Motor capable of directly driving rotating shaft

A rotary axis, direct technology, applied in the field of CNC machine tools, can solve problems such as the lack of positioning accuracy, and achieve the effect of small radial size, large torque and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

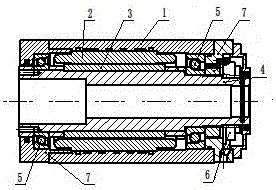

[0024] see figure 1 , the motor includes a motor casing 1, and the motor casing is provided with a motor stator 2, a motor rotor 3 and a hollow shaft 4 sequentially from outside to inside; the two ends of the hollow shaft pass through a screw bearing 5 respectively, and each screw bearing passes through the end The cover 7 is fixed with the hollow shaft, and the encoder 6 is fixed at one end of the hollow shaft.

[0025] The motor housing is cylindrical.

[0026] When in use, after the motor is energized, the rotor drives the hollow shaft to rotate, the hollow shaft is equipped with an encoder, the encoder rotates, and the reading head outputs measurement signals. The motor drive system controls the precise movement of the motor based on the measured feedback signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com