Preparation method and application of tobacco endogenous spice of Boshan aromatic tobacco

A Baoshan oriental tobacco, endogenous technology, applied in tobacco, application, preparation of tobacco, etc., can solve the problems of cumbersome extraction process, unclear extract, poor application effect, etc., and achieve simple and practical method, low cost, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

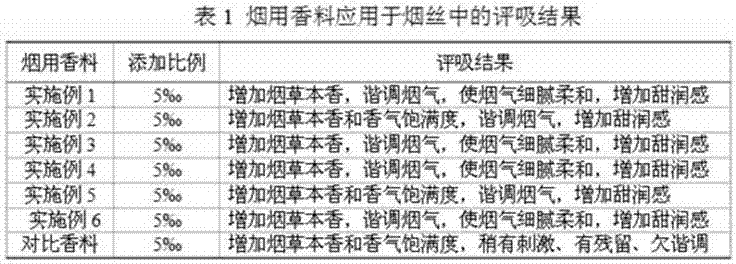

Examples

Embodiment 1

[0028] (1) Take Baoshan Oriental Tobacco (tobacco leaves were purchased from Komatini-Basma, Baoshan, Yunnan, including the fragments obtained by pulverizing Baoshan Oriental Tobacco leaves and / or the discarded tobacco powder collected during the cigarette production process, for the convenience of illustrating this example. The middle grade is used, but it is not limited to this example) 300g of tobacco leaves, crushed (about 50-200 mesh), put into an ultra-high pressure extraction tank (this example adopts UHP900ⅹ2 ultra-high pressure device), and added 10 times the volume ratio concentration It is 95% ethanol aqueous solution, soak Baoshan oriental tobacco powder for 30min at room temperature, pressurize to 100MPa, release the pressure immediately after maintaining the pressure for 1min, repeat 3 times, filter the extract, and concentrate the filtrate to 450g.

[0029] (2) 500g of AB-8 macroporous resin, packed into a column for pretreatment according to the instructions, (s...

Embodiment 2

[0031] (1) Take 300g of Baoshan Oriental Tobacco (the same variety as in Example 1), put it into an ultra-high pressure extraction tank (same as Example 1) after pulverizing (about 50-200 mesh), and add 10 times the volume of 95% In ethanol aqueous solution, soak Baoshan oriental tobacco powder for 30min at room temperature, pressurize it to 100MPa, release the pressure immediately after maintaining the pressure for 1min, repeat 3 times, filter the extract, and concentrate the filtrate to 450g.

[0032] (2) 500g of D101 macroporous resin, packed into a column for pretreatment according to the instructions (http: / / www.sep-bj.com / news / html / ?456.html), and the 450g sample obtained in step (1) was loaded, The flow rate was controlled at 5mL / min, and then eluted with an ethanol aqueous solution with a concentration of 30% by volume, and the flow rate was controlled at 3mL / min. After washing, the effluent was basically colorless. The ethanol eluent was collected and concentrated to 3...

Embodiment 3

[0034] (1) Take 300g of Baoshan Oriental Tobacco (the same variety as in Example 1, the top grade), put it into an ultra-high pressure extraction tank (UHP900ⅹ2 ultra-high pressure device) after crushing (about 50-200 mesh), add 8 times the amount of water, room temperature Soak for 60min, pressurize to 600MPa, release the pressure immediately after maintaining the pressure for 10min, repeat 3 times, filter the extract, and concentrate the filtrate to 450g.

[0035](2) 500g of ADS-17 macroporous resin, according to the requirements of the instructions, pre-pack the column, load the 450g sample obtained in step (1), control the flow rate at 5mL / min, and then elute with ethanol water solution with a volume ratio concentration of 40% , the flow rate is controlled at 3mL / min, the effluent is basically colorless after washing, the ethanol eluate is collected, concentrated to 30g, and the endogenous flavor of Baoshan oriental tobacco is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com