Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106 results about "Methyl diethanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

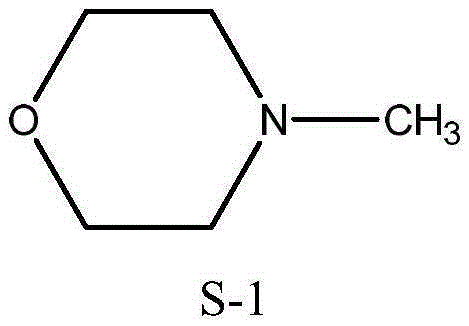

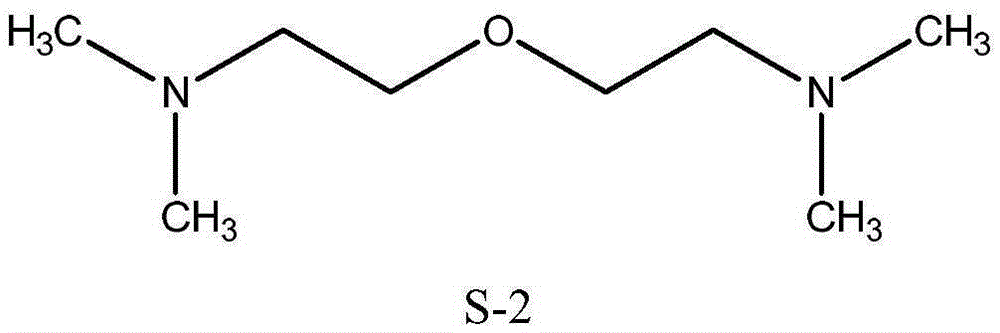

Methyl diethanolamine, also known as N-methyl diethanolamine and more commonly as MDEA, is the organic compound with the formula CH₃N(C₂H₄OH)₂. It is a colorless liquid with an ammonia odor. It is miscible with water, ethanol and benzene. A tertiary amine, it is widely used as a sweetening agent in chemical, oil refinery, syngas production and natural gas.

Absorbing liquid for eliminating sulfide from gas mixture

InactiveCN1421264AReduce processing stepsEconomical desulfurization methodDispersed particle separationSulfur preparation/purificationSulfolaneMorpholine

The present invention belongs to gas producing technology. The absorbing liquid for eliminating sulfide from gas mixture includes main absorbent comprising steric hindrance amine and N-methyl diethanolamine; cosolvent of one or several of sulfolane, N-methyl pyrrolidine, polyglycol dialkyl ether, morpholine and its derivative; catalyst of one or several of C2-C12 alkanolamine, piperazine and its derivative, quinoline, urea and metal phthalocyanine complex. Using the absorbing liquid can eliminate H2S, COS, mercaptan, thioether and other sulfide in less steps.

Owner:江苏蓝电环保股份有限公司

Metal rust-preventive oil comprising butyl acrylate

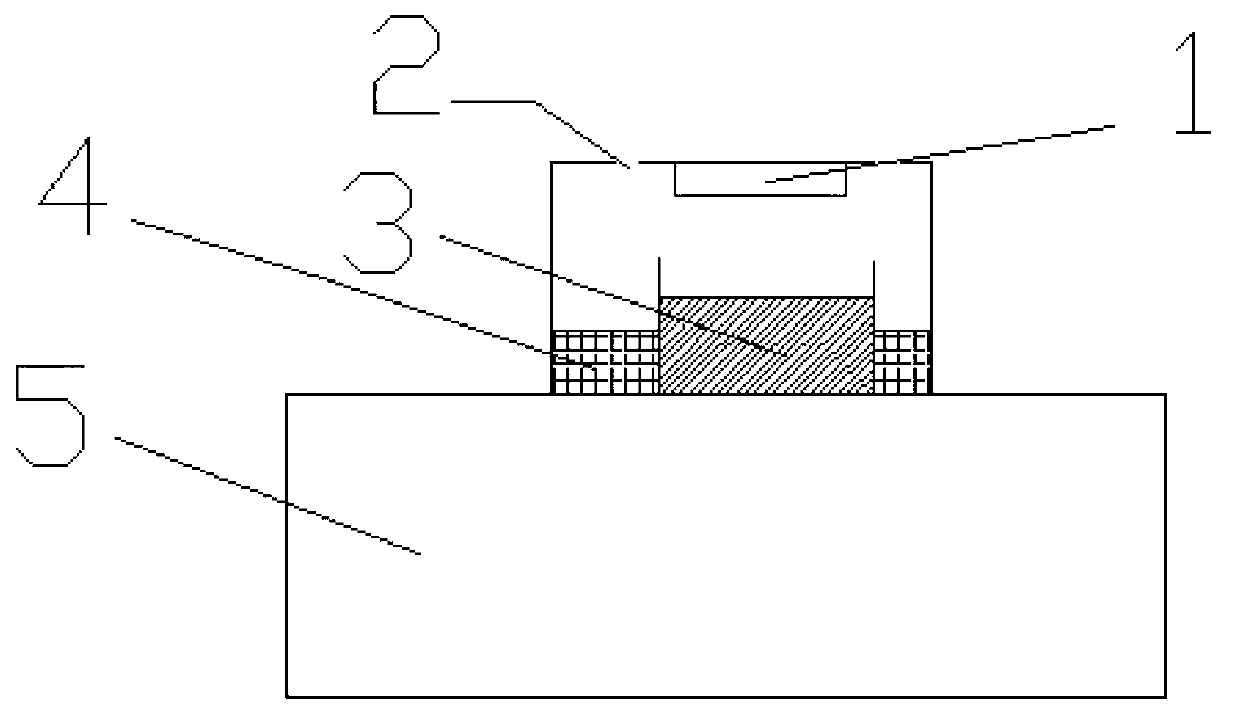

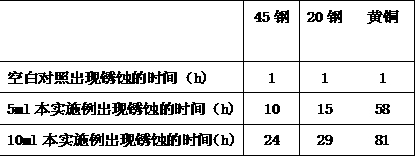

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

High-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas

InactiveCN101844035AHigh mercaptan removalHigh acid gas loadDispersed particle separationSulfolaneTert-Butylamine

The invention discloses a high-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas, which comprises serotonin, wherein the serotonin consists of N-methyl diethanolamine and ethoxy ethanol tert-butylamine, and also comprises sulfolane and N-Hydroxyethyl piperidine. The weight ratio of the serotonin in the desulfurizing agent is 70 to 85 percent; the weight ratio of the sulfolane in the desulfurizing agent is 5 to 10 percent; and the weight ratio of the N-Hydroxyethyl piperidine in the desulfurizing agent is 10 to 20 percent. By mixing physical and chemical solvent and abstracting the advantages of the physical and chemical solvent, so on the premise that the removal effect of H2S is ensured, the organic sulfur can be removed high efficiently; and the desulfurizing agent has large acid gas load, strengthens the reaction speed between the H2S and MDEA and TBEE, so the consumption of the desulfurizing agent is small during the gas purification process, and the regeneration energy consumption of the solvent is low.

Owner:四川省精细化工研究设计院

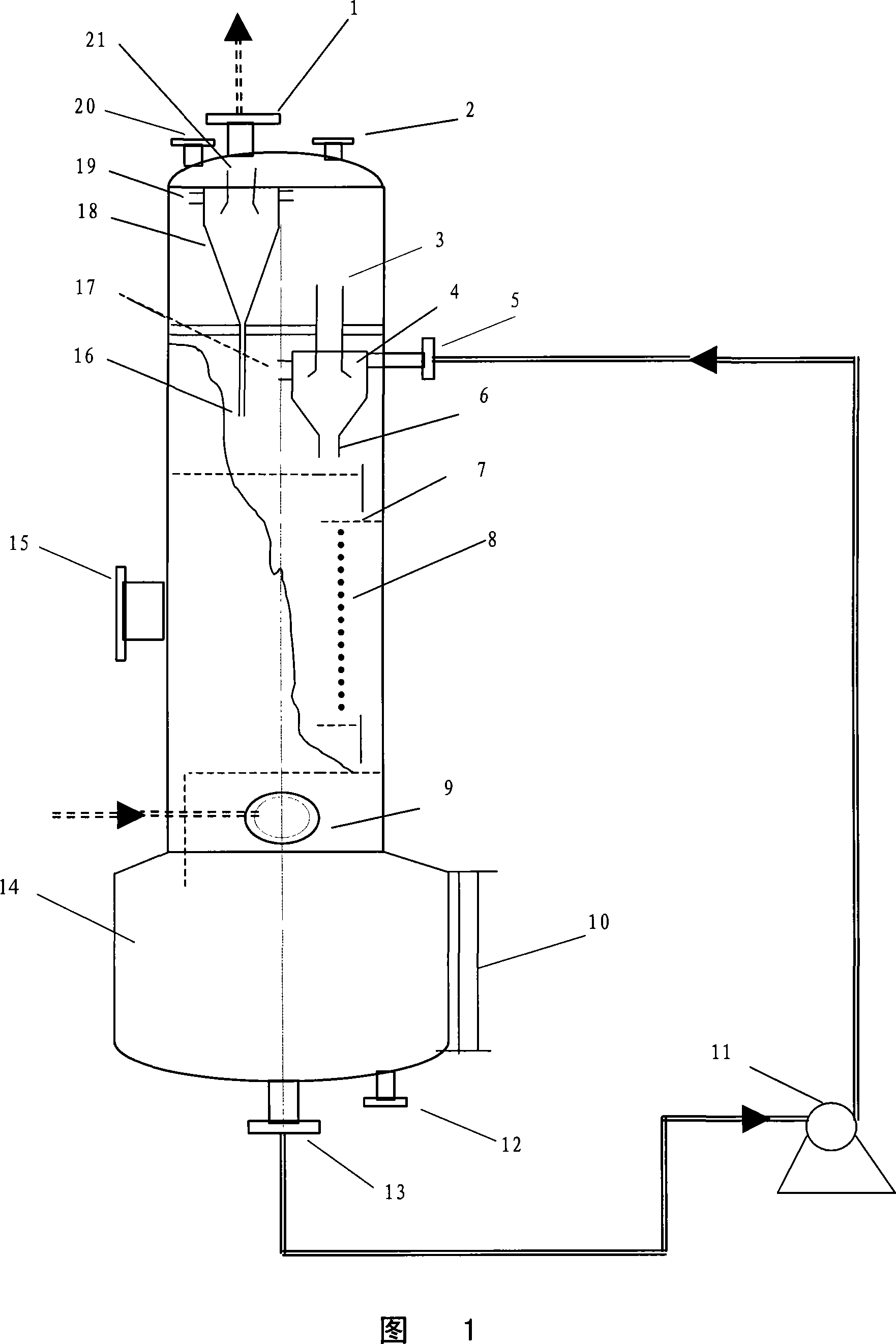

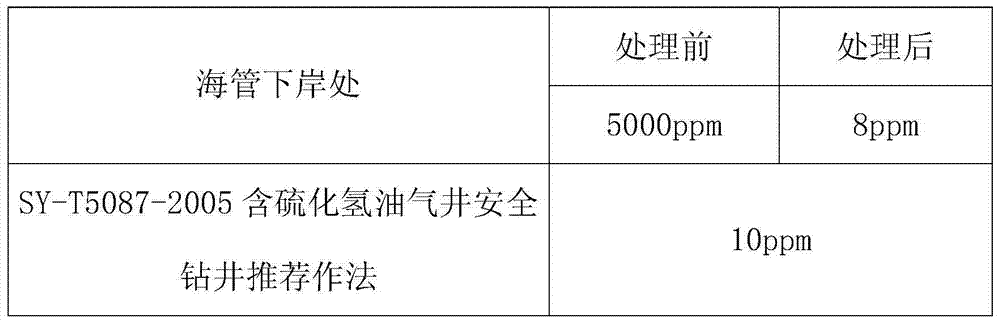

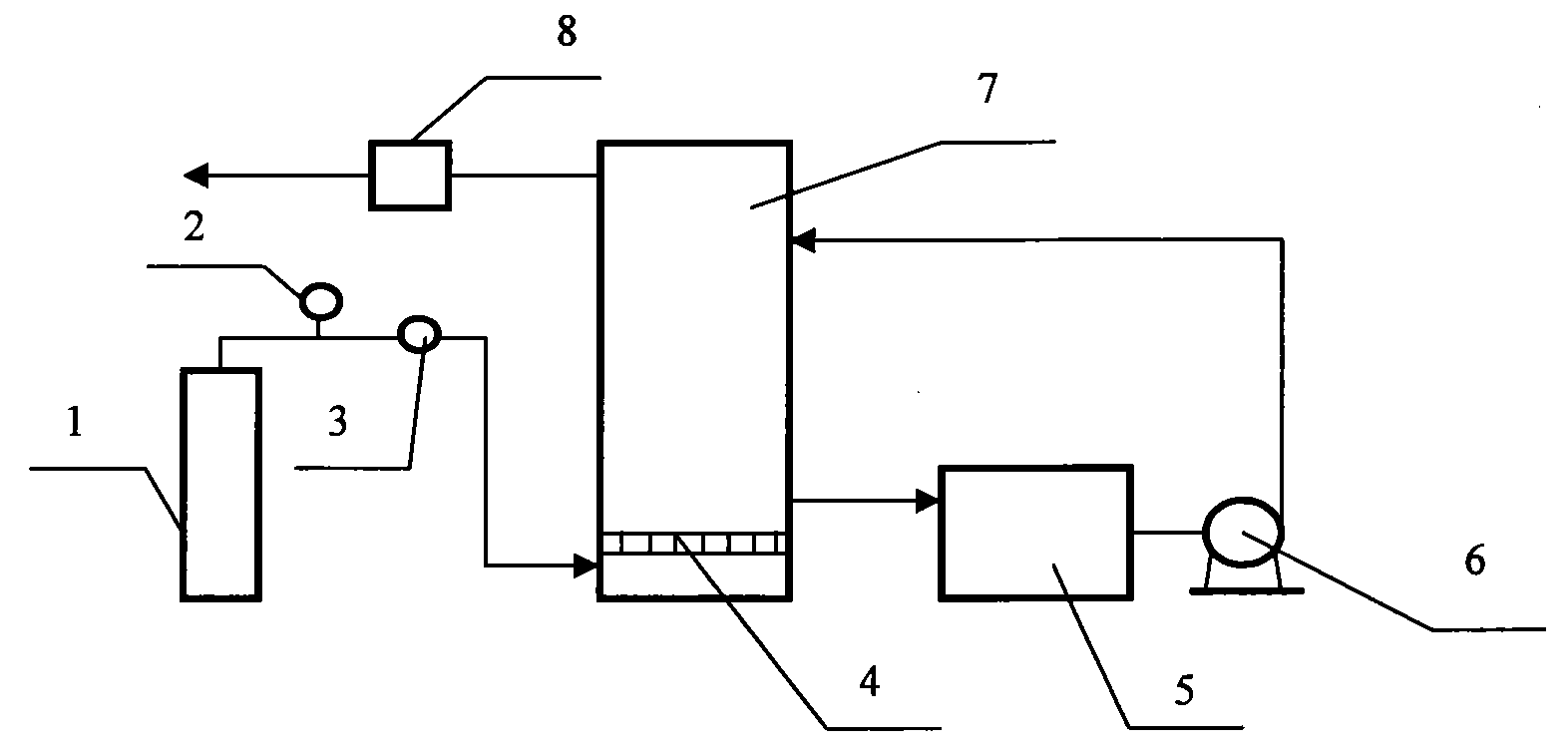

Method and device for removing hydrogen sulphide from mixture gas containing low-concentration hydrogen sulphide

ActiveCN101062460AEliminate bad odorSolve absorptionDispersed particle separationProduct gasLow density

The invention provides a H2s removing method from the gas mixture, comprising a provision of absorption of liquid, with the solution selected from N-methyl diethanolamine, aminoethanol and their mixture, under 0. 05-0. 30MPa absolute pressure, keeping the 18-42deg.C absorption liquid contact with the 20-52deg.C low density H2S gas, absorbing mixture gas through countercurrent and vortex, lowering the mixture gas H2S into 10ppm or even lower, separating the mixture gas for swirl gas and liquid separation. It also provides a low density H2S gas mixture to remove it.

Owner:EAST CHINA UNIV OF SCI & TECH

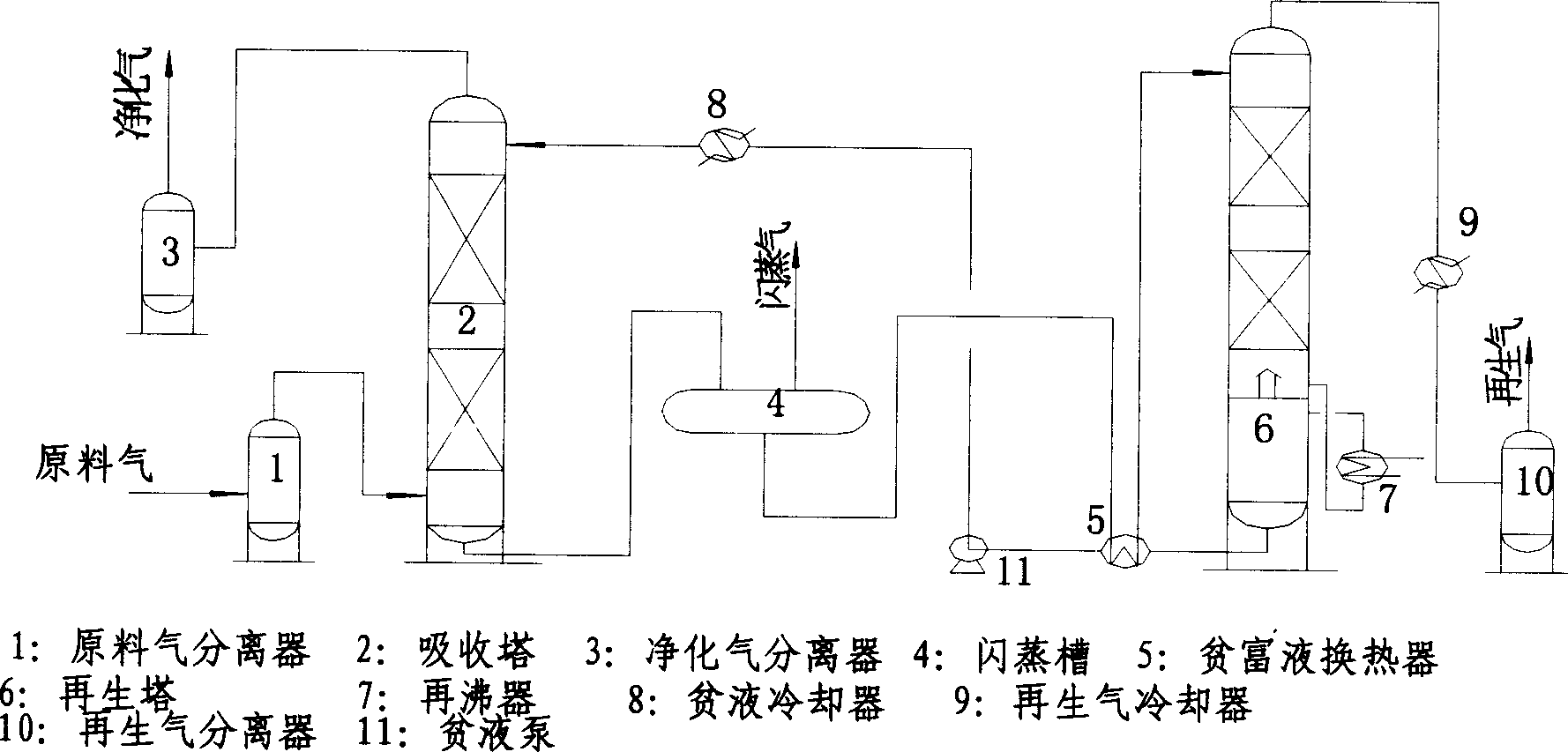

Solvent for eliminating H2S from gas mixture

InactiveCN1887406APromote absorptionImprove the desorption effectDispersed particle separationSulfolaneOrganic sulfide compound

The present invention is method of adding one kind of secondary amine and one kind of organic amine with steric effect into water or sulfolane solution of N-methyl diethanolamine to obtain the activator for removing H2S from gas mixture with or without CO2. The present invention provides two solution recipes. The recipe I for the solution suitable for removing H2S from gas mixture containing no or less organic sulfide consists of N-methyl diethanolamine 30-50 wt%, secondary amine 1-10 wt%, steric amine 1-15 wt% and water for the rest. The recipe II for the solution suitable for removing H2S from gas mixture containing organic sulfide consists of N-methyl diethanolamine 30-40 wt%, secondary amine 1-5 wt%, steric amine 1-15 wt%, water 5 wt% and sulfolane for the rest.

Owner:HUAXI CHEM INST CHENGDU CITY

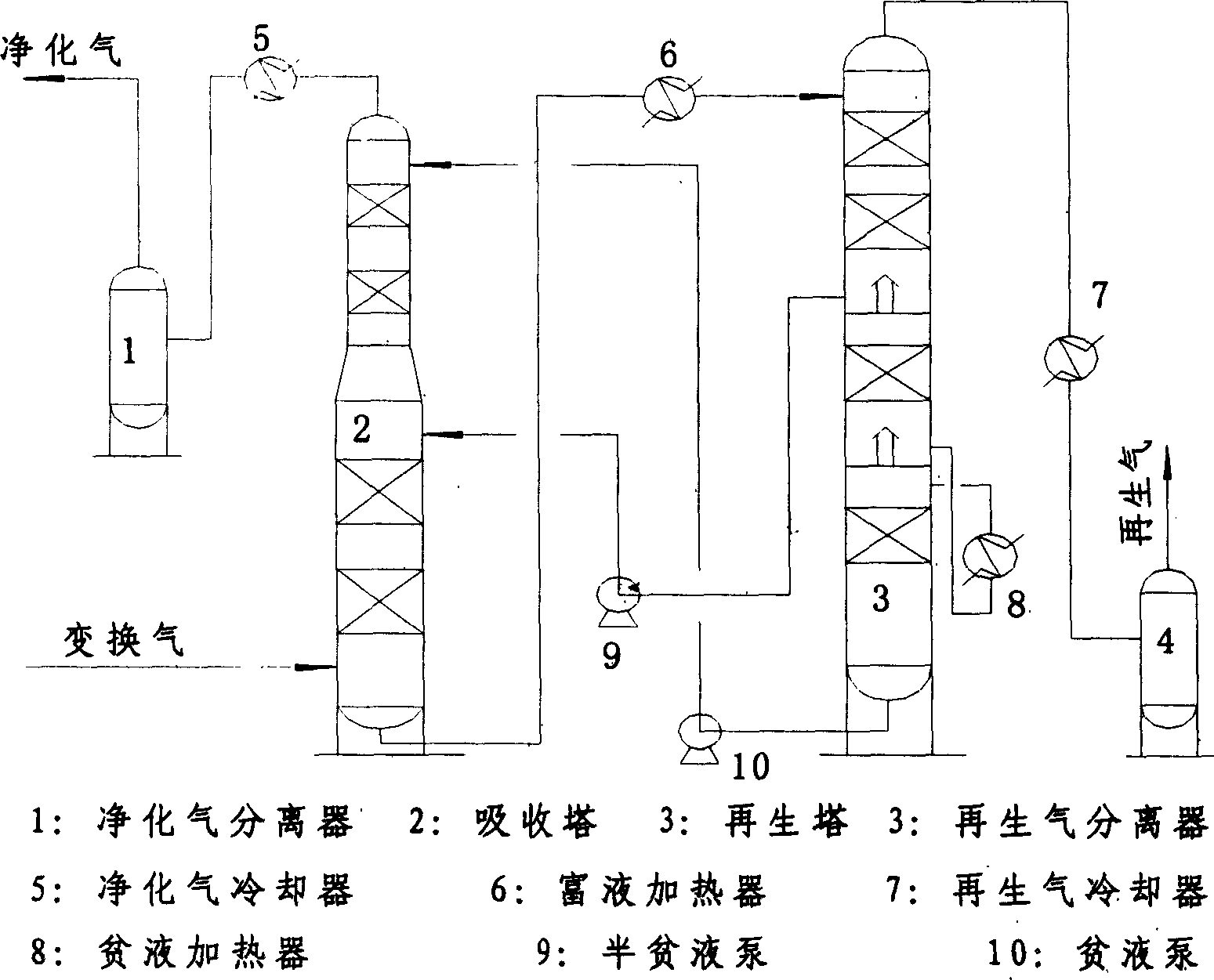

Solvent for eliminating CO2 from gas mixture

The present invention is method of adding diazacyclo compound and organic amine with steric effect into N-methyl diethanolamine to obtain the activator for removing CO2 from gas mixture. The present invention provides two solution recipes. The recipe I for the solution suitable for removing CO2 from gas mixture of low operation pressure consists of N-methyl diethanolamine 30-50 wt%, substituted cyclopentyl dinitride 1-10 wt% and steric amine 1-5 wt%. The recipe II the solution suitable for removing CO2 from gas mixture of high operation pressure consists of N-methyl diethanolamine 30-60 wt%, cyclohexyl dinitride 1-8 wt% and steric amine 1-15 wt%.

Owner:HUAXI CHEM INST CHENGDU CITY

Heavy grease stain environment-friendly type water base cleaning compound

InactiveCN103834487AGood decontamination effectGood compatibilityOrganic detergent compounding agentsSurface-active detergent compositionsWater basedTriclosan

The invention discloses a heavy grease stain environment-friendly type water base cleaning compound comprising 10-15% of surfactant, 1-3% of additive, 1-5% of antiseptic, 3-5% of organic amine and remaining tap water; the ingredient of the surfactant comprises 4-5% of aliphatic acid methyl esters ethoxylate, 2-3.5% of APG, 1-3% of fatty alcohol polyoxyethylene ether sodium sulfate (AES), 0.5-1% of straight chain sodium alkyl benzene sulfonate (LAS) and 0.5-2% of aliphatic acid methyl esters ethoxylate; the additive is one or more from a group formed by sodium citrate, citric acid, lactic acid and DL-malic acid; the organic amine is one or more from a group formed by triethanolamine, n-butylamine, diethanolamine and N-methyl diethanolamine; the antiseptic at least is triclosan or tetrachloro isophthalonitrile; through the said method, the heavy grease stain environment-friendly type water base cleaning compound has anti bacterium, heavy grease stain cleaning and environmental protection performances.

Owner:SUZHOU LOTTE CHEM TECH

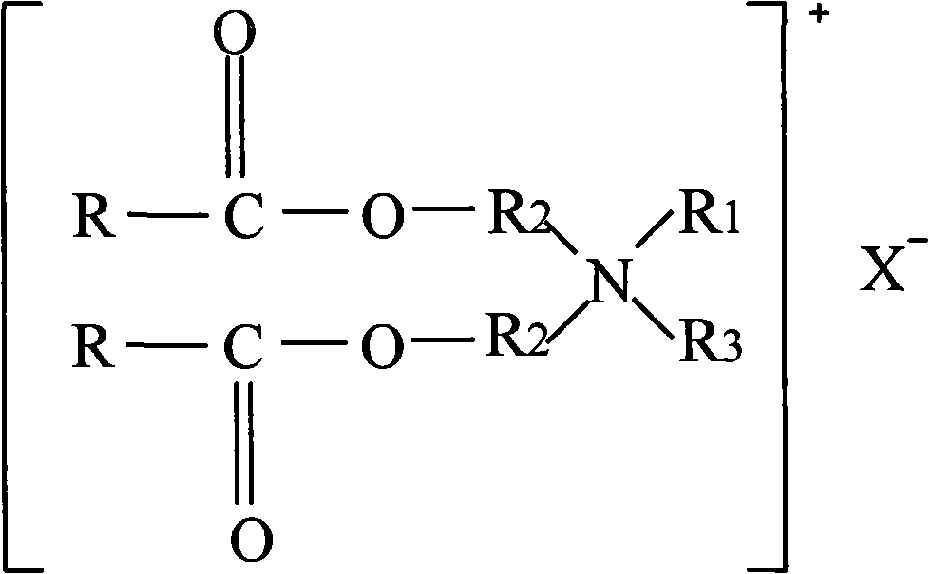

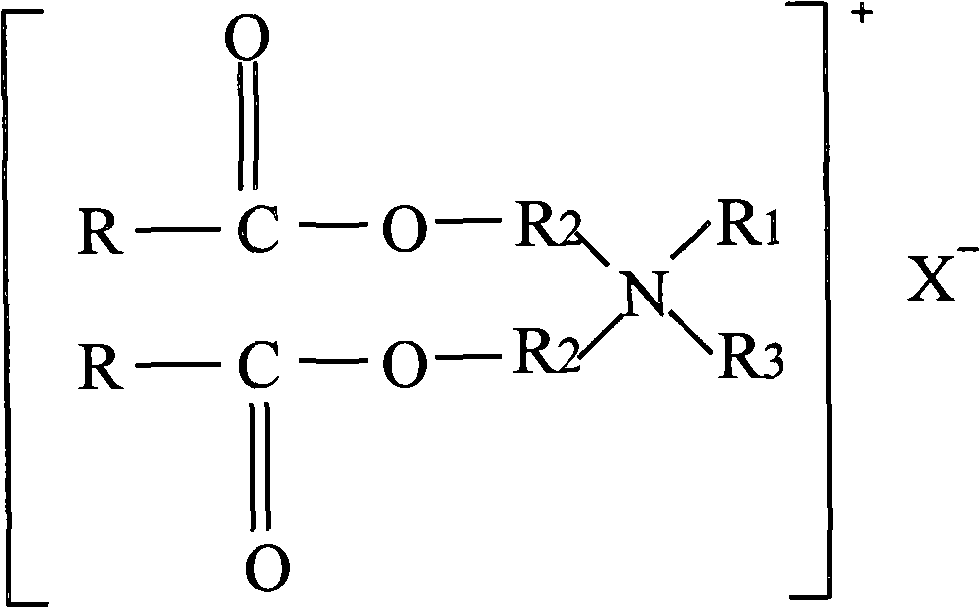

Method for synthesizing dual-long-chain ester based quaternary ammonium salt

InactiveCN101575299AImprove conversion rateGood choiceBiocideOrganic compound preparationHigh concentrationCarboxylic acid

The invention relates to a method for synthesizing a dual-long-chain ester based quaternary ammonium salt, which belongs to the technical field of surfactants. The method comprises the following steps: using long-chain alkyl fatty acid to react with N-methyl diethanolamine and triethanolamine to prepare long-chain carboxylic acid based tertiary amine; and performing alkylation on the long-chain carboxylic acid based tertiary amine to prepare the dual-long-chain ester based quaternary ammonium salt. The method uses two steps of esterification reaction and continuous production, thus the raw material conversion rate is high, the selectivity is good, and the obtained product has high active matter content, light color, excellent biodegradability, low ecological toxicity and excellent environmental compatibility; and the product can improve the grade of compounding a product, is easy to be prepared into a high-concentration product, reduces the production and packing cost, and is convenient to use. The dual-long-chain ester based quaternary ammonium salt is a cationic surfactant, and the using method thereof in various aspects of fabric softeners, leather softeners, bactericides and the like is same as the using method of other cationic surfactants.

Owner:JIANGNAN UNIV

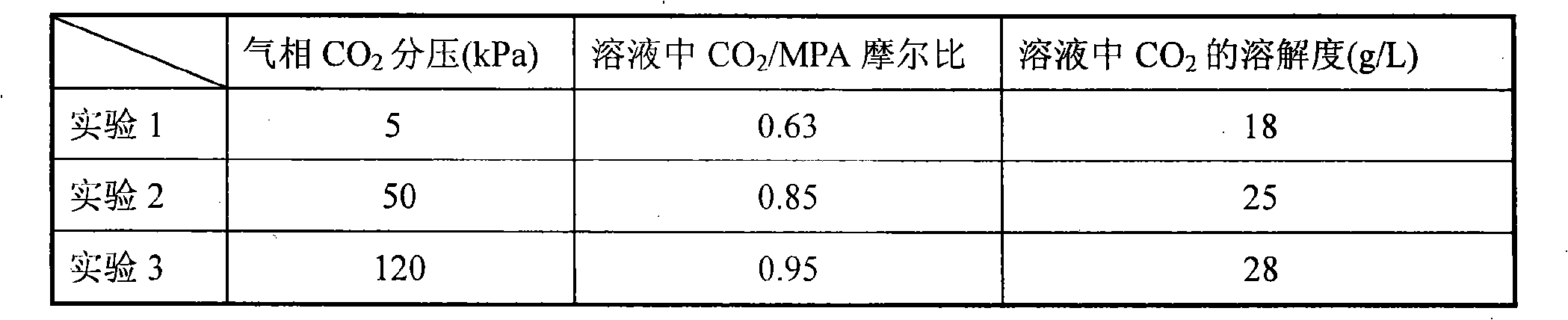

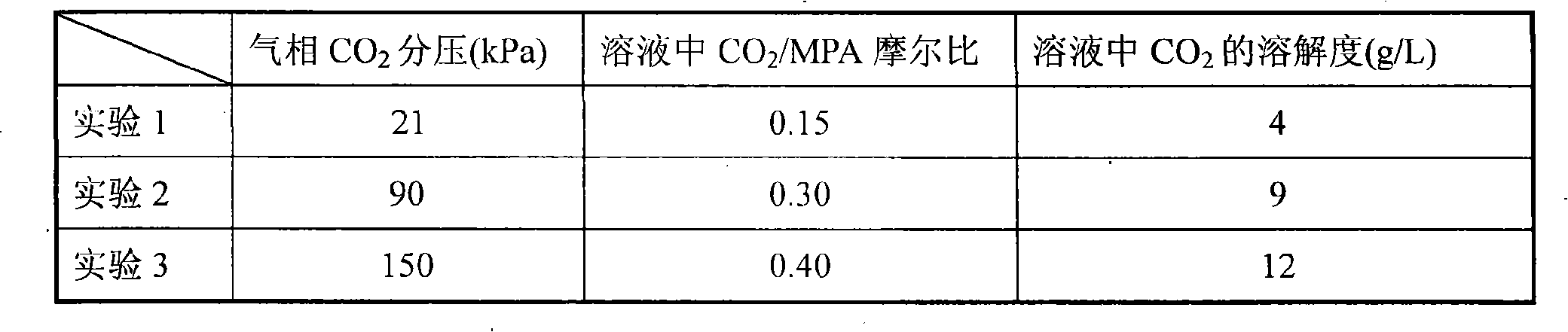

Absorbing solvent for capturing or separating carbon dioxide from gas mixture or liquid gas

The invention pertains to the field of chemical materials and in particular relates to a sorption solvent which catches or separates carbon dioxide from gaseous mixtures or liquefied gases. The solvent comprises n-propanolamine with a content range of 5-60wt% and other components with a total content range of 40-95wt%; other components comprise monoethanol amine, diethanolamine, methyl diethanolamine, diisopropanol amine, 2-amido-2-methyl-1-propyl alcohol, organic amine, water, physical solvent, inorganic salt and one or more accessory ingredients. The number of carbon atoms between the amidocyanogen and the hydroxide radical of the n-propanolamine is three; nitrogen atoms can form a hydrogen bond with the hydrogen atoms on oxygen atoms, or oxygen atoms can form a hydrogen bond with the hydrogen atoms on nitrogen atoms, thus forming a ring structure composed of six atoms; such molecular structure is similar to that of secondary amine, can reduce the formation of amino carbonates and improve the solubility and desorption degree of CO2; meanwhile, the formation of the six-element ring molecular structure increases the stability of molecular and can reduce the degradation loss of solvents in service process.

Owner:TSINGHUA UNIV

Highly selective desulfurization solvent and preparation method thereof

The invention relates to a highly selective desulfurization solvent. The highly selective desulfurization solvent is at least prepared from the raw materials: an organic amine component which is taken as a main component and consists of triethanolamine in a monoamine type, N-methyl-diethanolamine and N-hydroxyethyl piperazine in a diamines type as well as a mixed additive component consisting of a desulfurization accelerator and a defoamer, so that as the desulfurization solvent contains the organic amine component consisting of the triethanolamine, the N-methyl-diethanolamine and the N-hydroxyethyl piperazine, supplemented by the mixed additive component consisting of the desulfurization accelerator and the defoamer, by virtue of the synergistic effect among the components, when being used for treating a mixed raw gas with high carbon-sulfur ratio, the desulfurization solvent is relatively high in the selectivity for removing sulfuretted hydrogen and can be used for effectively lowering the energy consumption of a desulfurization system.

Owner:PANJIN XINANYUAN CHEM IND

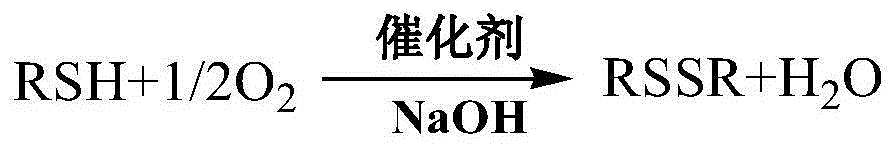

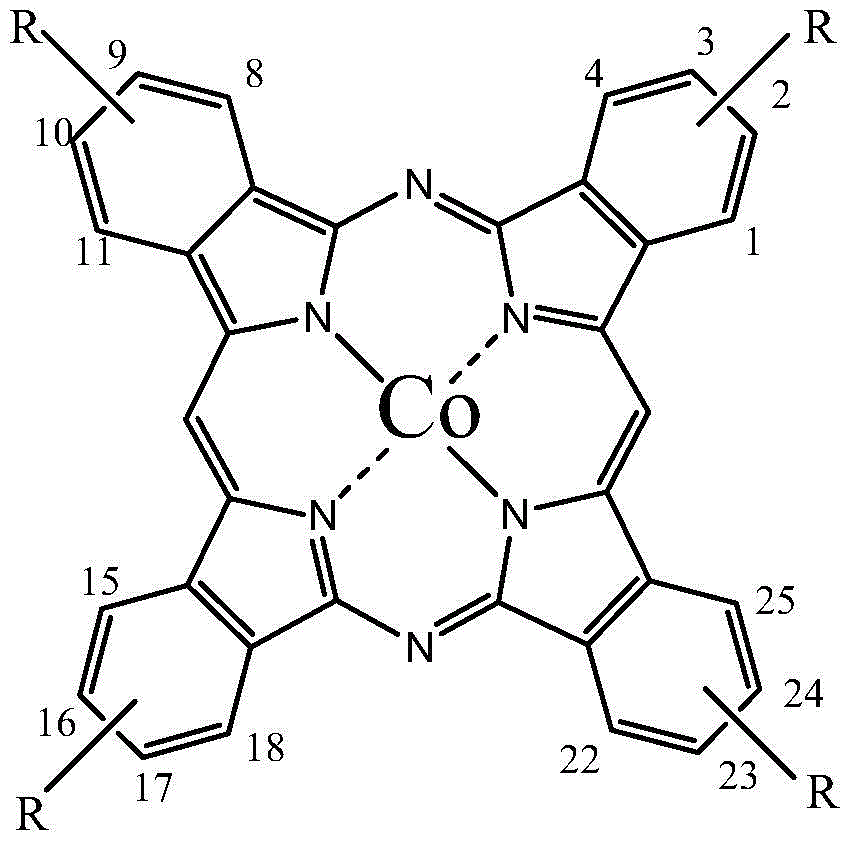

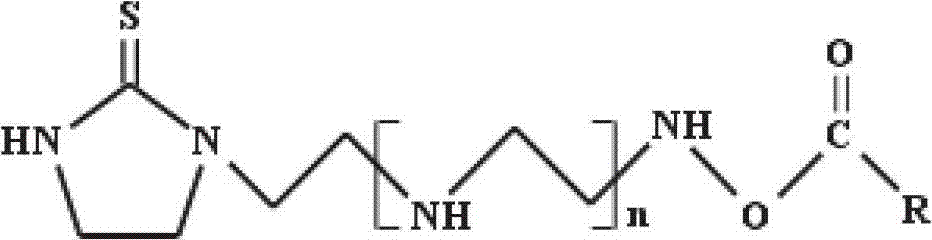

Liquid cobalt sulfonated phthalocyanine catalyst for liquefied petroleum gas mercaptan removal

ActiveCN104785296AImprove solubilityGood water solubilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPhthalocyanineCobalt

The invention discloses a liquid cobalt sulfonated phthalocyanine catalyst for liquefied petroleum gas mercaptan removal; the liquid catalyst is composed of an active component tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt, a stabilizer propylene glycol dimethyl ether, one or a combination of N-methyl diethanolamine or triethanolamine, an emulsifier octadecyl dimethyl benzyl ammonium chloride and an NaOH solution. The invention also discloses a tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt structure designed for the first time, and a catalytic conversion effect of the liquid catalyst on liquefied gas mercaptan. The catalyst active component tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt has extremely good solubility in water and alkali liquids, and has higher mercaptan removal activity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Cationic waterborne polyurethane/organic montmorillonoid composite resin and preparation method thereof

The invention discloses a cationic waterborne polyurethane / organic montmorillonoid composite resin. Organic montmorillonoid containing hydroxyl functional group is utilized as modifier and mixed with polymer polyalcohol and castor oil in an ultrasonic homogenizer for a period of time, then the mixture is dehydrated under vacuum condition, and polyisocyanates is added to prepare NCO sealed end prepolymer, and then cationic hydrophilic monomer methyl diethanolamine is added to introduce hydrophilic functional group to polyurethane molecular chain. After reaction, dibastic alcohol with small molecular weight is added for carrying out chain expansion reaction. After reaction, acetic acid is added to neutralize tertiary nitrogen atom on main molecular chain of polyurethane, so as to form ammonium base cation. After emulsification by watering, solvent with low molecular weight such as acetone and the like is removed by distillation, thus obtaining the cationic waterborne polyurethane / organic montmorillonoid composite resin.

Owner:QINGDAO UNIV OF SCI & TECH +1

Wool oil for production of fibers

The invention discloses wool oil for production of fibers. The wool oil is prepared by components including, by weight, 40-60 parts of spindle oil, 2-4 parts of lauryl polyoxyethylene ether (9), 1-2 parts of cocoyl methyl diethanolamine, 0.5-1 part of dimethyl silicone fluid, -805-10 parts of tweens, 1-2 parts of N,N-dimethyldodecylamine-N-oxide sol, 1-3 parts of sodium oleate, 1-3 parts of triethanolamine, 1-3 parts of glycerol and 0.5-1.5 parts of monododecyl potassium quercetin phosphate. The wool oil for production of fibers is capable of smoothing fibers and enabling the fibers to be soft and antistatic. Fibers treated by the wool oil are not easy to generate static electricity or anti-fuzzing during opening, combing, drawing and spinning, evenness and smoothness during slivering, roving and fine spinning are guaranteed, and further, fabrics knitted by the fibers treated with the wool oil are fine and smooth with neat and clear texture.

Owner:博罗县富得针织有限公司

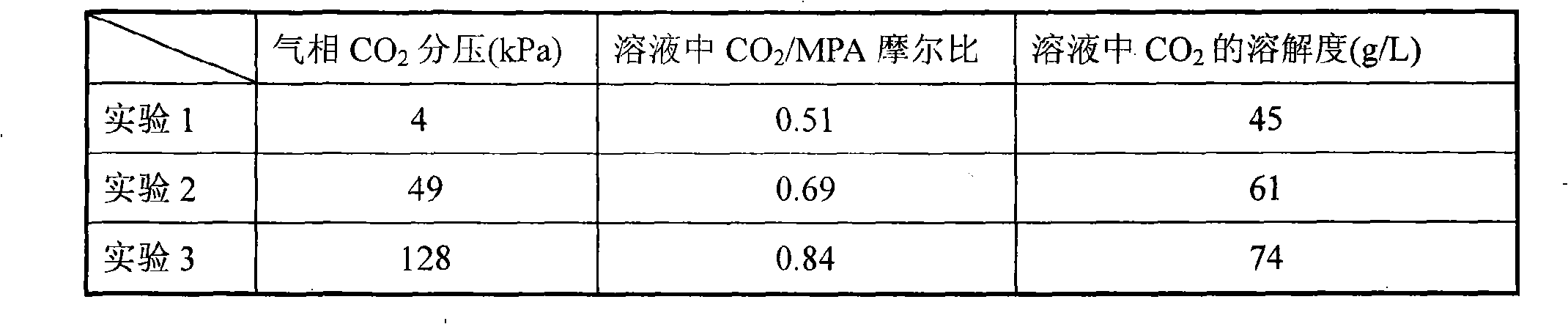

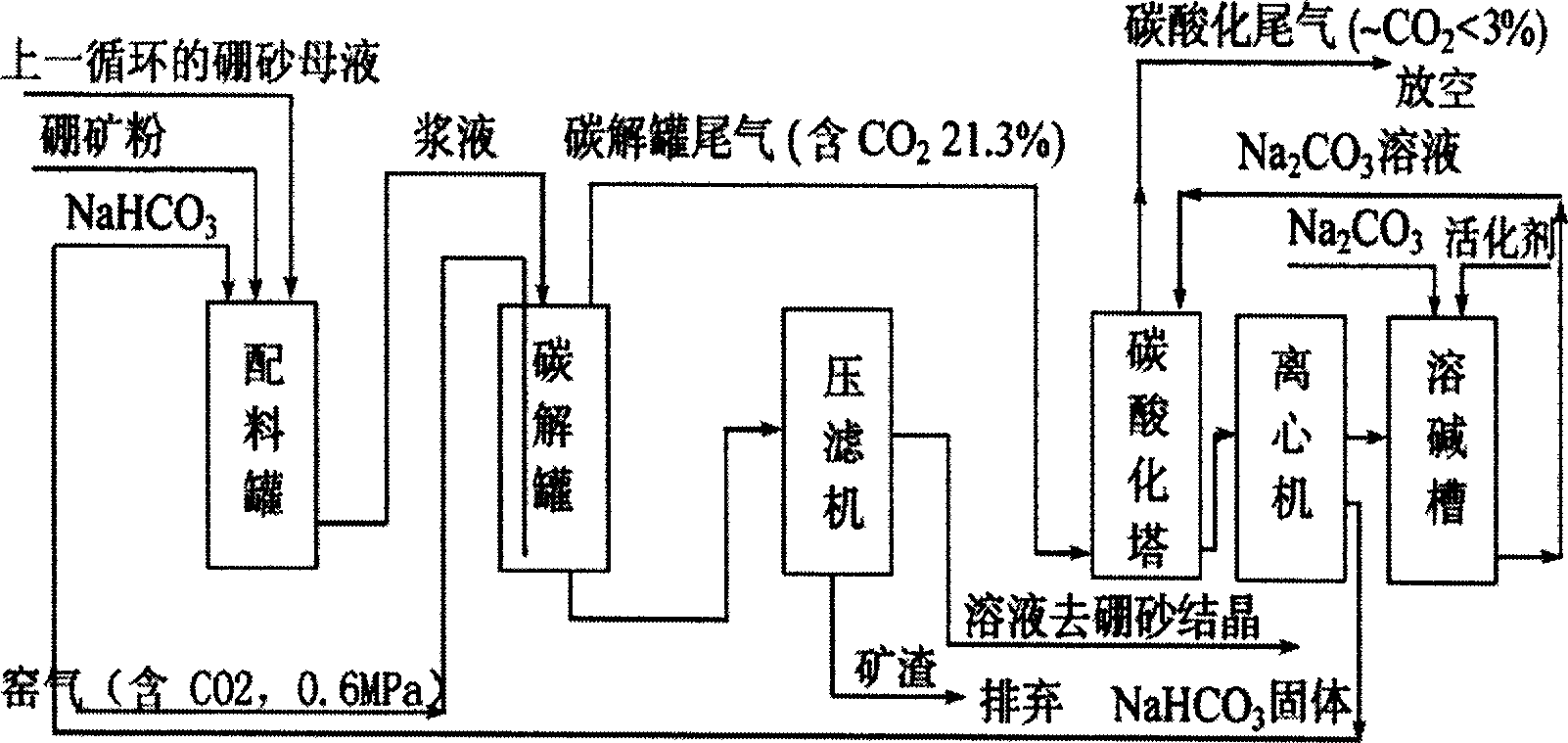

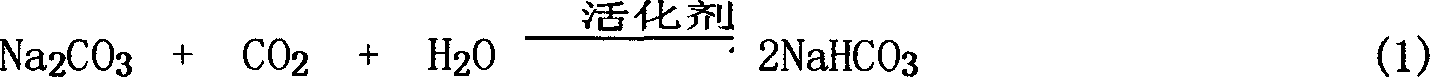

Technology of carbon alkali method for producing borax by adding activator

InactiveCN1785805ASolve the shortcomings of traditional production technologyPromote decompositionBoratesDecompositionSlurry

The present invention relates to a technological process for producing borax by using activator-added carbon alkaline process. It is characterized by that in the solution 0.05-0.2 mol / L of diethanolamine (DEA) or methyl diethanolamine (MDEA) can be added as activator, and Na2 solid of NaHCO3,boron mineral powder and boric acid mother liquor obtained from last circulation are used, and made into slurry, then in the carbon decomposition tank the boron mineral powder can be decomposed so as to obtain the invented borax.

Owner:吕秉玲

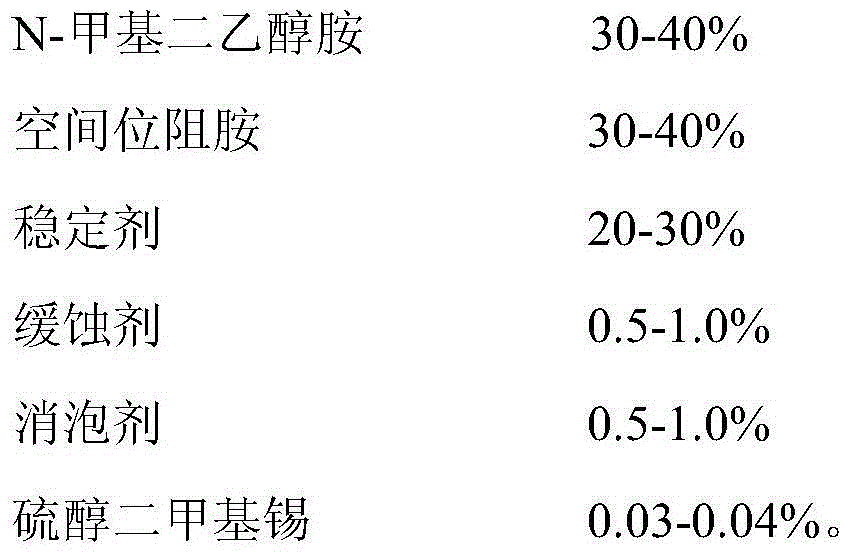

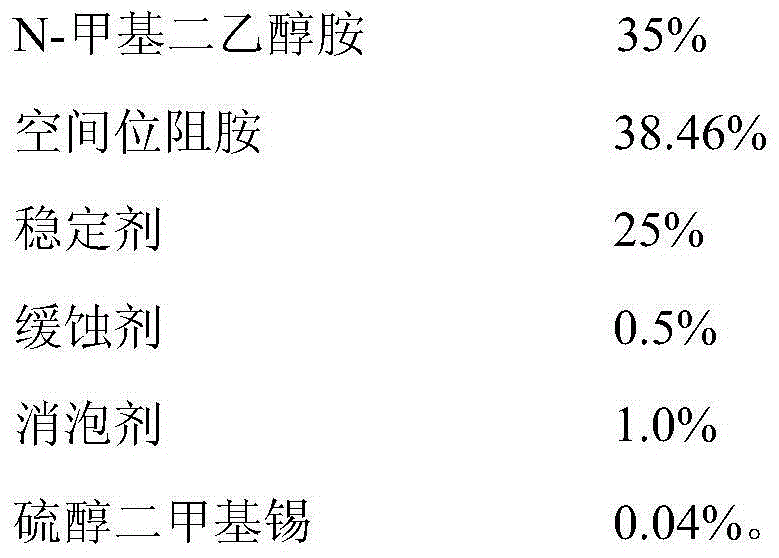

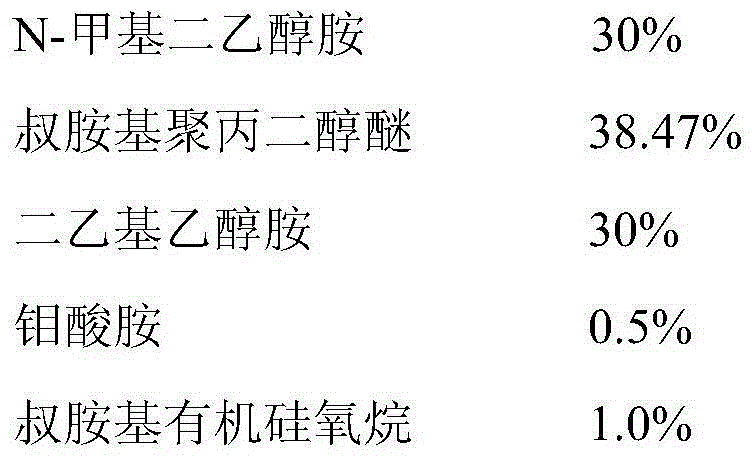

Composite desulfurization agent and preparation method thereof

InactiveCN105567322AEliminate the effects ofChange the balanceGaseous mixture working upSulfurHindered amine light stabilizers

The present invention belongs to the field of refinery gas desulfurization, and particularly relates to a composite desulfurization agent and a preparation method thereof, wherein the composite desulfurization agent is prepared from the following raw materials by weight: 30-40% of N-methyl diethanolamine, 30-40% of sterically hindered amine, 20-30% of a stabilizer, 0.5-1.0% of a corrosion inhibitor, 0.5-1.0% of a defoaming agent, and 0.03-0.04% of dimethyl tin mercaptide. According to the present invention, the removal effects of organic sulfur and inorganic sulfur are ensured, the service life of the amine liquid is effectively prolonged, the amine liquid forming period is prolonged, the amine liquid service life is increased, the amine liquid circulation amount is reduced, and the energy consumption of the apparatus is saved by more than or equal to 35%.

Owner:CHINA PETROLEUM & CHEM CORP

Water-soluble crude oil desulfurizing agent and preparation method thereof

InactiveCN104263404AExcellent instant desulfurization performanceAchieve protectionHydrocarbon oils refiningCompound aSulfur

The invention relates to a water-soluble crude oil desulfurizing agent and a preparation method thereof, and belongs to the technical field of crude oil desulphurization for offshore oilfields. The water-soluble crude oil desulfurizing agent takes water as a solvent, and the solute of the water-soluble crude oil desulfurizing agent comprises the following components in percentage by weight: 10%-15% of methanal, 6%-22% of methyl diethanolamine, 32%-34% of diethanolamine, and 5%-7% of sodium nitrite. The preparation method for the water-soluble crude oil desulfurizing agent comprises the following steps: (1) compounding a sodium nitrite solution according to the proportion of 60g-90g of sodium nitrite and 1000ml of water at the temperature of 25-60 DEG C; (2) dripping the diethanolamine into the methyl diethanolamine according to the proportion of 8ml-24ml of diethanolamine and 200ml of the methyl diethanolamine, and cooling the diethanolamine and the methyl diethanolamine for 48-72 hours at the temperature of 2-6 DEG C; (3) adding a methanal solution into the cooled mixed solution according to the proportion of 30ml of methanal of which the weight percentage is 20%-30%; (4) placing the solution which is compounded in the steps on a shaking table, and shaking the solution for 60-80 minutes; (5) standing the solution which is shaken in the step (4) for 24 hours to obtain the desulfurizing agent. The desulfurizing agent and the preparation method disclosed by the invention have the advantages that the technology is simple, raw materials are easy to obtain, the sulfur capacity is high, instantaneous desulphurization is realized, and the broad-spectrum performance is strong.

Owner:E TECH ENERGY TECH DEV CORP

Volatile corrosion inhibitor containing natural gas with carbon dioxide

The invention relates to a volatile corrosion inhibitor containing natural gas with carbon dioxide and mainly solves the problem that carbon dioxide contained in natural gas severely corrodes steel so as to greatly minimize the lifetime of oil and gas well. The volatile corrosion inhibitor comprises the following components of: by weight, 10-20% of N-methyl diethanolamine, 1-3% of Penetrant JFC-2, 3-10% of benzotriazol, 4-15% of 5,7 dinitrogen-8-hydroxyquinoline, and 52-82% of anhydrous ethanol. The content of each component is the weight percent of the gross weight of the corrosion inhibitor. The volatile corrosion inhibitor containing natural gas with carbon dioxide has high inhibition efficiency and will not influence the lifetime of the oil and gas well.

Owner:大庆中浮石油技术开发有限公司

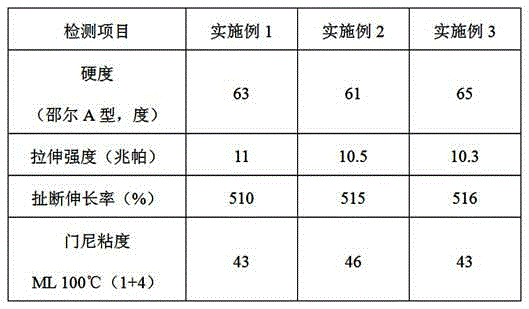

Method for preparing regenerated rubber

InactiveCN104629137AImprove performanceLow action temperaturePlastic recyclingMolecular sieveUltrasonic assisted

The invention discloses a method for preparing regenerated rubber and relates to the technical field of production of regenerated rubber. The method for preparing the regenerated rubber comprises the following steps: cleaning waste rubber, drying, cutting rubber, grinding and sieving with a molecular sieve to obtain rubber powder; uniformly mixing a certain mass of N-methyl diethanolamine and benzene substances, adding iron oxide and carrying out heat preservation to obtain a desulfurizer; transferring the rubber powder into an ultrasonic extraction device, dropwise adding the desulfurizer and a softener, uniformly stirring, carrying out ultrasonic-wave-assisted desulfurization to obtain a product and tabletting the product to obtain the regenerated rubber. According to the method, since the desulfurization is performed by virtue of the ultrasonic-wave-assisted desulfurizer method and the effect temperature is low, the disadvantage that carbon-carbon bonds are easy to rupture at high temperature so that the performances of the regenerated rubber is degraded is avoided and the method has the advantages of short desulfurization time, good desulfurization effect and excellent performance of regenerated rubber.

Owner:南京中配橡塑制品有限公司

Composite absorbent used for smoke decarbonization

InactiveCN102743954AHigh absorption loadFast absorption rateDispersed particle separationAntioxidantDiethylenetriamine

The invention discloses a composite absorbent used for smoke decarbonization and composed of the following components by mass: 15%-30% of absorption main body, 4%-10% of activating agent and 0.05%-1% of antioxidant and water as the balance. The absorption main body is ethanolamine MEA or N-methyl-diethanolamine MDEA, the activating agent is diethylenetriamine (DETA), and the antioxidant is sodium metavanadate. The absorbent is high in absorption load, high in absorption rate, good in regenerability, low in corrosivity and capable of effectively reducing device corrosion and the like, saves cost and reduces energy consumption. The absorbent is suitable for smoke decarbonization with CO2 density as 1%-40%, and is wide in CO2 density adaptation face.

Owner:CHONGQING UNIV

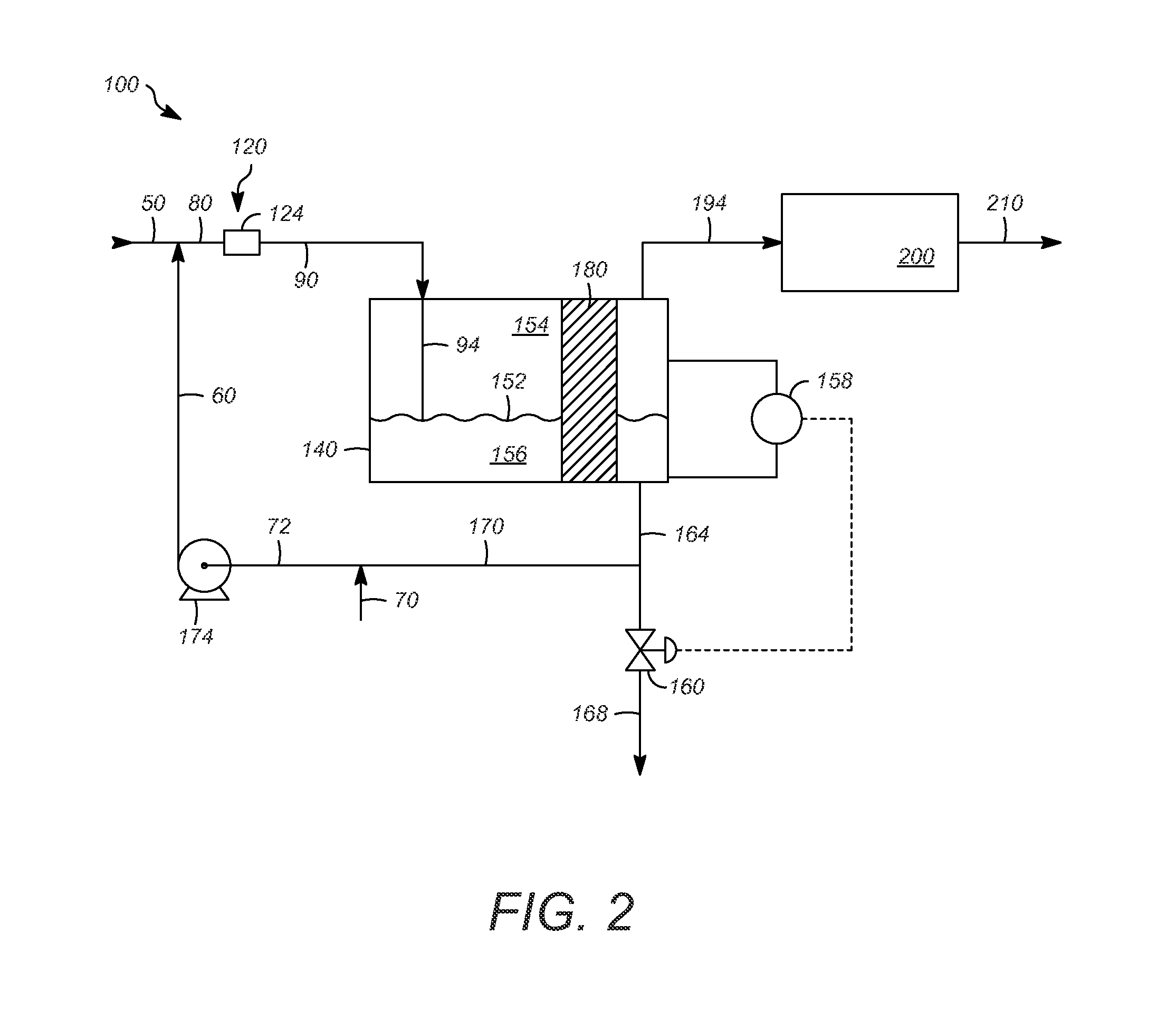

Process for treating a liquid hydrocarbon stream

ActiveUS20140371509A1Low costMinimise carryoverTreatment with plural serial refining stagesHydrocarbonsLiquid stateLiquid hydrocarbons

One exemplary embodiment can be a process for treating a liquid hydrocarbon stream. The process can include passing the liquid hydrocarbon stream previously contacted with a solvent having an alkanolamine consisting of diethanolamine, a methyl diethanolamine, or a mixture thereof, and an alkali to a vessel. Generally, the vessel contains a coalescing zone for removing at least one of hydrogen sulfide and carbonyl sulfide.

Owner:UOP LLC

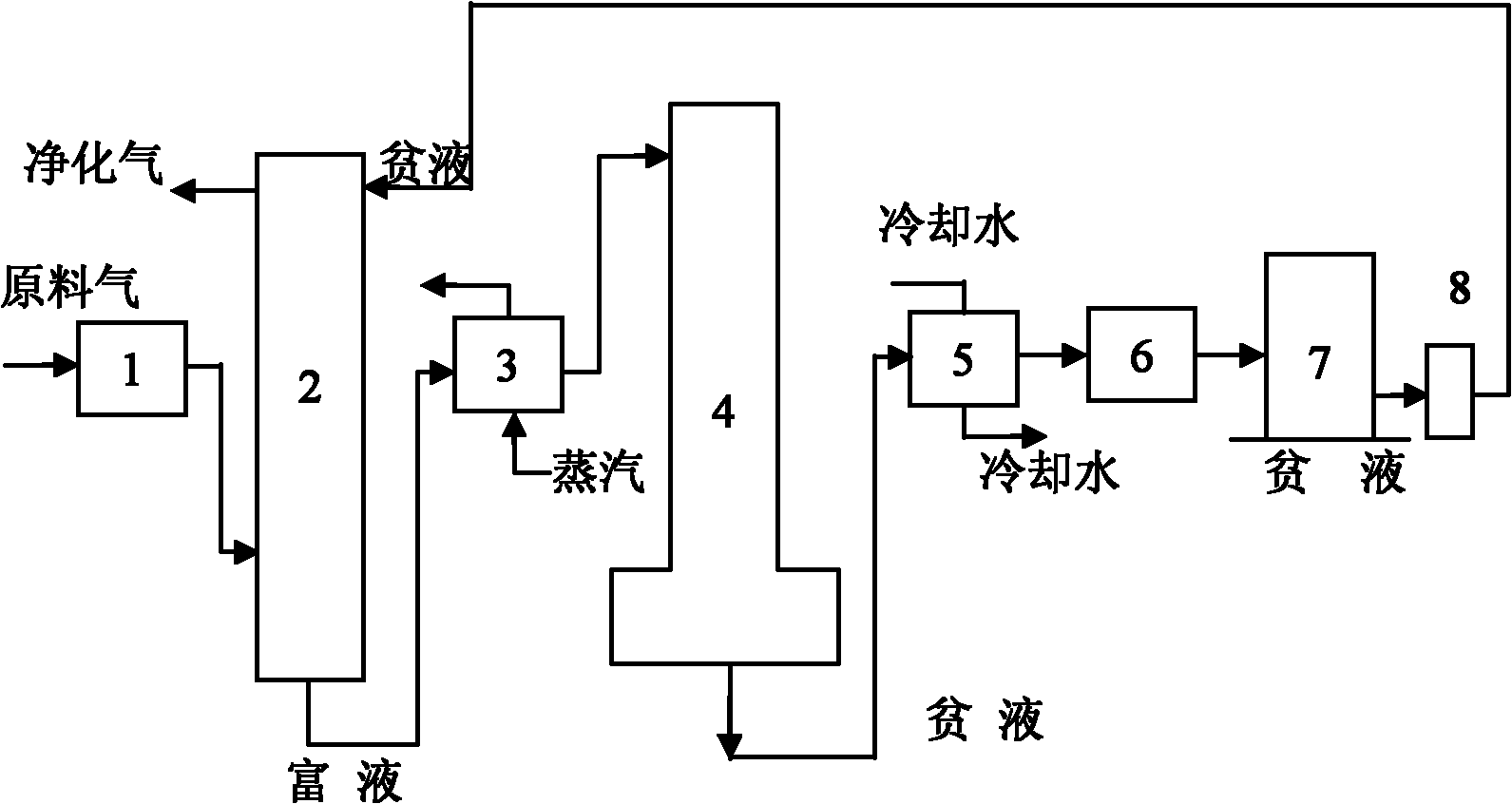

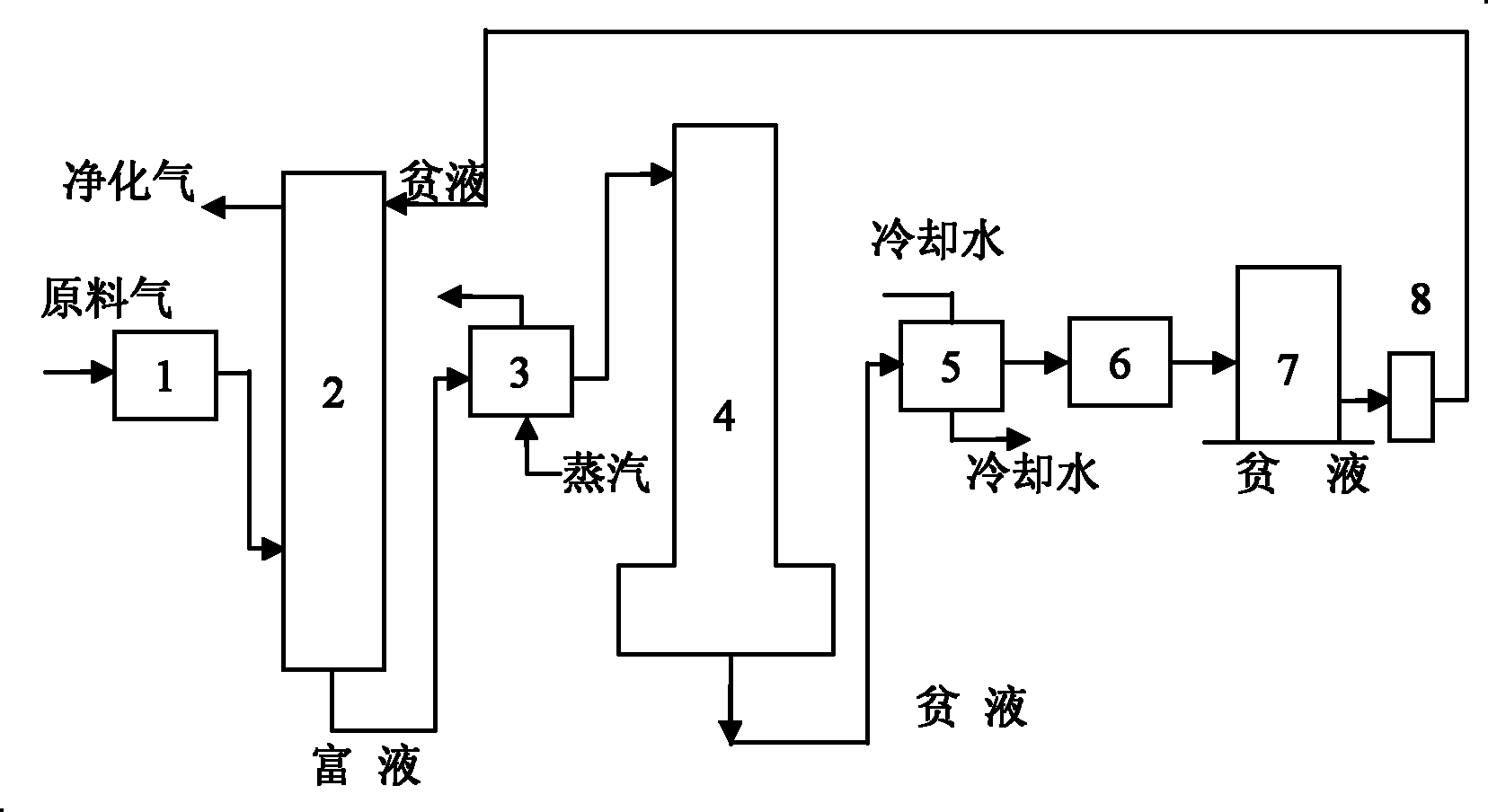

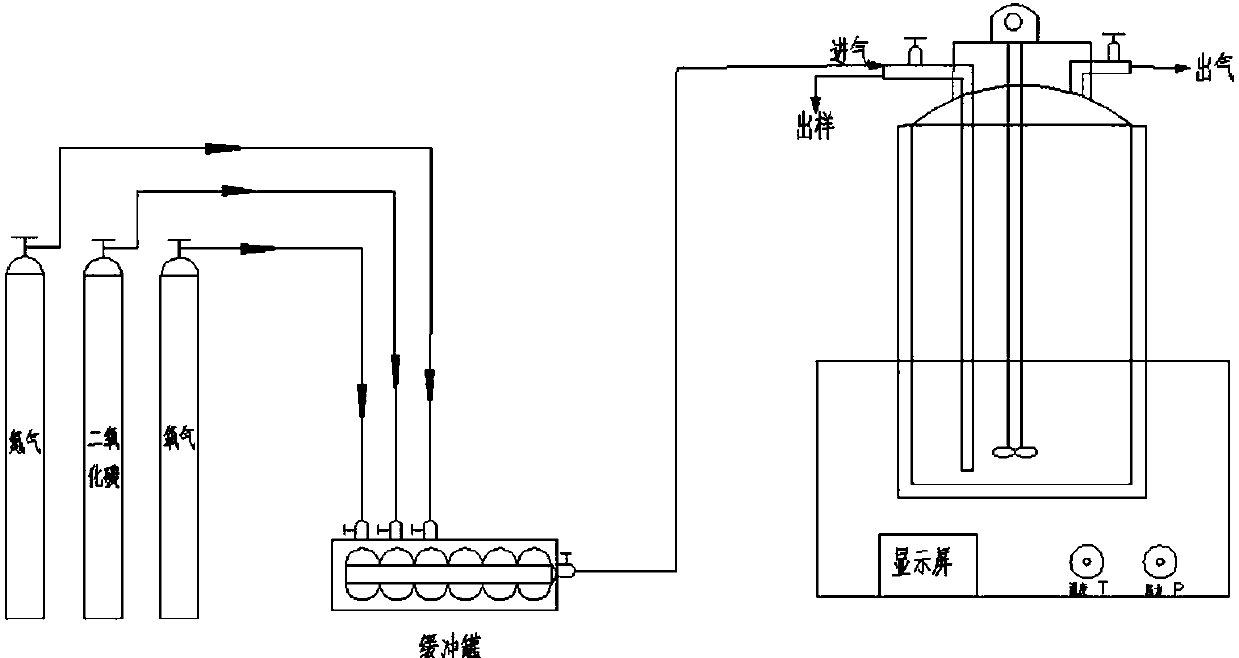

Compound decarburization solution for removing carbon dioxide in natural gas and preparation method thereof

InactiveCN102757831AHigh absorption loadLess corrosiveProductsReagentsCo2 absorptionDefoaming Agents

Disclosed is a compound decarburization solution for removing carbon dioxide in natural gas and a preparation method thereof. The compound decarburization solution comprises, by weight, 28.0% to 55.0% of N- methyl diethanolamine, 4.0% to 12.0% of an activating agent, 0.1% to 2.0% of a corrosion inhibitor, 0. 02% to 0.2% of a stabilizing agent, and 0.01% to 0.1% of a defoaming agent, with the balance being water. The preparation method includes feeding nitrogen into a reaction still before preparation; setting the temperature of the reaction still, adding the N- methyl diethanolamine and the water and stirring the mixture; adding the activating agent, the corrosion inhibitor, the stabilizing agent and the defoaming agent into the reaction still; stirring the mixture till the mixture is uniform, and performing discharge to obtain the product compound decarburization solution. According to the compound decarburization solution for removing carbon dioxide in natural gas and the preparation method thereof, the preparation process is protected by the nitrogen; the compound decarburization solution has the advantages of being high in absorption load of carbon dioxide, low in corrosion, high in thermo-stability, little in degradation loss and low in regeneration power consumption, and capable of obtaining purified natural gas and high-purity carbon dioxide while used in the natural gas processing; the whole process is protected by the nitrogen in the preparation, and oxygen is prevented from contacting with the solution, accordingly, risks of solution degradation and ineffectiveness of the stabilizing agent are reduced, and the oxygen content and the corrosion of decarburization devices are decreased.

Owner:天津中油科远石油工程有限责任公司 +1

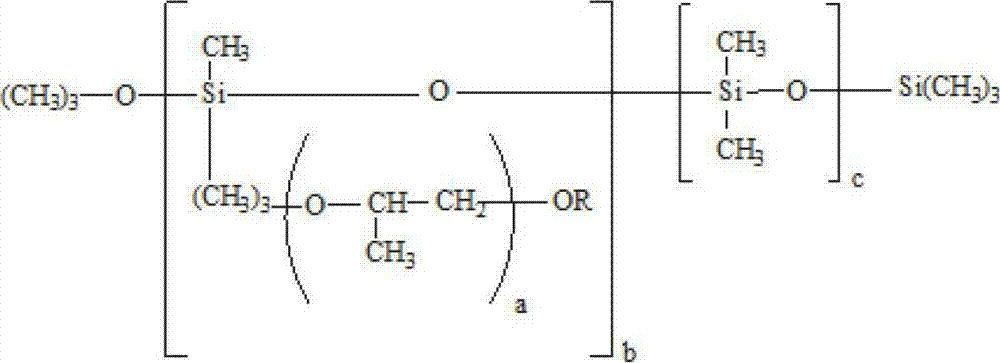

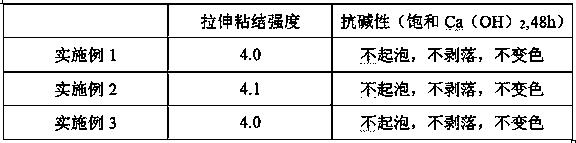

High-viscosity two-component epoxy paint

InactiveCN109575757AViscosity adjustableGood compatibilityEpoxy resin coatingsNitrile rubberPolyamide

The invention discloses high-viscosity two-component epoxy paint. The high-viscosity two-component epoxy paint comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 60 to 65 parts of E-42 epoxy resin, 10 to 20 parts of butyl benzyl glycidyl ether, 10 to 15 parts of n-butyl glycidyl ether, 30 to 40 parts of heavy calciumcarbonate, 50 to 60 parts of talcum powder, 1 to 5 parts of triethylene diamine, 2.5 to 5 parts of nitrile rubber, 0.5 to 0.8 part of Deuchem 904s, and 0.2 to 0.5 part of Deuchem6801; and the component B is prepared from the following raw materials in parts by weight: 30 to 40 parts of polyamide, 30 to 40 parts of talcum powder, 10 to 20 parts of n-butyl glycidyl ether, 1 to 3 parts of methyl diethanolamine, 0.2 to 0.4 part of Deuchem904s, and 0.1 to 0.3 part of Deuchem6801; and a weight ratio of component A to component B is 1: 1. The epoxy paint provided by the invention is immobile, good inadhesiveness, good in tensile bonding strength, good in alkali resistance, pollution-free and environment-friendly.

Owner:FUZHOU ROYAL FLOOR

Preparation method of novel ternary compound organic amine medicament capable of absorbing CO2 with little water

PendingCN109758871ALarge absorption loadImprove stabilityDispersed particle separationAir quality improvementAbsorption capacityFlue gas

The invention relates to a preparation method of a novel ternary compound organic amine medicament capable of absorbing CO2 with little water. The preparation method and the proportion are as follows:according to the molar ratio of 20 to (1-20) to 6, the novel ternary compound organic amine medicament is prepared by mixing DETA (diethylenetriamine), TETA (triethylenetetramine) or TEPA (tetraethylenepentamine) and MDEA (N-methyl diethanolamine) or PZ (piperazine) in a solution with a total amine concentration of 0.8 mol / L, according to the preparation conditions, the temperature is 293 K, thepressure is 101.325 Kpa, and the mixing condition is that every two preparation solutions are uniformly mixed at normal temperature and normal pressure. The preparation method of the novel ternary compound organic amine medicament capable of absorbing CO2 with the little water has the advantages that the novel ternary compound organic amine medicament is a flue gas CO2 absorbent with large absorption capacity, good stability of the solution, low energy consumption, high flue gas purification degree, large absorption load, low regeneration energy consumption of the absorbent, fast desorption rate, large desorption load, low oxidation degradation and thermal degradation degree of the solution and less corrosion to equipment.

Owner:SENUO TECH CO LTD

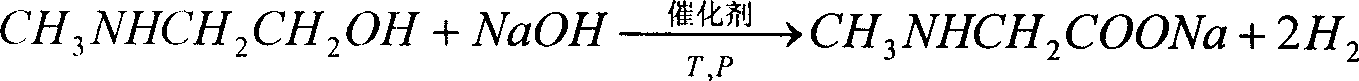

Method for synthesizing natrium sarkosine from methyl - ethanolamine

InactiveCN101003488ASimple post-processingNo chemical hazardOrganic compound preparationAmino-carboxyl compound preparationDehydrogenationReaction temperature

This invention relates to a method for synthesizing sodium sarcosinate from methyl monoethanolamine. The method comprises: adding methyl monoethanolamine 100 parts with deionized water 150-300 parts, lye 100-200 parts and metal-modified Cu framework catalyst (200-400 mesh) 5-15 parts, performing catalytic dehydrogenation reaction at 120-200 deg.C and 0.5-1.5 MPa for 2-8 h. The method does not produce NaCl during reaction, thus has simple post-treatment, and can be used to prepare daily chemical and pharmaceutical products. Besides, the method is harmless to operators and environment. The byproduct H2 can be recycled. The raw material, methyl monoethanolamine, is a byproduct of methyl diethanolamine preparation.

Owner:ZHEJIANG UNIV

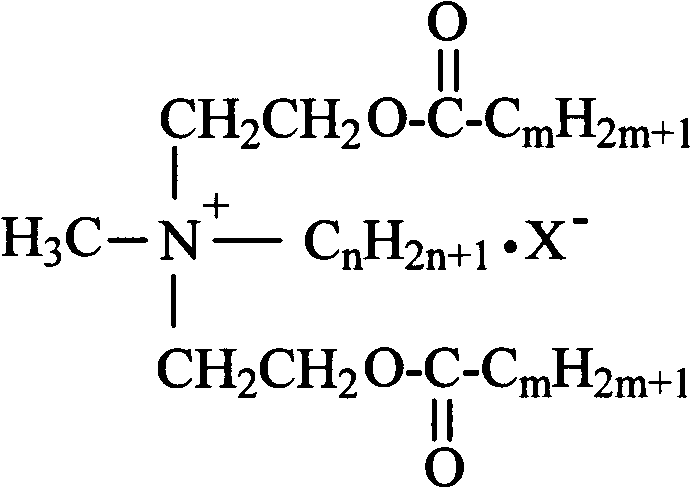

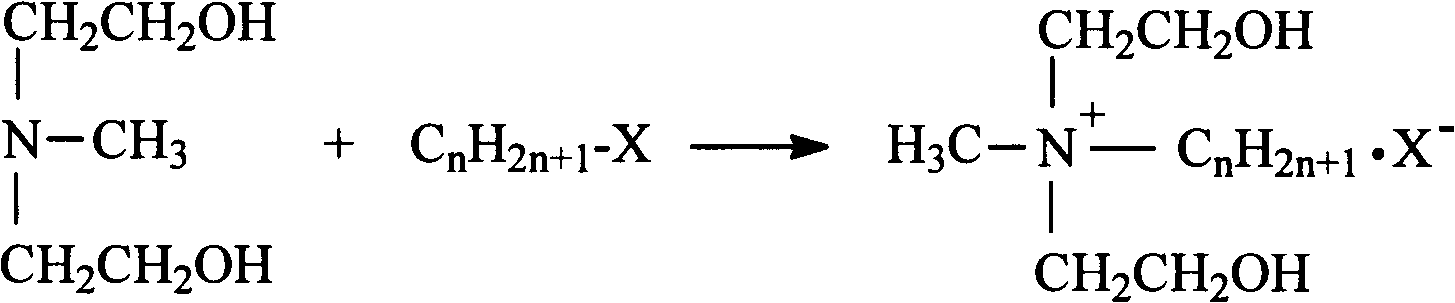

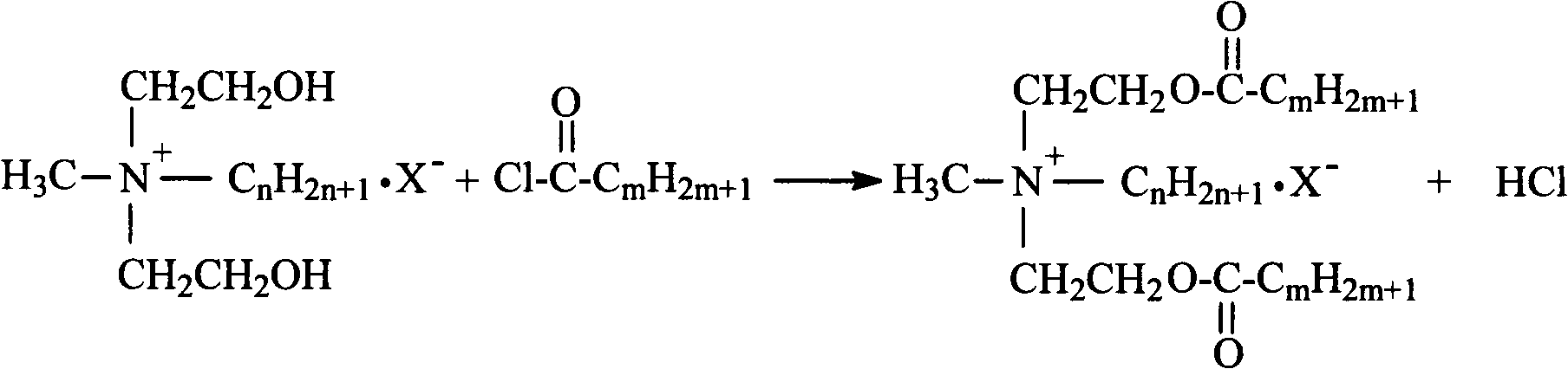

Synthetic process of double-long-chain diester quaternary ammonium salt

InactiveCN102432477AImprove conversion rateHigh content of active substancesOrganic compound preparationTransportation and packagingQuaternary ammonium cationHalomethane

The invention provides a double-long-chain diester quaternary ammonium salt. Diester is introduced into a molecular structure, so that the degradability is enhanced greatly, and environmental friendliness is realized. The invention further provides a synthetic process of the double-long-chain diester quaternary ammonium salt. The process comprises the following steps of: mixing N-methyl diethanolamine with short-chain alkyl halide, adding an appropriate amount of solvent, and reacting under certain reaction conditions to obtain dihydroxyethyl ammonium halide serving as a reaction intermediate; mixing the dihydroxyethyl ammonium halide with long-chain alkyl acyl chloride, adding an appropriate amount of solvent, and reacting under certain reaction conditions; and performing rotary steaming at the end of the reaction and repeatedly recrystallizing to obtain a final solid product. In the synthetic process, a nonconventional quaternary ammonium salt synthesis route for quaternary amination and esterifying in sequence is adopted, so that the raw material transformation ratio is high, an intermediate product is easy to separate and purify, the reaction conditions are mild, the final product is in light color and has high active matter content, the solvent can be recycled, no three wastes is produced, and the use of the conventional toxic alkylation reagents such as dimethyl sulfate, halomethane and the like is avoided in the synthetic process.

Owner:JIANGNAN UNIV

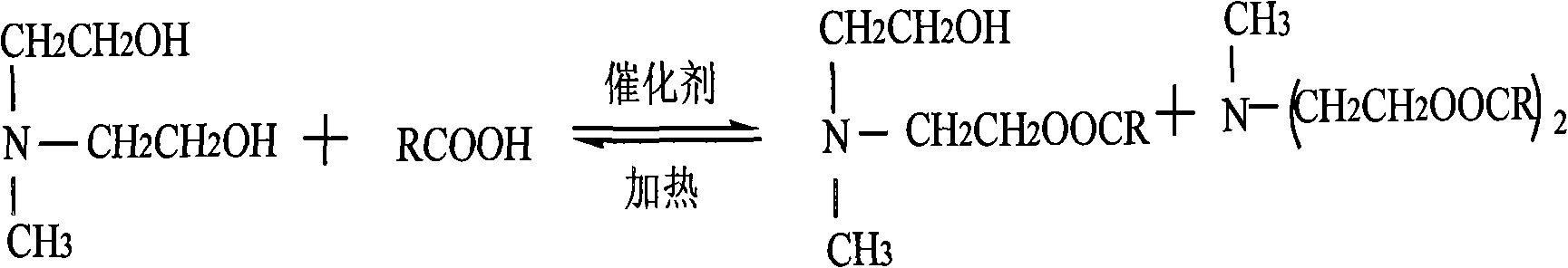

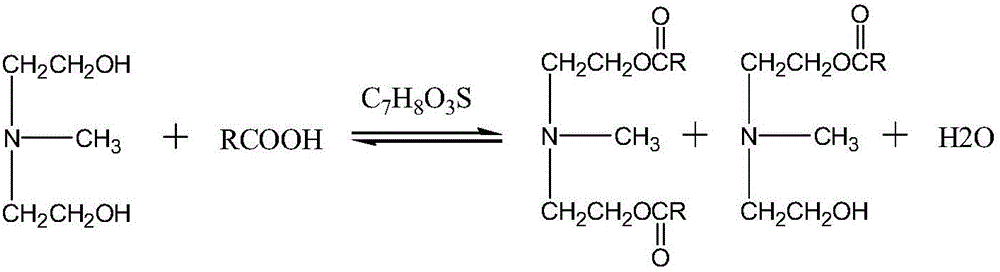

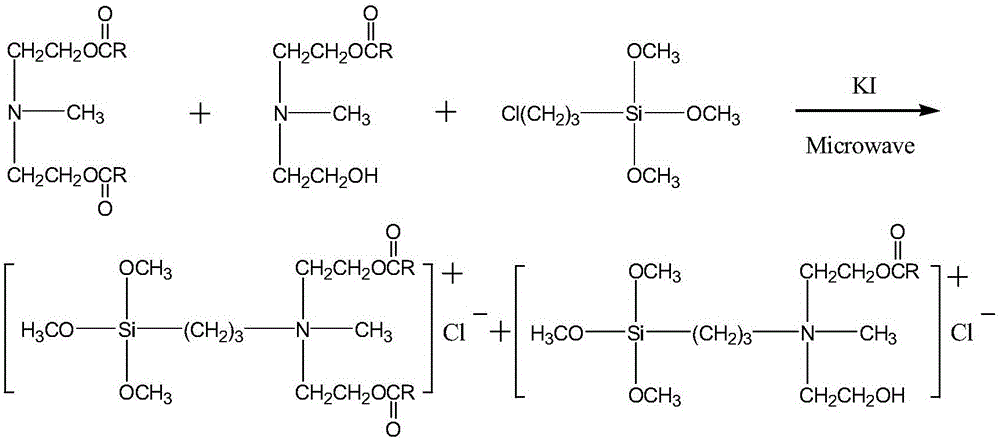

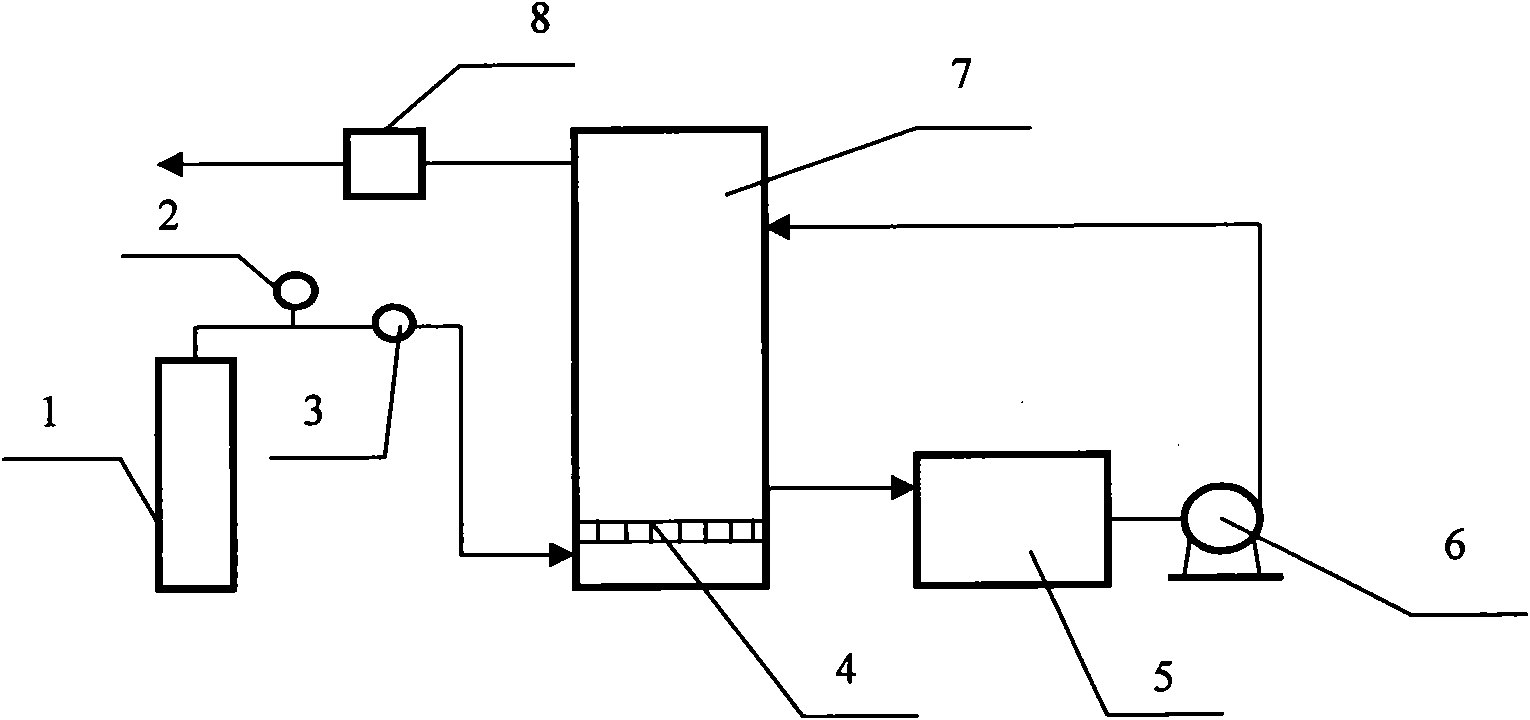

Preparation method of novel ester organosilicon quaternary ammonium salt

ActiveCN106188124AExcellent antibacterial washabilityGroup 4/14 element organic compoundsVegetal fibresMicrowave methodSilanes

The invention discloses a preparation method of novel ester organosilicon quaternary ammonium salt: methyl diethanolamine laurate mono(bis) ester group propyl trialkoxyl silyl ammonium chloride. The preparation method is characterized by comprising two steps: (1) synthesis of methyl diethanolamine laurate mono(bis) ester: carrying out esterification reactions between N-methyl diethanolamine and lauric acid in the presence of a catalyst namely p-toluenesulfonic acid; (2) synthesis of methyl diethanolamine laurate mono(bis) ester group propyl trialkoxyl silyl ammonium chloride: carrying out quaternization reactions between methyl diethanolamine laurate mono(bis) ester and gamma-chloropropyl trialkoxyl silane in a DMF solvent in the presence of a catalyst namely potassium iodide, wherein methyl diethanolamine laurate mono(bis) ester group propyl trialkoxyl silyl ammonium chloride is synthesized through a microwave method. The invention also provides a cotton fabric finishing agent, which comprises 800 mg / L of the ester organosilicon quaternary ammonium salt: methyl diethanolamine laurate mono(bis) ester group propyl trialkoxyl silyl ammonium chloride.

Owner:WEST ANHUI UNIV

Composite flue gas desulfurization agent and preparation method thereof

The invention relates to a composite flue gas desulfurization agent and a preparation method thereof, and relates to the technical field of flue gas desulfurization. The desulfurization agent is of a mixed water solution which is formed by mixing methyl diethanolamine (MDEA) and 2-octyl sodium dodecyl sulfate as a surfactant at room temperature, wherein the mass percentage of the methyl diethanolamine (MDEA) accounts for 1.0 to 12.0 percent of a solvent water, and the concentration of the 2-octyl sodium dodecyl sulfate (GC20S ) is 3.4 x 10-6-30 x 10-6mol / L. The composite desulfurization agent effectively reduces surface tension. Through the test of surface tension, the surface tension of the desulfurization agent reduces by 20 to 30 percent under the same temperature conditions compared with the single component MDEA, so that the gas is easy to form small bubbles; and the gas liquid specific surface area is effectively increased, the mass transfer rate is improved, and the desulfurization efficiency reaches to more than 95%.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

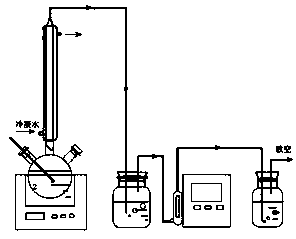

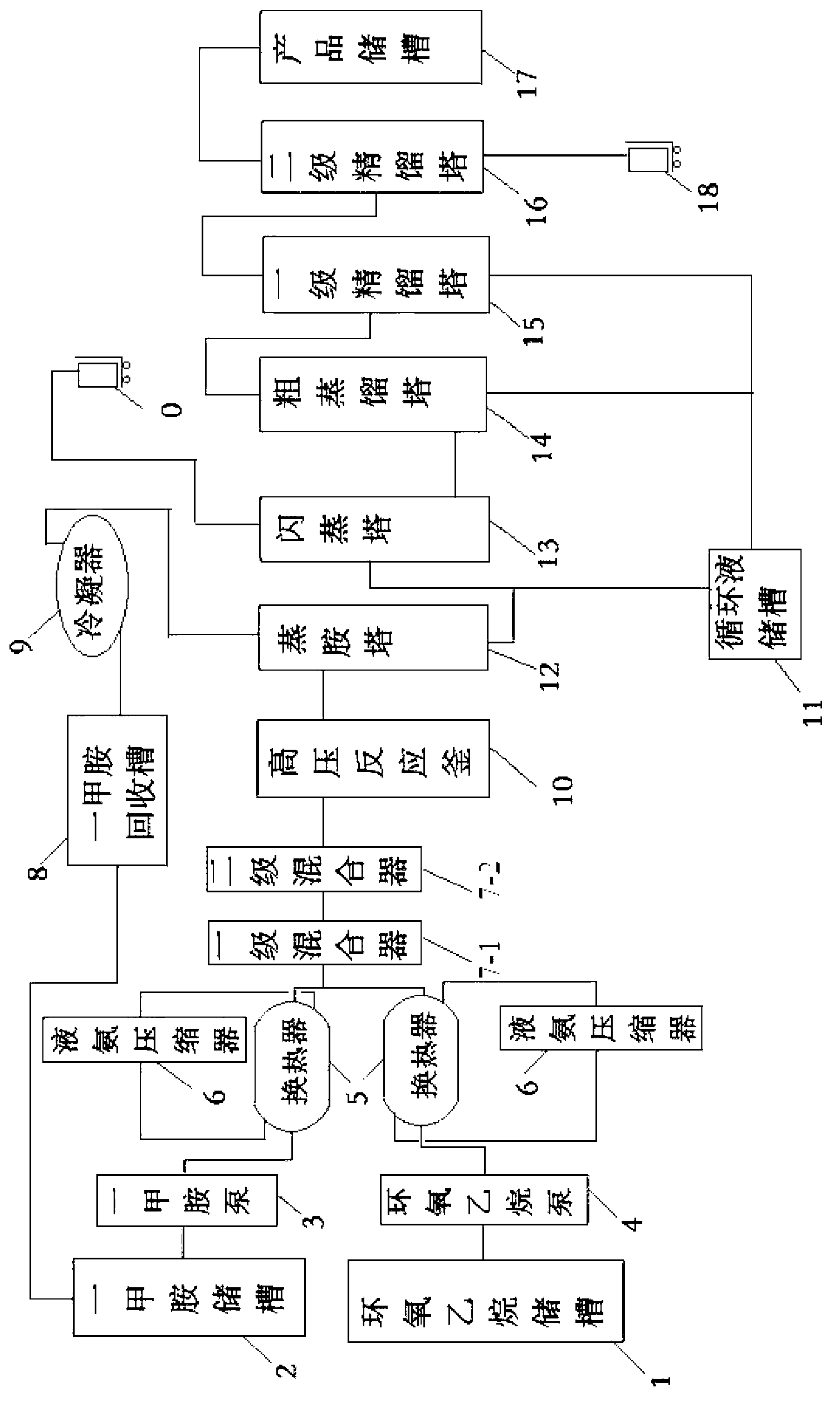

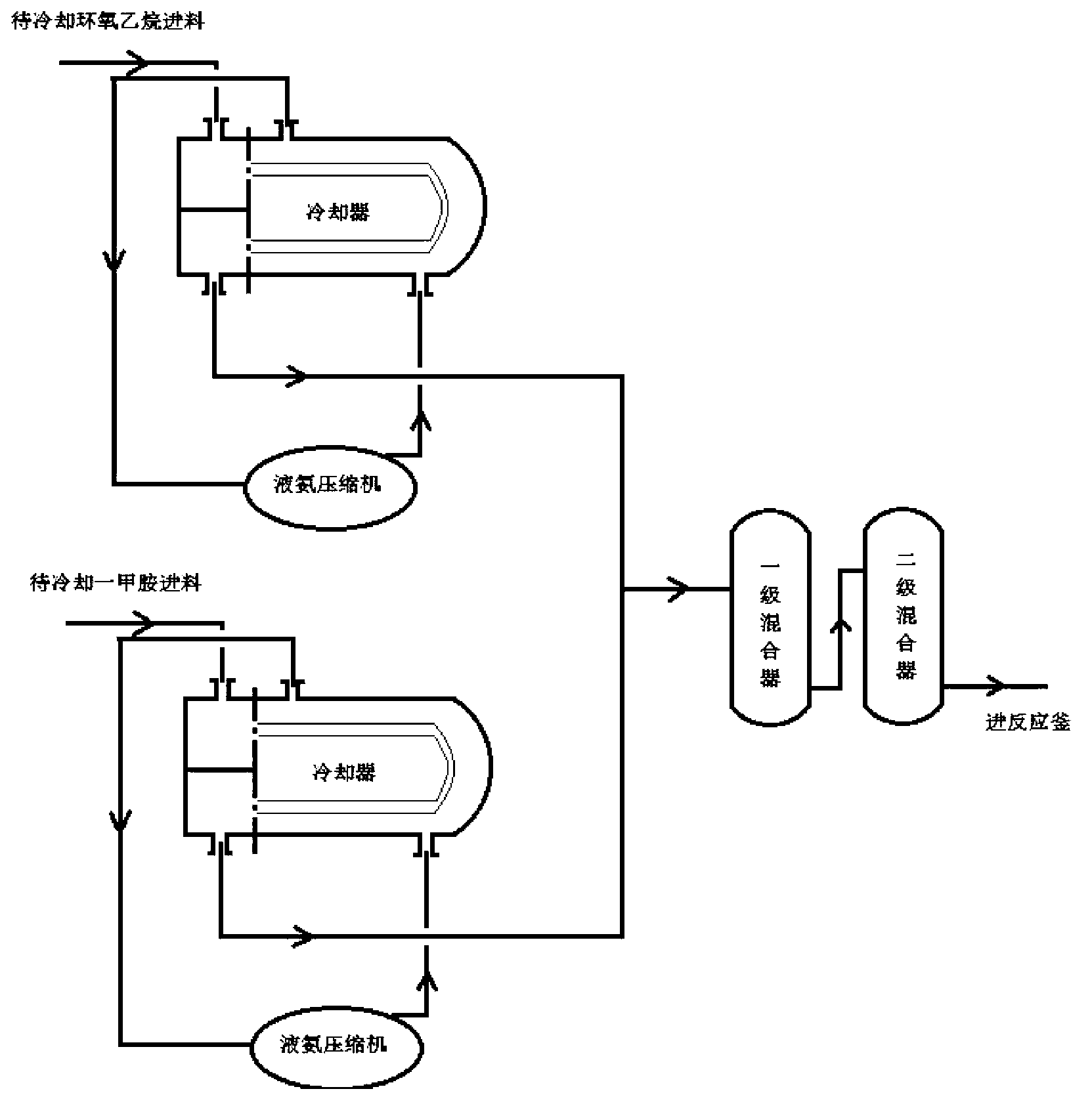

Preparation method of N-methyl diethanolamine

ActiveCN103073437AAdequate responseImprove responseOrganic compound preparationAmino-hyroxy compound preparationManufacturing technologyDistillation

The invention relates to a manufacturing technology of organic amine, in particular to a preparation technological method of N-methyl diethanolamine. The preparation method comprises the following steps: respectively injecting ethylene epoxide and monomethylamine into heat exchangers for being cooled, and then injecting ethylene epoxide and monomethylamine into a mixer for being premixed; injecting the mixed raw material into a reaction kettle for reaction when the reaction pressure is kept at 4.5-5 MPa and the reaction temperature is kept at 120-135 DEG C; injection reaction liquid into a pressure-relief device to remove excess methylamine; injecting amine-removed substrate into a flash vaporization absorption tower for being processed so as to remove moisture and light component impurities; and finally utilizing a tertiary distillation and rectification column to separate N-methyl diethanolamine product. The preparation method solves the problems of overlong reaction time, low conversion rate, excessive side reaction and the like, which are caused by insufficient premixing in a conventional process, increases the MDEA (methyl diethanolamine) content from 70-80 percent in the original process to more than 90 percent, improves the reaction yield, lowers the unit consumption of raw materials, reduces energy consumption and also avoids environmental pollution.

Owner:NINGBO ZHETIE JIANGNING CHEM +1

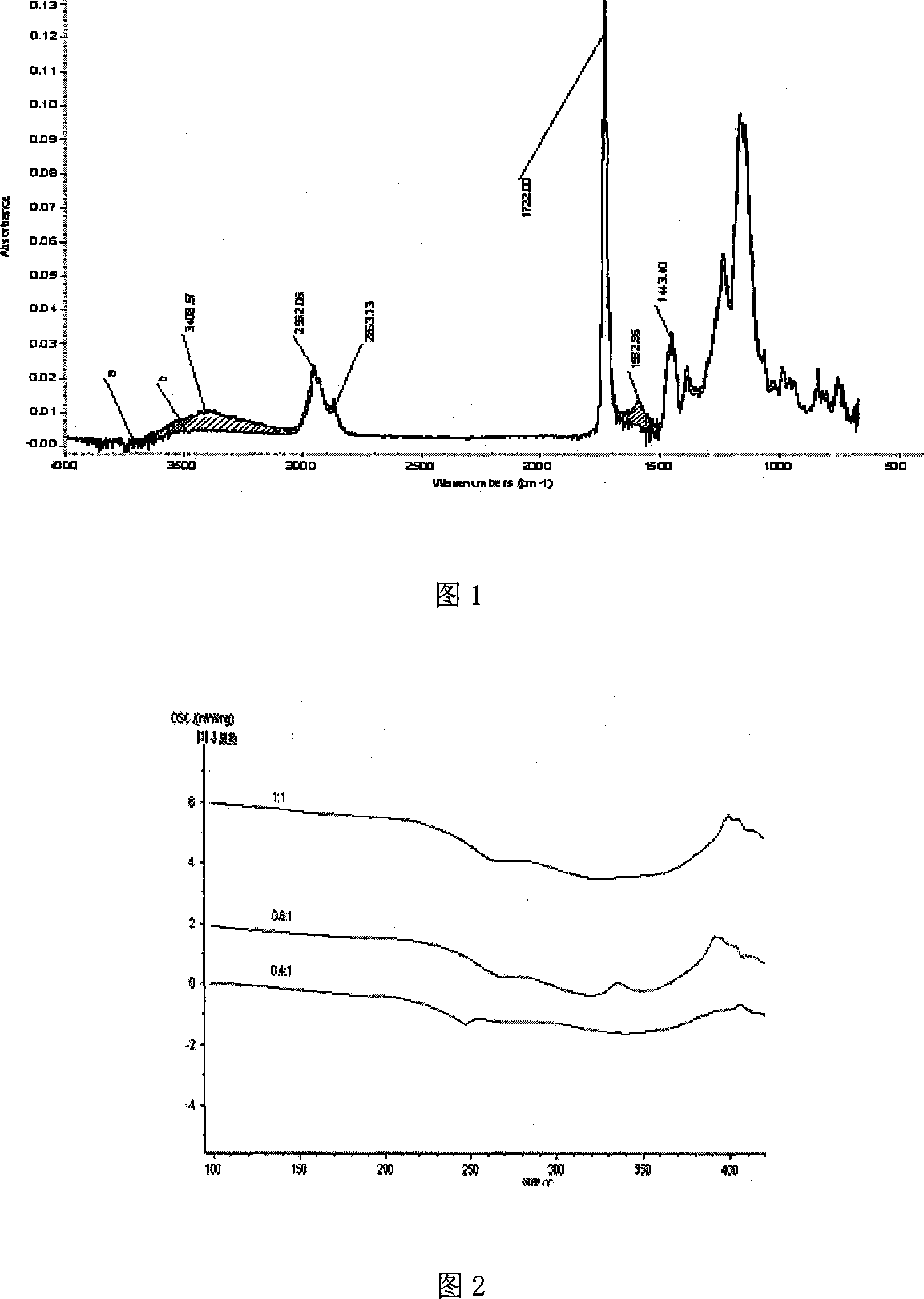

Method for synthesizing polyurethane/polyacrylate ionomer emuldion

The invention relates to a synthesis method of ionomer emulsion of polyurethane / polyacrylate. The method includes steps of: charging poly(propylene glycol) PPG, toluene diisocyanate TDI, and N-methyl diethanolamine MDEA into acetone, using dibutyltin dilaurate as catalyst, obtaining polyurethane PU; regulating pH value of polyurethane to 6, adding the polyurethane PU into water for emulsification under stirring, and obtaining emulsion; mixing the emulsion with mixed monomer to react at the temperature of 60-70 DEG C. for 3-4 hours, with azodiisobutyronitrile as catalyst, obtaining polyurethane / polyacrylate. Polyurethane (PU) and polyacrylate (PA) in synthesized PUA has great compatibility, and it is proven that there is ionic bond effect in the system by infrared spectrum (FTIR), thermo analysis (DSC) and viscosity, which enhances compatibility between PU and PA, therefore ionomer PUA is synthesized.

Owner:SHANGHAI UNIV

Preparation method for series of polyurethane catalysts

ActiveCN105348120AHarm reductionSimple processPhysical/chemical process catalystsOrganic compound preparationSolid acidDimethyl ethanolamine

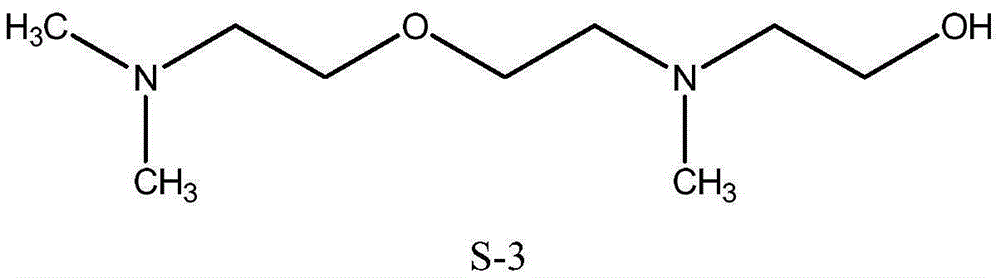

The invention discloses a preparation method for a series of polyurethane catalysts. The preparation method comprises the following steps: SioO2 and Al2O3 with different ratios are employed as carriers, soaked in an ammonium sulfate aqueous solution, dried and roasted, and a silicon-aluminum-loaded solid acid catalyst is prepared; then a mixture of N,N-dimethyl ethanolamine and N-methyl diethanolamine is employed as a raw material, the raw materials and the silicon-aluminum-loaded solid acid catalyst accounting for 1-10% of the total weight of the raw material are added in an autoclave and a reaction is carried out; the filtrate after the reaction is subjected to rectification separation and therefore N-methyl morpholine, 2-dimethylaminoethyl ether and N,N,N'-trimethyl-N'-hydroxyethyl-bis-amino ethyl ether are obtained respectively.

Owner:恒光新材料(江苏)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com