A water-lubricated thrust bearing assembly

A technology of thrust bearings and water lubrication, which is applied to pump components, parts of pumping devices for elastic fluids, non-variable pumps, etc., and can solve submersible pump failures, high motor rotor temperature, and wear-resistant rubber layers Loose and other problems, to achieve the effect of strong axial bearing capacity, good corrosion resistance, and strong anti-wear ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

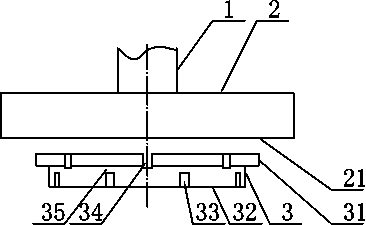

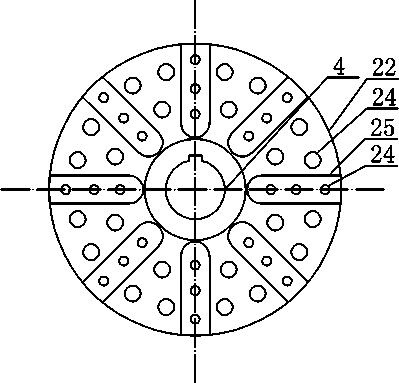

[0021] Such as figure 1 As shown, the water-lubricated thrust bearing assembly of the present invention includes a thrust plate 2 and a stainless steel thrust plate 3, and a fan ring friction block 31 matching with the friction surface of the thrust plate is provided on the thrust plate, and a Motor shaft 1 mounting hole 4.

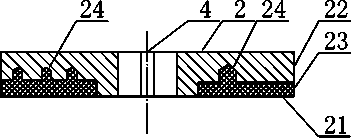

[0022] Such as figure 2 As shown, the thrust plate 2 includes a hard metal base 22, and the annular end surface of the metal base on the side in contact with the annular friction block of the thrust plate fan is covered with a non-metallic wear-resistant layer 23, and a stainless steel thrust plate is formed on the metal base. The non-metallic friction-resistant annular end face 21 of disc friction fit, the non-metallic wear-resistant layer is a carbon fiber modified polyphenylene sulfide wear-resistant layer, and the carbon fiber modified polyphenylene sulfide is combined on the metal substrate by high-temperature injection molding, and the carbon fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com