A kind of preparation method of composite reinforced metal foam sandwich panel

A foam metal and sandwich panel technology, applied in the direction of chemical instruments and methods, metal layered products, synthetic resin layered products, etc., can solve the problems of high cost and unsatisfactory effect, and achieve low processing and manufacturing costs and comprehensive mechanics The effect of excellent performance and simple composite strengthening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

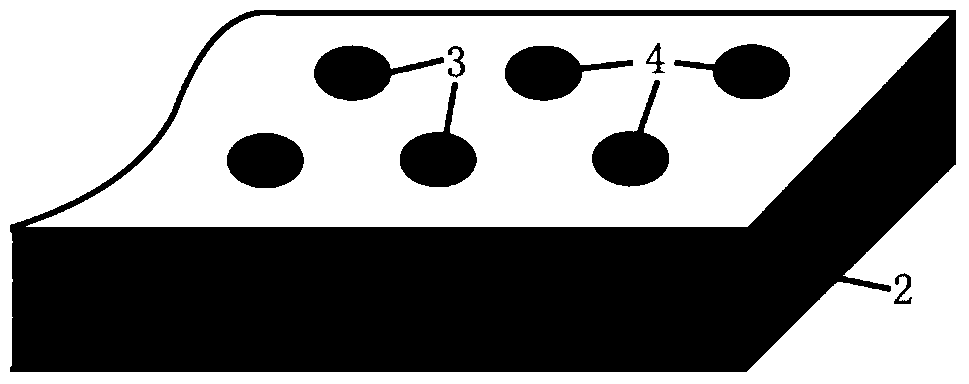

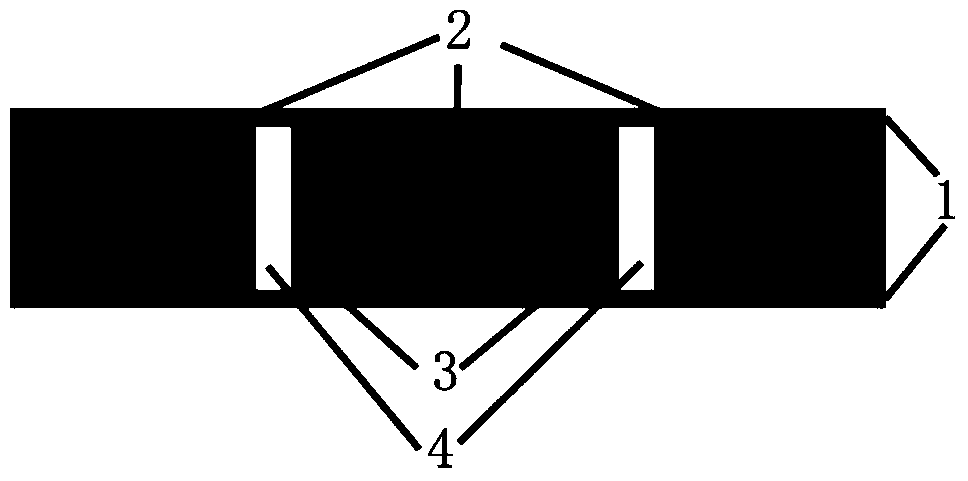

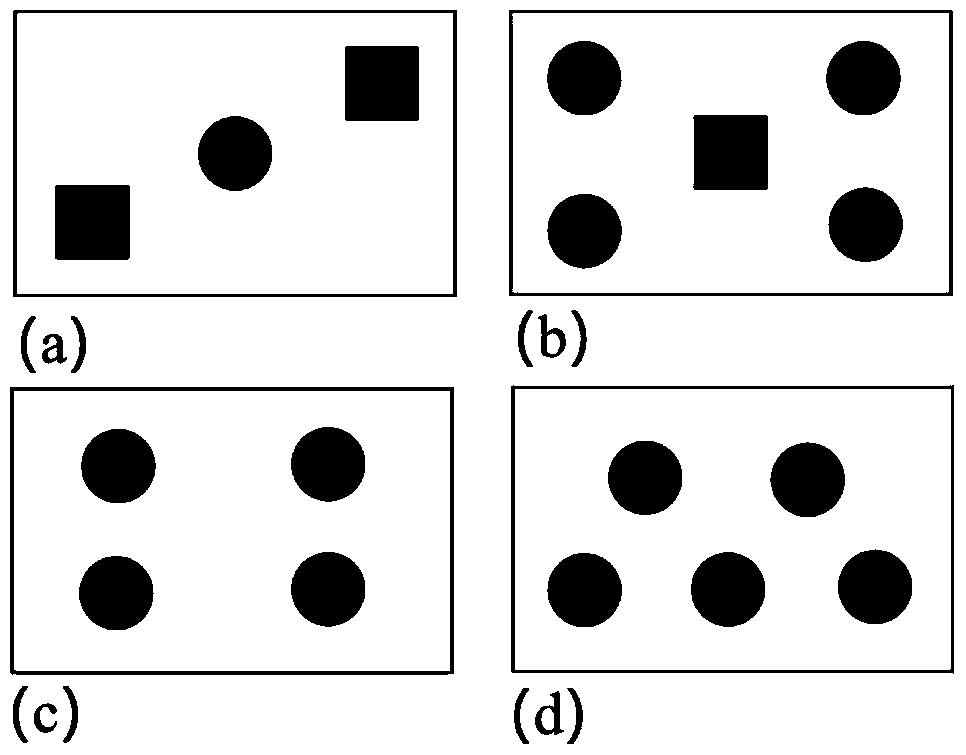

[0026] Embodiment 1: 1) Processing of metal foam. First, the closed-cell foamed aluminum is processed into the required core structure by cutting machine or wire cutting according to the size of the core body of the sandwich panel, and then a series of through-hole structures are processed along the thickness direction by means of drilling or wire cutting. The size of the hole is consistent with the cross-sectional size of the pipe fitting structure, and an appropriate gap can be left. The size of the gap is less than 0.1mm. The number and distribution are determined according to specific needs. Generally, it is an array structure arranged in a certain order, such as figure 1 and image 3 shown. Among them, the metal foam is closed-cell aluminum foam with a density of 0.54-0.81g / cm 3 , The porosity is 70-80%.

[0027] 2) For the processing of reinforced metal pipe fittings and panels. The metal 304 stainless steel round tube is processed into a short tube with the same siz...

Embodiment 2

[0029] Embodiment 2: 1) Processing of metal foam core. First, the closed-cell foamed aluminum is processed into the required core structure by cutting machine or wire cutting according to the size of the core body of the sandwich panel, and then a series of through-hole structures are processed along the thickness direction by means of drilling or wire cutting. The size of the hole is consistent with the cross-sectional size of the pipe fitting structure, and an appropriate gap can be left. The size of the gap is less than 0.1mm. The number and distribution are determined according to specific needs. Generally, it is an array structure arranged in a certain order, such as figure 1 and image 3 shown. Among them, the metal foam is closed-cell aluminum foam with a density of 0.1-0.54g / cm 3 , The porosity is 80-95%.

[0030] 2) For the processing of reinforced metal pipe fittings and panels. The 2024 aluminum alloy round tube is processed into a short tube with the same size ...

Embodiment 3

[0032] Embodiment 3: 1) Processing of metal foam core. First, the open-cell foam copper is processed into the required core structure by cutting machine or wire cutting according to the core size of the sandwich panel, and then a series of through-hole structures are processed along the thickness direction by means of drilling or wire cutting. The size of the hole is consistent with the cross-sectional size of the pipe fitting structure, and an appropriate gap can be left. The size of the gap is less than 0.1mm. The number and distribution are determined according to specific needs. Generally, it is an array structure arranged in a certain order, such as figure 1 and image 3 shown. Among them, the metal foam is copper foam with open cells, the average pore diameter is 2.27mm, and the porosity is 95%.

[0033] 2) For the processing of reinforced metal pipe fittings and panels. The metal 304 stainless steel round tube is processed into a short tube with the same size as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com