Needle roller and cylindrical roller combination bearing

A technology of cylindrical roller bearings and cylindrical rollers, applied in the field of bearings, can solve problems such as damage to fixed shafts and needle rollers, and achieve the effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

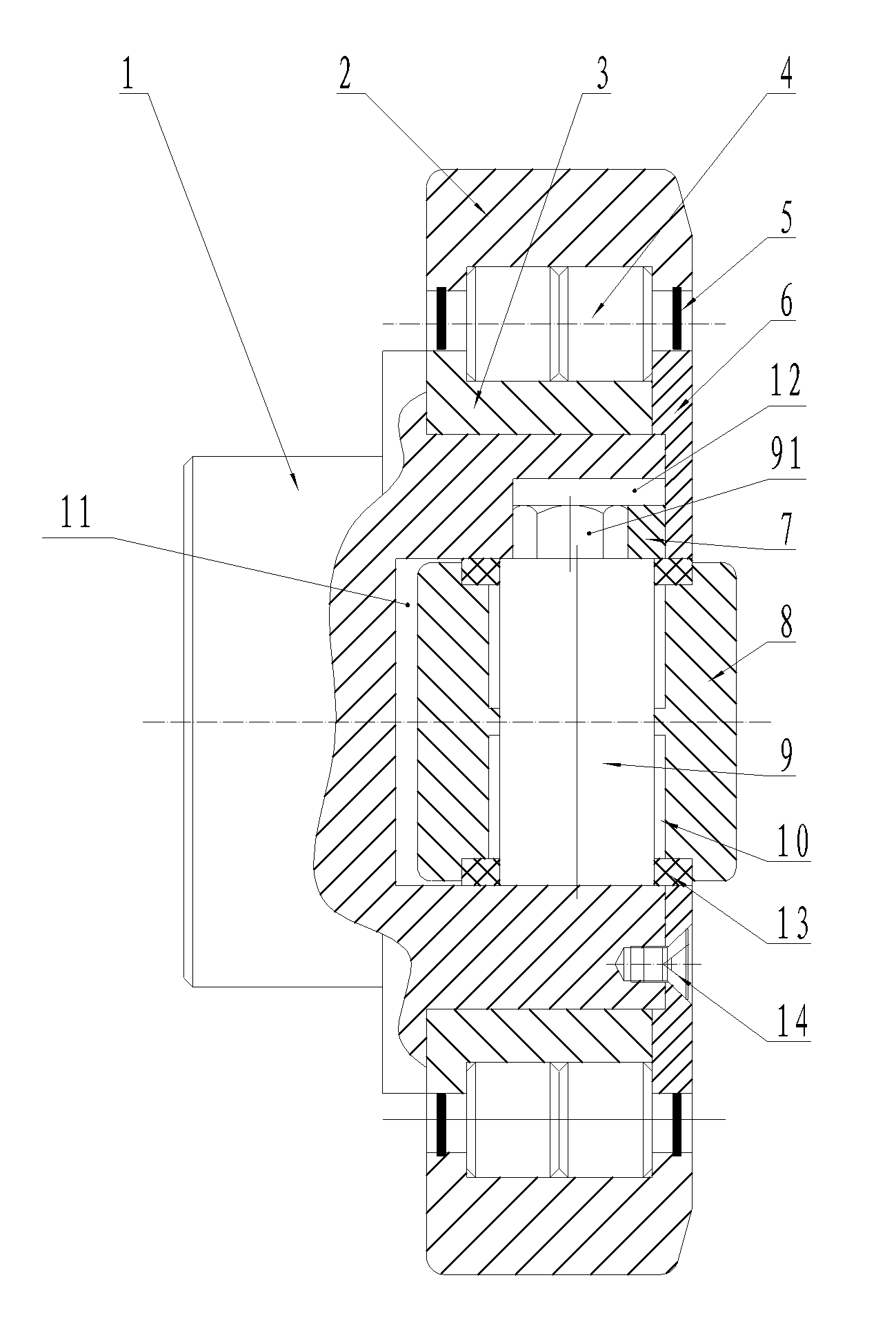

[0023] An embodiment of a combined needle roller and cylindrical roller bearing, such as figure 1 As shown, including the support 1, the outer peripheral surface of the support 1 is a cylindrical surface, the rear end of the support 1 is provided with a counterbore 11 forward along its axis, and the rear end surface of the support 1 is set on the two side walls of the counterbore. There is a U-shaped card slot 12, and the counterbore 11 is installed in the U-shaped card slot on the side wall with a fixed shaft 9 on the rear end side of the support 1, and the fixed shaft 9 has an outer square column structure protruding through its two ends The anti-rotation of the pressing platform 91 is assembled into the U-shaped slot, and the fixed shaft 9 is provided with step surfaces respectively matched with the upper and lower side walls of the counterbore 11, and the rear end surface of the support 1 is threaded for fixing The shaft 9 is pressed against the end cover 6 in the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com