Oil-based drilling fluid lubricant and preparation method thereof

An oil-based drilling fluid and lubricant technology, applied in the field of oil drilling, can solve the problems of drilling fluid foaming, ignoring the adhesion and lubrication properties of mud cakes, and poor temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

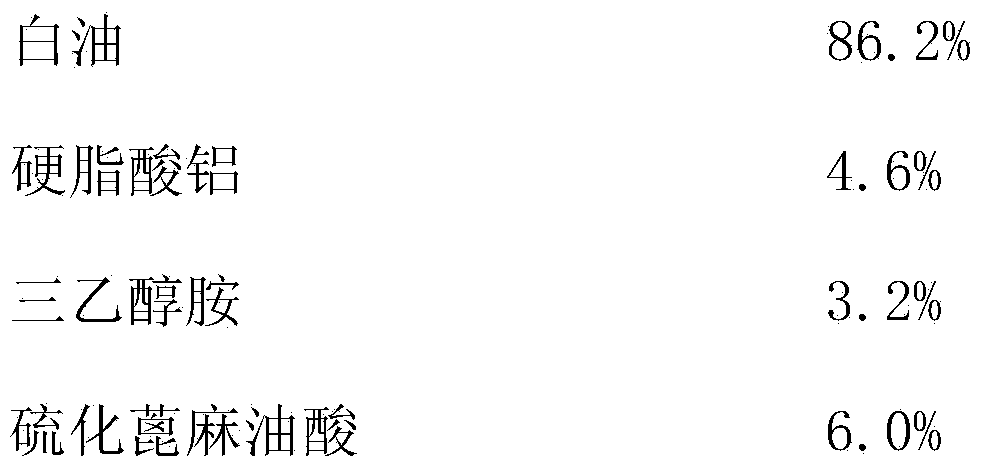

Embodiment 1

[0022] Mix the reaction raw materials according to the following components and mass percentages, heat and stir at 120°C until the solids are completely dissolved, and cool to room temperature to obtain the oil-based drilling fluid lubricant of the present invention.

[0023] White oil 86.2%

[0024] Aluminum stearate 4.6%

[0025] Triethanolamine Sulfurized Ricinoleate 9.2%

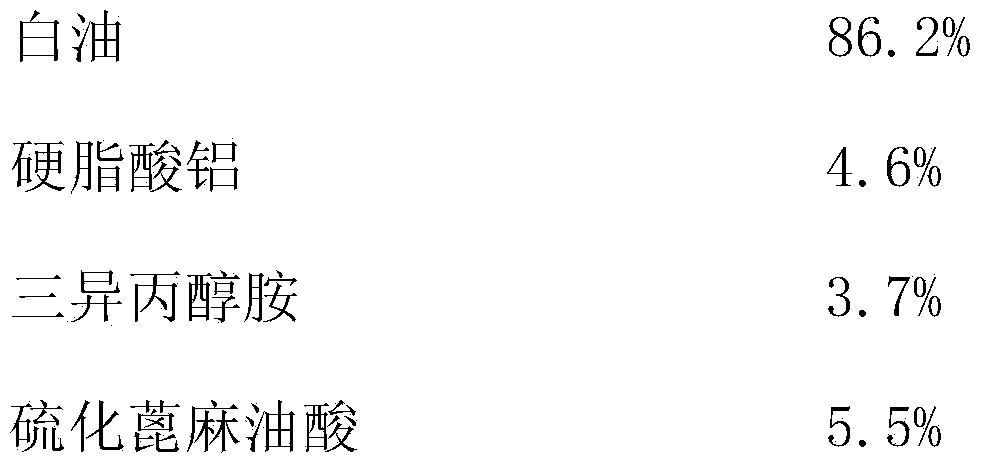

Embodiment 2

[0027] Mix the reaction raw materials according to the following components and mass percentages, heat and stir at 80°C until the solids are completely dissolved, and cool to room temperature to obtain the oil-based drilling fluid lubricant of the present invention.

[0028]

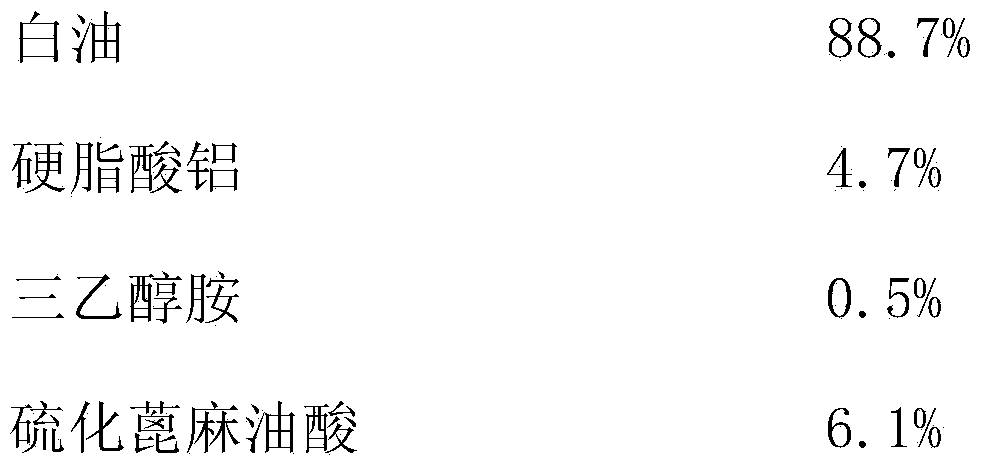

Embodiment 3

[0030] Mix the reaction raw materials according to the following components and mass percentages, heat and stir at 150°C until the solids are completely dissolved, and cool to room temperature to obtain the oil-based drilling fluid lubricant of the present invention.

[0031] White oil 86.2%

[0032] Aluminum stearate 4.6%

[0033] Triisopropanolamine Sulfurized Ricinoleate 9.2%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com