Pressed cage, self-aligning roller bearing, and method of manufacturing pressed cage

A manufacturing method and cage technology, applied in the direction of roller bearings, rolling contact bearings, rotating bearings, etc., can solve problems such as the deviation of the bending degree of the connection part, and achieve the effect of excellent precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

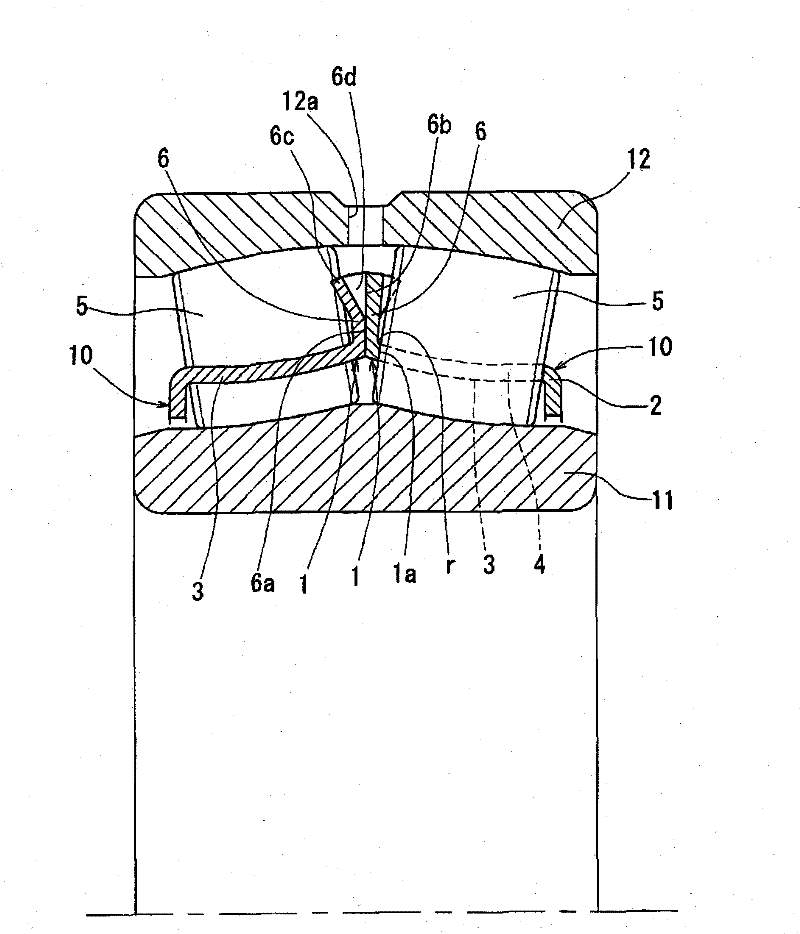

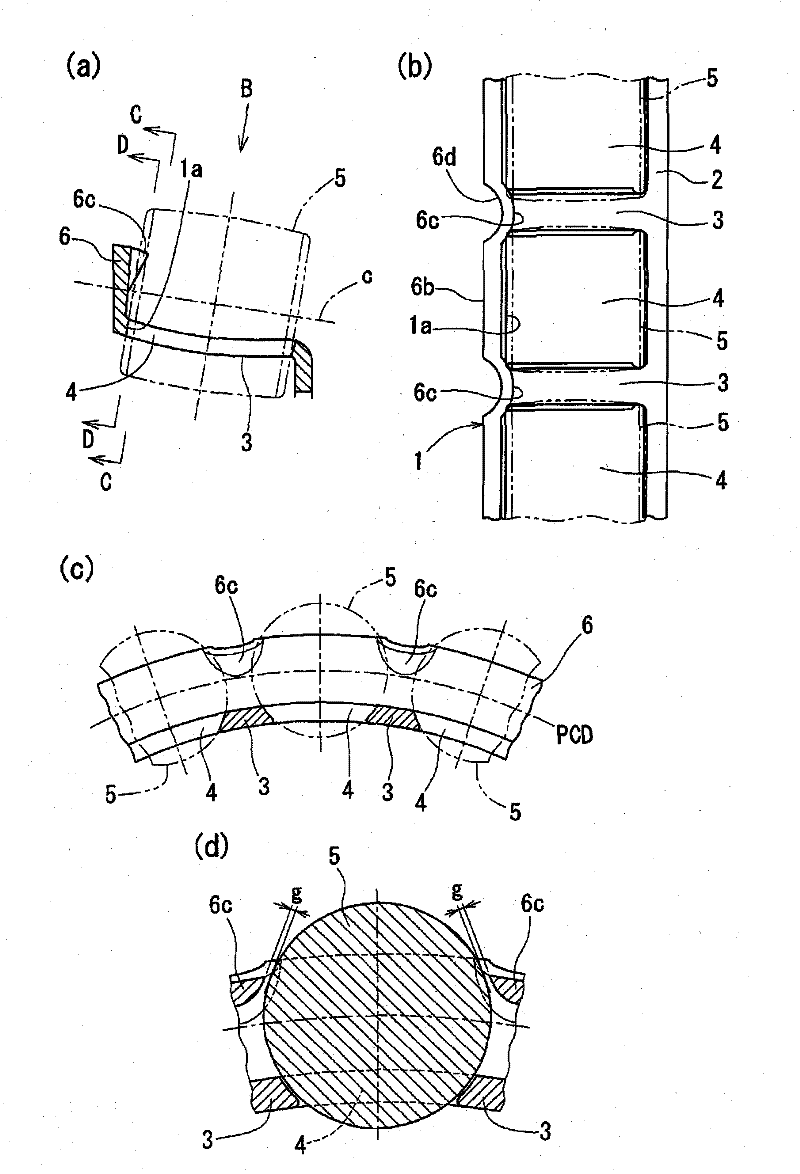

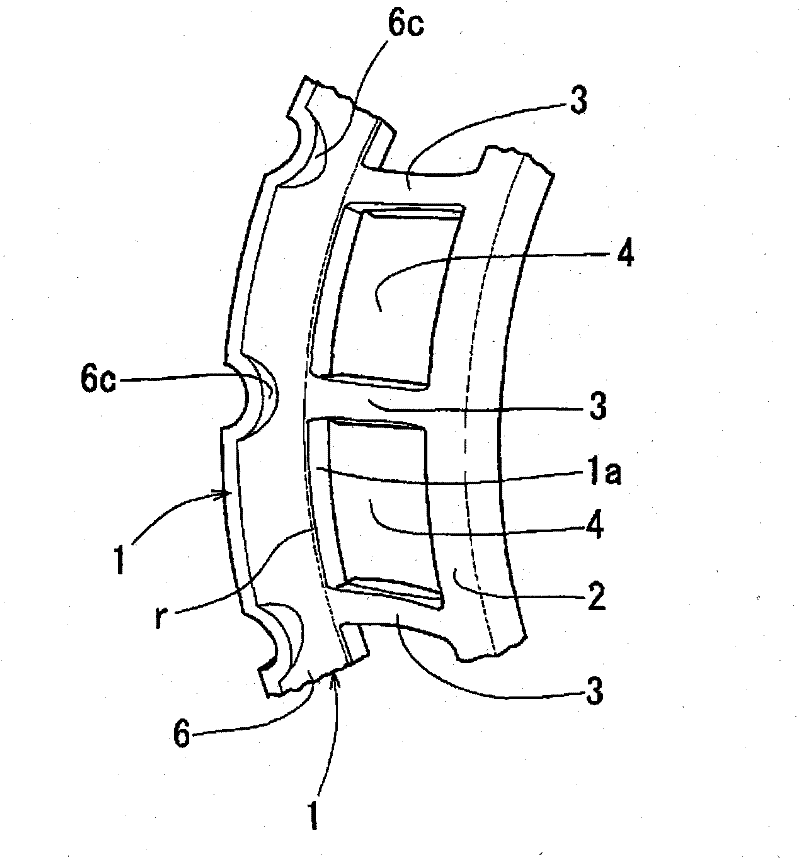

Method used

Image

Examples

reference example 1

[0160] In the stamped cage according to Reference Example 1, bottom expansion was not performed. The above-mentioned pressed cage can be arranged concentrically with the inner ring 431 so that each pocket 423 is located on the raceway surface 432 of the inner ring 431 . By pressing the rollers 421 into the pockets 423 with each pocket 423 disposed on the raceway surface 432, the flange 424 pressed by one end surface of the roller 421 falls so that the other end surface of the roller 421 enters the pocket. The hole 423 and the roller 421 are located between the two ribs 433 , 434 . In this state, the roller 421 is surrounded by the two posts 425, 425, the two retaining parts 426, 426, the raceway surface 432 of the inner ring 431, and the two ribs 433, 434. The cage, rollers 421, and inner ring 431 are integrated. Therefore, the inner ring assembly can be assembled by performing the press-fitting operation of the rollers 421 into all the pockets 423 .

[0161] As described a...

reference example 4

[0169] Reference Example 4 does not form a simple second flange like Reference Example 3, but forms the same two second anti-off portions 473, 473 as the anti-off portion 474. Therefore, even if the above-mentioned invalidation occurs, there is no problem. It is possible to more reliably prevent the roller 421 from falling out.

[0170] The press cage according to Reference Example 4 is provided with a roller guide system that guides in the radial direction by sliding contact between the columns 476 and the rolling surfaces of the rollers 421 . In the roller guide system, there is a high possibility that the roller 421 will run aground on the column 476 due to abnormal operation. If the anti-slip portion 473 is added as in Reference Example 4, the outer peripheral portion of the roller 421 can be supported by the two anti-slip portions 474, 474 and the two second anti-slip portions 473, 473. It is also possible to reliably maintain the circumferential division of the rollers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com