Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

513 results about "Leak testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

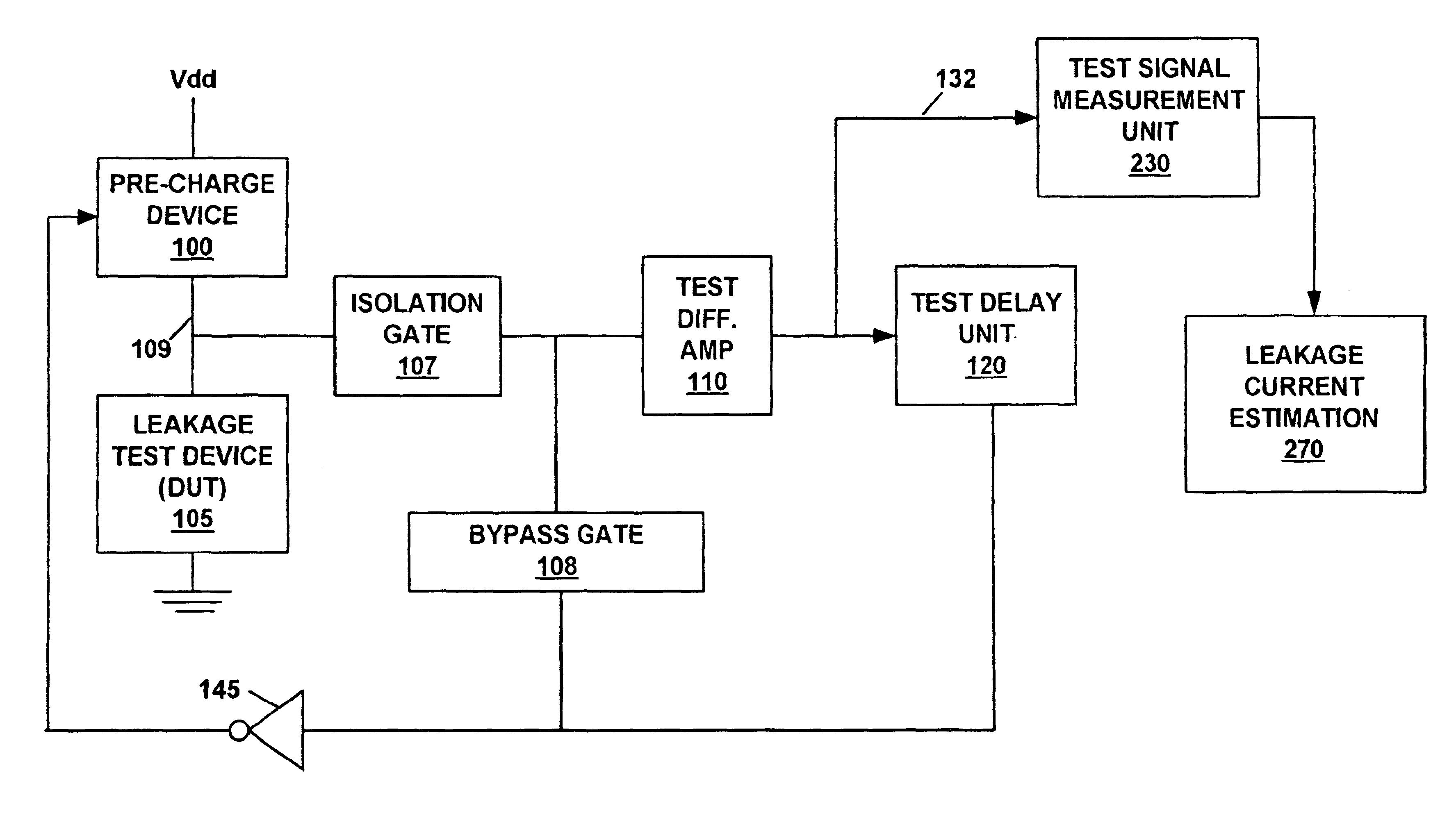

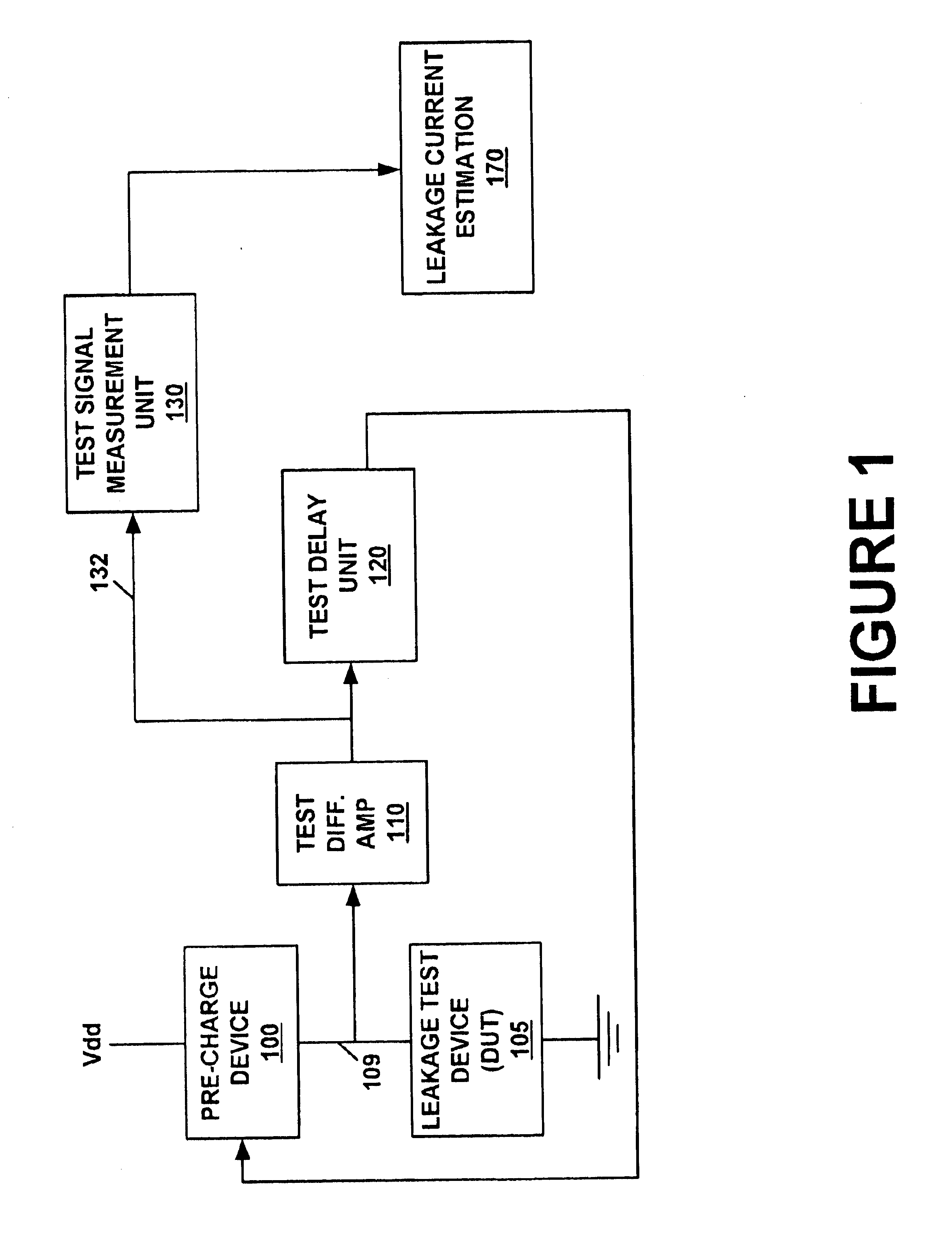

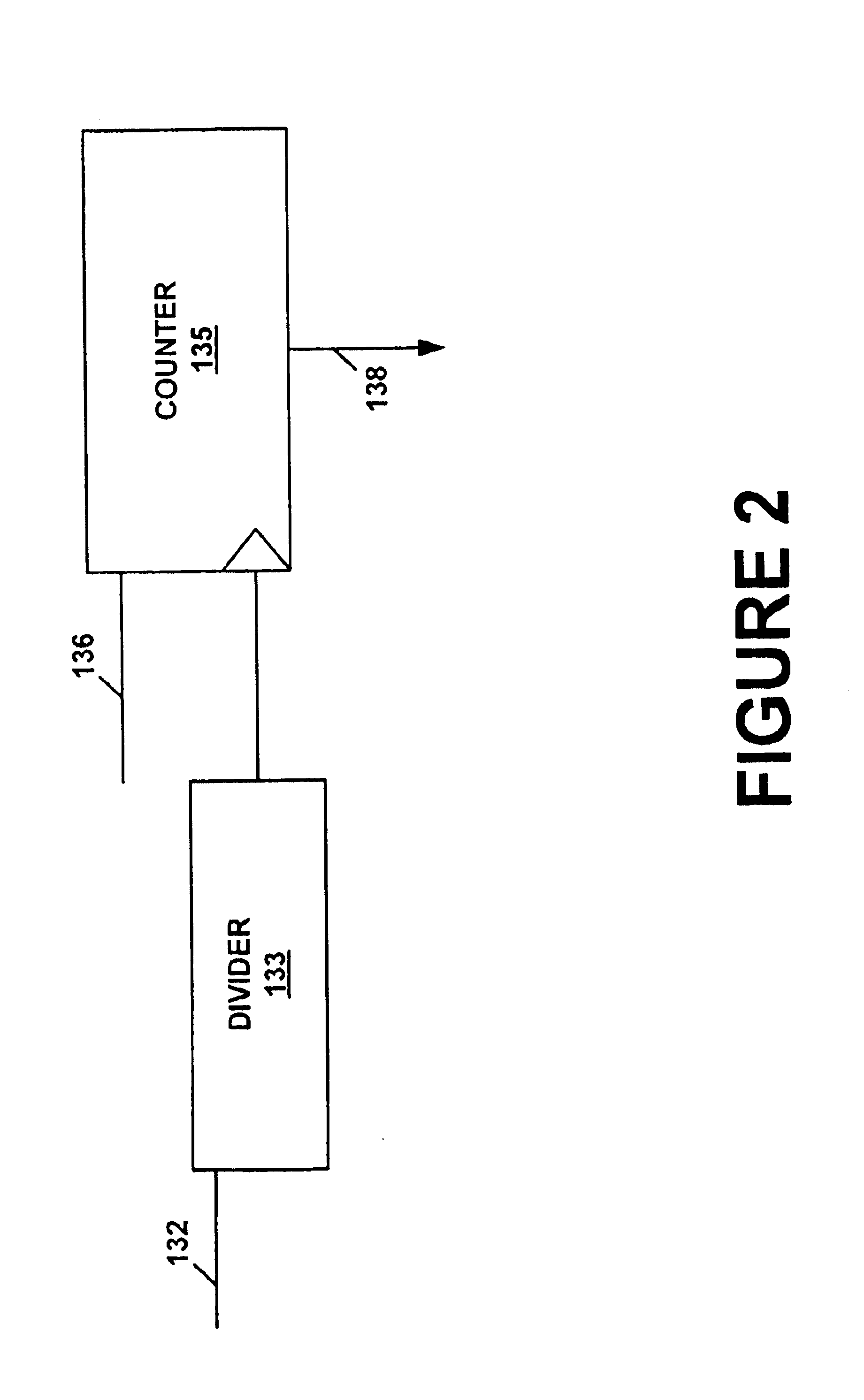

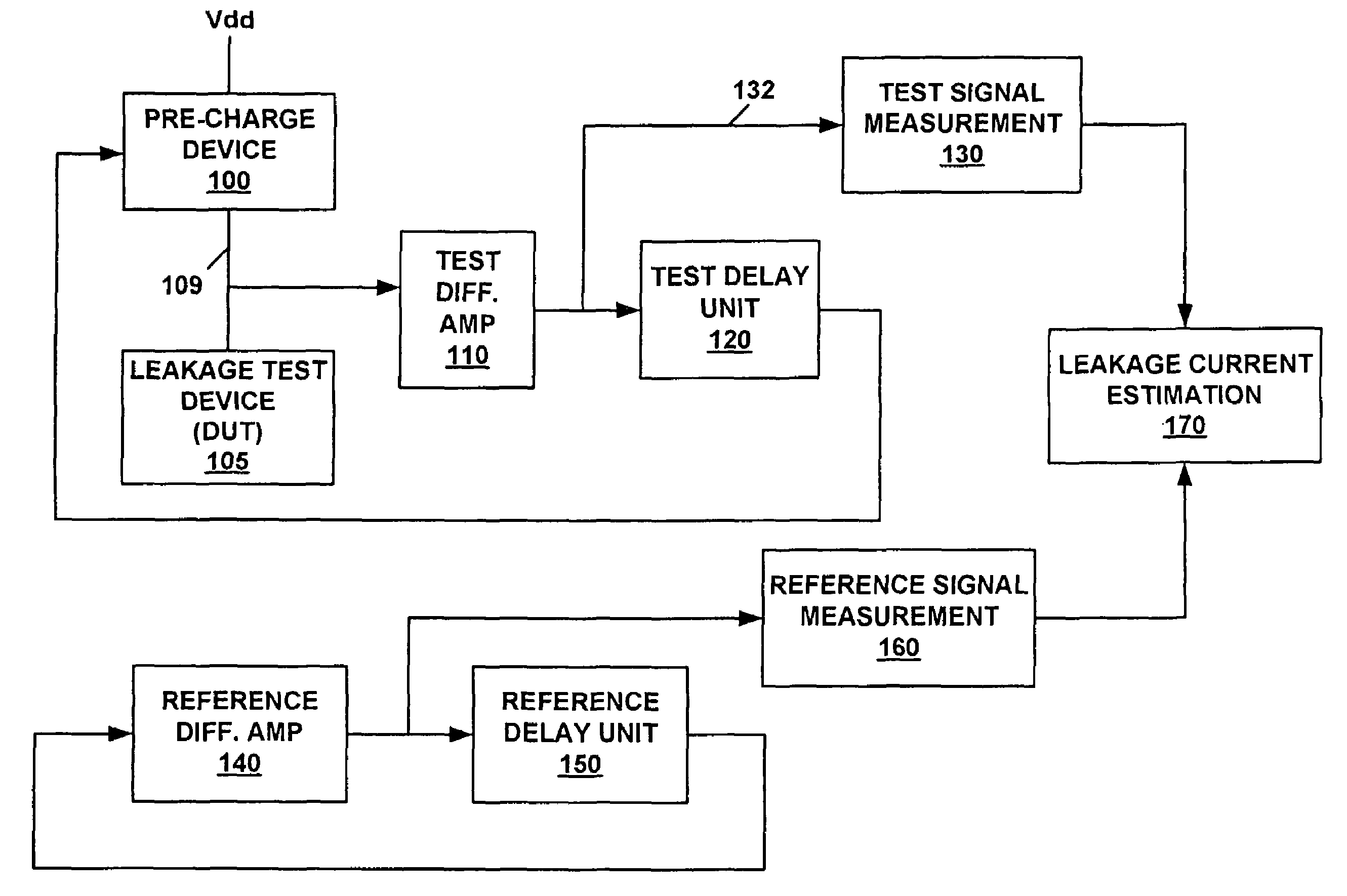

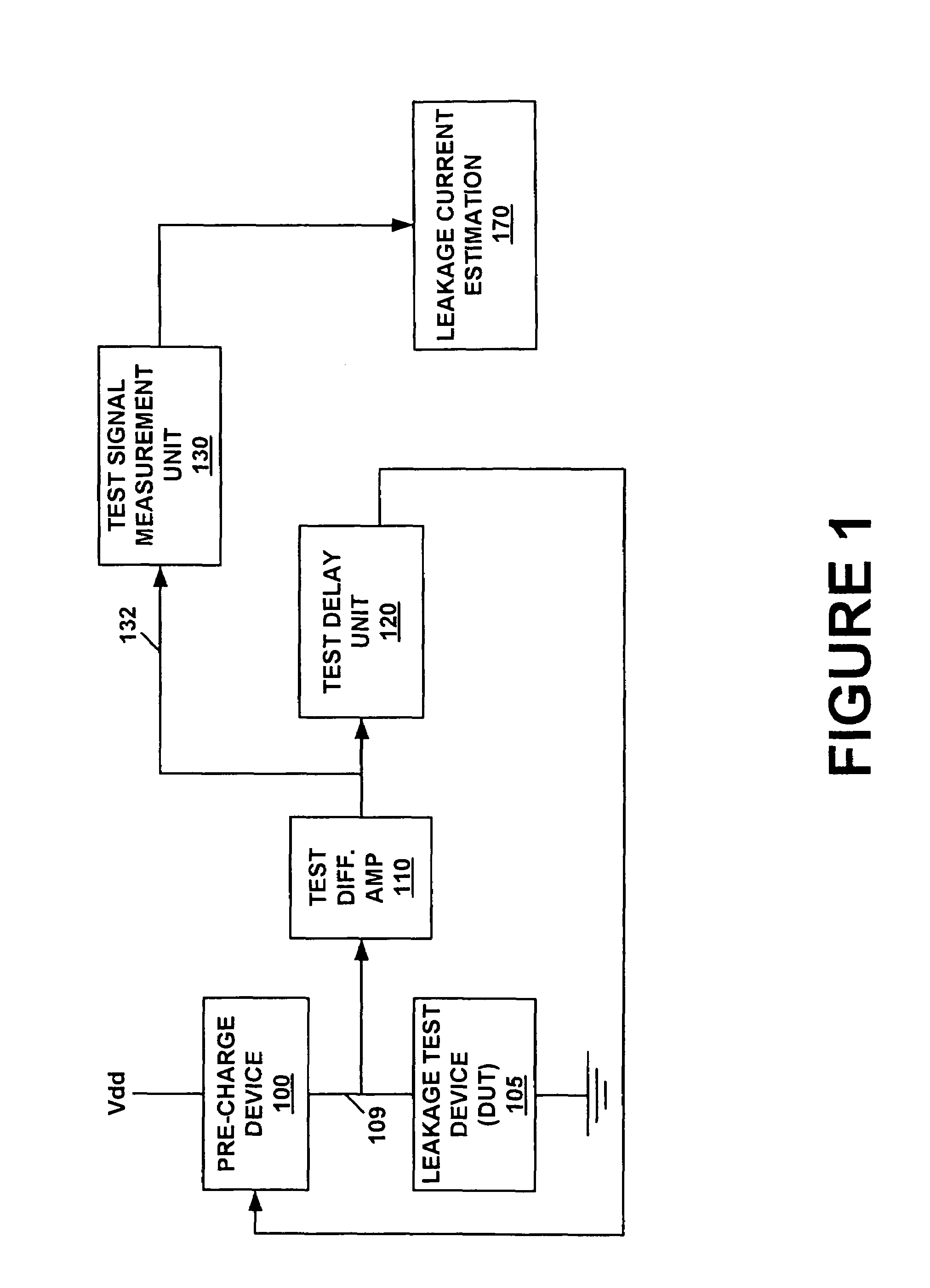

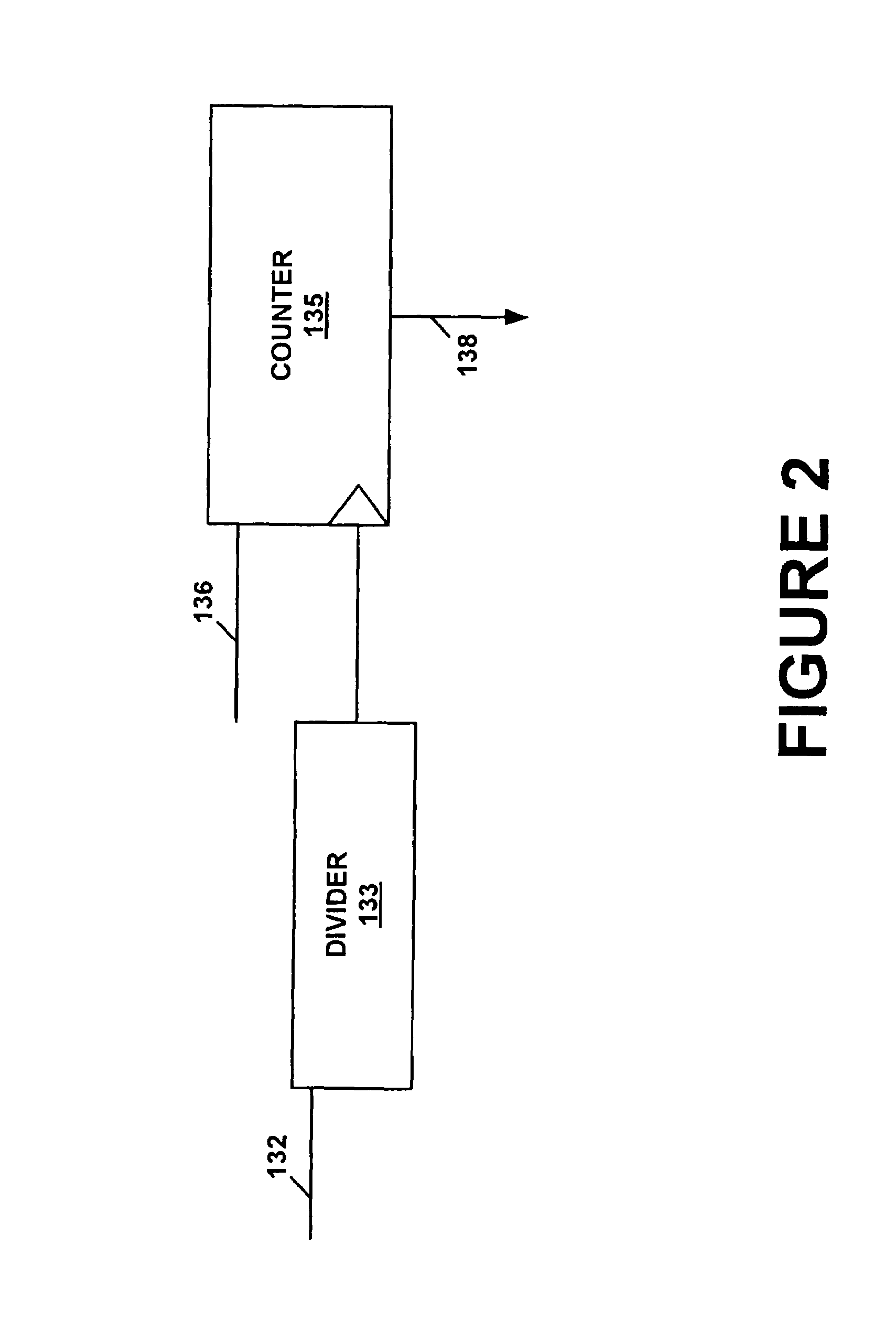

System and method for measuring transistor leakage current with a ring oscillator

InactiveUS6882172B1Accurate measurementAccurately leakage currentElectronic circuit testingShort-circuit testingLeakage testDrain current

A method of measuring the transistor leakage current. In one embodiment, the method involves driving a ring oscillator with a dynamic node driver having a leakage test device biased to an off state to produce a test signal. The test signal is extracted and the frequency is measured. The leakage current is estimated from the measured frequency.

Owner:META PLATFORMS INC

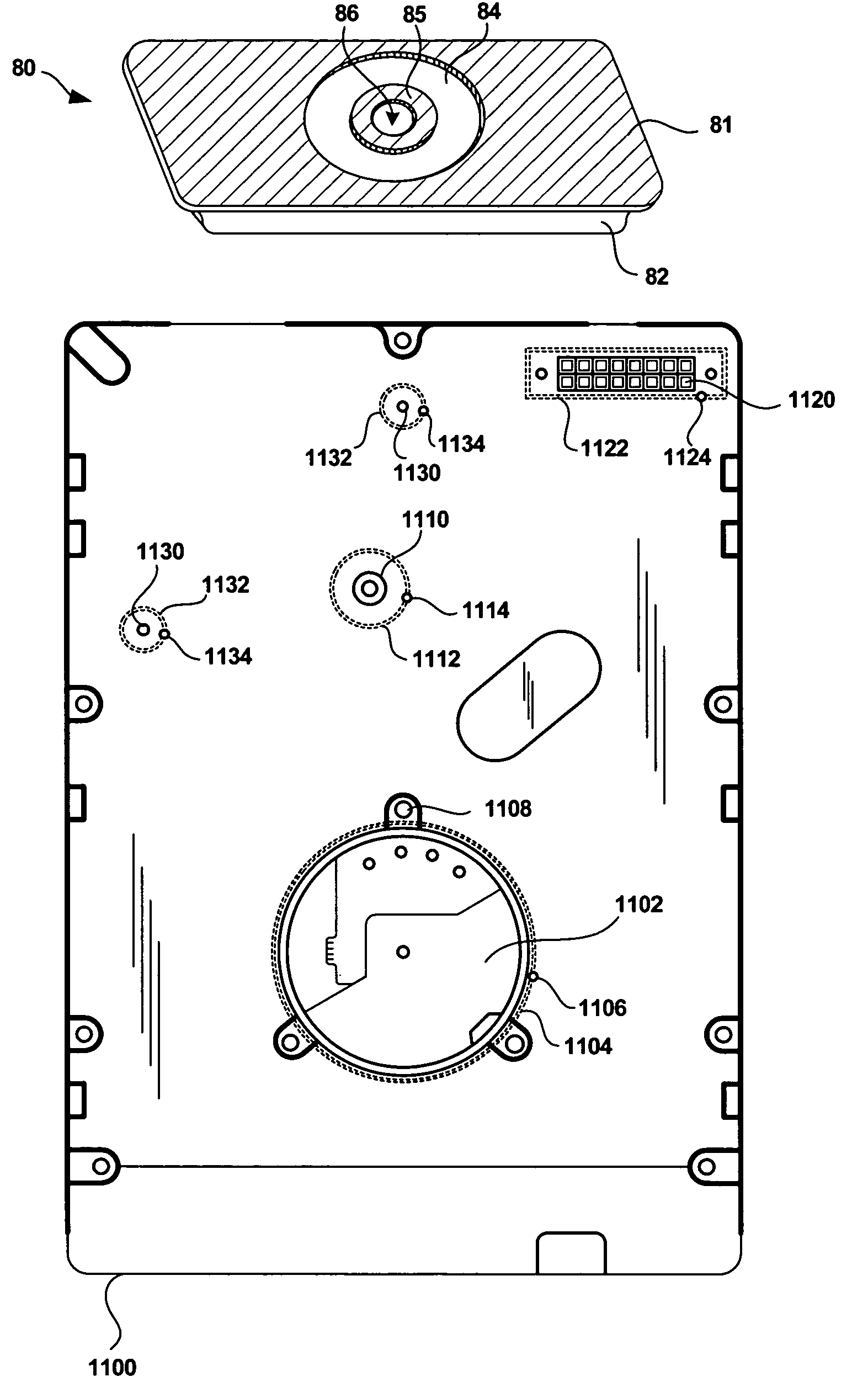

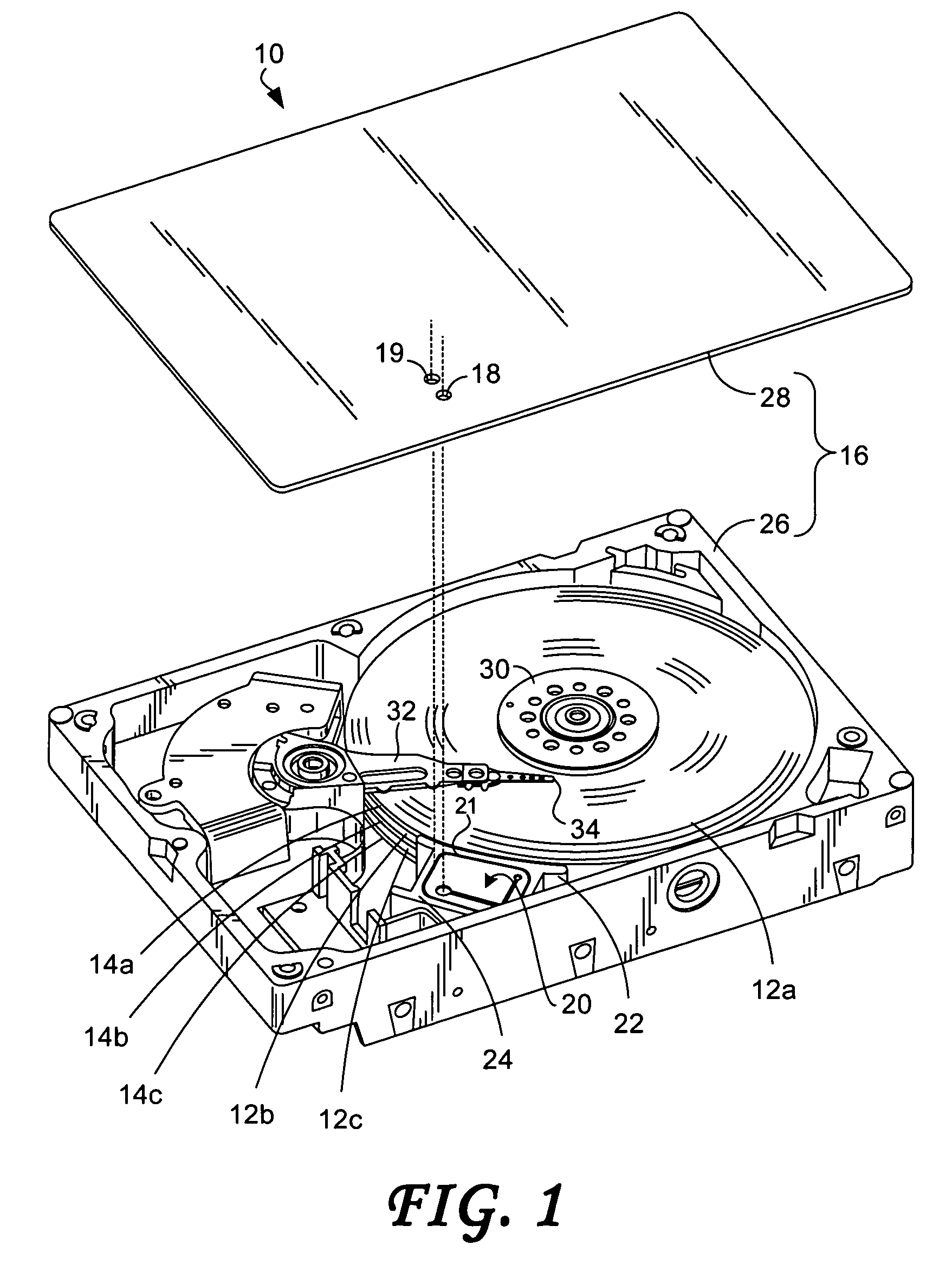

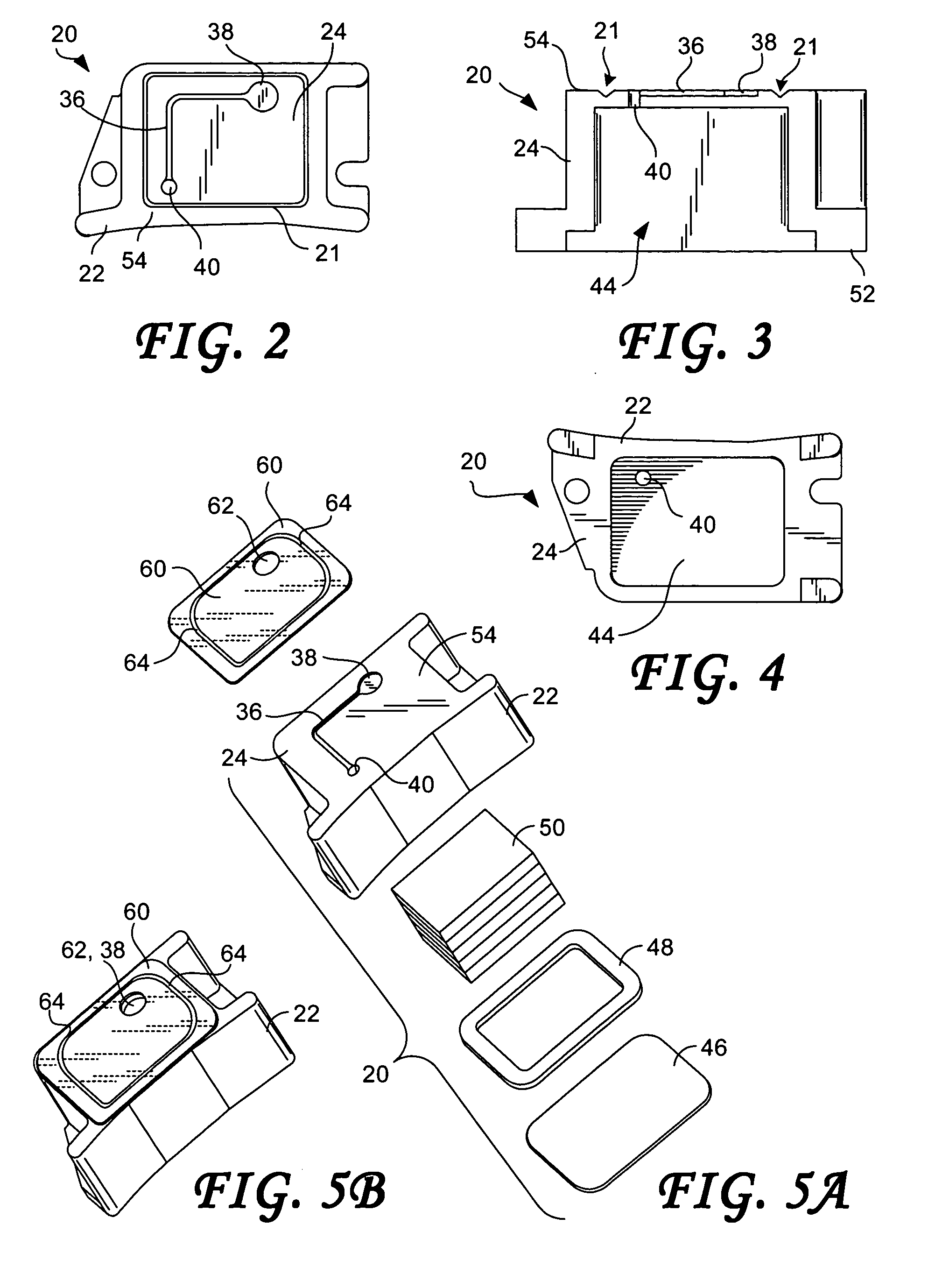

Disk drive configured to enable non destructive leak detection at the interface between a drive sub-component and the disk drive housing

ActiveUS7274534B1Undesired vibrations/sounds insulation/absorptionRecord information storageTest channelNon destructive

A disk drive includes a disk drive housing having a breather hole and a separate leak testing hole, both the breather hole and the leak testing hole being formed through the disk drive housing, and a drive sub-component attached to a surface of the disk drive housing so as to form an interface between the sub-component and the surface of the housing. The interface defines an interface outer perimeter and a sealed airflow testing channel in fluid communication only with the leak testing hole to enable a non-destructive detection of leaks at the interface. The airflow testing channel may be disposed within the interface outer perimeter.

Owner:WESTERN DIGITAL TECH INC

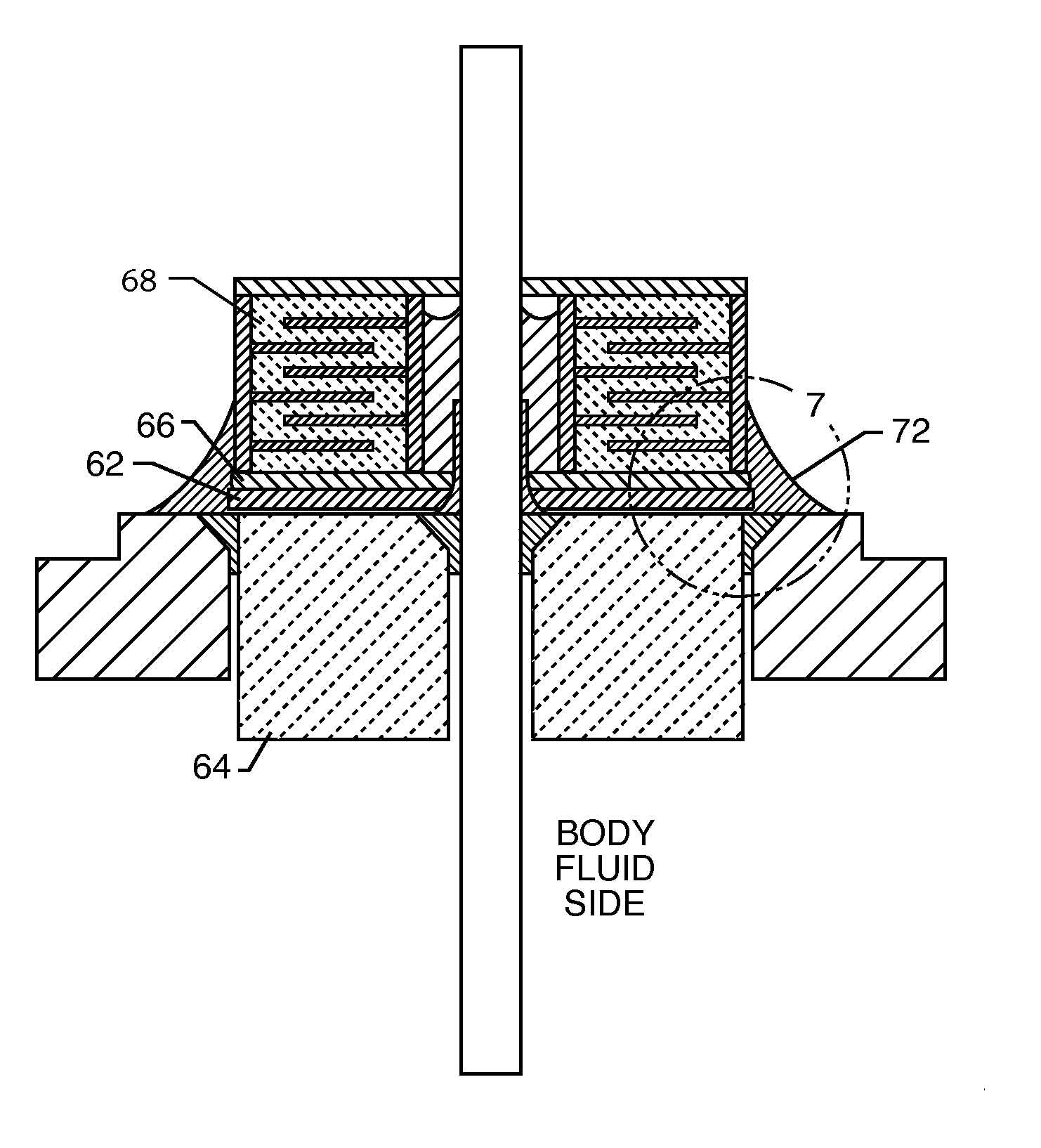

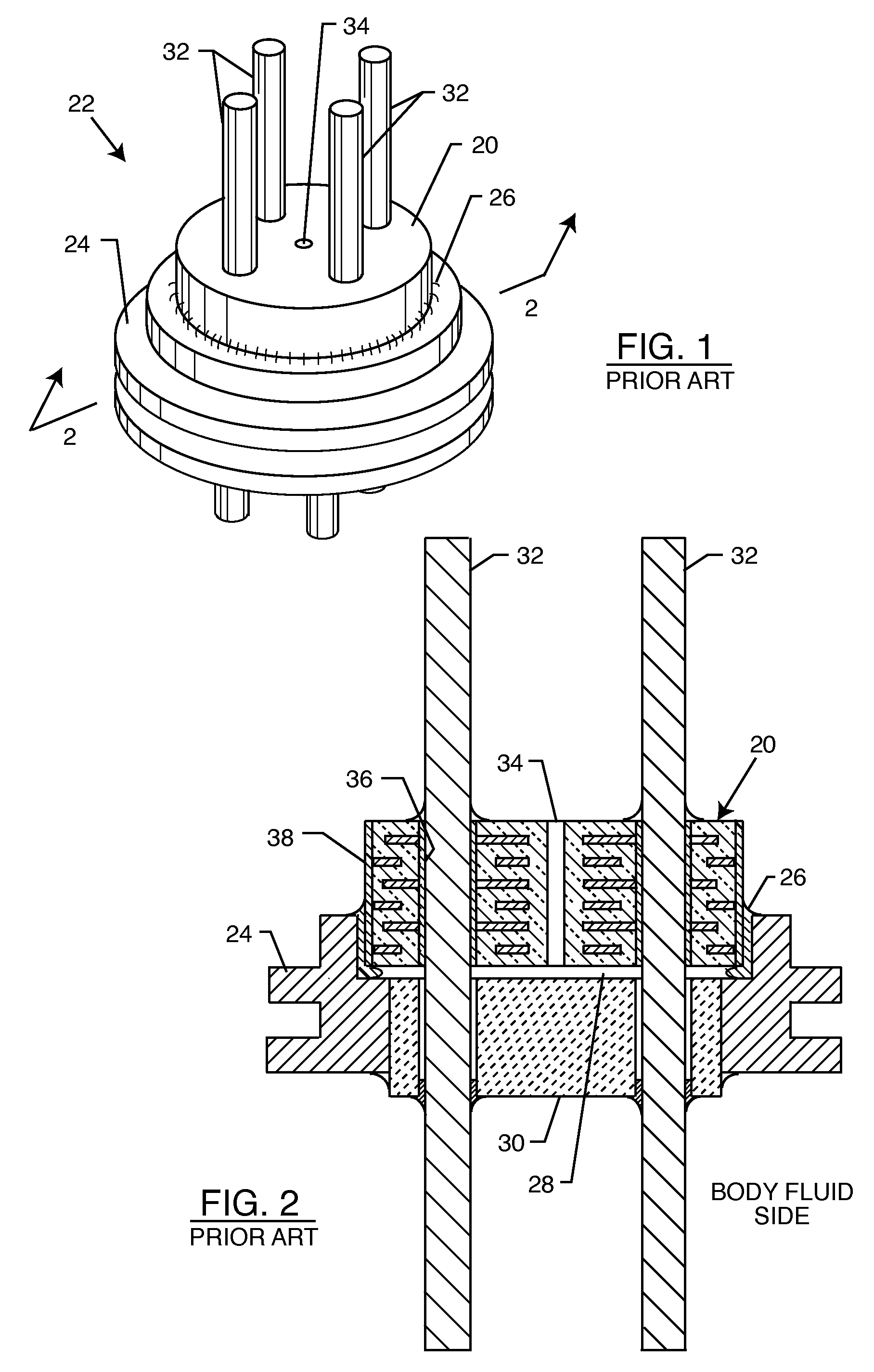

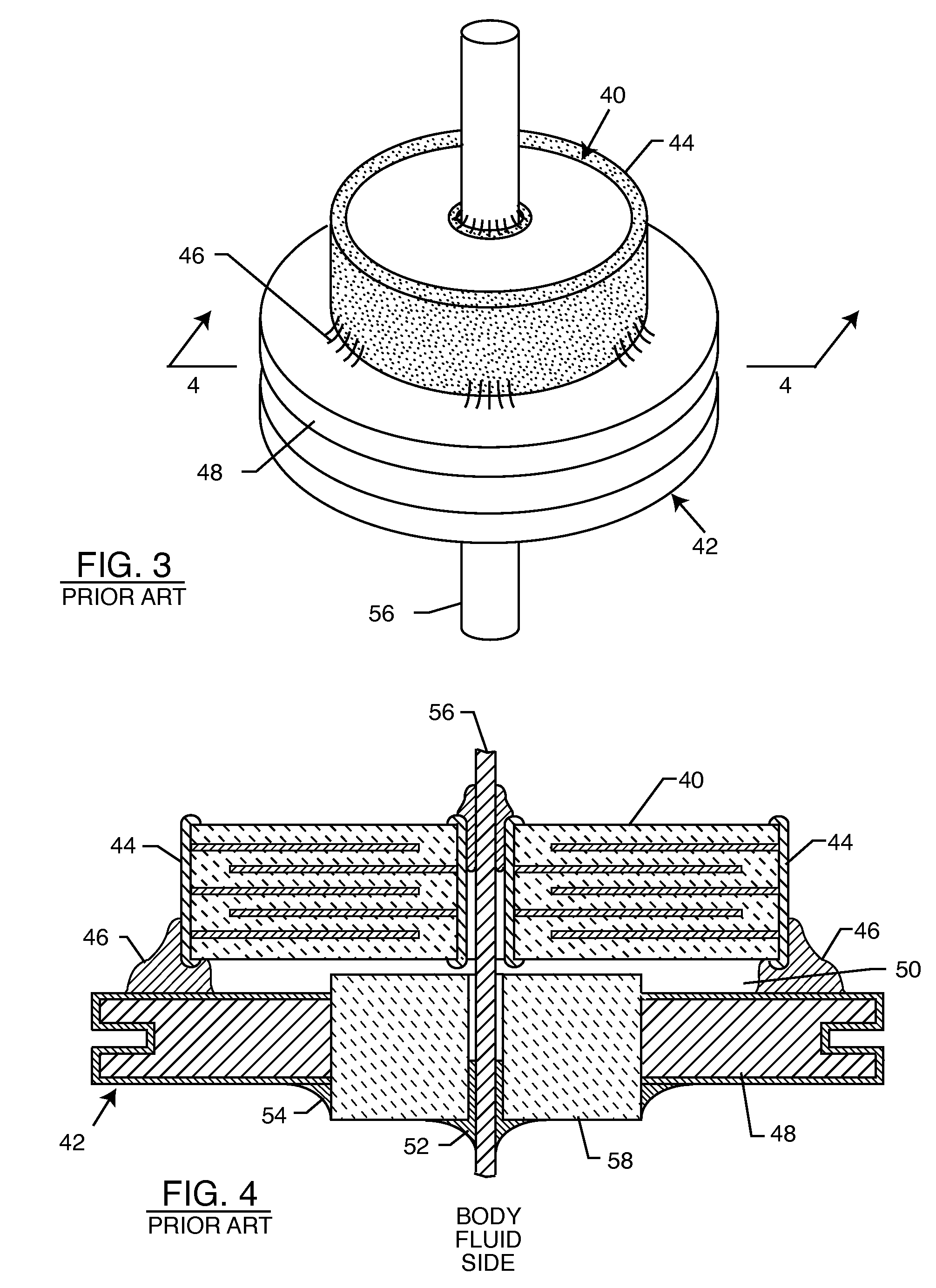

Feedthrough filter terminal assemblies with breathable components to facilitate leak testing

ActiveUS7797048B2Avoid flowPrevent arcing or high-voltage flashoverAnti-noise capacitorsElectrotherapyGround planeConformal coating

A feedthrough terminal assembly for an active implantable medical device (AIMD) includes a conductive terminal pin or lead wire which extends through a conductive ground plane of the AIMD in non-conductive relation. A feedthrough capacitor associated with the terminal pin or lead wire has first and second sets of electrode plates coupled, respectively, to the conductive pin or lead wire and to the ground plane. A breathable electromechanical connection material conductively couples the capacitor's electrode plates to respective components of the AIMD, which allows helium gas to pass freely therethrough during a standard pressurized or vacuum pull helium leak detection test. A breathable washer may be disposed between an alumina insulator and a surface of the capacitor. An additional further breathable coating or conformal coating may be placed over a surface of the feedthrough capacitor disposed toward the interior of the AIMD.

Owner:WILSON GREATBATCH LTD

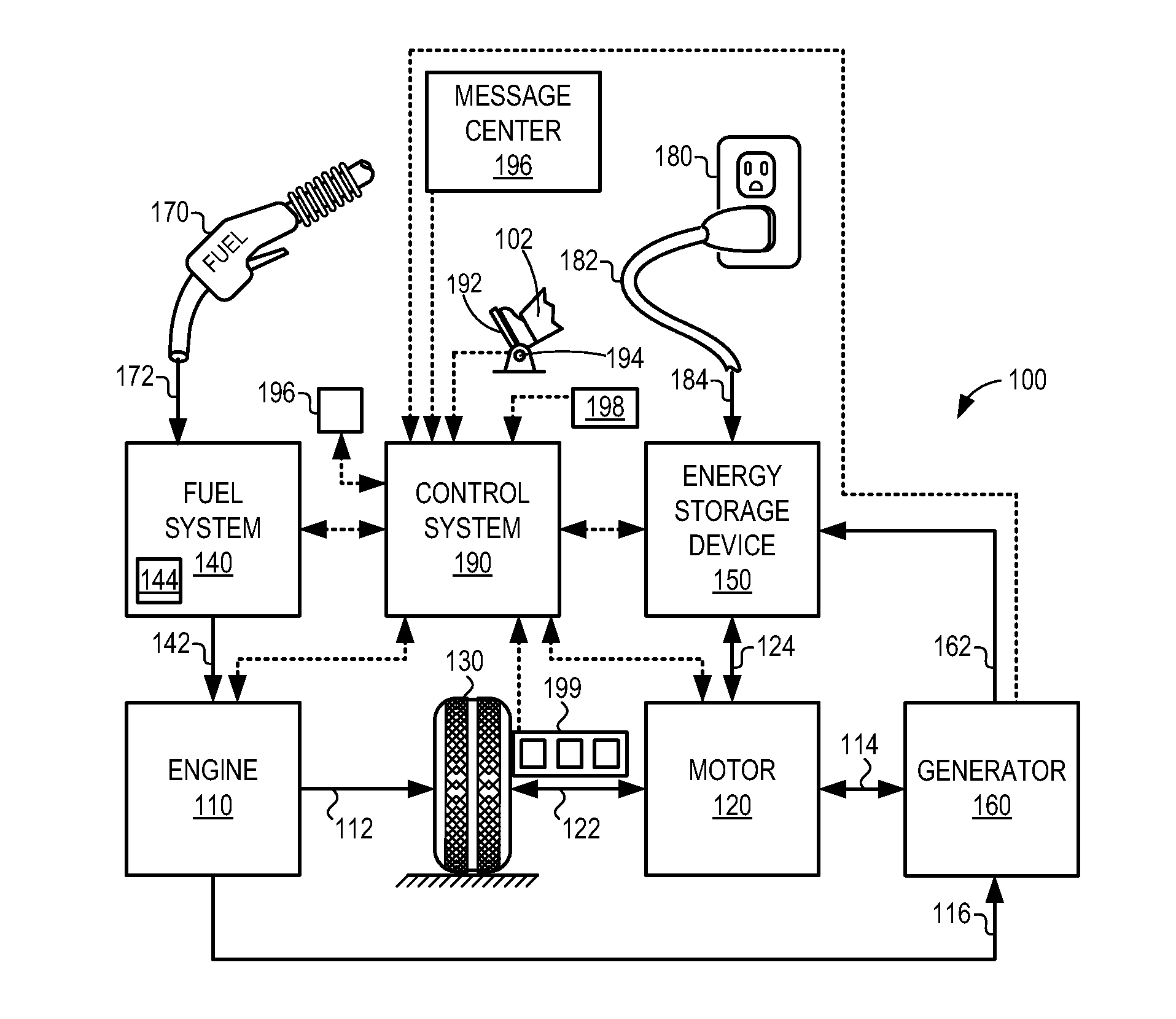

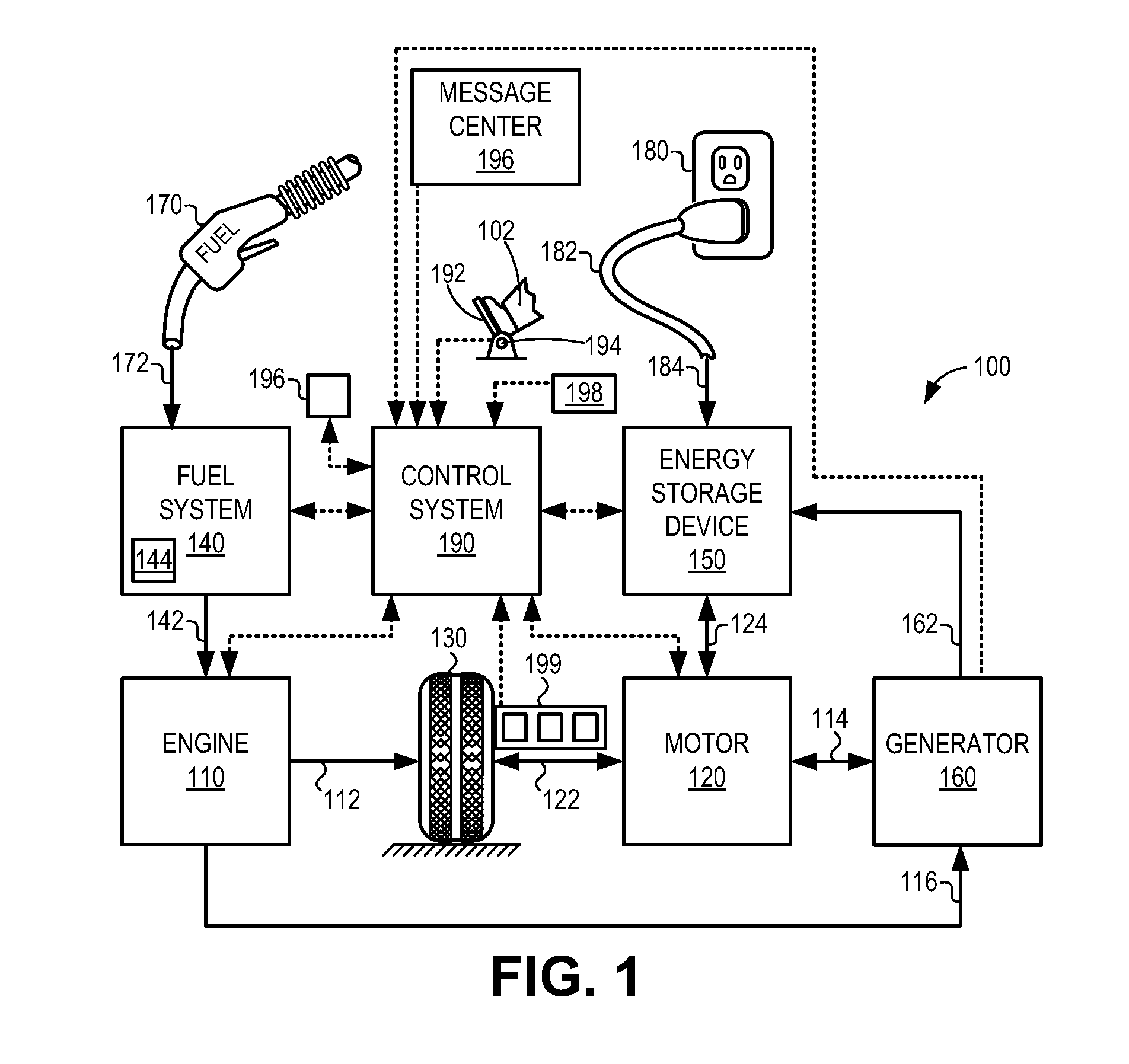

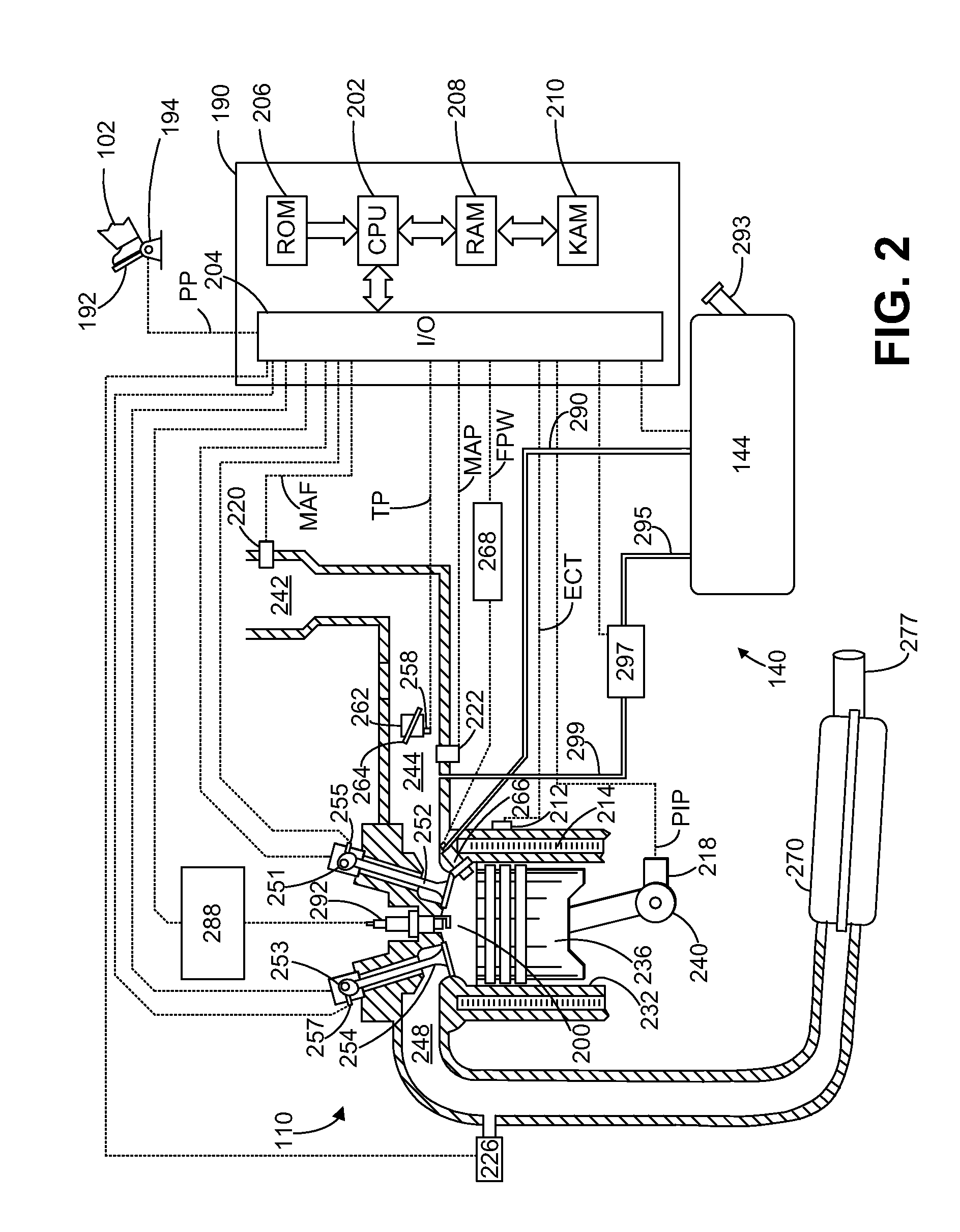

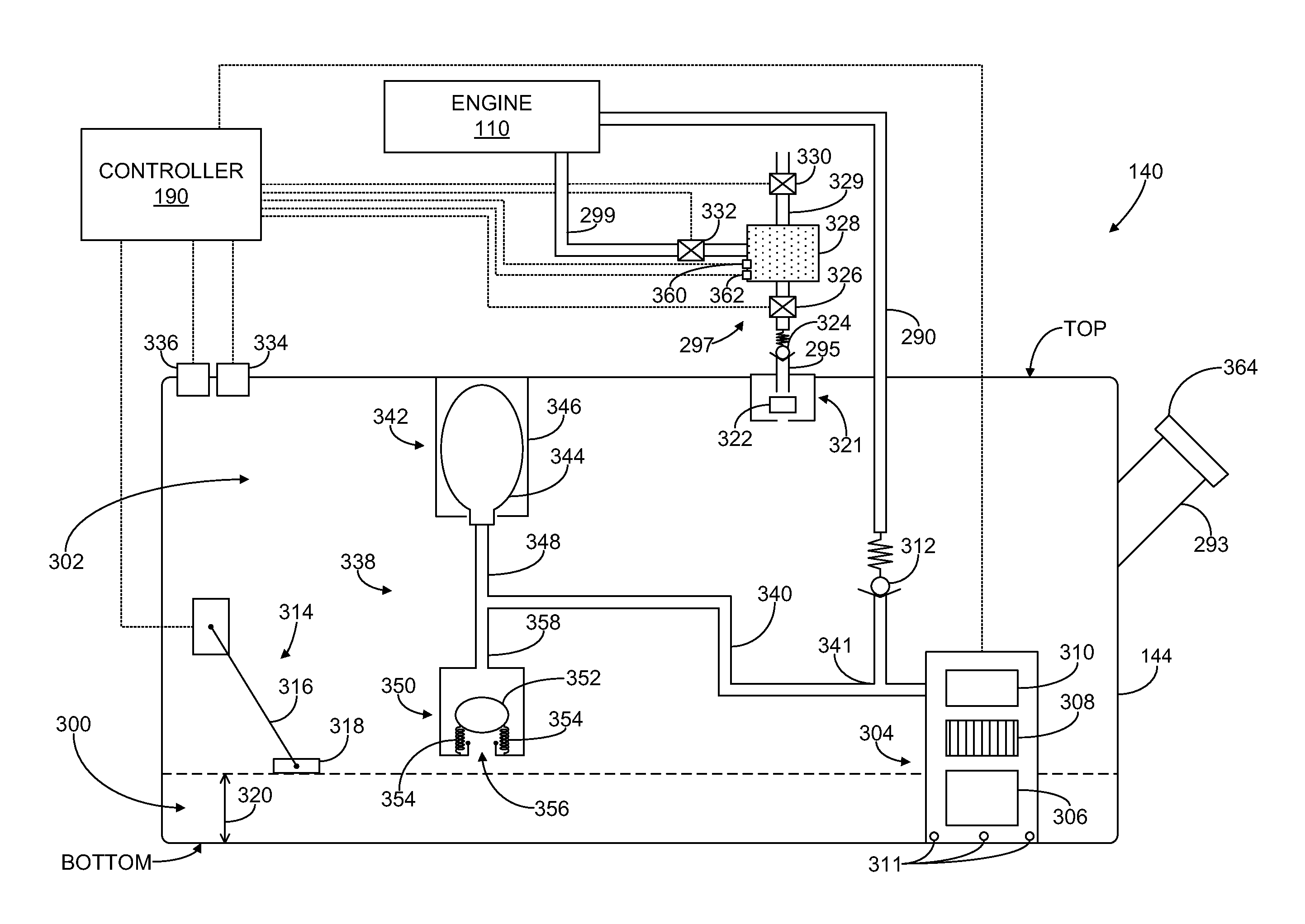

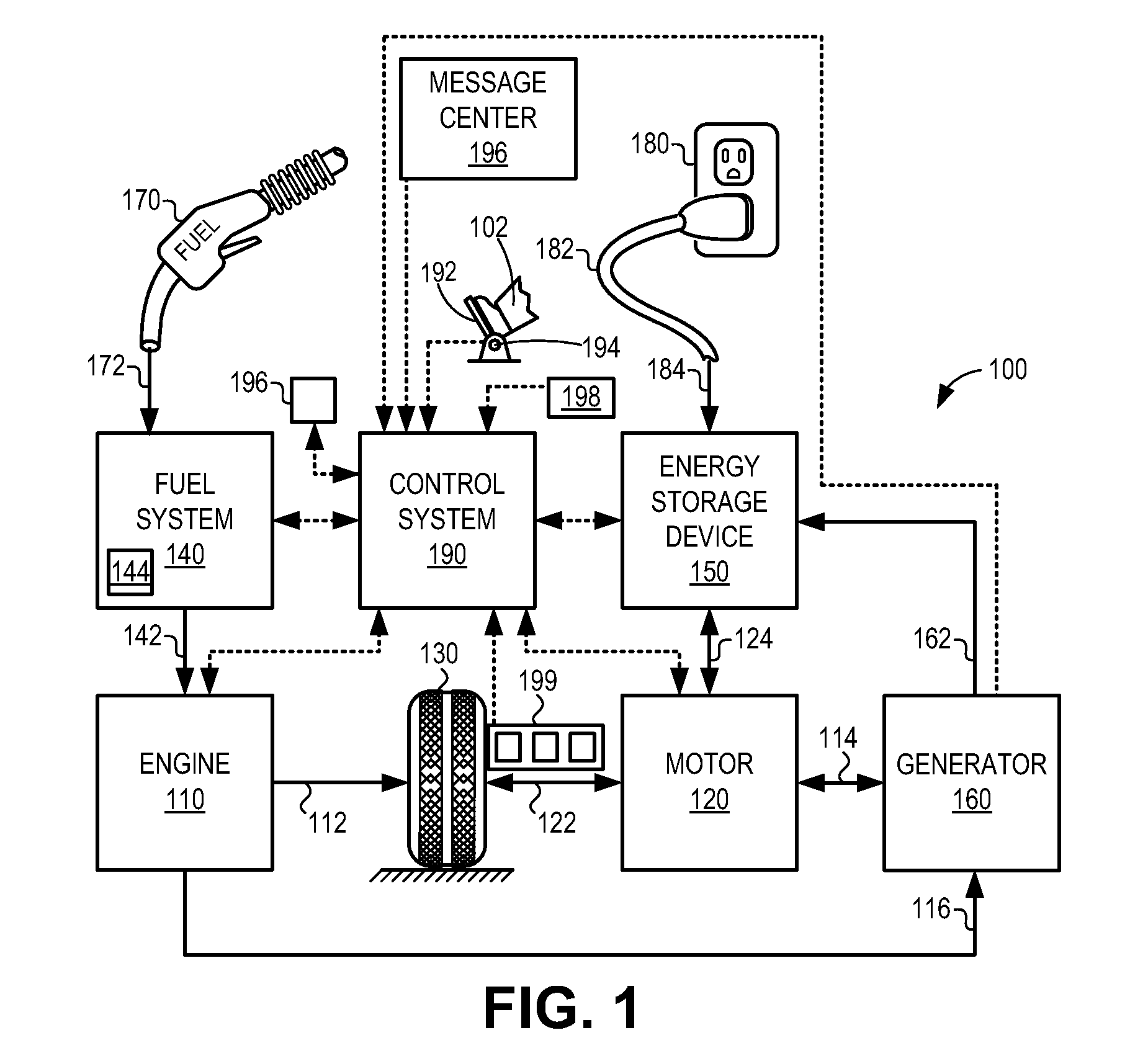

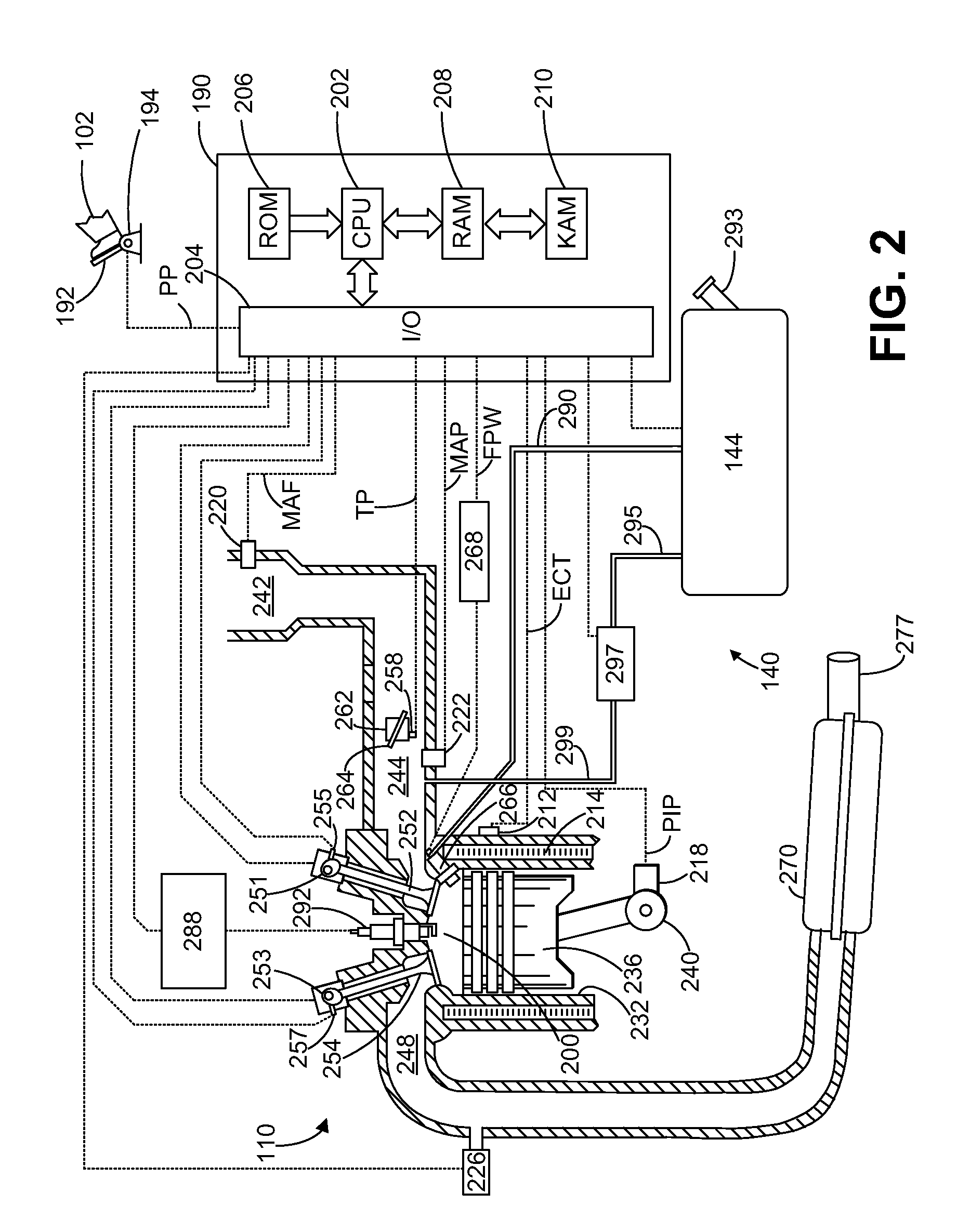

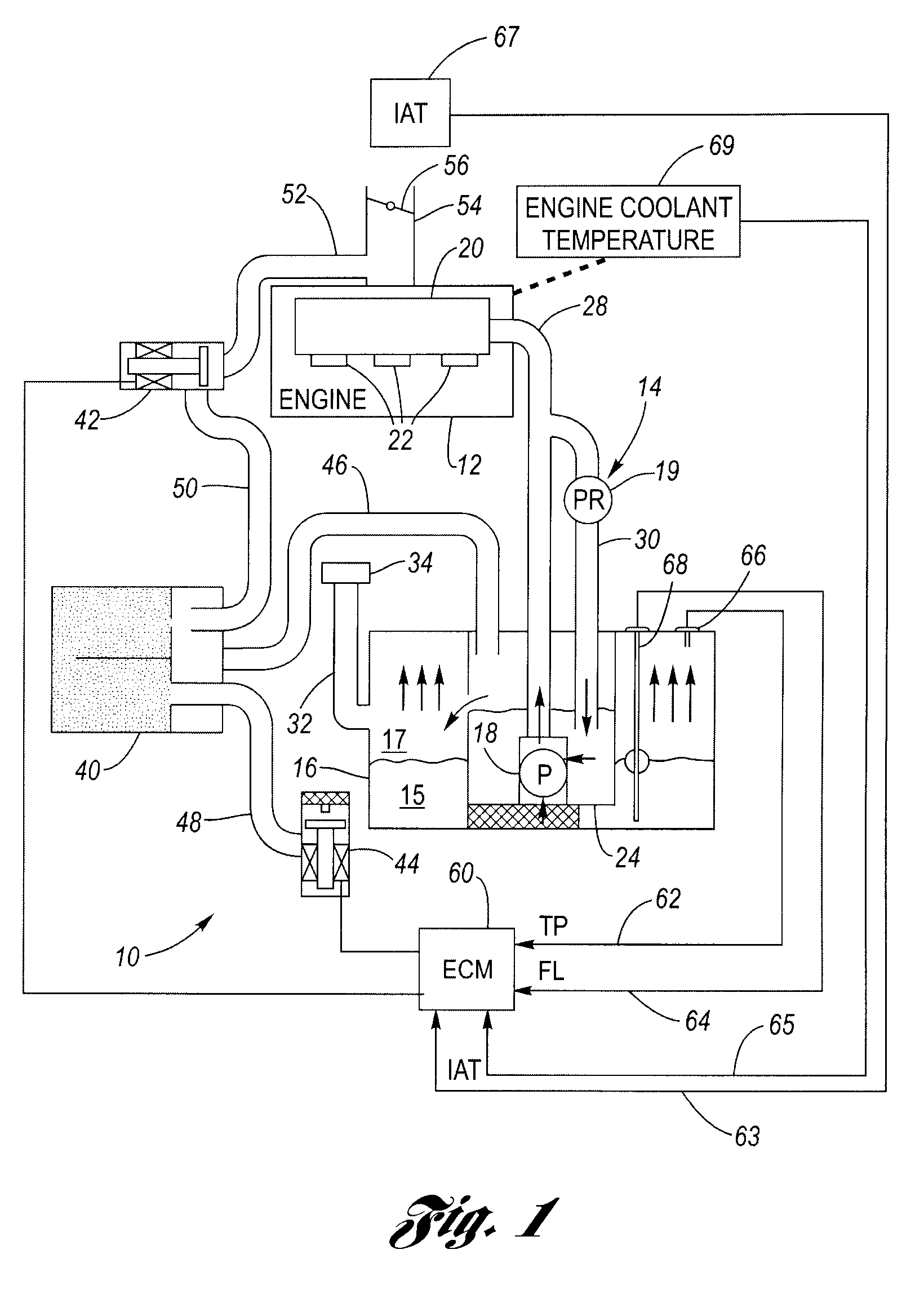

Automotive Fuel System Leak Testing

ActiveUS20110139130A1Reduce materialReduce installation costsAnalogue computers for vehiclesDetection of fluid at leakage pointFuel tankAutomotive fuel

Systems and methods for performing leak testing on fuel system components in hybrid vehicles during engine-off operating conditions are disclosed. For example, a fuel tank may include a pressure accumulator which may be filled with fuel via a fuel pump in order to generate a vacuum which may be used to diagnose leaks in the fuel system.

Owner:FORD GLOBAL TECH LLC

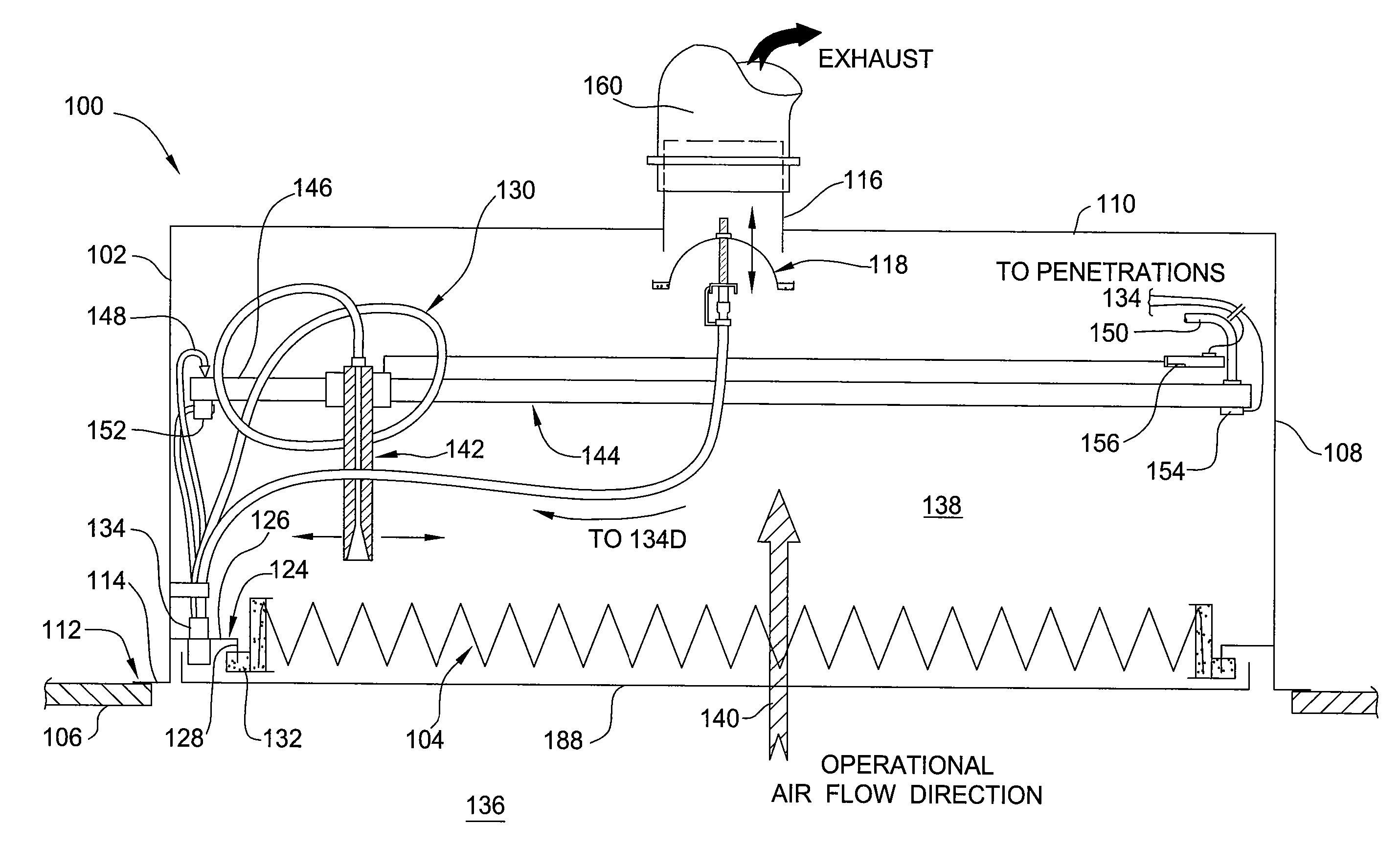

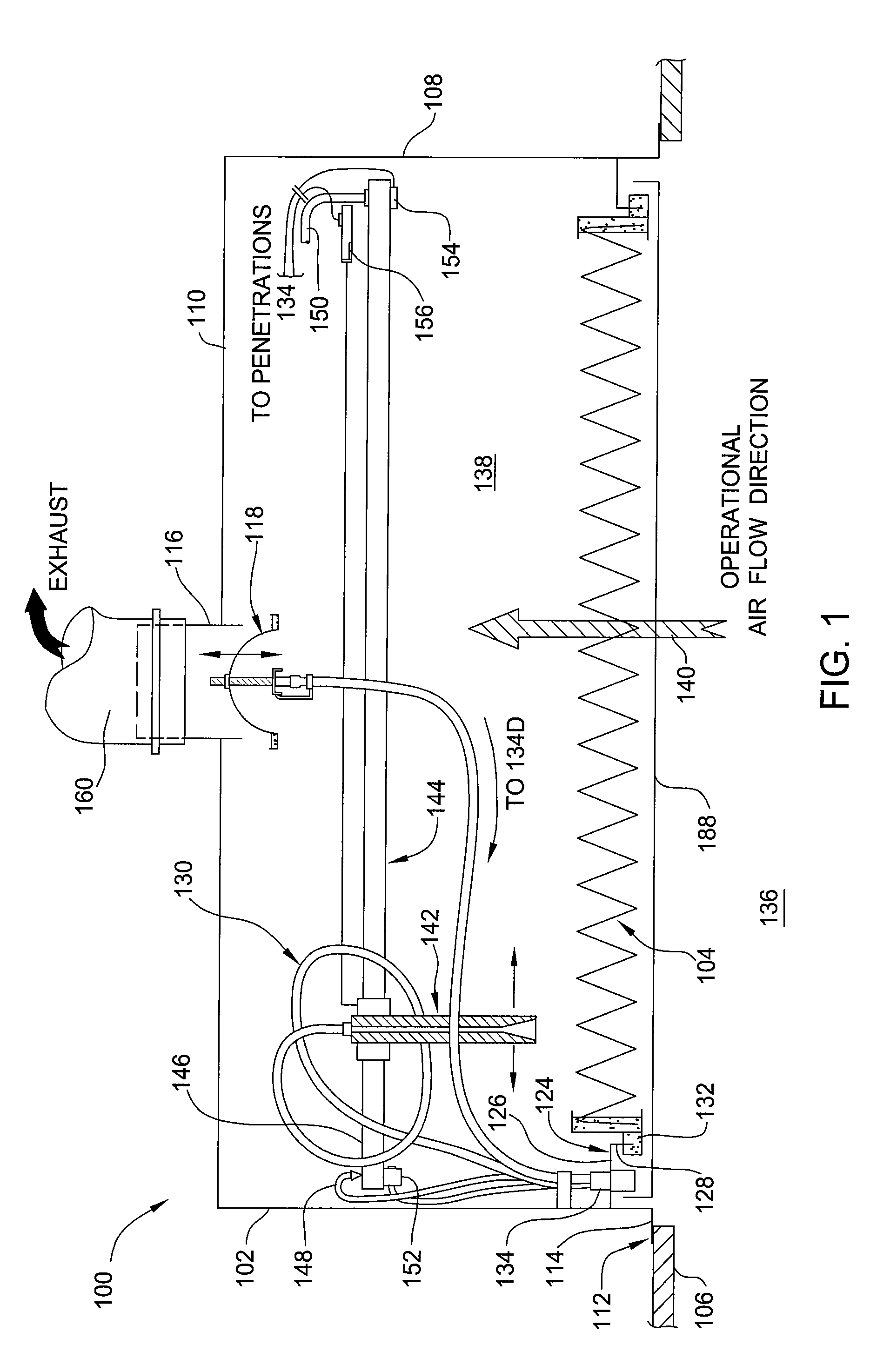

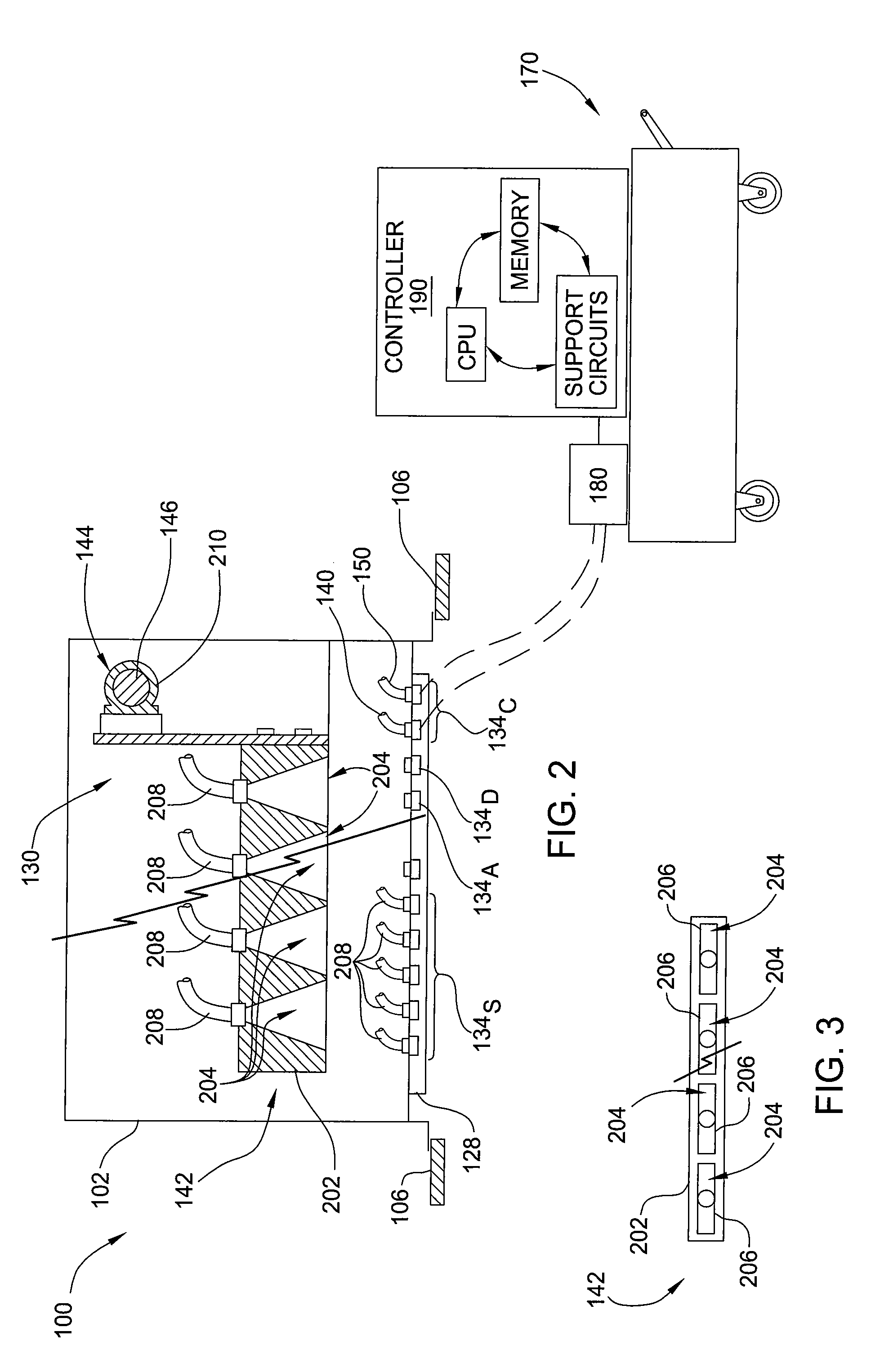

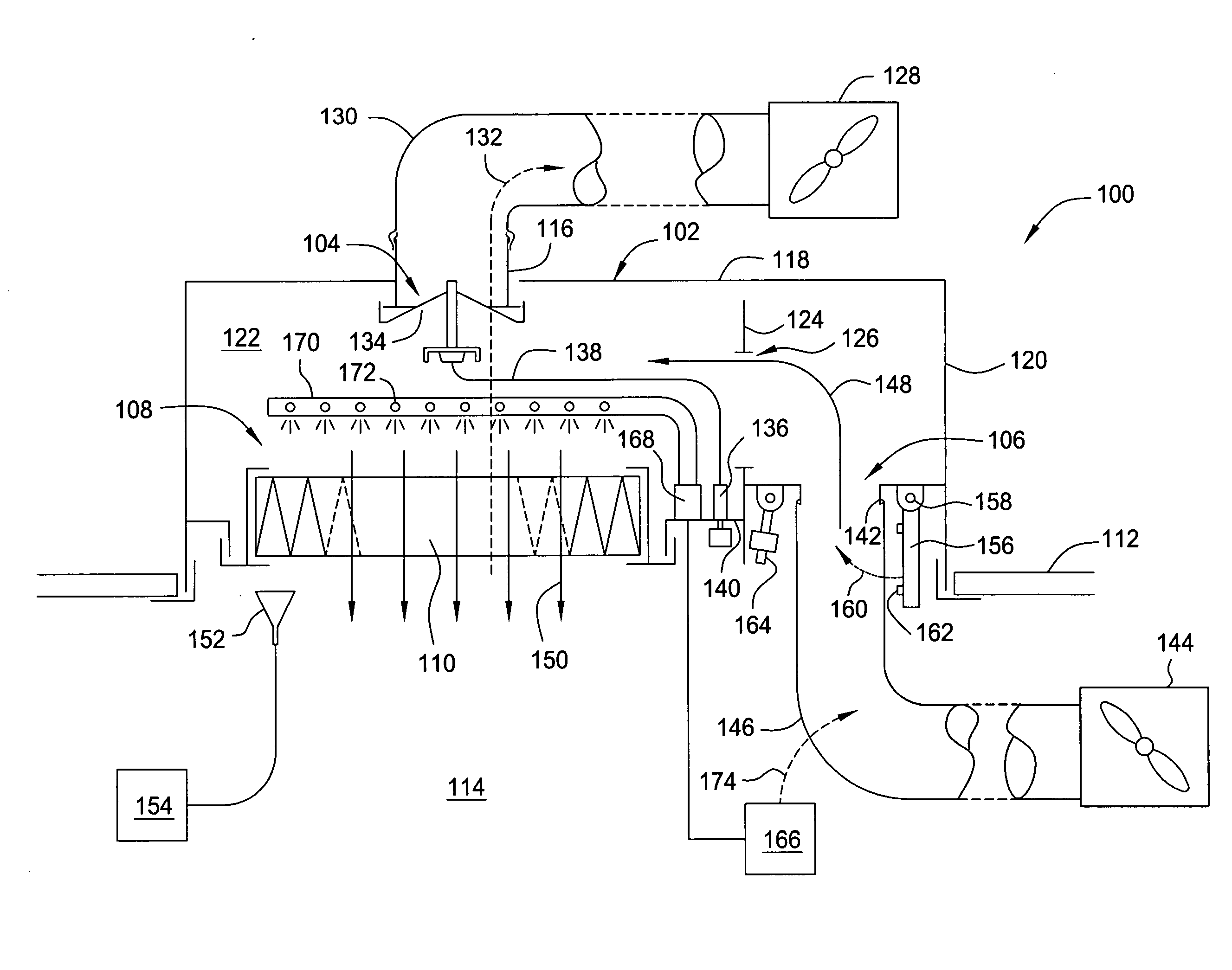

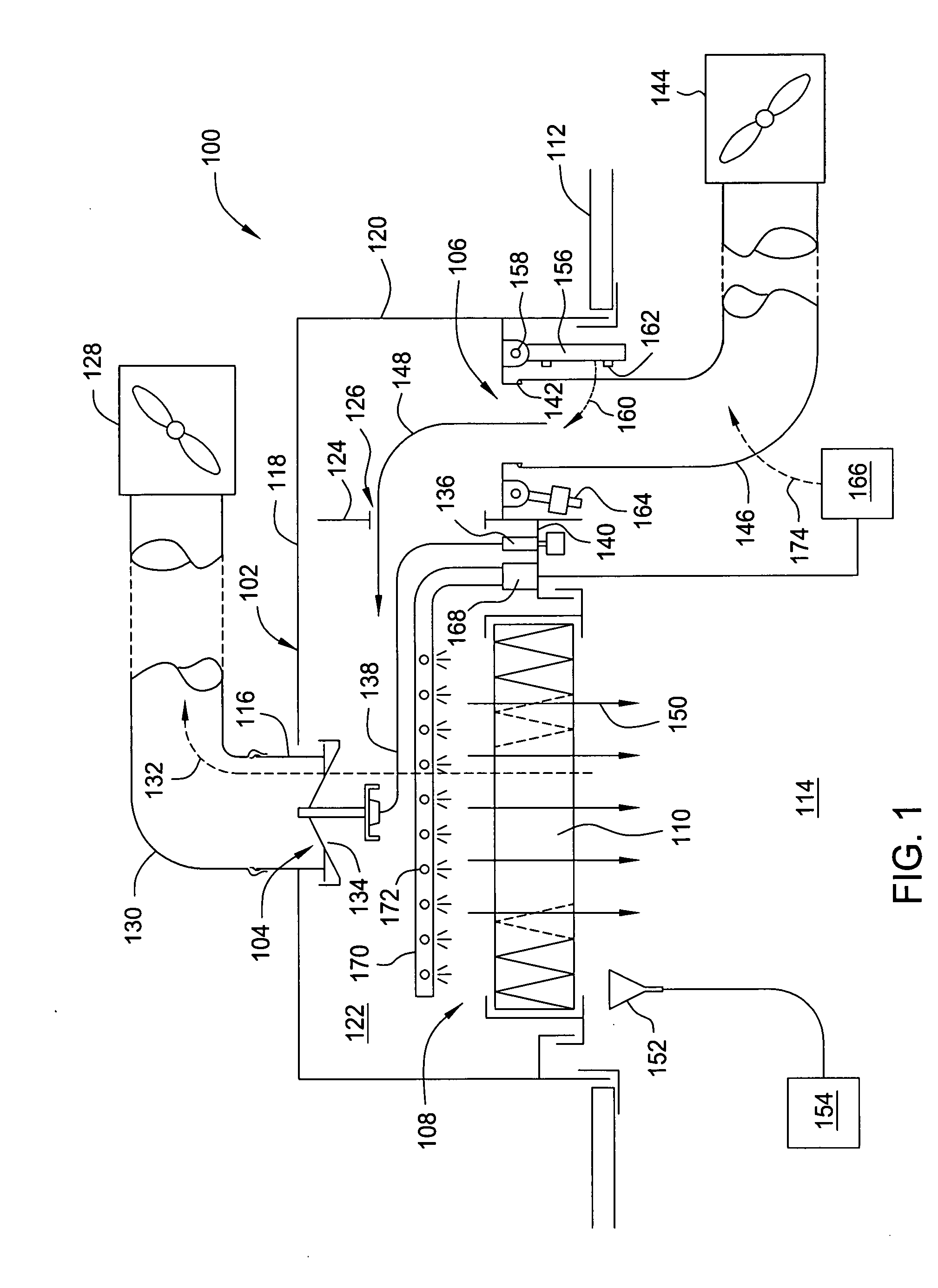

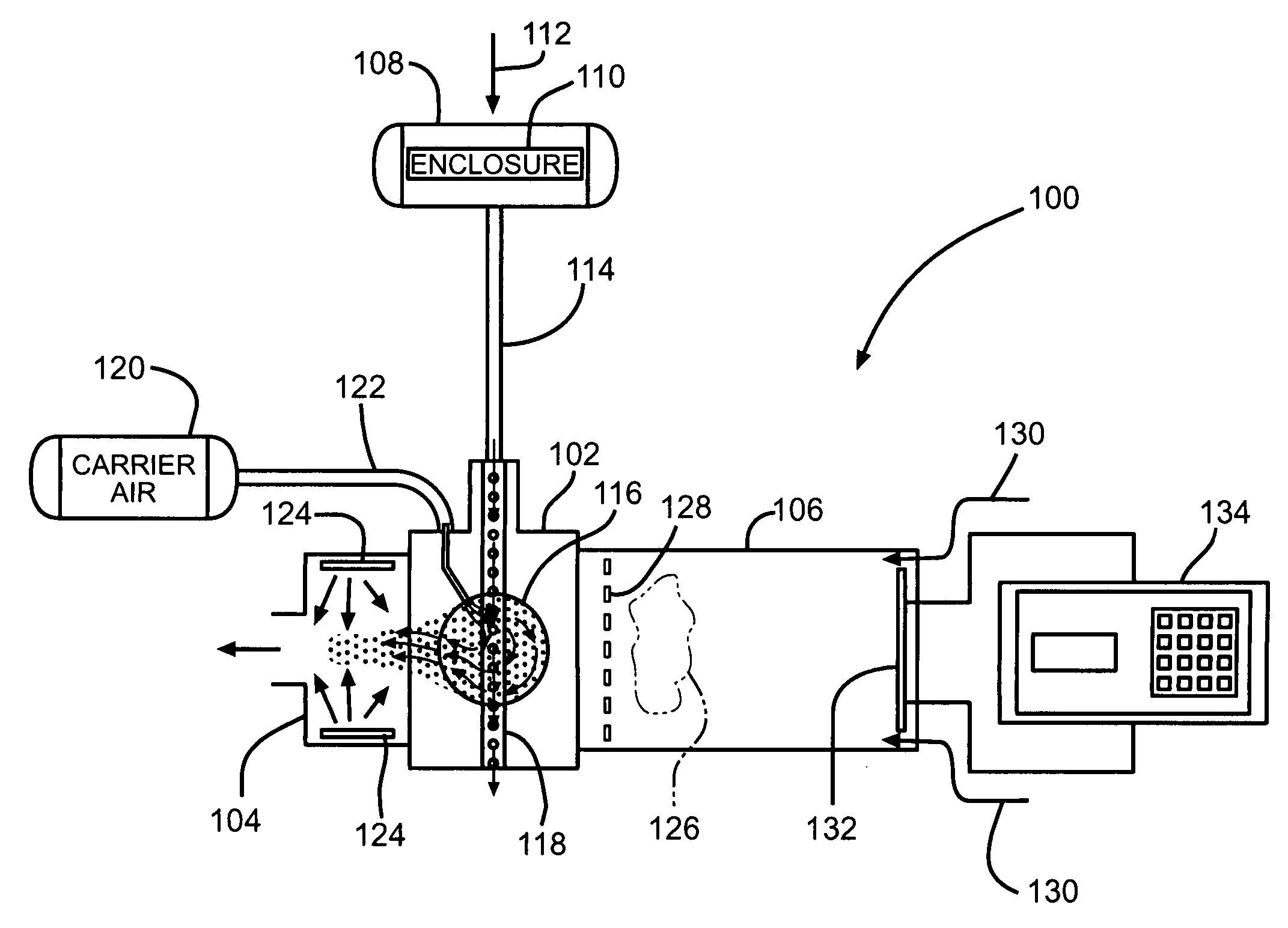

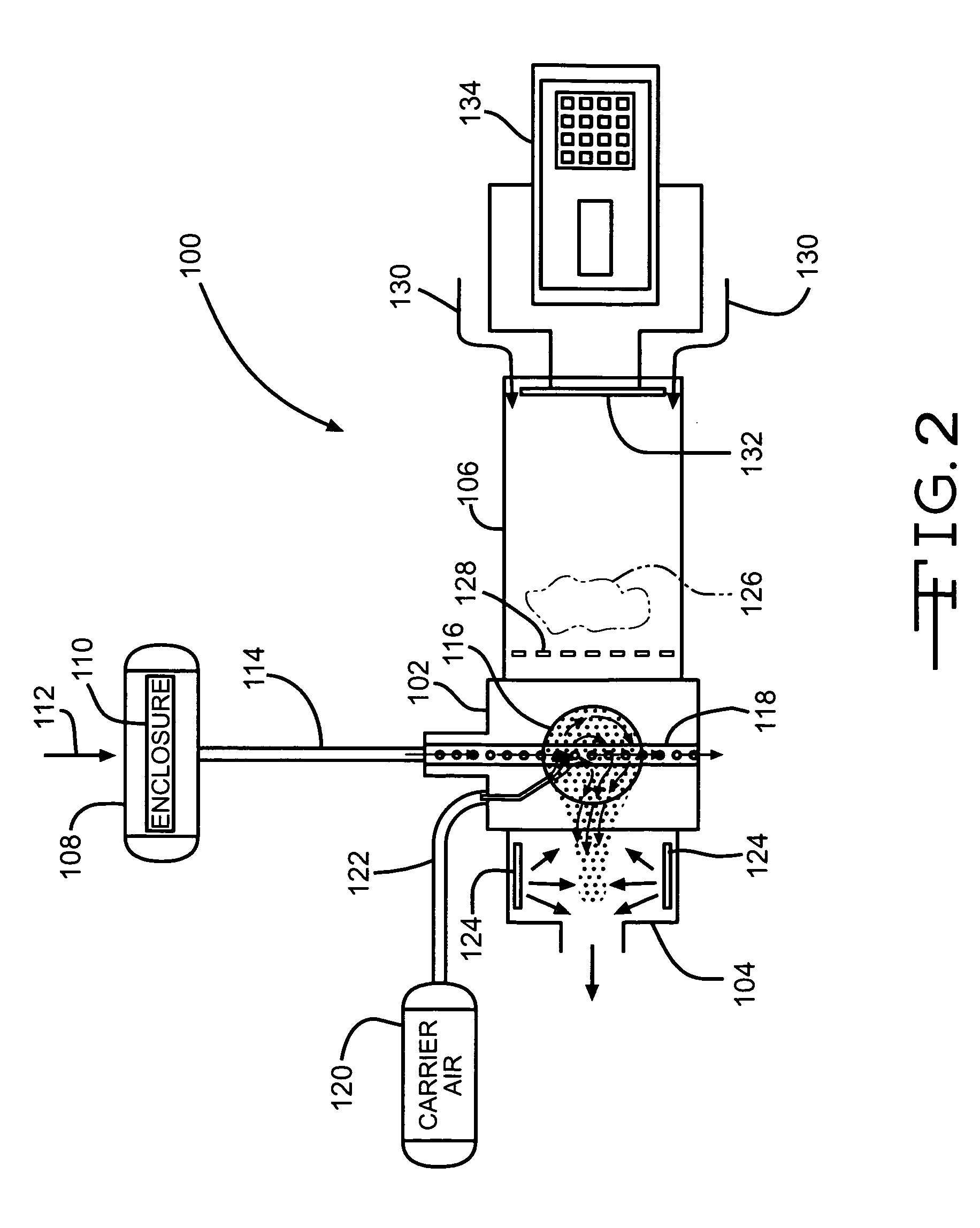

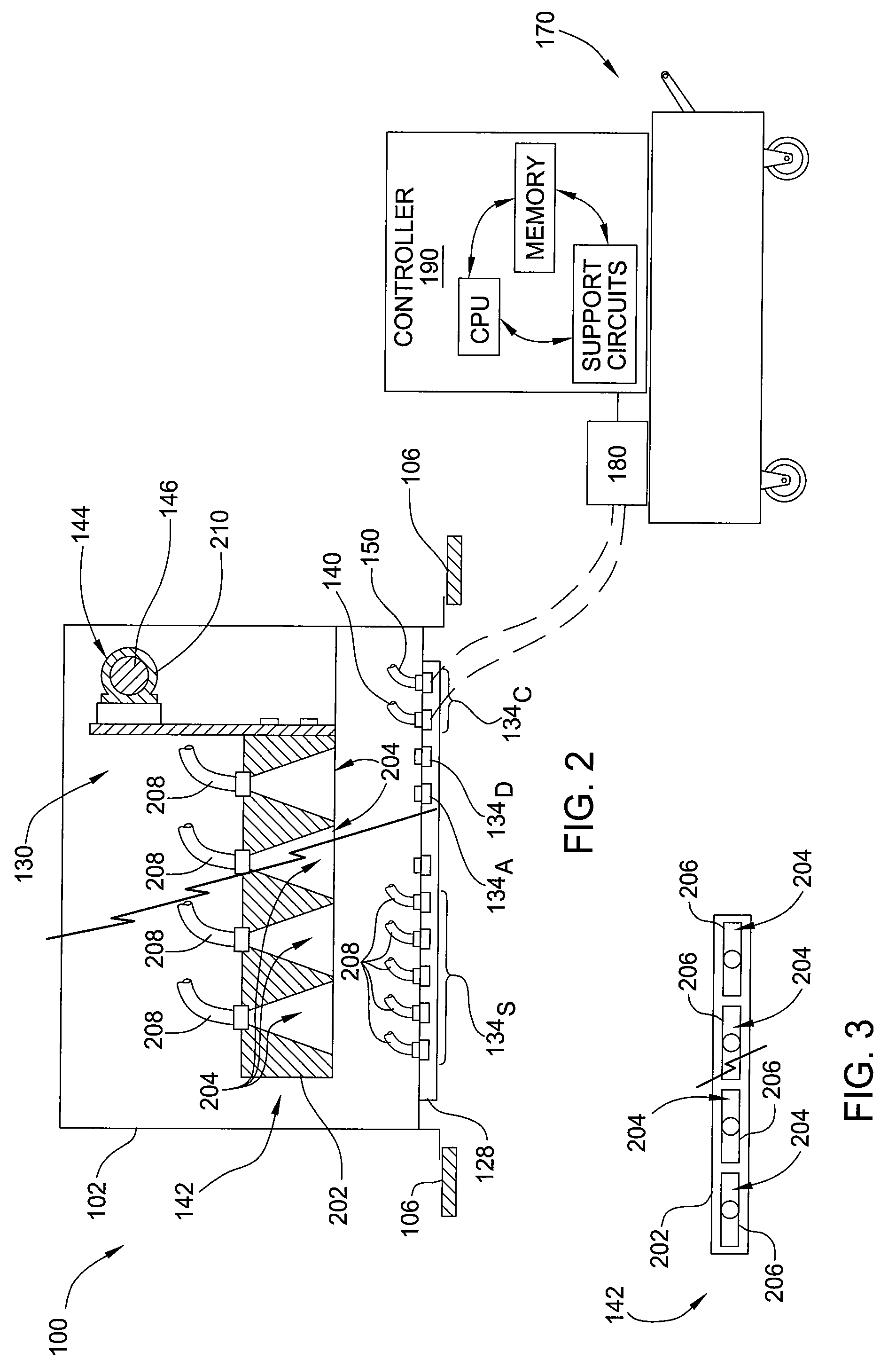

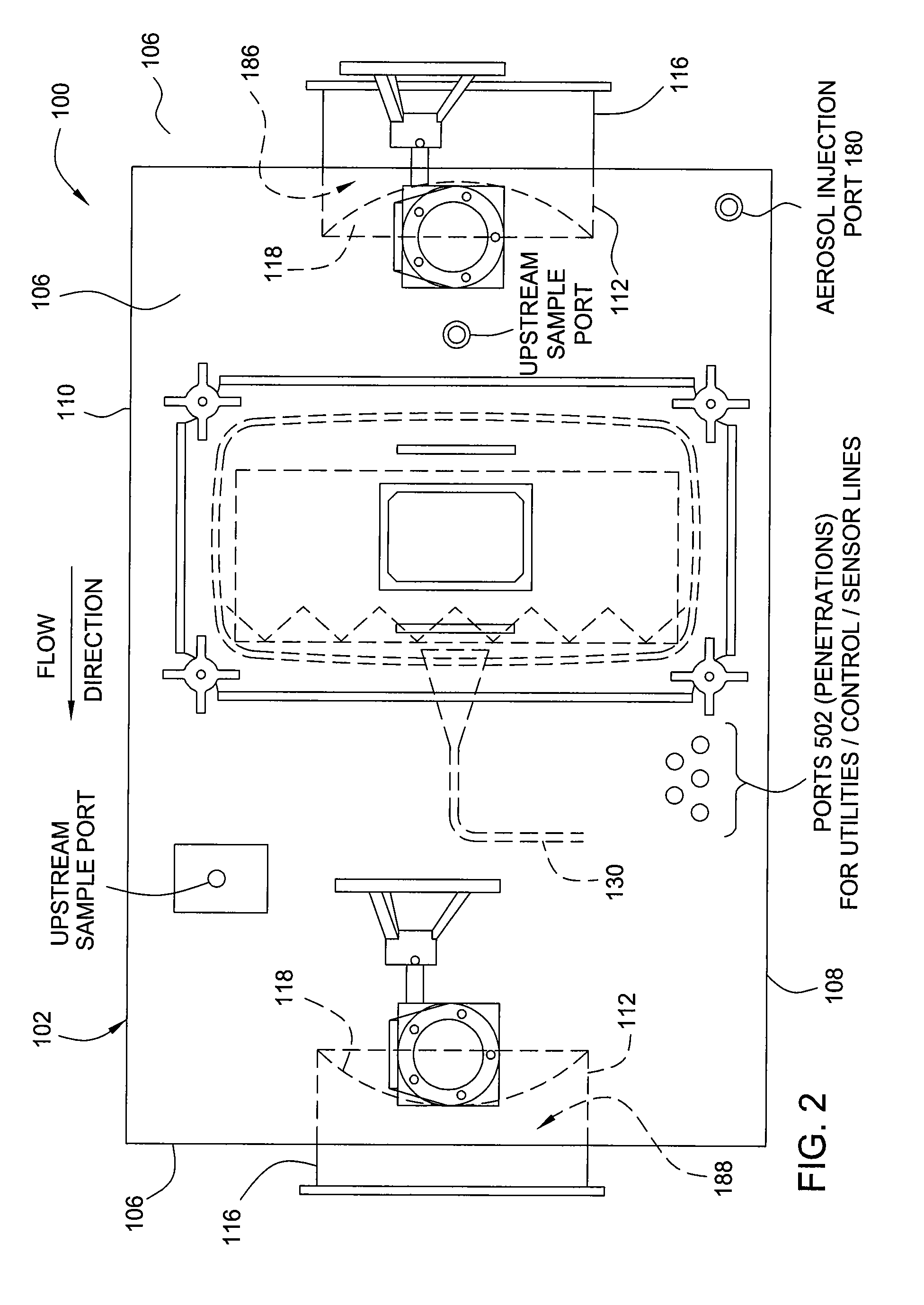

Exhaust filter module with mechanically positionable scan probe

Embodiments of the invention generally provide a filter module having a mechanically positionable test probe disposed therein and a method for testing a filter. In one embodiment, a filter module includes a housing adapted to receive a filter element. A sample probe suitable for leak testing the filter element is disposed in the interior volume of the housing. The sample probe may be moved to scan the filter by an actuator. In another embodiment, a method for testing a filter includes challenging a room side of a filter element disposed in a housing with a test aerosol, moving a probe disposed within the housing to obtain samples for testing and determining if the samples exceed a predefined leak criteria.

Owner:CAMFIL USA

Leak detection system

InactiveUS7174771B2Detection of fluid at leakage pointMeasurement of fluid loss/gain rateLeakage testControl theory

Owner:MICHIGAN AQUA TECH

Automotive fuel system leak testing

ActiveUS8074627B2Improve installationSimple materialDetection of fluid at leakage pointAnalogue computers for vehiclesFuel tankAutomotive fuel

Systems and methods for performing leak testing on fuel system components in hybrid vehicles during engine-off operating conditions are disclosed. For example, a fuel tank may include a pressure accumulator which may be filled with fuel via a fuel pump in order to generate a vacuum which may be used to diagnose leaks in the fuel system.

Owner:FORD GLOBAL TECH LLC

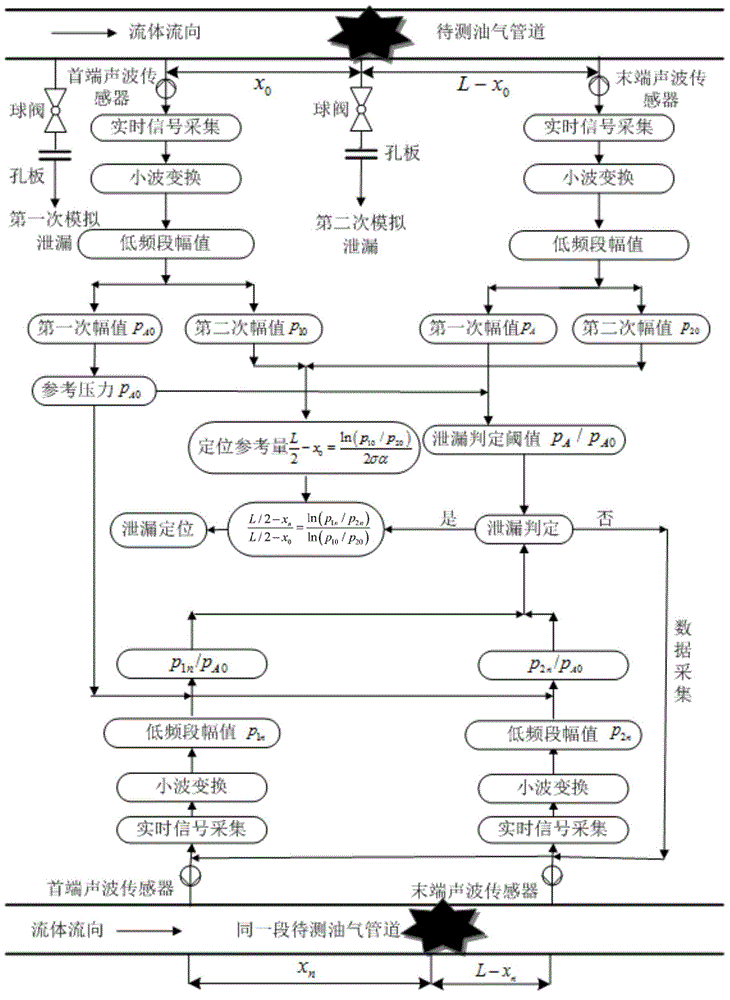

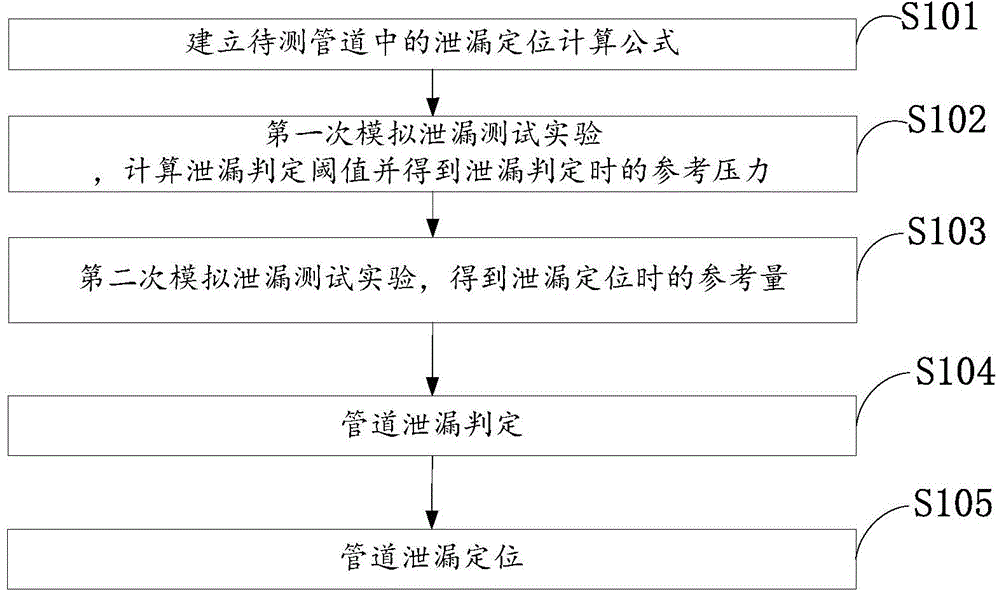

Oil and gas pipeline leakage positioning method based on sound wave amplitude

The invention discloses an oil and gas pipeline leakage positioning method based on sound wave amplitude. The oil and gas pipeline leakage positioning method comprises the following steps of establishing a leakage positioning computing formula in a to-be-tested pipeline; performing the first simulating leakage testing experiment at the upstream of a sensor at the head end, enabling sound wave sensors at the head end and the tail end to collect leakage sound wave signals which are propagated along the pipeline medium, and obtaining a leakage detection threshold value and the reference pressure; performing the second simulating leakage testing experiment between the sensors at the two ends of the to-be-tested pipeline, enabling the sound wave sensors at the head end and the tail end to collect leakage sound wave signals which are propagated along the pipeline medium, and obtaining the amplitude of a low-frequency sound wave signal; normally monitoring the to-be-tested pipeline, and detecting the leakage according to the leakage detection threshold value obtained by the first leakage testing experiment; according to the second leakage testing experiment and the positioning computing formula, positioning the leakage. The oil and gas pipeline leakage positioning method has the advantage that by not considering the computing of the sound wave propagation speed and the computing of the time difference, the mounting of a GPS (global positioning system) clock is avoided, the cost is low, the sensitivity is high, and the suitability for the oil and gas pipeline is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

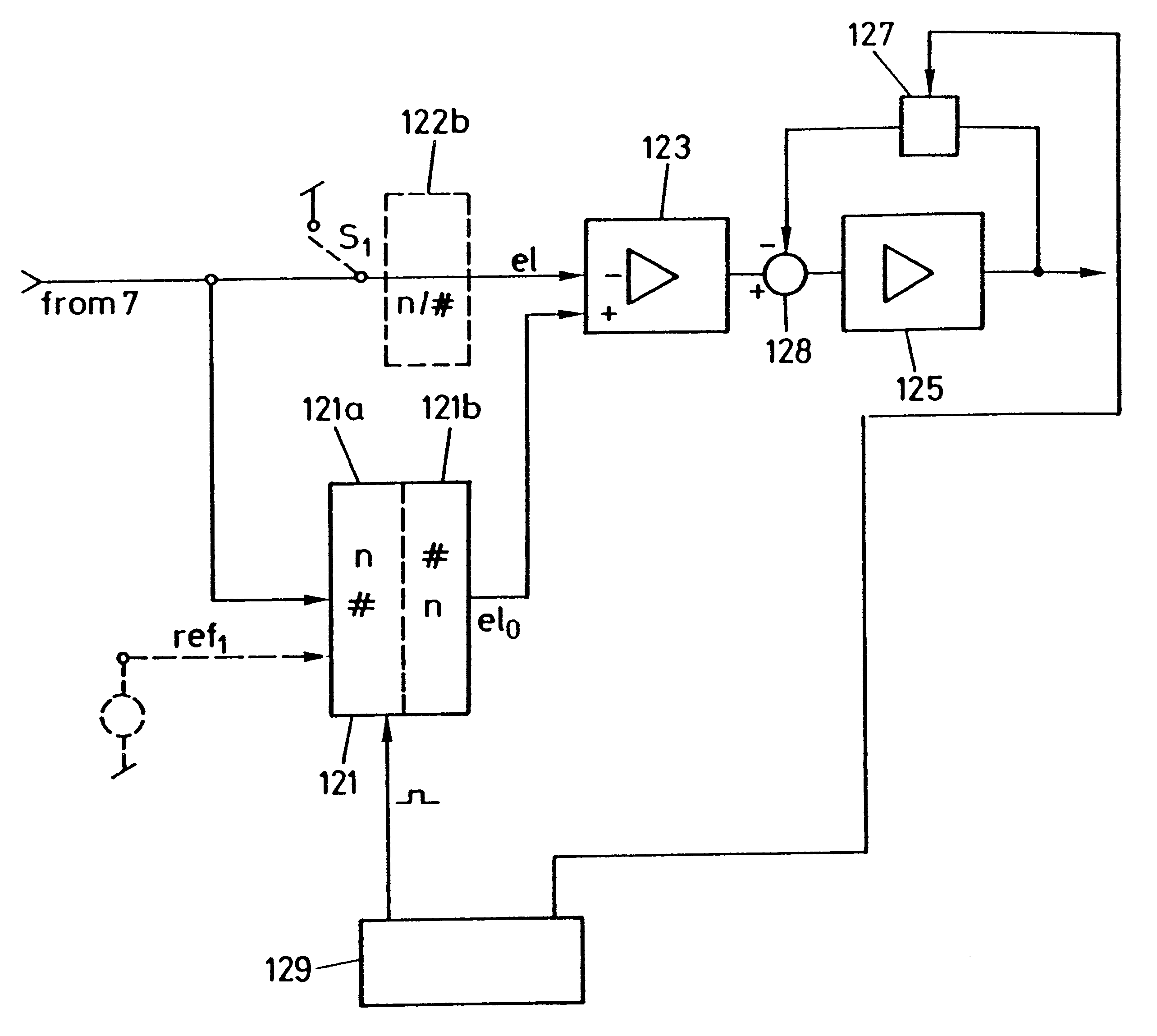

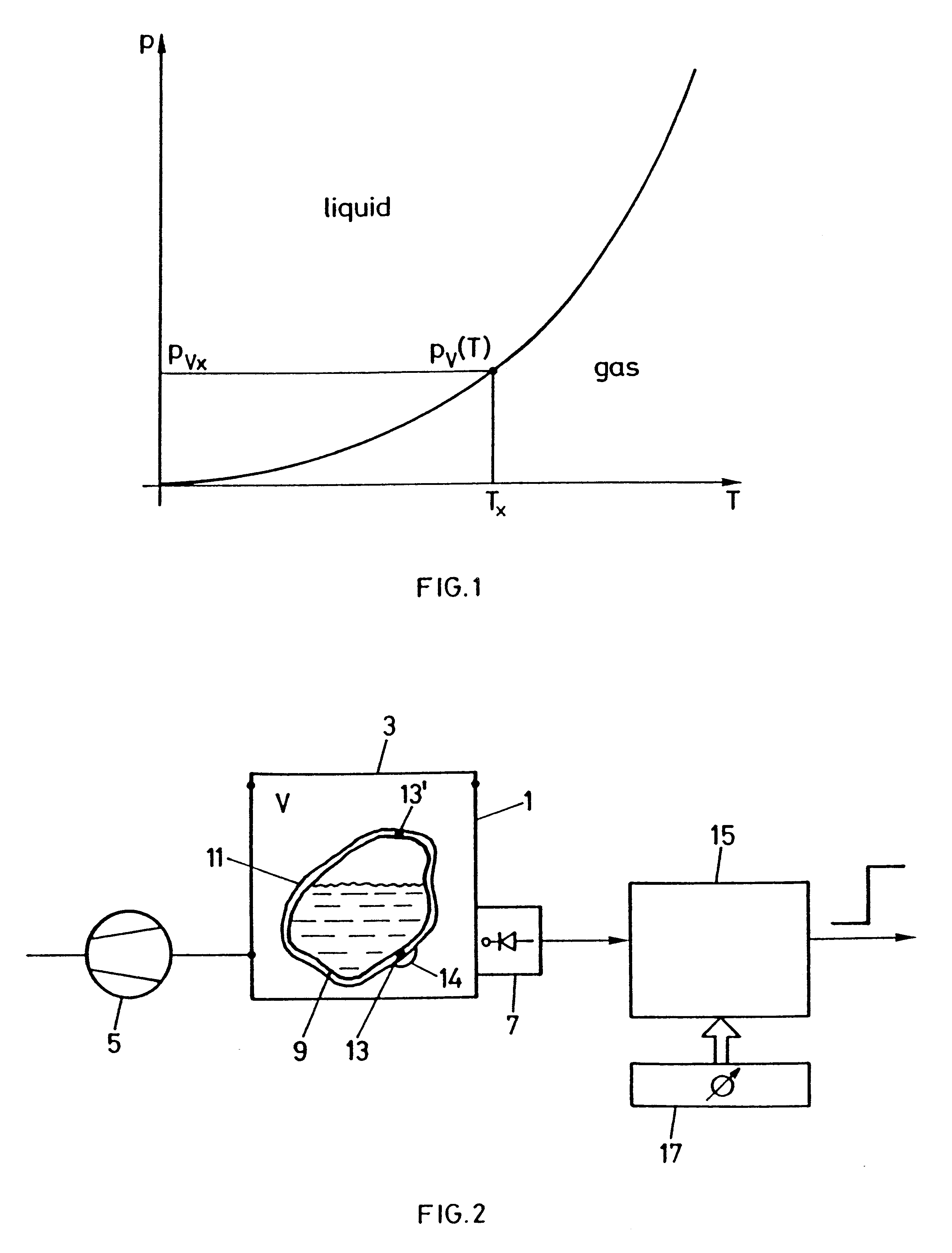

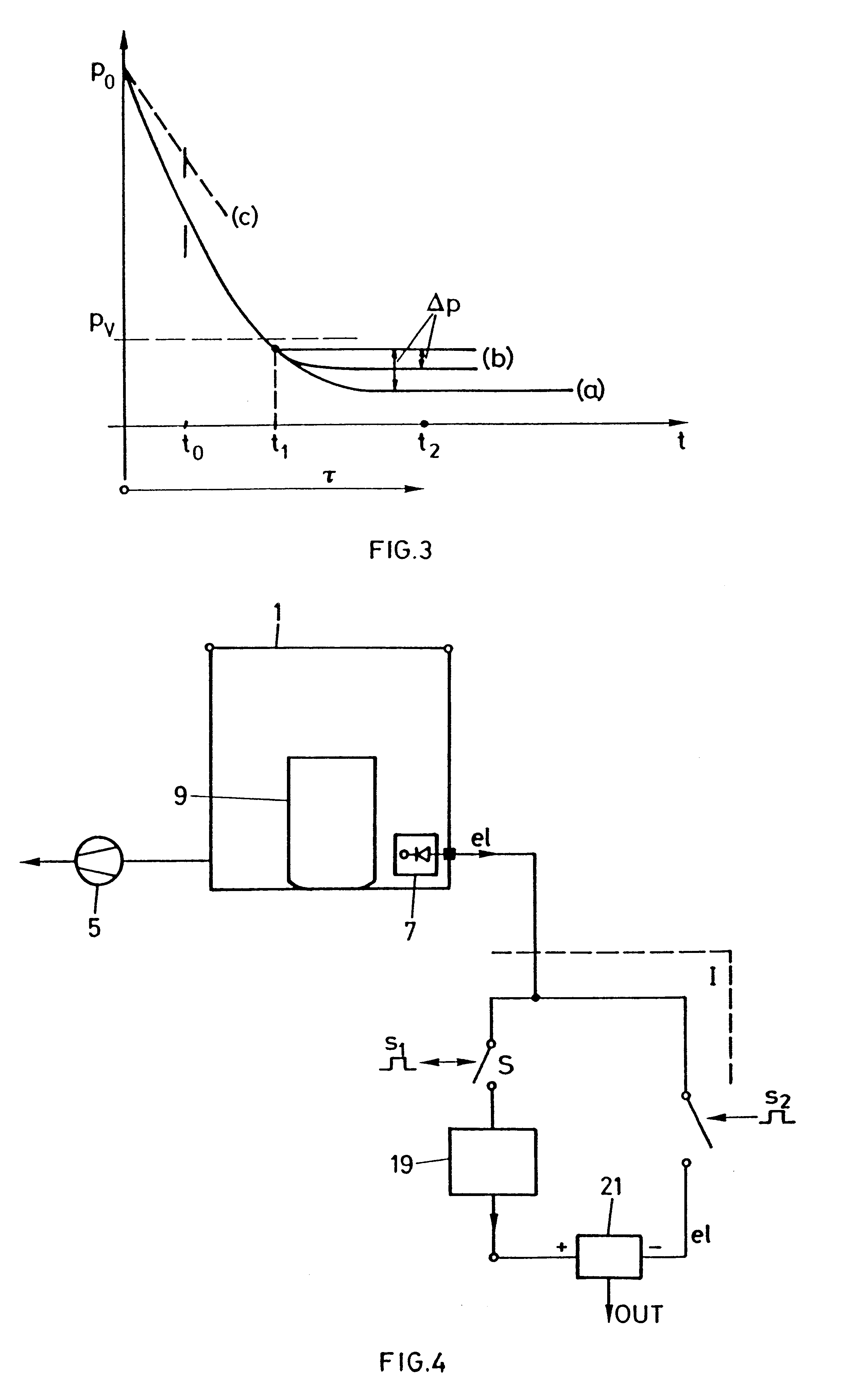

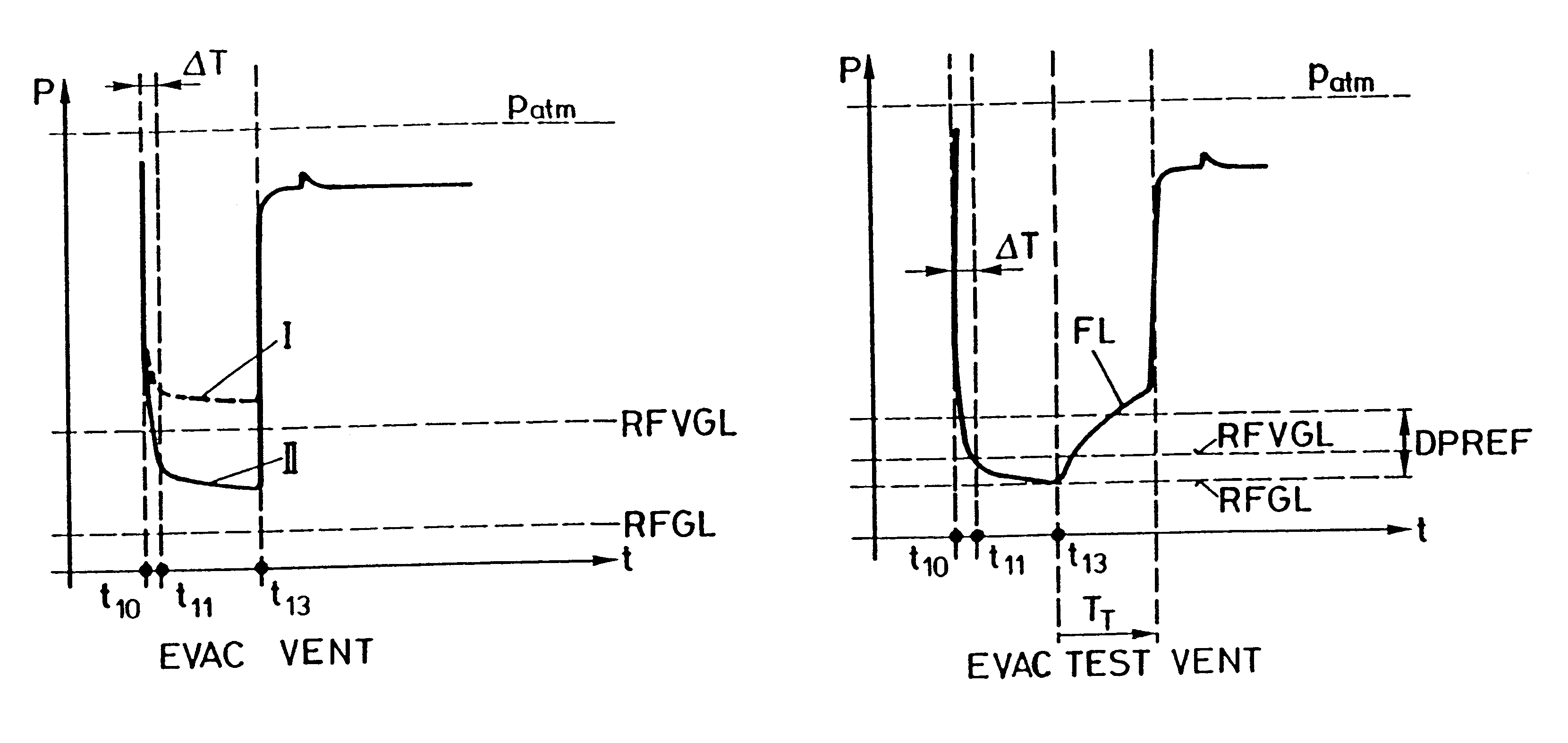

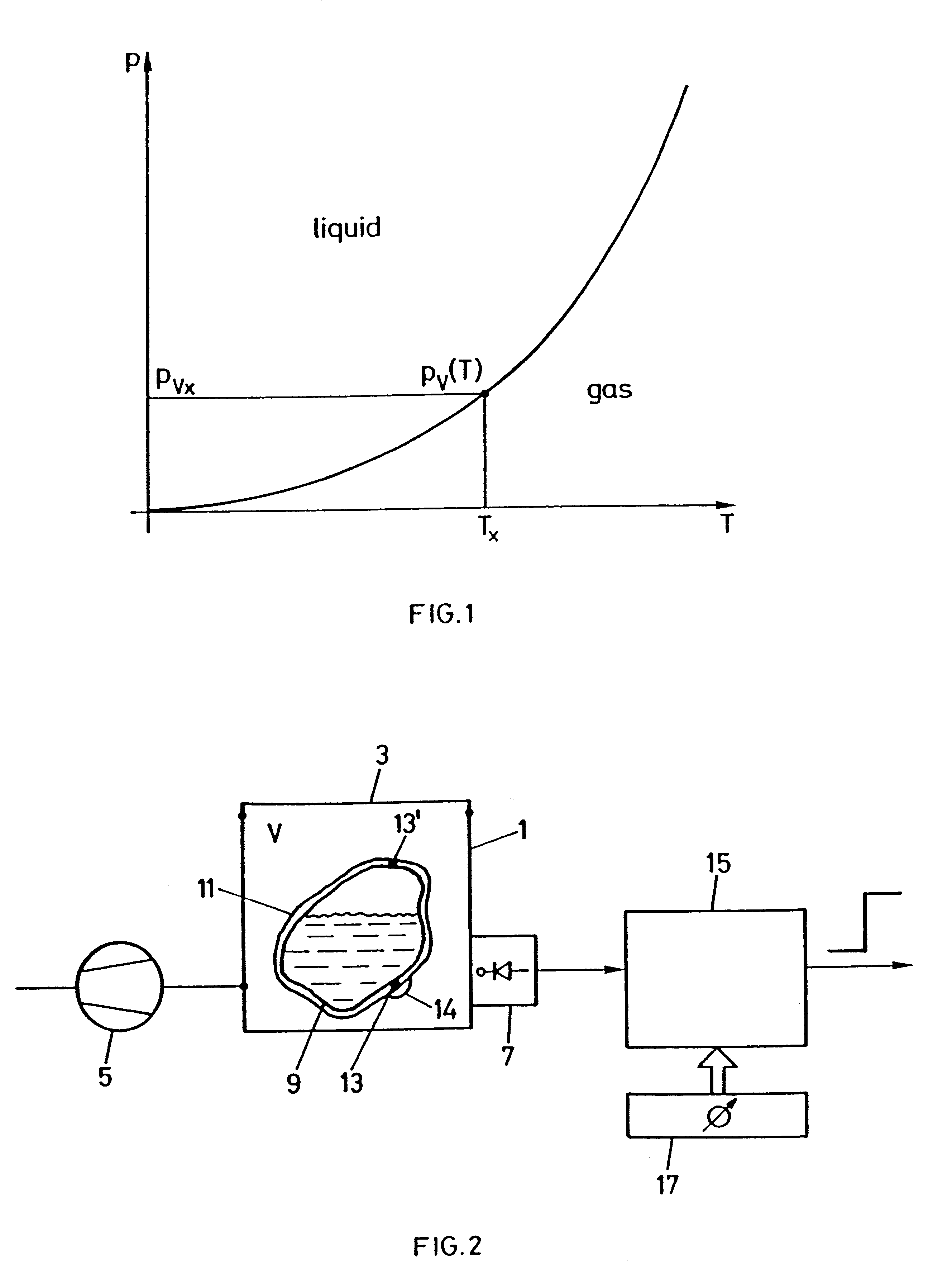

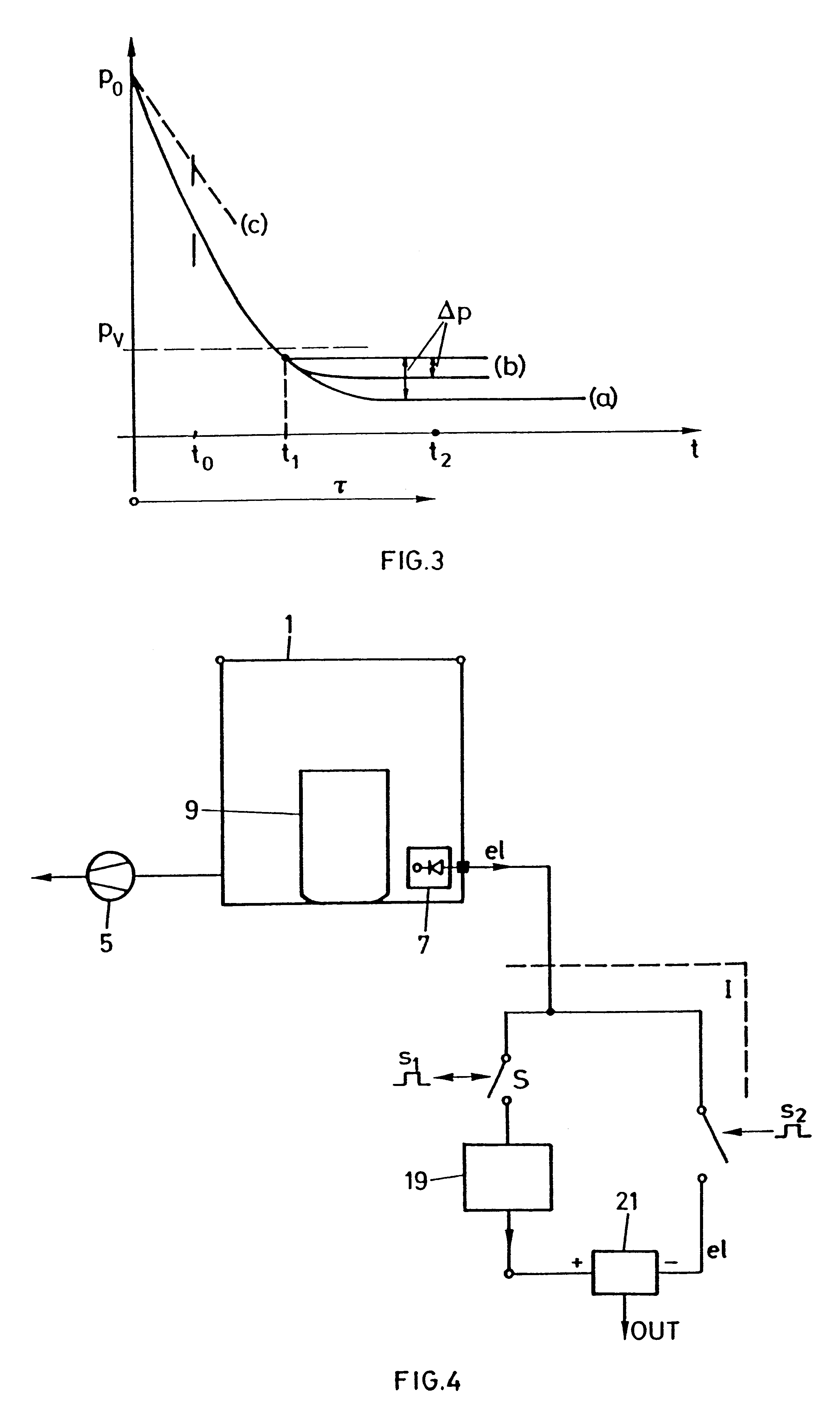

Method for leak testing and leak testing apparatus

InactiveUS6202477B1Equipment is cheapDetection of fluid at leakage pointMeasurement of fluid loss/gain rateVacuum pressureEvaporation

For leak testing closed containers (9) which are filled with a filling product containing at least one liquid component the container is introduced in a test cavity (1) which is evacuated at least down to vapour pressure of that liquid component. The pressure in the surrounding of the container (9) and thus within test cavity (1) is monitored. Monitoring is performed by a vacuum pressure sensor (7), whereas lowering pressure surrounding the container (9) is performed by a vacuum pump (5). Leakage is detected by monitoring a pressure change in the surrounding of the container which is due to evaporation of liquid emerging from a leak and being evaporated in the low pressure surrounding.

Owner:WILCO AG

Method for leak testing and leak testing apparatus

InactiveUS6305215B2Equipment is cheapDetection of fluid at leakage pointMeasurement of fluid loss/gain rateVacuum pressureEvaporation

For leak testing closed containers (9) which are filled with a filling product containing at least one liquid component the container is introduced in a test cavity (1) which is evacuated at least down to vapor pressure of that liquid component. The pressure in the surrounding of the container (9) and thus within test cavity (1) is monitored. Monitoring is performed by a vacuum pressure sensor (7), whereas lowering pressure surrounding the container (9) is performed by a vacuum pump (5). Leakage is detected by monitoring a pressure change in the surrounding of the container which is due to evaporation of liquid emerging from a leak and being evaporated in the low pressure surrounding.

Owner:WILCO AG

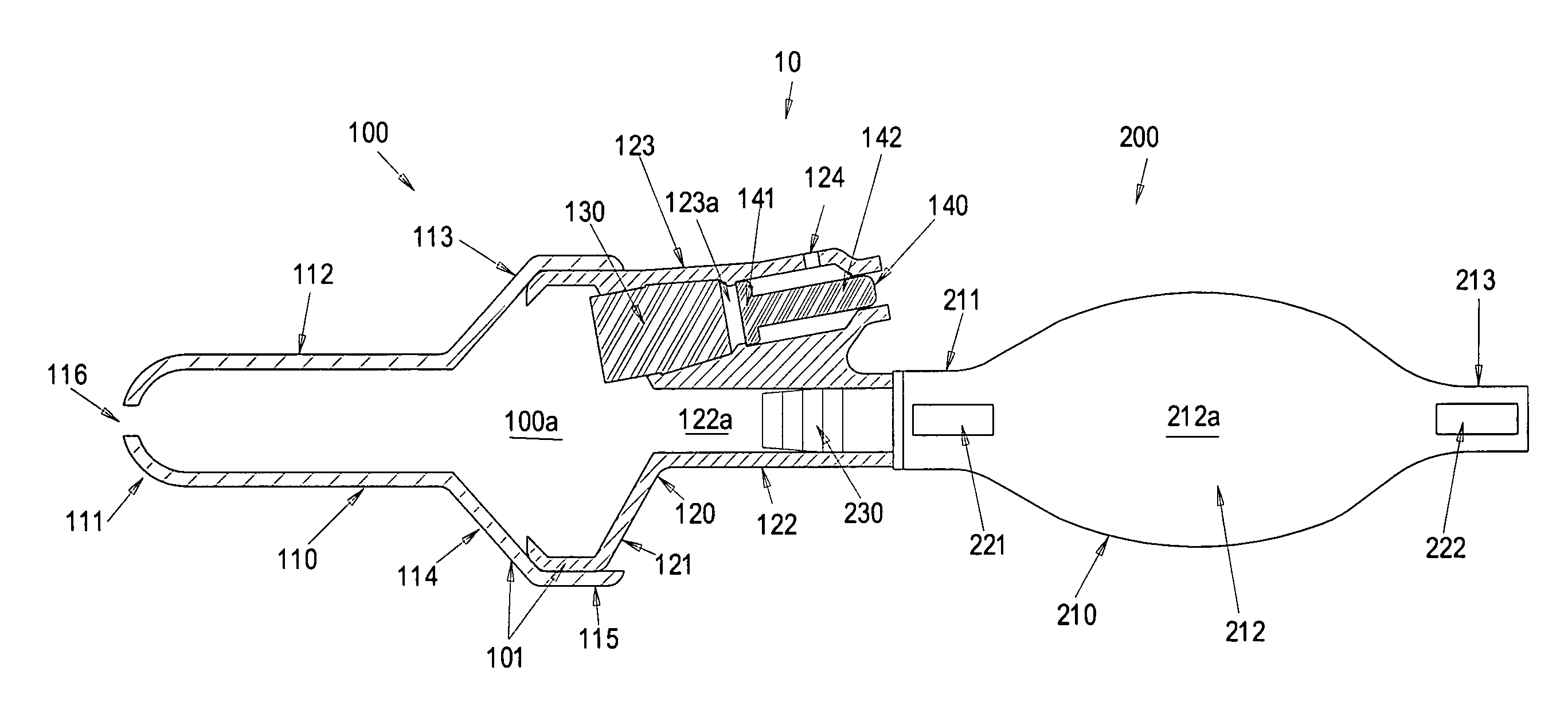

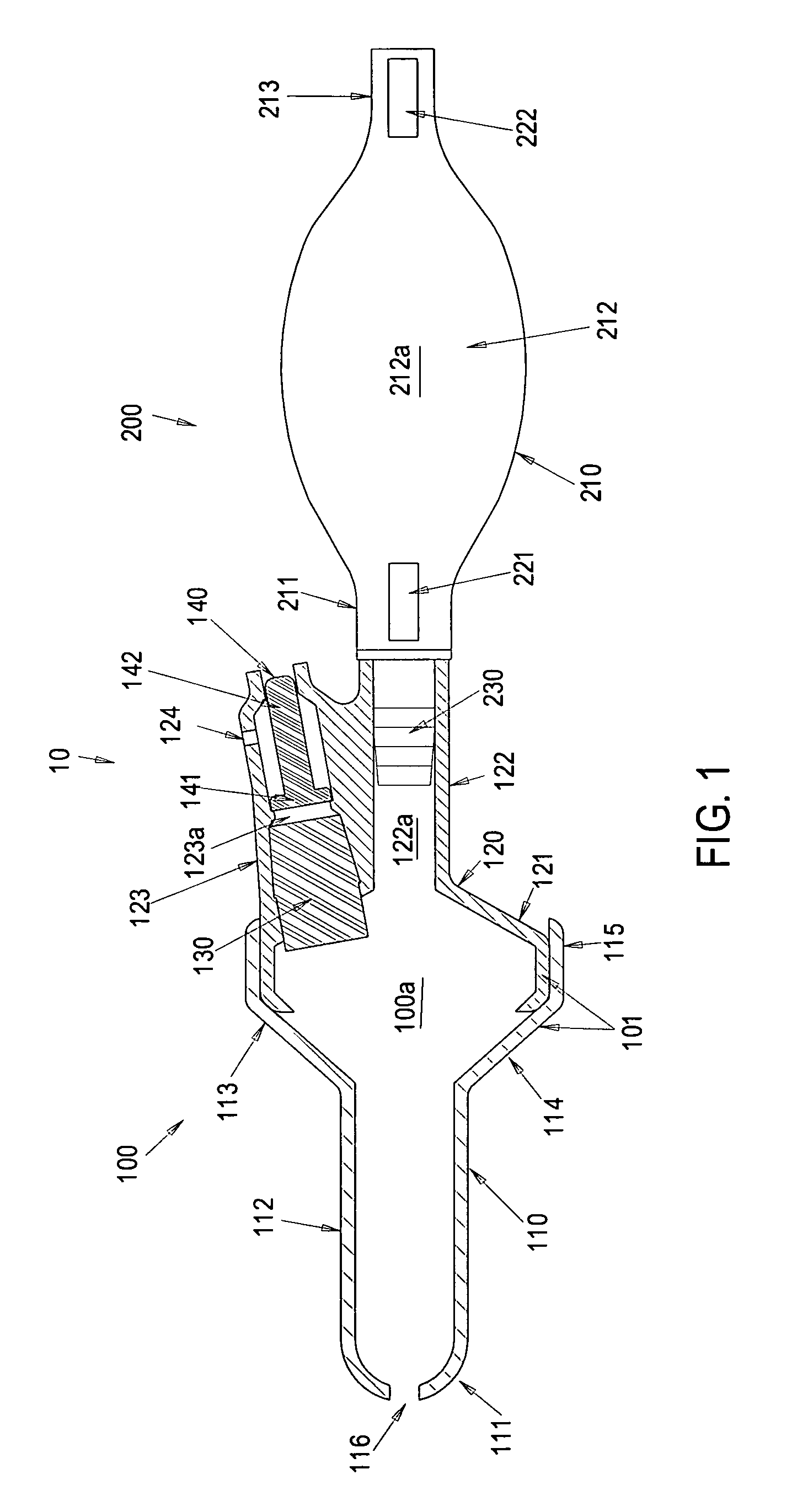

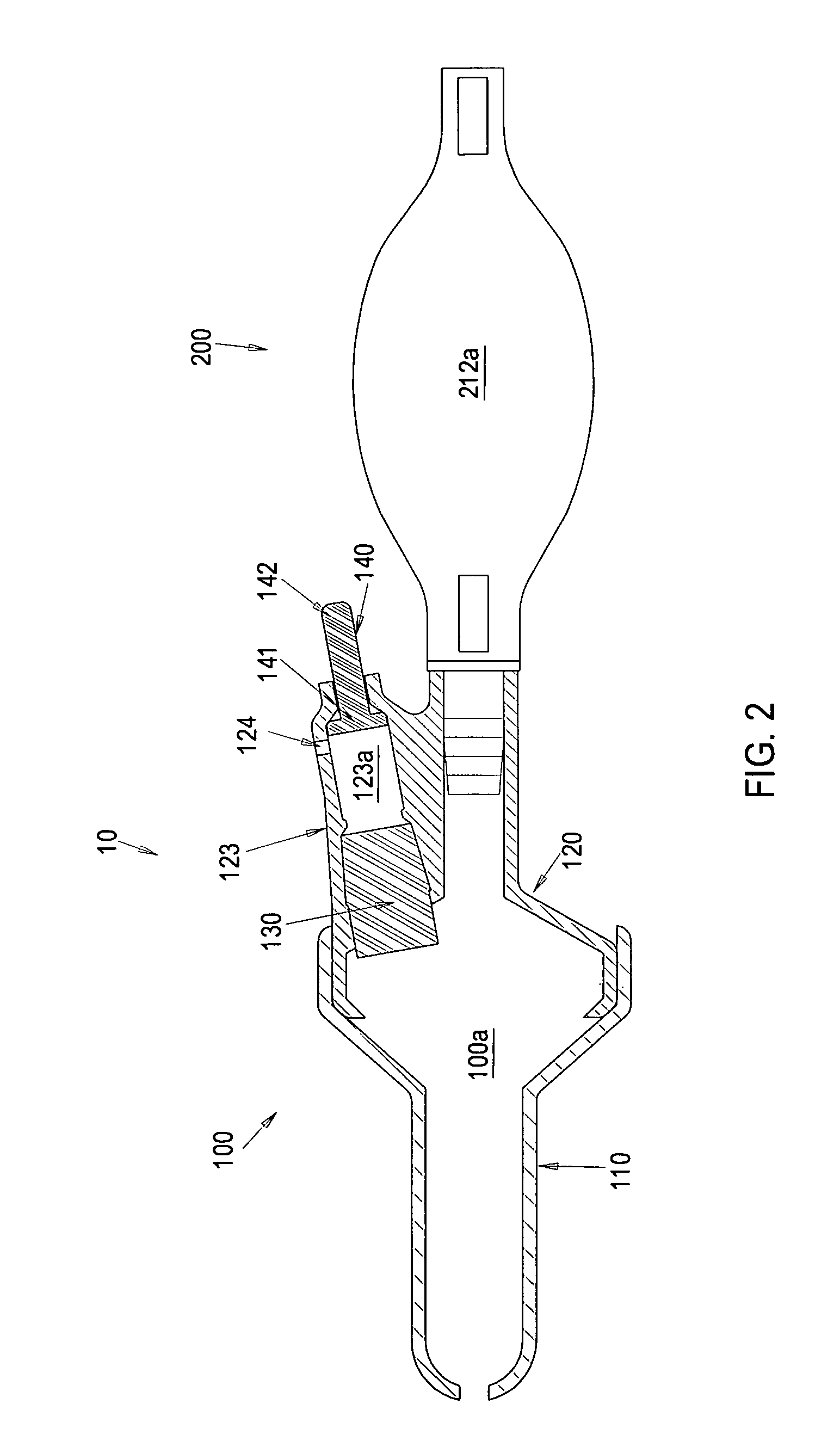

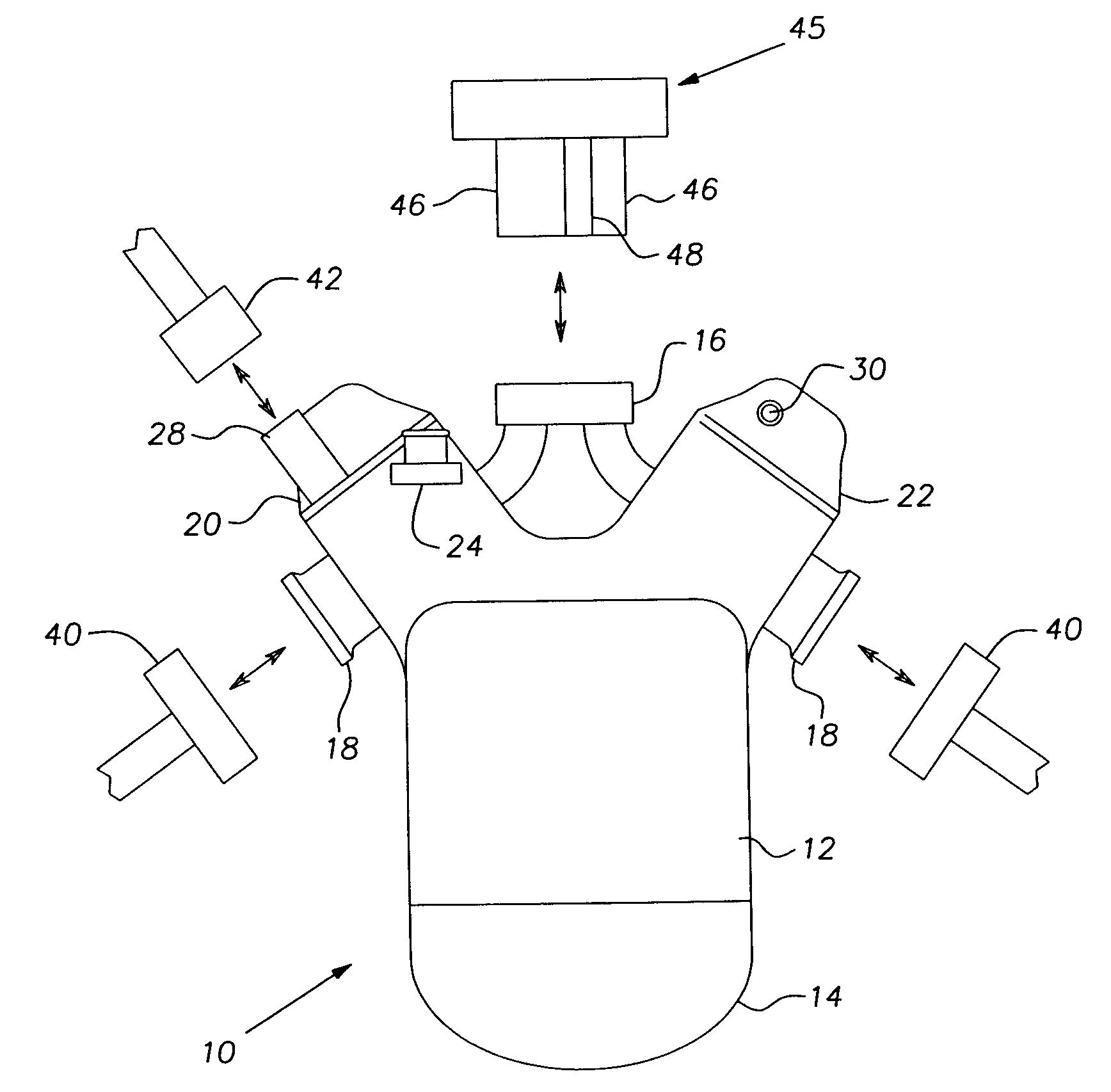

Anastomosis leak testing apparatus and methods

ActiveUS8216159B1Easy to useMore compactSurgeryPerson identificationRectal TubeGastrointestinal anastomosis

Anastomosis leak testers for testing for leaks in gastrointestinal anastomoses in patients include an inflation pump and a conduit part. The inflation pump has a compressible portion and a mechanism for providing a uni-directional flow of air through the inflation pump upon intermittent compressing thereof. Conduit parts have an interior space, a portion to be inserted into an anus of a patient or arm to be mated to a gastric tube, rectal tube or endoscope, a pressure relief valve and an indicator pin, and a rearward arm connected to the inflation pump. Upon actuation of the inflation pump, air flows through the inflation pump and through the conduit part into the patient's bowel. When the air pressure in the bowel exceeds a specified pressure, air is released through the pressure relief valve and ejects the indicator pin, which alerts the surgeon that the desired rectal pressure has been reached.

Owner:TOOLS FOR SURGERY

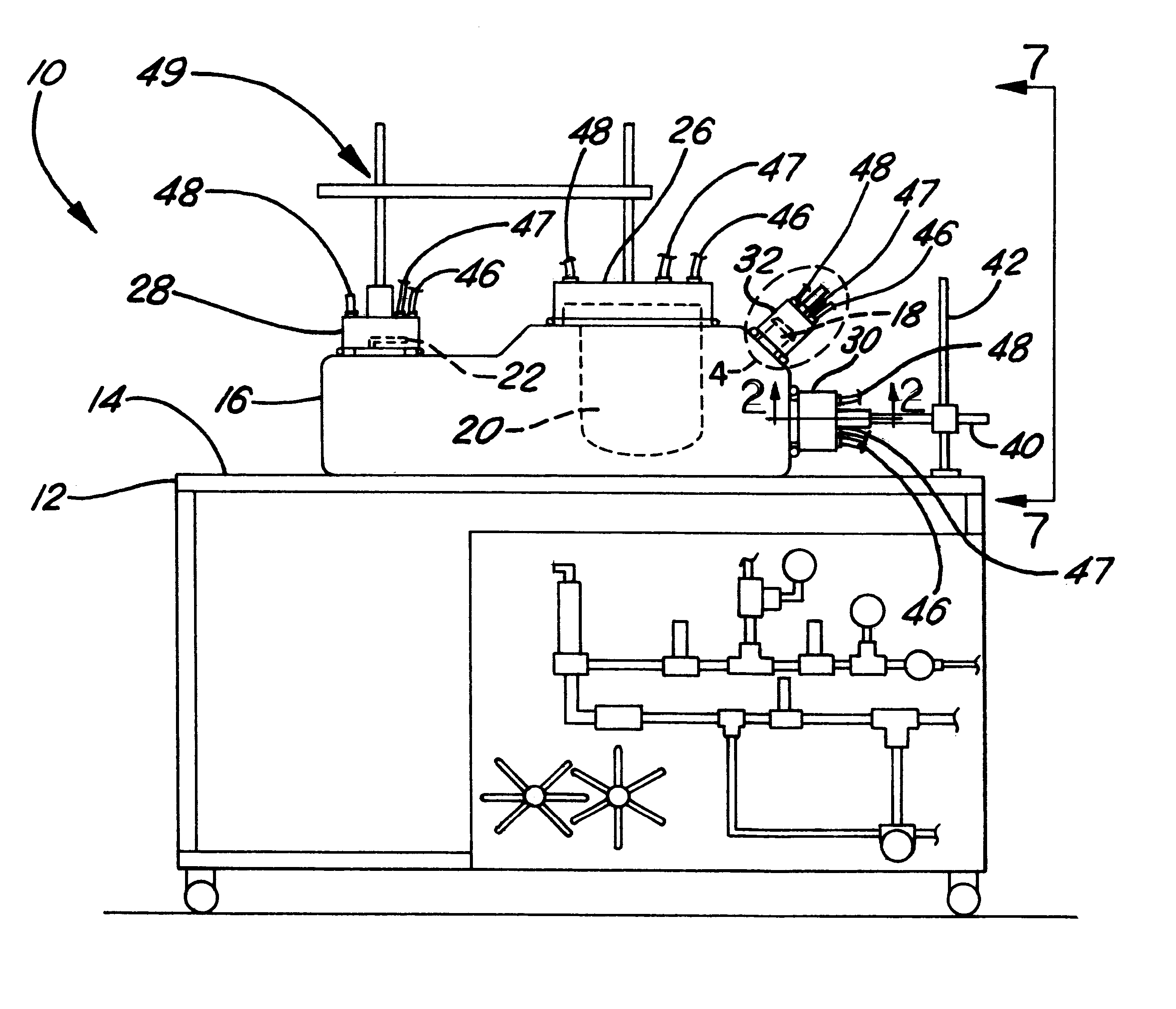

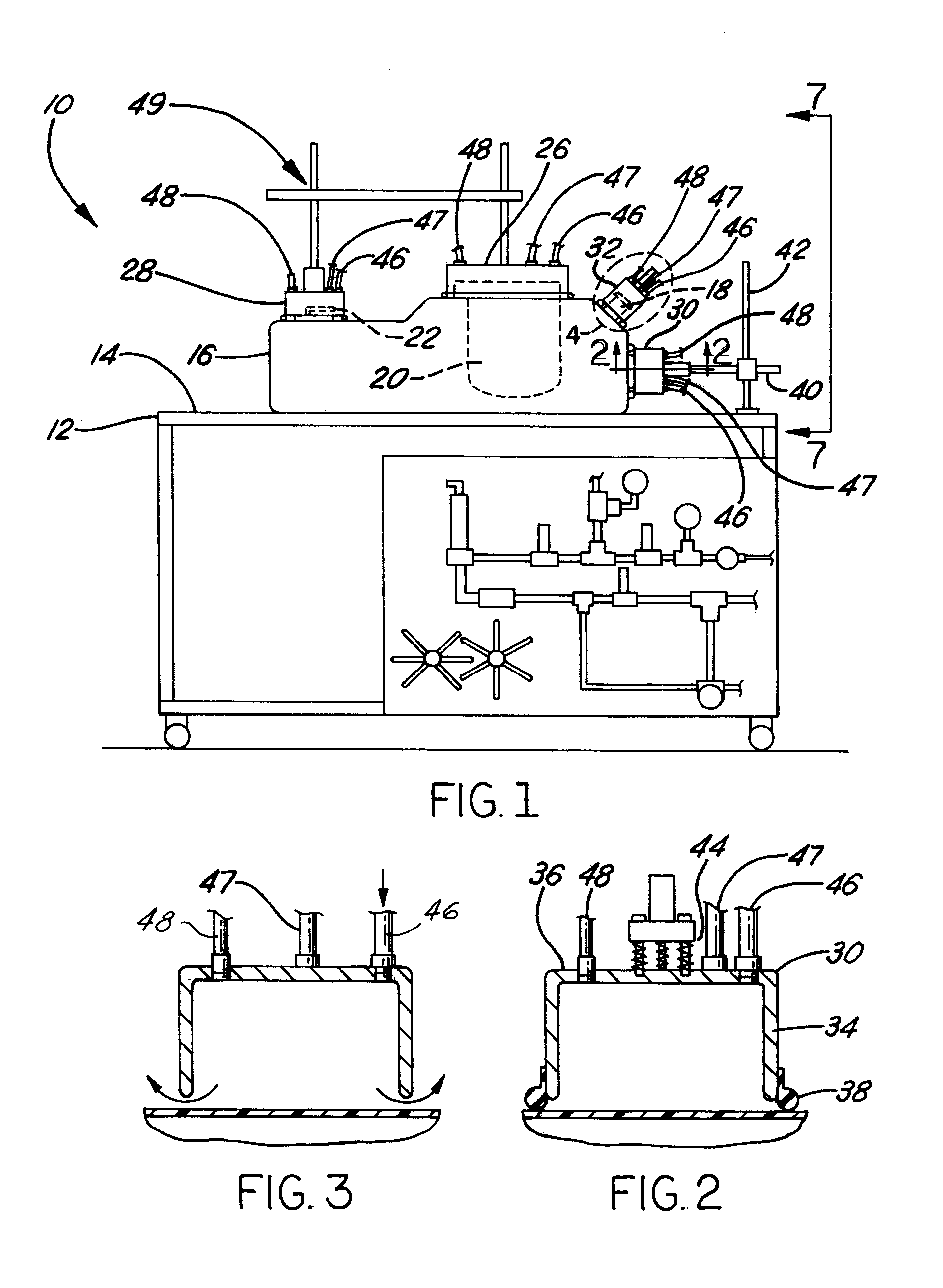

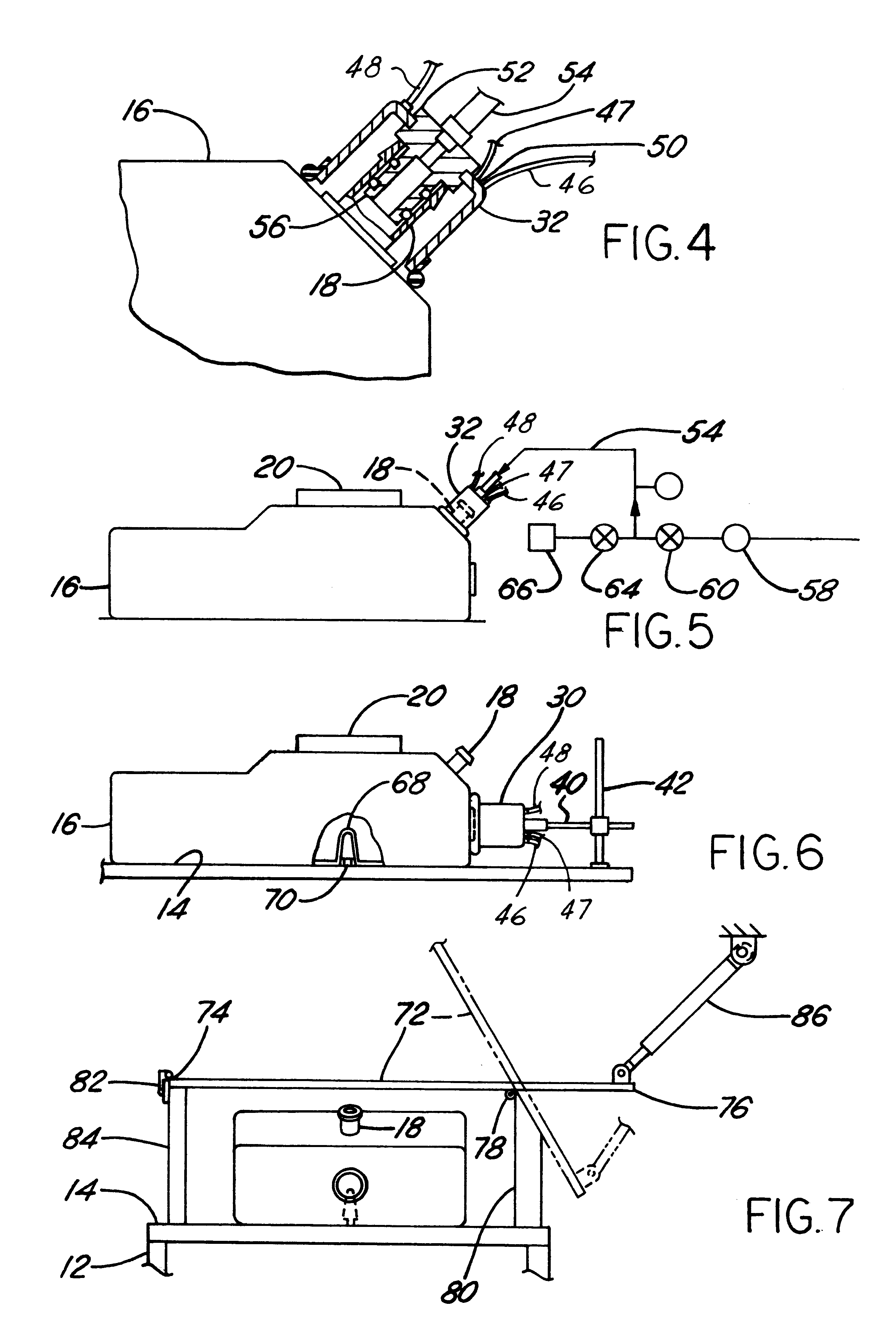

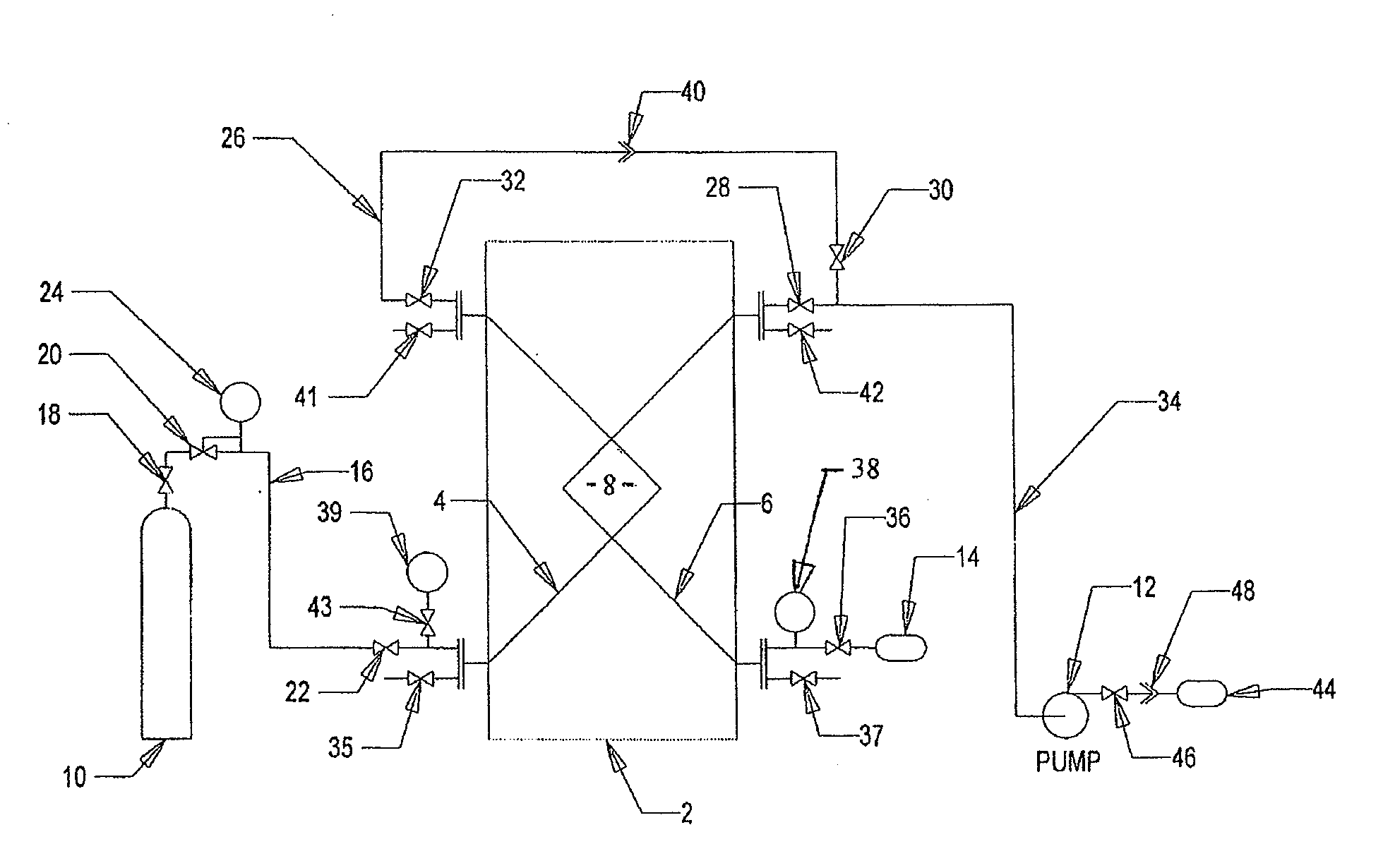

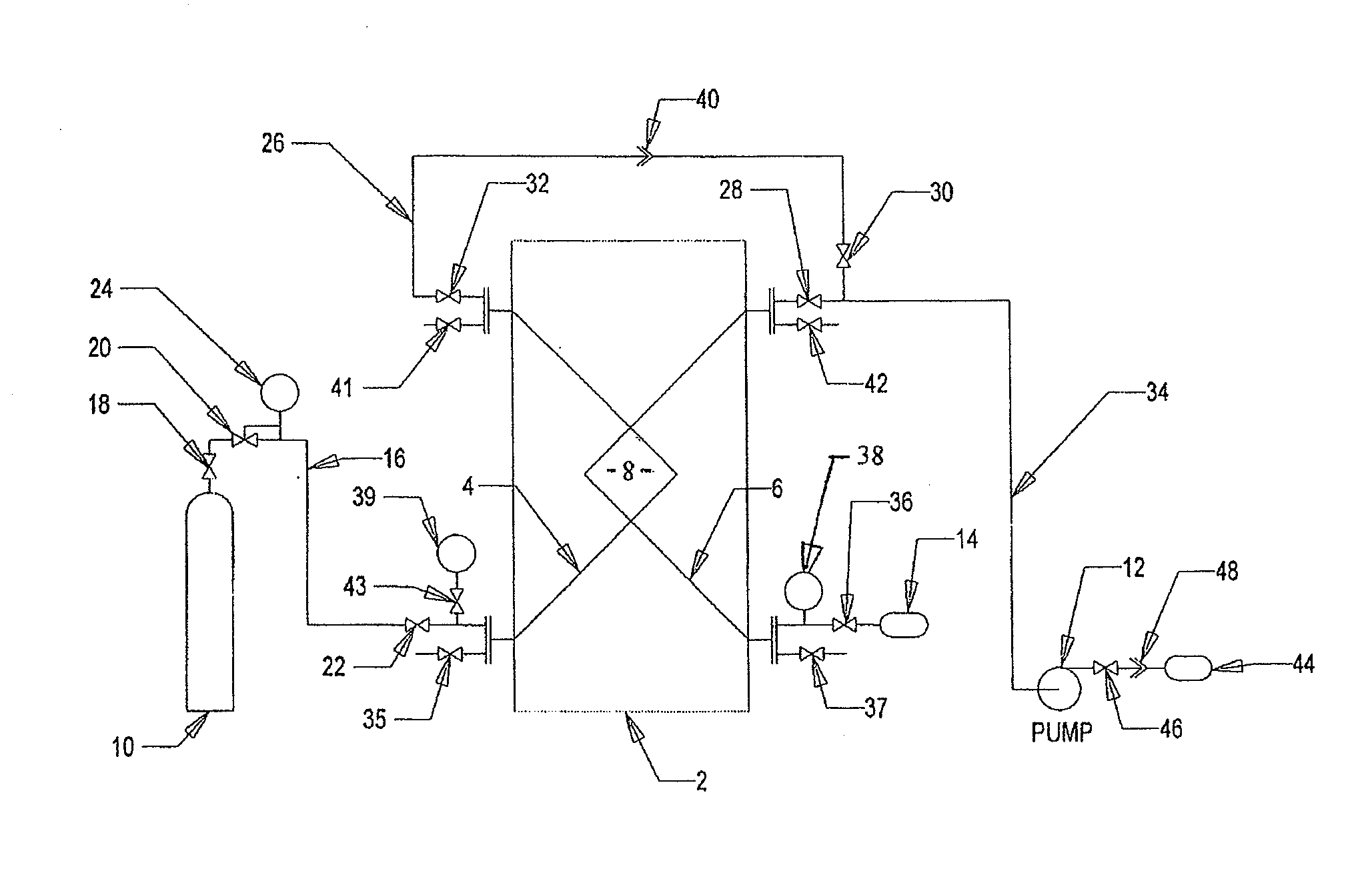

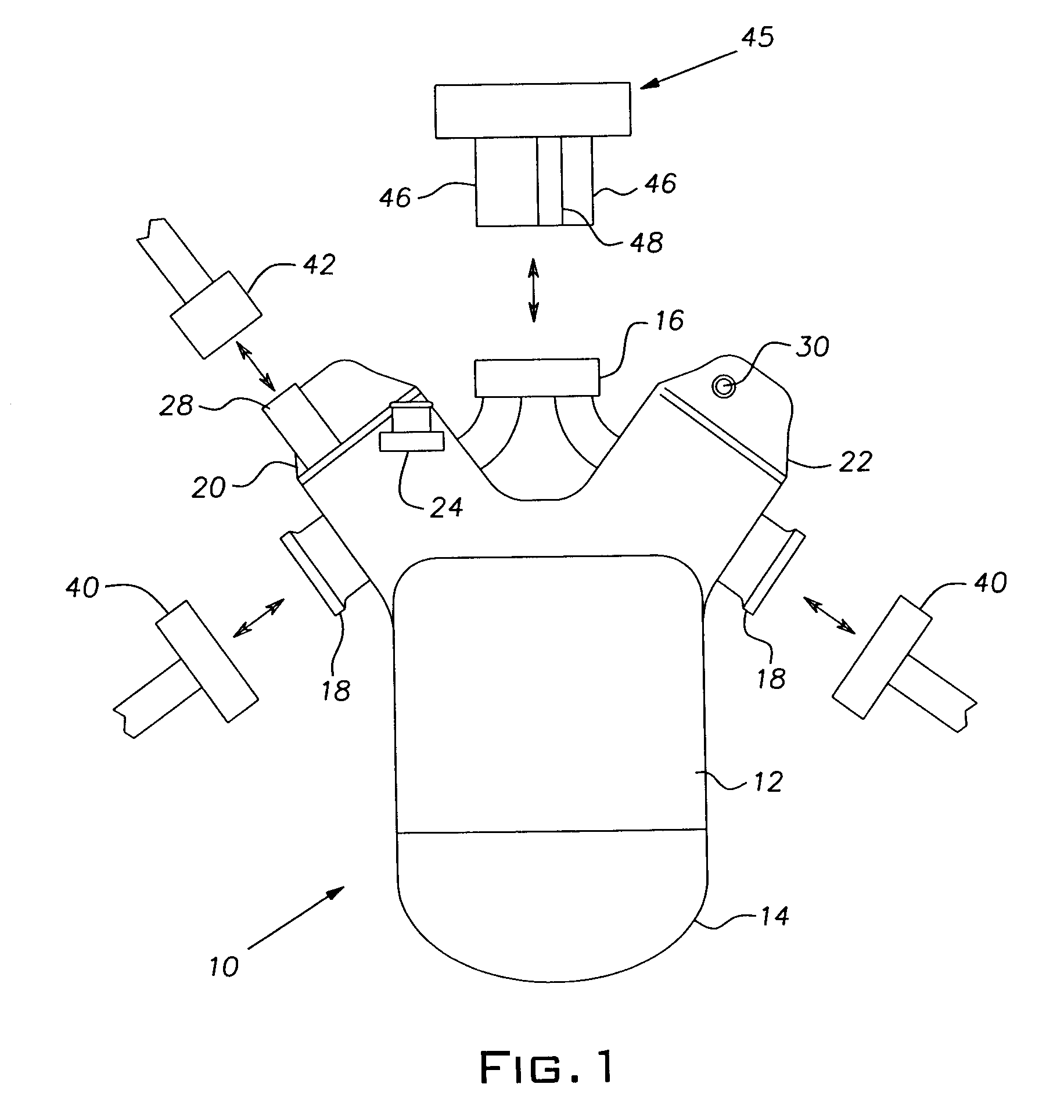

Helium leak tester for vehicle fuel tanks

InactiveUS6289722B1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateFuel tankLeak testing

A method of leak testing a walled tank (16) that has multiple joints containing closures or closure devices (18, 20, 22, 24) closing openings in the wall. Rims (38) of multiple cups (26, 28, 30, 32) are disposed against the tank wall to place the cup interiors in substantial sealed covering relation to underlying zones of the tank wall containing joints to be checked. A tank seal (52) is disposed fluid-tight against a fill spud (18) in the tank wall, and a test gas, helium, is introduced into the interior of the tank. Gas from within the interior of each cup is sampled via a respective sampling conduit (48), and a purge gas is introduced into the interior of each cup via a respective purge conduit (46) while the gas from the interior of each cup is being sampled via the respective sampling conduit.

Owner:AUTOMOTIVE COMPONENTS HOLDINGS

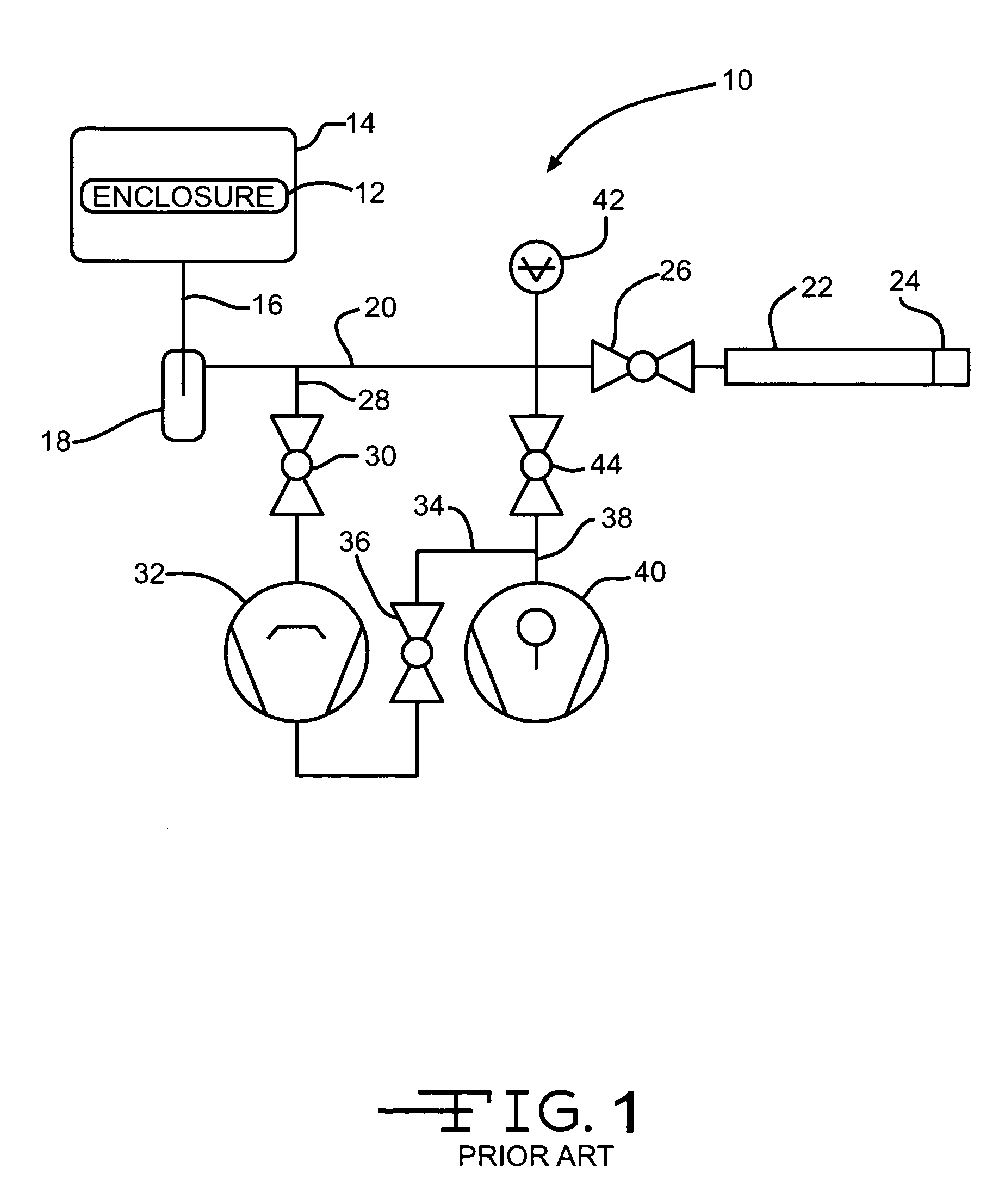

System and method for leak detection

InactiveUS20060179922A1Consistent amountMinimize durationDetection of fluid at leakage pointWorking fluidStream flow

A leak testing control assembly for a leak testing system of a type that cooperates with a test part interface that is coupled with a test part. In a broad aspect the leak testing control assembly includes a working fluid generator for applying a working fluid having a fluidic pressure to a test part. A flow controller assembly is coupled to the working fluid generator. The flow controller assembly includes a flow controller element for controlling the flow rate of the working fluid. A pressure level measuring element is positioned relative to the test part for measuring the fluidic pressure. A control system is coupled to the flow controller assembly and the pressure level measuring element. A user interface is coupled to the control system for providing user interaction with the leak testing control assembly. During operation, the control system 1) facilitates application of the fluidic pressure at a selected relatively constant flow rate; and, 2) interprets the value of the fluidic pressure, after the application of the fluidic pressure at the selected relatively constant flow rate, to determine whether the test part is free of leaks.

Owner:SACCA GIUSEPPE

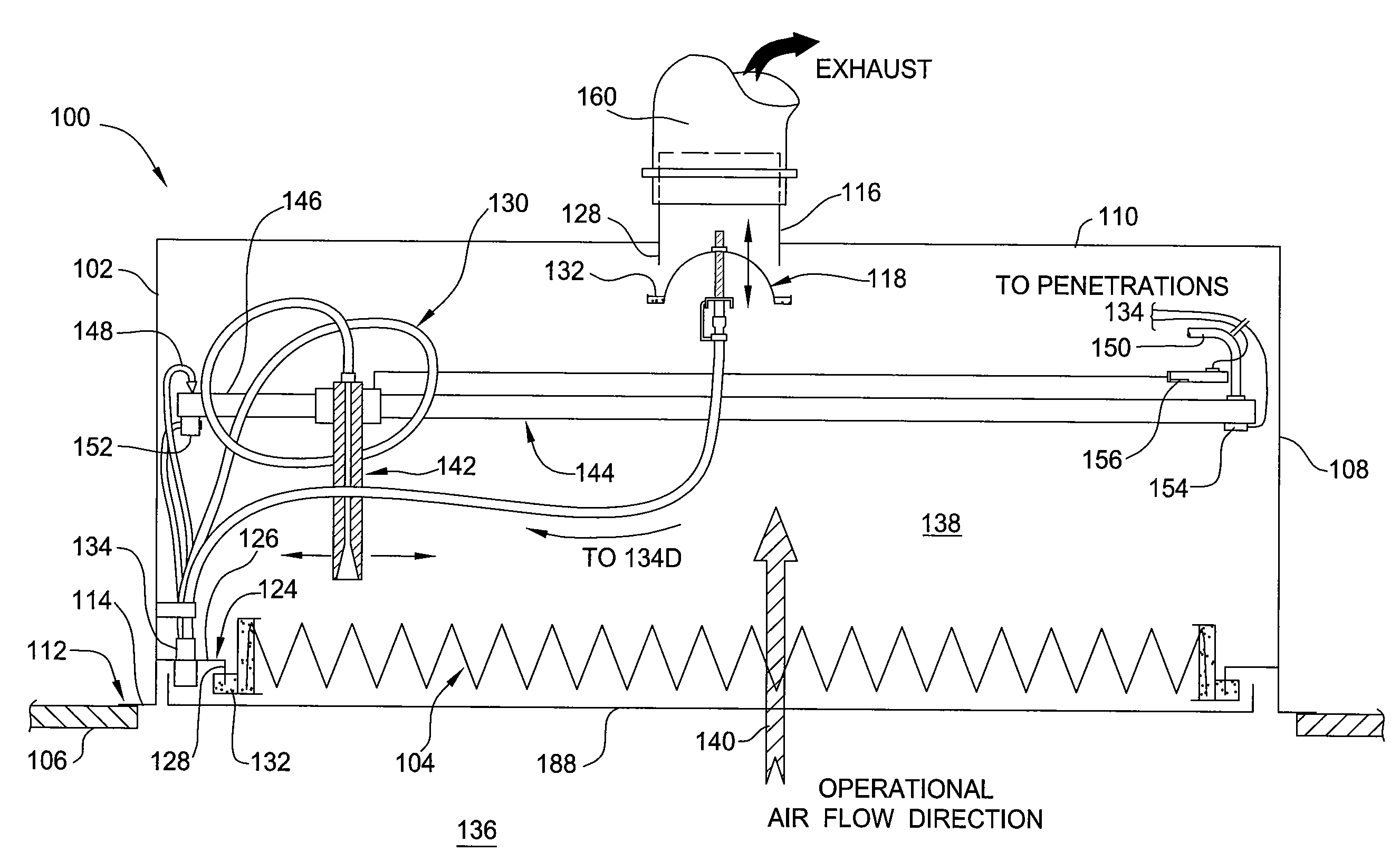

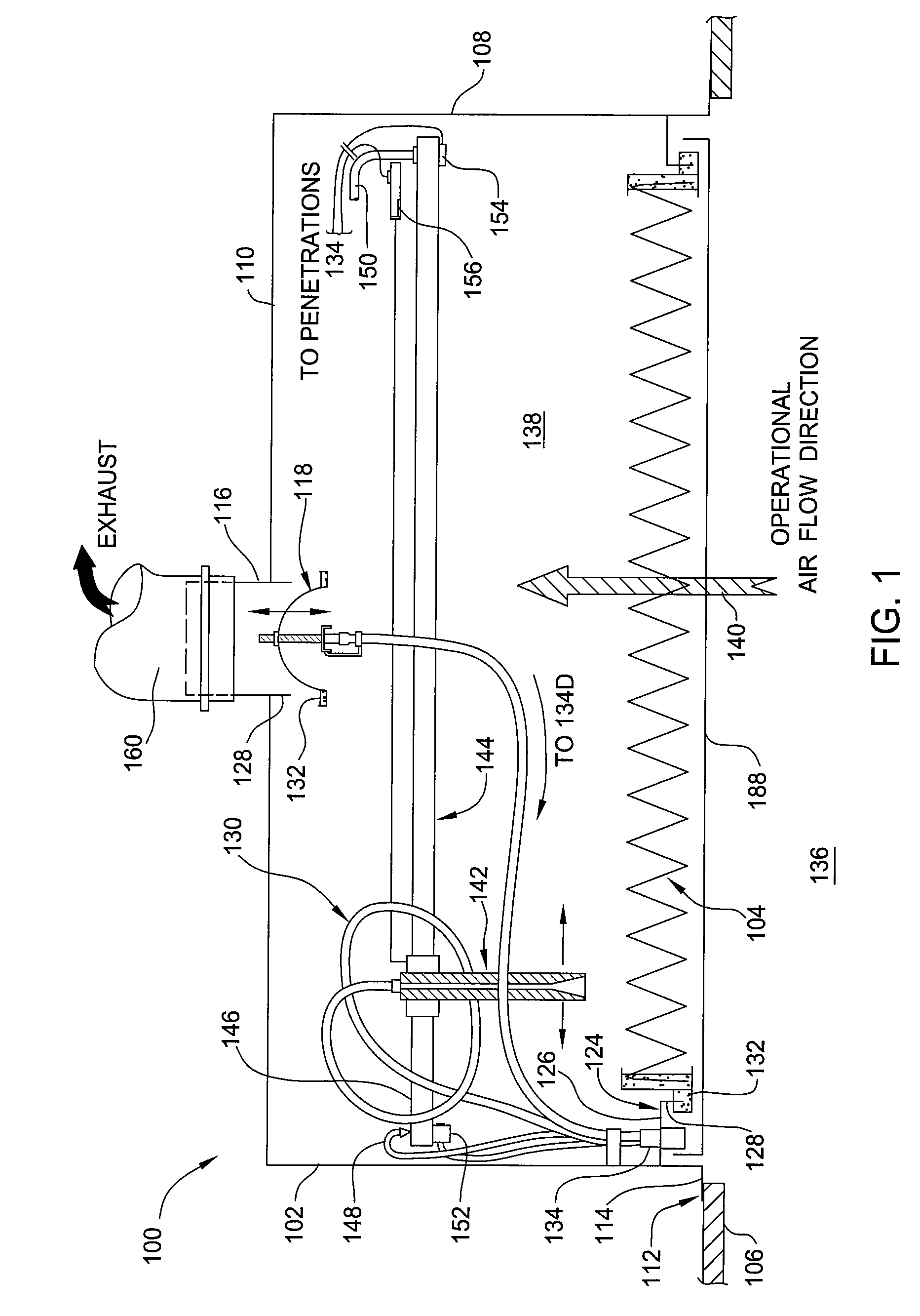

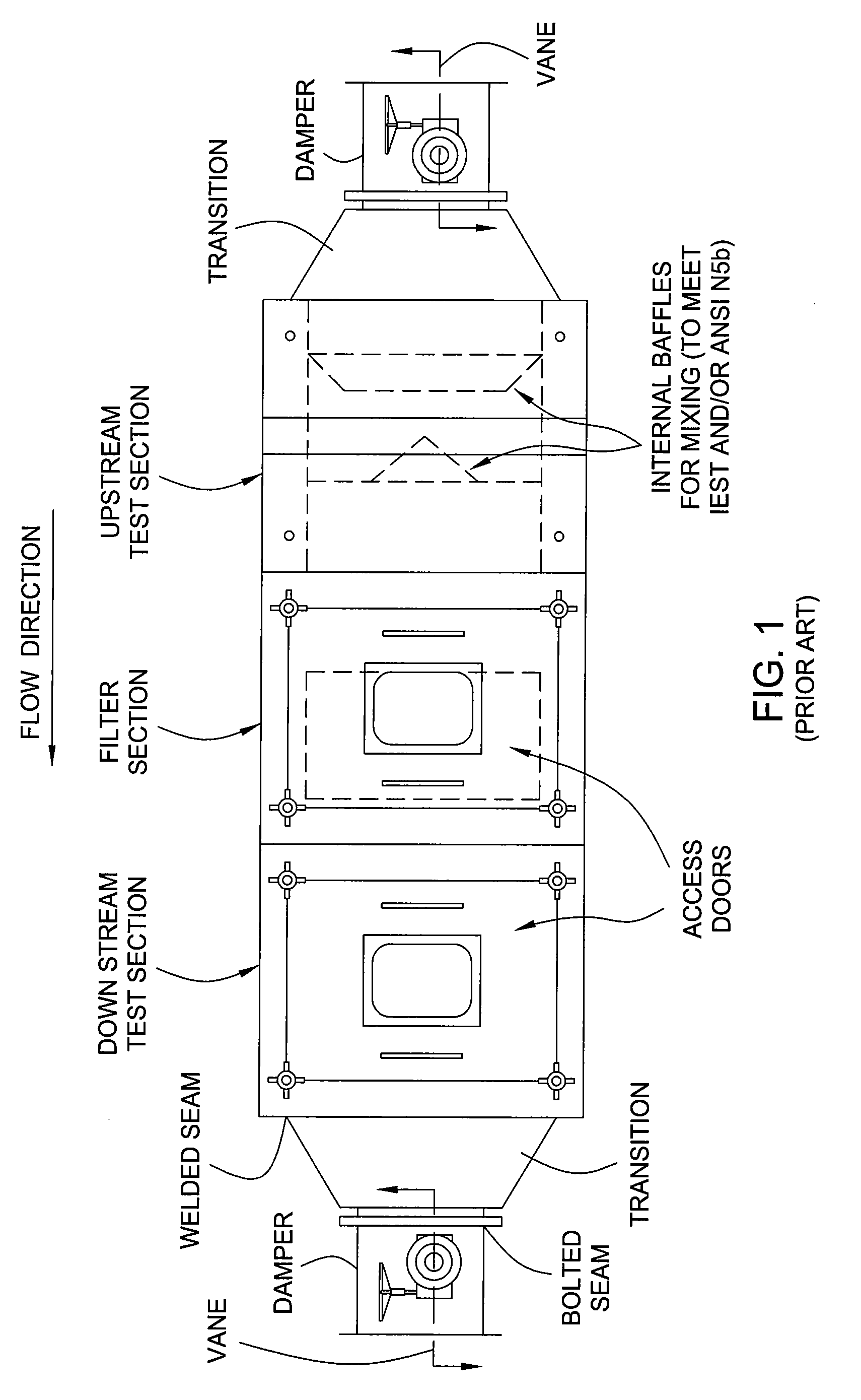

Scan testable filter housing assembly for exhaust applications

ActiveUS20060042359A1Detection of fluid at leakage pointCombination devicesLeak testingFilter element

A filter housing assembly for exhaust applications and method of testing the same is provided. In one embodiment, the filter housing assembly includes a housing having a filter receiving aperture, a first air flow port configured to couple the housing to an exhaust system and a second air flow port sized to deliver a flow capable of providing at least 75 feet per minute of air flow through the filter receiving aperture. A filter element is sealingly disposed in the filter receiving aperture of the housing. A cap is provided that operably seals the second air flow port when not in use. In another embodiment, a method for testing a filter housing assembly for exhaust applications includes providing air through a filter element disposed in the housing in a direction opposite an operational air flow direction, leak testing the filter element from a roomside of the filter element, and, flowing air through the filter element after leak testing in the operational direction.

Owner:CAMFIL USA

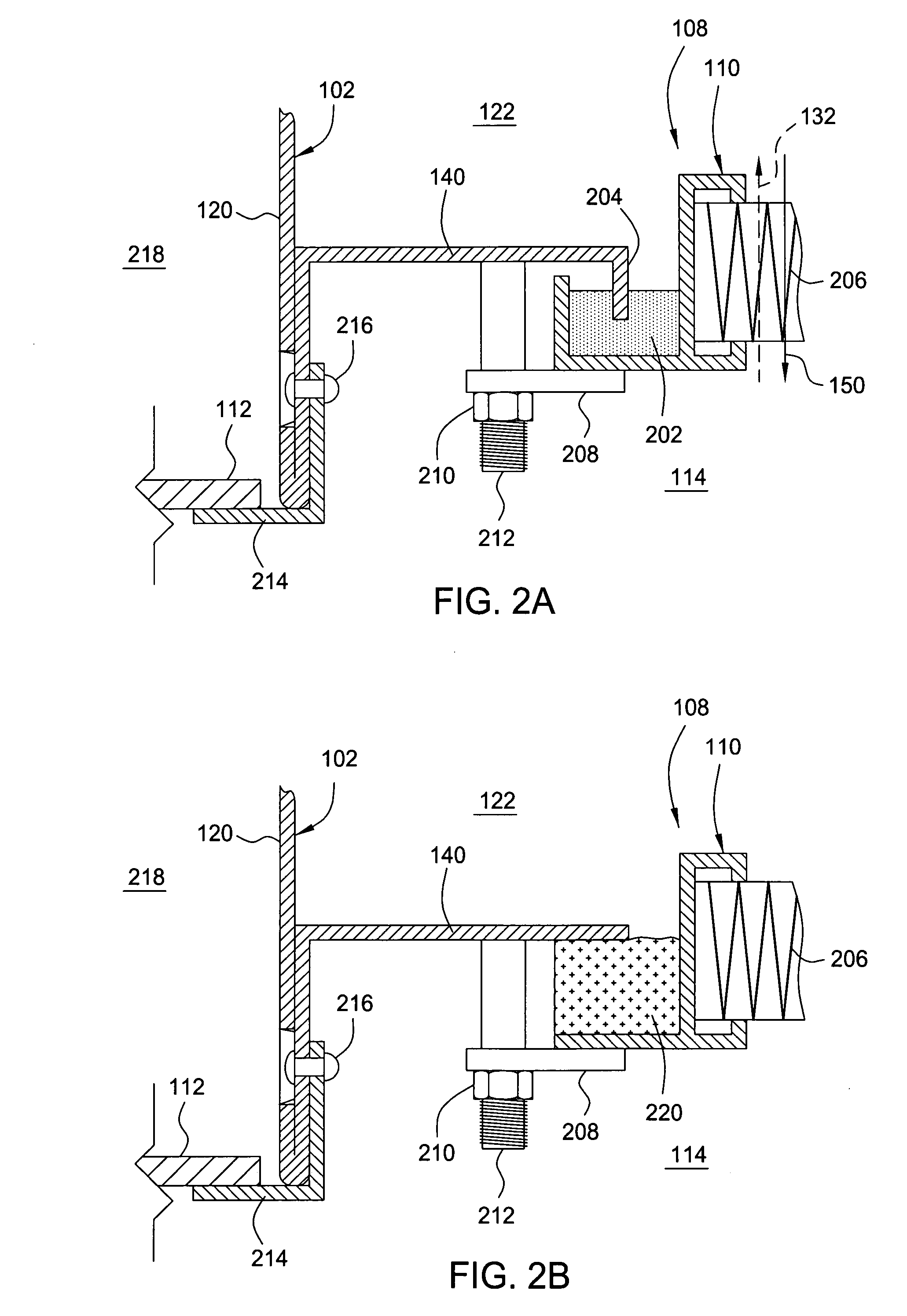

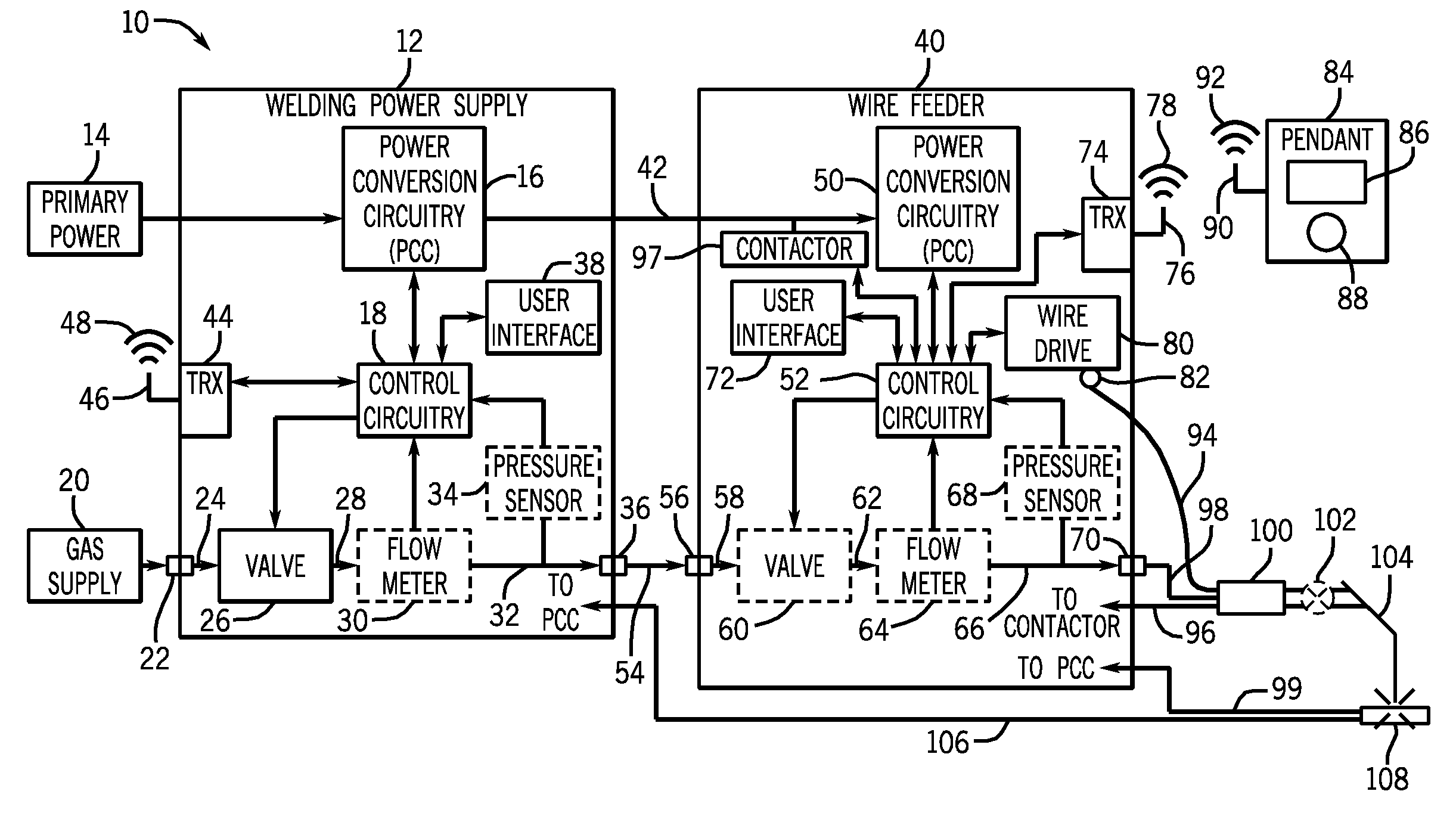

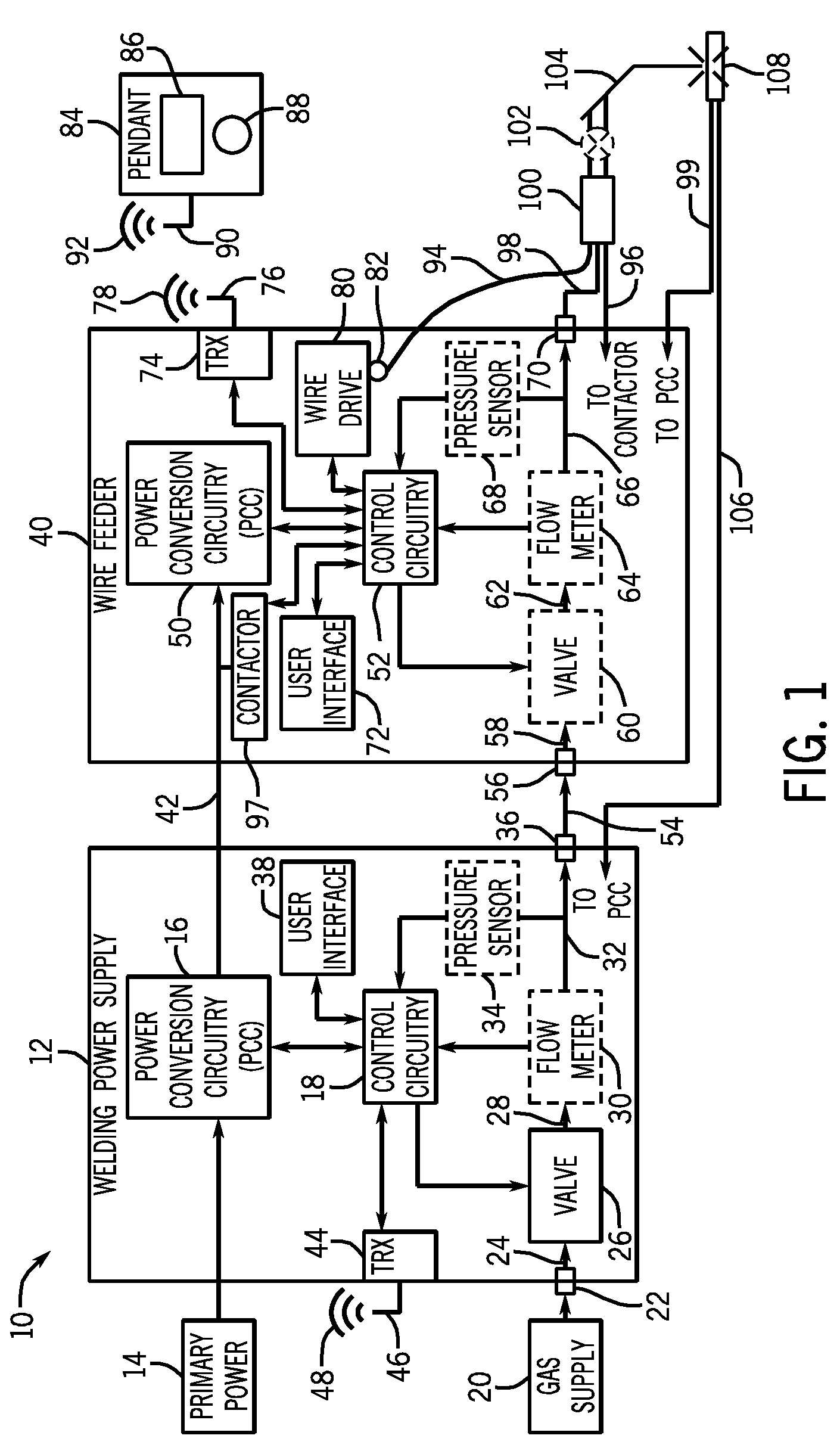

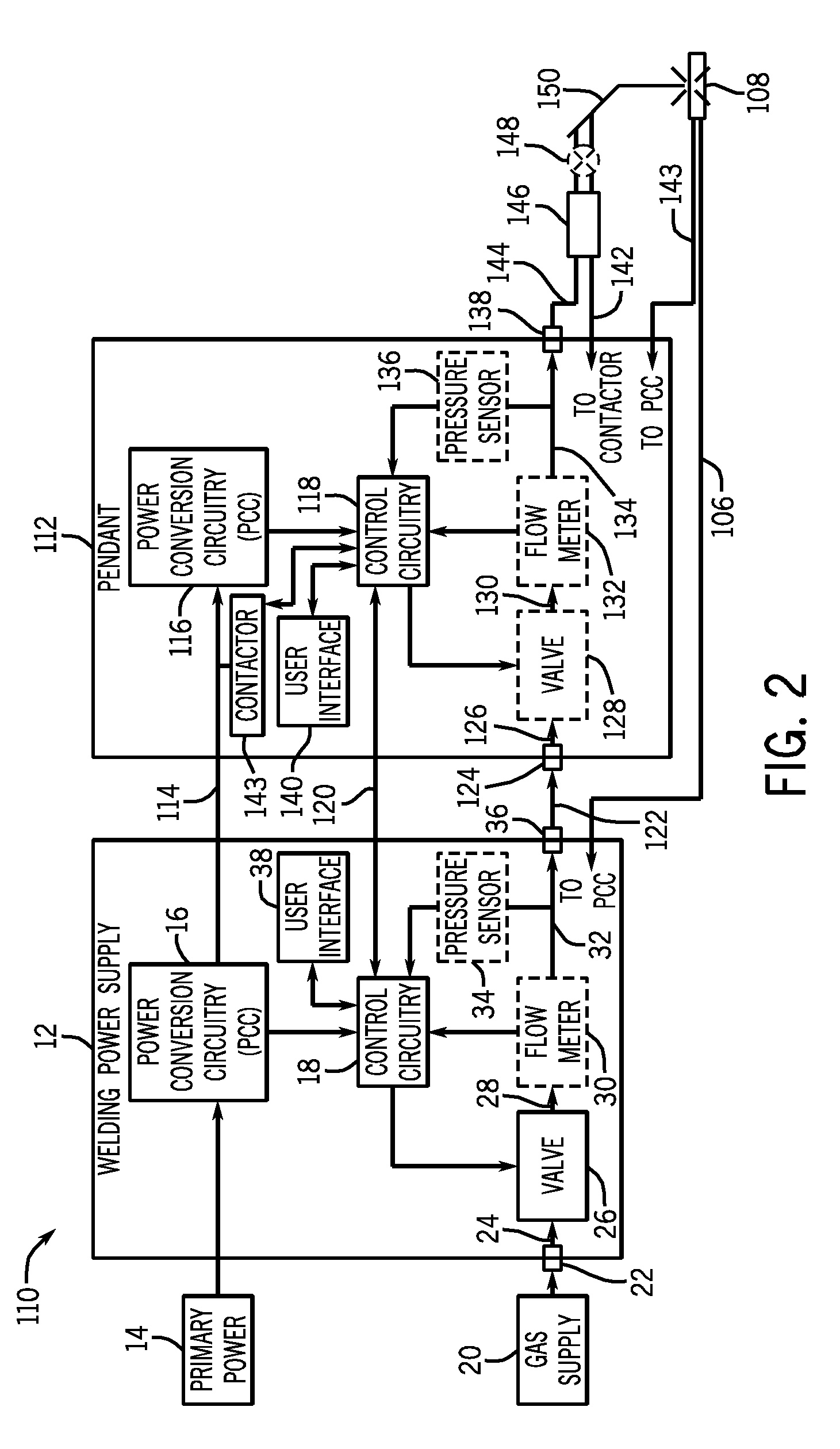

Welding gas leak detection system and method

ActiveUS20110284500A1Arc welding apparatusFluid-tightness measurementWelding power supplyShielding gas

A method and system for detecting a welding gas leak is provided. One welding power supply includes a gas valve configured to control the flow of shielding gas to a welding device through a gas line. The welding power supply also includes a sensor coupled to the gas line and configured to detect a parameter of the shielding gas. The welding power supply includes control circuitry coupled to the gas valve and to the sensor, and configured to control the operation of the gas valve, and to receive device value representative of the detected parameter. The control circuitry is further configured to determine a leak test result based upon the parameter value, and to provide an operator indicator of the leak test result.

Owner:ILLINOIS TOOL WORKS INC

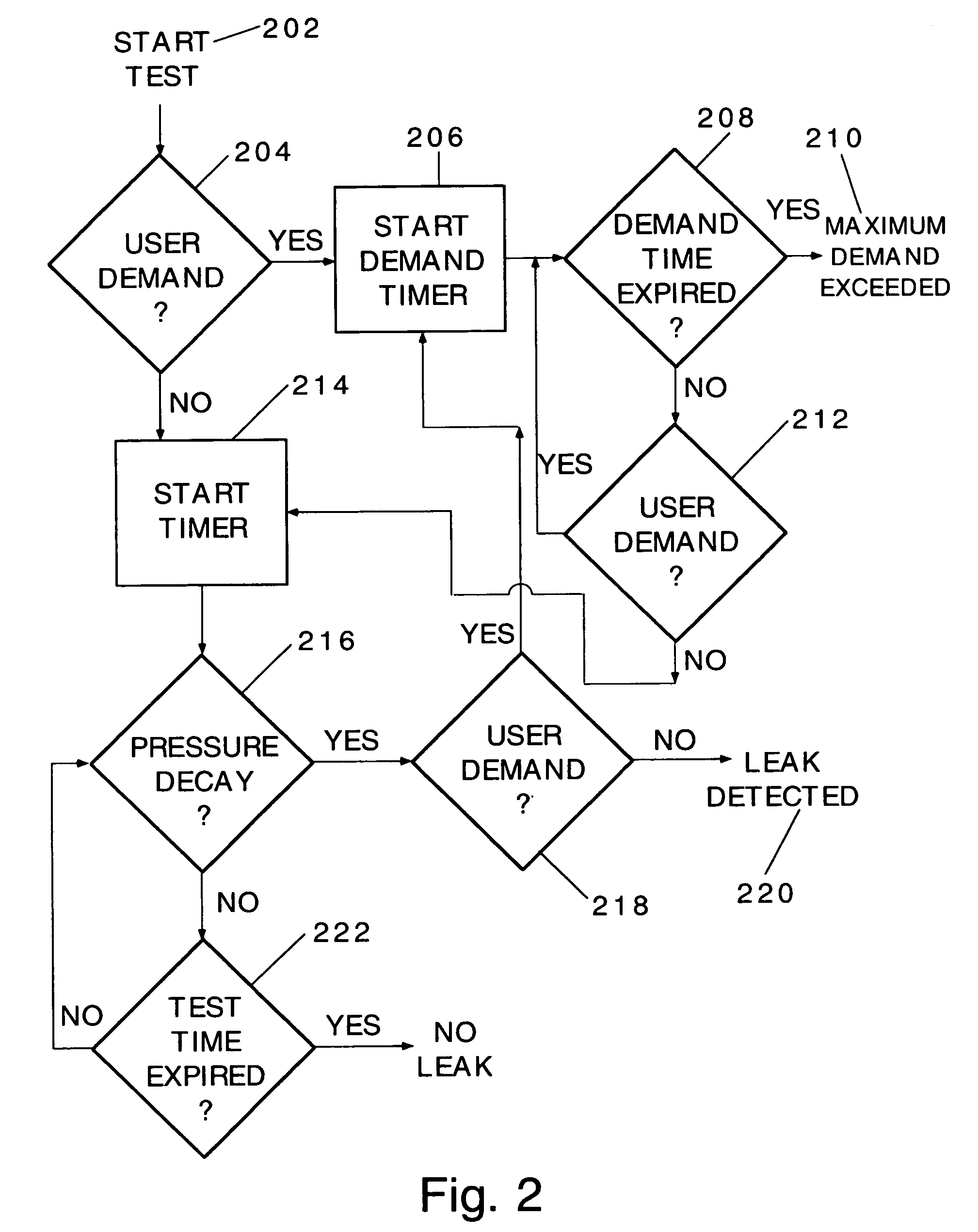

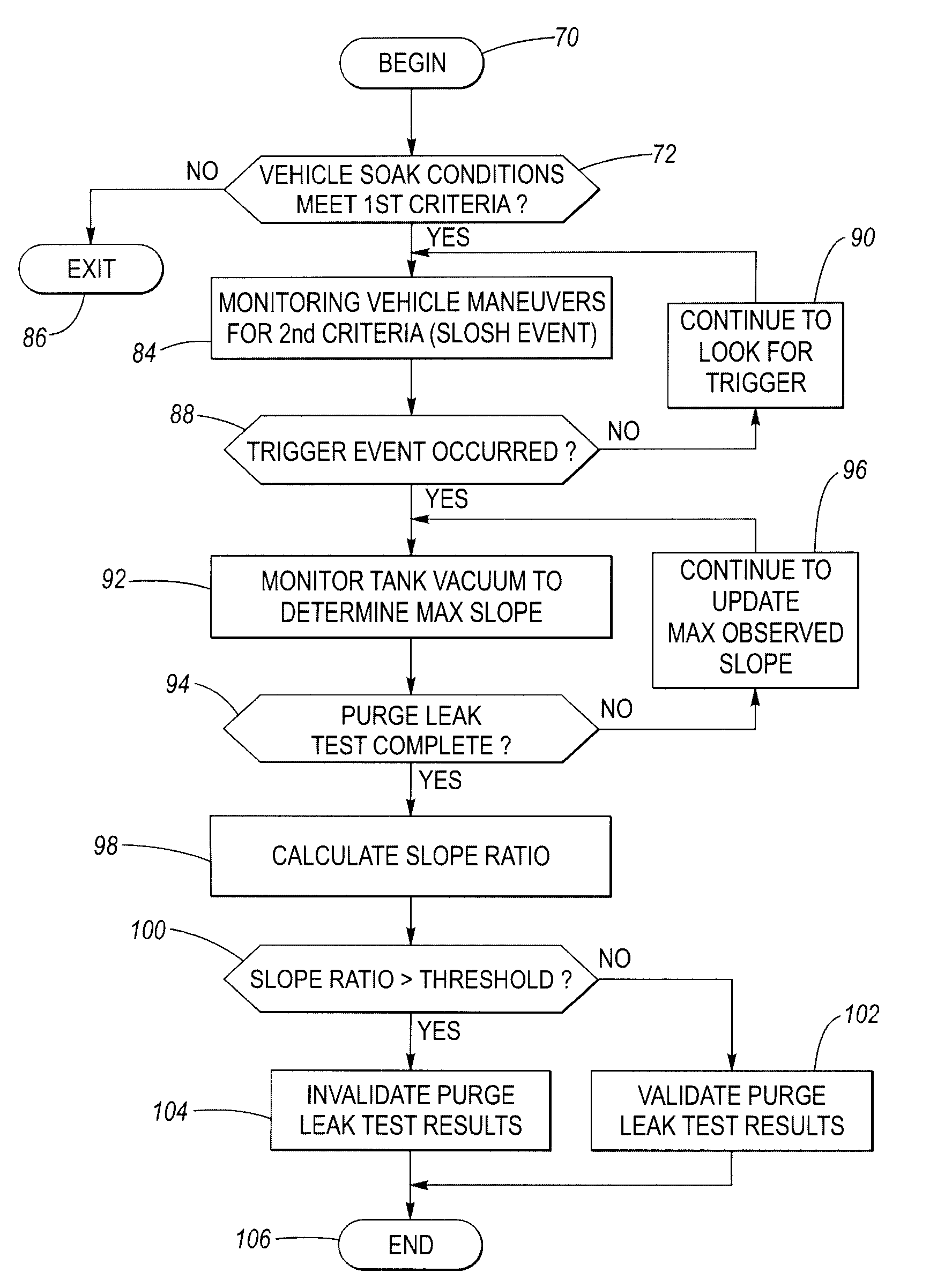

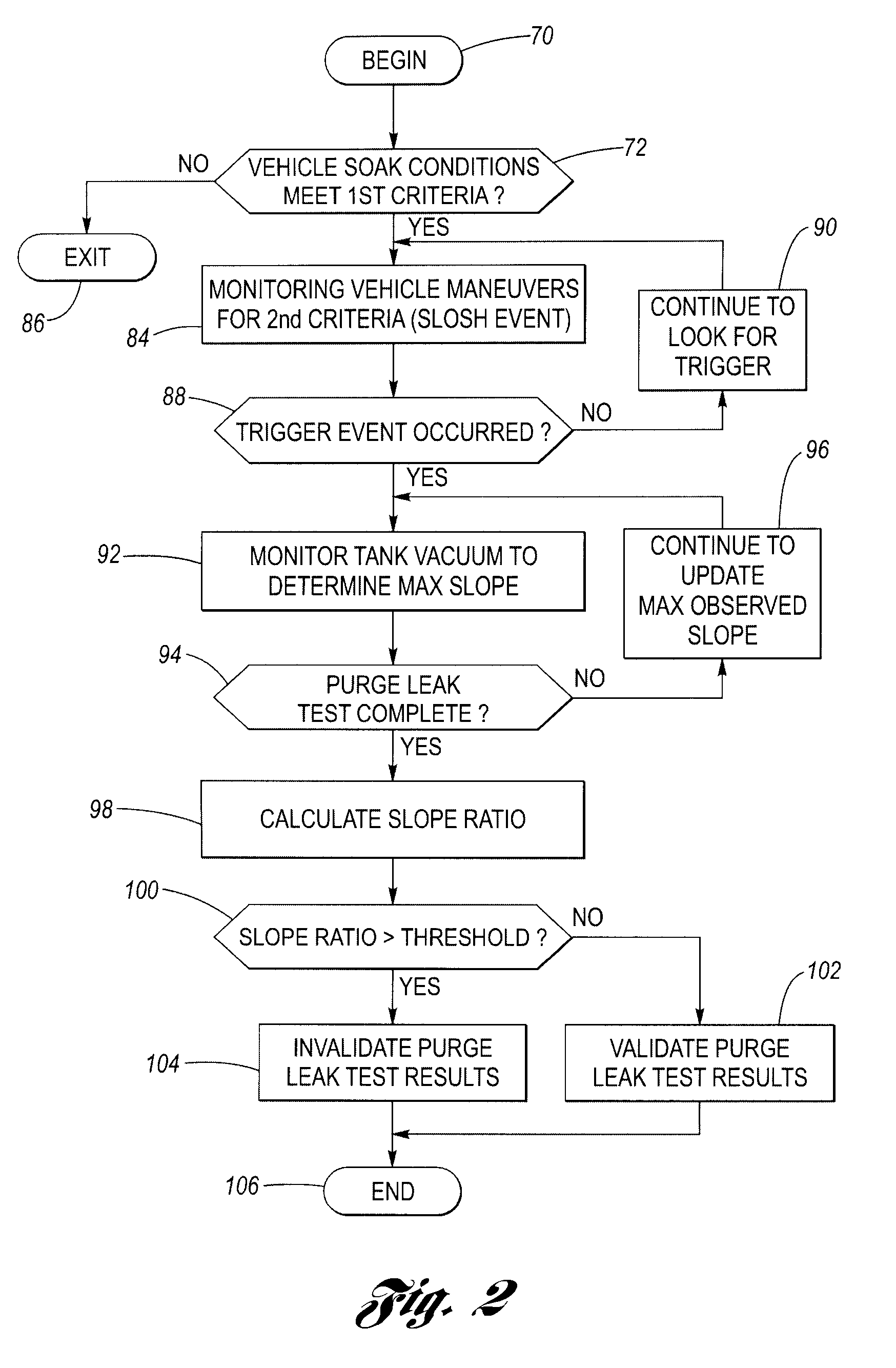

Method of validating a diagnostic purge valve leak detection test

ActiveUS7350512B1Reduction and elimination of false failureShort timeDetection of fluid at leakage pointNon-fuel substance addition to fuelSimulationLeak testing

A system and method for evaluating the integrity of a leak detection test for a purge valve of a fuel system in a vehicle reduces or eliminates false failures. The method is executed on an engine control module (ECM) and is configured to determine when vehicle soak conditions meet first criteria conducive to fuel vapor condensation in the fuel tank. The first criteria include a predetermined temperature drop in ambient air temperature between successive drive cycles. The ECM is further configured to determine when a vehicle maneuver meets second criteria indicative of the capability of the maneuver to initiate fuel slosh in the fuel tank, to thereby establish a trigger event. The ECM is further configured to determine, after the trigger event, the maximum slope of a fuel tank vacuum increase. The ECM is still further configured to produce a slope ratio as a function of the maximum vacuum increase slope and a reference vacuum slope corresponding to a slope that is unaffected by any slosh / condensation events. The ECM is configured to invalidate a purge leak test when the slope ratio exceeds a threshold.

Owner:DELPHI TECH IP LTD

System and method for leak detection

InactiveUS7174772B2Consistent amountMinimize durationDetection of fluid at leakage pointWorking fluidStream flow

A leak testing control assembly for a leak testing system of a type that cooperates with a test part interface that is coupled with a test part. In a broad aspect the leak testing control assembly includes a working fluid generator for applying a working fluid having a fluidic pressure to a test part. A flow controller assembly is coupled to the working fluid generator. The flow controller assembly includes a flow controller element for controlling the flow rate of the working fluid. A pressure level measuring element is positioned relative to the test part for measuring the fluidic pressure. A control system is coupled to the flow controller assembly and the pressure level measuring element. A user interface is coupled to the control system for providing user interaction with the leak testing control assembly. During operation, the control system 1) facilitates application of the fluidic pressure at a selected relatively constant flow rate; and, 2) interprets the value of the fluidic pressure, after the application of the fluidic pressure at the selected relatively constant flow rate, to determine whether the test part is free of leaks.

Owner:SACCA GIUSEPPE

Leak testing of hermetic enclosures for implantable energy storage devices

Methods for testing the hermeticity of casings for power sources intended to power implantable medical device by sensing the presence of vapors escaping from an electrolyte contained therein are described. More broadly, the present leak detection methods are applicable to any sealed enclosure having a first part sealed to a second part with a liquid contained therein. The liquid need not occupy the entire volume of the enclosure, but must contain at least one component having a vapor pressure at 25° C. of more than about 0.1 mm Hg. This component can assist in the functioning of the device such as an electrolyte, or be added for the sole purpose of leak detection.

Owner:WILSON GREATBATCH LTD

System and method for measuring transistor leakage current with a ring oscillator

InactiveUS7038483B1Accurate measurementElectronic circuit testingShort-circuit testingLeakage testDrain current

A method of measuring the transistor leakage current. In one embodiment, the method involves driving a ring oscillator with a dynamic node driver having a leakage test device biased to an off state to produce a test signal. The test signal is extracted and the frequency is measured. The leakage current is estimated from the measured frequency.

Owner:META PLATFORMS INC

Heat Exchanger Leak Testing Method and Apparatus

A method for detecting the presence of a leak between two fluid paths of an assembled plate heat exchanger by evacuating one or both fluid paths to a low pressure, introducing a test gas to one of the fluid paths to create a pressure differential between the fluid paths, and testing for the presence of test gas in the second fluid path.

Owner:APV NORTH AMERICA

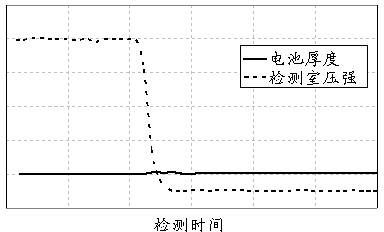

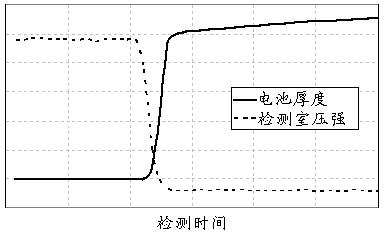

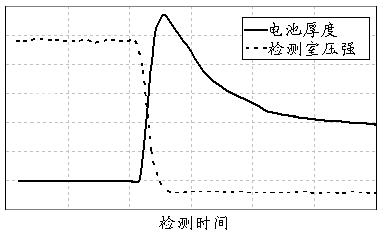

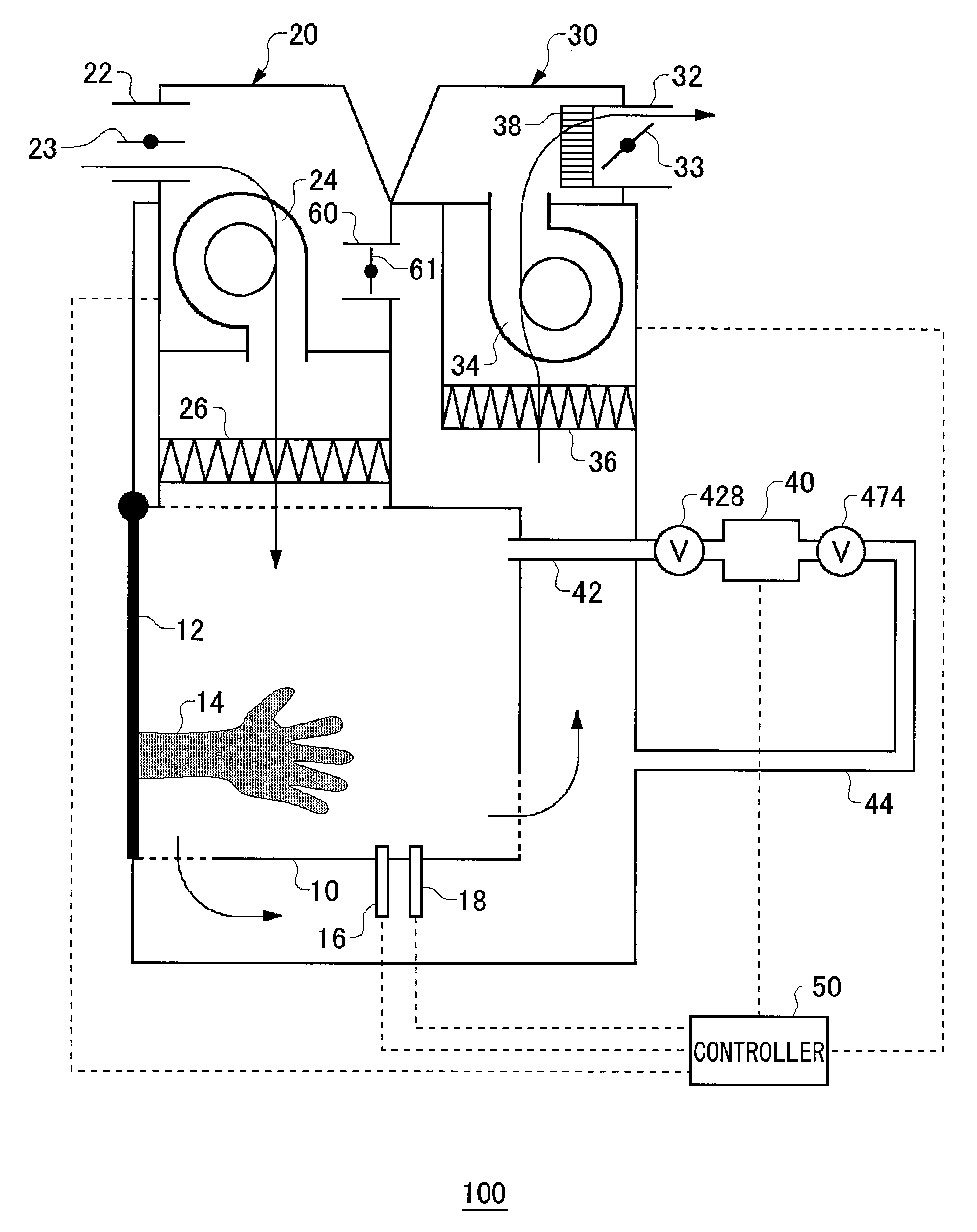

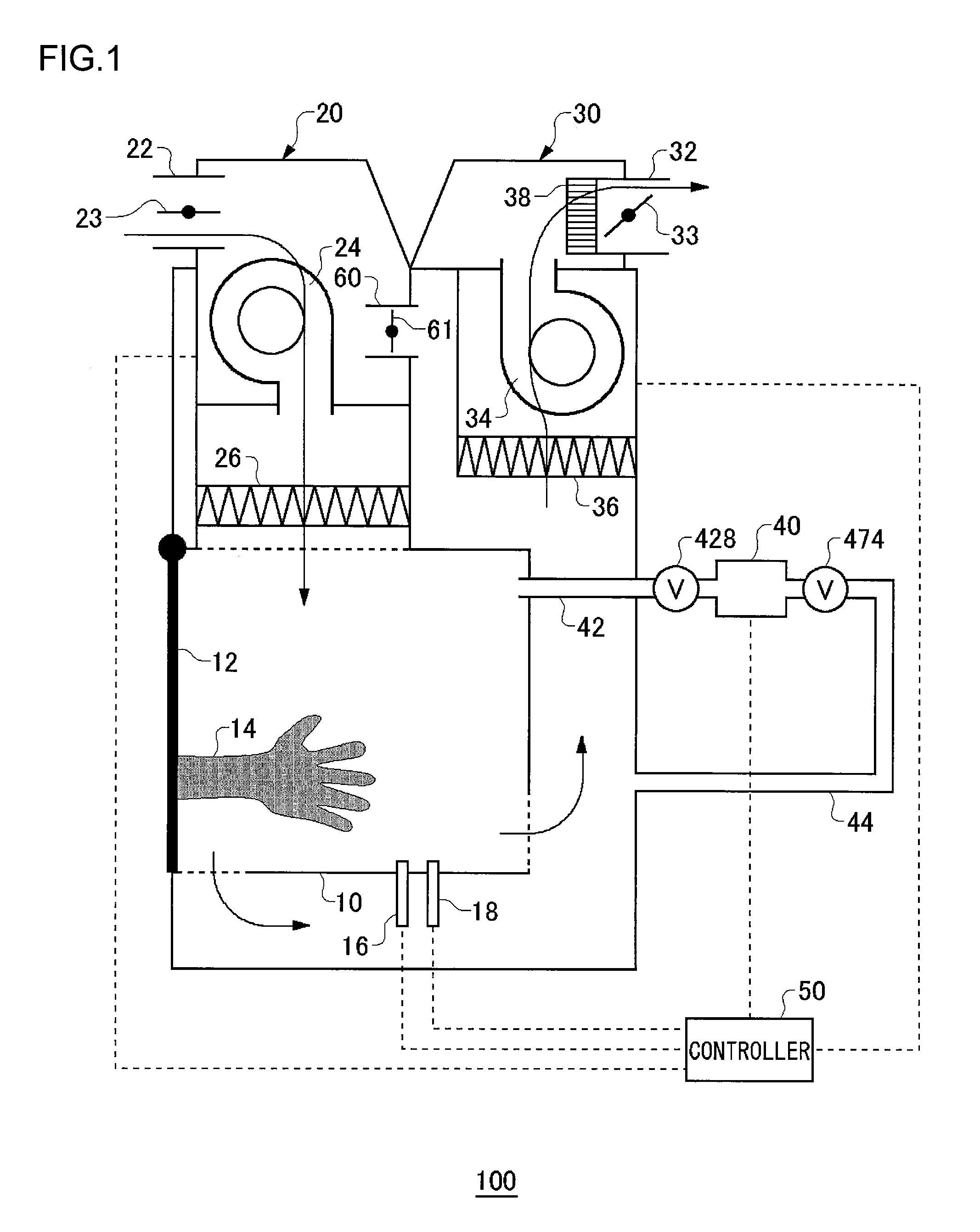

Flexible packaging article airtightness detection device and detection method

ActiveCN102269641AFast judgment of tightnessHigh sensitivityFluid-tightness measurement by detecting dimension changeUsing optical meansOptical measurementsEngineering

The invention discloses a device for detecting the tightness of a flexible packaged article, comprising: a detection chamber, a vacuuming device capable of evacuating the detection chamber, and a device for real-time and continuous detection of the thickness of the flexible packaging article in the detection chamber during the vacuuming process. Laser thickness measurement system, and identification system for automatic judgment of tightness. The device for detecting the tightness of the flexible package article of the present invention has the advantages of defect quantification, defect location, high sensitivity, and accurate detection of tiny air leakage. The sealing detection device adopts optical measurement system, software automatic recording and judgment integration technology, and is suitable for high-efficiency and automatic online continuous production detection. In addition, the invention also discloses a method for detecting the tightness of a flexible package.

Owner:DONGGUAN AMPEREX TECH +1

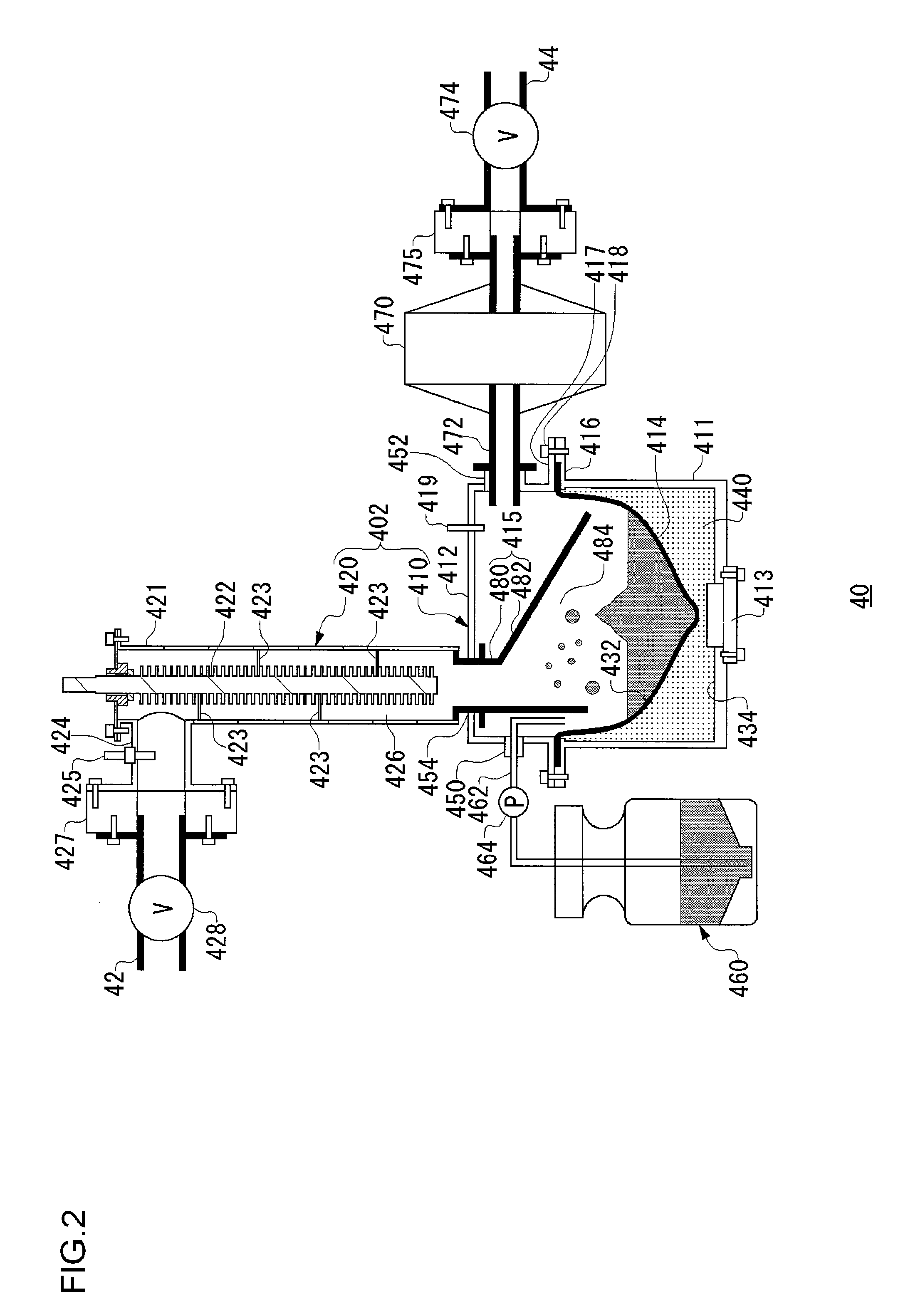

isolator

InactiveUS20110058986A1Shorten the timeEasy dischargeMeasurement of fluid loss/gain rateApparatus sterilizationEngineeringLeak testing

An isolator includes a work chamber, a sterilizing substance supply unit, a gas flow channel pressure adjustment unit, a work chamber barometer, and a controller. The controller is configured to control execution of a gas flow channel leak test for checking a gas leak in a gas flow channel based on a detection result by the work chamber barometer after making the gas flow channel pressure adjustment unit increase or decrease the pressure in the gas flow channel, and is configured to control supply of the sterilizing substance by the sterilizing substance supply unit. The controller performs heating of a heater, which accompanies the supply of the sterilizing substance, in parallel with the gas flow channel leak test.

Owner:PHC HLDG CORP

Exhaust filter module with mechanically positionable scan probe

Owner:CAMFIL USA

Thin, Smooth Nitrile Rubber Gloves

A nitrile-rubber medical exam glove composed of a glove body which is a flexible layer of nitrile-butadiene rubber. The glove body has a chlorinated first surface forming a donning side of the glove body and an un-chlorinated second surface forming a grip side of the glove body. The elastomeric glove also includes a substantially uniform distribution of a release agent distributed over the un-chlorinated second surface of the glove body. The elastomeric glove has: (a) an average thickness of between about 0.03 to 0.12 mm in a palm region of the glove body as measured in accordance with ASTM D3767, procedure A; (b) an un-chlorinated second surface of the glove body characterized by a Surface Root Mean Square Roughness of from about 3.00 μ m to about 6.55 μ m; and (c) a failure rate of less than about 1 percent when the elastomeric glove is subjected to pinhole leak testing generally in accordance with ASTM D5151-06.

Owner:OWENS & MINOR INT LTD +3

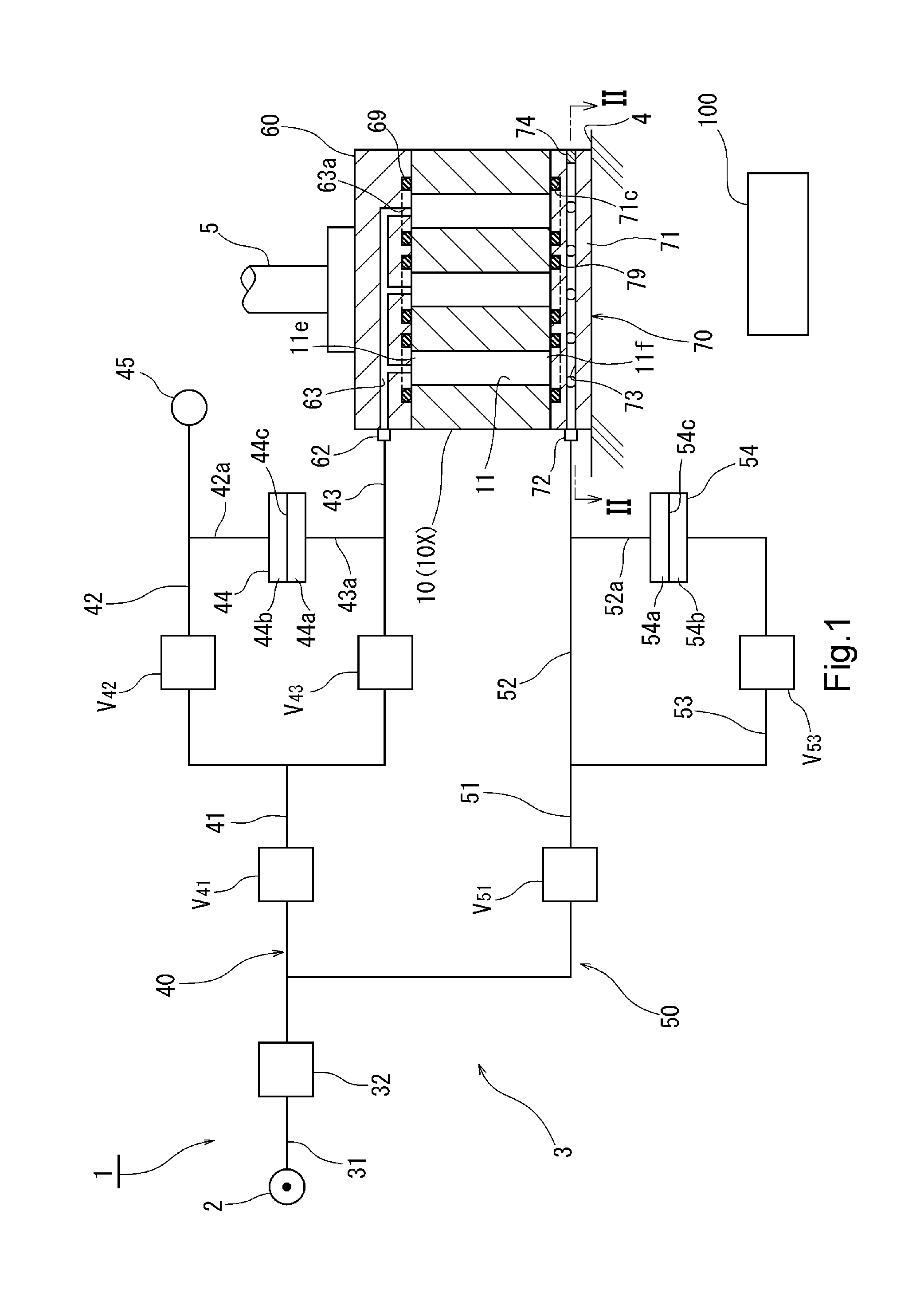

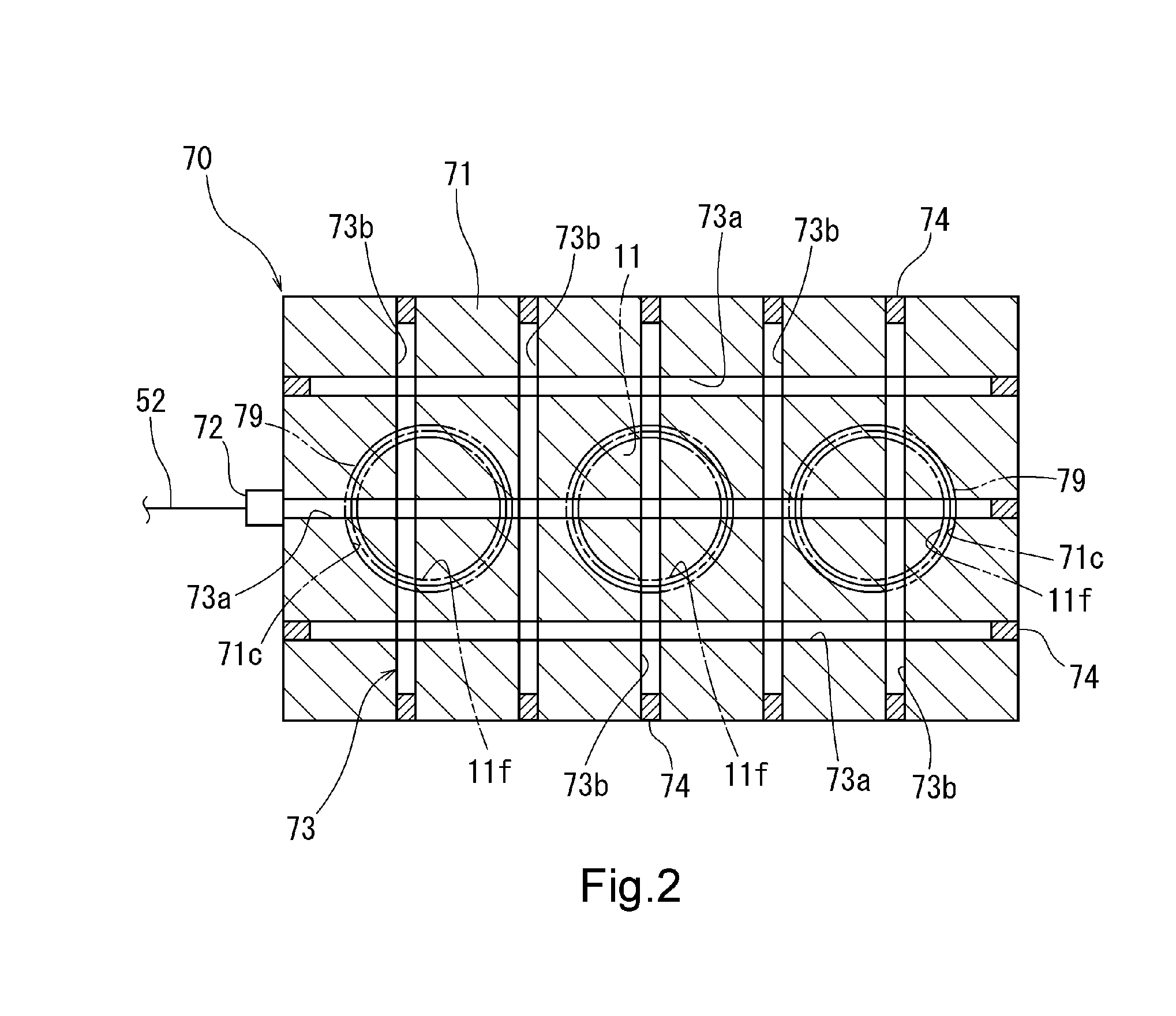

Apparatus and method for leak testing

ActiveUS8205484B2Improve accuracyImprove thermal conductivityDetection of fluid at leakage pointMeasurement of fluid loss/gain rateInternal pressureHeat sensitive

A leak testing apparatus 1 includes a heat sensitive member 70 having a body 71 made of a material having high thermal conductivity. The body 71 is abutted against an outer surface of a workpiece 10 to close an opening of an inner space 11 of the workpiece 10. A pressure chamber 73 is formed inside the body 71 as arranged along the outer surface and as arranged over an area wider than the opening. Pressurized gas is introduced to the pressure chamber 73. Data on pressure change in the inner space 11 of the workpiece 10 is compensated based on inner pressure information regarding the pressure chamber 73, and leak judgment is made.

Owner:FUKUDA CO LTD

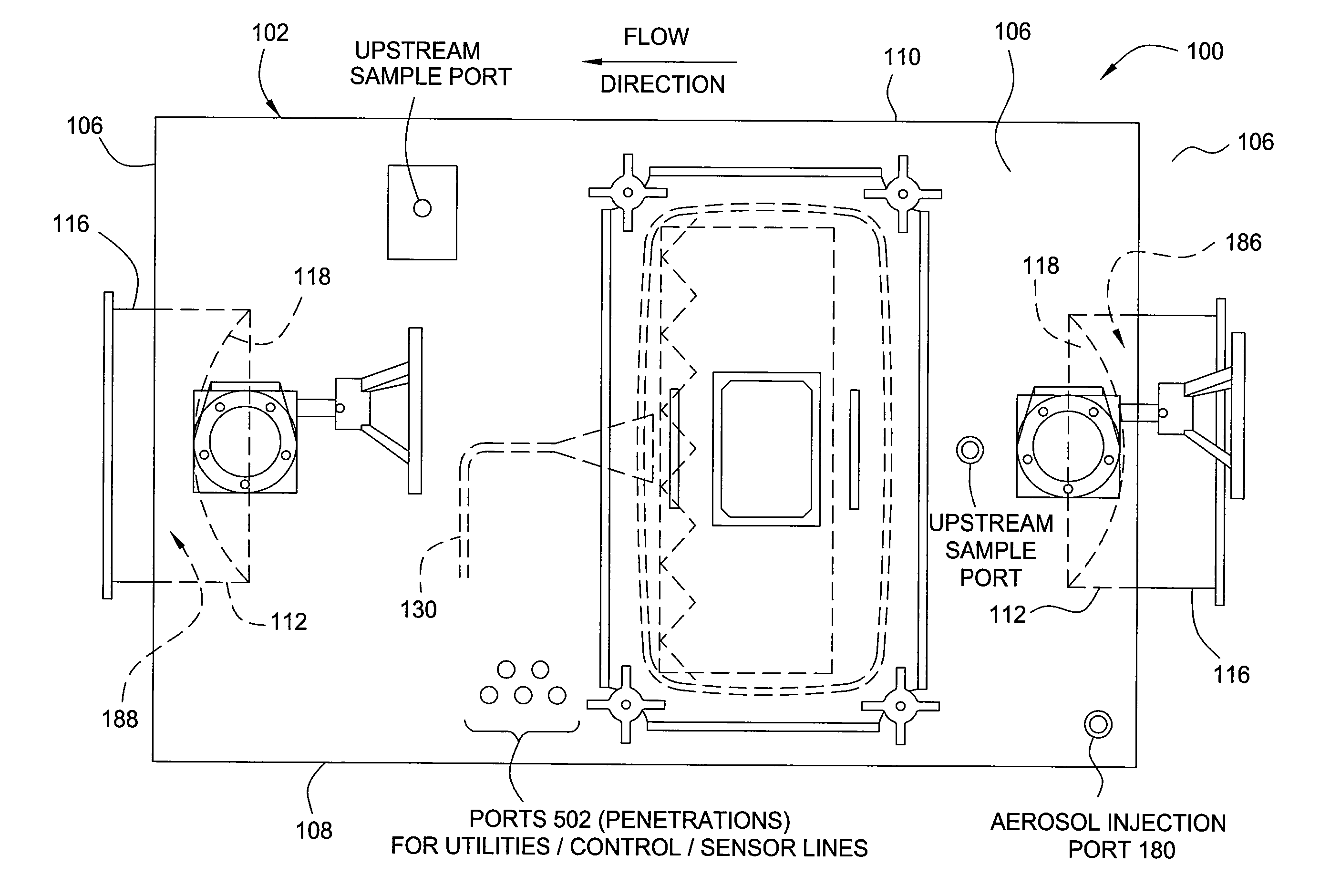

Integrated containment system

Embodiments of the invention generally provide a containment system having integrated bubble tight-dampers. In another embodiment, the containment system includes an integral auto-scan mechanism disposed in the housing of the containment system so that a filter element, disposed in the housing, may be leak tested without accessing the interior of the housing. In yet another embodiment, a method for testing a filter disposed in a containment system includes challenging an upstream side of a filter element disposed in a housing of the containment system with a test aerosol, and automatically moving a probe disposed within the housing to obtain samples for leak testing.

Owner:CAMFIL USA

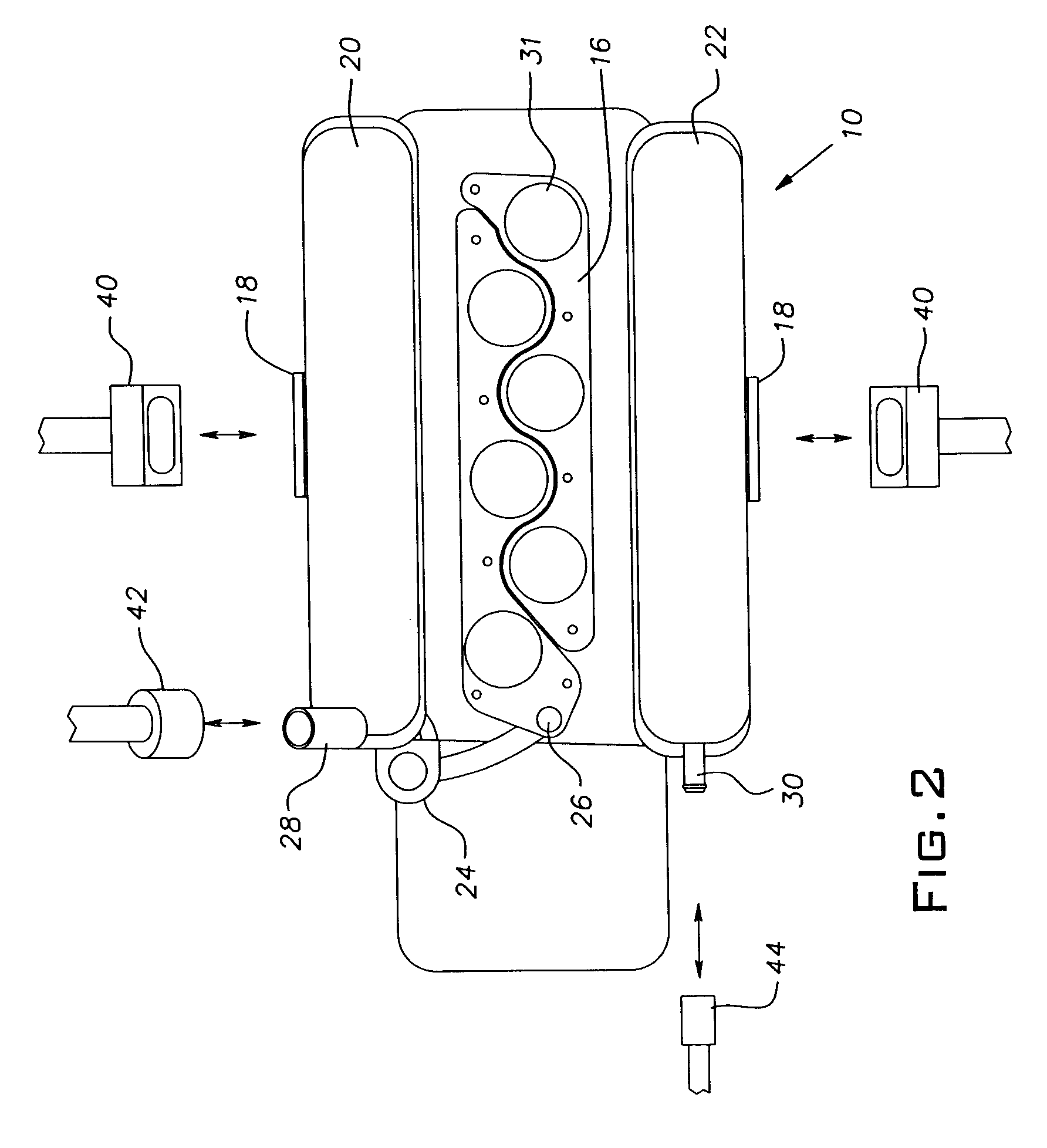

Engine oil leak test system and method

InactiveUS20070157714A1Detection of fluid at leakage pointEngine testingAutomatic controlLeak testing

A system and method for testing partially assembled engines for possible oil leaks. The system includes engine pressurizing devices that are automatically controlled by a controller according to a predetermined control program based upon the engine model type being tested. The pressurizing devices introduce pressurized air into the engine oil system. A leak testing unit monitors the pressurized engine for pressure drops indicative of an oil seal leak. Air pressure leaks resulting from inherently air-porous EGR valves are compensated for by an EGR compensating unit, which provides pressurized air to an intake side of the EGR valve. The flow of pressurized air through the EGR compensating unit is monitored to determine whether there is a problem with the EGR valve.

Owner:HONDA MOTOR CO LTD

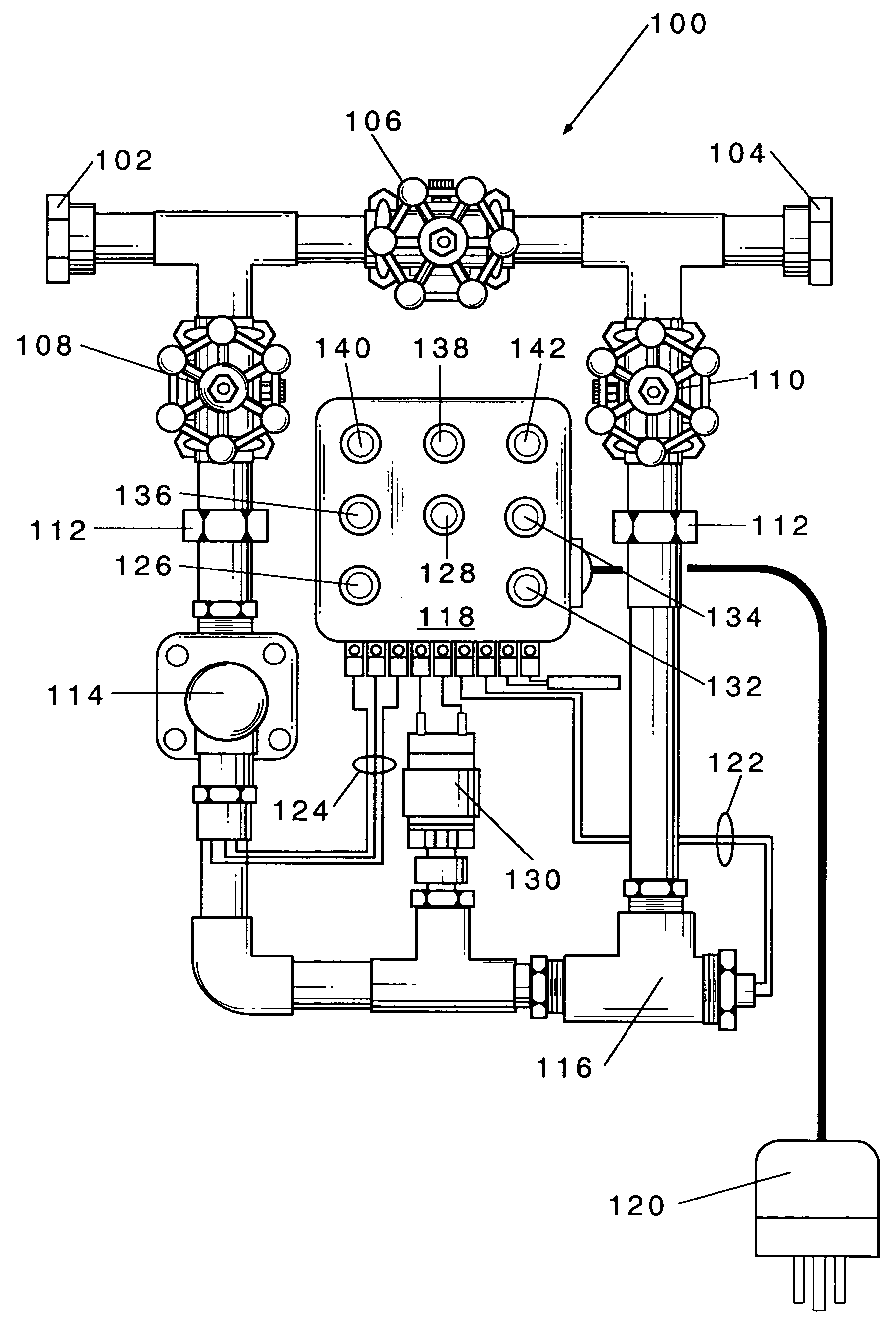

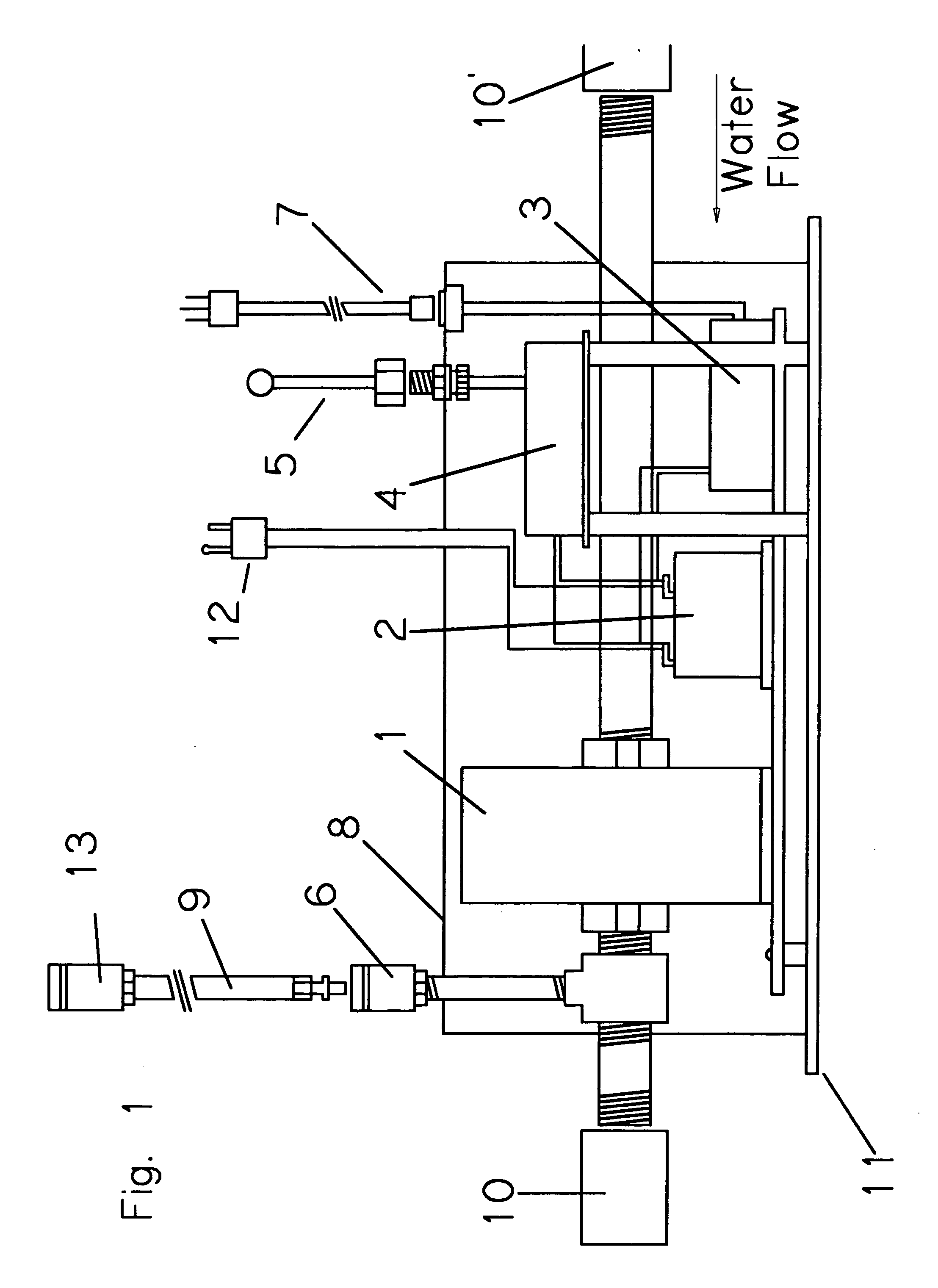

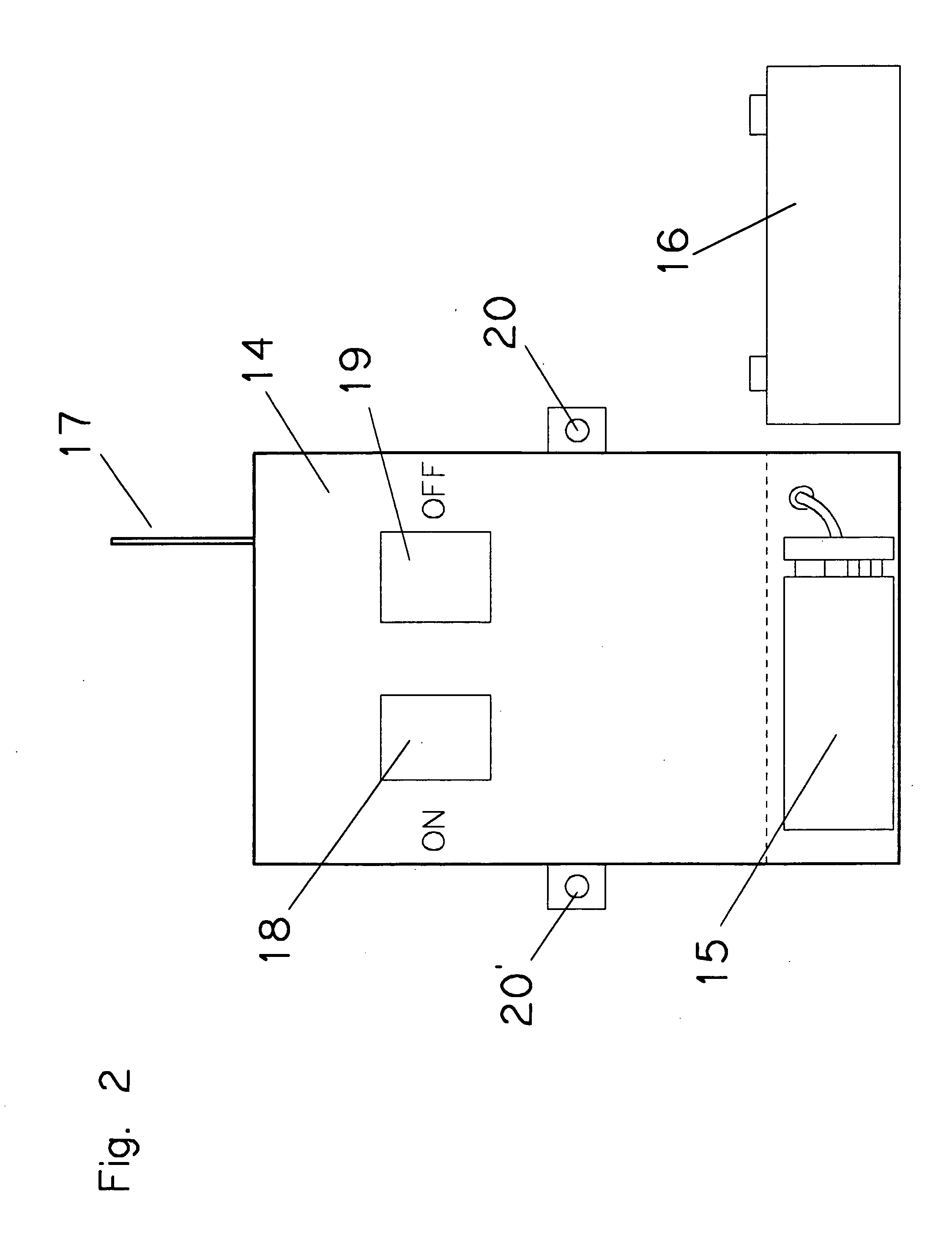

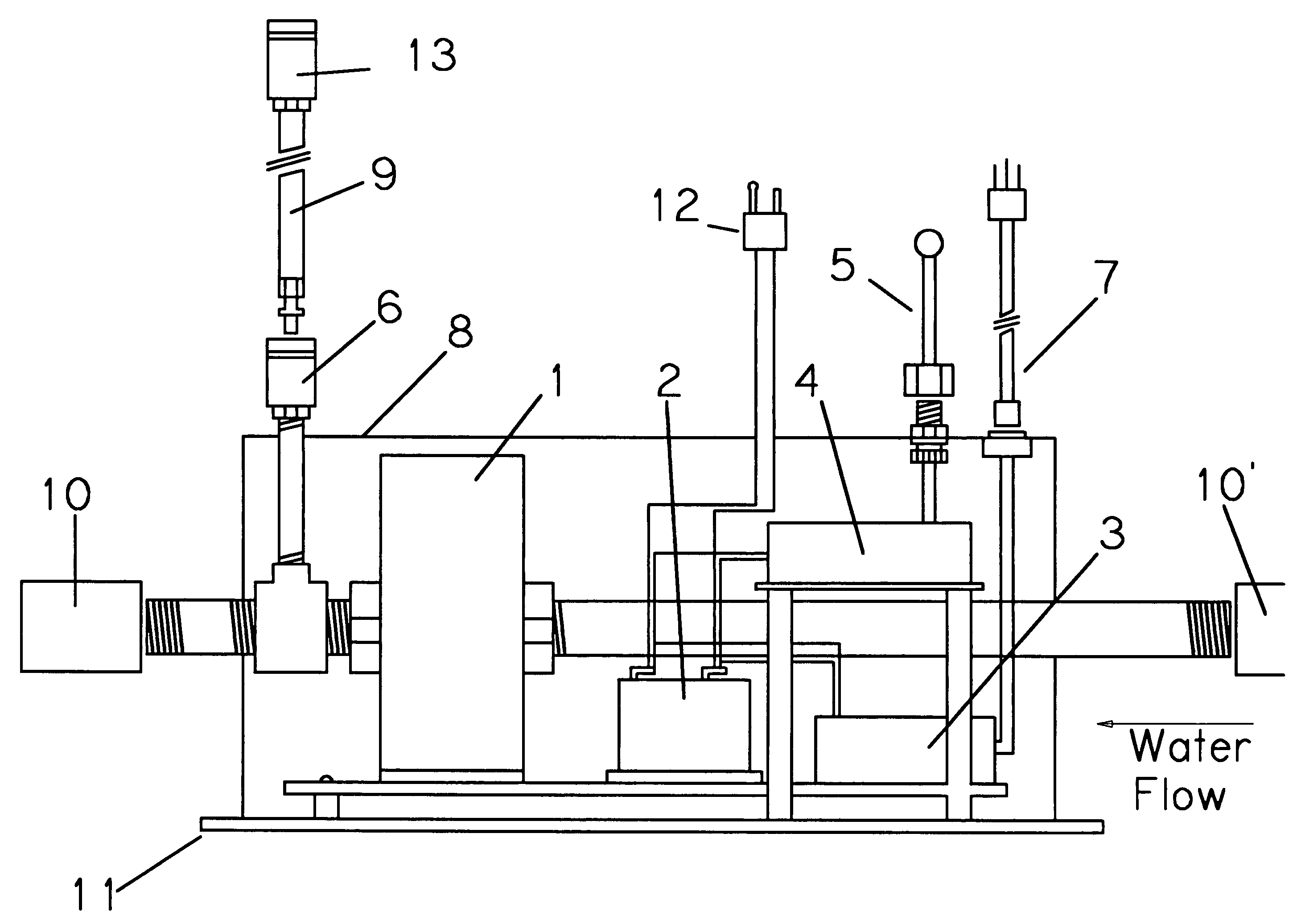

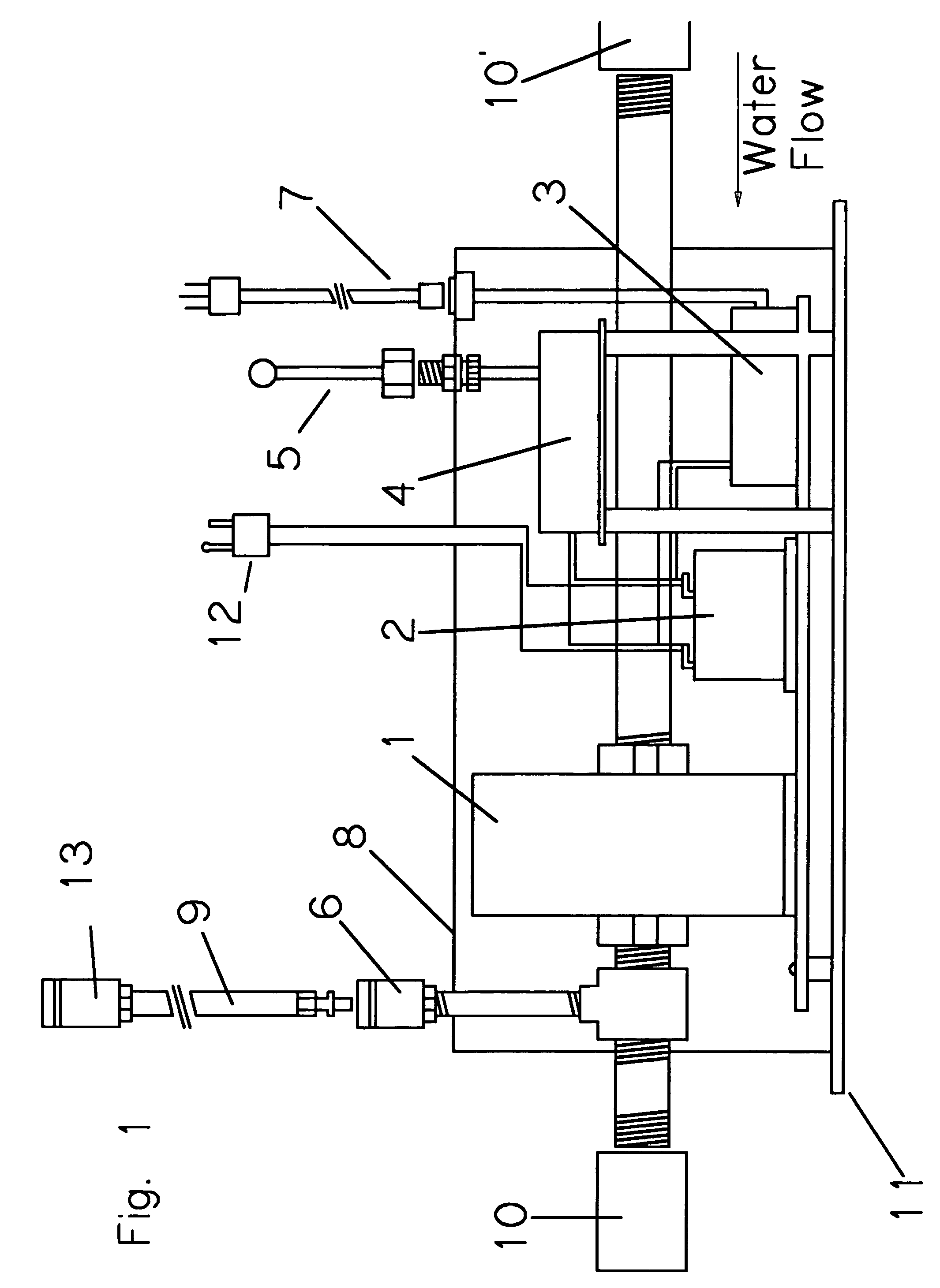

Wireless remote controlled water shut-off and leak testing system

InactiveUS20050127315A1Eliminate minute water leakEliminate the minute water leaksPlug valvesMeasurement of fluid loss/gain rateElectronic controllerInjection port

A remote controlled system for shutting off a water supply and testing for leaks, having within a sealed housing a motorized ball valve device with an electronic controller, antenna, power supply, battery-charging device and an evacuation / injection port. The controller receives signals through the antenna from a wireless remote control device, when either of two buttons on the remote control device is pressed the controller receives the wireless RF signal and activates the motorized ball valve device which either stops or starts the water flow through the water line. The battery-charging device is connected to a source of alternating current by a power plug. If the system is installed below-ground an external battery charging device that operates by solar means is connected using matching quick connectors and positioned on the outside of the sealed housing.

Owner:HOLLINGSWORTH LYNDOL WADE +1

Wireless remote controlled water shut-off and leak testing system

InactiveUS7147204B2Eliminate the minute water leaksPlug valvesMeasurement of fluid loss/gain rateElectronic controllerElectrical battery

Owner:HOLLINGSWORTH LYNDOL WADE +1

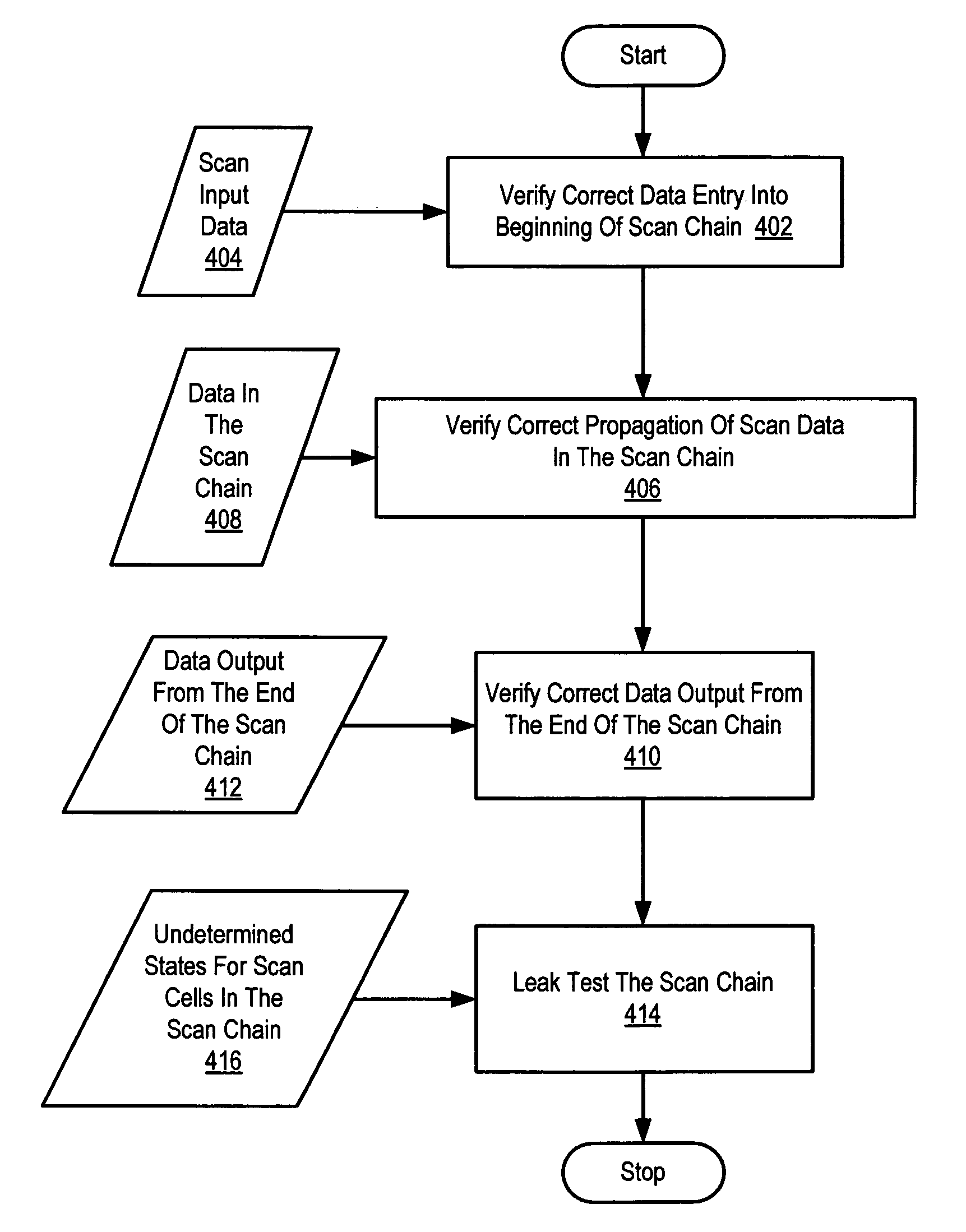

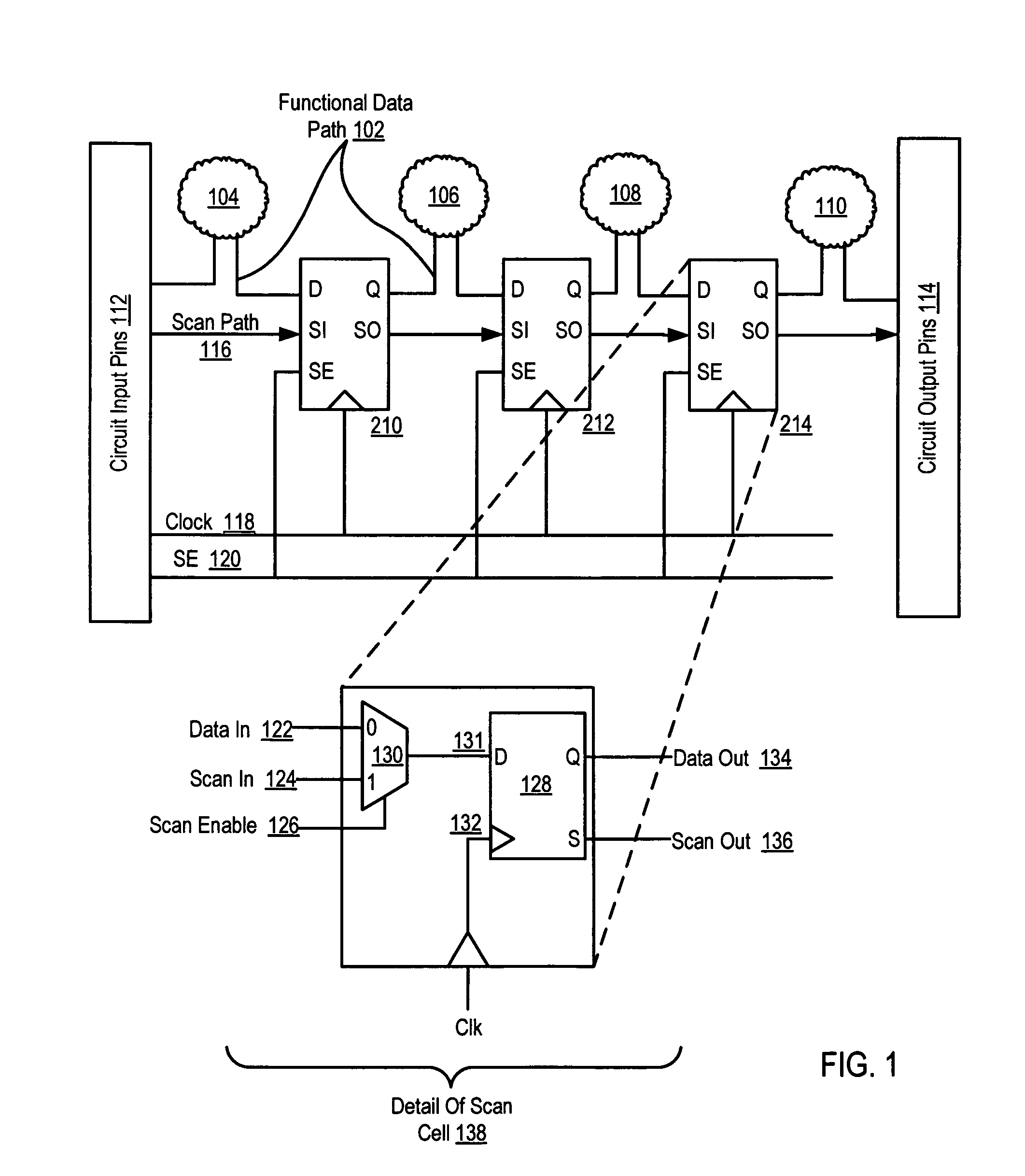

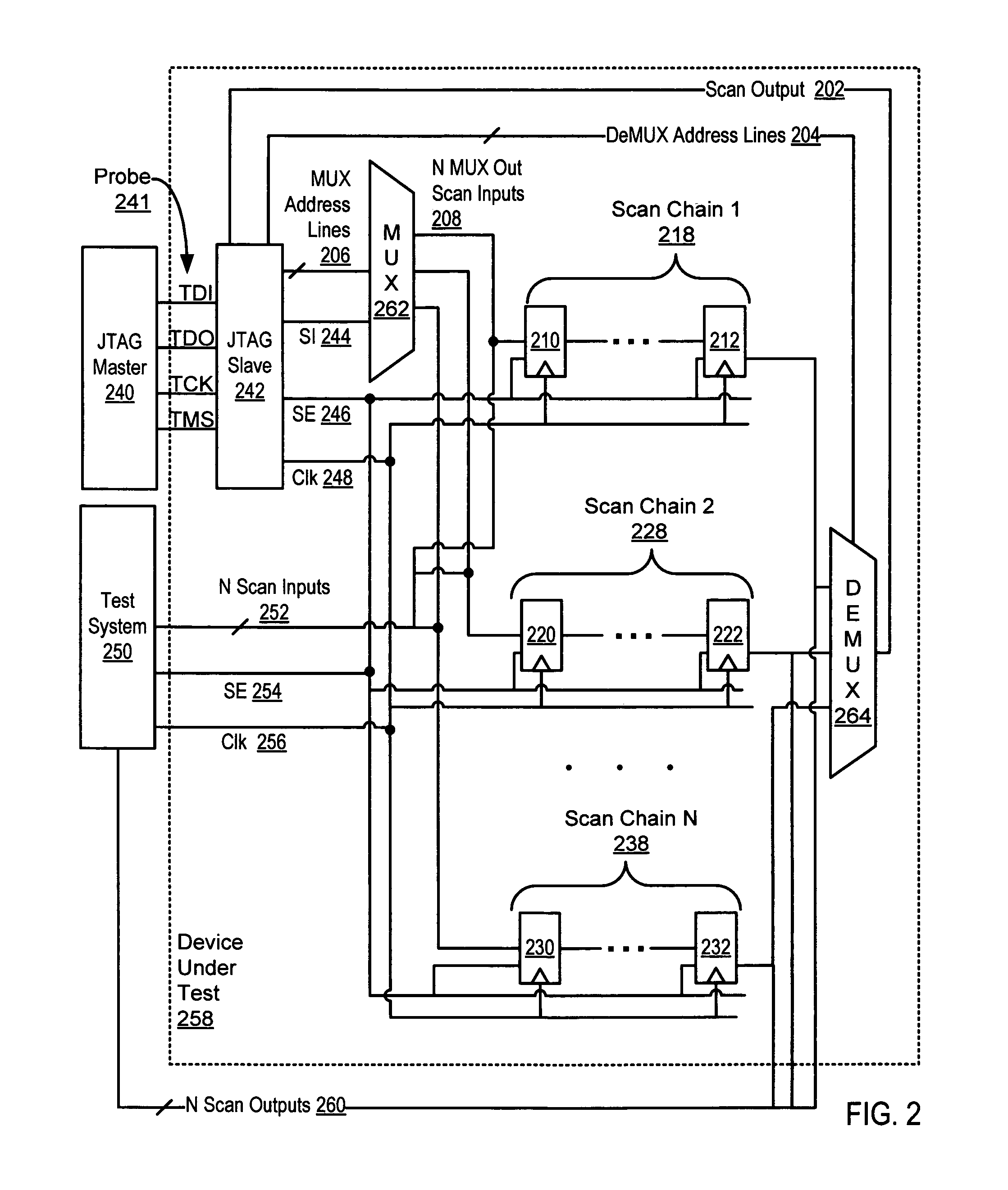

Scan verification for a scan-chain device under test

InactiveUS7386775B2Electronic circuit testingError detection/correctionComputer hardwareLeak testing

Methods, apparatus, and products are disclosed for scan verification for a simulated device under test (‘DUT’), the DUT having scan chains, scan inputs, and scan outputs that include verifying correct data entry from the scan inputs of the DUT into the beginning of the scan chain, verifying correct propagation of scan data in the scan chain between the scan inputs and the scan outputs, verifying correct data output from the end of the scan chain to the scan outputs, and leak testing the scan chain with undetermined states for scan cells in the scan chain.

Owner:GOOGLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com