Spherical roller bearing solid cage center-diameter and angle measuring method

A solid cage, spherical roller technology, applied in the direction of angle/taper measurement, mechanical diameter measurement, etc., can solve the problems of the roller is not easy to fix, the angle is inaccurate, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

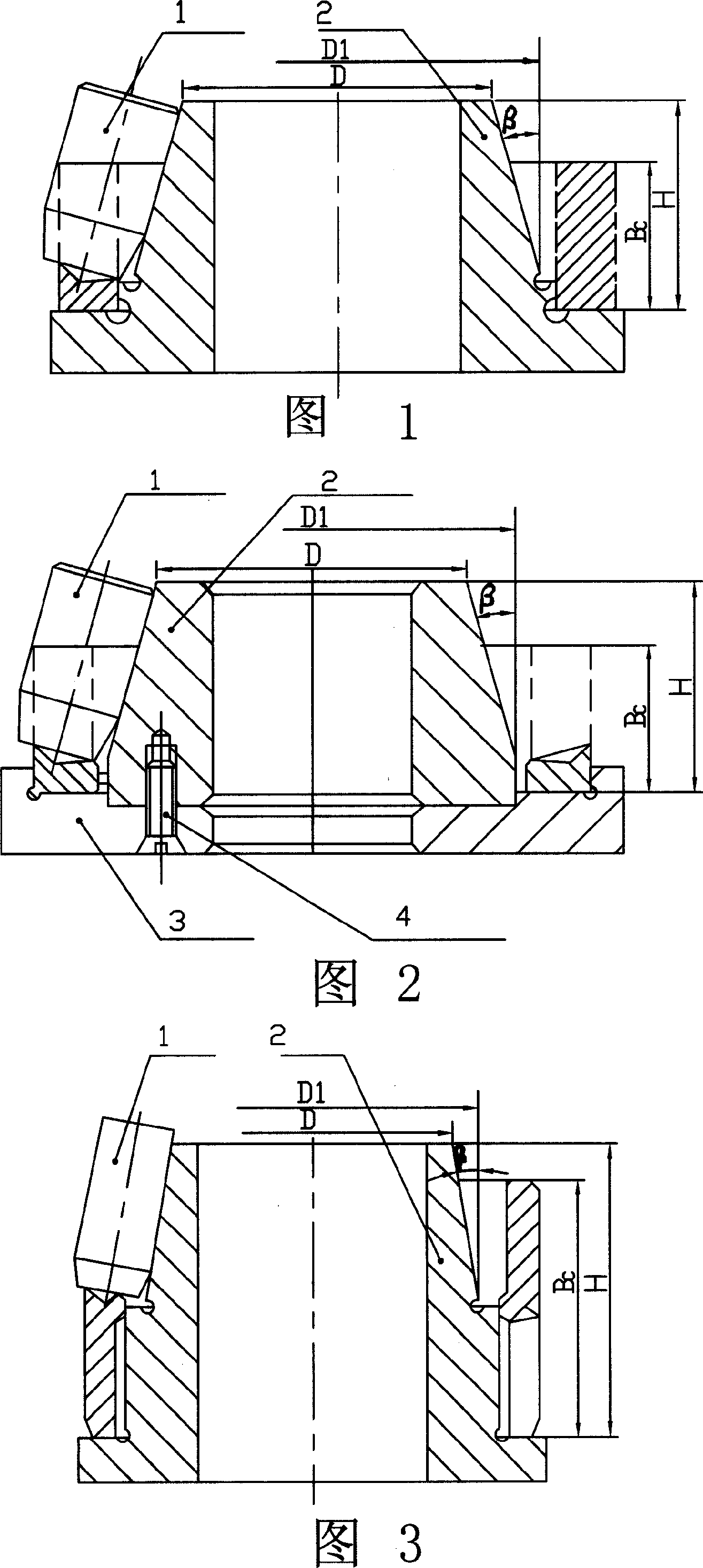

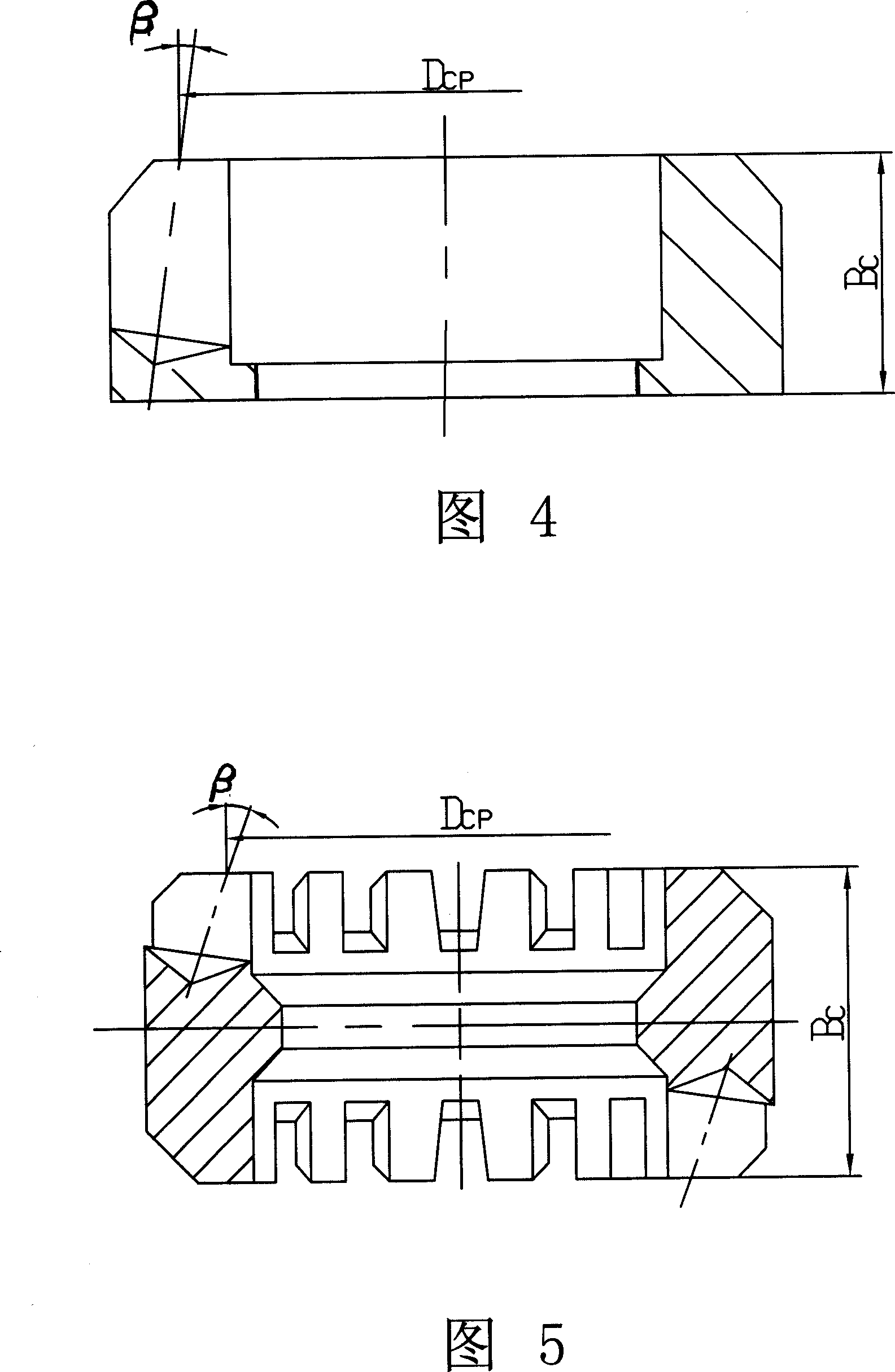

[0016] A method for measuring the central diameter and angle of a solid cage of a spherical roller bearing, characterized in that the method includes the following steps: firstly process and manufacture a central measuring die, the central measuring die is a conical measuring die body 2 and a roller 1, and the central measuring die is The diameter of the roller in the measuring mold is the minimum value of the measured pocket. The upper difference of the diameter tolerance is 0, the lower difference is -0.01mm, and the angle tolerance is ±3′. -0.3mm; the measuring die body 2 in the central measuring die is conical, and the diameter of its small head is D, which is passed by the formula D=D cp -d / Cosβ-2×a×tgβ can be obtained, the diameter of the big head is D1, which can be obtained by the formula D1=D+2×B C ×tgβ can be obtained, the cone height of the cone is H, which is passed by the formula H=B C +a can be obtained, where: Dcp is the center diameter of the product drawing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com