Integrated water lubrication bearing for thruster with hub flange

A water-lubricated bearing, integrated technology, applied in the direction of rotary propeller, propulsion power transmission, ship propulsion, etc., can solve the problems of reducing the bearing capacity of the thrust plate, poor lubrication and cooling performance, and shortening the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

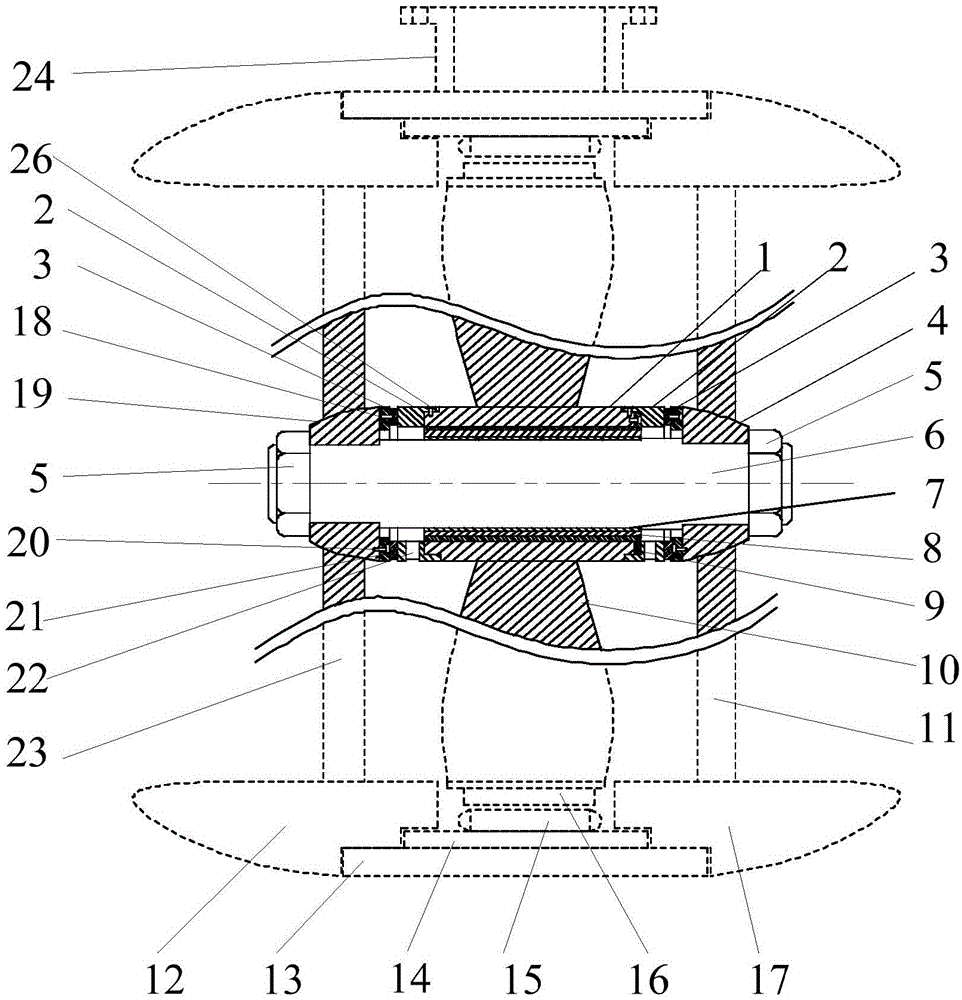

[0032] The integrated water-lubricated bearing used for hub rim propeller provided by the present invention has a structure such as figure 1 As shown, it is mainly composed of a thrust plate 2, a support ring 3, a shaft sleeve 7, a rubber slat 8, a propeller hub copper sleeve 9 and a thrust shoe 21. Among them: the propeller hub copper sleeve 9 is installed in the propeller hub from the front end of the propeller hub 1, there is a blind hole 25 on the front end surface of the propeller hub, and the end flange of the propeller hub copper sleeve 9 has a counterbore 28, which is used to prevent the propeller The locking bolt of the hub copper sleeve is higher than the flange surface to ensure the flatness of the flange end surface, so that the thrust disc 2 can be completely attached to the flange after it is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com