A convenient and stable thread structure

A thread and external thread technology, applied in the field of convenient and stable thread structure, can solve the problems of long meshing time, weak ability to bear axial force, instability, etc., and achieve the effect of short meshing time and strong axial bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

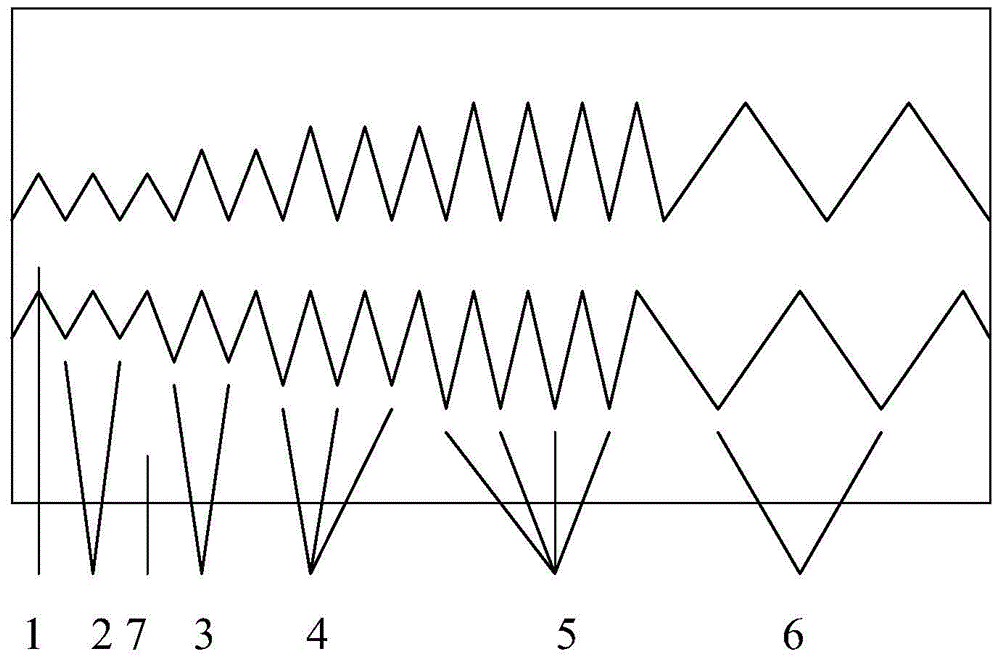

[0023] like Figure 1 As shown, a convenient and stable thread structure is applied to the complete thread part of the external thread and the internal thread, which includes external thread 1, internal thread 7 and thread 2, thread 3, thread 4, thread 5, thread 6. The thread height of thread 2 is slightly less than the thread height of thread 3, the thread height of thread 3 is slightly less than the thread height of thread 4, the thread height of thread 4 is slightly less than the thread height of thread 5, the thread height of thread 5 is equal to the thread height of thread 6 . At the same time, the thread 2, thread 3, thread 4, thread 5, and thread 6 can adopt any thread type and thread thickness respectively. Thread 2, thread 3, thread 4, thread 5 are variable pitch threads, and thread 6 is equal pitch thread. The problem of rotation progress caused by different tooth thickness and tooth shape is solved by the difference of variable pitch thread and number of teeth.

...

Embodiment 2

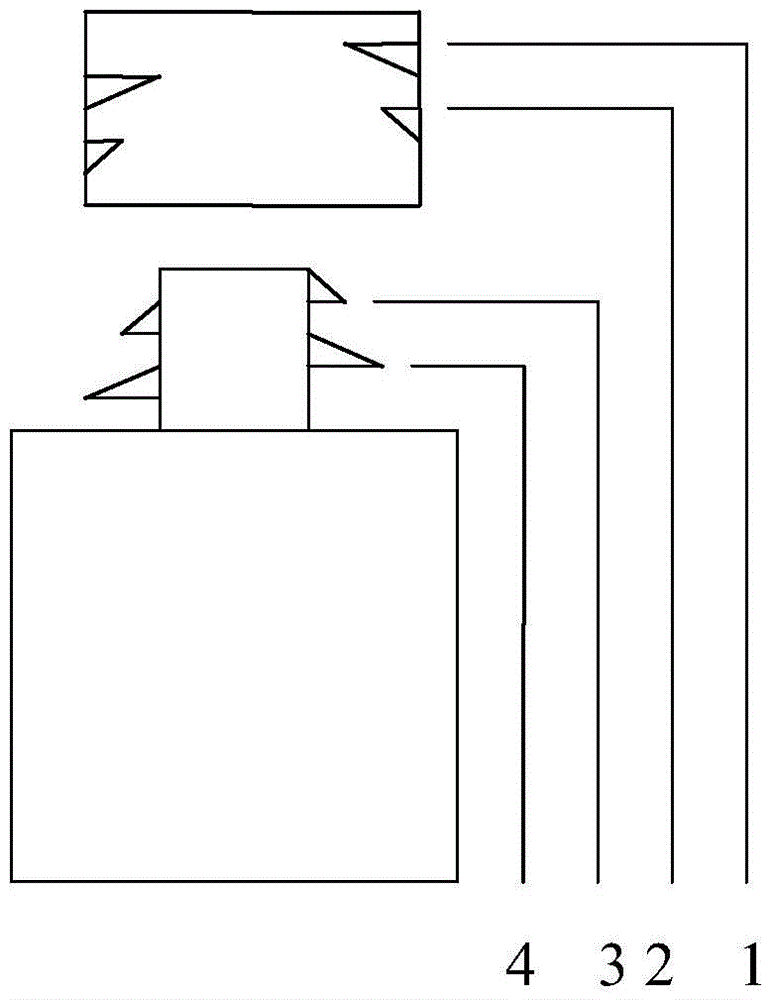

[0026] like Figure II As shown, a convenient and stable thread structure is applied to the bottle caps of mineral water and beverages. It includes internal thread 1, internal thread 2 and external thread 3, external thread 4. The tooth height of the internal thread 1 is slightly larger than that of the internal thread 2, and the tooth height of the external thread 4 is slightly larger than that of the external thread 3. Its internal thread is integrally matched with the teeth of the complete thread on the external thread. The tooth shape of the inner thread 1, the inner thread 2, the outer thread 3, and the outer thread 4 can be the thread shape of the ordinary mineral water and beverage bottle caps.

[0027] When using, press the bottle cap into the bottle mouth, and then rotate 90°~180° to tighten.

Embodiment 3

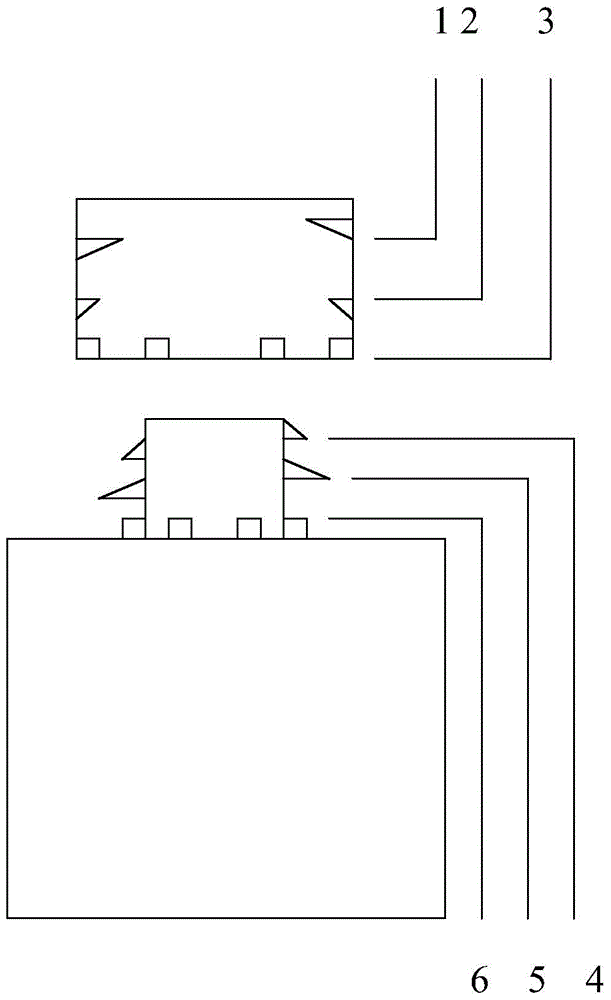

[0029] like Figure 3 As shown, a convenient and stable thread structure is applied to the bottle caps of mineral water and beverages. It includes internal thread 1, internal thread 2, internal thread snap 3 and external thread 4, external thread 5, and external thread snap 6. The tooth height of the internal thread 1 is slightly larger than that of the internal thread 2, and the tooth height of the external thread 4 is slightly larger than that of the external thread 3. Its internal thread is integrally matched with the teeth of the complete thread on the external thread. After the meshing is completed, the inner thread is locked with the buckle on the outer thread. The tooth shape of the inner thread 1, the inner thread 2, the outer thread 4, and the outer thread 5 can be the thread shape of the ordinary mineral water and beverage bottle caps.

[0030] When in use, press the bottle cap into the bottle mouth, then rotate 90°~180° to tighten, and at the same time make the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com