Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1199results about "Lubrication pressure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

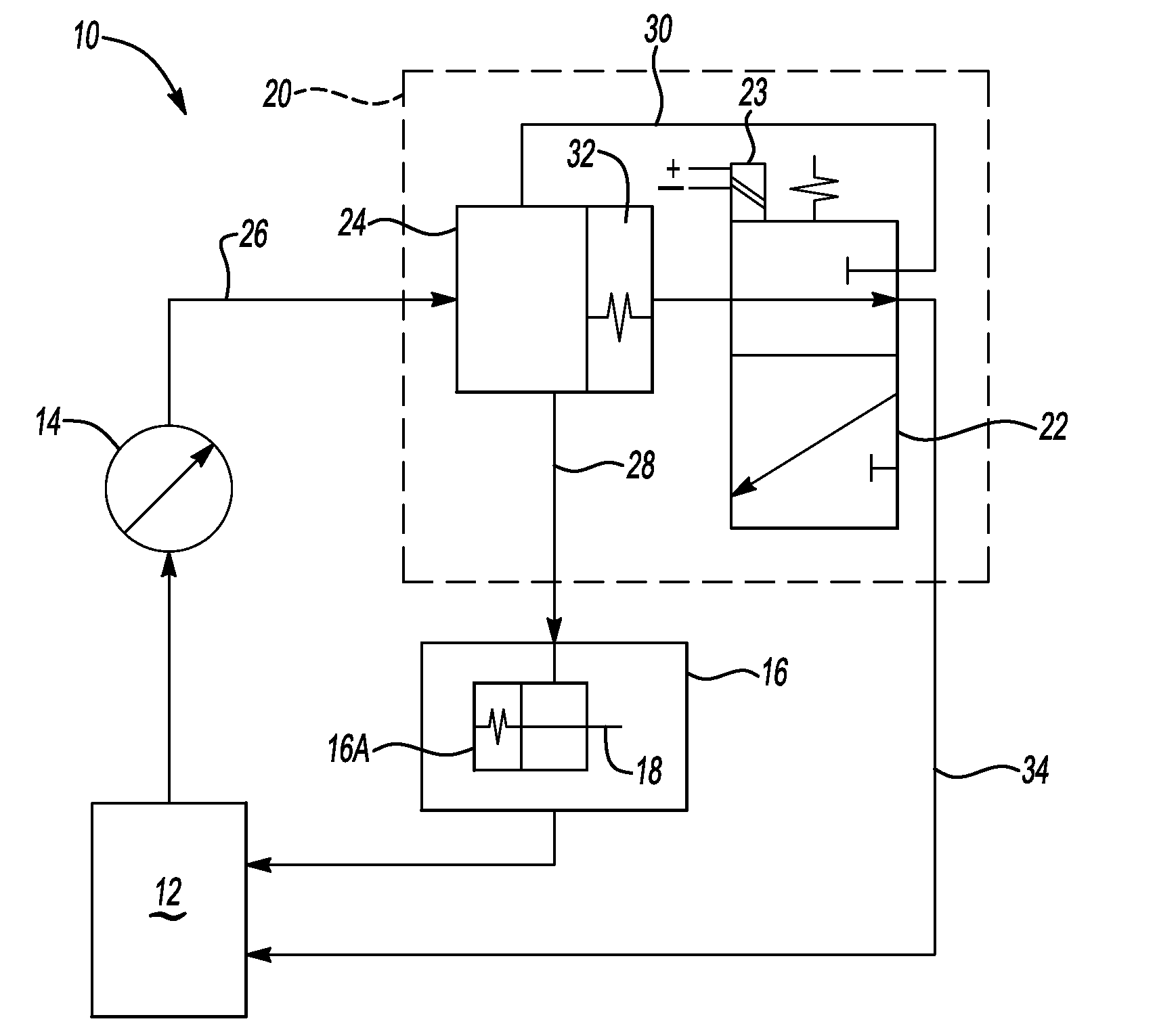

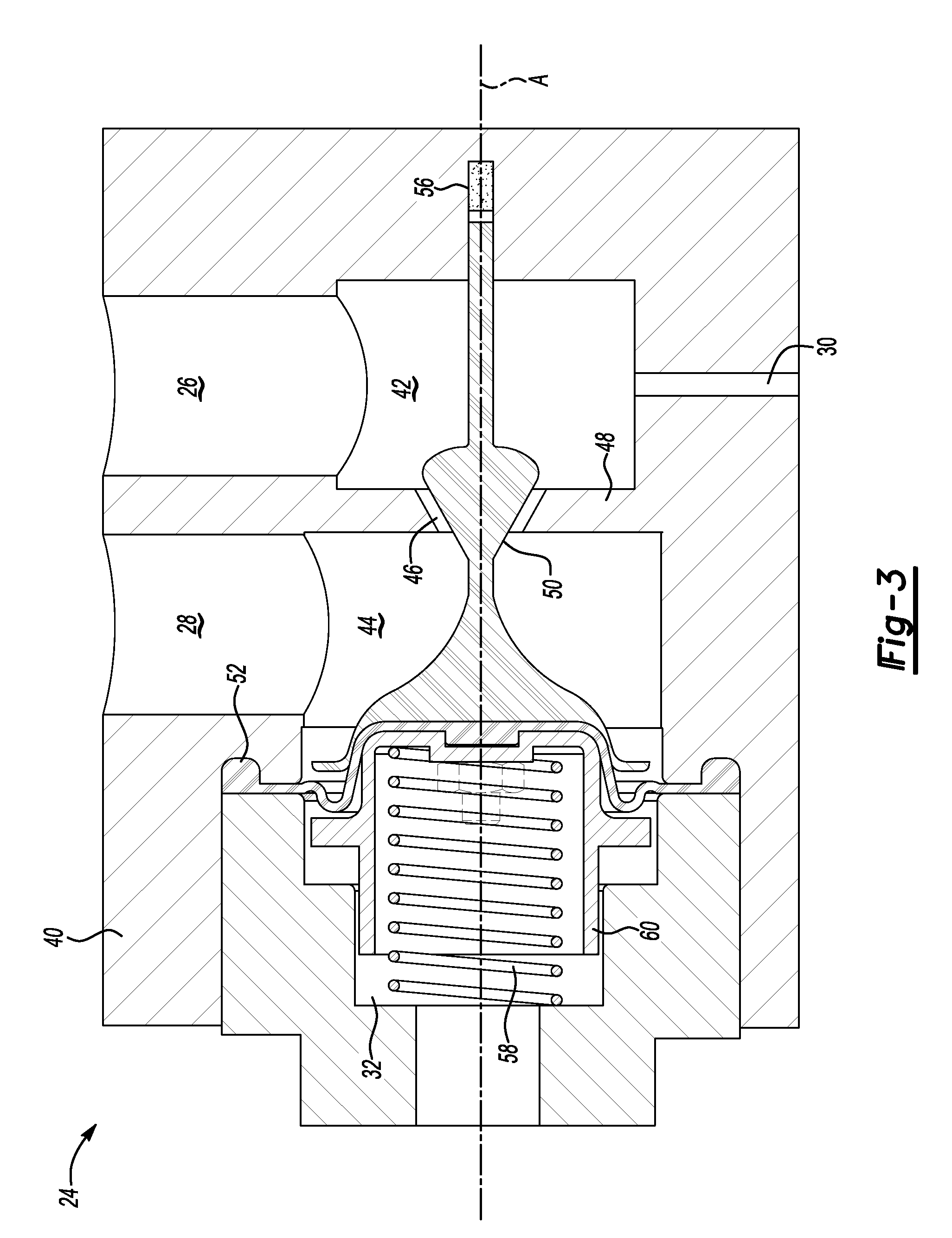

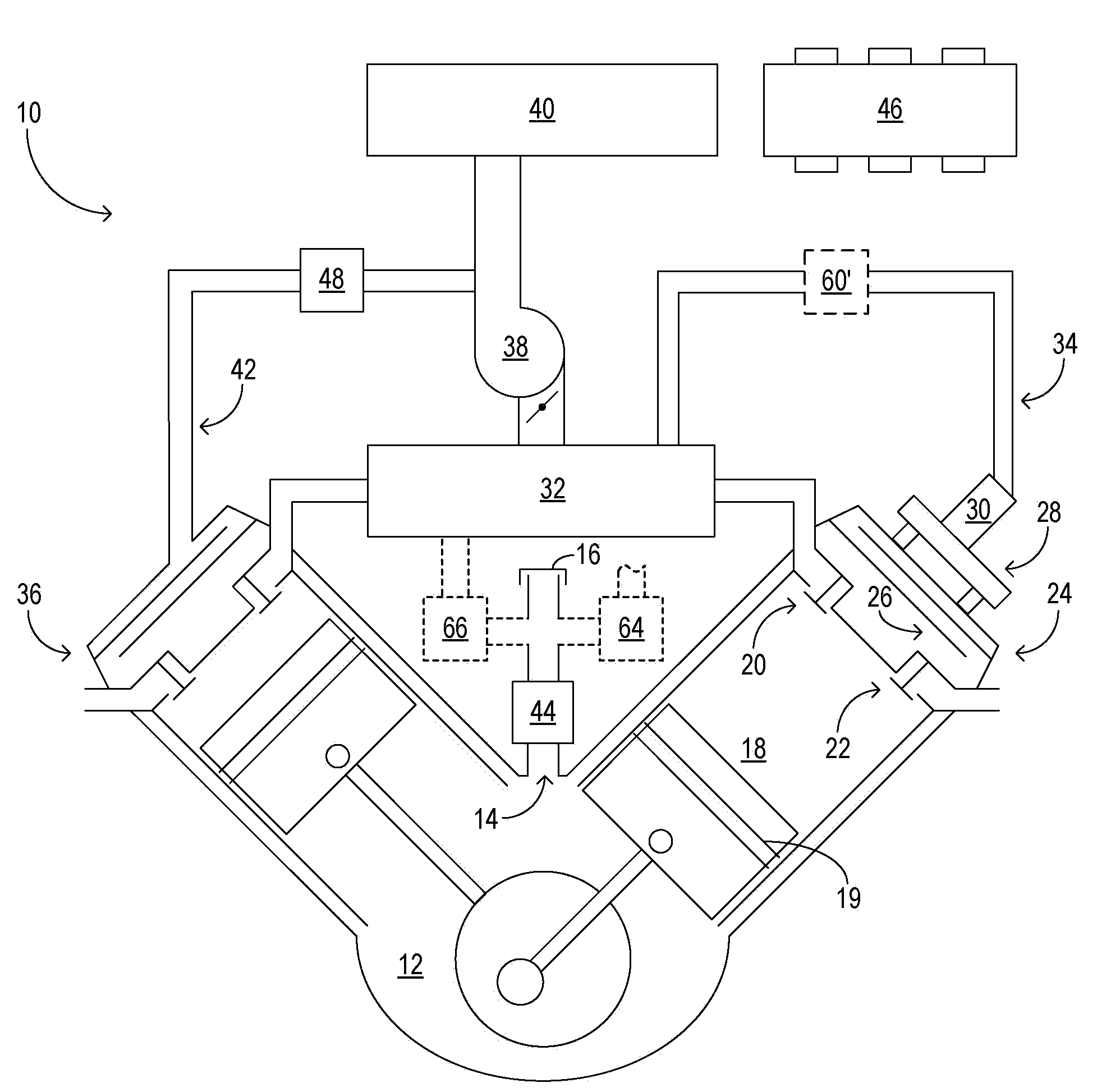

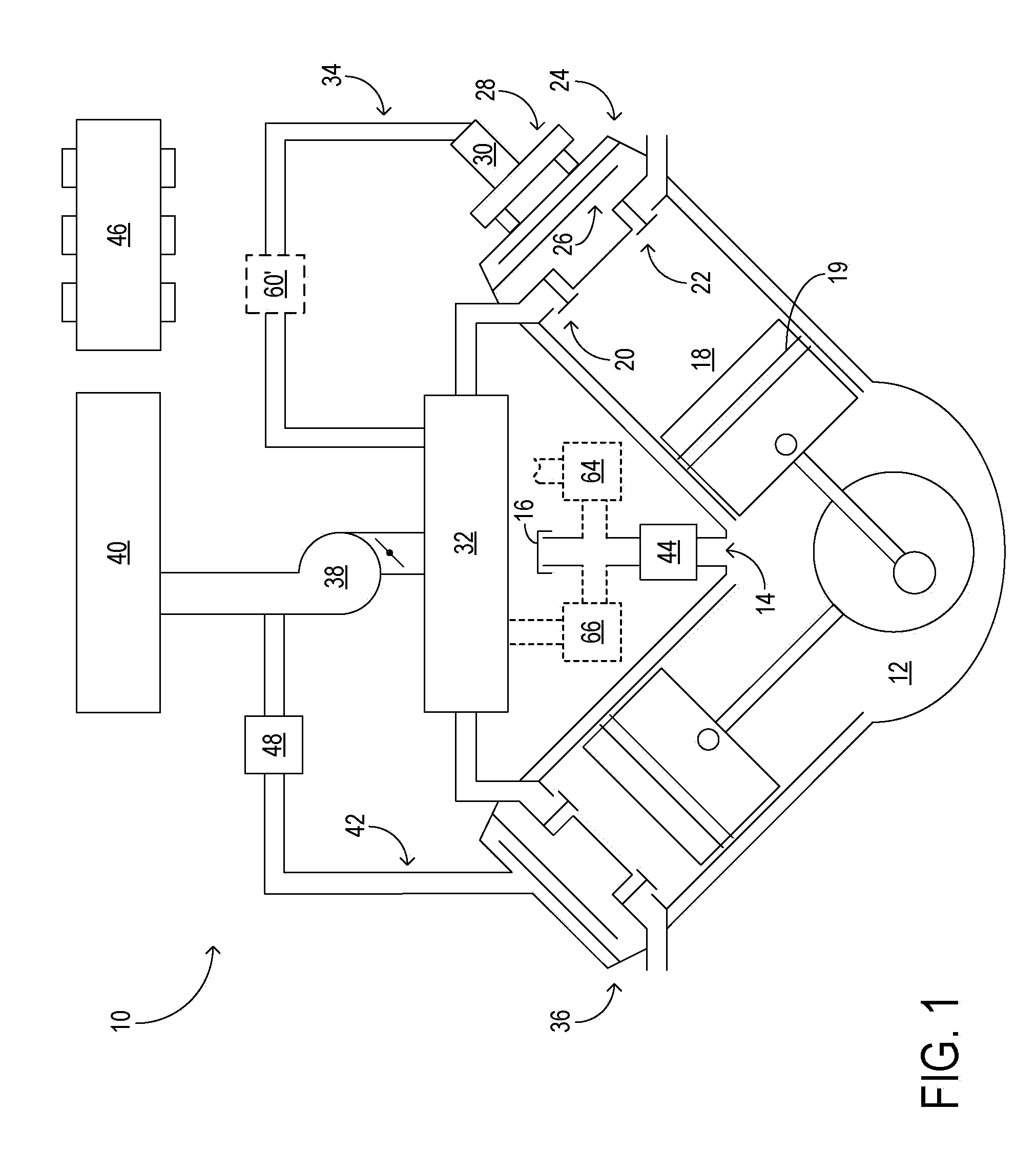

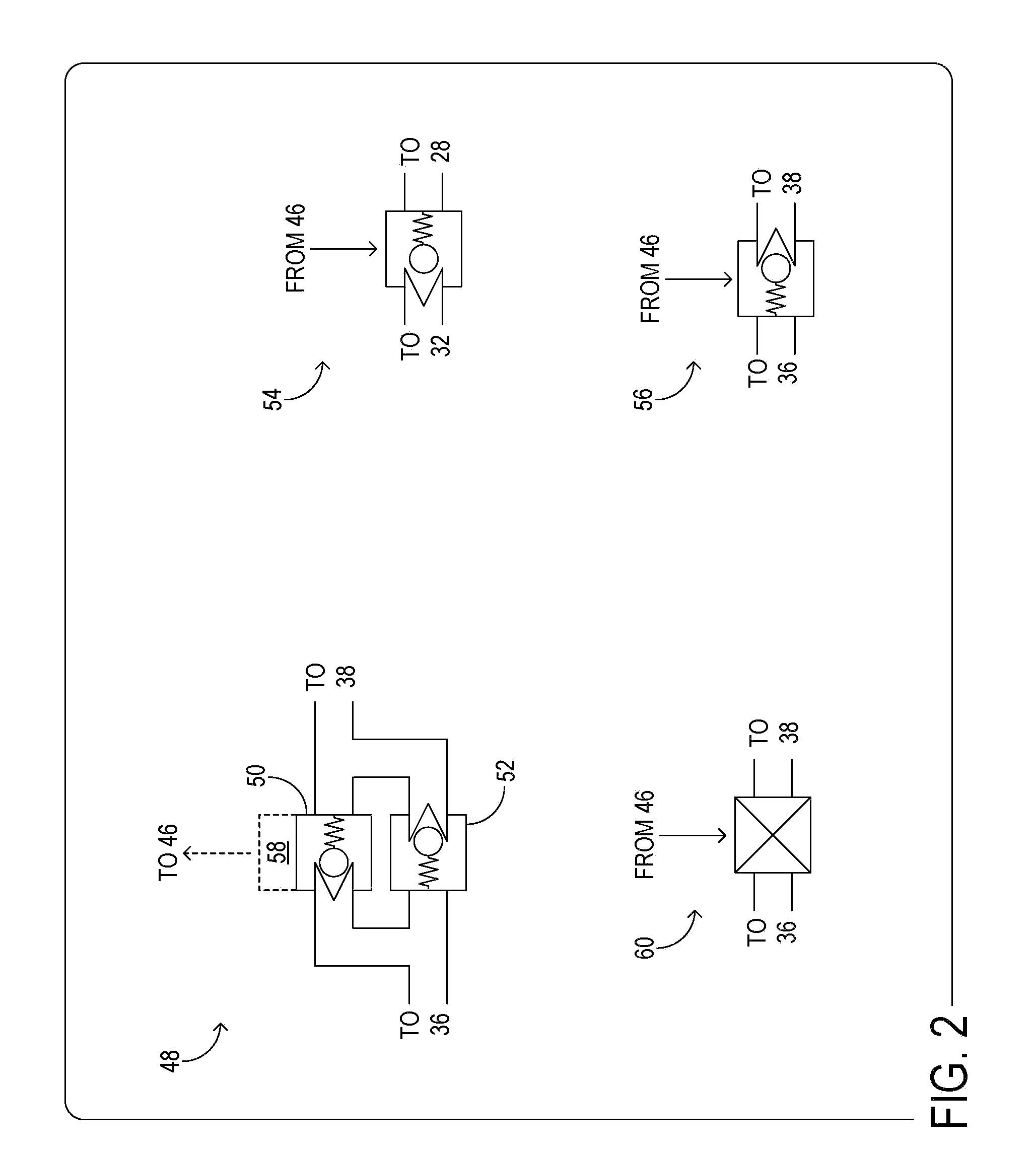

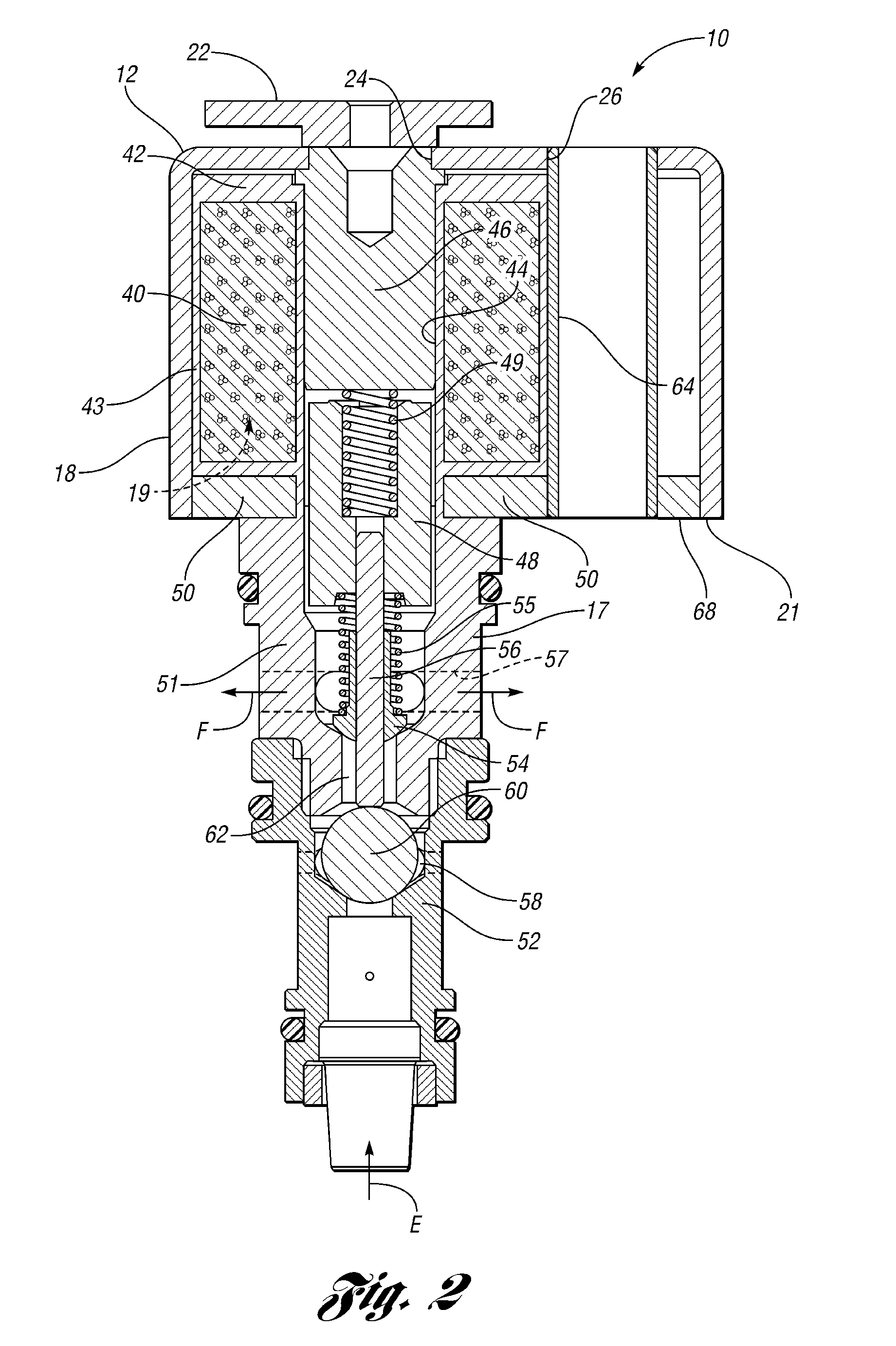

Valvetrain oil control system and oil control valve

InactiveUS20100018482A1Reduce fuel consumptionOperating means/releasing devices for valvesPipeline systemsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

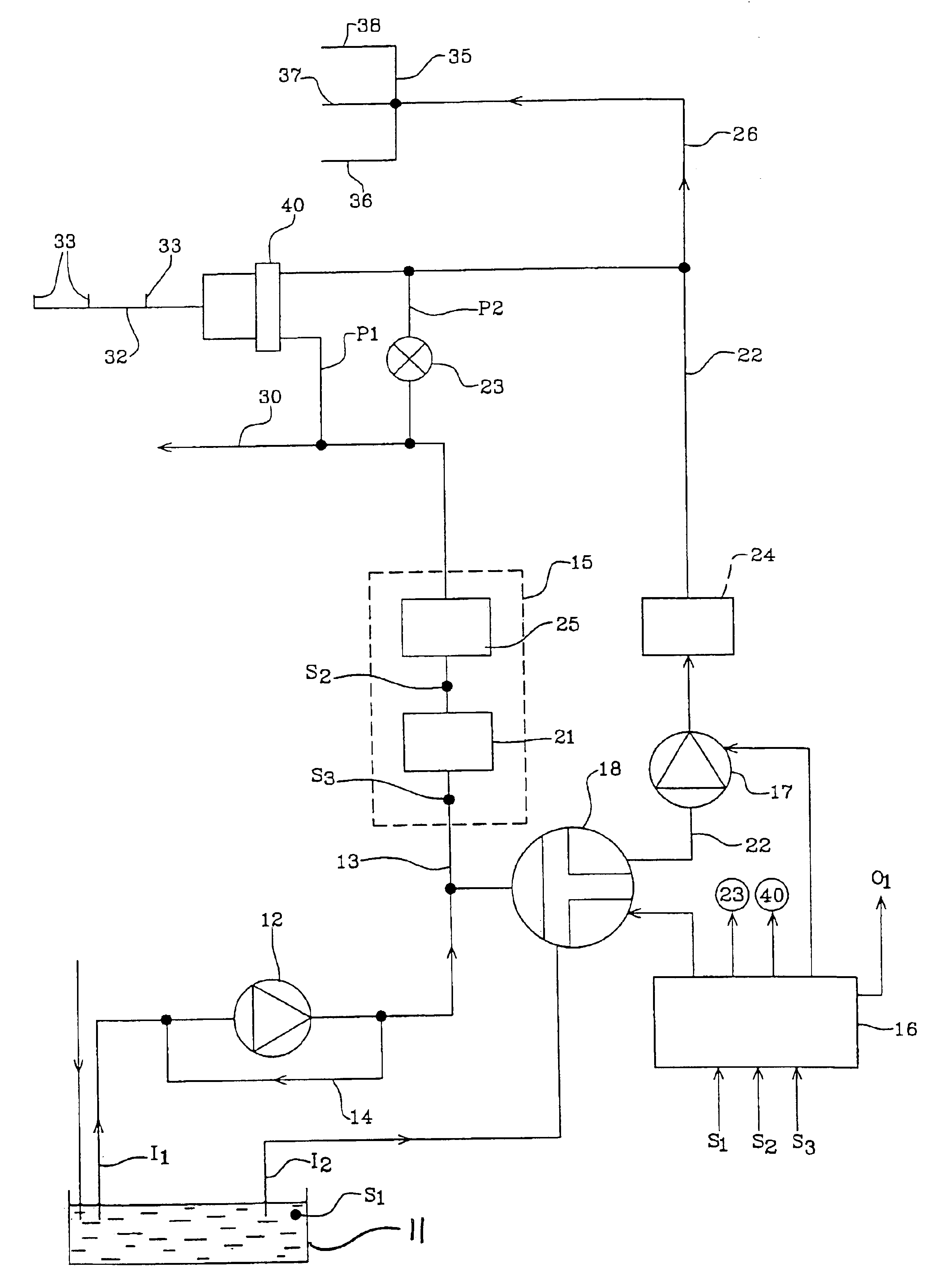

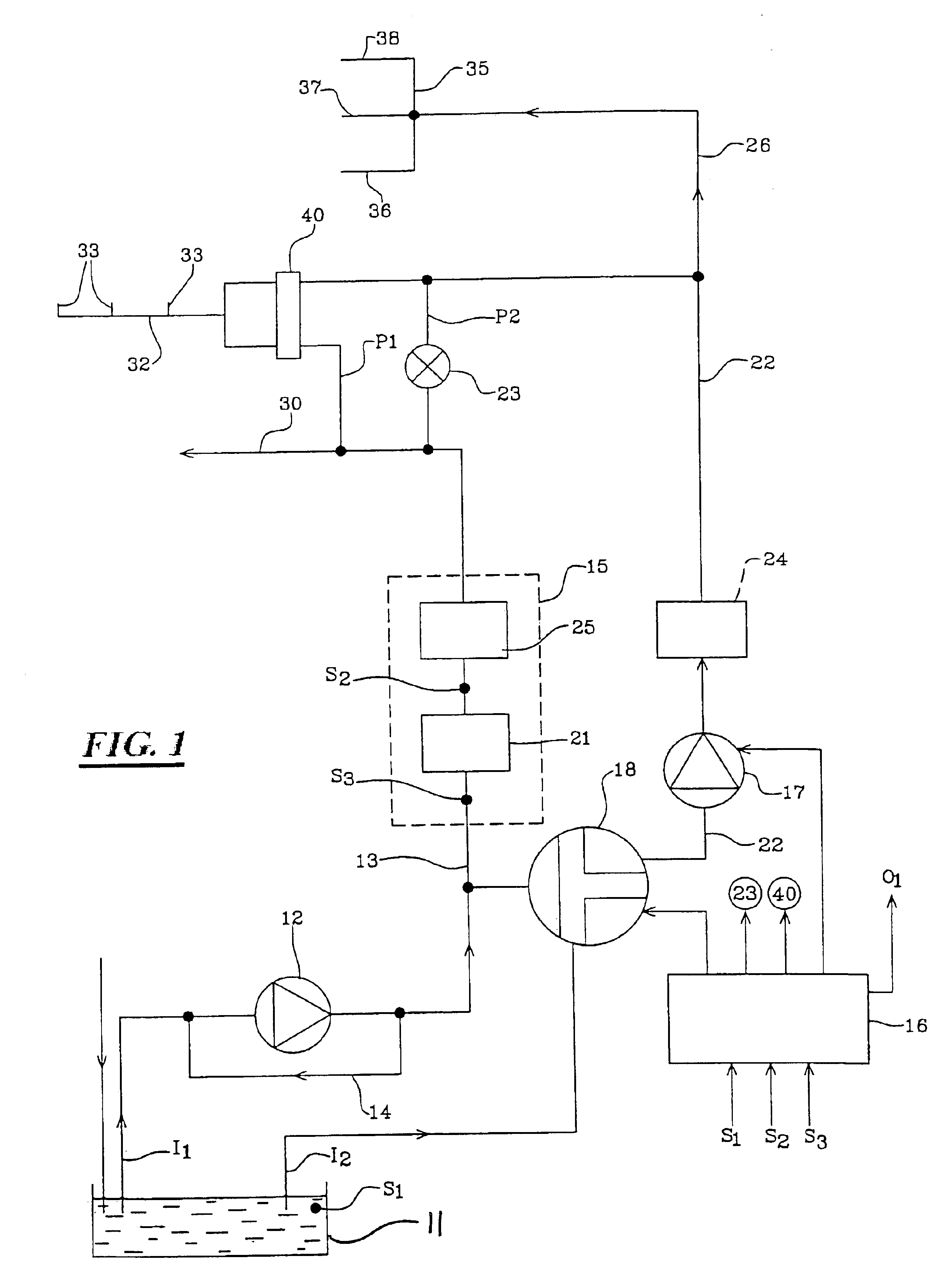

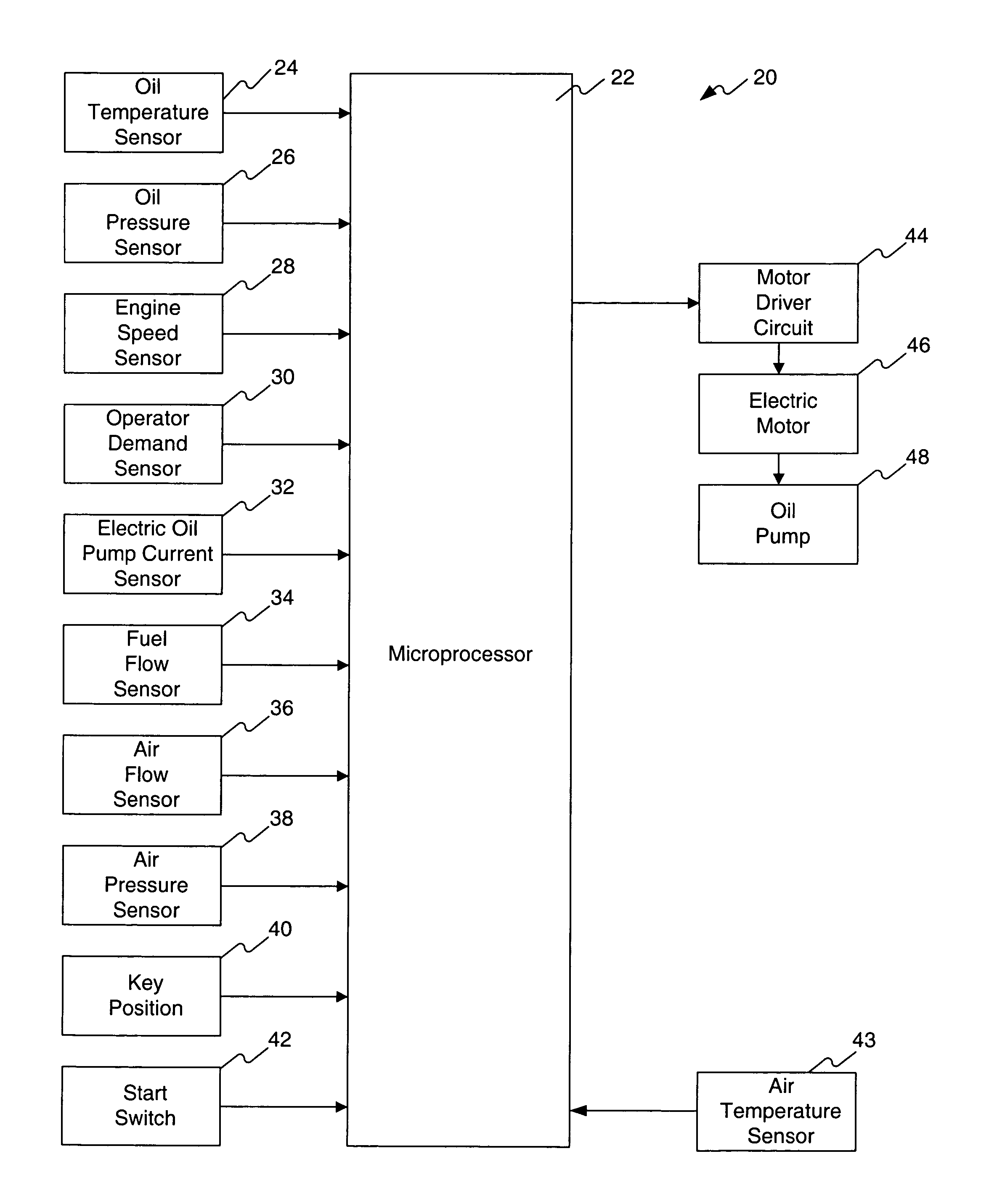

Engine lubrication system

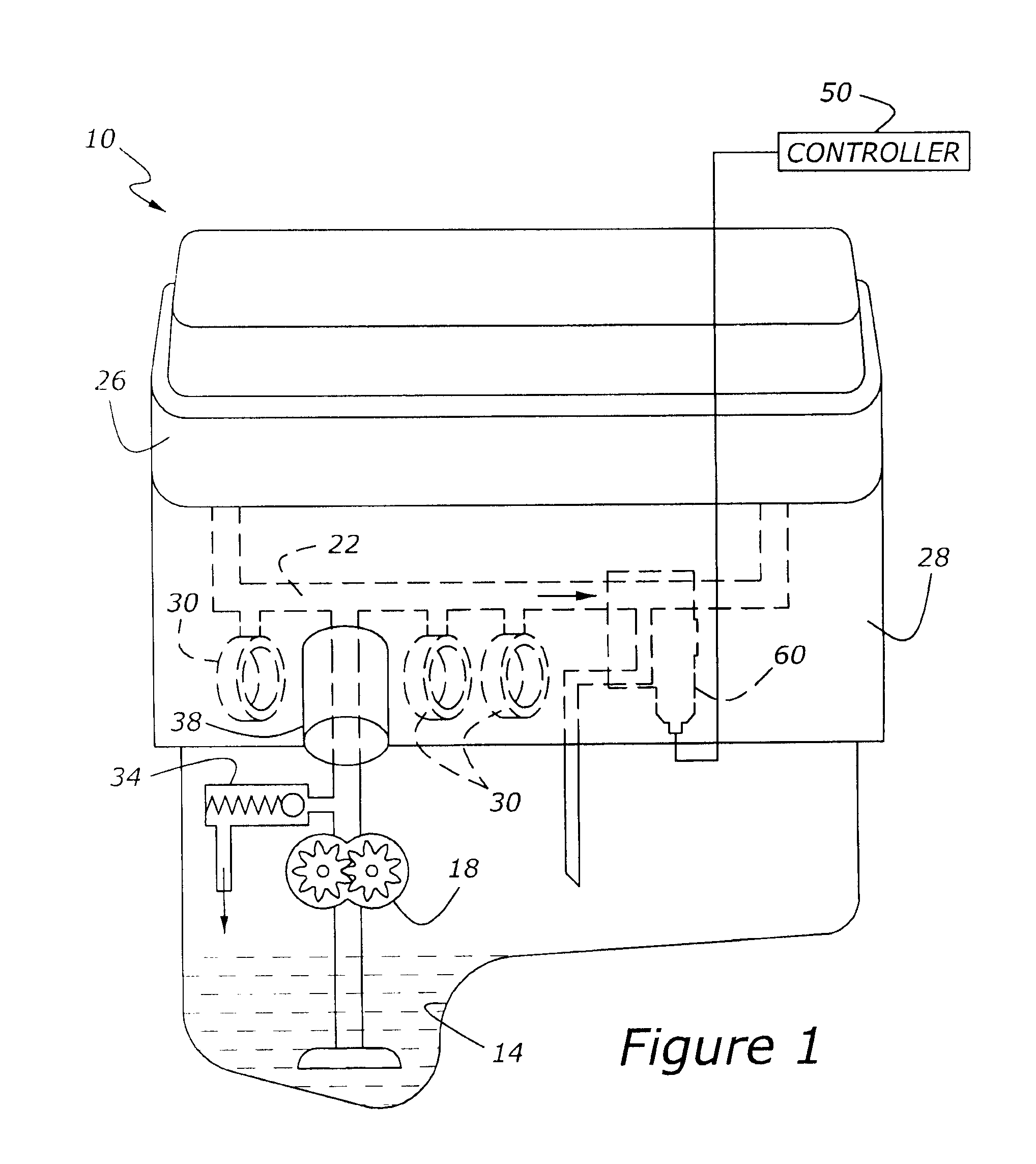

ActiveUS6941922B2Small sizeLubrication of auxillariesLubricant conduit arrangementsLine tubingEngineering

A lubrication system for an engine including a sump for lubricant, a main pump operable to pump lubricant to first lubrication positions within the engine, and an auxiliary lubricant pump also operable to pump lubricant to second lubrication positions within the engine and wherein the auxiliary pump is an electrically driven pump which is controlled by a system controller the output of the auxiliary pump being controlled according to engine operating conditions, the main pump in use, pumping lubricant to the first lubrication positions within the engine along a main lubricant feed line, and the auxiliary pump when operated pumping lubricant to the second lubrication positions within the engine along an auxiliary feed line, and wherein the main and auxiliary feed lines, are connected via a communication passage which includes a closeable communication valve, the communication valve when closed preventing the flow of lubricant from the auxiliary feed line to the first lubrication positions, and when open permitting the flow of lubricant from the auxiliary feed line to the first lubrication positions.

Owner:PIERBURG PUMP TECH UK

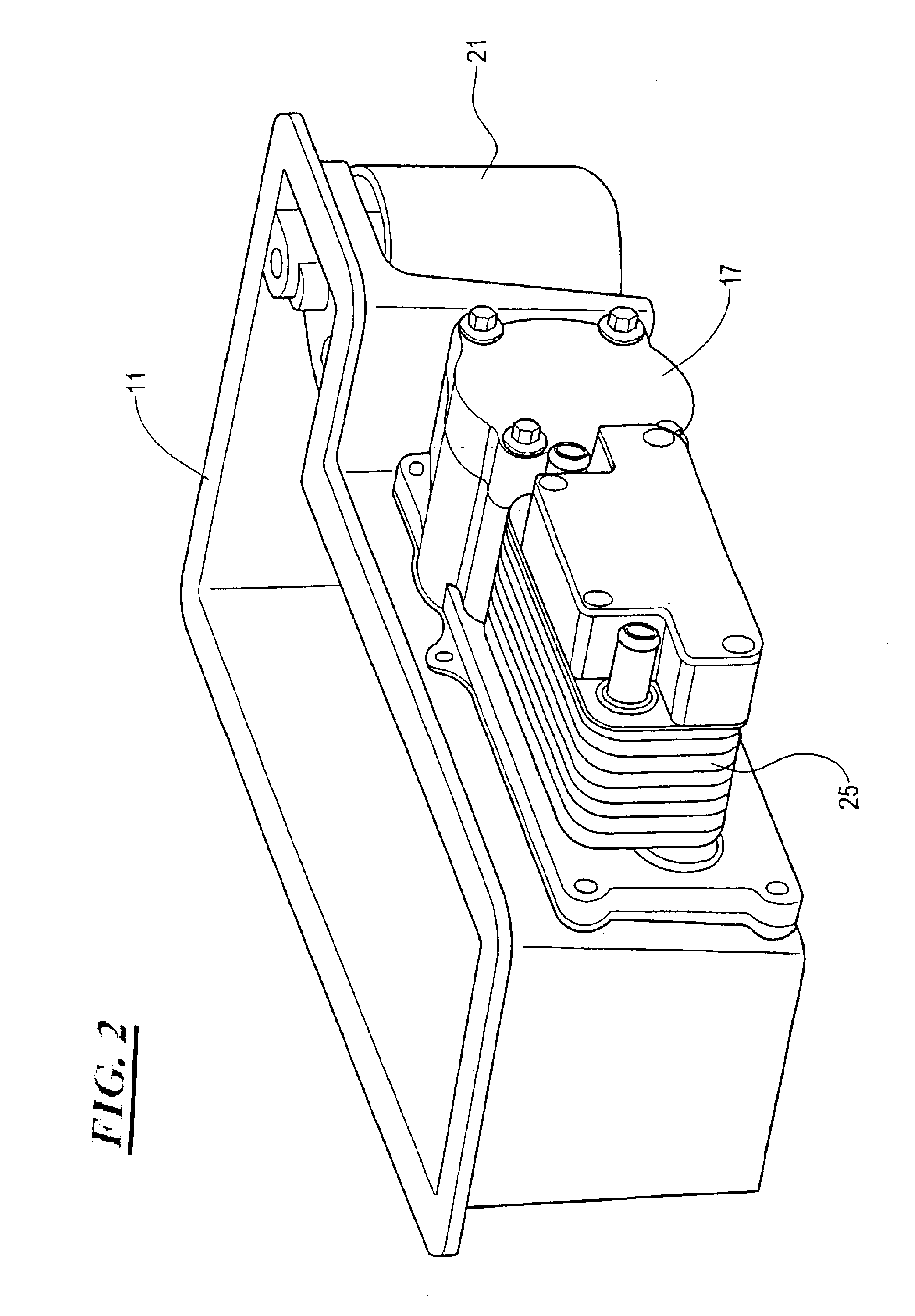

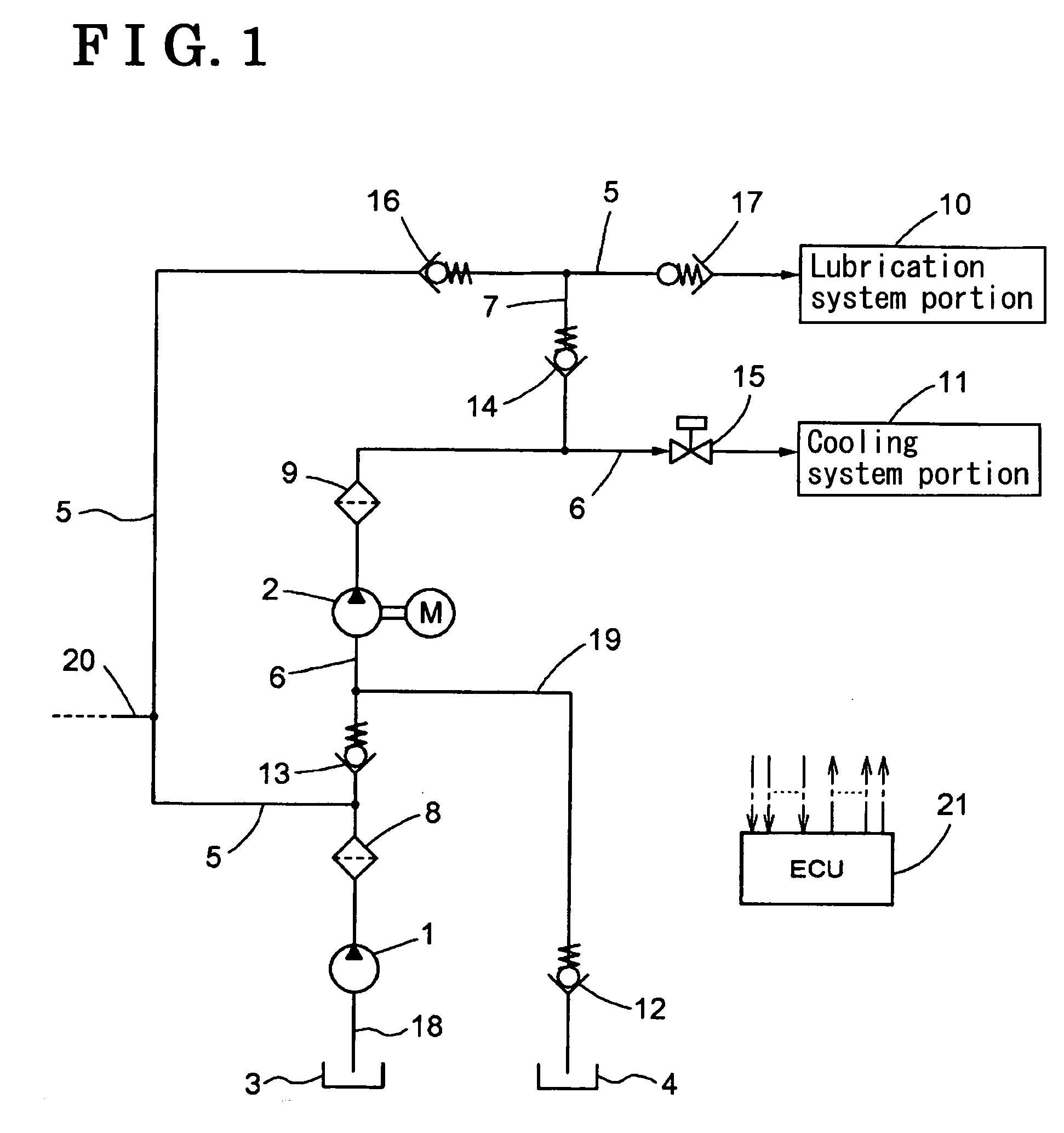

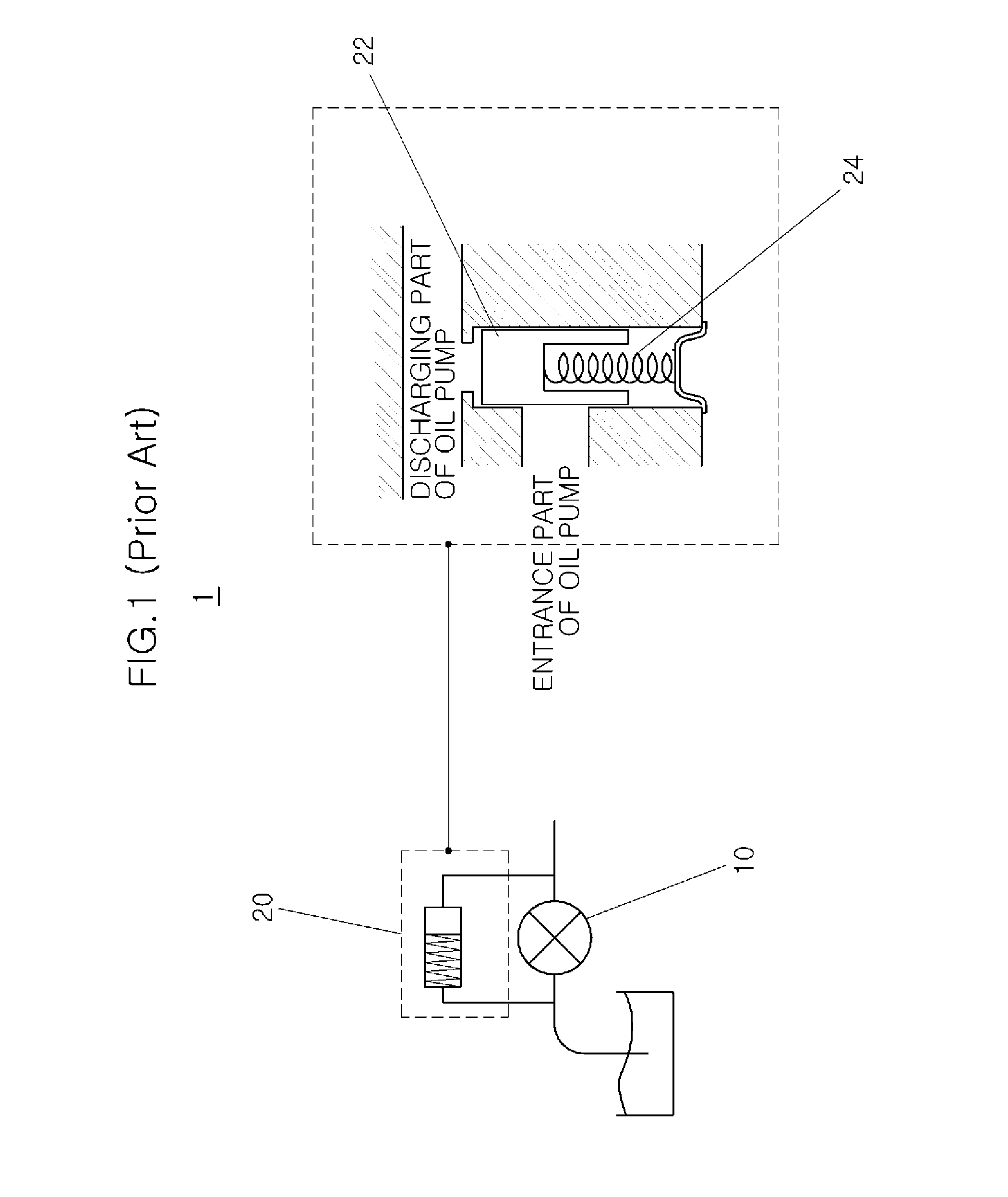

Oil supply device for engine

An oil supply device for an engine includes a first oil suction passage, a second oil suction passage, a first pump for sucking and discharging oil from the first oil suction passage, a second pump arranged in series with the first pump, the second pump for sucking and discharging oil from at least one of the first pump and the second oil suction passage, a check valve for blocking oil circulation, a first oil passage, a second oil passage, a third oil passage for establishing communication between the first oil passage and the second oil passage, and a supply volume control device for varying oil supply volume to a lubrication system portion, to a cooling system portion, or to the lubrication system portion and the cooling system portion in accordance with a change in at least one of an engine oil temperature, an engine rotation speed, and an engine load.

Owner:AISIN SEIKI KK

Crankcase breech detection for boosted engines

InactiveUS20100147270A1Prolonged duty cycleIncreased blow-byCombustion enginesLubrication pressure controlMobile vehicleAtmospheric air

Methods for indicating whether a crankcase of an engine is breeched are provided. One example method comprises restricting a communication of the crankcase with atmosphere, acting to increase or decrease a crankcase pressure, and indicating whether the crankcase is breeched based on the crankcase pressure. Another example method comprises sensing a crankcase pressure component, and indicating whether the crankcase is breeched based on the crankcase pressure component, the crankcase communicating with atmosphere via a conduit, a restrictedness of the conduit responsive to one or more of a crankcase pressure and a signal from an electronic control unit of the motor vehicle. Still other examples provide more particular methods for indicating whether the crankcase is breeched, and example configurations that enable the various methods.

Owner:FORD GLOBAL TECH LLC

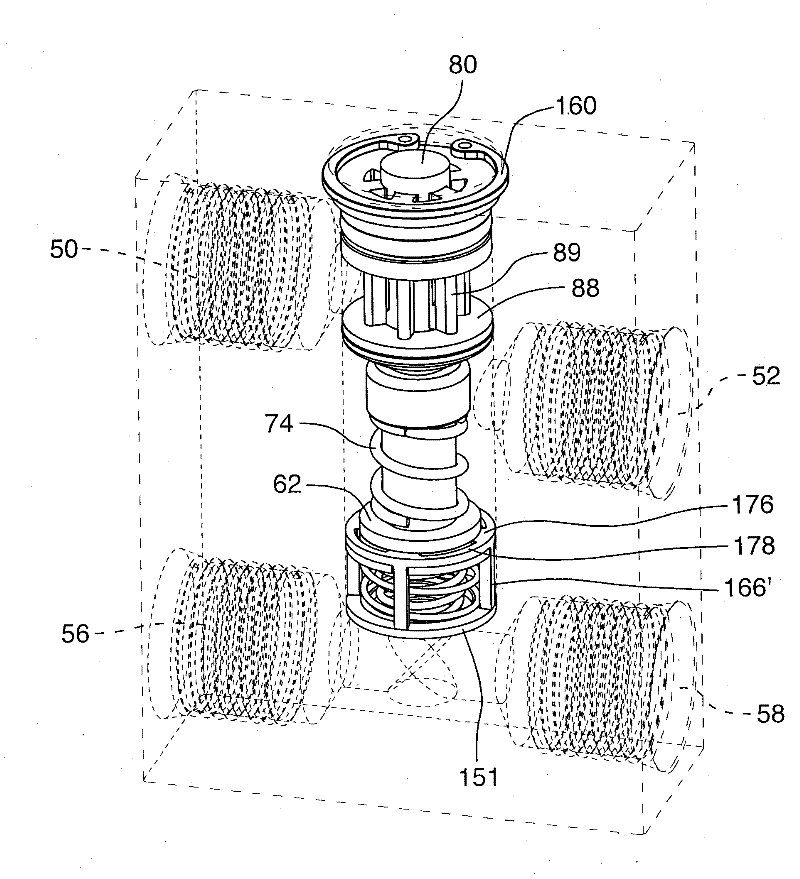

Thermal by-pass valve with pressure relief capability

ActiveCN102224367AOperating means/releasing devices for valvesCoolant flow controlActuatorValve seat

A by-pass valve for a heat exchanger circuit that includes a cooler (12) has a chamber (48) and ports for flow of fluid into and out of this chamber. A thermally sensitive actuator (64) is mounted in the chamber and can extend or retract in dependence on its body temperature as influenced by temperature of the fluid. A by-pass valve seat (154) is arranged in a valve housing along with a by-pass valve member (62) movable by the actuator into or out of engagement with the seat. A relief valve is mounted in the chamber and has a relief valve member (210) movable between closed and open positionsin order to close or open pressure relief ports. This relief valve member is biased towards the closed position. Excessive pressure build up in an end section of the chamber causes the relief valve member to move to its open position.

Owner:DANA CANADA CORP

Valvetrain oil control system and oil control valve

InactiveUS8327750B2Reduce fuel consumptionOperating means/releasing devices for valvesServomotor componentsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

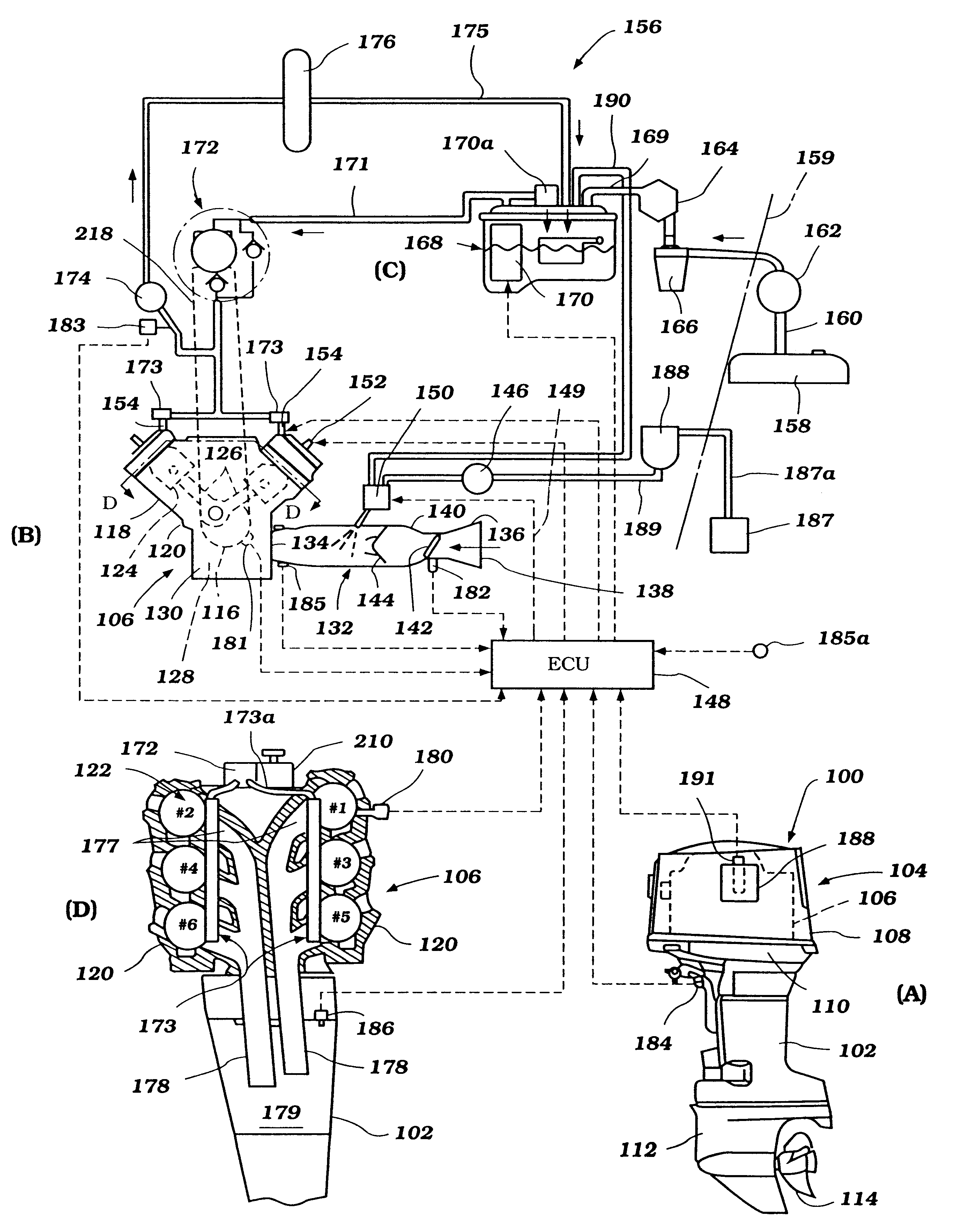

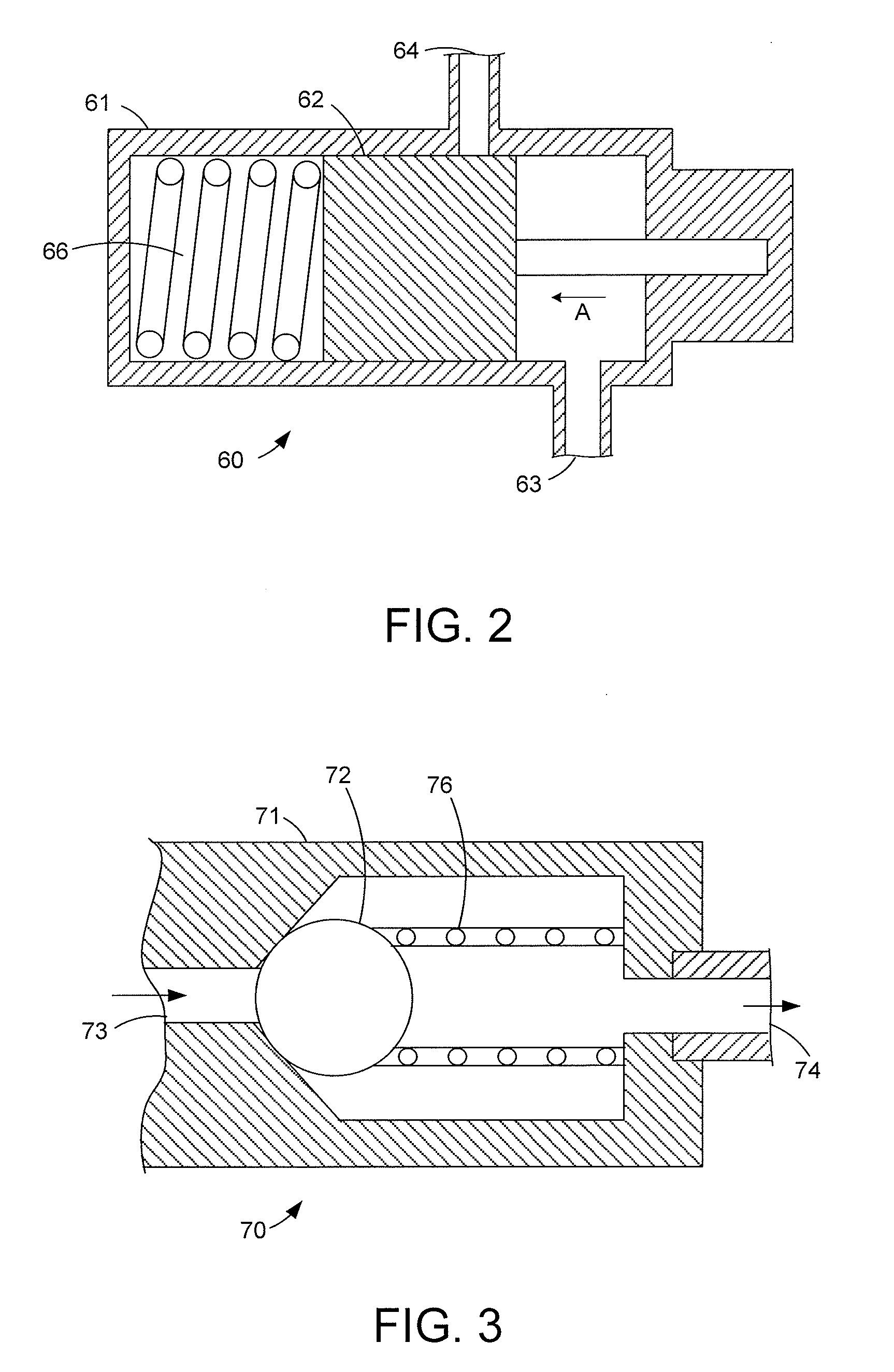

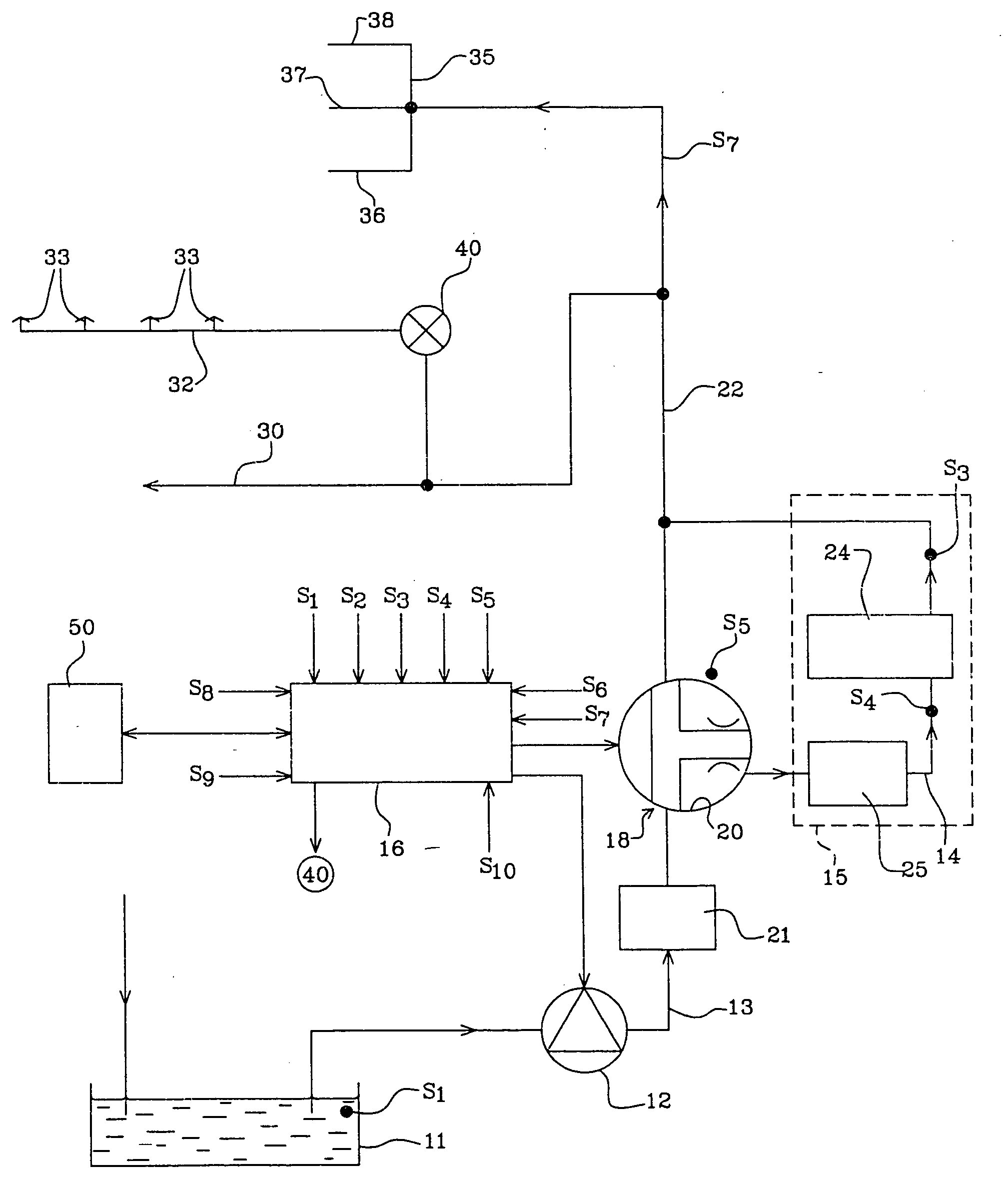

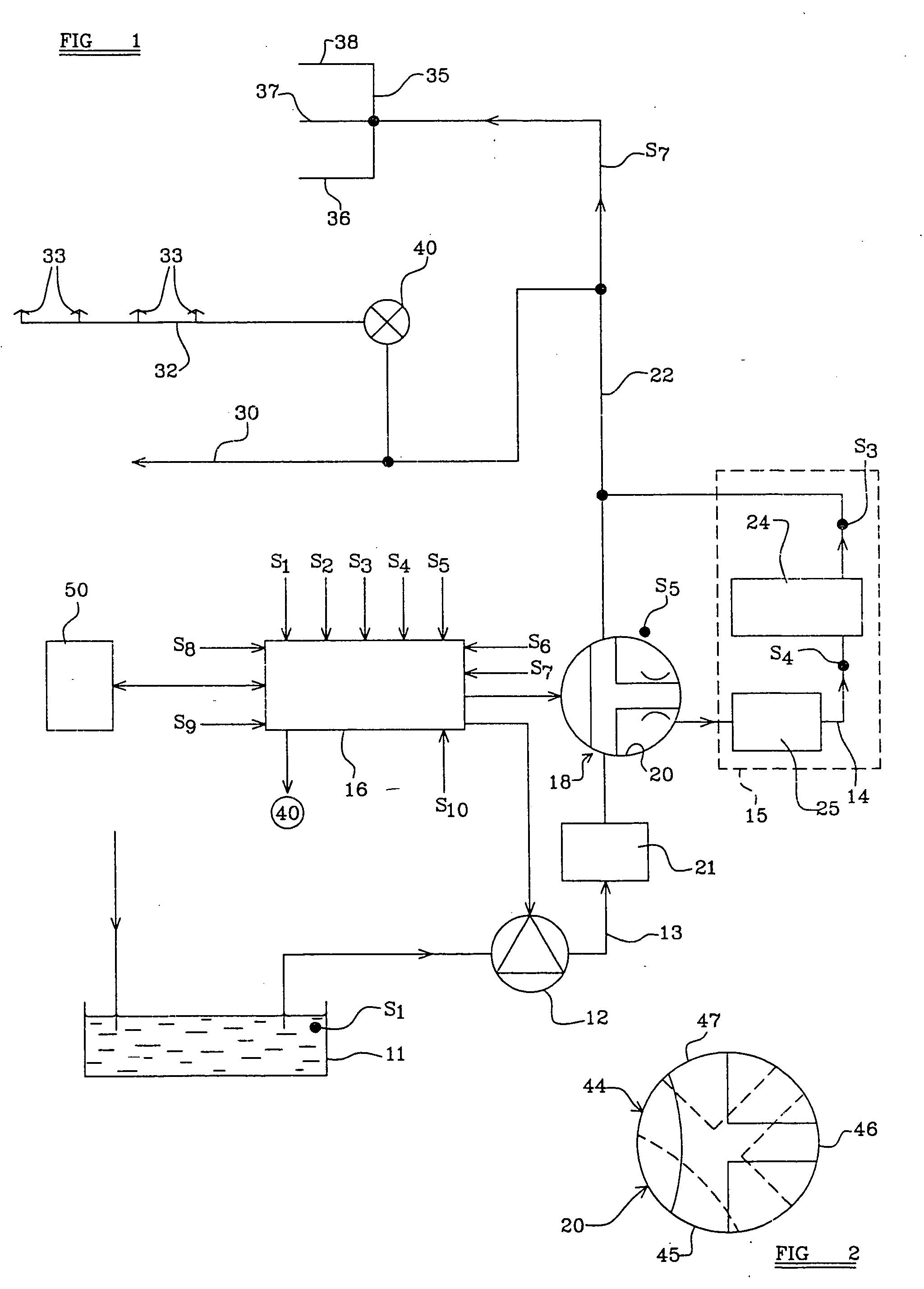

Oil injection lubrication system and methods for two-cycle engines

InactiveUS6422183B1Reduced deposit formationAvoid corrosionCombustion enginesEngine operating parametersSolenoid valveControl signal

The present invention provides an improved oil injection lubrication system for two-cycle engines. The system includes a variable output oil pump, the output of which can be varied in relation to the throttle level. The system also includes a solenoid valve unit containing a plurality of solenoid valves that regulate the flow of oil from the oil pump to each cylinder. The electronic control unit sends control signals to the solenoid valve unit to regulate the flow of oil based upon factors relating to the operation of the engine in accordance with a control scheme. The factors may include those that apply to all of the engine's cylinders (i.e., do not vary between the cylinders), such as intake air temperature, atmospheric pressure, battery voltage, engine break-in period, and load frequency among others.

Owner:SANSHIN KOGYO CO LTD

Dry sump oil tank assembly

A tank assembly for a dry sump lubrication system for an internal combustion engine is disclosed. The tank assembly includes a tank having an upper tank portion and a lower tank portion. An interface assembly is disposed at the lower tank portion and is configured to operably deliver and receive a lubricant to and from the engine. A first end of a return tube in fluid communication with a second end is configured to receive lubricant from the engine at the interface assembly. The second end opposite the first end is in fluid communication with the upper tank portion. In this manner, a return hose and a feed hose may be connected to a same portion of the tank assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC

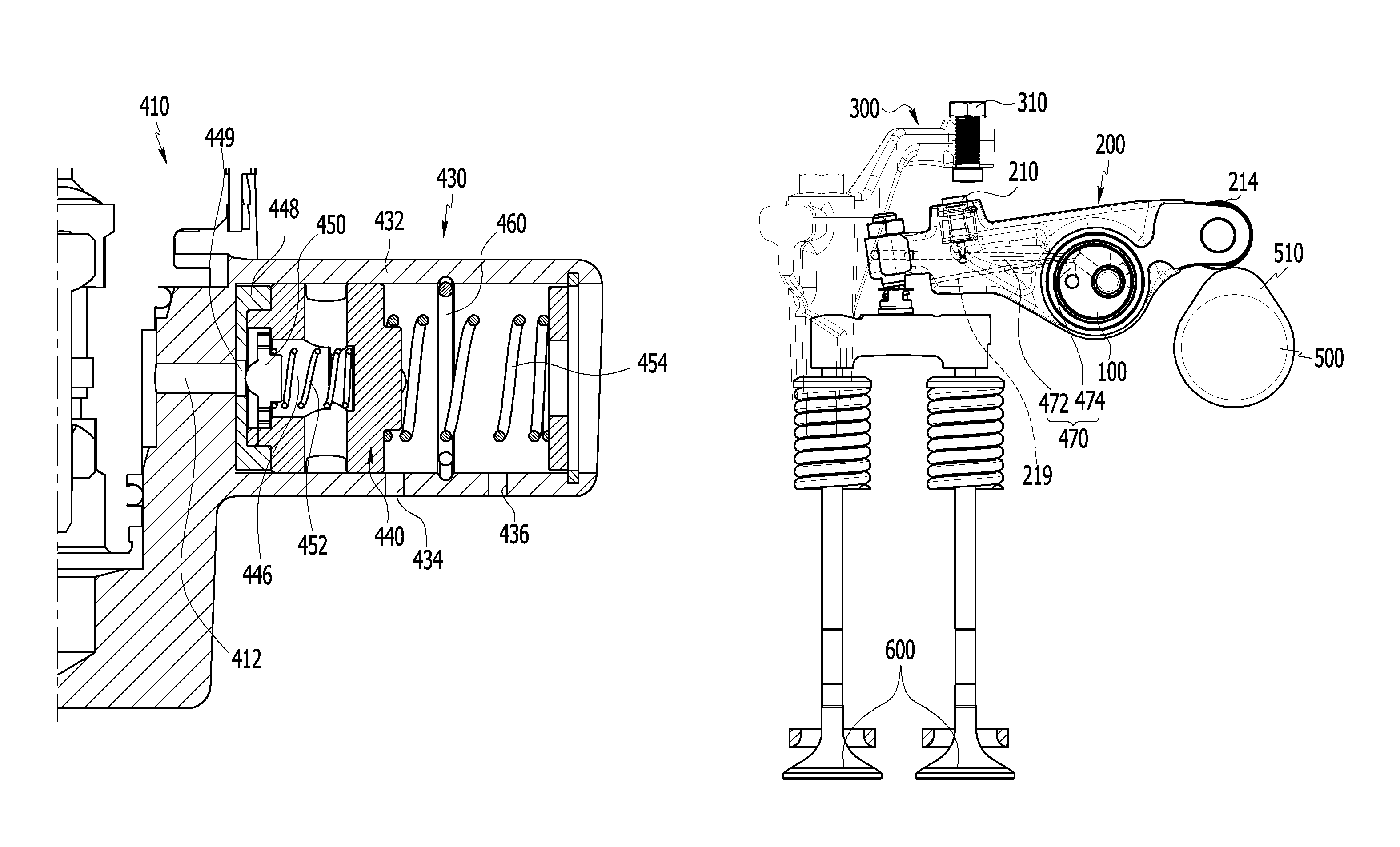

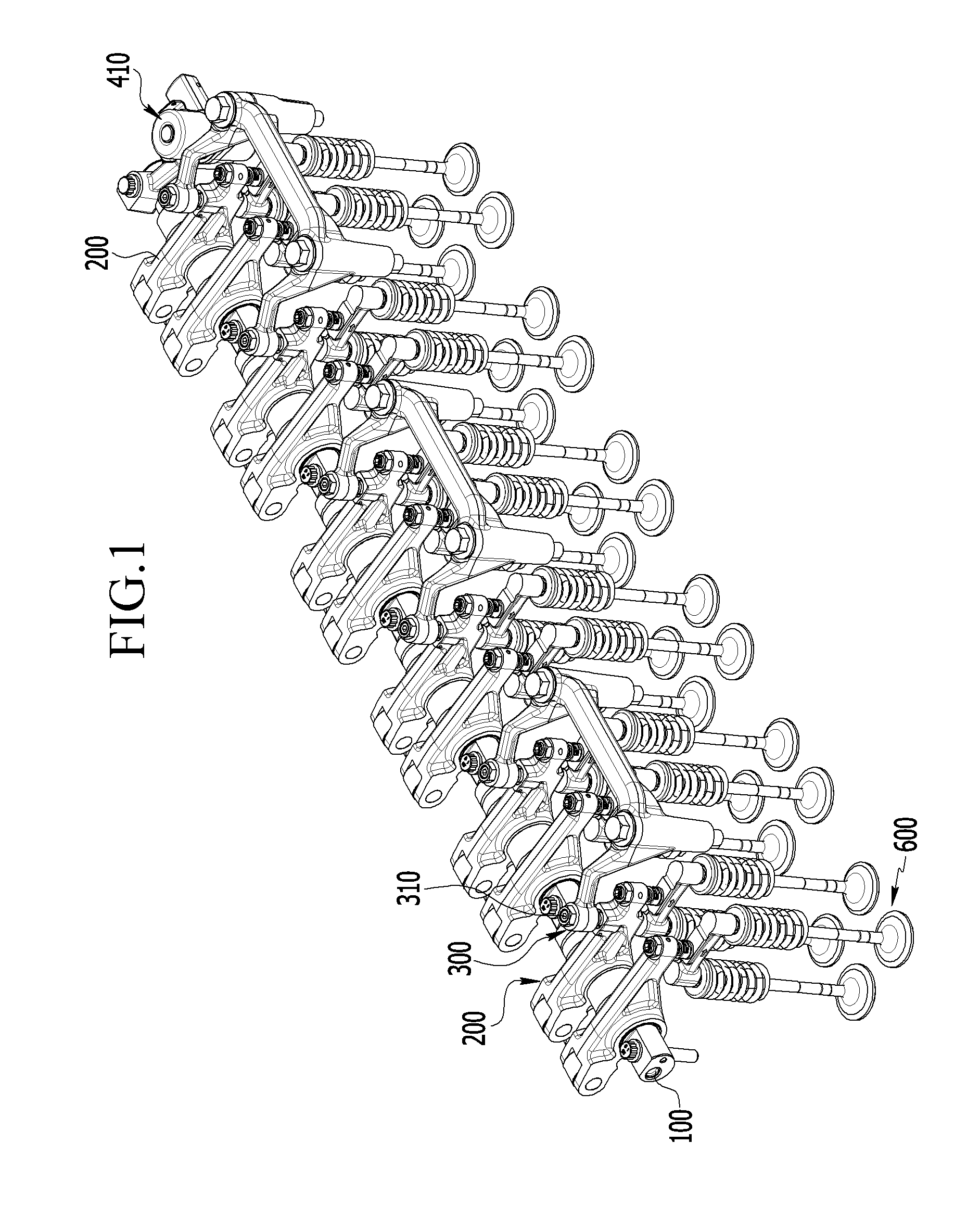

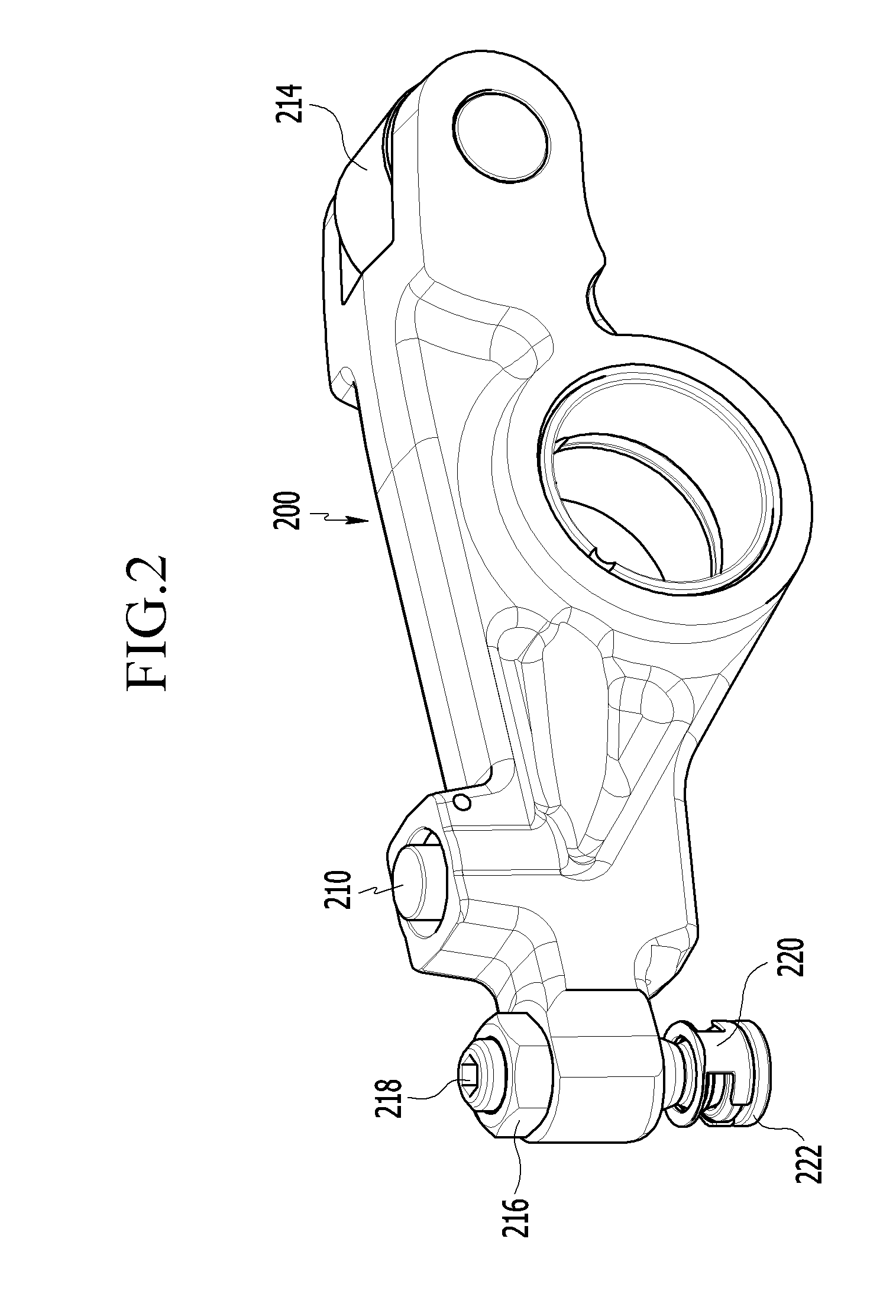

Engine brake and engine provided with the same

An engine brake may include a rocker shaft, a rocker arm pivoting around the rocker shaft, an actuator piston disposed to the rocker arm and selectively protruded there from, a stopper disposed to a corresponding position of the actuator piston for the rocker arm to open a valve when the actuator piston is protruded and a hydraulic pressure supply portion selectively supplying hydraulic pressure to the actuator piston.

Owner:HYUNDAI MOTOR CO LTD +1

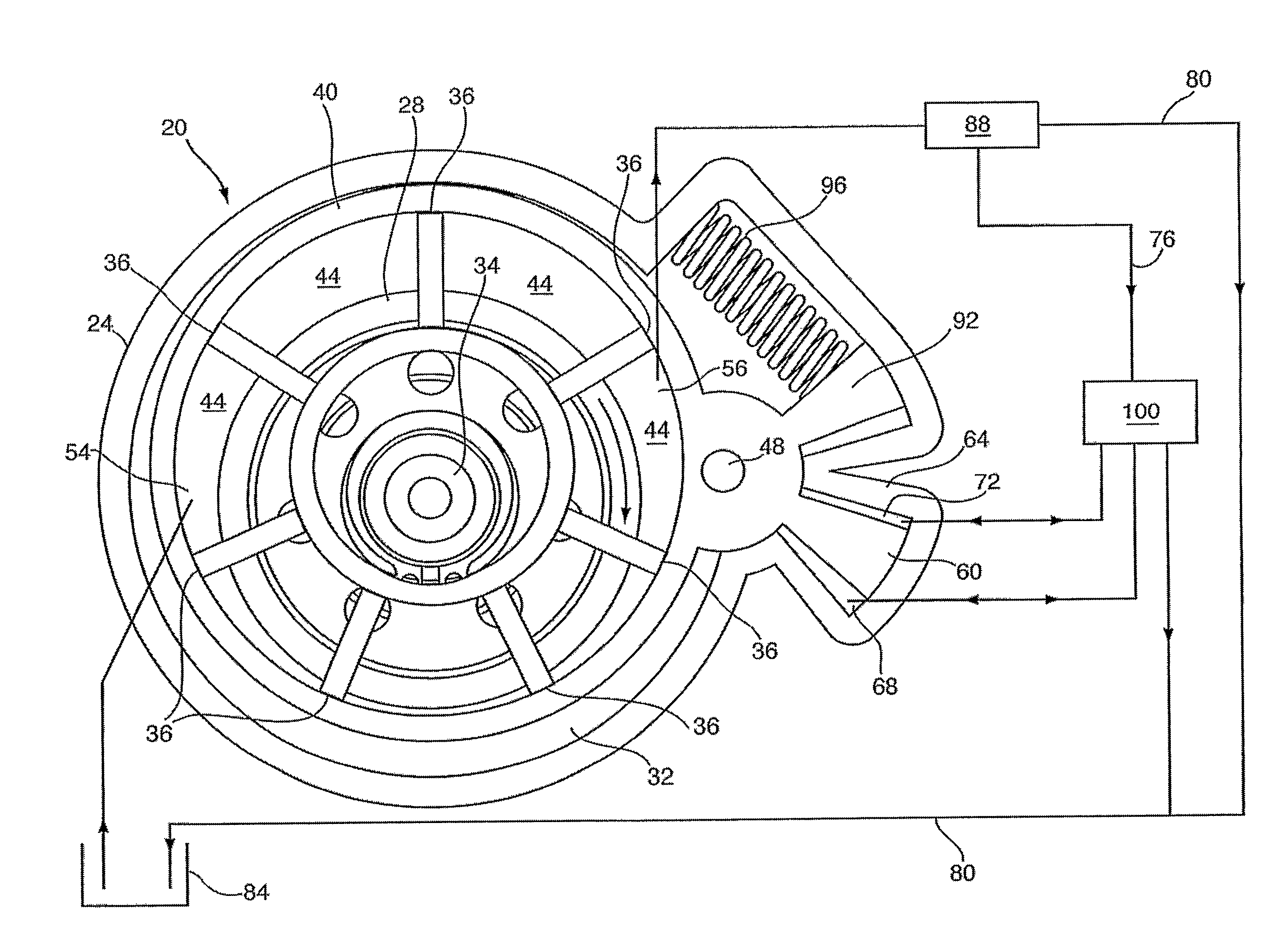

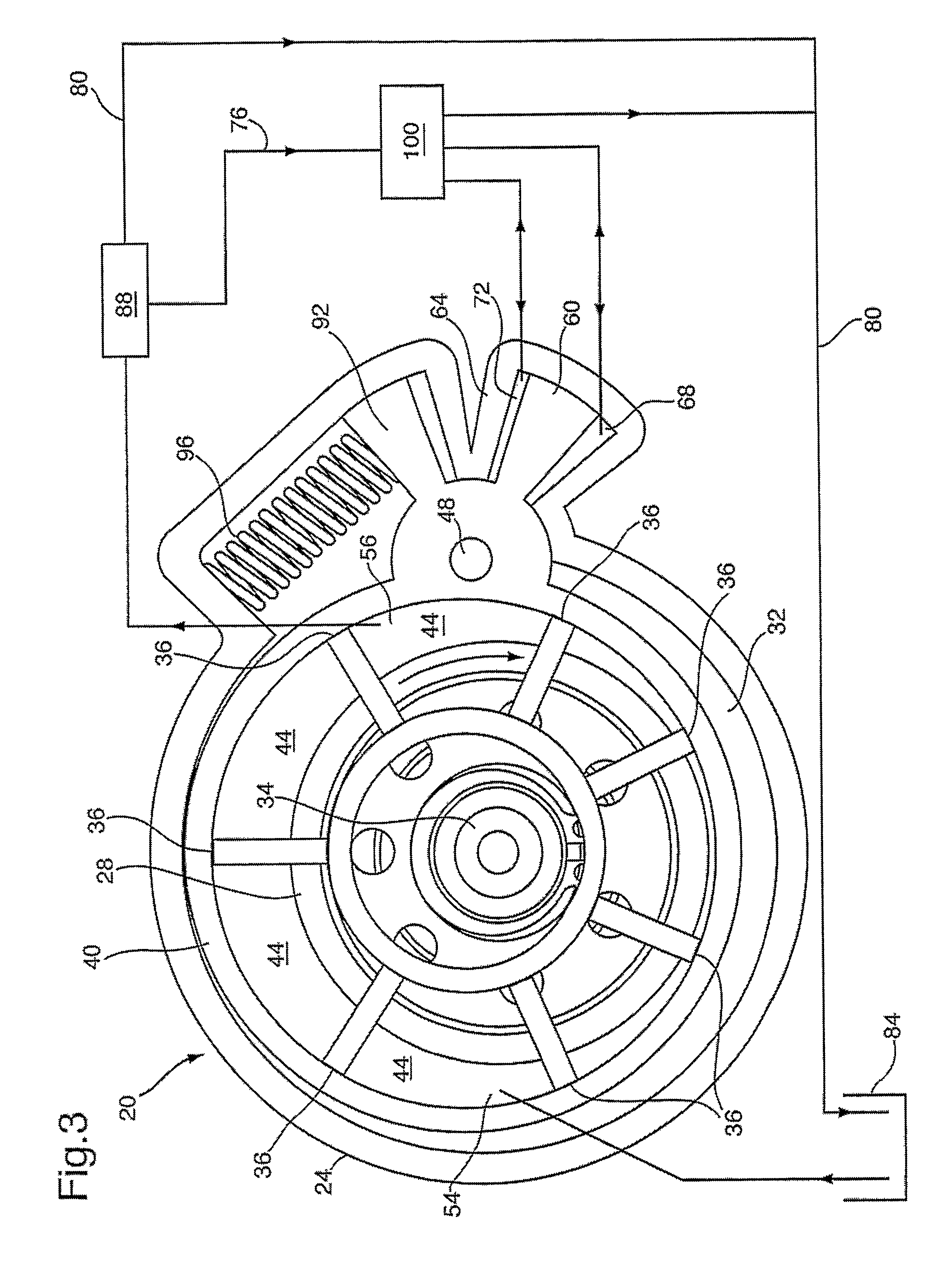

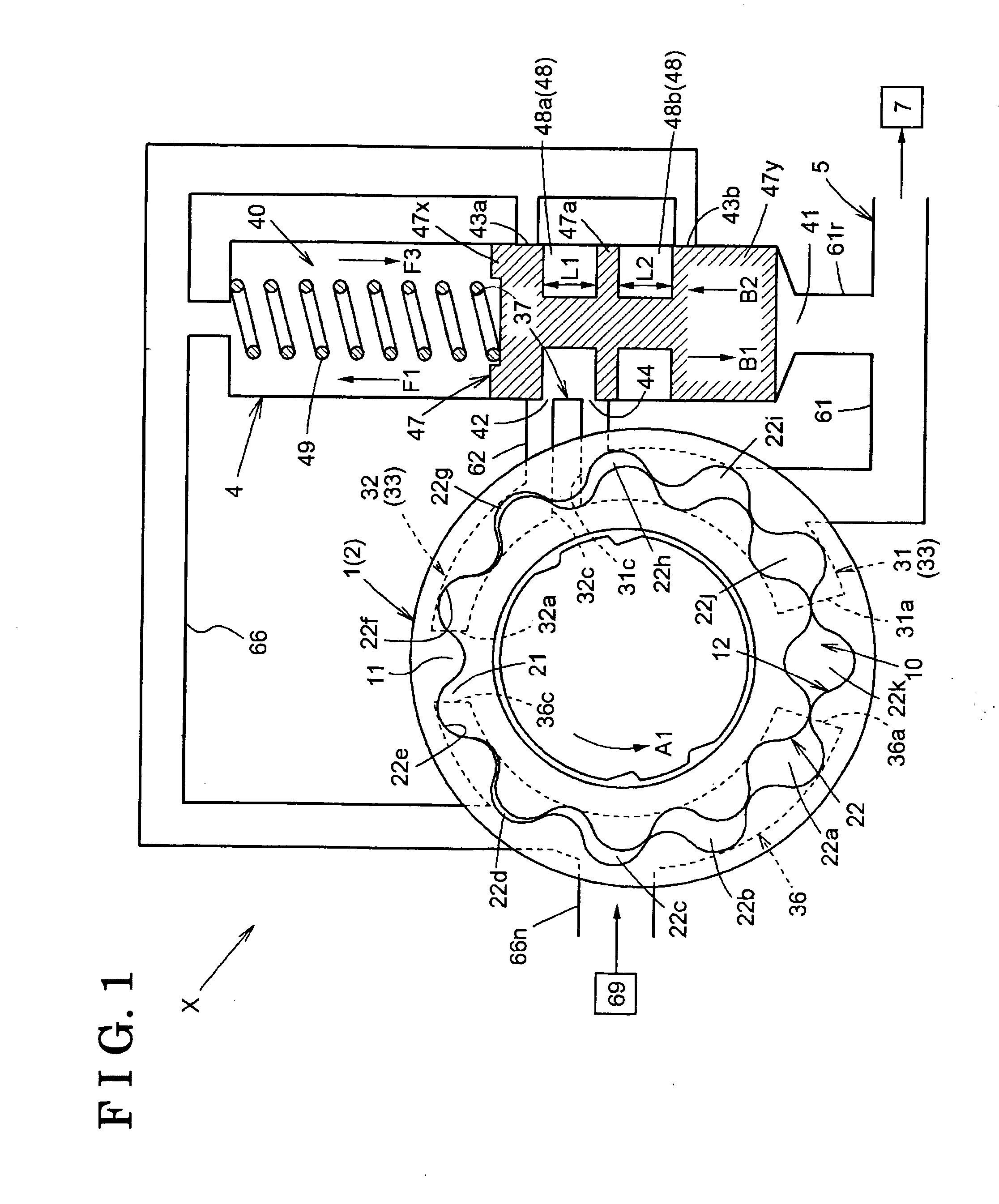

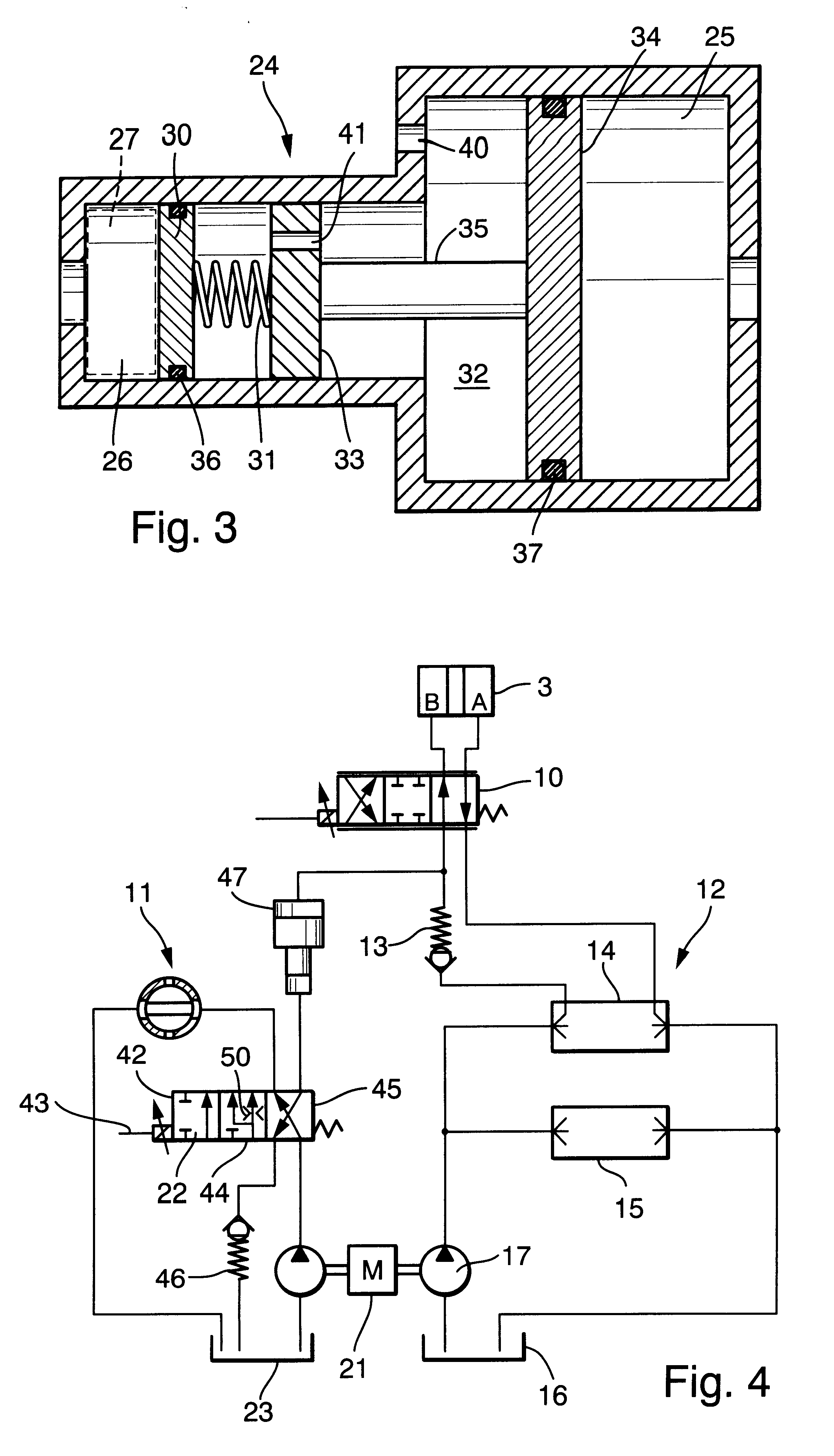

Continuously variable displacement vane pump and system

A vane pump (20) is provided which has an output pressure hat can be selected from a continuous range of pressures, independent of the operating speed of the pump. The pump has first (68) and second (72) control chambers which create opposed forces on the pump control ring (40) to selectively move the pump control ring (40) between maximum displacement and minimum displacement positions. In one embodiment, the control chamber (68) which urges the ump control ring to the minimum displacement position is continually supplied with pressurized working fluid during operation of the ump while the control chamber (72) which urges the pump control ring to the maximum displacement position can selectively be supplied with pressurized working fluid, isolated, or can be relieved of pressurized working fluid to alter the displacement of the pump.

Owner:HANON SYST EFP CANADA LTD

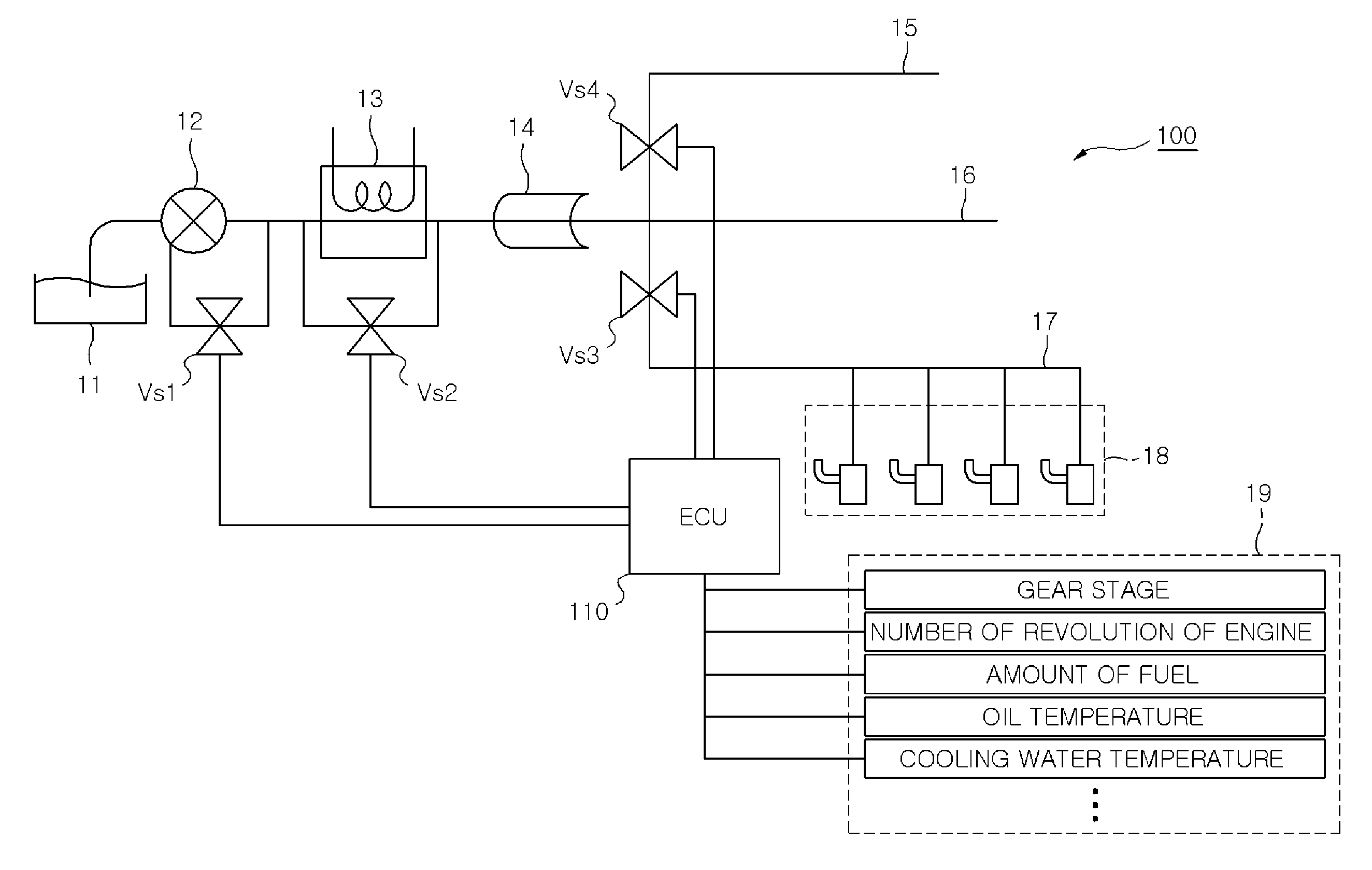

System for controlling hydraulic pressure and flow rate of oil in engine and control method thereof

InactiveUS20120048228A1Avoid friction lossLubrication of auxillariesLubricant conduit arrangementsElectronic controllerSolenoid valve

A system for controlling hydraulic pressure and flow rate of oil in an engine, may include a first solenoid valve disposed in a channel connecting an inlet and an outlet of an oil pump supplying oil from an oil pan to the engine, and an electronic controller controlling the first solenoid valve on the basis of number of revolution of the engine, load of the engine, and temperature of the oil.

Owner:HYUNDAI MOTOR CO LTD +1

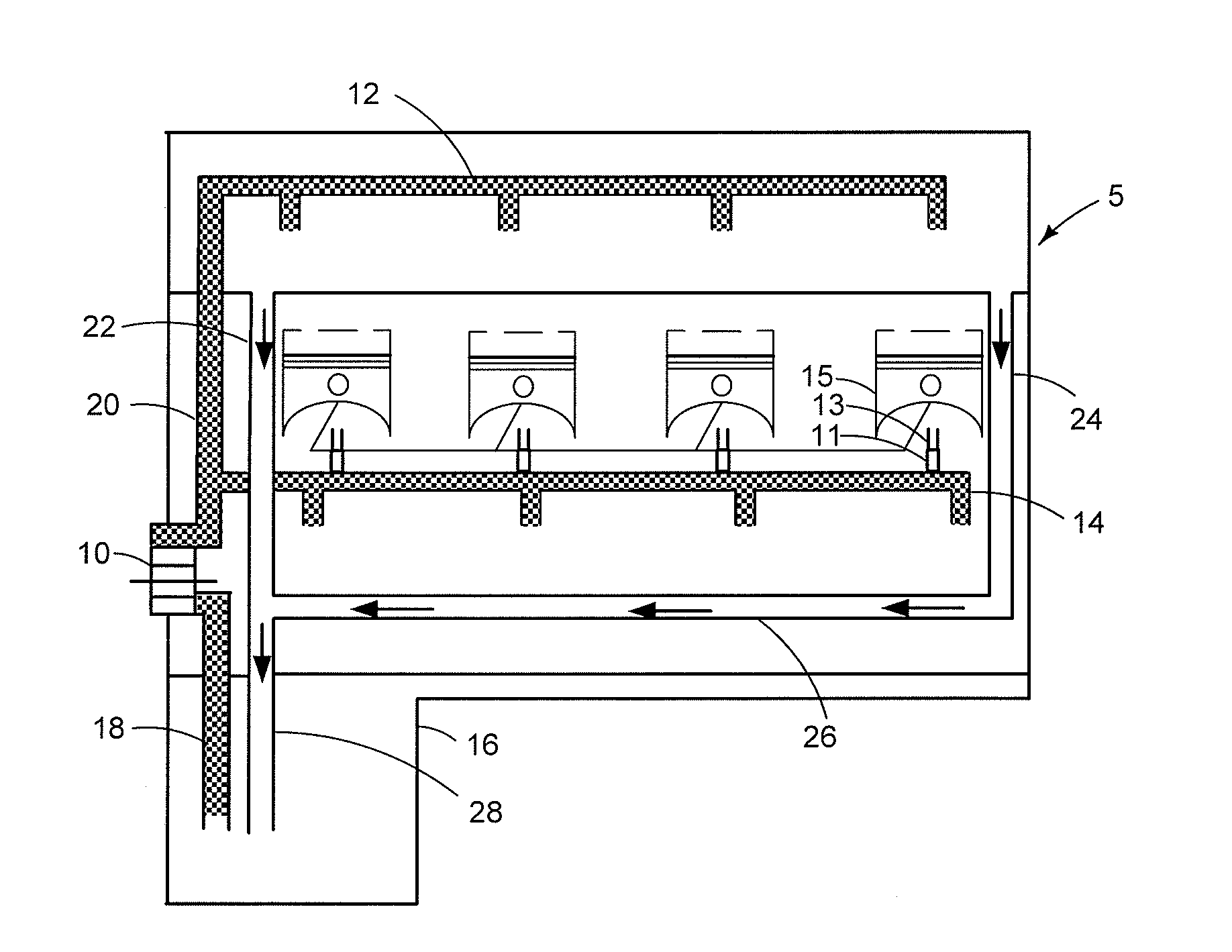

Oil supply system for an engine

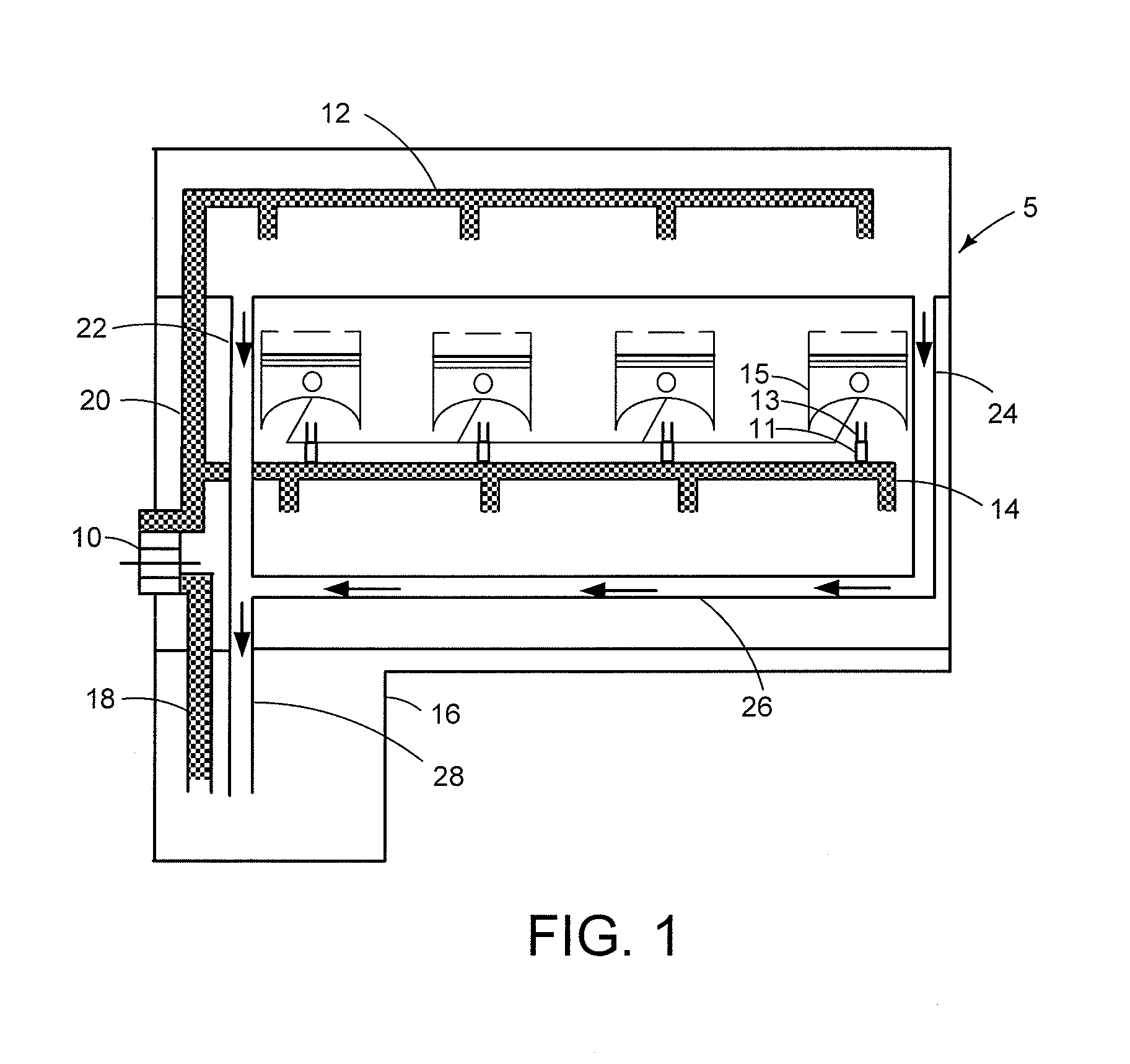

ActiveUS20110283968A1Reduce fuel usageLiquid coolingLubrication of auxillariesInternal combustion enginePiston

An oil supply system for a reciprocating piston internal combustion engine is disclosed in which the supply of oil to piston cooling jets is controlled by pressure operated valves designed to open at a pre-defined valve opening pressure. The pressure of oil supplied by a pump is controlled to be below this pre-defined valve opening pressure during operation of the engine in which piston cooling is not required, and the pressure of oil is controlled to above the pre-defined valve opening pressure when piston cooling is required. The control of the pump is by an electronic control unit based upon a combination of engine speed and engine load.

Owner:FORD GLOBAL TECH LLC

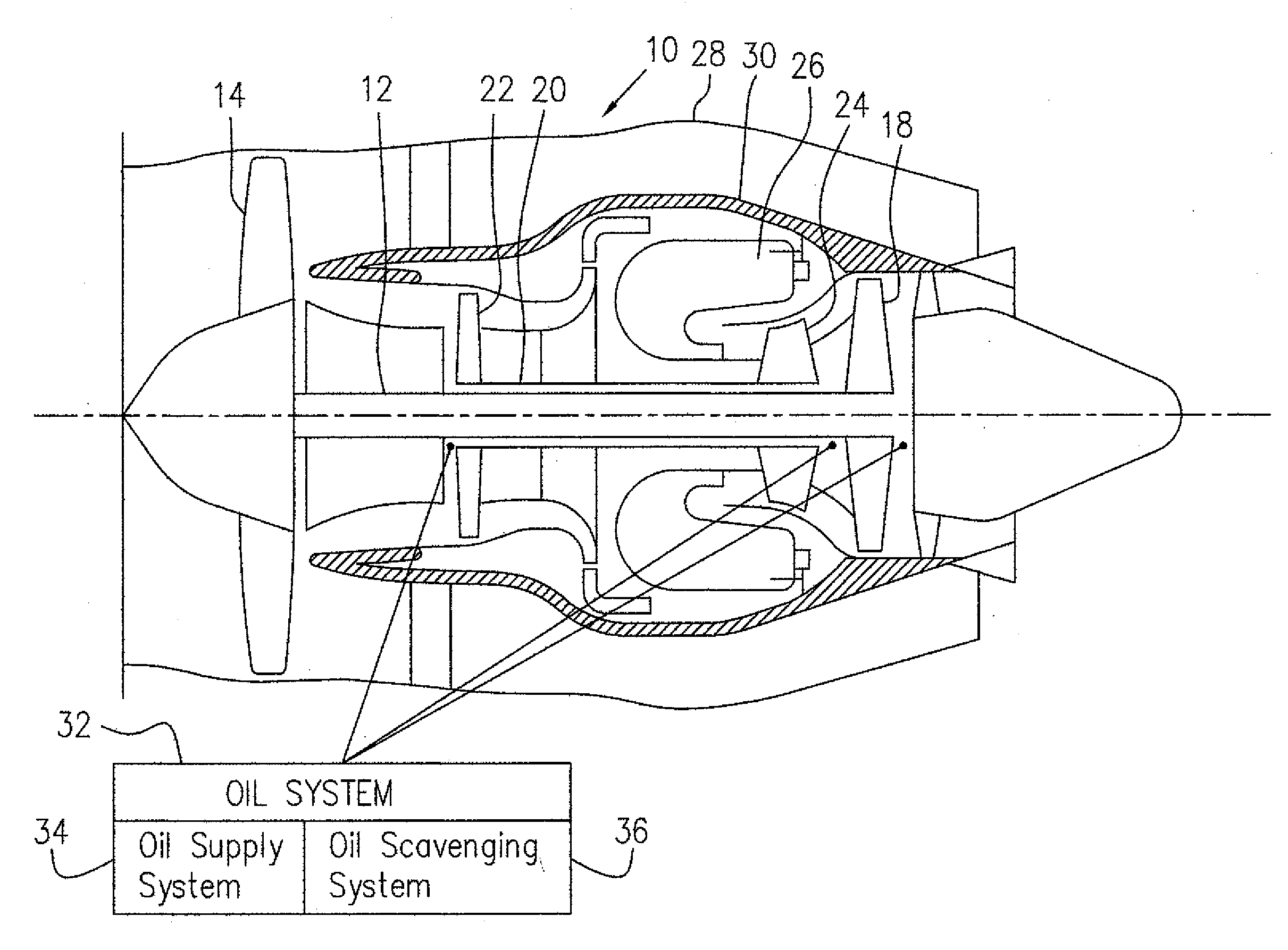

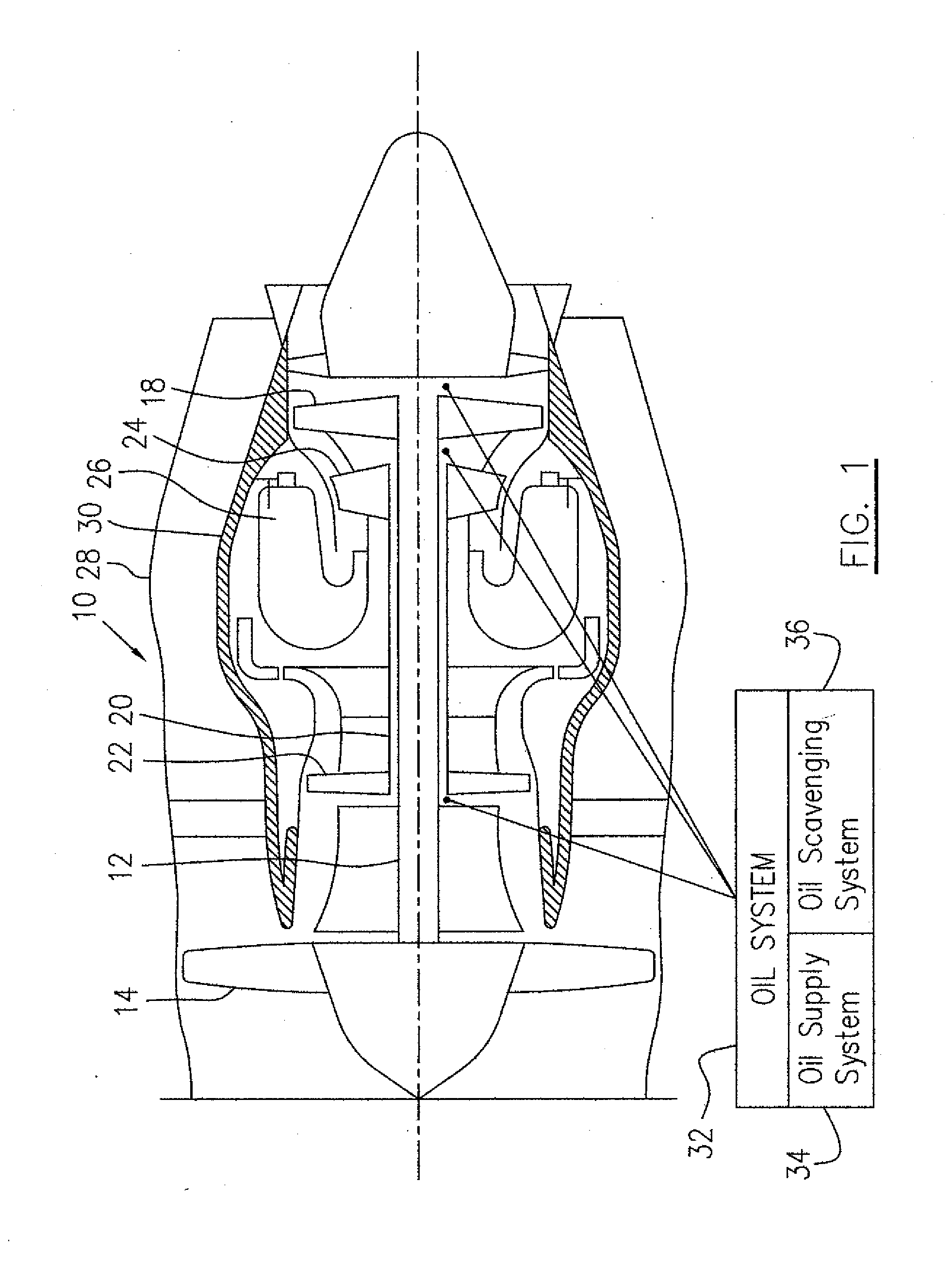

Gas turbine oil scavenging system

ActiveUS20090101444A1Low levelLow engine powerTurbinesDrip or splash lubricationFuel tankGas turbines

A method for scavenging oil in a gas turbine engine comprises using a driving fluid flow to drive a flow of a fluid collected in an oil system of the engine to pass through an ejector and then the driven flow of the fluid is directed to be discharged into an oil tank.

Owner:PRATT & WHITNEY CANADA CORP

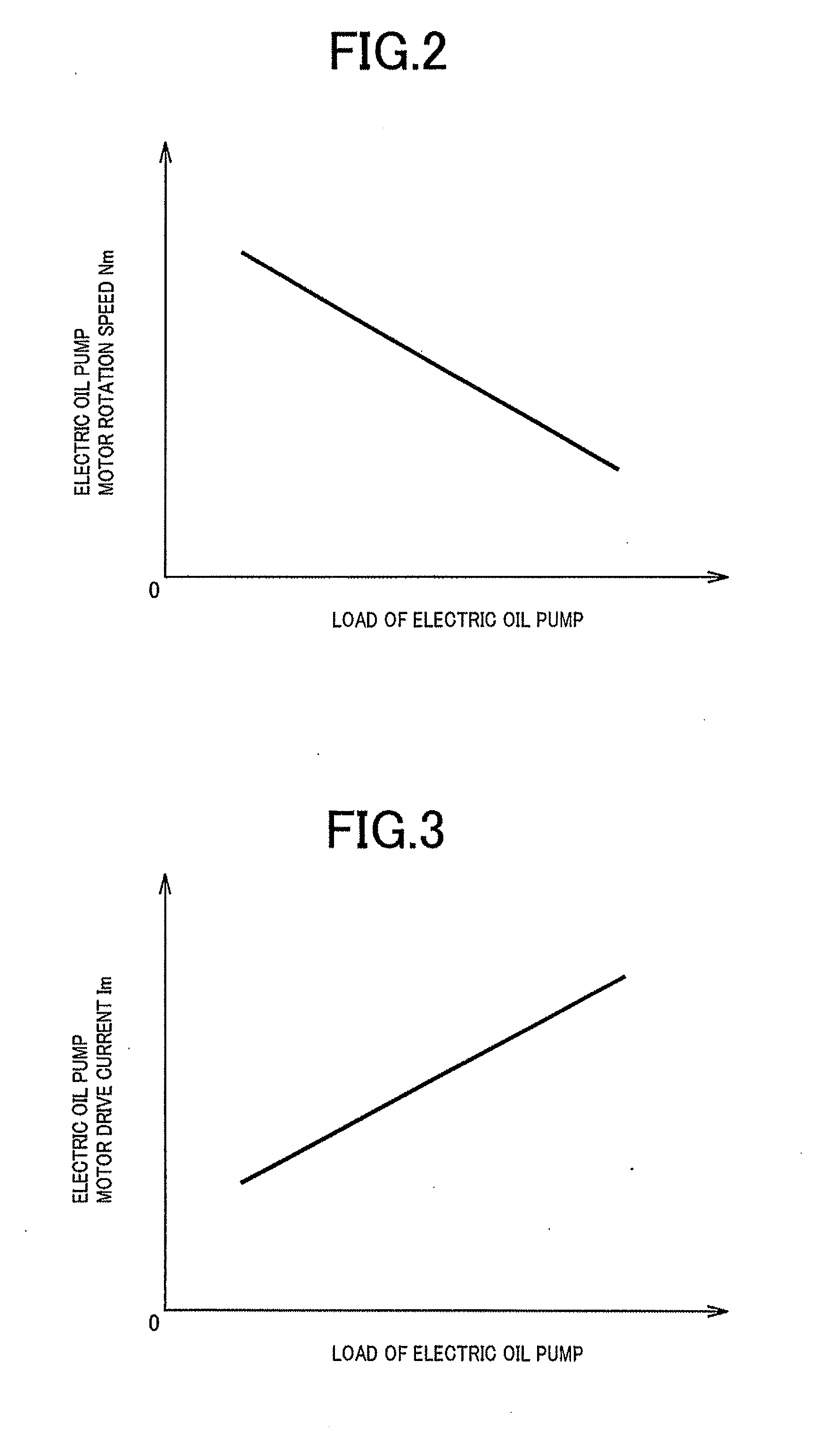

Control device of vehicle oil supply device

InactiveUS20130319366A1Improve fuel efficiencyWasteful operation of the electric oil pump is reducedLubrication of auxillariesGearing controlCheck valveOil pressure

A control device has a mechanical oil pump driven by an engine and an electric oil pump supplying oil via a check valve in an oil passage connecting the mechanical oil pump and the electric oil pump, the check valve allowing a flow of the oil from the electric oil pump side to the mechanical oil pump side while blocking a flow in an opposite direction, regardless of the pressure of the electric oil pump. When the check valve is closed under an oil pressure condition in which the electric oil pump outputs a maximum output oil pressure while the mechanical oil pump is driven by the engine at idle, the control device is configured to drive the electric oil pump during stop of the mechanical oil pump, and to stop the electric oil pump based on a load increase after start of the mechanical oil pump.

Owner:TOYOTA JIDOSHA KK

Lubricant supply system and method for controlling gearbox lubrication

A lubricant supply system for a gearbox includes a lubricant flow circuit having, in fluid flow sequence: a variable-flow rate first pump; an lubricant cooler; and a gearbox. The system also includes: a first temperature sensor for sensing a temperature of lubricant circulating within the lubricant flow circuit; a pressure sensor for sensing a pressure of lubricant circulating within the lubricant flow circuit; and a controller operably connected to the pressure and temperature sensors and to the first pump. The controller is operable to control flow of the pump in response to the sensed temperature and to the sensed pressure.

Owner:GENERAL ELECTRIC CO

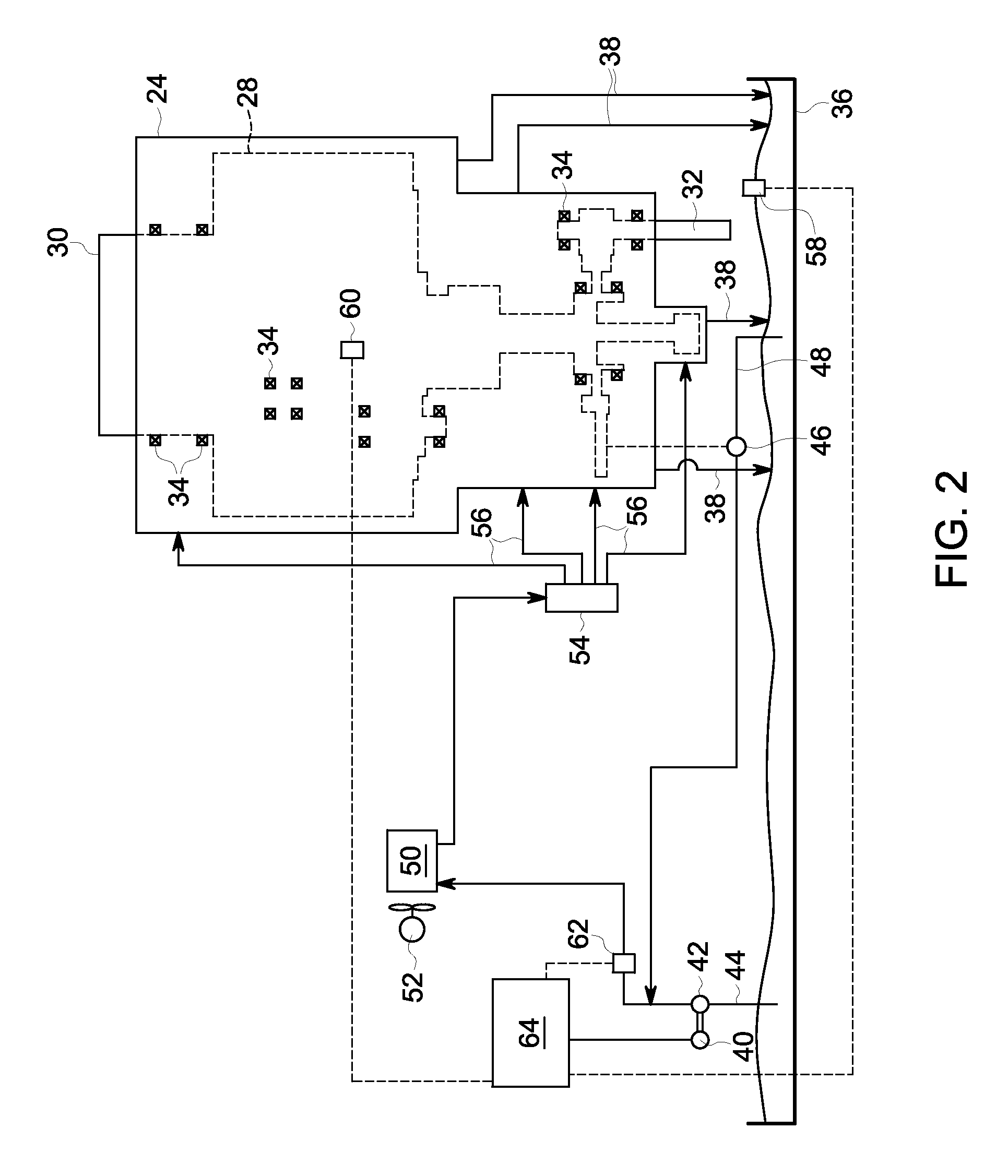

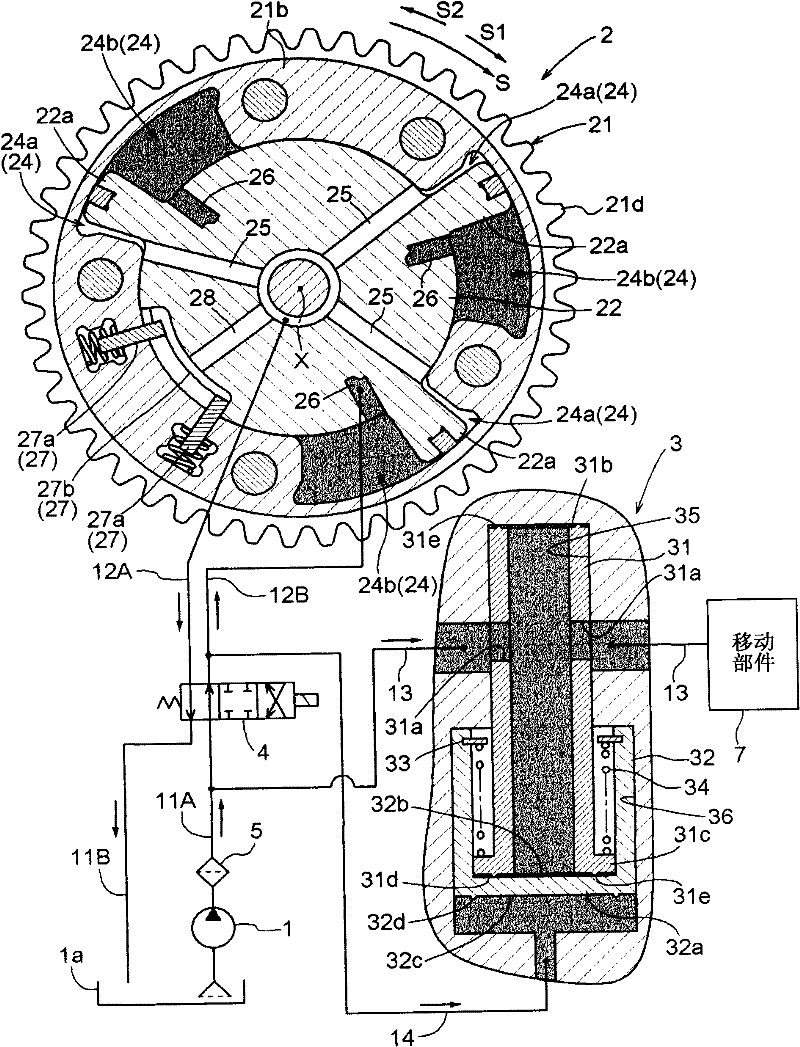

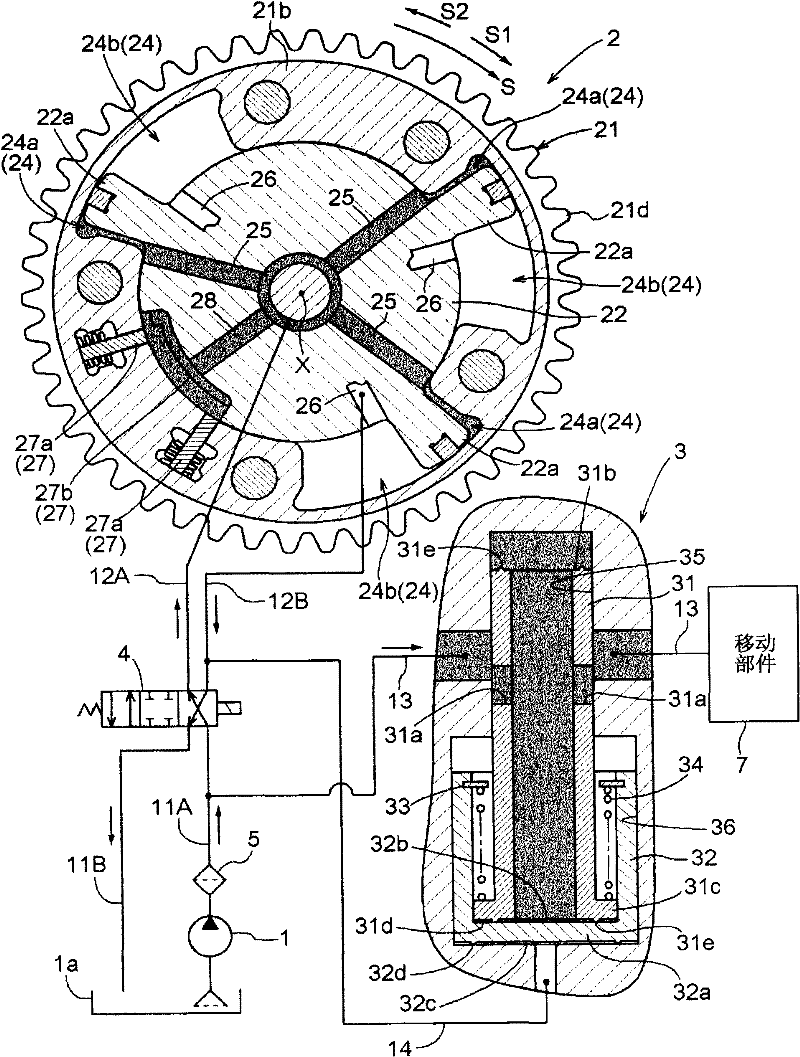

Oil pressure control apparatus

An oil pressure control apparatus includes a control valve mechanism (4) being in communication with a pump (1) via a first fluid passage (11A) and being in communication with a control apparatus (2) via a second fluid passage (12B), a third fluid passage (13) diverging from the first fluid passage to supply oil to a predetermined portion (7) other than the control apparatus, and a fluid passage dimension regulating mechanism (3) including a movable member (31) provided at the third fluid passage and including an opening (31 a) for regulating a fluid passage dimension of the third fluid passage. The fluid passage dimension regulating mechanism is in communication with a fourth fluid passage (14) diverging from the second fluid passage and biases the movable member to a side increasing the fluid passage dimension by applying the hydraulic pressure of the fourth fluid passage to the movable member separately from the hydraulic pressure of the third fluid passage.

Owner:AISIN SEIKI KK

Engine lubrication system

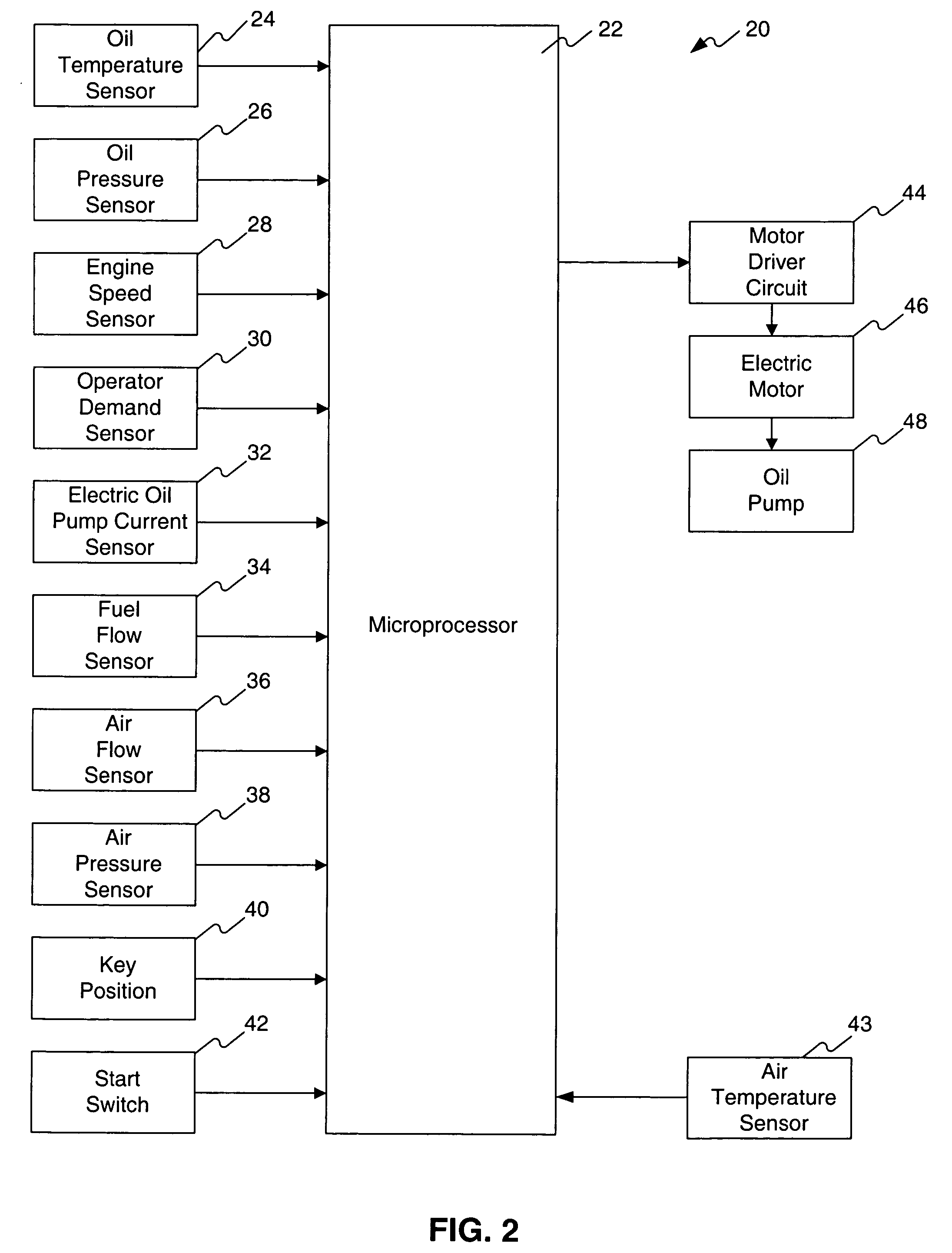

InactiveUS20040031463A1Increase temperatureEasy to disassembleLubricant conduit arrangementsMachines/enginesSystem controllerLubrication

A lubrication system for an engine includes a sump for lubricant, a pump to pump lubricant along a lubricant feed line to lubrication positions within the engine, and a lubricant conditioner, and wherein the pump is an electrically driven pump which is controlled by a system controller, there being a diverter valve which is under the control of the controller selectively to divert at least a proportion of the lubricant from the lubricant feed line to the lubricant conditioner.

Owner:PIERBURG PUMP TECH UK

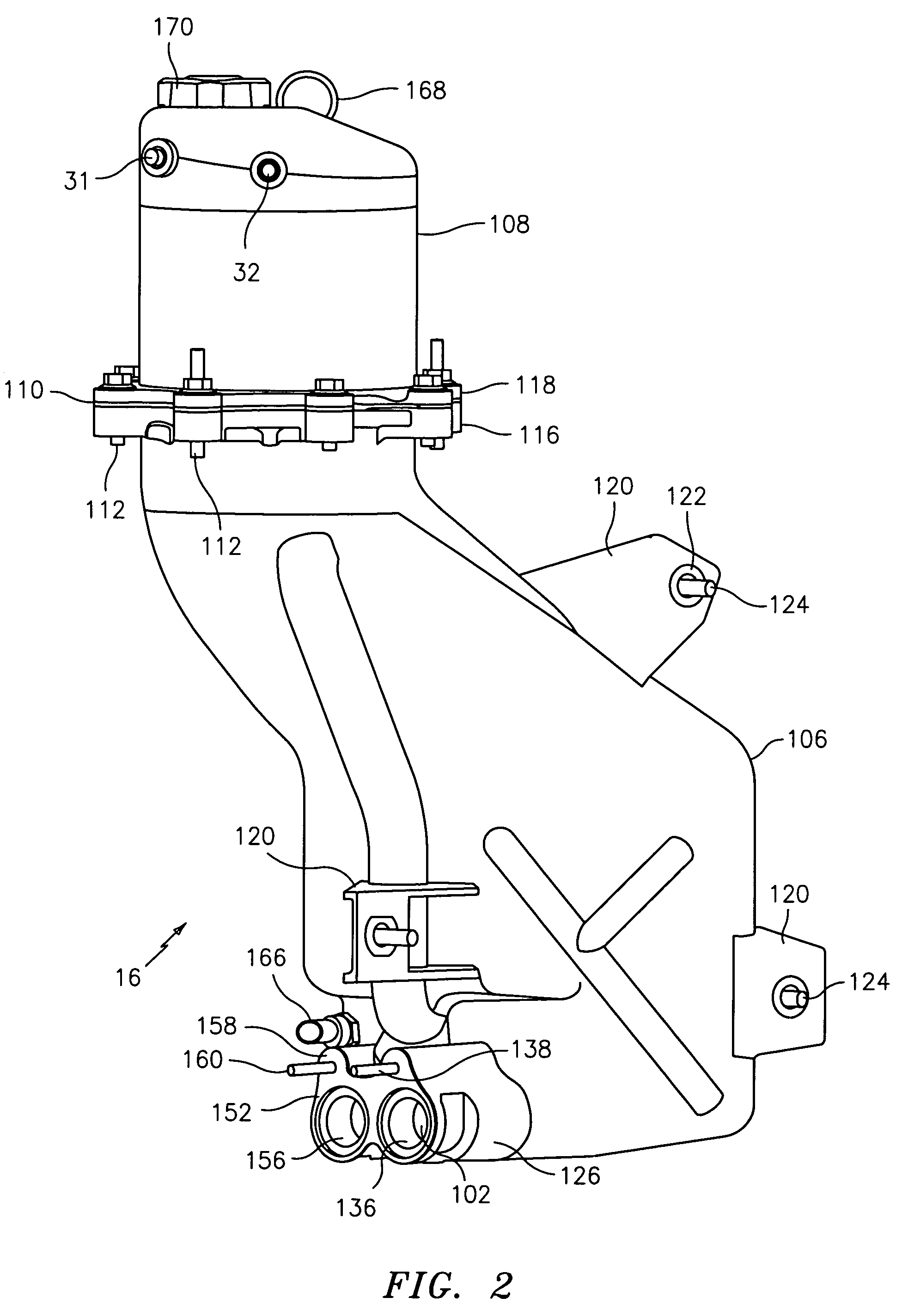

Lubricant cooling system for outboard motor

InactiveUS6418887B1Liquid coolingCoolant flow controlOperating temperature rangeInternal combustion engine

An outboard motor contains a four-cycle engine. The engine includes a lubricant supply system that recirculates lubricant through the engine to lubricate the moving components of the internal combustion engine. The lubricant supply system includes a lubricant cooler. The lubricant cooler is selectively bypassed by lubricant and / or coolant to maintain the proper operating temperature range for the lubricant, depending upon the lubricant temperature and / or the coolant temperature.

Owner:SANSHIN KOGYO CO LTD

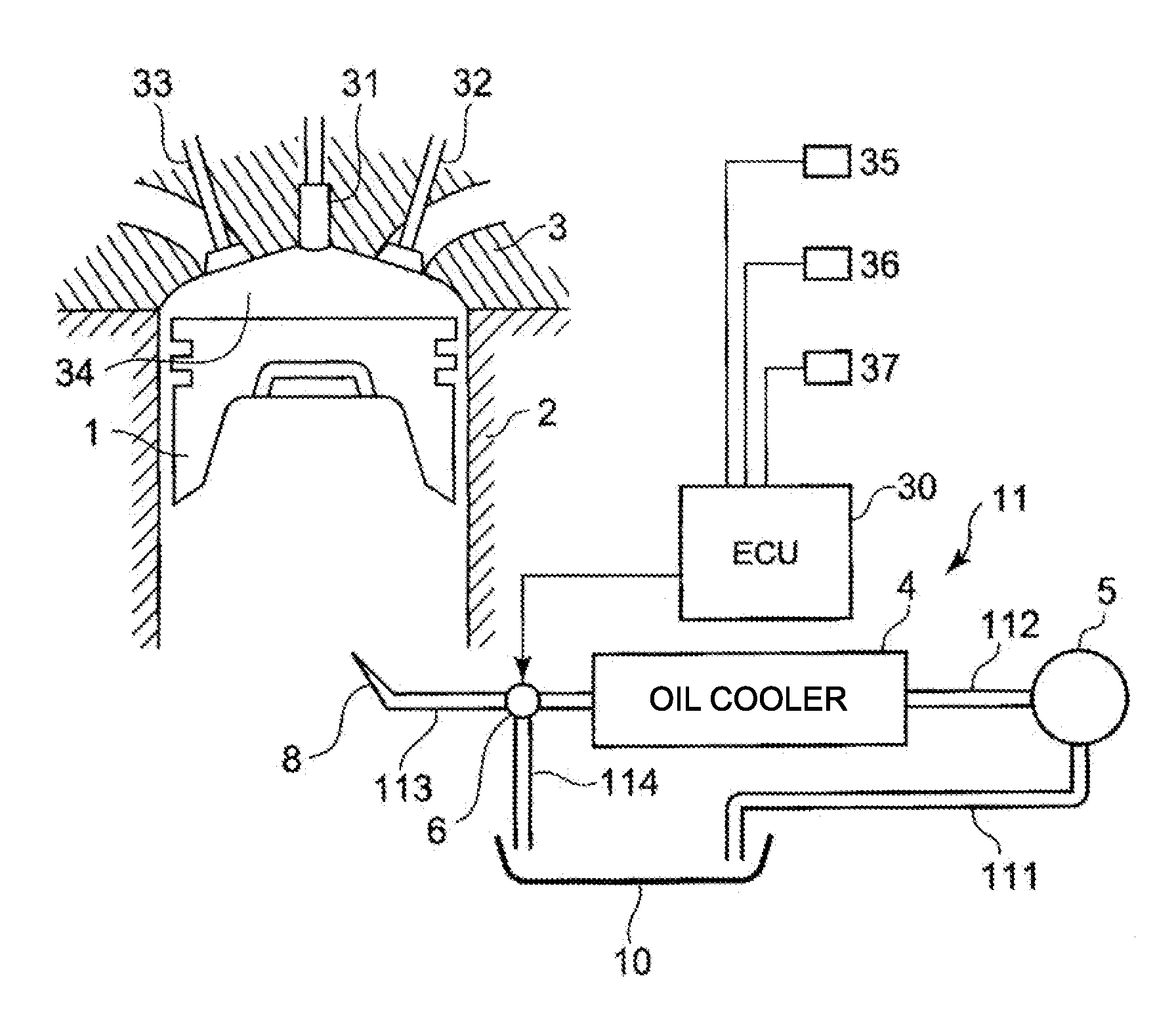

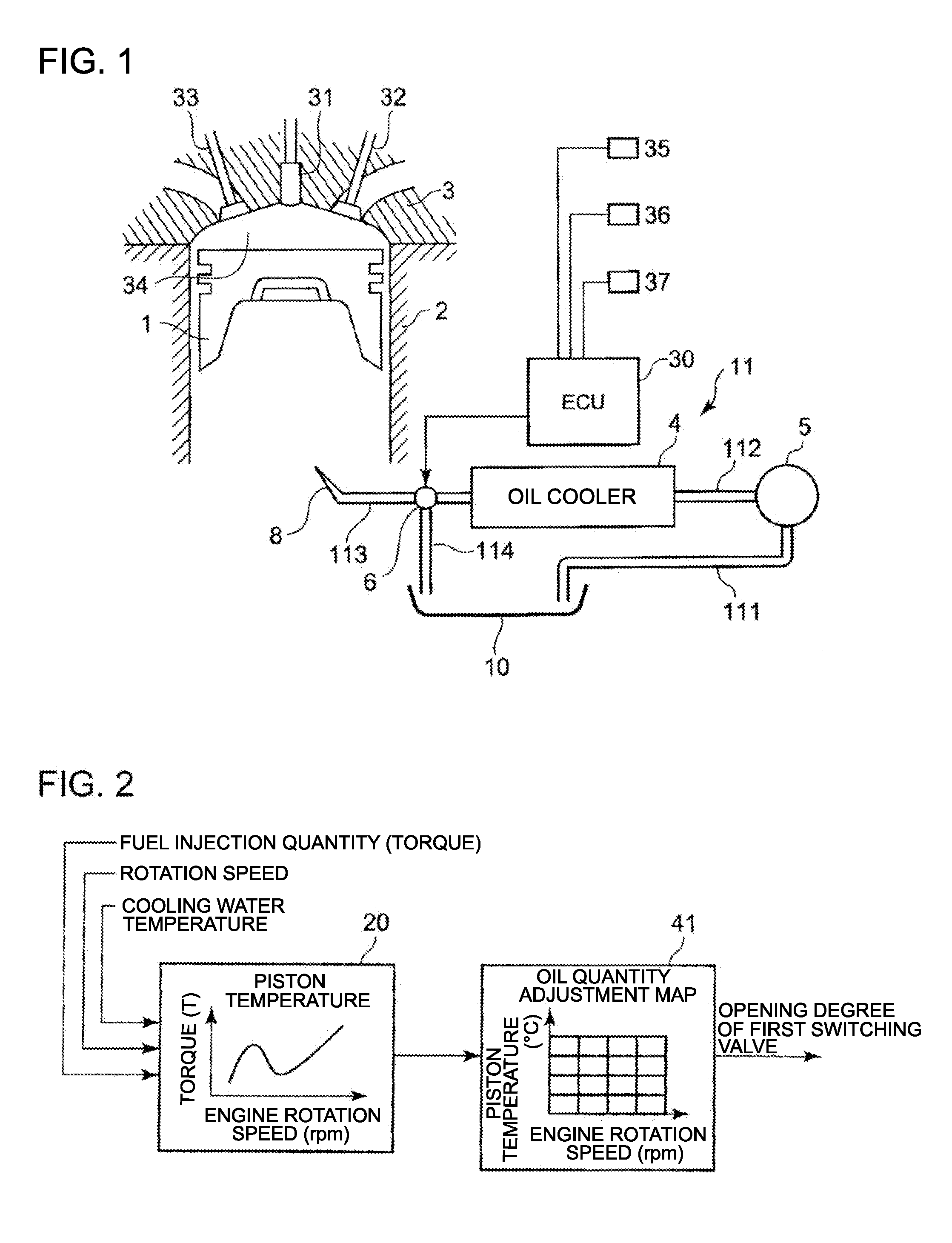

Cooling device for engine

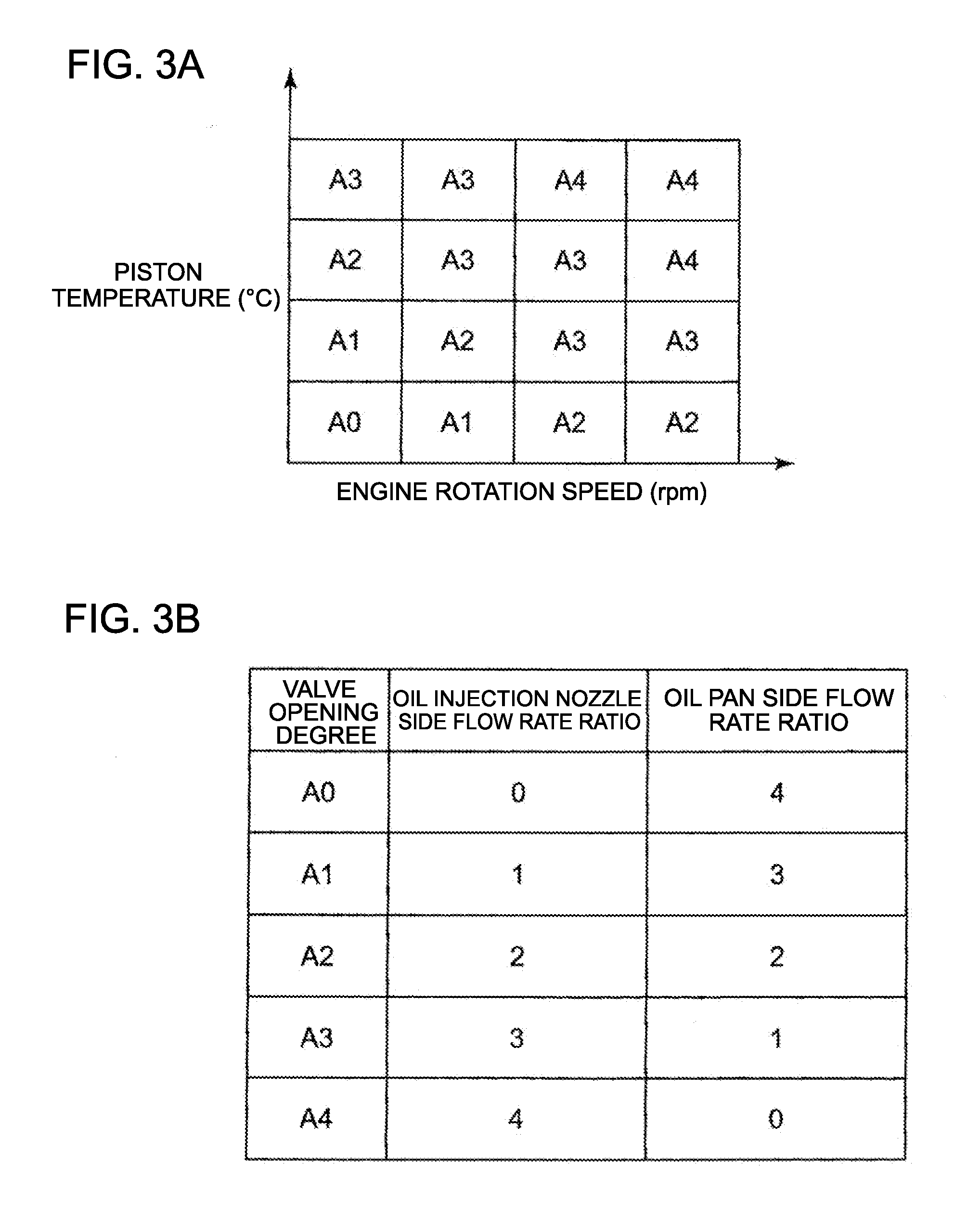

ActiveUS20130139768A1Fine cooling controlEasy to operateLiquid coolingCoolant flow controlPistonPetroleum engineering

Disclosed is an oil jet device for cooling a piston, including: an oil cooler 4 that is disposed upstream of an oil injection nozzle 8; an oil pump 5 that is disposed upstream of the oil cooler 4; a first switching adjustment valve 6 that is disposed between the oil injection nozzle 8 and the oil cooler 4 and adjusts a flow dividing ratio at which the cooling oil from the oil cooler 4 is distributed to the oil injection nozzle 8 side and to an oil pan side; and a control unit that has an oil quantity adjustment map 4 for switching the first switching adjustment valve 6 based on a piston temperature calculation map 20 for calculating the temperature of the piston 1 using detection values acquired respectively by a cooling water temperature sensor 35, a rotation speed sensor 36 and a load sensor 37.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

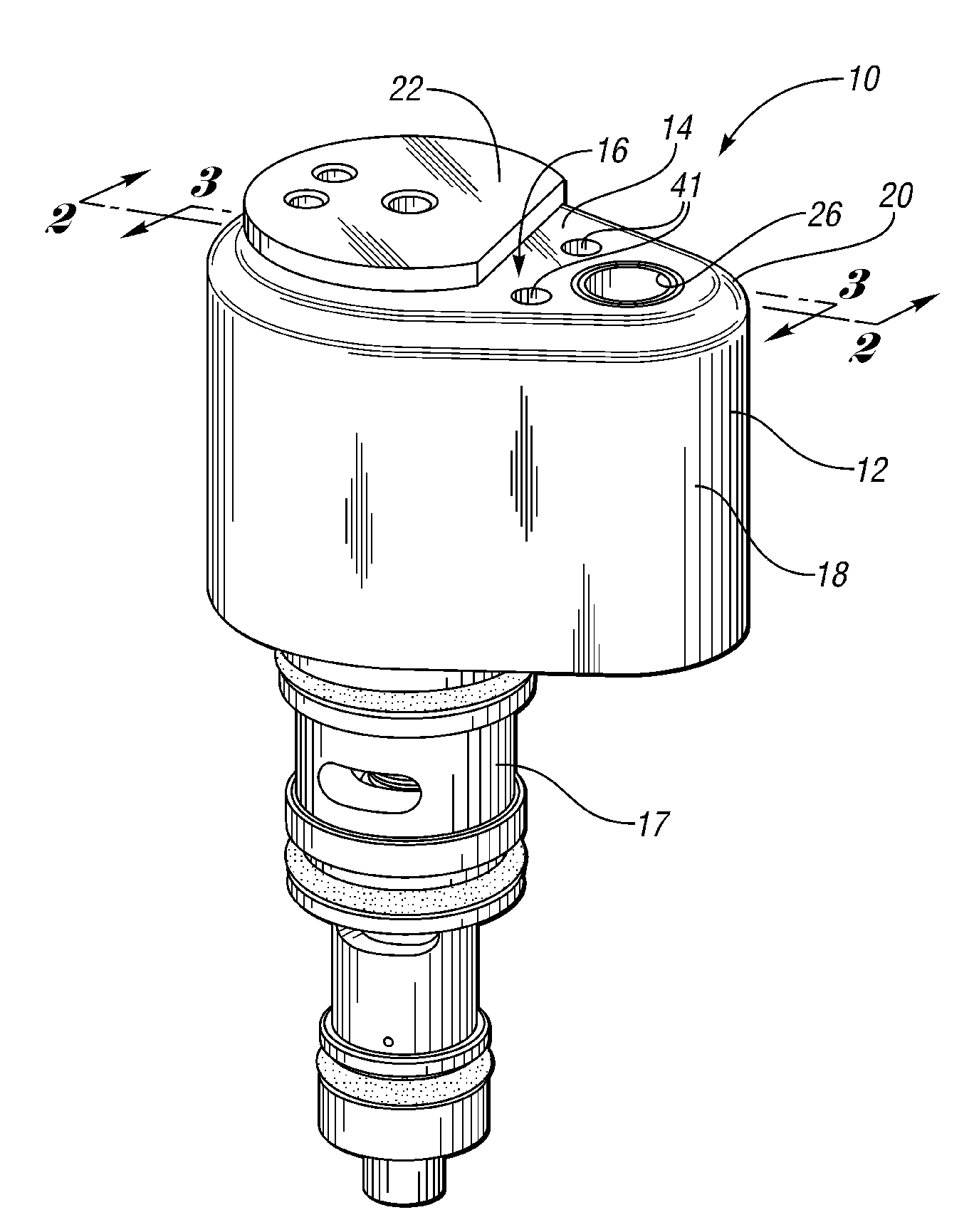

Engine valve assembly with valve can mountable to an engine cover

InactiveUS20100019186A1Easy accessEasy to installOperating means/releasing devices for valvesMagnetsEngine valveVALVE PORT

An engine valve assembly is provided with a valve housing configured to promote easy fastening and removal of the valve assembly from an engine cover. The housing has a first wall and a side wall that extends therefrom to partially define an interior cavity with a cavity opening opposite the first wall. In some embodiments, the first wall has a generally teardrop-shaped surface. The first wall has a valve opening and a fastener opening that is spaced from and aligned with the valve opening along the first wall. A valve body is supported by the valve housing at least partially within the interior cavity, and may be press-fit therein. The valve housing mounts to the engine cover with the fastener inserted through the fastener opening to extend through the interior cavity and fasten to the engine cover, with the valve body extending into the engine cover.

Owner:EATON CORP

Oil supply system for engine

An oil supply system for an engine includes a pump body provided with a first outlet port and a second outlet port. The oil supply system further includes a hydraulic-oil-delivery passage, a first oil passage, a second oil passage and a return hydraulic passage. The valve body divides a hydraulic-oil receiving portion for receiving the hydraulic oil in the hydraulic-pressure control valve chamber into a first valve chamber and a second valve chamber. When the hydraulic pressure oil delivered to the hydraulic-oil-delivery passage is in a predetermined value, the hydraulic oil discharged out of the second outlet port is delivered to the hydraulic-oil-delivery passage via the first valve chamber. When the hydraulic pressure delivered to the hydraulic-oil-delivery passage exceeds the predetermined value, the hydraulic oil discharged out of the second outlet port is delivered to the hydraulic-oil-delivery passage via the second valve chamber.

Owner:AISIN SEIKI KK

Oil supply system for internal combustion engine with dual mode pressure limiting valve

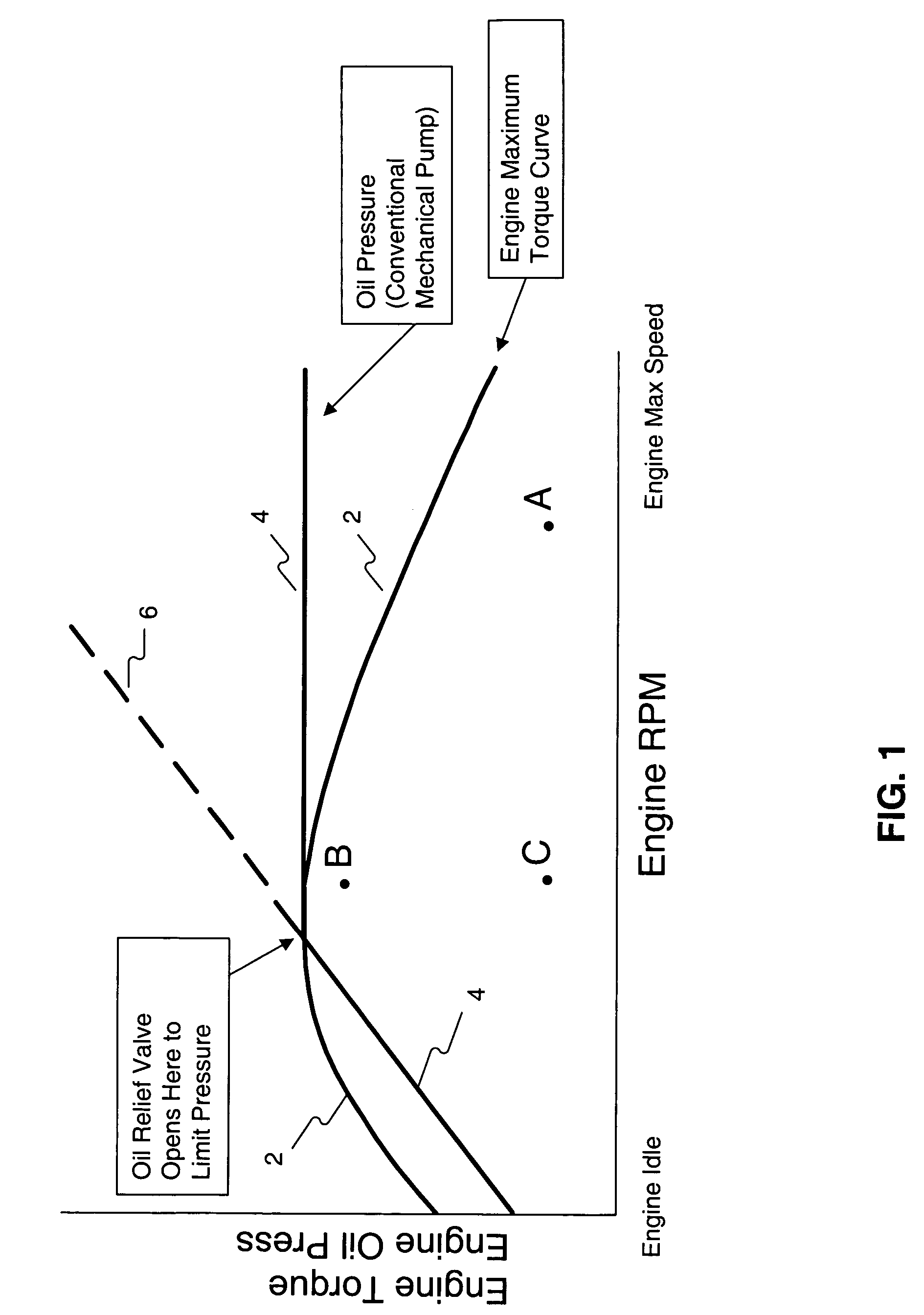

ActiveUS20100192898A1Minimizing parasitic lossReduce engine fuel consumptionLubrication of auxillariesLubricant conduit arrangementsExternal combustion engineDual mode

A lubricating oil supply system for internal combustion engine includes an oil reservoir and oil pump connected with a lubrication distribution network including a piloted pressure relief valve which selectively controls the pressure within the distribution network to at least one pressure value that is less than the maximum pressure produced by a primary pressure relief valve associated with the oil pump, while also protecting the lubrication distribution network from an unwanted overpressure condition.

Owner:FORD GLOBAL TECH LLC

Oil supply system for engine

An oil supply system for an engine includes a pump body provided with a first outlet port and a second outlet port. The oil supply system further includes a hydraulic-oil-delivery passage, a first oil passage, a second oil passage and a return hydraulic passage. The valve body divides a hydraulic-oil receiving portion for receiving the hydraulic oil in the hydraulic-pressure control valve chamber into a first valve chamber and a second valve chamber. When the hydraulic pressure oil delivered to the hydraulic-oil-delivery passage is in a predetermined value, the hydraulic oil discharged out of the second outlet port is delivered to the hydraulic-oil-delivery passage via the first valve chamber. When the hydraulic pressure delivered to the hydraulic-oil-delivery passage exceeds the predetermined value, the hydraulic oil discharged out of the second outlet port is delivered to the hydraulic-oil-delivery passage via the second valve chamber.

Owner:AISIN SEIKI KK

Engine hydraulic control apparatus

InactiveUS20090229561A1Reduce frictionReduction in load of oilLubrication of auxillariesAir coolingEngineeringCrankshaft

A hydraulic control apparatus (1) is provided with an oil pump (4) that draws oil from an oil pan (3) due to the rotation of the crankshaft, a piston jet (6) that open when the hydraulic pressure of the oil that has been drawn from this oil pump (4) attains a valve opening pressure Qa and injects oil toward a piston through an oil injection path (5), a relief valve (8) that is disposed on an oil return path (7) and opens when the hydraulic pressure of the oil that has been drawn by the oil pump (4) has attained a valve opening pressure Qb, and a switching valve (9) that is disposed on the oil return path (7). The valve opening pressure Qb is set to a pressure that is lower than that of the valve opening pressure Qa.

Owner:TOYOTA JIDOSHA KK

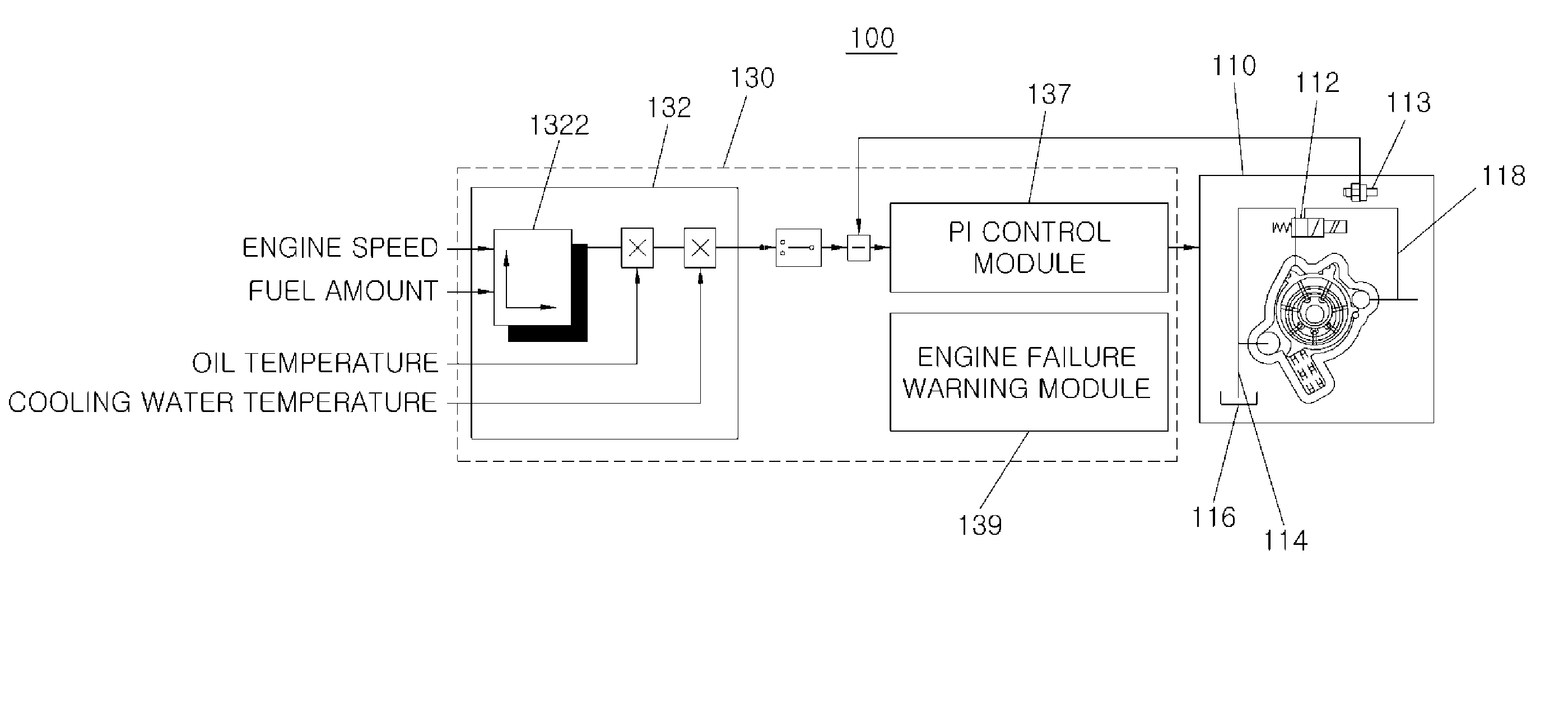

Oil pump control system for vehicle

InactiveUS20130151113A1Low efficiencyMaximize efficiencyAnalogue computers for vehiclesClutchesControl systemControl valves

An oil pump control system for a vehicle, may include an oil pump configured to supply oil to an engine, an oil pressure control valve regulating oil pressure value of a discharging part in the oil pump, an oil pressure sensor sensing and outputting the oil pressure value of the discharging part in the oil pump, and a controller receiving a signal of the oil pressure value, determining a target oil pressure value of the discharging part in the oil pump in response to information relating to an oil pressure and operation state of the engine among vehicle information inputted from outside, comparing the sensed oil pressure value inputted from the oil pressure sensor with the target oil pressure value, and performing feedback control to drive the oil pressure control valve.

Owner:HYUNDAI MOTOR CO LTD +1

Apparatus for angular adjustment of camshafts relative to crankshafts in combustion engines

An apparatus for varying the phase of the camshaft in the combustion engine of a motor vehicle has an adjuster which is connected to the camshaft and is operable to adjust the phase of the camshaft prior and subsequent to starting of the engine. To this end, the adjuster is connected with a hydraulic drive system which can operate the adjuster while the engine is idle. Once the engine is started, the drive system receives pressurized fluid from the lubricating circuit of the engine. Prior to starting of the engine, the drive system receives pressurized fluid from a source other than the lubricating circuit or from a source which is provided in addition to the lubricating circuit. The other source is preferably the hydraulic circuit of the power steering system (such as a speed-sensitive power steering system) of the motor vehicle.

Owner:ATLAS FAHRZEUGTECHN GMBH

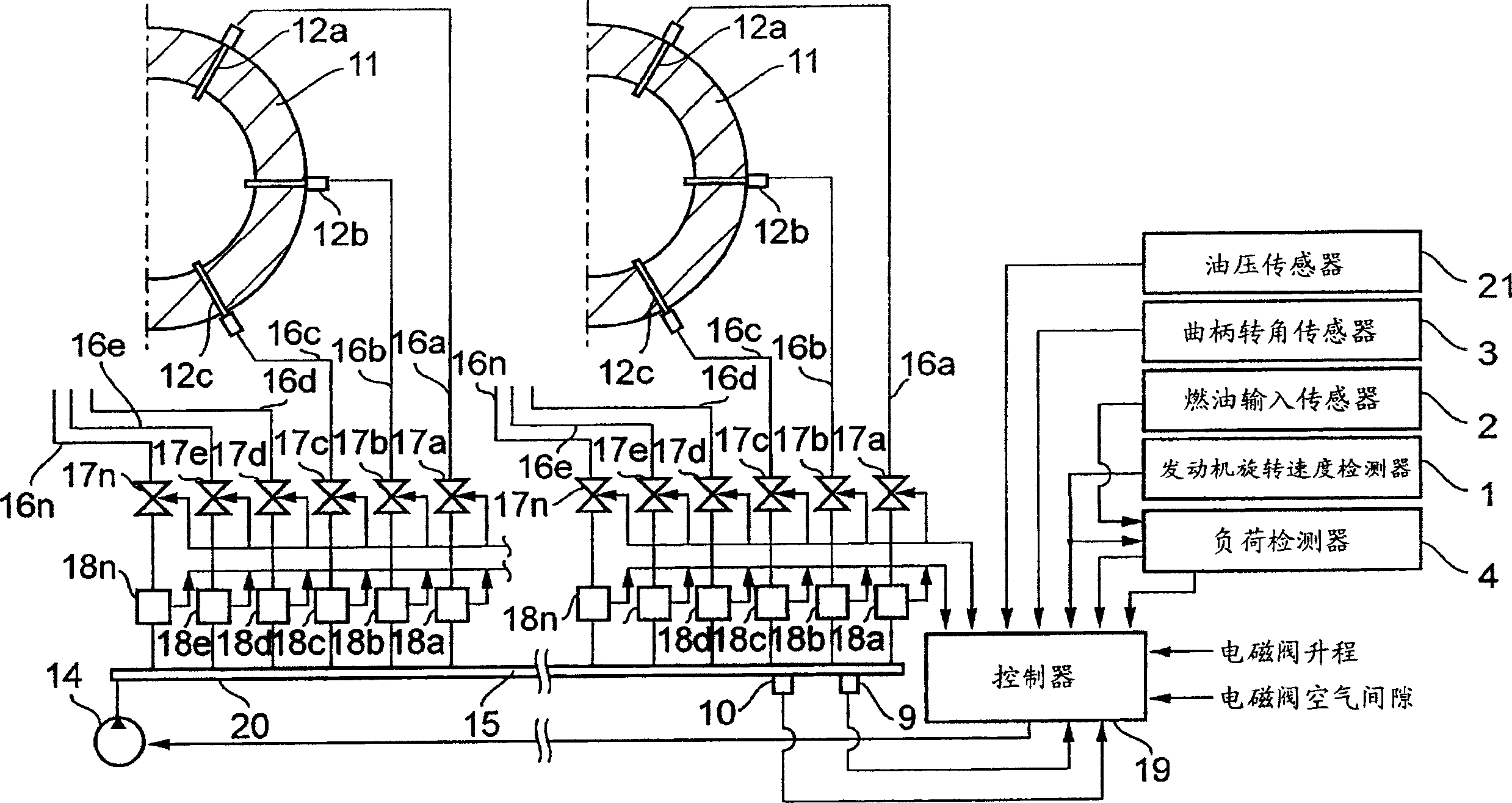

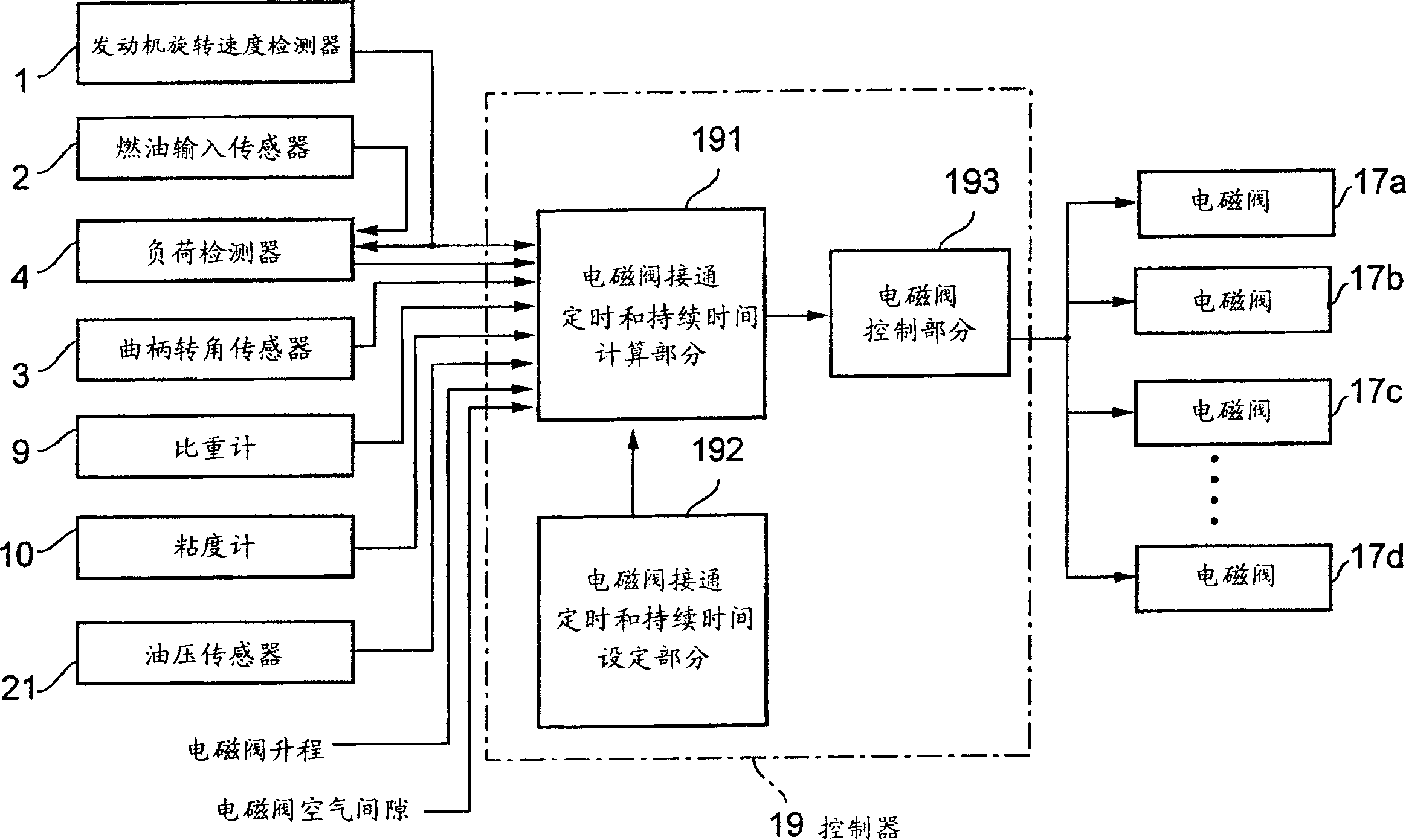

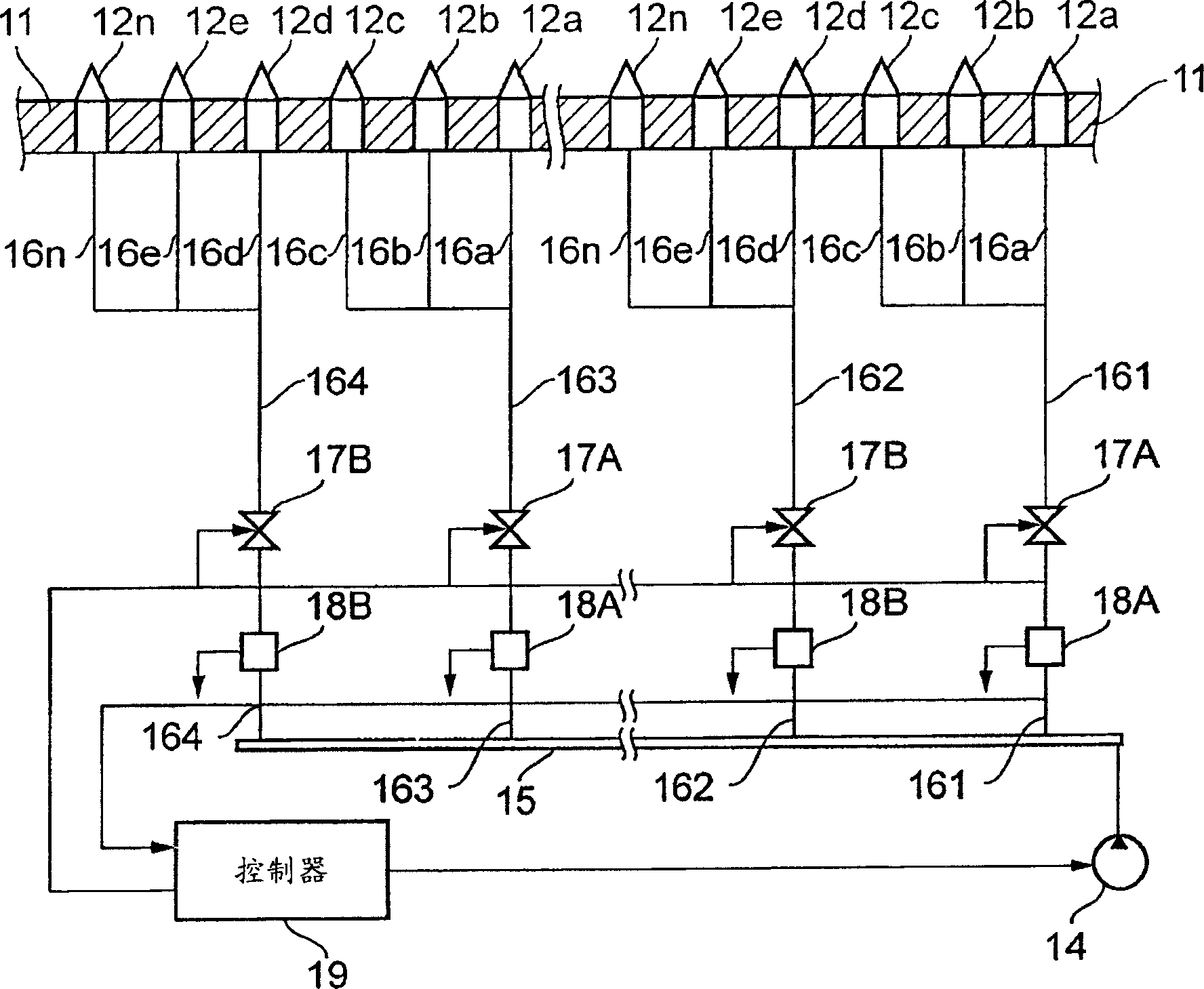

Internal combustion engine with cylinder lubricating system

InactiveCN1676888AReduce supplySupply impactElectrical controlCylinder headsExternal combustion enginePiston ring

An internal combustion engine with a cylinder lubricating system is proposed; with the system it becomes possible to supply lube oil of required amount at required timing to each of lubricators, and normal supply of lube oil is possible even when malfunction occurs in some of the lubricators or magnetic valves, and further the timing and amount of lube oil supply can be adjusted even in engine operation in accordance with varying factors such as properties of lube oil, lube oil pressure, etc., resulting in a reduction of lube oil consumption. Lubricating oil pressure-fed by a lubricating oil pump is accommodated in a common lube oil feeding section, the lubricating oil accumulated in said common lube oil feeding section is supplied to a plurality of lubricators (injectors) through oil passages connecting said common lube oil feeding section to said lubricators and injected to the inner surfaces of cylinders of the engine by said lubricators, a plurality of electromagnetic valves are provided for opening or closing the oil passages and the timing and period of opening of each of the valves are controlled independently so that lube oil is injected from the lubricators to spaces between piston rings once per one reciprocation of piston.

Owner:MITSUBISHI HEAVY IND LTD +1

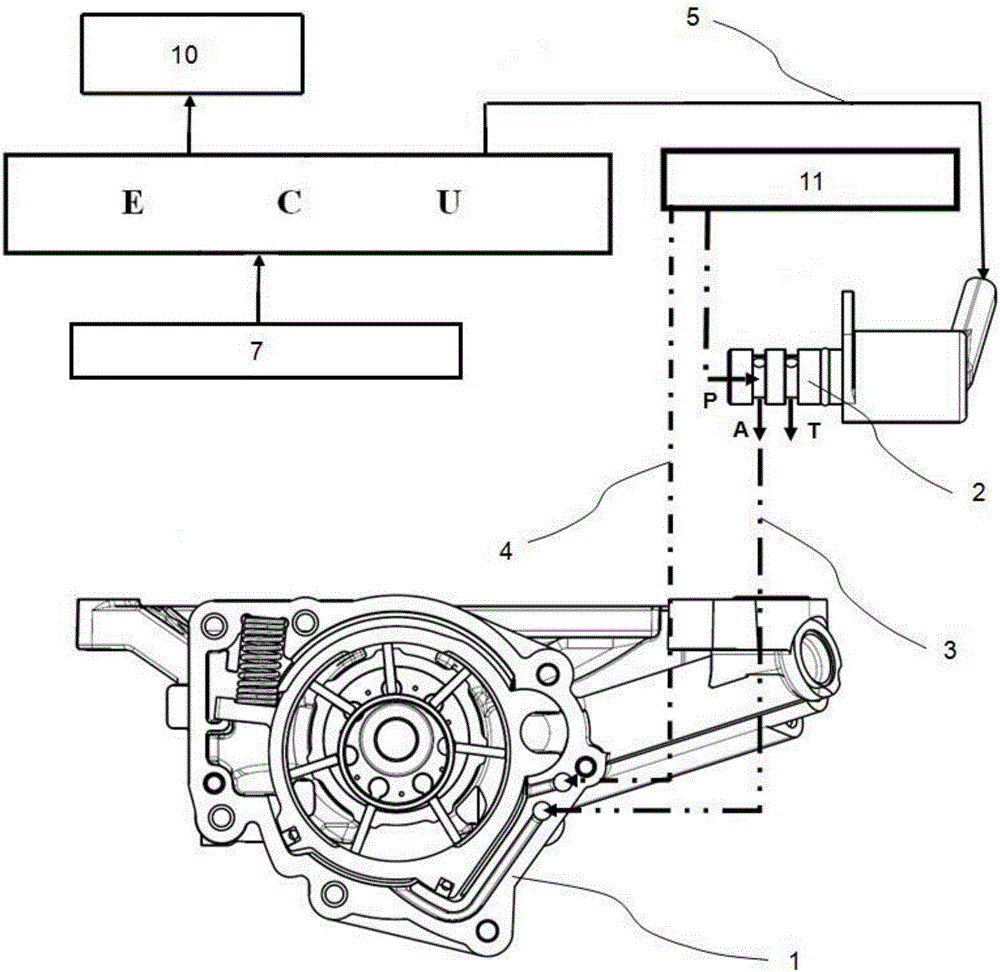

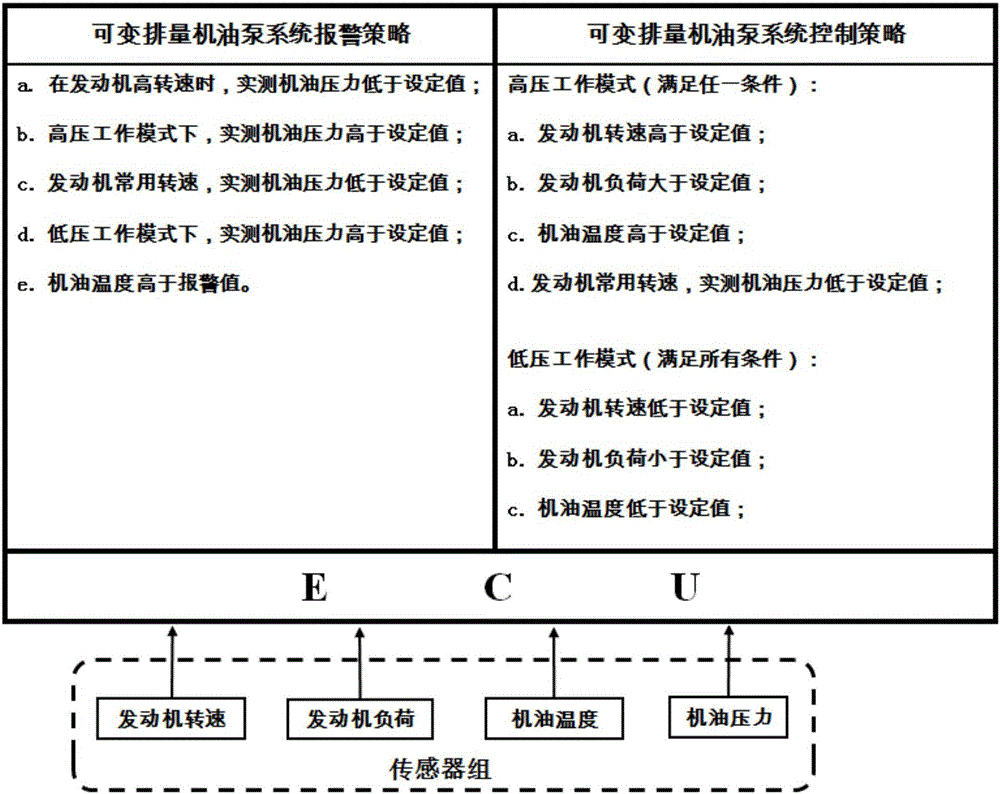

Variable displacement oil pump control system and control method thereof

InactiveCN106567755ADisplacement intelligent adjustmentSolve the problem of high fuel consumption due to excess oil pump capacityEngine loadEngine revolutionsControl signalControl system

The invention provides a variable displacement oil pump control system and a control method thereof. A first feedback oil duct and a second feedback oil duct of the control system are both connected between a main oil duct and a variable displacement oil pump. An electromagnetic valve is installed on the first feedback oil duct and is connected with an ECU through a wiring harness. A sensor set is in signal connection with the ECU. The ECU receives detection signals of the sensor set, control signals are sent to the electromagnetic valve after the detection signals are analyzed and judged by a control strategy module inside the ECU, and the electromagnetic valve executes corresponding movements according to the control signals. By the adoption of the control method, the ECU is used for receiving the engine rotating speed, engine loads, oil temperature signals and oil pressure signals sent by the sensor set, and the working mode of the variable displacement oil pump can be intelligently selected through the internal control strategy module inside according to the actual using conditions of an engine. By means of the variable displacement oil pump control system and the control method thereof, the displacement of the oil pump can be intelligently adjusted, the problem that the capacity of a commonly-used working condition oil pump of the engine is excessive and thus oil consumption is made high is solved, and the oil economy of an entire vehicle is improved.

Owner:CHINA FIRST AUTOMOBILE

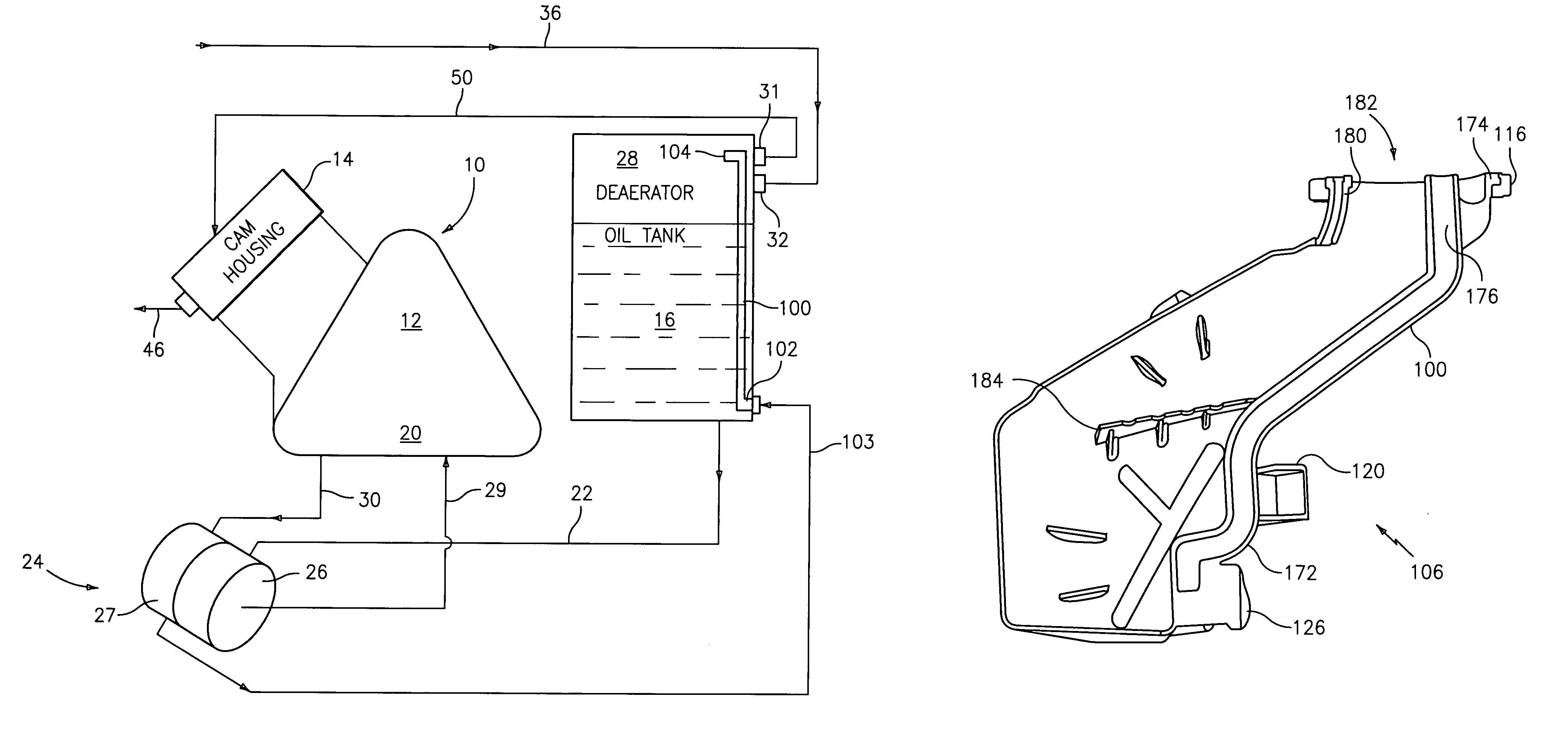

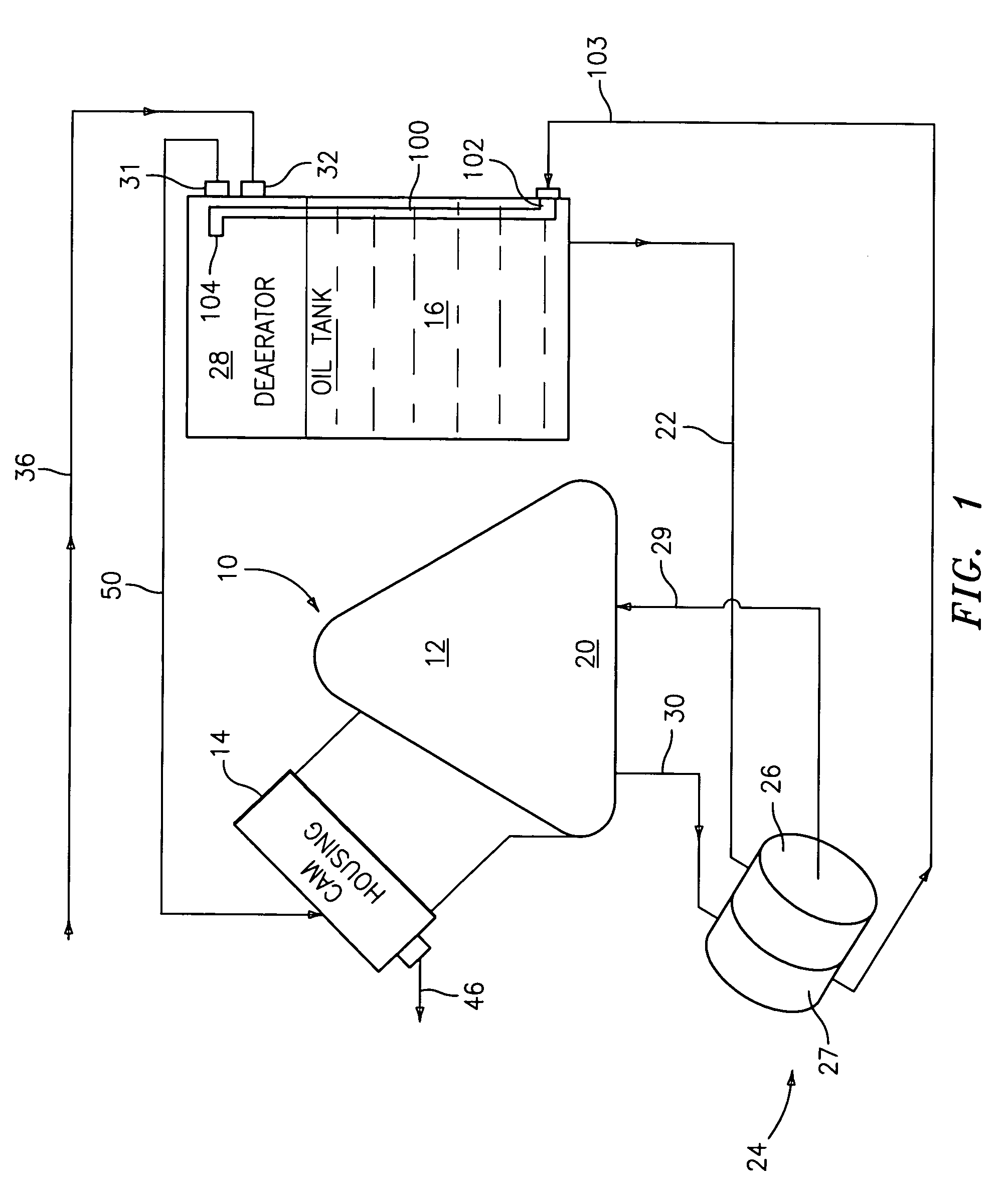

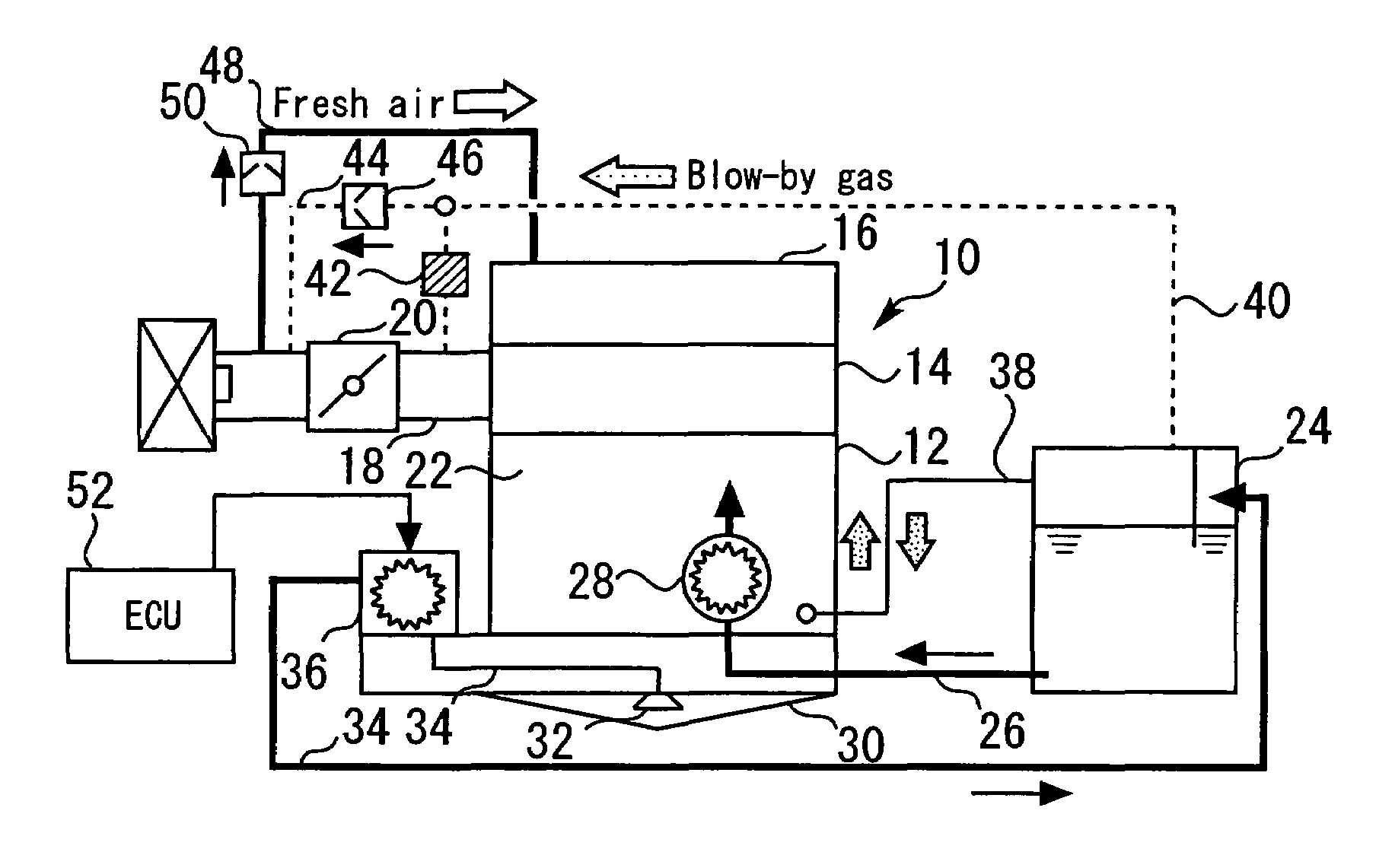

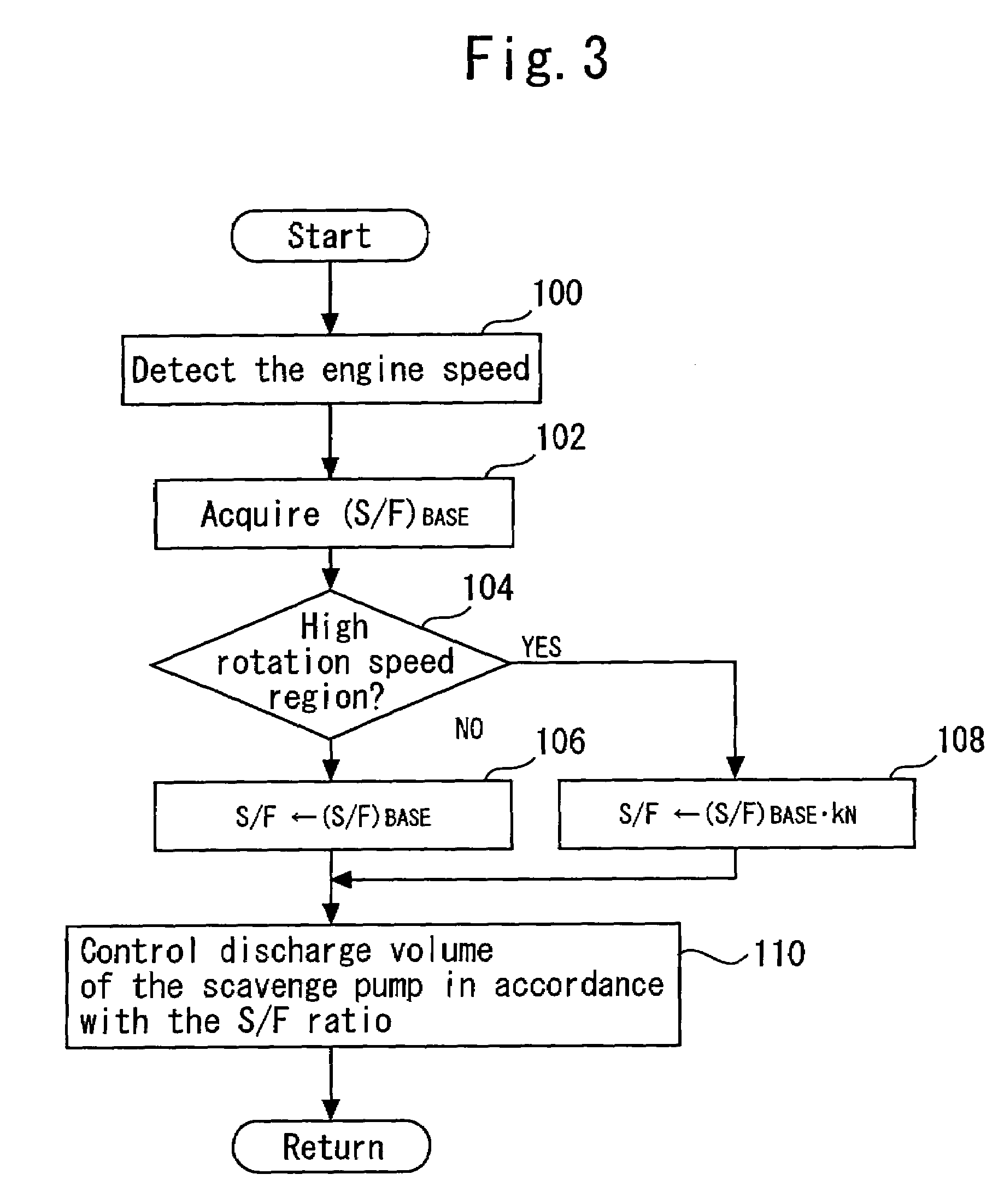

Control apparatus for dry sump type internal combustion engine

ActiveUS7174876B2Effectively deteriorationImprove energy consumptionElectrical controlLubrication of auxillariesExternal combustion engineEngineering

A feed pump 28 that is driven by the axial torque of an internal combustion engine 10 is installed. An electric scavenge pump 36 is installed. A base value for the ratio (S / F ratio) between the discharge volume of the scavenge pump 36 and feed pump 28 is calculated. The base value is corrected so that the S / F ratio is lower in a region where the engine speed is high than in a region where the engine speed is low. The discharge volume of the scavenge pump 36 is controlled in accordance with the S / F ratio that is corrected in the above manner.

Owner:TOYOTA JIDOSHA KK +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com