A double outer ring full ball bearing

A full-ball bearing, double outer ring technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problem of difficult filling of rolling elements in full-ball bearings, prevent external dust from entering, enhance sealing, and ensure diameter. effect on load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

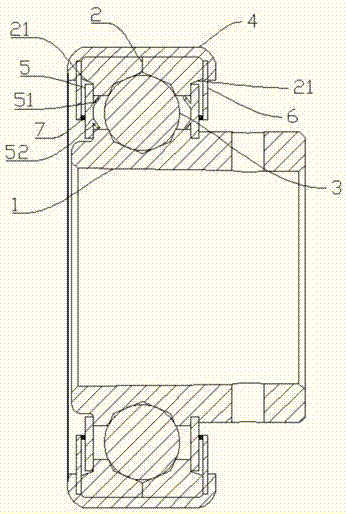

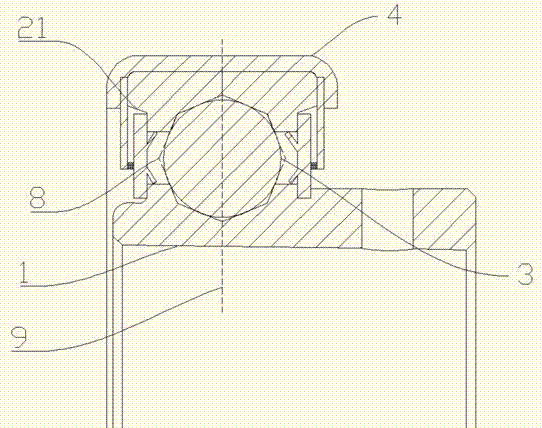

[0015] Embodiment 1: as figure 1 , figure 2 with image 3 As shown, a double outer ring full ball bearing includes an inner ring 1, a first outer ring 2 and balls 3, and the inner ring 1 and the first outer ring 2 are respectively provided with raceways.

[0016] In order to facilitate loading of balls, the first outer ring 2 is composed of two half outer rings 21 arranged symmetrically. The two outer ring halves 21 are clamped by the second outer ring 4 .

[0017] The overall section of the raceway is set according to a regular octagon 8, which is circumscribed on the circumference of the ball 3, and the contact between a longest diagonal 9 of the regular octagon 8 and the two half outer rings face overlap.

[0018] The corresponding positions of the inner ring 1 and the first outer ring 2 are provided with sealing grooves, and a rubber sealing ring 5 is provided in the sealing grooves, and the rubber sealing ring 5 is made of NBR.

[0019] On the outside of the rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com