Method for preparing aminoglucose hydrochloride

A technology of glucosamine hydrochloride and hydrochloric acid, which is applied in the field of preparation of glucosamine hydrochloride, can solve the problems of reducing product purity, increasing cost, sticking to pans, etc., and achieves improving purity and yield, saving cost and reducing dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

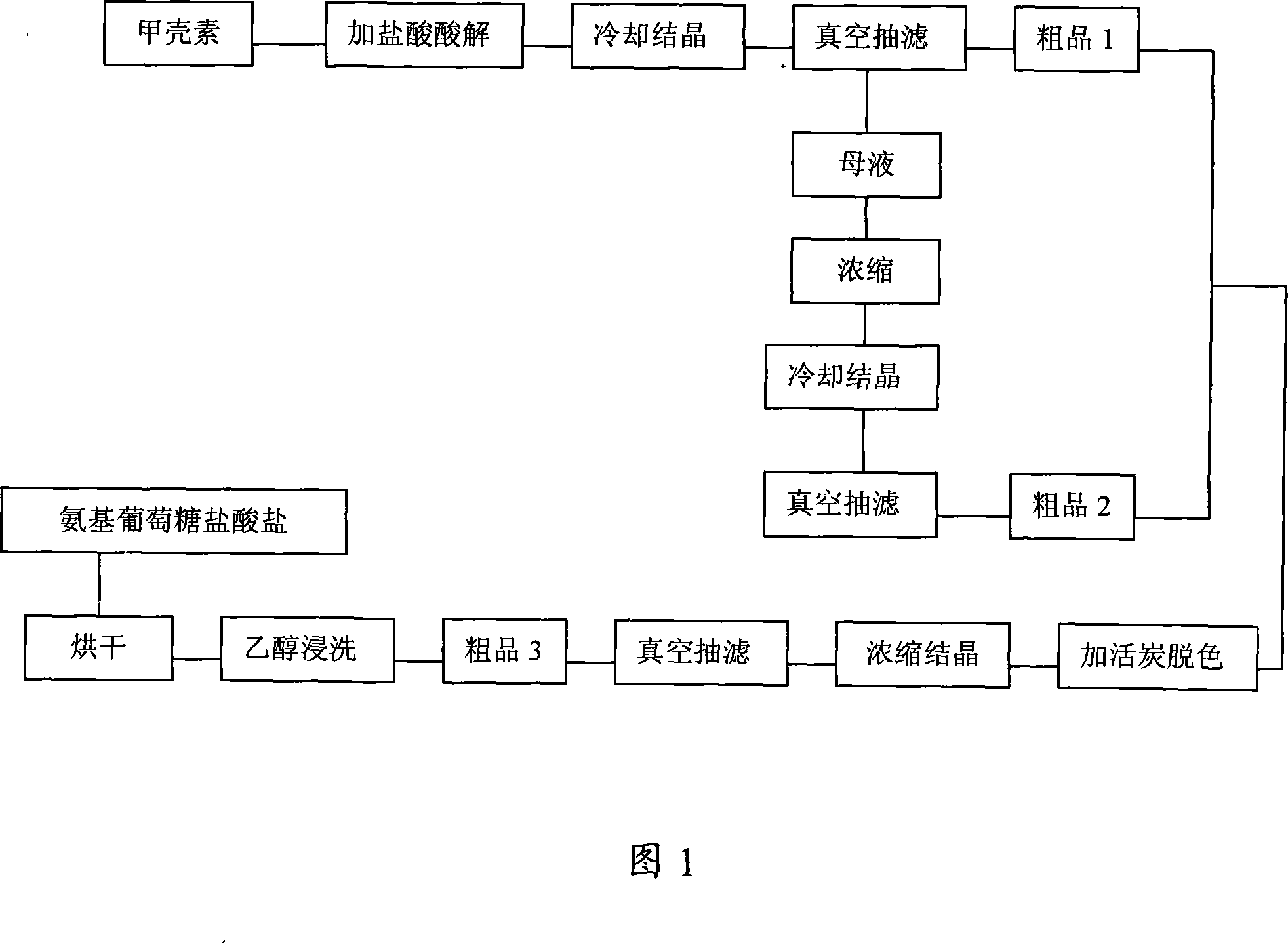

Image

Examples

Embodiment 1

[0022] Weigh 600Kg of chitin and 1200Kg of hydrochloric acid with a concentration of 30%, prepare the vacuum reactor in advance, suck the prepared hydrochloric acid into the reactor, close the feed valve, start stirring, open the feed port, and start to put in chitin. Turn on the steam and raise the temperature to 40°C, stop the steam, close the temperature rise after the feeding is completed, control the vacuum in the reactor to not exceed 0.3MPa, start to calculate the holding time when it reaches 88°C, the holding time is 4.5 hours, open the cooling water inlet and outlet valve, Let the temperature in the kettle drop to 40°C, open the vent valve, and transfer the feed liquid to the double-layer vacuum filtration tank for cooling and crystallization for 3.5 hours. The first layer of filter cloth in the double-layer vacuum filtration tank is 300 mesh, and the second layer of filter cloth 500 mesh; turn on the vacuum pump and open the feed valve, suck the mother liquor into the...

Embodiment 2

[0024] Weigh 300Kg of chitin and 800Kg of hydrochloric acid with a concentration of 32%, prepare the vacuum reactor in advance, suck the prepared hydrochloric acid into the reactor, close the feed valve, start stirring, open the feeding port, and start to put in chitin. Turn on the steam and raise the temperature to 40°C, stop the steam, close the heating after the feeding is completed, control the vacuum in the reactor to not exceed 0.3MPa, and start to calculate the holding time when it reaches 85°C, the holding time is 3.5 hours, open the cooling water inlet and outlet valve, Let the temperature in the kettle drop below 40°C, open the vent valve, and transfer the feed liquid to a double-layer vacuum filter tank for cooling and crystallization for 3.5 hours. The first layer of filter cloth in the double-layer vacuum filter tank is 300 mesh, and the second layer of filter cloth The cloth is 500 mesh; turn on the vacuum pump and open the feed valve, suck the mother liquor into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com