Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Dry sump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dry-sump system is a method to manage the lubricating motor oil in four-stroke and large two-stroke piston driven internal combustion engines. The dry-sump system uses two or more oil pumps and a separate oil reservoir, as opposed to a conventional wet-sump system, which uses only the main sump (U.S.: oil pan) below the engine and a single pump. A dry-sump engine requires a pressure relief valve to regulate negative pressure inside the engine, so internal seals are not inverted.

Oil pump

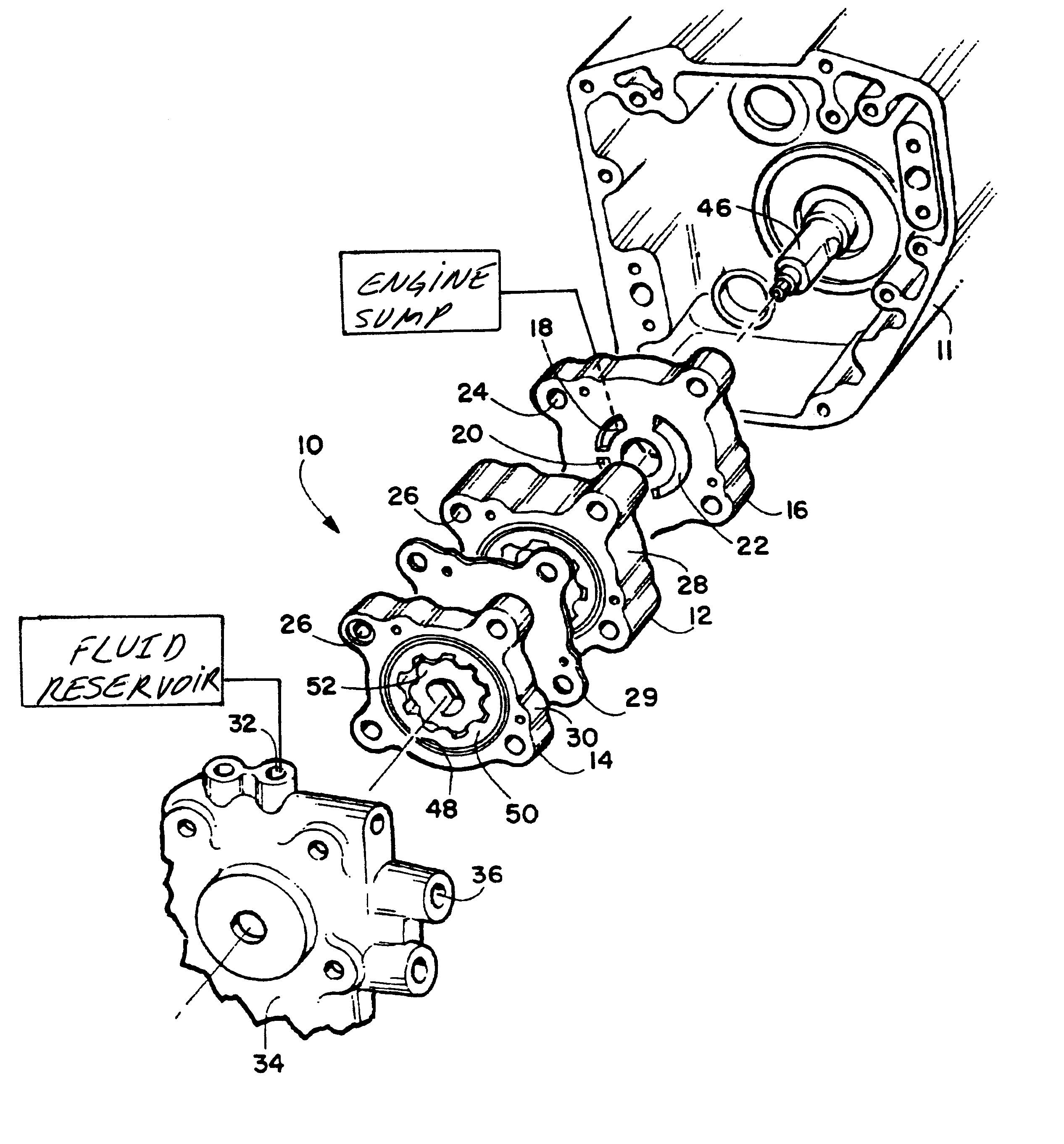

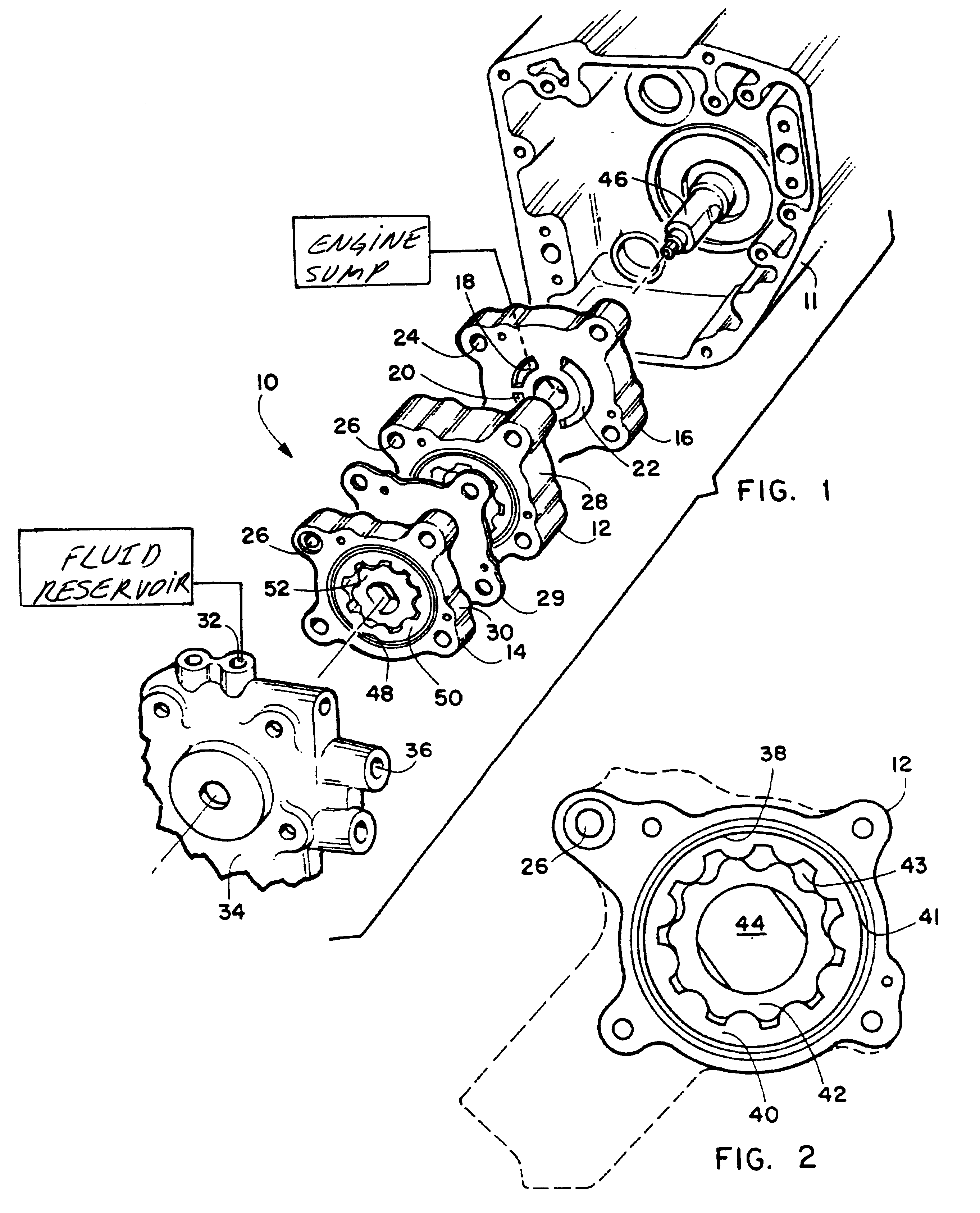

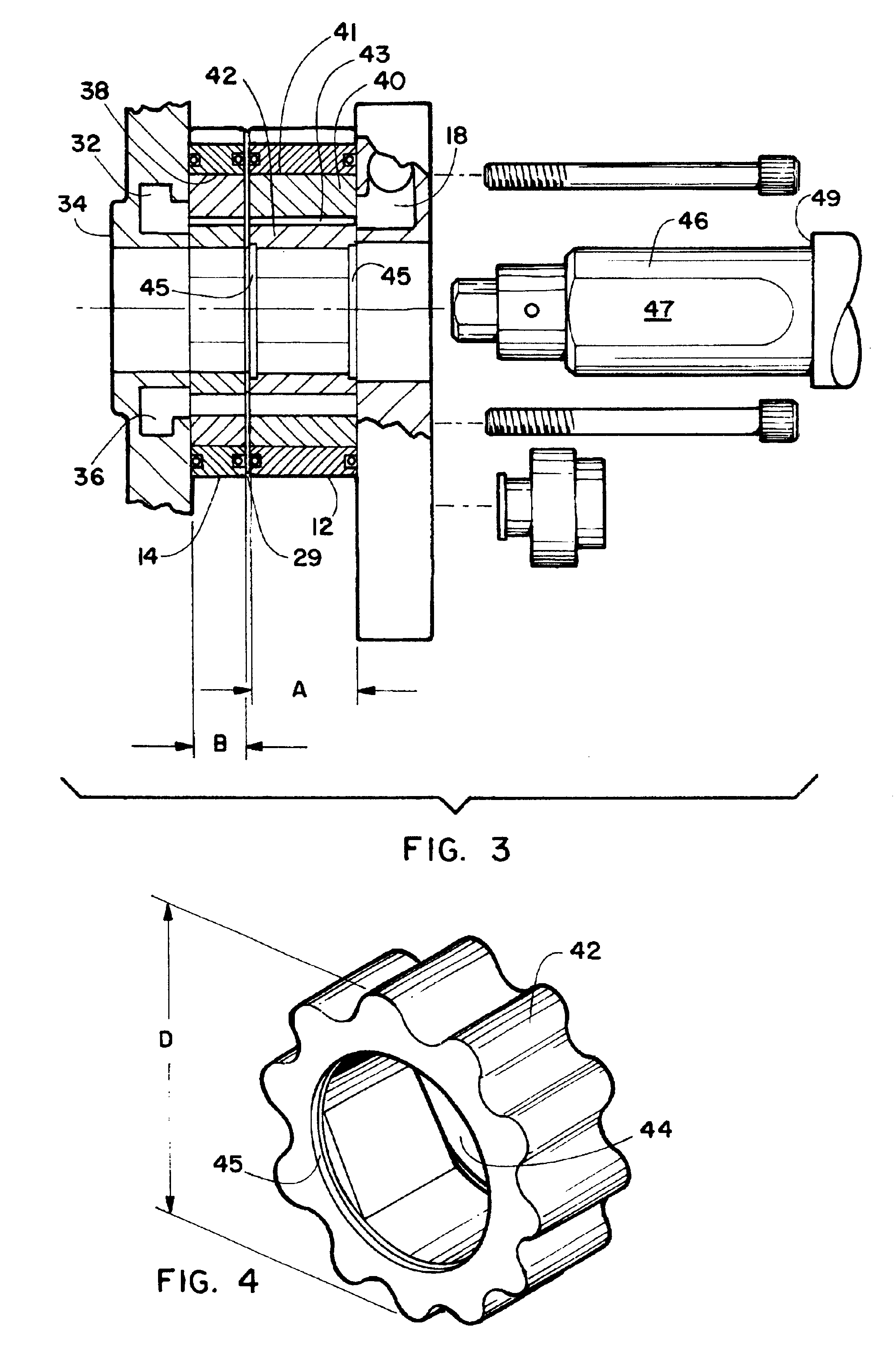

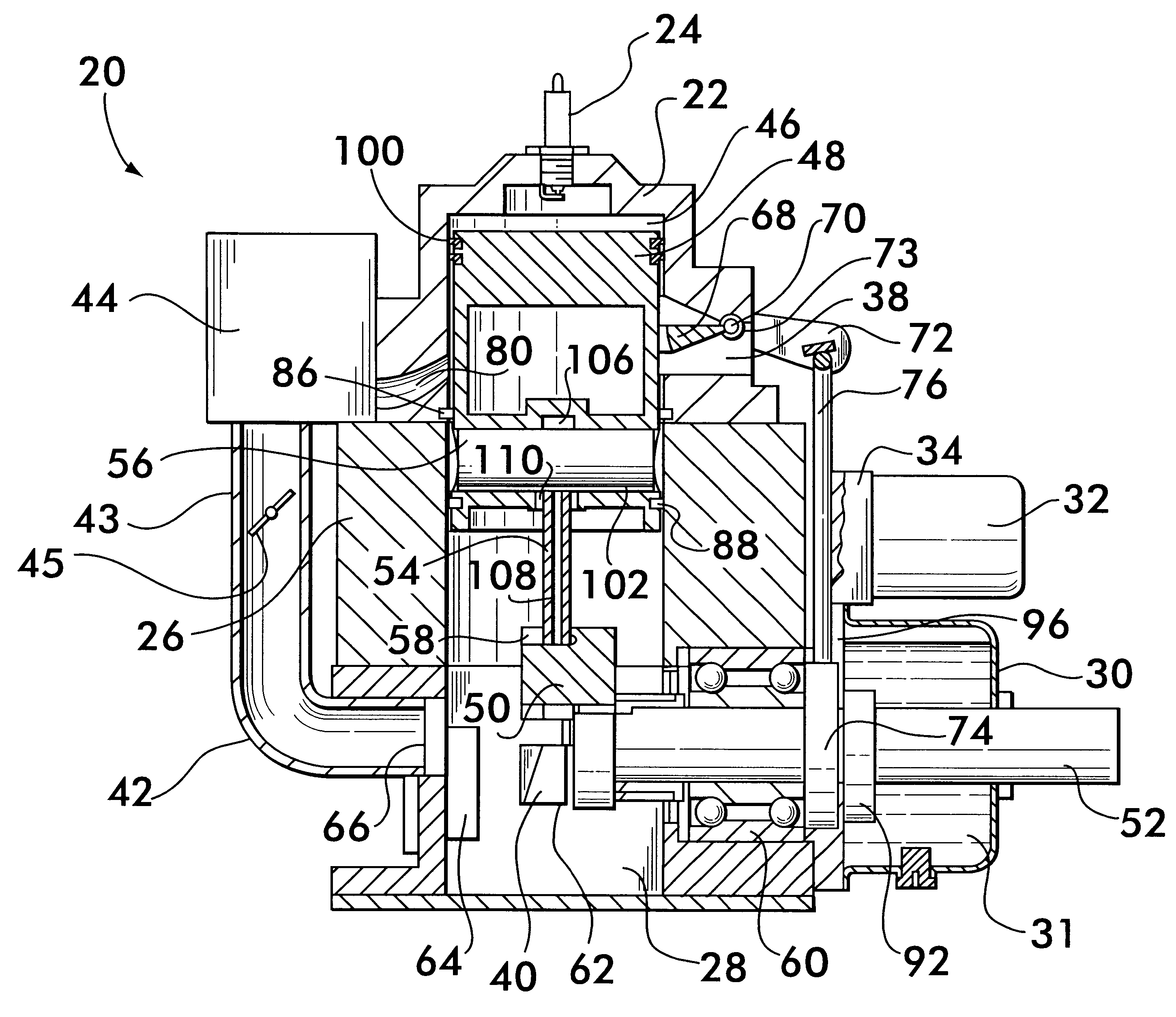

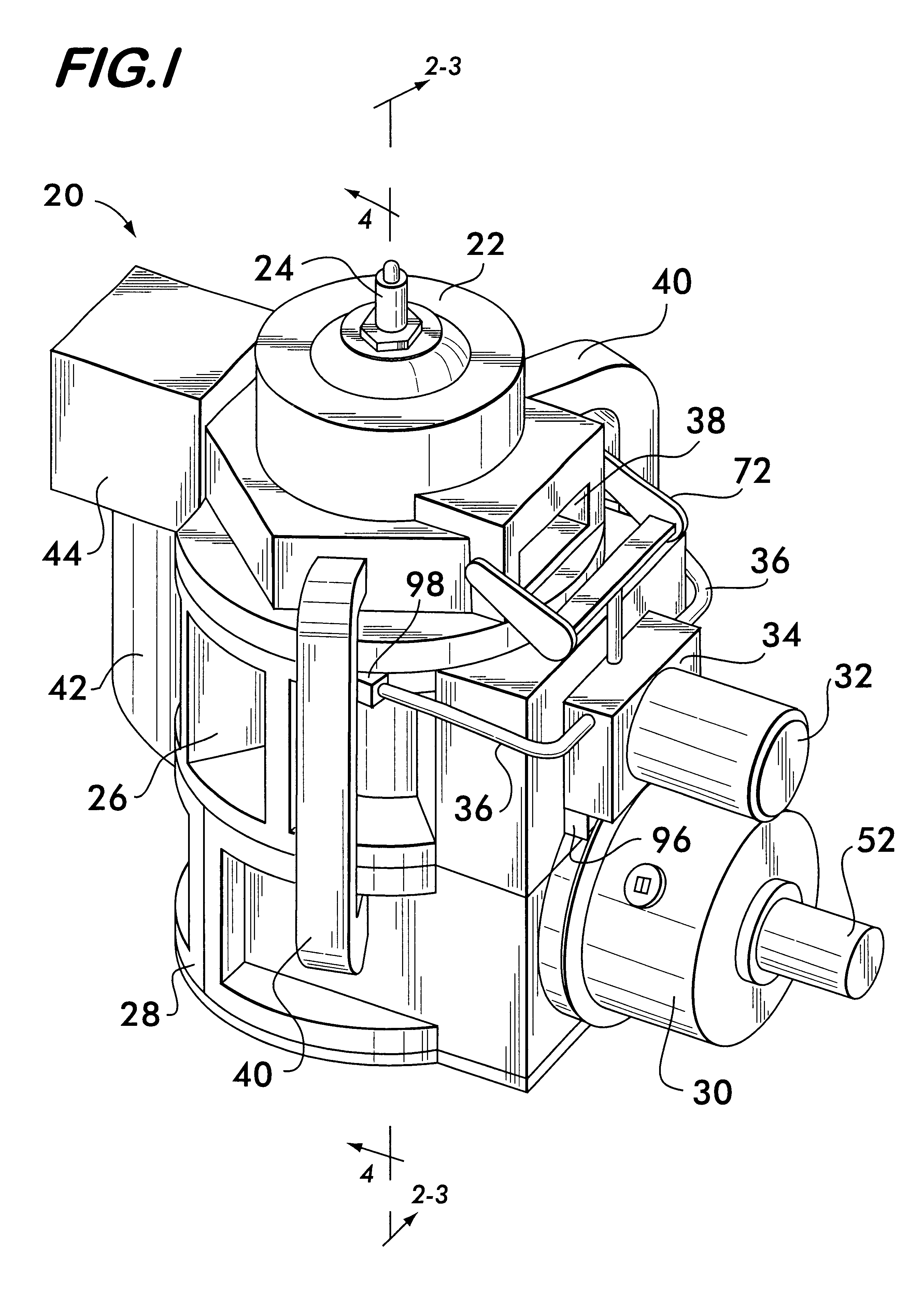

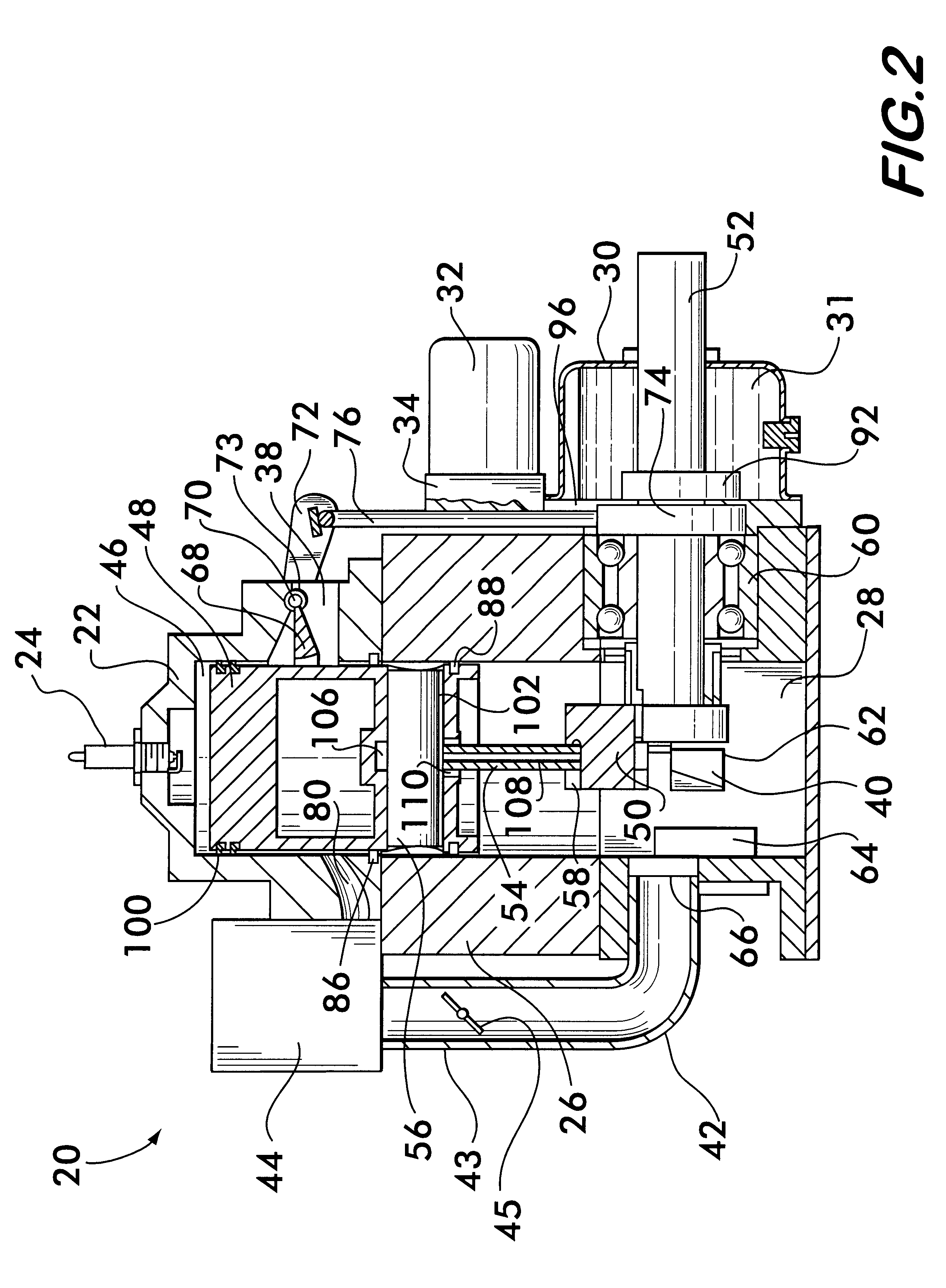

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

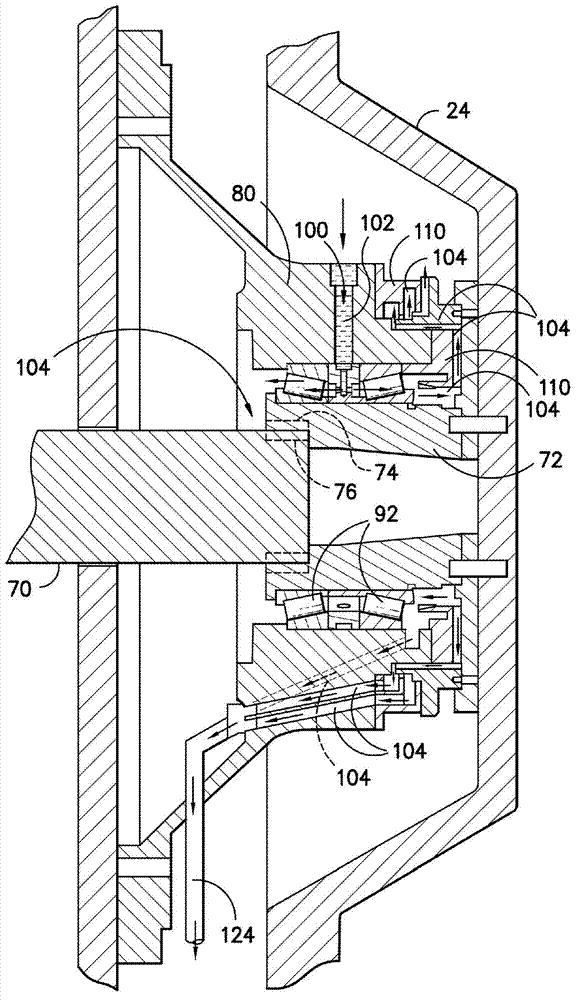

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

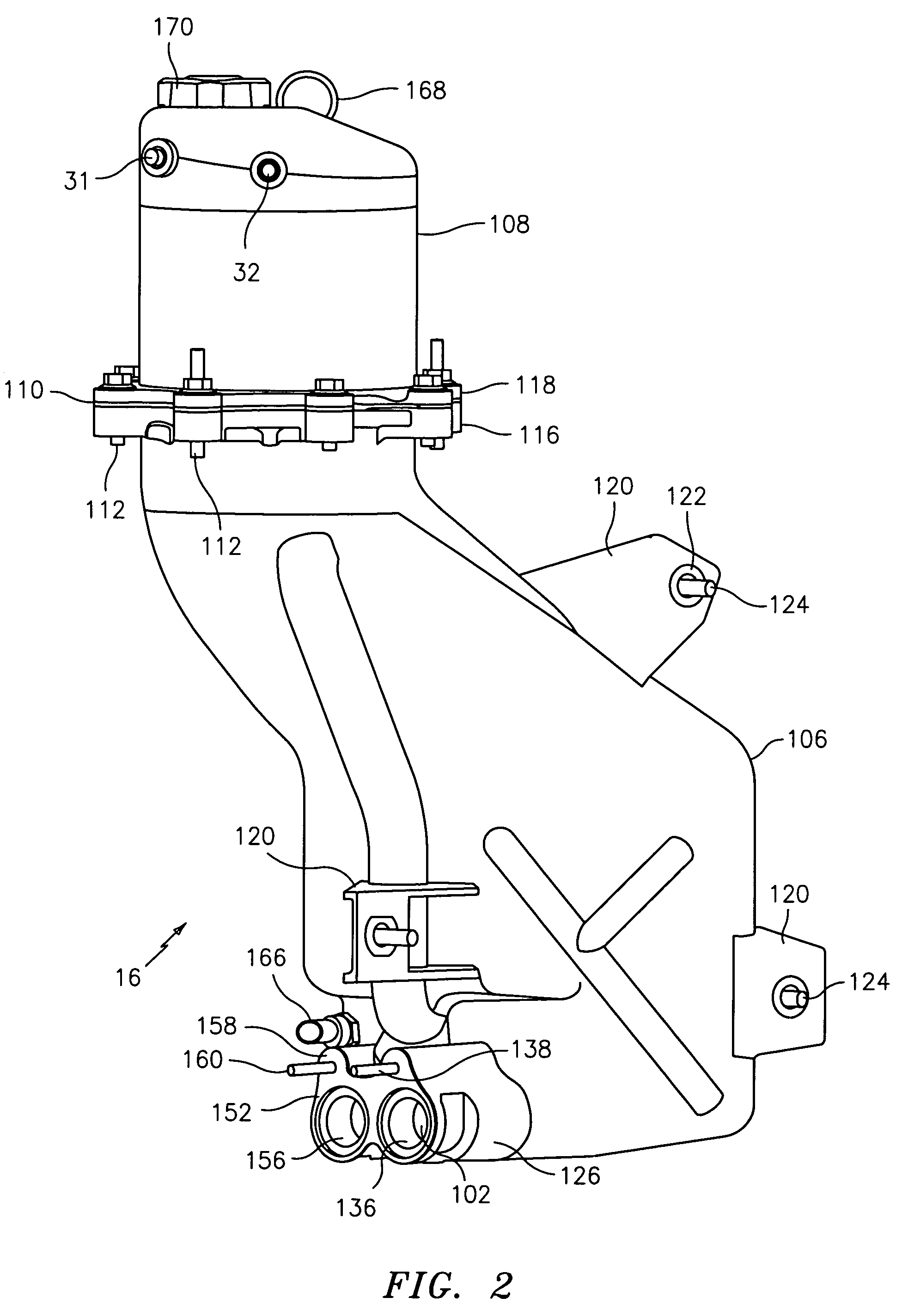

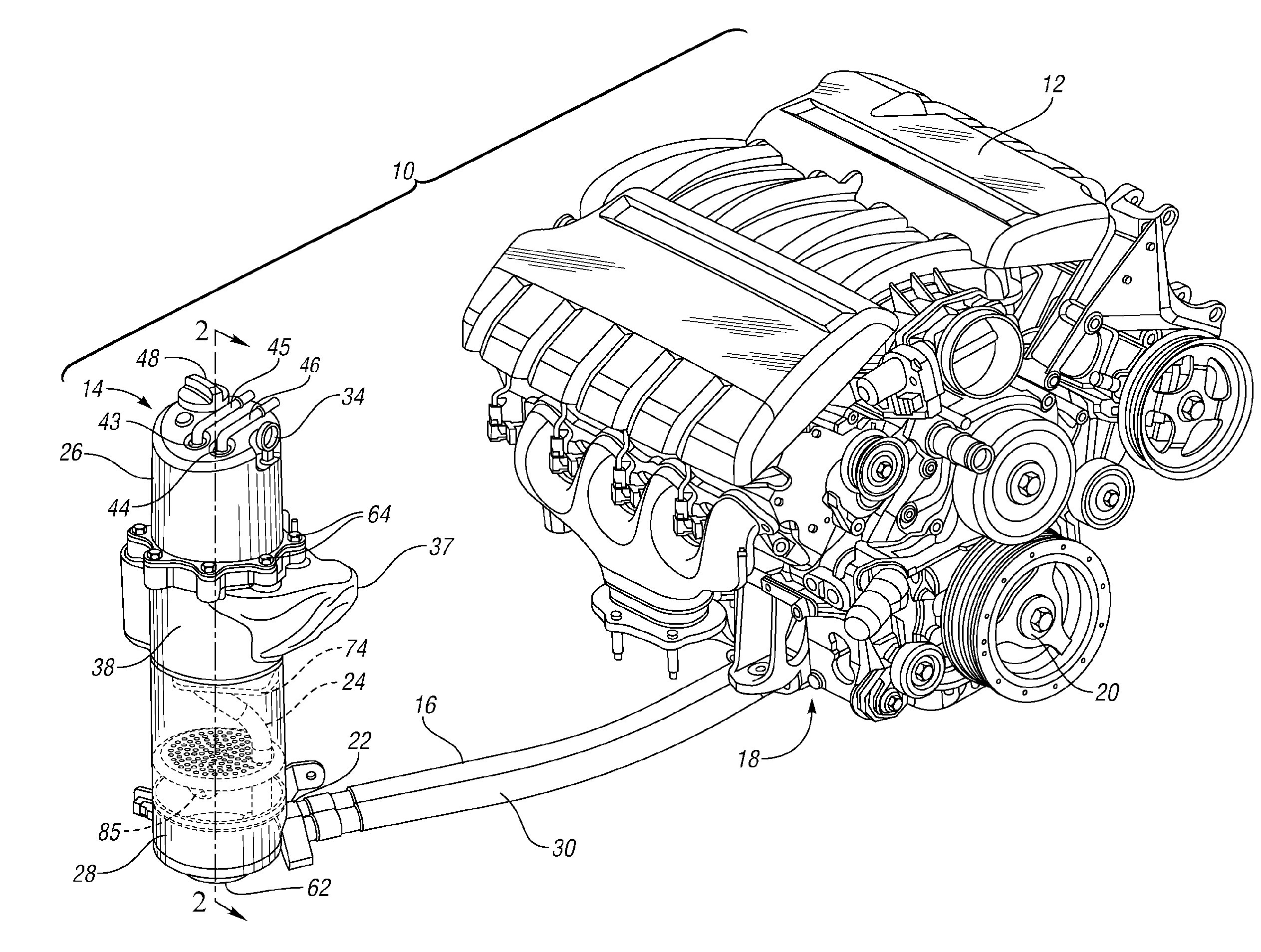

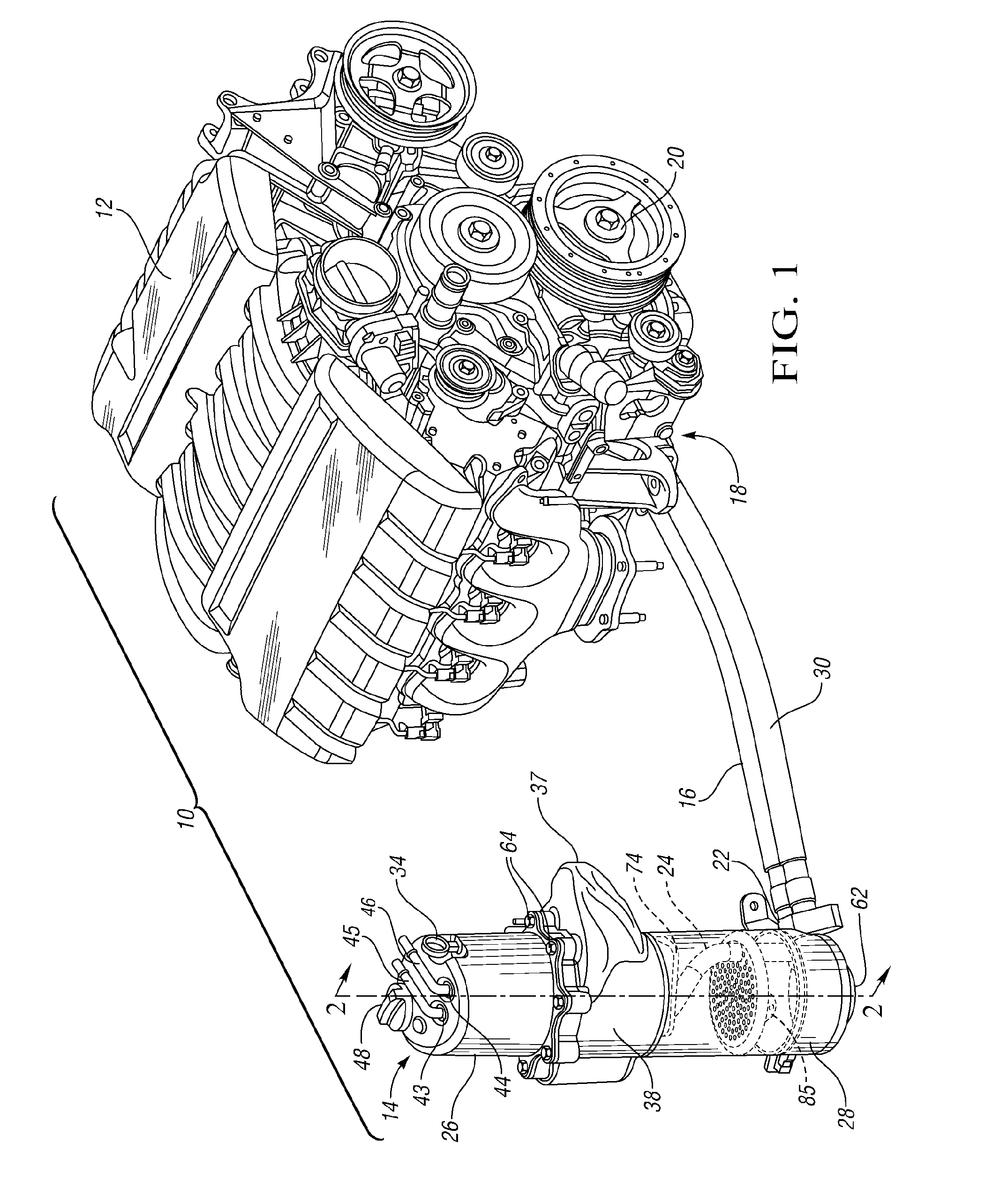

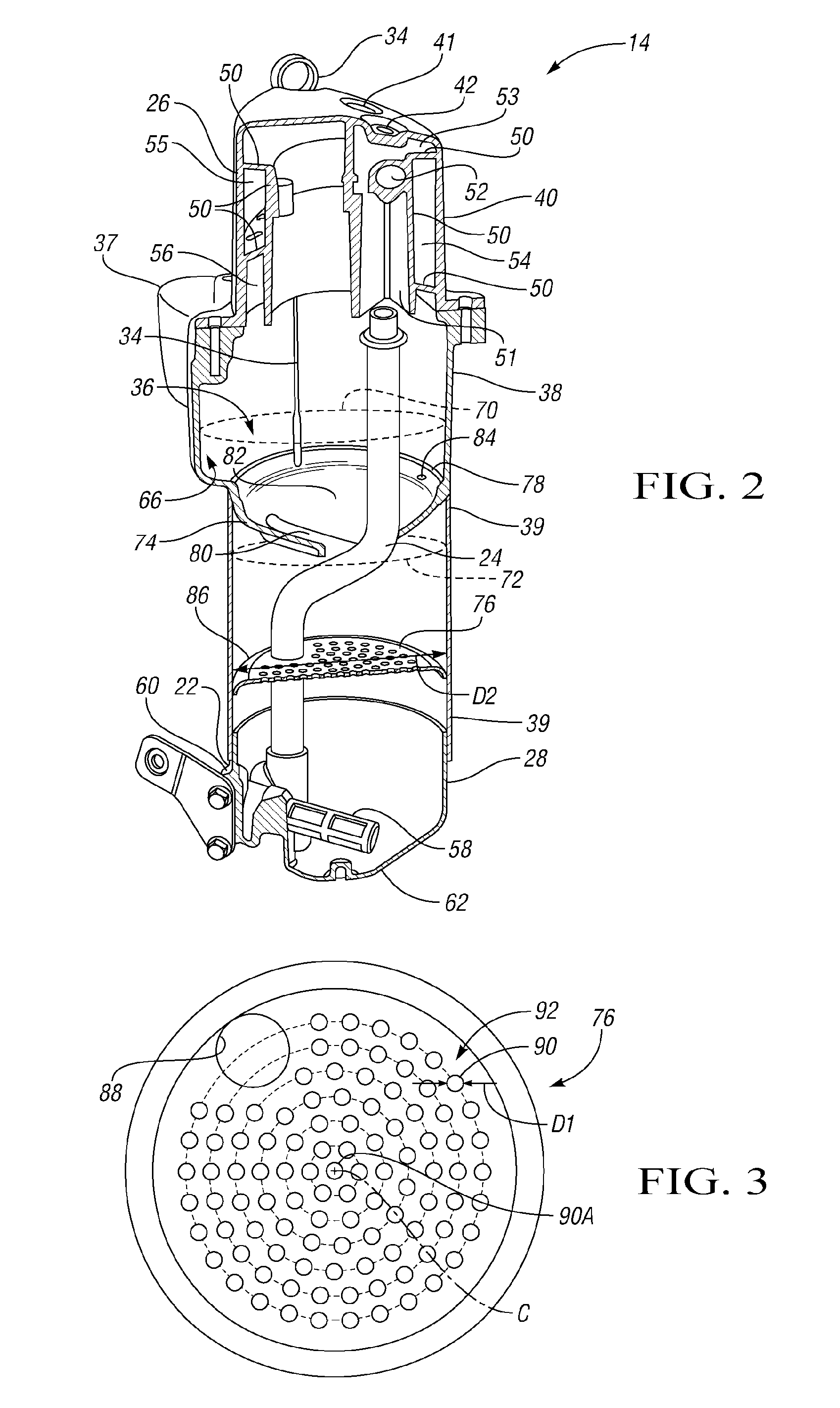

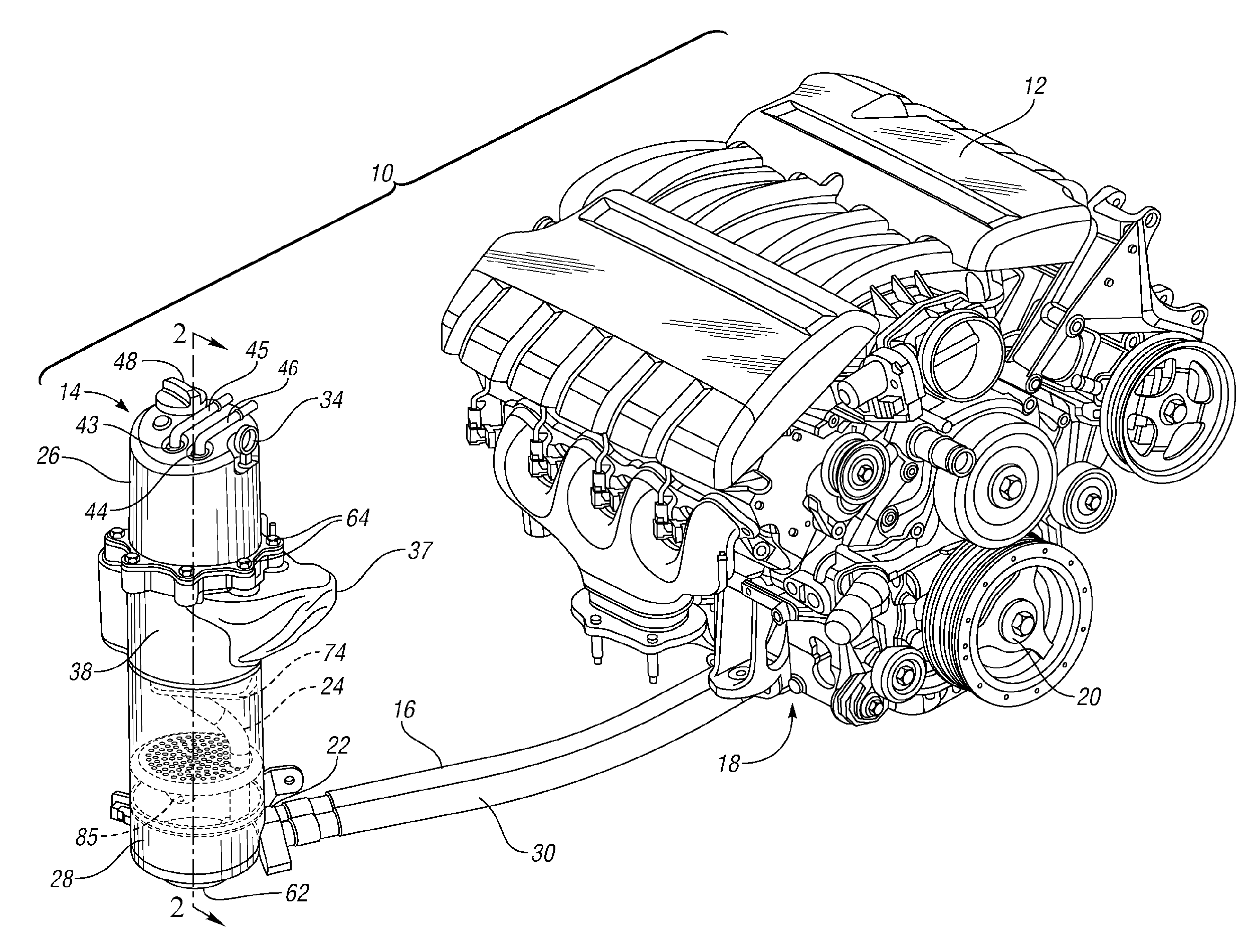

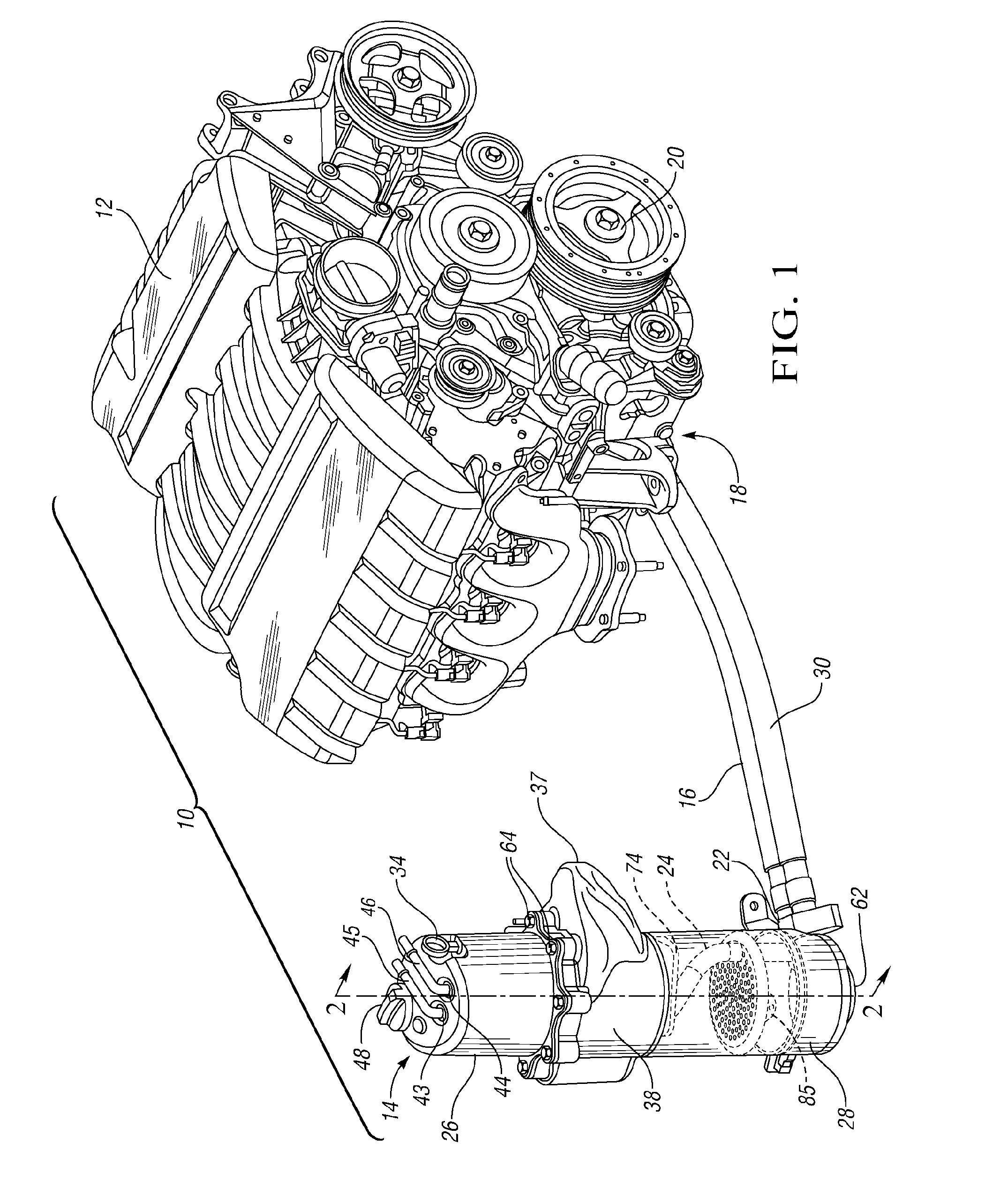

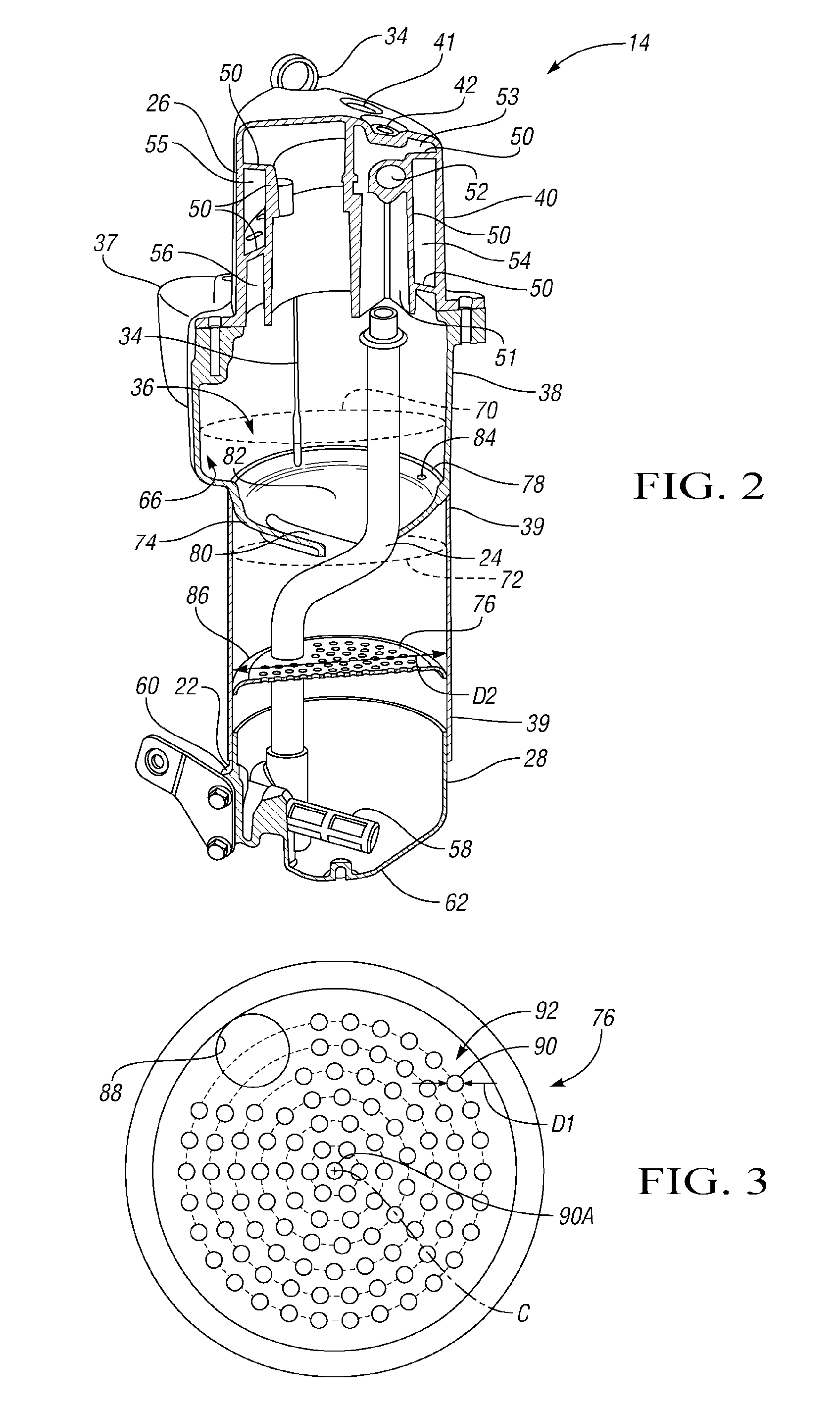

Dry sump oil tank assembly

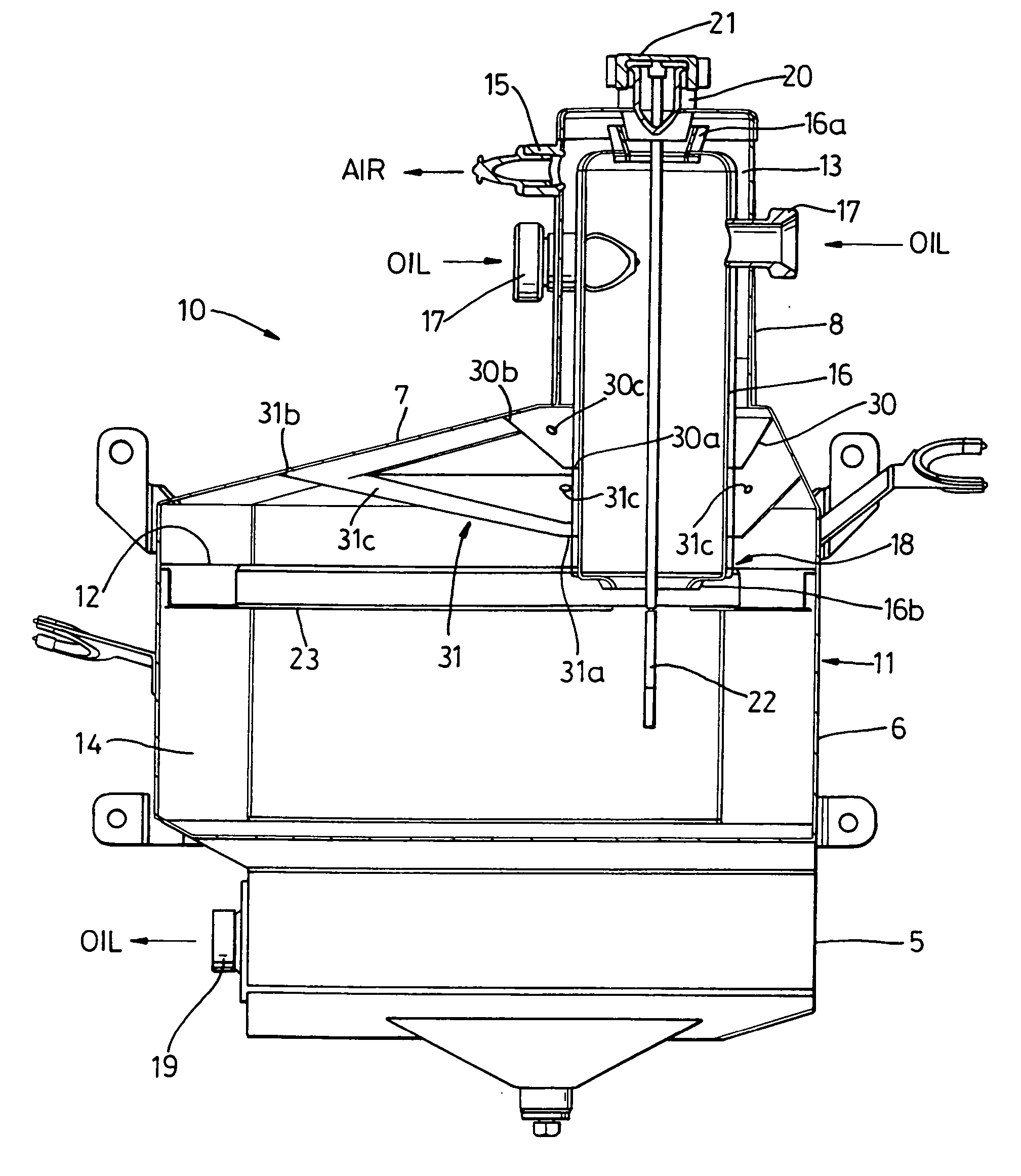

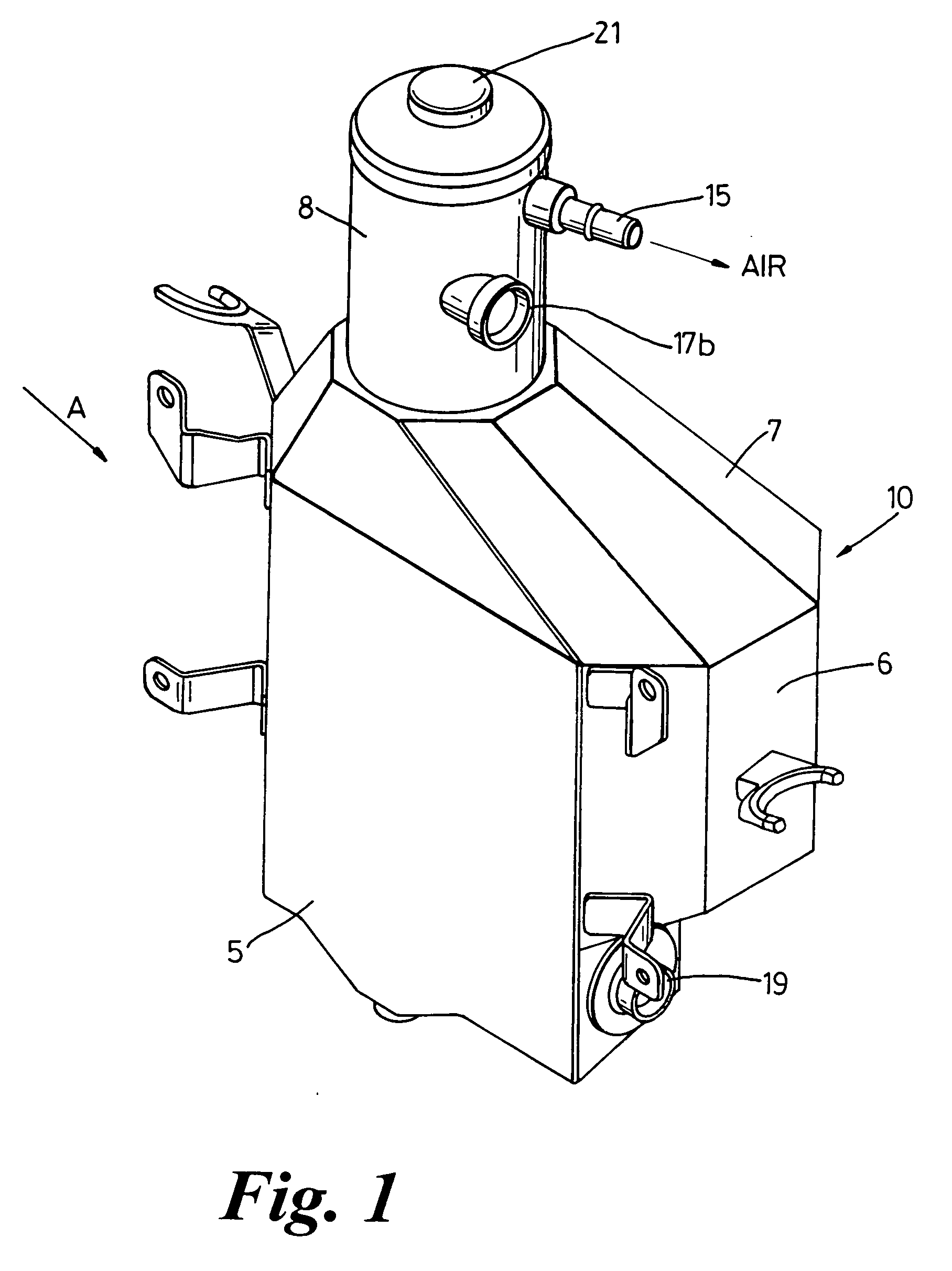

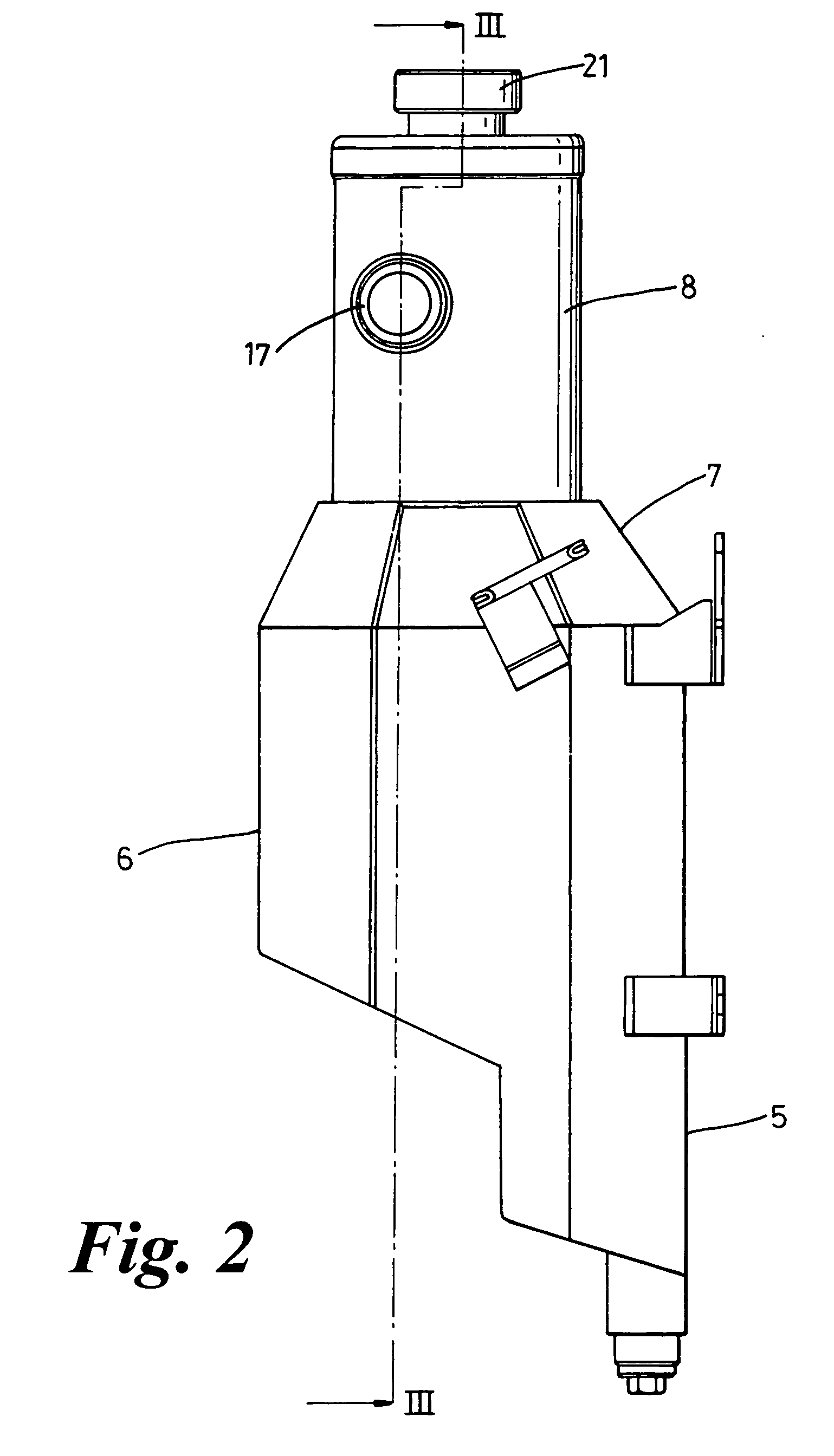

A tank assembly for a dry sump lubrication system for an internal combustion engine is disclosed. The tank assembly includes a tank having an upper tank portion and a lower tank portion. An interface assembly is disposed at the lower tank portion and is configured to operably deliver and receive a lubricant to and from the engine. A first end of a return tube in fluid communication with a second end is configured to receive lubricant from the engine at the interface assembly. The second end opposite the first end is in fluid communication with the upper tank portion. In this manner, a return hose and a feed hose may be connected to a same portion of the tank assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC

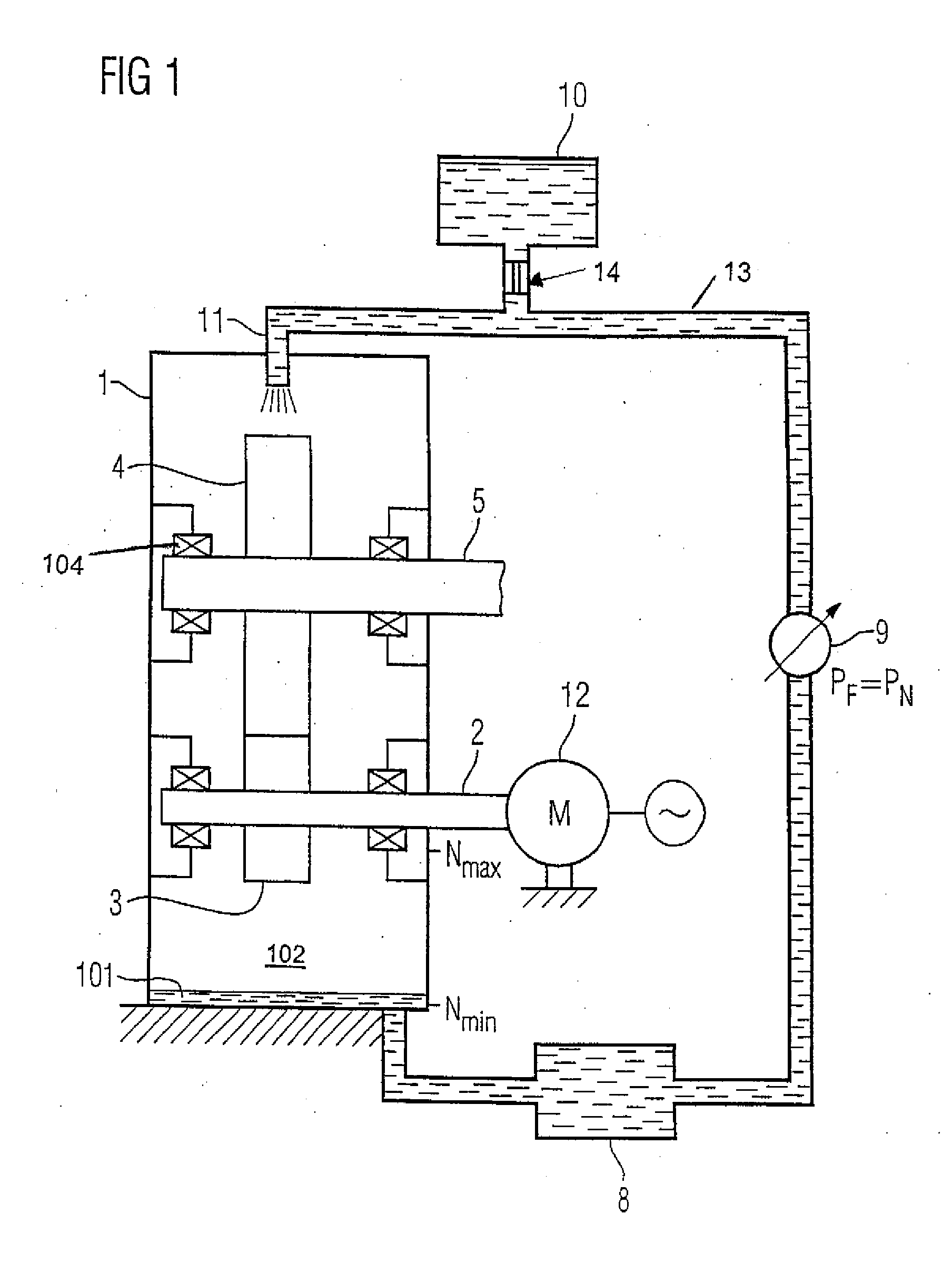

Gear unit with improved lubricant supply

InactiveUS20130133454A1Reliable supplyLower energy requirementsGear lubrication/coolingOilsumpsGear wheelEngineering

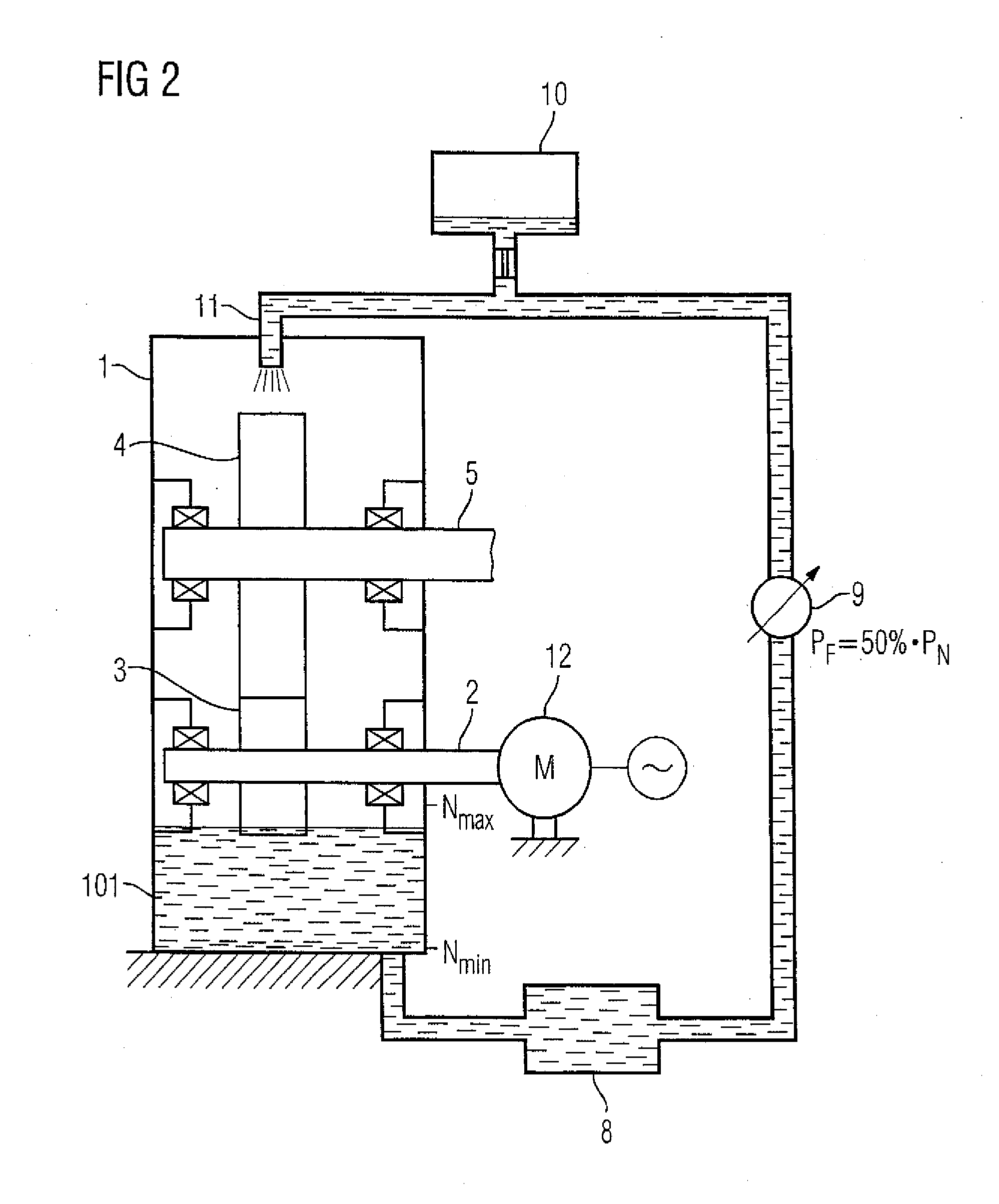

In order to implement a reliable supply of lubricant to gear unit components during emergency or spinning operation of a gear unit, level control is provided in a lubricant sump of the gear unit as a function of the operating state by means of a control unit associated with a lubricant pump. During normal operation the level is adjusted to dry sump level. In contrast, the lubricant pump is switched off in emergency or spinning operation, so that a splash lubrication level is automatically achieved in the lubricant sump.

Owner:SIEMENS AG

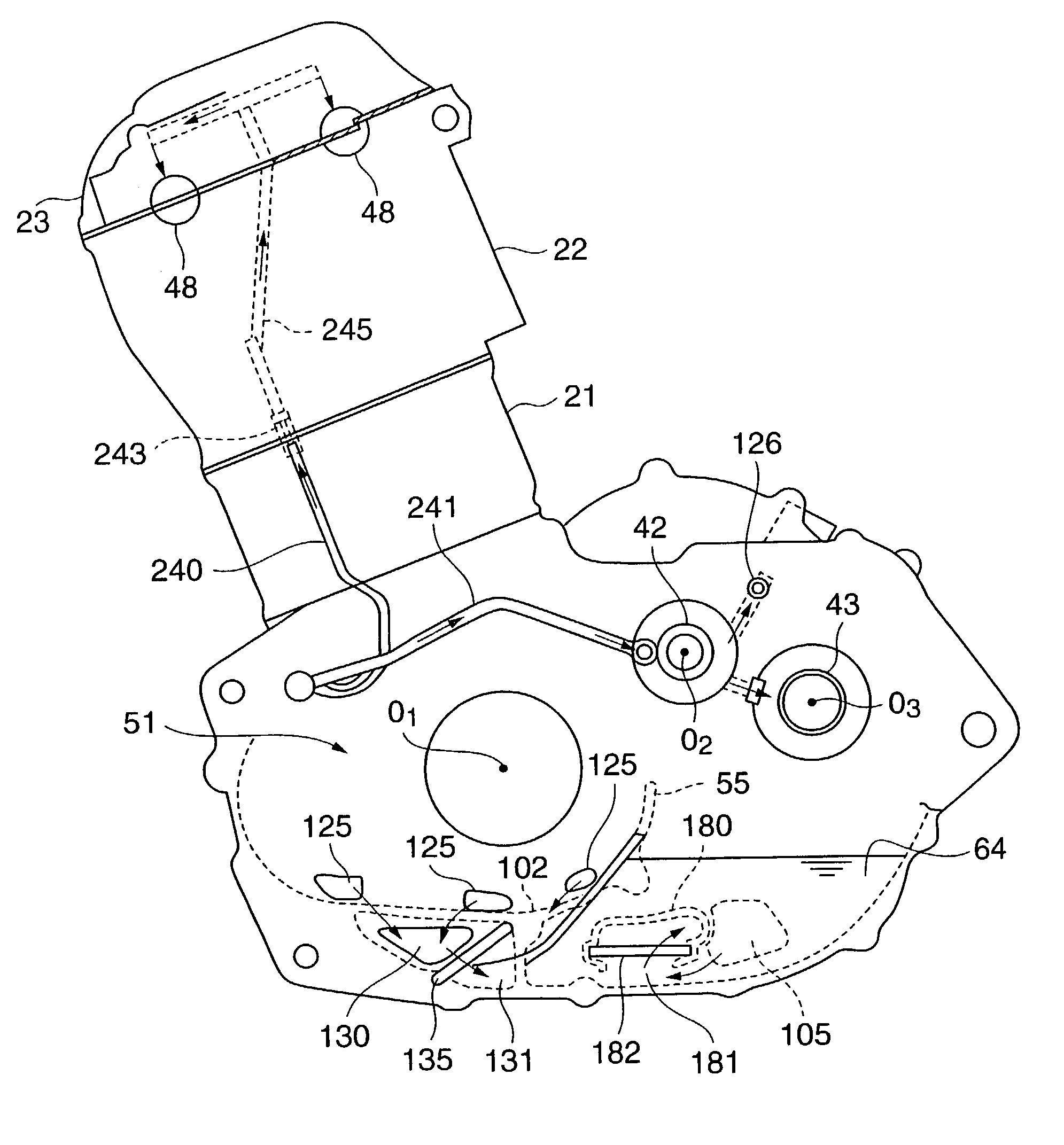

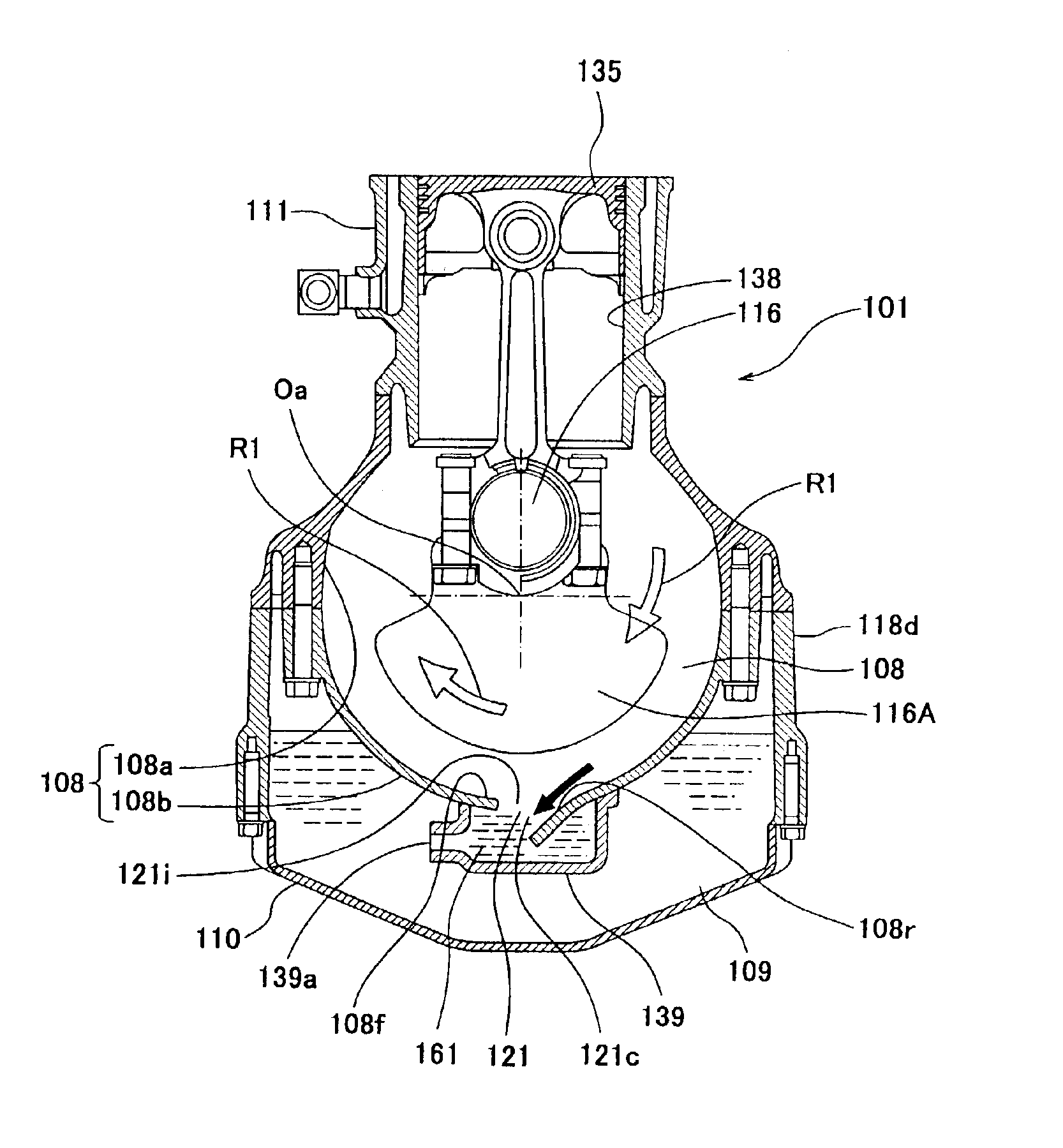

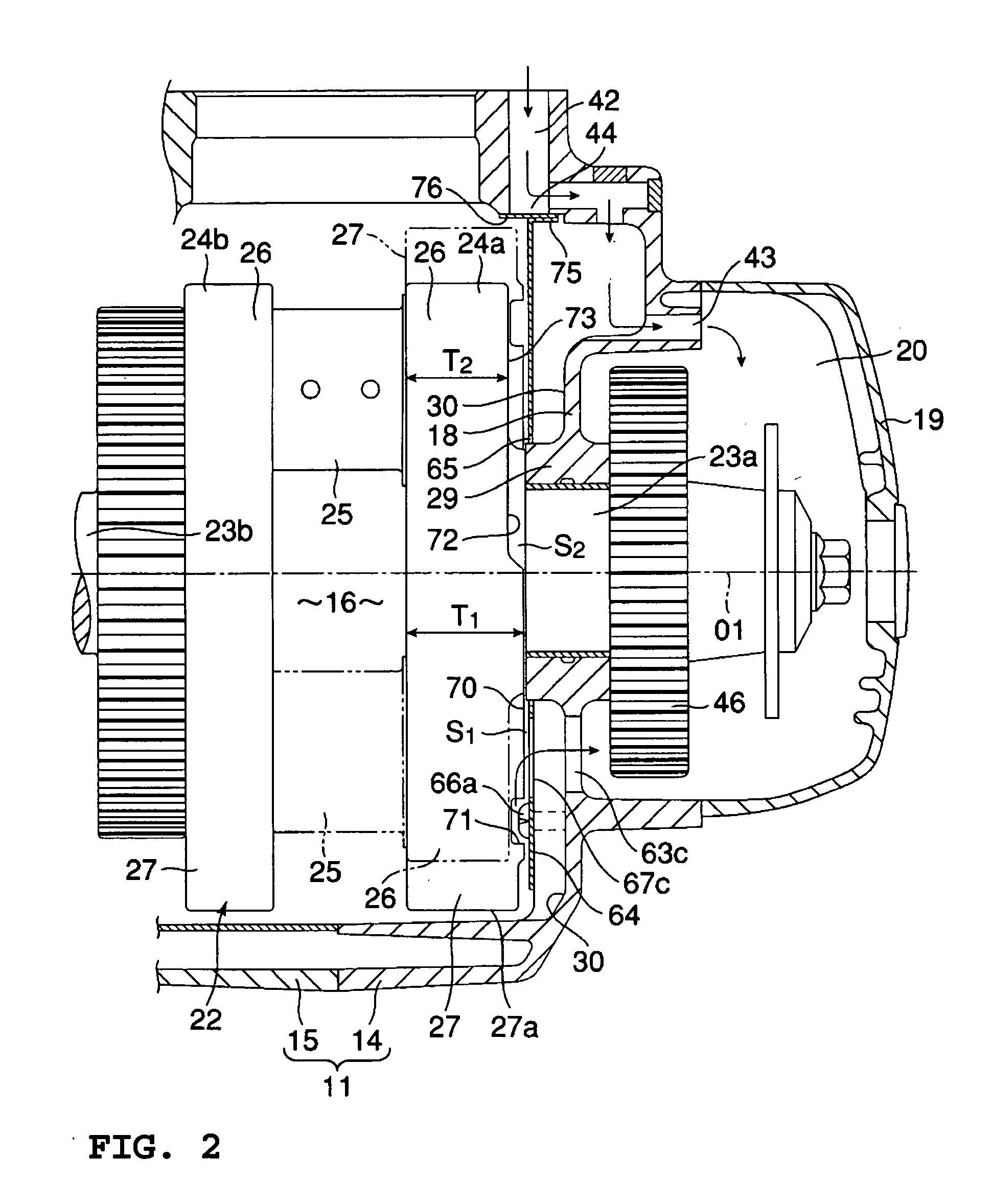

Dry-sump lubrication type four-stroke cycle engine

InactiveUS7040454B2Easy to usePrecision lubricationLubrication of auxillariesLubricant conduit arrangementsAir pumpFour-stroke engine

The interior of a crankcase is divided into a front crank chamber and a rear transmission chamber by a partition wall of a given height. A lower part of the transmission case is used as an oil reservoir chamber for reserving lubricating oil. Opposite ends of the crankcase are covered with covers to form a generator chamber and a clutch chamber. The crank chamber is connected to the generator chamber by a drain passage to drain oil collected in the crank chamber into the generator chamber. A scavenging pump placed in the clutch chamber sucks the oil collected in the generator chamber through an oil passage extending across the crankcase under the crank chamber and discharges the oil into an air space in the clutch chamber.

Owner:KAWASAKI HEAVY IND LTD

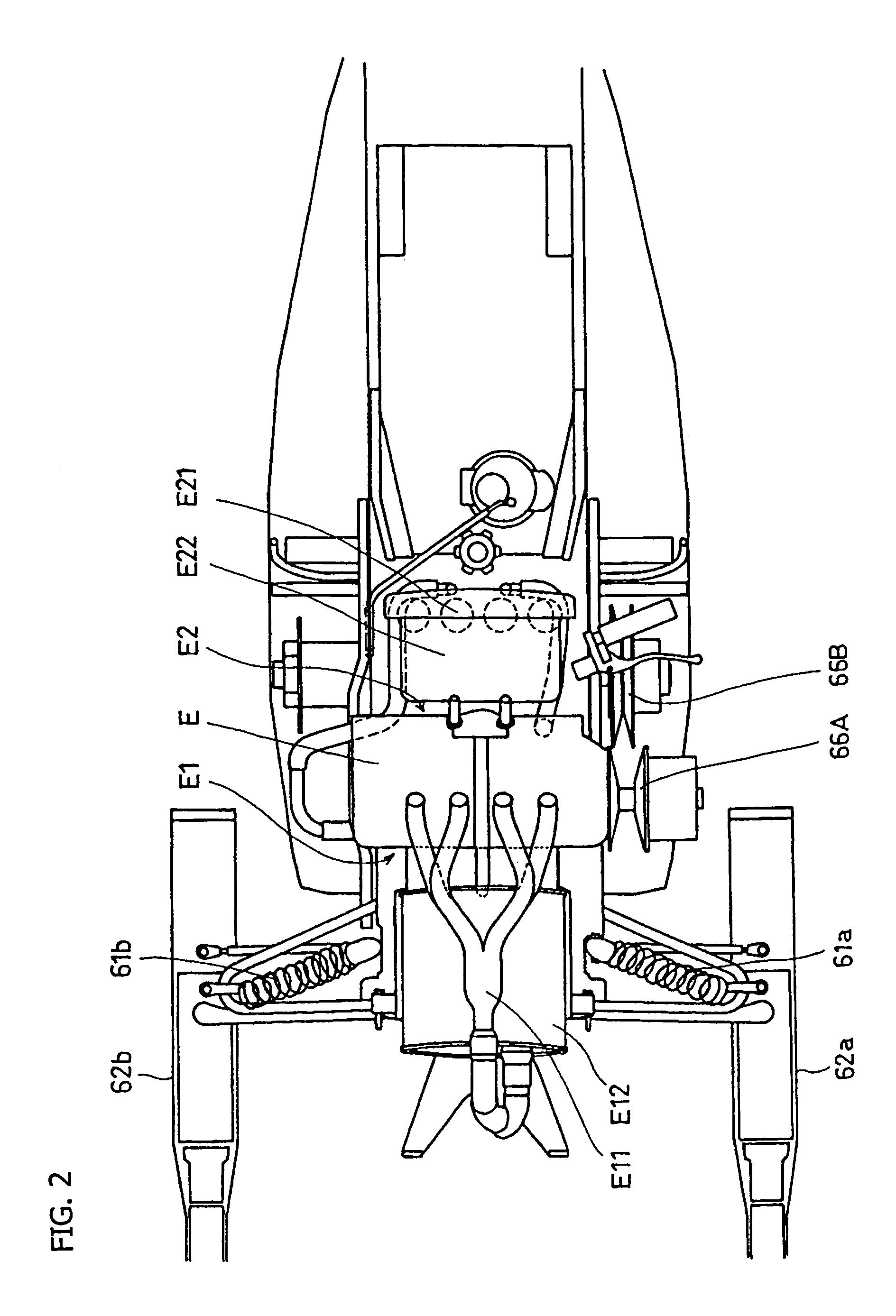

Engine and personal watercraft equipped with engine

InactiveUS6889651B2Efficient arrangementEfficiently dead spacePower plants using condensersLubrication of auxillariesCylinder headFuel tank

Owner:KAWASAKI MOTORS LTD

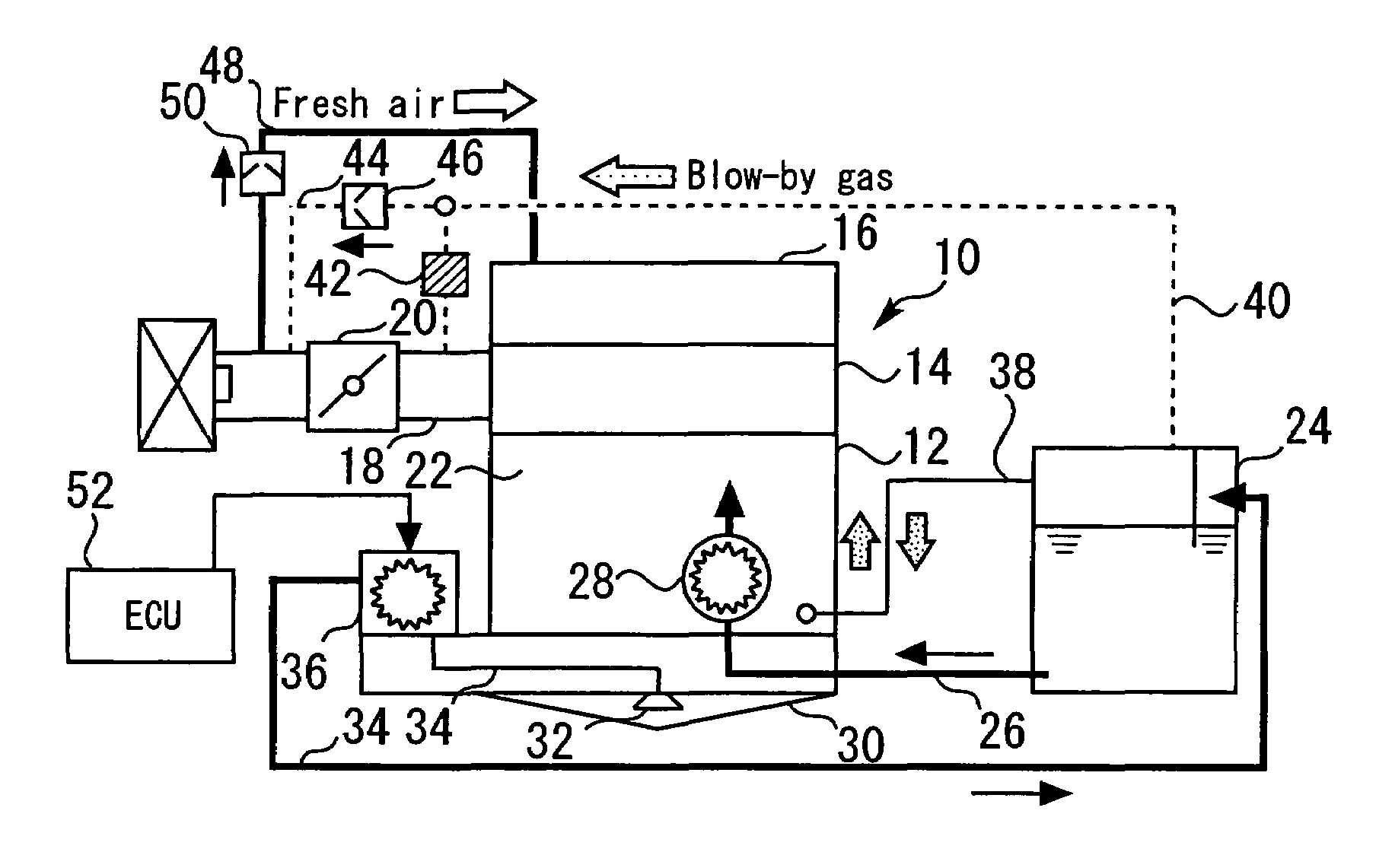

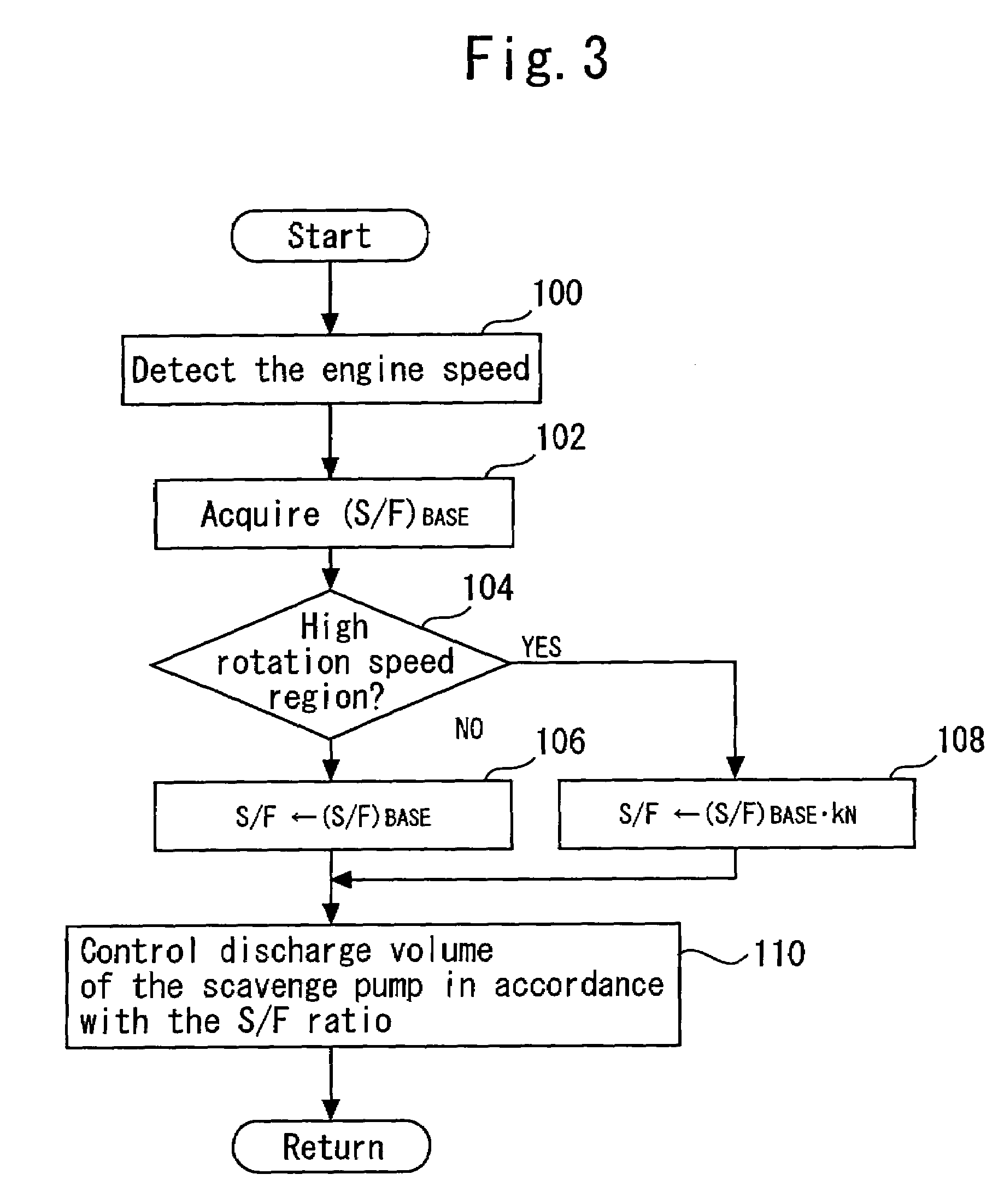

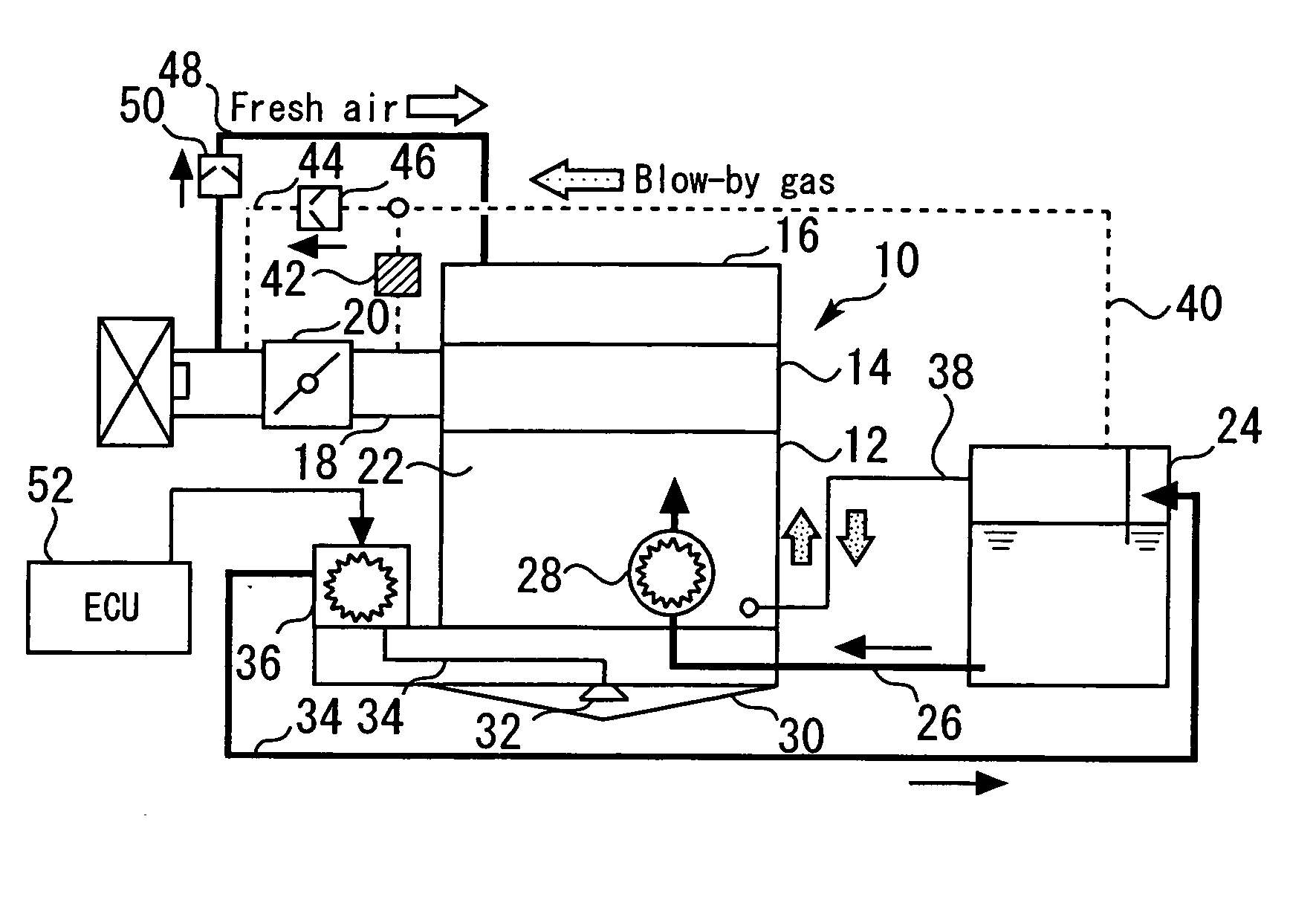

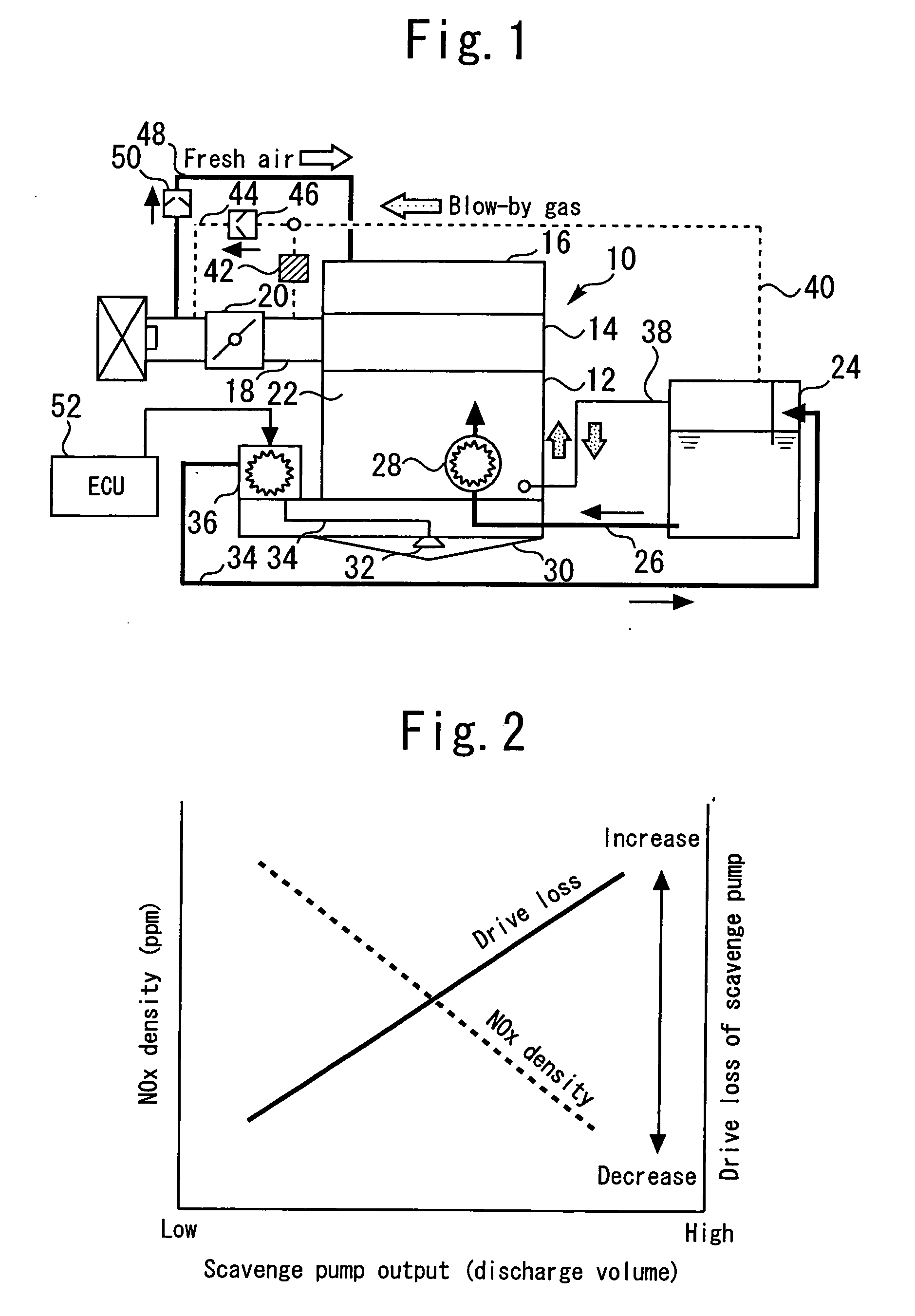

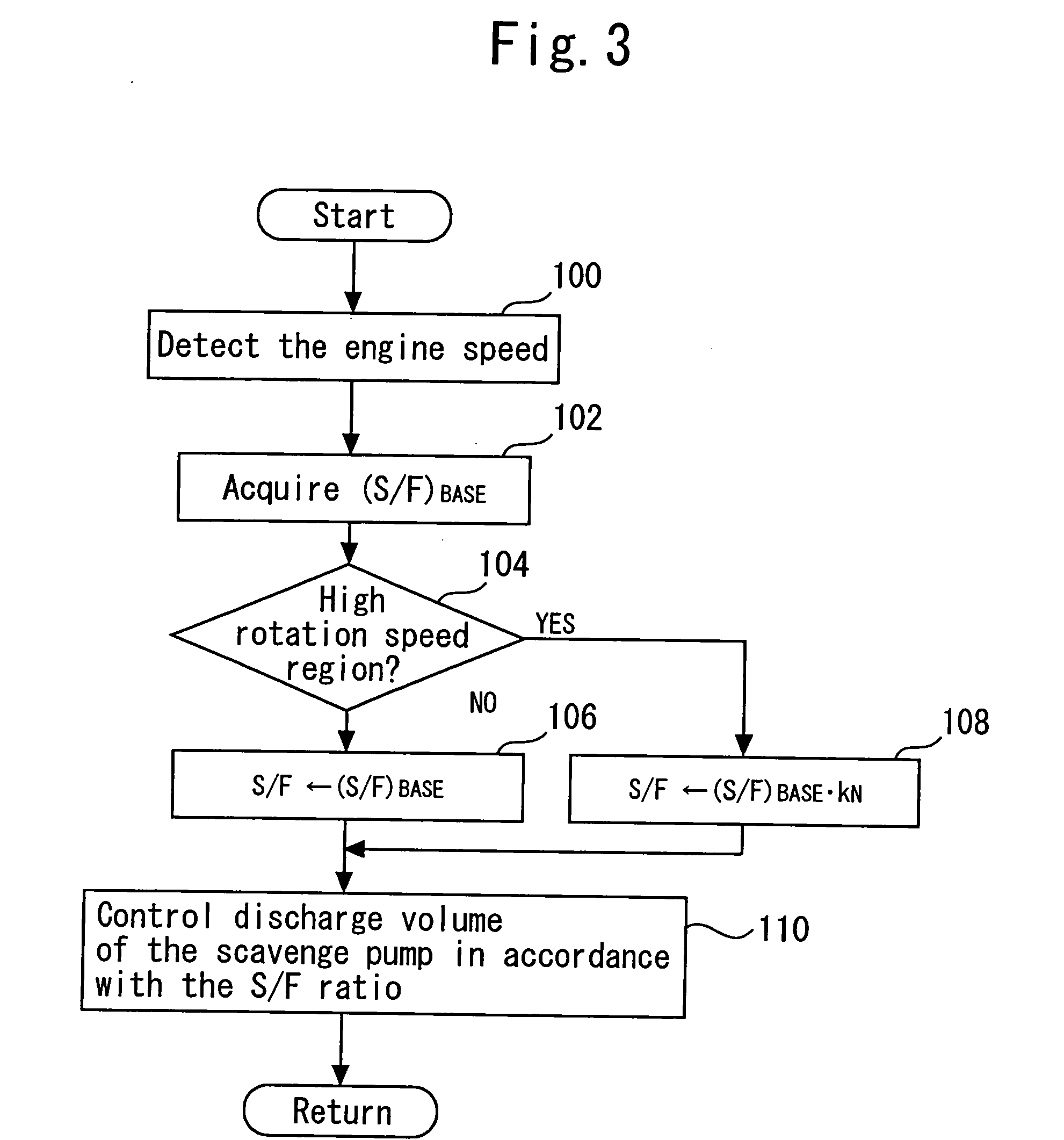

Control apparatus for dry sump type internal combustion engine

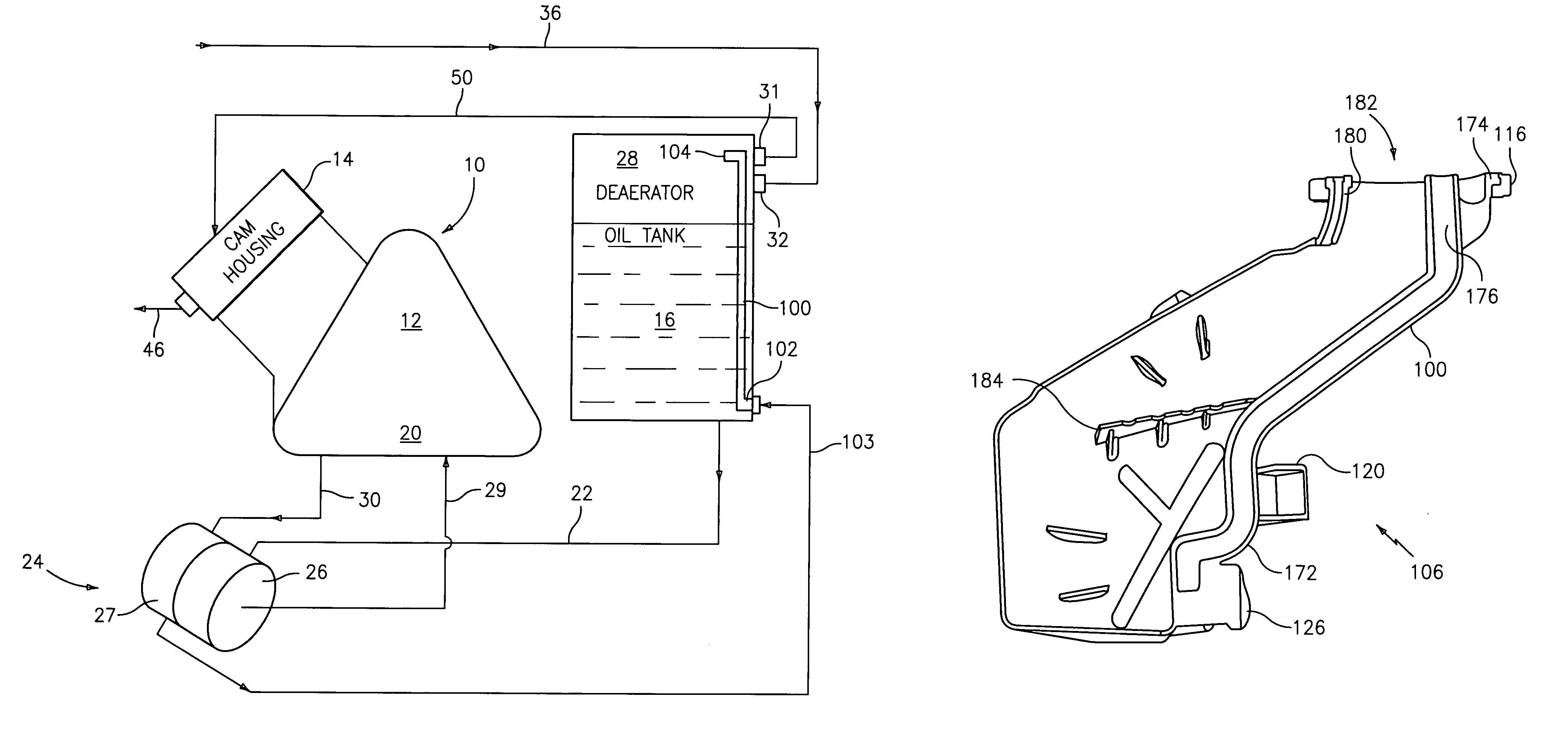

ActiveUS7174876B2Effectively deteriorationImprove energy consumptionElectrical controlLubrication of auxillariesExternal combustion engineEngineering

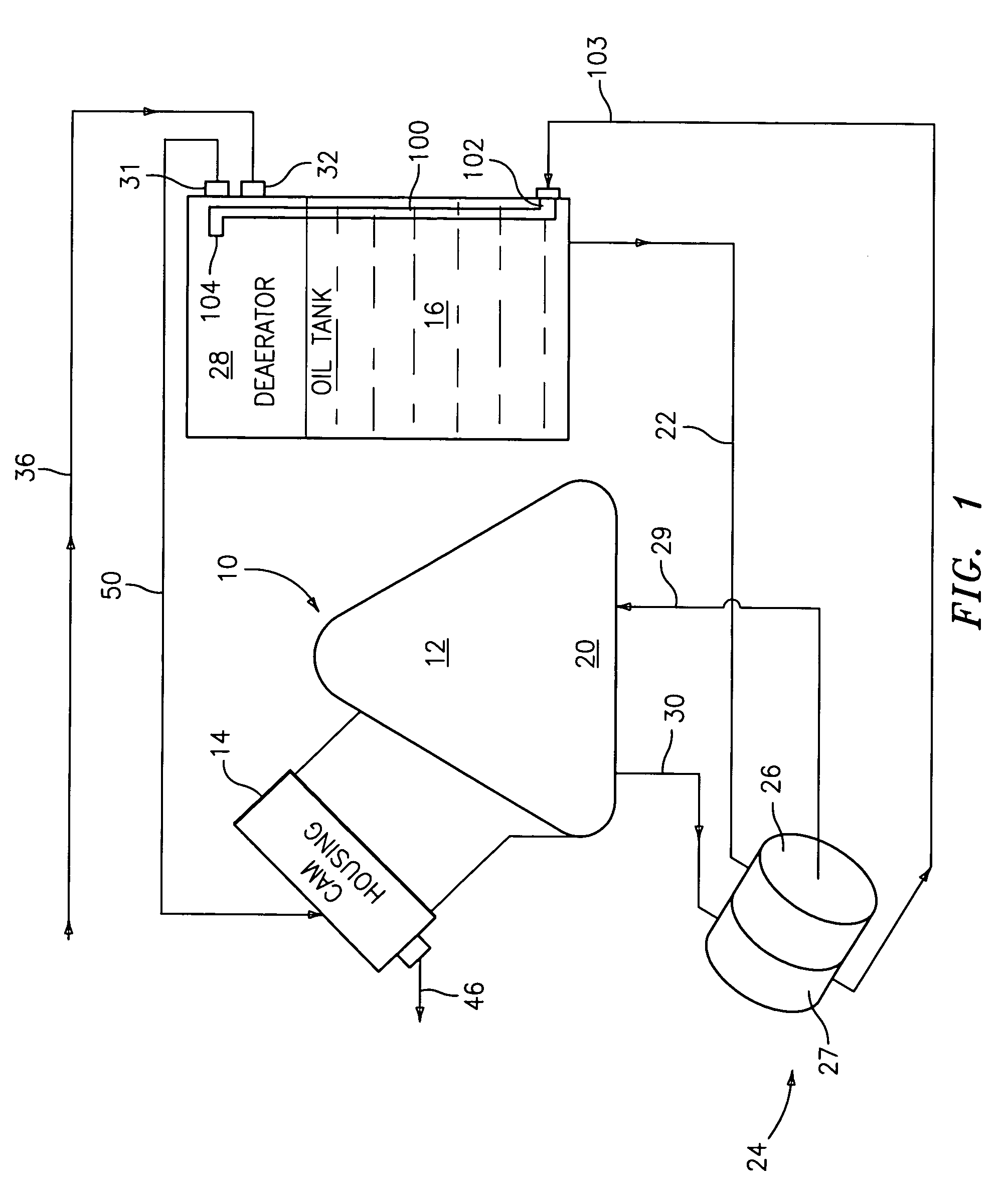

A feed pump 28 that is driven by the axial torque of an internal combustion engine 10 is installed. An electric scavenge pump 36 is installed. A base value for the ratio (S / F ratio) between the discharge volume of the scavenge pump 36 and feed pump 28 is calculated. The base value is corrected so that the S / F ratio is lower in a region where the engine speed is high than in a region where the engine speed is low. The discharge volume of the scavenge pump 36 is controlled in accordance with the S / F ratio that is corrected in the above manner.

Owner:TOYOTA JIDOSHA KK +1

Dry sump oil tank assembly for a vehicle

ActiveUS20090211552A1Increase heightIncrease volumeLubrication of auxillariesCombustion enginesDry sumpWaste management

A dry sump oil tank assembly for a vehicle is provided with a housing defining an internal cavity. The housing is configured with a laterally-extending portion to add lateral volume to the internal cavity and has at least one internal baffle attached to the housing within the internal cavity below the laterally-extending portion and configured to reduce sloshing of oil within the cavity. The dry sump oil tank assembly is particularly useful for high performance applications, such as racing vehicles, and may utilize components from standard vehicle applications, thus maximizing the economies of scale of producing such components and being suited for a vehicle that may be typically used in standard driving conditions, but occasionally subjected to high performance use.

Owner:GM GLOBAL TECH OPERATIONS LLC

Lubrication system for a four cycle engine

InactiveUS6848528B2Improve cylinder chargingSimple wayInternal combustion piston enginesClosed-circuit pressure lubricating systemsEngineeringDry sump

A dry sump lubrication system for a four cycle engine is disclosed. The dry sump lubrication system has at least two lubricant storage chambers. A first lubricant storage chamber stores a first volume of lubricant. The first lubricant storage chamber may be located in a lower part of the crankcase. A second lubricant storage chamber is an oil tank and stores a second volume of lubricant. The oil tank may be secured to the output end of the crankcase. The first lubricant storage chamber is capable of storing at least 30% of a total volume of lubricant within the dry sump lubrication system.

Owner:BRP ROTAX

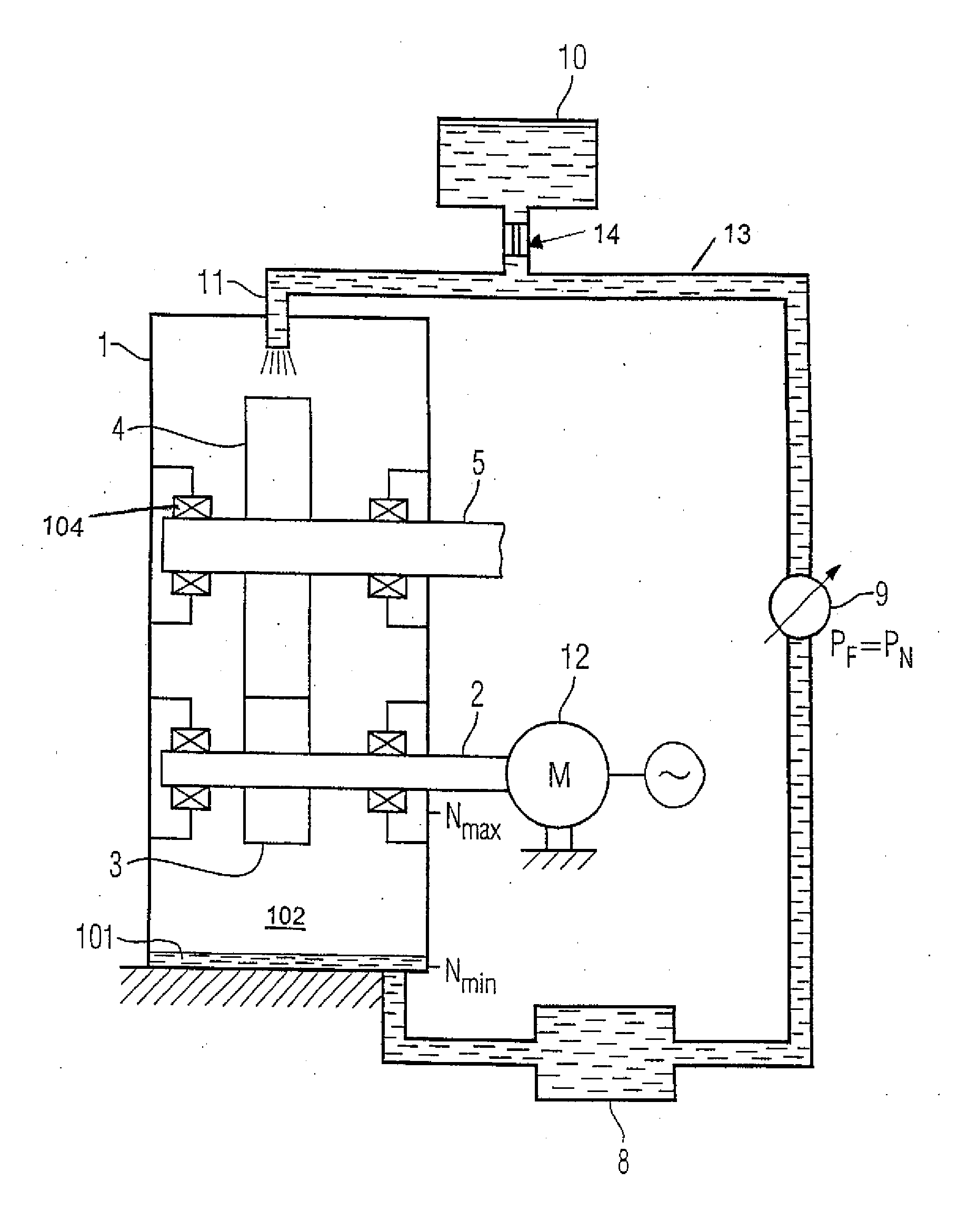

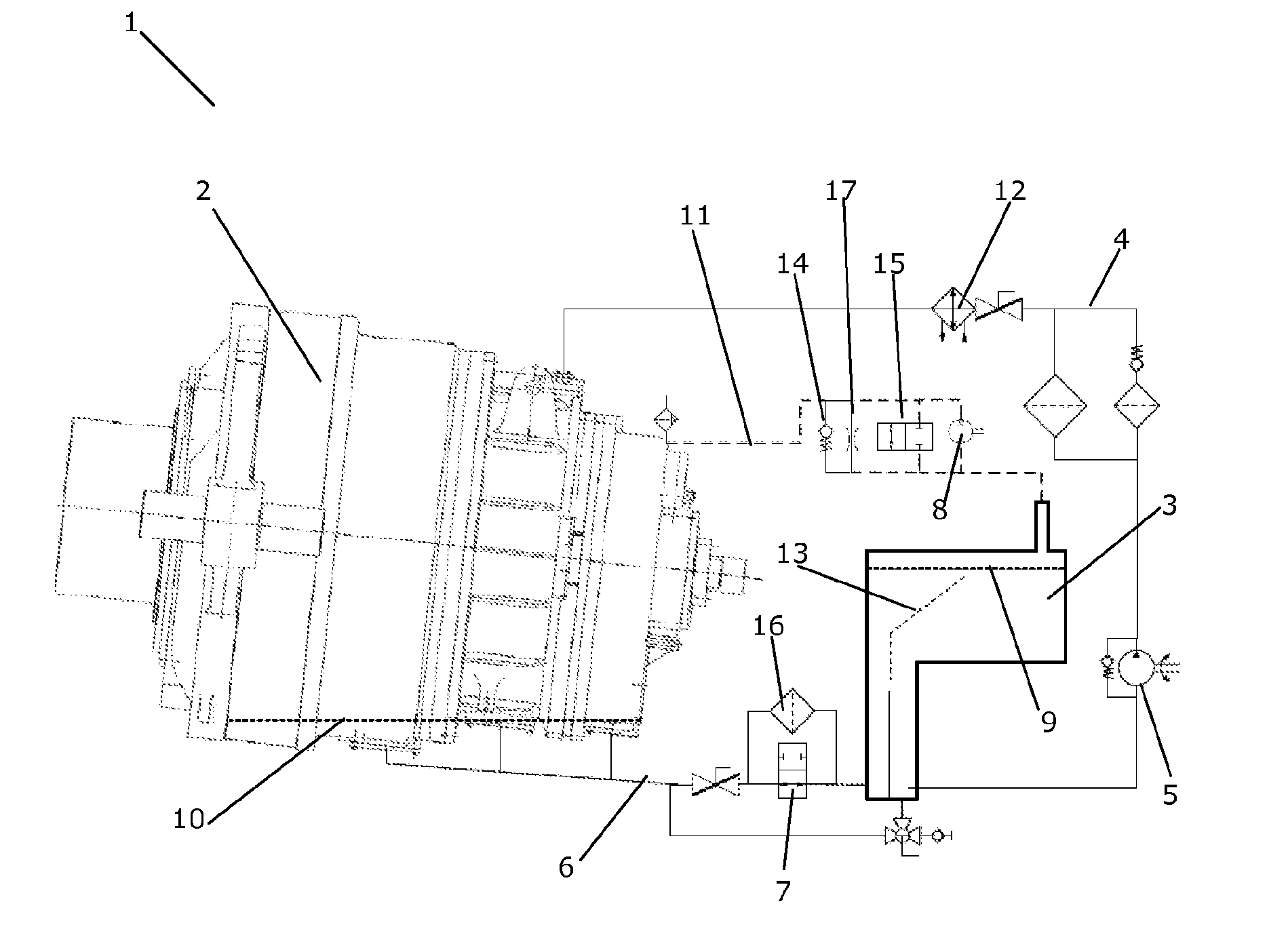

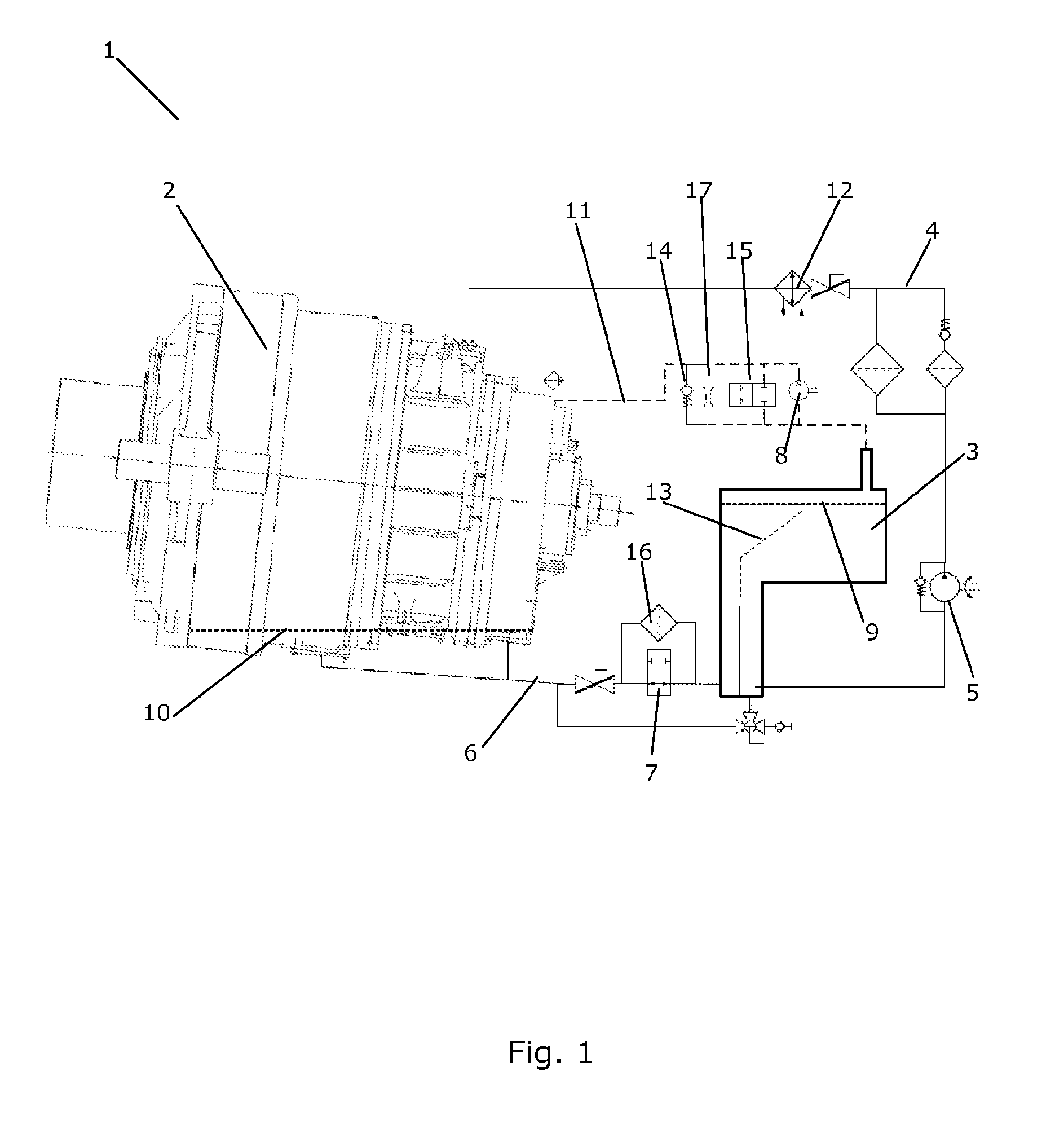

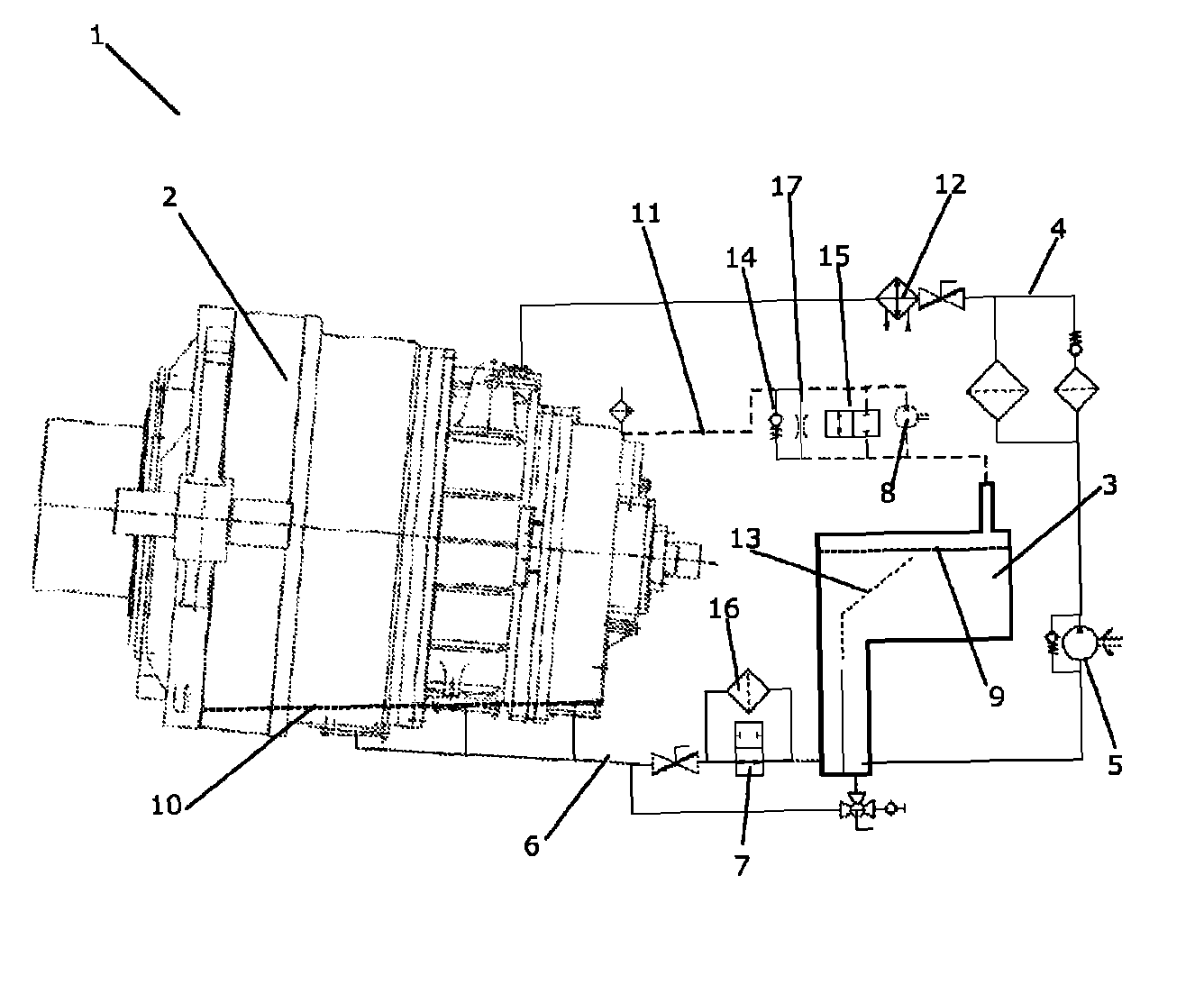

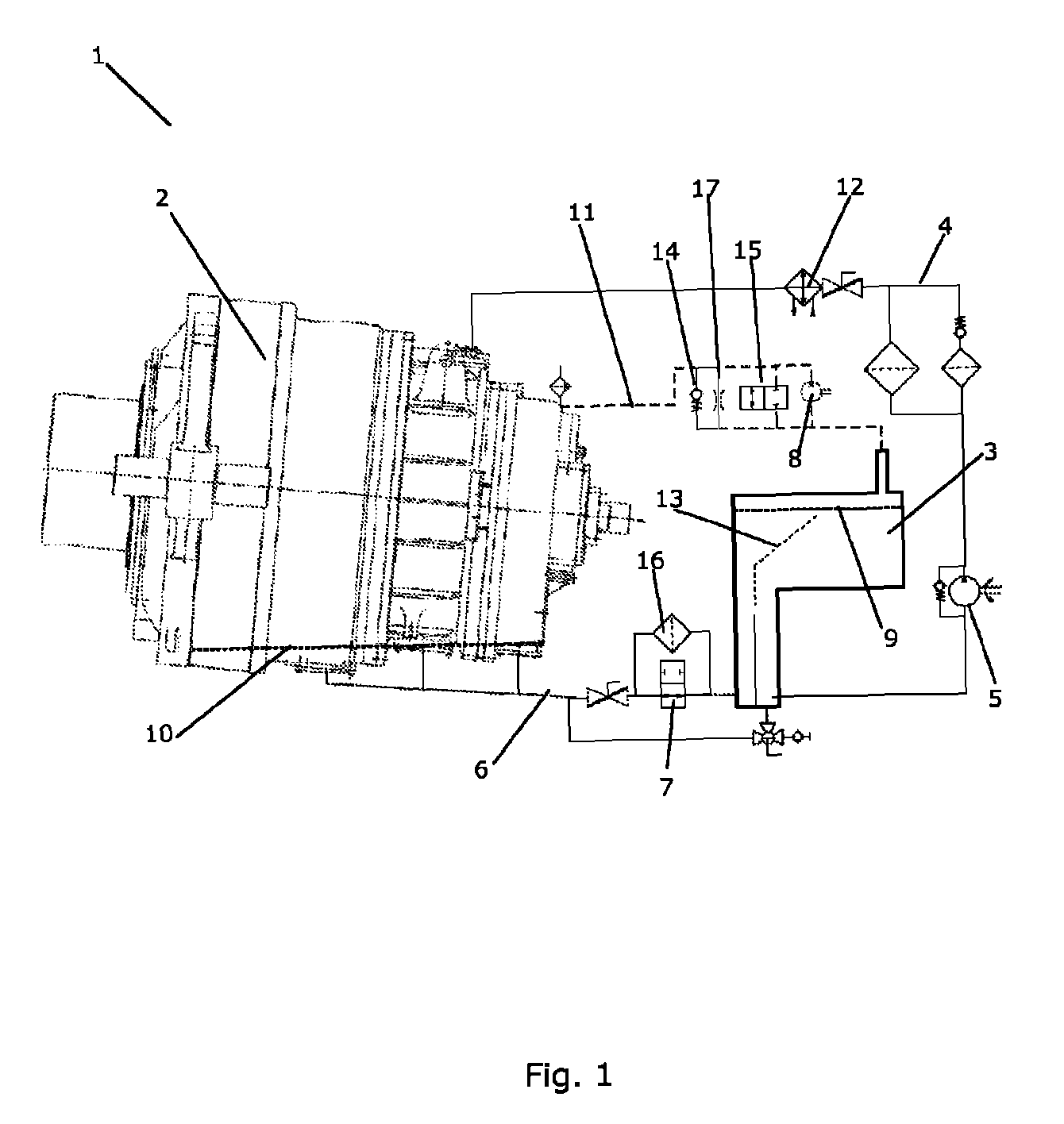

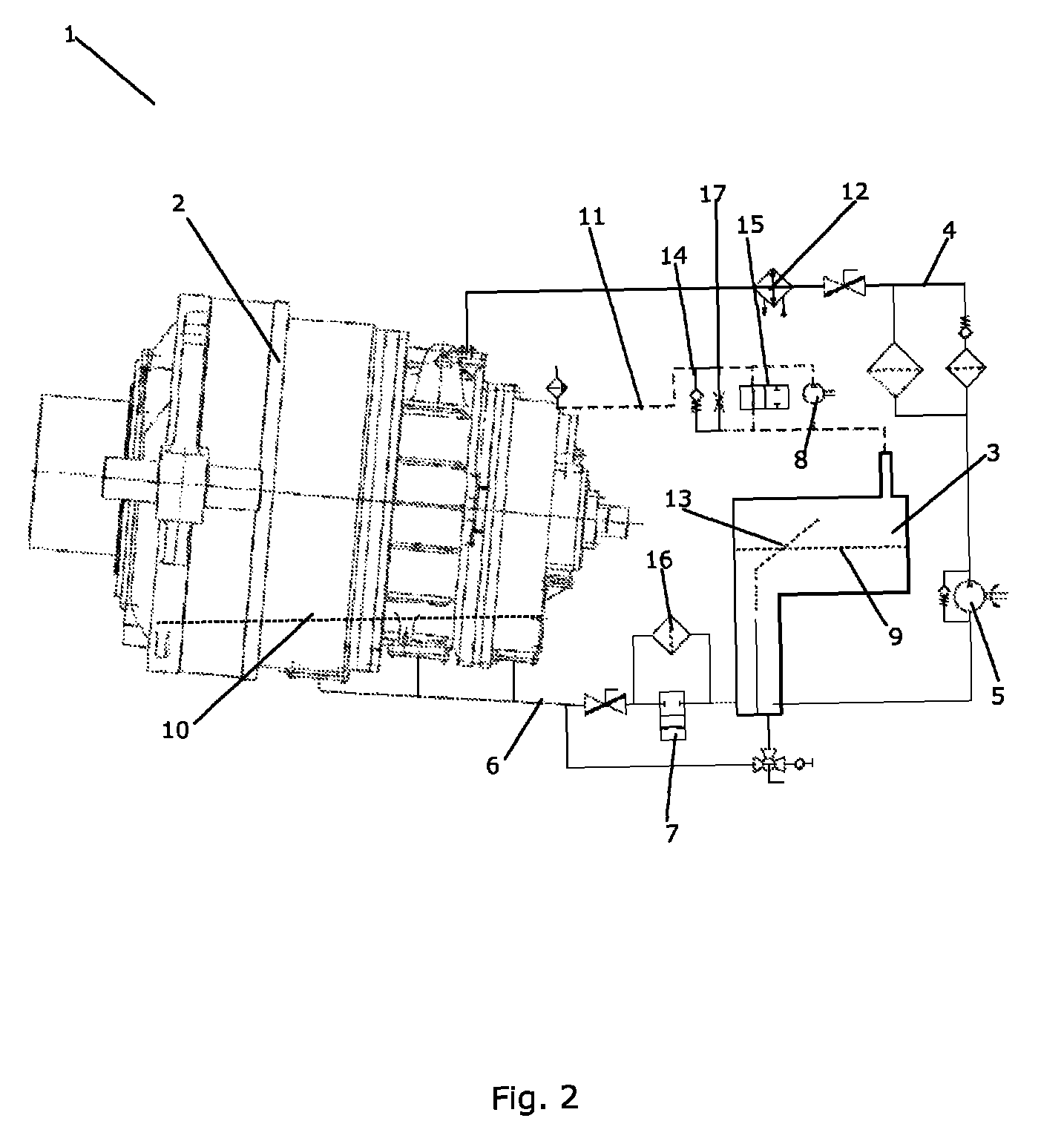

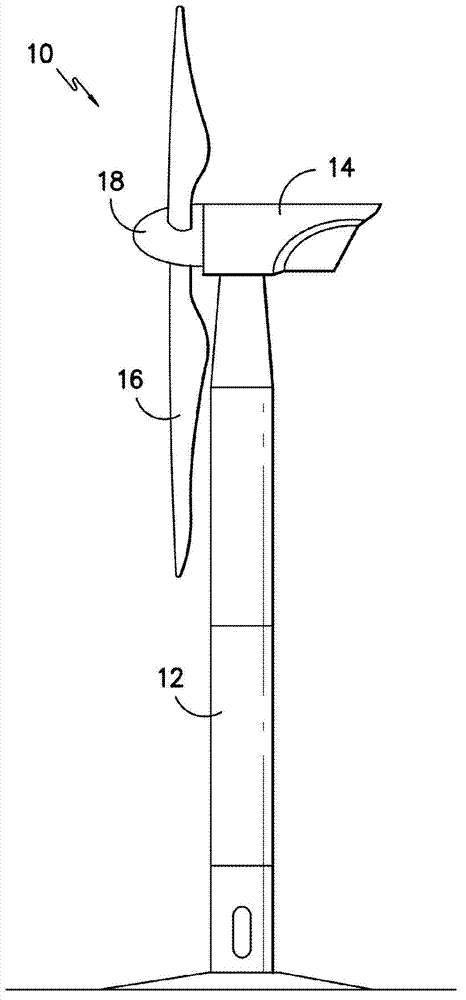

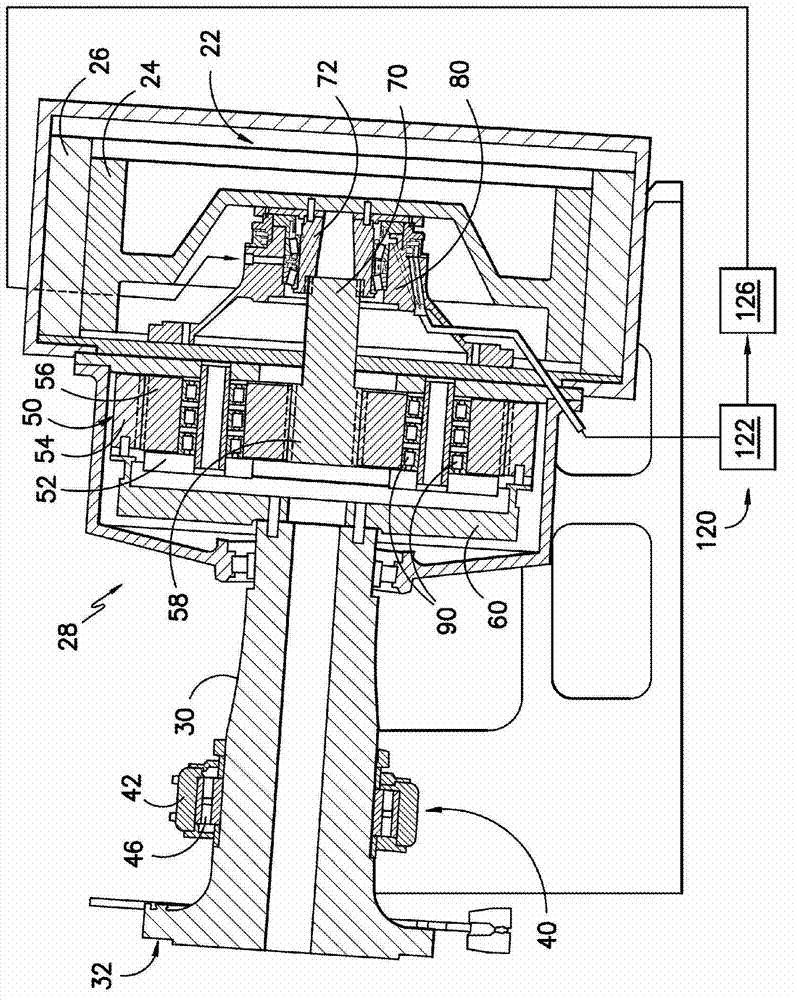

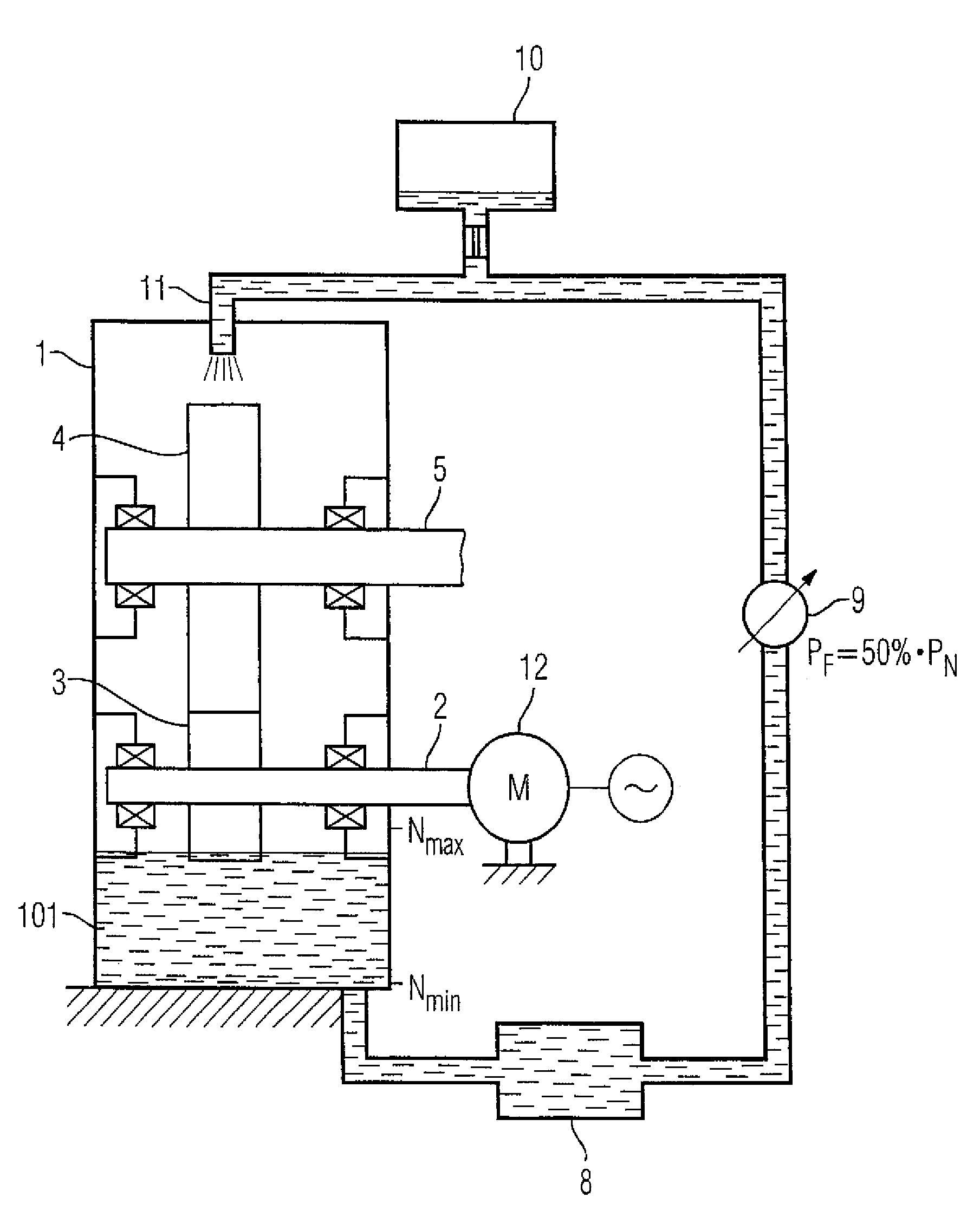

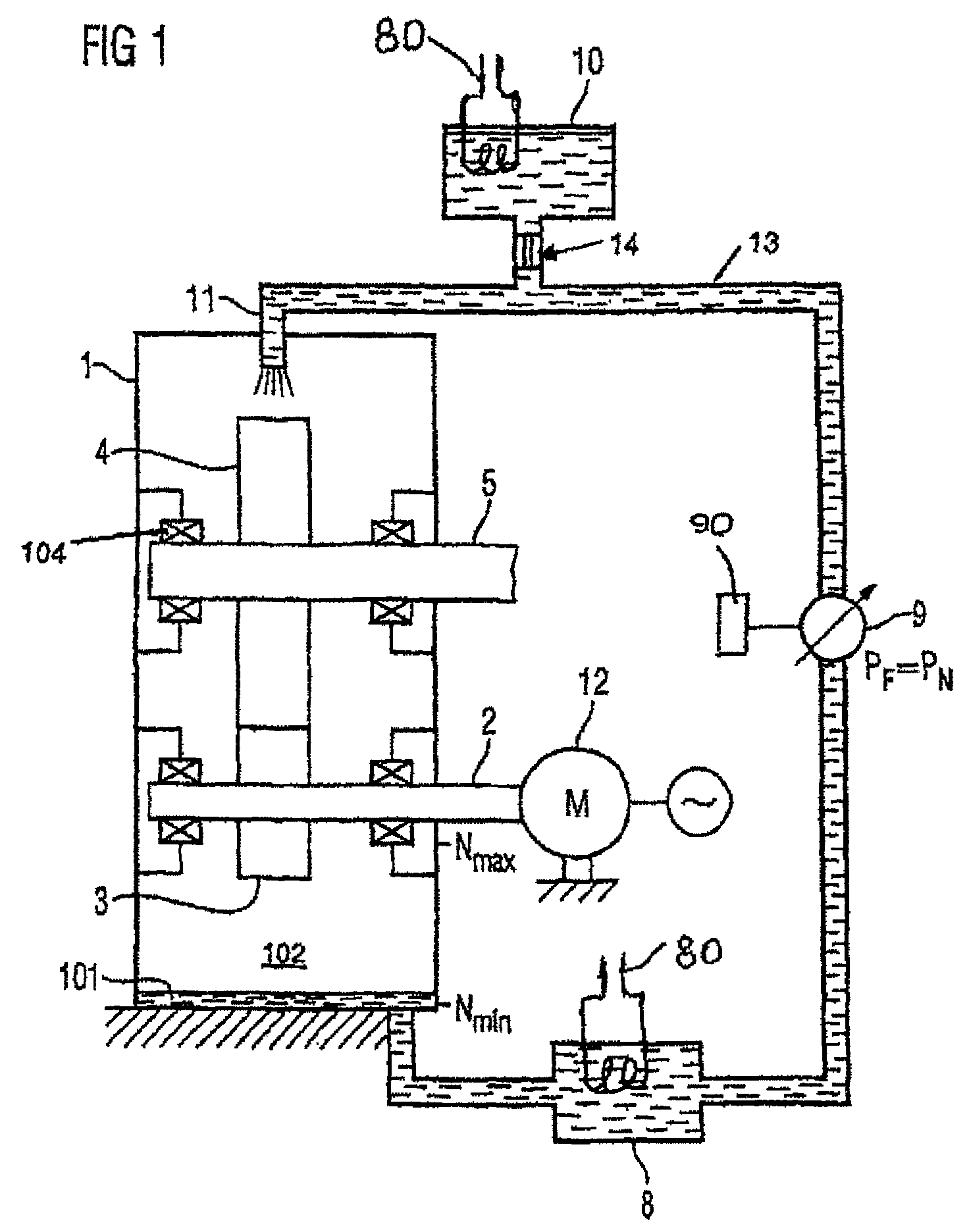

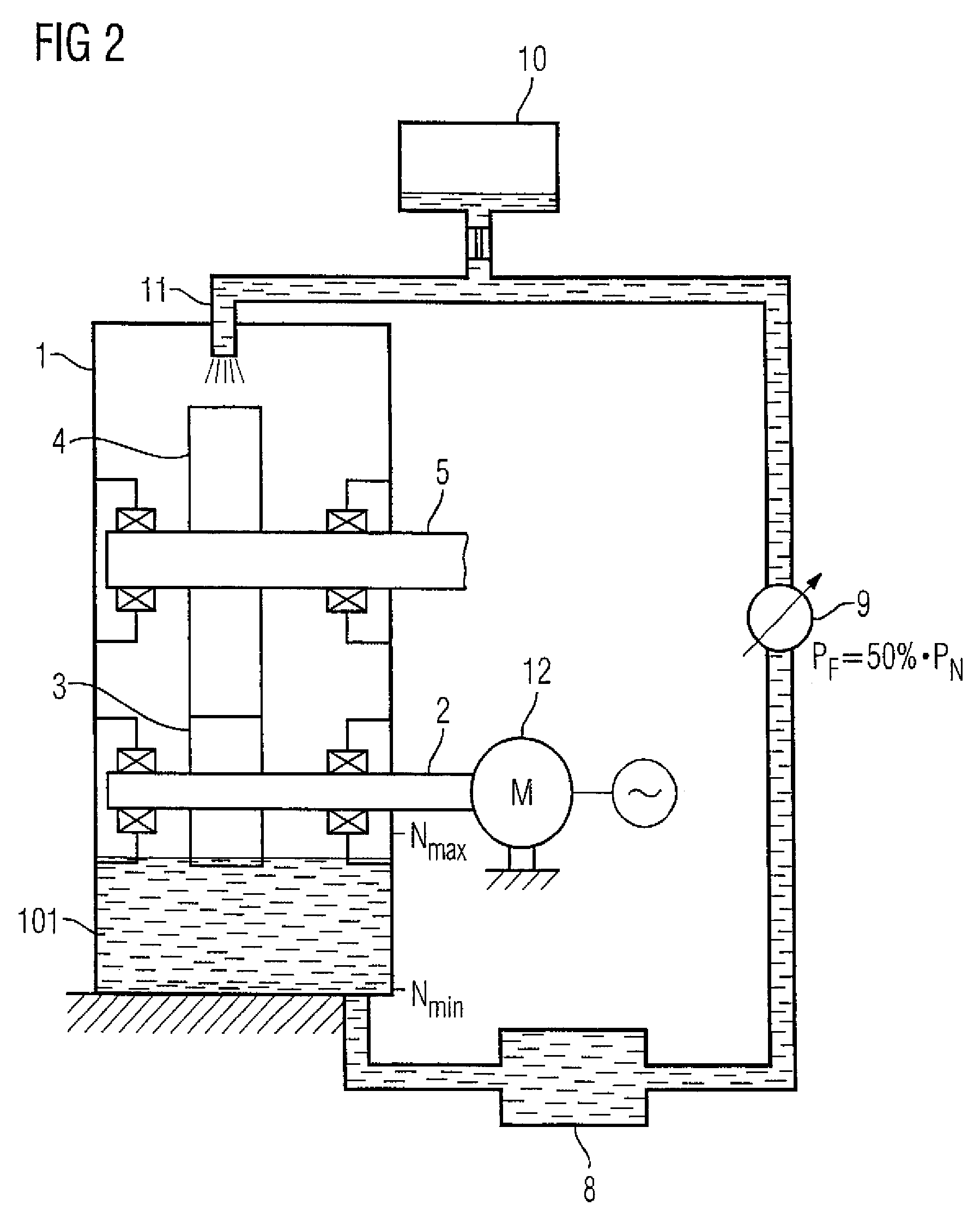

Lubrication system for a gear system providing emergency lubrication

ActiveUS20120211307A1Reduce pressureReduce lossesMachines/enginesWind energy generationSTI OutpatientDry sump

A lubrication system for a gear system for a wind turbine is disclosed. The lubrication system comprises a reservoir adapted to contain lubricant, first pump means arranged to supply lubricant from the reservoir to the gear system via a first fluid connection, and vacuum generating means arranged in fluid connection with the reservoir, thereby maintaining a total air pressure in the reservoir which is lower than an ambient pressure during normal operation. The lowered total air pressure in the reservoir draws lubricant from the gear system into the reservoir, thereby increasing the lubricant level in the reservoir and decreasing the lubricant level in the gear system, allowing the lubrication system to be operated in a ‘dry sump mode’. In the case of an emergency or during start-up the vacuum generating means is stopped, thereby increasing the total air pressure in the reservoir. This causes a decrease in the lubricant level in the reservoir and an increase in the lubricant level in the gear system, allowing the lubrication system to be operated in a ‘wet sump mode’.

Owner:VESTAS WIND SYST AS

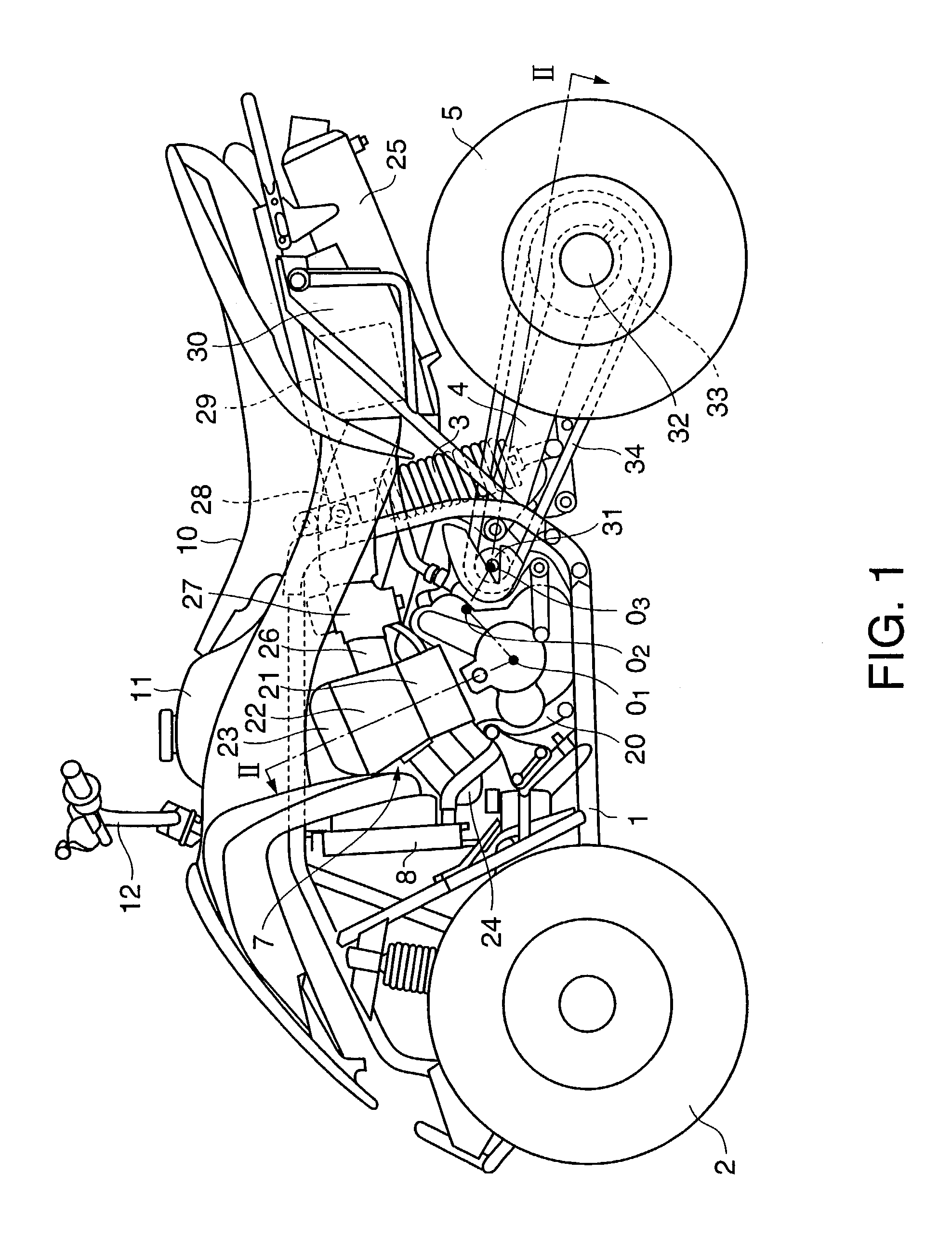

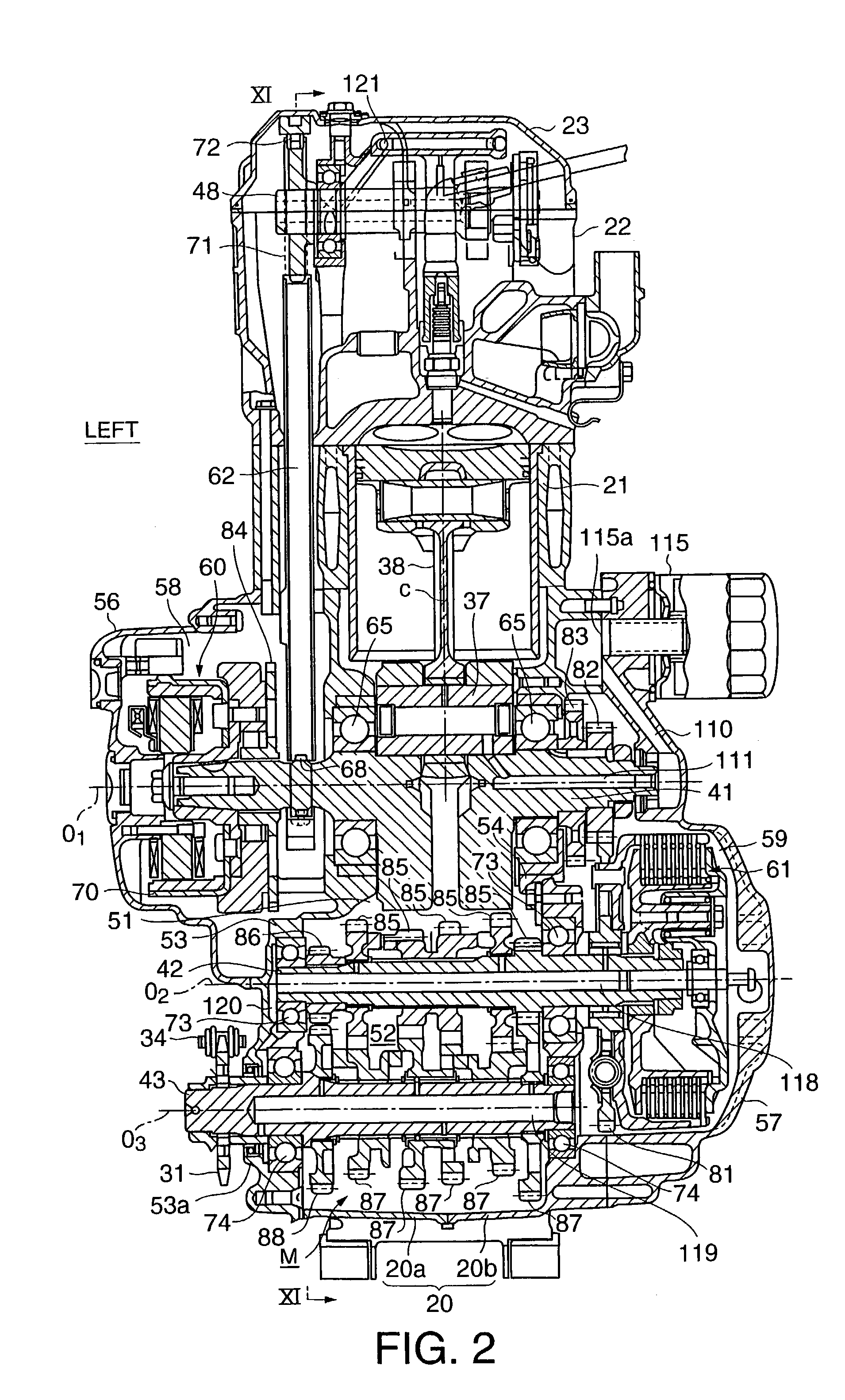

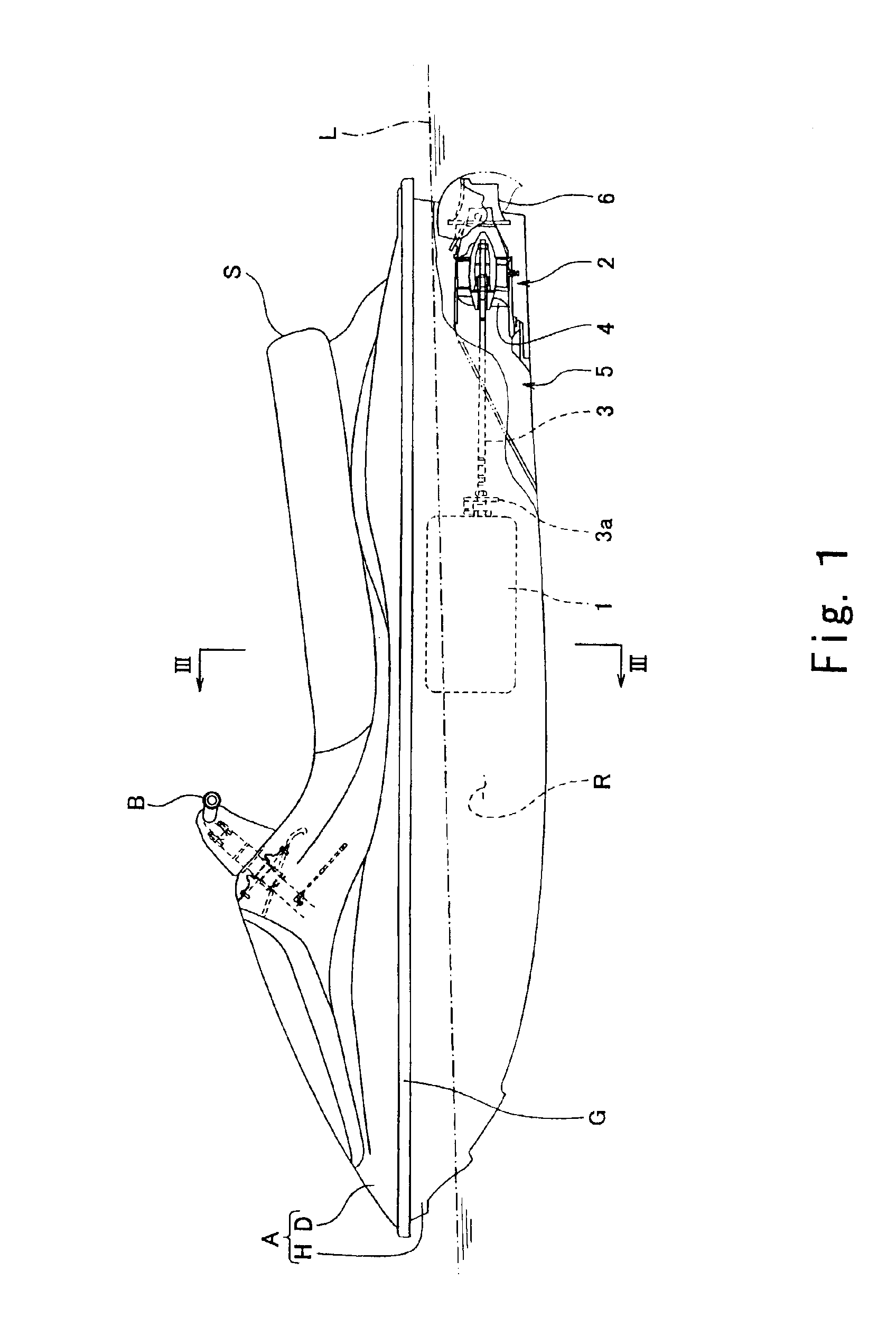

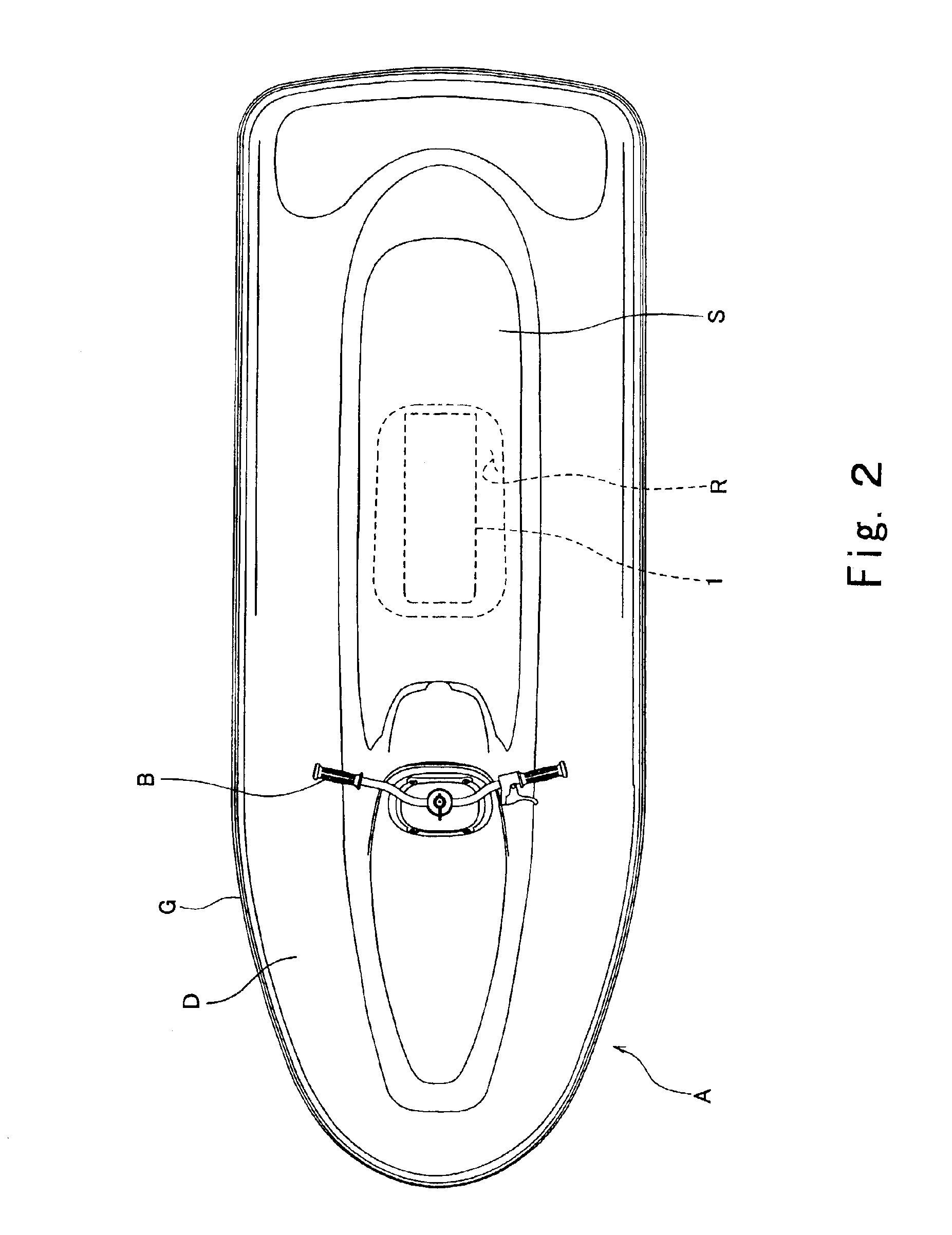

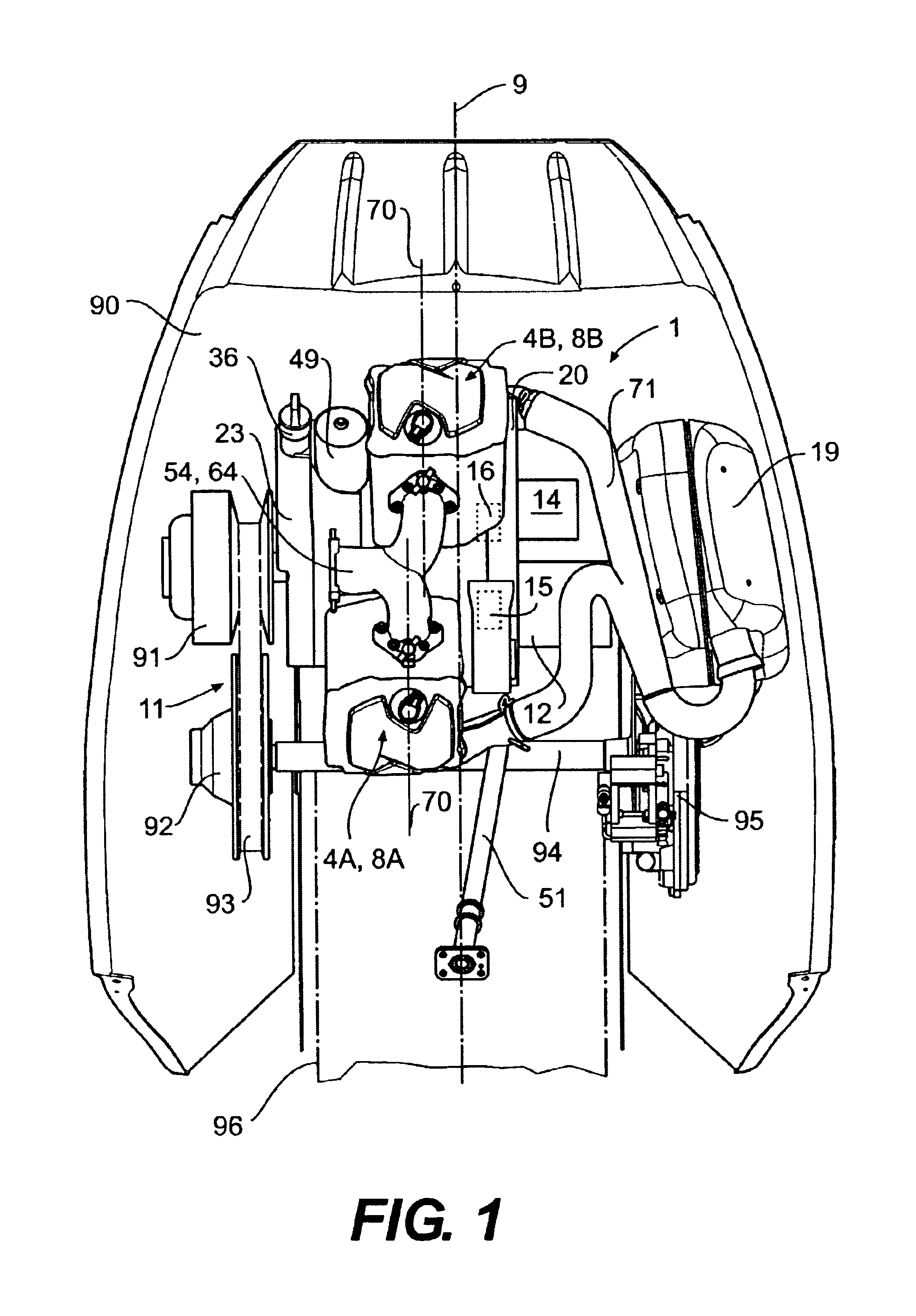

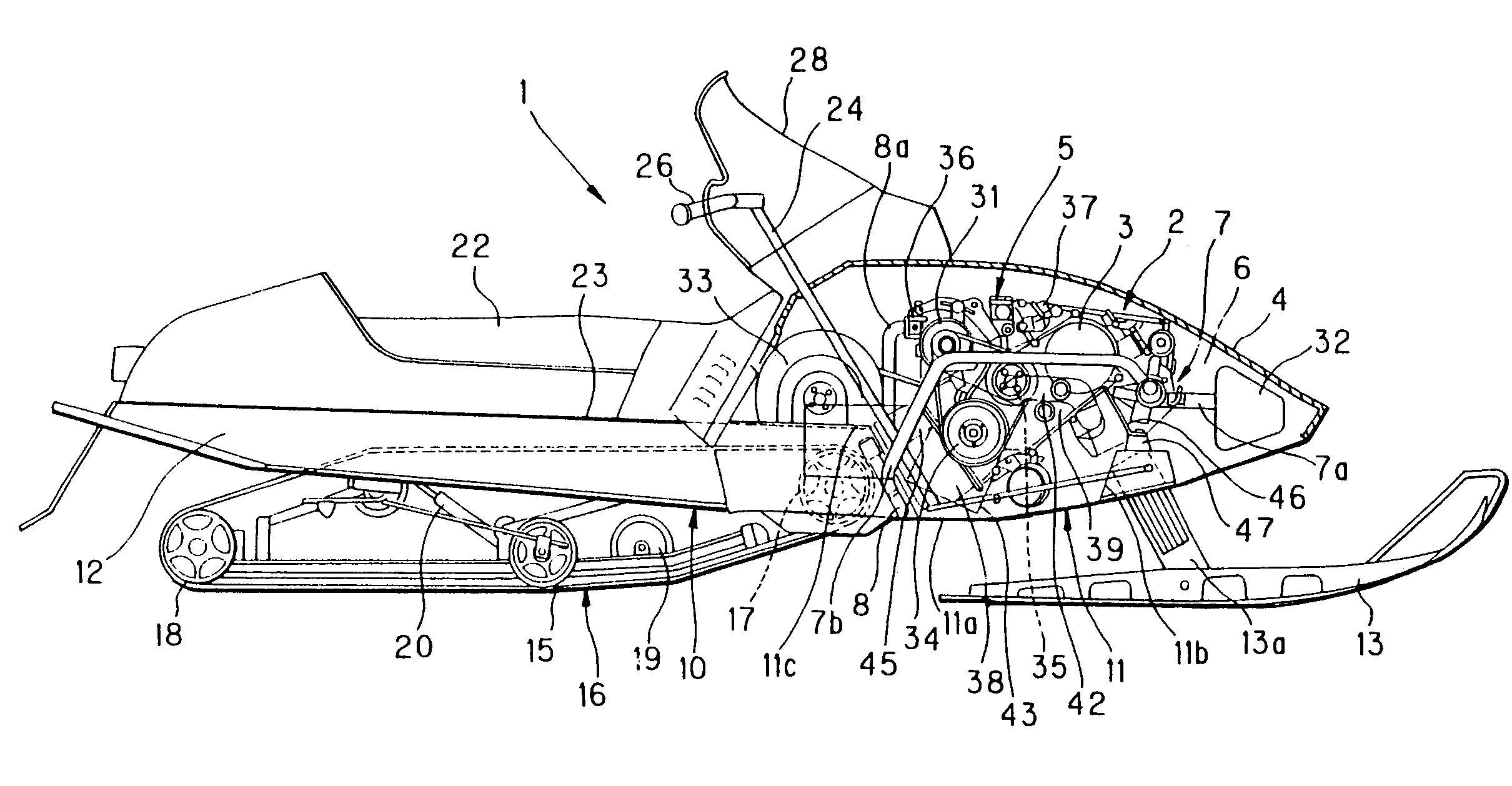

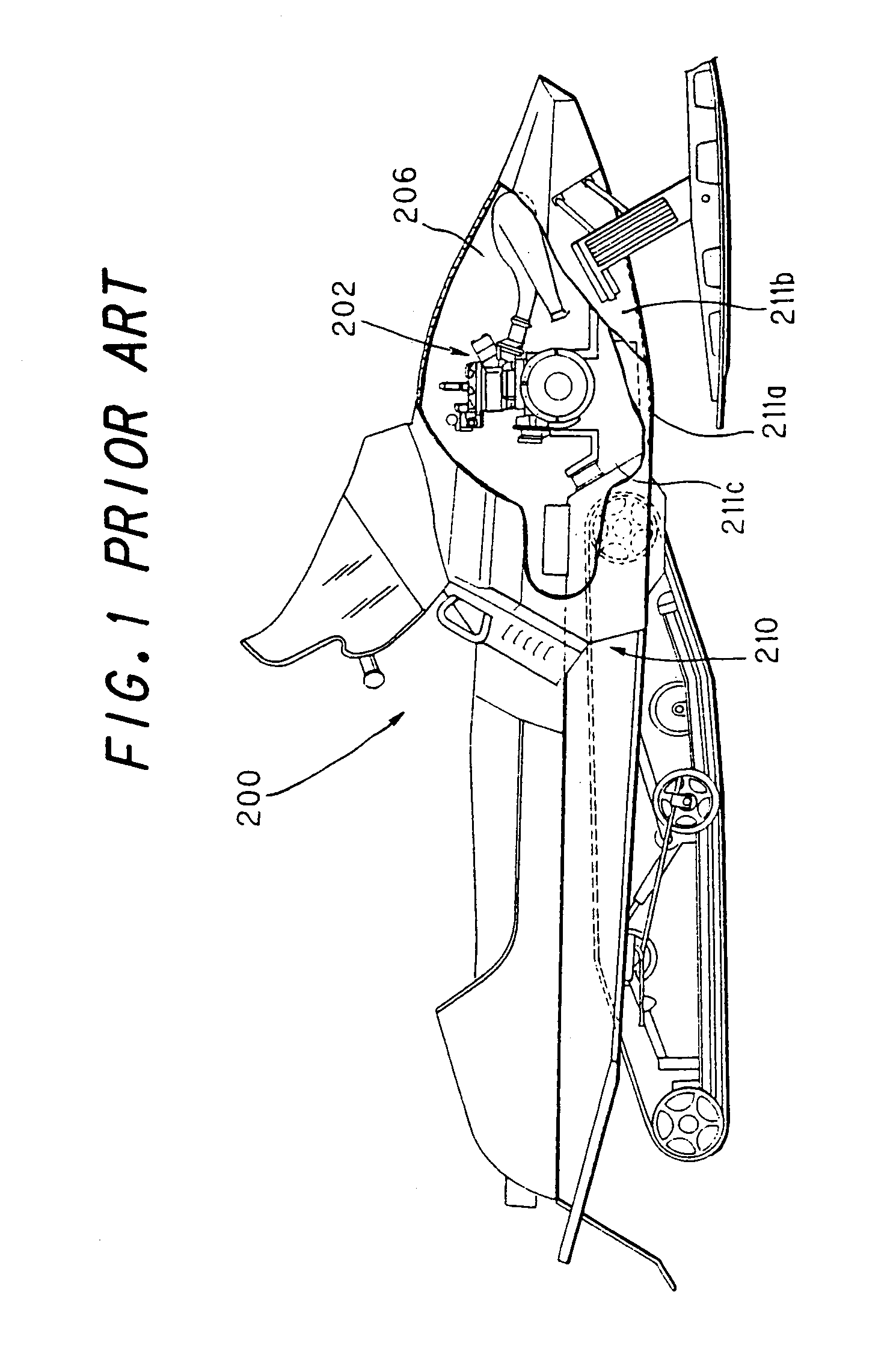

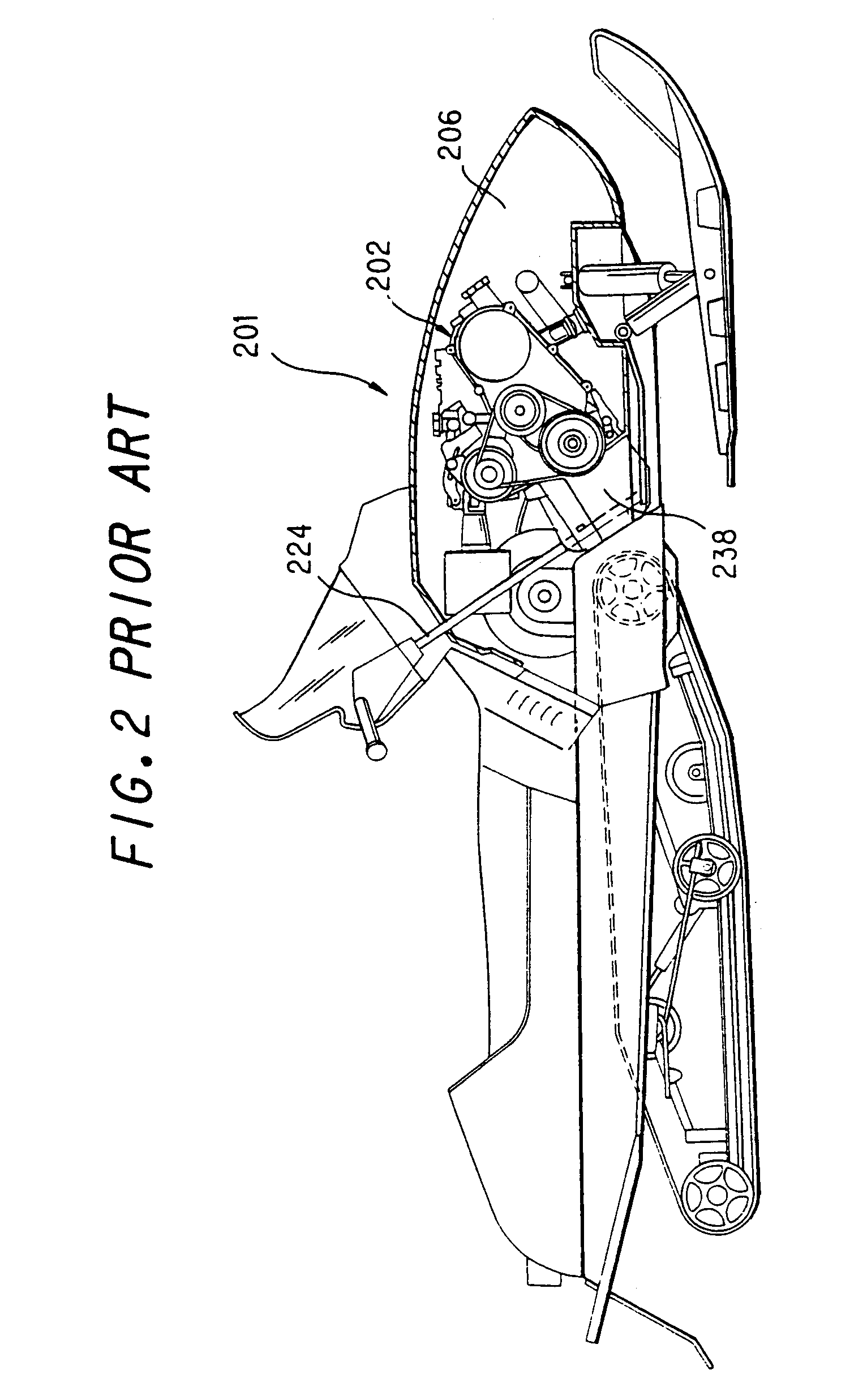

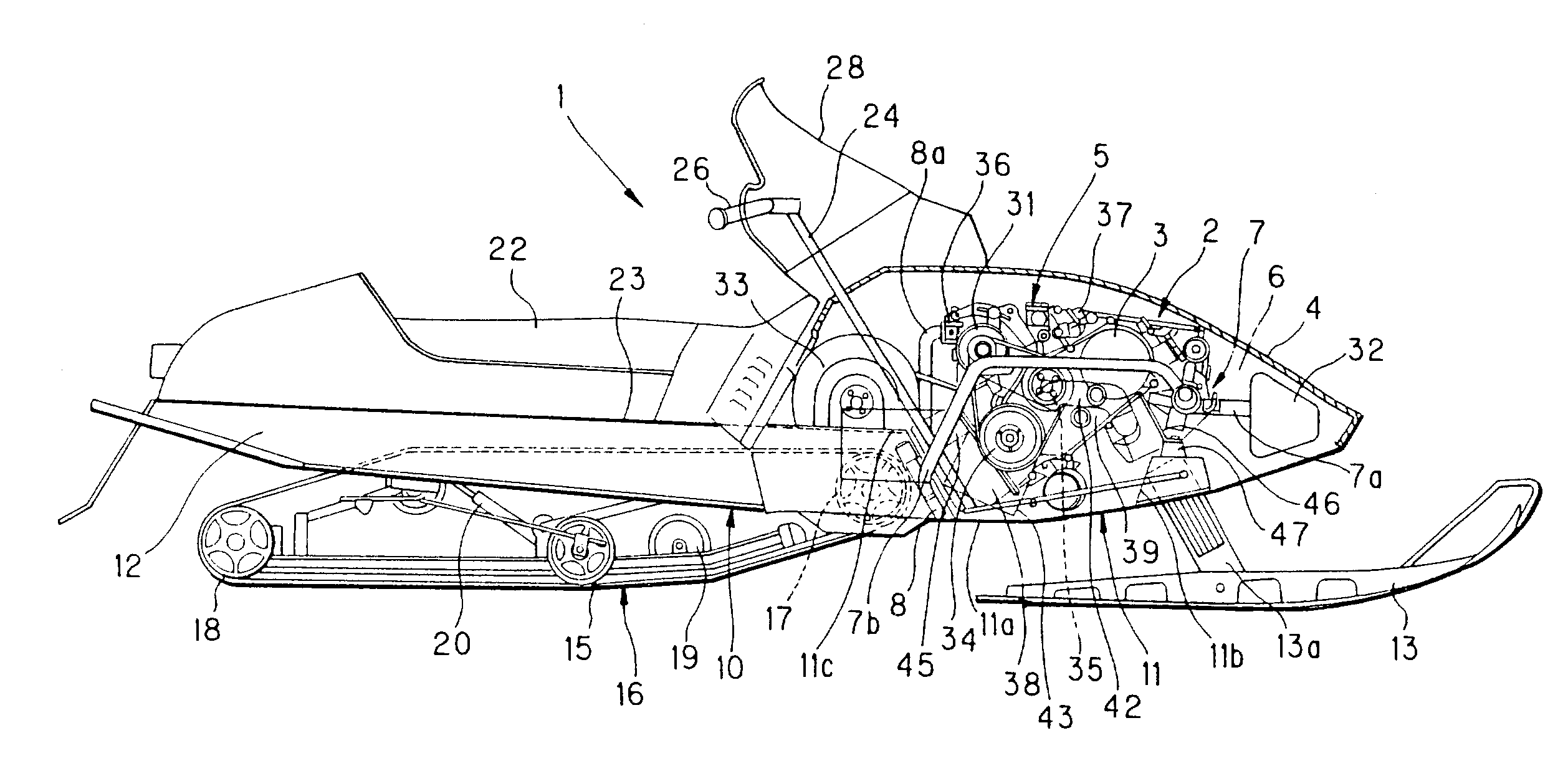

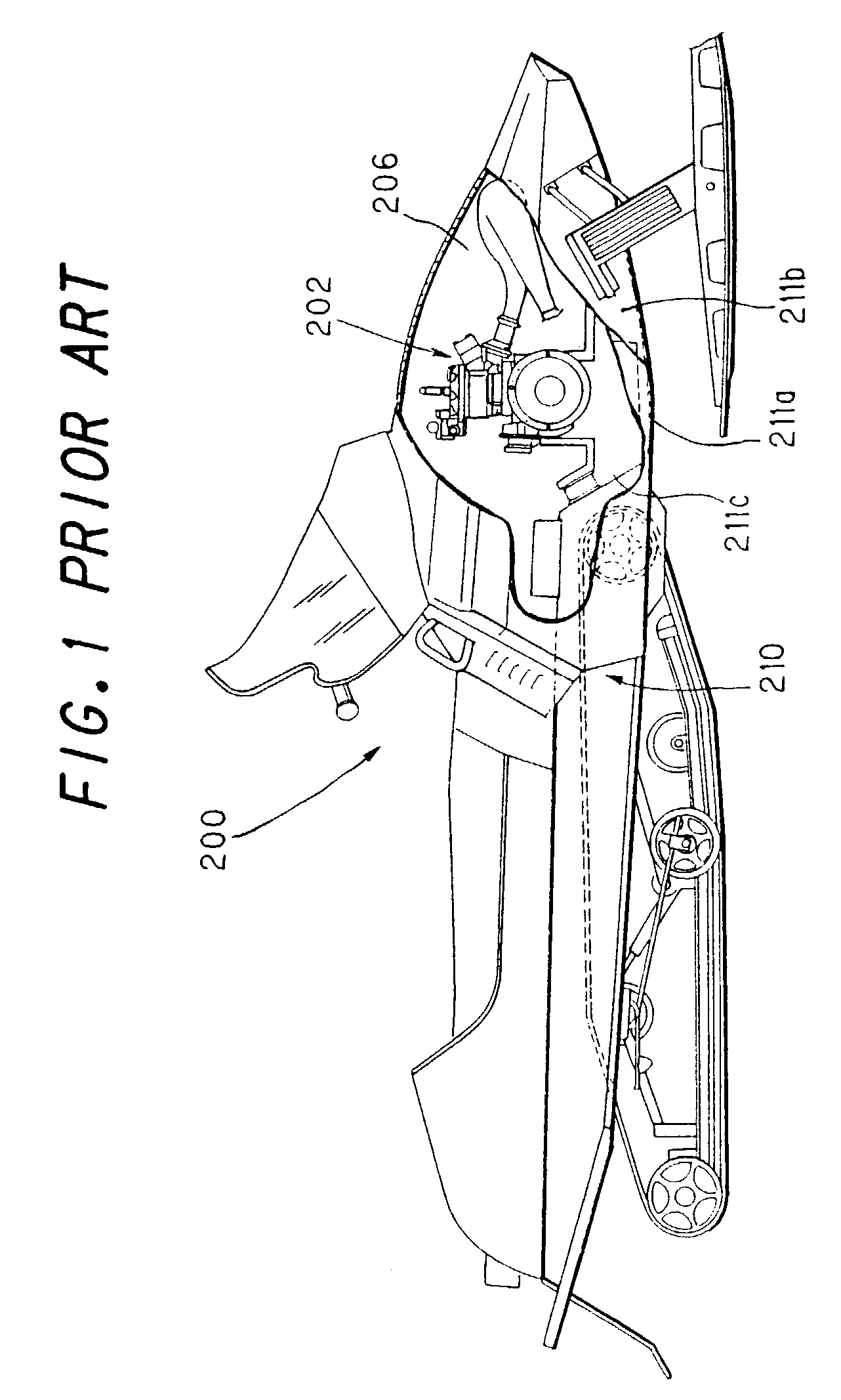

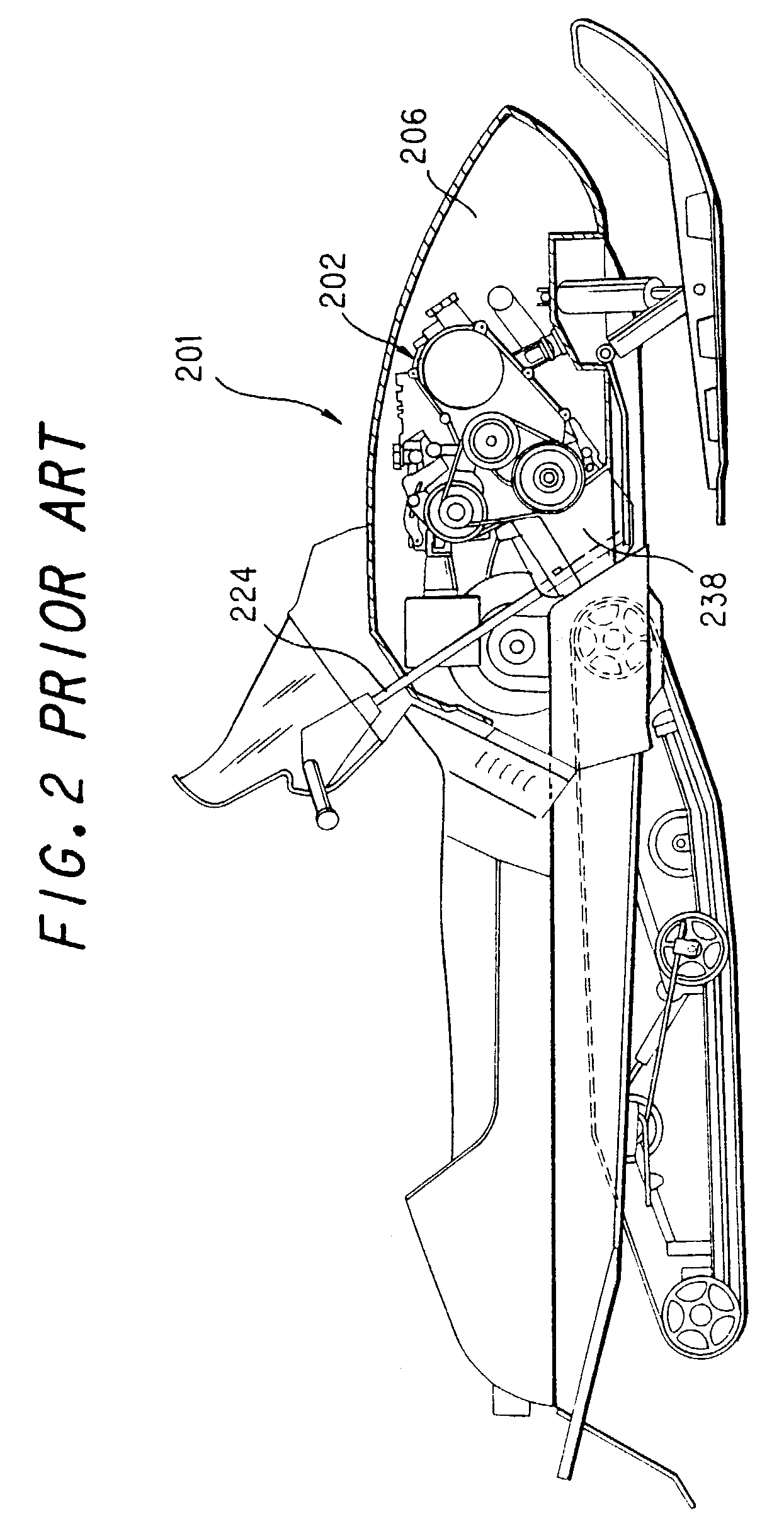

Snowmobile four-cycle engine arrangement

InactiveUS7198127B2Save spaceImprove maintenance workabilityMachines/enginesRider propulsionCylinder headFuel tank

A snowmobile four-cycle engine arrangement, includes: a four-cycle engine arranged in an engine compartment formed in the front body of a snowmobile with its crankshaft laid substantially parallel to the body width and having a cylinder case inclined forwards with respect to the vehicle's direction of travel. The engine employs a dry sump oil supplying system and an oil tank separate from the engine is provided. Another snowmobile four-cycle engine arrangement includes: a four-cycle engine having a cylinder head at its top, arranged in the engine compartment and inclined forwards with respect to the vehicle's direction of travel with an intake path provided on the upper portion of the engine body. An intercooler for cooling the intake air is arranged in a tunnel created inside the body frame for accommodating a track belt.

Owner:SUZUKI MOTOR CORP

Snowmobile four-cycle engine arrangement

InactiveUS7036619B2Simplify communication pathLow costMachines/enginesRider propulsionCylinder headFuel tank

A snowmobile four-cycle engine arrangement, includes: a four-cycle engine arranged in an engine compartment formed in the front body of a snowmobile with its crankshaft laid substantially parallel to the body width and having a cylinder case inclined forwards with respect to the vehicle's direction of travel. The engine employs a dry sump oil supplying system and an oil tank separate from the engine is provided. Another snowmobile four-cycle engine arrangement includes: a four-cycle engine having a cylinder head at its top, arranged in the engine compartment and inclined forwards with respect to the vehicle's direction of travel with an intake path provided on the upper portion of the engine body. An intercooler for cooling the intake air is arranged in a tunnel created inside the body frame for accommodating a track belt.

Owner:SUZUKI MOTOR CORP

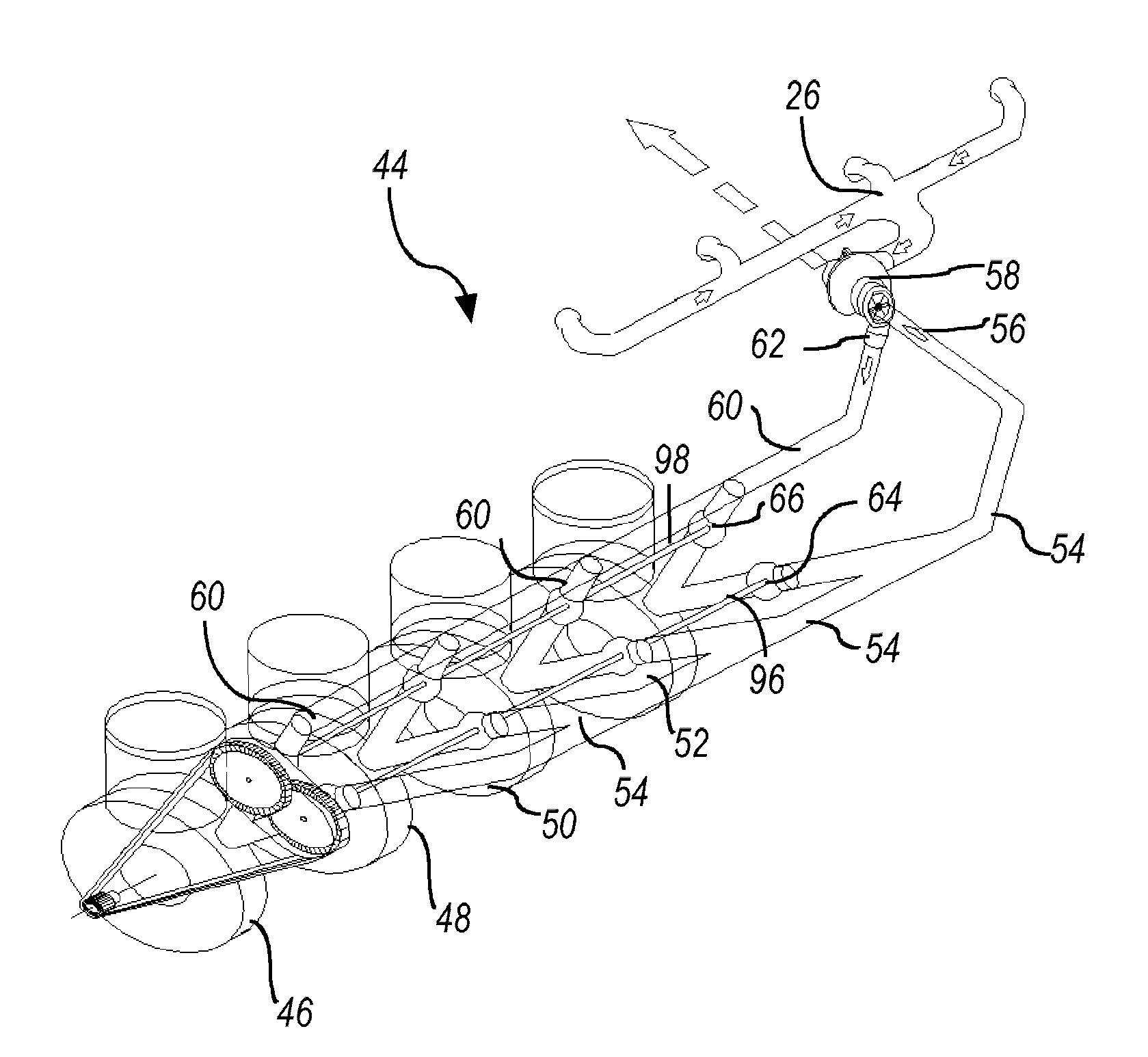

Engine with dry sump lubrication, separated scavenging and charging air flows and variable exhaust port timing

InactiveUS6397795B2Emission reductionImprove efficiencyCylinder headsOutput powerEngineeringCylinder block

An engine is disclosed having an improved lubrication system and scavenging system. An oil sleeve is positioned between the cylinder and the crankcase, the sleeve having a bore sized to receive the piston. The piston and sleeve define an annular oil space which is connected to a reservoir by oil lines. A fixed seal is positioned surrounding the piston between the cylinder and the oil sleeve. A movable seal is mounted on and surrounds the piston. On the power stroke the movable seal moves away from the fixed seal, drawing oil from the reservoir into the annular oil space. On the compression stroke, the movable seal moves toward the fixed seal, forcing the oil from the annular oil space into the piston wrist pin and through conduits to the crank and main bearings and then back to the reservoir. Separate scavenging and charging tubes connect the crankcase to the cylinder.

Owner:HARE NICHOLAS S

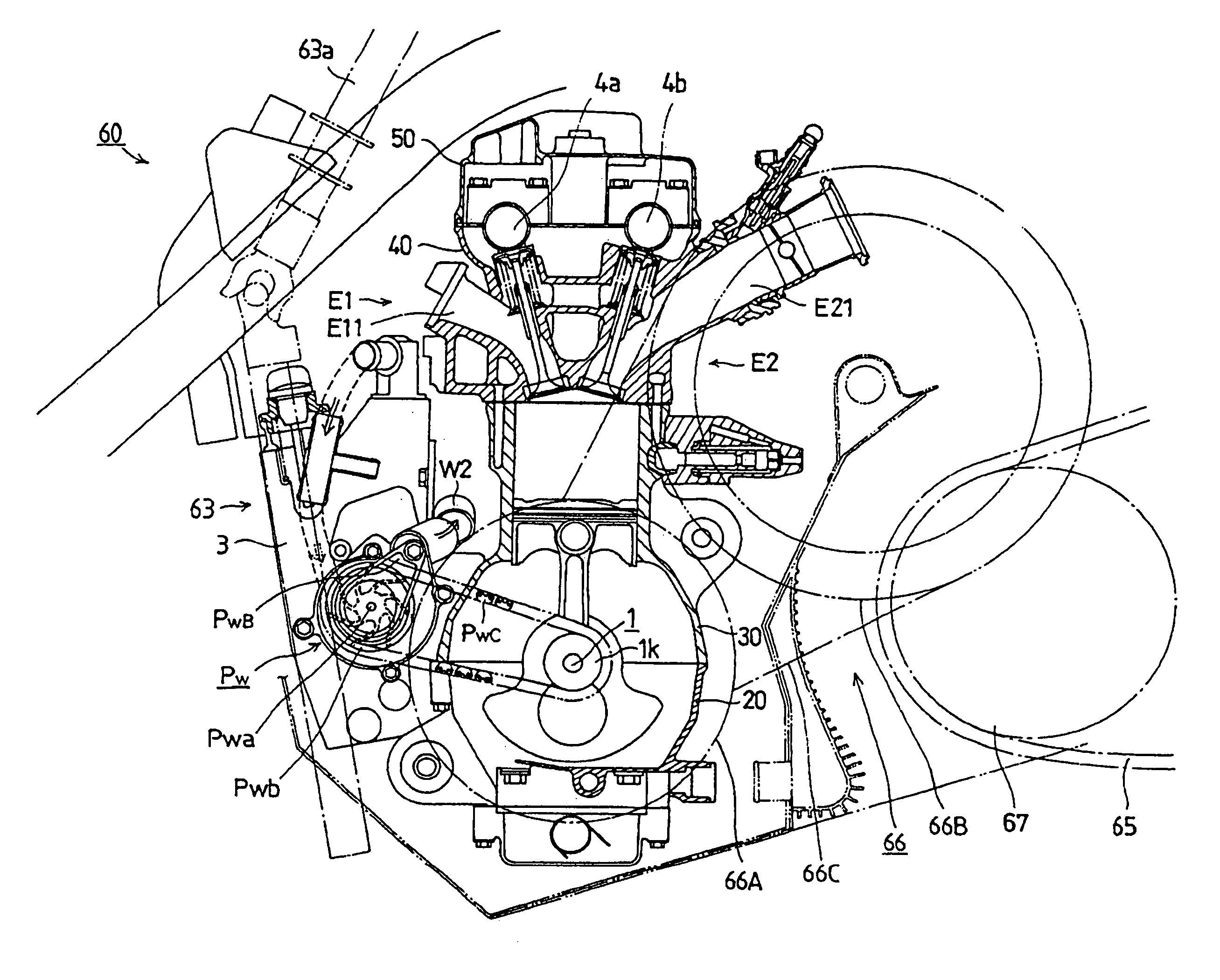

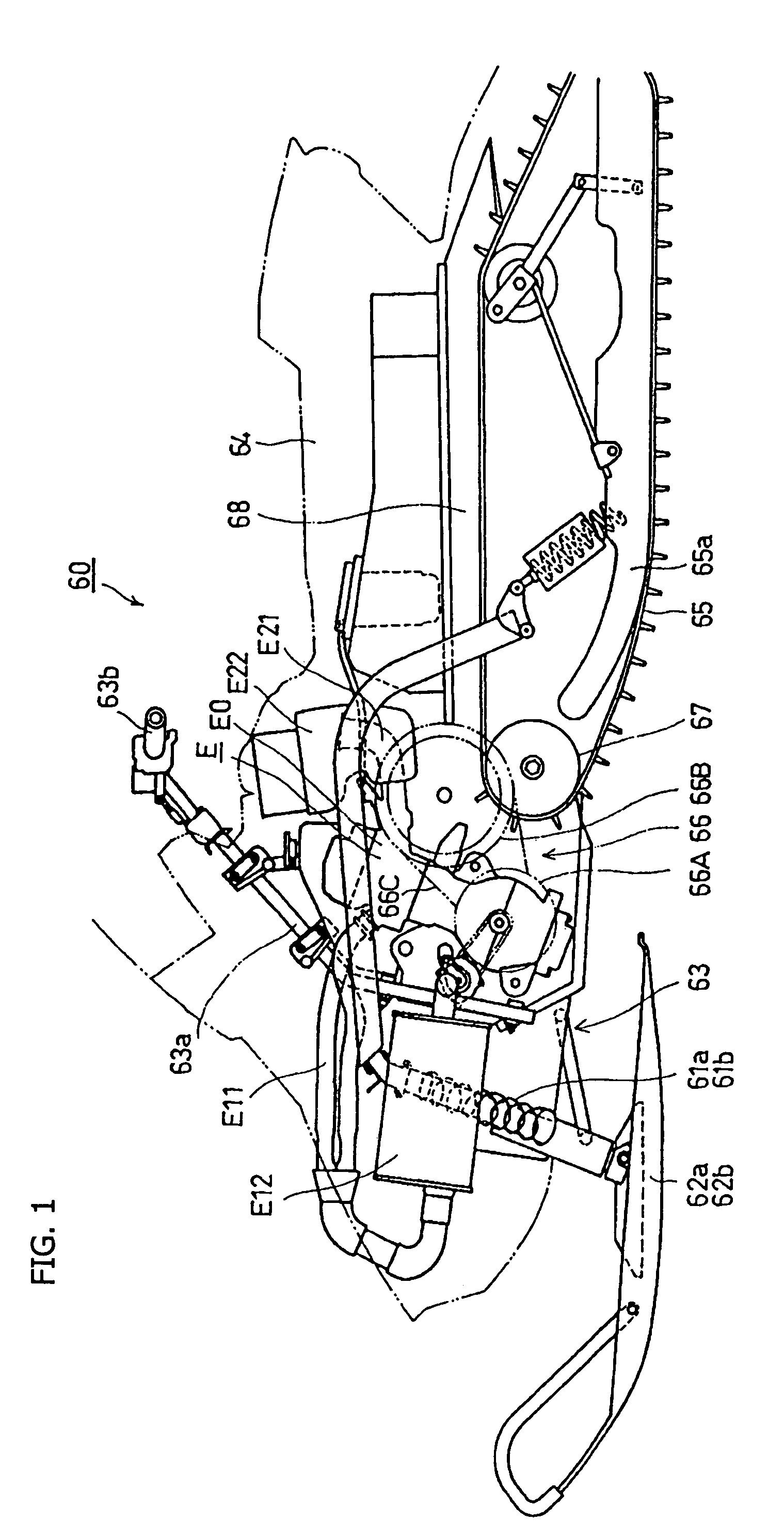

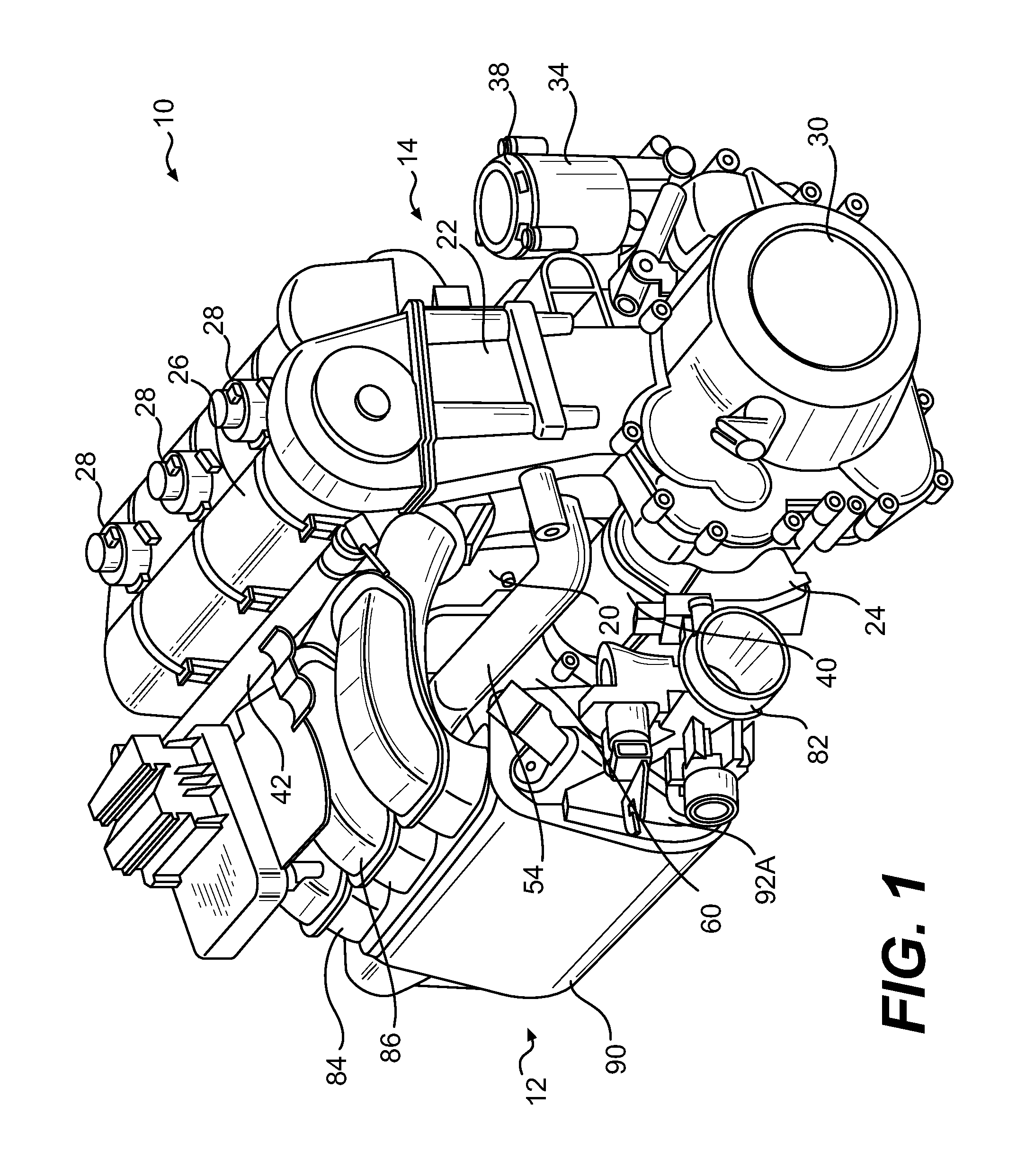

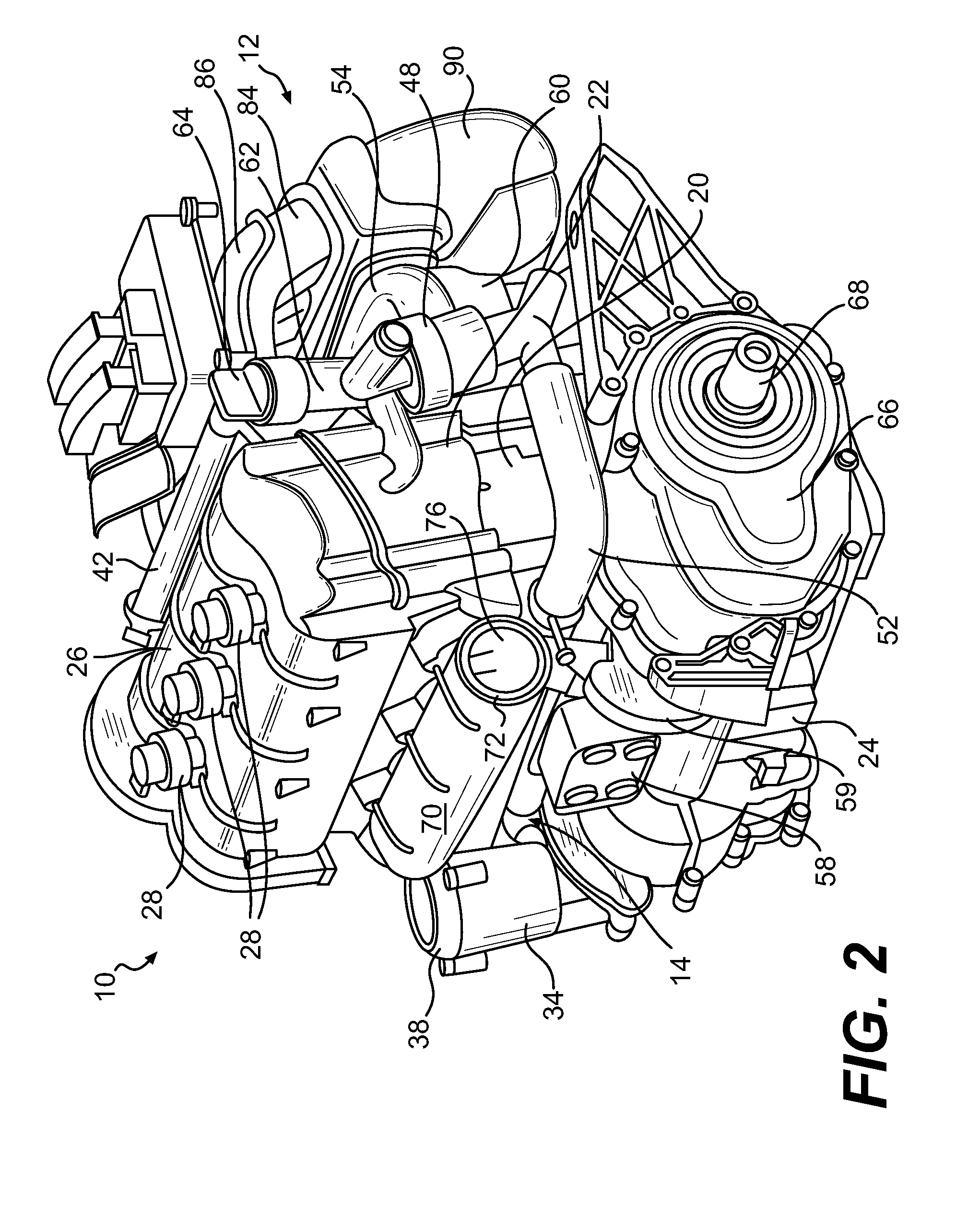

Snowmobile, and the arrangement of the engine and accessory components thereof

A snowmobile, having an arrangement of components in which the layout of various accessory devices is improved for an internal combustion engine mounted thereon. A dry sump oil tank, a water pump and a starter motor are disposed in a concentrated space at a forward-facing portion of an internal combustion engine, which is mounted on a snowmobile at a position close to the front side of a body of the snowmobile. A steering shaft is arranged close to the front portion of the internal combustion engine, and is accommodated by modifying the shape of closely adjacent parts. Accordingly, the limited available space in a snowmobile is effectively used, and a rider riding in back of the engine can easily and closely approach the engine. The limited space inside the snowmobile cover is used effectively, by efficiently arranging selected accessory devices for an internal combustion engine mounted on the snowmobile.

Owner:HONDA MOTOR CO LTD

Control apparatus for dry sump type internal combustion engine

ActiveUS20060102429A1Improve energy consumptionReduce the concentration of nitrogen oxidesElectrical controlLubrication of auxillariesEngineeringInternal combustion engine

A feed pump 28 that is driven by the axial torque of an internal combustion engine 10 is installed. An electric scavenge pump 36 is installed. A base value for the ratio (S / F ratio) between the discharge volume of the scavenge pump 36 and feed pump 28 is calculated. The base value is corrected so that the S / F ratio is lower in a region where the engine speed is high than in a region where the engine speed is low. The discharge volume of the scavenge pump 36 is controlled in accordance with the S / F ratio that is corrected in the above manner.

Owner:TOYOTA JIDOSHA KK +1

Lubrication system for a gear system providing emergency lubrication

ActiveUS8997934B2Reduce pressureReduce lossesGear lubrication/coolingMachines/enginesWet sumpAmbient pressure

Owner:VESTAS WIND SYST AS

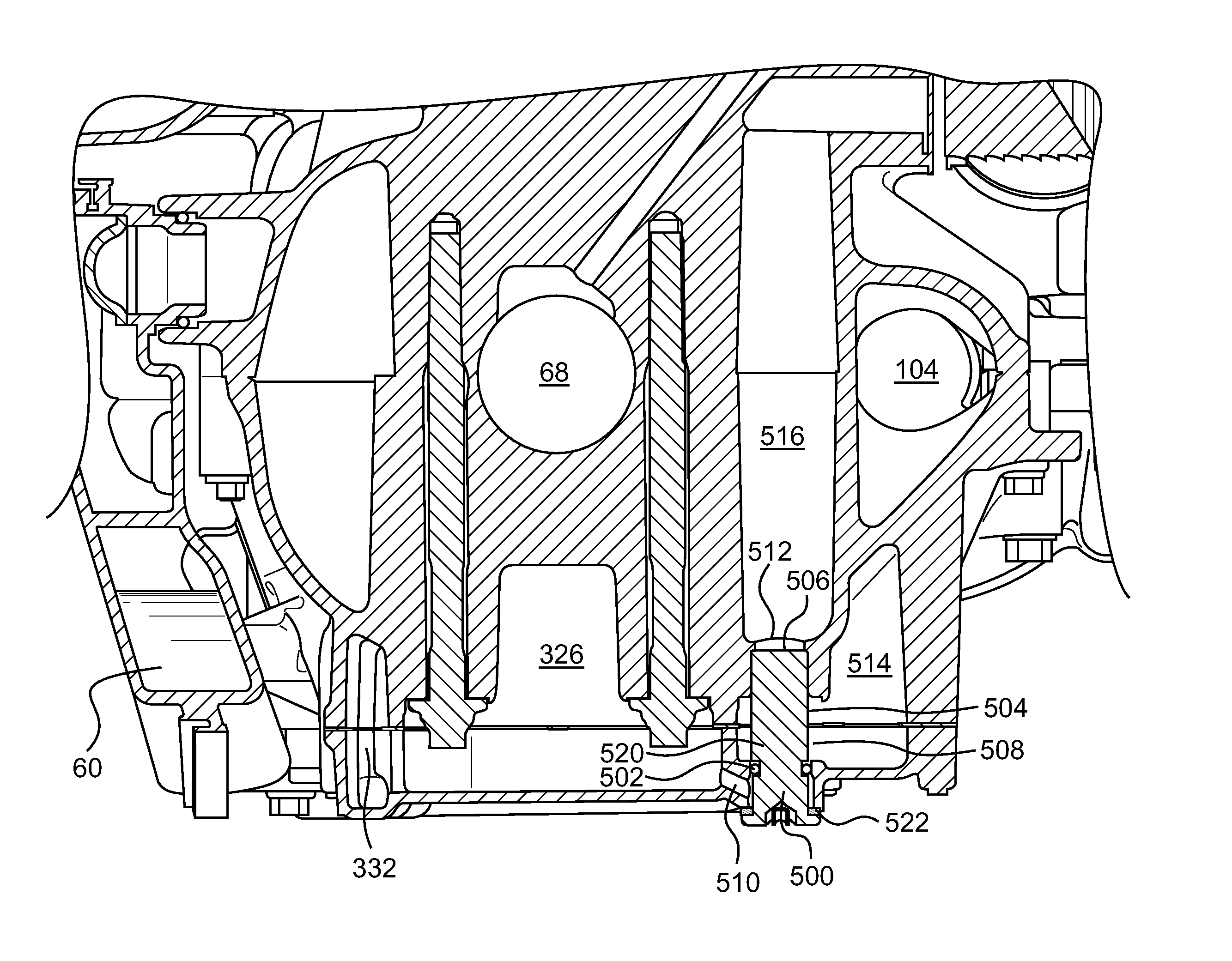

Lubrication system for a dry sump internal combustion engine

ActiveUS8464684B2Lubrication of auxillariesLubricant conduit arrangementsInternal combustion engineDry sump

An internal combustion engine (10) dry sump lubrication system including multiple oil paths through the engine, the engine being constructed and arranged such that when the engine is mounted on a vehicle and the vehicle is level and upright and the engine is not in operation, oil in each of the multiple oil paths collects at oil collection portions (3,26,514,516) within the engine, each oil collection portion being at a low portion with respect to gravity in one of the oil paths; a plurality of oil drainage openings (510,512,508) fluidly connected to the oil collection portions; and a single drain plug (500) simultaneously removeably sealing each of the oil drainage openings, whereby substantially all of the oil in the system is drained from the system when the single drain plug is removed.

Owner:BRP ROTAX

Drivetrain and method for lubricating bearing in wind turbine

A drivetrain for a wind turbine and a method for lubricating a bearing in a drivetrain of a wind turbine are disclosed. The drivetrain includes a rotatable component and a bearing surrounding the rotatable component. The drivetrain further includes a lubrication passage in fluid communication with the bearing for providing lubrication fluid thereto, and a drainage passage in fluid communication with the bearing for removing lubrication fluid therefrom. Further, the drivetrain includes a dry sump in fluid communication with the drainage passage. The dry sump includes a pump operable to flow lubrication fluid from the drainage passage.

Owner:GENERAL ELECTRIC CO

Oil tank for dry sump engines

ActiveUS20060124099A1Reduce trafficReduce resistanceLiquid degasificationLubrication of auxillariesDry sumpWaste management

An oil tank for a dry sump engine has a housing having an upper region and a lower region in which the oil is contained. The lower region has an oil outlet to feed a pump which supplies oil to the engine. The upper region houses a swirl tube connected to an oil inlet for air to separate from the incoming oil. The upper region includes an air outlet and is provided with two dished baffle plates each shaped to form a collector area which slopes towards the swirl tube in order to reduce droplets of condensation formed in the upper region flowing into the lower region. The wall of the swirl tube is heated by the incoming oil to promote vaporisation of droplets of condensation collected in the collector area.

Owner:ASTON MARTIN LAGONDA LIMITED

Dry sump oil tank assembly for a vehicle

InactiveUS8028672B2Increase volumeIncrease the internal volumeLubrication of auxillariesLubricant conduit arrangementsDry sumpAutomotive engineering

A dry sump oil tank assembly for a vehicle is provided with a housing defining an internal cavity. The housing is configured with a laterally-extending portion to add lateral volume to the internal cavity and has at least one internal baffle attached to the housing within the internal cavity below the laterally-extending portion and configured to reduce sloshing of oil within the cavity. The dry sump oil tank assembly is particularly useful for high performance applications, such as racing vehicles, and may utilize components from standard vehicle applications, thus maximizing the economies of scale of producing such components and being suited for a vehicle that may be typically used in standard driving conditions, but occasionally subjected to high performance use.

Owner:GM GLOBAL TECH OPERATIONS LLC

Gear unit with improved lubricant supply

InactiveUS9297454B2Reliable supplyLower energy requirementsGear lubrication/coolingOilsumpsGear wheelEngineering

In order to implement a reliable supply of lubricant to gear unit components during emergency or spinning operation of a gear unit, level control is provided in a lubricant sump of the gear unit as a function of the operating state by means of a control unit associated with a lubricant pump. During normal operation the level is adjusted to dry sump level. In contrast, the lubricant pump is switched off in emergency or spinning operation, so that a splash lubrication level is automatically achieved in the lubricant sump.

Owner:SIEMENS AG

Light turbo compound engine variant

ActiveUS8683987B2Internal combustion piston enginesExhaust apparatusCycle controlExternal combustion engine

Owner:R&D MACHMA

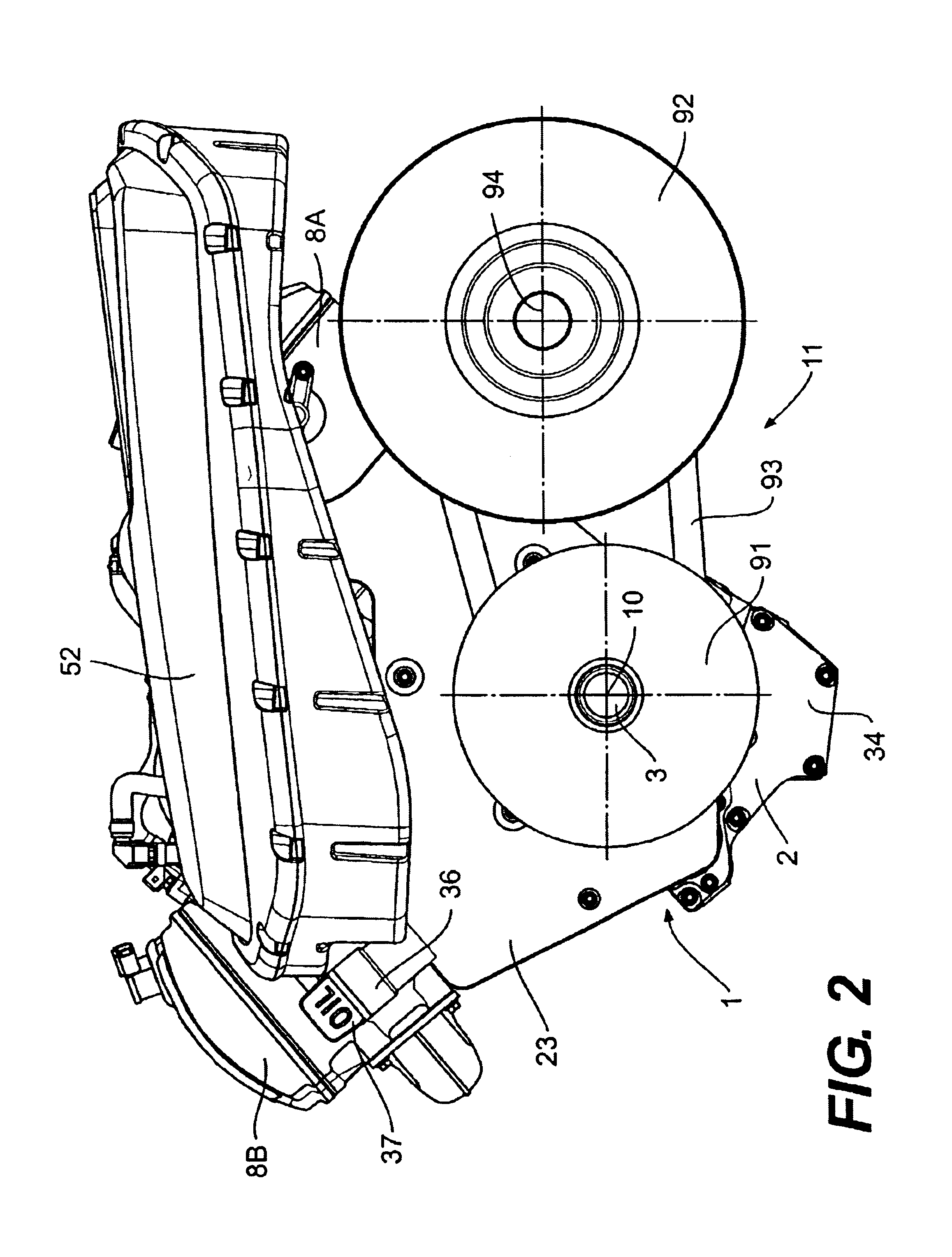

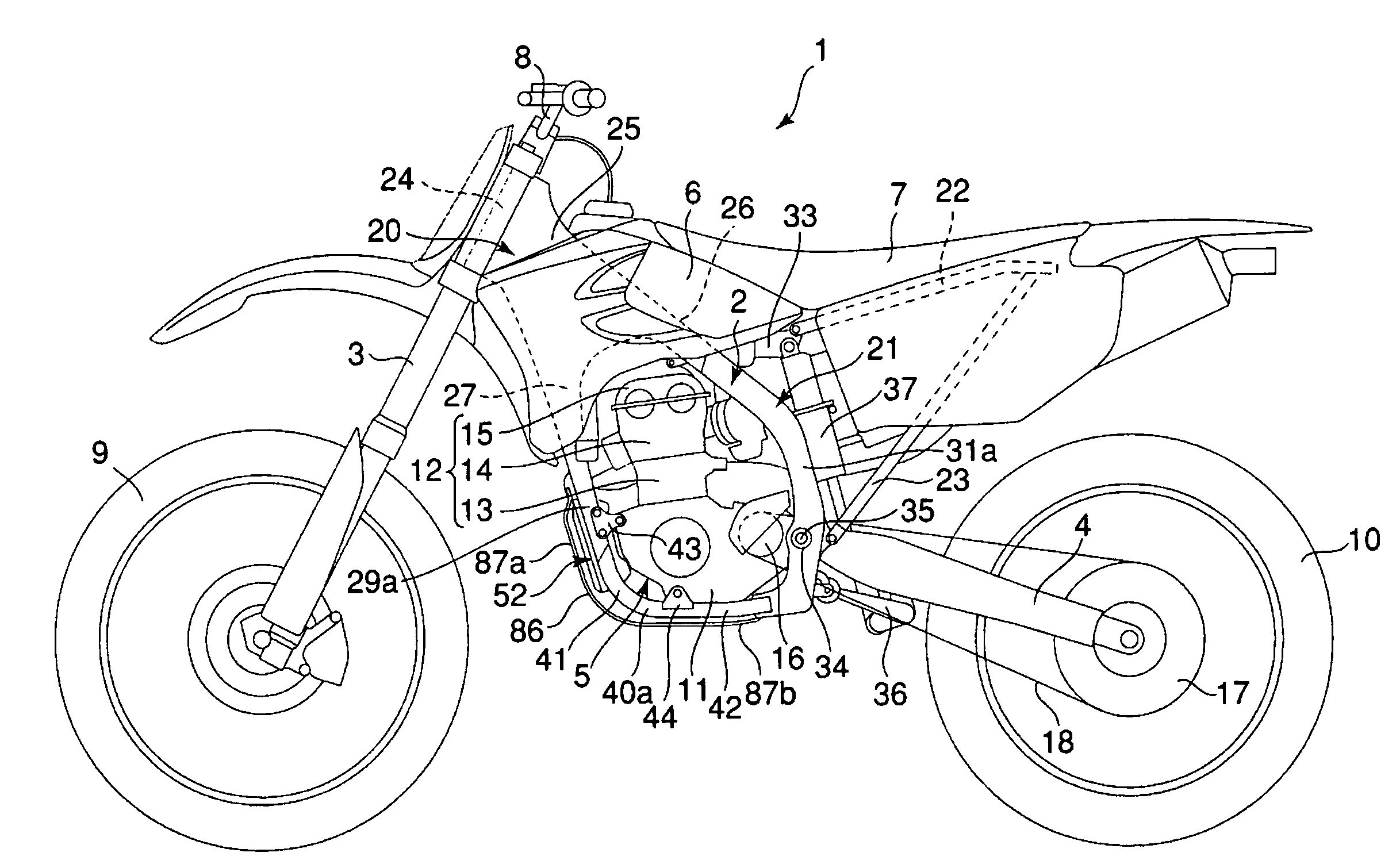

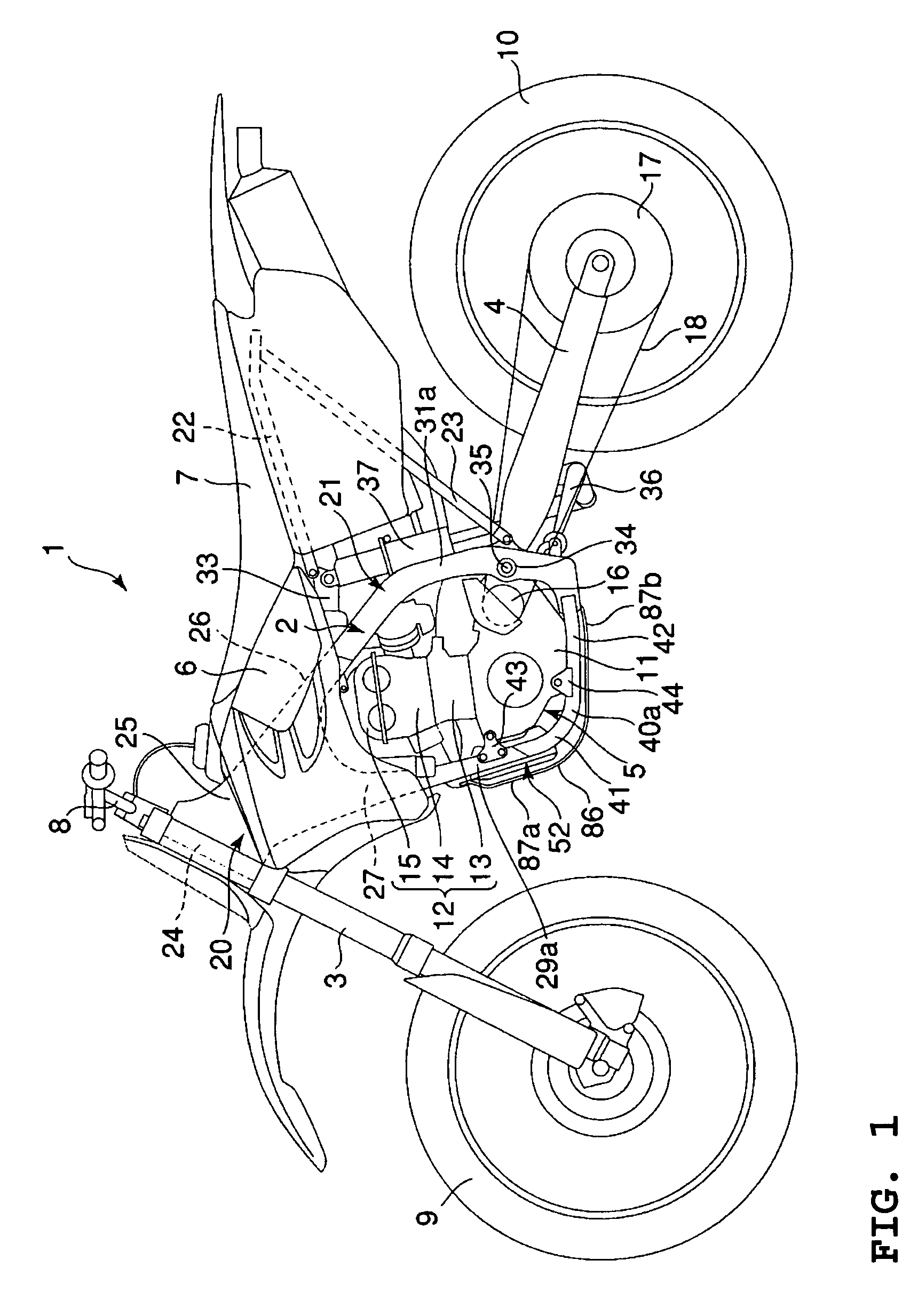

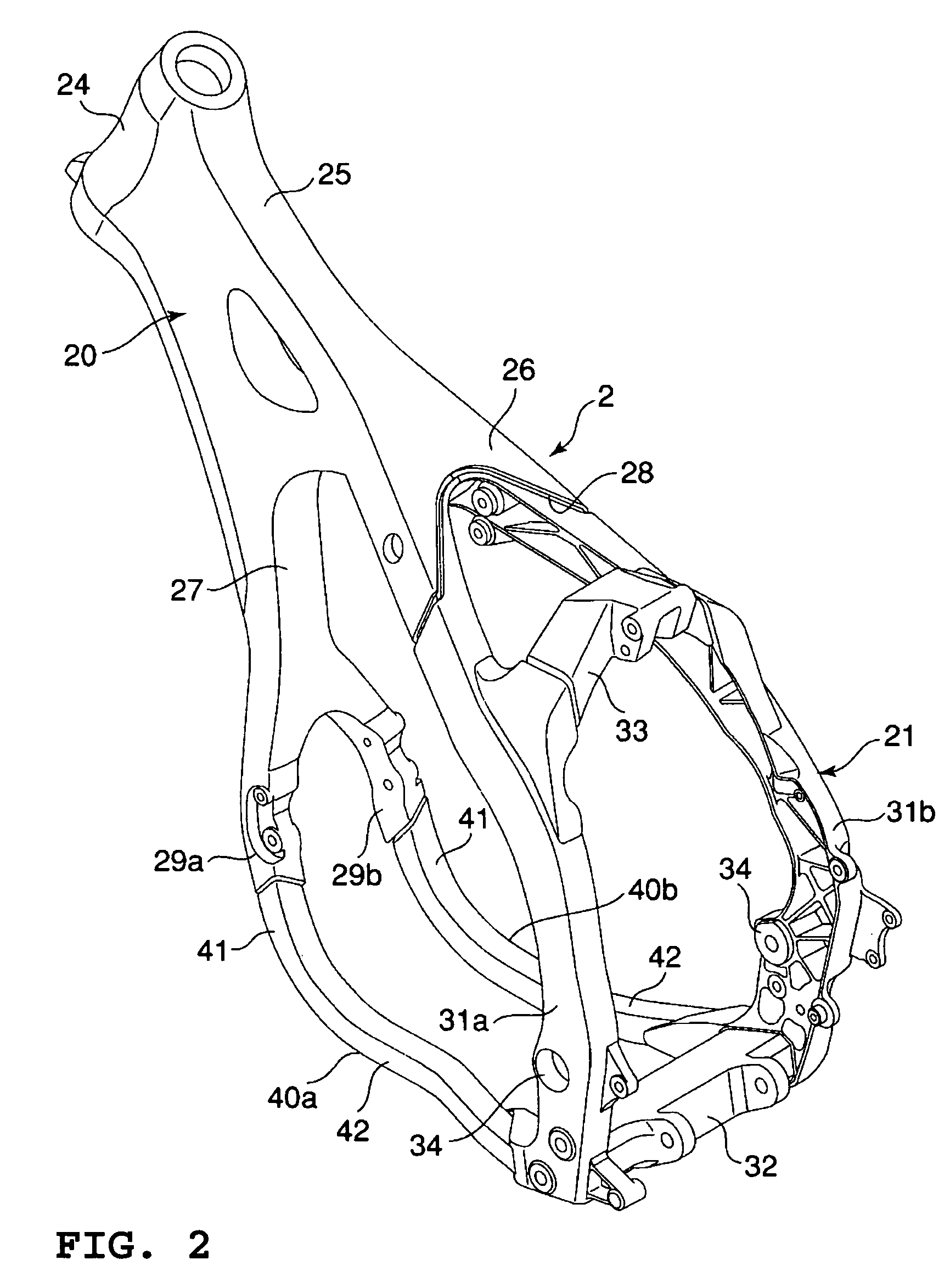

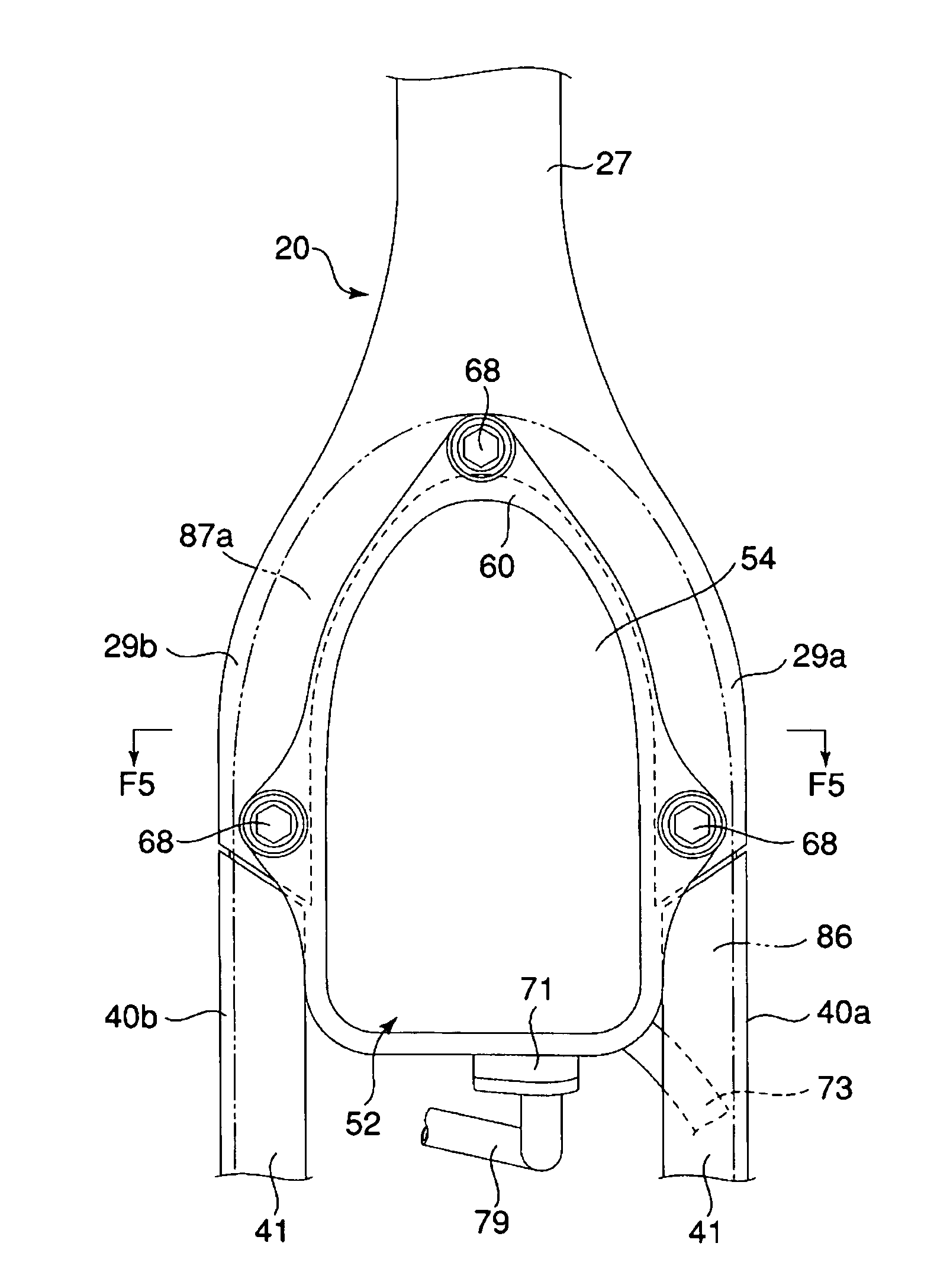

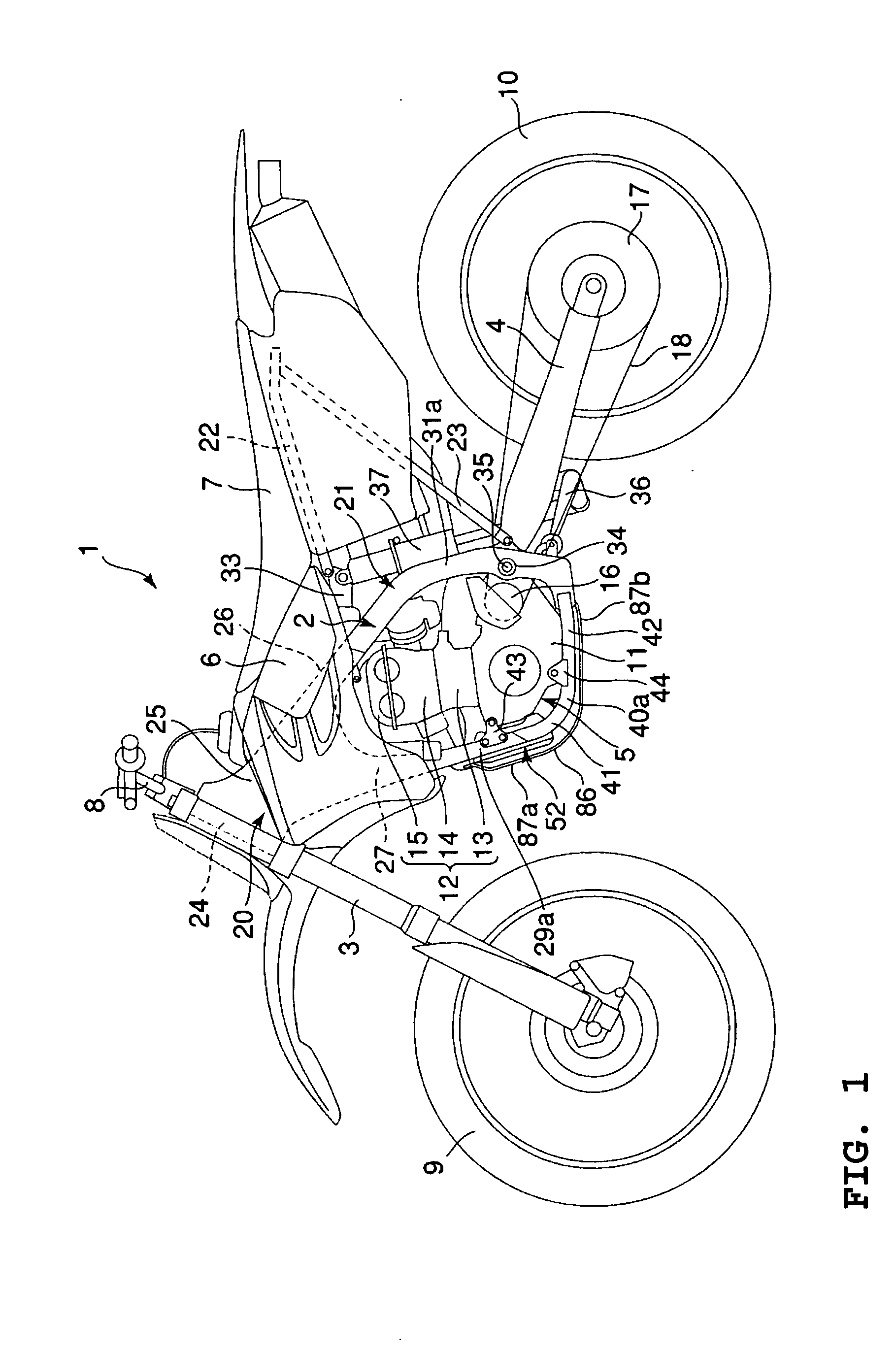

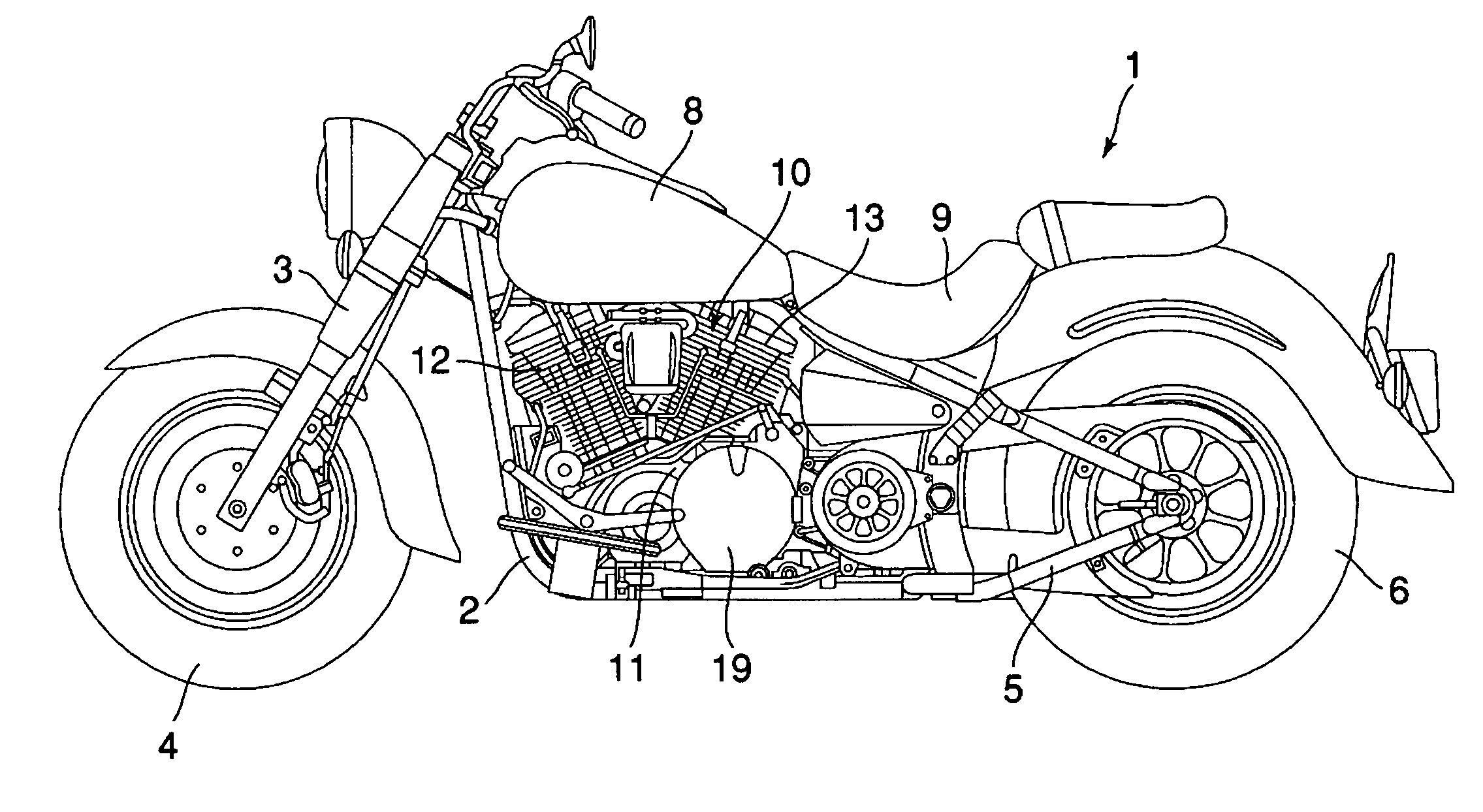

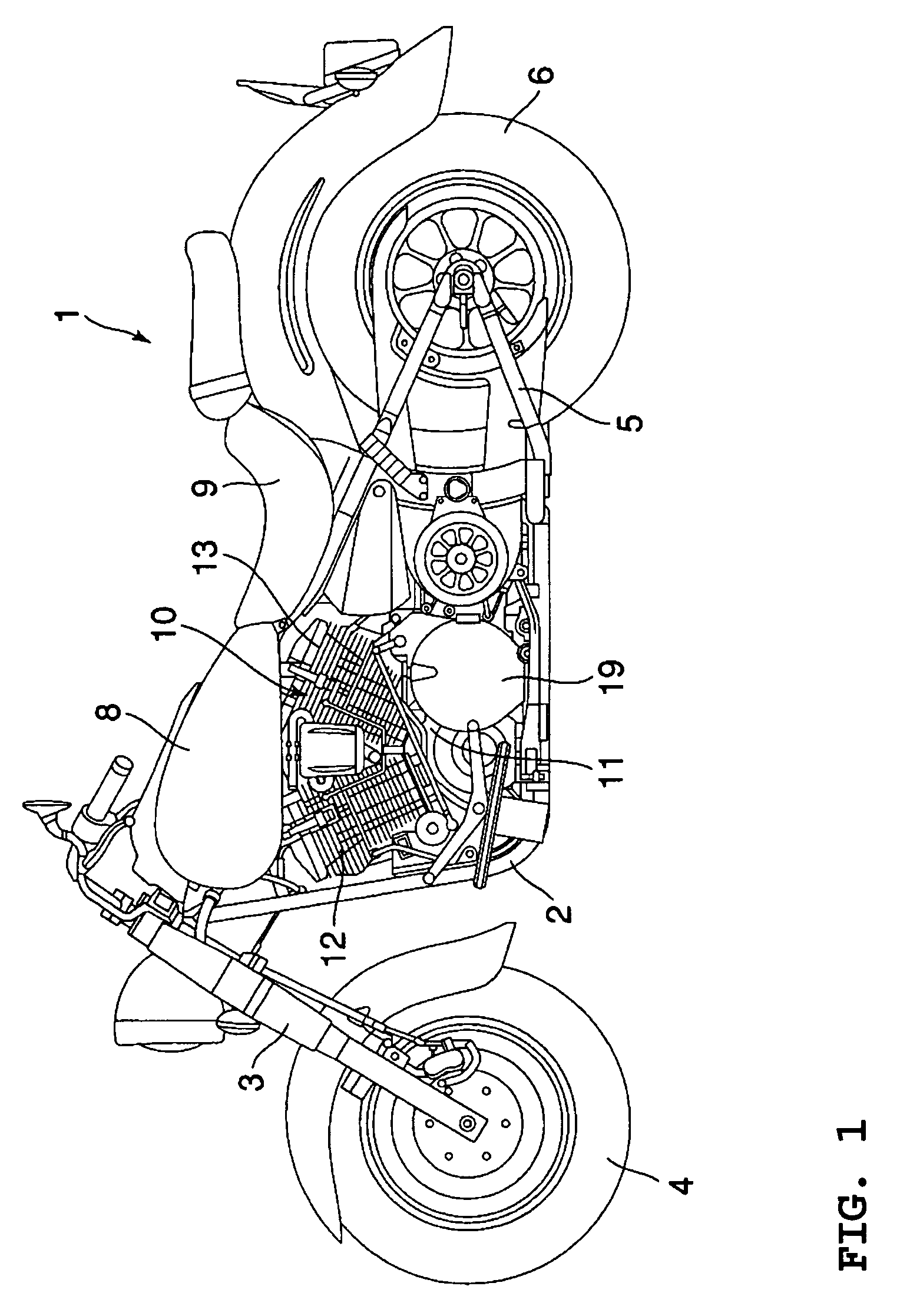

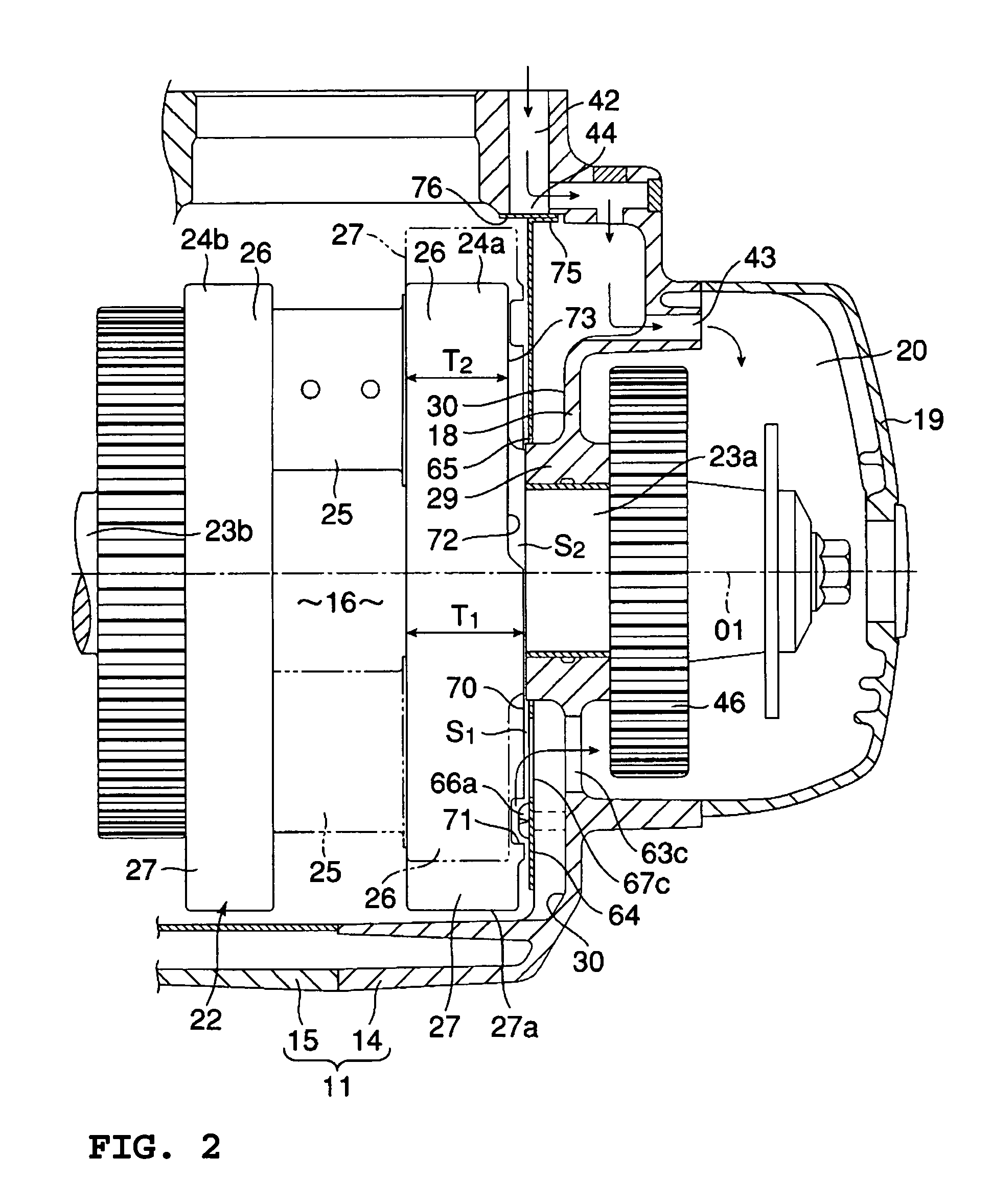

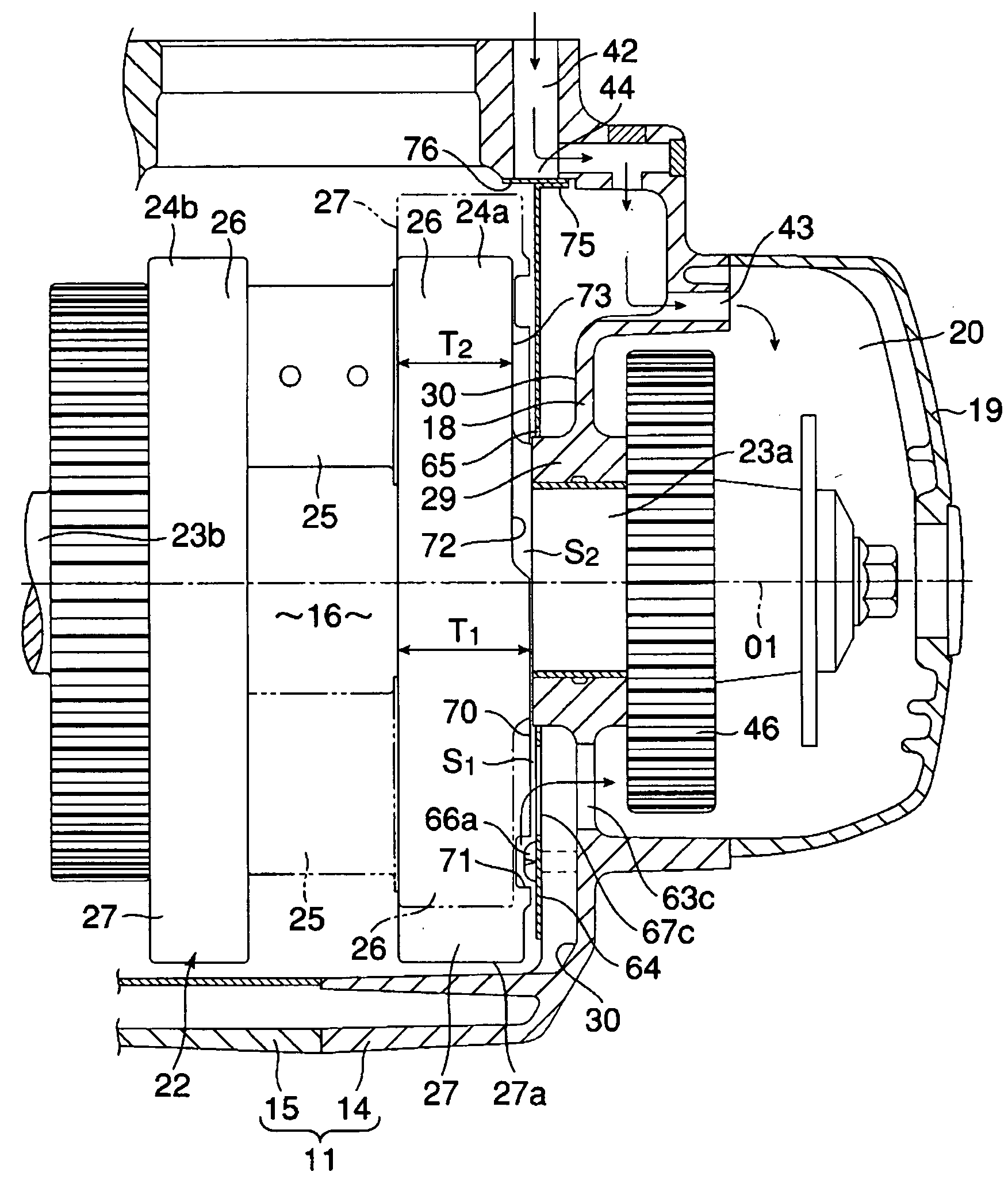

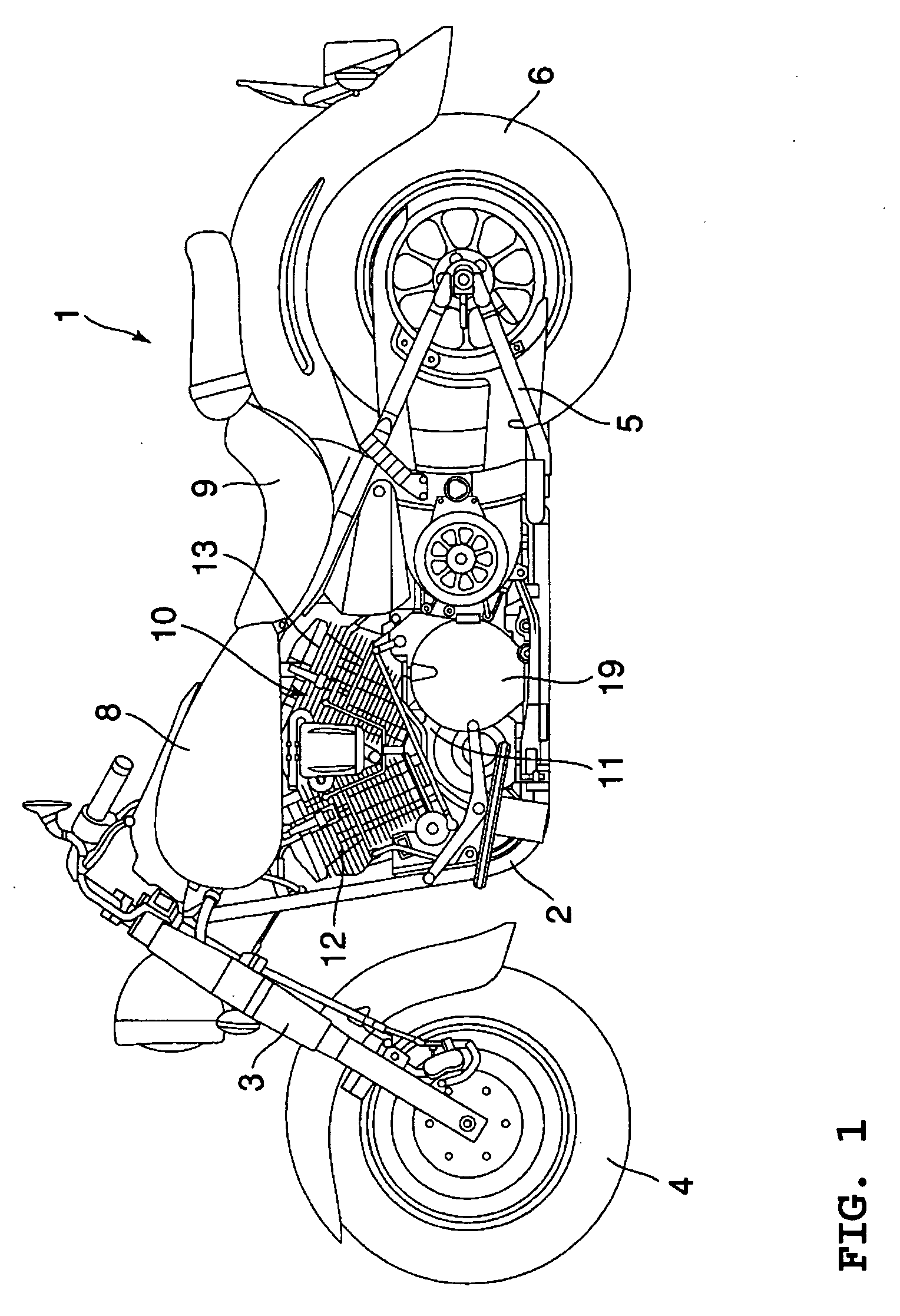

Dry sump type lubrication device for a motorcycle

InactiveUS7171938B2Increase pressureAvoid damageLubrication of auxillariesCycle equipmentsFuel tankFour-stroke engine

A dry sump type lubrication device for a motorcycle includes a four stroke engine having, in a crankcase bottom, a first oil pump for collecting lubricating oil and a second oil pump for delivering lubricating oil. A frame supporting the four-stroke engine and having left and right down tubes running around the crankcase from the crankcase front thereof toward a region therebelow is provided. An oil tank is disposed in a region surrounded by a forward end of the crankcase and the left and right down tubes, a return passage for the lubricating oil collected by the first oil pump to be returned to the oil tank. A feed passage for the lubricating oil returned to the oil tank to be introduced into the second oil pump and an overflow passage for the lubricating oil in the oil tank to be returned to the four-stroke engine are also provided.

Owner:YAMAHA MOTOR CO LTD

Dry sump type lubrication device for a motorcycle

InactiveUS20050217631A1Increased tank pressureAvoid damageLubrication of auxillariesCycle equipmentsFuel tankFour-stroke engine

A dry sump type lubrication device for a motorcycle includes a four stroke engine having, in a crankcase bottom, a first oil pump for collecting lubricating oil and a second oil pump for delivering lubricating oil. A frame supporting the four-stroke engine and having left and right down tubes running around the crankcase from the crankcase front thereof toward a region therebelow is provided. An oil tank is disposed in a region surrounded by a forward end of the crankcase and the left and right down tubes, a return passage for the lubricating oil collected by the first oil pump to be returned to the oil tank. A feed passage for the lubricating oil returned to the oil tank to be introduced into the second oil pump and an overflow passage for the lubricating oil in the oil tank to be returned to the four-stroke engine are also provided.

Owner:YAMAHA MOTOR CO LTD

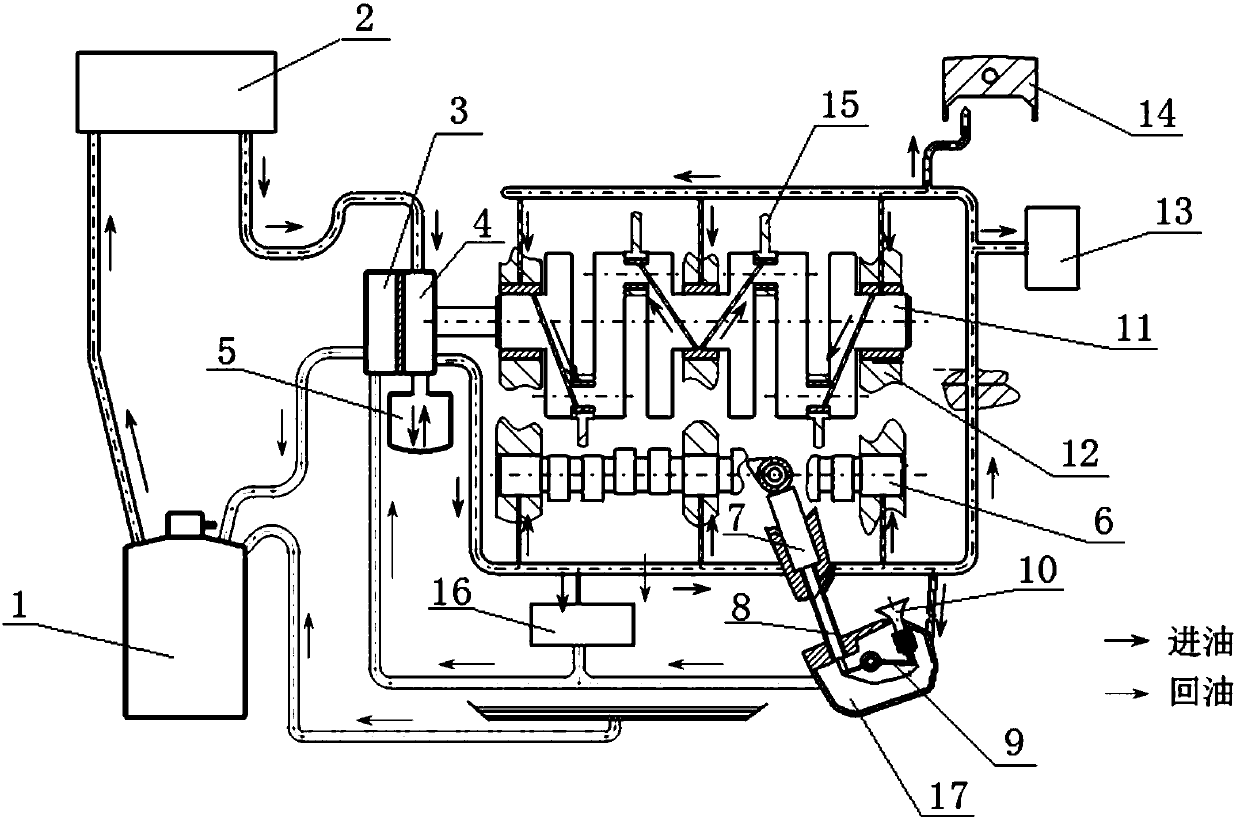

Engine lubricating system and engine

PendingCN107559063AReduce weightSimple structureMachines/enginesLubricant mounting/connectionFuel tankDry sump

The invention discloses an engine lubricating system and an engine. The engine lubricating system comprises two parts, namely oil suction part and oil return part; the oil suction part comprises a lubricating oil tank, an air cooling oil cooler and a main oil pump which are connected in sequence, the main oil pump sucks the lubricating oil in the lubricating oil tank into the air cooling oil cooler to be cooled under the driving of a crankshaft, and the cooled lubricating oil enters the main oil passage under the action of the main oil pump; the oil return part comprises two parts, the first part is as follow: the lubricating oil entering a piston cooling nozzle, a main bearing, a camshaft bearing and an accessory system flows back to a dry-type oil sump under the action of gravity, and the lubricating flowing back to the dry-type oil sump is pressed back to the lubricating oil tank under the action of the air pressure of a crankcase; and the second part is as follow: the lubricating oil entering a supercharger and a valve cover of the air valve is sucked back to the lubricating oil tank under the action of an oil return pump and through an external oil return pipe. According to the engine lubricating system and the engine, the oil can be directly taken out from the lubricating oil tank by a lubricating oil pump, the situation that the oil cannot be sucked is avoided, limitation on the flying angle of a aircraft is small, the aircraft can do more actions, and flight performance is improved.

Owner:芜湖钻石航空发动机有限公司

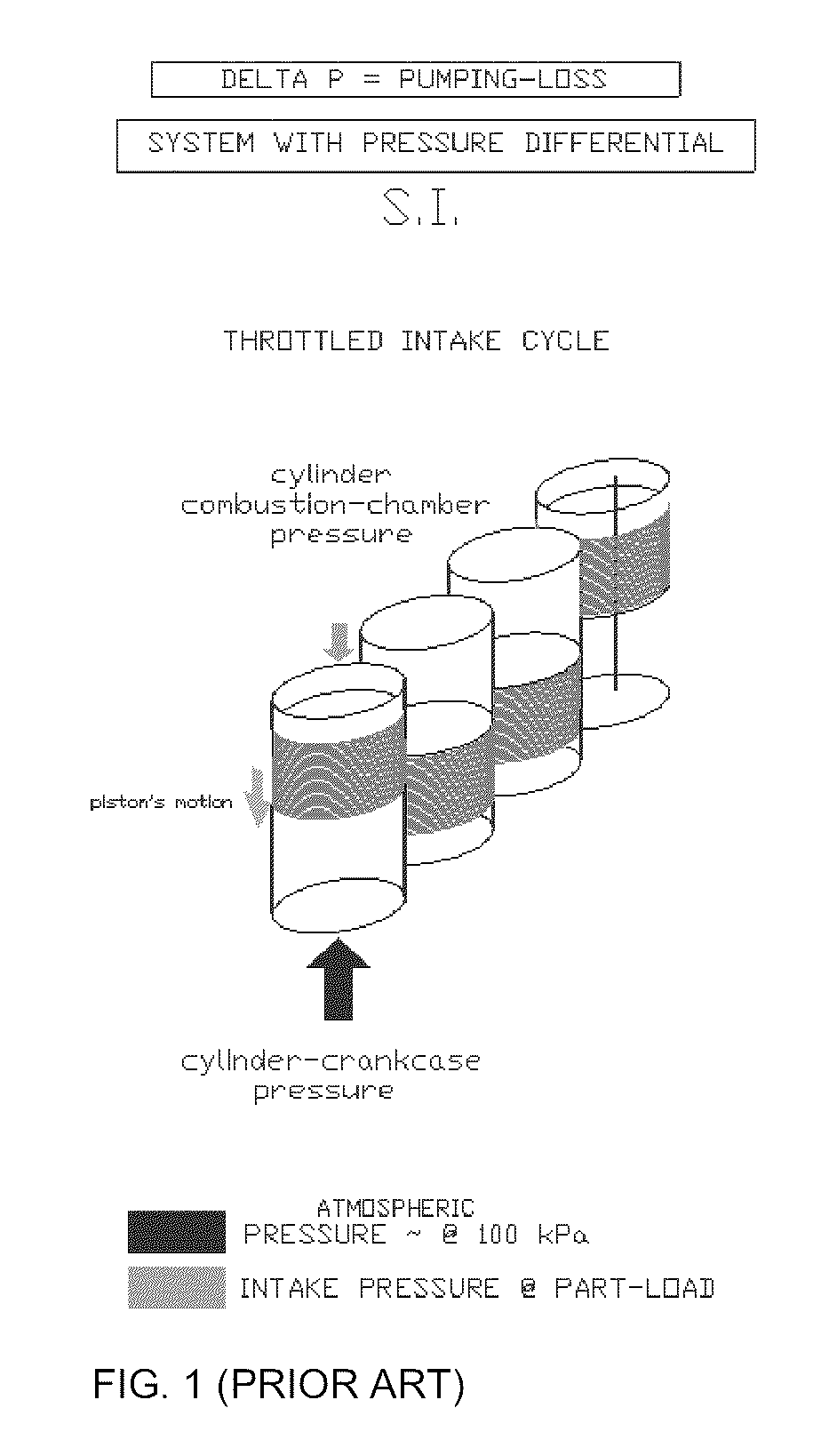

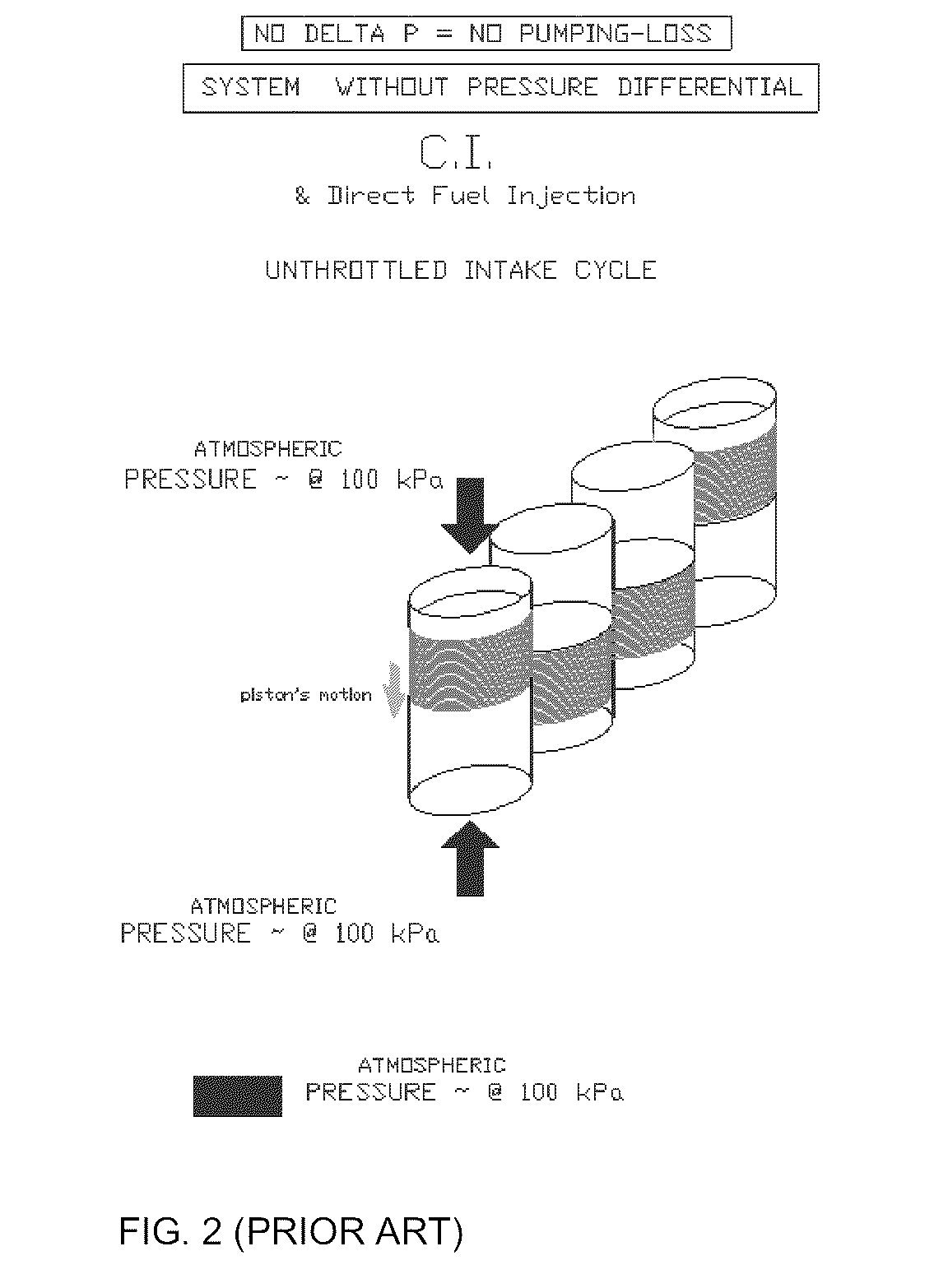

Dry-sump, four-stroke engine lubrication device

ActiveUS7013860B2Suppress pressure fluctuationsPumping loss is reducedLubrication of auxillariesLubricant conduit arrangementsTop dead centerReciprocating motion

Owner:YAMAHA MOTOR CO LTD

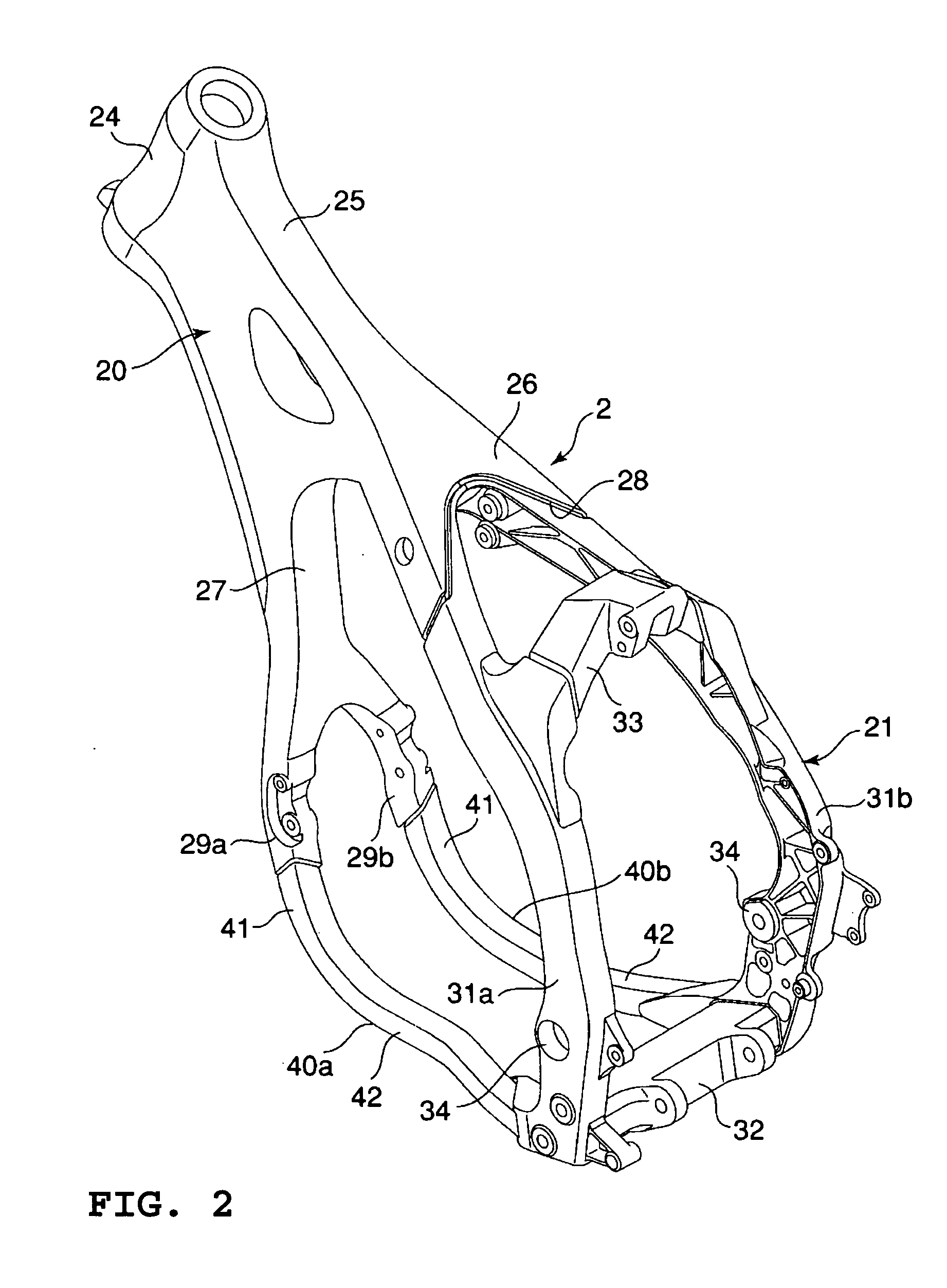

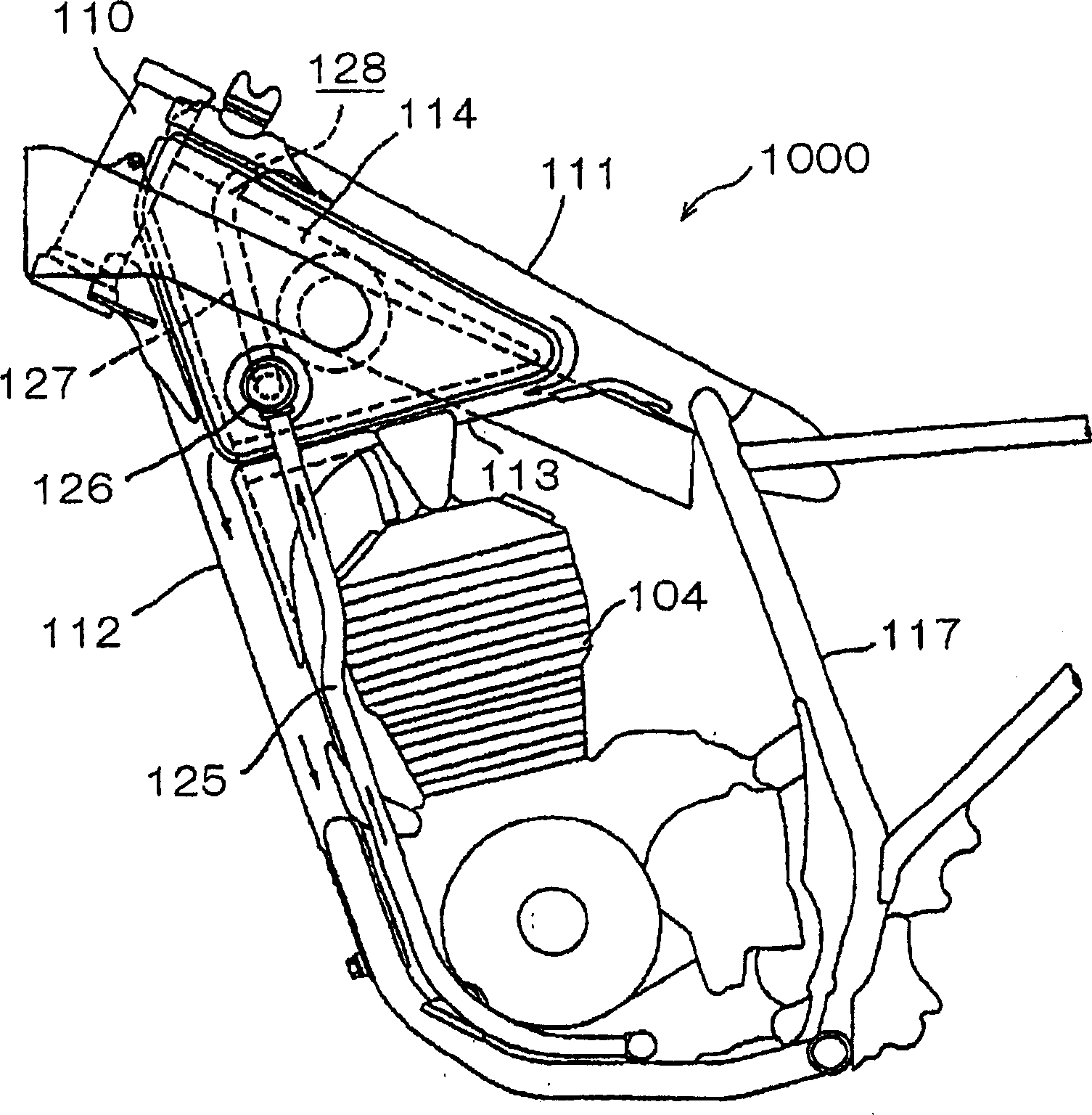

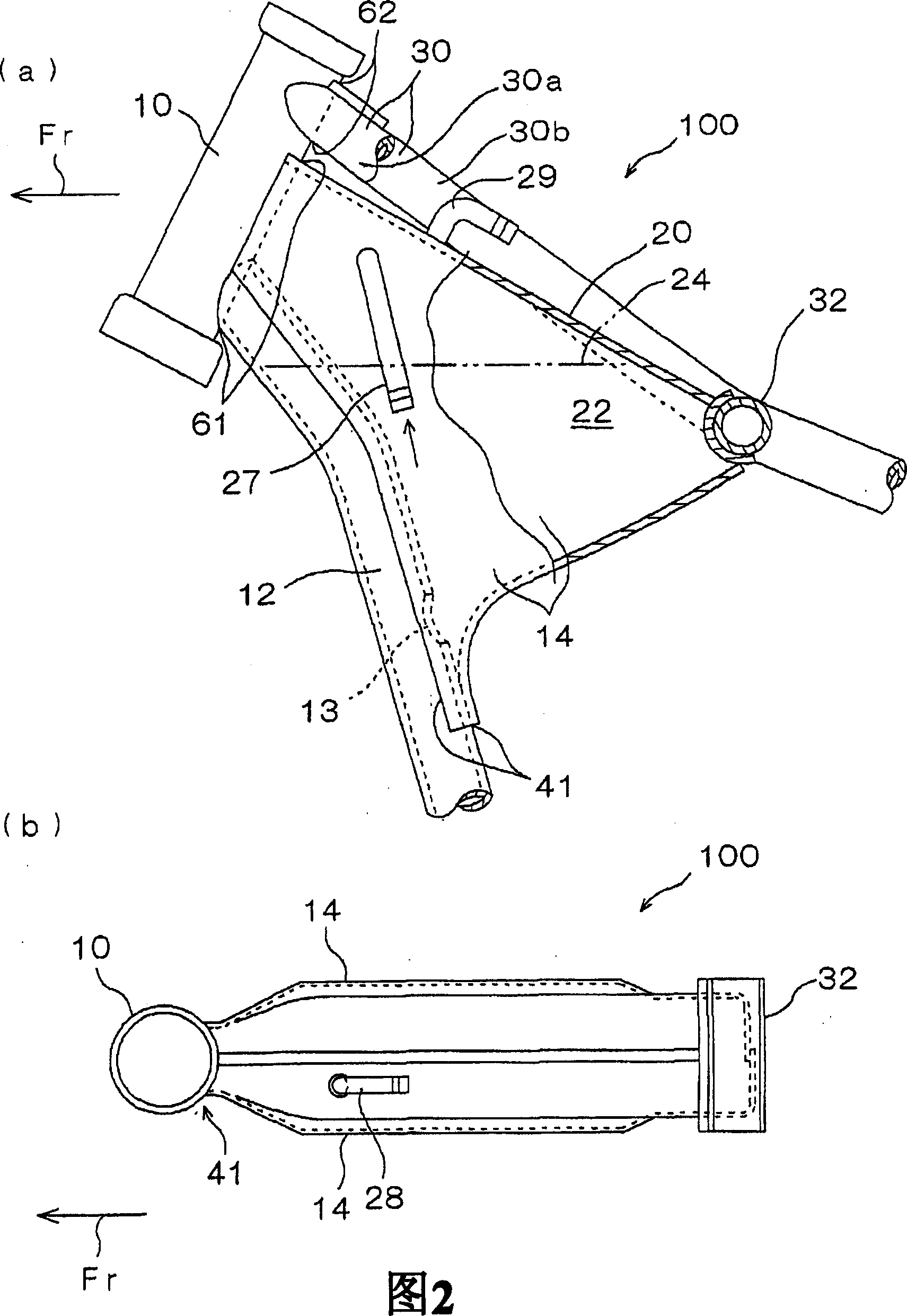

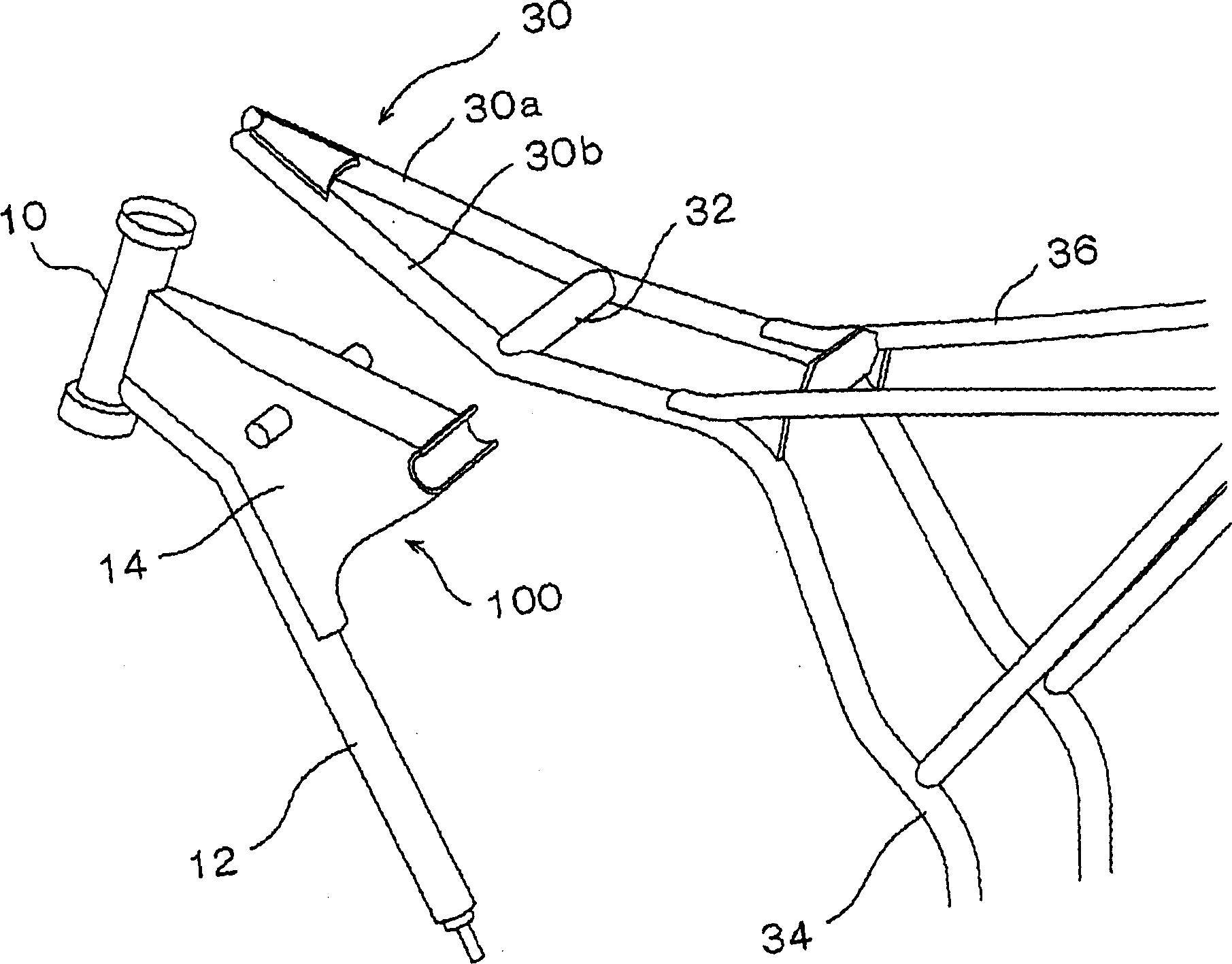

Method of manufacturing motorcycle and tank-in frame of motorcycle

A method for manufacturing a motor cycle that adopts a dry sump system as a lubricating system and includes a tank in frame utilizing a portion of a vehicle body frame, the method includes steps of (a) forming an oil tank assembly 100 from a head pipe 10, a down tube 12 and a gusset 14, (b) carrying out a leakage test of a space defined by the head pipe 10, the down tube 12 and the gusset 14, and (c) connecting a main frame to the head pipe of the oil tank assembly after the step (b), the main frame extending rearward from the head pipe. <IMAGE>

Owner:YAMAHA MOTOR CO LTD

Dry-sump, four-stroke engine lubrication device

ActiveUS20050011483A1Suppress pressure fluctuationsPumping loss is reducedLubrication of auxillariesLubricant conduit arrangementsTop dead centerReciprocating motion

A lubrication device for a dry-sump, four-stroke engine includes a crankcase having a divider wall, a crank chamber and a separate adjoining chamber with the divider wall interposed in between the crank chamber and separate chamber. A crankshaft is housed in the crank chamber and is driven by the reciprocating movement of the pistons. A crank web faces the divider wall, and the divider wall has a through hole for connecting the crank chamber with the separate chamber, and is opened by the crank web when the piston moves from a top dead center position toward a bottom dead center position, and is closed by the crank web when the piston moves from the bottom dead center toward the top dead center position. A return hole connects the crank chamber and the separate chamber, for returning lubricant oil that flowed by way of the through hole into the separate chamber from the crank chamber, back to the crank chamber by utilizing pressure fluctuations within the crank chamber.

Owner:YAMAHA MOTOR CO LTD

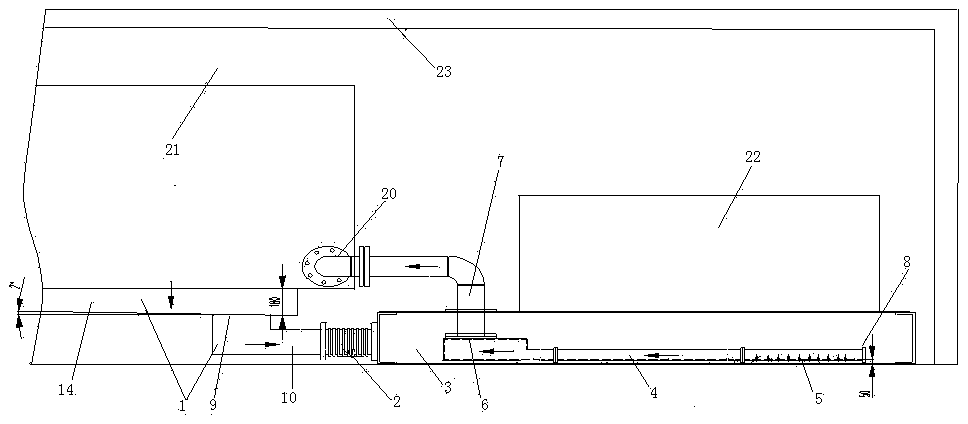

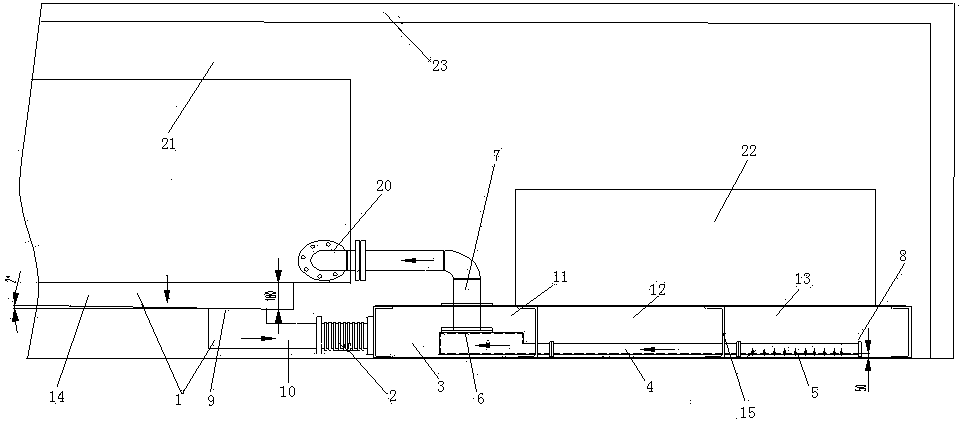

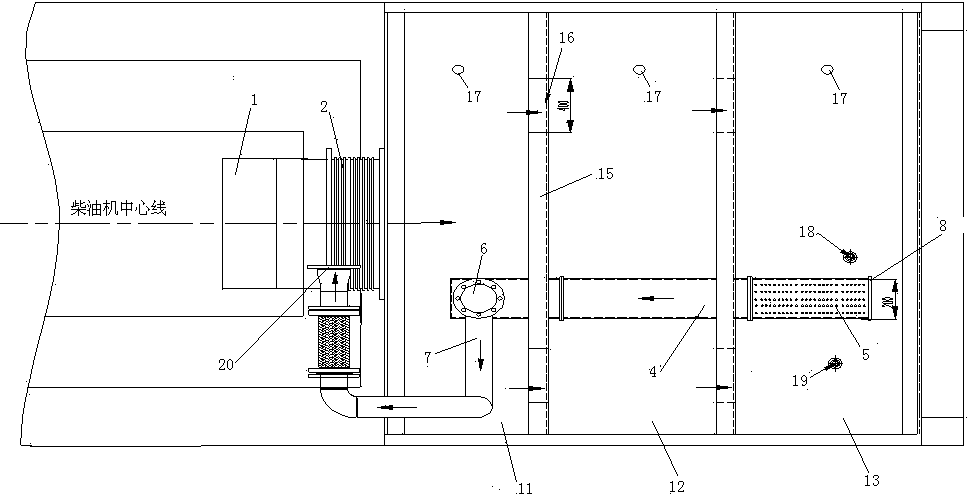

Lubrication oil tank of large-power box type diesel generating set

ActiveCN103867255ACompact structureReasonable arrangementMachines/enginesEngine lubricationDieselingDiesel generator

The invention belongs to the field of diesel engine oil systems and particularly relates to a lubrication oil tank of a large-power box type diesel generating set. The lubrication oil tank comprises a lubrication oil tank body and a main engine oil pump. The lubrication oil tank is characterized in that the lubrication oil tank body is composed of a dry type oil bottom shell, a square corrugated pipe and a secondary oil tank, wherein the dry type oil bottom shell is composed of a shell body of the dry type oil bottom shell and an oil returning opening of the dry type oil bottom shell; one end of the square corrugated pipe is connected with the oil returning opening of the dry type oil bottom shell and the other end of the square corrugated pipe is connected with the secondary oil tank so that the secondary oil tank and the secondary oil tank are connected to form a whole body; an oil suction pipe of the main engine oil pump, an oil suction opening of the main engine oil pump and an oil returning opening of the main engine oil pump are arranged in the secondary oil tank; one part of the oil suction pipe of the main engine oil pump is arranged in the secondary oil tank and is connected with the oil suction opening of the main engine oil pump by the oil returning opening of the main engine oil pump; the other part of the oil suction pipe of the main engine oil pump penetrates out of the secondary oil tank to be arranged outsides to be connected with other devices of the generating set. The lubrication oil tank of the large-power box type diesel generating set is compact in structure, reasonable in arrangement and good in engine oil cycling performance; the oil storage volume is large; the box type diesel generating set is convenient to move, low in investment cost, low in noises and the like.

Owner:SICHUAN CRRC YUCHAI ENGINE CO LTD

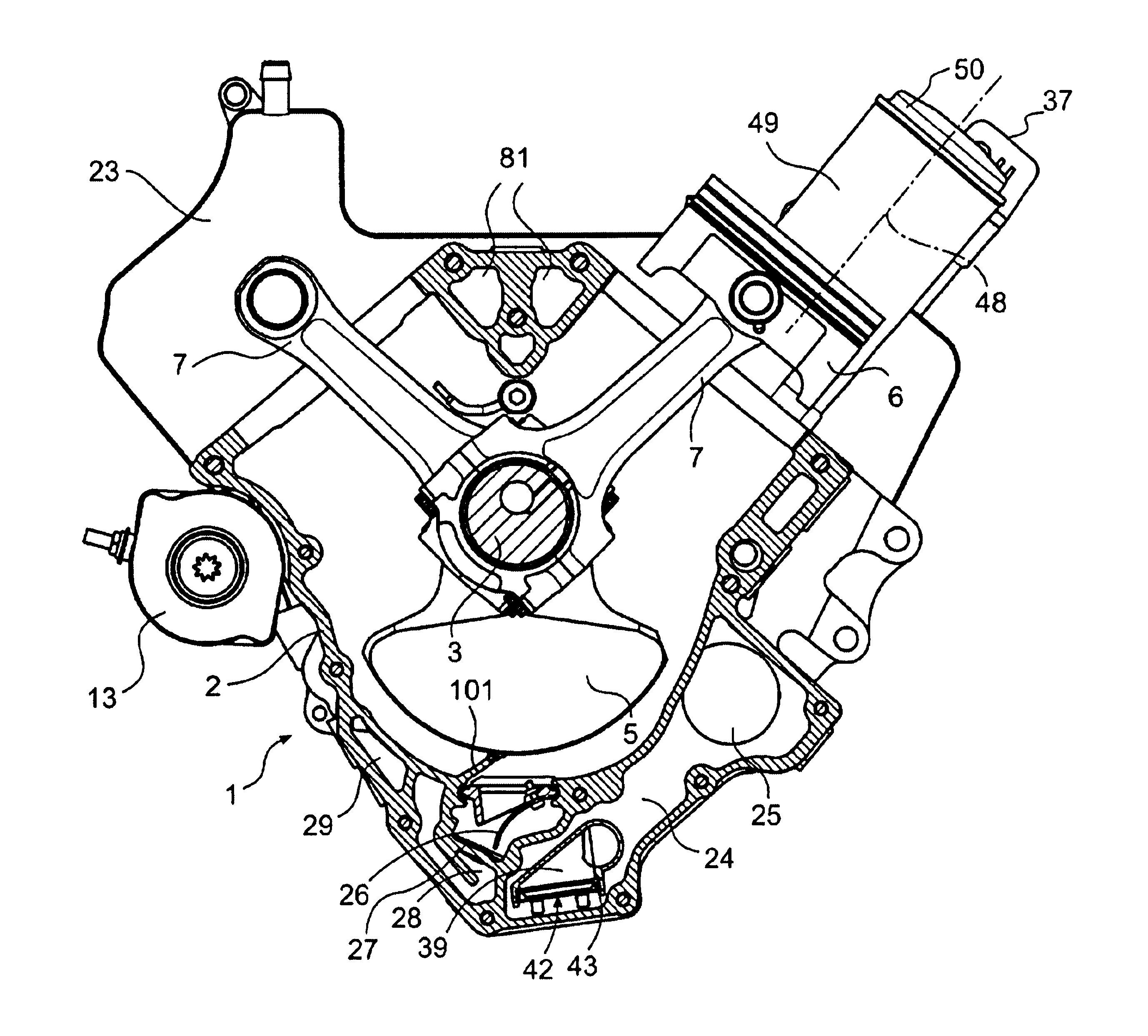

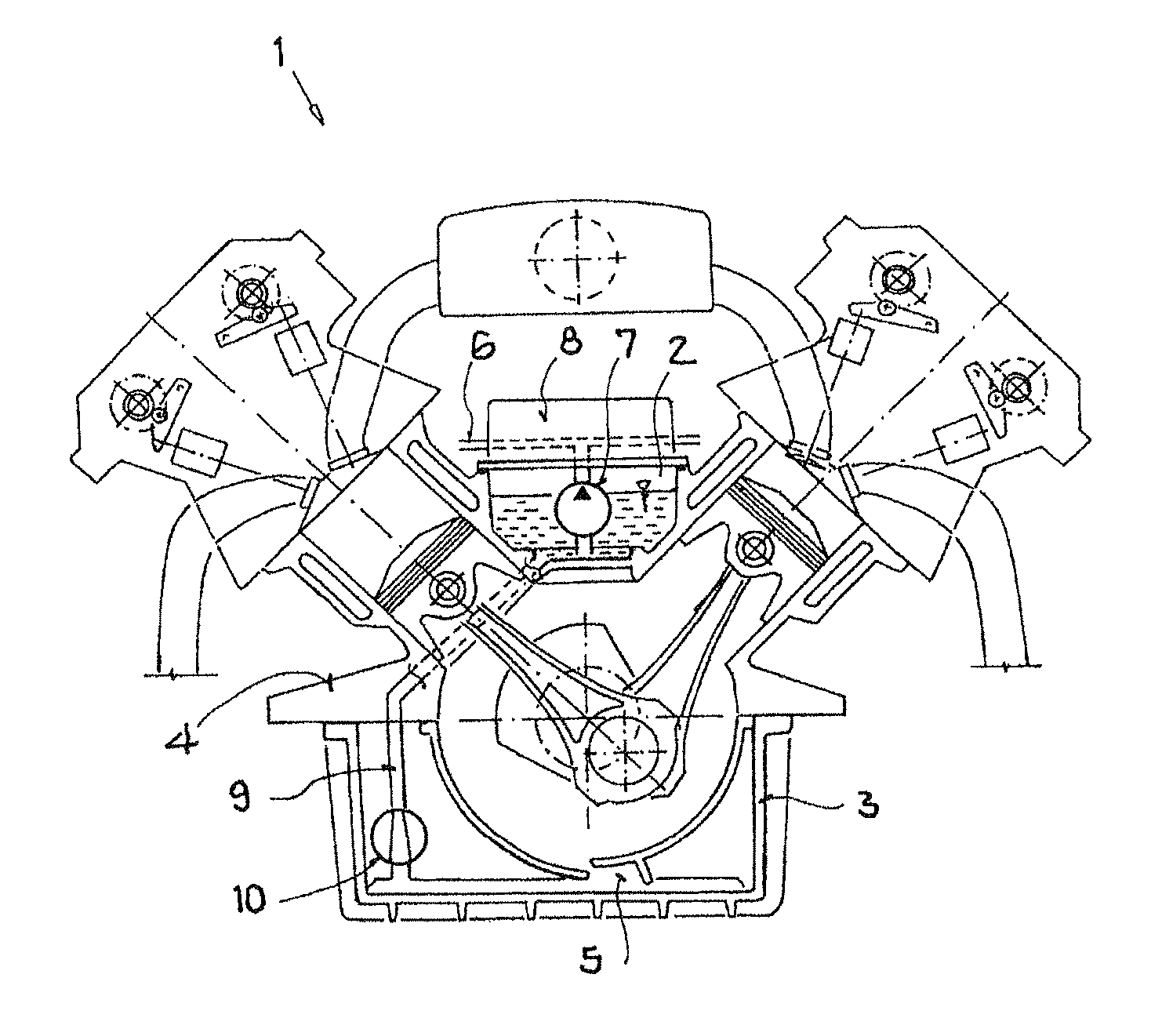

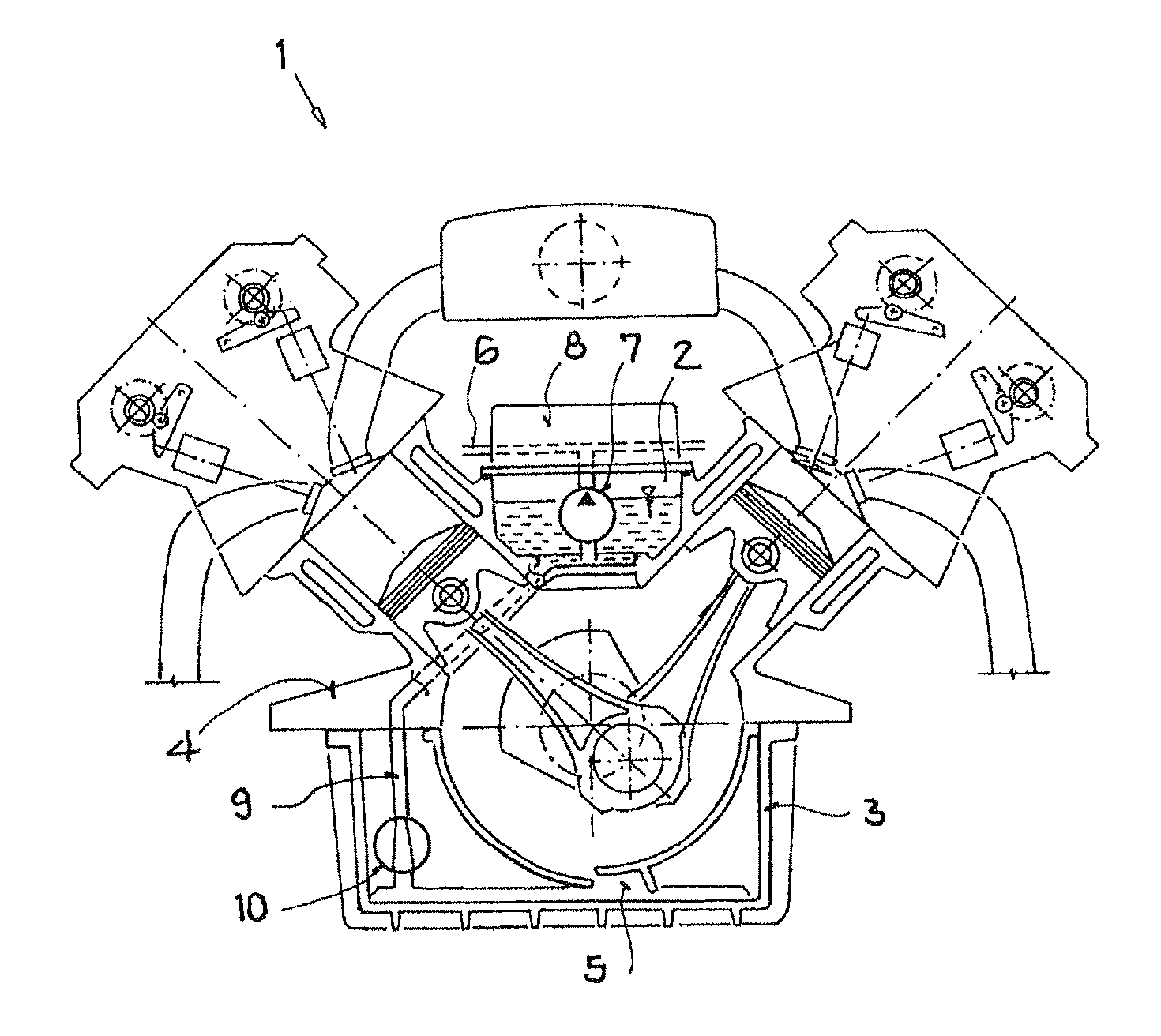

Internal combustion engine having a cylinder crankcase and a V-shaped cylinder configuration

ActiveUS8156905B2Replacement costAdditional costs in the casting of the cylinder crankcase are minimalCasingsLubrication of auxillariesExternal combustion engineDry sump

An internal combustion engine having a cylinder crankcase and a v-shaped cylinder configuration and having a lubricant circuit which operates according to the dry sump principle and has a lubricant reservoir, wherein the lubricant reservoir is located within the cylinder crankcase in the space between the cylinders.

Owner:AUDI AG

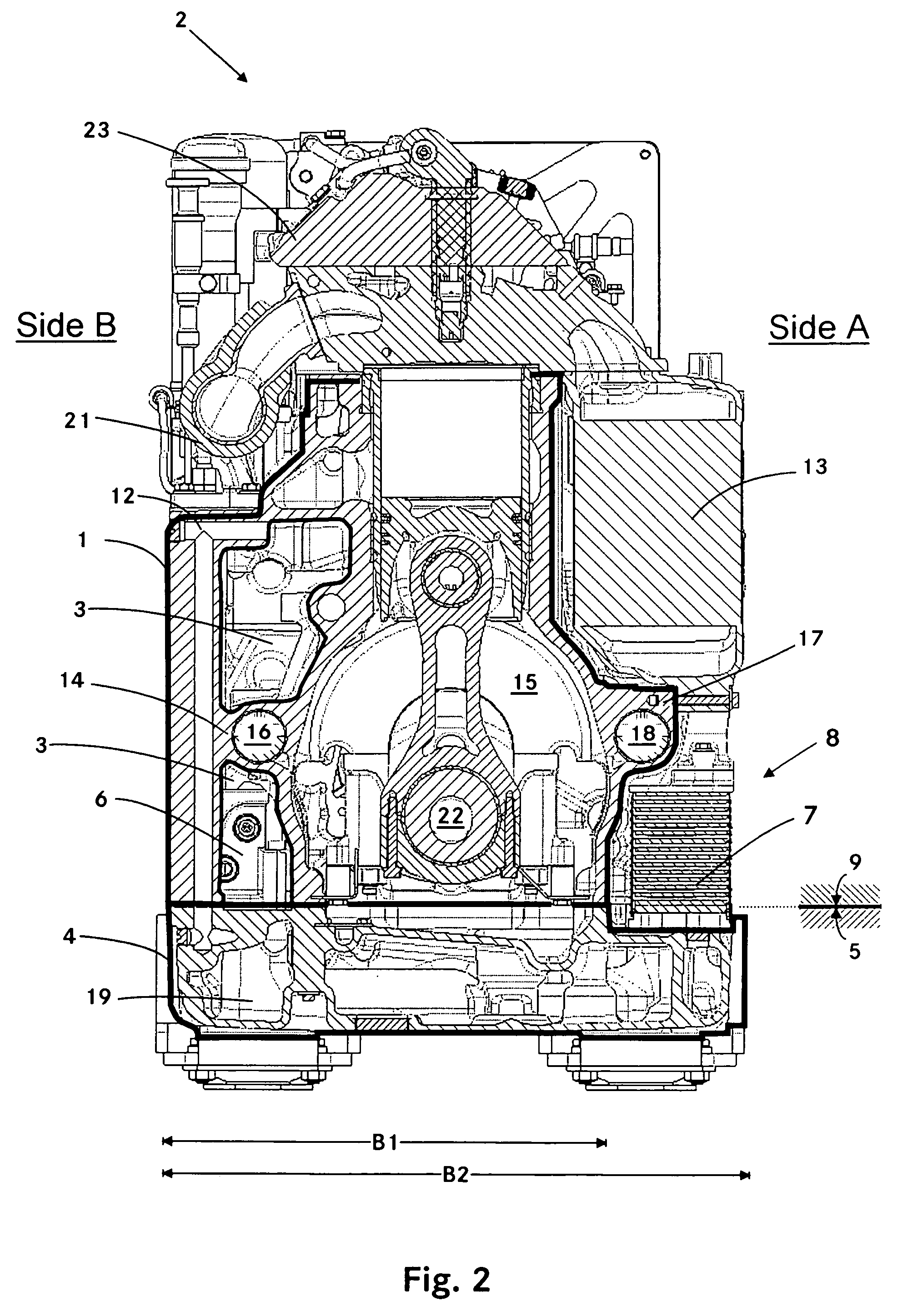

Crankcase with bottom plate

ActiveUS7267093B2Inhibition releaseOperational securityCasingsLubrication of auxillariesEngineeringDry sump

In a crankcase for an internal combustion engine, including a lubricant chamber for the collection of lubricant, and a bottom plate for providing dry sump lubrication closing the crankcase and being sealingly joined to the bottom end of the crankcase, wherein the crankcase includes auxiliary equipment comprising pumps for pumping lubricant into the lubricant chamber and from the lubricant chamber to various lubrication points, the bottom plate has a width exceeding the width of the crankcase so that it forms a section which is disposed outside the crankcase and auxiliary equipment is disposed on this section outside the crankcase.

Owner:ROLLS ROYCE SOLUTIONS GMBH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com