Preparation method of indium phosphide seed crystal

A technology of indium phosphide and seed crystal, which is applied in the field of preparation of indium phosphide seed crystal, can solve the problem of the influence of indium phosphide single crystal growth, uncontrollable seed crystal orientation angle, dense dislocation of indium phosphide single crystal or electrical Performance exceeds the standard and other problems, to achieve the effect of improving the quality of crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

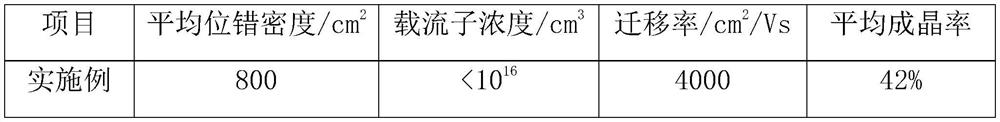

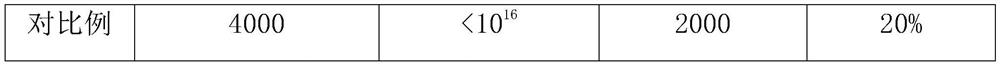

Examples

Embodiment

[0024] S1: Adjust the angle of the indium phosphide single crystal head and take a test sample.

[0025] A1: Slice the indium phosphide single crystal head to obtain an indium phosphide wafer with a thickness of 0.8-1.2mm, and cut and break the indium phosphide wafer to obtain square pieces. That is to say, the circular indium phosphide wafer is uniformly cut into four small openings with a tool at the edge using the existing method, and then the edge of the indium phosphide wafer is partly split along the small openings to form four mutually perpendicular , the intersecting section, which is a cleavage surface, thus changing the indium phosphide wafer from a circle to a square, that is, a square piece. Since the circular indium phosphide wafer is inconvenient to locate during detection, the circle The shaped indium phosphide wafer is broken into square pieces, which is convenient for positioning operation.

[0026] A2: Use a square piece to measure the actual crystal orienta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com