Fully synthetic stainless steel cold rolling mill compound and application thereof

A cold rolling and composition technology, which is applied in the field of fully synthetic stainless steel cold rolling liquid composition, can solve the problems of short service life, poor lubricating extreme pressure and the like, and achieve long service life, good lubricity, and good environment. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

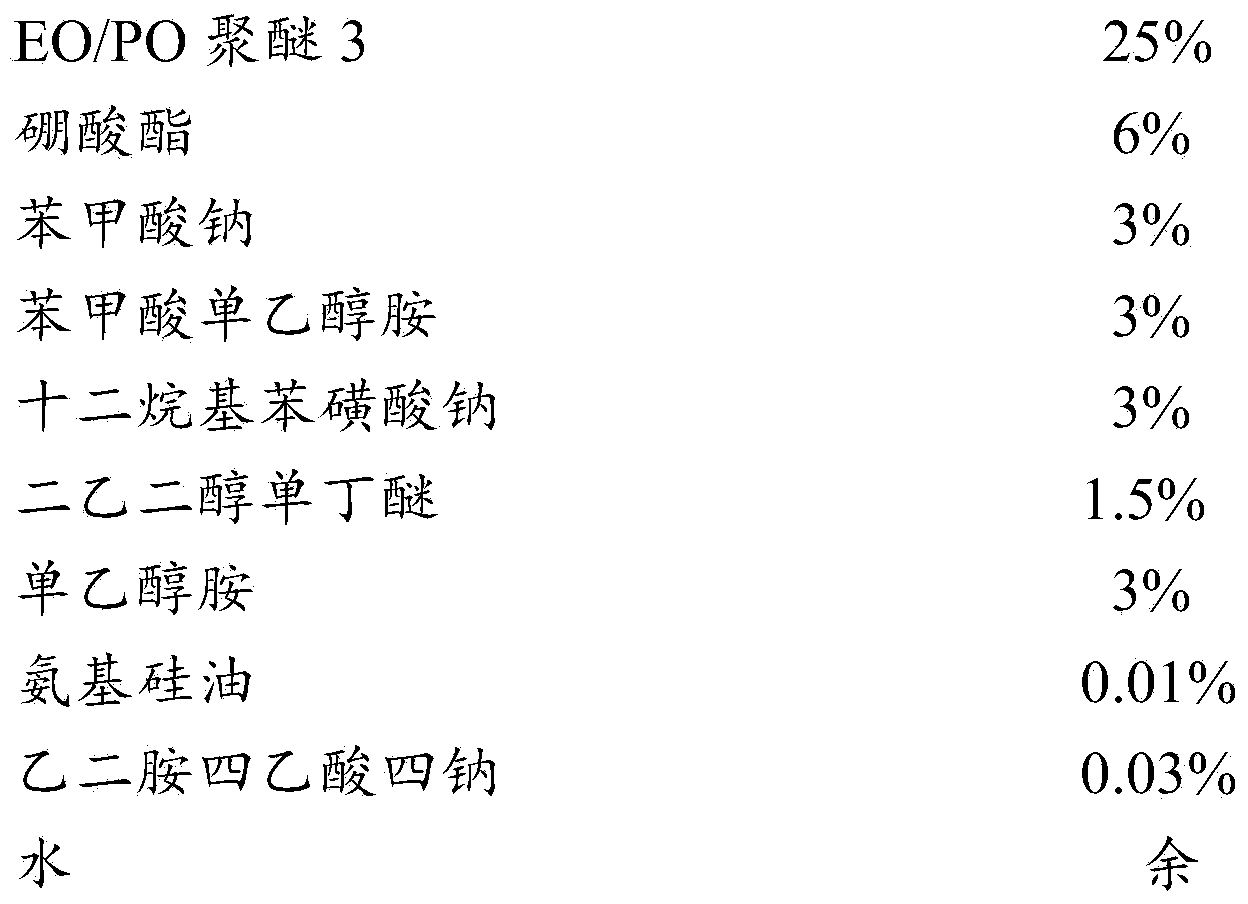

[0035] Heat the deionized water to 35°C, and add the required amount of water-soluble lubricant, water-soluble extreme pressure agent, water-soluble anti-rust agent, coupling agent, pH regulator, cleaning agent, defoamer and chelating agent in sequence while stirring. Mixture, adjust the pH value to 7.5-8.5, stop stirring and heating after fully stirring for 1.5 hours, filter and fill after standing for 1.5 hours. The specific components and contents of each component in the composition are shown in Table 2. Wherein, the content of each component is the number of parts. In each embodiment, deionized water is used to supplement 100 parts, and the content of component water is omitted.

Embodiment 1

[0037]

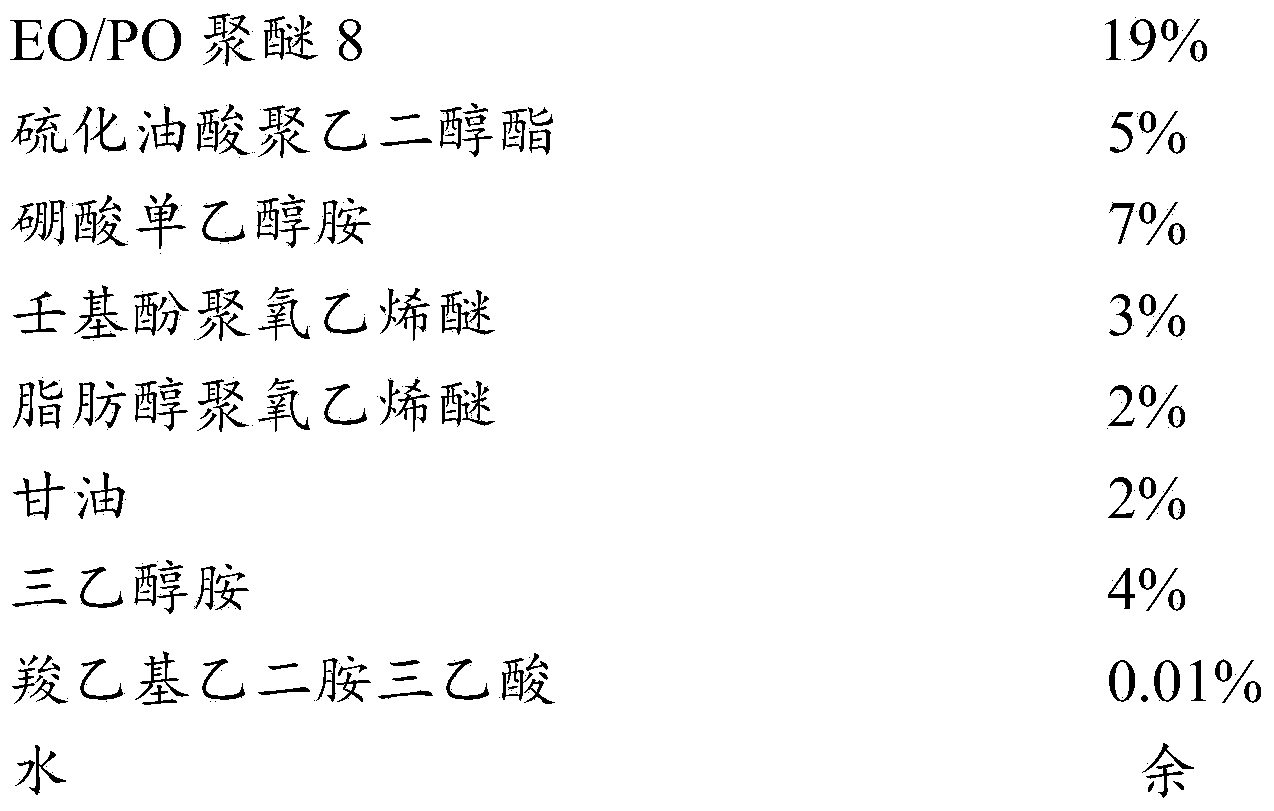

Embodiment 2

[0039]

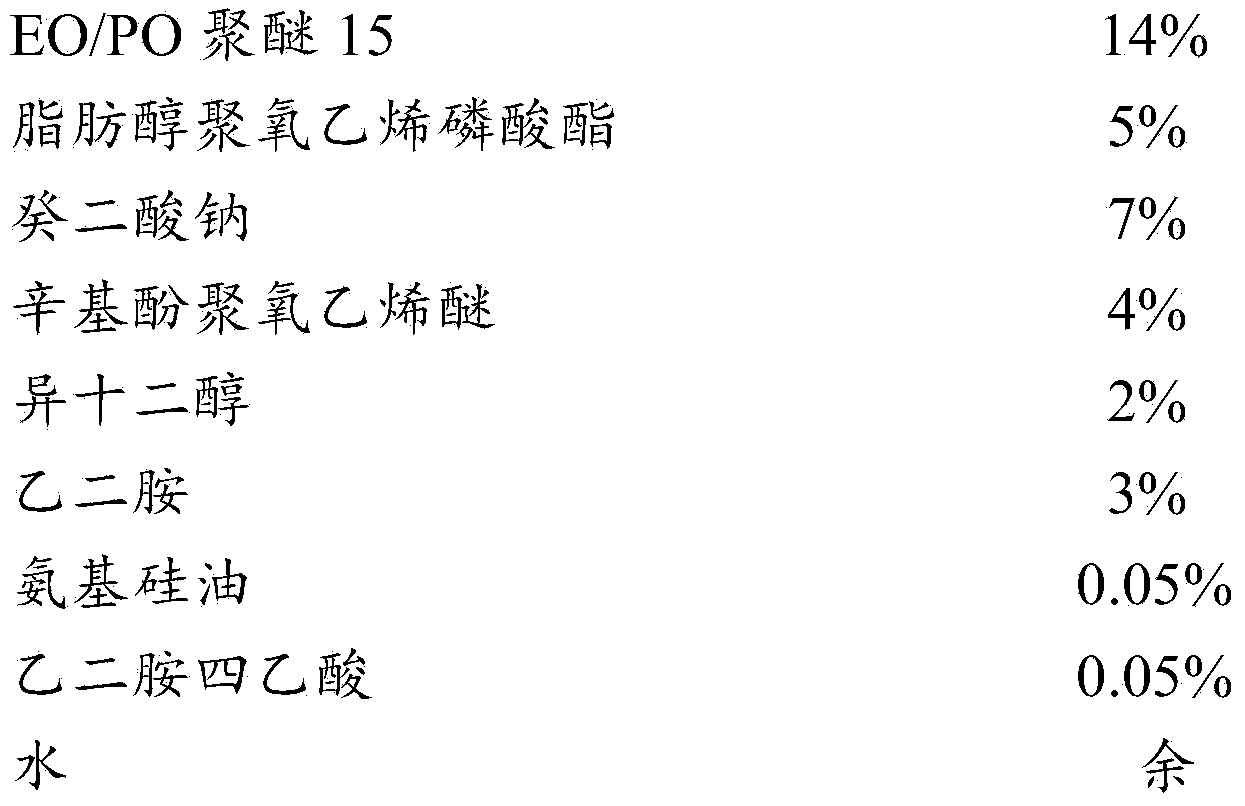

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com