Hard alloy welding circular saw blade without tooth-shaped structure

A hard alloy, toothless technology, applied in the direction of circular saws, metal sawing equipment, saw blades, etc., can solve the problems of inconsistent shape and specification, poor cutting quality, and reduced cutting efficiency, so as to increase the brazing area, Reduce the risk of breakage and reduce the effect of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

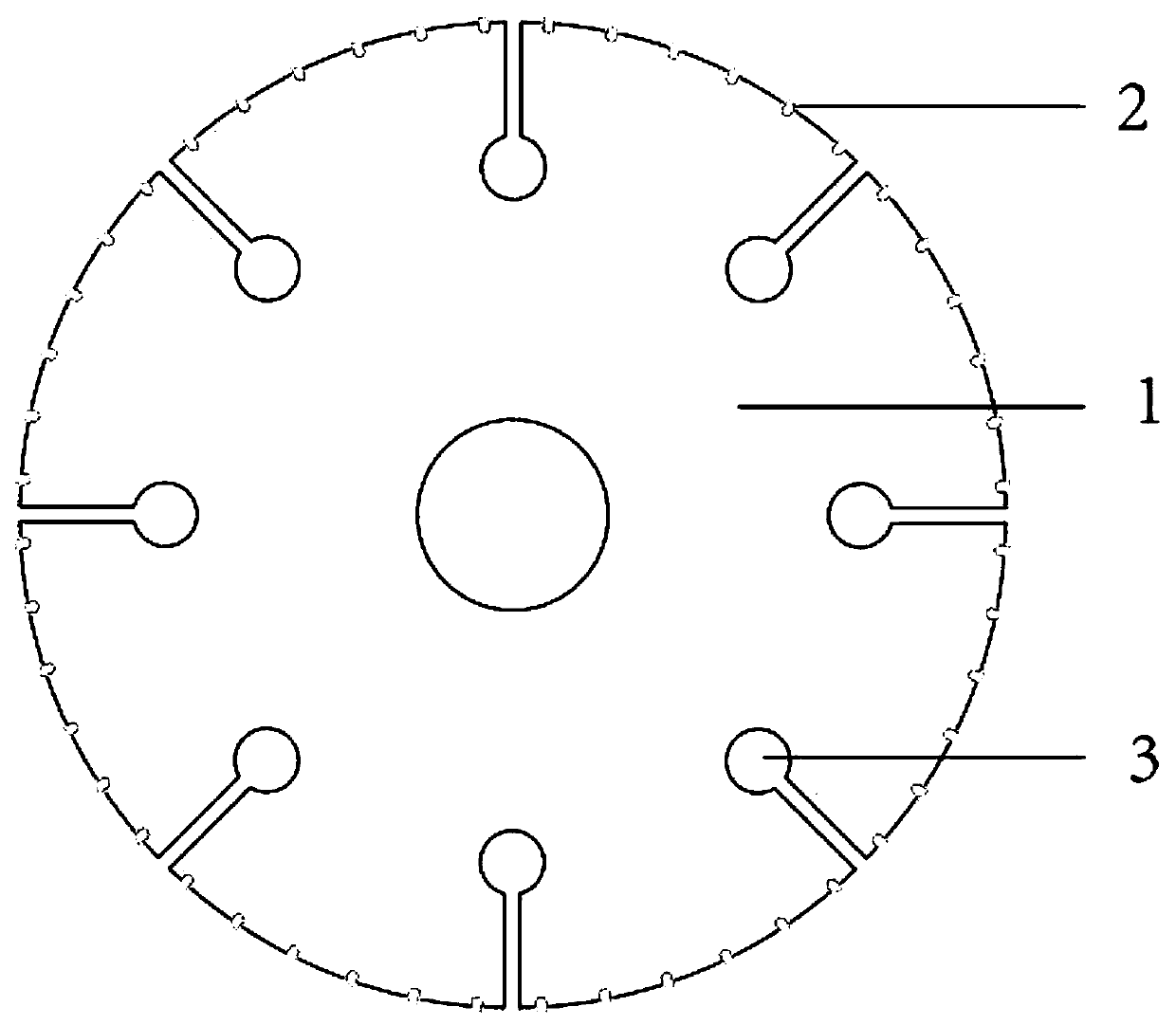

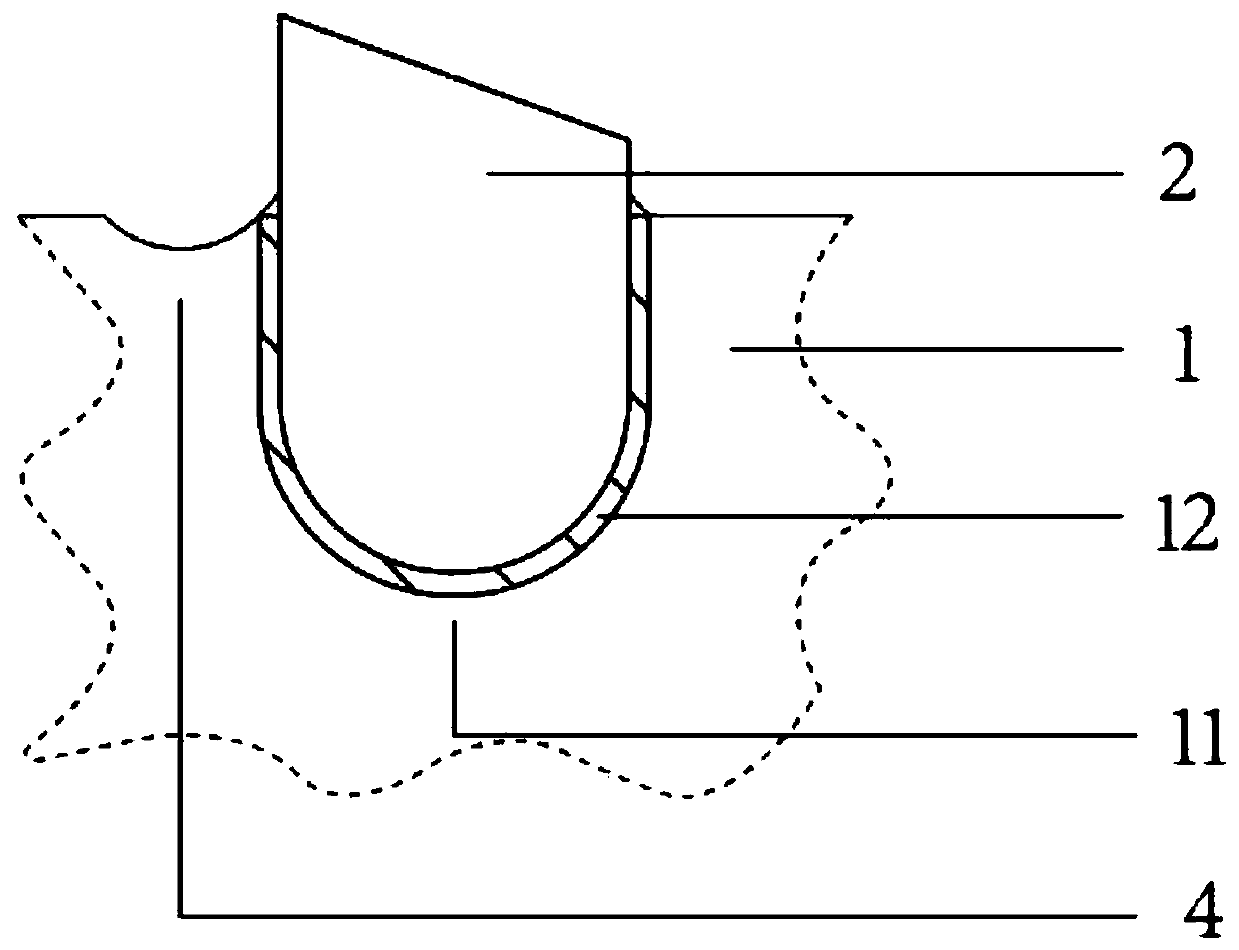

[0023] Embodiment 1: as Figure 1-2 A cemented carbide welded circular saw blade without a toothed structure is shown, including a saw blade base 1 , the saw blade base 11 is circular, has no toothed structure, and has a smooth outer edge;

[0024] A plurality of particle cutter heads 2 are arranged in order along the outer edge of the saw blade base 1, and each particle cutter head 2 can be sharpened as required.

[0025] The outer edge of the saw blade base 1 can be provided with an expansion groove 3;

[0026] The outer edge of the saw blade base 1 has a plurality of grooves as the foundation pit 11, the particle cutter head 2 is embedded in the foundation pit 11 and welded to the saw blade base 1 by brazing material, and the brazing filler metal welding part forms a Brazing material layer 12, the lower half of described particle cutter head 2 is embedded in foundation pit 11, improves the impact resistance of particle cutter head 2 structurally, has increased the brazing ...

Embodiment 2

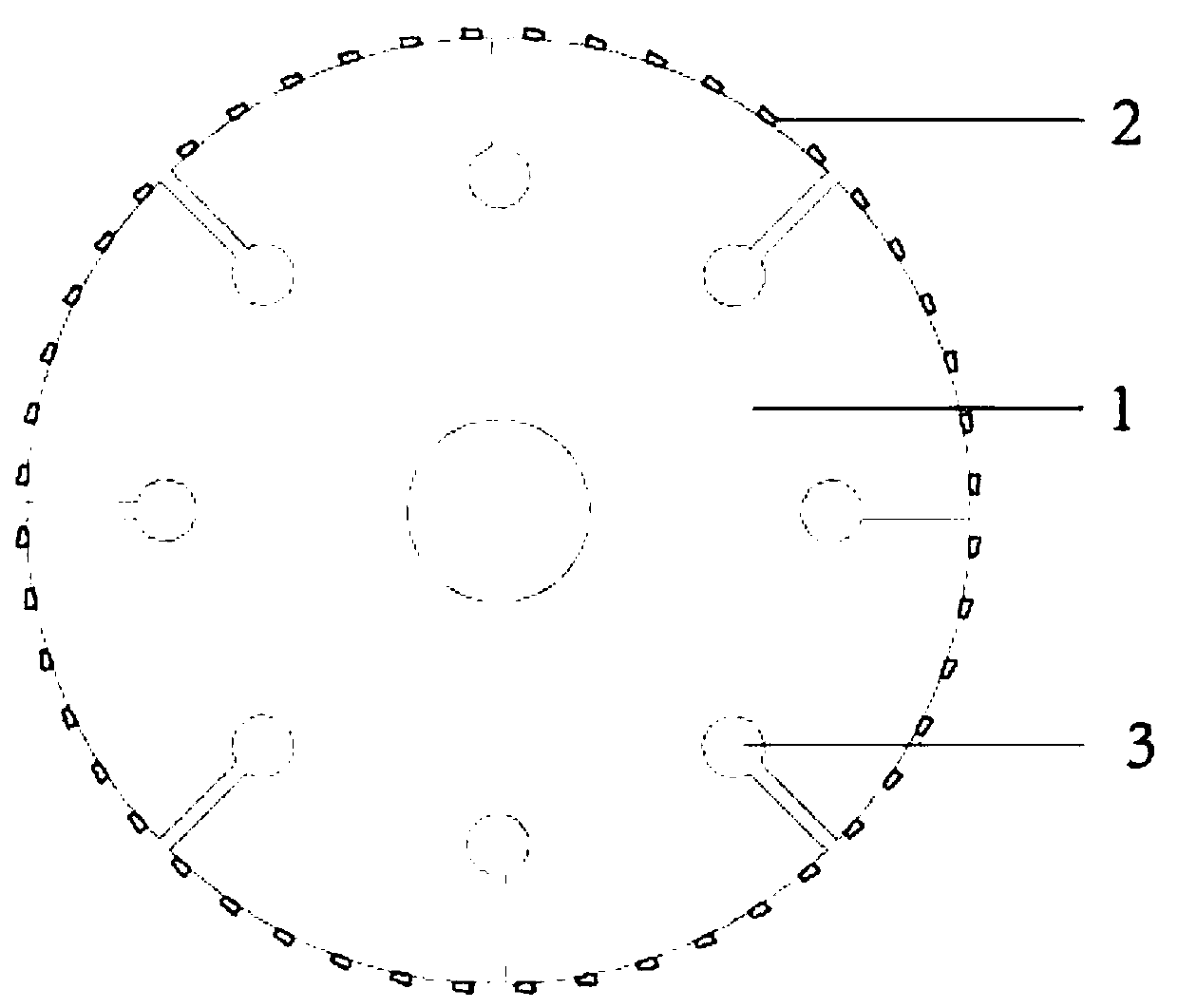

[0035] Embodiment 2: According to Figure 3-Figure 4 A cemented carbide welded circular saw blade without a toothed structure is shown, including a saw blade base 1 , the saw blade base 11 is circular, has no toothed structure, and has a smooth outer edge;

[0036] A plurality of particle cutter heads 2 are arranged in order along the outer edge of the saw blade base 1, and each particle cutter head 2 can be sharpened as required.

[0037] The outer edge of the saw blade base 1 can be provided with an expansion groove 3;

[0038] The particle cutter head 2 is welded and connected to the outer edge of the saw blade substrate 1 by means of solderless resistance butt welding, the bottom of the particle cutter head 2 is arc-shaped, and the welding position of the particle cutter head 2 is the melting point. Weld area 21.

[0039] The thickness of the saw blade base 1 is 0.5-2.5 mm, and the outer diameter of the saw blade base 1 is 50-400 mm.

[0040] The particle cutter head 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com