Straight-line servo driver and robot

A servo driver and linear technology, applied in the direction of electromechanical devices, electric components, control mechanical energy, etc., can solve the problems of large space occupied by the servo driver, many internal components of the weight of the linear servo motor, and low transmission efficiency, so as to improve the transmission efficiency, The effect of improving detection efficiency and accuracy and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

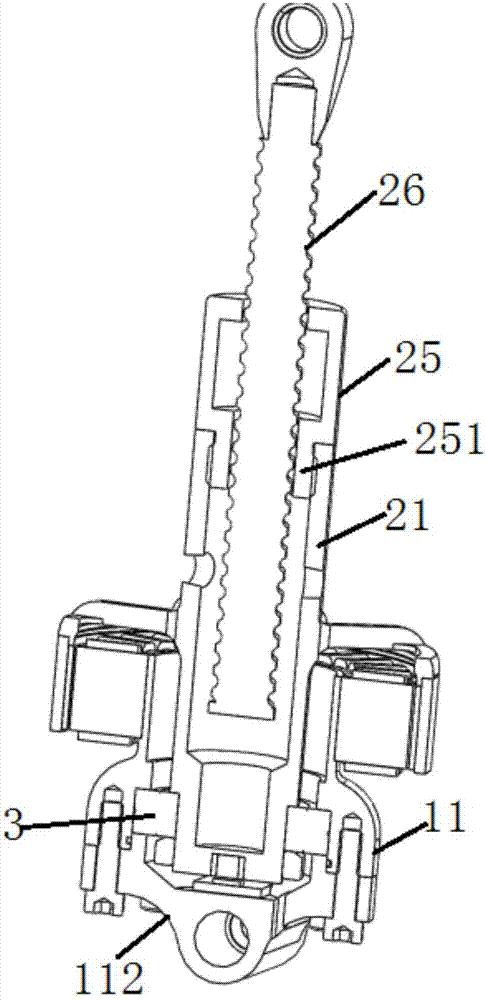

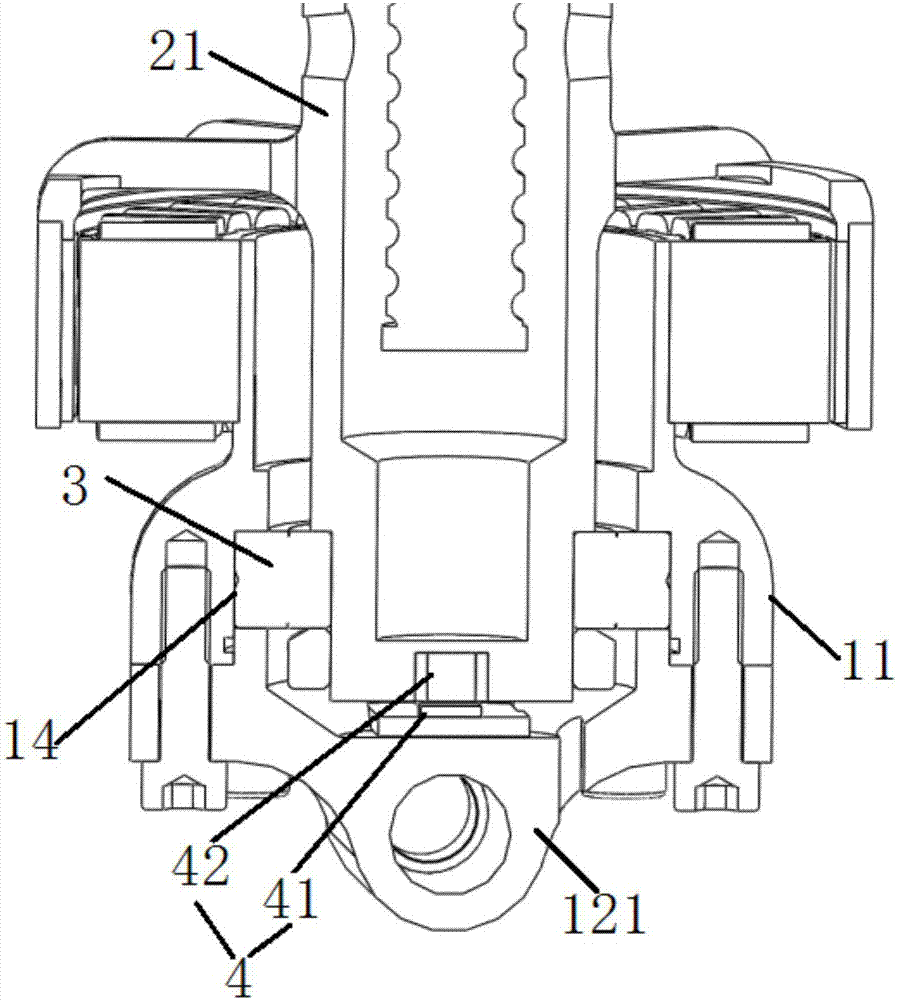

[0068] This embodiment provides a linear servo driver, such as figure 1 and figure 2 As shown, it includes a stator assembly 1 , a rotor assembly 2 , a detection assembly 4 and a bearing 3 .

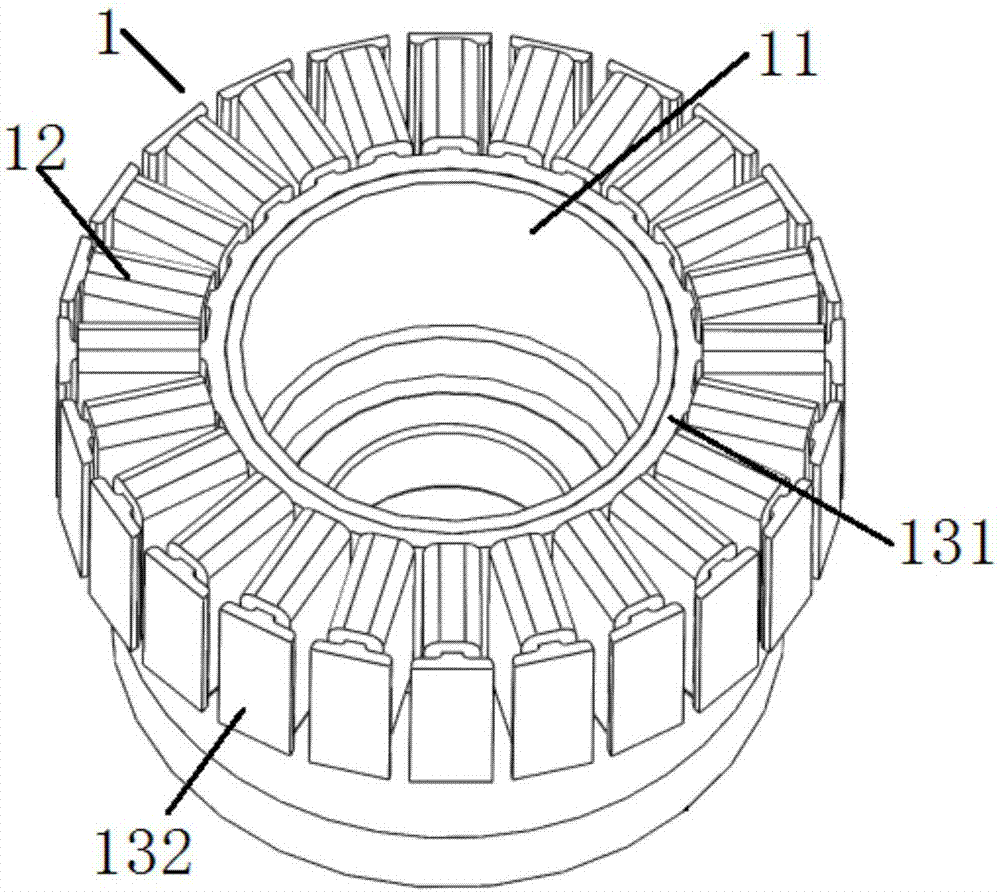

[0069] like image 3 , Figure 4 and Figure 7 As shown, the stator assembly 1 includes a first housing 11 , a coil 12 and a soft magnet 13 . The first housing 11 includes a cover body 111 with a first inner cavity and an end cover 112 . The two ends of the cover body 111 are respectively provided with a first opening and a second opening for connecting the first inner cavity with the outside world. The end cover 112 Removably secured to the second opening, for example with a screw or bolt assembly. The end cover 112 forms a fixed end at the second opening of the first housing 11 , and the end cover 112 is detachably arranged to facilitate the installation or removal of components located in the first inner cavity.

[0070] like image 3 and Figure 4 As shown, the soft magnetic...

Embodiment 2

[0086] This embodiment provides a linear servo driver. Compared with the driver provided in Embodiment 1, the differences are:

[0087] In addition to the magnetic sensing element 41 and the second permanent magnet 42 in Embodiment 1, the detection assembly 4 can also be of other structures. For example, the detection component 4 is replaced by a photoelectric encoder, the second permanent magnet 42 is replaced by a code disc, and the magnetic sensitive element 41 is replaced by a photosensitive element. At this time, the photosensitive element illuminates the code disc with light, and the light passes through the code disc and is reflected back to the photosensitive element. , the photosensitive element detects the change in the intensity of the light absorbed by the code disc, thereby detecting the rotation angle or speed of the second casing 21 relative to the first casing 11 . Alternatively, the detection component 4 can also be replaced by other types of encoders. It onl...

Embodiment 3

[0089] This embodiment provides a linear servo driver. Compared with the driver provided in Embodiment 1 or Embodiment 2, the difference is that the lead screw nut 25 is not provided with an annular flange 251, but only includes a nut body. The orientation of the nut body is The end surface of the end cover 112 is directly fixed on the first opening of the second housing 21, for example, by using screws or bolts, or other fasteners. Alternatively, the lead screw nut 25 can be replaced with an existing flange, the flange is sleeved and rotatably matched with the lead screw, and the flange is fixed on the end face of the first housing 11 where the first opening is located, Through the rotational cooperation between the flange plate and the lead screw 26, when the flange plate rotates, the lead screw 26 moves linearly.

[0090] As an alternative embodiment, the rotor assembly 2 may not be provided with the above-mentioned lead screw nut 25 or flange, and the inner wall surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com