Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Overcome centrifugal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

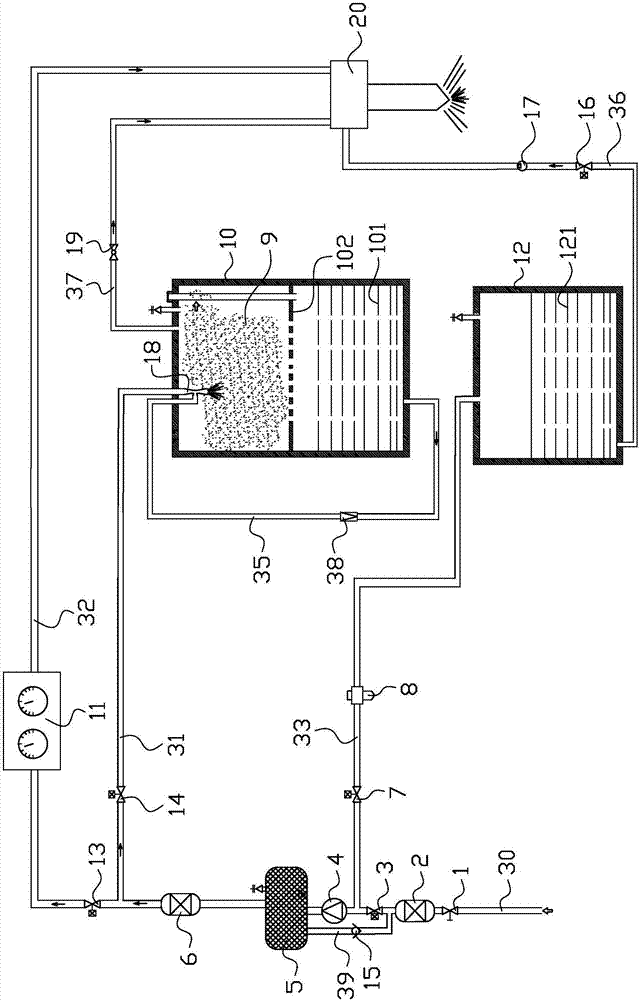

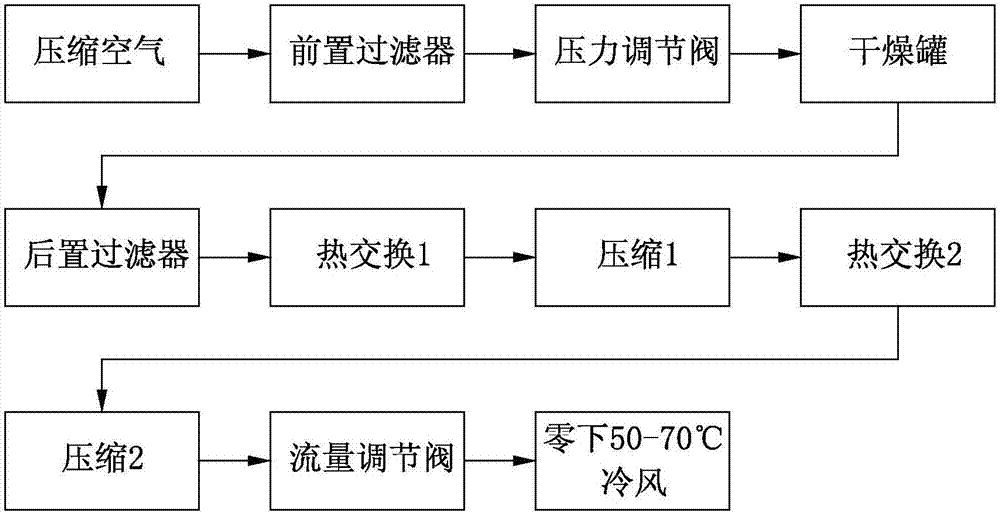

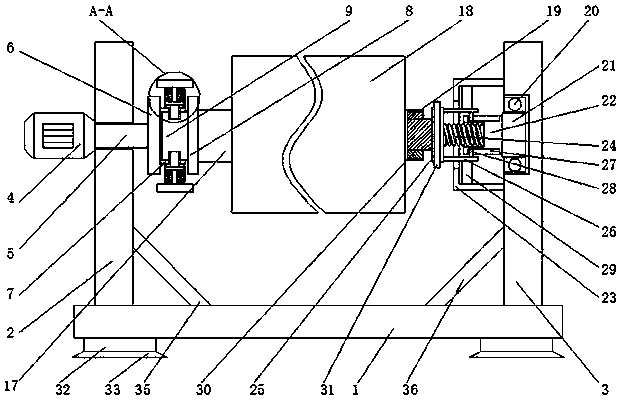

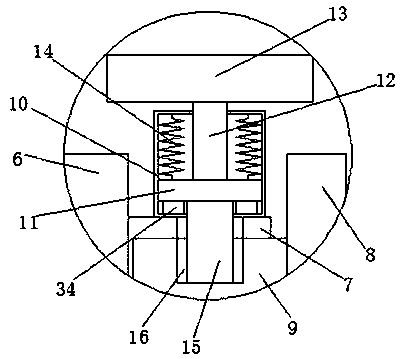

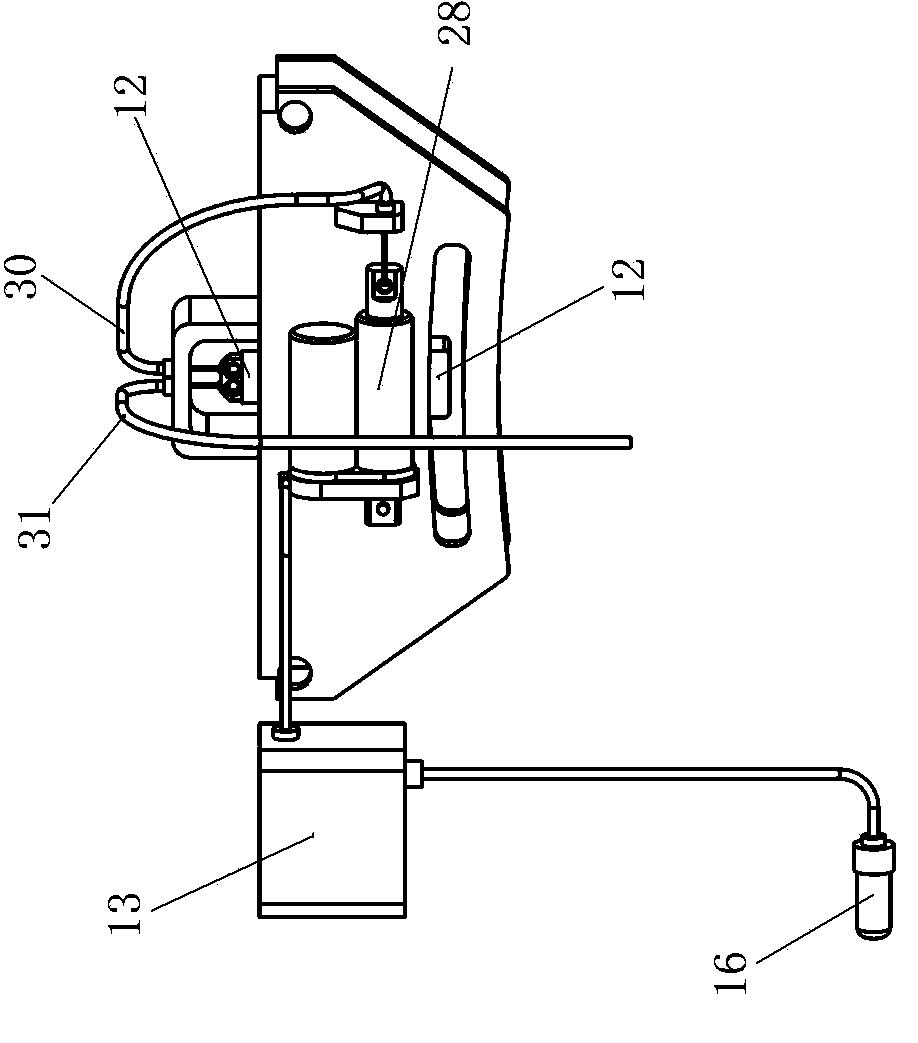

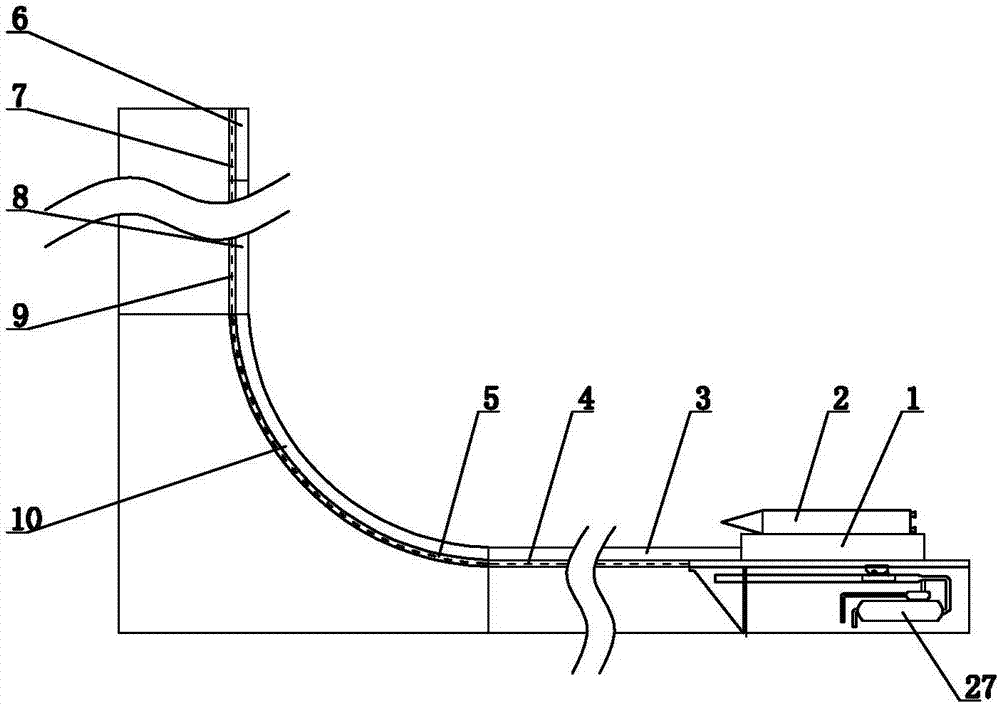

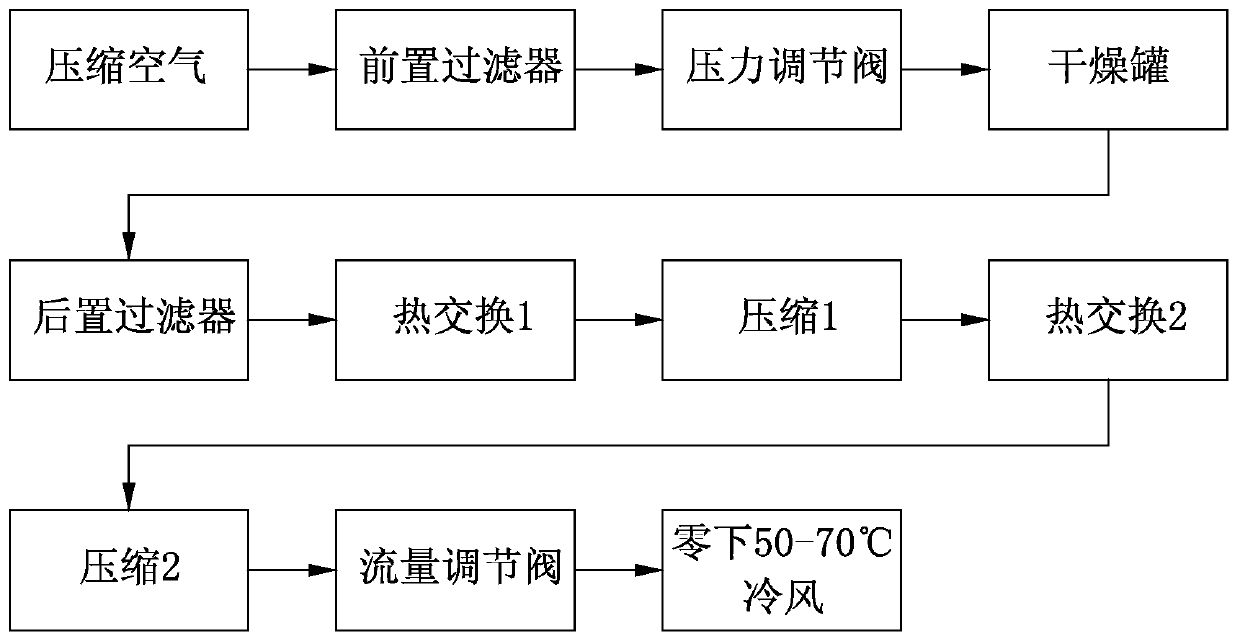

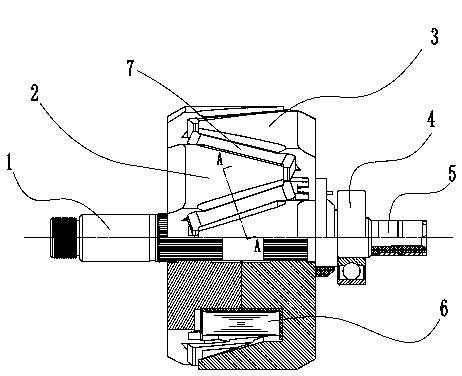

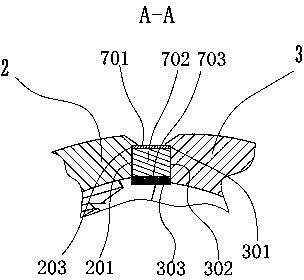

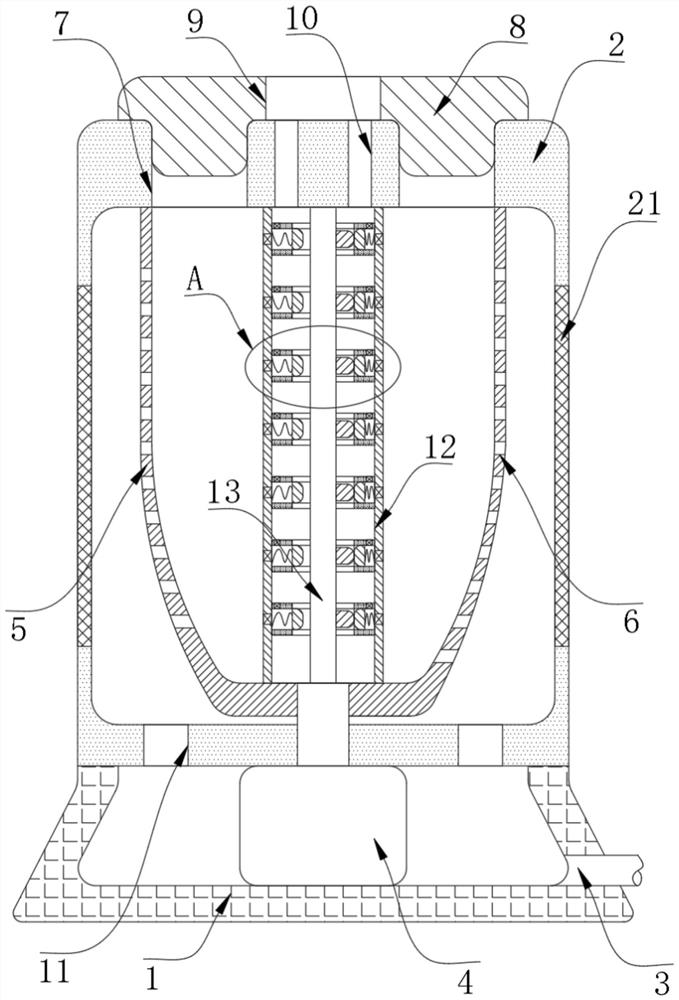

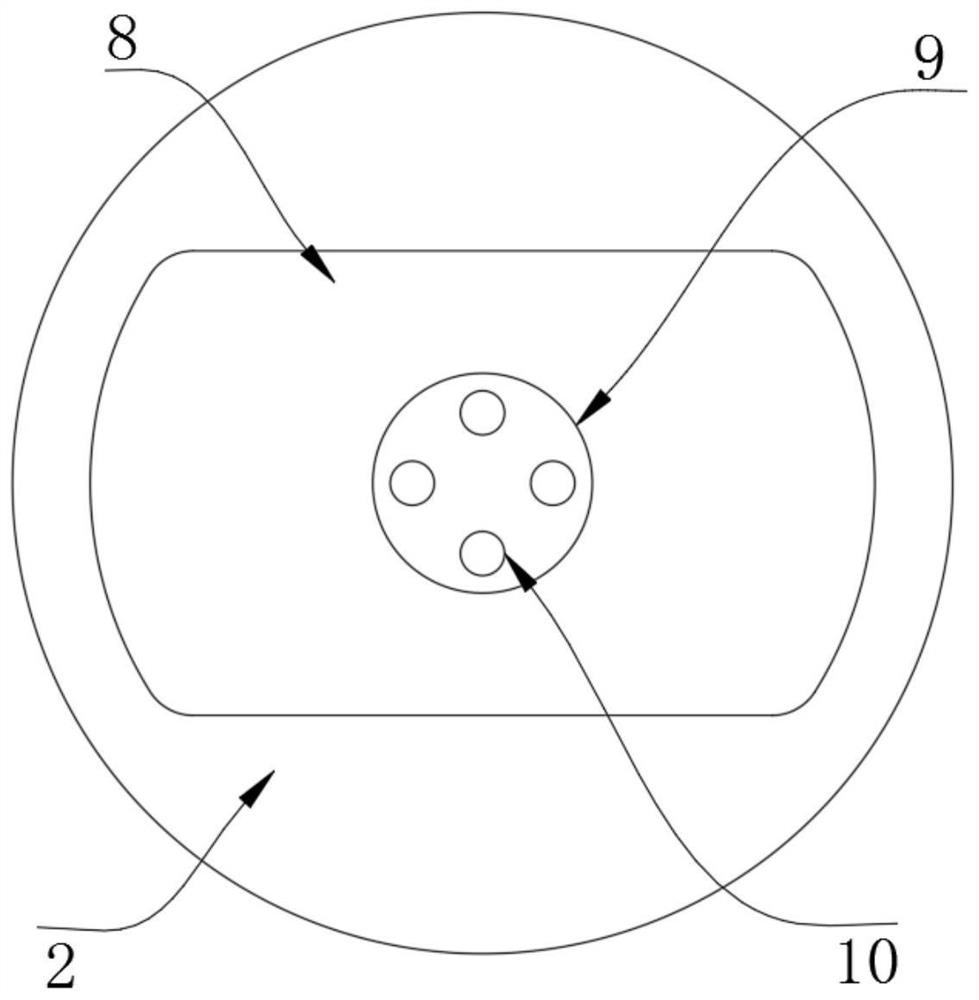

Low temperature water mist and oil mist cutting cooling lubrication supply system

ActiveCN106863002AImprove permeabilityExtend your lifeMaintainance and safety accessoriesAviationSprayer

The invention discloses a low temperature water mist and oil mist cutting cooling lubrication supply system. A Venturi atomization sprayer is arranged at the upper portion of an inner cavity of an atomization chamber, an air inlet of the Venturi atomization sprayer is connected to the outlet end of an air tank through a first air conveying pipe, an eddy atomization sprayer comprises an eddy pipe and an oil-water mixing sprayer, the eddy pipe is connected to the outlet end of the air tank through a second air conveying pipe, and a compression refrigerator is arranged on the second air conveying pipe; the oil-water mixing sprayer is connected with the water tank through a water pipe, and is connected with the atomization chamber through an oil mist conveying pipe; and cold air refrigerated through the compression refrigerator and the eddy pipe is mixed with oil mist coming from the atomization chamber and water coming from the water tank at the position of the oil-water mixing sprayer. By means of the system, advantages of low-temperature cold air and composite spraying mist are combined, and therefore when a cutter is used for machining difficultly-machined materials such as the titanium alloy, the high-temperature alloy and the aviation composite material, the cutting temperature is rapidly decreased, the machining process is more efficient, and the service life of the cutter is prolonged.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

Bicycle

Owner:朴庚熙

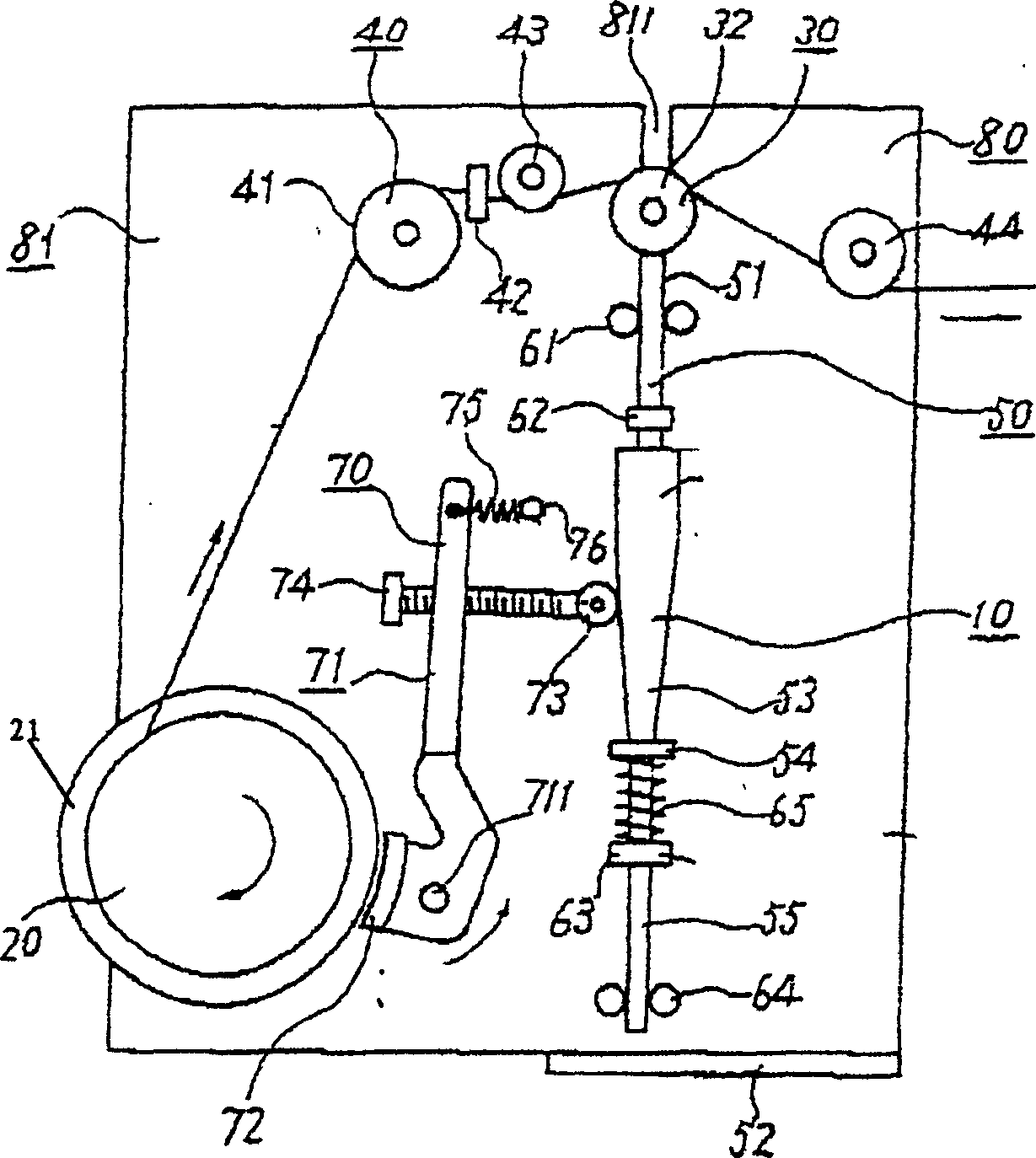

Wire material supplying mechanism of tubular braided fabric braiding machine

The invention is a thread feeding mechanism for tubular braided fabric braiding machine, composed of machine frame and thread tension adjust mechanism composed of tension detecting mechanism and braking device, where the tension detecting mechanism is composed of fixed roller group and floating roller mechanism, wherein the floating roller mechanism is composed of floating roller, supporting shaft and drive rod, and there is cut groove arranged in the machine frame, the supporting shaft is arranged in the cut groove and fixed with the drive rod, the drive rod is arranged in the machine tool through a base and a guide roller group, the medium segment of the drive rod is a truncation cone, the braking device is composed of mechanical arm and braking hoof, wherein the mechanical arm is arranged on the machine frame through a rotating shaft and a screw run through the mechanical arm, wherein one end of the screw contacts with the truncation cone. The invention adopts floating roller to detecting thread tension, and the moving direction of the drive rod is particular to the radius of a rotary table, able to overcome the centrifugal force of the rotary table and prevent the occurrence of axial offset of the drive rod and ensure normal auto adjustment of thread tension.

Owner:上海哈依投资咨询有限公司 +1

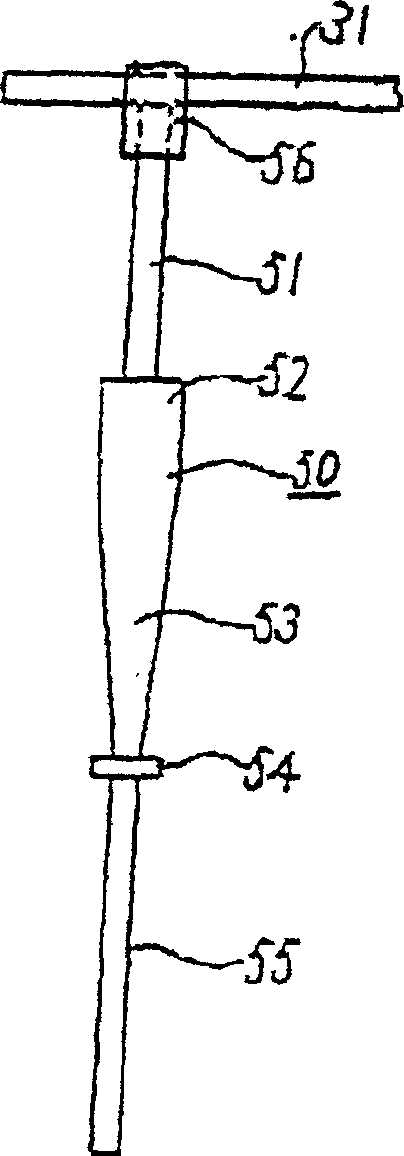

Twin-lock quick-release locking mechanism

ActiveCN101289054AEnsure safe lockingSolve the problem of safe useElectric propulsion mountingCamCentrifugal force

The invention provides a double-lock fast dismounting latch mechanism which comprises a double latch mechanism, a fast unlocking mechanism and fittings. One end of a suspension link of the double latch mechanism is arranged at a suspension link locating seat fixed on the side surface of a front door of an inner box body and can rotate by surrounding the suspension link locating seat; the other end can be hung on the head part of a handle to carry out locking; the handle is locked by a bolt to form a first lock; simultaneously, one bolt fixedly arranged at the lower part of the suspension link locating seat is inserted into a jack at the lower part of a handle seat at the front door to form a second lock; the fast unlocking mechanism is also fixedly arranged at the front door; a double bolt is driven by a cam mechanism to control the double latch mechanism and realize the locking or unlocking of the double locks. The mechanism of the invention has the advantages of reliable locking, being convenient and fast to unlock and realizing fast mounting and dismounting of the battery; simultaneously, a centrifugal force and vibration generated when an automobile turns are overcome and the requirements of safe locking of the battery as well as fast mounting and dismounting are ensured.

Owner:北京辉程动力科技有限公司

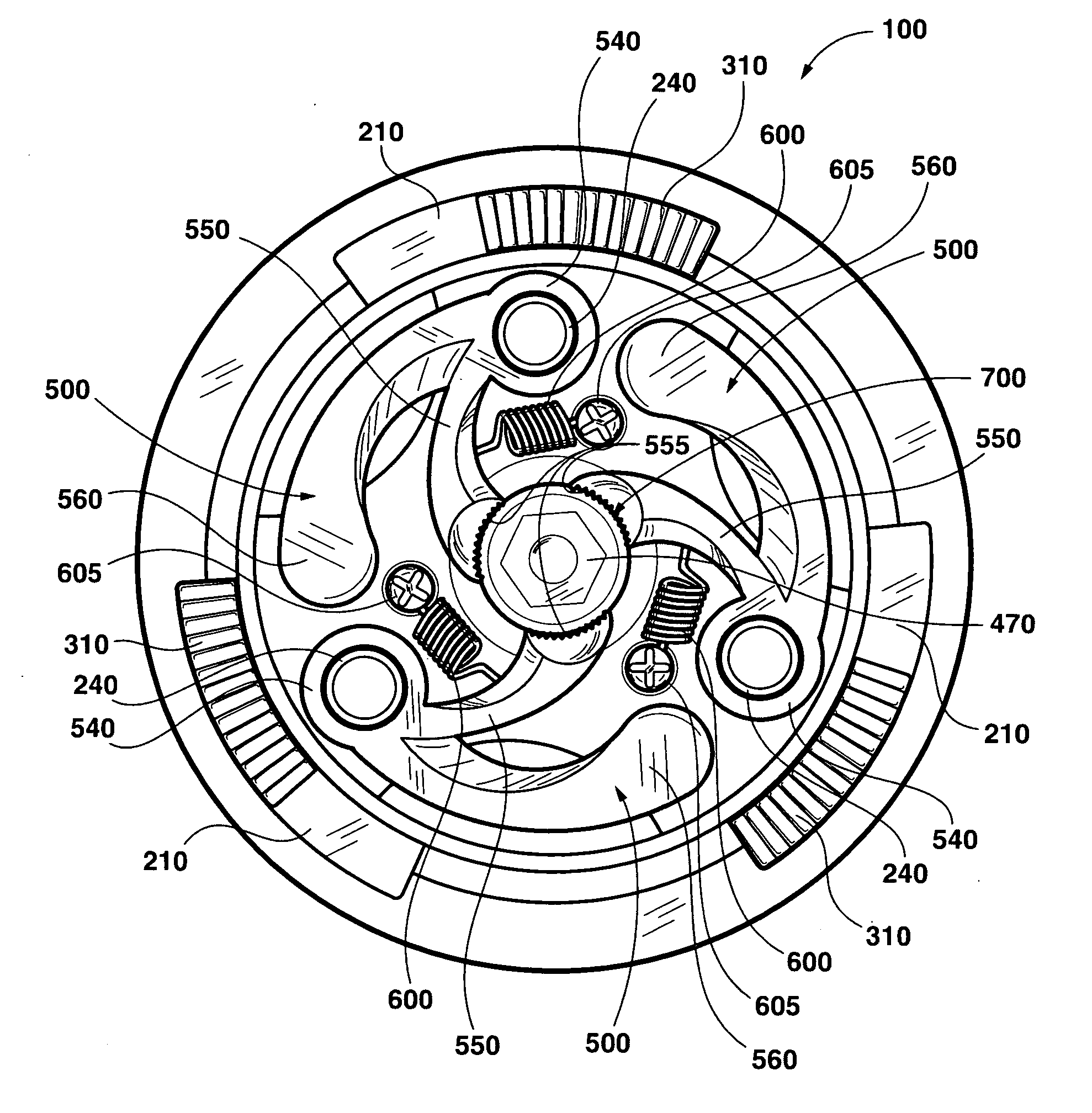

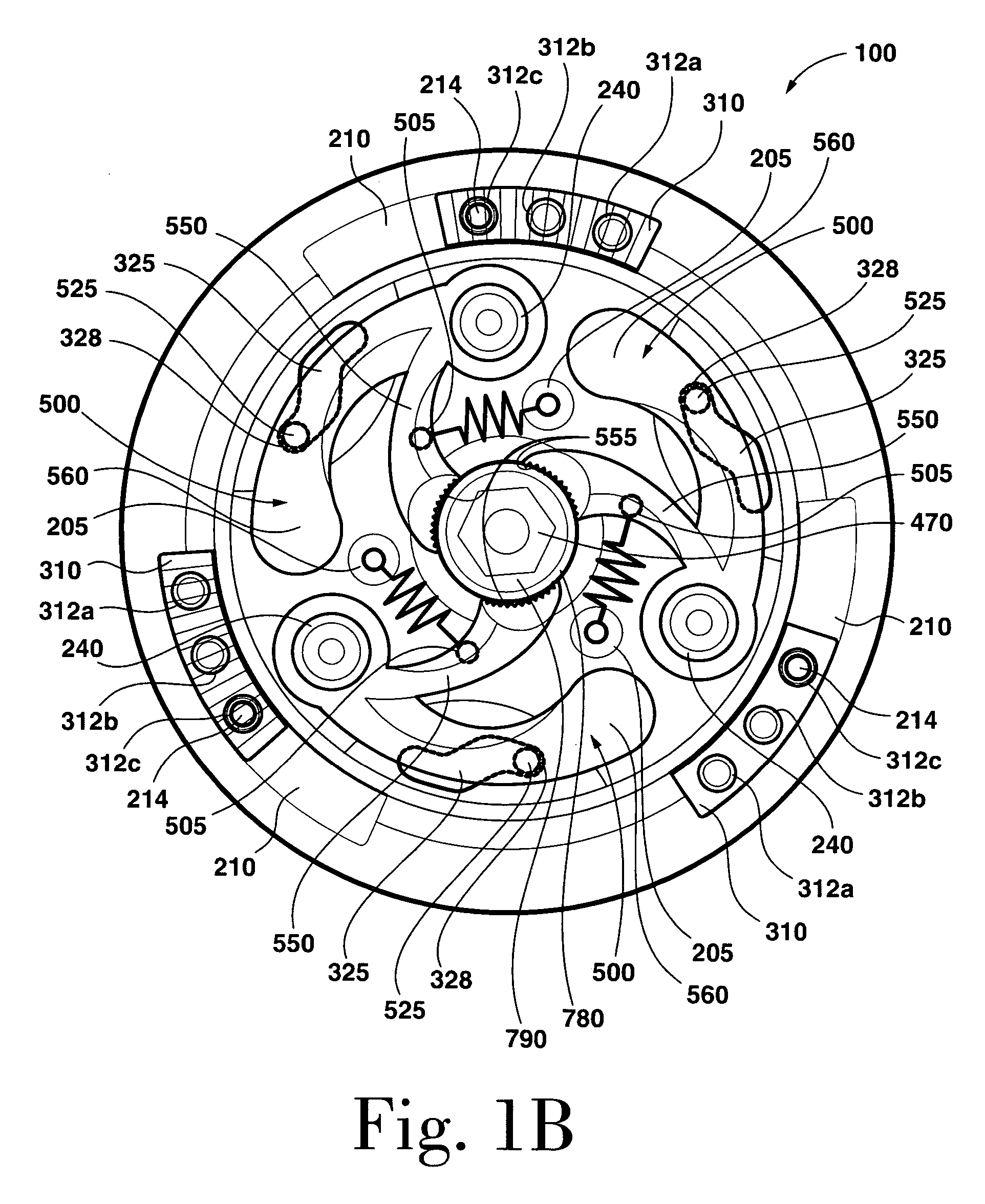

Multi-function yo-yo

A multi-function yo-yo switchable between operation as a fixed-axle yo-yo, a free-axle yo-yo, and a centrifugal-clutch yo-yo (i.e., a yo-yo which operates as a free-axle yo-yo when it spins sufficiently rapidly, and as a fixed-axle yo-yo when it spins sufficiently slowly). Within one or both of the fly disks is one or more rotational-speed governors, and about the axle is a cylindrical axle sleeve which is rotatable about the axle. Each governor is spring-biased to an inwards position where a contact pad on the governor contacts the axle sleeve, forcing the axle sleeve to rotate with the fly disks and axle. However, when the yo-yo spins sufficiently rapidly, the governors are thrown by centrifugal force to a radially-outwards position where the contact pads are not in contact with the axle sleeve so that the axle sleeve may rotate independently of the fly disks. A function control switch on the exterior of the yo-yo is easily accessible and allows rapid switching between yo-yo functions. Preferably, the switch has multiple throw levers about the exterior of the yo-yo to facilitate quick access. In its first position, the switch locks the governors in the inwards position and the yo-yo operates as the fixed-axle yo-yo. In its second position, the switch locks the governors in the outwards position and the yo-yo operates as the free-axle yo-yo. In its third position, the positions of the governors is determined by the balance between centrifugal force and the spring biasing, and the yo-yo operates as the centrifugal-clutch yo-yo.

Owner:HOCHSTRASSER ALEX

Convenient-to-disassemble cloth winding drum device for textile machinery

The invention discloses a convenient-to-disassemble cloth winding drum device for textile machinery. The convenient-to-disassemble cloth winding drum device for the textile machinery comprises a bottom plate, a fixing plate is fixedly connected to the left side of the top of the bottom plate, a stabilizing plate is fixedly connected to the right side of the top of the bottom plate, the top of theleft side of the fixing plate is fixedly connected with a rotary motor, an output shaft of the rotary motor is fixedly connected with a rotary shaft, and one end, away from the rotary motor, of the rotary shaft penetrates through the fixing plate and extends to the right side of the rotary shaft to be fixedly connected with a first connecting plate. According to the device, through the mutual cooperation among a handle, a mounting plate, a connecting spring, a sliding block, a stretching plate, a fixing groove, a first connecting block, a second connecting block, a threaded sleeve, a threadedrod, a third connecting plate, a fixing pulling block, a transverse plate, a supporting plate, a rotating block, an annual shell, a connecting shaft and a rolling bearing, the convenient dismounting effect is achieved, the dismounting is very convenient, the dismounting speed is increased, the working time and energy are reduced, the working efficiency is greatly improved, and great convenience isbrought to users.

Owner:重庆市远康纺织品有限公司

Sectional rotor structure for permanent magnet synchronous motor

ActiveCN102545435ANot easy to breakExtended service lifeMagnetic circuit rotating partsEngineeringPermanent magnet synchronous motor

A sectional rotor structure for a permanent magnet synchronous motor comprises a rotating shaft, a rotor core, permanent magnets, rotor pole shoes, a front end-plate and a rear end-plate, wherein a plurality of rotor baffles are arranged between the two end-plates; the rotor pole shoes are independent of one another and axially distributed at intervals together with the rotor baffles; the rotor baffles divide axially a rotor into a plurality of rotor units; two end surfaces of the rotor pole shoes in each rotor unit are respectively clung to the end surfaces of the adjacent rotor baffles; the rotor pole shoes in each rotor unit correspond to the permanent magnets; through holes allowing the permanent magnets to penetrate are formed on the rotor baffles; pole shoe draw-in bolts penetrate the front end-plate, the rotor pole shoes, the rotor baffles and the rear end-plate and axially lock the rotor pole shoes and the rotor baffles, which are arranged between the front and the rear end-plates; and the corners of the through holes of the rotor baffles are in arc transition, and clearances are kept between the permanent magnets and the permanent-magnet through holes on the rotor baffles. The sectional rotor structure for the permanent magnet synchronous motor has the advantages of high mechanical strength and suitability for motors rotating at high speed.

Owner:ZHEJIANG UNIV

Tiltable frame intelligent support system and implementation method thereof

InactiveCN104175829AOvercome centrifugal forceAccident freeDeflectable wheel steeringResilient suspensionsBalance shaftVehicle frame

The invention relates to a tiltable frame intelligent support system applicable to small tricycles and four-wheelers. The principle that corresponding edges of a parallelogram are parallel after stretching deformation of the parallelogram is used in combination with a stable triangular relation formed by a multifunctional vertical balance shaft and a damping system, the multifunctional vertical balance shaft, the damping system and a frame form a lockable and separable unique structure. When a vertical lock is unlocked, a vehicle body can tilt freely in a certain left-right angle range. The system comprises an intelligent electronic detecting mechanism, when the speed of a vehicle reaches to a preset value, the vertical lock is unlocked, the multifunctional vertical balance shaft is separated from the vertical lock, the vehicle enters a free driving state, and a driver can tilt the vehicle body leftwards or rightwards according to road conditions; when the speed of the vehicle is lower than the lowest preset value, the vertical lock is locked automatically, the vertical lock automatic locks the multifunction vertical balance shaft when the vehicle body enters an erection state for the first time to allow the vehicle to enter a stabilized state. By the system, centrifugal force generated by inertia during vehicle turning is overcome effectively, and vehicle safety coefficient and driving fun are increased greatly.

Owner:董国涛

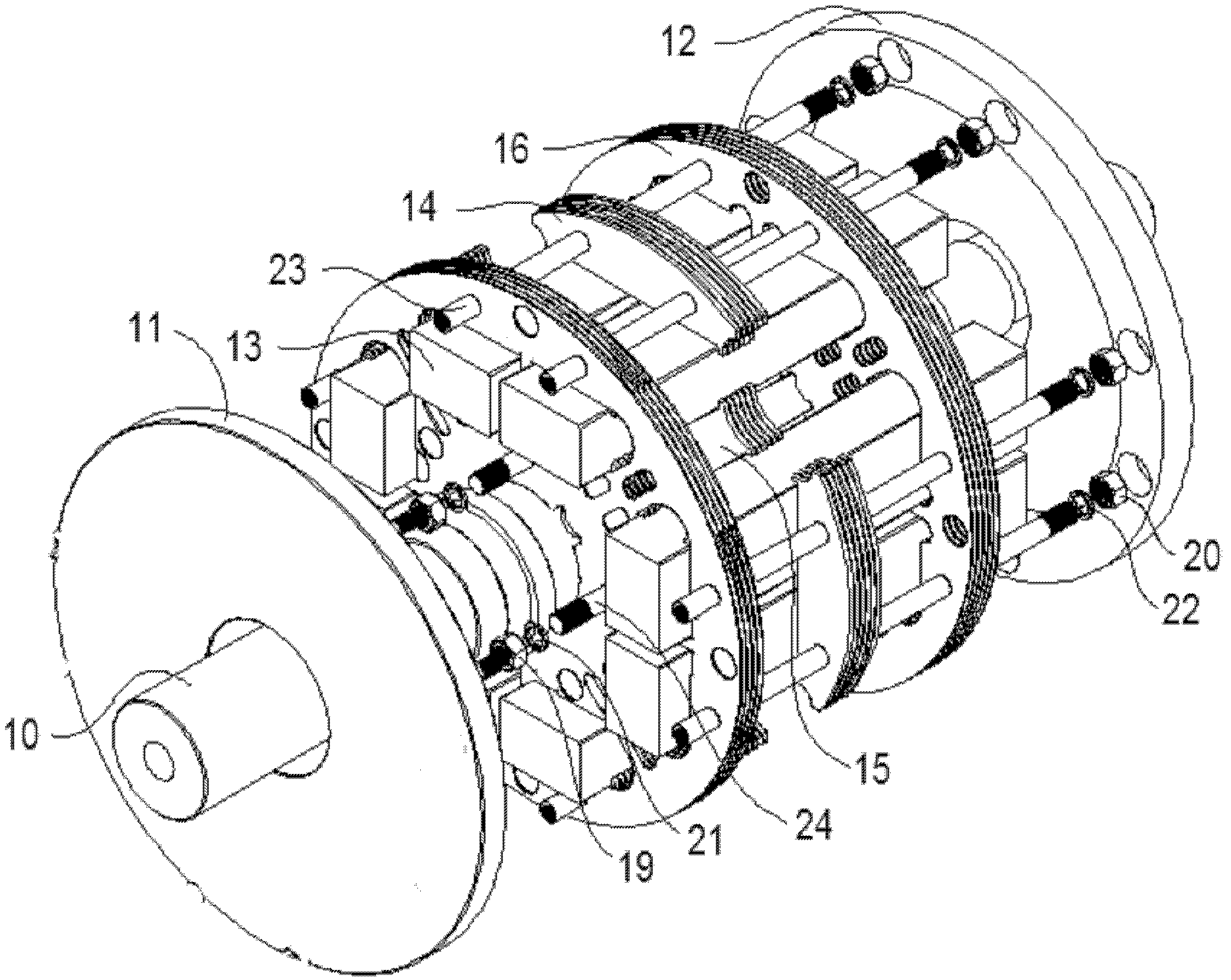

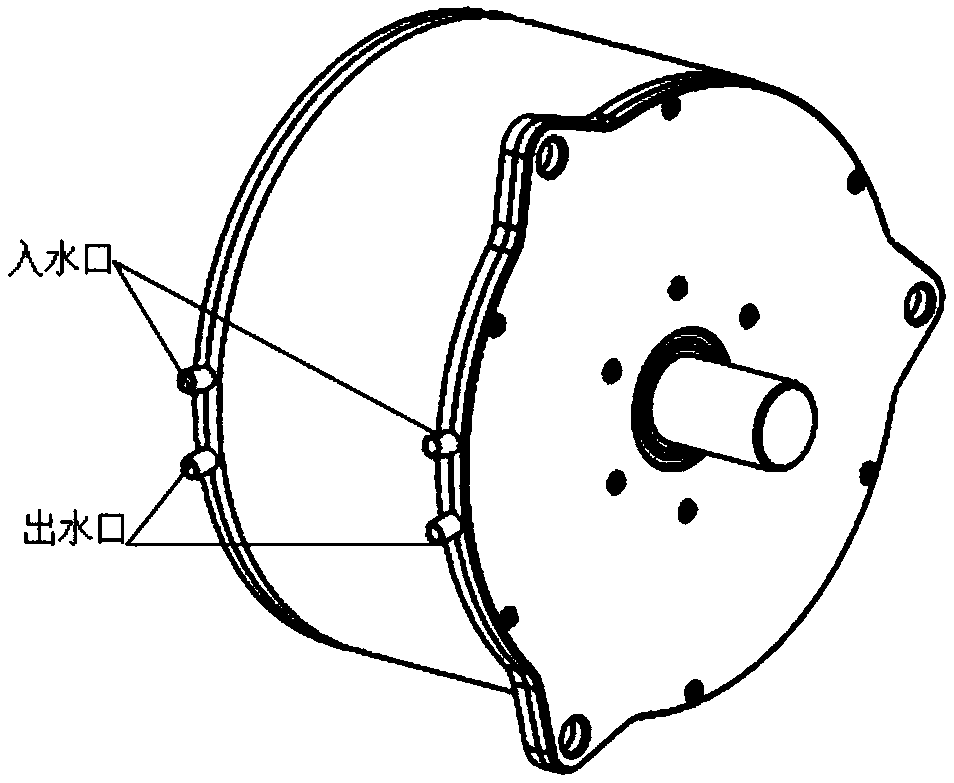

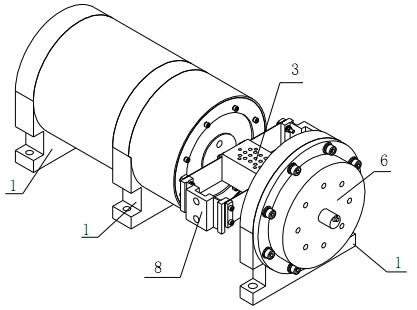

Ultrahigh-speed permanent magnet disk motor and installation method thereof

PendingCN109904951AEasy to installReduce axial effective air gapMagnetic circuit rotating partsMechanical energy handlingMagnetElectrical and Electronics engineering

The invention relates to an ultrahigh-speed permanent magnet disk motor. The motor comprises a first stator core, a second stator core, a stator winding, an enclosure, a heat dissipation pipeline, a front end cover, a rear end cover, a high-speed rotor and ceramic bearings, wherein the high-speed rotor comprises a high-speed rotor core, permanent magnets, a rotor sheath and a rotor shaft; and thehigh-speed rotor core is installed on the rotor shaft in a sleeving mode, permanent magnet wedge-shaped installing slots are processed in the radial direction to install the permanent magnets, the permanent magnets are installed at the two axial sides of the high-speed rotor core, and the rotor sheath is installed on the high-speed rotor core. The motor has high mechanical strength and is suitablefor ultrahigh-speed running; and moreover, a good heat dissipation system is designed, and the situation that the permanent magnets are demagnetized during ultrahigh-speed running of the disk motor is prevented. The invention not only provides an ultrahigh-speed permanent magnet motor scheme but also discloses a motor assembling method.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

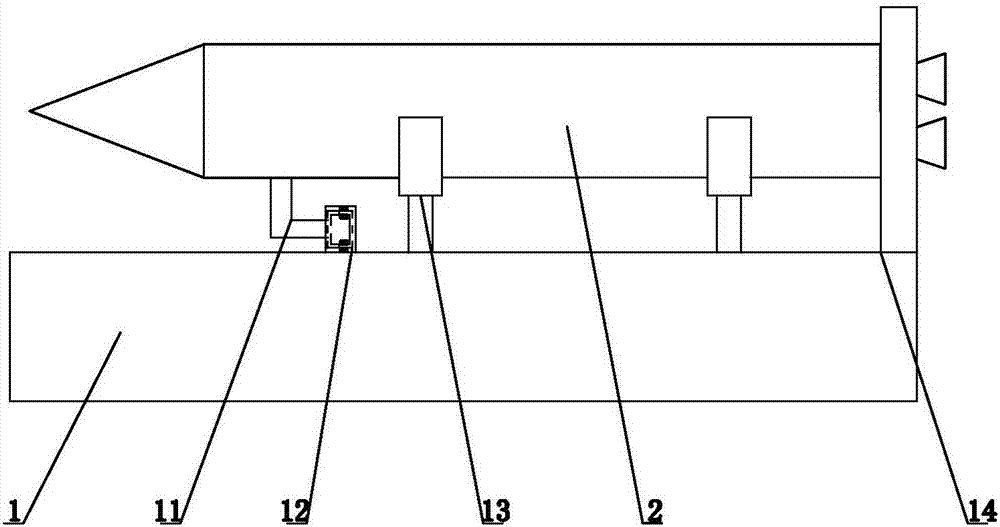

Launching catapult launching system and booster launching method thereof

InactiveCN106871723AOvercome centrifugal forceIncrease the initial velocityRocket launchersRocket launchSelf-energy

The invention provides a launcher launch system and a booster launch method thereof, which belong to the field of booster devices and include horizontal tracks, arc tracks and vertical tracks connected in sequence; Orbit, arc orbit and vertical orbit; it can make the rocket launch use ground resources to obtain the initial velocity, can reduce its own energy consumption, and can reduce the pollution of the rocket jet to the ground environment.

Owner:STATE GRID OF CHINA TECH COLLEGE +3

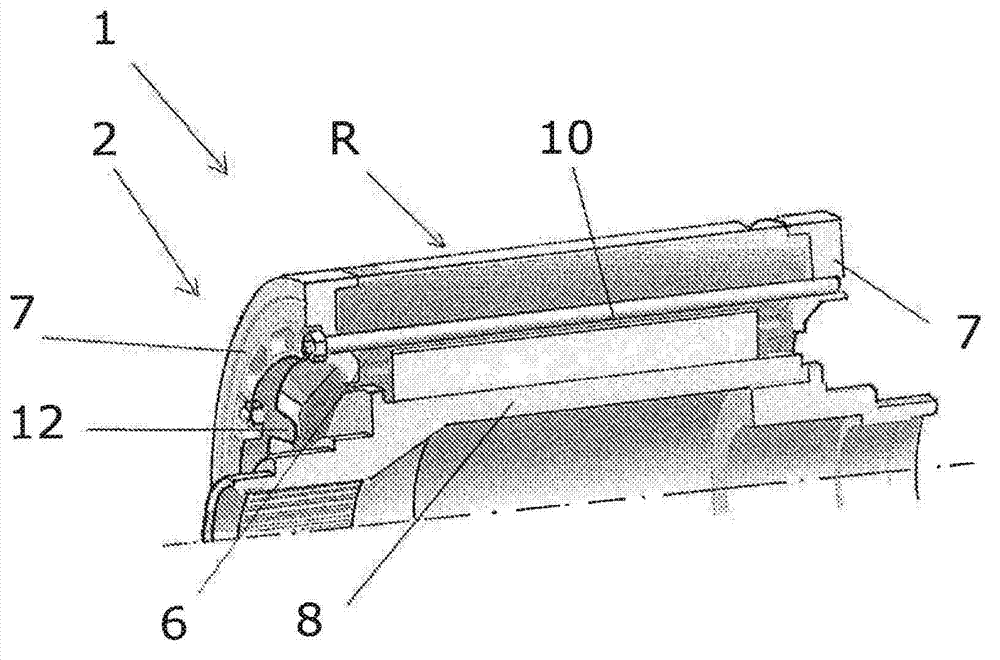

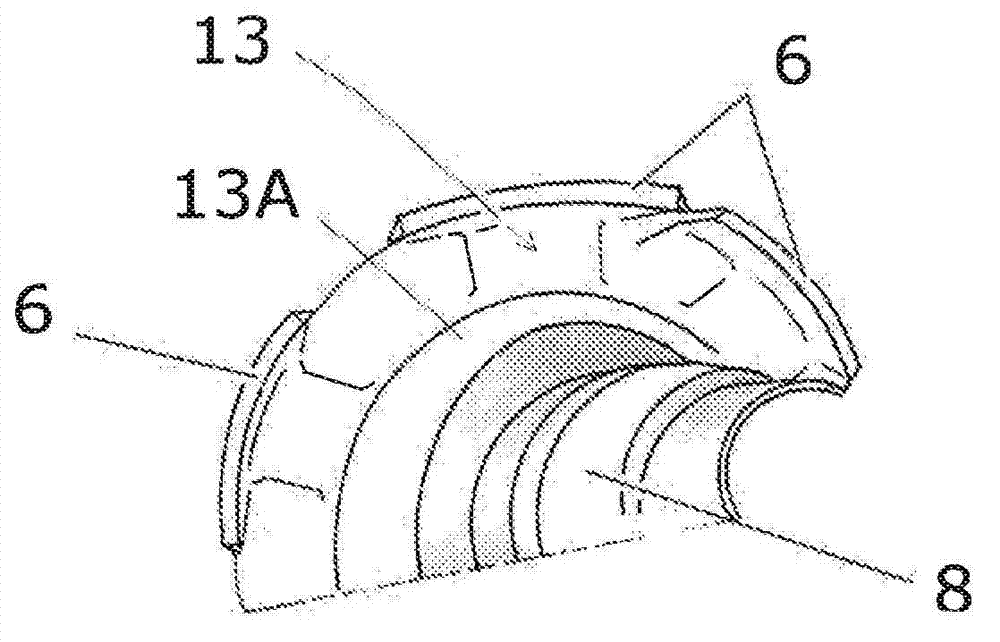

Rotor for electrical machine, in particular for a synchronous motor

InactiveCN103026592ALow costReduced heat carrying capacityWindings insulation shape/form/constructionMagnetic circuit rotating partsSynchronous motorElectric vehicle

The present invention relates to a rotor (R) of an electrical machine, in particular a synchronous motor of electric vehicle drives, which rotor (R) comprises a rotor shaft (8), a sheet stack (3), windings, and a restraining system (2) with support elements. The support elements of the restraining system include support rings (7) which protect winding heads (4) projecting from the sheet stack (3) in the axial direction against, preferably radial, stresses. In the invention the elements of the restraining system (2) protecting the winding heads (4) from stresses also include axially inner end caps (6) which are configured on the one hand as support means for the finished winding heads (4) in the operating state and on the other hand as guide and support means during the winding of the pole windings of the rotor (R) about the axial edge of the sheet stack (3). The axially outer support rings (7) cooperate with the axially inner end caps (6) in such a manner that the support rings (7) can absorb the centrifugal forces acting on the end caps (6) of the winding heads (4).

Owner:BRUSA ELECTRONICS AG

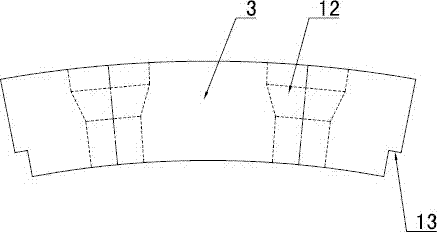

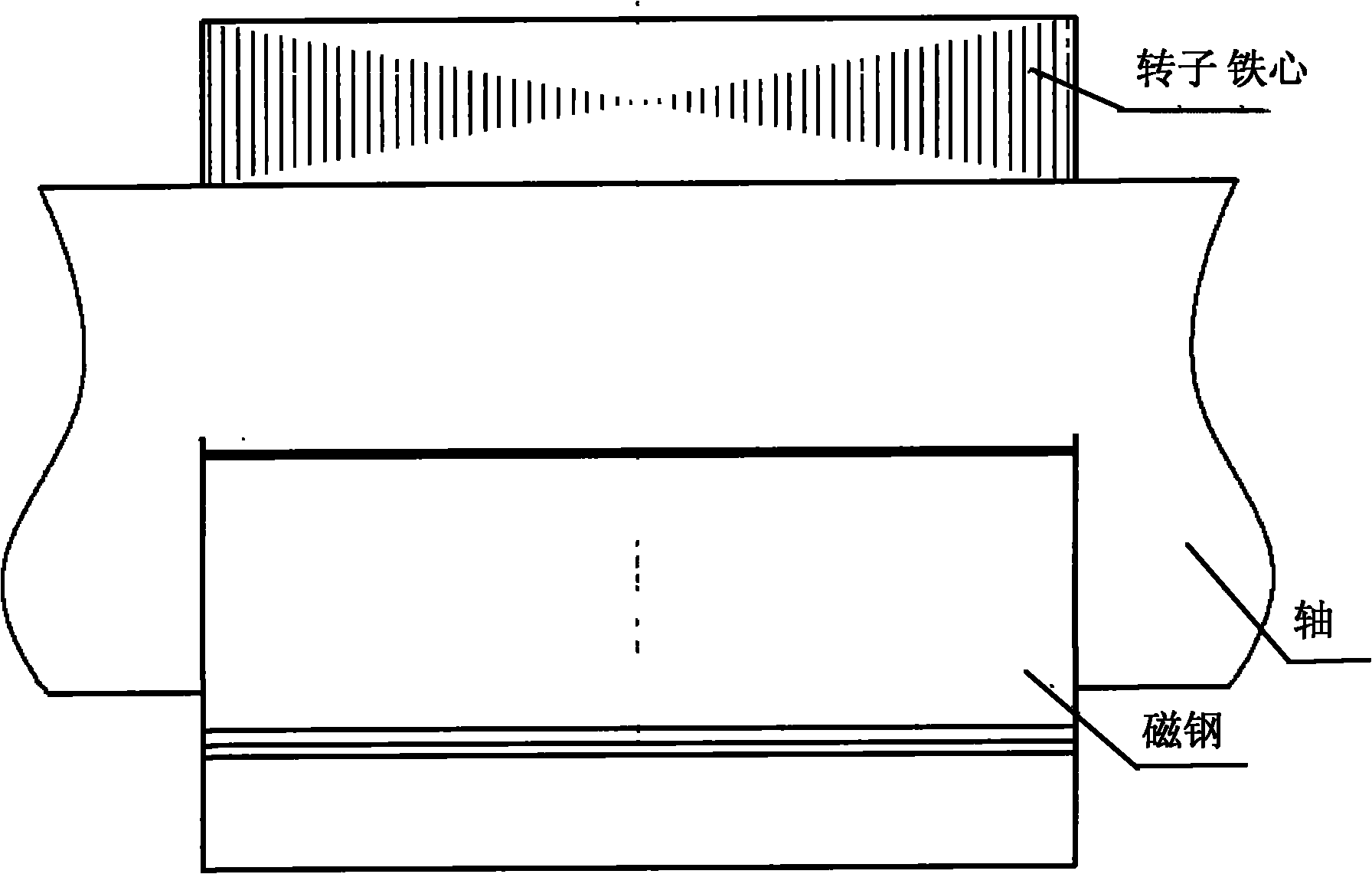

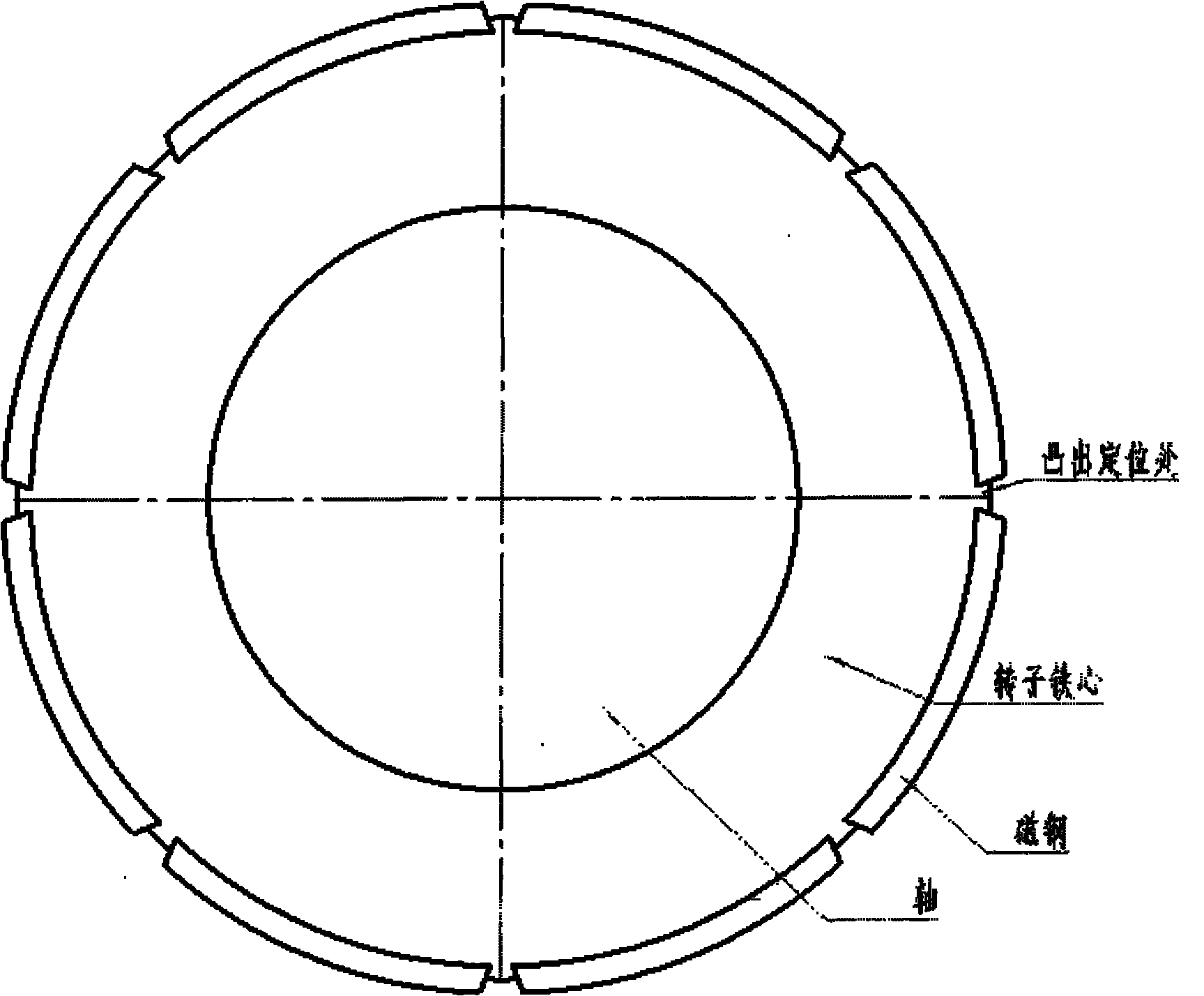

High-power high-speed permanent magnet generator rotor surface-mounting type fixing permanent magnet structure and method

InactiveCN102931784AEasy to assembleNo displacementMagnetic circuit rotating partsManufacturing stator/rotor bodiesFiberAdhesive

The invention discloses a high-power high-speed permanent magnet generator rotor surface-mounting type fixing permanent magnet structure and method and belongs to the field of permanent magnet generator devices and manufacturing methods. The high-power high-speed permanent magnet generator rotor surface-mounting type fixing permanent magnet structure and method is characterized in that a plurality of bosses (5) used to position permanent magnets (3) are uniformly distributed on the surface of each permanent magnet area along the axial direction, a plurality of spliced permanent magnets (3) are fixed on the surface of each permanent magnet area through high-strength adhesives, two neighboring permanent magnets (3) in circumferential direction are separated and positioned through the bosses (5), the permanent magnets (3) are fastened with rotor cores (2) together through fastening bolts (7), carbon fiber binding belts (8) are wound on the outer surfaces of the permanent magnets (3), and rotor baffles (6) are fixedly arranged on two ends of the permanent magnets (3) in the axial direction. The high-power high-speed permanent magnet generator rotor surface-mounting type fixing permanent magnet structure and method enables the permanent magnets to overcome centrifugal force, maintain fixed and firm and work safely.

Owner:SHANDONG SHANBO ELECTRIC MACHINE GROUP

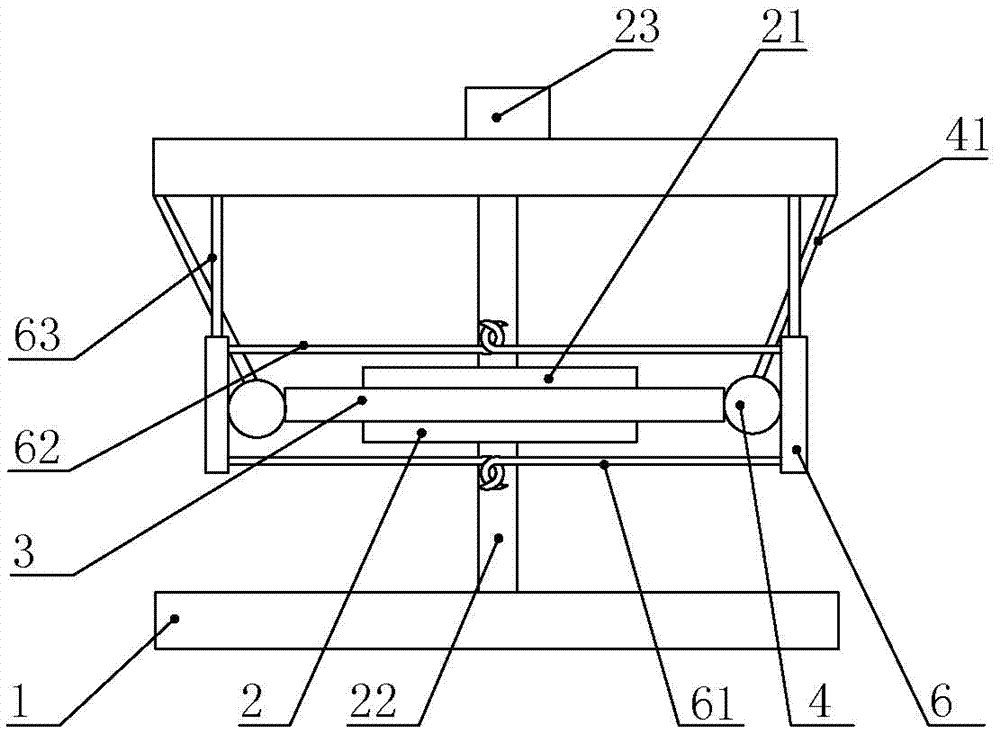

Vibrating table for centrifugal machine

The invention relates to a vibrating table for a centrifugal machine, which comprises a stand. A vibrating table moving coil for generating vibrations and a test platform for a carrier belt to test workpieces are arranged on the stand, and the left end of the test platform is linked with the vibrating table moving coil through a platform push rod; the right end of the test platform is connected with a deviation correcting mechanism for preventing the vibrating table moving coil from excessively deviating on axial direction through a deviation correcting push rod; an aluminum frame of the vibrating table moving coil is provided with supporting mechanisms for preventing the moving coil from twisting or circumferentially rotating, convex edges are uniformly distributed on the aluminum frame, and one supporting mechanism is arranged between any two adjacent convex edges; each supporting mechanism comprises an axial spring installed on the convex edges along the axial direction of the moving coil and a radial spring installed along the radial direction of the moving coil to connect the axial spring and the aluminum frame; and the right end and the left end of the aluminum frame are both provided with radial springs. The invention has the advantages of correcting the deviation of a moving part in centrifugation environment and being directly used for the centrifugal machine.

Owner:ZHEJIANG UNIV

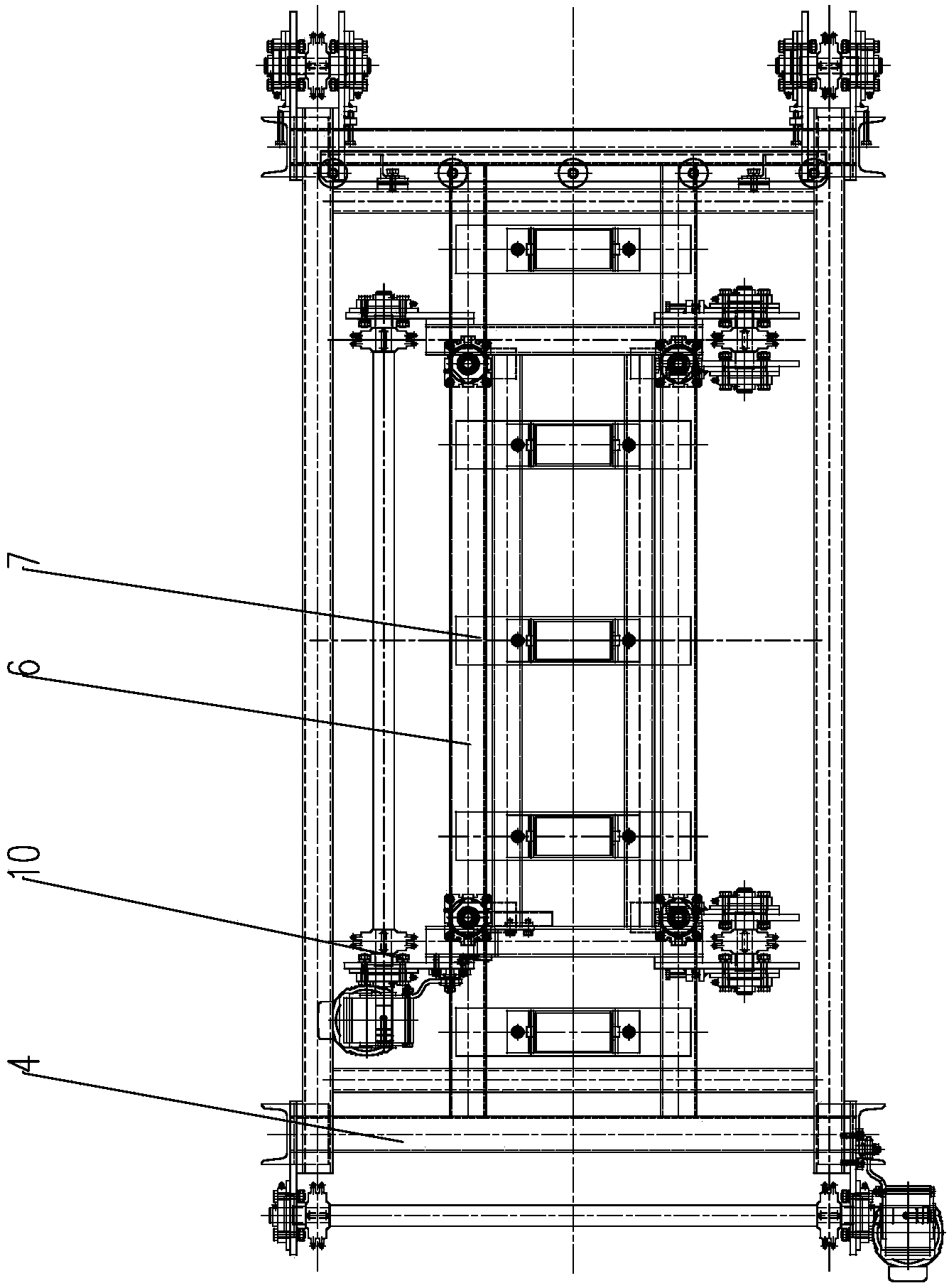

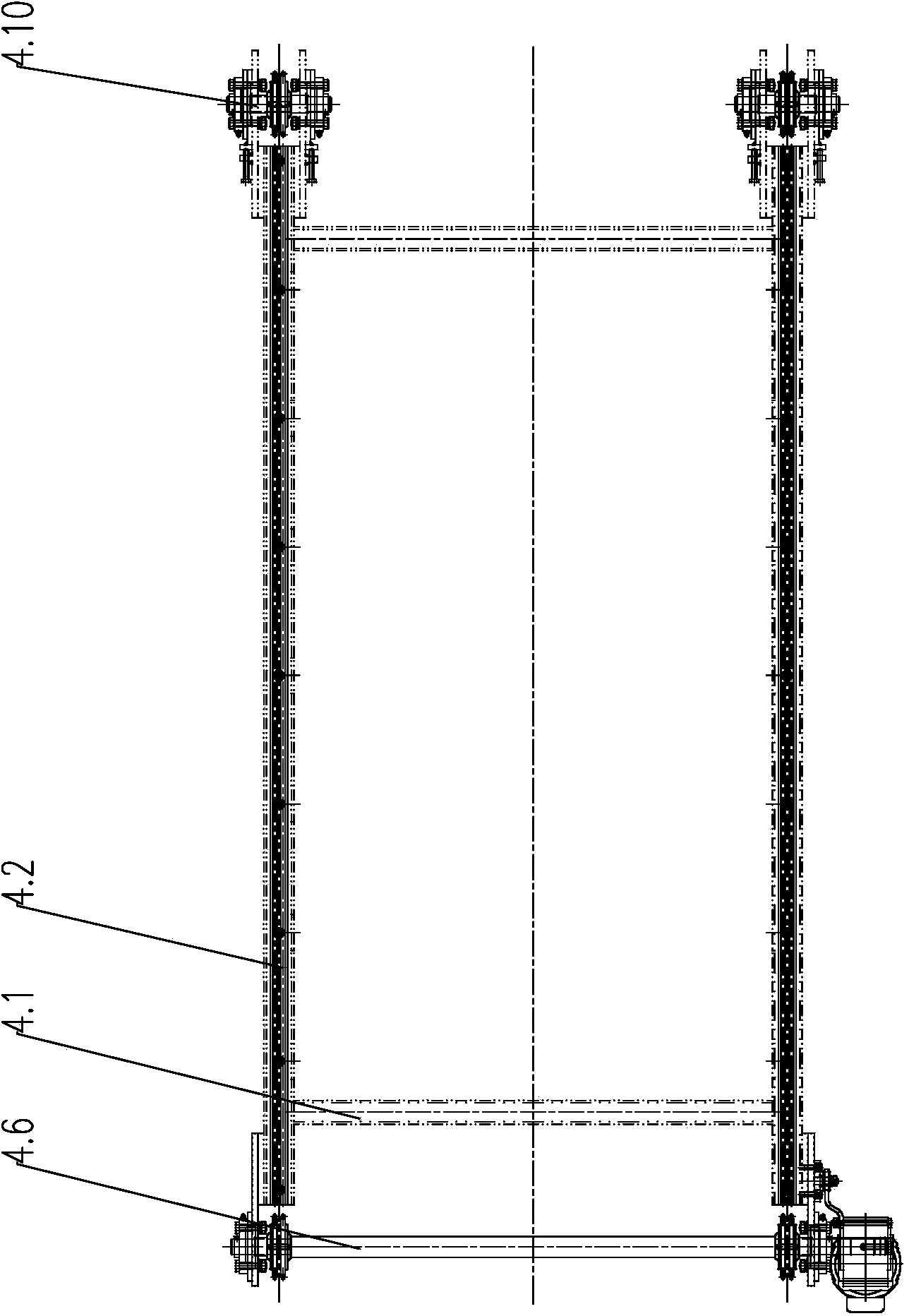

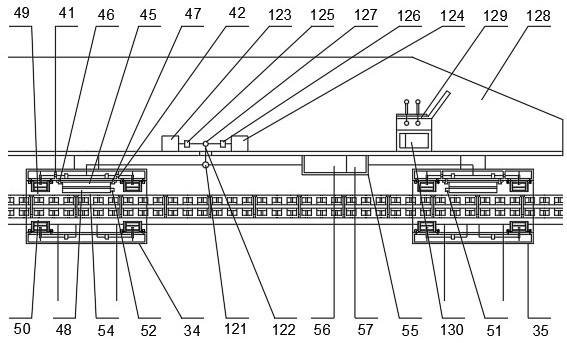

Double-chain conveying type carrying device

The invention relates to a double-chain conveying type carrying device and particularly relates to a multilayer-movement carrying device capable of realizing longitudinal and horizontal conveying and conversion of goods and belongs to the technical field of transferring and carrying devices. The double-chain conveying type carrying device comprises an installing frame, wherein an upper horizontal moving mechanism is fixed at the upper part of the installing frame, and a lower horizontal moving mechanism is fixed at the lower part of the installing frame; the upper horizontal moving mechanism is horizontally arranged and can realize horizontal movement of the goods; the lower horizontal moving mechanism and the upper horizontal moving mechanism are same in structure. The installing frame is connected with an upper bracket and a lower bracket from top to bottom in sequence, an upper jacking mechanism is fixed on the upper bracket, and the upper end of the upper jacking mechanism is connected with an upper longitudinal moving mechanism, which is longitudinally arranged, and can realize longitudinal movement of the goods. The double-chain conveying type carrying device has the advantages that multilayer independent conveying can be realized, the operation and control of all the layers are not interfered, the way of the goods can be changed without rotation after the way of the goods is changed by a cross-shaped or T-shaped way-distributing port, and the original direction of the goods can be kept all the time, so that the operating stability is improved.

Owner:MIRACLE AUTOMATION ENG CO LTD

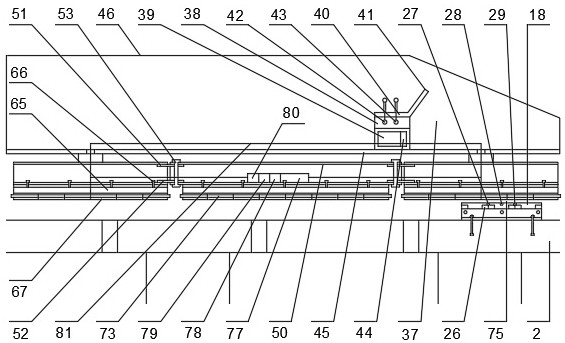

Processing method for wooden guitar

ActiveCN107379196ANo manual operationReduce labor costsGuitarsProfiling/shaping machinesEngineeringComplex problems

The invention discloses a processing method for a wood guitar. The processing method comprises the following steps: A, selecting materials; B, drying; C, cutting; D, grinding a handle body and side plates; and E, grinding a panel. A grinding device is used to grind the panel, and the grinding device comprises a rack, and further comprises a fixing mechanism for fixing grinding balls, wherein an upper clamping plate and a lower clamping plate used for clamping the guitar panel are arranged on the rack; the upper clamping plate and the lower clamping plate are connected with a rotary shaft; the rotary shaft is connected with a drive mechanism; the grinding balls are arranged at the two sides of the guitar panel; and a first connecting rope is connected between each grinding ball and the rack. The step of grinding the panel comprises the following specific steps of: a, putting the guitar panel onto the rack, and clamping the guitar through the upper clamping plate and the lower clamping plate; b, fitting the grinding balls to the sides of the panel, and fixing the grinding balls by the fixing mechanism; and c, starting a drive mechanism for rotating the guitar panel, and grinding the guitar panel through the grinding balls. The invention aims to provide the processing method for the wood guitar, and the processing method solves the problem that manual guitar grinding operation is complex, and improves guitar production efficiency.

Owner:贵州金韵乐器有限公司

Low temperature water mist oil mist cutting cooling lubrication supply system

ActiveCN106863002BImprove permeabilityExtend your lifeMaintainance and safety accessoriesAviationSprayer

The invention discloses a low temperature water mist and oil mist cutting cooling lubrication supply system. A Venturi atomization sprayer is arranged at the upper portion of an inner cavity of an atomization chamber, an air inlet of the Venturi atomization sprayer is connected to the outlet end of an air tank through a first air conveying pipe, an eddy atomization sprayer comprises an eddy pipe and an oil-water mixing sprayer, the eddy pipe is connected to the outlet end of the air tank through a second air conveying pipe, and a compression refrigerator is arranged on the second air conveying pipe; the oil-water mixing sprayer is connected with the water tank through a water pipe, and is connected with the atomization chamber through an oil mist conveying pipe; and cold air refrigerated through the compression refrigerator and the eddy pipe is mixed with oil mist coming from the atomization chamber and water coming from the water tank at the position of the oil-water mixing sprayer. By means of the system, advantages of low-temperature cold air and composite spraying mist are combined, and therefore when a cutter is used for machining difficultly-machined materials such as the titanium alloy, the high-temperature alloy and the aviation composite material, the cutting temperature is rapidly decreased, the machining process is more efficient, and the service life of the cutter is prolonged.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

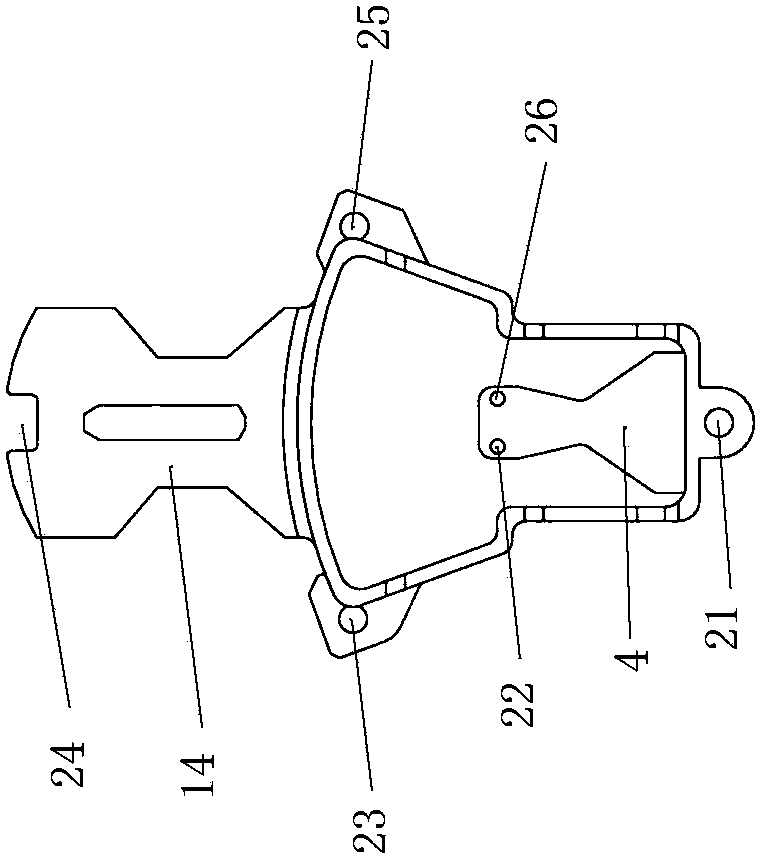

Rotor structure of vehicular generator

ActiveCN103545957AAvoid destructionNot easy to damageMagnetic circuit rotating partsNylon materialInjection moulding

A rotor structure of a vehicular generator comprises a rotating shaft, a front claw pole, a rear claw pole, a rear bearing, a collector ring, and an exciting coil assembly, wherein the front claw pole, the rear claw pole, the rear bearing, the collector ring and the exciting coil assembly are disposed on the rotating shaft. The front claw pole, the rear claw pole and the exciting coil assembly are press-fitted in a whole through the rotating shaft. The rotor structure is characterized in that a channel forms between each two adjacent claws of the front and rear claw poles, a packaged permanent magnet is fixed in each channel and made with a metal support plate, a permanent magnet member and a bottom shell by injection moulding, each permanent magnet member is disposed between the corresponding metal support plate and the corresponding bottom shell, and the bottom shells are made of plastic or nylon material. The rotor structure is simple to assemble, and damage of the permanent magnet member is prevented; compared to the existing rotor structure, the rotor structure has the advantages that yield of rotor production is increased and generator failure caused by the damage of the permanent magnet members occurs less likely.

Owner:JINZHOU HALLA ELECTRICAL EQUIP

Intelligent rail-holding high-temperature superconducting maglev train system

InactiveCN113815426AEnhanced auto-suspensionImprove stabilityRailway tracksSliding/levitation railway systemsConvertersEngineering

The invention discloses an intelligent rail-holding high-temperature superconducting maglev train system, which is characterized in that a plurality of magnetic circuits of four electromagnetic rails of an intelligent rail-holding subsystem are linearly arranged, a plurality of single coils are connected in series in the same direction, the four electromagnetic rails generate a continuous and uniform magnetic field in the rail direction, pinning magnetic flux generated by 16 monitoring type intelligent Dewars of an independent system unit surrounds the four electromagnetic rails, the acting force of automatic suspension, automatic stabilization and automatic guiding of the maglev train is enhanced, the electromagnetic field intensity of four electromagnetic rails and a middle electromagnetic rail of a section can be controlled and the electromagnetic field can be turned off under the control of a photoelectric proximity switch and a wireless remote control receiving module of a plurality of section converters, the four electromagnetic rails outside the section and the middle electromagnetic rail are all in a power-off state; and a moving magnetic field generated by the electromagnetic rails in the section drive a variable-frequency linear generator rotor, and the linear generator rotor induces alternating current.

Owner:朱幕松

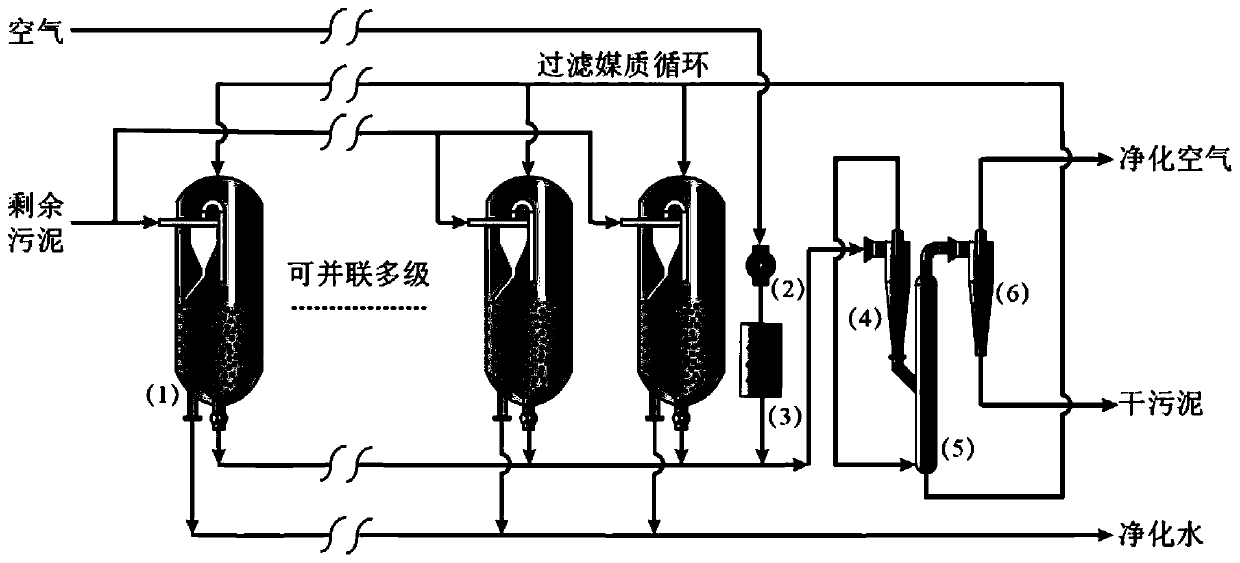

Dewatering method and device for excess sludge

InactiveCN110183089AReduce concentrationLighten the subsequent filter loadSludge treatment by de-watering/drying/thickeningFluidized bedFiltration

The invention relates to a dewatering method and device for excess sludge and provides the dewatering method for the excess sludge. The method comprises the following steps: (A), vortex concentrationof surplus sludge; (B), filtration of the excess sludge by a fluidized bed; (C), vortex autorotation dewatering; (D), airflow acceleration sorting; (E), sludge vortex autorotation re-dewatering and particle capture. The invention also provides the dewatering device for the excess sludge.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

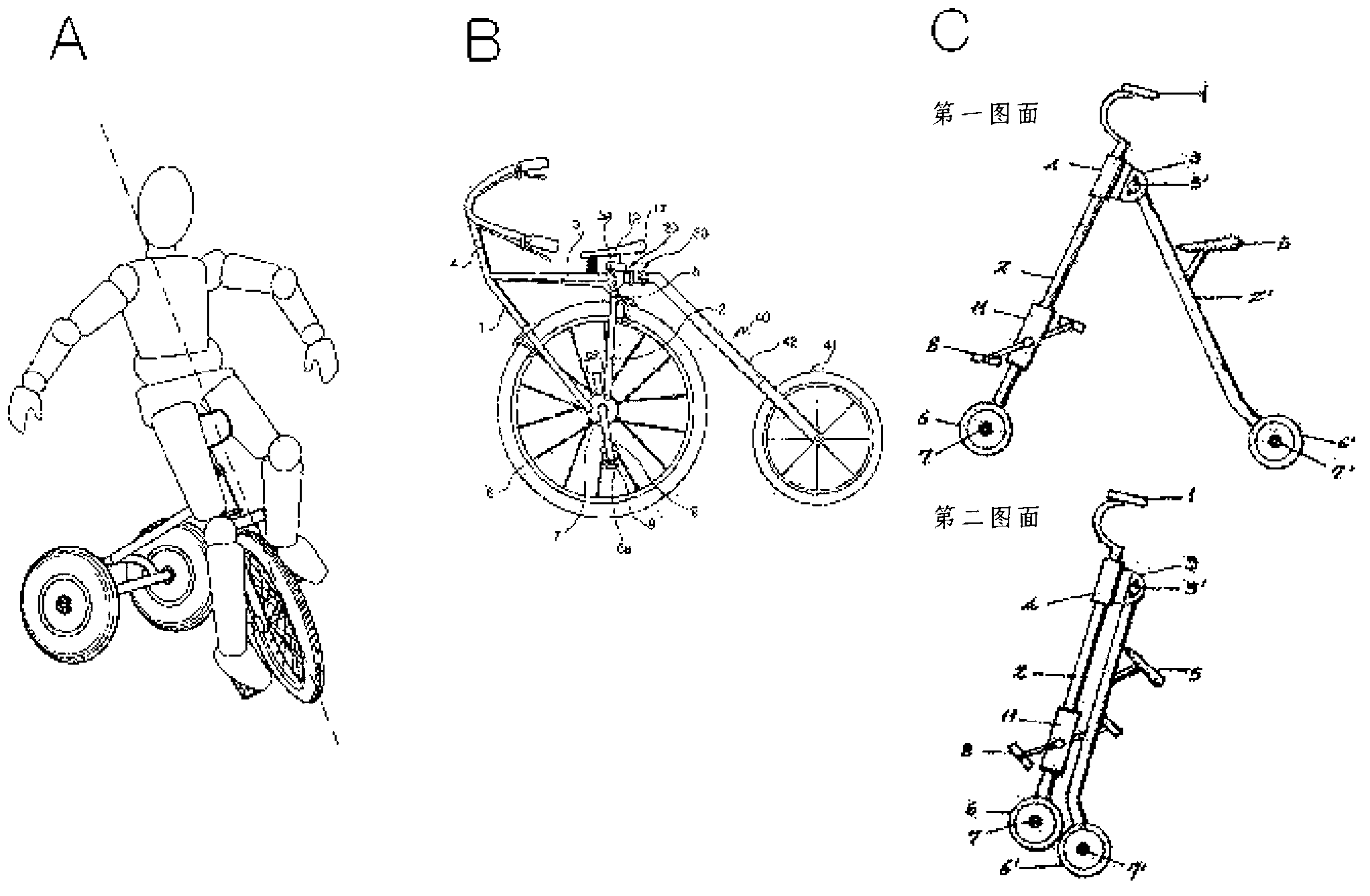

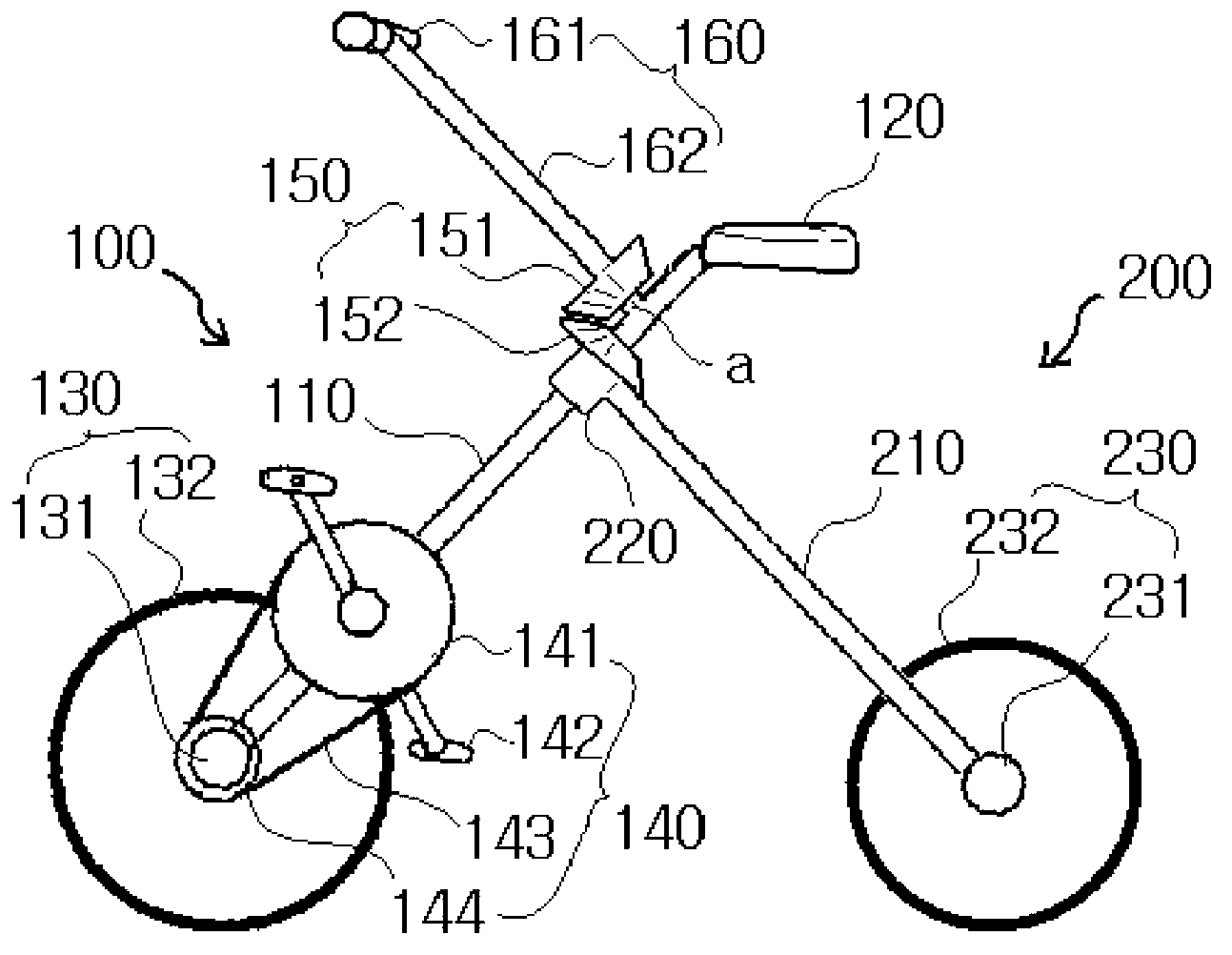

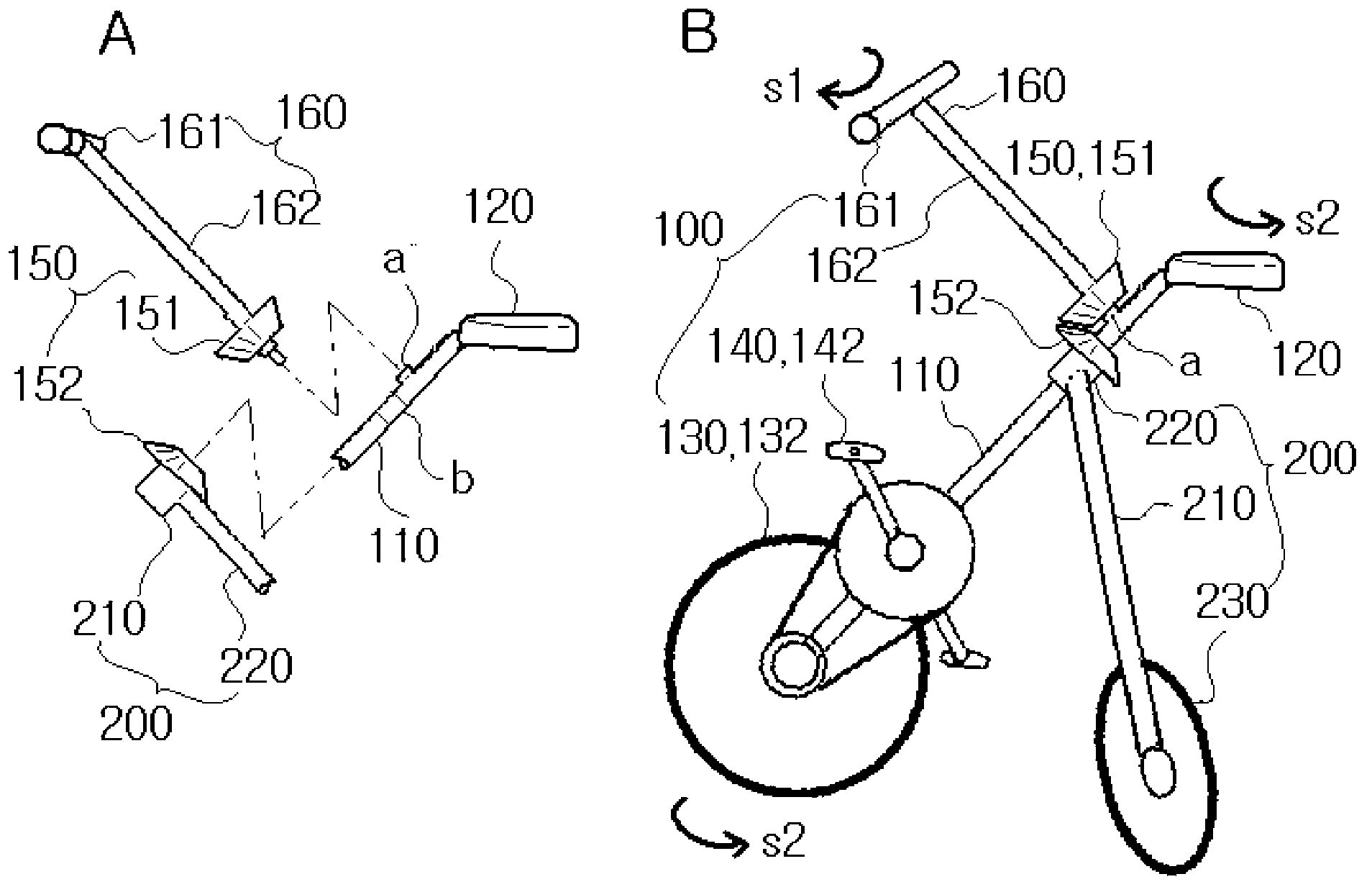

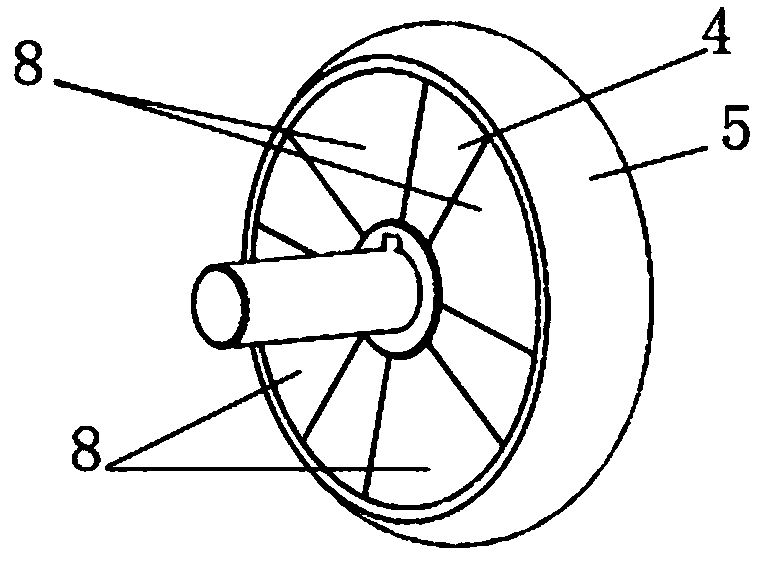

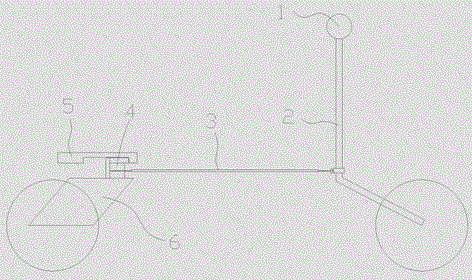

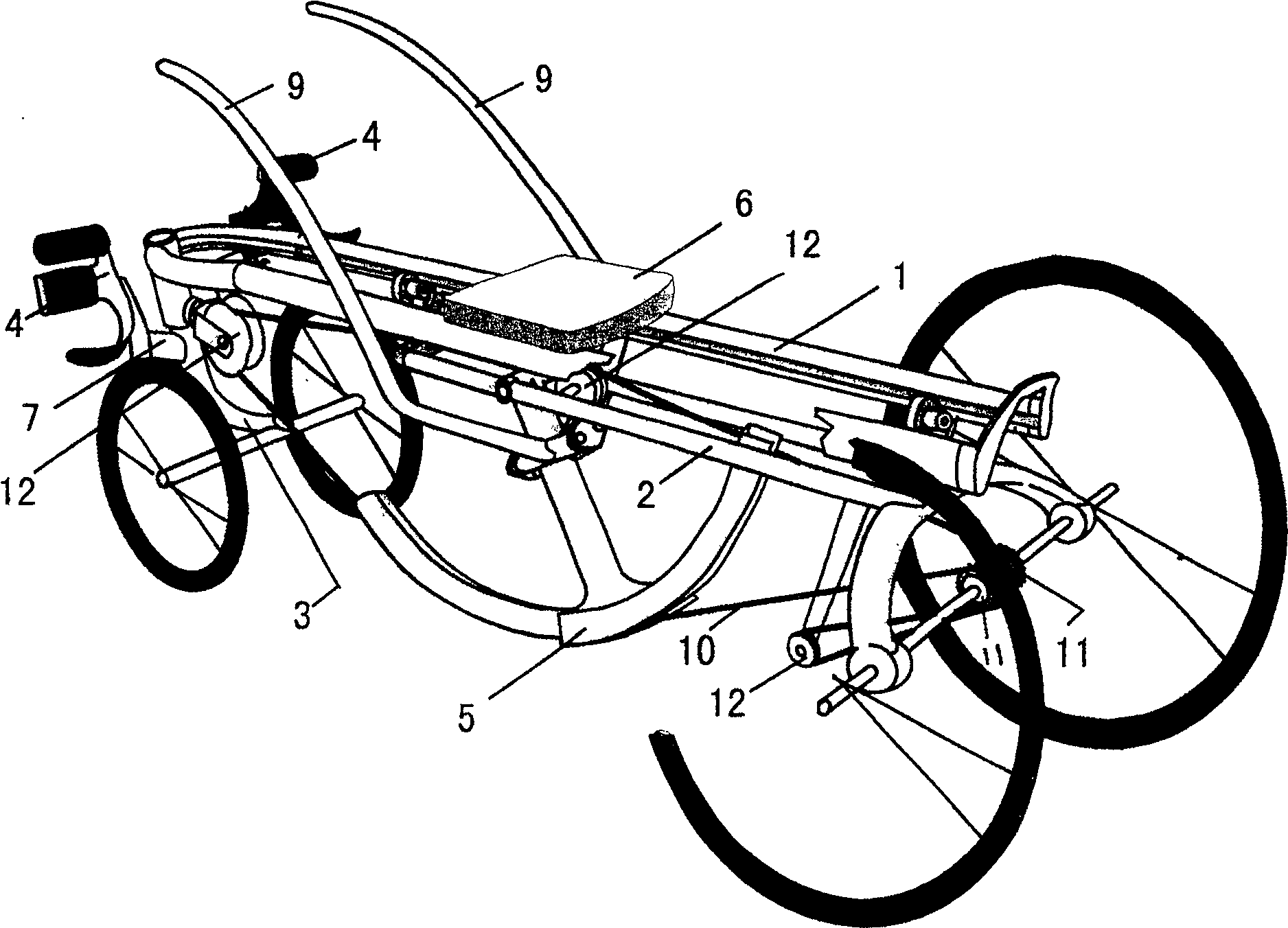

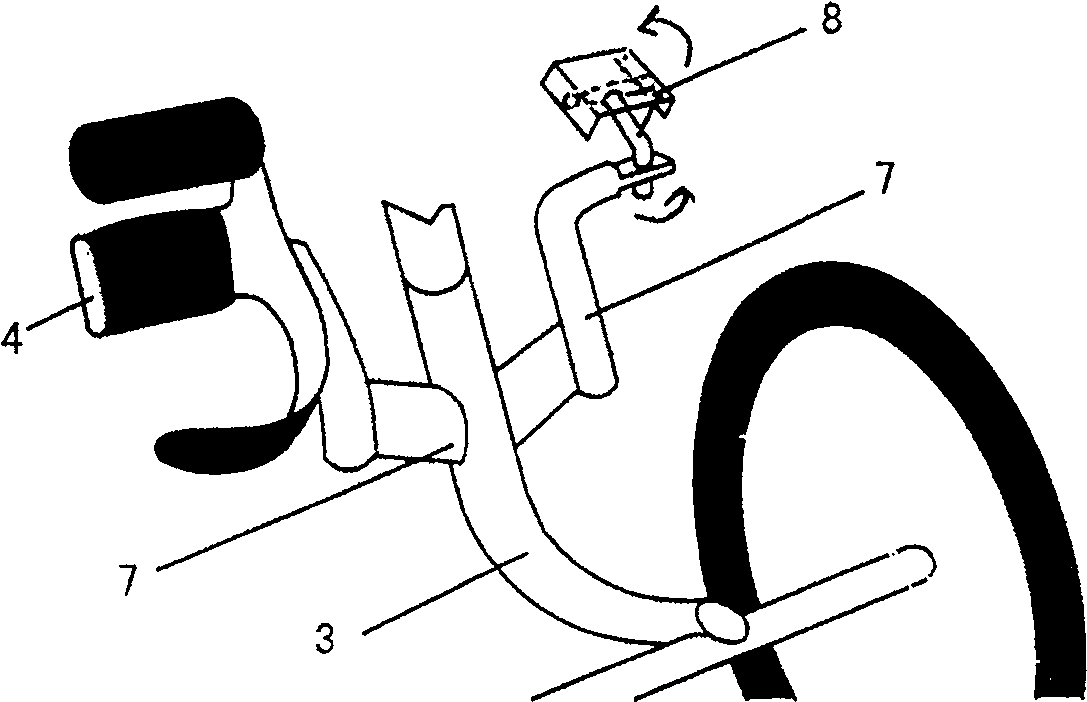

Bicycle driven by rowing and sliding

InactiveCN101085630AOvercome centrifugal forceChange the force structureCyclesCycle saddlesEngineeringCentrifugal force

The invention relates to a slide drive bicycle. It solves the centrifugal force issue while turning and monotonic in power. It uses dual parallel main beam, front and rear of the main beam connected to the front and rear of the sub beam in parallel, front of the main beam fixed with two wheels or a wheel front fork, rear of the sub beam installed with rear shaft of two wheels, both sides of the front fork installed with pedal steering device, front of the sub beam installed with dual slot chain plate driving device, main beam installed with slide seat.

Owner:张东

Elevated half-tube intelligent five-rail high-temperature superconducting maglev train system

InactiveCN113829888AImprove efficiencyReduce copper lossRailway tracksElectric energy managementConvertersRotor (electric)

According to an elevated half-tube intelligent five-rail high-temperature superconducting maglev train system, a plurality of magnetic circuits of four electromagnetic rails of an elevated half-tube intelligent five-rail subsystem are linearly arranged and connected with a plurality of single coils in series in the same direction, and the four electromagnetic rails generate a continuous and uniform magnetic field in the rail direction; pinning magnetic fluxes generated by high-temperature superconducting blocks in 12 monitoring type intelligent Dewar are correspondingly arranged on the four electromagnetic rails in the half tubes respectively, the four electromagnetic rails are surrounded, and the acting force of automatic suspension, automatic stabilization and automatic guiding of the maglev train is enhanced; a plurality of section converters supply power under the control of a photoelectric proximity switch and a wireless remote control receiving module, the electromagnetic field intensity of the electromagnetic rails and the middle electromagnetic rail in the four sections can be controlled, the electromagnetic field can be turned off, and the four electromagnetic rails and the middle electromagnetic rail outside the sections are all in a power-off state; the electromagnetic rails in the interval generate a moving magnetic field to drive a linear direct-current permanent magnet motor rotor; and a linear alternating current generator rotor synchronously induces alternating current output.

Owner:朱幕松

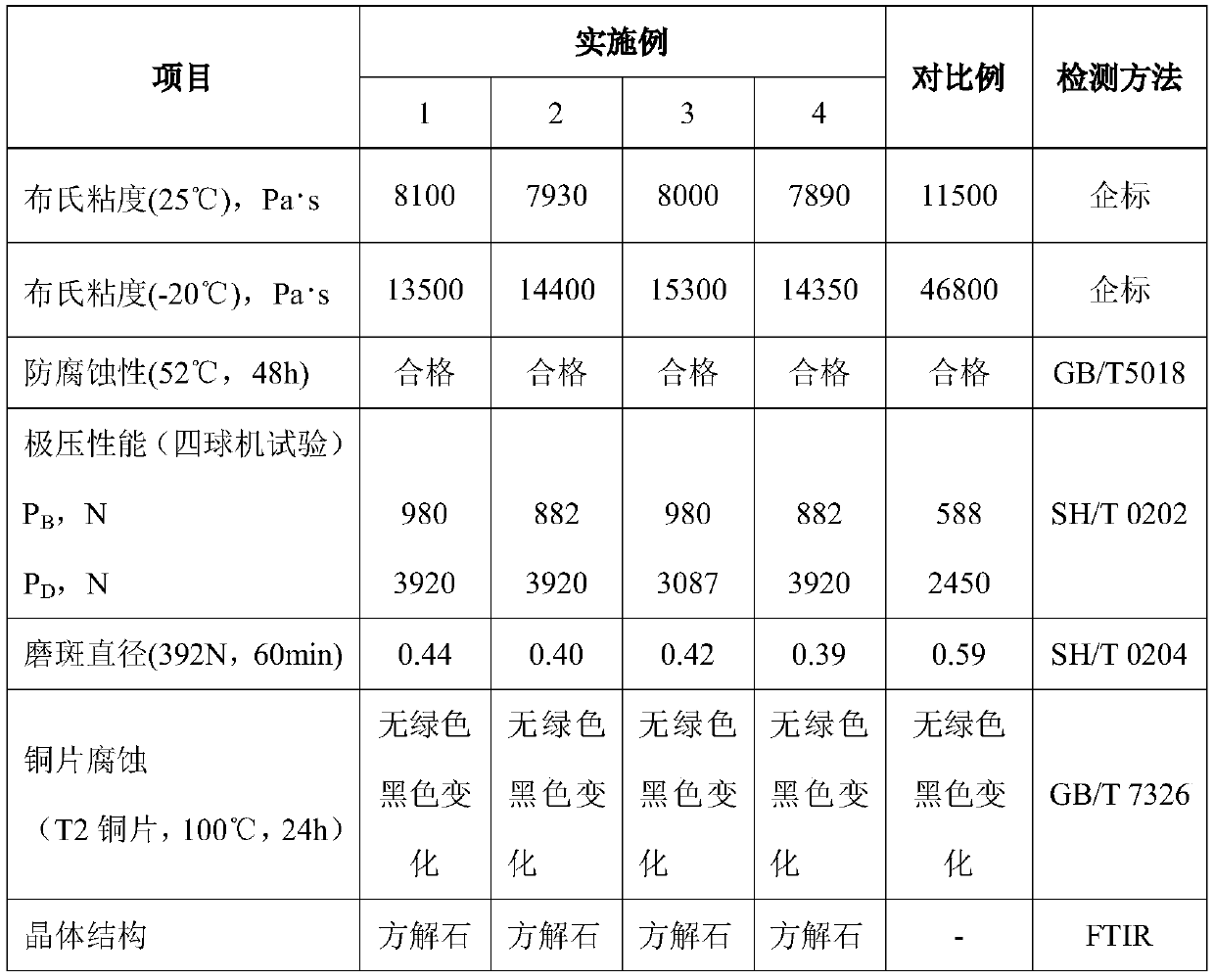

Composite calcium sulfonate type railway wheel rail lubricating grease and preparation method thereof

ActiveCN111500343AImprove featuresWide temperature rangeLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to composite calcium sulfonate type railway wheel rail lubricating grease that comprises 10-30% of high-base-number calcium sulfonate, 65%-85% of base oil, 0.1%-0.6% of mixed alcohol, 0.2%-0.6% of organic acid, 0.2%-0.7% of 12-hydroxystearic acid, 0.1%-0.4% of boric acid, 0.1%-0.3% of calcium hydroxide, 0.3%-0.8% of antioxidant, 0.1%-0.4% of antirust agent and 0.8%-1.2% of solid additive. The percentage is the mass percentage of the total amount of the lubricating grease as a base number. The preparation method comprises the following steps: adding the high-base-number calcium sulfonate and the base oil into a reaction kettle, and fully stirring; adding water, alcohol and acid, heating to 80-89 DEG C, and keeping the constant temperature for 1-3 hours; adding calciumhydroxide, boric acid and 12-hydroxystearic acid, and compounding at 95-100 DEG C for 0.5-1 hour; raising the temperature to 130 to 150 DEG C and dehydrating; and cooling to 80-90 DEG C, adding an additive, shearing, homogenizing and degassing to obtain the product. According to the invention, the lubricating grease has excellent mechanical stability, extreme pressure antiwear property, water resistance, rust prevention and adhesion, is not hardened after long-term storage, can keep excellent pumpability and injection capacity, adapts to temperature change in south and north winter and summerin China, and can be used in all weathers.

Owner:无锡中石油润滑脂有限责任公司

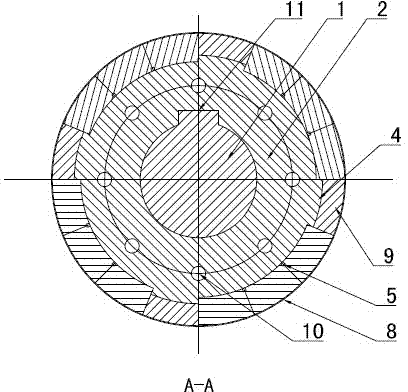

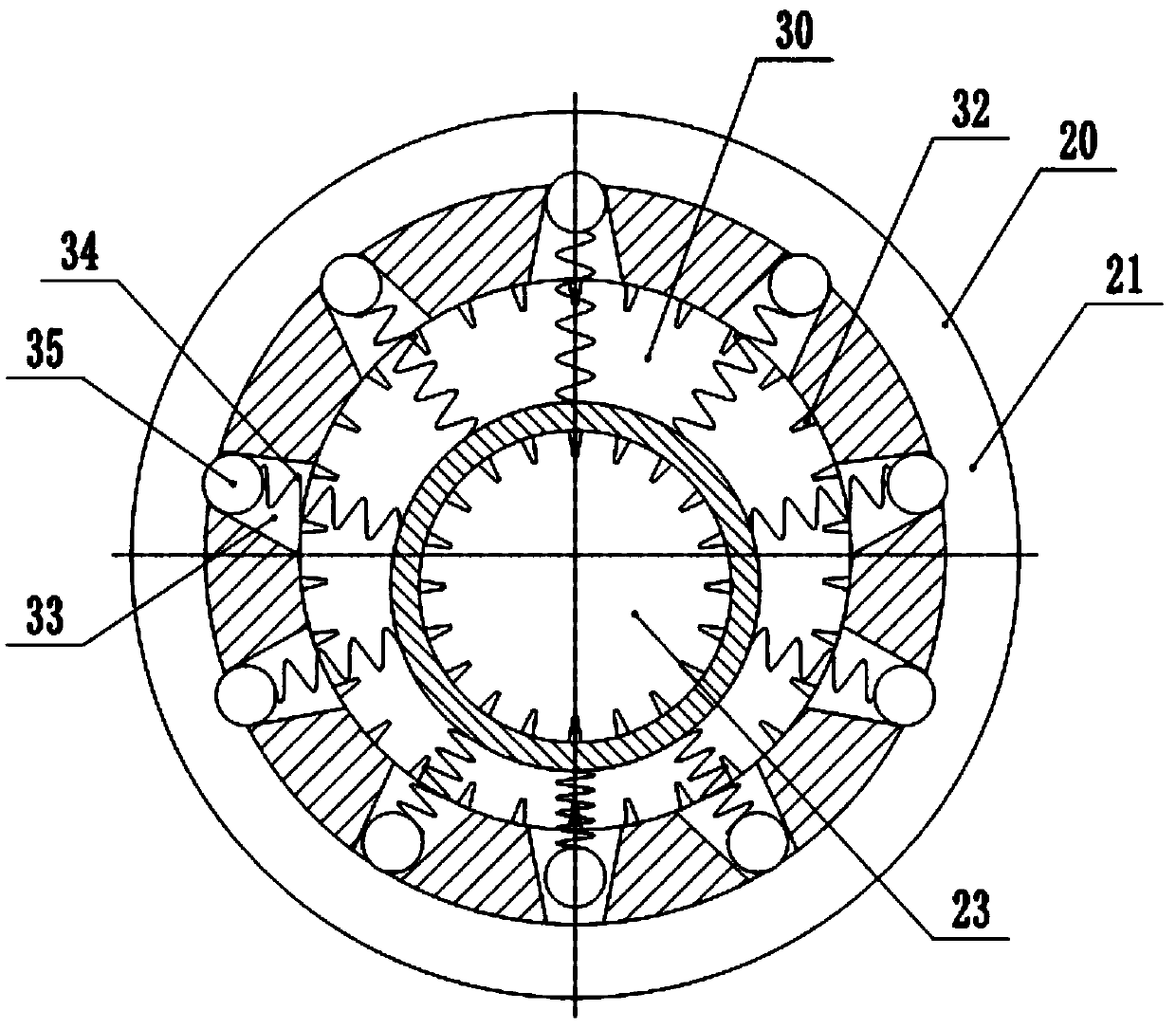

Tangential permanent magnet synchronous motor rotor structure

InactiveCN102570666AExtended service lifeOvercome centrifugal forceMagnetic circuit rotating partsPermanent magnet synchronous motorNon magnetic

A tangential permanent magnet synchronous motor rotor structure comprises a rotating shaft, magnetism isolating shaft sleeves, permanent magnets, rotor pole shoes, a left end plate and a right end plate; the permanent magnets and the rotor pole shoes are distributed at intervals along the circumferences of the magnetism isolating shaft sleeves; the permanent magnets are clung to the rotor pole shoes; a plurality of rotor partition boards made from non-magnetic materials are arranged between the two end plates; the rotor pole shoes are independent from one another; the rotor pole shoes and the rotor partition boards are distributed at intervals in the axial direction; the rotor partition boards divide a rotor into a plurality of rotor units in the axial direction; and two end surfaces of one rotor pole shoe in each rotor unit are clung to the end surfaces of adjacent rotor partition boards; through holes allowing the magnetism isolating shaft sleeves to penetrate are formed on the rotor partition boards; stretching bolts penetrate the left end plate, the rotor pole shoes, the rotor partition boards and the right end plate respectively; and the stretching bolts lock the left and the right end plates and the rotor pole shoes, the permanent magnets and the rotor partition boards between the left and the right end plates in the axial direction. The tangential permanent magnet synchronous motor rotor structure has the advantage of high mechanical strength and is applicable to high-speed rotating motors.

Owner:ZHEJIANG UNIV

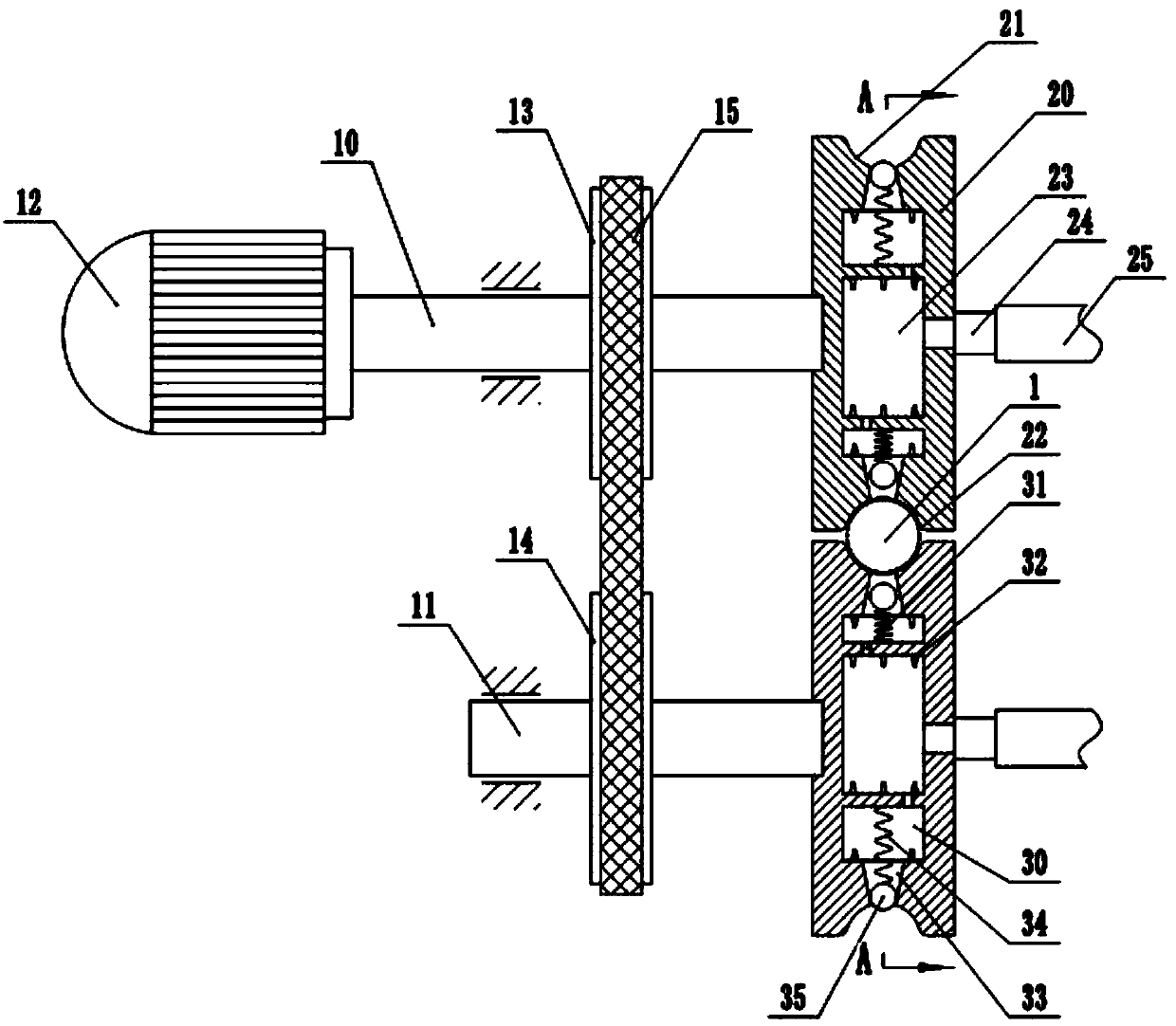

Yarn sizing device

ActiveCN109680433AImprove sizing effectImprove wettabilityTextile treatment machine arrangementsTextile treatment with treating outlet contectYarnTextile production

The invention relates to the technical field of textile production equipment, and particularly discloses a yarn sizing device. The device comprises two sizing wheels, wherein an annular groove is formed in the outer profile of each sizing wheel; a transfer cavity is eccentrically formed in each sizing wheel, an annular mixing cavity is formed in each sizing wheel, and the annular mixing cavity andthe transfer cavity are not coaxially arranged; a diversion passage is formed in the side wall of each transfer cavity, a plurality of size outlets are formed in the side wall of each annular mixingcavity along the circumference; an elastic part is fixed on one side, far from the size outlets, of each annular mixing cavity; magnetic balls positioned in the size outlets are fixed at free ends ofthe elastic parts; when balls in two sizing wheels are repulsed when approaching; and a driving mechanism for driving the sizing wheels to rotate and a supply mechanism for supplying size into the transfer cavity are arranged on the rack. By adopting the technical scheme, the problem of poor yarn sizing effect due to the fact that yarns cannot be soaked with caked size in the prior art can be solved.

Owner:蔡涛

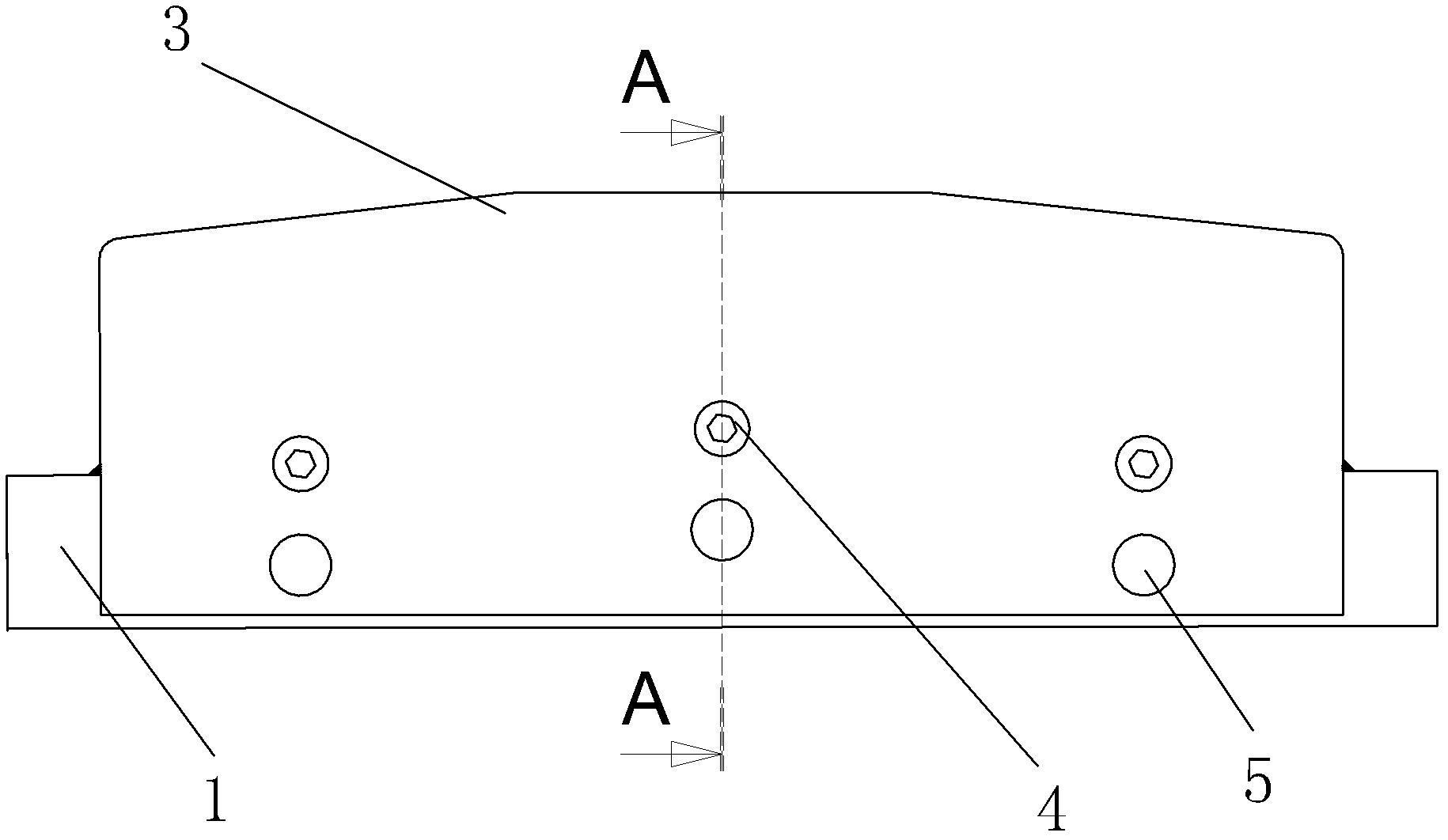

Semi-embedded structure of rotor of permanent magnet synchronous motor

InactiveCN102035279AIncrease in sizeShorten the lengthMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention relates to a semi-embedded structure of a rotor of a permanent magnet synchronous motor. The structure has the advantages of a convex type rotor and an inserting type rotor, thereby being capable of reducing the larger flux leakage caused by an embedded type rotor, and being capable of guaranteeing that an electric machine can stably run at more than 10000rpm. The structure is characterized in that the rotor of the permanent magnet synchronous motor is of the semi-embedded structure, and magnet steel is embedded in an iron core of the rotor, so that the rotor can not be thrown out caused by the overlarge centrifugal force when the rotor rotates at high speed. The semi-embedded structure of the rotor of the permanent magnet synchronous motor is convenient to machine, saves the material, avoids the flux leakage, improves the capability of the rotator, and is good for the popularization and the use of the high-efficiency permanent magnet synchronous motor.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

A magnet assembly installation method for a permanent magnet motor

ActiveCN102290928AOvercome centrifugal forceOvercoming unilateral magnetic pullManufacturing stator/rotor bodiesEngineeringPermanent magnet motor

The invention relates to a method for installing magnet components of a permanent magnet motor. The method comprises the following steps that firstly a magnet is placed on a magnet base so as to aim the periphery of the magnet at the periphery on the surface of the magnet base; secondly a magnet protective cover of a non-magnetic conductive material is sleeved in the magnet, the magnet is fully covered by the magnet protective cover, fixing bolts are utilized to pass through the magnet protective cover and are screwed in the magnet base so as to fix the magnet on the magnet base; thirdly the magnet protective cover is connected with the magnet base so as to integrally connect the magnet protective cover with the magnet base; and fourthly escaping fixing screw nail holes used for escaping and fixing screw nail caps are formed at the side of the magnet protective cover when a plurality of magnet protective covers are connected in sequence, and counter bores are also formed on the magnet base corresponding to the escaping fixing screw nail holes, partial of the fixing screw nail caps are also arranged in the counter bores, and the magnet components are finished installing.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

A kind of dehydration processing method of down and down anti-caking

ActiveCN112268430BAvoid concentrated accumulationImprove dehydration efficiencyDrying solid materials without heatDrying machines with non-progressive movementsElectric machineProcess engineering

The invention discloses an anti-caking down dehydration processing method, which comprises the following processing steps: feeding, dehydration, and collection. The processing equipment used in the above-mentioned dehydration processing method for anti-caking down down includes a collection box and a fixed The processing box at the upper end of the collection box, the side wall of the collection box is inserted with a water outlet pipe, the inner bottom of the collection box is fixed with a motor, the output shaft of the motor runs through the bottom of the processing box and is fixed with a drum, A plurality of water outlet holes are opened through the side wall of the drum. The advantage is that: in the present invention, by setting the lower end of the drum to be narrow and the upper end wide, and the inner wall of the lower part is arc-shaped, so that when the drum rotates at high speed, the down accumulated at the bottom will quickly move along the inner wall of the drum under the action of centrifugal force. Move upwards, so that it is relatively evenly distributed on the inner wall of the drum, so as to avoid the concentrated accumulation of a large amount of down and make the dehydration process more efficient.

Owner:杭州金弘三鸟羽绒制品有限公司

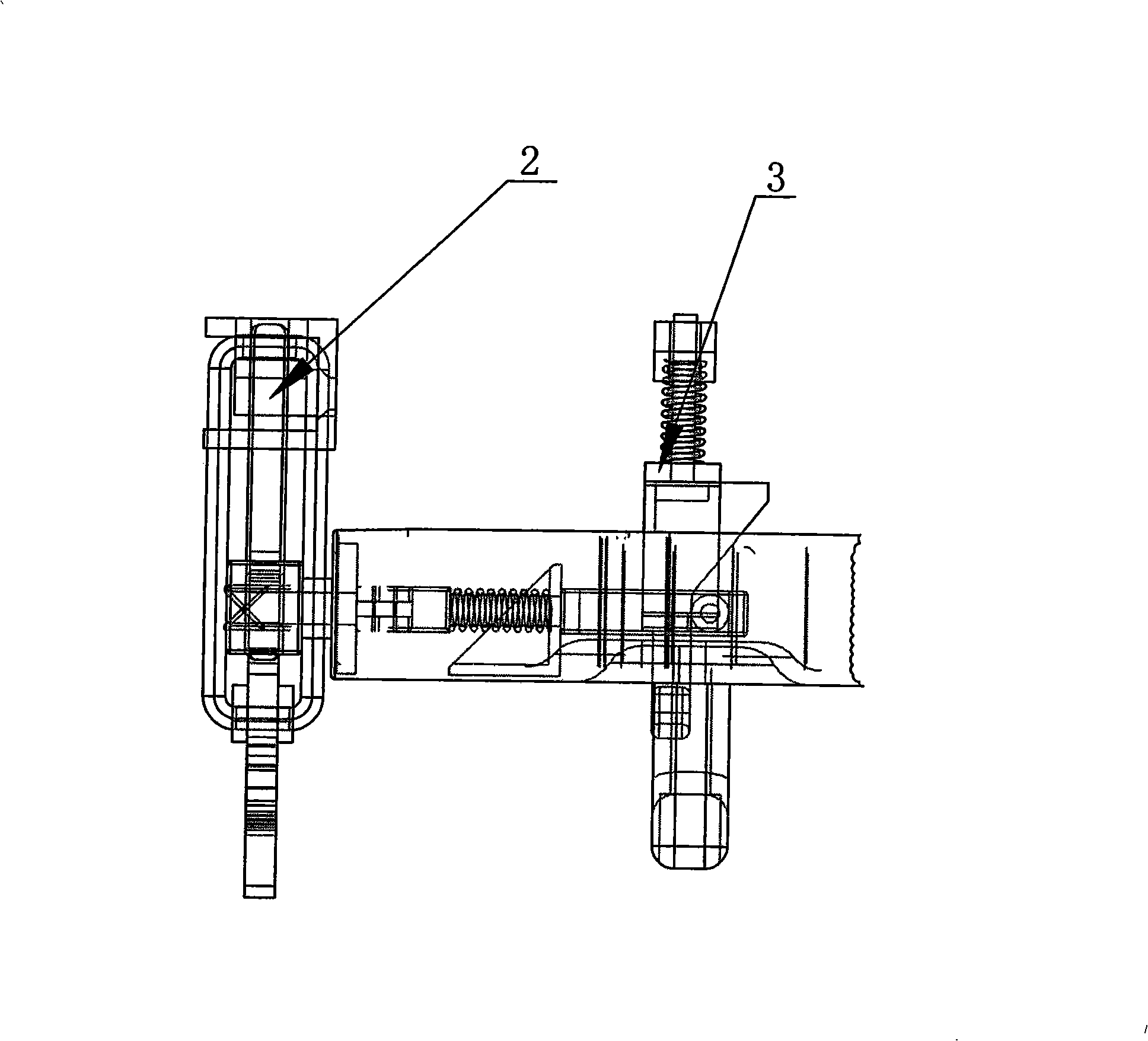

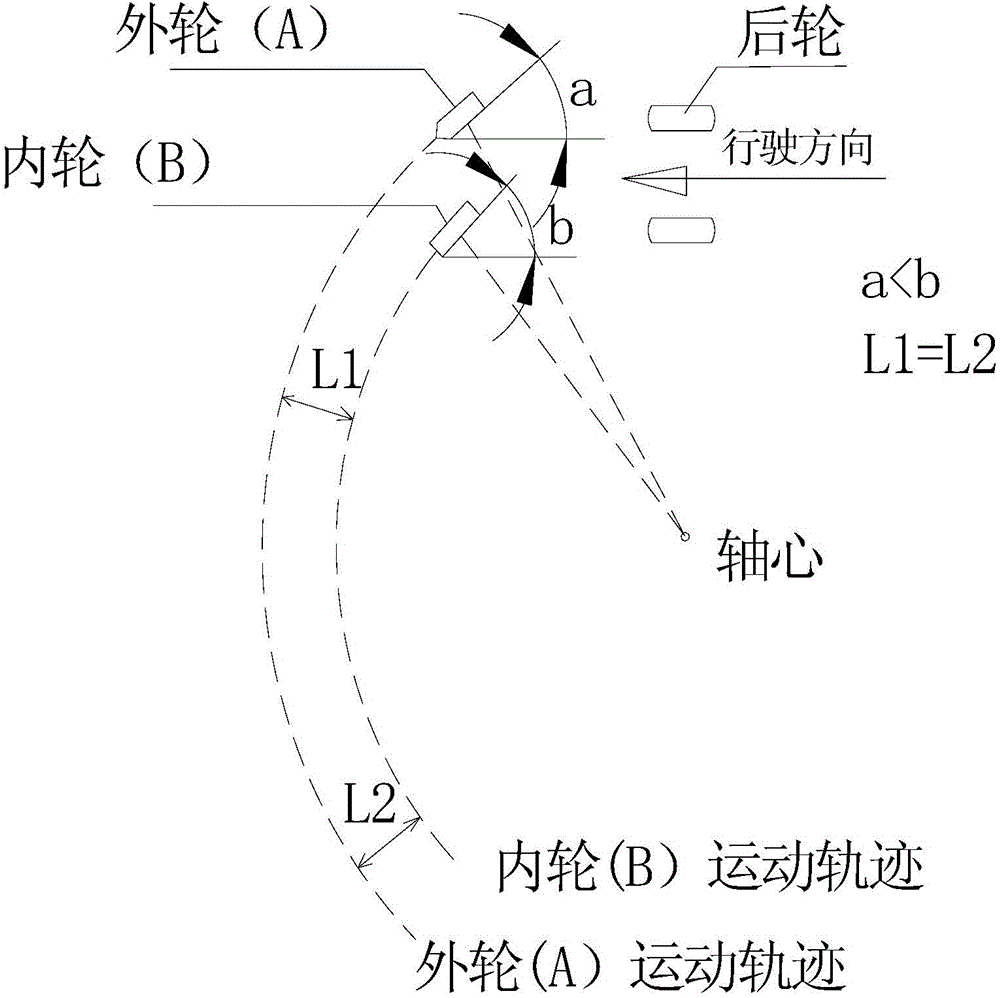

System for horizontally transferring center of gravity of tricycle

The invention provides a system for horizontal transferring the center of the gravity of a tricycle, and relates to the technical field of the steering adjustment of a vehicle. The system comprises a vehicle frame. The system is characterized in that a center seat frame which can be adjusted right and left and a center rotary wheel mechanism which is used for driving the center seat frame to be adjusted right and left are arranged at the upper end of the vehicle frame, the center rotary wheel mechanism is connected with a steering shaft by a transmission mechanism, and the upper end of the steering shaft is connected with a steering handle / disc. The system for horizontal transferring the center of the gravity of a tricycle, provided by the invention, can be used for directly, synchronously and horizontally transferring the center of the gravity of the vehicle when the vehicle turns, so that the centrifugal force of the vehicle can be overcome under the condition of keeping changeless posture of a driver and a passenger when the vehicle turns, and the safety of the vehicle, the driver and the passenger can be ensured.

Owner:BENGBU TANGREN MACHINERY SCI & TECH

Smart steering mechanism for car

InactiveCN104097687AOvercome centrifugal forceIncrease the lengthSteering linkagesSteering wheelEngineering

The invention discloses a smart steering mechanism for a car. The smart steering mechanism comprises an isosceles triangle steering pull rod, an adjusting rod, a left driven steering rocker, a right driven steering rocker, a steering push rod and a steering shaft center fixedly connected to a car chassis. The driven steering rockers are symmetrical. By the smart steering mechanism, lateral sliding of steering wheels is avoided, operability and safety are increased, car wheel abrasion is reduced, and travelling resistance and fuel consumption are reduced.

Owner:刘海云

Bicycle driven by rowing and sliding

InactiveCN100513248COvercome centrifugal forceChange the force structureCyclesRider propulsionEngineeringCentrifugal force

The invention relates to a slide drive bicycle. It solves the centrifugal force issue while turning and monotonic in power. It uses dual parallel main beam, front and rear of the main beam connected to the front and rear of the sub beam in parallel, front of the main beam fixed with two wheels or a wheel front fork, rear of the sub beam installed with rear shaft of two wheels, both sides of the front fork installed with pedal steering device, front of the sub beam installed with dual slot chain plate driving device, main beam installed with slide seat.

Owner:张东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com