[0005] The beneficial effect of the intelligent track-holding high-temperature superconducting maglev train system is that: the

magnetic field distribution generated by the permanent

magnet track built by the permanent magnets used in the existing high-temperature superconducting maglev trains is limited by the

magnetization intensity and

magnetization direction of the unit permanent

magnet, and lacks Denaturation, the magnetic field of the permanent magnet track cannot be turned off, resulting in magnetic

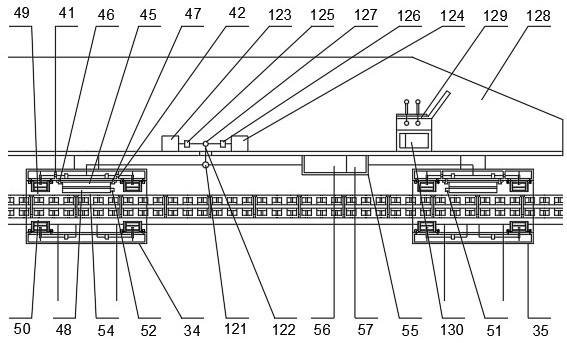

pollution of the whole permanent magnet track; the four electromagnetic tracks of the intelligent rail holding subsystem are all intelligently controlled electromagnetic tracks; the multiple magnetic circuits of the four electromagnetic tracks are straight The arrangement and multiple single coils are connected in series in the same direction, so that the four electromagnetic tracks can generate a continuous and uniform magnetic field along the track direction. The magnetic

field strength and magnetic field distribution can make the suspension force of the high-temperature superconducting block placed in the suspension area reach the required The required strength, and can move smoothly along the direction of the track, so as to achieve the purpose of replacing the permanent magnet track; the upper left electromagnetic track, the upper right electromagnetic track, the lower left electromagnetic track, and the lower right electromagnetic track form a 4-angle symmetrical balance moment; 16 of the independent system unit A monitoring intelligent Dewar produces a stable pinning

magnetic flux, which has both repulsive and attractive magnetic forces. The repulsive magnetic force of the upper left electromagnetic track and the upper right electromagnetic track and the attractive magnetic force of the lower left electromagnetic track and the lower right electromagnetic track support the independent system unit. Gravity; the pinned magnetic flux generated by the 16 monitoring-type intelligent Dewars of the independent system unit surrounds the 4 electromagnetic rails, which strengthens the automatic suspension, automatic stabilization and

automatic guidance of the independent system unit, and overcomes the force of the train when turning

Centrifugal force stabilizes the steering of the train, and the diamagnetic effect of the high-temperature superconducting block enables the independent system unit to be stably suspended between the four electromagnetic rails without precise

active control; Intelligent power supply under the

sequential control of the receiving module, the

electromagnetic field strength of the 4 electromagnetic tracks and the middle electromagnetic track in the section can be controlled, the electromagnetic field can be turned off, and the 4 electromagnetic tracks outside the interval and the middle electromagnetic track are in a power-off state, and the smart track It not only saves energy, but also avoids magnetic

pollution; the variable frequency

linear motor adopts the mode of driving multiple short movers by the

stator of the section section, and there are intervals between the multiple short movers, and the electromagnetic track in the section is a variable frequency

linear motor and a linear generator. The

stator of the interval segment, the

magnetic levitation train unit represents a plurality of short movers, the length of the electromagnetic track in the interval is longer than that of the

magnetic levitation train set; the multiple single coils of the interval segment

stator are all connected in series, and the interval segment stator is connected with the variable frequency

linear motor mover and the linear motor The magnetic flux density of the multiple single-coil parts close to the generator movers is large, so that the impedance of the multiple single-coils is large, the

voltage drop is large, and the useful power is large; the multiple single-coil magnetic fluxes of the remaining parts of the section segment stator The density is small, so that the impedance of the multiple single coils is small, the

voltage drop is small, and the useless power is small; under the condition that the air gap between the multiple short movers and the section stator is stable, during the

linear motion of the multiple short movers In the middle, the front and rear section

converters continuously supply power to the front and rear section stators. In order to maximize the stress area of multiple short movers for the section section stators, the useful power of the front section section stators changes from small to large. The useful power of the section stator changes from large to small, which causes

copper loss defects in the 3-phase coil of the section stator, and makes the work efficiency of the

frequency conversion linear motor and linear generator not high; but there is no friction in the

high temperature superconducting maglev train Resistance, the

frequency conversion linear motor can accelerate the maglev train to 600 km / h without a large drive power, the

power consumption of the maglev train

control system is small, so that the power of the linear generator is small, even if the

frequency conversion linear motor and linear generator The work efficiency is not high and does not affect the energy-saving effect of the maglev train; when the maglev train leaves the stator of the rear section, the impedance of multiple single coils of the stator of the rear section is small, so that the output current of the

frequency modulation and

voltage regulation module is greater than the rated value, and the electronic

frequency modulation The voltage regulating module is automatically

shut down, and the stator in the rear section is automatically powered off; the failure of any part of the high-temperature superconducting magnetic

levitation mechanism, power supply mechanism, traction mechanism, control mechanism and braking mechanism of the independent system unit does not affect the normal work of other independent system units , once a power outage accident occurs in the intelligent track subsystem, the maglev train set will descend, and multiple left and right

brake shoe planes will be supported on the left upper and right upper electromagnetic track planes, and the maglev train set will automatically perform emergency braking to avoid accidents; Multiple monitoring intelligent Dewars are equipped with high-temperature superconducting blocks. When low-temperature

liquid nitrogen is injected into multiple Dewars, the high-temperature superconducting blocks cool down to a superconducting state. Due to the complete

diamagnetism of the high-temperature superconducting blocks, The maglev train set can be suspended between 4 electromagnetic rails. Due to the pinning effect of the high-temperature superconducting blocks, the maglev is self-stabilizing without any maglev

control system; the temperature of multiple high-temperature superconducting blocks can be seen on the monitor to; the

positive pressure liquid nitrogen replenishment Dewar tank, the negative pressure gas

nitrogen recovery Dewar tank and a plurality of solenoid valves constitute a simple low-temperature

refrigeration system, and realize intelligent

temperature control; the monitoring intelligent Dewar high temperature ultra- The bracket of the guide block can meet the requirements of high

mechanical strength during the high-speed running of the train; the upper and lower vacuum chambers and the annular

vacuum chamber of the monitoring intelligent Dewar reduce the

heat leakage of the Dewar system; under the protection of the

brass high-temperature superconductor cavity , so that the high-temperature superconducting block material can run safely and stably; the power supply system of the intelligent track saves the high-voltage

catenary power supply system of the prior art, and the power supply reliability is improved; there is no

frictional resistance in the high-temperature superconducting maglev train, and the frequency conversion linear motor is A high-speed 2-pole 3-phase AC induction asynchronous variable frequency motor, therefore, the section stator does not need a large driving power to accelerate the maglev train to 600 km / h, and the energy-saving effect of the intelligent rail-holding high-temperature superconducting maglev train system is remarkable

Login to View More

Login to View More  Login to View More

Login to View More