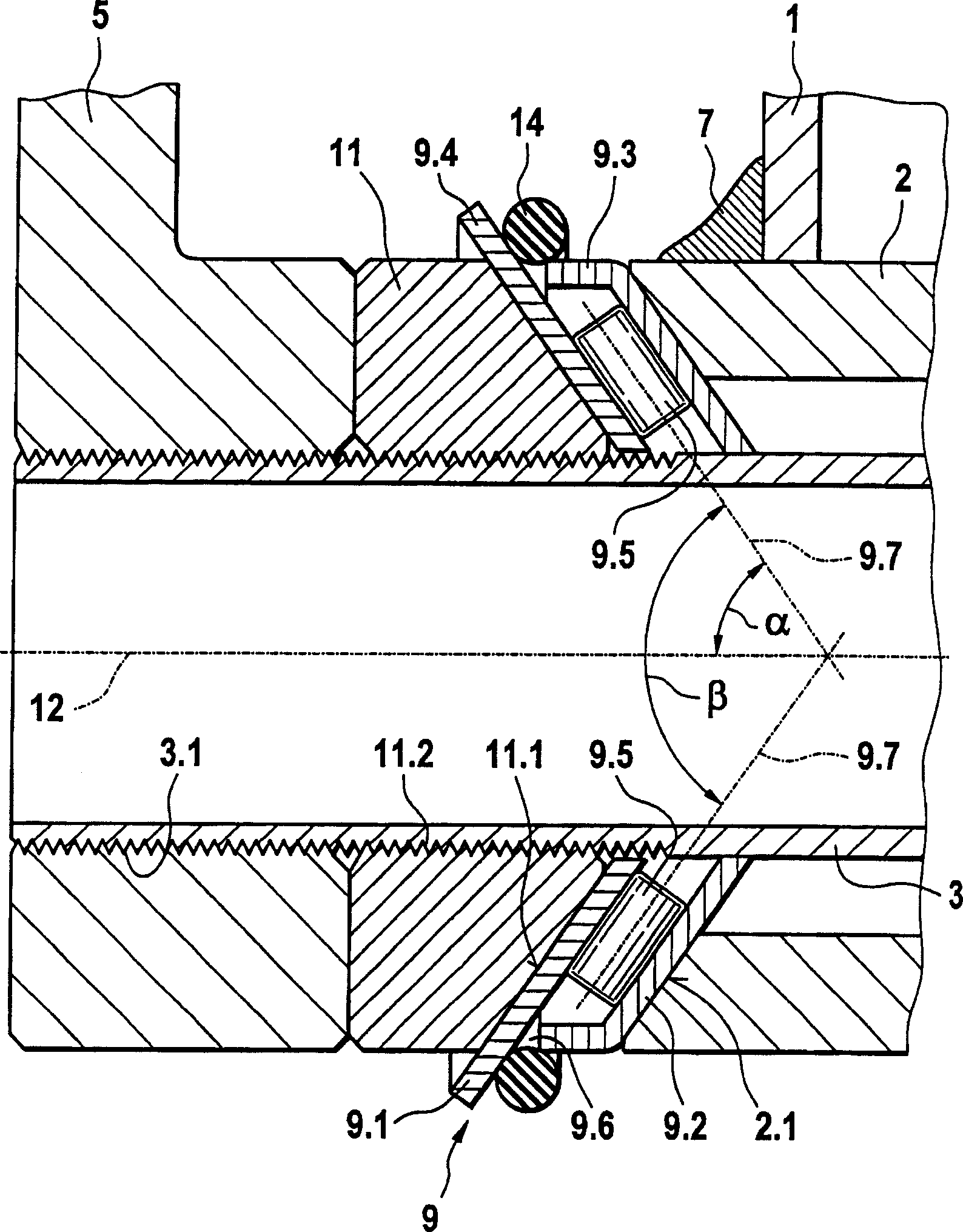

Crank bearing unit

InactiveCN1880163ALow costDriving effectVehicle cranksBearing componentsNeedle roller bearingRolling-element bearing

The pedal bearing unit has a pedal bearing axle (3) connected to the pedal cranks (4,5) and housed rotatable in a housing (2) through two spaced rolling bearings formed as axial inclined needle bearings (8,9) whose bearing needles (8.5, 9.5) have rotary axles (8.7, 9.7) which roll at an angle inclined to a bearing axle on associated tracks between two flat metal washer disc (8.1,8.2, 9.1,9.2). The inclined needle bearings are tensioned against one another through conical contact bearing faces (2.1, 10.1, 11.1) The flat washer discs are made through chipless shaping and subjected to a hardening process.

Owner:INA SCHAEFFLER KG

A double outer ring full ball bearing

The invention discloses a double-outer-ring full ball bearing. The double-outer-ring full ball bearing comprises an inner ring, a first outer ring and a ball, wherein rolling channels are correspondingly formed in the inner ring and the first outer ring. The double-outer-ring full ball bearing is characterized in that the first outer ring is composed of two symmetricalhalf outer rings; the two half outer rings are clamped through a second outer ring; sealing grooves are formed in the corresponding positions of the inner ring and the first outer ring, and rubber sealing rings are arranged in the sealing grooves in a matching manner; retainer rings are tightly clamped on the outer sides of the rubber sealing rings and between the second outer ring and the first outer ring; and the inner sides of the retainer rings are stuck with second rubber rings which are matched with the rubber sealing rings in an abutting manner; and sealing lips, which are in abutting contact with the first outer ring and the inner ring, are arranged on the inner sides of the rubber sealing rings.

Owner:ANHUI LIDA AUTOMOBILE BEARING MFG

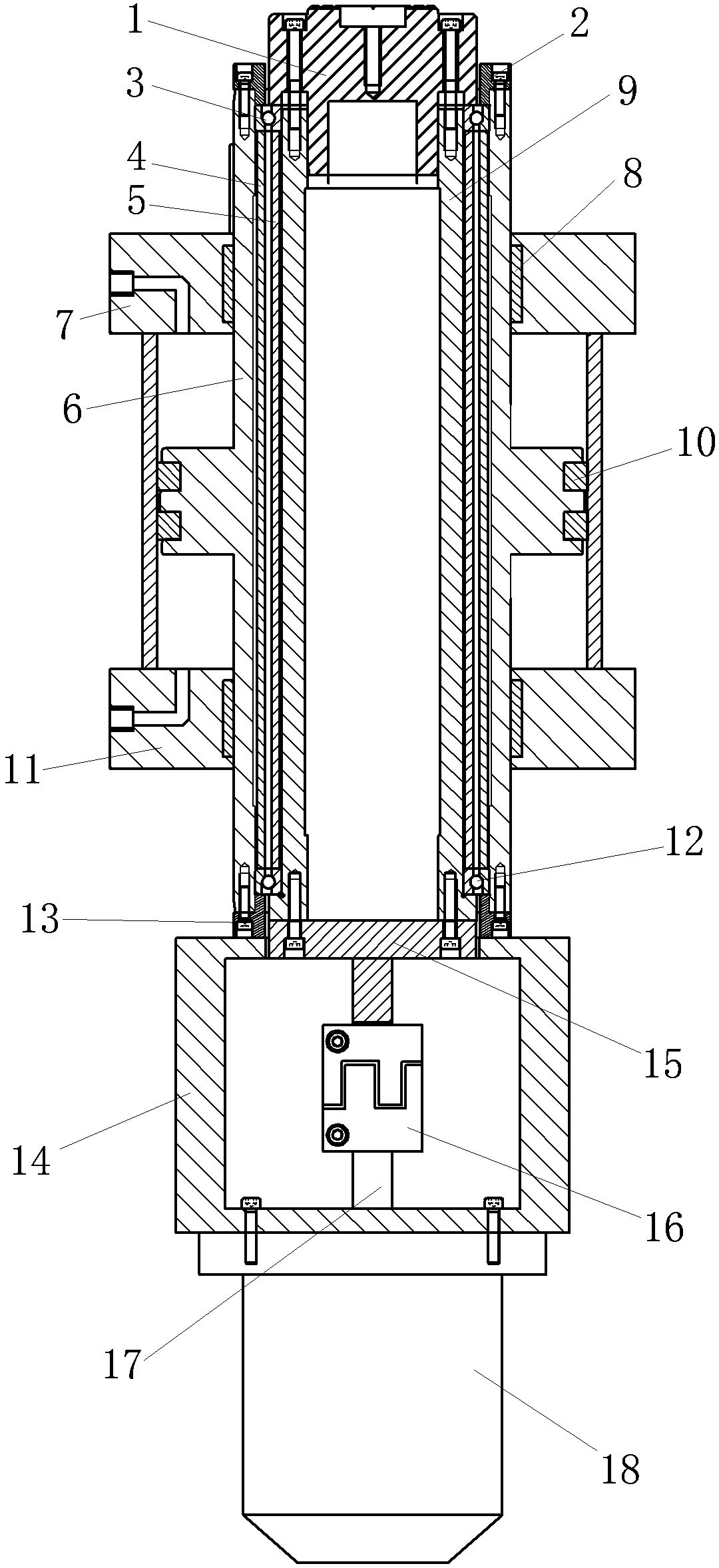

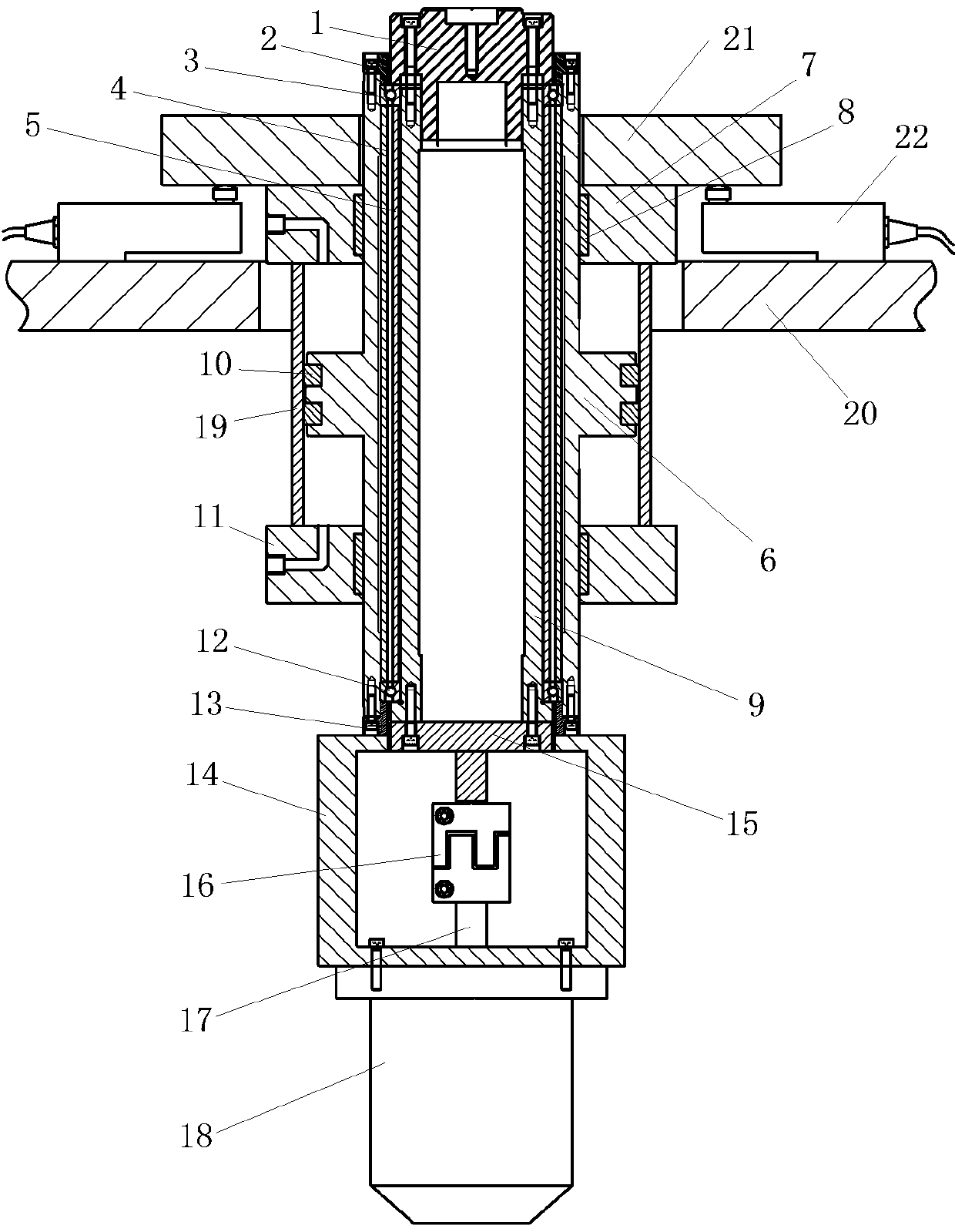

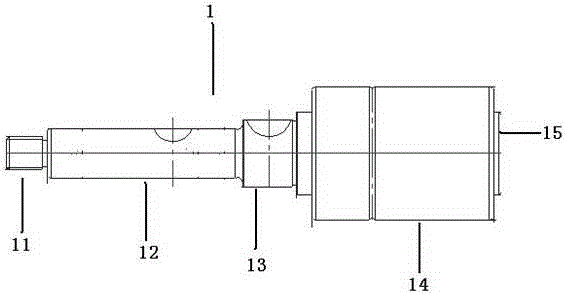

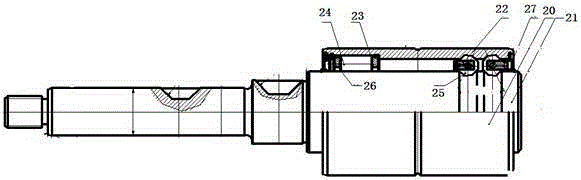

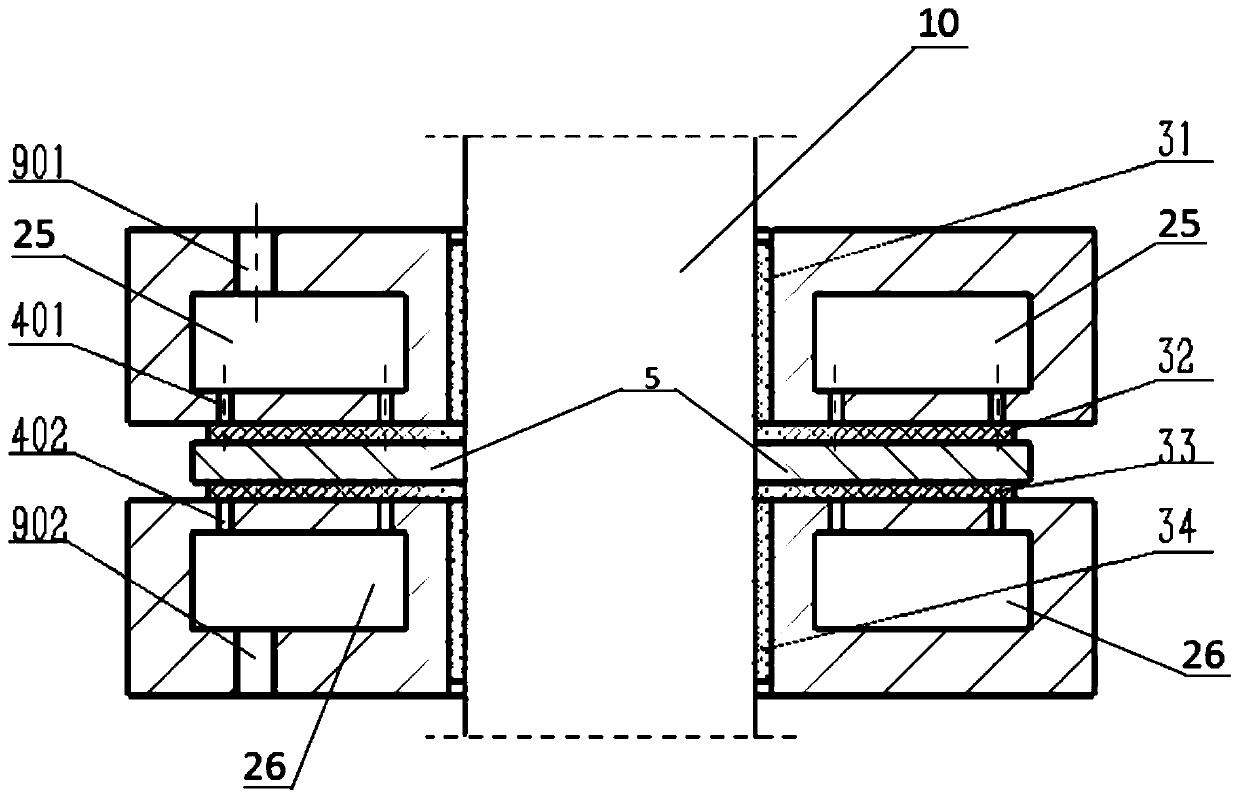

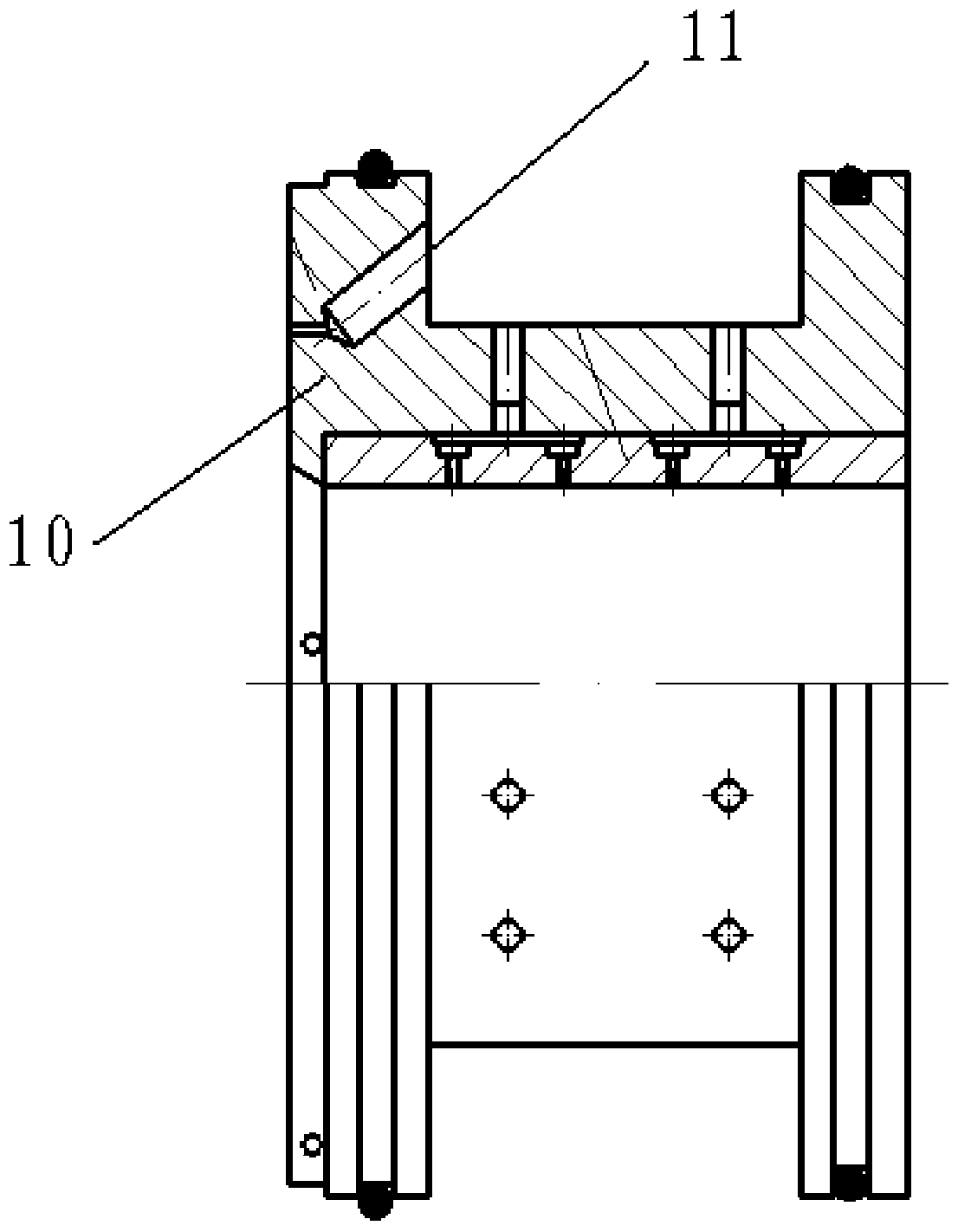

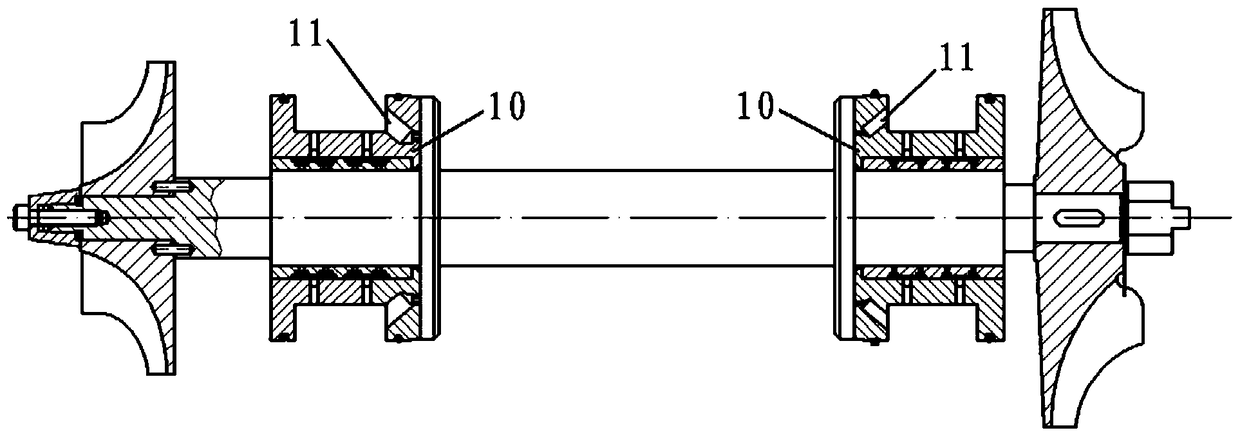

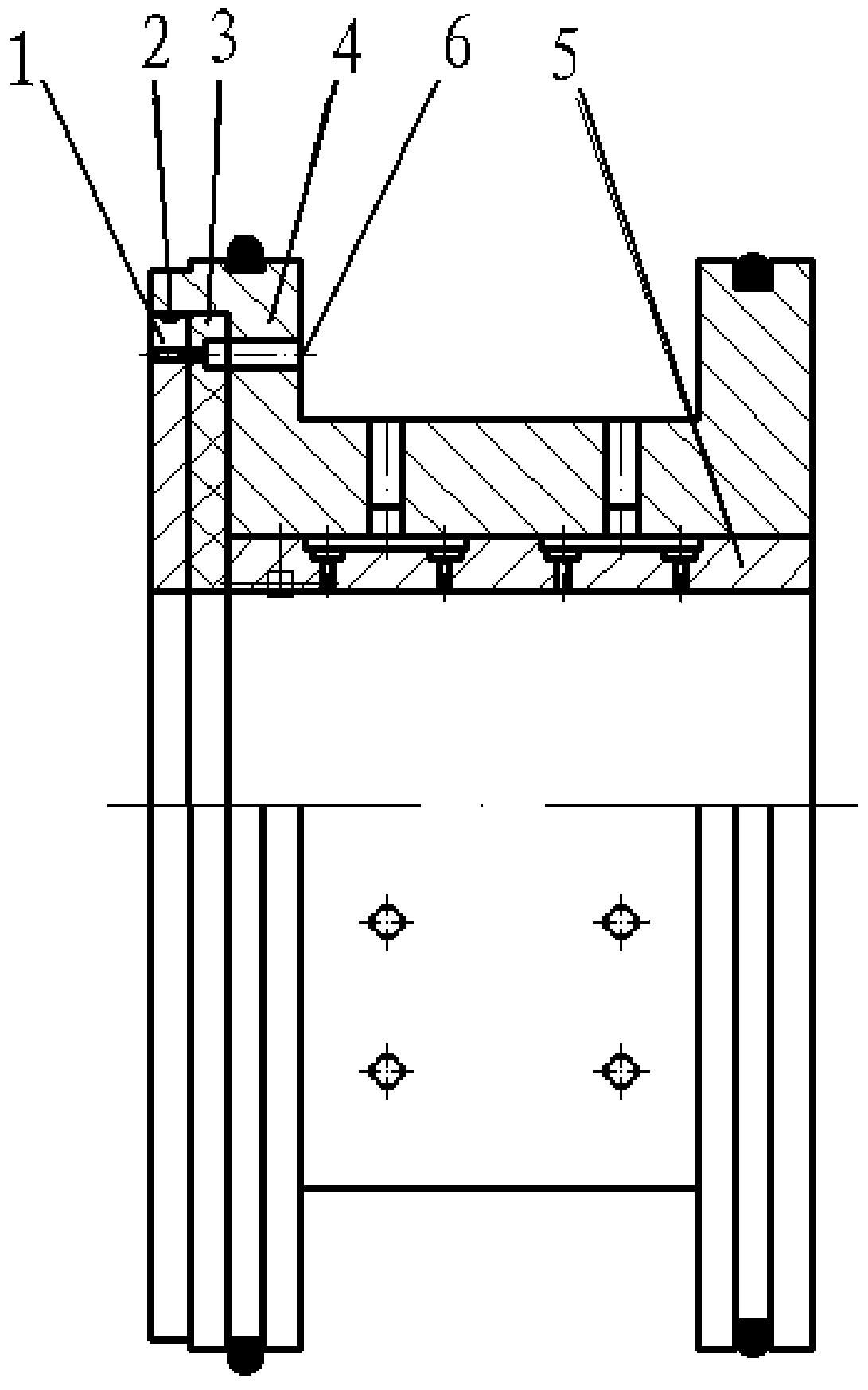

Axial load and rotary load loaded loading device

ActiveCN109855867AHigh precisionLarge axial loadMachine bearings testingApparatus for force/torque/work measurementHollow cylinderCylinder block

The invention relates to an axial load and rotary load loaded loading device. The loading device comprises a cylinder, the cylinder comprises a hollow cylinder body and an axial loading plunger in sliding fit with the cylinder body, the axial loading plunger is assembled with a rotating shaft by relative positioning during loading, one end of the rotating shaft is in transmission connection with arotating motor, and the other end of the rotating shaft can output rotary load and axial load. The rotating shaft drives the rotating shaft to rotate to realize rotary loading, the cylinder plunger transmits the axial load to the rotating shaft to realize axial loading, the rotating motor can realize stepless rotary load loading, and the cylinder can realize stepless axial load loading; and compared with a traditional manual loading manner, the device is characterized by high precision and capability of loading high axial load and high rotary load.

Owner:LUOYANG BEARING RES INST CO LTD

An integral shaft-connected fan clutch bearing

The invention discloses an integral shaft-connect type fan clutch bearing. The bearing adopts a row of rollers and double-row steel balls, the double-row steel balls adopt an angular contact structure in a geometric form, the bearing comprises a bearing outer ring, a mandrel, a steel ball holder, a roller holder and a seal ring, wherein channels and a raceway are machined on the bearing outer ring and used for bearing the rolling elements and guiding the rotation of rolling elements, the rolling elements comprise the steel balls and the cylindrical rollers, the mandrel is inserted into the bearing outer ring in the axial direction, inner channels are machined on the outer diameter of the mandrel and used for bearing the steel balls and guiding the rotation of the steel balls, an inner raceway is further machined on the outer diameter of the mandrel and used for bearing the cylindrical rollers, the steel ball holder is arranged between the bearing outer ring and the mandrel and makes the steel balls distributed in the channels at equal intervals, the roller holder adopts a design of a cylinder-shaped structure and a spring collar structure, a spring collar is assembled on the bearing outer ring in a matched mode to prevent the cylindrical rollers from springing out in the axial direction, and the sealing ring is installed in a seal groove formed in the end of the bearing outer ring in a pressed mode and remains still with the bearing outer ring.

Owner:长沙优力电驱动系统有限公司

A water-lubricated thrust bearing assembly

InactiveCN105673547BStrong axial bearing capacityStrong wear resistancePump componentsPumpsWater channelHard metal

The invention discloses a water-lubricated thrust bearing assembly. The assembly comprises a thrust disc and a stainless steel thrust disc, wherein the thrust disc comprises a hard metal substrate, the annular end surface of the metal substrate at the contact sides of the thrust disc sector-ring shaped friction blocks is covered with a non-metal wear-resisting layer, the stainless steel thrust disc comprises a stainless steel annular substrate and a plurality of sector-ring shaped friction blocks on one side of the annular substrate, a lubrication water channel is formed between the adjacent sector-ring shaped friction blocks, the corresponding number of the stainless steel sector-ring shaped support blocks with the sector-ring shaped friction blocks are arranged on the other side of the annular substrate, a cool water channel is formed between the adjacent sector-ring shaped support blocks, the sector-ring shaped support blocks and the sector-ring shaped friction blocks are arranged in the circumferential direction in the staggered way, the symmetry axis of the sector-ring shaped support block coincides with the projection of the middle line of the lubrication water channel in the annular end surface of the substrate. The water-lubricated thrust bearing assembly has features of great axial bearing capacity, good cooling effect, great wear resisting capacity, high corrosion resistance, low operation resistance, and long service life.

Owner:衡水凯达模压制品有限公司

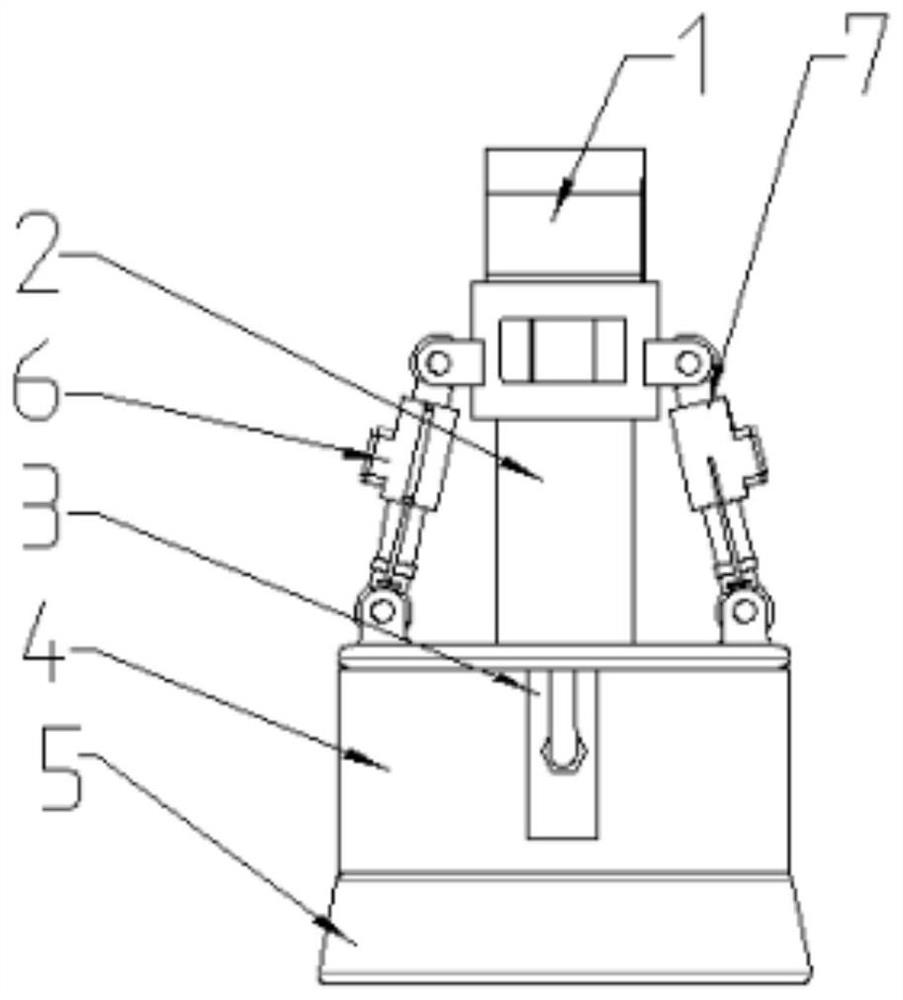

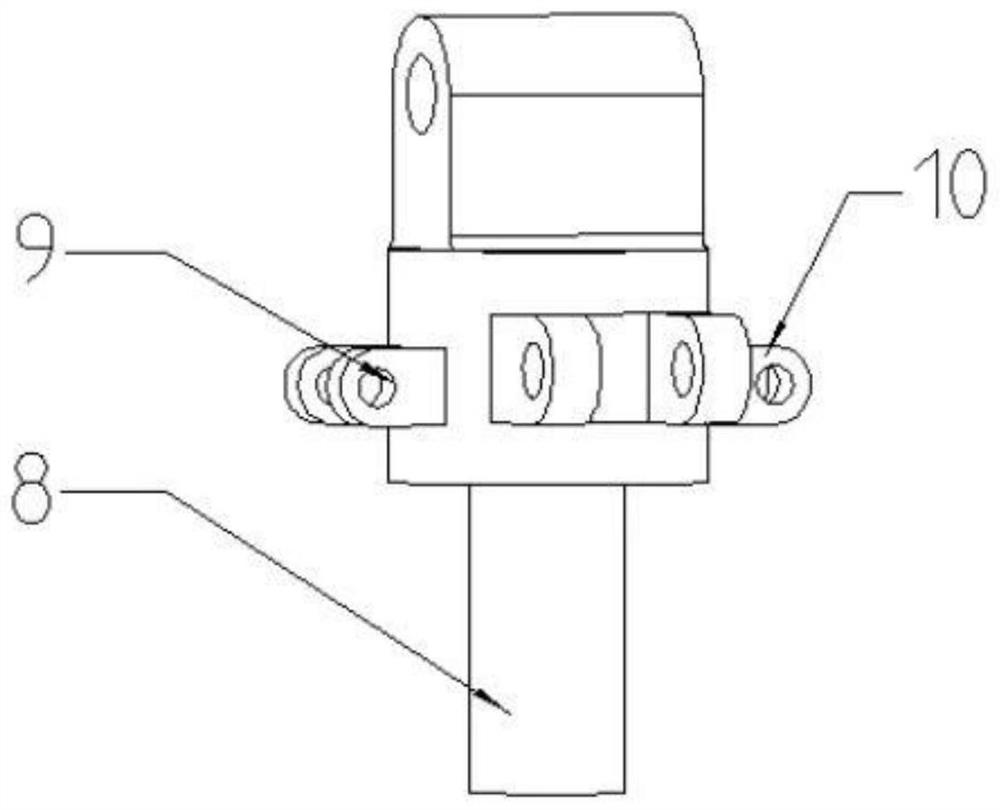

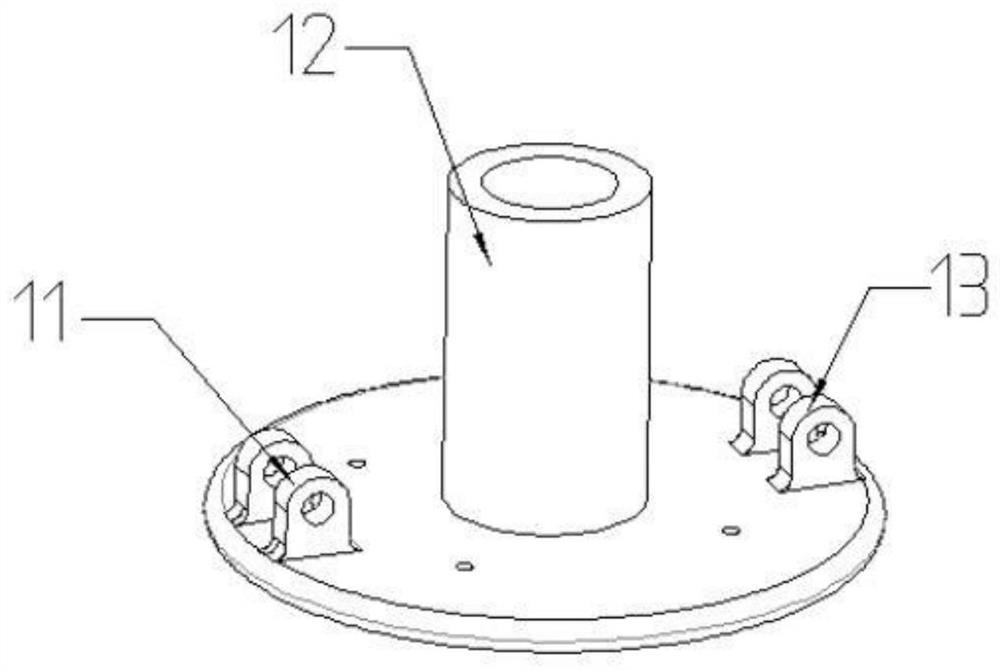

Air Quenching Method and Device Applicable to Engine Pistons

ActiveCN111663088BSmooth rotationSufficient gripping forceFurnace typesHeat treatment furnacesCooling effectAluminium matrix

The invention provides an air quenching method and device suitable for engine pistons. The method includes the following steps: Step 1: Clamp the engine piston to be quenched between upper and lower clamping rods, and the clamping rods respectively include clamping rods. Hold the head and bearing; Step 2: Set up a compressed air nozzle that is eccentric to the left and right of the axis of the engine piston around the engine piston, and spray compressed air to the engine piston through the compressed air nozzle, so that the engine piston will revolve around its own axis under the action of compressed air Rotary, where the engine piston is cast from aluminum alloy or aluminum matrix composite. The present invention utilizes the compressed air generally available at the production site as the air source for the air quenching of the engine piston. The high-speed airflow formed by the compressed air ejected from the nozzle in the compressed state itself has the cooling effect of expanding and absorbing heat. At the same time, the high flow rate can Takes heat away quickly.

Owner:SHANGHAI JIAOTONG UNIV +1

Turbocharger

ActiveCN106369056BImprove efficiencyIncrease speedInternal combustion piston enginesGas cushion bearingsImpellerTurbocharger

The invention discloses a turbocharger, comprising a turbine housing, a turbine, a rotary shaft, a radial thrust bearing and an axial thrust bearing, an impeller and an impeller housing, wherein the turbine is arranged in the turbine housing; the rotary shaft is connected with the turbine; each of the radial thrust bearing and the axial thrust bearing sleeves the rotary shaft; the impeller is connected with the other end of the rotary shaft; the radial thrust bearing is an air dynamic pressure foil radial thrust bearing; the axial thrust bearing is an air static pressure axial thrust bearing. The turbocharger has the advantages that a turbocharger rotor system is supported by a combined structure of the air static pressure axial thrust bearing and the air dynamic pressure foil radial thrust bearing, so that the effects of no lubricating oil, high efficiency, high rotation speed and the like are achieved; the air static pressure axial thrust bearing can bear great axial load; two types of gas differing in medium and respectively positioned at a turbine end and an impeller end can be isolated by a high-pressure air film formed by the air static pressure axial thrust bearing; meanwhile, the air dynamic pressure foil radial thrust bearing can be adapted to a high temperature environment, and no cooling device is needed in the turbocharger.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

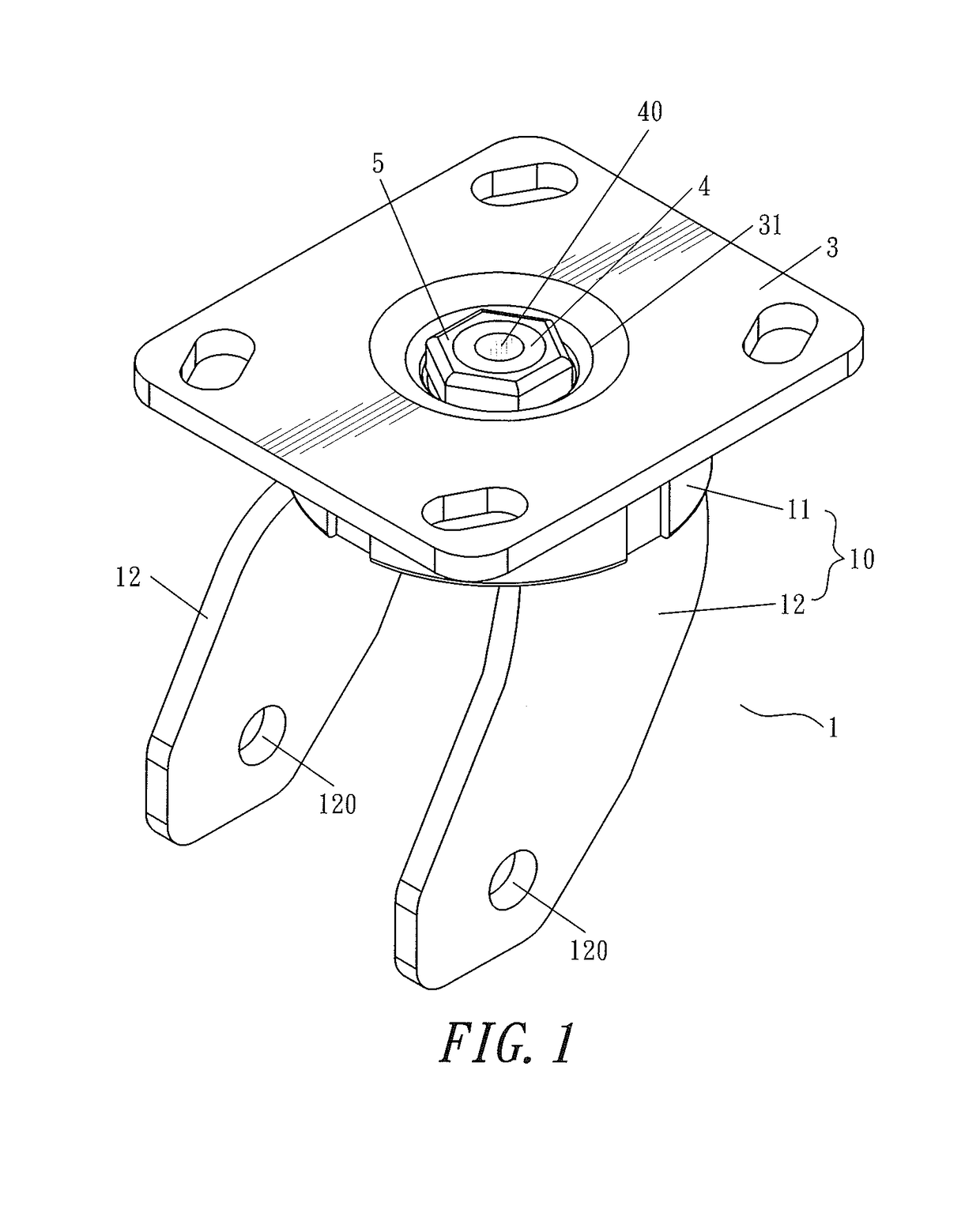

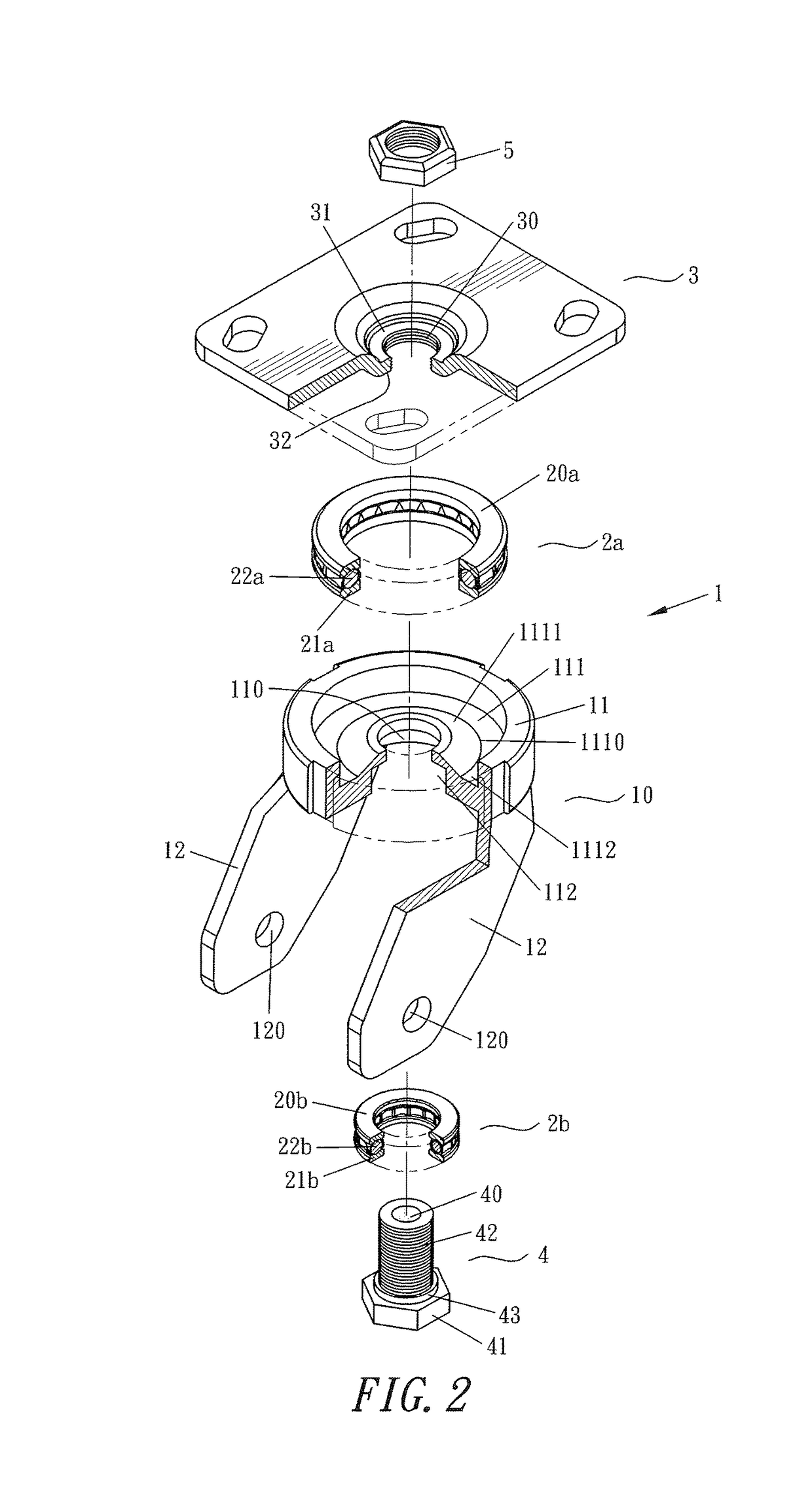

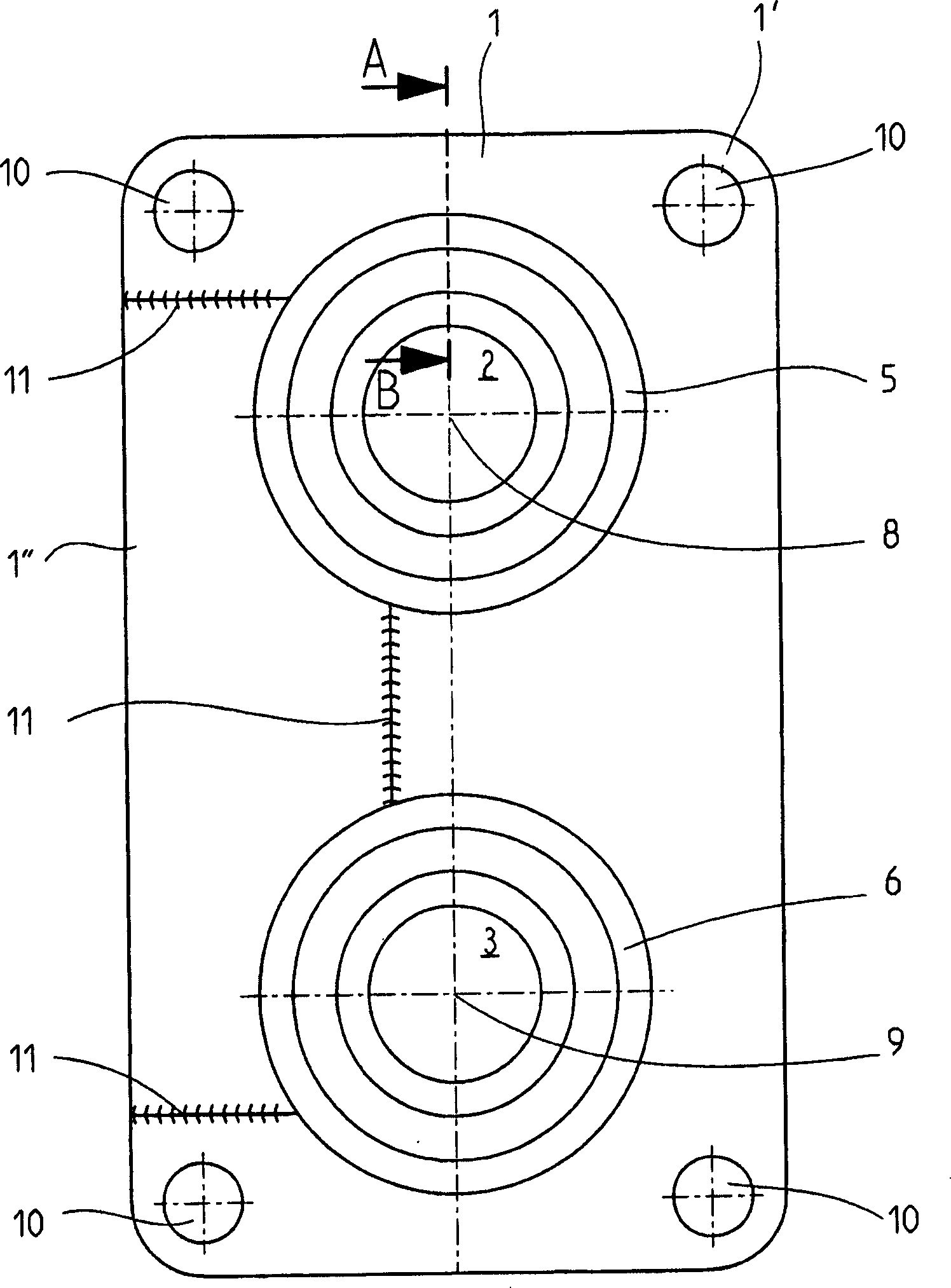

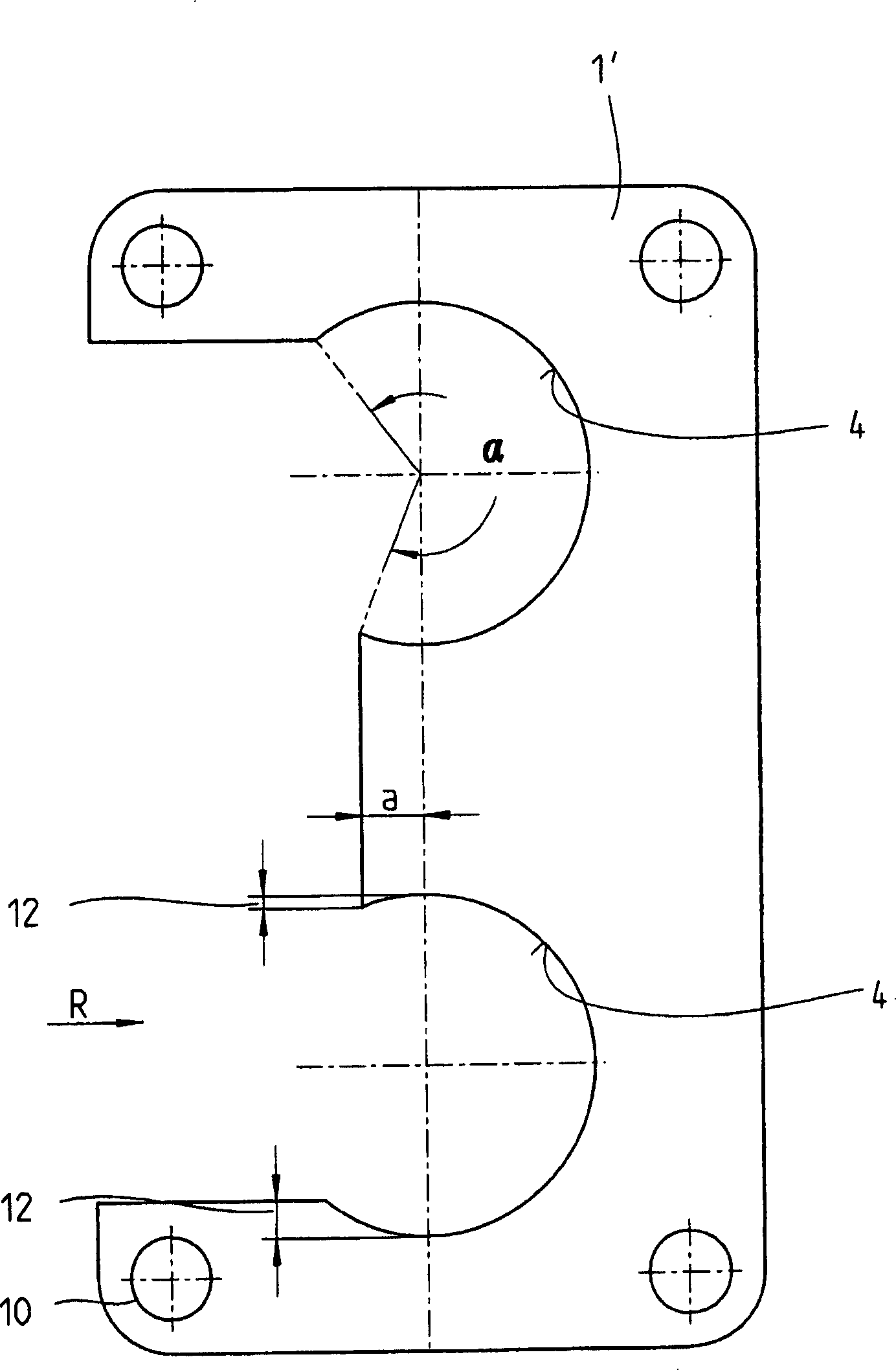

Caster structure

InactiveUS9862228B1Prevent the screws from being loosenedSmall thicknessBall bearingsCastorsThrust bearingMechanical engineering

A caster structure has a screw hole formed at the middle of a carrying plate and provided for passing, screwing, and pressing a screw, and then screwing and pressing tightly with a nut, so that the installed screw has a smaller thickness to lower the center of gravity of an installed wheel in addition to giving a dual nut fixing effect. The caster has bearings which are mainly thrust bearings for bearing a relatively larger axial gravity to prevent the bearing from being damaged by gravity and the balls from falling out. The bearings are limited and positioned securely to prevent installation gaps and dusts, to maintain a flexible rotation of the caster.

Owner:CHEN FR

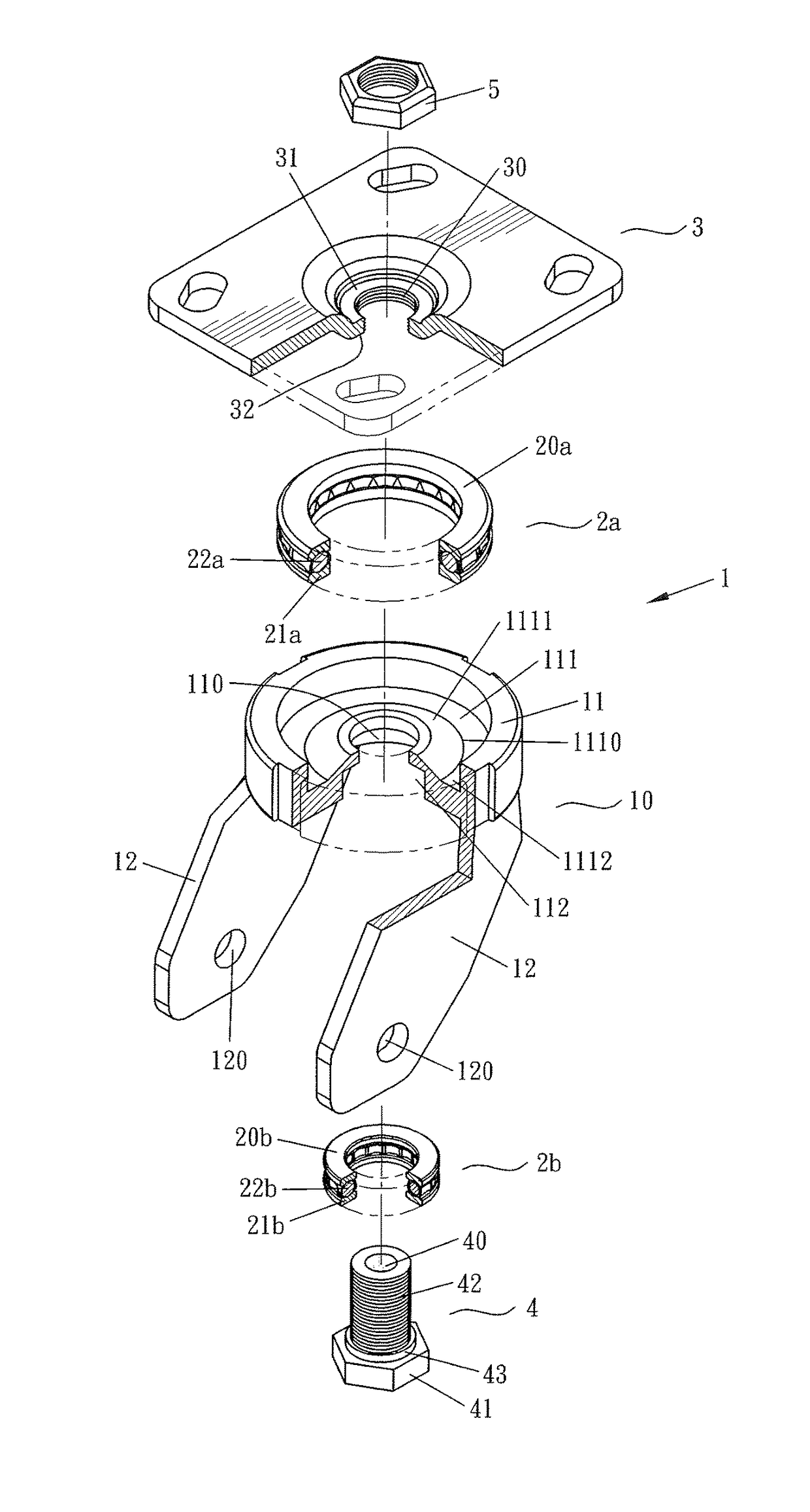

Bearing device

ActiveCN101117980BEasy to operateSimplify the installation processBearing unit rigid supportEngineering

Owner:AB SKF

A thrust surface floating gas static pressure bearing

The invention discloses a gas static pressure bearing with a floating thrust surface. The gas static pressure bearing comprises a bearing body, a bearing lining, a floating thrust surface body and an elastic plate, wherein the bearing body sleeves the bearing lining; one end of the bearing body is connected with one end of the elastic plate in a sealing manner; the other end of the elastic plate is connected with the floating thrust surface body in the sealing manner; the elastic plate and the floating thrust body are connected with one end, in the axial direction, of the bearing body in sequence; a plurality of gas holes which are communicated in a matched manner are formed in the bearing body, the elastic plate and the floating thrust body; the elastic plate is made of an elastic material. According to the technical scheme, the thrust surface is changed to be in a floating type structure, so that a gas film clearance between the gas bearing and a shaft body is uniform, eccentric force of the bearing is reduced, and the axial bearing capacity of the gas bearing is greatly improved; and therefore, the gas bearing can be used for bearing a high axial load and achieving the high flow and the high rotating speed.

Owner:SHANGHAI QIYUAN GAS DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com