Double-row self-aligning roller bearing

一种滚子轴承、自调心的技术,应用在滚子轴承、滚动接触轴承、轴承等方向,能够解决磨耗、滚动寿命短、接触面压变大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

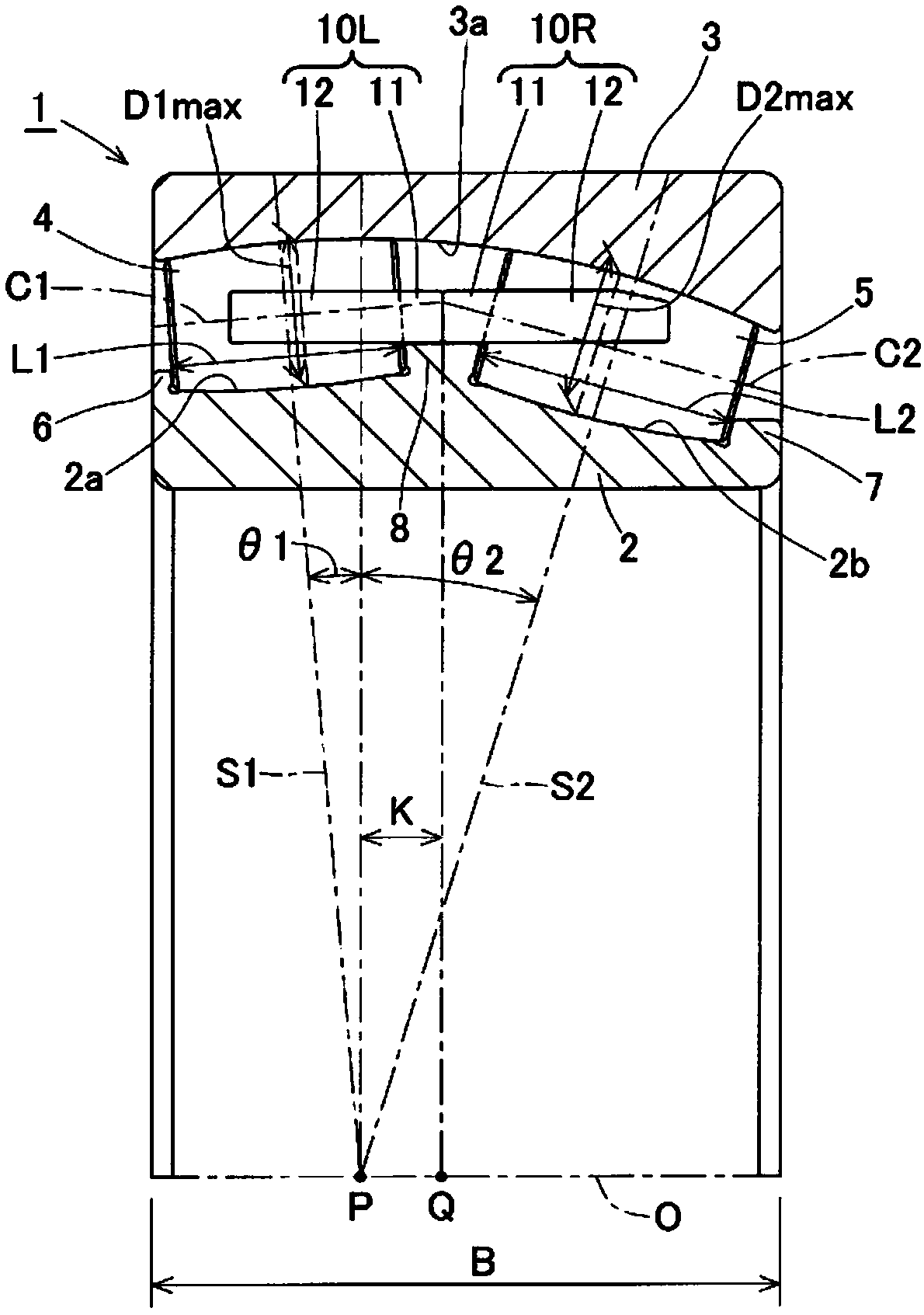

[0058] combine figure 1 , the first embodiment of the present invention will be described. In this double-row self-aligning roller bearing 1, two rows of left and right rollers 4 and 5 are interposed between the inner ring 2 and the outer ring 3 in the bearing width direction. The raceway surface 3 a of the outer ring 3 has a spherical shape, and the outer peripheral surfaces of the left and right rows of rollers 4 and 5 have a cross-sectional shape along the raceway surface 3 a of the outer ring 3 . In other words, among the outer peripheral surfaces of the rollers 4, 5, arcs along the raceway surface 3a of the outer ring 3 are curved surfaces of revolution around the centerlines C1, C2. Two rows of raceway surfaces 2 a , 2 b are formed on the inner ring 2 along the cross-sectional shape of the outer peripheral surfaces of the left and right rows of rollers 4 , 5 . Flanges (small flanges) 6 and 7 are respectively provided at both ends of the outer peripheral surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com