Processing method of hot sprayed gradient coatings based on time after time laser refusing

A laser remelting and gradient coating technology, applied in coating, device for coating liquid on surface, surface pretreatment, etc., can solve problems such as effective remelting and effective bonding, improve bonding performance, overcome grain length, etc. Larger, less impactful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

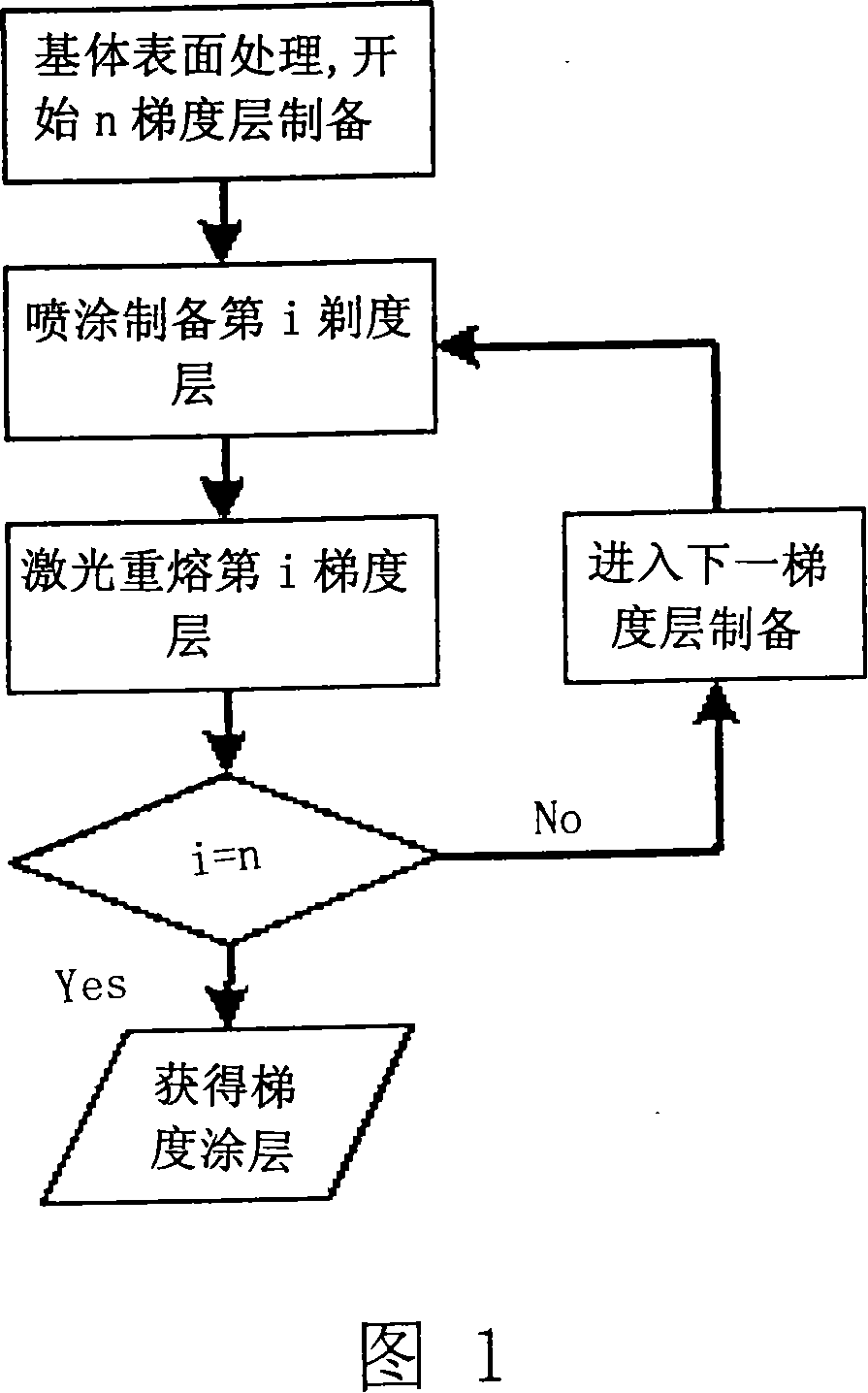

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] As shown in Figure 1.

[0025] A thermal spray gradient coating processing method based on multiple laser remelting, the steps are:

[0026] First, the surface of the substrate is purified and activated;

[0027] Secondly, spraying the first transition material on the surface of the substrate by using a thermal spraying device to obtain the first transition coating;

[0028] Third, after the transitional coating is cooled, use a high-power laser to perform the first laser remelting treatment on the obtained coating to achieve the metallurgical bond between the coating and the substrate;

[0029] Fourth, spray a second transition material on the surface of the first transition coating after laser remelting to prepare a second transition coating;

[0030] Fifth, use the laser again to perform a second laser remelting treatment on the resulting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com