Parallel flexible mechanism for precise assembly

A flexible mechanism, parallel technology, applied in manipulators, program-controlled manipulators, comprehensive factory control, etc., can solve problems such as the influence of passive compliant mechanism on compliance performance, unsuitable parts for light-load high-speed assembly, assembly inertial force assembly instability, etc. The effect of strong axial bearing capacity, low production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

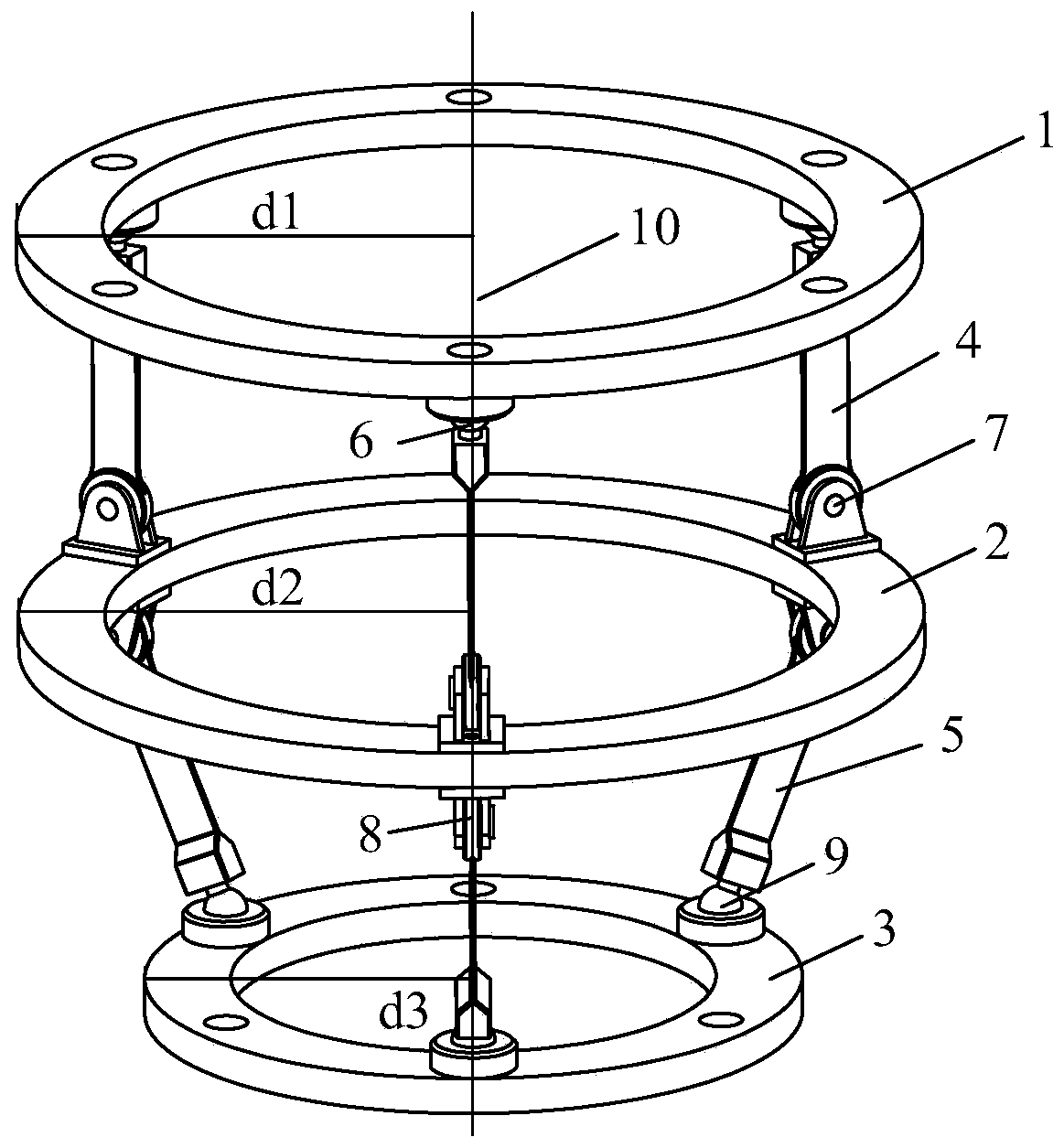

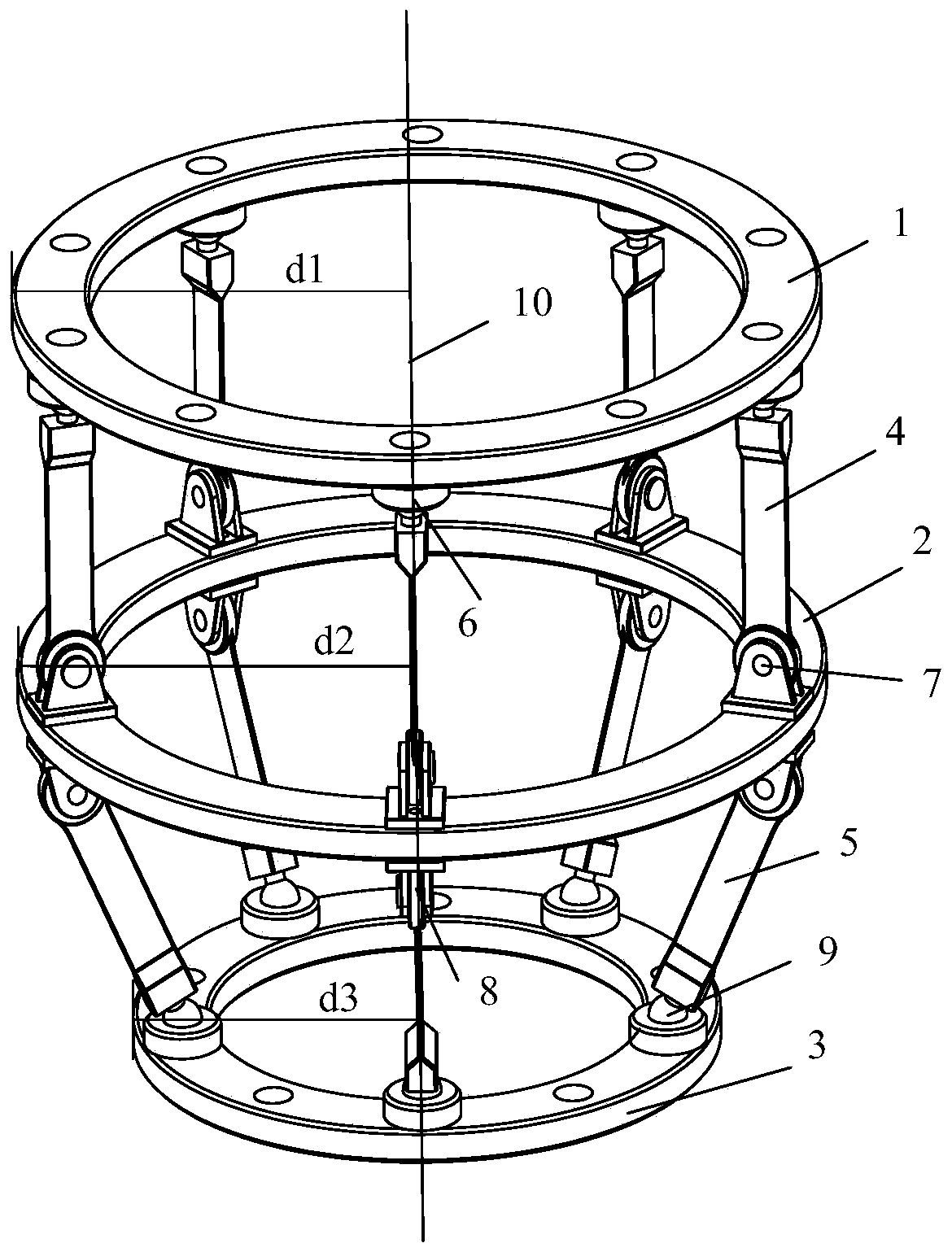

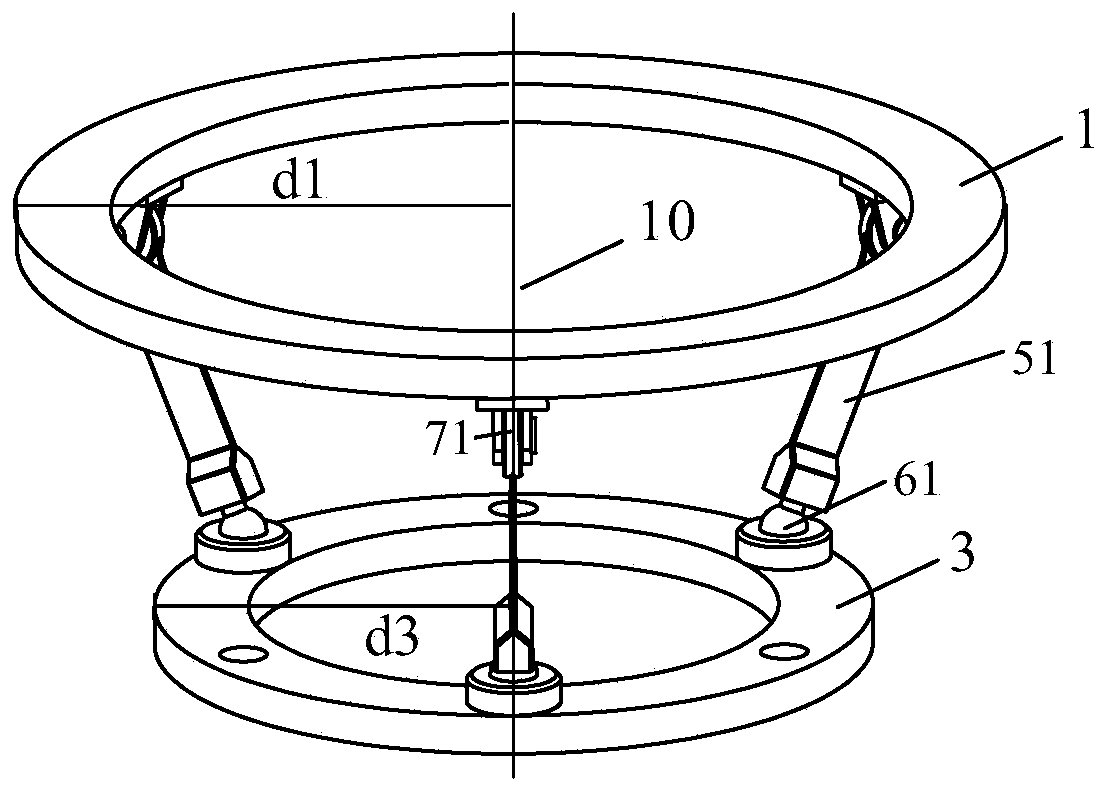

[0025] like figure 1 As shown, the present invention proposes a parallel flexible mechanism for precision assembly, including an upper platform 1, a lower platform 3 and an intermediate platform 2 arranged coaxially, and a Several first flexible branch chains 4, and several second flexible branch chains are provided between the middle platform 2 and the lower platform 3. The numbers of the first flexible branch chain 4 and the second flexible branch chain 5 are both N, N≥3, figure 1 Shown is a flexible mechanism with three first flexible branches 4 and three second flexible branches 5 .

[0026] Several first flexible branch chains 4 are evenly distributed circumferentially between the upper platform 1 and the middle platform 2, and have the same size and structure; one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com