Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

952results about "Oilsumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

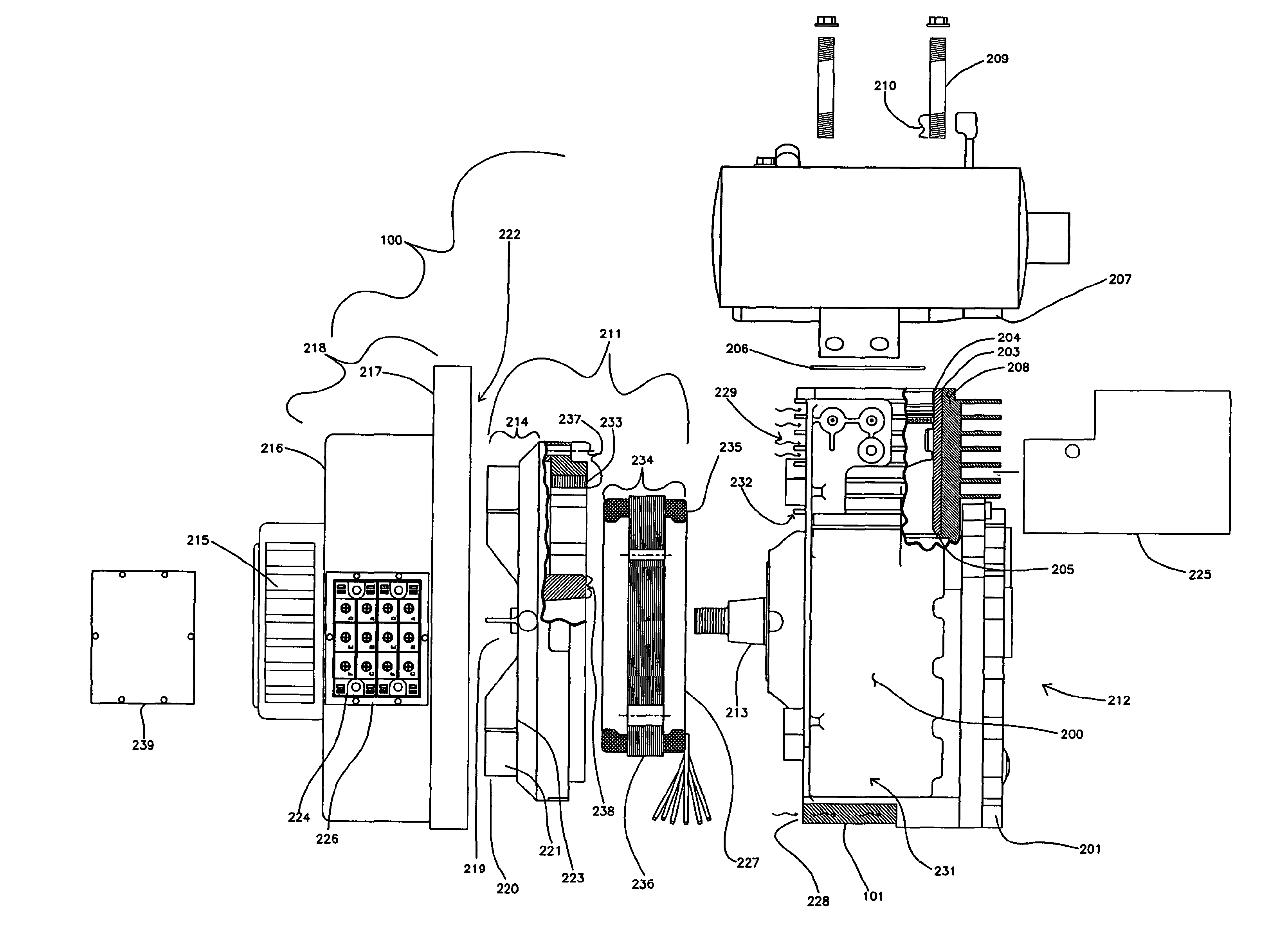

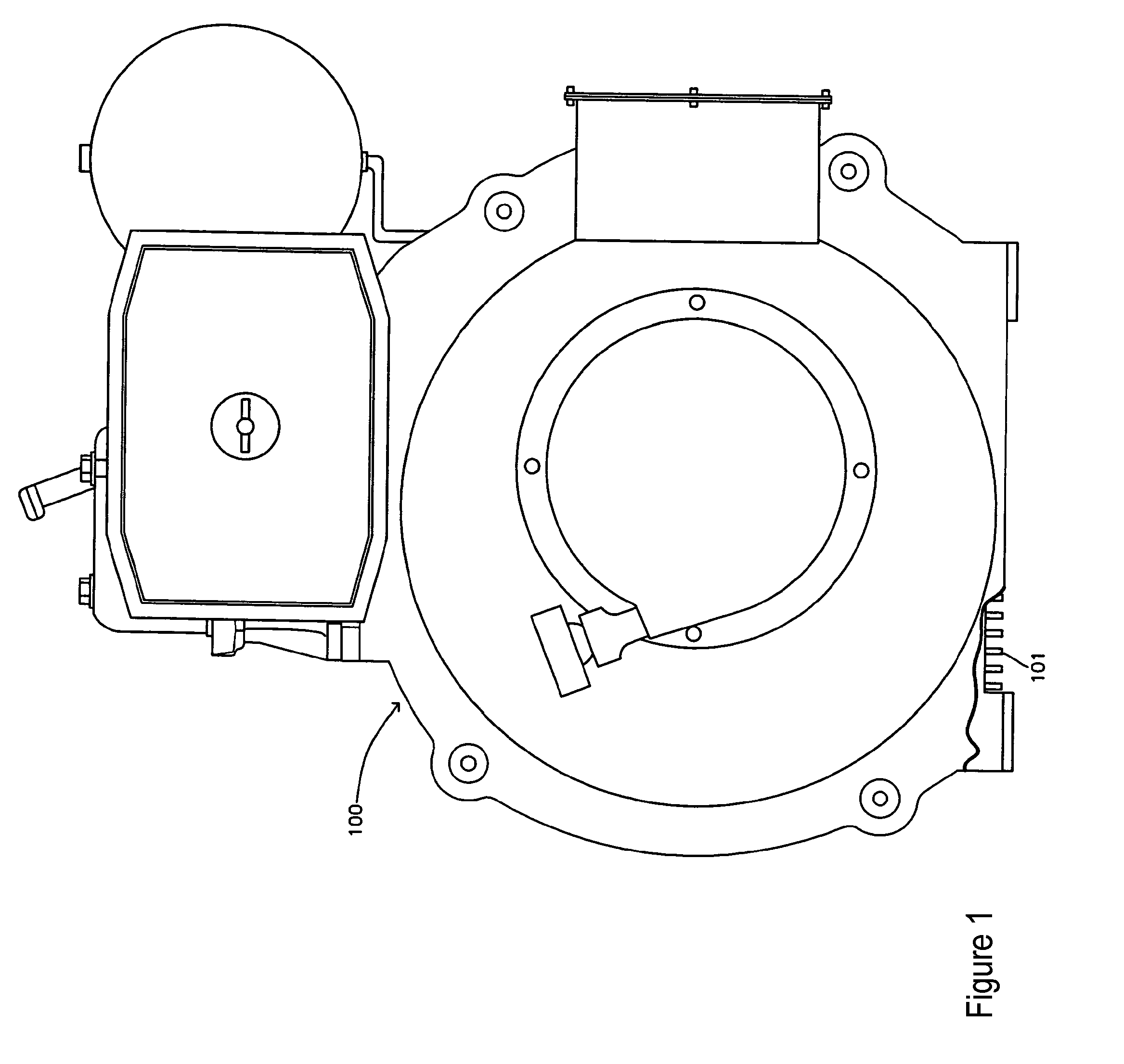

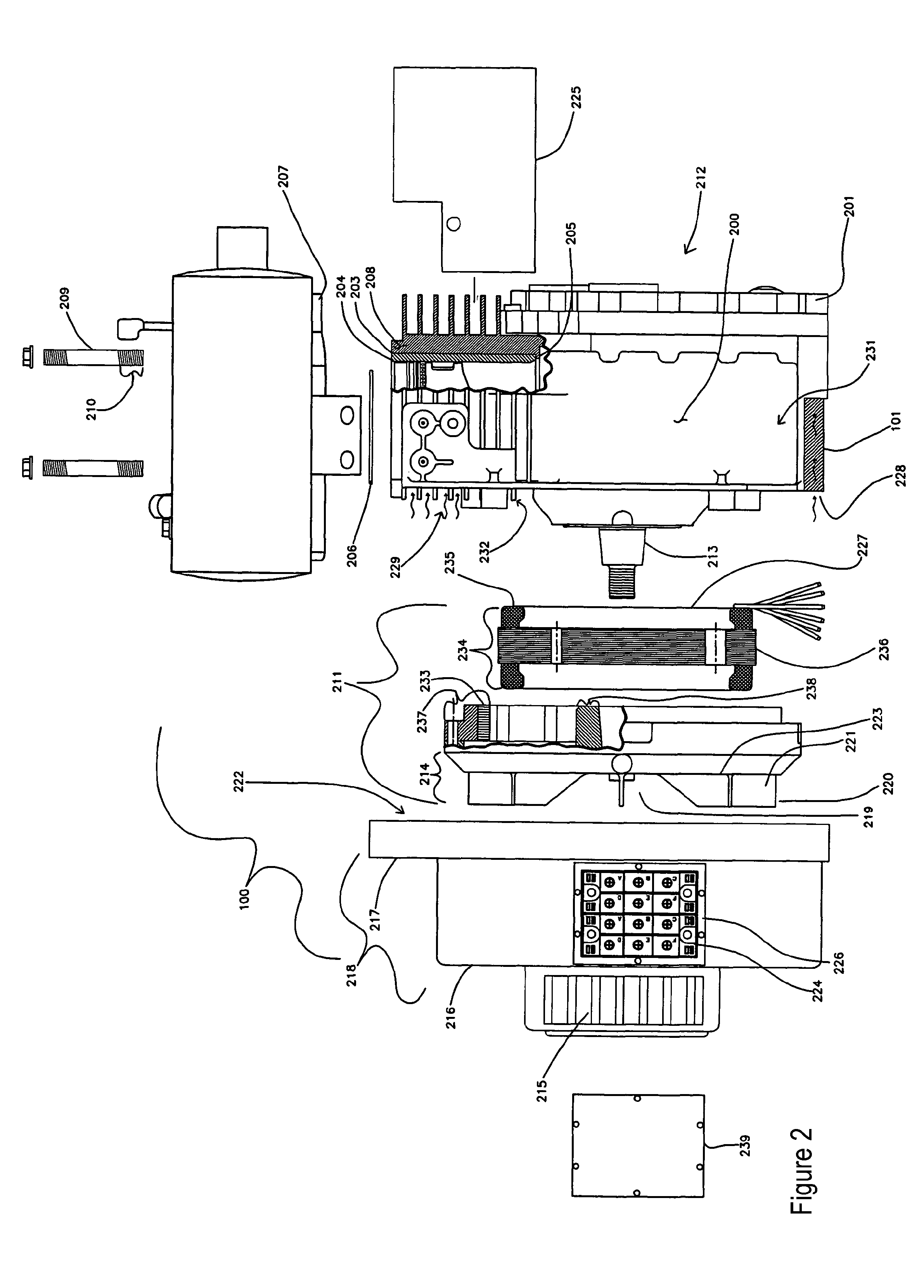

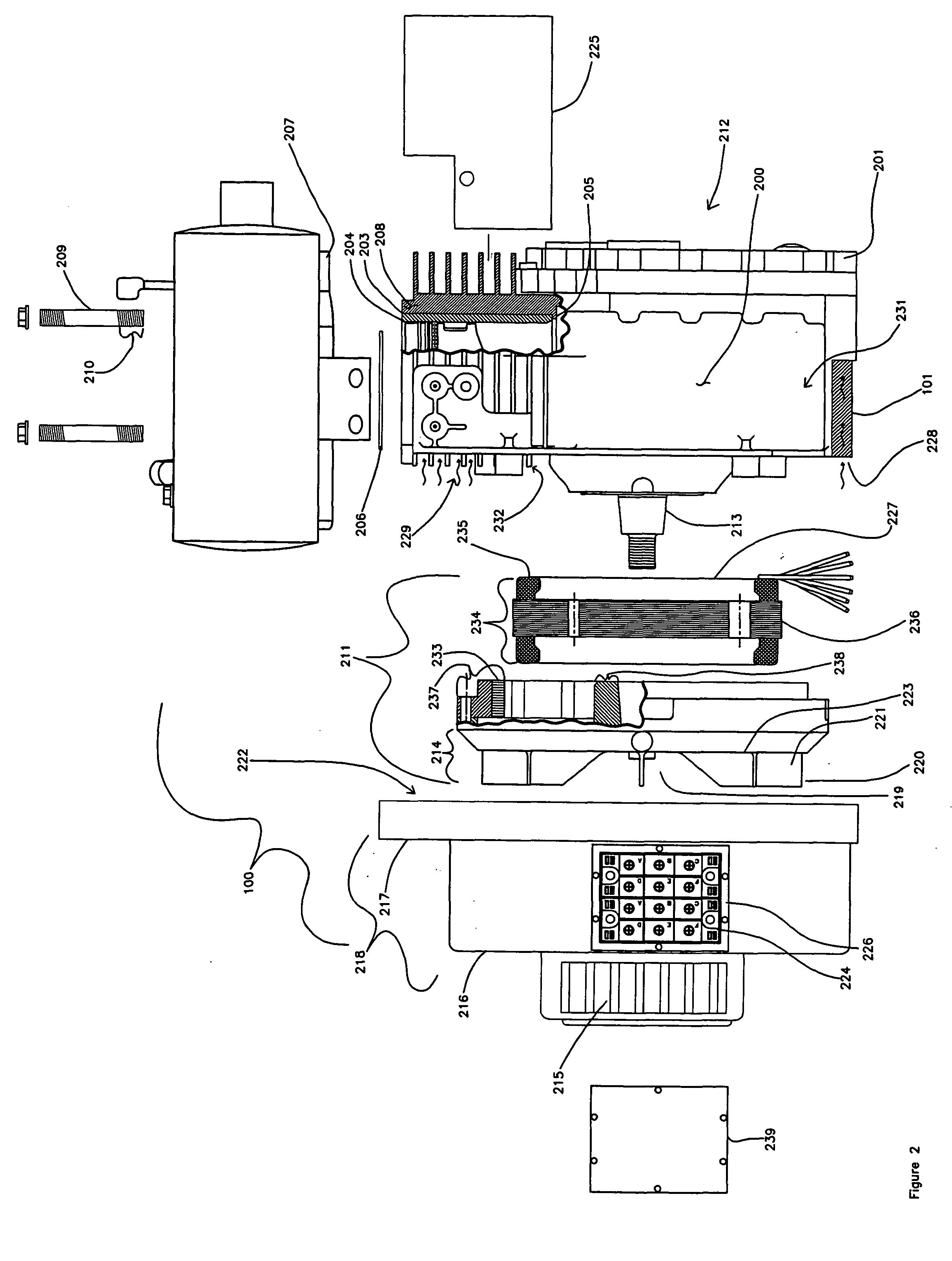

Lightweight Portable Electric Generator with Integrated Starter/Alternator

ActiveUS20070227470A1Improve torque performanceLow costMagnetic circuit rotating partsAir coolingAlternatorFuel efficiency

A compact and lightweight electric generator for portable power applications employs a new engine design and integration approach for reducing engine, generator, and starter weight. A unique flywheel alternator / starter configuration that generates electrical power, rotates the engine for starting, provides inertia for smooth engine operation, pressurized air for cooling, and inertia for the alternator. An engine cowling provides rotating component protection, a fan shroud mechanism, cooling air ducts, and a cooling mechanism for handling large quantities of heat produced by rectified power conversion. An electrical hook up that allows the generator to provide transient surge capacity for starting inductive loads, or improved load leveling and fuel efficiency.

Owner:MAINSTREAM ENG

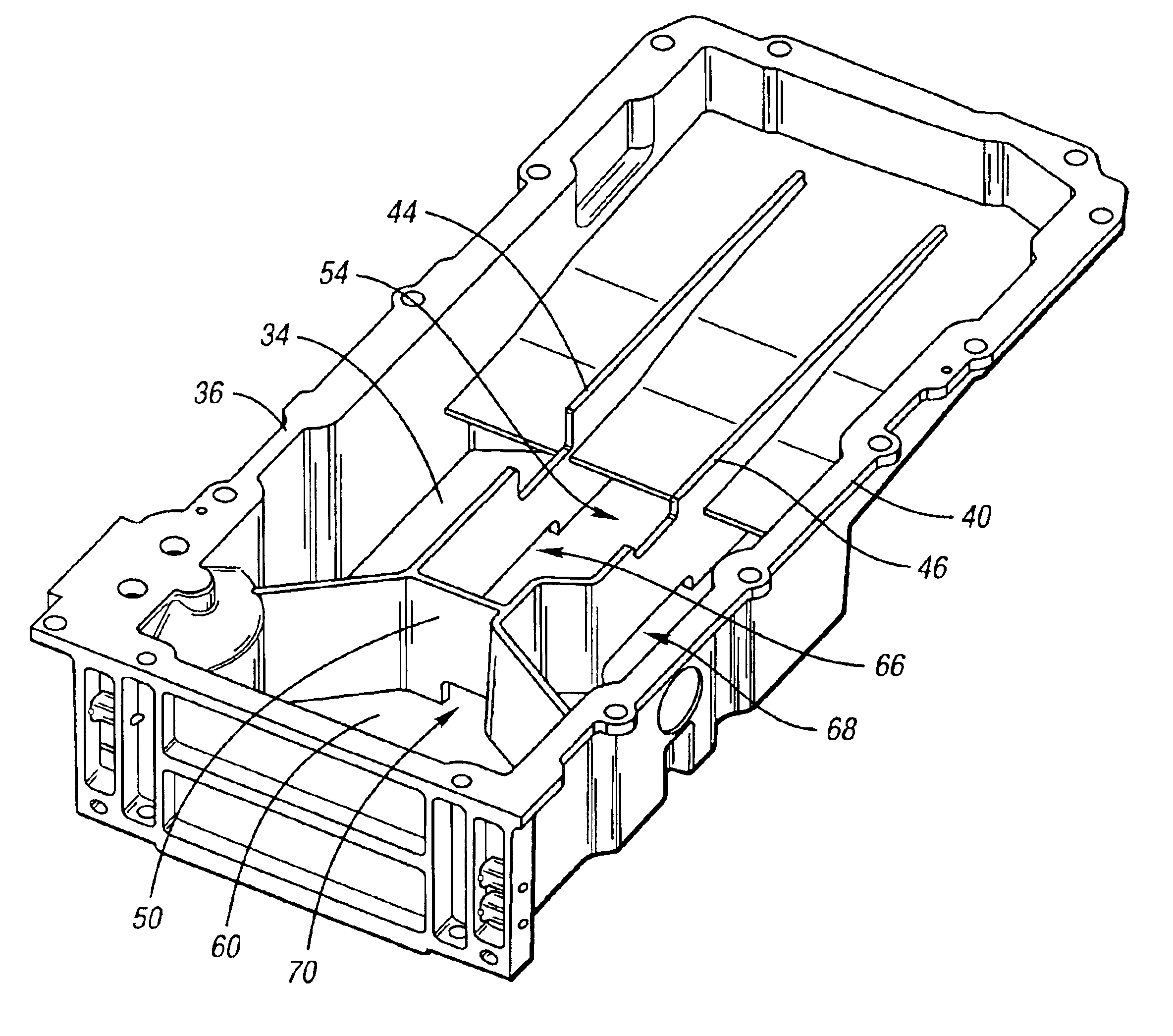

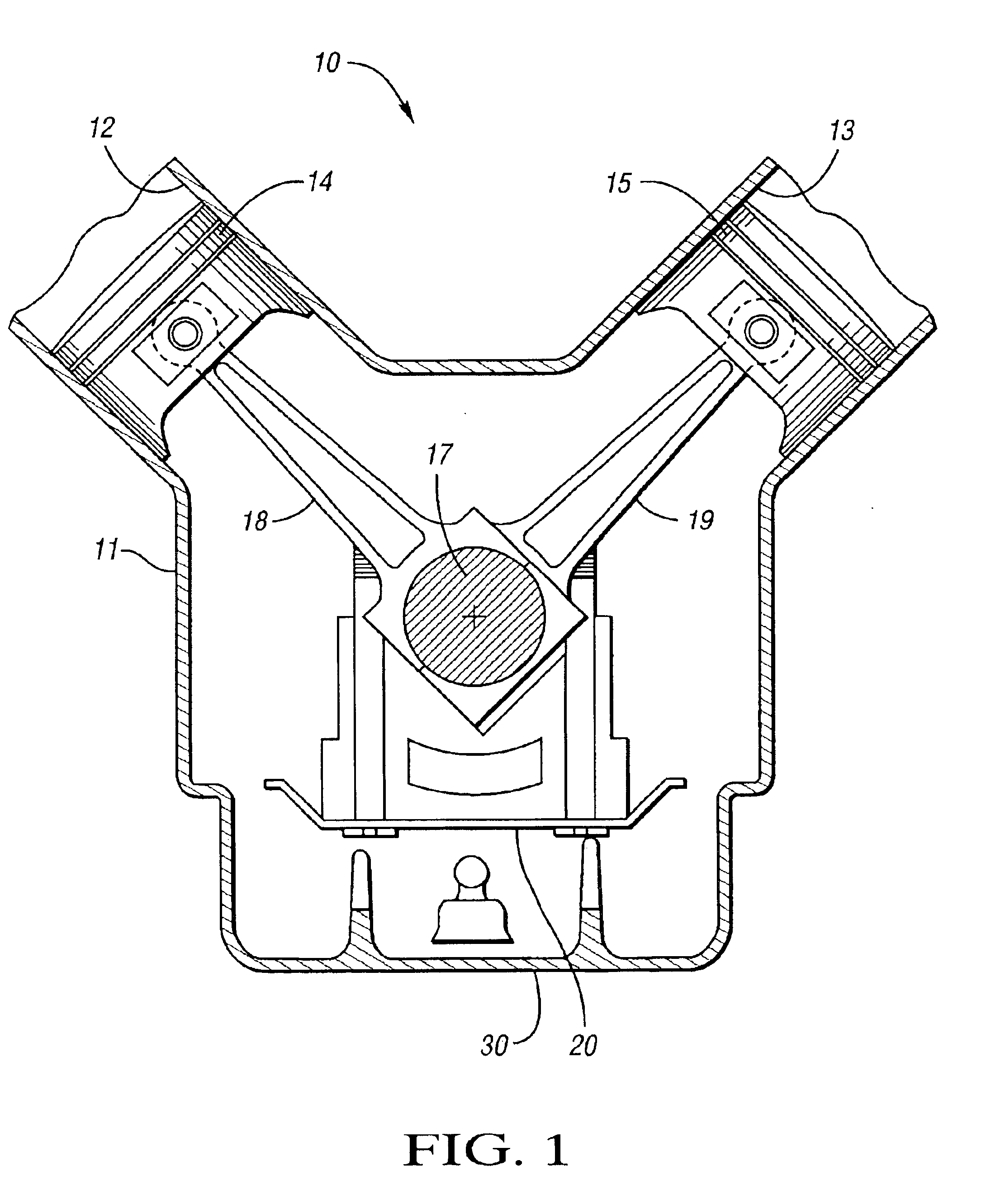

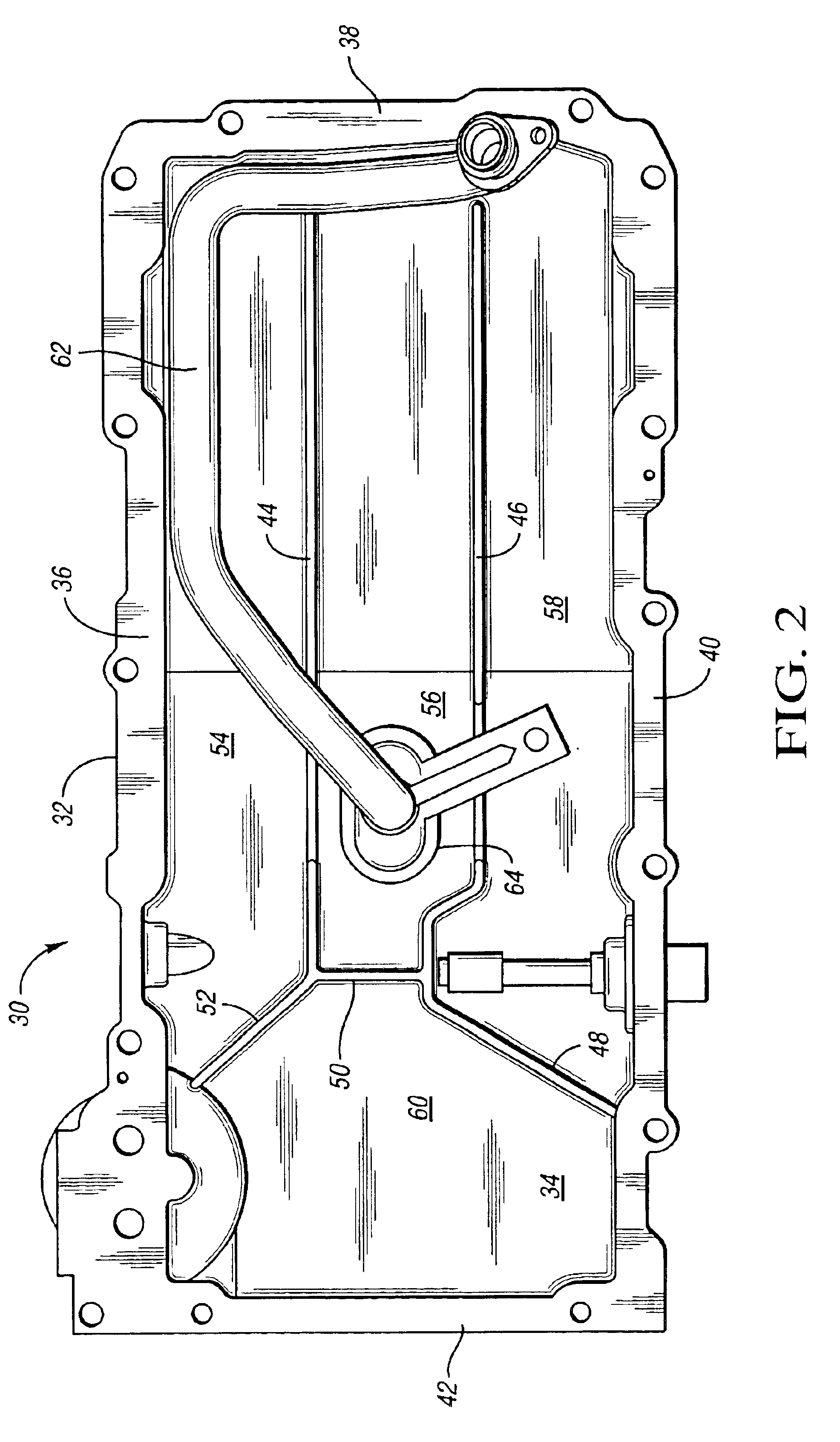

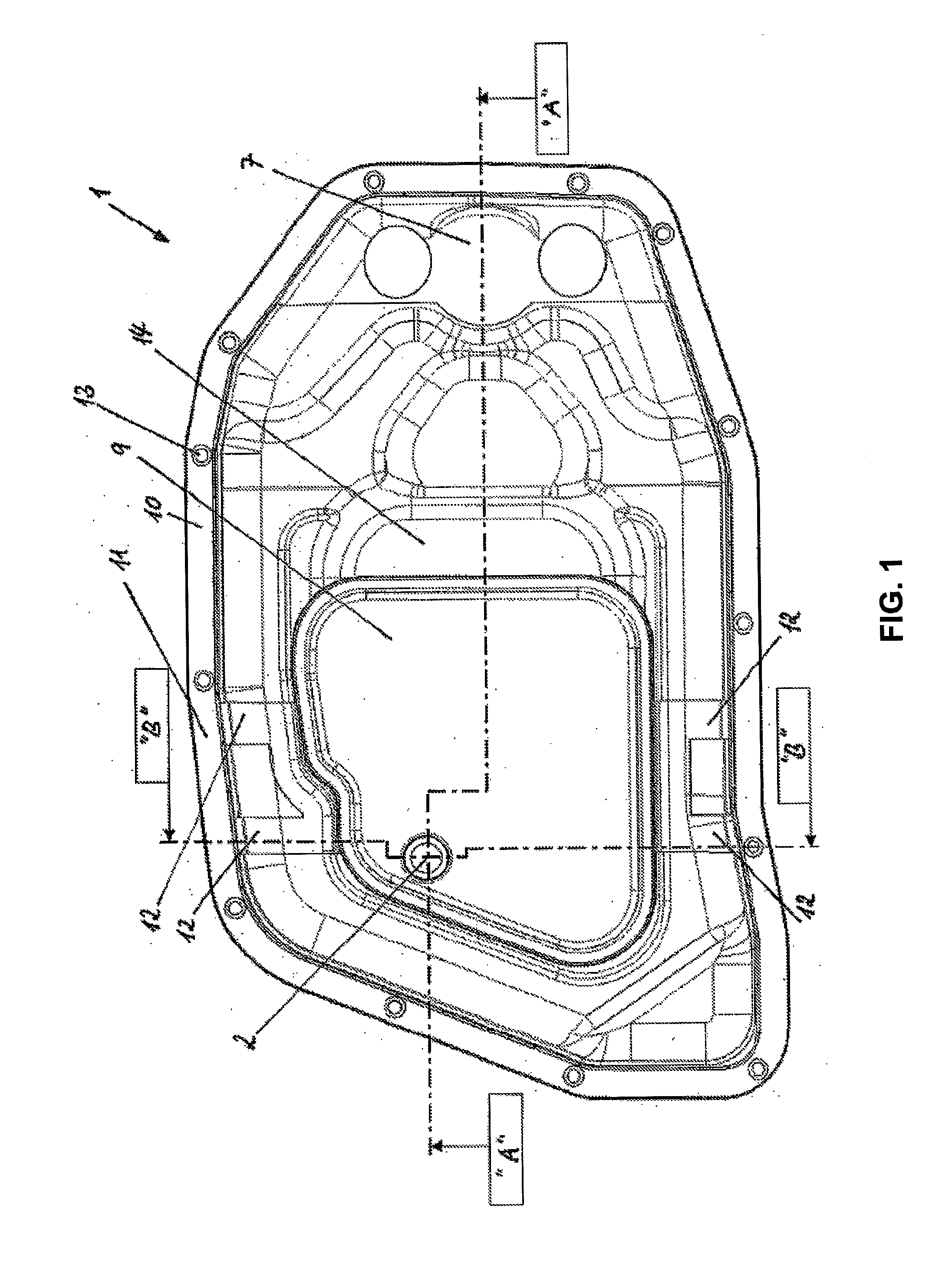

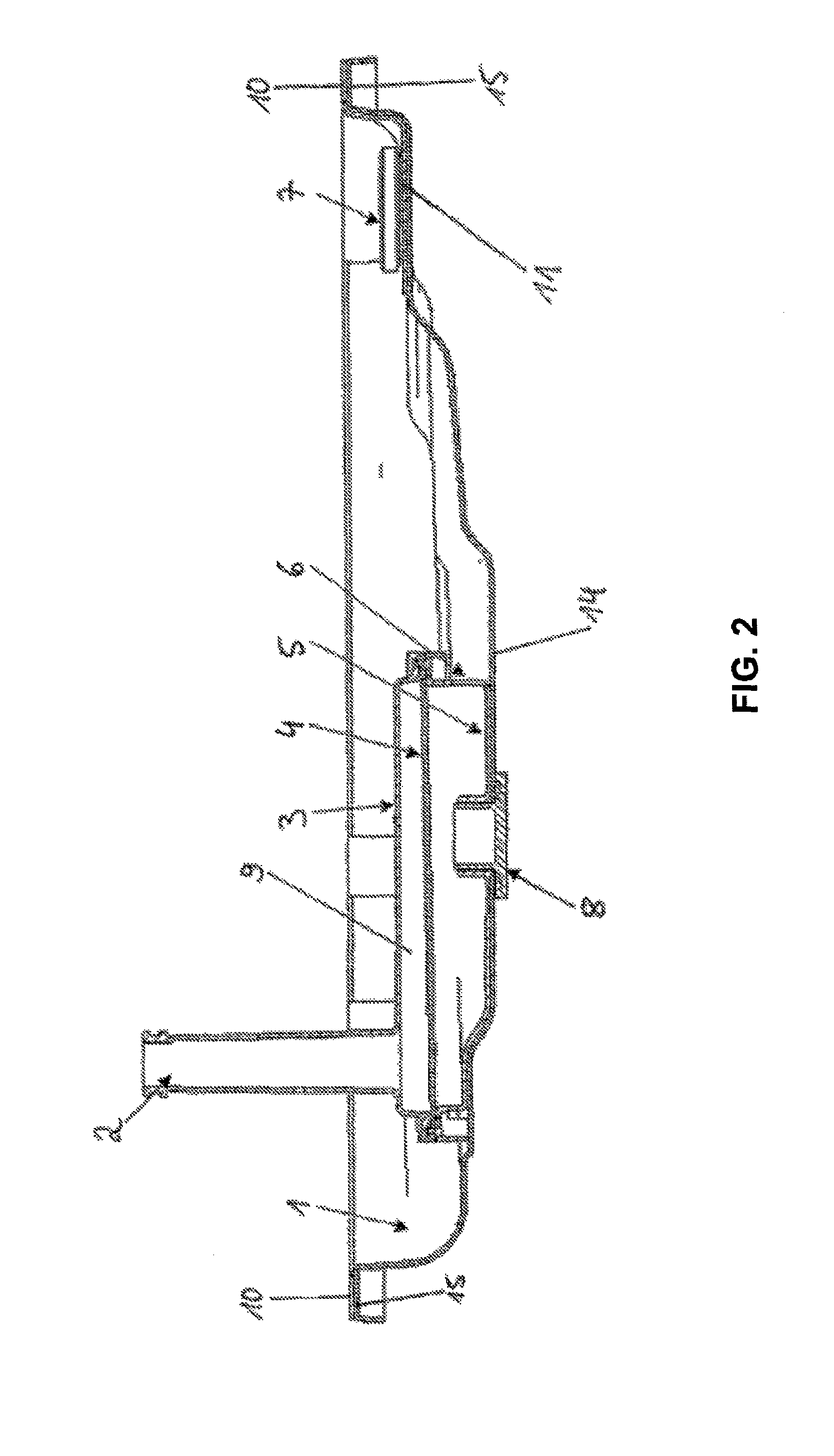

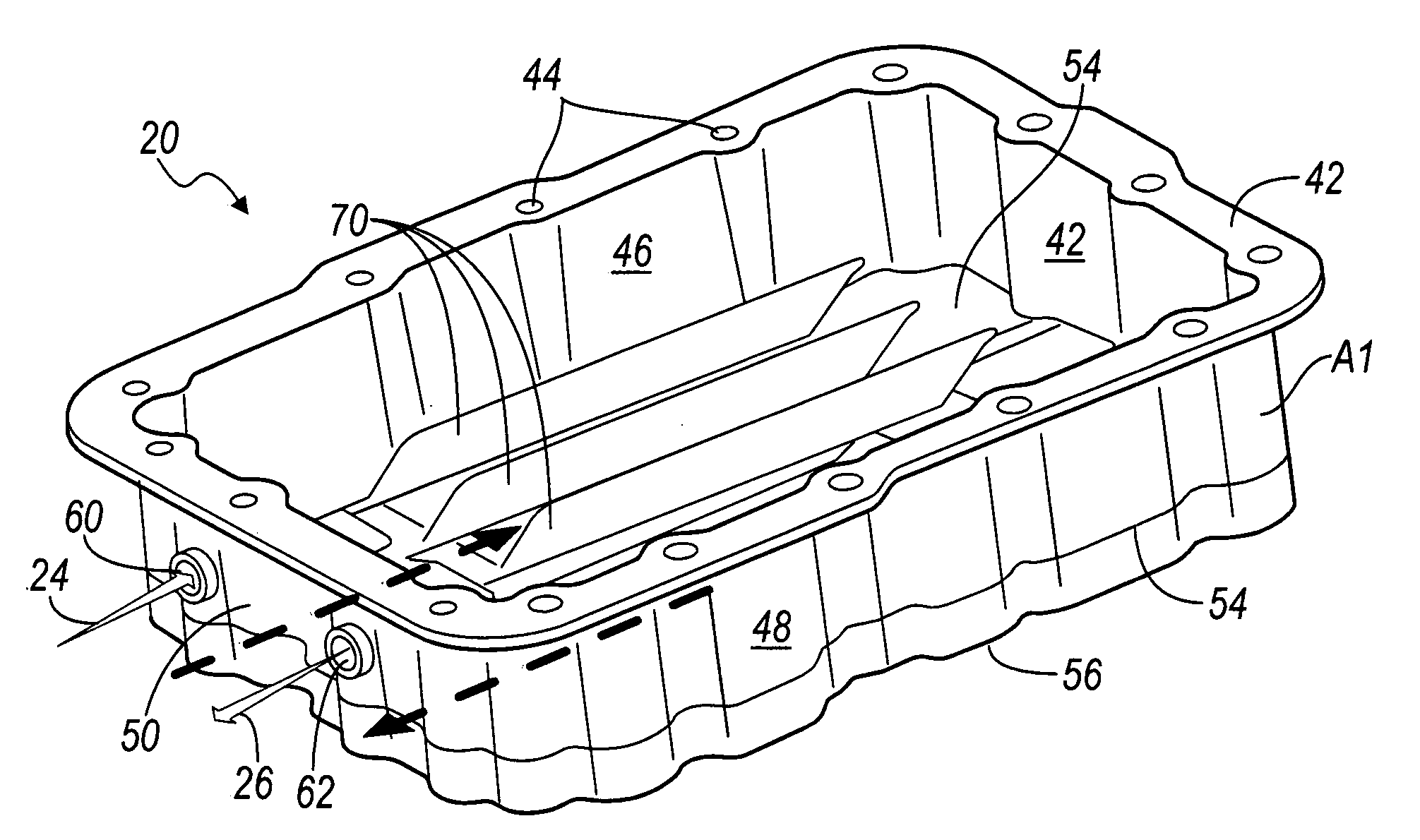

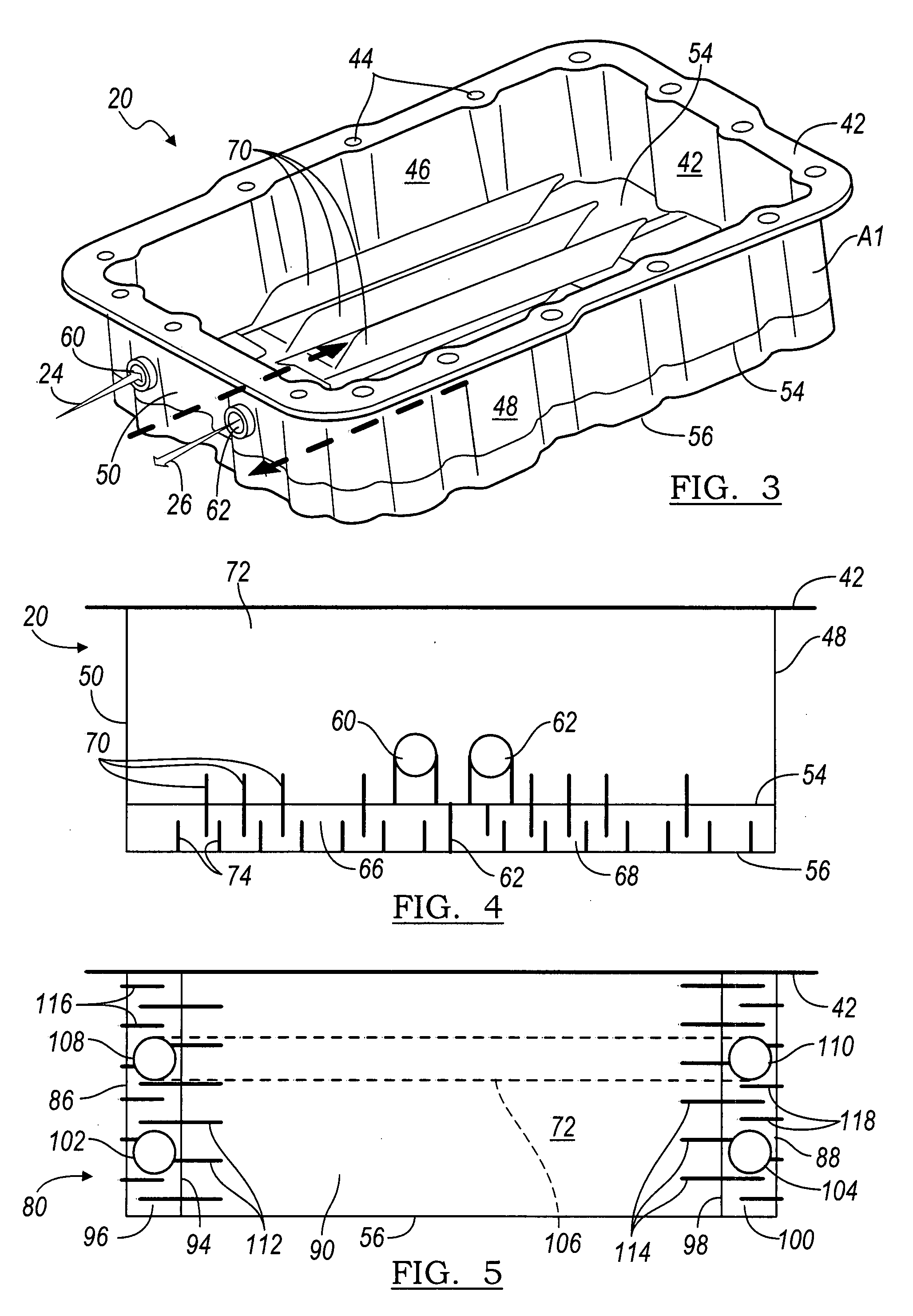

Oil pan with vertical baffles for oil flow control

ActiveUS6845743B1Low costReducing of oil quantity of oilCasingsLubrication of auxillariesWaste management

Owner:GM GLOBAL TECH OPERATIONS LLC

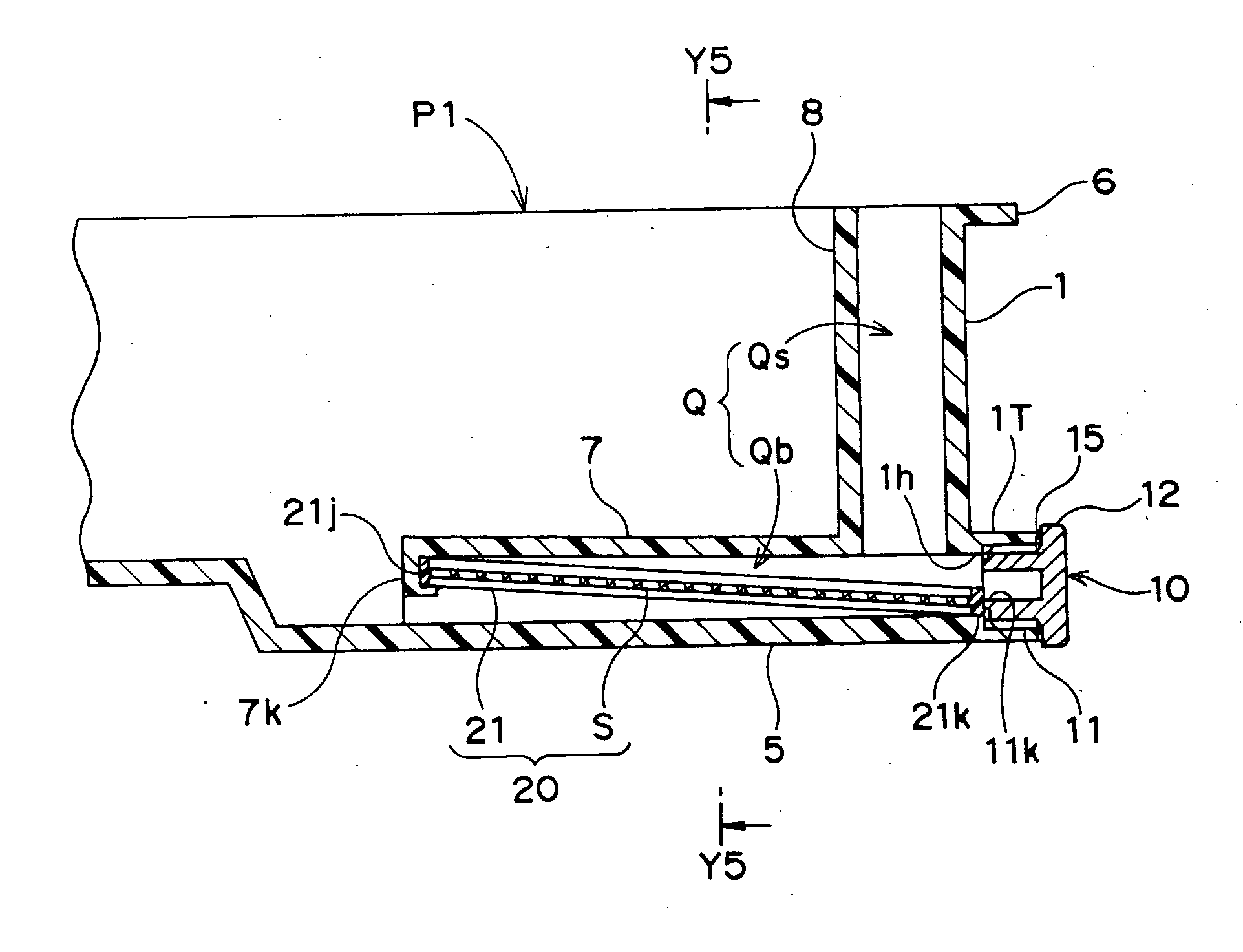

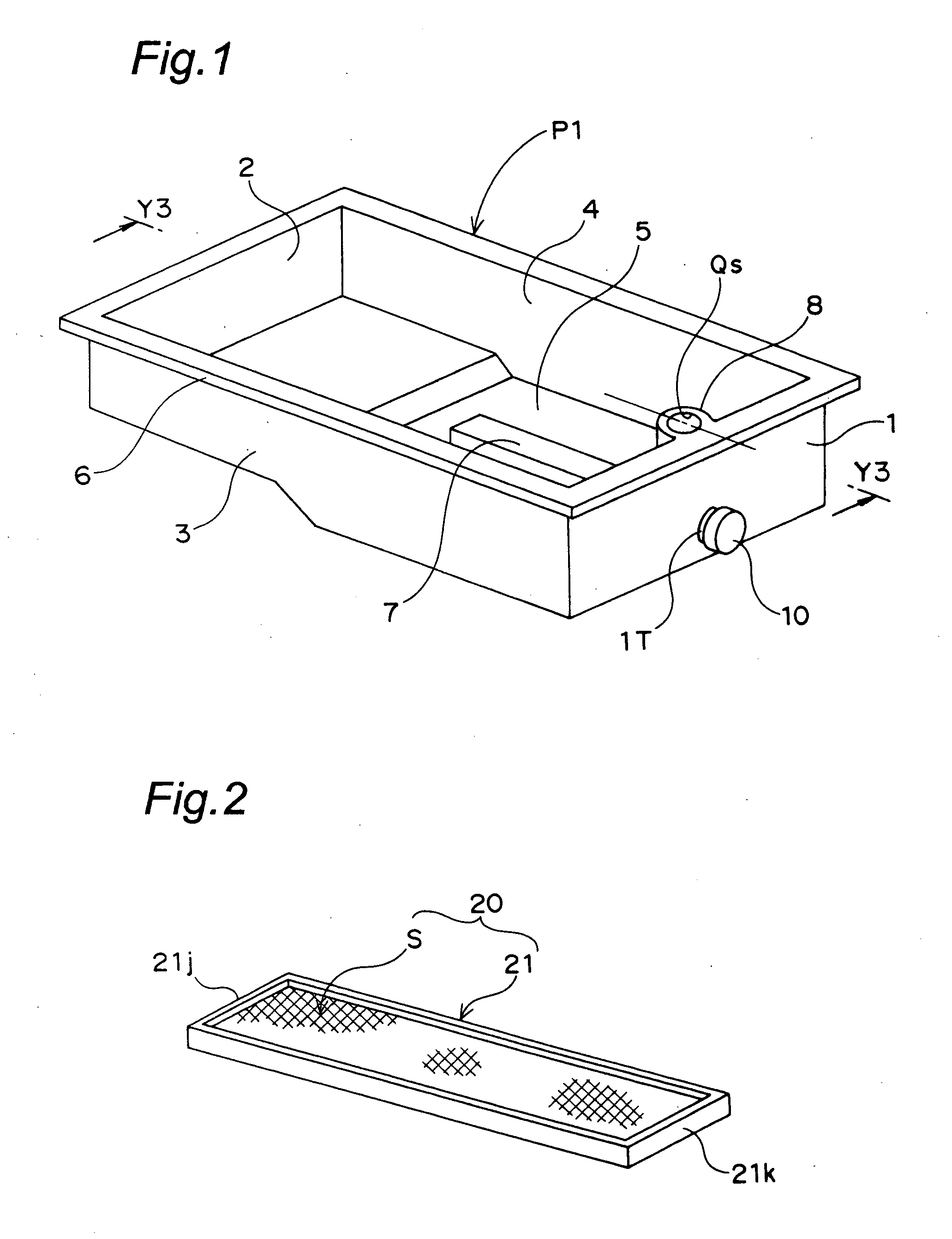

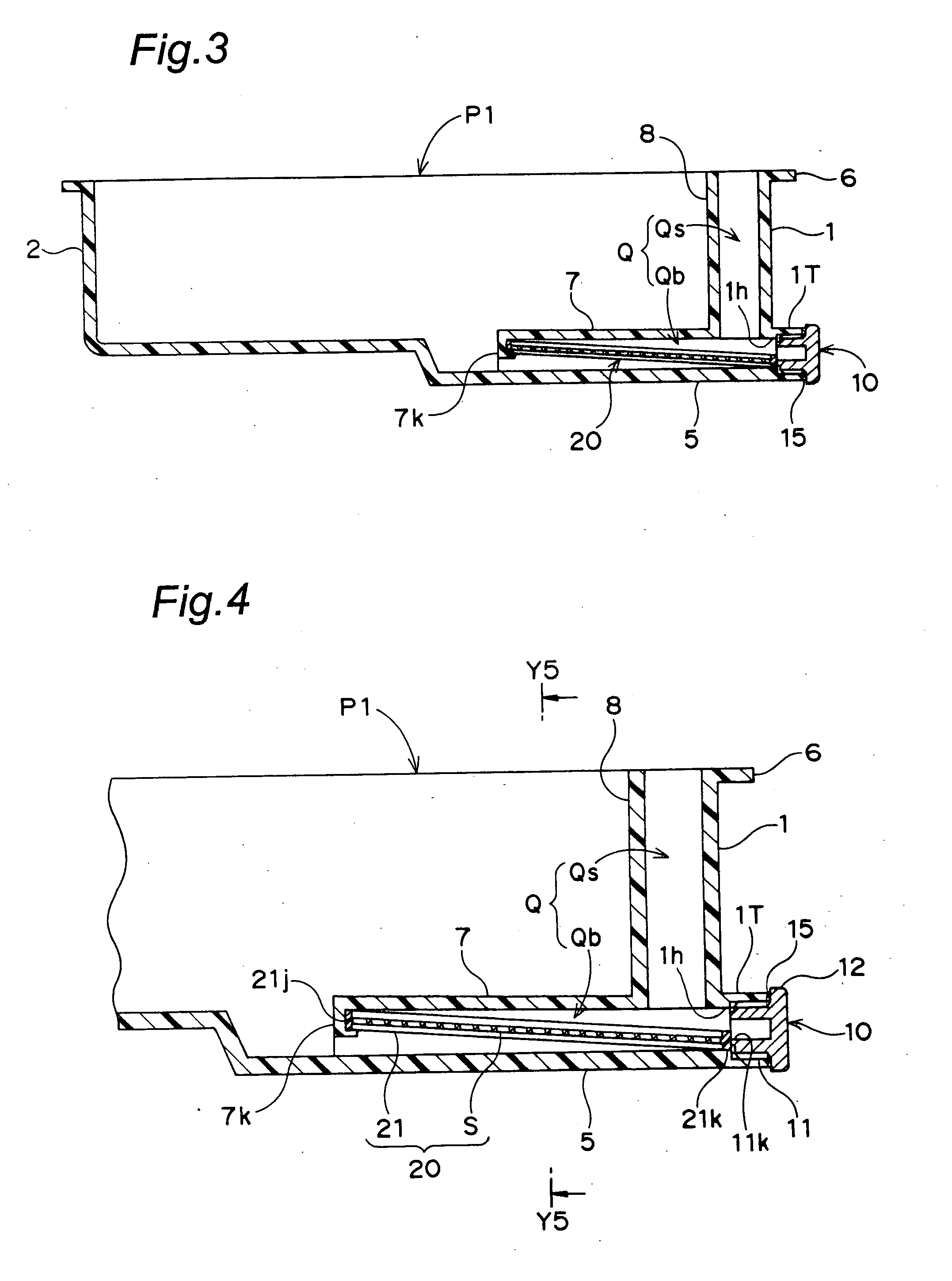

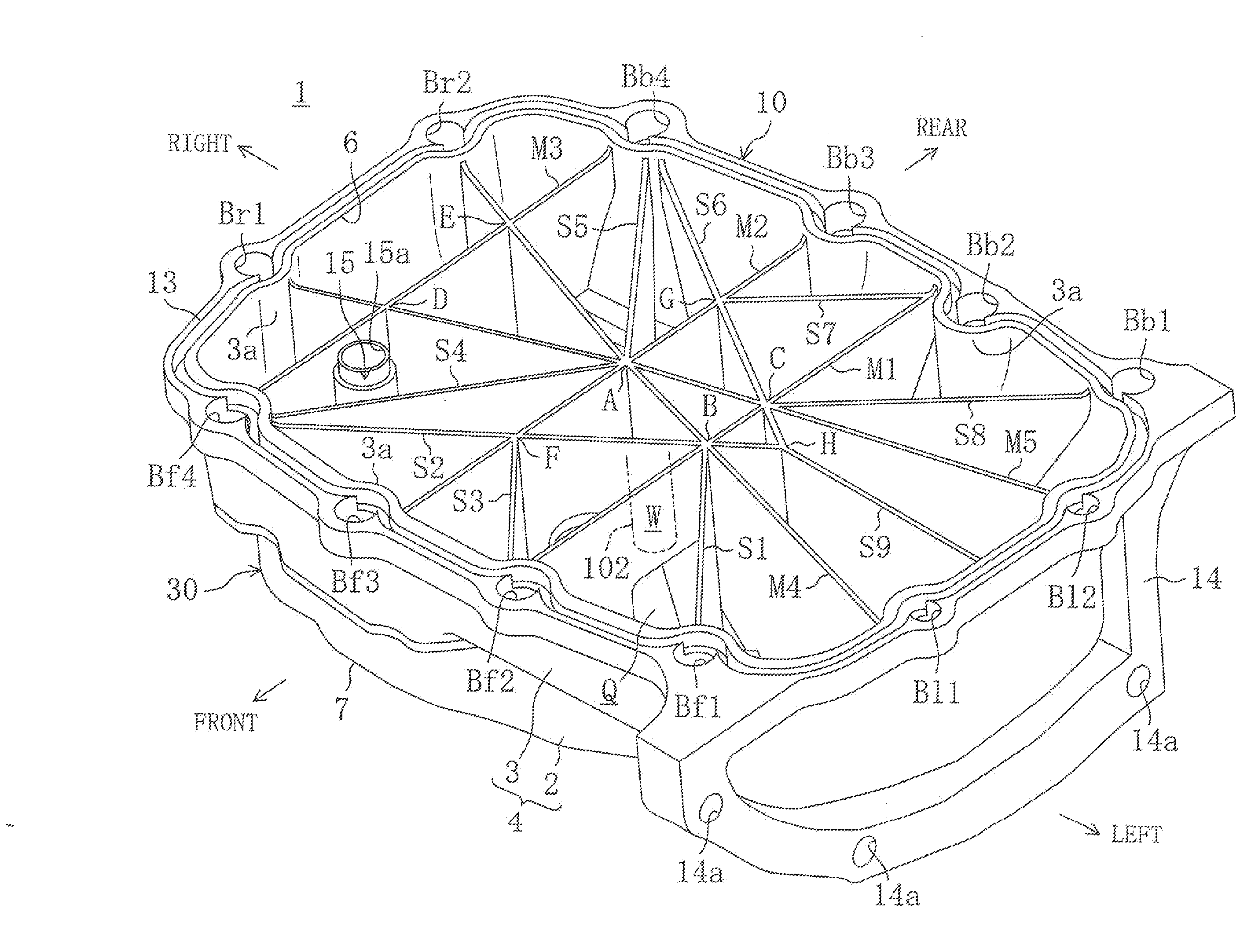

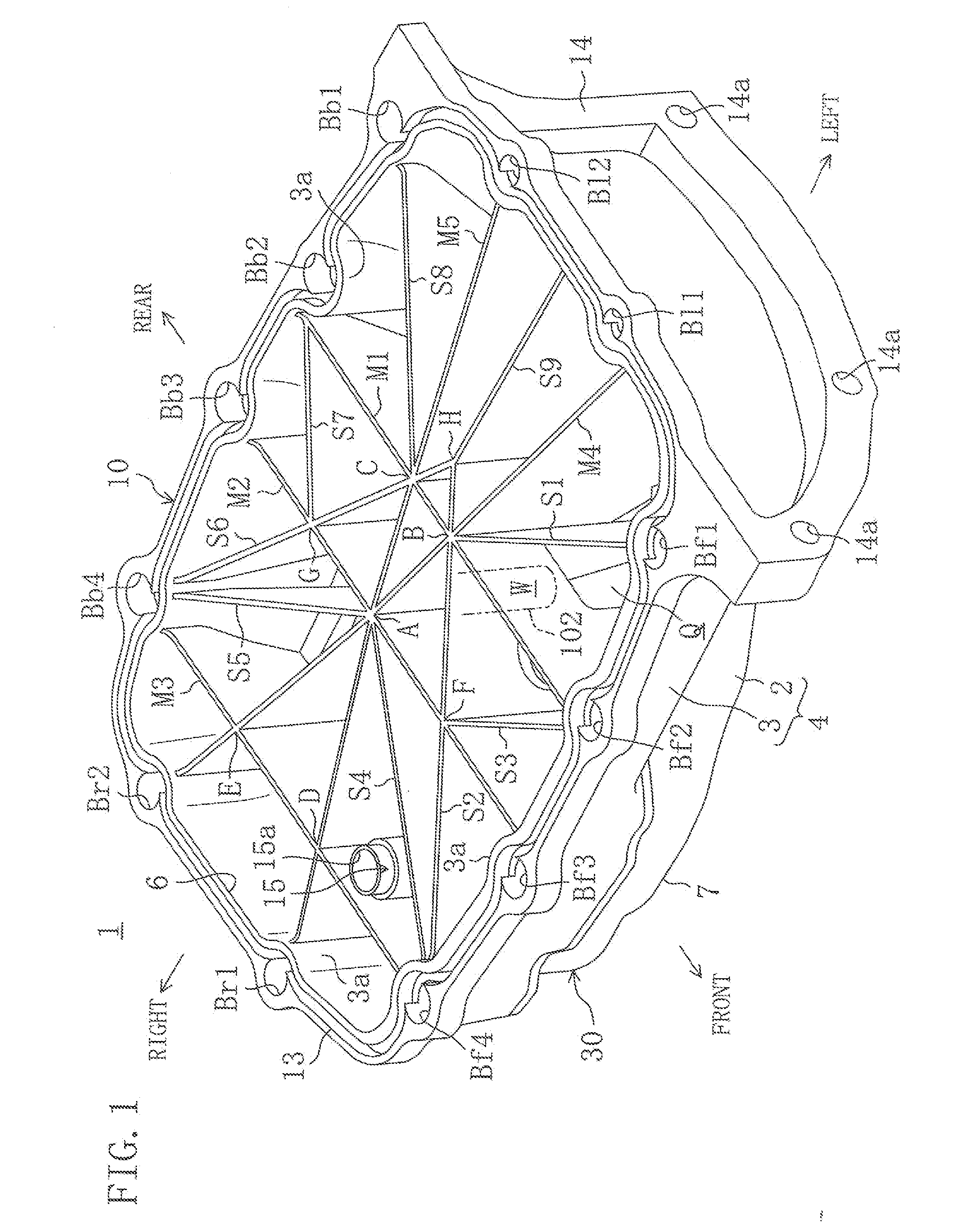

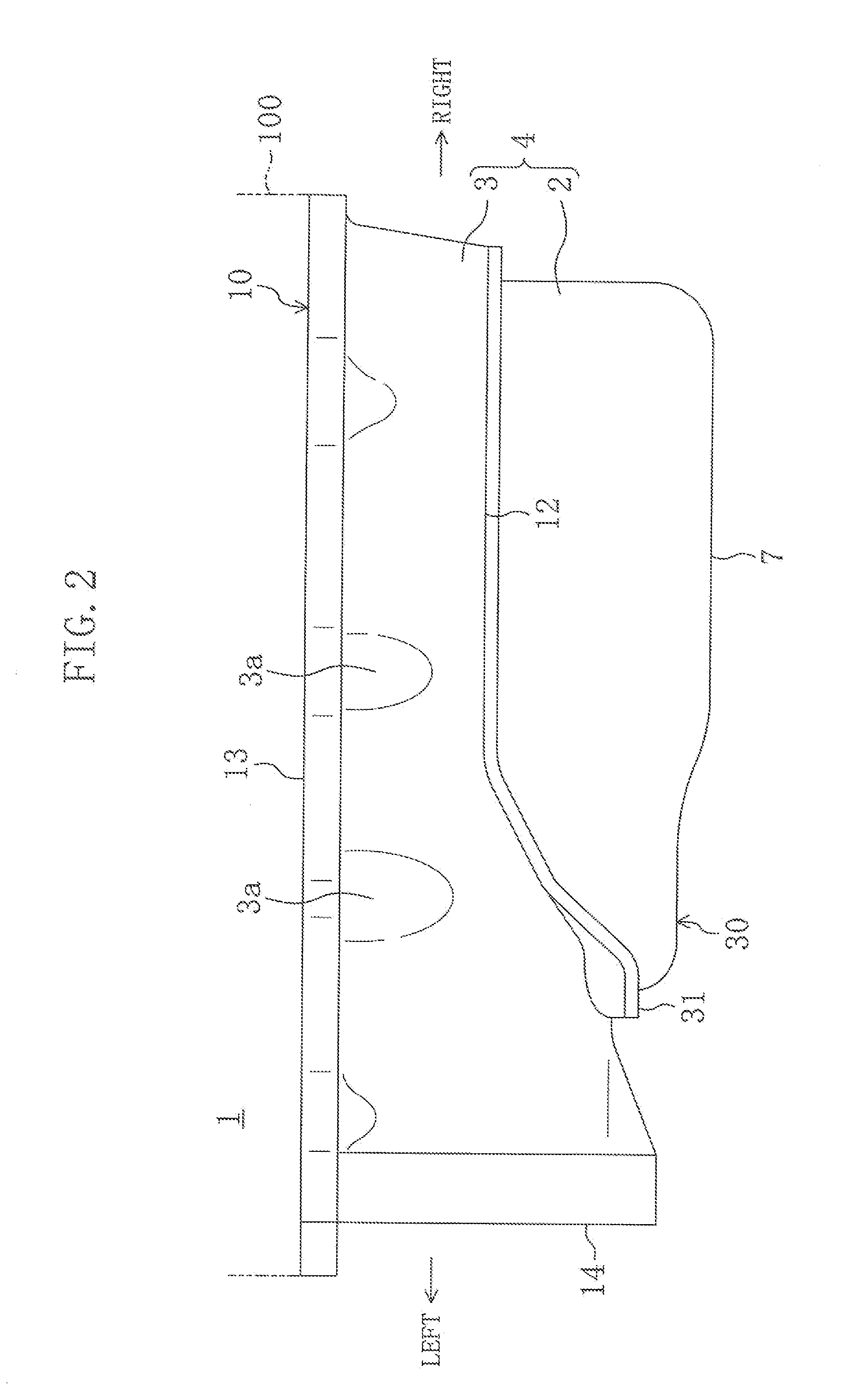

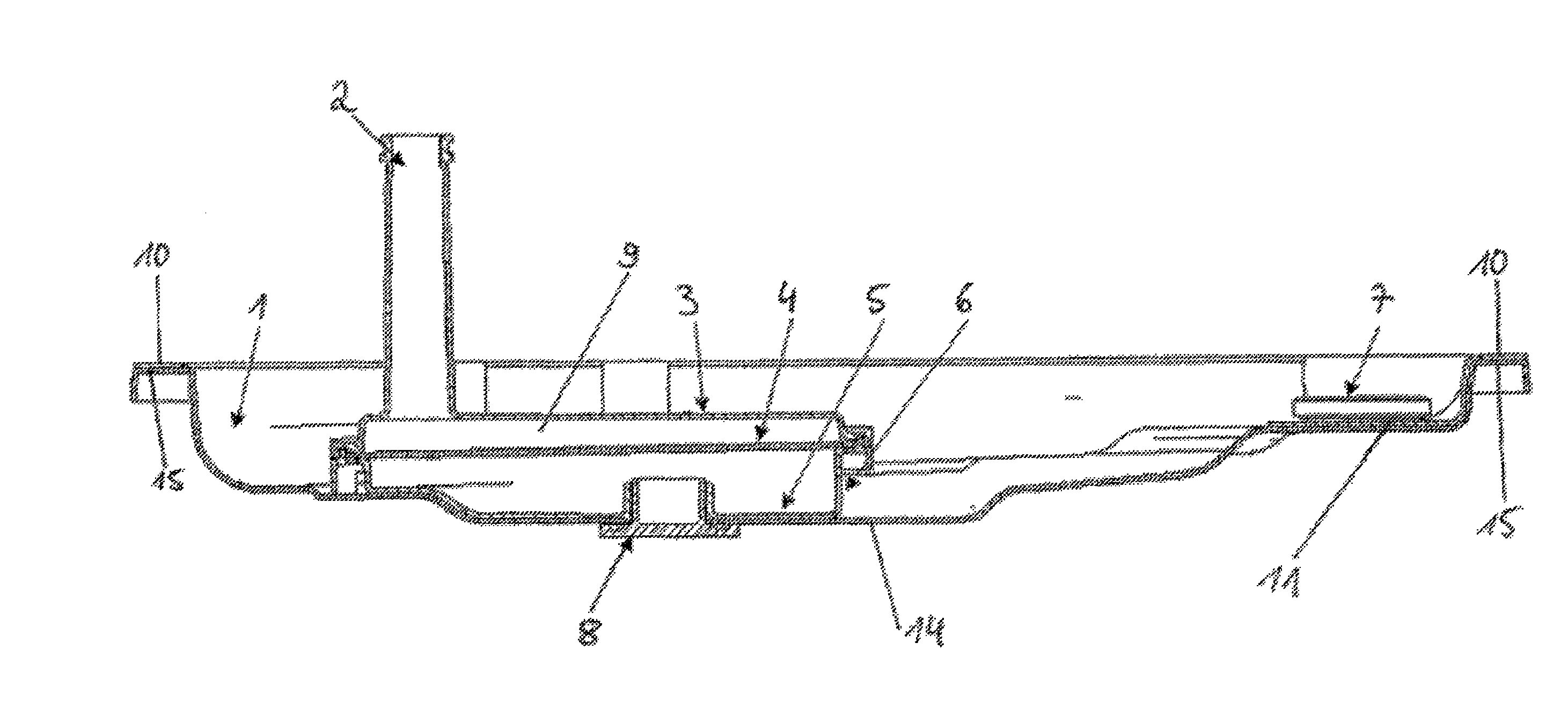

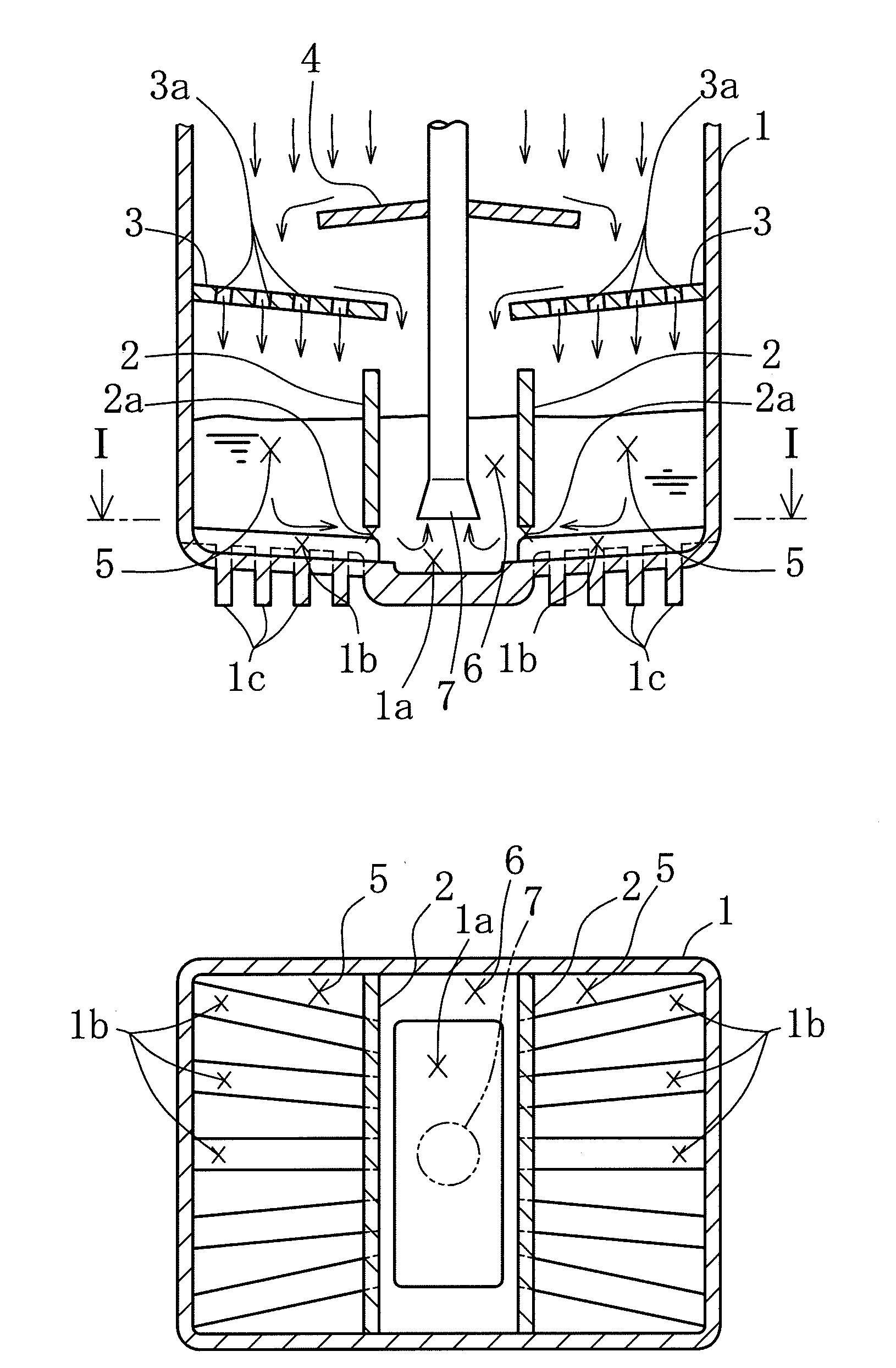

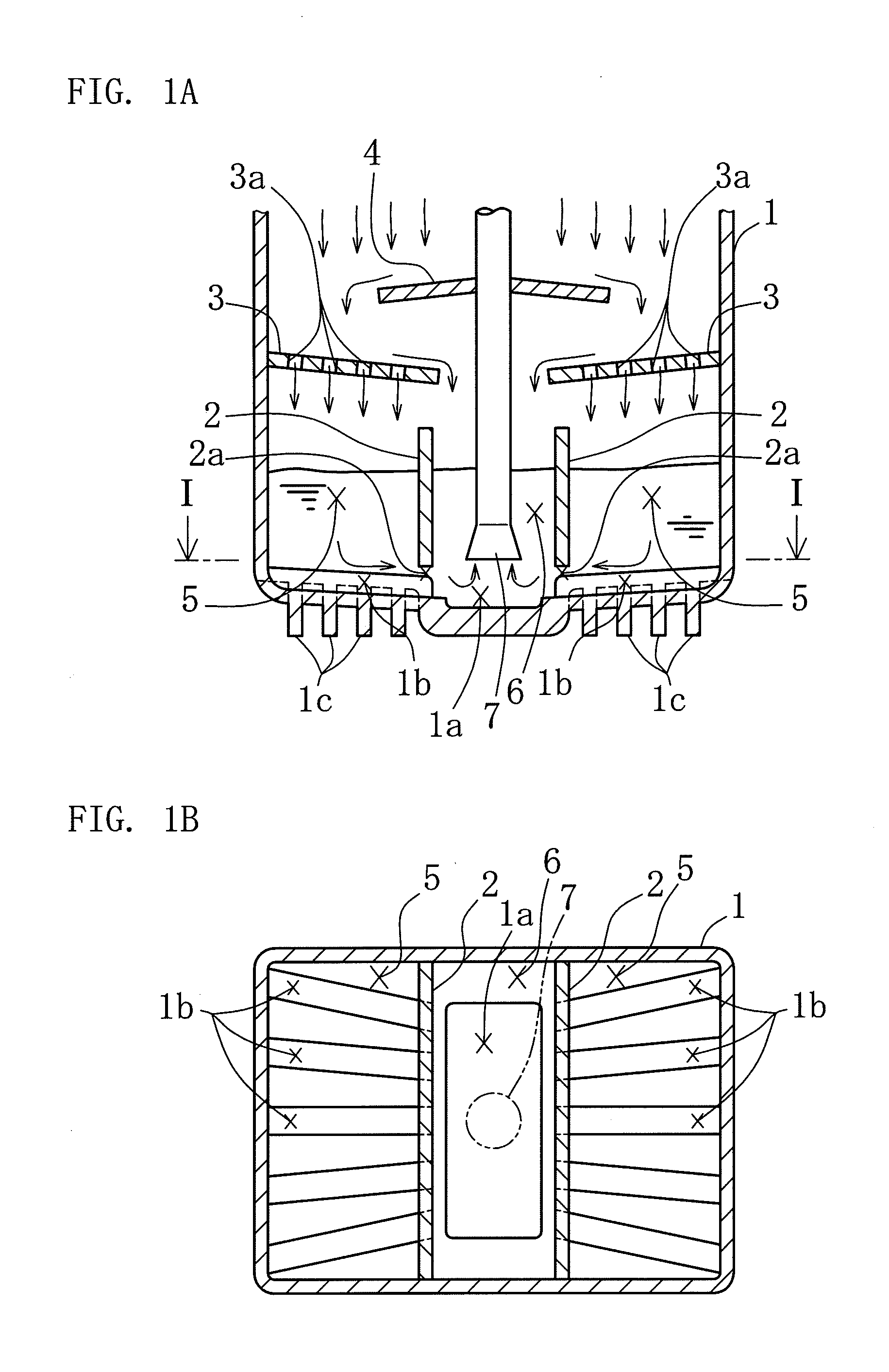

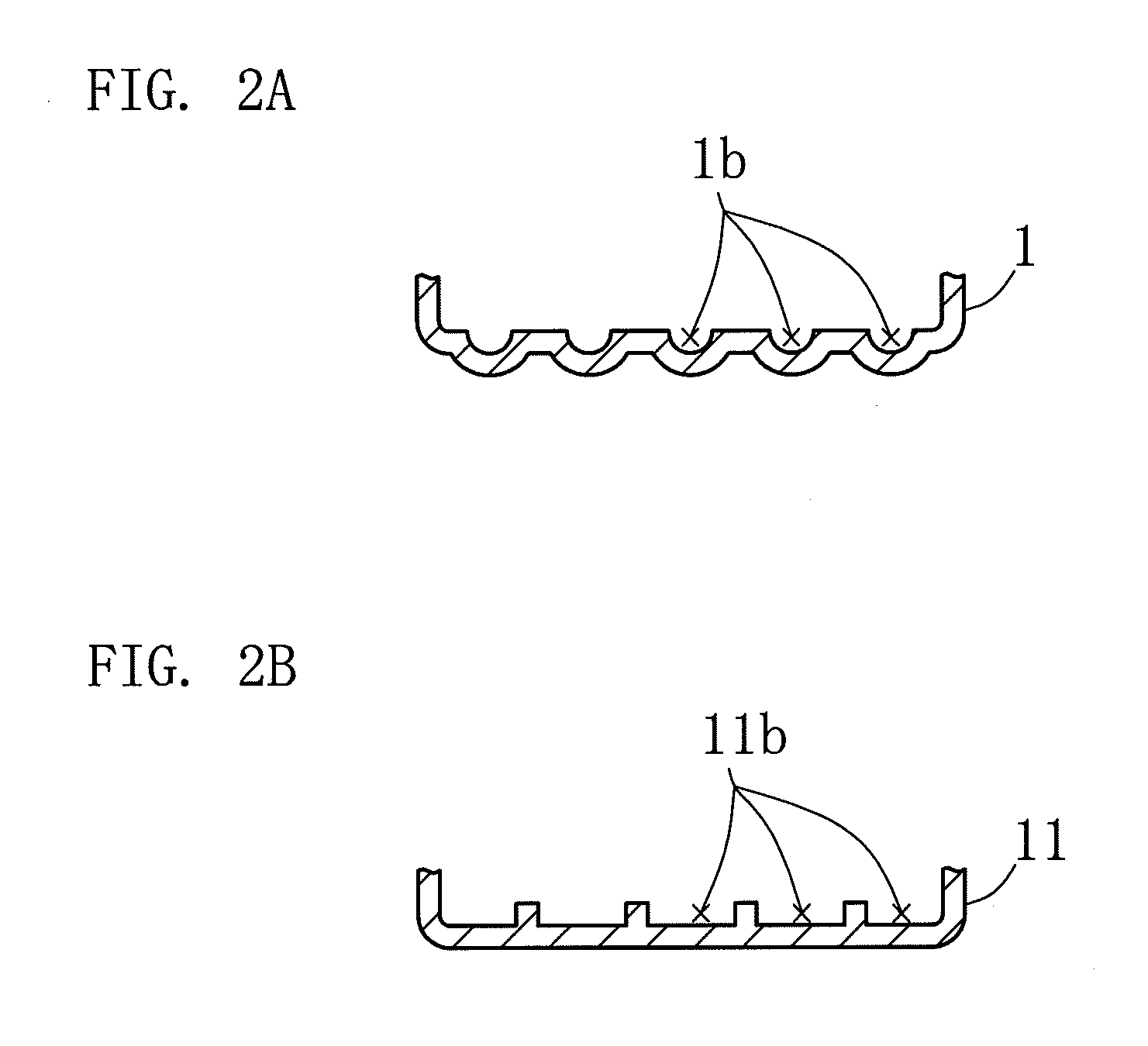

Oil pan with built-in filtering element

InactiveUS20060219620A1Supporting rigidity of the filter is highEasy to assembleOilsumpsMachines/enginesFilter elementWaste management

The present invention provides an oil pan with a built-in filtering element which does not easily receive influence of lateral swing of oil, which has high support rigidity of a filter, or which has excellent assembling operability of the filter, or which is light in weight as compared with a conventional oil pan. The oil pan P1 with a built-in filtering element has a filter 20. The filter 20 is provided therein with an oil flow path Q which is in communication with an oil pump. The filter 20 filters oil flowing toward the oil pump. An oil flow path includes a bottom flow path Qb having a flow path wall 7 extending along a bottom wall 5 of the oil pan, and a side flow path Qs having a flow path wall 8 extending along a first sidewall 1 of the oil pan. The first sidewall includes a drain hole 1h which opens at the bottom flow path and through which the filter can be inserted into the bottom flow path. The bottom flow path is provided with a filter retaining portion 7k which retains the inserted filter. The drain hole is provided with a plug fixing portion 1m which fixes a closing plug 10 of the drain hole. The closing plug is formed with a filter receiver 11k against which a terminal end 20k of the inserted filter is abutted.

Owner:DAIKYONISHIKAWA CORP

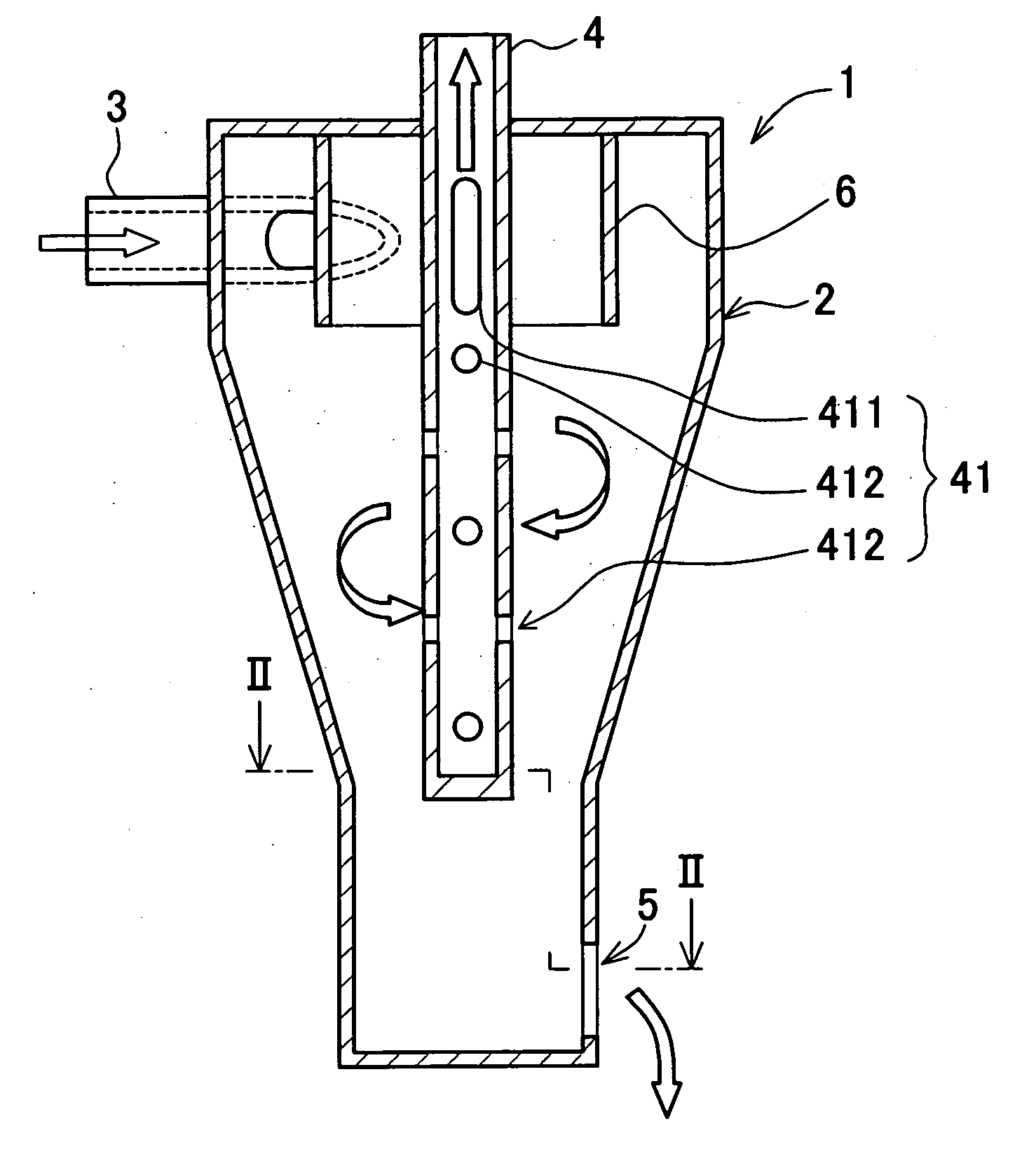

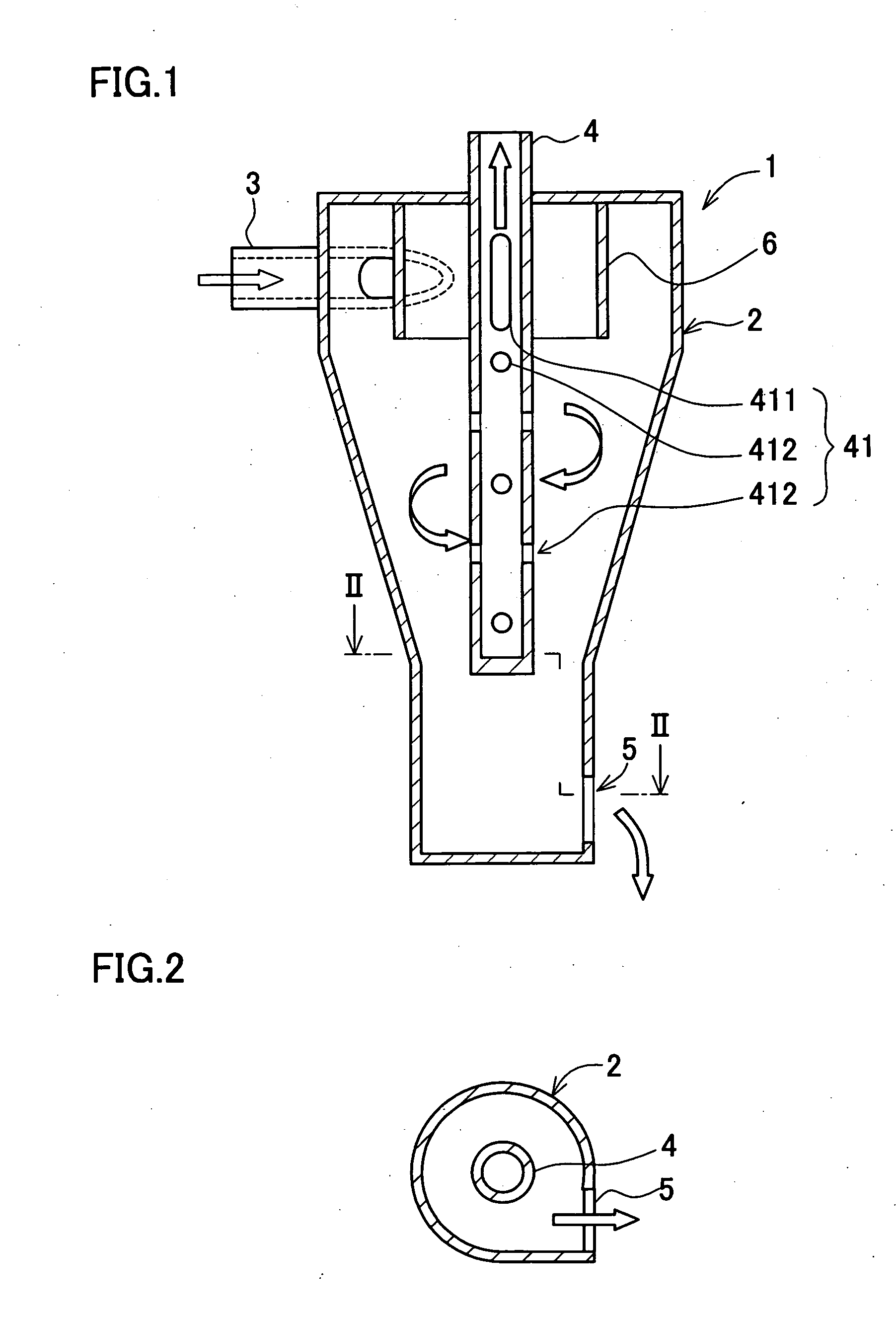

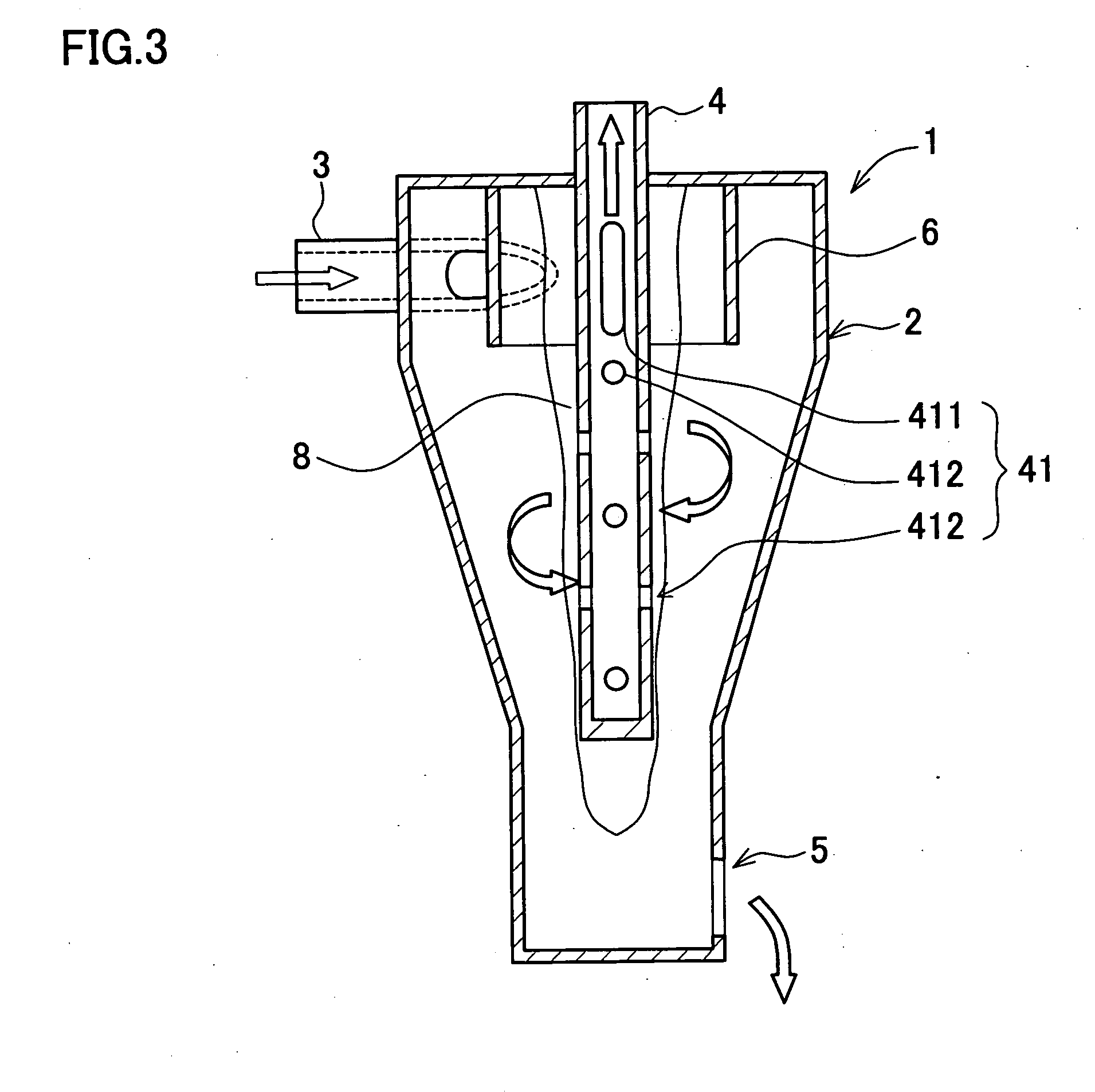

Bubble separator

InactiveUS20070163442A1High bubble separation efficiencyLiquid degasificationReversed direction vortexProduct gasAir bubble

A bubble separator includes a body with a generally cylindrical shape, an oil induction portion, a gas discharge portion with a generally cylindrical shape, an oil discharge portion, and an upper partition. The oil induction portion is provided on the body, and introduces bubble-containing oil to inside the body. The gas discharge portion is provided extending from a ceiling portion of the body, and discharges separated bubbles to outside the body. The oil discharge portion is provided on the body, and discharges separated oil to outside the body. The upper partition is provided extending from the ceiling portion, and is formed on a periphery of the gas discharge portion. According to the bubble separator of the present invention, the upper partition can prevent bubble-containing oil from directly blowing into the discharge hole of the gas discharge portion and discharging to outside the body together with separated gas.

Owner:TOYOTA BOSHOKU KK

Unit for recovering and converting the thermal energy of the exhaust gases of an internal combustion engine of a vehicle

ActiveUS20120102934A1Least impact production costReduced dimensionNon-fuel substance addition to fuelInternal combustion piston enginesThermal energyExternal combustion engine

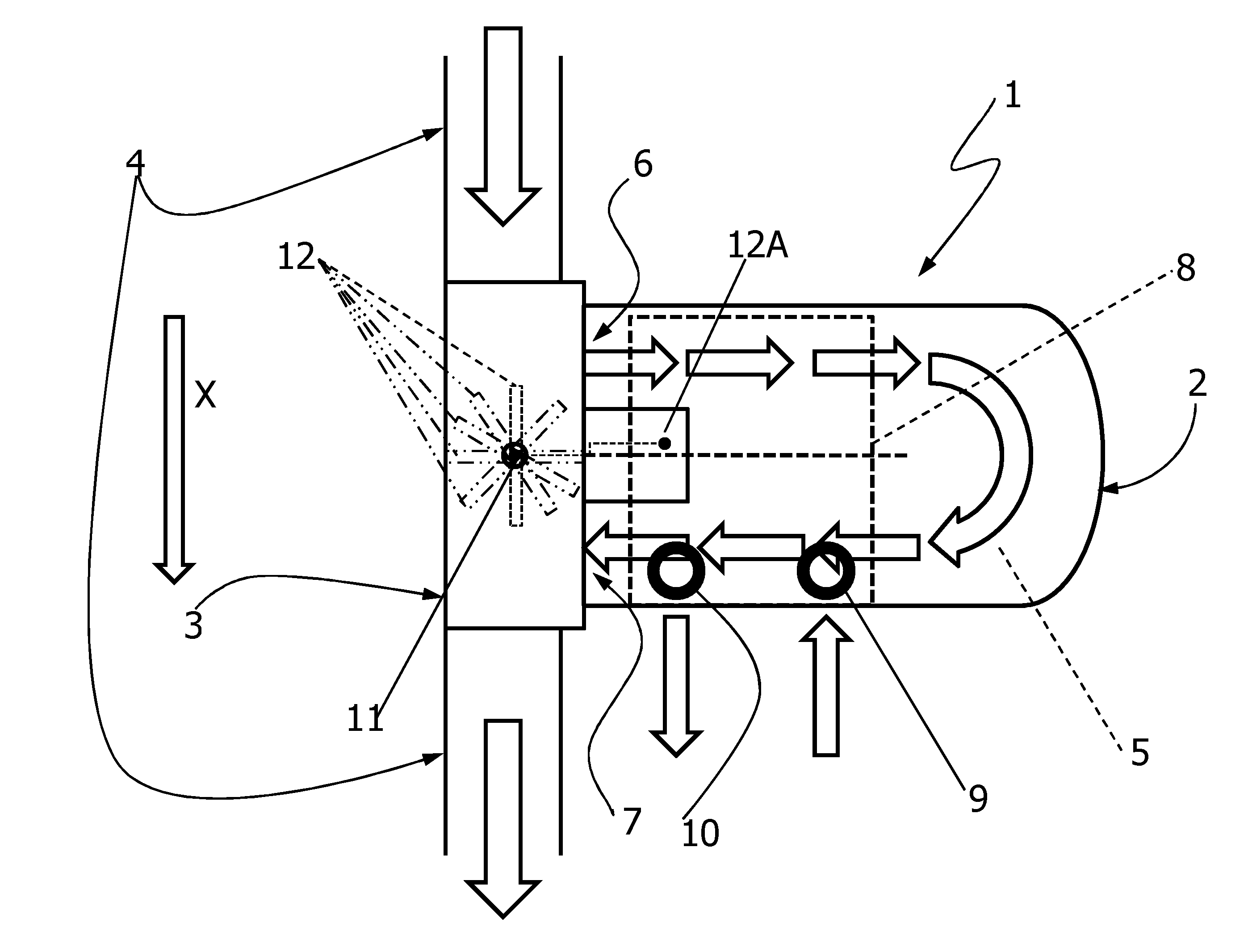

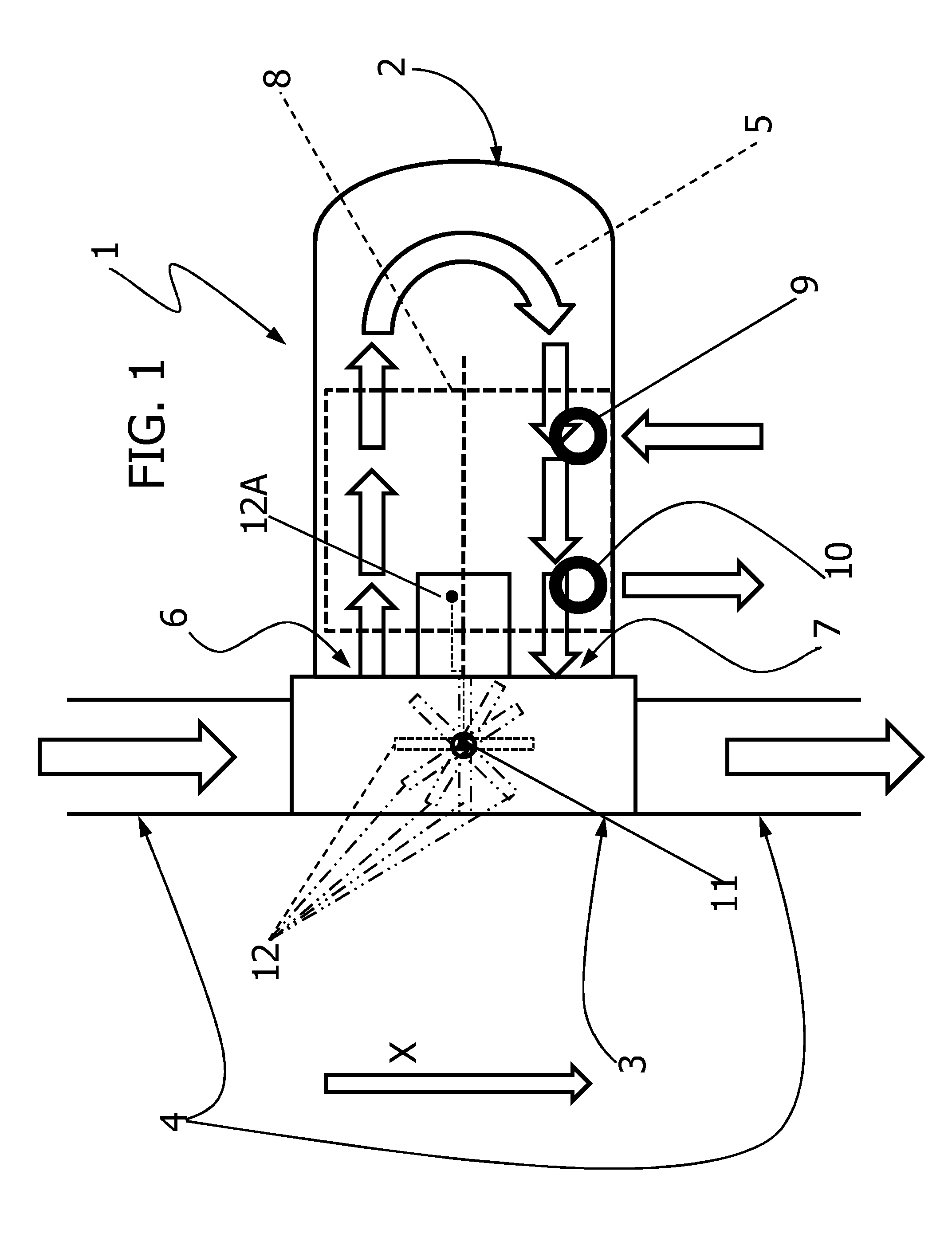

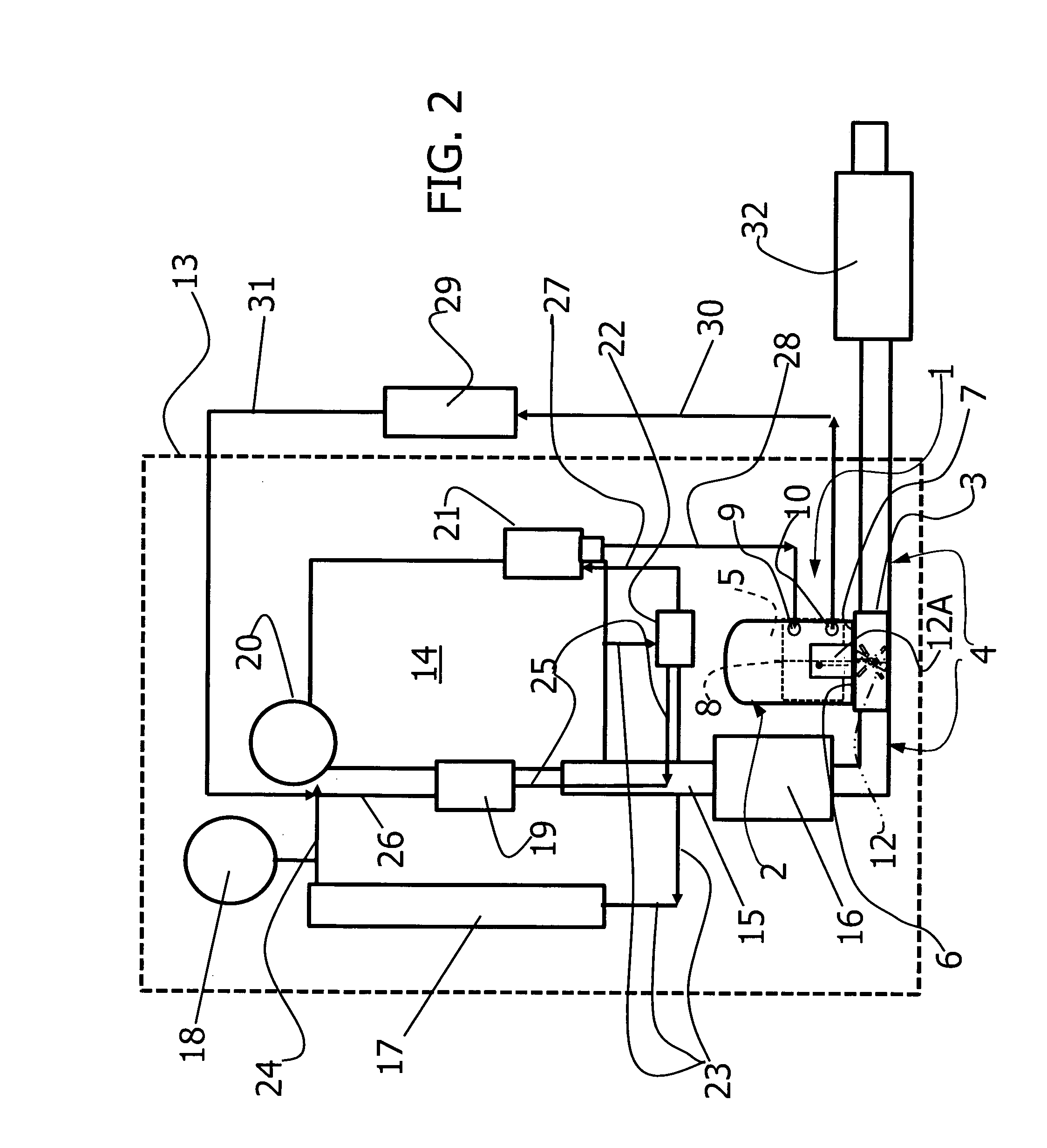

A unit (1, 1′) for recovering and converting thermal energy from the exhaust gases of an internal combustion engine (14) of a vehicle comprises a heat exchanger (2, 2′) to be traversed by exhaust gases flowing along a by-pass path (5,5′) branching out from an exhaust gas main line (4) of said internal combustion engine (14) and valve means (12) for controlling the flow of the exhaust gases through said path, said valve means (12) being driven by an actuator device (12A). The by-pass path (5, 5′) is a U-shaped path defined entirely within the heat exchanger (2, 2′),starting from an inlet section (6, 6′) and ending at an outlet section of the heat exchanger, the inlet and outlet sections (7,7′) being located on a same side of the heat exchanger (2) and both opening on an interface conduit portion (3) interposed in said exhaust gas main line (4). The heat exchanger (2, 2′) is arranged so that said U-shaped path is oriented transversely to the direction of the exhaust gas main line (4), in such a manner that the exhaust gases traversing the heat exchanger flow firstly in the transverse direction away from the exhaust gas main line (4) and then back in the transverse direction towards the exhaust gas main line (4), The valve means (12) are arranged within said interface conduit portion (3), between merging points of the inlet and outlet portions (6,7) of the heat exchanger (2,2′).

Owner:CENT RICERCHE FIAT SCPA

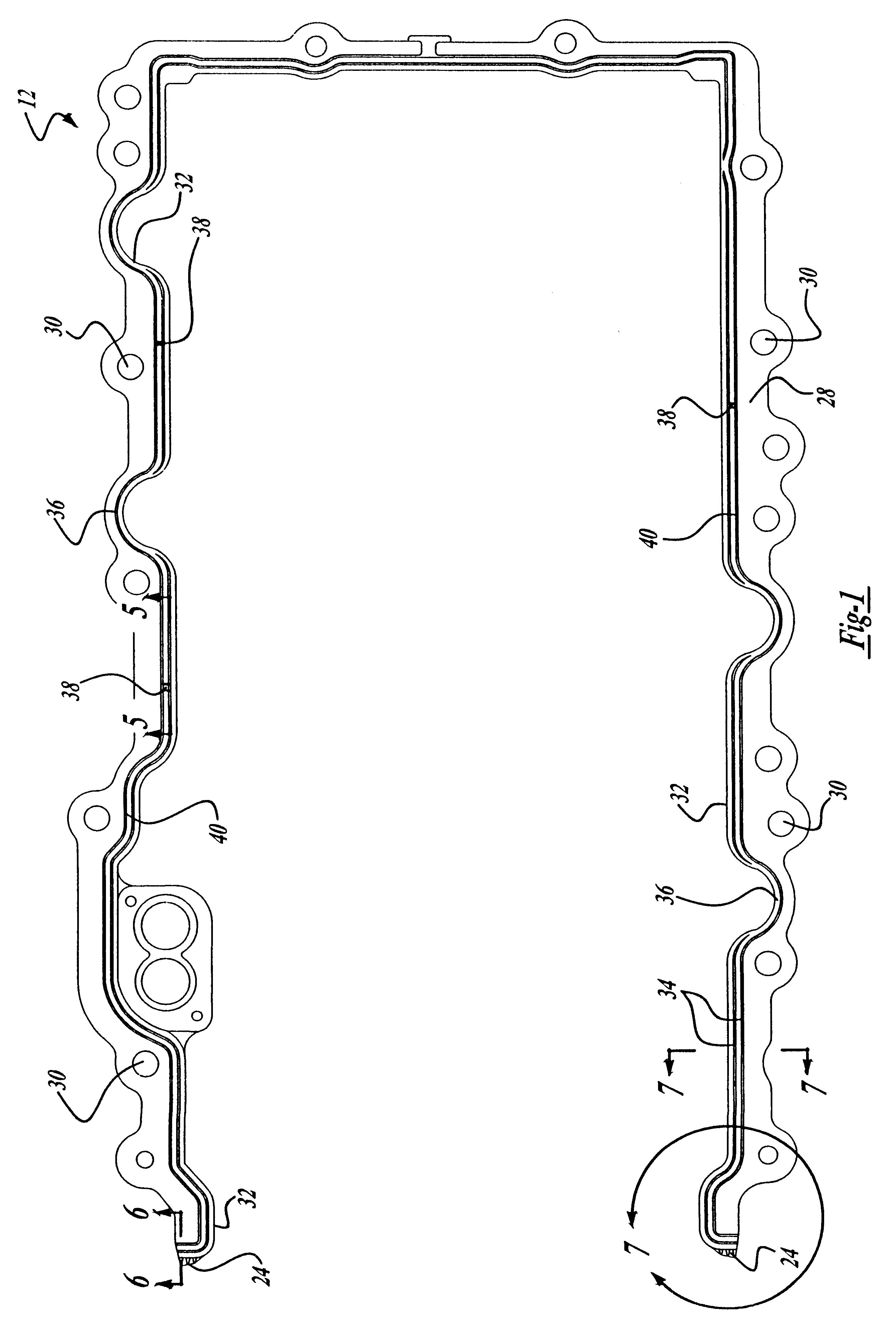

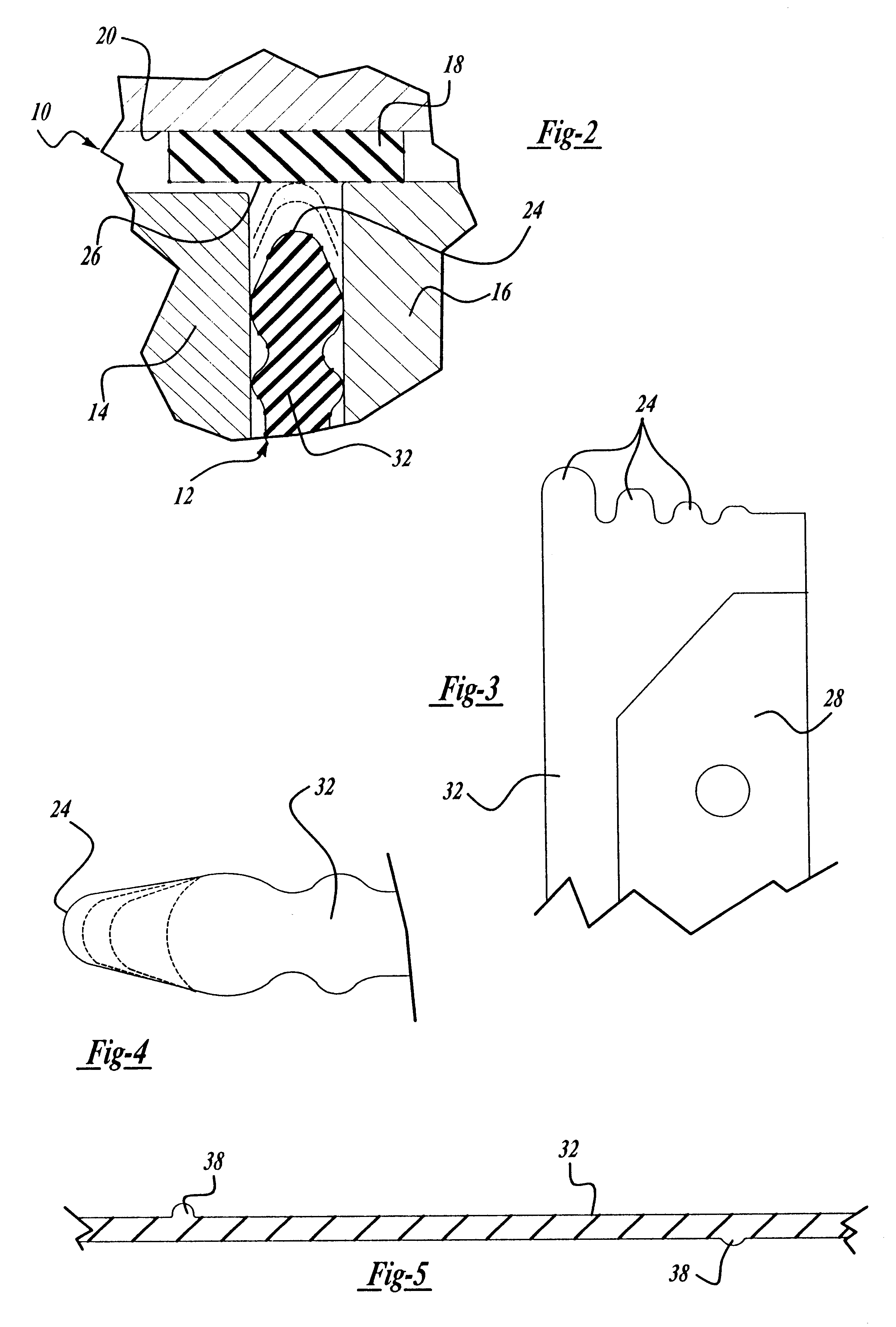

T-joint gasket assembly

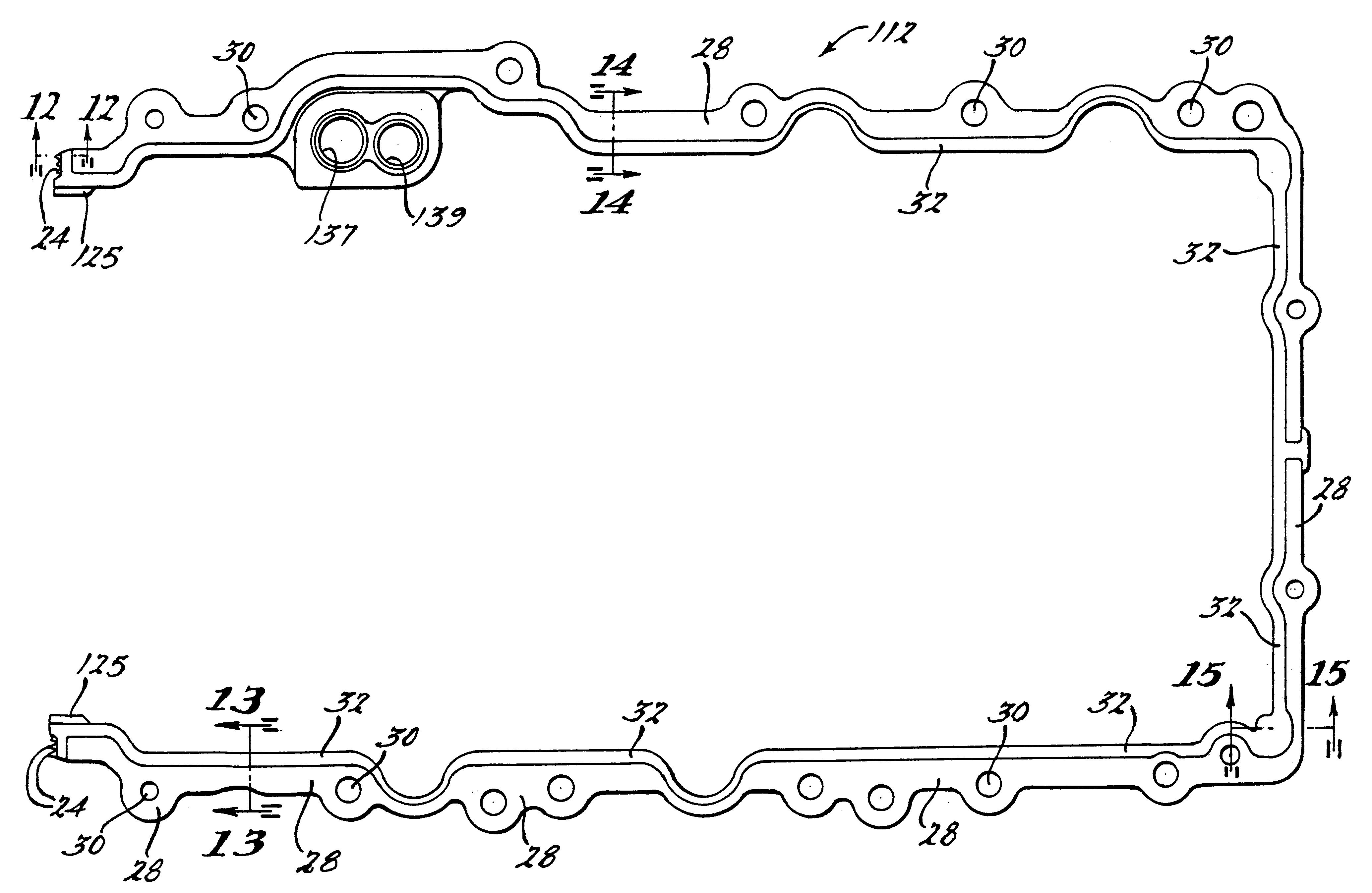

InactiveUS6173966B1Control is neededImprove cleanlinessEngine sealsSealing arrangements for enginesEngineeringSeal finger

A T-joint gasket assembly for sealing a first surface, a second surface adjacent to the first surface and a third surface intersecting the first and second surfaces, said first, second and third surfaces generally forming a T-joint, said T-joint being sealed absent an external sealant such as an RTV sealant agent, said gasket assembly comprising: a first gasket member which has at the ends thereof a plurality of sealing beads and at least one sealing finger, a second gasket member positioned generally coextensive with said third surface, and being oriented so as to provide a T-joint like connection with said first gasket member, with both the first gasket member and the second gasket member including a supportable elastomeric sealing material to carry out the gasket sealing, said second gasket member possessing a plurality of elastomeric sealing pads thereon, said sealing beads and said sealing finger of the first gasket member being provided to make sealing contact with said sealing pads on said second gasket member to form a sealed T-joint.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

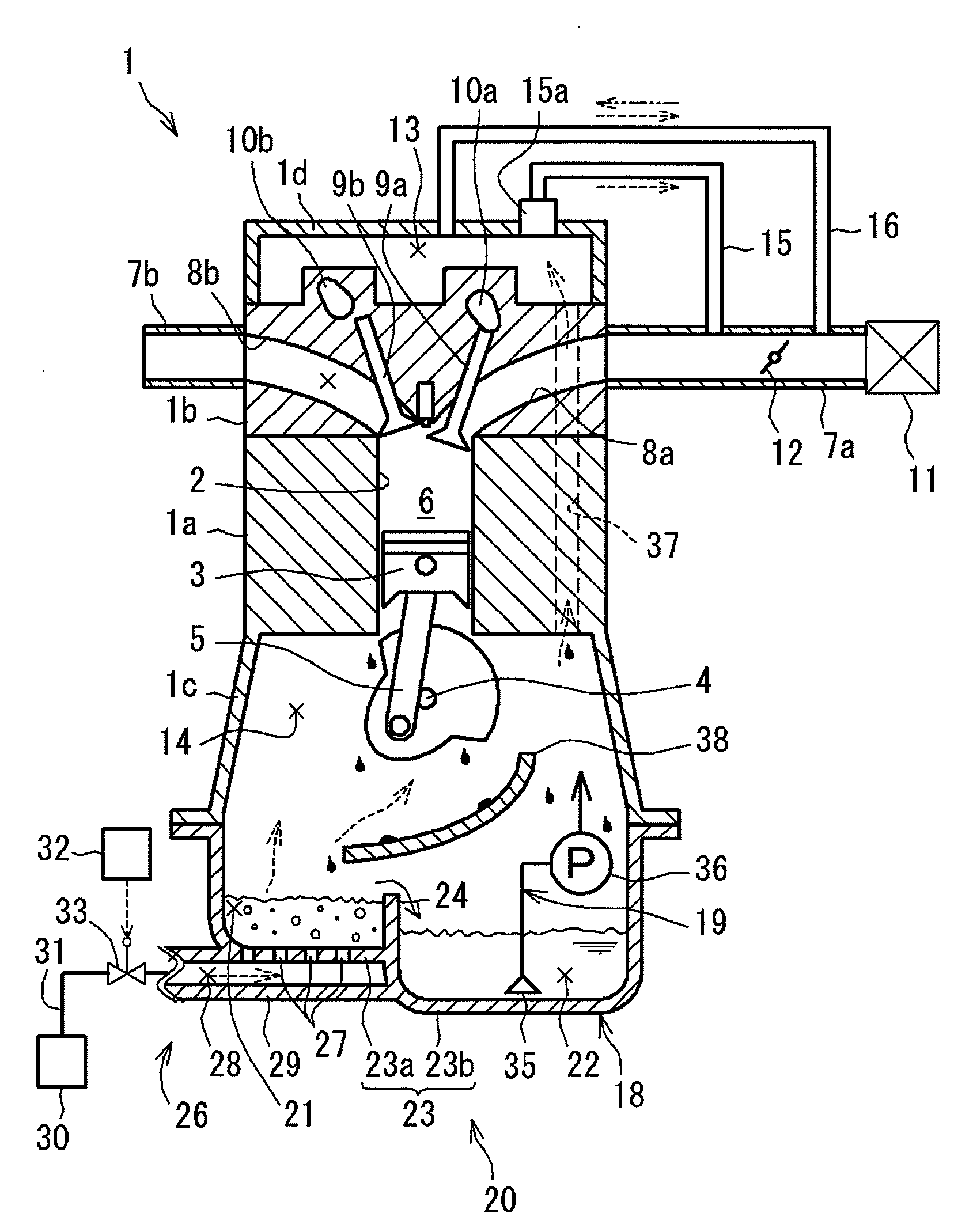

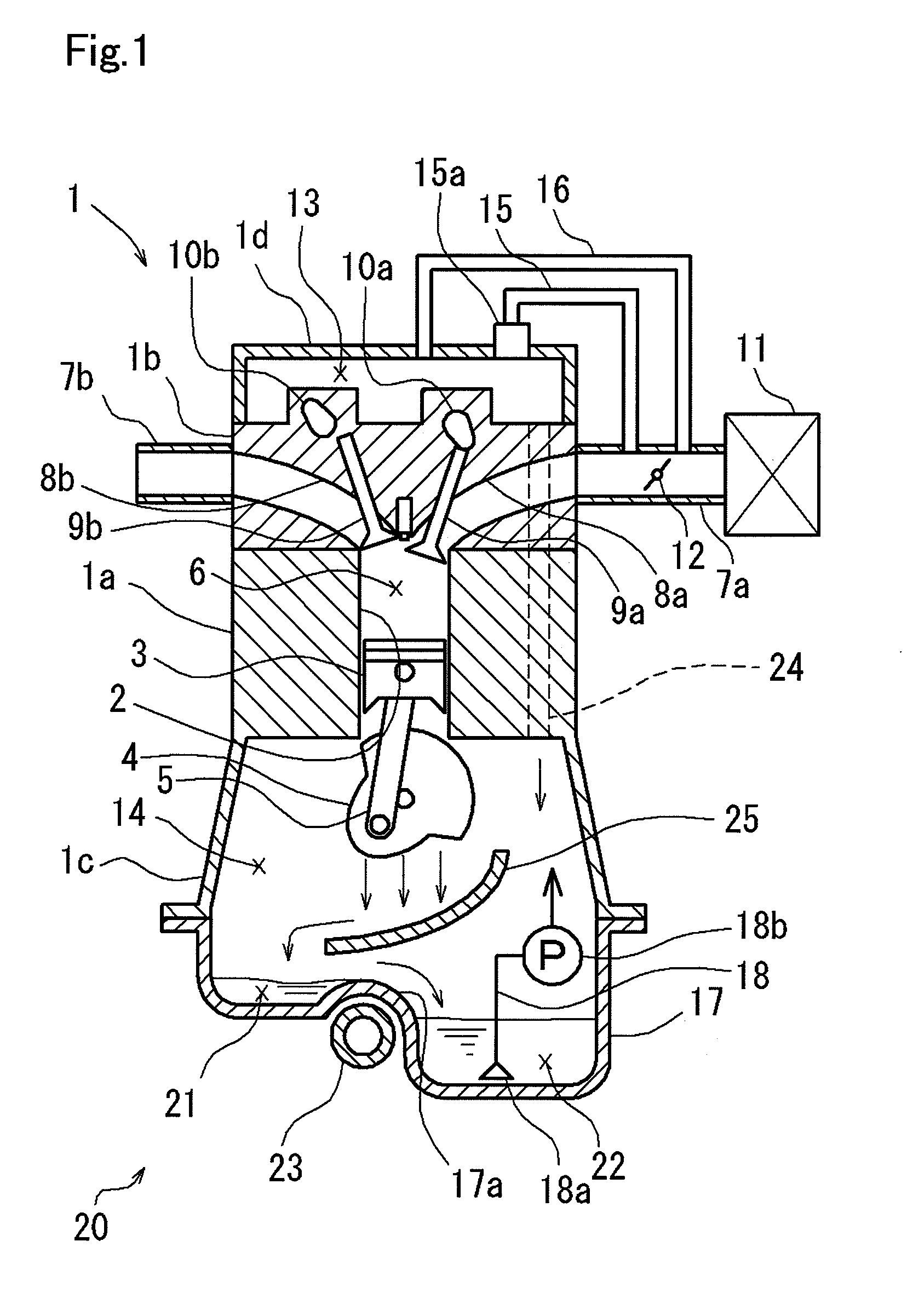

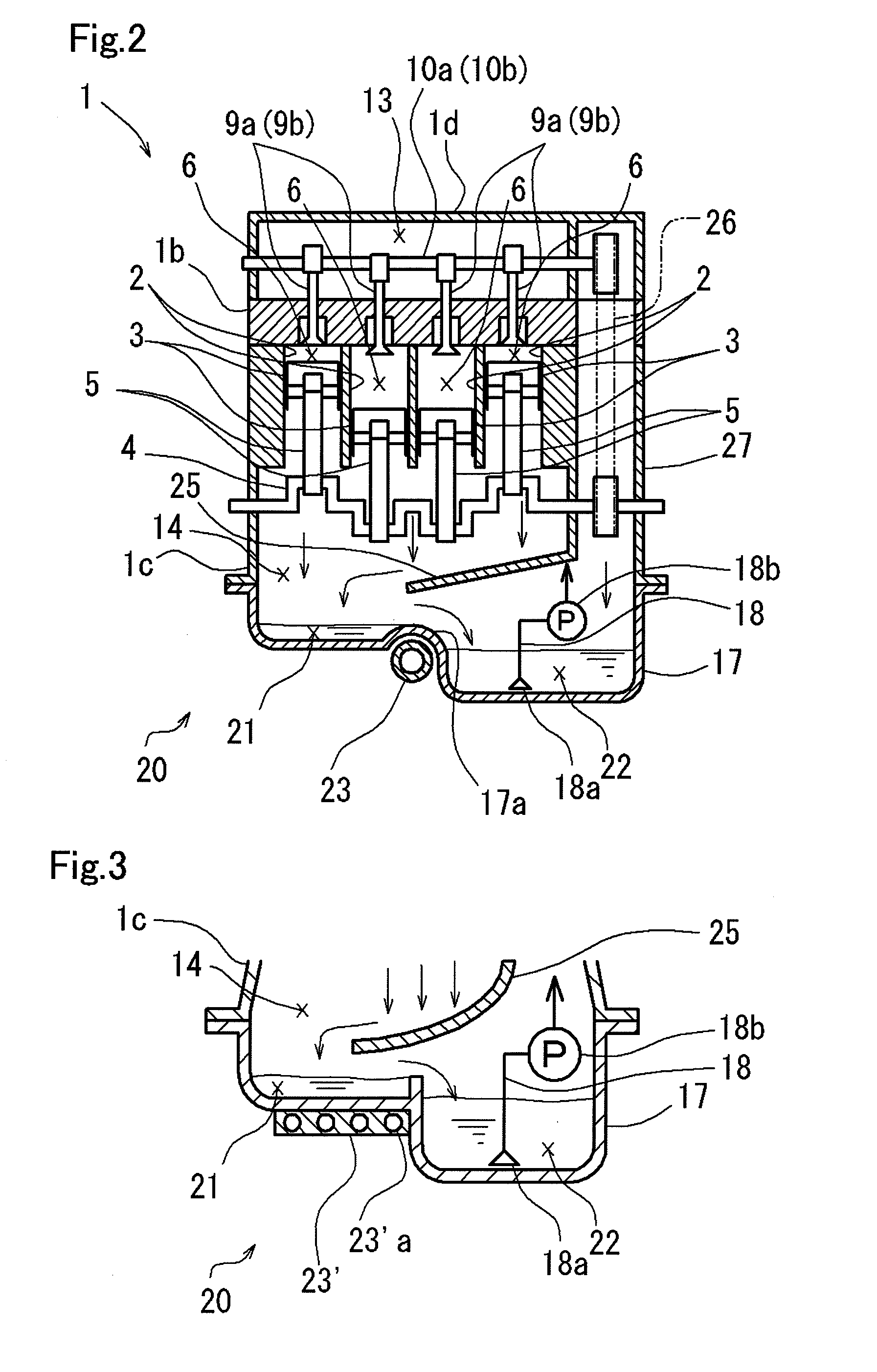

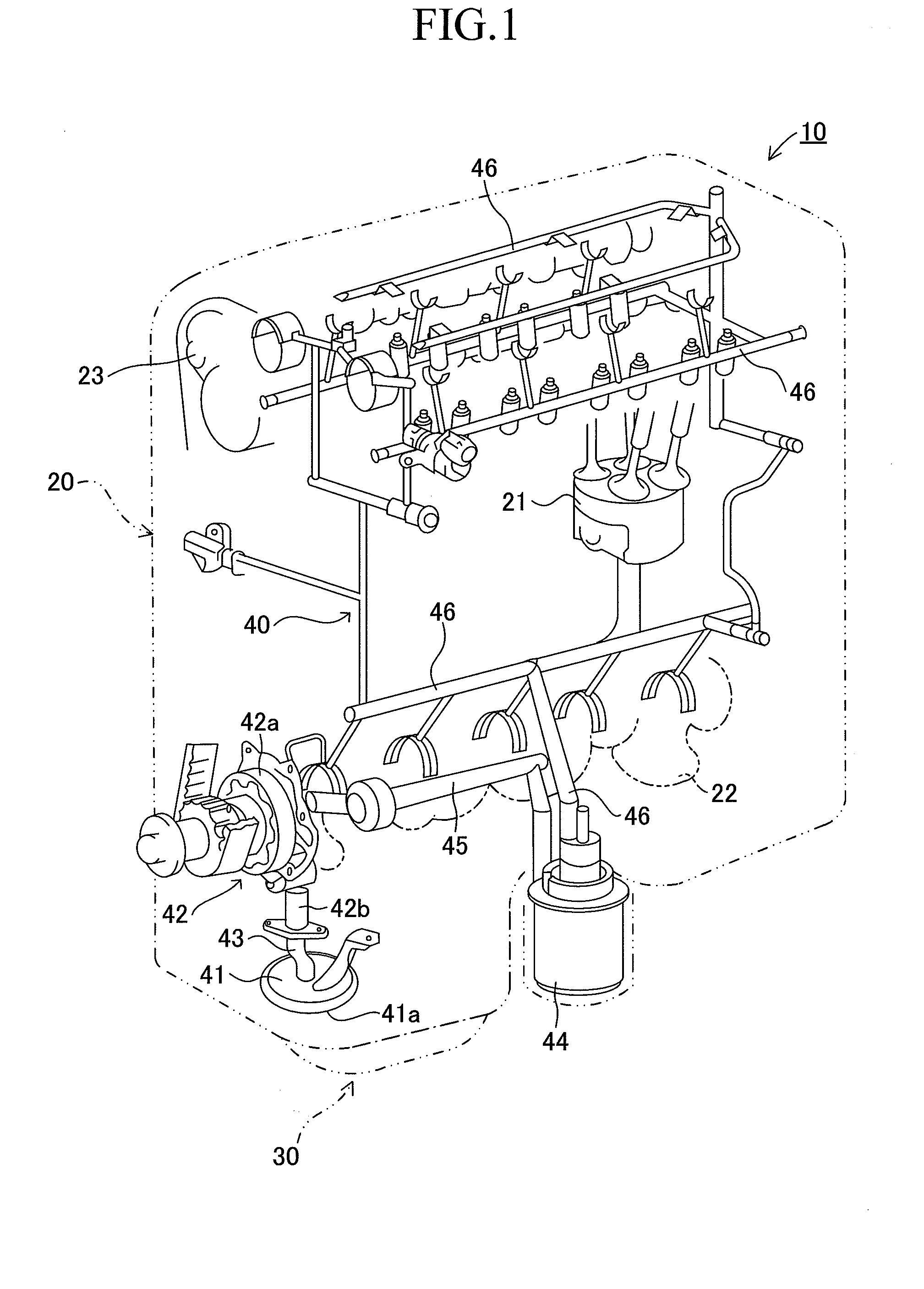

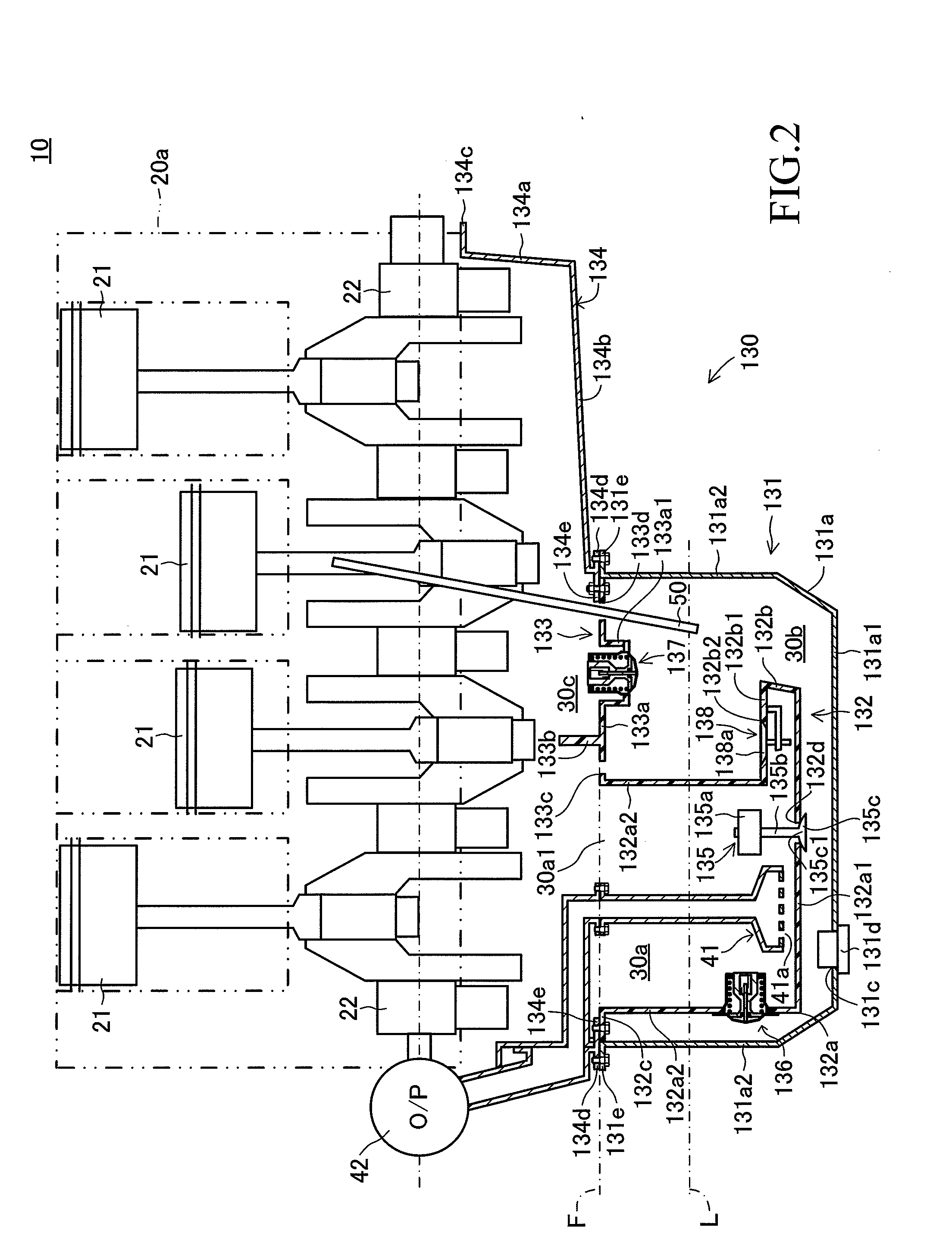

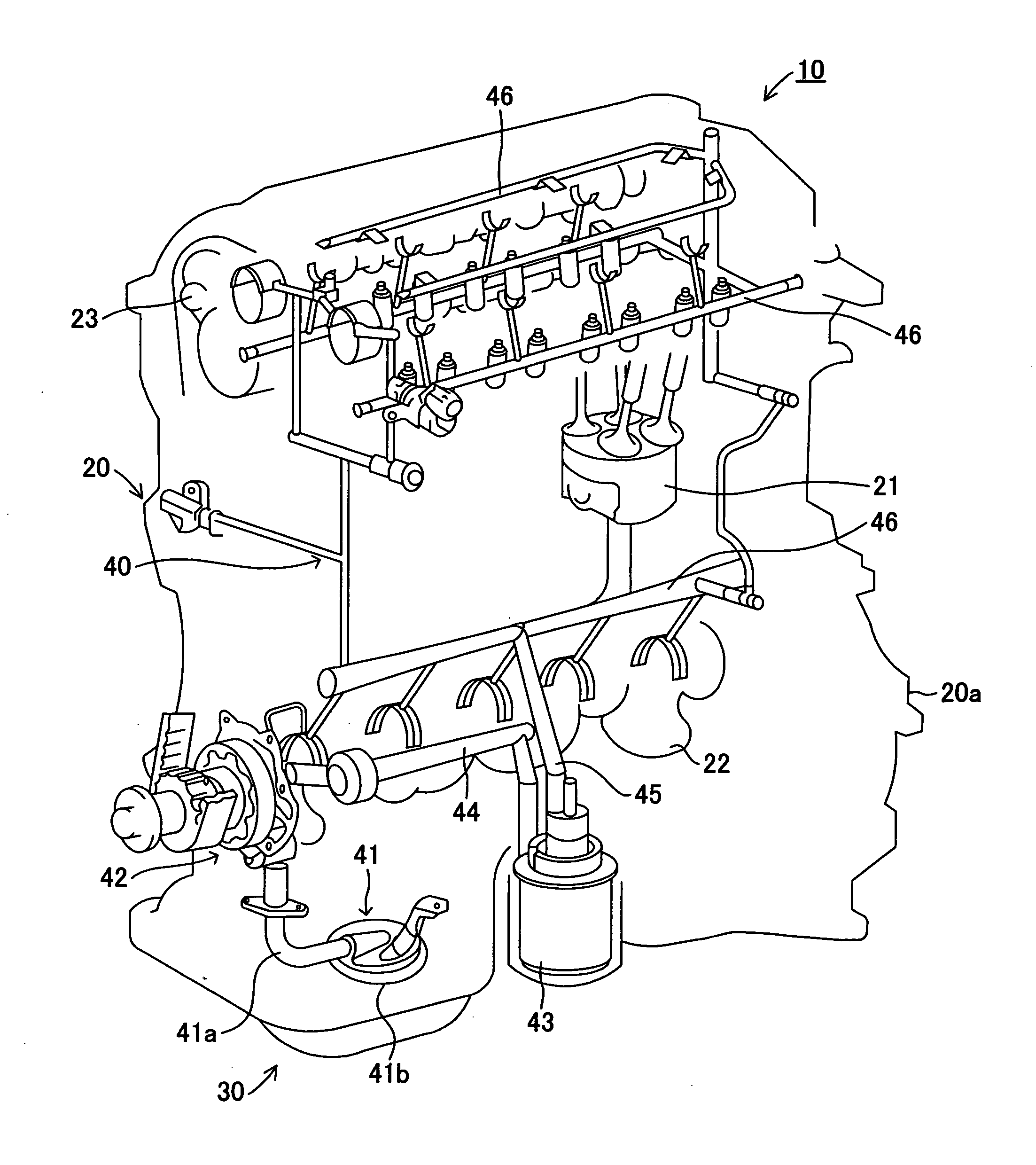

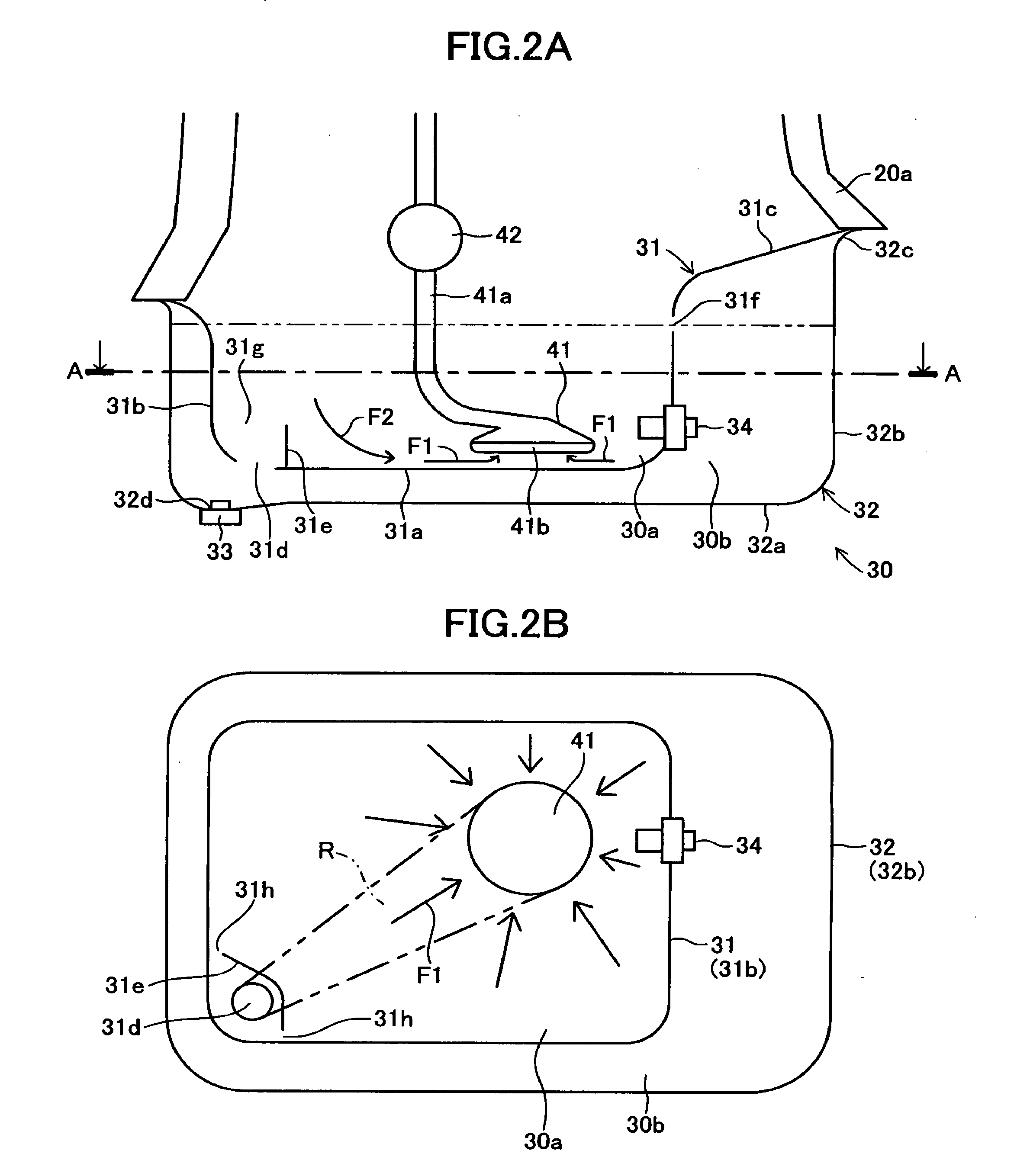

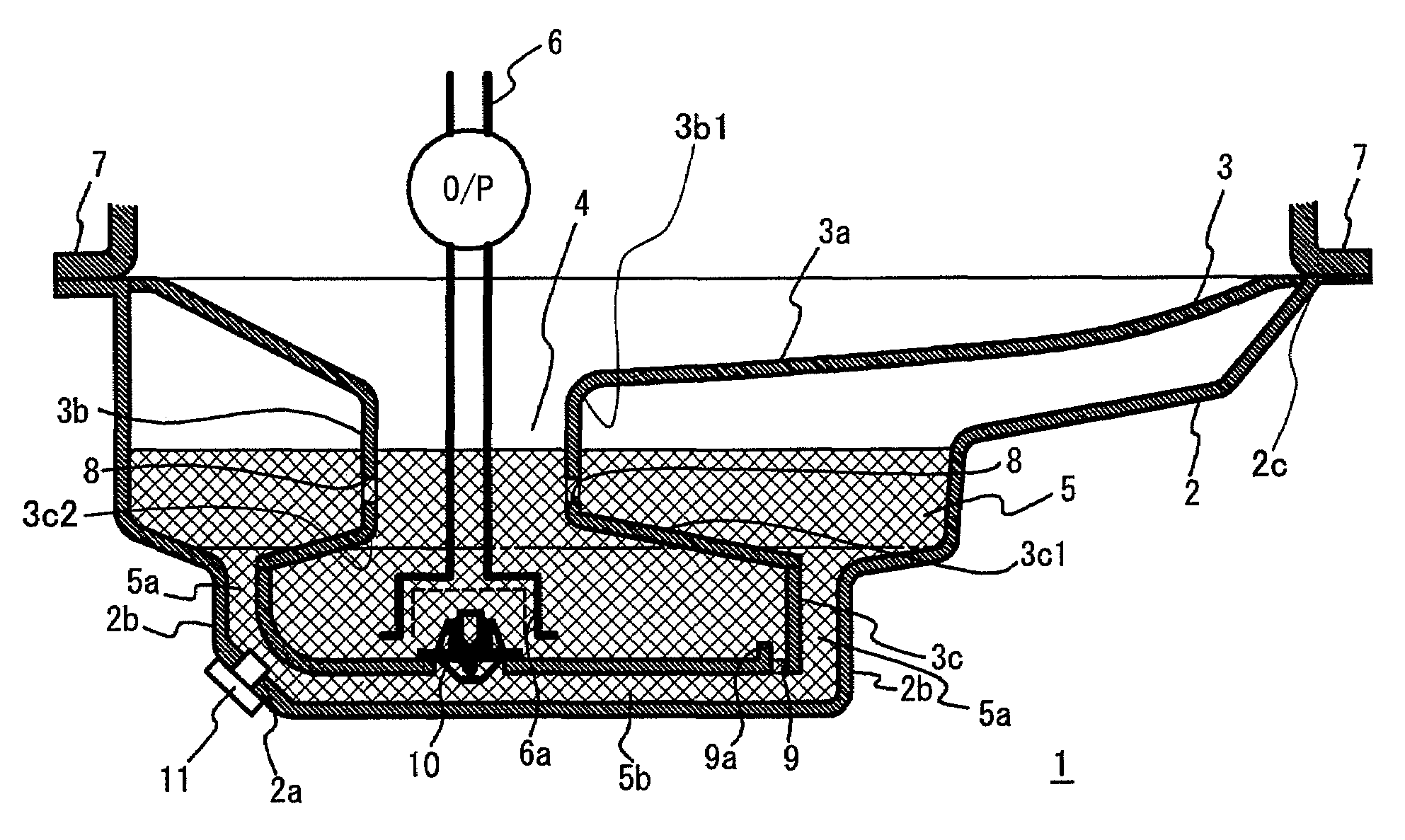

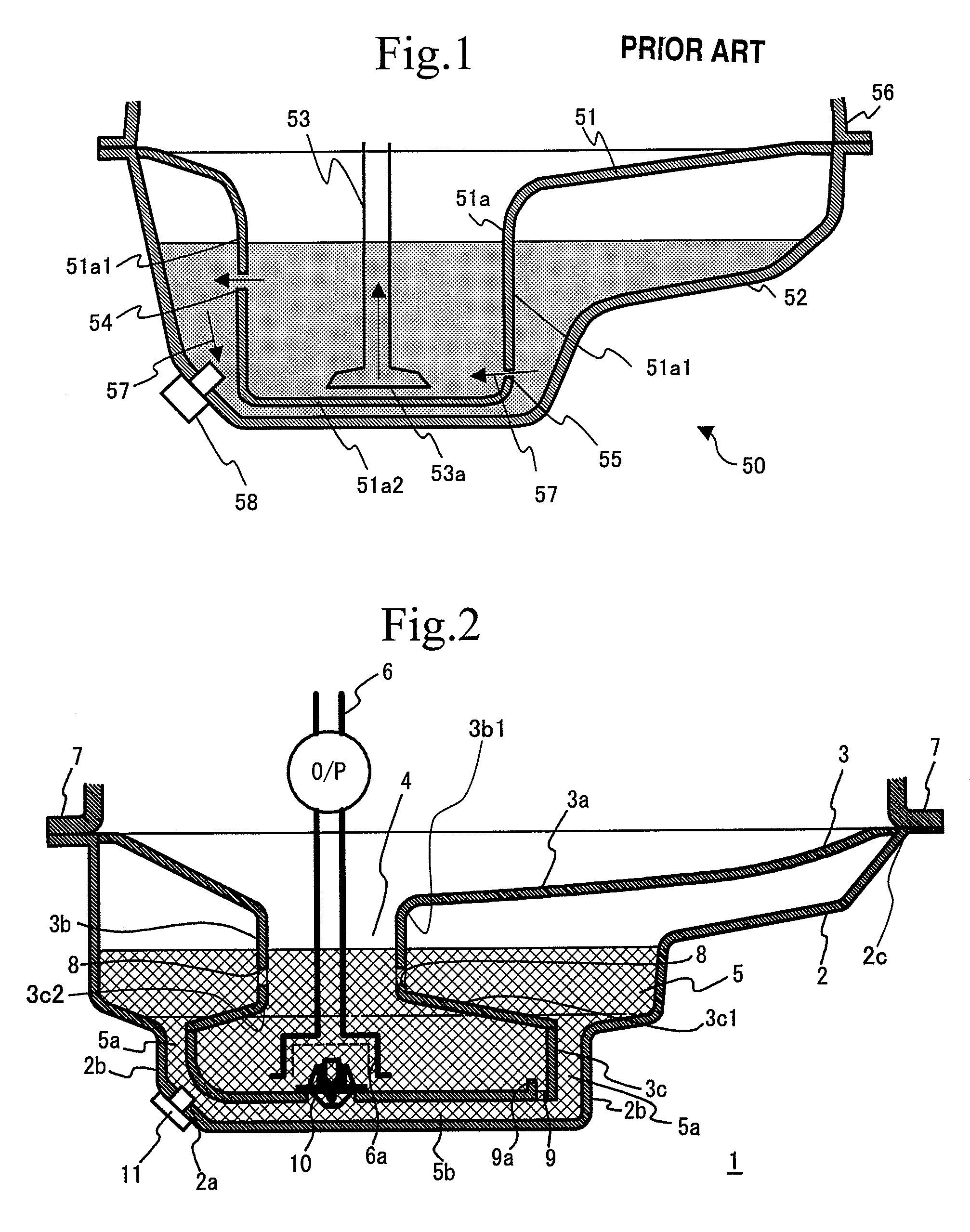

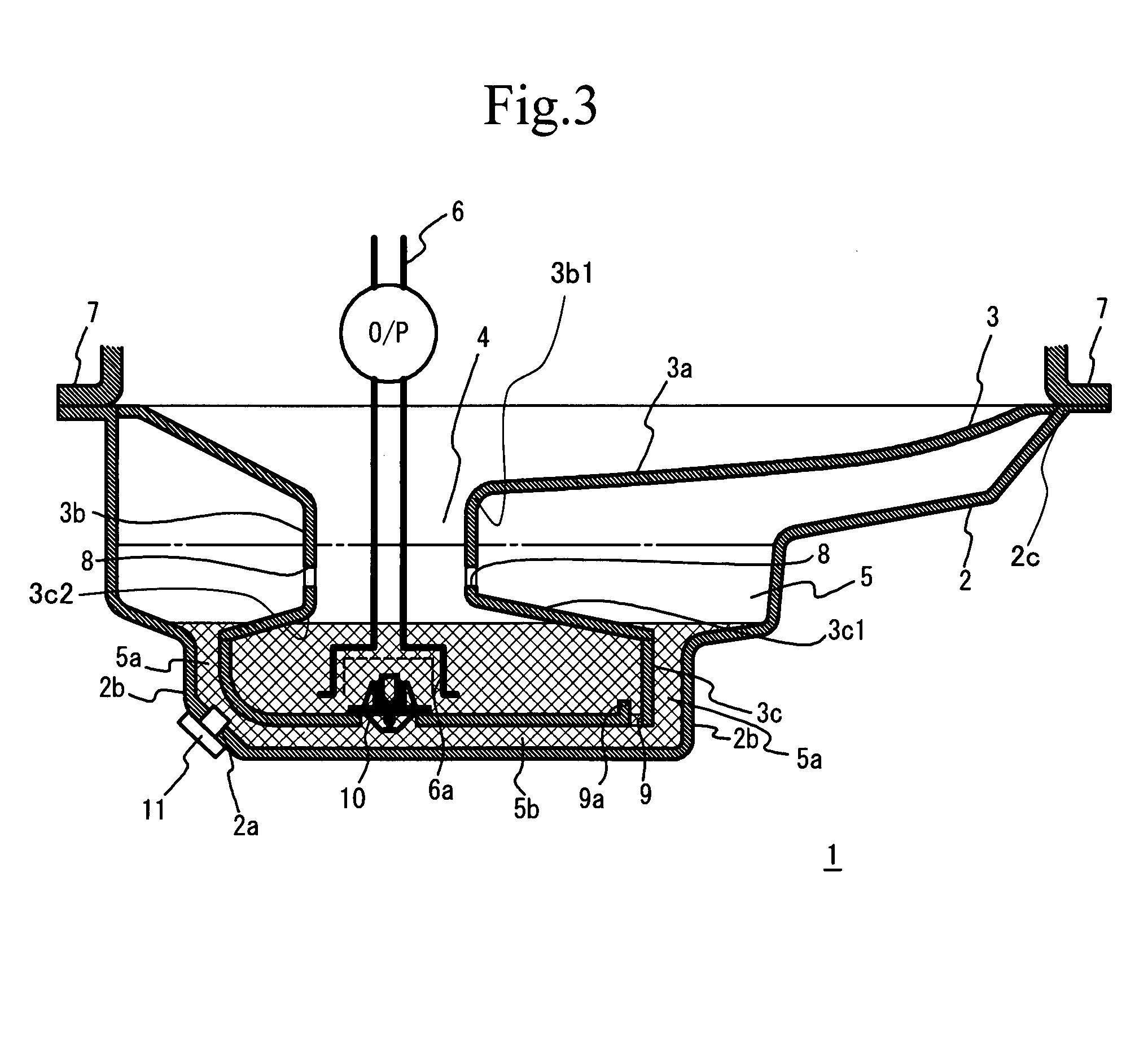

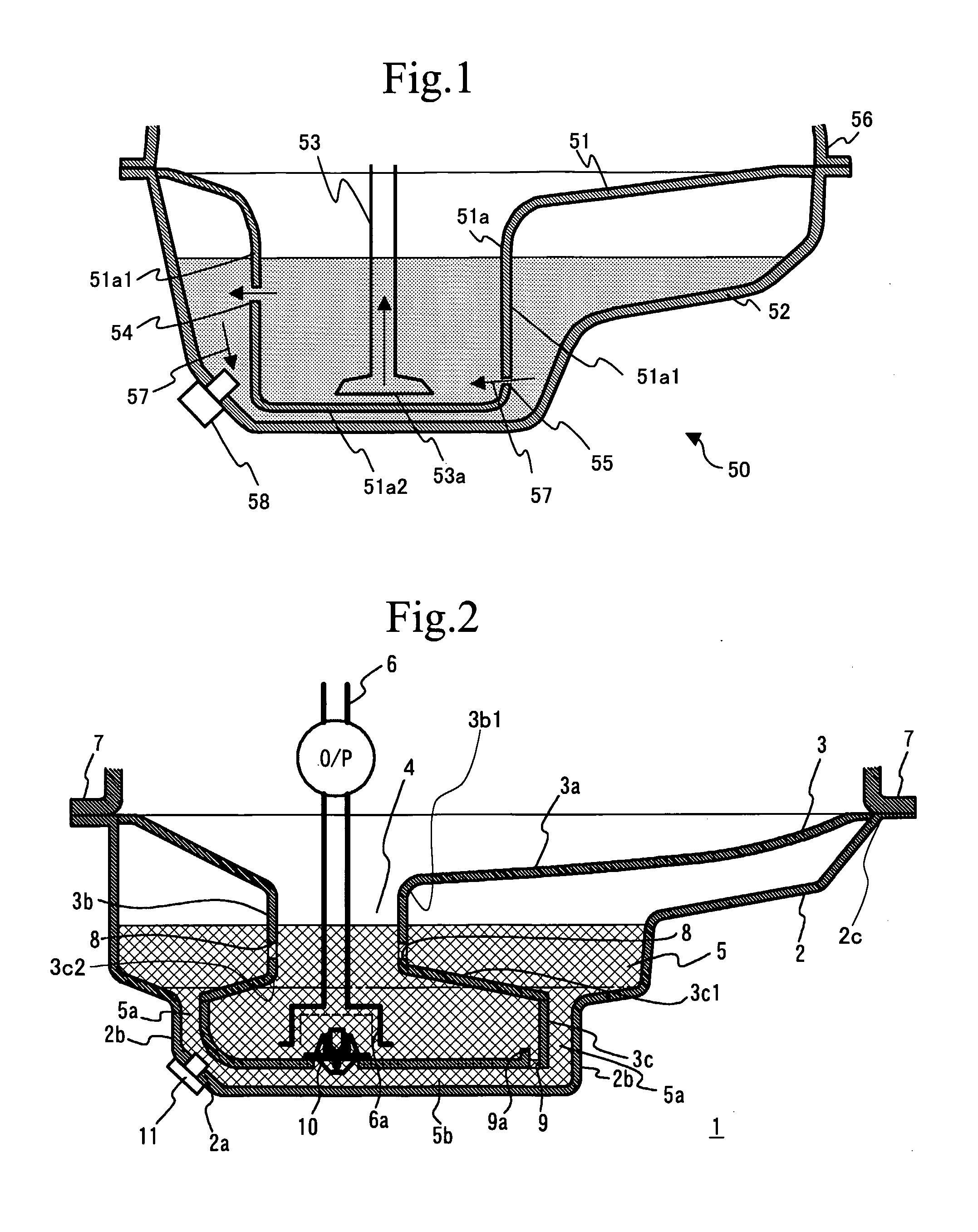

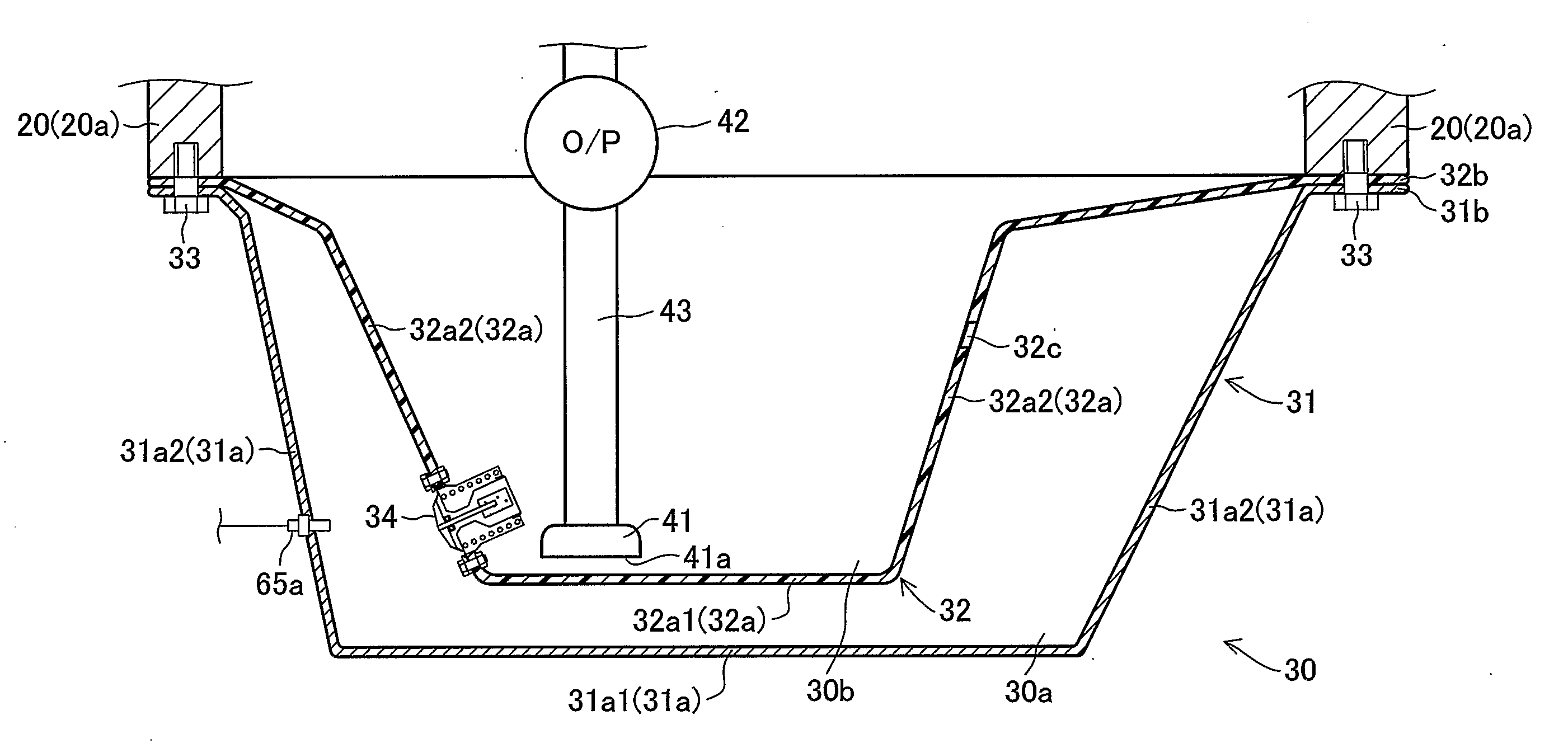

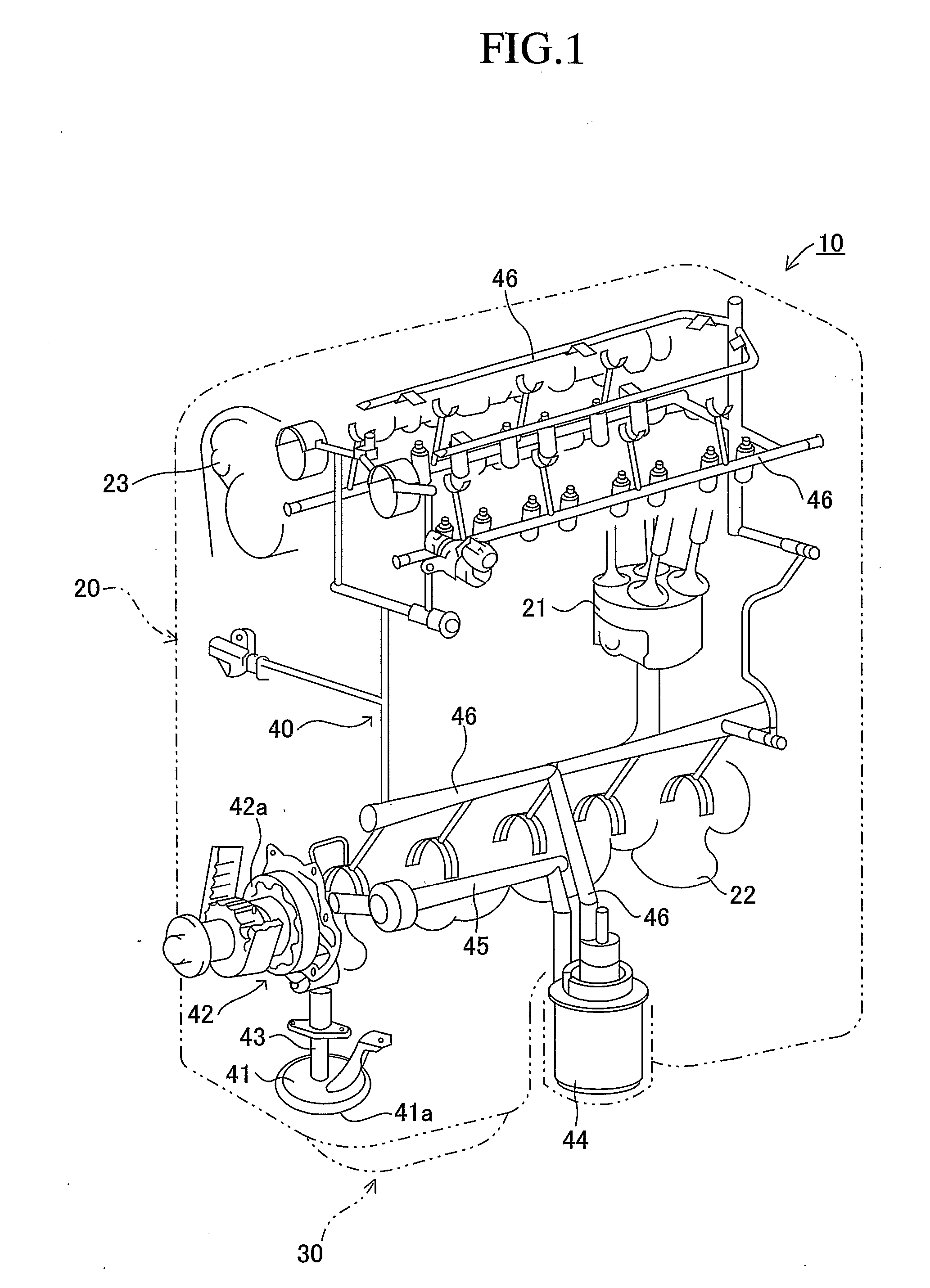

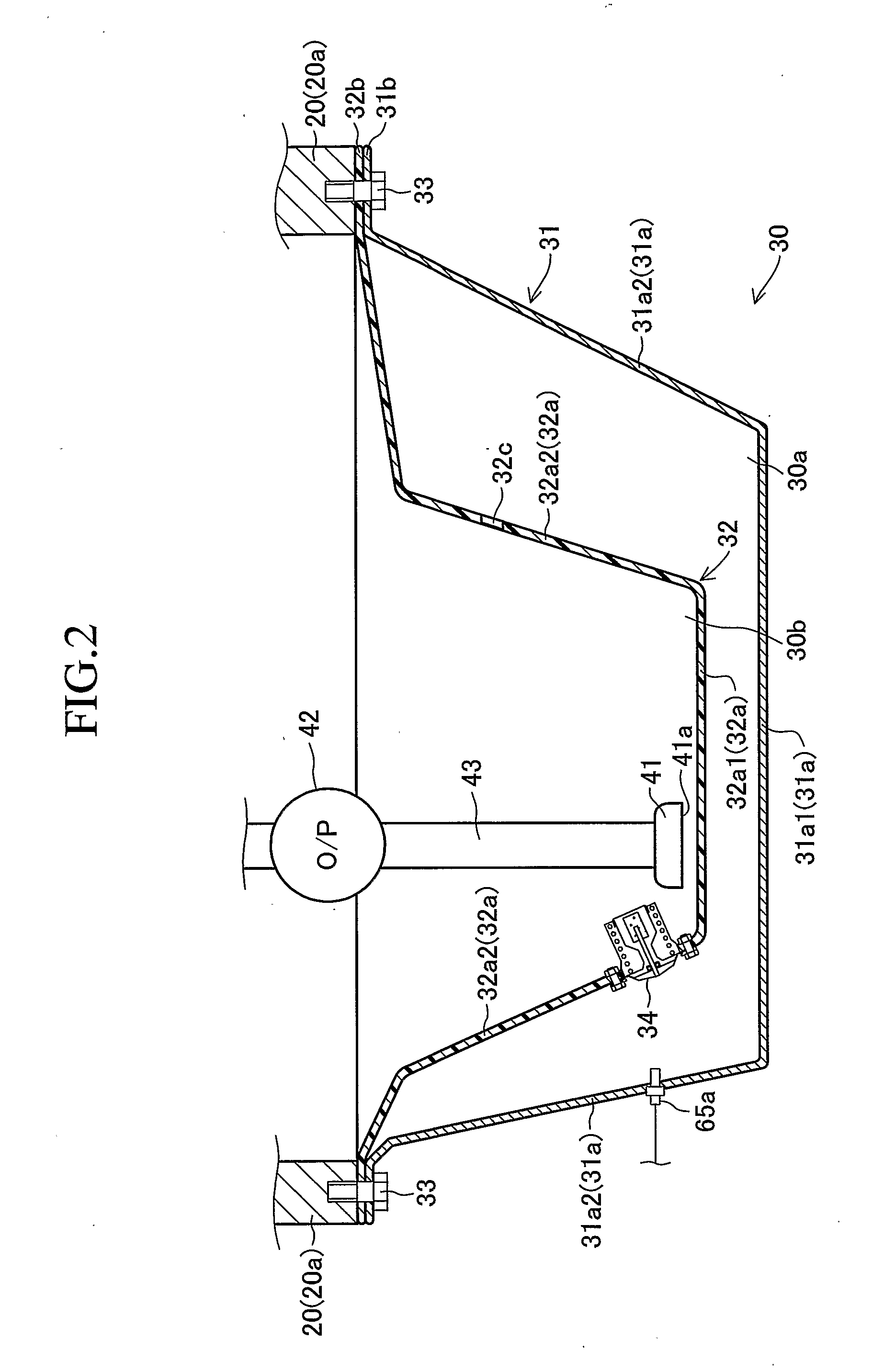

Diluting fuel-in-oil separating apparatus of internal combustion engine

InactiveUS20090277416A1Small volumePrevent degradationExhaust apparatusSilencing apparatusEngineeringInternal combustion engine

The diluting fuel-in-oil separating apparatus includes an oil container (an oil pan) and a fuel eliminator (a heater, a bubble generator). The oil container contains lubricating oil of the internal combustion engine, and has a first compartment and a second compartment divided from the first compartment, such that the lubricating oil is introduced from the first compartment into the second compartment. The fuel eliminator eliminates fuel from the lubricating oil in the first compartment. The second compartment is provided with an oil passage having an oil pump supplying the lubricating oil from the second compartment to lubricated parts of the internal combustion engine.

Owner:TOYOTA BOSHOKU KK

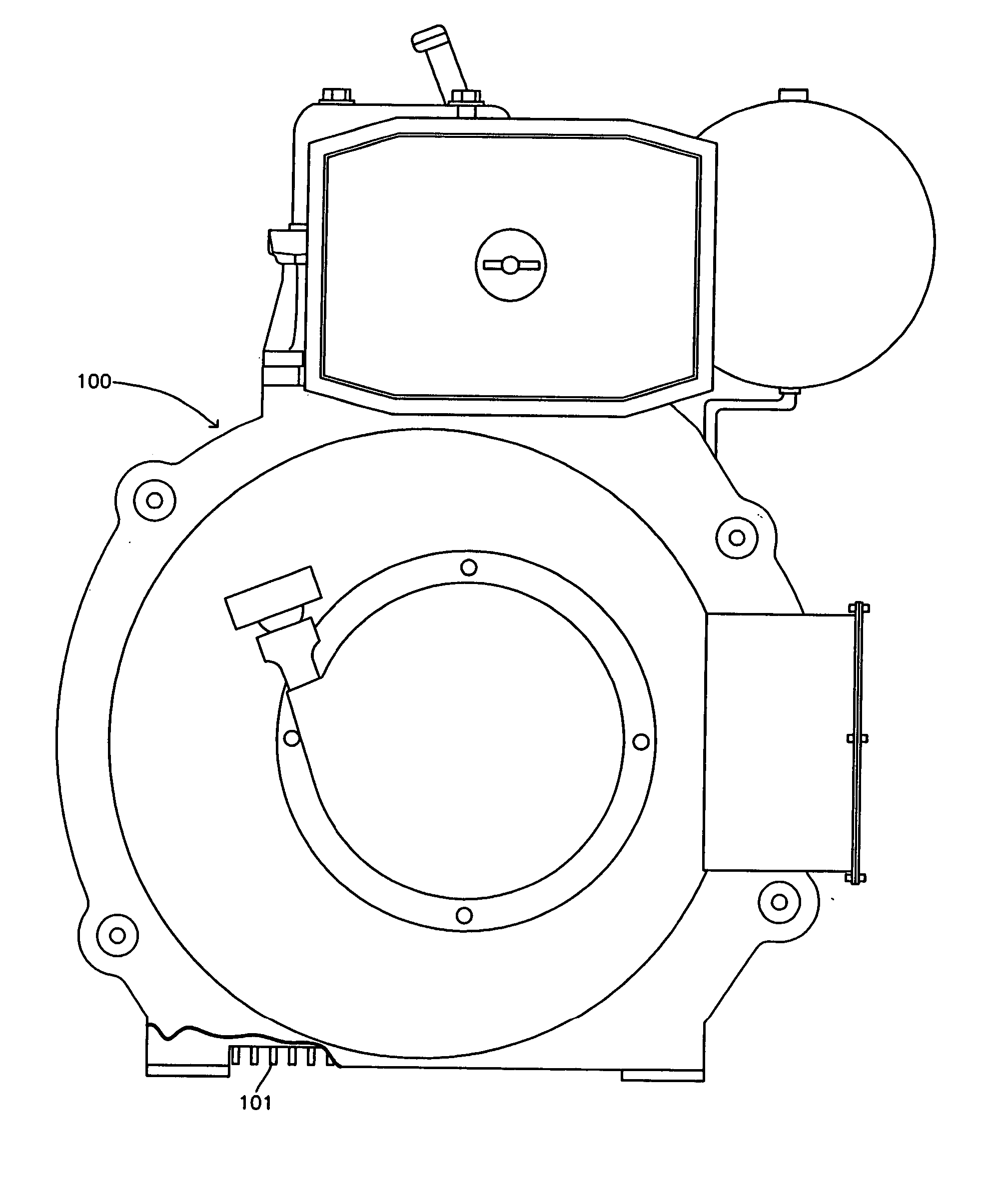

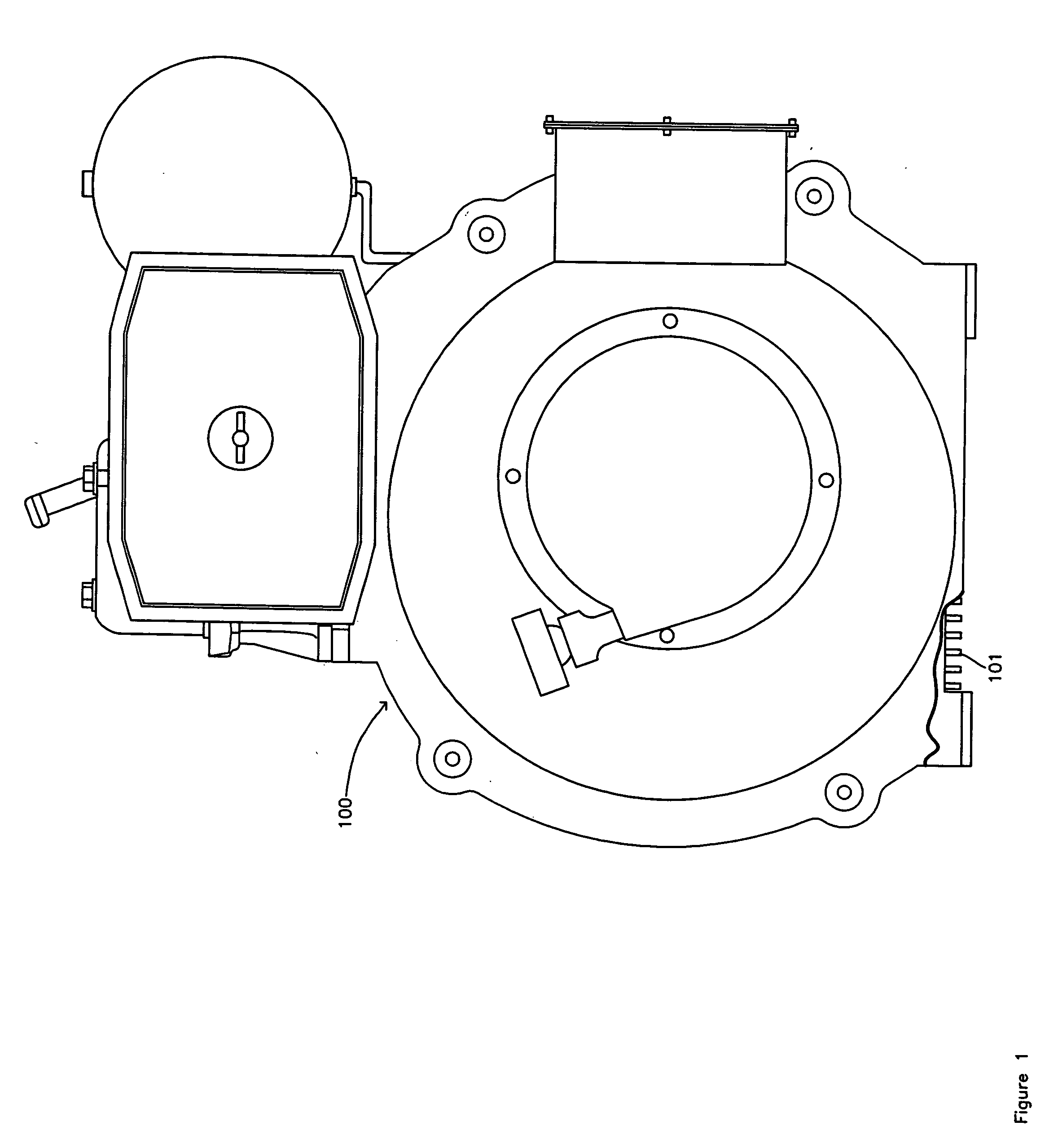

Lightweight portable electric generator

InactiveUS20050046191A1Eliminate excessive componentReduce weightMagnetic circuit rotating partsAir coolingAlternatorPortable power

A compact and lightweight electric generator for portable power applications employs a new engine design and integration approach for reducing engine and generator weight. A unique flywheel alternator generates electrical power and provides inertia for the engine, pressurized air for cooling, and inertia for the alternator. An engine cowling provides rotating component protection, a fan shroud mechanism, cooling air ducts, and a cooling mechanism for handling large quantities of heat produced by rectified power conversion.

Owner:MAINSTREAM ENG

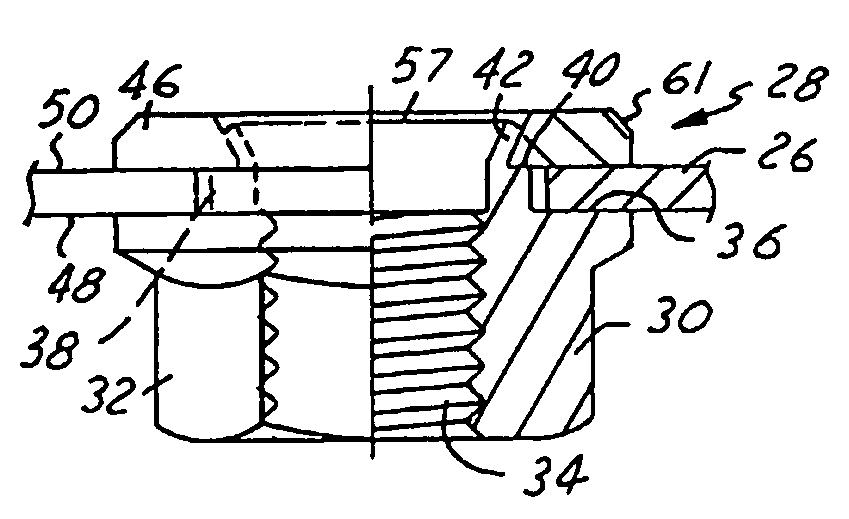

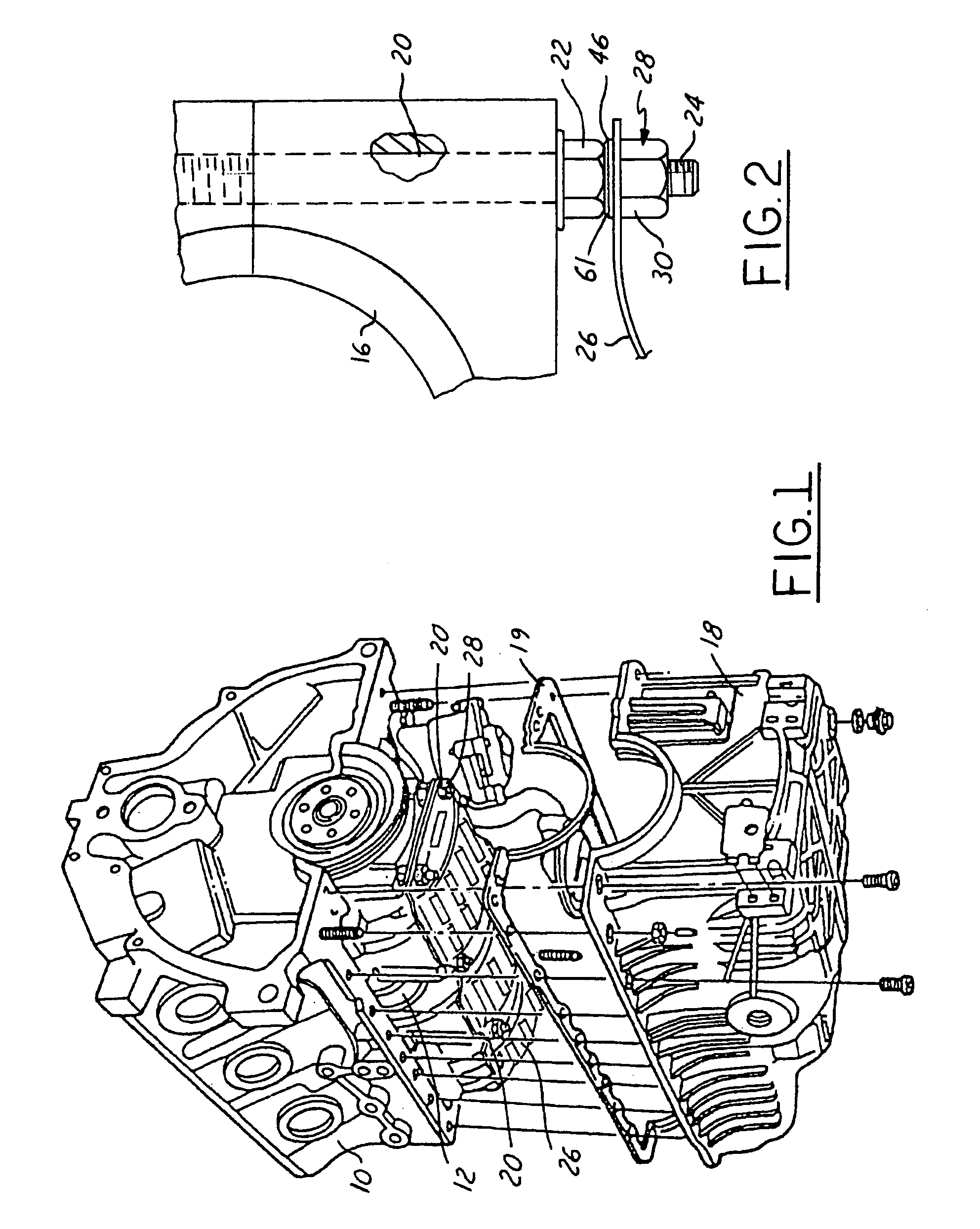

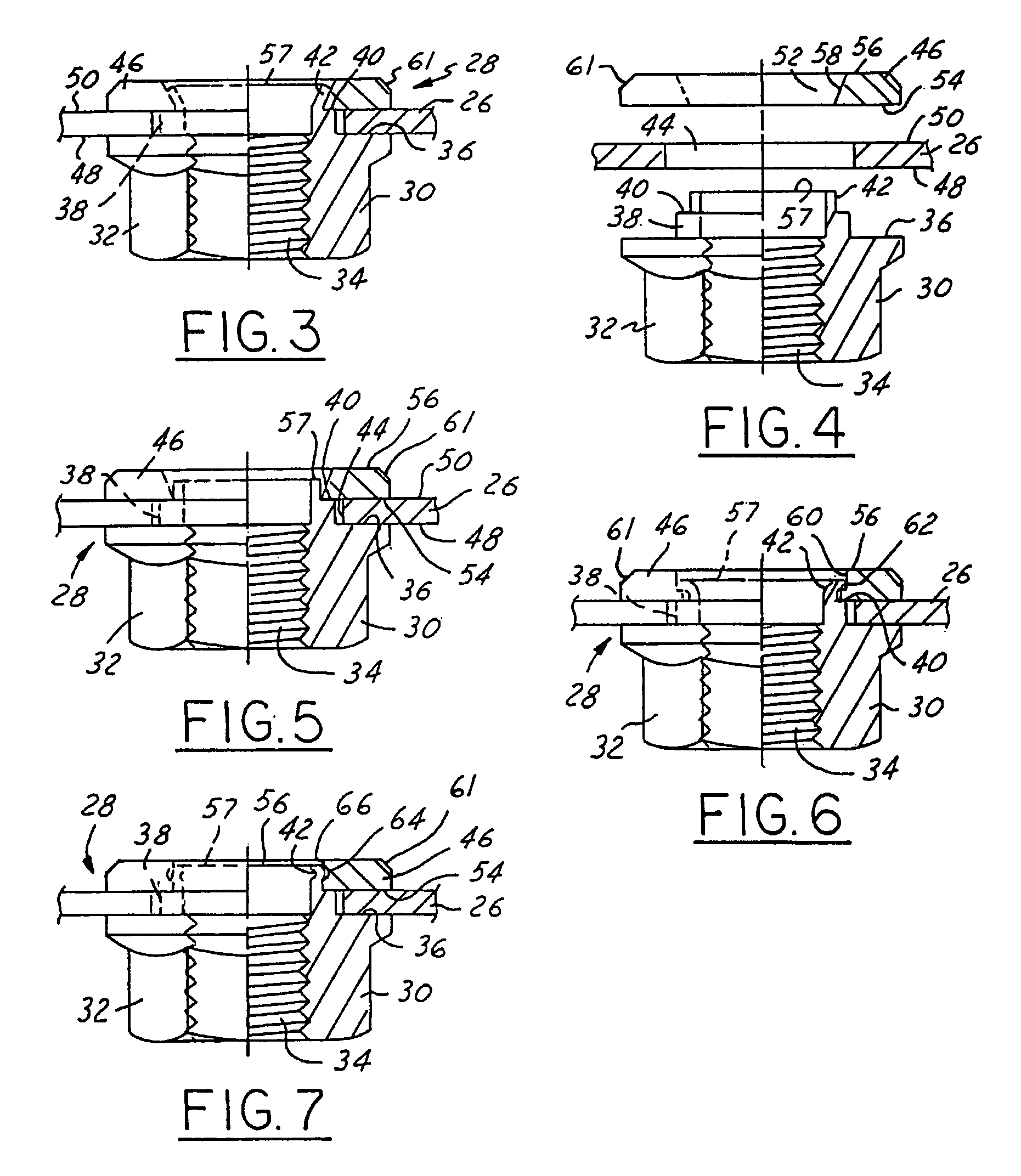

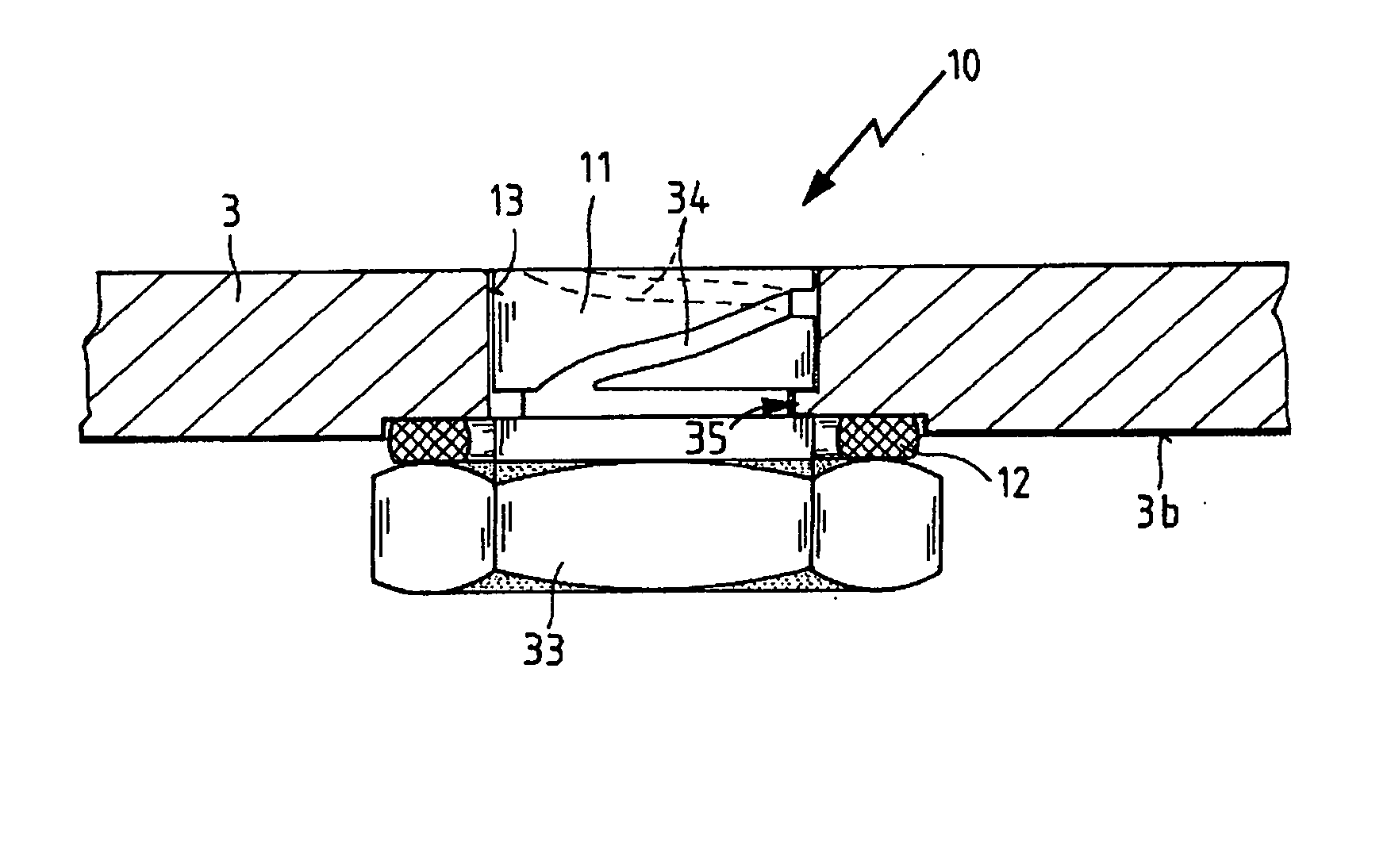

Windage tray with improved captured nut

InactiveUS6932044B1Accurately obtainedAccurately retainingCasingsLubrication of auxillariesEngineeringInternal combustion engine

A windage tray (26) has a captured nut (30) mounted to a retaining washer (46) through a central aperture (52) that has a tapered interior wall (58) which wholly retains a collar (42) of the captured nut for mounting the tray onto an internal combustion engine (10).

Owner:GENERAL FASTENERS

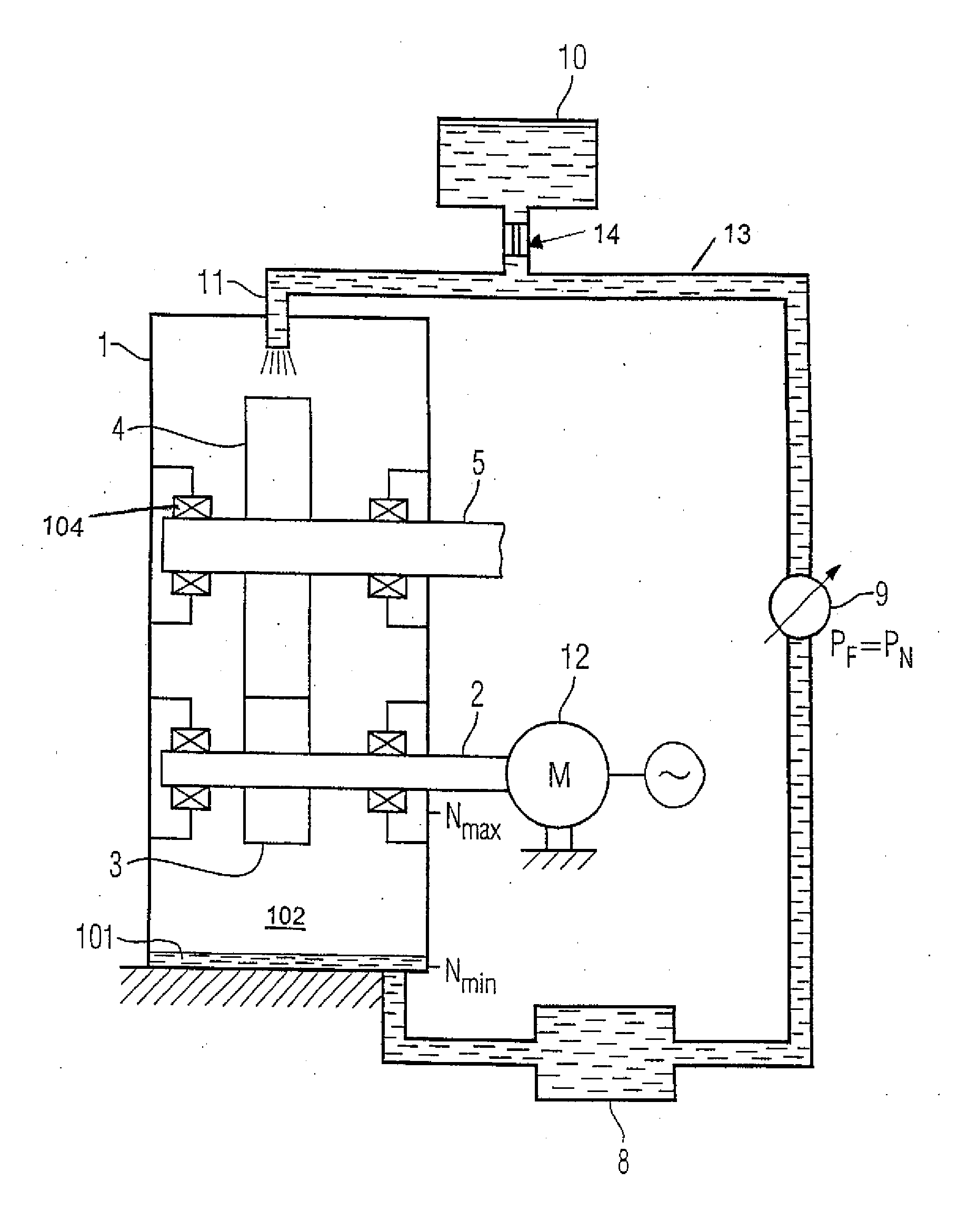

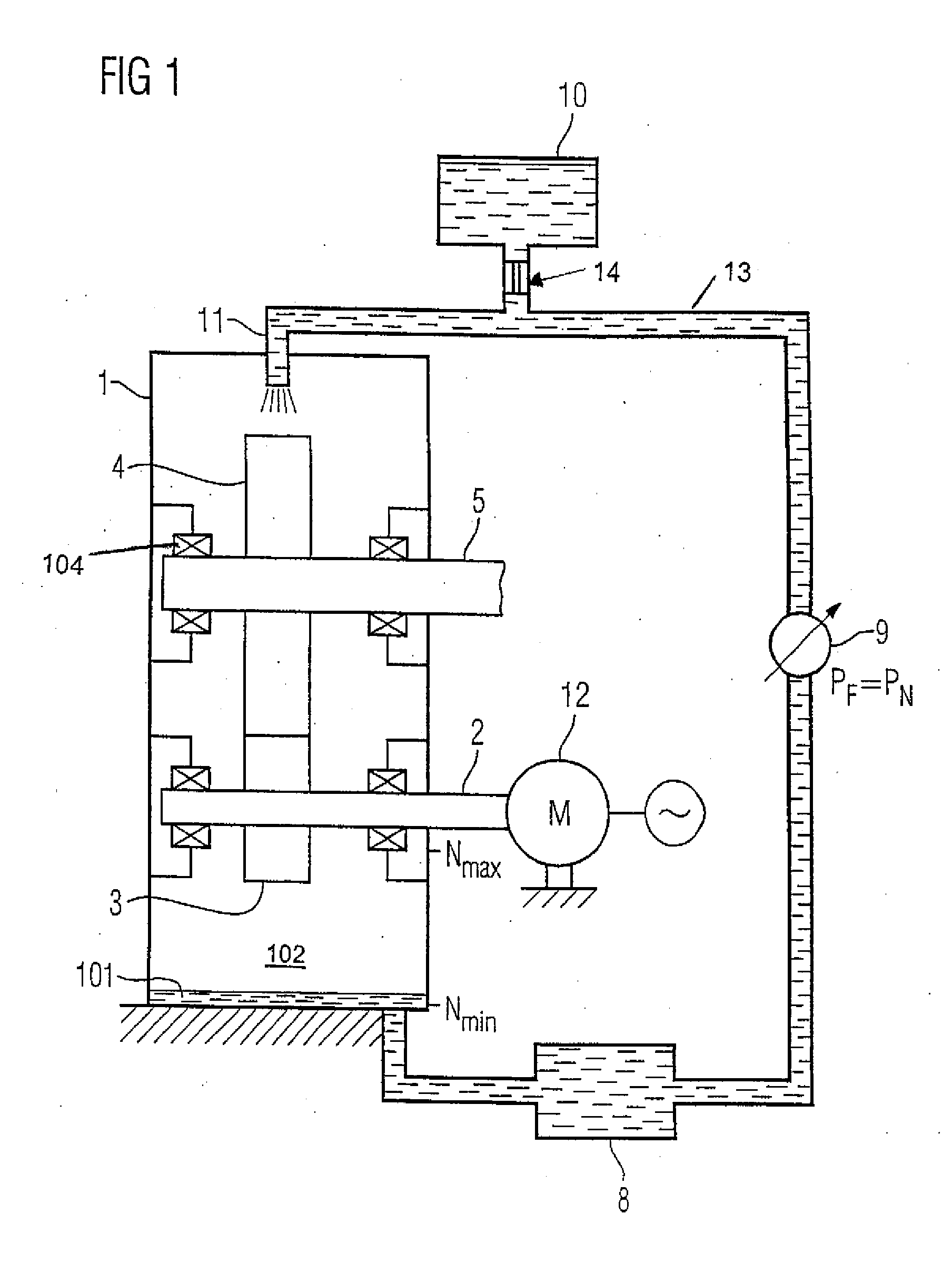

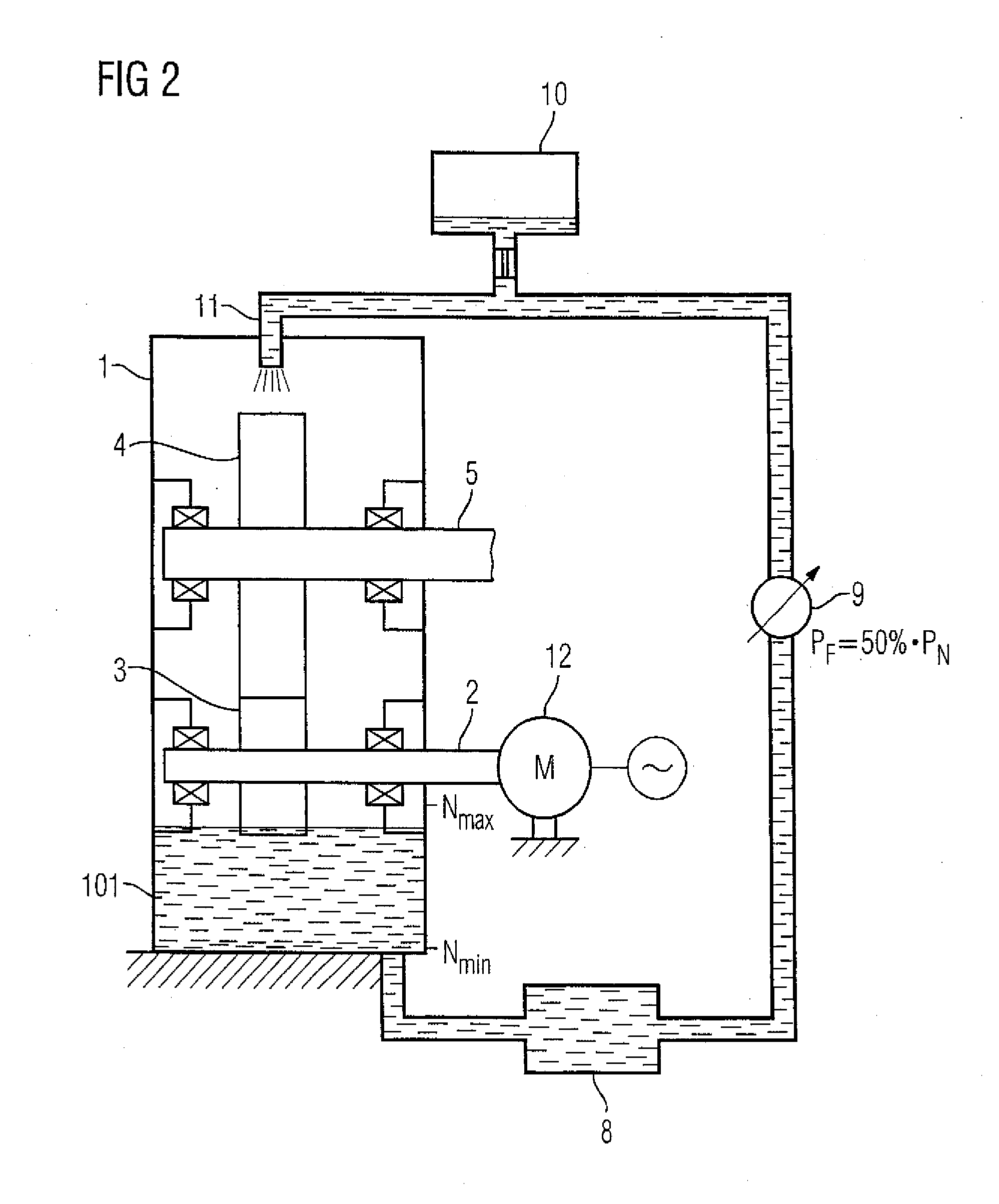

Gear unit with improved lubricant supply

InactiveUS20130133454A1Reliable supplyLower energy requirementsGear lubrication/coolingOilsumpsGear wheelEngineering

In order to implement a reliable supply of lubricant to gear unit components during emergency or spinning operation of a gear unit, level control is provided in a lubricant sump of the gear unit as a function of the operating state by means of a control unit associated with a lubricant pump. During normal operation the level is adjusted to dry sump level. In contrast, the lubricant pump is switched off in emergency or spinning operation, so that a splash lubrication level is automatically achieved in the lubricant sump.

Owner:SIEMENS AG

Oil pan

InactiveUS20100162988A1Improve insulation performanceLow viscosityCasingsNon-fuel substance addition to fuelPetroleum engineering

An oil pan made of resin includes an oil reservoir. The oil reservoir includes a bottom wall and a peripheral wall rising from a periphery of the bottom wall and having an opening at a top of the oil reservoir. A rib is provided in the oil reservoir.

Owner:DAIKYONISHIKAWA CORP

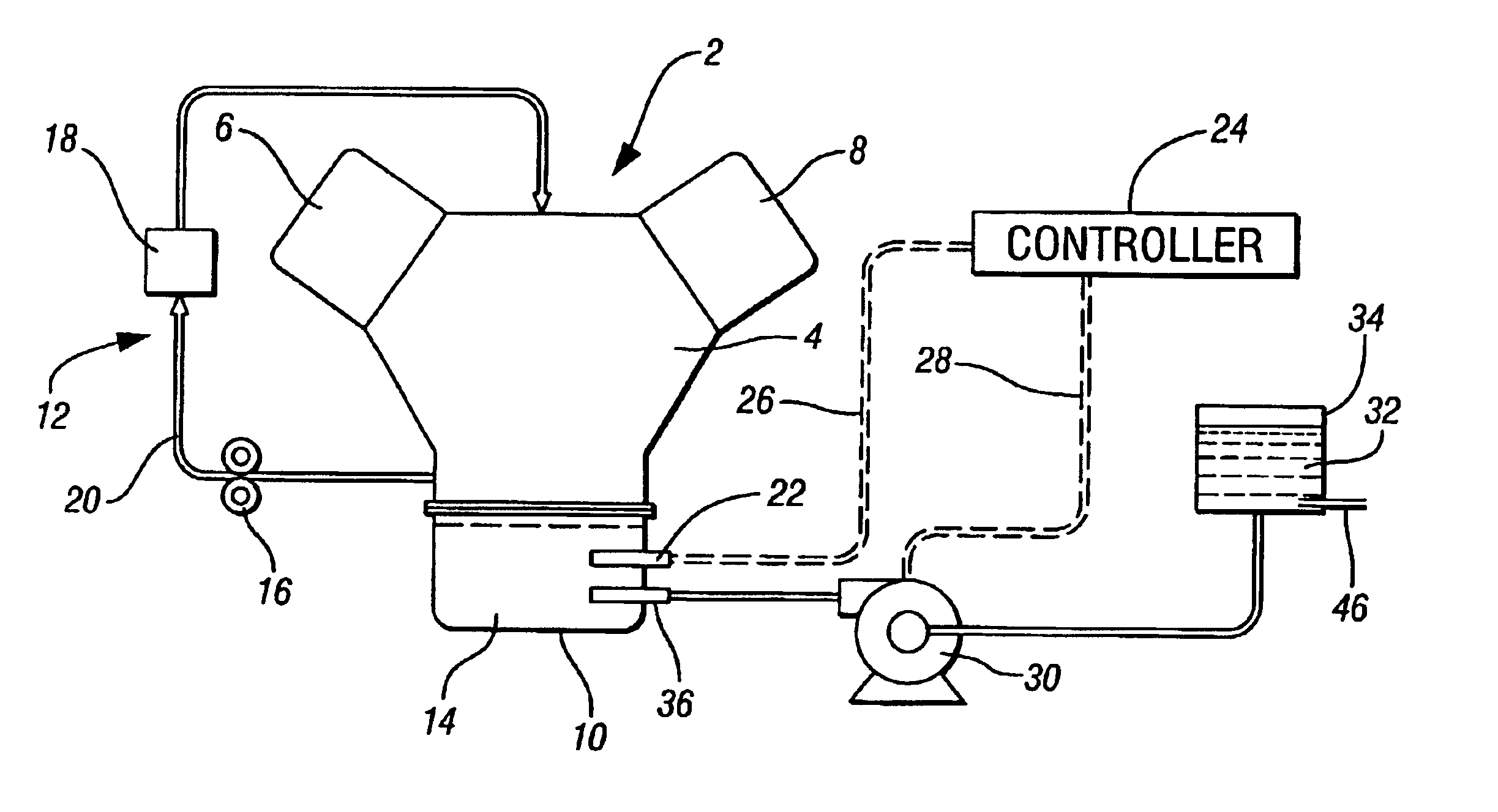

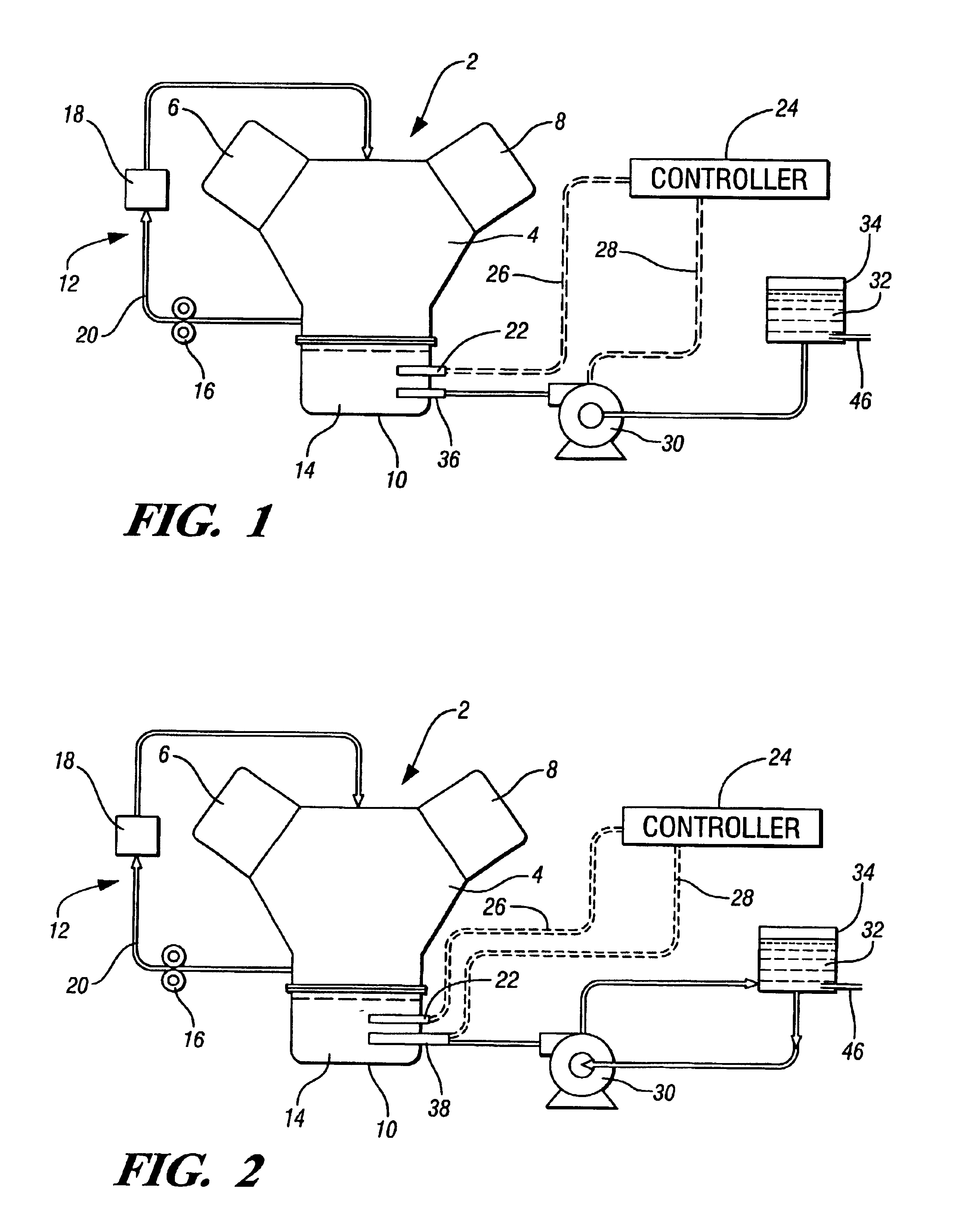

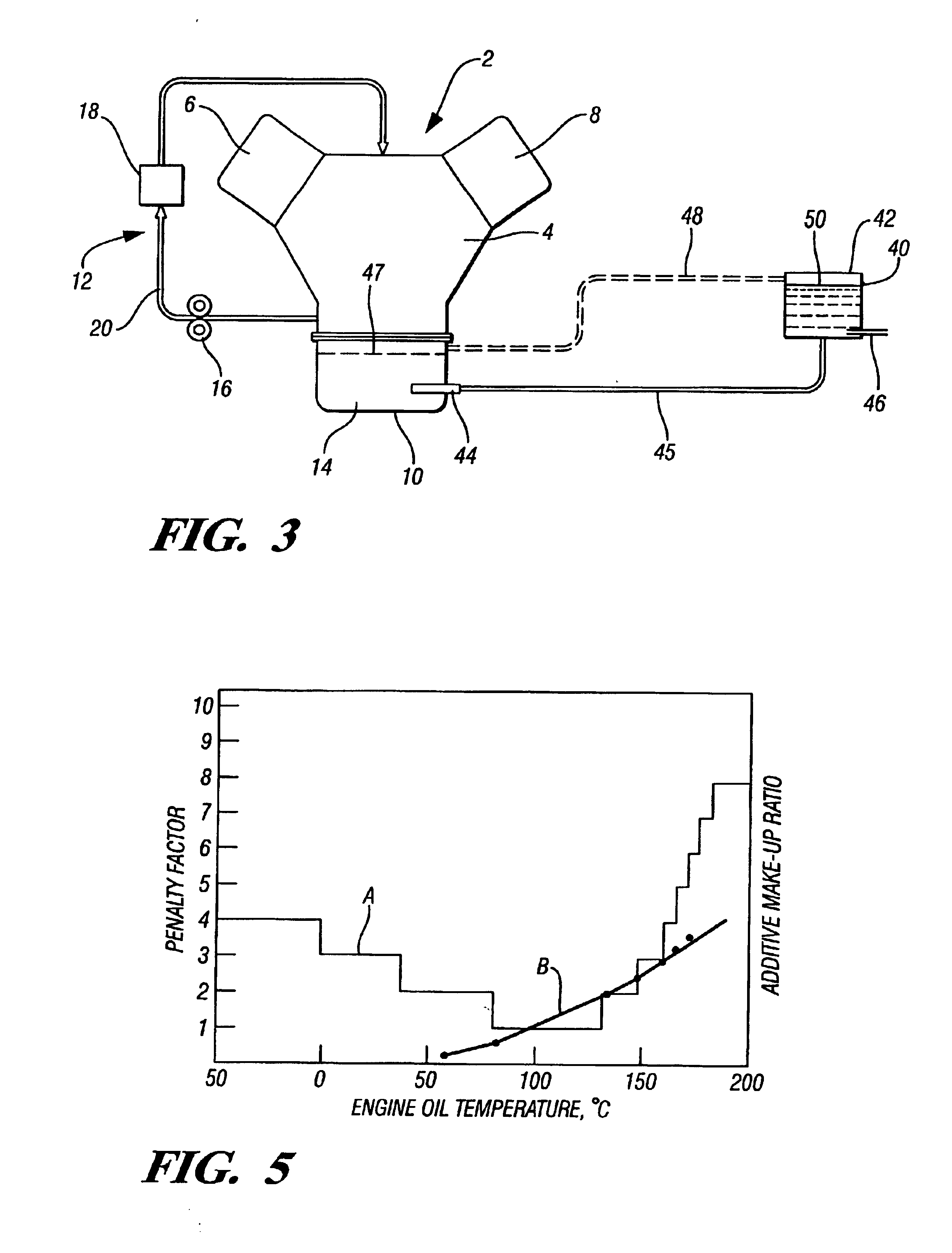

Automatic additive replenishment system for IC engine lubricating oil

InactiveUS6938585B2Extended service lifeExtension of timeCrankshaftsLubrication of auxillariesOperant conditioningPetroleum engineering

Method and apparatus for automatically replenishing additives lost from the lubricating oil of an IC engine, by injecting controlled quantities of the additive into the oil. The amount and frequency of injection is controlled by either the operating conditions of the oil (e.g. its thermal history), or changes the properties of the oil (e.g. its electrochemical activity, or dielectric constant).

Owner:GM GLOBAL TECH OPERATIONS LLC

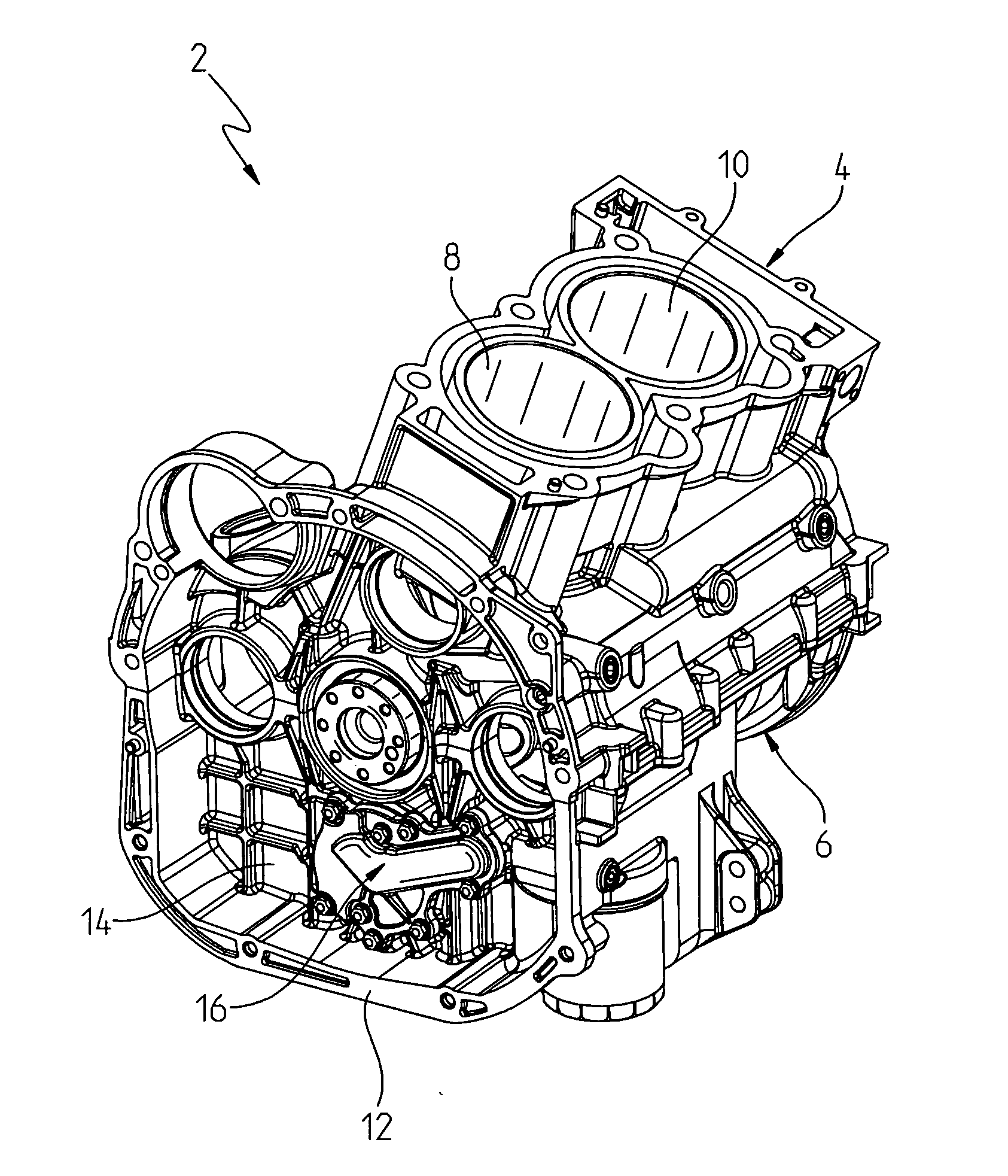

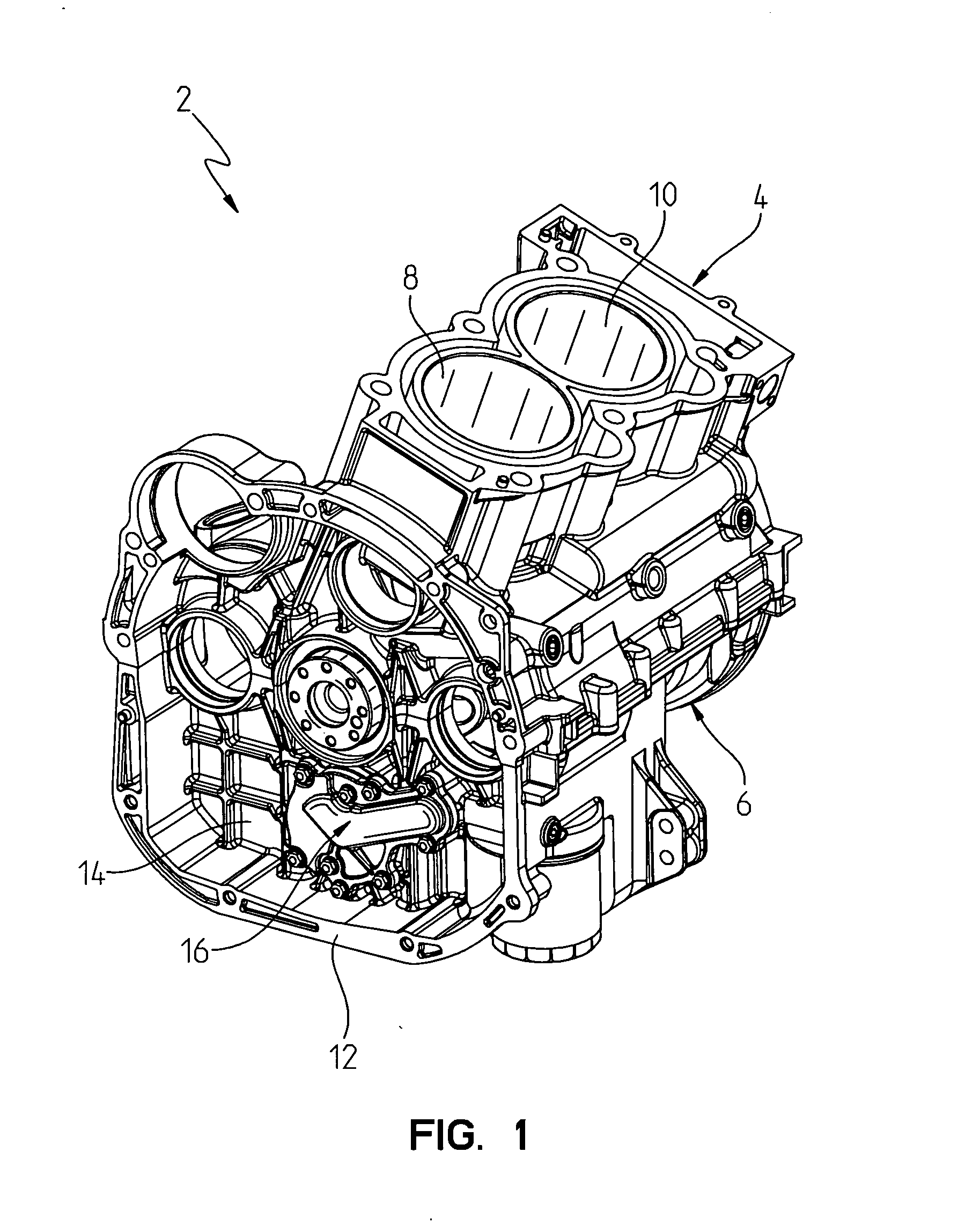

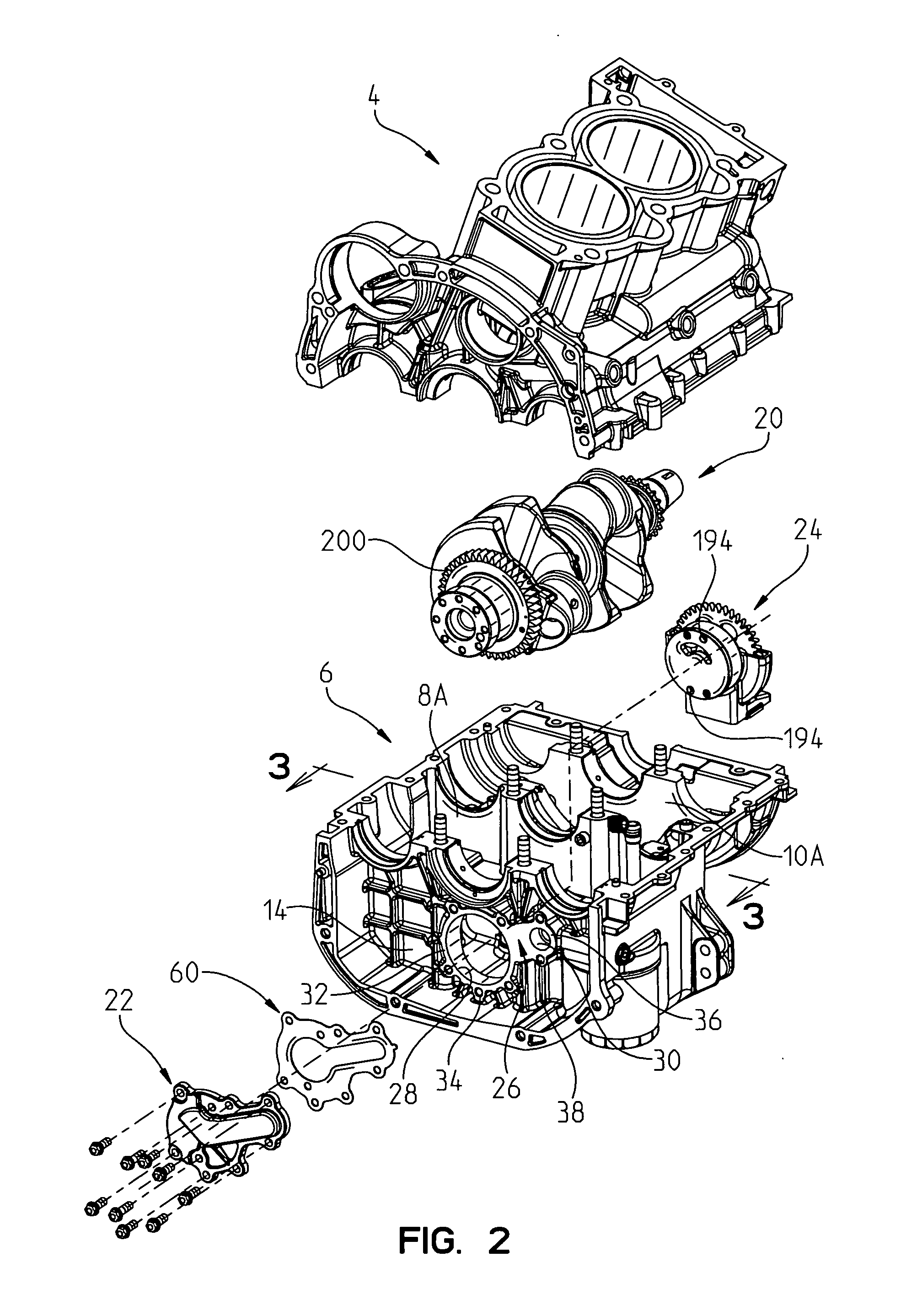

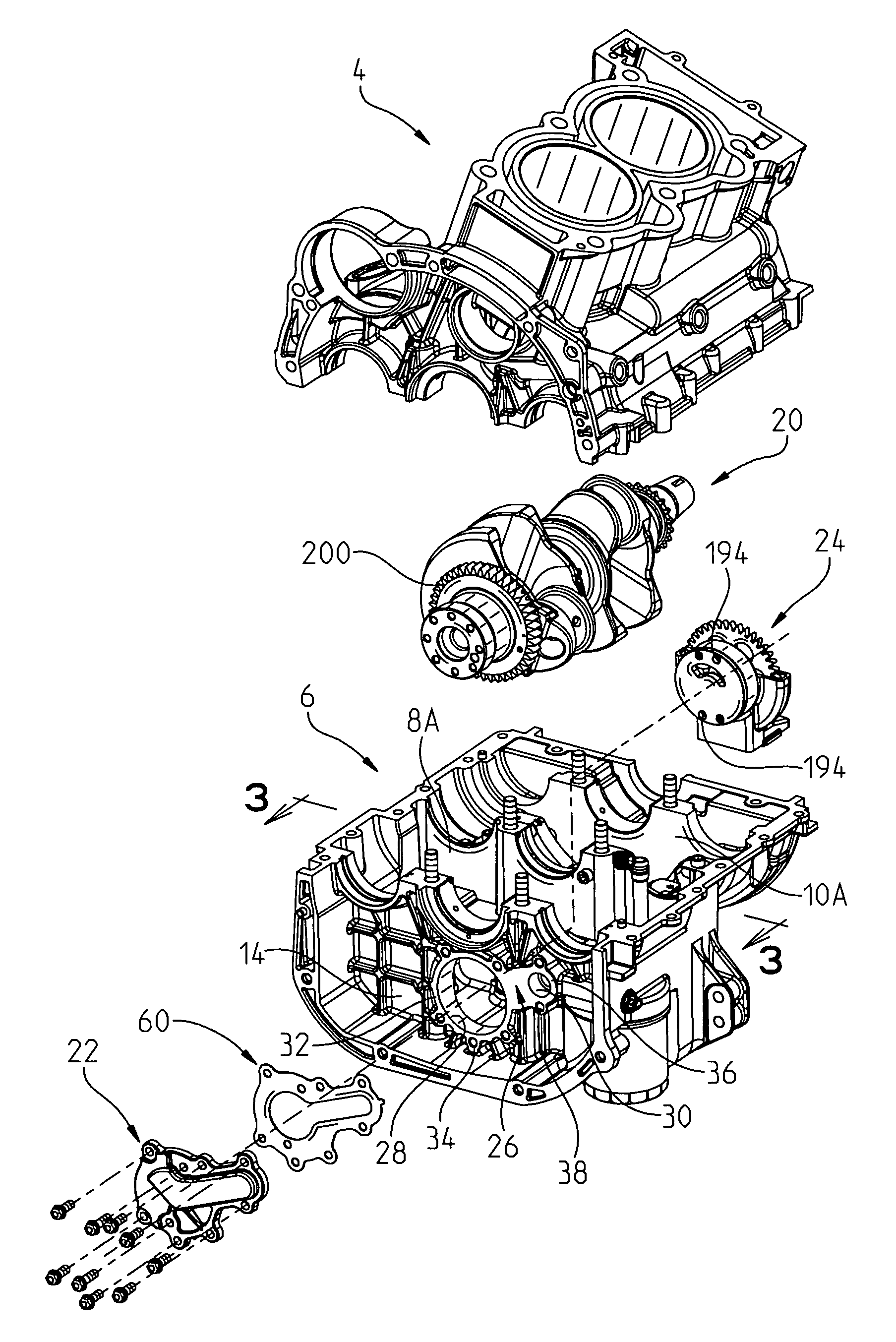

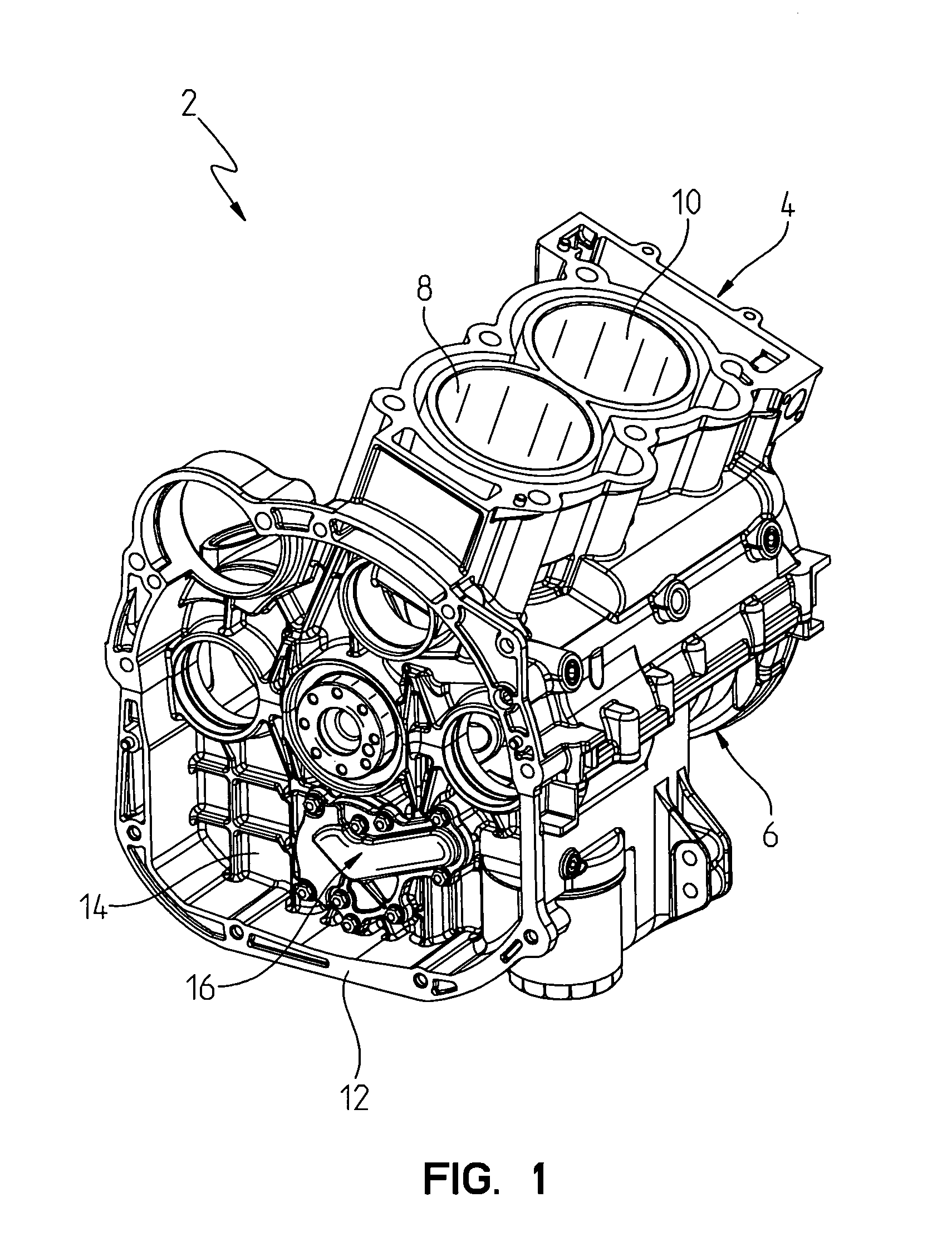

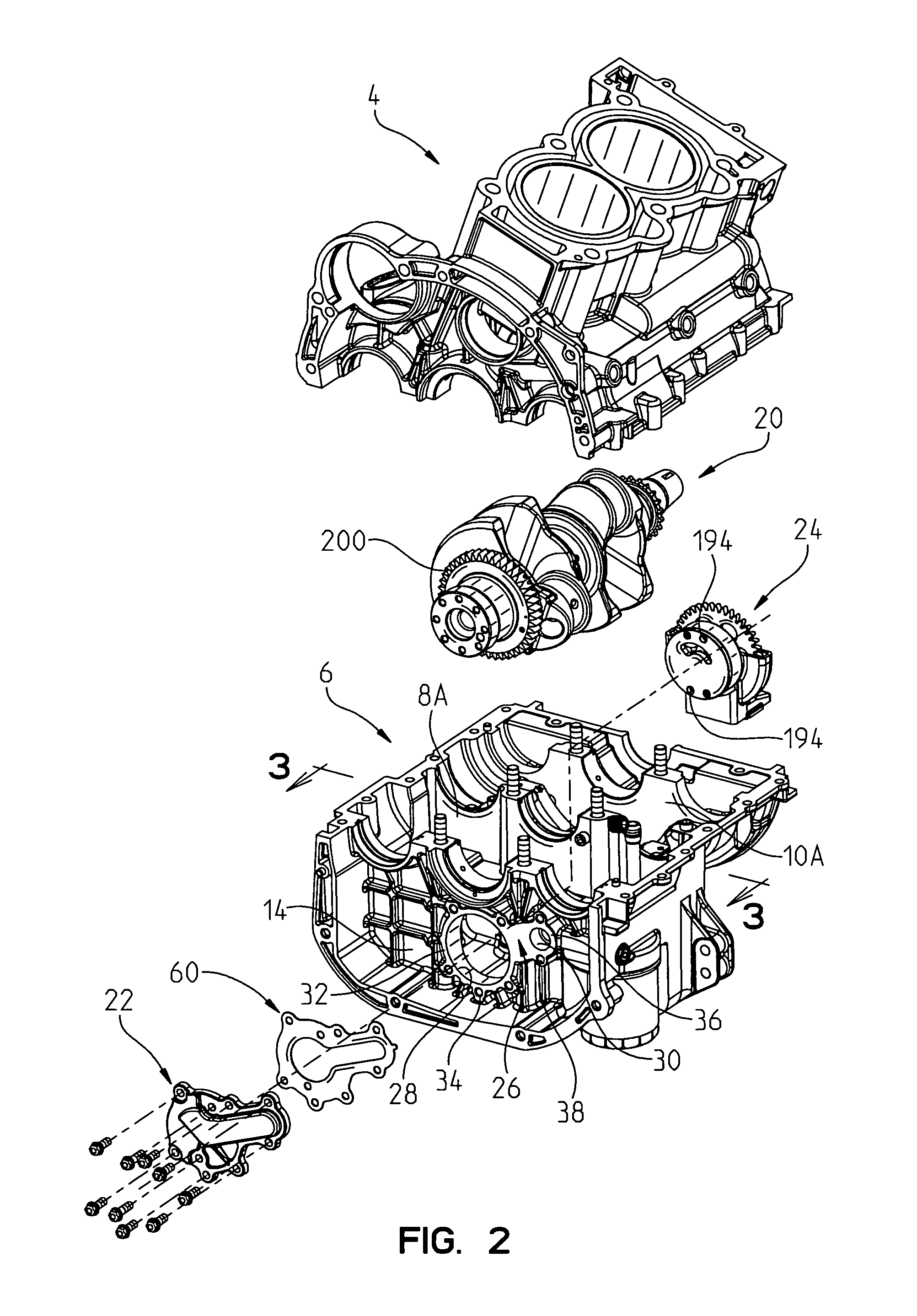

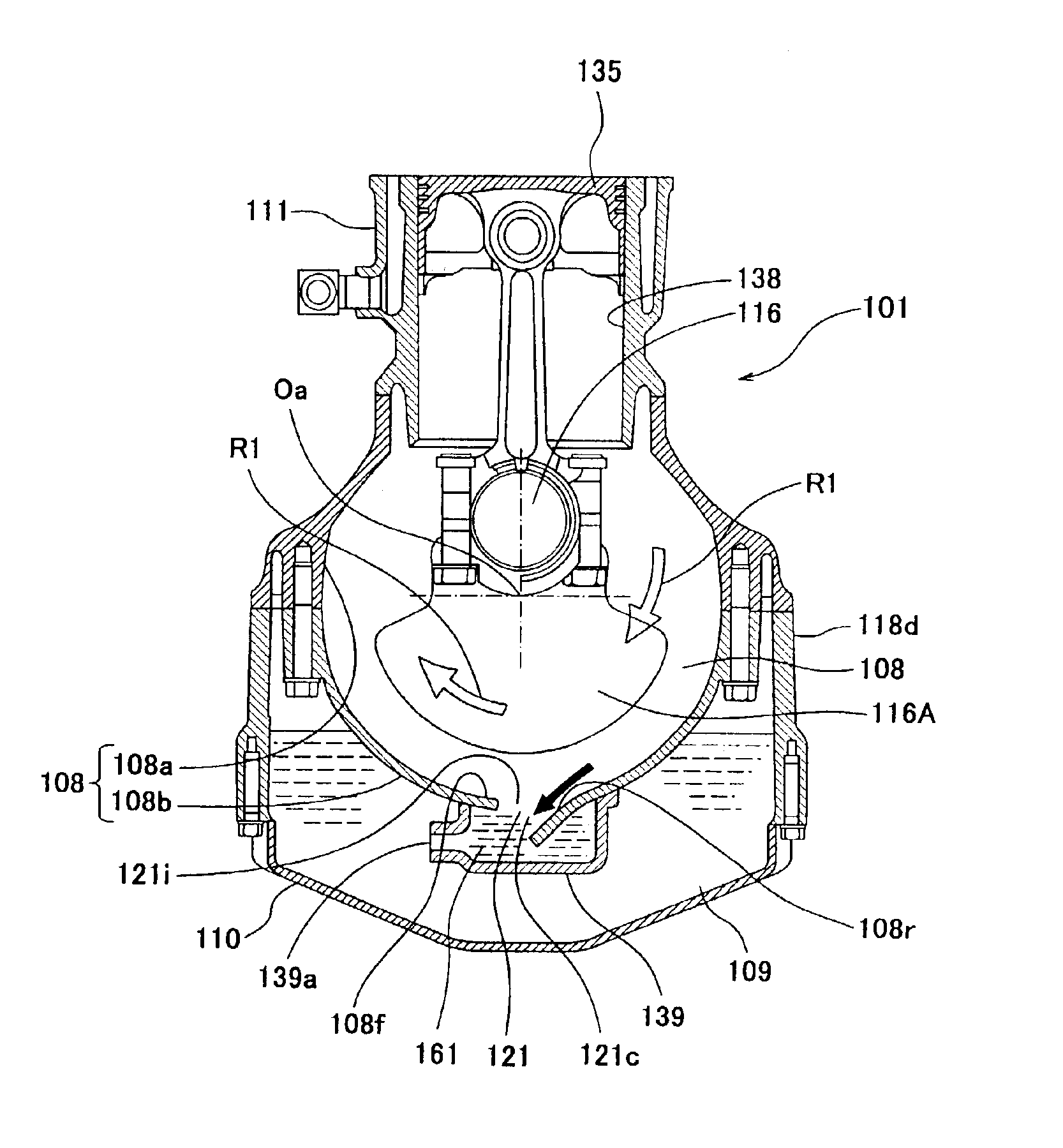

Wet oil sump for four cycle engine

ActiveUS20100012075A1Lubrication of auxillariesLubricant conduit arrangementsGear wheelSports equipment

An oil pump assembly is shown for wet oil sump applications at extreme angles for power sports equipment. The oil pump is comprised of a pump body, an oil pick-up and a driven gear shield, where these components may be integrally formed from die cast aluminum. The pump body includes a rotor body housing a gerotor assembly for pumping. The oil pump is attached to the rear wall of the crankcase and below the crankshaft, and is driven by the crankshaft.

Owner:POLARIS IND INC

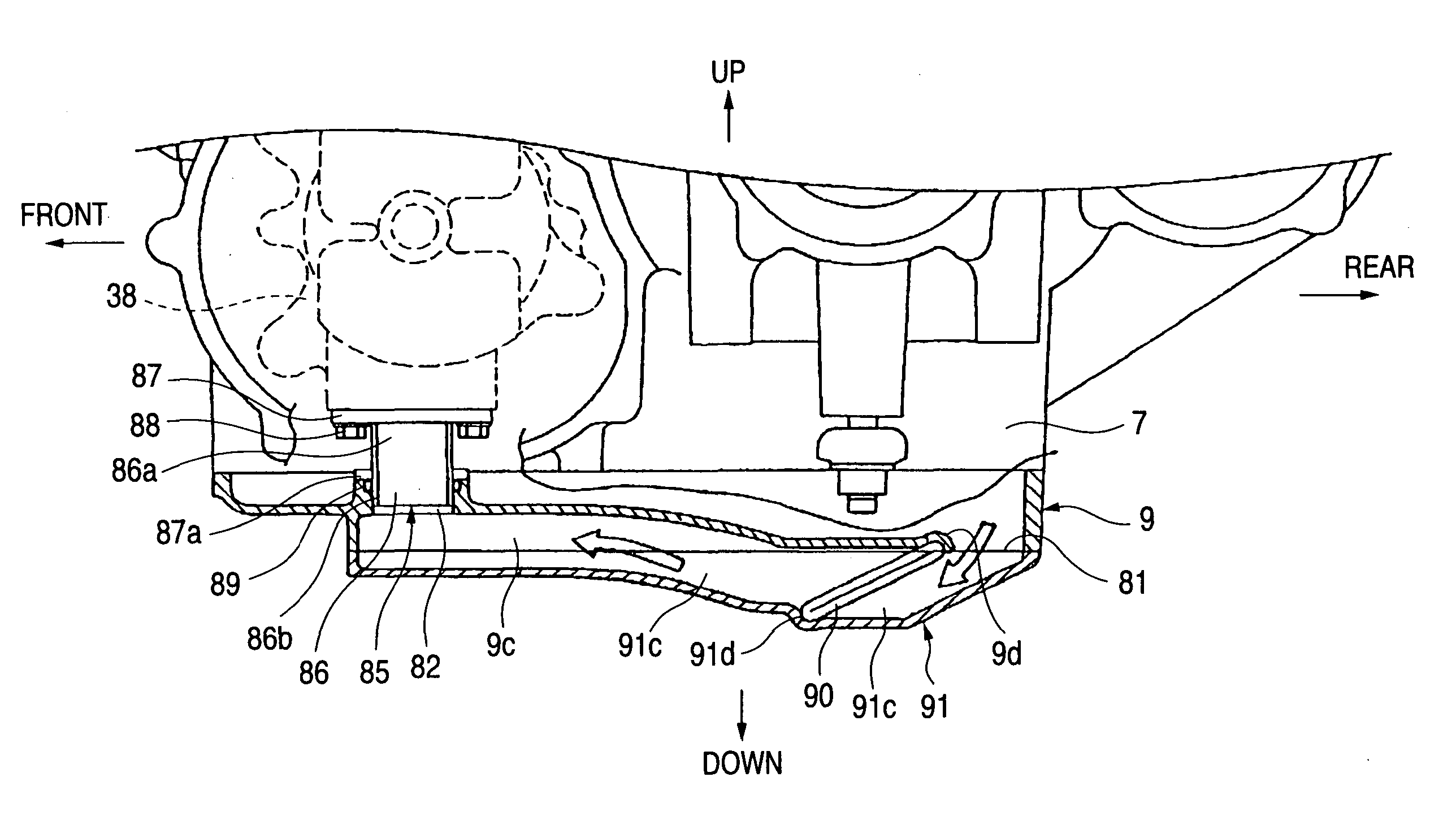

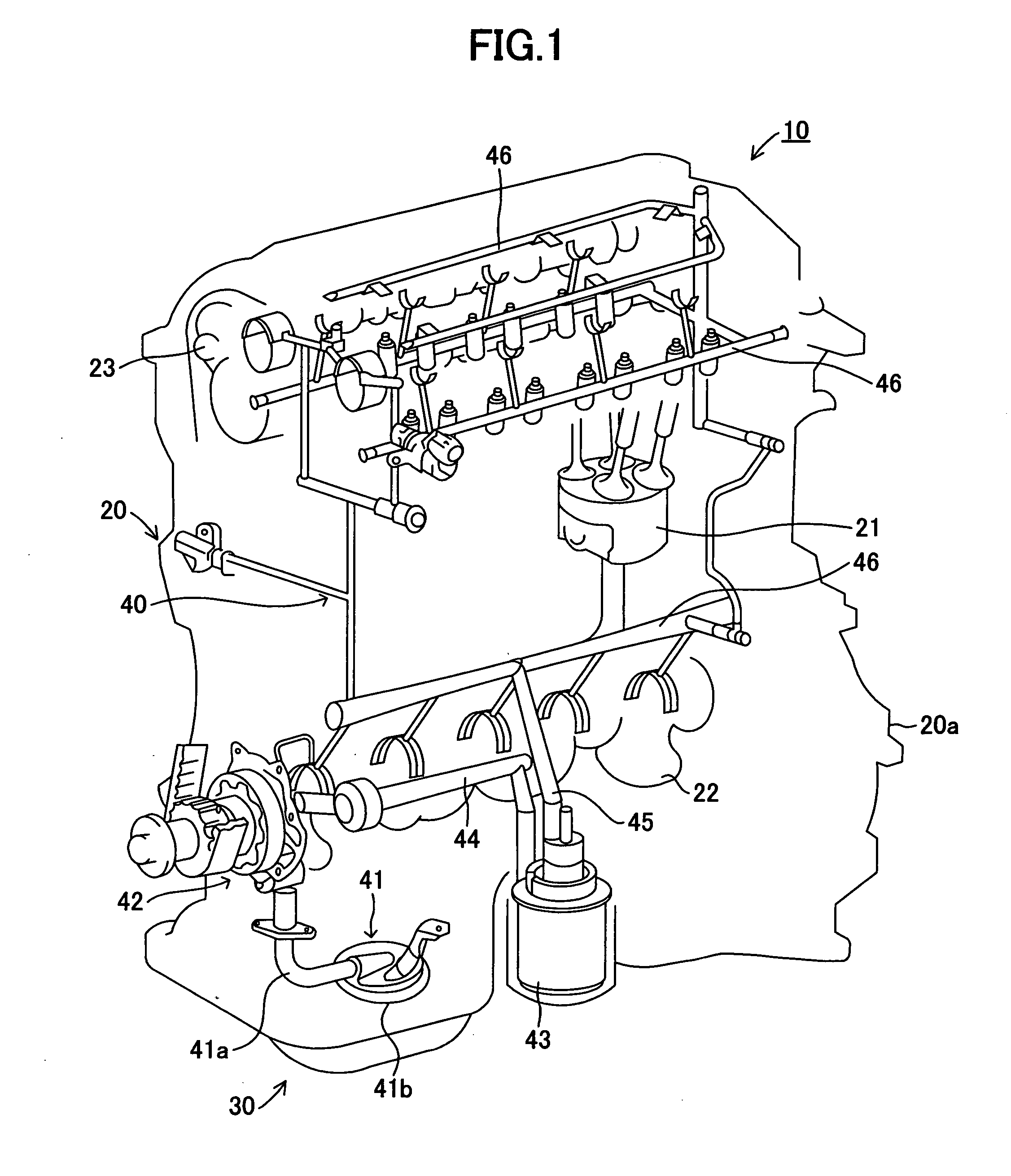

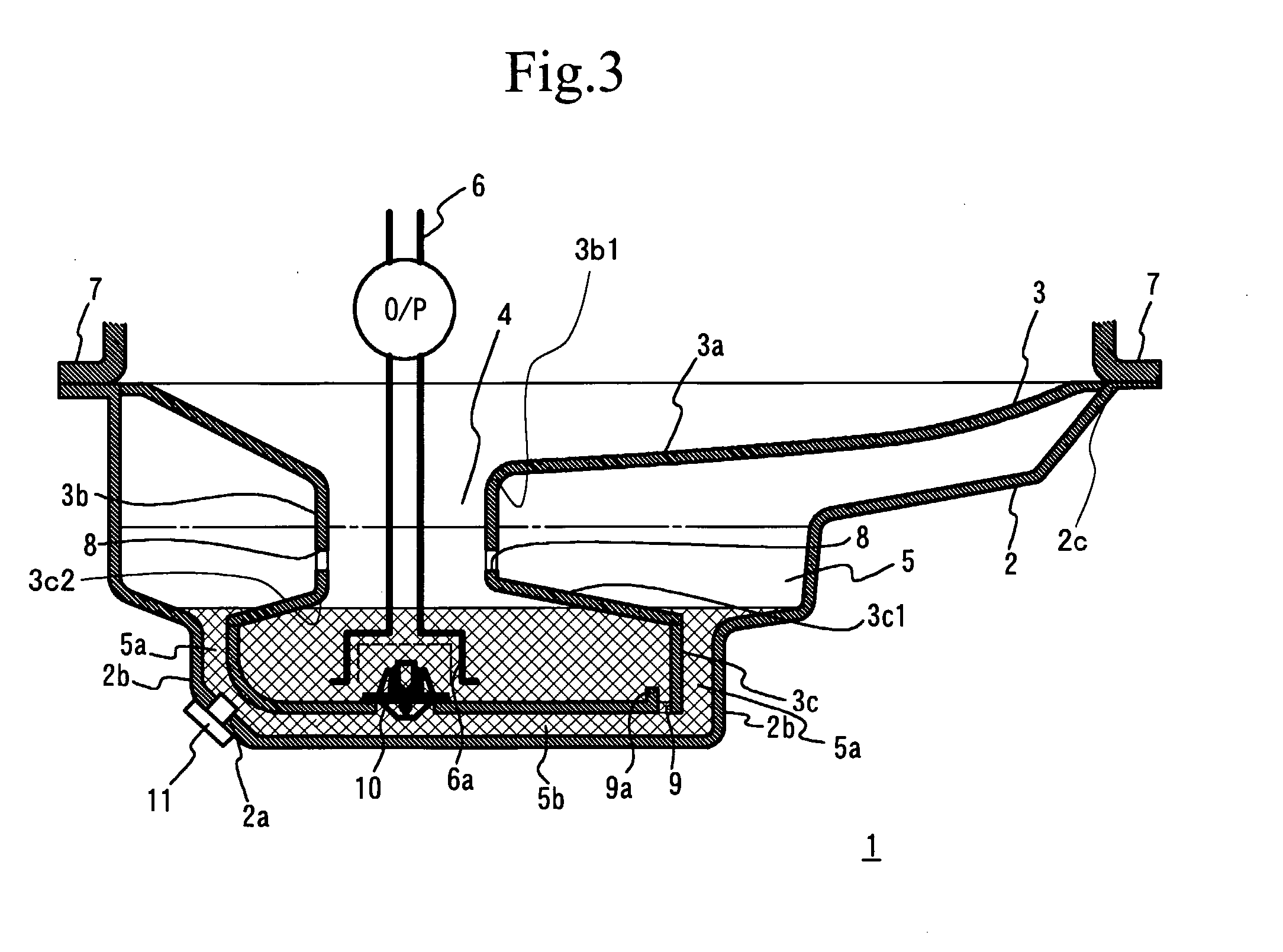

Oil pan structure for four-cycle engine

InactiveUS20040084250A1Reduce the overall heightSimple configurationCasingsOilsumpsCrankcaseLubrication

An oil pan structure for a four-cycle engine, in which oil stored in an oil pan is sucked up by an oil pump through an oil strainer and in which oil lubrication is performed by supplying the sucked oil again to each of parts of the engine to be lubricated. In this oil pan structure, a bottom portion of the oil pan is formed nearly like a bowl by being swelled to a side, which is opposite to a crankcase, from an attaching peripheral portion, to which a crankcase lower-part is attached, toward a central portion thereof. An oil pan cover covering a part of the bottom portion is separately provided thereon. Oil passages and are formed from the oil pan cover and the bottom portion. An oil introduction opening portion and an oil suction opening portion 82 are formed in the bottom portion.

Owner:SUZUKI MOTOR CORP

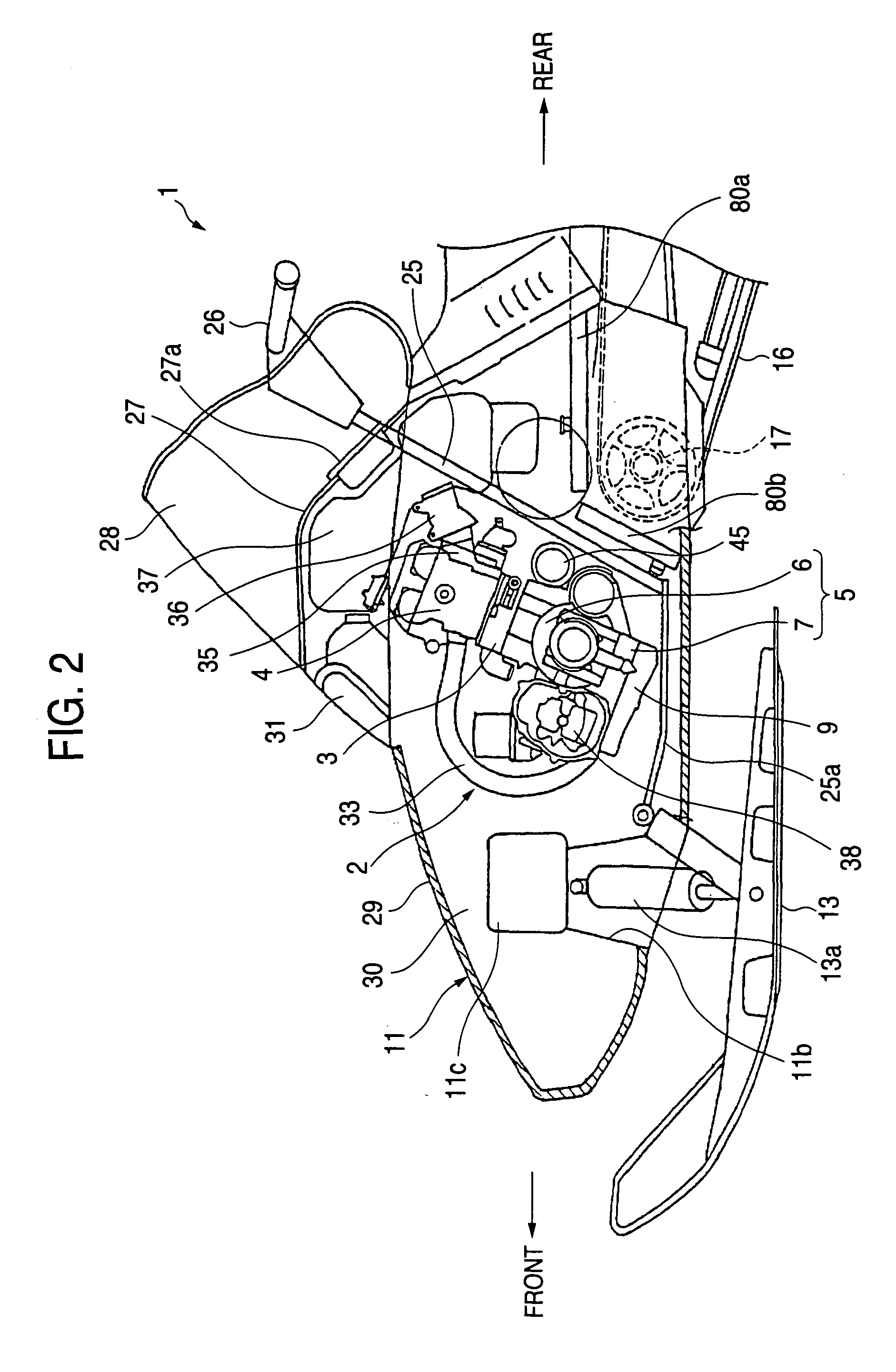

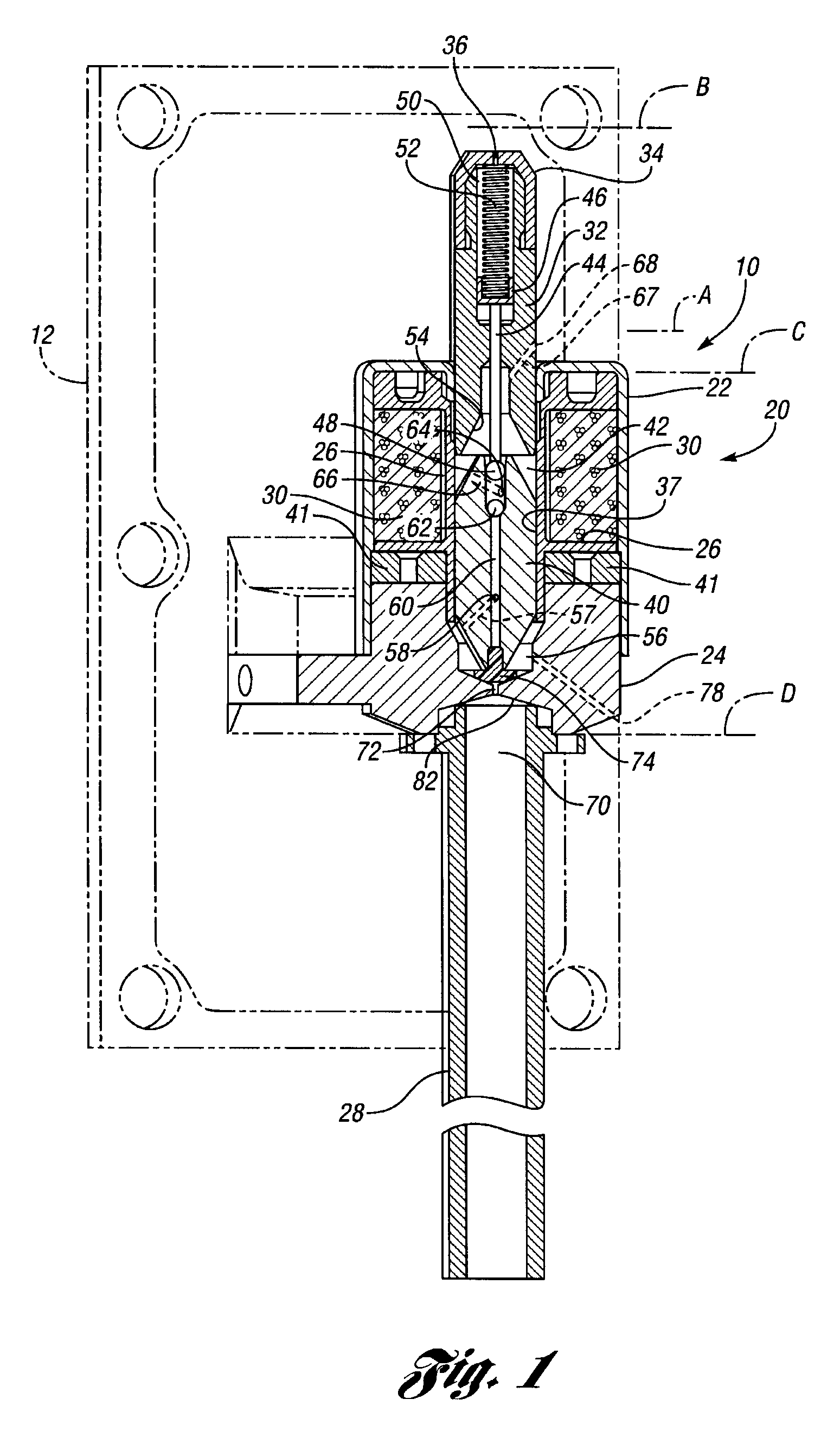

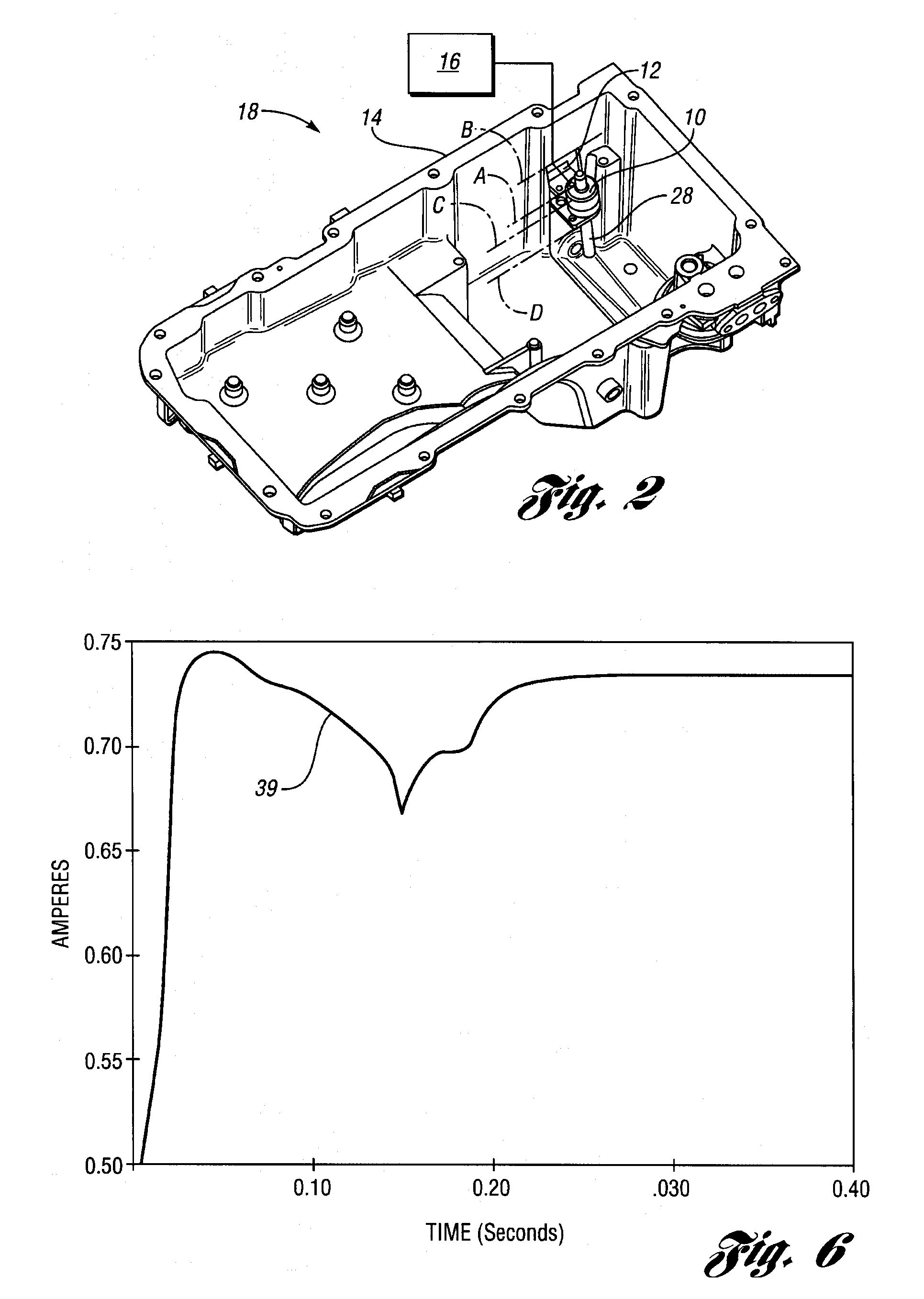

Integrated oil condition and level sensor

InactiveUS20080250851A1Accurate detectionIncrease currentFlow propertiesEngine testingLevel sensorOil viscosity

An oil condition and level sensor is provided that includes a solenoid body, a coil, an armature and a pole piece. The solenoid body defines an armature chamber between the armature and the pole piece. The armature is movable in the armature chamber in response to energizing of the coil. In an oil condition sensing system, the coil is operatively connected to a controller which can determine at least one of an oil temperature, oil viscosity, oil level, and an oil change occurrence. In one embodiment, four oil levels, including an overfill oil level and an excessively low oil level may be detected. The sensor is referred to as an integrated oil condition and level sensor as multiple sensing functions are integrated into one sensor.

Owner:EATON CORP

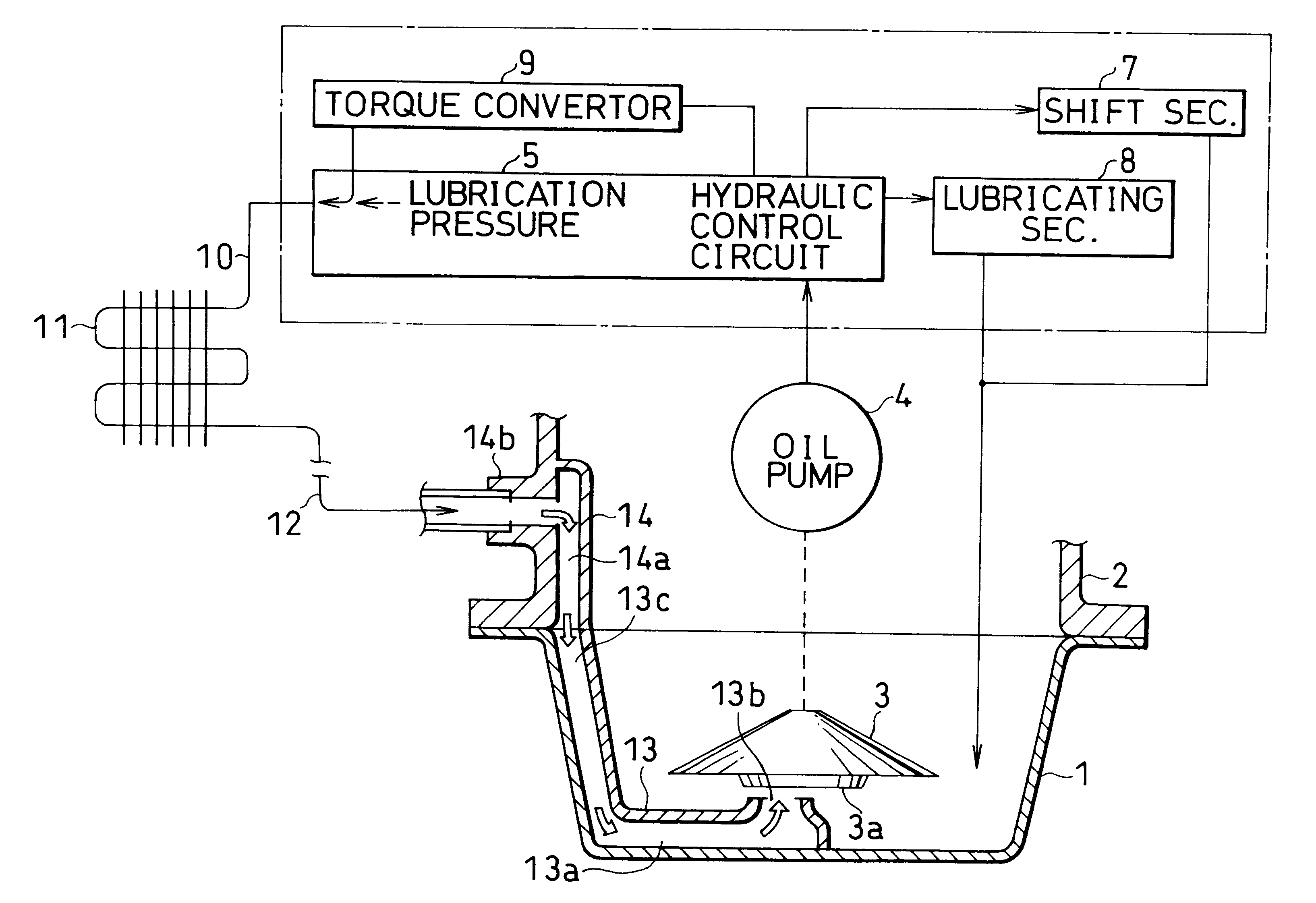

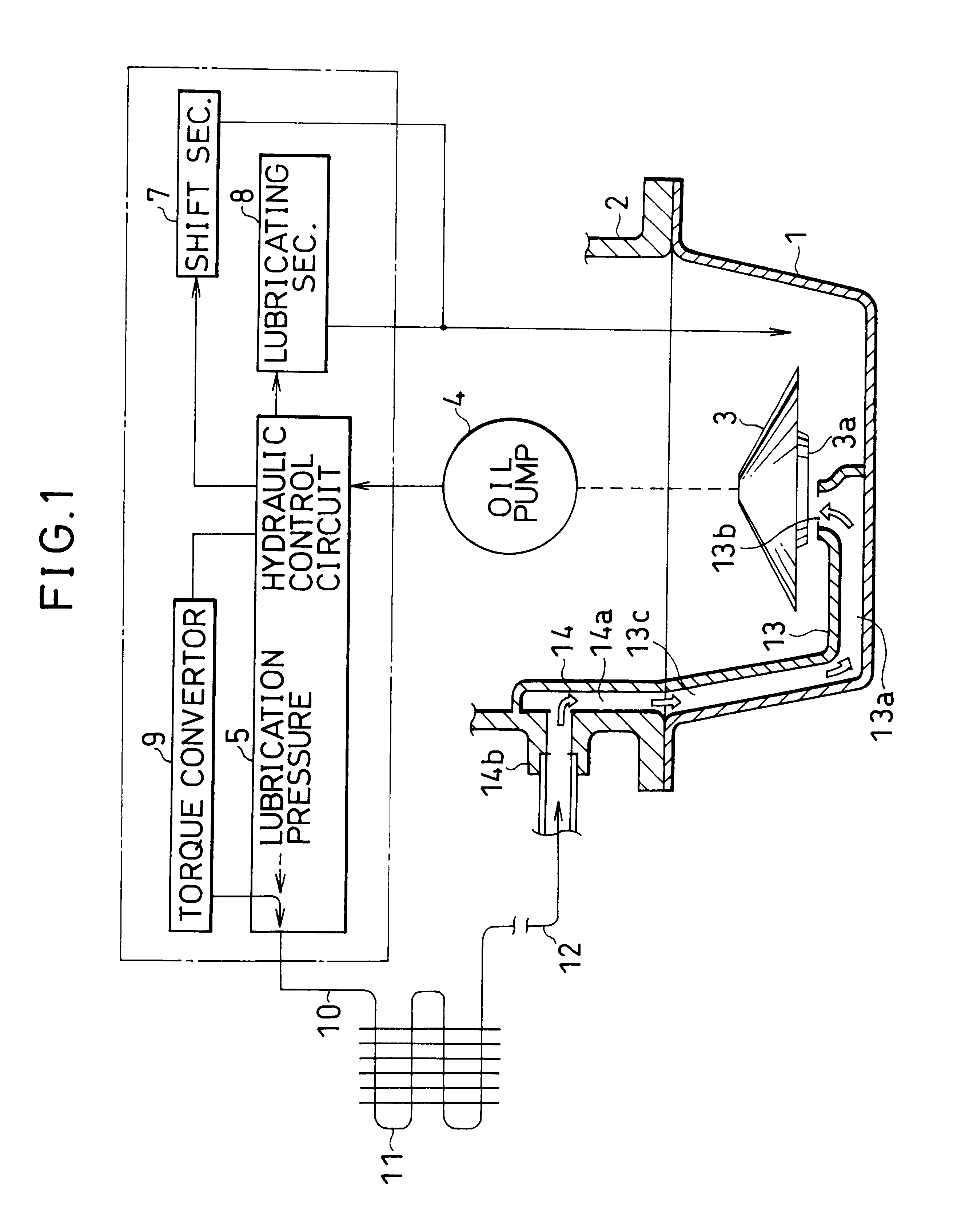

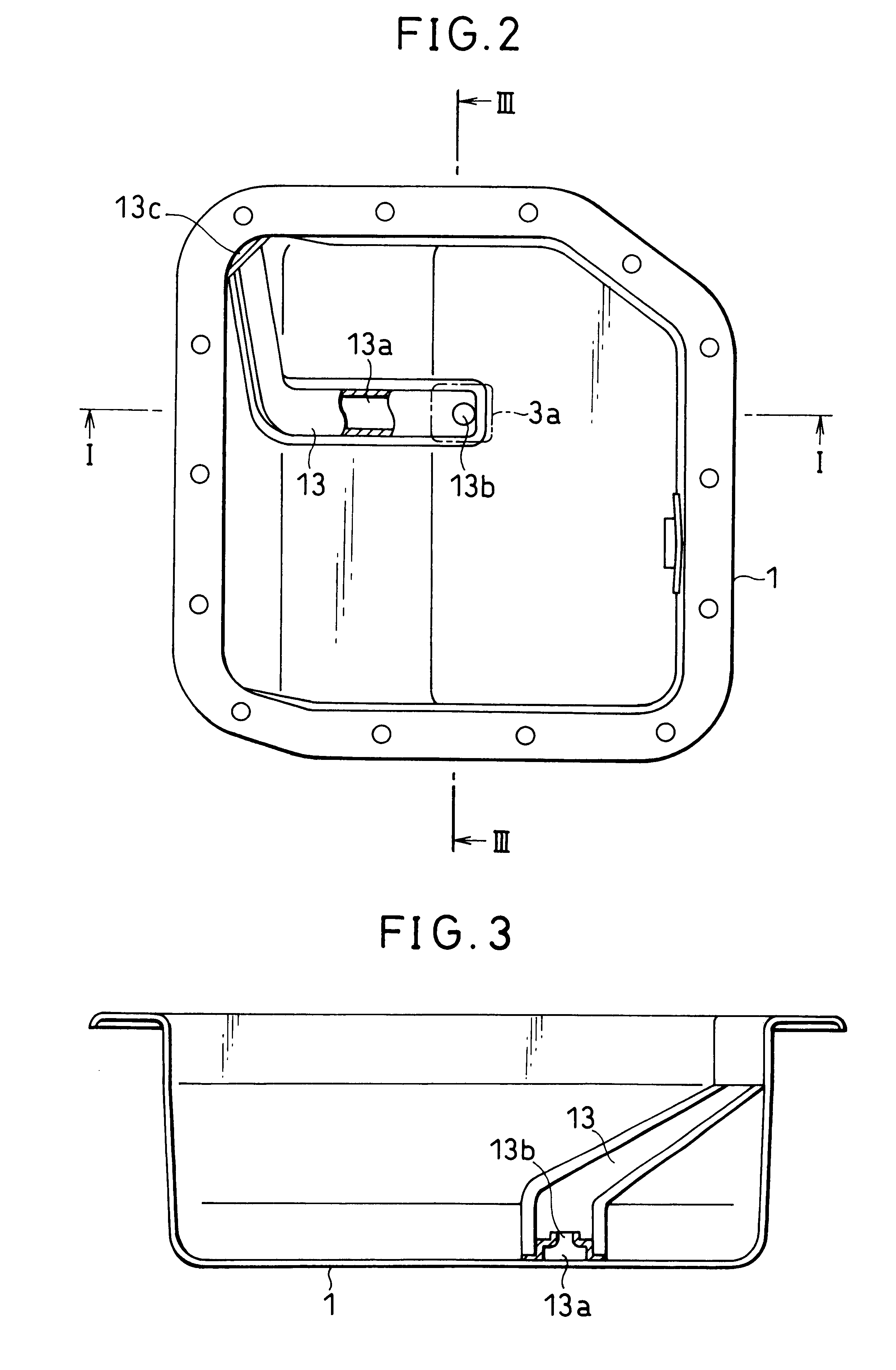

Oil circulating apparatus for automatic transmission

A part of oil sucked by an oil pump is circulated to an oil pan through a hydraulic control circuit, an oil cooler and an oil passage provided in a transmission case and the oil pan. The oil guided to the oil pan is gushed out from a discharge port of the oil passage toward a suction port of an oil strainer communicating with the oil pump. The discharge port of the oil passage is disposed opposite and adjacent to the suction port of the oil strainer so that only the oil containing a small number of bubbles is sucked by the oil pump.

Owner:FUJI JUKOGYO KK

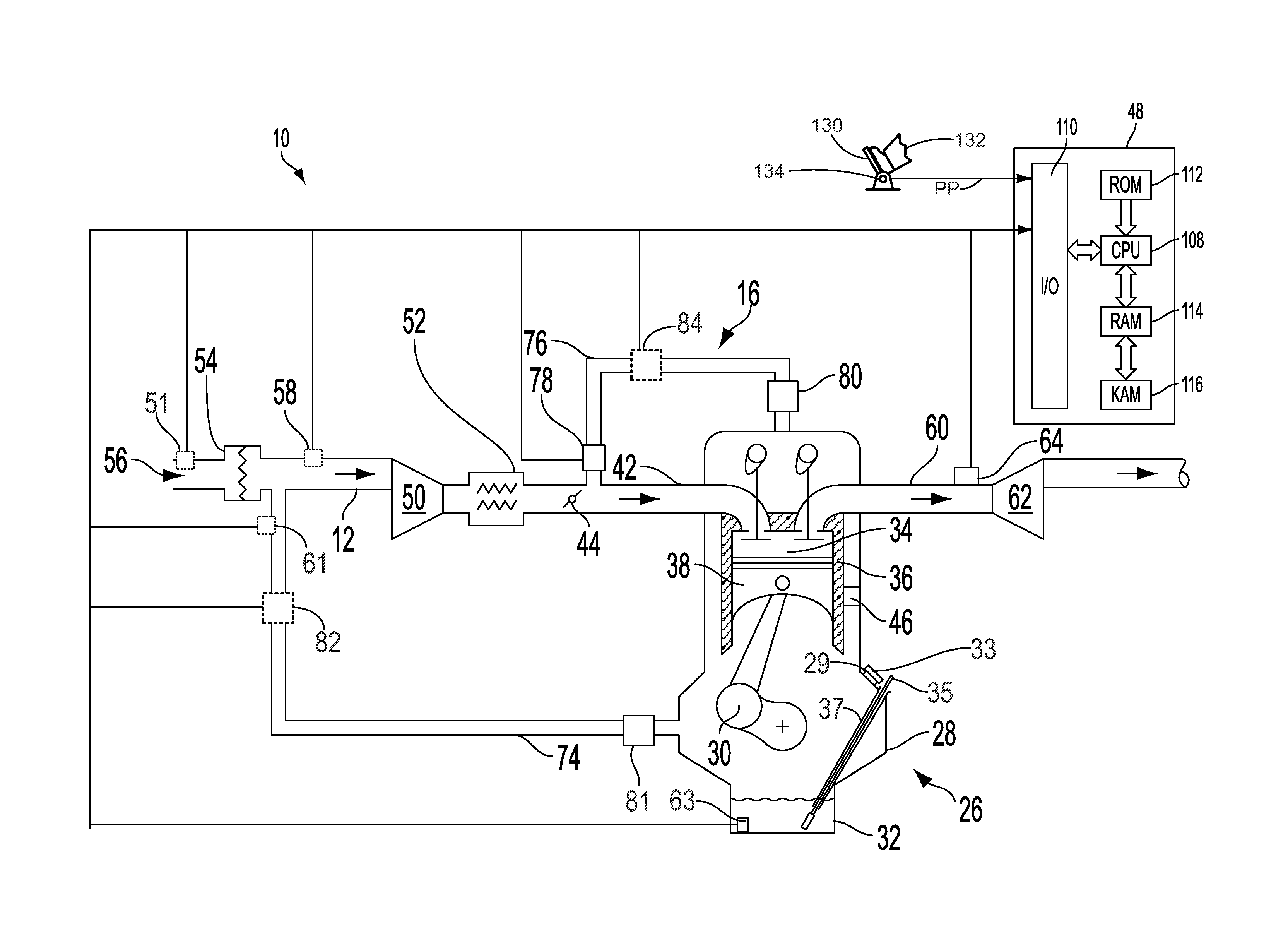

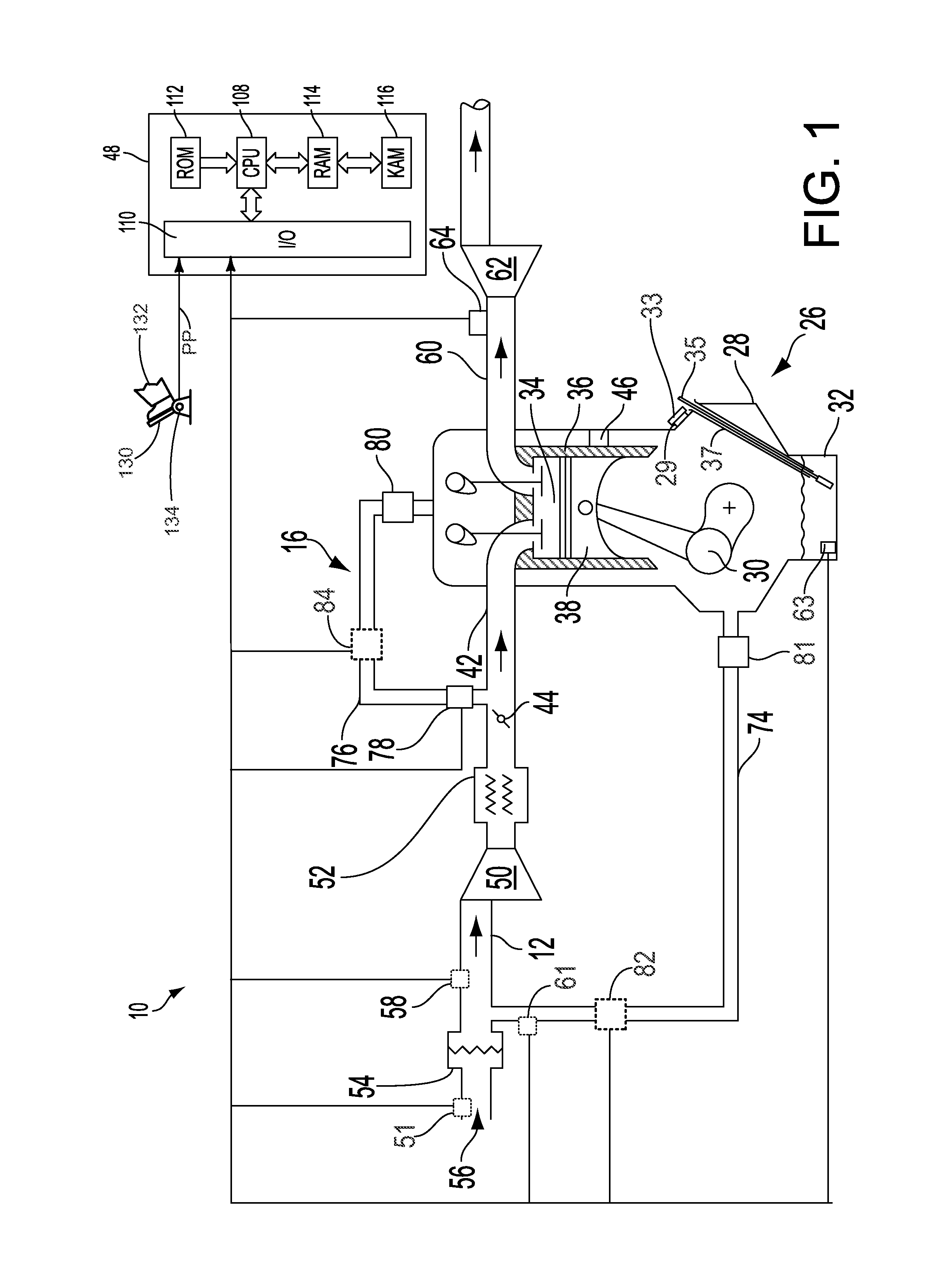

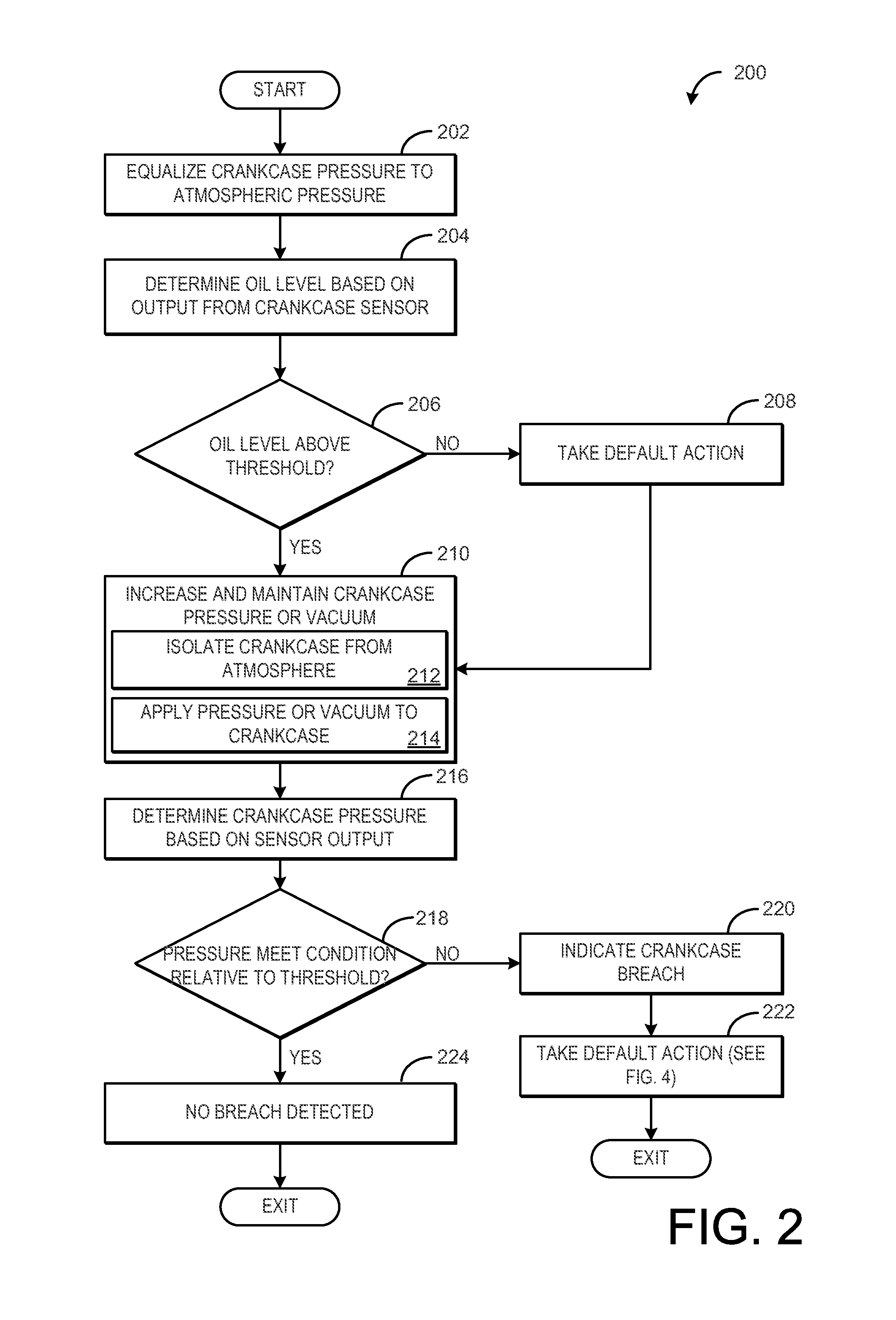

Method for determining crankcase breach and oil level

ActiveUS20130282255A1Reduce degradationIncreased complexityAnalogue computers for vehiclesInternal-combustion engine testingEngineeringCrankcase ventilation system

Embodiments for detecting crankcase breach are provided. In one example, a method includes indicating both crankcase ventilation system degradation and a crankcase oil sump level based on a common crankcase sensor. In this way, the same sensor can provide both crankcase breach detection and oil level determination.

Owner:FORD GLOBAL TECH LLC

Wet oil sump for four cycle engine

An oil pump assembly is shown for wet oil sump applications at extreme angles for power sports equipment. The oil pump is comprised of a pump body, an oil pick-up and a driven gear shield, where these components may be integrally formed from die cast aluminum. The pump body includes a rotor body housing a gerotor assembly for pumping. The oil pump is attached to the rear wall of the crankcase and below the crankshaft, and is driven by the crankshaft.

Owner:POLARIS IND INC

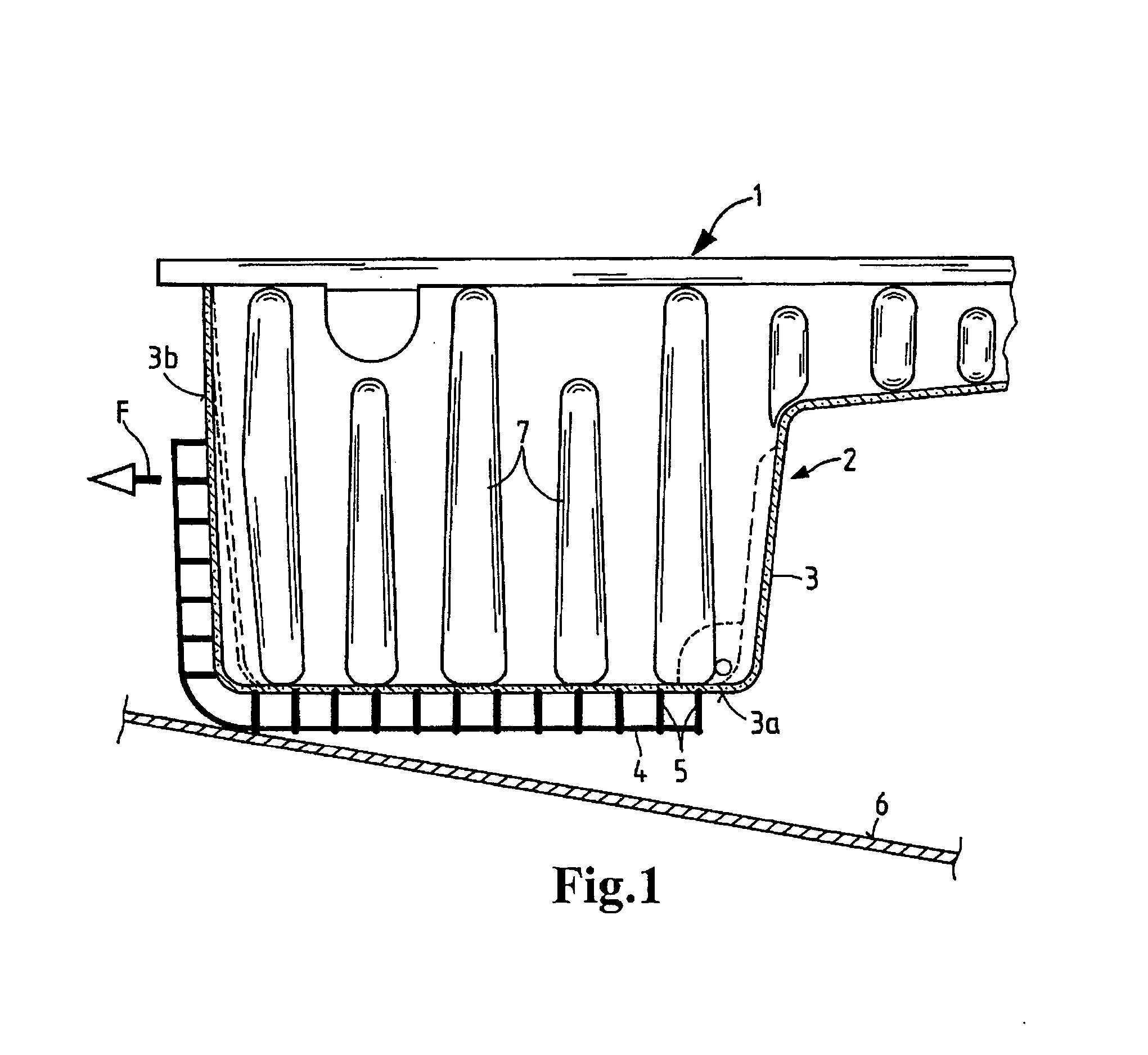

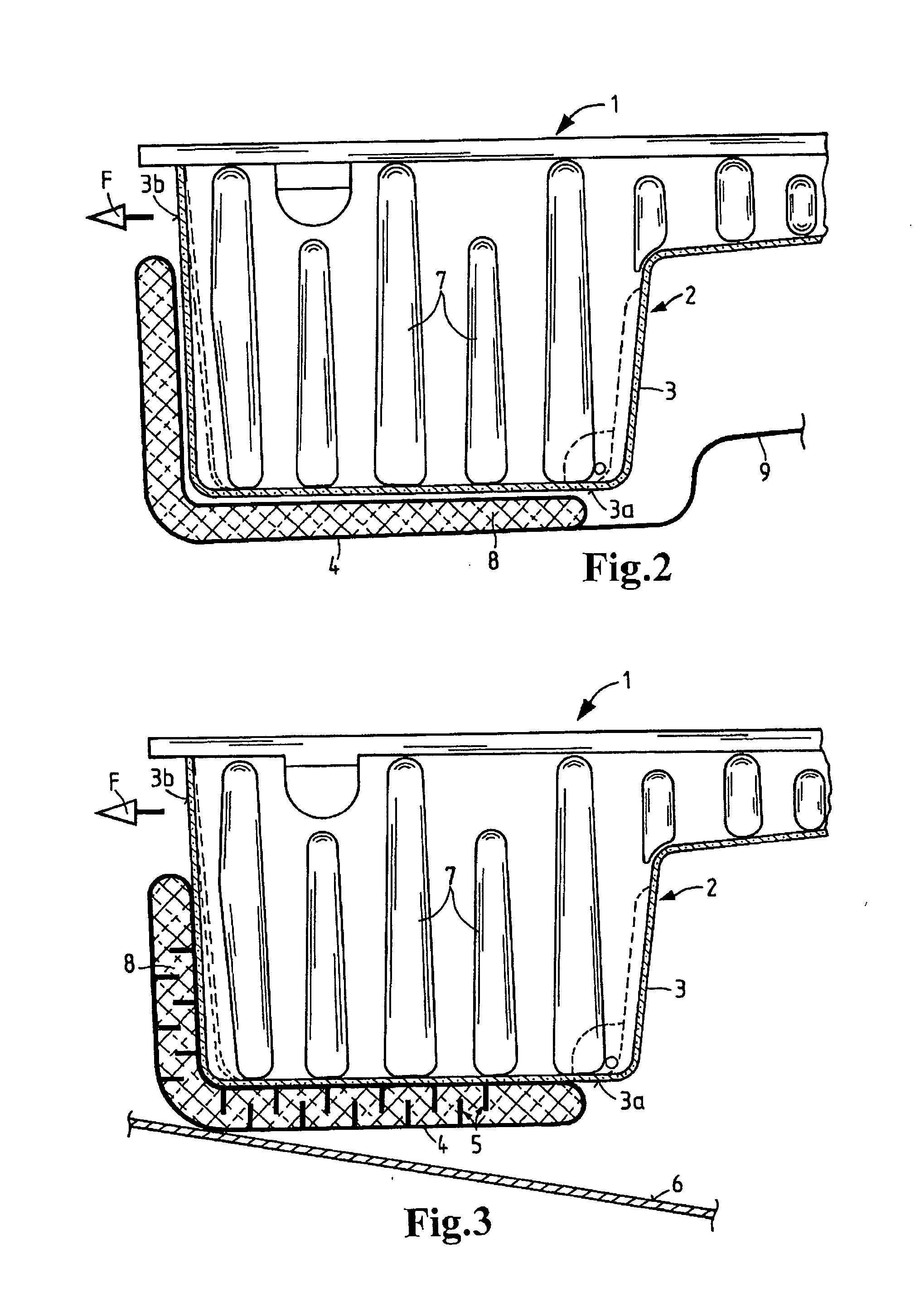

Lubrication device and oil pan

ActiveUS20090014248A1Improve deteriorationCasingsGear lubrication/coolingLubricationWaste management

Owner:TOYOTA JIDOSHA KK

Oil Sump Having Oil Filter on Carrier Unit

ActiveUS20100038296A1Easy to engageReduce in quantityWater/sewage treatmentOilsumpsFilter mediaCylinder block

An oil sump, preferably made of plastic or metal, is provided for engines or transmissions, the oil sump comprising a filter housing including a filter housing top shell, a filter housing bottom shell, a filter medium, a filter inlet, and the filter outlet, and having an oil drain opening in a floor area of the oil sump, implemented in such a way that it is closable using an oil drain screw having external thread, which comes from the oil sump outer side. The oil sump also includes a carrier unit having a frame, on which the filter housing is fastened and which is used as a seal upon fastening of the oil sump on the associated unit, in particular on an engine block or a transmission unit.

Owner:IBS FILTRAN KUNST METALLERZEUGNISSE

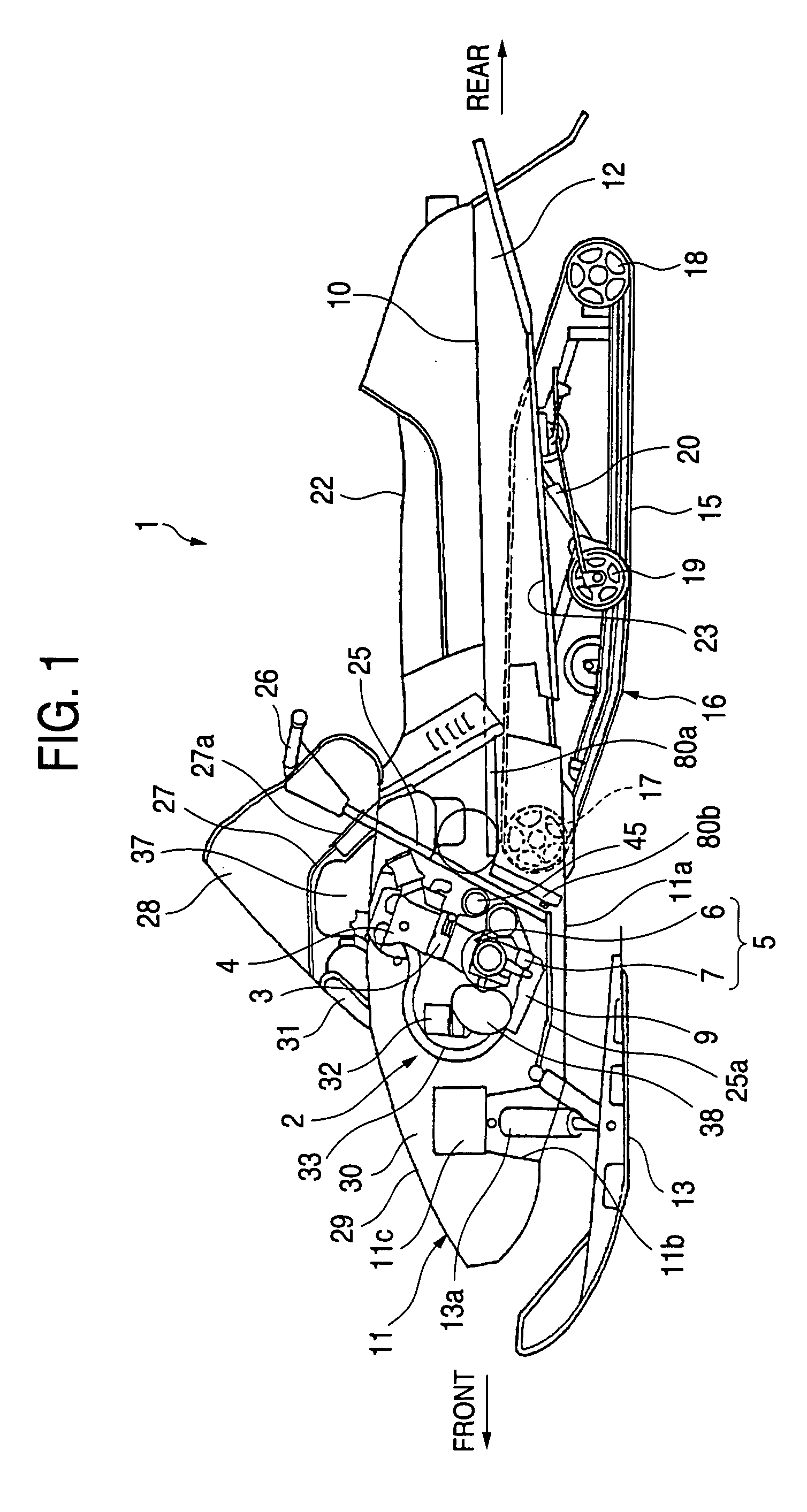

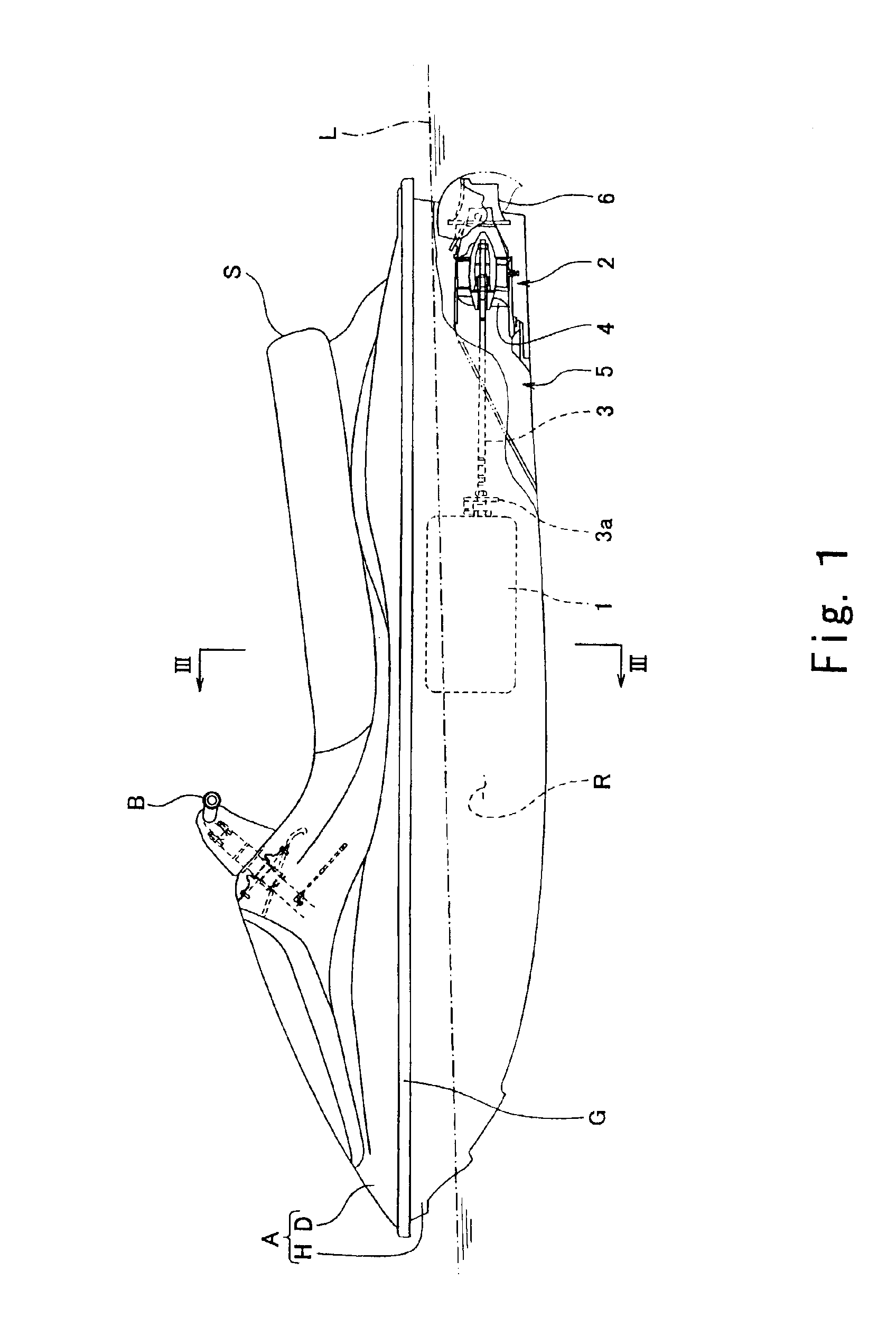

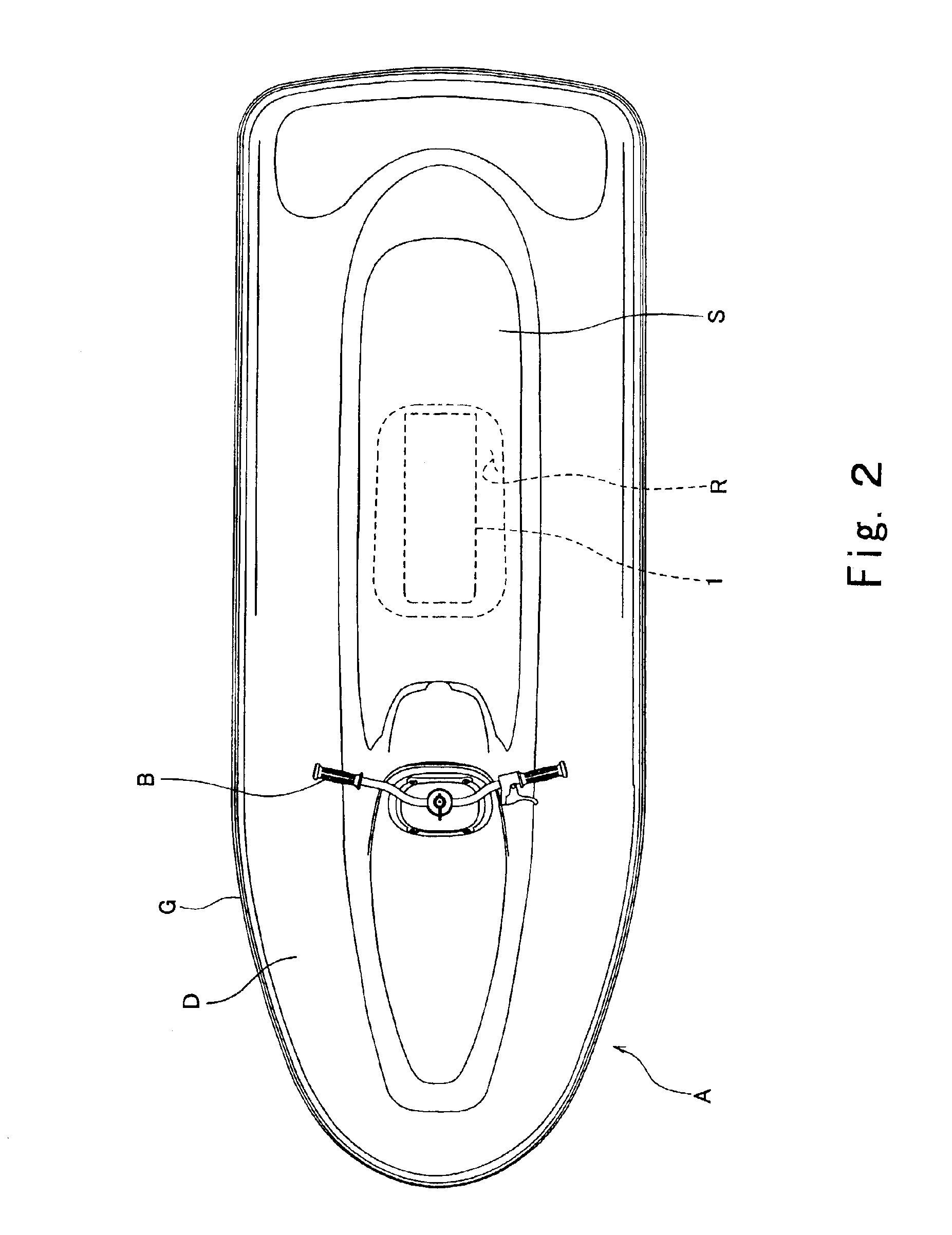

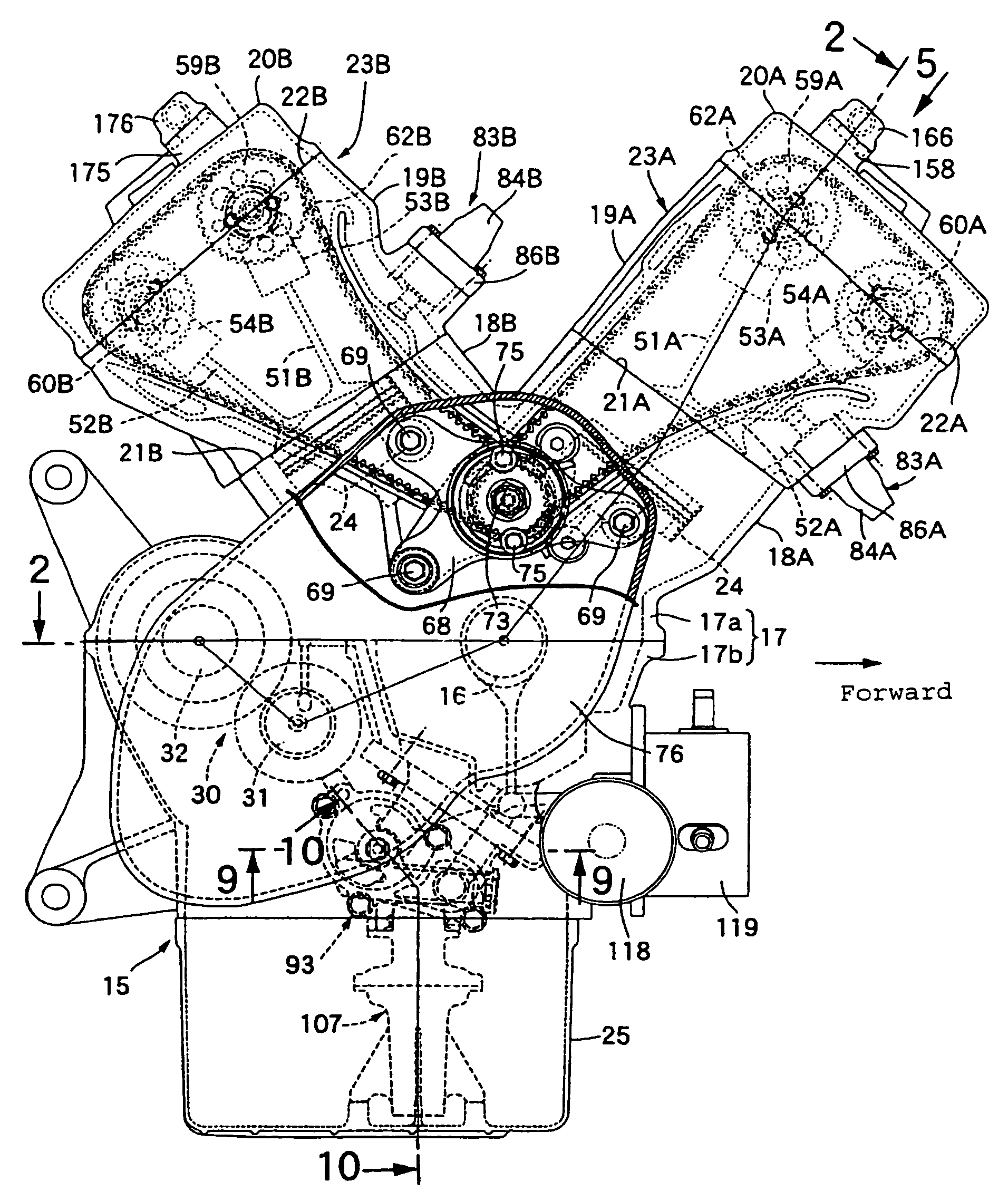

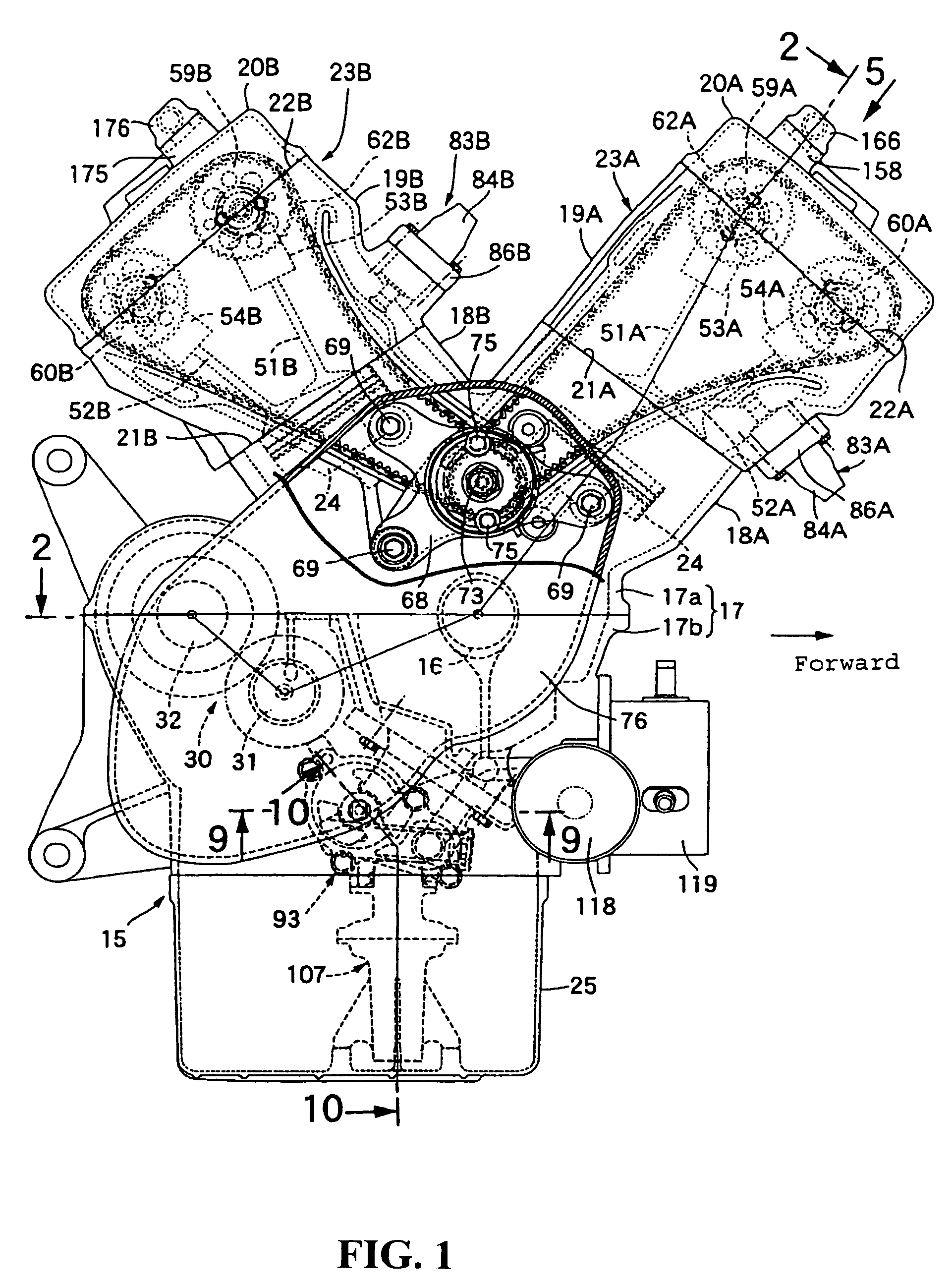

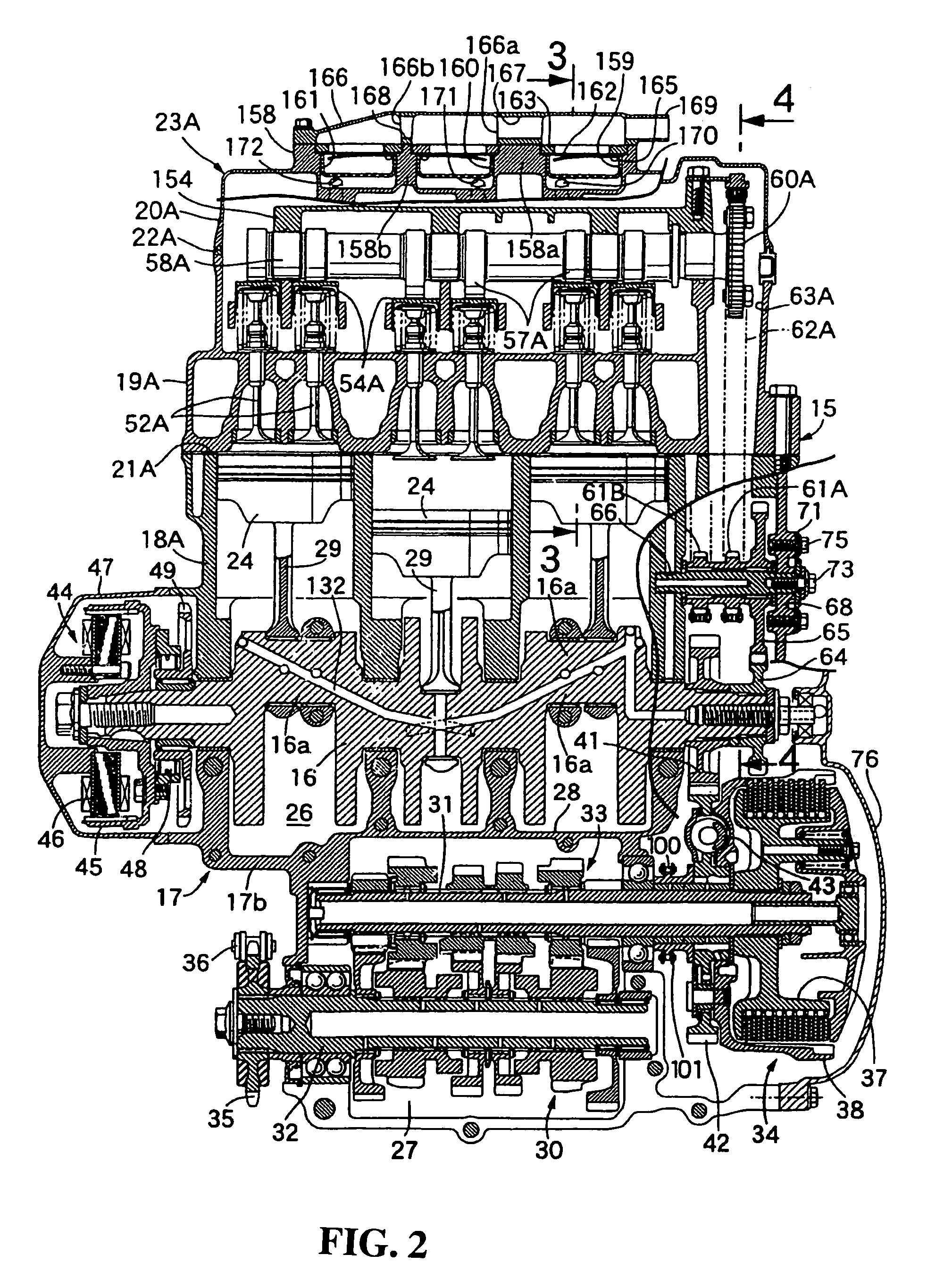

Engine and personal watercraft equipped with engine

InactiveUS6889651B2Efficient arrangementEfficiently dead spacePower plants using condensersLubrication of auxillariesCylinder headFuel tank

Owner:KAWASAKI MOTORS LTD

Oil strainer support structure in engine

ActiveUS7261079B2Small sizeIncrease weightLubrication of auxillariesLubricant conduit arrangementsCrankcaseEngineering

In an engine wherein an upper end portion of a casing of an oil strainer disposed within an oil pan is supported on a crank case side and a suction port is formed in a lower end of the casing whose lower portion is formed in a funnel shape, the oil strainer is supported firmly while preventing an increase in weight and size of the engine and an increase in the number of parts. A plurality of vertically long plate-like strainer support portions are integrally formed on a lower side face of a casing of an oil strainer for abutting against and for being supported by the bottom of an oil pan.

Owner:HONDA MOTOR CO LTD

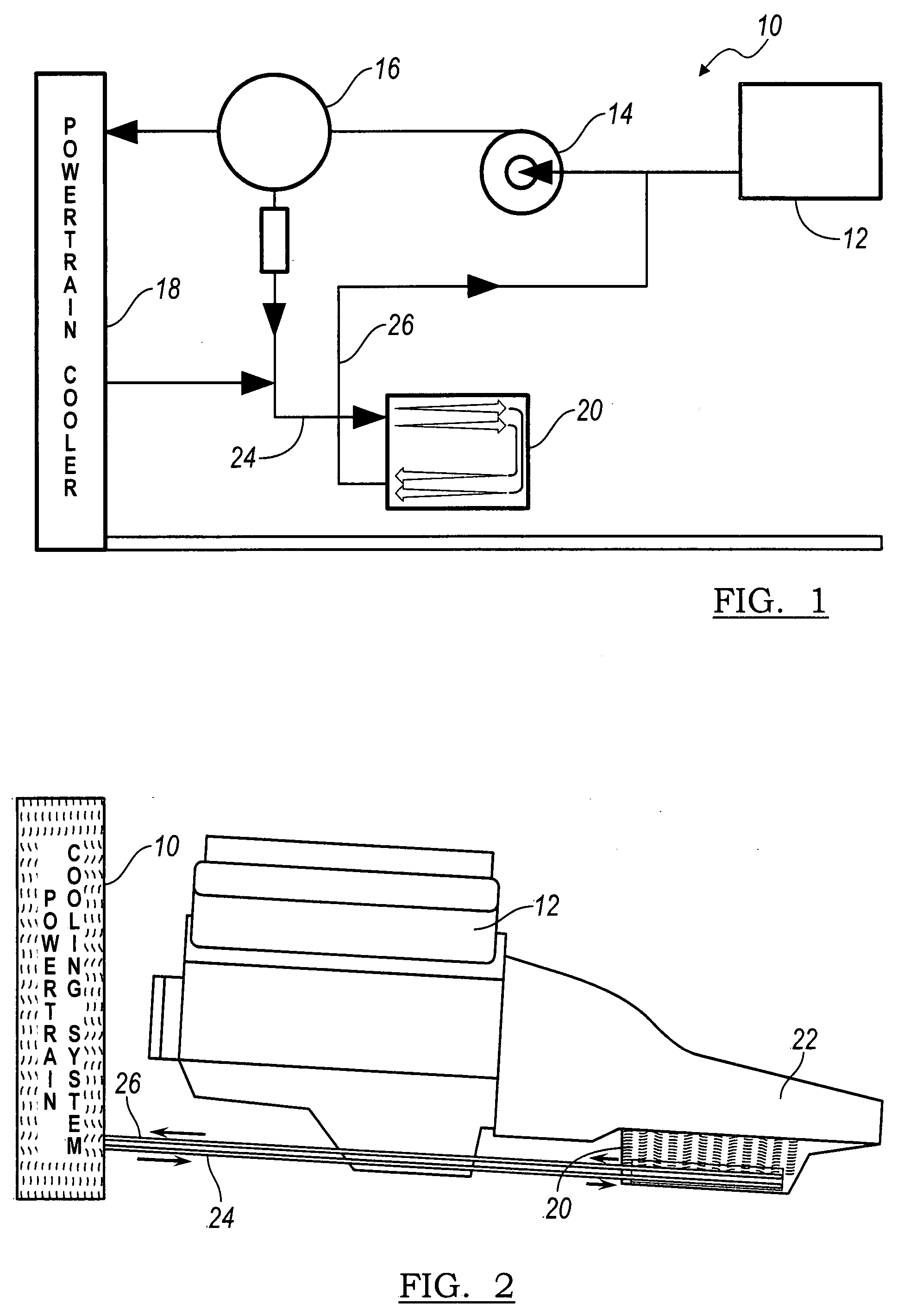

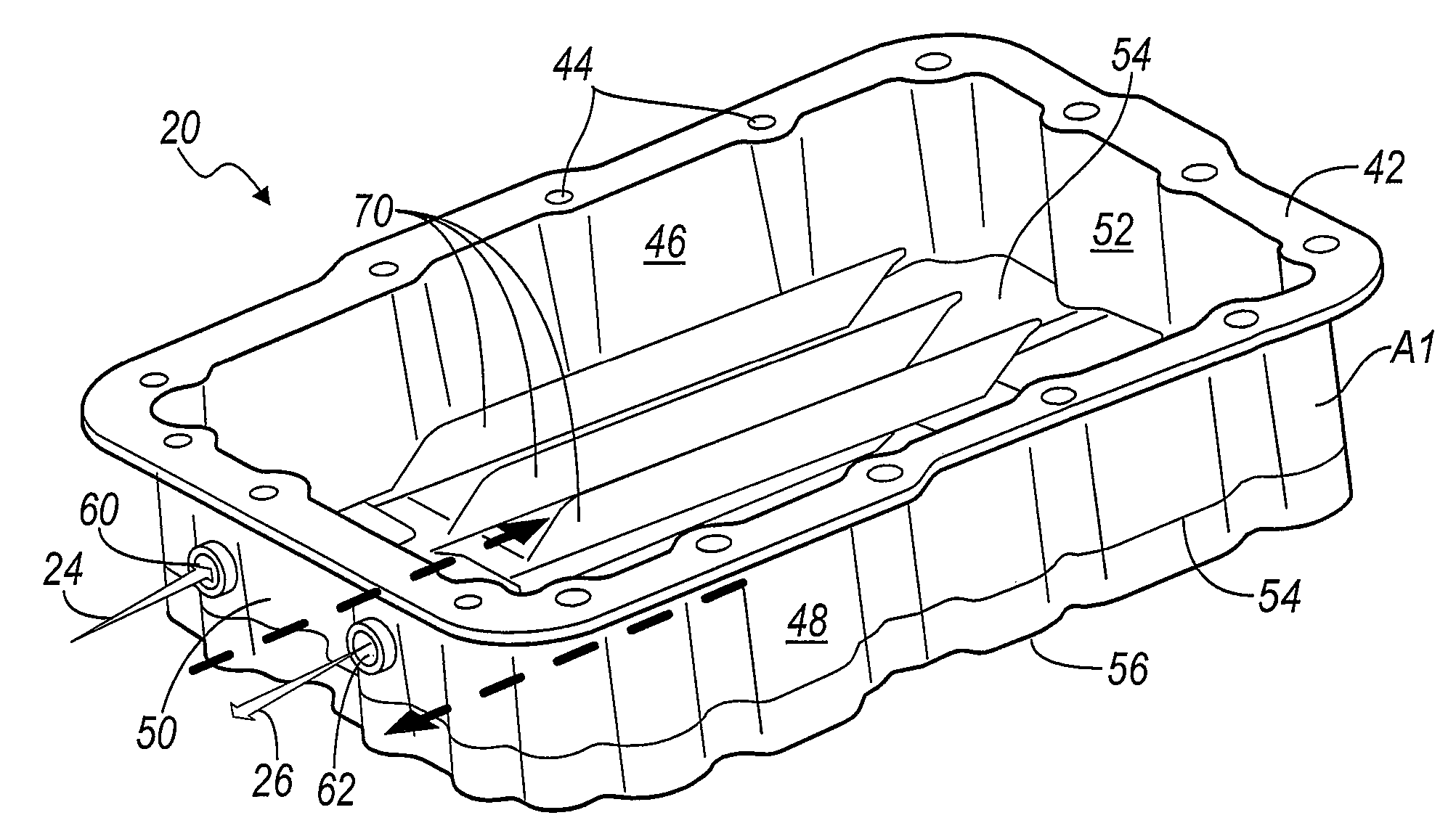

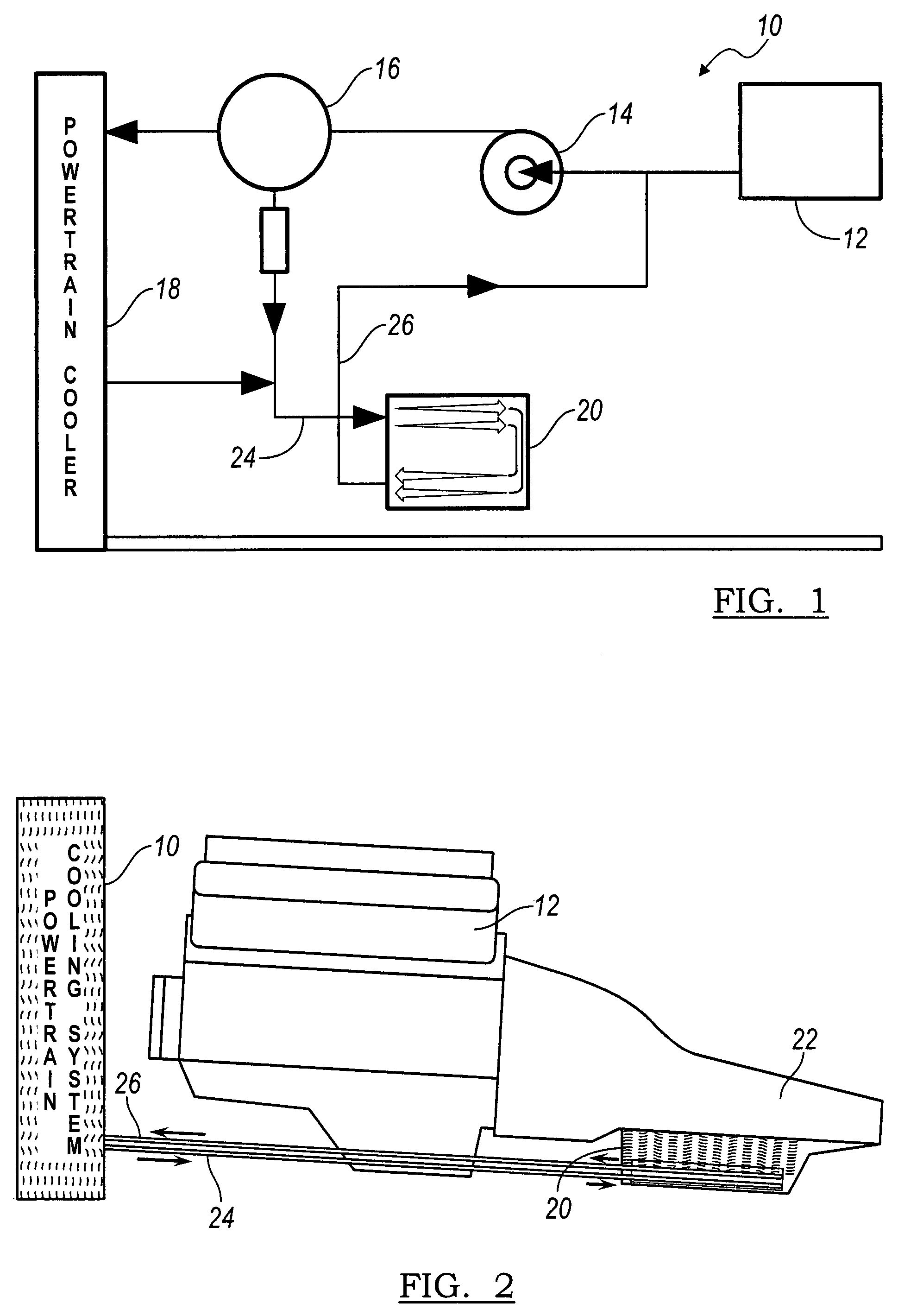

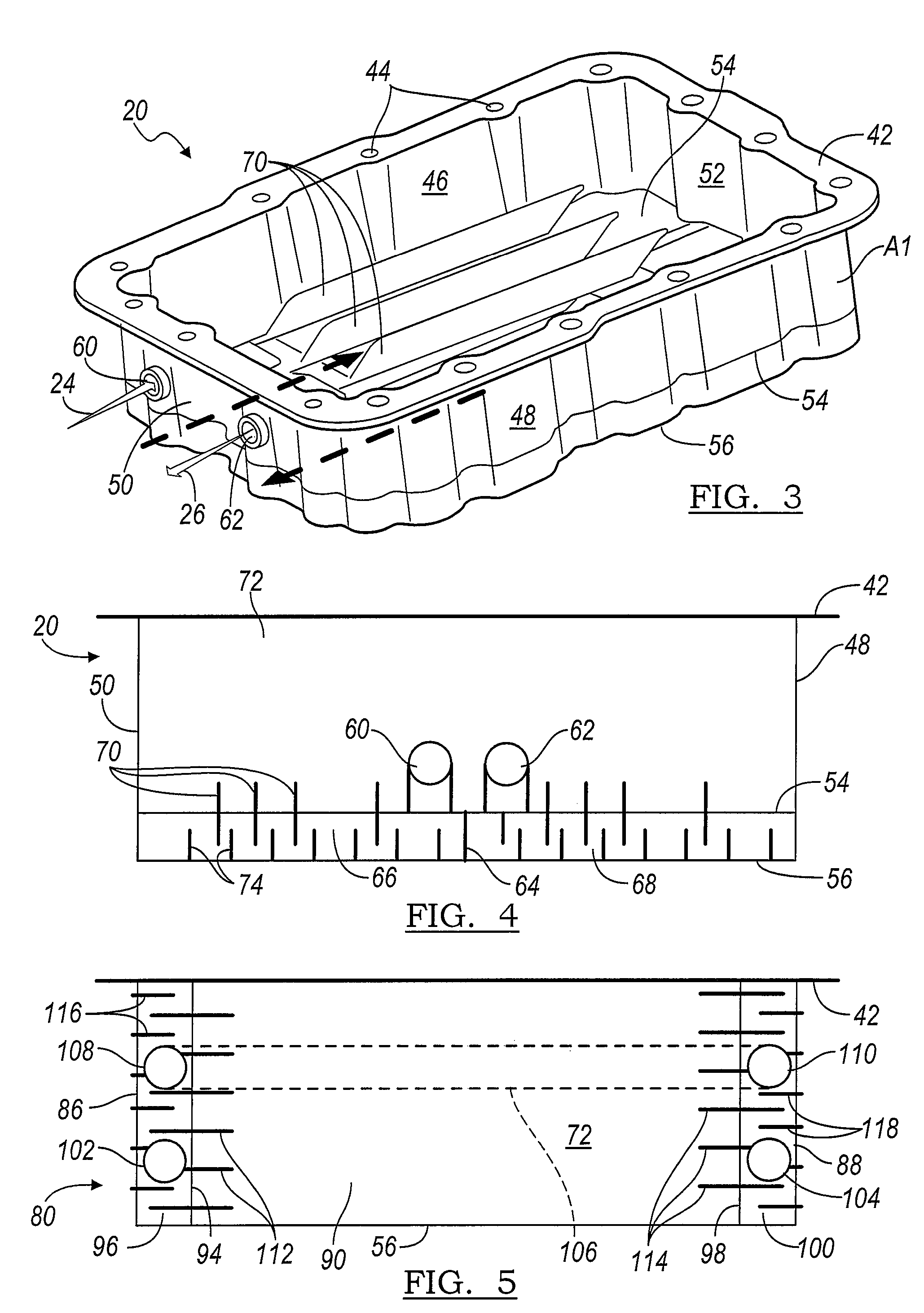

Transmission oil pan

InactiveUS20080257625A1Guaranteed normal transmissionEasy to operateOilsumpsSuperstructure subunitsEngineeringCoolant

An oil pan includes a chamber for containing a liquid, a first passage for containing a coolant and forming a first flow path along a length of the chamber, including a first surface located between the chamber and the first passage, and a second passage for containing the liquid coolant, communicating with the first passage and forming a second flow path along a length of the chamber, including a second surface located between the chamber and the second first passage.

Owner:FORD GLOBAL TECH LLC

Oil Pan and Lubricating Device

InactiveUS20080210491A1Reduce the temperatureSimple configurationCrankshaftsOperating means/releasing devices for valvesEngineeringCylinder block

An oil pan is provided with an oil pan separator that partitions a first chamber that communicates with a moving part inside a cylinder block and a second chamber outside the first chamber. A communicating hole is provided to a bottom panel of the oil pan separator. The communicating hole is shielded from a strainer.

Owner:TOYOTA JIDOSHA KK

Oil pan structure

An oil pan structure is provided that can prevent overheating when the temperature of oil is high, and can rapidly raise the temperature when the temperature of the oil is low. The oil pan structure includes: an oil pan main body; a partitioning wall that partitions the inside of the oil pan main body into a first area and a second area; a plate-shaped baffle plate that is provided at an upper portion of the oil pan main body and inclines downward from the first area toward the second area. The oil pan structure further includes: an oil retaining portion at a lower portion of the second area and an oil cooling portion at a lower portion of the first area, at the bottom wall of the oil pan main body; an upper communication opening that communicates an upper surface side and a lower surface side thereof in the baffle plate; a lower communication opening at a lower end side of the partitioning wall that communicates the first area and the second area as well as causes oil that has fallen into the first area after passing through the upper communication opening to flow into the second area via the oil cooling portion.

Owner:TOYOTA BOSHOKU KK

Transmission oil pan

InactiveUS7637337B2Guaranteed normal transmissionEasy to operateOilsumpsSuperstructure subunitsEngineeringMechanics

An oil pan includes a chamber for containing a liquid, a first passage for containing a coolant and forming a first flow path along a length of the chamber, including a first surface located between the chamber and the first passage, and a second passage for containing the liquid coolant, communicating with the first passage and forming a second flow path along a length of the chamber, including a second surface located between the chamber and the second first passage.

Owner:FORD GLOBAL TECH LLC

Dual-chamber type oil pan and engine equipped with same

InactiveUS7654241B2Rapid temperatureEffectively prevented from being suckedCasingsOilsumpsEngineeringCylinder block

Owner:TOYOTA JIDOSHA KK

Dual-Chamber Type Oil Pan and Engine Equipped with Same

Owner:TOYOTA JIDOSHA KK

Oil pan for an internal combustion engine

InactiveUS20070170390A1Increase self-locking abilitySimple designCapsOperating means/releasing devices for valvesEngineeringInternal combustion engine

Owner:MANN HUMMEL GMBH

Oil Pan Apparatus

InactiveUS20080083586A1Problem is exacerbatedCrankshaftsProportioning devicesThermostatOil temperature

An oil temperature sensor is externally mounted on a side plate of an oil pan cover that constitutes an external cover for an oil pan apparatus. The oil temperature sensor can output a signal in accordance with the oil temperature prevailing near a thermostat valve apparatus in a second chamber. If the second chamber oil temperature rises immediately after startup of an engine, a CPU judges that an open valve failure has occurred, that is, the thermostat valve apparatus is stuck open. If the oil temperature of the second chamber is not raised when an adequate amount of time has elapsed after the end of a warm-up operation, the CPU judges that a closed valve failure has occurred, that is, the thermostat valve apparatus is stuck closed.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com