Ball cage and angular contact ball bearing

A technology of angular contact ball bearing and ball cage, which is applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of large contact area, short life, large starting torque, etc., to achieve small contact area, prolong life, Weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

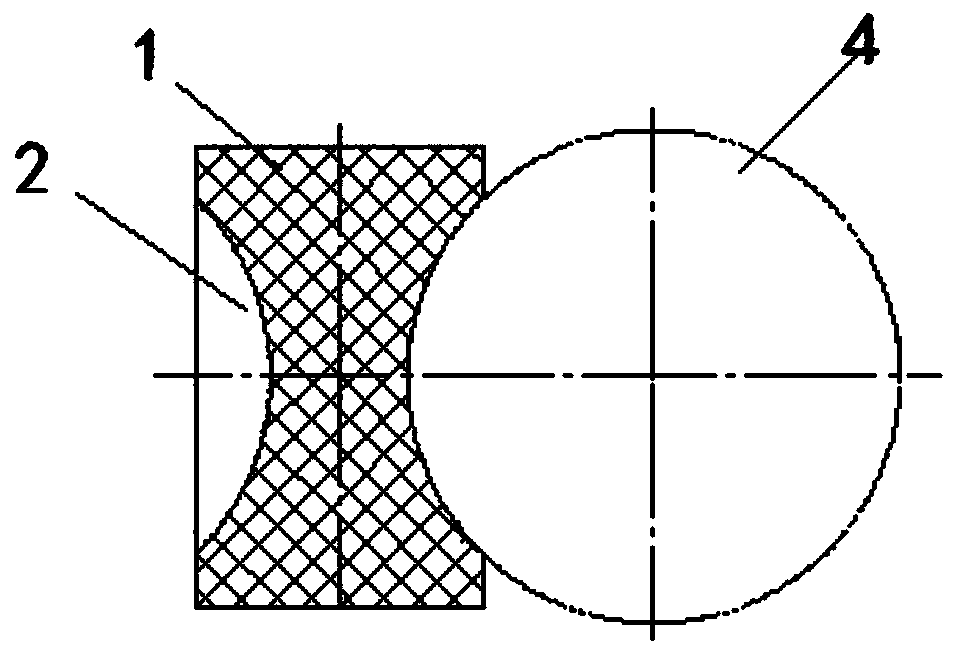

[0028] This embodiment provides a ball cage, such as figure 1 As shown, in this embodiment, the ball cage includes a plurality of frame bodies 1, and ball pockets 2 are provided on both sides of each frame body 1, and the surface of each ball pocket 2 is used to contact with the bearing balls 4. The linear distance between any two points on any cross-section of the bearing is less than the diameter of the bearing ball 4, and a frame body 1 is provided between two adjacent bearing balls 4, and the contact area between the split cage and the bearing ball 4 is small , Slow wear, prolonging the life of the bearing ball 4; the split cage is light in weight, reducing the weight of the bearing and the starting moment of the bearing.

[0029] Furthermore, the frame body 1 is made of lightweight nylon material, which is not only light in weight but also has good toughness and good wear resistance, so that the weight of the bearing can be reduced and the life of the bearing can be prolo...

Embodiment 2

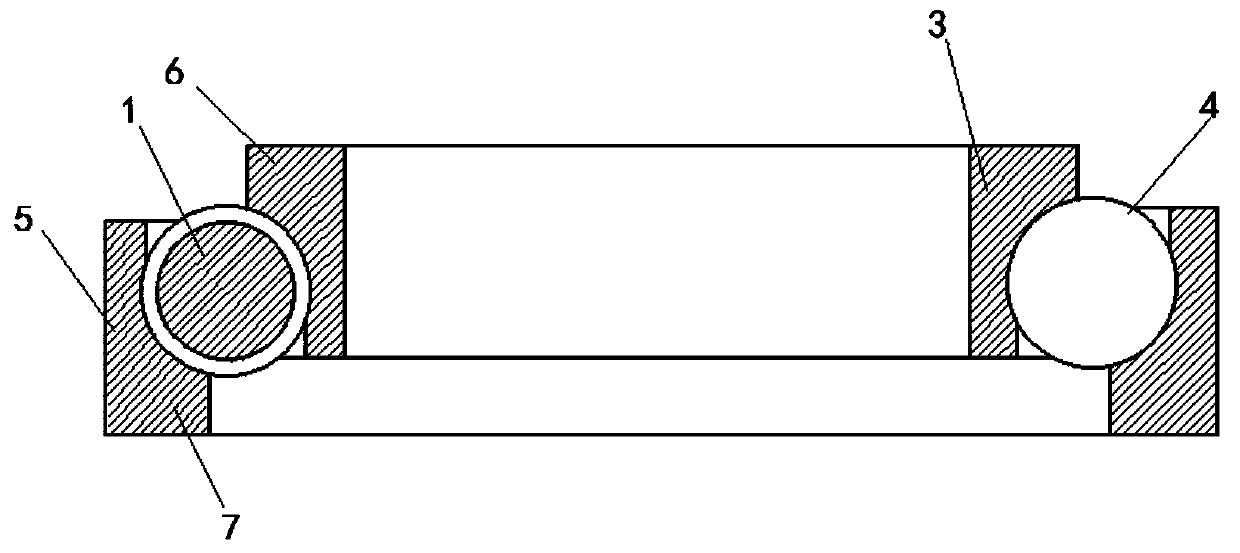

[0032] This embodiment provides an angular contact ball bearing, such as figure 2 As shown, in this embodiment, the angular contact ball bearing includes bearing inner ring 3, bearing balls 4, bearing outer ring 5 and the ball cage described in Embodiment 1, between the bearing inner ring 3 and bearing outer ring 5 A ball slideway is provided, and each bearing ball 4 can slide in the ball slideway. The ball cage is arranged in the ball slideway and is used to separate the bearing balls 4 and prevent the bearing balls 4 from falling off. There are multiple bearing balls 4, and the bearing balls 4 and The number of frame bodies 1 is the same, and the split-type bearing cage is arranged between each bearing ball 4, so that the bearing cage does not affect the setting of the bearing inner ring 3 and the bearing outer ring 5, that is, the bearing ball 4 and the bearing inner ring 3 and the bearing The optional range of the contact point position of the outer ring 5 is increased, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com