Neutral cleaning agent and preparation method thereof

A cleaning agent and neutral water technology, applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of high surface tension, poor wettability of narrow gaps, etc., to reduce surface tension, good Cleaning effect, effect of improving washing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

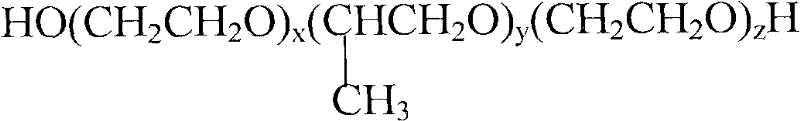

Method used

Image

Examples

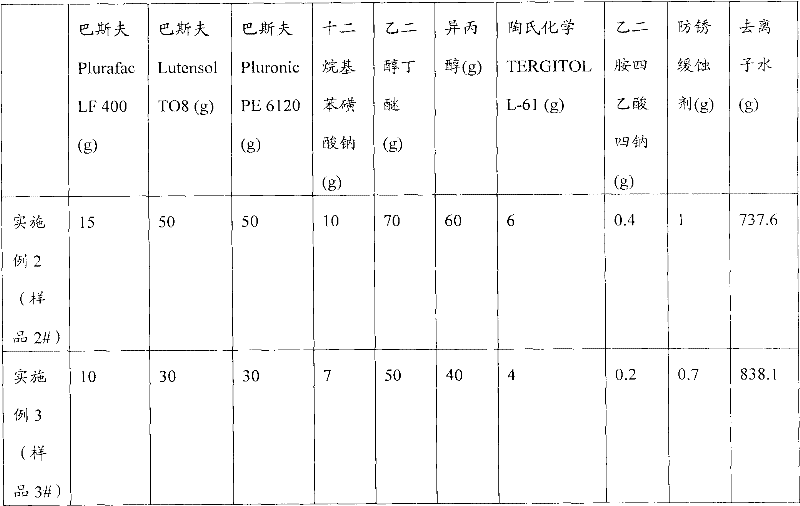

Embodiment 1

[0058] Weigh respectively fatty alcohol alkoxy surfactant (BASF Plurafac LF 400) 5g, fatty alcohol polyoxyethylene ether surfactant (BASF Lutensol TO8) 10g, polyether surfactant (BASF Pluronic PE 6120) 10g, Sodium dodecylbenzene sulfonate 5g, butyl glycol ether 30g, isopropanol 20g, defoamer (Dow Chemical TERGITOL L-61) 2g, then add the above-mentioned raw materials in the stirrer. 458.7 g of deionized water was added into the stirrer, and then the resulting mixture was stirred for 30 minutes at a stirring speed of 100 rpm. Add 458.7g deionized water, 0.1g tetrasodium ethylenediaminetetraacetate, 0.5g rust and corrosion inhibitor (5-methylbenzotriazole and sodium silicate ratio of 5: 1 mixture) in the stirrer , and then continue to stir the resulting mixture at a stirring speed of 100 rpm for 2.5 hours until uniformly mixed. Get sample 1#.

[0059] Using PHS-3C precision PH meter (Shanghai Jinmai Instrument Co., Ltd.), DDS-307 conductivity meter (Shanghai Jinmai Instrument C...

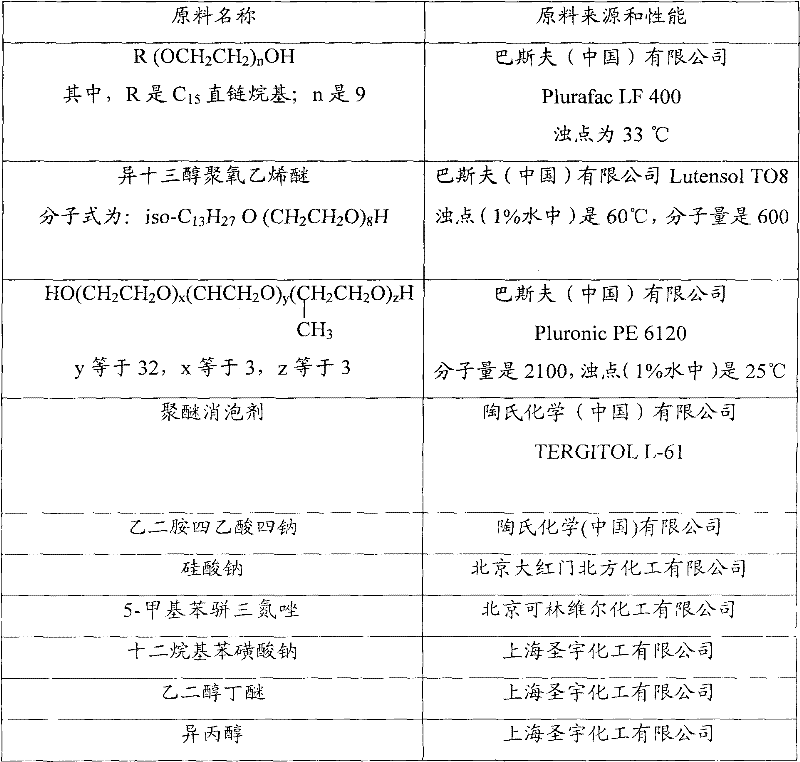

Embodiment 2-3

[0061] In Example 2-3, the cleaning agent was prepared using basically the same process conditions as in Example 1, and the changed material parameters are shown in Table 1.

[0062] Table 1

[0063]

[0064] Adopt the method identical with embodiment 1 to measure, and the pH of sample 2# is 7.8, and conductivity is 1.23 μ s, and specific gravity is 1.02 g / ml; The pH of sample 3 # is 7.5, and conductivity is 1.2 μ s, and specific gravity is 1.02 g / ml ml.

Embodiment 4

[0066] Sample 3CTI certification testing of RoHS six hazardous substances

[0067] testing base

[0068]

[0069] Test results

[0070] Test items

content

Lead (Pb)

N.D.

Cadmium (Cd)

N.D.

Mercury (Hg)

N.D.

Hexavalent Chromium (Cr(VI))

N.D.

Polybrominated biphenyls (PBBs)

N.D.

Polybrominated diphenyl ethers (PBDEs)

N.D.

[0071] Note: -N.D. = not detected (less than method detection limit)

[0072] -mg / kg=ppm=parts per million

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com