Cooling liquid for diamond cutting line to cut solar silicon chips

A technology for cutting solar silicon wafers and diamond wires, applied in the direction of lubricating compositions, etc., can solve the problems of unsatisfactory dispersion of silicon powder and iron impurities, etc., achieve good lubrication and cooling effects, ensure surface properties, and good dispersion effect

Active Publication Date: 2013-01-02

FUNDANT CHANGZHOU ADVANCED METAL TECH

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] The technical problem to be solved by the present invention is to overcome the unsatisfactory dispersing effect of the existing water-based cooling liquid on the silicon powder and iron impurities produced in the cutting process, and provide a cooling liquid for diamond wire cutting of solar silicon wafers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

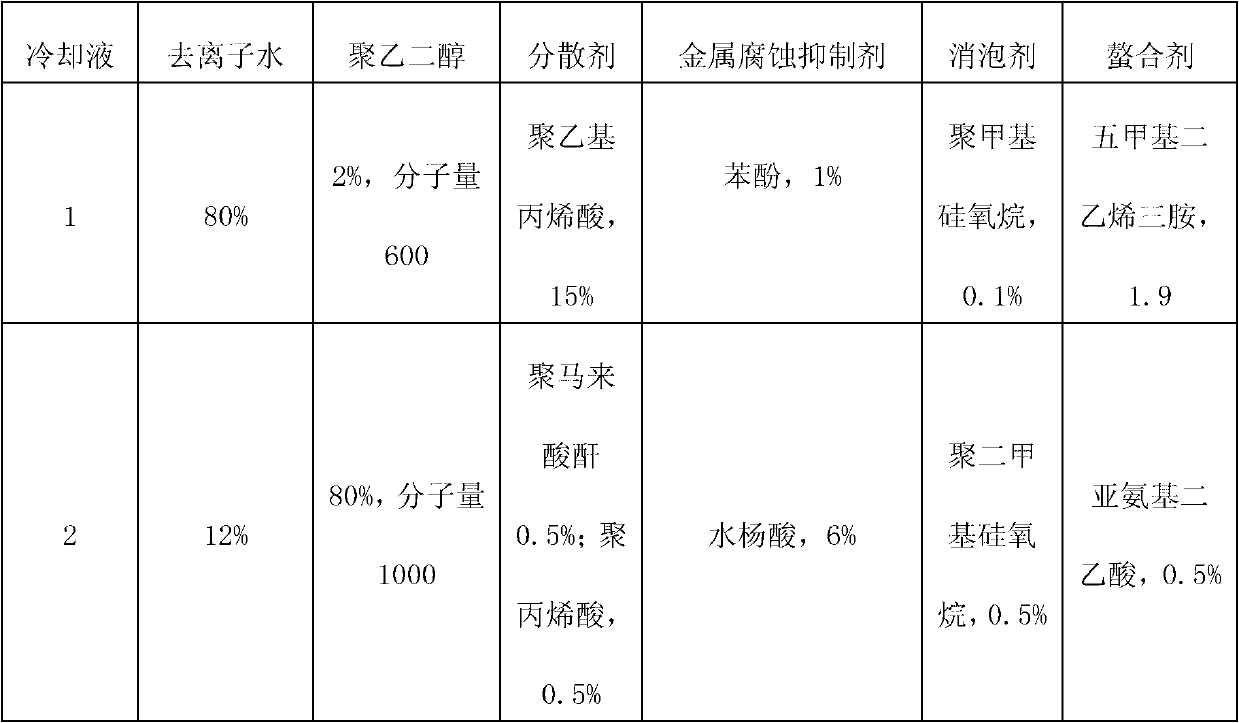

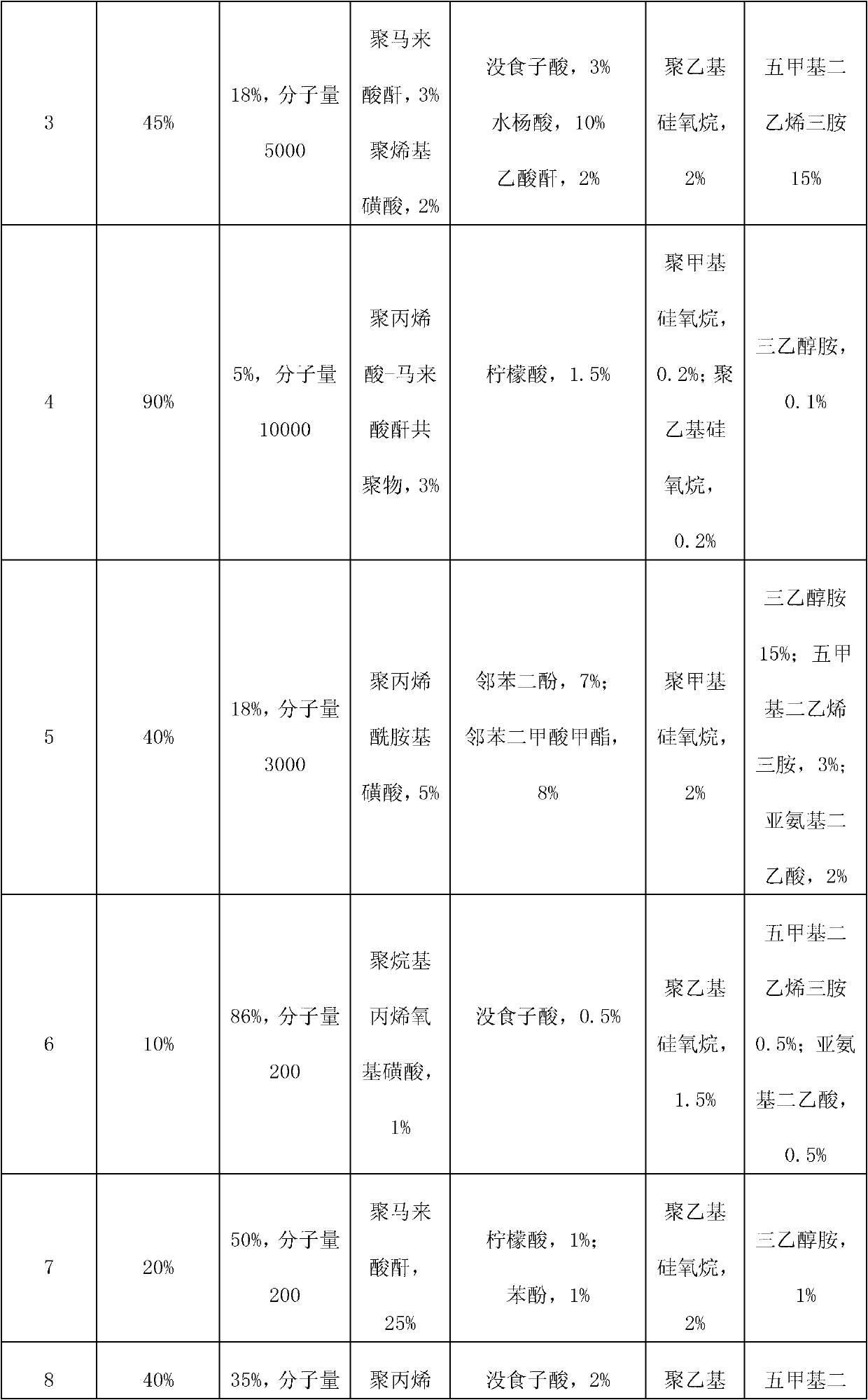

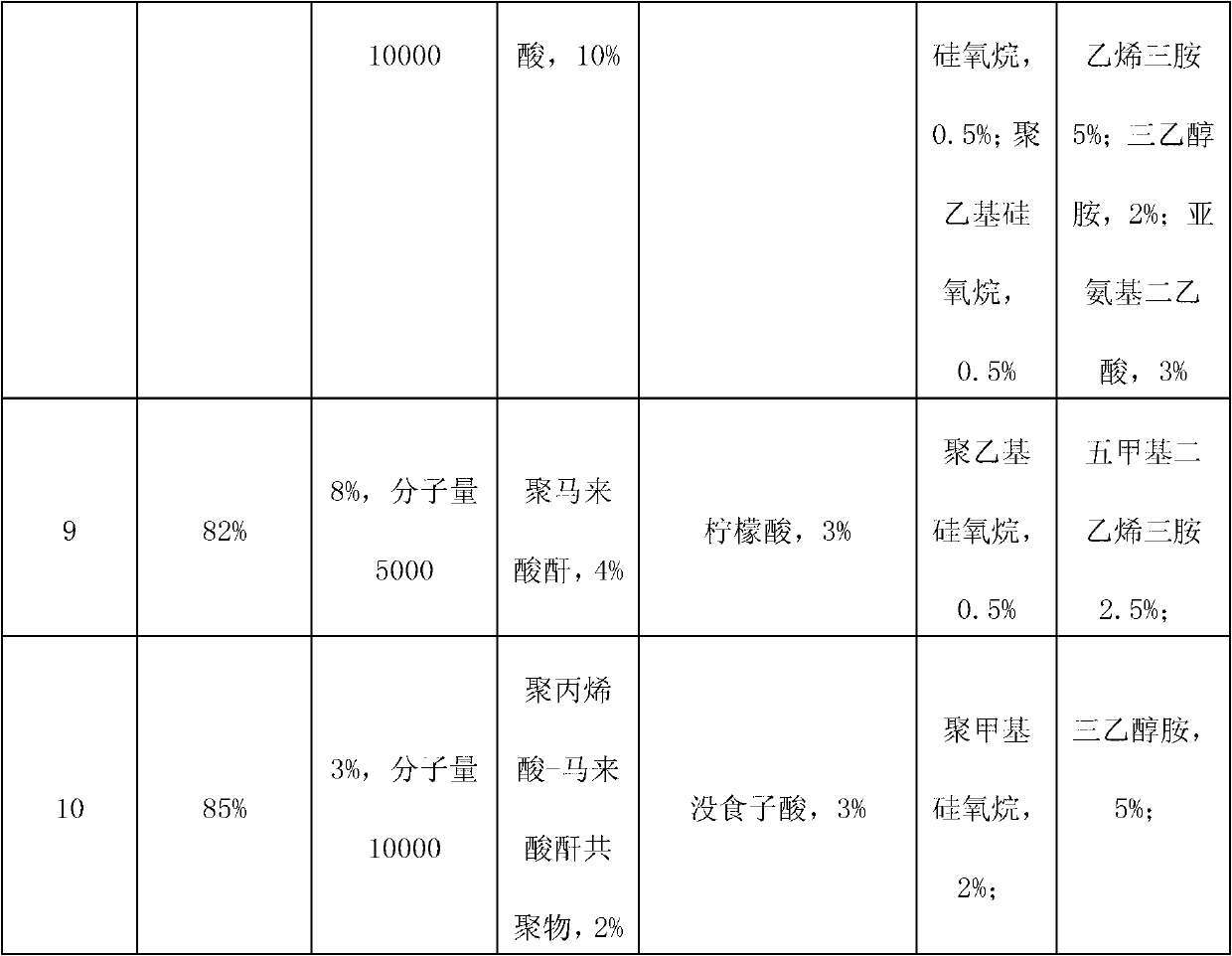

[0026]

[0027]

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a cooling liquid for a diamond cutting line to cut solar silicon chips, which comprises the following components by mass percent: 10 to 90 percent of water, 2 to 86 percent of polyethylene glycol, 1 to 25 percent of dispersing agent, 0.1 to 20 percent of chelate, 0.5 to 15 percent of metal corrosion inhibitor and 0.1 to 2 percent of defoamer. The cooling liquid can be matched with the diamond cutting line for cutting, has good lubricating and cooling effects, effectively reduces the line breaking rate, has a good dispersant effect on silicon powder and iron tramp produced during the cutting process, guarantees the surface performance of the silicon chips, is low in cost and is pollution-free and environmentally friendly.

Description

technical field [0001] The invention relates to a cooling liquid for diamond wire cutting solar silicon wafers. Background technique [0002] With the rapid development of the world economy, energy consumption is increasing, and all countries in the world need the application and popularization of new energy. As the greenhouse gas effect caused by carbon dioxide emissions causes global warming and causes natural disasters, the demand for clean and renewable energy is particularly strong in countries around the world. Since the global crisis caused by the subprime mortgage crisis in the United States in 2007 has spread and expanded, in order to stimulate economic growth, countries have adopted more active measures to encourage the use of renewable energy. The Obama administration of the United States proposed to invest 150 billion US dollars in clean energy in the next 10 years; the European Union set a target to increase the proportion of renewable energy to 20% of the ener...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M173/02C10M169/04

Inventor 励征

Owner FUNDANT CHANGZHOU ADVANCED METAL TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com