Production method of fructus lycii wine

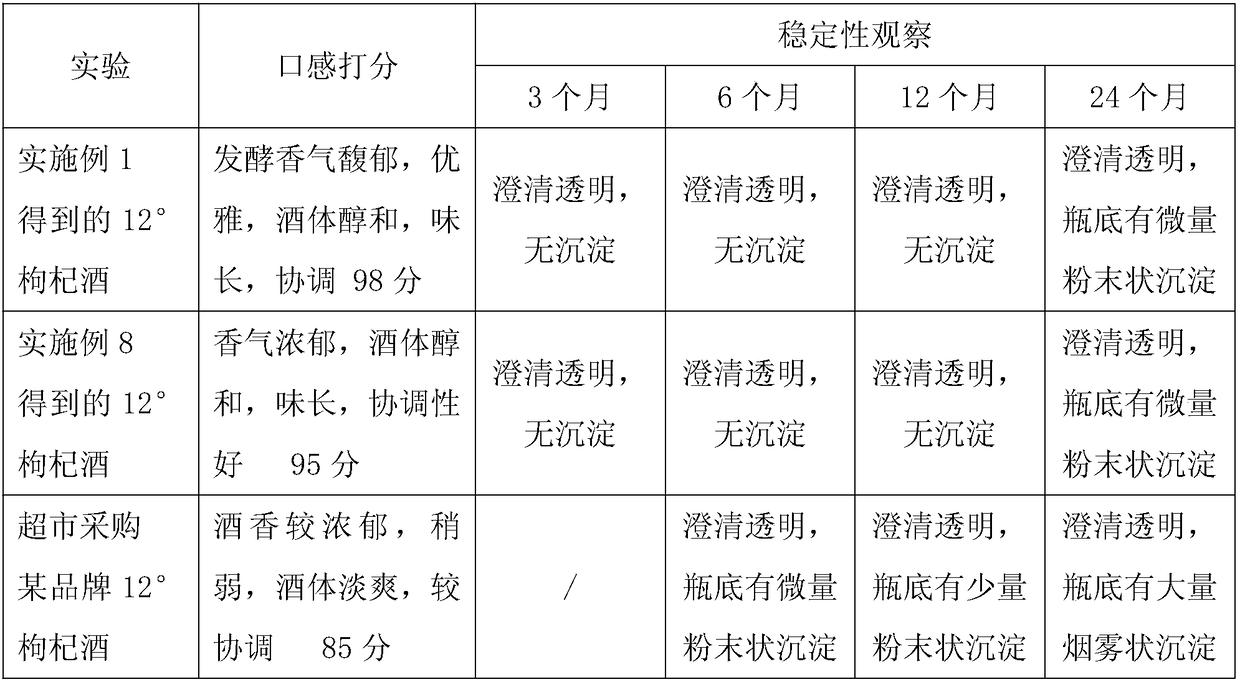

A production method and a technology for wolfberry wine, which are applied in the field of food and beverage processing, can solve the problems of inconspicuous aroma of wolfberry wine, unimproved nutritional value, unstable wine body, etc., and achieve the effects of improving aroma and nutritional value and colloidal system stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1) Preparation of wolfberry juice: dry wolfberry is hot-extracted to obtain wolfberry juice, and the wolfberry juice contains the extracted wolfberry residue;

[0064] 2) The first step of fermentation: the wolfberry juice is enzymatically hydrolyzed and sterilized, and the expanded seed liquid of Geotrichum candidum is inoculated, and the first fermentation liquid is obtained after 1 day of fermentation;

[0065] 3) Intermediate treatment: Add calcium carbonate powder to the fermentation broth in the first step, stir to fully dissolve it, and perform open backflow. Use the grain saccharification solution to adjust the solid content so that the alcohol content during the later alcohol fermentation can reach at least 12°;

[0066] 4) Heat treatment: the first fermentation broth of intermediate treatment is heat treated at 75-90°C for 15-16 seconds;

[0067] 5) Alcohol fermentation: the processed fermentation broth is 1:1 inoculated with Saccharomyces cerevisiae and Kluyveromyces ...

Embodiment 2

[0078] 1) Preparation of wolfberry juice: dry wolfberry is subjected to hot extraction to prepare wolfberry juice, and the wolfberry juice does not contain the extracted wolfberry residue;

[0079] 2) The first step of fermentation: Lycium barbarum juice is enzymatically hydrolyzed, sterilized, inoculated with Lactobacillus salivarius, Lactobacillus acidophilus, Lactobacillus rhamnosus, Leuconostoc mesenteroides subspecies of mesenteric seed liquid in equal proportions, fermentation 5 Tiande first fermentation broth;

[0080] 3) Intermediate treatment: Add calcium carbonate powder to the fermentation broth in the first step, stir to fully dissolve, and perform open inversion, adjust the solid content with fructose syrup, so that the alcohol content of the later alcohol fermentation can reach at least 3-12° ;

[0081] 4) Alcohol fermentation: the processed fermentation broth is inoculated with Saccharomyces cerevisiae for alcohol fermentation, the fermentation temperature is 16-26°C,...

Embodiment 3

[0092] 1) Preparation of wolfberry juice: dried wolfberry is soaked in water and beaten to prepare wolfberry juice;

[0093] 2) The first fermentation: the wolfberry juice is enzymatically hydrolyzed, sterilized, inoculated with Lactobacillus plantarum expansion solution, and fermented for 2 days to obtain the first fermentation solution;

[0094] 3) Intermediate treatment: Add calcium carbonate powder to the fermentation broth in the first step, stir to fully dissolve, and perform open backflow, adjust the solid content with sugar, so that the alcohol content of the later alcohol fermentation can reach at least 3-12°;

[0095] 4) Heat treatment: the fermentation broth of the first step of intermediate treatment is heat treated, and the treatment conditions are: 90°C, heat preservation for 15 seconds;

[0096] 5) Alcohol fermentation: the processed fermentation broth is inoculated with Kluyveromyces marxianus for alcohol fermentation, the fermentation temperature is 26°C, and the skin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com