Composite shot blasting reinforcement process to raise fatigue strength of titanium metal

A fatigue strength and shot peening technology, applied in the field of jet abrasives, can solve the problems of low fatigue strength, low strengthening effect, and large dispersion, and achieve the effect of simple equipment and easy operation of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

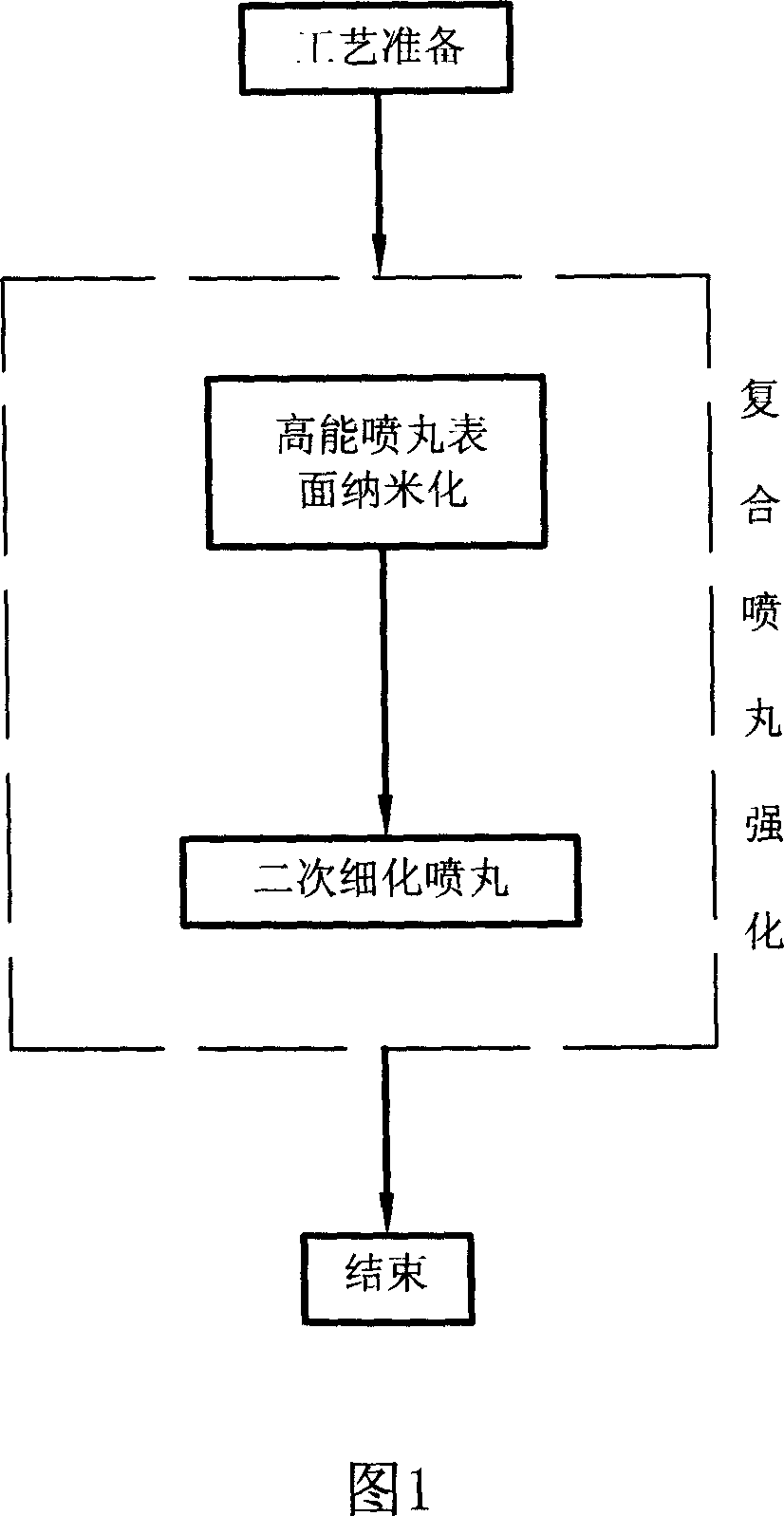

[0009] A method of improving the fatigue strength of titanium metal by using composite shot peening. This method can form a certain depth of nano-surface layer on the surface of the material through high-energy shot peening treatment, and generate very high and deep residual compressive stress on the surface layer. Then, the roughness of the nano-surface layer can be reduced, the surface damage caused by severe plastic deformation can be repaired, and the micro-cracks on the surface can be bridged by secondary refinement shot peening, so that the excellent performance of the nano-surface layer can be fully exerted. , so that the fatigue strength of the material is improved with the help of the excellent performance of the nano-surface layer and the higher residual compressive stress.

[0010] The specific process includes:

[0011] 1. Clean the surface

[0012] Clean up the surface attachments and other dirt of the shot blasted parts;

[0013] 2. High energy shot peening sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com